Page 1

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications technology

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

© KROHNE 12/2002 7.30927.31.00

Addition to the

installation and operating instructions

CAPAFLUX IFM 5080 K / CAP-EEx

CAPAFLUX IFM 5080 K / CAP i-EEx

Compact electromagnetic

flowmeters

...with non-contact and capacitive electrodes

Page 2

WARNING!

Be sure to follow these instructions !

IMPORTANT!

These additional instructions are an extension to the Installation and Operating Instructions and only

apply to the EEx version of the CAPAFLUX IFM 5080 K / CAP-EEx or IFM 5080 K / CAP i-EEx

electromagnetic compact flowmeter. All technical information described in the “Installation and

Operating Instructions” are applicable, when not specifically excluded, completed or replaced by the

instructions in these additional instructions.

Contents

1 System components 3-6

1.1 General information 3-4

1.2 IFC 090 / CAP … -EEx signal converter 5

1.2.1 Electronics compartment 5

1.2.2 Terminal compartment 5

1.3 Electronics unit 6

2 Electrical connection 7-17

2.1 Equipotential bonding system 7

2.2 Connecting cables 7

2.3 Connection diagram 8

2.4 Regular IFC 090 / CAP - EEx electronics unit 9

2.5 Modis version IFC 090 / CAP i-EEx electronics unit 10

2.6 Connection diagrams MODIS 11-17

3 Operation of the signal converter 18

4 Maintenance 18

5 Service 19-24

5.1 General information for replacements 19

5.2 Replacement of electronics unit 20

5.3 Replacement of power fuse(s) 21-23

5.4 Changing power supply voltage 24

6 Declarations of conformity 25

7 EC-type examination Certificates 26-30

No changes regarding safety may be made to the devices. Unauthorized changes

might affect the explosion safety of the devices.

• The prescriptions and regulations as well as the electrical data described in

the EC-type examination certificate must be obeyed.

• Beside the instructions for electrical installations in non-hazardous

locations according to the applicable national standard (e.g. IEC 364),

especially the regulations in EN 60079-14 "Electrical installations in

hazardous locations" or equivalent national standard must be followed.

• Installation, establishment, utilization and maintenance are only allowed to

be executed by personnel with an education in explosion safety!

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 2

Page 3

1 System components

1.1 General information

This compact flowmeter complies with the European Directive 94/9/EC (ATEX 100a) and has been

approved for hazardous classified locations of Zone 1 and 2 under EC-type Examination Certificate

number:

KEMA 01 ATEX 2232 X

The compact flowmeter is available in two types, namely:

• IFM 5080 K/CAP-EEx regular explosion protected version;

• IFM 5080 K/CAP i-EEx, MODIS version. This type has intrinsical safe signal output circuits, which

are provided by two MODIS modules that are installed on the IFC090 K/CAP/i-EEx electronics unit.

Temperature classification

The regular IFM 5080 K/CAP-EEx compact flowmeter is designed for ambient temperatures (Ta) of

-20°C (special -40°C) up to +60°C.

The allowed process liquid temperature is a.o. limited by the maximum occuring surface temperature of

systems components in the combustible atmosphere that (possibly) surrounds the apparatus (first

column of the table). For dusts the second column of the table applies. Details see following table.

Max. surface

class

(for gases)

T6

T5

T4

The IFM 5080 K/CAP…-EEx compact flowmeter consists of the IFC 090 / CAP/…-EEx signal converter

unit, which is screwed on top of the IFS 5000 CAP-EEx primary head (i.e. measuring unit). The regular

compact flowmeter is marked with one of the following codes below, depending on the type of

protection of the terminal compartment:

temperature

(for dusts)

T 85°C 60°C 55°C not allowed

T 100°C 75°C 75°C 75°C

T 115°C 115°C 115°C 75°C

II 2 GD EEx d IIC T6…T4 (EEx d terminal compartment) or

II 2 GD EEx de IIC T6…T4 (EEx e terminal compartment)

In case of the MODIS version IFM 5080 K/CAP i-EEx, the electronics unit of type IFC 090 / CAPi-EEx

is provided with protective modules, which provide intrinsical safe output signals of category "ia". The

flowmeter is then marked with the codes:

II 2 GD EEx d [ia] IIC T6…T4 (EEx d terminal compartment) or

II 2 GD EEx de [ia] IIC T6…T4 (EEx e terminal compartment)

For details see the EC-type Examination Certificate in

instructions.

Maximum process liquid temperature Temperature

≤ 40°C

T

a

Ta ≤ 50°C

Sect. 7

at the end of these additional

Ta ≤60 °C

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 3

Page 4

Primary head

The primary head contains two field coils and the capacitive signal pick-up.

The primary head is constructed in type of protection flameproof enclosure (EEx d).

