KROHNE DK32, DK34, DK37 Specifications

Technical Datasheet

Technical Datasheet

DK32 - DK34 - DK37

DK32 - DK34 - DK37

DK32 - DK34 - DK37DK32 - DK34 - DK37

Technical DatasheetTechnical Datasheet

Variable area flowmeters

•

Local measurement, setting and monitoring of very low flow rates

•

Compact design, no inlet and outlet sections

•

High resistance to pressure and temperature

© KROHNE 11/2018 - 4000282606 - TD DK32-34-37 R07 en

CONTENTS

DK32 - DK34 - DK37

1 Product features 3

1.1 Variable area flowmeters in an all-metal design ............................................................ 3

1.2 Options for type DK metal ................................................................................................ 4

1.3 Functional principle.......................................................................................................... 6

2 Technical data 7

2.1 Technical data................................................................................................................... 7

2.2 Dimensions and weight .................................................................................................. 13

2.2.1 DK32, DK34 ........................................................................................................................... 13

2.2.2 DK32, DK34 with transmitter housing ESK3x ...................................................................... 15

2.2.3 DK37/M8M............................................................................................................................. 16

2.2.4 DK37/M8E.............................................................................................................................. 17

2.2.5 Minimum distances when installing several measuring devices ........................................ 18

2.3 Measuring ranges...........................................................................................................19

2.4 Differential pressure regulators .................................................................................... 21

3 Installation 24

3.1 Intended use ................................................................................................................... 24

3.2 Installation conditions ....................................................................................................25

4 Electrical connections 26

4.1 Electrical connection of the limit switches .................................................................... 26

4.2 Electrical signal output ESK3x for DK32, DK34............................................................. 27

4.2.1 Power supply......................................................................................................................... 28

4.2.2 Load for HART communication............................................................................................. 28

4.2.3 Configuration......................................................................................................................... 28

4.3 Settings of limit switches for DK37/M8M....................................................................... 29

4.4 Electrical signal output for DK37/M8E........................................................................... 30

4.4.1 Power supply......................................................................................................................... 31

4.4.2 Load for HART communication............................................................................................. 31

4.4.3 Configuration......................................................................................................................... 31

4.5 Grounding connections................................................................................................... 32

4.6 Ingress protection .......................................................................................................... 33

5 Order form 34

6 Notes 35

2

www.krohne.com 11/2018 - 4000282606 - TD DK32-34-37 R07 en

DK32 - DK34 - DK37

PRODUCT FEATURES

1.1 Variable area flowmeters in an all-metal design

The solid metal DK flowmeters are suitable for measuring liquids and gases.

Because of their robust design the flowmeters are particularly suited for difficult operating and

environmental conditions.

The extremely compact design and the elimination of inlet and outlet sections allows for simple

and cost-effective integration into measuring systems such as process analysers.

1

Highlights

• DK32 with horizontal connections - with valve

• DK34 with vertical connections - without valve

• DK37 with a higher measuring accuracy and larger indication

• Narrow design enabling a high packing density

• Easy installation and commissioning

Industries

• Chemical

• Petrochemical

• Oil & Gas

• Mechanical and plant engineering

• Analyser system building

• Compressor and pump technology

Applications

The devices are particularly suitable for the measurement of small quantities of:

• Process or carrier gases

• Nitrogen, CO

• Sample flows for process analysers

• Sealing gas or sealing liquid measurement on sealing systems

• Purge fluids for measuring systems

• Air or water

• Chemicals and additives

• Lubricating, cooling and anti-corrosive agents

or other industrial gases

2

www.krohne.com11/2018 - 4000282606 - TD DK32-34-37 R07 en

3

1

PRODUCT FEATURES

1.2 Options for type DK metal

DK32

DK32

DK32DK32

DK34

DK34

DK34DK34

DK32 - DK34 - DK37

• Horizontal process connections, rear

• For flow rates of 0.15...150 l/h liquid or 1.6...4800 l/h

gas

• Design with valve at bottom, valve on top or without

valve

• Vertical process connections

• For flow rates of 0.15...150 l/h liquid or 1.6...4800 l/h

gas

• Design without valve

DK32, DK34 with electrical signal outputs

DK32, DK34 with electrical signal outputs

DK32, DK34 with electrical signal outputsDK32, DK34 with electrical signal outputs

Electrical options:

Electrical options:

Electrical options:Electrical options:

• 1 or 2 limit switches, NAMUR

• 1 limit switch, Reed

• 4...20 mA current output and HART

®

communication

4

www.krohne.com 11/2018 - 4000282606 - TD DK32-34-37 R07 en

DK32 - DK34 - DK37

DK32, DK34 with flange connection adapter

DK32, DK34 with flange connection adapter

DK32, DK34 with flange connection adapterDK32, DK34 with flange connection adapter

DK37/M8E

DK37/M8E

DK37/M8EDK37/M8E

PRODUCT FEATURES

Flange connection adapters with a standard length of

250 mm / 9.8" and DN15/DN25 flanges can be used for

connection to the process instead of the NPT/G threads.