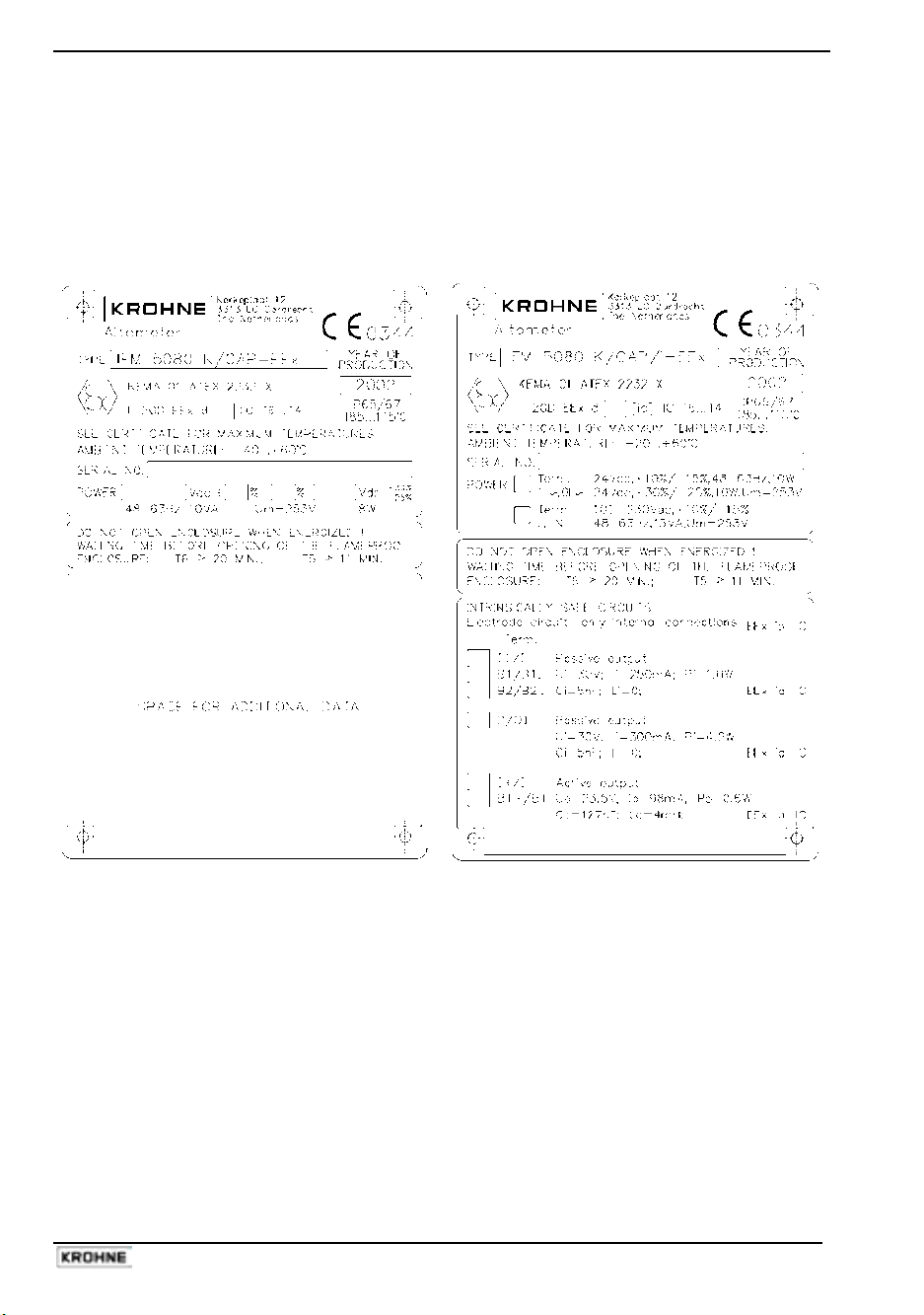

Data plates of CAPAFLUX IFM 5080 K/CAP/…-EEx flowmeters

IFM 5080 K/CAP-EEx

IFM 5080 K/CAP/i-EEx

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 4

Page 5

1.2 IFC 090 / CAP/…-EEx signal converter

The IFC 090 / CAP/…-EEx signal converter consists of a cylindrical housing of die-casted aluminum,

which has two separate compartments, divided from each other by an integrated wall with casted

flameproof terminal feed-through. The neck at the bottom of the housing contains a flameproof cable

feed-through. The signal converter housing is on both ends closed by a cylindrical threaded cover with

O-ring sealing. The housing has an ingress protection degree of IP 65 / IP 67 conform to EN 60529.

1.2.1 Electronics compartment

The electronics compartment accommodates the pre-certified IFC 090 / CAP…-EEx electronics unit

with approval number PTB 98 ATEX 2012 U. The electronics compartment is designed with type of

protection flameproof enclosure "d" according to EN 50018. It is closed by a threaded flameproof

display cover with glass window.

1.2.2 Terminal compartment

The terminal compartment has seven terminals for connection of the power supply and signal output

circuits. Sect. 2 (Connection diagram) shows the terminal arrangement for the regular and MODIS

version of the IFC 090 / CAP/…-EEx signal converter. The terminal arrangement of the MODIS version

(i.e. IFC 090 / CAP i-EEx) is shown in Sect. 2 (Modis Converter). Two of the terminals are used for

connection of the non-intrinsically safe power supply and four terminals (marked with "*") for the

intrinsically safe, category "ia" signal outputs of the MODIS modules. The non-intrinsically and

intrinsically safe terminals are separated from each other by a metal dividing plate, which is screwed to

the remaining (not connected) M4 terminal. The two non-intrinsically safe power supply terminals are

covered by an insulating plate.

The terminal compartment (with standard type of protection increased safety "e") is standard equipped

with two ATEX approved "EEx e" cable glands. The terminal compartment can also be provided as a

flameproof enclosure "d", in which case ATEX approved "EEx d" cable glands of size Pg13.5, Pg16 or

M20x1.5 are either factory installed or must be installed by the customer. For flameproof conduit

systems, the terminal compartment must have type of protection flameproof enclosure "d" according to

EN 50018. The conduits must be sealed by "EEx d" approved (within the ATEX 100a directive) sealing

devices (i.e. stopping box) directly at the conduit entrances of the as flameproof enclosure performed

terminal compartment.

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 5

Page 6

1.3 Electronics unit

This electromagnetic compact flowmeter can be equipped with the regular IFC 090 / CAP-EEx or with

the IFC 090 / CAP i-EEx electronics unit with intrinsically safe signal outputs (i.e. MODIS version). This

version is descripted in the following.

Regular IFC090-EEx electronics unit

The IFC 090 / CAP-EEx is used in the regular IFM 5080 K-EEx and can be equipped with one of the

following power supplies (depends on the area of application).

Electrical data for power supply

Power supply Terminal Function Electrical data

AC-versions

AC/DC-version

L

N

PE

L

L

FE

Live

Neutral

Protective Ground

Live

Neutral

Functional Ground

U

= 100/115/200/230 Vac -15/+10%

n

= approx. 10 VA, Um = 253 V

P

n

= 24 V ac/dc

U

n

AC: -15/+10%, P

DC: -25/+30%, P

= 253 V

U

m

=10 VA

n

=8 W

n

The IFC 090 / CAP-EEx electronics unit is equipped with the following in-/output circuits. Terminals B1,

B⊥ and B2 can be configured as status or pulse outputs or as control inputs via the software. See the

table below for the electrical data of these in-/output circuits.

Electrical data of in-/output circuits

Terminals Description Nominal voltage Maximum current

I+, I

B1, B⊥, B2

Current output 15 V 22 mA

Pulse, status, control in-/outputs 32 V 150 mA

IFC 090 / CAP i-EEx unit with MODIS modules

The IFC 090 / CAP i-EEx electronics unit is equipped with a pair of MODIS-modules. It is equipped with

one of the following power supplies.

Electrical data of IFC 090 / CAP i-EEx electronics unit

Power supply Terminals Function Electrical data

AC-version

AC/DC-version

L

N

PE

1L

0L

FE

Live

Neutral

Protective Ground

Live

Neutral

Functional Ground

U

= 100…230 Vac –15%/+10%

n

= 15 VA, Um = 253 V

P

n

= 24 Vac/dc

U

n

AC: -15%/+10% or 20.4…26.4 Vac

DC: -25%/+30% or 18…32 Vdc

= 10 W, Um = 253 V

P

n

Note

The mains fuses for both electronics units are listed in Sect. 6 of this manual.