• Electronic bargraph indicator

• 4...20 mA current output and HART

• For flow rates of 0.15...250 l/h liquid or 1.6...8000 l/h

gas

• Design with valve at bottom, valve on top or without

valve

®

communication

1

DK37/M8M

DK37/M8M

DK37/M8MDK37/M8M

DK32, DK37 with flow regulator

DK32, DK37 with flow regulator

DK32, DK37 with flow regulatorDK32, DK37 with flow regulator

Standard housing M8E: PPS, conductive plastic

Optional housing M8E/R: stainless steel 1.4404/CF8M

• Max. two limit switches (NAMUR)

• For flow rates of 0.15...250 l/h liquid or 1.6...8000 l/h

gas

• Design with valve at bottom, valve on top or without

valve

Standard housing M8E: PPS, conductive plastic

Optional housing M8E/R: stainless steel 1.4404/CF8M

The inlet or outlet pressure regulators are used to

provide constant flow rates in the case of variable inlet

or outlet pressures.

www.krohne.com11/2018 - 4000282606 - TD DK32-34-37 R07 en

5

1

PRODUCT FEATURES

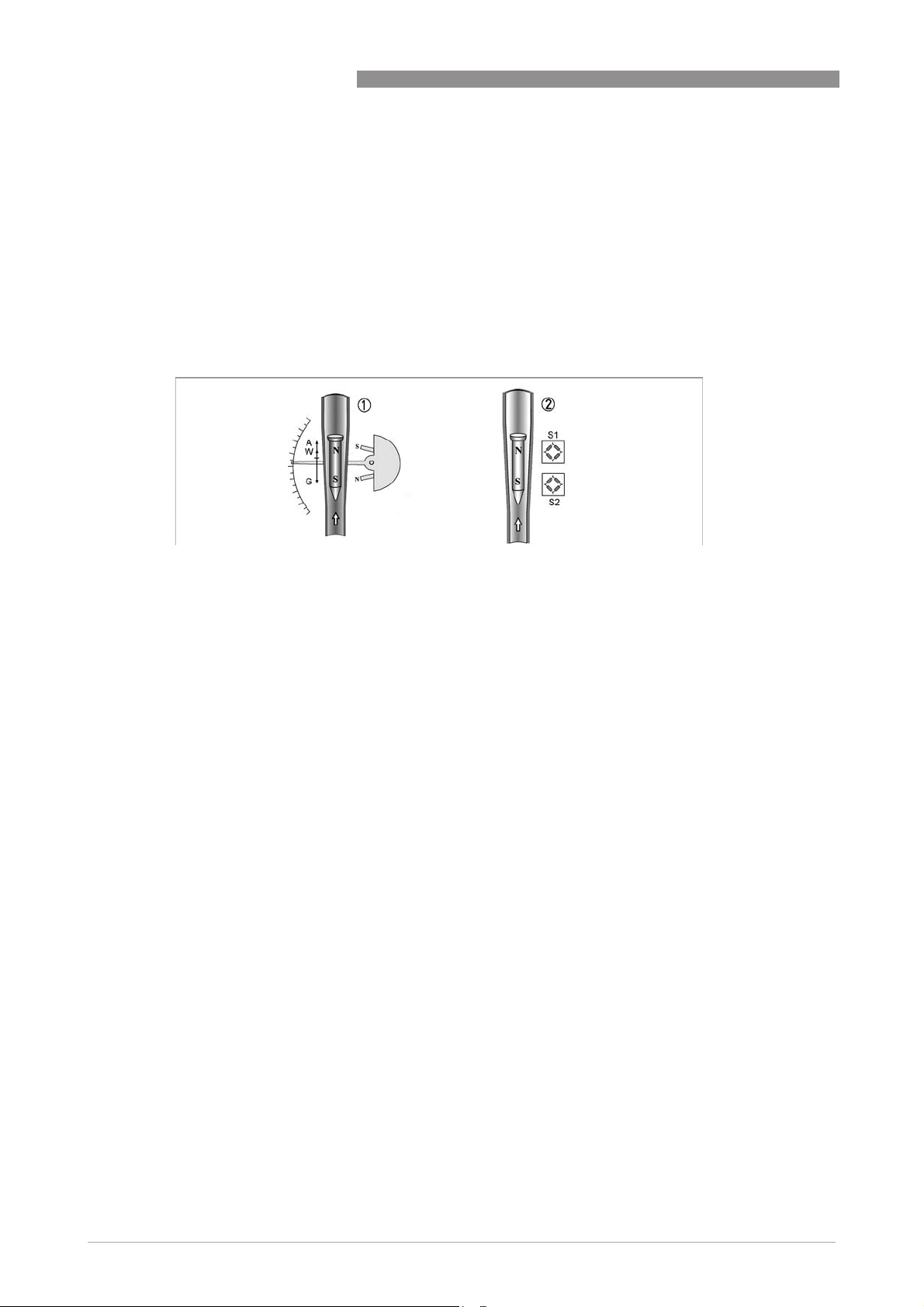

1.3 Functional principle

The flowmeter operates in accordance with the float measuring principle.