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 6

Page 7

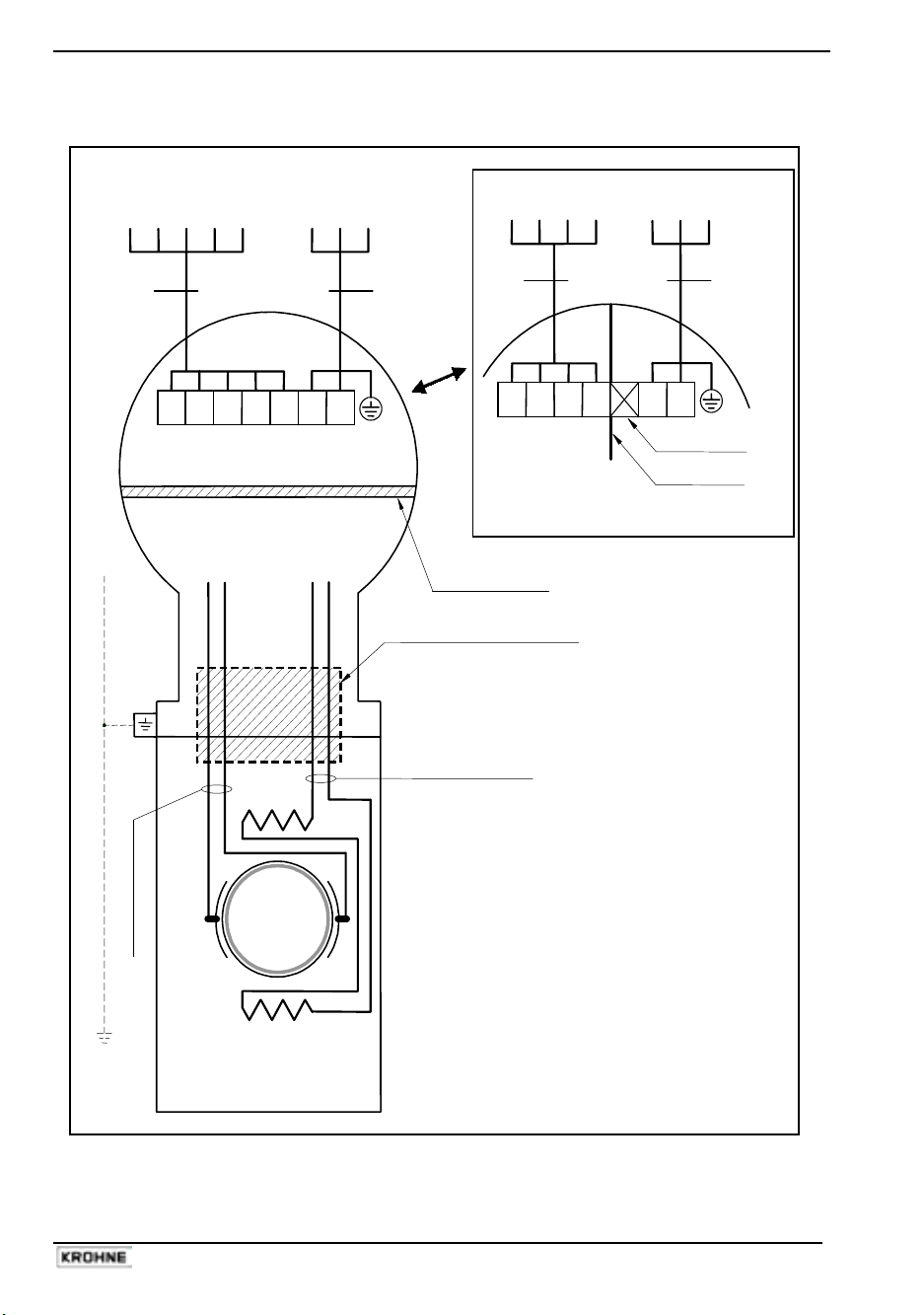

2 Electrical connection

2.1 Equipotential bonding system

All EEx and EEx/i flowmeters must always be incorporated into the equipotential bonding system of the

hazardous area. This connection can be achieved through the PE/FE conductor connected to the PE

terminal in the terminal compartment (see figure of terminal arrangement below) or through a separate

PE conductor, cross sectional area at least 4 mm

the converter housing.

2.2 Connecting cables

Note

The below described cables are shown in the following connection diagram.

Cable A:

Signal cable for current output and binary outputs (pulse and status output): The cable parameters must

be in accordance with the regulations in the EN 60079-14 "Electrical installations in hazardous

locations" or an equivalent national standard. For the MODIS version with IFC 090 / CAP i-EEx

electronics unit (right detail in connection diagram) the signal cable for the intrinsically safe signal in/outputs must also conform the requirements as specified in the relevant standard national code of

practice for the installation of electrical apparatus with type of protection Intrinsic Safety "i".

Cable B:

Power supply cable: The cable parameters must be in accordance with the regulations of the

EN 60079-14 "Electrical installations in hazardous locations" or an equivalent national standard.

Rated voltage:

Examples: H07...-., H05...-.

Equipotential bonding conductor

Cross-sectional area:

2

, connected to the external PE clamp, placed below

≥ 500 V

2

(equivalent to AWG 10)

4 mm

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 7

Page 8

2.3 Connection diagram

L N PE 100-230 Vac

SIGNAL IN-/OUTPUTS L L FE 24 Vac/dc

INTRINSICALLY SAFE

SIGNAL IN-/OUTPUTS L N PE 100-230 Vac

(i.e. MODIS) L L FE 24 Vac/dc

IFC 090/CAP-EEx

Signal Converter

B1 B⊥ B2 I+ I L N

BINARY CURRENT MAI NS

OUTPUTS OUTPUT SUPPLY

TERMINAL COMPARTMENT

Standard "EEx e" (Optional "EEx d")

ELECTRONICS COMPARTMENT (always "EEx d")

Electrode circuits Field coil circuits

(10-pole connector) (2-pole connector )

(OPTIONAL)

2

4 mm

≥

Coil

B A

PE

FE

Flameproof (EEx d)

terminal f eed-through

Flameproof (EEx d) cable feed-through

x x x x

IFC 090i/CAP-EEx

Signal Converter

Hazardous locations

of Zone 1 and 2

Field coil circuit (2 wires)

B A

1L 0L

Unused terminal

Separation plate

OPTION: MODIS

PE

FE

Flow tube

Electrode circuit (6 wires)