The measuring unit consists of a metal cone in which a float can move freely up and down.

The medium flows through the flowmeter from bottom to top.

The float adjusts itself so that the buoyancy force A acting on it, the form resistance W and its

weight G are in equilibrium: G = A + W

DK32 - DK34 - DK37

Figure 1-1: Functional principle

For DK32, DK34 and DK37/M8M 1 the flow-dependent height of the float in the measuring unit is

transmitted by means of a magnetic coupling on a scale.

For DK37/M8E, DK32/ESK and DK34/ESK 2 the flow-dependent height of the float in the

measuring unit is transmitted to the electronic display by means of a magnetic coupling on

sensors S1 and S2.

6

www.krohne.com 11/2018 - 4000282606 - TD DK32-34-37 R07 en

DK32 - DK34 - DK37

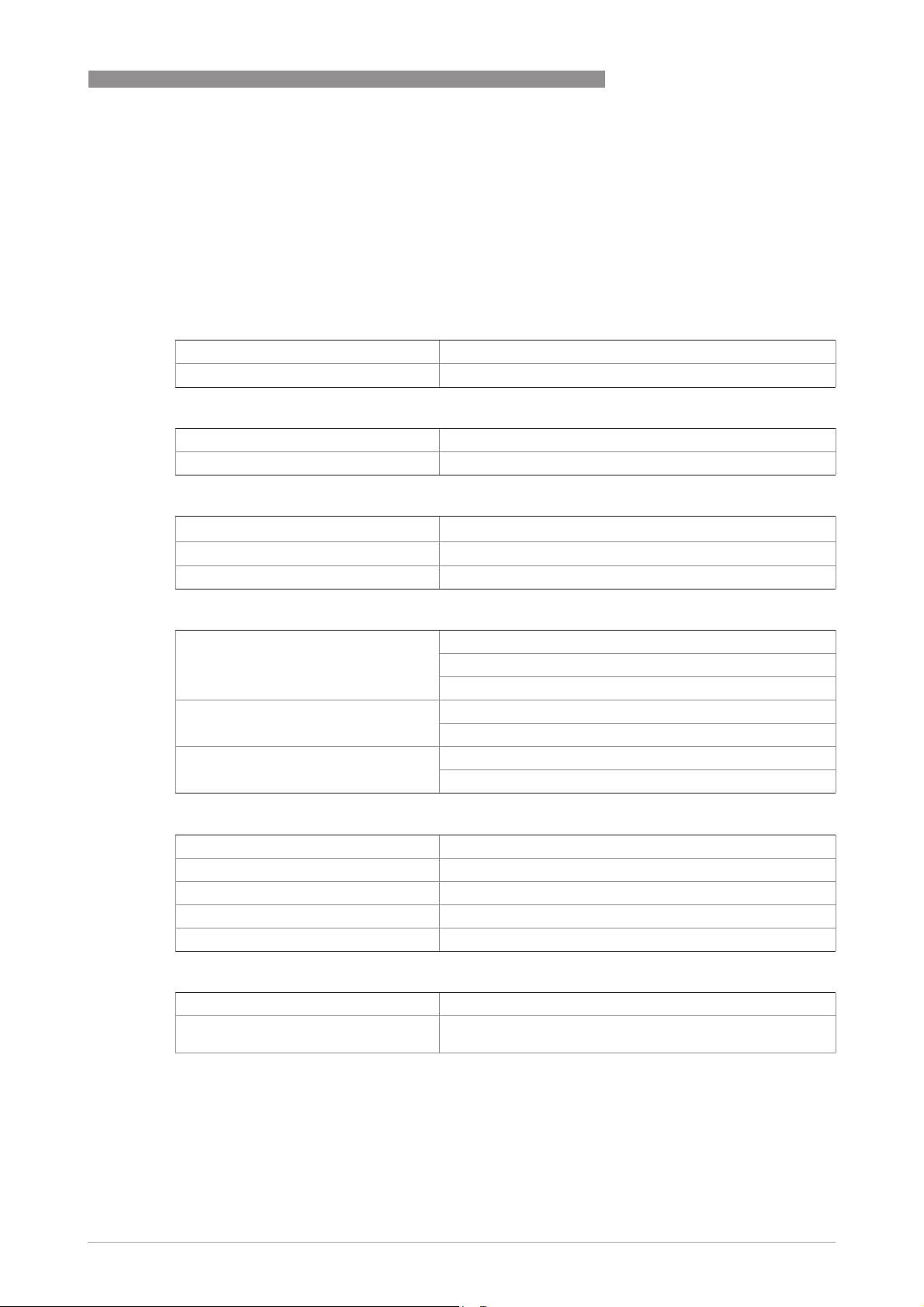

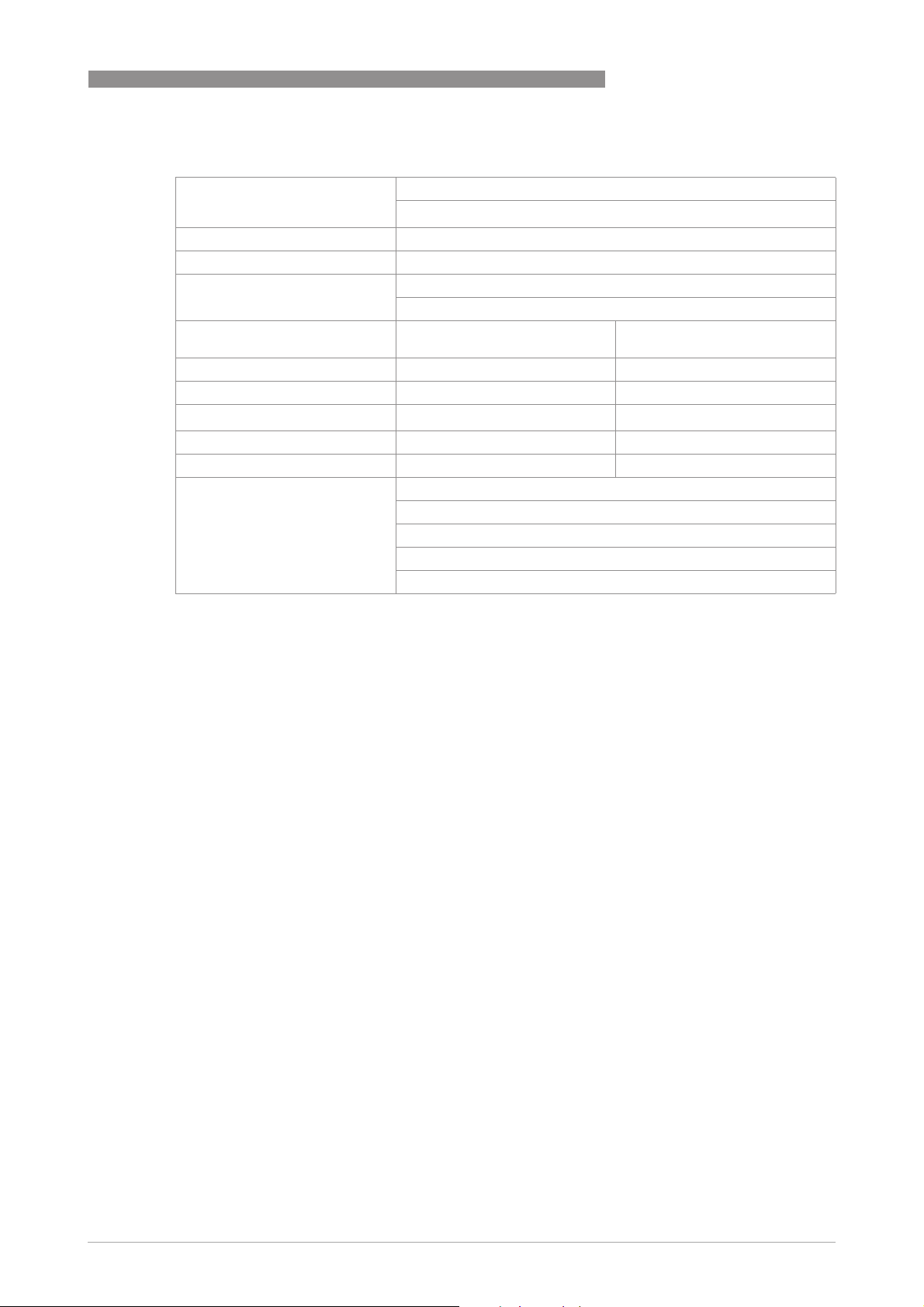

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

Measuring system

Application range Flow measurement of liquids or gases

Function / Measuring principle Float measuring principle

Measured value

Primary measured value Float position

Secondary measured value Operating volume flow, nominal volume flow or mass flow

Measuring accuracy

Directive VDI/VDE 3513, sheet 2 (qG = 50%)

DK32, DK34 4.0%

DK37 2.5%

TECHNICAL DATA

2

Operating conditions

Max. operating temperature TS Depending on the version (refer to nameplate)

Standard version: up to +150°C / +221°F

HT version: up to +200°C / +392°F

Max. operating pressure PS Depending on the version (refer to nameplate)

Standard version: 130 barg / 1885 psig

Max. test pressure PT Depending on the version (refer to nameplate)

Standard version: 202 barg / 2930 psig

1

1

Ingress protection

DK32, DK34 mechanical IP66/IP68

DK32, DK34 with limit switches K1/K2 IP65

DK32, DK34 with transmitter ESK3x IP66/IP68

DK37 with PPS indicator IP66

DK37 with stainless steel indicator IP66/IP67

Installation conditions

Inlet and outlet sections None

Protect devices from vibration and highfrequency oscillation

1 Higher pressures on request

Use in accordance with IEC 61298-3 in control room or field

with medium vibration level

www.krohne.com11/2018 - 4000282606 - TD DK32-34-37 R07 en

7

2

TECHNICAL DATA

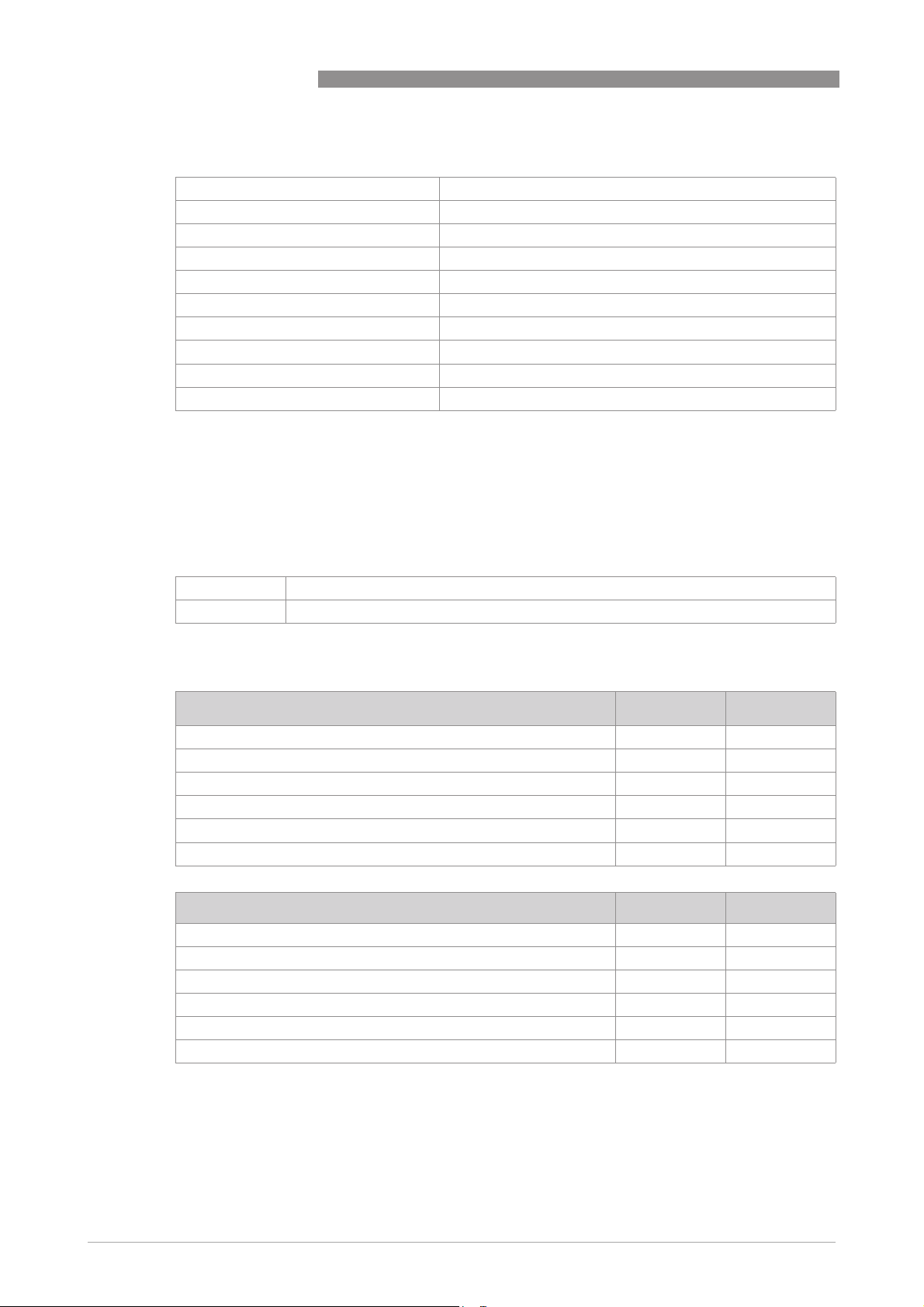