EQUIPOTENTIA L BONDING CONDUCTOR

E

Coil

E

IFS 5000/CAP-EEx

Primary Head

Flameproof (EEx d) enclosure

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 8

E = pre-amplifier + capacitive electrode plate

Page 9

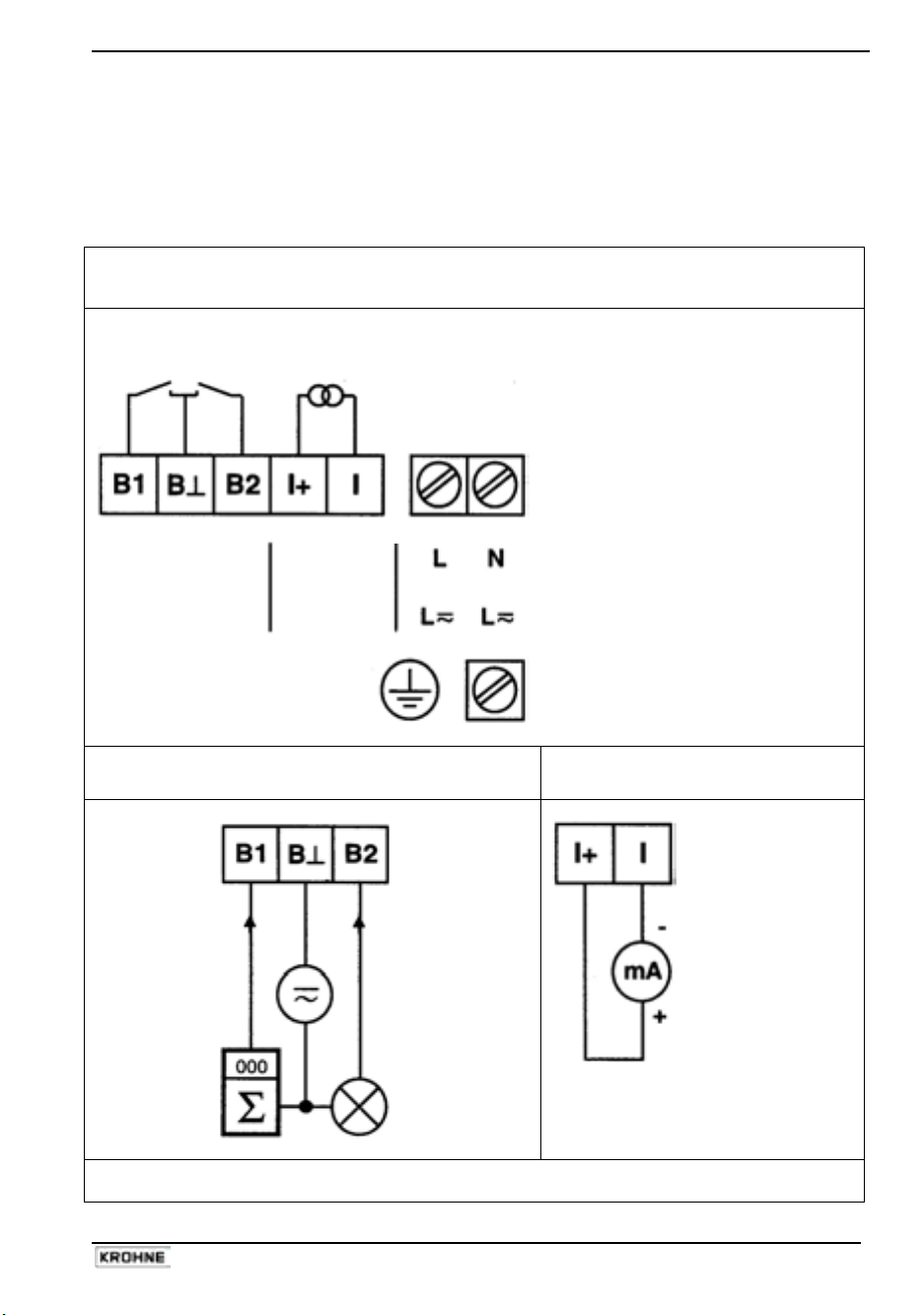

2.4 Regular IFC 090 / CAP-EEx electronics unit

The field cables that enter the terminal compartment of the IFC 090 / CAP-EEx signal converter unit (i.e.

power supply, current and binary outputs) are non-intrinsically safe. To connect external devices to the

signal output terminals, the wiring requirements for the type of protection of the compartment (standard:

increased safety "e", optional: flameproof "d") must be conform to the international or national standard

involved (e.g. EN 60079-14).

The terminal arrangement is shown below.

Terminal arrangement in terminal compartment

pulse and status

outputs or

control inputs

binary

outputs

current

output

100 - 240 V AC / 48 - 63 Hz

24 V AC / DC

PE Protective ground

FE Functional ground

Passive pulse/status output

I ≤ 150 mA

eiectronic

or electro mechanical

totalizer

I ≤ 150 mA

≤ 32 V DC

U

ext

≤ 24 V AC

e.g.

signal

indicator

Active current output

R

≤ 500 Ω

i

Note

The binary outputs (terminals B1, B⊥ and B2) can only be configured as passive outputs,

the current output (terminals I+ and I) can only be configured as active output.

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 9

Page 10

2.5 MODIS version IFC 090 / CAP i-EEx electronics unit

The field cables of the non-intrinsically safe power supply and the intrinsically safe, category "ia" signal

outputs enter the terminal compartment of the IFC 090 / CAP i-EEx signal converter unit via two

separate entrances. To connect external devices to the intrinsically safe signal output terminals, the

wiring requirements for their type of protection as well as of the compartment (standard: increased

safety "e", optional: flameproof enclosure "d") must be conform to the international or national standard

involved (e.g. EN 60079-14).

Terminal arrangement in terminal compartment

NC = not connected

Metal dividing

plate IS / non-IS

terminals

Connecting terminals

for intrinsically safe

signal in-/outputs

*** *

NC 1L 0L 24 Vac/dc

L N 100…240 Vac

PE

terminals for

non-intrinsically

safe power supply

Protective Earth terminal

Connecting

Cable entrance for

intrinsically safe

signal cable

The non-intrinsically safe terminals for connection of the power supply (1L

connected according to the relevant standard code of practice for electrical apparatus intended for use

in potentially hazardous locations, type of protection Increased Safety "e" or type of protection

Flameproof Enclosure "d", depending on the type of protection of the terminal compartment of the signal

converter housing.

To gain access to the connection terminals of the power supply, the half-circular cover plate of

insulating material must be slightly lifted at one end and then rotated downwards, see the instruction on

the cover plate. After connection of the power supply cable, the half-circular cover plate must be

restored into its original position, so that the minimum clearances and creepage distances towards the

intrinsically safe signal in-/output terminals are maintained.

For details, see diagram on terminals compartment MODIS on next page.

Cable entrance for

non-intrinsically

safe power supply

cable

and 0L) must be

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 10

Page 11

Terminal compartment MODIS version IFC 090 / CAP i-EEx

Insulating cover plate

Sticker with handling information

for insulating cover plate

Sticker indicating the intrinsically

safe signal in-/output circuits

The PE (or FE) conductor must be connected to the press-fitted M5 clamp terminal marked inside the

terminal compartment. This conductor must be guided through the rectangular opening in the metal

dividing plate that separates the non-intrinsically safe power supply terminals from the intrinsically safe

signal in-/output terminals.

2.6 Connection diagrams MODIS

Sect. 2.3 shows the block diagram of the EEx electromagnetic compact flowmeter. The power supply

(terminals 1L

ground conductor of the mains supply.

The IFC 090 / CAP i-EEx electronics unit is provided with intrinsically safe signal in-/output circuits due

to the installed pair of MODIS modules in accordance with the table below.

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 11

, 0L) is connected via cable B. The PE terminal must be connected to the protective

Page 12

Overview of MODIS modules

Module Terminal designation Function / Intrinsically safe maximum data

Current output (0/4-20 mA), passive

U

P-SA

I ⊥, I

= 30 V, Ii = 250 mA, Pi = 1.0 W

i

C

= 5 nF, Li ≈ 0

i

Pulse (frequency) output or status in-/output, all passive

FA-ST

B1, B1⊥ or B2, B2 ⊥

The function can be set by software

= 30 V, Ii = 250 mA, Pi = 1.0 W

U

i

C

= 5 nF, Li ≈ 0

i

Fieldbus module, type Profibus system, passive

U

F-PA

D, D ⊥

= 30 V, Ii = 300 mA, Pi = 4.2 W

i

C

= 5 nF, Li ≈ 0

i

Fieldbus module, type Fieldbus Foundation, passive

U

F-FF

D, D ⊥

= 30 V, Ii = 300 mA, Pi = 4.2 W

i

C

= 5 nF, Li ≈ 0

i

Intrinsically safe voltage source for the passive module

P-SA or FA-ST, so that active operation is possible.

= 23.5 V, Io = 98 mA, Po = 0.6 W

U

o

= 132 nF, Lo = 4 mH

C

o

DC-I

I+, B1+

Note!

When modules P-SA (or FA-ST) and DC-I are connected in

series, the internal capacitance C

subtracted from the C

of 127 nF.

C

o

of 132 nF. So the data plate will list a

o

of 5 nF must be

i

Besides the shown intrinsically safe maximum values for voltages and current -which are based on

certain fault conditions as prescribed by the standard EN 50 020 - the nominal values for current and

voltage must also be respected otherwise a proper functioning of the modules is not guaranteed!

Nominal voltage and current values for the MODIS modules

MODIS module Nominal values for voltage and current

P-SA

(passive current output )

Current: 4 ... 20 mA

Working voltage: 8 ... 30V

Voltage drop : 8V at 4mA

FA-ST

(frequency / pulse / status output

or control input)

Working voltage: 6 ... 30V

Working current: < 110 mA

Voltage drop: in ON-state: < 2V at 110 mA

Leakage current in OFF-state: < 900 µA at 30V

Control input:

Input voltage LOW level: < 3V

Input voltage HIGH level: > 7V

Frequency range : 0 .. 12 KHz

DC-I

(active voltage source)

Voltage: 20V

Current 30 mA

Internal resistance: 260 Ω

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 12

Page 13

The active module DC-I is needed in the 24 Vac/dc power supply version to form an active current or

pulse output in combination with one of the passive modules P-SA or FA-ST. Due to limited space it is

not available for 100...230 Vac supply versions.

Possible combinations of the installed MODIS modules for the 24 Vac/dc power supply

version of the IFC 090 / CAP i-EEx

IFC 090 /

Part No. MODIS modules Terminal designation

CAP i-EEx

version

Ex-i1

Ex-i2

Ex-i3

Ex-i4

Ex-i5

Ex-i6

Ex-i7

Ex-i8

X317.01.440.0

X317.01.450.0

X317.01.460.0

X317.01.470.0

X317.01.480.0

X317.01.490.0

X317.01.xxx.0

X317.01.xxx.0

P-SA FA-ST

P-SA F-PA

P-SA DC-I I+

FA-ST F-PA B1

FA-ST DC-I B1+

FA-ST FA-ST B2

P-SA F-FF

FA-ST F-FF B1

I ⊥

I ⊥

I ⊥

I B1

I D

D

B1⊥

B1

B2⊥

I D

D

B1⊥

B1⊥

D ⊥

I

D ⊥

B1

B1 ⊥

D ⊥

D ⊥

Possible combinations of the installed MODIS modules for the 100-230 Vac power supply

version of the IFC 090 / CAP i-EEx

IFC 090 /

Part No. MODIS modules Terminal designation

CAP i-EEx

version

Ex-i1

Ex-i2

Ex-i4

Ex-i6

Ex-i7

Ex-i8

Due to mechanical and electrical limitations, only the listed pairs of MODIS modules are possible. The

two modules each use two terminals of the bottom four terminals of the flameproof terminal feedthrough in the dividing wall between the electronics and terminal compartment of the signal converter

housing, except for the combination with module DC-I (only applicable for 24 Vac/dc versions), where

only two of the four terminals are used. Interconnection of the two modules, P-SA with DC-I or FA-ST

with DC-I is made internally.

The flameproof terminal feed-through has seven terminals in total, the top two terminals are used for

connection of the power supply, the third one is only used for mounting of a metal dividing plate with

insulating cover plate. The remaining four are used for the intrinsically safe signal in-/output circuits of

the installed MODIS modules.

The metal dividing plate and the insulating cover plate warrant the required separation distances (i.e.

clearances, creepage distances and distances through insulation) between the non-intrinsically safe

power supply terminals and the intrinsically safe signal in-/output circuits. The insulating cover plate is

provided with a sticker that contains important instructions how to remove and re-install the cover plate

and the conditions under which it should be established (circuits not live !).

Important !

X317.01.560.0 P-SA FA-ST

X317.01.570.0 P-SA F-PA

X317.01.580.0 FA-ST F-PA B1

X317.01.590.0 FA-ST FA-ST B2

X317.01.600.0 P-SA F-FF

X317.01.610.0 FA-ST F-FF B1

Carefully follow the instructions on the sticker that is glued to the top of the insulating

cover plate that covers the non-intrinsically safe power supply terminals !

I ⊥

I ⊥

I ⊥

I B1

I D

D

B1⊥

B1

B2⊥

I D

D

B1⊥

B1⊥

D ⊥

D ⊥

B1 ⊥

D ⊥

D ⊥

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 13

Page 14

For the connection diagrams of the intrinsically safe signal in-/outputs of the installed MODIS modules in

the IFC 090 / CAP i-EEx electronics unit (see figures on the following pages). It has to be noted that the

intrinsically safe signal in-/outputs may only be connected to the following listed apparatus' (registering

devices like amp-meters, pulse counters, etc.):

EEx-approved intrinsically safe apparatus;

EEx-approved associated apparatus;

Passive apparatus as defined in your national standard for installation of electrical apparatus in

hazardous locations (e.g. EN 60079-14).

Other types of apparatus may only be connected to the intrinsically safe signal in-/outputs through EExapproved safety barriers, isolating interface units and the like. These barriers or units are not depicted in

the connection diagrams for reasons of readability. It is assumed that they are an integrated part of the

registering devices or as separate devices connected in series with them. The registering devices may

only be installed in the hazardous location if they also have a type of protection for explosion safety

according to the European Standards of the EN 500xx series, or if they are constructed as prescribed in

your standard national code of practice.

When the intrinsically safe signal in-/outputs are connected to other intrinsically safe or associated

apparatus, the maximum safety values (i.e. entity parameters) of all intrinsically safe circuits have to be

considered.

Important !

The 100…230 Vac power supply versions of the IFC 090 / CAP i-EEx signal

converter electronics unit with MODIS modules can only be equipped with passive

outputs. Therefore the connection diagrams with the numbers 2, 4, 5, 7, 9, 11 and 12

are applicable for the 100…230 Vac power supply versions.

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 14

Page 15

Connection diagrams 1 to 4 of the intrinsically safe signal in-/outputs

1 Current output I

2 Current output I

active

passive

Version: Ex-i3

I = 4 - 20 mA U

Ri = 350 Ω

I = 4 - 20 mA

Versions: Ex-i1, Ex-i2, Ex-i7

= 8.1 - 30 V

ext

R

≤ (U

i

- 8) / 0.022

ext

IFC 090 / CAP i-EEx IFC 090 / CAP i-EEx

hazardous area hazardous area

safe area or safe area or

hazardous area ( * )

hazardous area ( * )

3 Pulse output P

Version: Ex-i5

U

= 20 V DC U

int

R

= 260 Ω

int

4 Pulse output P

active

Versions: Ex-i1, Ex-i4, Ex-i6, Ex-i8

= 6 - 30 V DC

ext

I

≤ 110 mA

max

passive

UL = 20×RL / (260+RL)

IFC 090 / CAP i-EEx IFC 090 / CAP i-EEx

hazardous area hazardous area

safe area or safe area or

hazardous area ( * )

hazardous area ( * )

passive counter passive counter

with external supply

( * ) Important note:

Only if the measuring devices are also explosion protected !