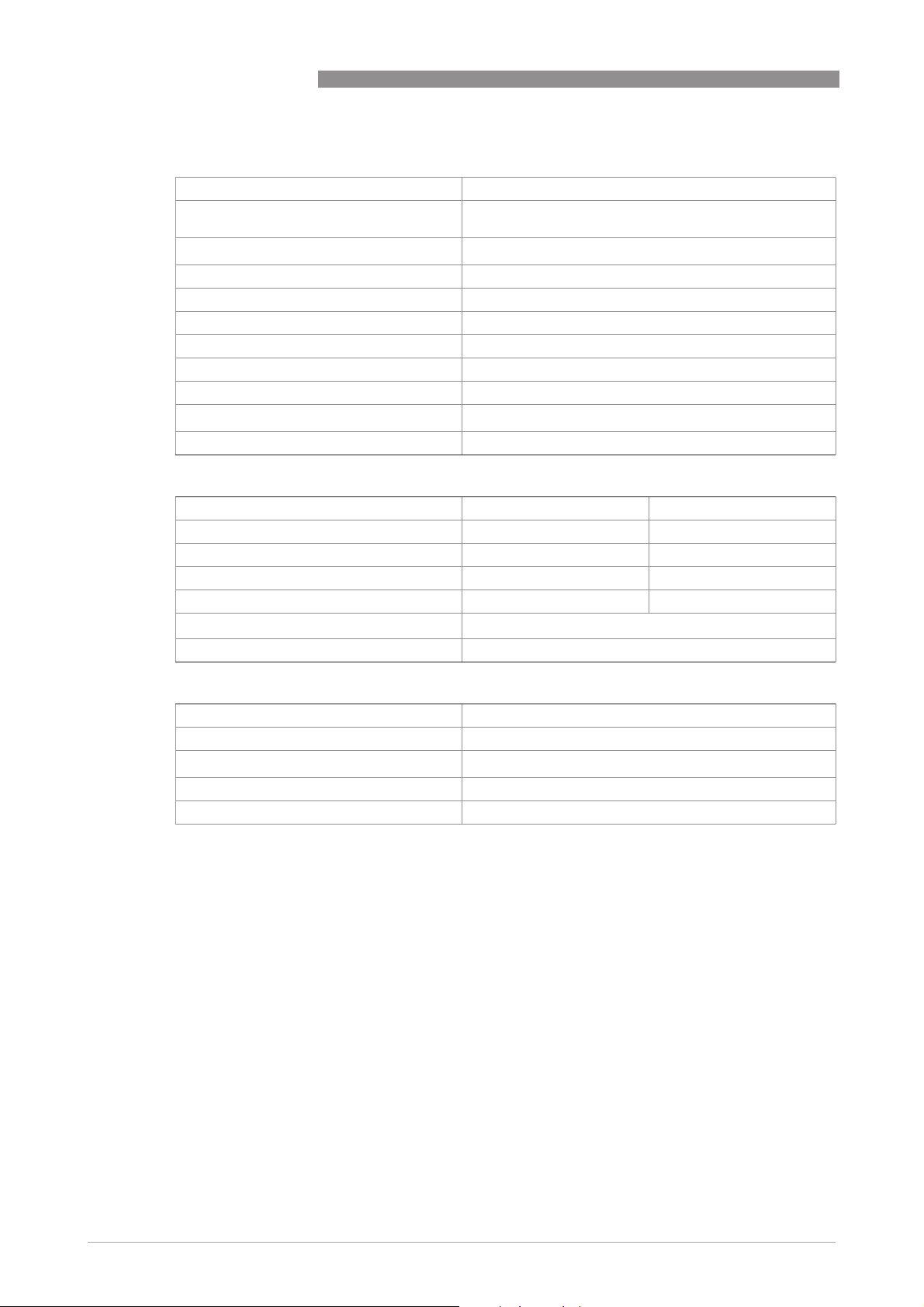

Materials

Top fitting, bottom fitting, cone CrNi steel 1.4404 / 316 L

Lock screw CrNi steel 1.4404 / 316 L

Float, standard CrNi steel 1.4404 / 316 L or titanium

Dosing unit CrNi steel 1.4571 / 316 Ti

Valve stem CrNi steel 1.4404 / 316 L

Gasket of lock screw PTFE

Gasket of dosing unit FPM/PTFE, PTFE, FFKM

Indicator housing of DK32, DK34 Die-cast aluminium with powder coating

Indicator housing of DK37/M8_/ PPS

Indicator housing of DK37/M8_/R/ Stainless steel 1.4408/CF8M

1 Other gasket materials on request

Other options on request:

• Surface passivation of all metallic, wetted parts

• Special materials: e.g. Hastelloy

1

®

, Monel®, Inconel®, titanium a.o.

DK32 - DK34 - DK37

Process connection

Standard 1/4 NPT (female)

Option G1/4, Ermeto, Serto, Gyrolok, Swagelok, flanges

1 Other connections on request

1

Temperatures

Max. product temperature at T

DK34, DK32, DK37 without valve -80…+150 -112...+302

DK32, DK37 with valve FPM/PTFE -25…+150 -13...+302

DK32, DK37 with valve FFKM -20…+150 -4...+302

DK32, DK37 with valve PTFE -40…+150 -40...+302

DK32 HT, DK34 HT high-temperature with FFKM -20…+200 -4...+392

DK32, DK34 with transmitter ESK3x -40...+140 -40...+284

Permissible ambient temperature 1 [°C] [°F]

DK32, DK34, DK37/M8M without electrical built-ins -40…+70 -40...+158

DK32, DK34, DK37/M8M with limit switch I7S2002-N or SJ2-SN -40…+70 -40...+158

DK32, DK34, DK37/M8M with limit switch SC2-N0 -25…+70 -13...+158

DK32, DK34 with transmitter ESK3x -40…+70 -40...+158

DK37/M8E -40…+70 -40...+158

DK32 HT, DK34 HT high-temperature -25…+200 -13...+392

< +40°C / +104°F 1 [°C] [°F]

amb.

1 For restrictions in hazardous areas refer to the temperature tables in the supplementary Ex

instructions

8

www.krohne.com 11/2018 - 4000282606 - TD DK32-34-37 R07 en

DK32 - DK34 - DK37

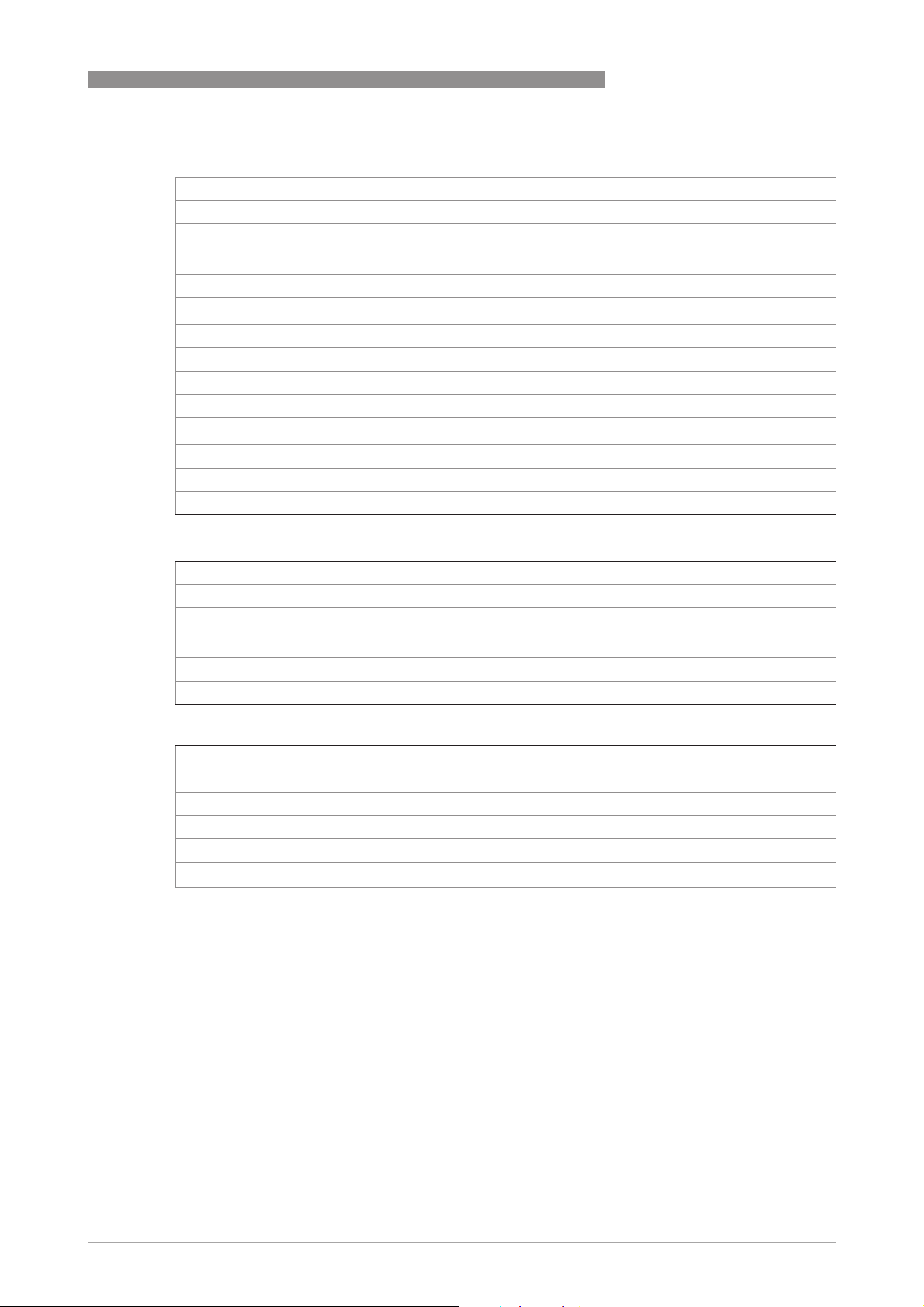

Indicator DK32, DK34, DK37/M8M with limit switch

TECHNICAL DATA

2

DK32 - 34 /K./S

DK37/M8M

DK32 - 34 /K./S Clamping range: 4.5...10 mm / 0.18...0.4"