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 15

Page 16

Connection diagrams 5 to 8 of the intrinsically safe signal in-/outputs

5 Pulse output P

6 Status output S

passive

active

Versions: Ex-i1, Ex-i4, Ex-i6, Ex-i8

U

= 6 - 30 V U

ext

I

≤ 110 mA

max

Version: Ex-i5

= 20 V DC

int

R

= 260 Ω

int

for active EC UL = 20×RL / (260+RL)

IFC 090 / CAP i-EEx IFC 090 / CAP i-EEx

hazardous area hazardous area

safe area or safe area or

hazardous area ( * )

hazardous area ( * )

7 Status output S

Versions: Ex-i1, Ex-i4, Ex-i6, Ex-i8

U

= 6 - 30 V U

ext

I

≤ 110 mA

max

Connection to terminals B1/B1⊥ and/or B2/B2⊥

8 Control input C

passive

Version: Ex-i5

= 20 V DC

int

I

≤ 6 mA

contact

active

IFC 090 / CAP i-EEx IFC 090 / CAP i-EEx

hazardous area hazardous area

safe area or safe area or

hazardous area ( * )

hazardous area ( * )

( * ) Important note:

Only if the measuring devices are also explosion protected !

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 16

Page 17

Connection diagrams 9 to 12 of the intrinsically safe signal in-/outputs

9 Control input C

10 HART active

passive

Versions: Ex-i1, Ex-i4, Ex-i6, Ex-i8

U

= 7 - 30 V DC

ext

Connection to terminals B1/B1⊥ and/or B2/B2⊥

Version: Ex-i3

IFC 090 / CAP i-EEx IFC 090 / CAP i-EEx

hazardous area hazardous area

safe area or safe area or

hazardous area ( * )

hazardous area ( * )

to HART

communicator

or SMART converter

11 HART passive 12 Fieldbus

Versions: Ex-i1, Ex-i2, Ex-i7

Versions: Ex-i2, Ex-i4, Ex-i7, Ex-i8

IFC 090 / CAP i-EEx IFC 090 / CAP i-EEx

to next HART device to next Fieldbus

device

or bus terminator

hazardous area

hazardous area

safe area or

hazardous area ( * )

safe area or

hazardous area (

*

)

Bus supply device

to HART to Bus master

communicator

or SMART converter

Bus supply device

( * ) Important note:

Only if the measuring devices are also explosion protected !

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 17

Page 18

3 Operation of the signal converter

The compact flowmeters are always equipped with magnet sensors. In that way it is possible to change

the settings of the converter with aid of the magnet-bar without the necessity to open the flameproof

converter housing in the hazardous area.

It must be noted that the IFC 090 i/CAP-EEx versions Ex-i2 and Ex-i3, following menus do not apply.

(see also Sect. 4.4. "Table of settable functions" in the standard "Installation and operating instructions"

of the IFC090 K/F signal converter)

1.01 Æ VALUE P

1.06 Output/input B1

1.07 Output/input B2

1.06 PULS B1

1.06 STATUS B1

1.07 STATUS B2

1.06 CONTROL B1

1.07 CONTROL B2

3.02 Æ VALUE P

3.07 HARDWARE

Fct. Text Description and settings

1.00

3.00

3.02 FLOWMETER ...

3.07 HARDWARE

As a consequence, the chapters included in the standard Installations and operating instructions, giving

detailed descriptions of these menus, must be skipped.

1.00 OPERATION Operations menu

1.01 FULL SCALE ...

Æ VALUE P

1.06 Output/Input B1

1.07 Output/Input B2

1.06 PULS B1

1.06

1.07

1.06

1.07

3.00 INSTALL. Installation menu

STATUS B1

STATUS B2

CONTROL B1

CONTROL B2

Æ VALUE P

4 Maintenance

The IFM 5080 K/CAP/…-EEx electromagnetic compact flowmeters are maintenance free with regard to

the flowmetering properties. Within the scope of the periodical inspections, which are required for

electrical apparatus that are installed and used in hazardous classified locations, it is recommended to

check the flameproof enclosure on signs of damage or corrosion. This concerns the converter housing

and the primary head housings.

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 18

Page 19

5 Service

Contact your (local) KROHNE sales representative for the ordering information of spare parts or

replacements of IFC 090/CAP…-EEx electronics units and/or power fuses.

5.1 General information for replacements

IMPORTANT !

Before opening

• Make absolutely sure there is no explosion hazard!

• If necessary provide a ”Gas-free certificate” !

• Make sure that all connecting cables are safely isolated from the power supply !

When the instructions above are strictly followed, the cover (with glass window) of the electronics

compartment may be removed. First unscrew the recessed head screw of the interlocking device by a

hollow-head screw wrench size 3, until the cover can rotate freely. Unscrew the cover with the special

plastic wrench (black) that is supplied with the apparatus.

After opening

• The copper ground strip at the back of the electronics unit must be securely screwed to the housing

(back-end of electronics compartment) by screw SE (see figure below). The electronics unit is

screwed into the electronics compartment by two screws D. Before screws SE and D can be

accessed, the display unit must be removed via screws A.

• Before the cover is screwed back into the housing, the screw-thread must be clean and well-greased

with an acid and resin-free grease, e.g. silicone grease.

• Screw the cover as tight as possible into the housing by hand, until it cannot be opened by hand

anymore. Screw the recessed head screw of the interlocking device tight.

IFC 090 / CAP-EEx electronics unit after removal of display unit

Note:

SE

Safe earth

connection

The following instructions must be followed carefully, if the IFC 090 / CAP/…-EEx

signal converter housing has to be opened respectively closed again!

A

Power fuse in fuse-holder

D

Mains transformer

B

SE

Signal converter housing

C

Flat cable of display unit

D

Power supply PC-board

A

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 19

Page 20

5.2 Replacement of electronics unit

Display unit of IFC 090 / CAP…-EEx

Refer to the standard Installation and

Operating Instructions for detailed

A

information about resetting and

reprogramming the new electronics unit

after replacement. The customer specific

data (like the value of the internal

totalizer) are stored in DATAPROM IC-18,

which must be transferred from the "old"

to the "new" electronics unit. See Sect.

8.7 of the standard Installation and

Operating Instructions for detailed

information.

A

Before commencing work, note the instructions in Sect. 5.1,

Then continue as follows:

1. Remove the display cover of the electronics compartment.

2. Unscrew the two screws A (M3) of the display unit (see figure above) and turn it carefully aside.

3. Disconnect the

circuit connector (item C). See figures in Sect. 5.1 and the following.

4. Unscrew the two mounting screws D of the electronics unit and unscrew SE, which fixes the copper

ground strip to the back of the housing. A screwdriver with a long shaft (≥ 200 mm) is most suitable for

unscrewing screw SE (e.g. screwdriver type Philips No. 2).

5. Carefully remove the electronics unit of the converter housing (see the remark below).

6. Check if the voltage setting (only applicable for AC power supplies) and power fuse rating are correct

on the new electronics unit. If necessary, change the voltage setting or replace the power fuse (see

Sect. 5.3 and 5.4 of this manual).

7. Carefully insert the electronics unit (keep cables aside, see remark below). Then mount the unit

completely into the housing and fix the screws. First the two screws D, then screw SE and reconnect

the

2-pole

plugs on the electronics unit (see figure in Sect. 5.1).

8. Finally screw the display unit back on the frame of the electronics via the two screws A.

9. Screw the cover of the electronics compartment back into the housing.

Note the instructions of Sect. 5.1 ("After opening") during reassembling.

IMPORTANT !

2-pole

field circuit connector (item B in figure on last page) and the

field circuit connector B and the

Carefully keep the connecting cables of the field coil and electrode circuits to the

side of the housing, while removing respectively inserting the electronics unit into

the signal converter housing. This is to prevent damaging of the connecting

cables!

10-pole

“Before opening".

10-pole

electrode

electrode circuit connector C to the right counter-

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 20

Page 21

5.3 Replacement of power fuse(s)

The power fuse(s) of the different IFC 090 / CAP…-EEx electronics units (regular or MODIS) have a

different rating and are located on slightly different locations on the power supply printed circuit board.

Only the power fuse on the 100…230 Vac power supply version of the regular IFC 090 / CAP-EEx

electronics unit can be reached without removing the complete unit out of the housing (only the display

unit has to be unscrewed).

Regular IFC 090 / CAP-EEx with 24 Vac/dc power supply

Note

1. Remove the cover of the electronics compartment.

2. Unscrew the two screws marked with A of the display unit and turn it carefully aside.

3. Disconnect the

connector (item C). See figures in Sect.5.1 and 5.2.

4. Unscrew the two mounting screws D of the electronics unit and screw SE, which fixes the

copper ground strip to the integrated aluminum dividing wall at the back of the electronics

compartment. Use a screwdriver with a long shaft (≥ 200 mm) like type Philips No. 2 for

5. The defective power fuse(s) F1 and/or F2 (see following figure) can be replaced now. The 24 Vac/dc

6. Reassemble in reverse order (points 3 through 1).

IFC 090 / CAP-EEx electronics unit with 24 Vac/dc power supply

Before commencing work, read the instructions in Sect. 5.1 ("Before opening"). Then continue

as follows:

2-pole

field circuit connector (item B) as well as the

screw SE. Then take out the electronics unit, but be careful with the connecting cables, so that

they do not get damaged.

power supply uses two sub-miniature fuses type TR 5 that are rated T1.25 A in accordance with IEC

127-3 publication (part No. 5.09080.00.00).

Note

Read the instructions of Sect. 5.1 ("After opening") during reassembling.

10-pole

electrode circuit

F1

F2

F1 and F2 fuses of power supply

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 21

Page 22

V

p

y

Regular IFC 090 / CAP-EEx with 100 … 230 Vac power supply

Note

1. Remove the cover of the electronics compartment

2. Unscrew the two screws A of the display unit and turn the display unit carefully aside.

3. The fuse-holder, in which the power fuse in accordance with IEC 127-2 size Ø5 x 20 mm is

Note

4. Reassemble the unit in reverse order (points 2 and 1).

Note

Before commencing work, read the instructions in Sect. 5.1 ("Before opening").

Then continue as follows:

mounted, is now accessible to replace the defect power fuse F1 by a new fuse with the same

rating. The rating depends on the voltage setting of the power supply unit. The power supply of

100/115 Vac requires a fuse of T200mA (part No. 5.05678.00.00) and the 200/230 Vac requires a

fuse of T125 mA (part No. 5.06627.00.00).

The fuse rating is also shown by the yellow sticker that is glued on the mains transformer, which

can only be seen after the regular IFC 090 / CAP-EEx electronics unit is completely removed from

the flameproof signal converter housing. See the next figure.

In case of any doubt about the fuse rating or the voltage setting of the unit, remove the

complete unit from the housing as described in Sect. 5.2 and check in the following figure

depicted items. Change when needed !

Read the instructions of Sect. 5.1 ("After opening") during reassembling.

Power supply version 115/230 Vac

Mains

transformer

Indication of

voltage

selector

Sticker with fuse

Side of dis

Power fuse F1

(in fuse holder)

oltage

Voltage selector

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 22

la

unit

Page 23

MODIS version IFC 090 / CAP i-EEx

Note

Before commencing work, read the instructions in Sect. 5.1 ("Before opening").

Then continue as follows:

1. Remove the cover of the electronics compartment

2. Unscrew the two screws A of the display unit and turn it carefully aside.

3. Disconnect the

2-pole

field circuit connector (item B) and the

10-pole

electrode circuit connector

(item C). See figures in Sect. 5.1 and 5.2 for details.

4. Unscrew the two screws D and screw SE by a screwdriver with a long shaft (200 mm). Take out the

electronics unit, but do not damage the connecting cables. See the note IMPORTANT.

5. The defective power fuse (see following figure) can be replaced now. Use a fuse rated at

T1.25H250V (part No. 5.06232.00.00) for the 24 Vac/dc power supply and a fuse rated at

T1.6H250V (Part No. 5.07823.00.00) for the 100…230 Vac power supply. Note that the locations are

slightly different (the 24 Vac/dc supply version is shown).

6. Reassemble in reverse order (points 4 through 1).

Note

Read the instructions of Sect. 5.1 ("After opening") during reassembling

.

Important!

Carefully keep the connecting cables of the field coil and electrode circuits to the side

of the housing, while removing or inserting the electronics unit into the signal converter

housing. This is to prevent damaging of the connecting cables!

IFC 090 / CAP i-EEx electronics unit (24 Vac/dc version is shown)

NOTE:

The power fuse on the 100…230 Vac version is located on a slightly different

position than the fuse of the 24 Vac/dc version ! See location "

Fuse_230V

".

Fuse_230V

PTB 97 ATEX 2265 U

[EEx ia] IIC

PTB 97 ATEX 2265 U

Power fuse (24 Vac/dc power supply)

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 23

Page 24

5.4 Changing power supply voltage

This only applies to the regular IFC 090 / CAP-EEx electronics unit with 100-230 Vac power supply.

Note

1. Remove the cover of the electronics compartment.

2. Unscrew the two screws A of the display unit and turn the display unit carefully aside.

3. Unscrew the two mounting screws D of the electronics unit and screw SE, which fixes the copper

ground strip at the back of the housing. A screwdriver with a long shaft (200 mm) can best be used to

unscrew SE (e.g. screwdriver type Philips No. 2).

4. Disconnect the

5. The voltage setting of the power supply can be changed by turning the dummy dual-in-line block (i.e.

voltage selector, see last figure in Sect. 5.3) over 180° in its socket. The position of the notch on the

dummy dual-in-line block indicates the voltage setting. Also see the sticker that is glued on the mains

transformer.

6. Reassemble in reverse order (points 4 through 1).

7. Screw the cover of the electronics compartment back into the housing.

Note

IMPORTANT!

Before commencing work, read the instructions in Sect. 5.1 ("Before opening").

Then continue as follows:

2-pole

Note the instructions of Sect. 5.1 ("After opening") during reassembling.

Carefully keep the connecting cables of the field coil and electrode circuits to the

side of the housing, while inserting the electronics unit into respectively removing it

from the signal converter housing. This is to prevent damaging of the connecting

cables!

and

10-pole

connectors and carefully remove the electronics unit.

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 24

Page 25

6 Declarations of conformity

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 25

Page 26

7 EC-type examination Certificates

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 26

Page 27

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 27

Page 28

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 28

Page 29

CAPAFLUX IFM 5080 K/CAP-EEx and CAPAFLUX IFM 5080 K/CAP i-EEx 29

Page 30

Australia

KROHNE Australia Pty Ltd.

Unit 19 No.9, Hudson Ave.

Castle Hill 2154, NSW

TEL.: +61(0)2-98948711

FAX: +61(0)2-98994855

e-mail: krohne@krohne.com.au

Austria

KROHNE Austria Ges.m.b.H.

Modecenterstraße 14

A-1030 Wien

TEL.: +43(0)1/203 45 32

FAX: +43(0)1/203 47 78

e-mail: info@krohne.at

Belgium

KROHNE Belgium N.V.

Brusselstraat 320

B-1702 Groot Bijgaarden

TEL.: +32(0)2-4 66 00 10

FAX: +32(0)2-4 66 08 00

e-mail: krohne@krohne.be

Brazil

KROHNE Conaut

Controles Automaticos Ltda.

Estrada Das Águas Espraiadas, 230 C.P. 56

06835 - 080 EMBU - SP

TEL.: +55(0)11-4785-2700

FAX: +55(0)11-4785-2768

e-mail: conaut@conaut.com.br

China

KROHNE Measurement Instruments Co. Ltd.

Room 7E, Yi Dian Mansion

746 Zhao Jia Bang Road

Shanghai 200030

TEL.: +86(0)21-64677163

FAX: +86(0)21-64677166

Cellphone: +86(0)139 1885890

e-mail: info@krohne-asia.com

CIS

Kanex KROHNE Engineering AG

Business-Centre Planeta, Office 403

ul. Marxistskaja 3

109147 Moscow/Russia

TEL.: +7(0)095-9117165

FAX: +7(0)095-9117231

e-mail: krohne@dol.ru

Czech Republic

KROHNE CZ, spol. s r.o.

Sobe˘s˘ická 156

CZ-63800 Brno

TEL.: +420 545 532 111

FAX: +420 545 220 093

e-mail: brno@krohne.cz

Algeria

Argentina

Bulgaria

Camaroon

Canada

Chile

Columbia

Croatia

Denmark

Ecuador

Egypt

Finland

French Antilles

Greece

Guinea

Hong Kong

Hungary

Indonesia

Ivory Coast

Iran

Ireland

Israel

Japan

Jordan

Kuwait

Marocco

Mauritius

Mexico

New Zealand

Pakistan

Poland

Portugal

Saudi Arabia

Senegal

Singapore

Slovakia

Slovenia

Sweden

Tai wan

Thailand

Turkey

Tunesia

Venezuela

Yugoslavia

France

KROHNE S.A.S.

Usine des Ors

BP 98

F-26 103 Romans Cedex

TEL.: +33(0)4-75 05 44 00

FAX: +33(0)4-75 05 00 48

e-mail: info@krohne.fr

Germany

KROHNE Messtechnik

GmbH & Co. KG

Ludwig-Krohne-Straße

D-47058 Duisburg

TEL.: +49(0)203-301-0

FAX: +49(0)203-301 389

e-mail: krohne@krohne.de

India

KROHNE Marshall Ltd.

A-34/35, M.I.D.C.

Industrial Area, H-Block,

Pimpri Poona 411018

TEL.: +91(0)20-744 20 20

FAX: +91(0)20 -744 20 40

e-mail: pcu@vsnl.net

Italy

KROHNE Italia Srl.

Via V. Monti 75

I-20145 Milano

TEL.: +39(0)2-4 30 06 61

FAX: +39(0)2-43 00 66 66

e-mail: krohne@krohne.it

Korea

Hankuk KROHNE

2 F, 599-1

Banghwa-2-Dong

Kangseo-Ku

Seoul

TEL.: +82(0)2665-85 23-4

FAX: +82(0)2665-85 25

e-mail: flowtech@unitel.co.kr

Netherlands

KROHNE Altometer

Kerkeplaat 12

NL-3313 LC Dordrecht

TEL.: +31(0)78-6306300

FAX: +31(0)78-6306390

e-mail: postmaster@krohne-altometer.nl

KROHNE Nederland B.V.

Kerkeplaat 12

NL-3313 LC Dordrecht

TEL.: +31(0)78-6306200

FAX: +31(0)78-6306405

Service Direkt: +31(0)78-6306222

e-mail: info@krohne.nl

Norway

Krohne Instrumentation A.S.

Ekholtveien 114

NO-1526 Moss

P. O. Box 2178, NO-1521 Moss

TEL.: +47(0)69-264860

FAX: +47(0)69-267333

e-mail: postmaster@krohne.no

Internet: www.krohne.no

South Africa

KROHNE Pty.Ltd.

163 New Road

Halfway House Ext. 13

Midrand

TEL.: +27(0)11-315-2685

FAX: +27(0)11-805-0531

e-mail: midrand@krohne.co.za

Spain

I.I. KROHNE Iberia, S.r.L.

Poligono Industrial Nilo

Calle Brasil, n°. 5

E-28806 Alcalá de Henares-Madrid

TEL.: +34(0)91-8 83 21 52

FAX: +34(0)91-8 83 48 54

e-mail: krohne@krohne.es

Switzerland

KROHNE AG

Uferstr. 90

CH-4019 Basel

TEL.: +41(0)61-638 30 30

FAX: +41(0)61-638 30 40

e-mail: info@krohne.ch

United Kingdom

KROHNE Ltd.

Rutherford Drive

Park Farm Industrial Estate

Wellingborough,

Northants NN8 6AE, UK

TEL.: +44(0)19 33-408 500

FAX: +44(0)19 33-408 501

e-mail: info@krohne.co.uk

USA

KROHNE Inc.

7 Dearborn Road

Peabody, MA 01960

TEL.: +1-978 535-6060

FAX: +1-978 535 -1720

e-mail: info@krohne.com

Overseas Representatives

Other Countries:

KROHNE Messtechnik

GmbH & Co. KG

Ludwig-Krohne-Str.

D-47058 Duisburg

TEL.: +49(0)203-301 309

FAX: +49(0)203-301 389

e-mail: export@krohne.de

Subject to change without notice

Loading...

Loading...