DK37/M8M Clamping range: 3...7 mm / 0.12...0.28"

DK32 - 34/K./L Ø Connecting cable: 6.3 mm / 0.25"; 0.75 mm²

Limit switches SC2-N0

Connection type NAMUR 2-wire 2-wire

Switching element function Normally closed Normally closed

Nominal voltage U

Pointer vane not detected ≥ 3mA ≥ 3mA

Pointer vane detected ≤1mA ≤1mA

DK32 - DK34 with Reed contact Type: SPDT (3-wire, normally closed and normally open)

1 Reduced values for Ex

0

Cable gland: M16 x 1.5

1

2

SJ2-SN (safety-oriented)

SJ2-SN (safety-oriented)

SJ2-SN (safety-oriented)SJ2-SN (safety-oriented)

1

1

Terminal connection: 1.5 mm

Cable length: approx. 1.7 m / 5.6 ft (other lengths on request)

SC2-N0

SC2-N0SC2-N0

I7S2002-N

I7S2002-N

I7S2002-NI7S2002-N

8VDC 8VDC

Switching reproducibility: < 5% of full scale range

Switching capacity: 12 VA

Max. switching capacity: 30 VDC

Max. switching current: 0.5 A

www.krohne.com11/2018 - 4000282606 - TD DK32-34-37 R07 en

9

2

TECHNICAL DATA

Transmitter ESK3x for DK32, DK34

Cable entry M16 x 1.5 or 1/2" NPT

Clamping range of cable gland 3...7 mm / 0.12...0.28" (PA gland) or 5...10 mm / 0.2...0.39"

Terminal connection

Measuring signal 4...20 mA = 0…100% flow value in 2-wire technology

Power supply 12...32 VDC (non-Ex)

Power supply influence < 0.1%

Dependence on load impedance < 0.1%

Temperature influence <0.3%/10 K

Max. external resistance / load 500 Ω (24 VDC), 800 Ω (32 VDC)

Min. load for HART

NAMUR type test acc. to NE 95 Fulfills NE 21, NE 43, NE 107

ESK3x - electrical characteristics

Process variable flow rate Values [%]

Upper range limit +103.125 20.5

Device error identification < -2.5 or >106.25 <3.6 or > 21

Maximum 118.75 23.0

Multi-Drop operation - 4.0

Min. U

ext.

Capacitance number (CN) 2

DK32 - DK34 - DK37

(stainless steel gland)

2

1.5 mm

®

250 Ω

Values [%] Signal output [mA]

Values [%]Values [%]

12 VDC

Signal output [mA]

Signal output [mA]Signal output [mA]

ESK3x HART Device

Manufacturer name (code) KROHNE Messtechnik (0x0045)

Model name ESK3x (0x45BA)

HART® protocol

Device revision 1

Equipment category Transmitter

Revision 7.6

10

www.krohne.com 11/2018 - 4000282606 - TD DK32-34-37 R07 en

DK32 - DK34 - DK37

Indicator DK37/M8E

Cable gland M16 x 1.5

Clamping range 3...7 mm / 0.12...0.28"

Terminal connection

Measuring signal 4...20 mA = 0…100% flow value in 2-wire technology

Power supply 14.8...30 VDC

Min. power supply for HART

Power supply influence <0.1%

Dependence on load impedance <0.1%

Temperature influence <10 µA/K

Max. external resistance / load 640 Ω (30 VDC)

Min. load for HART

Software firmware version 01.15

Identification number 3204090400

NAMUR type test acc. to NE 95 Fulfills NE 21, NE 43

TECHNICAL DATA

2

2.5 mm

®

®

20.5 VDC

250 Ω

2

M8E HART® configuration

Manufacturer name (code) KROHNE Messtechnik (69)

Model name M8E (230)

HART® protocol

Device revision 1

Physical Layer FSK

Equipment category Transmitter

Revision 5.1

M8E process variable

Process variable flow rate Values [%]

Upper range limit +102.5 (±1%) 20.24...20.56

Device error identification >106.25 ≥21.00

Maximum 112.5 22

Multi-Drop operation - 4.5

Min. U

ext.

Values [%] Signal output [mA]

Values [%]Values [%]

14.8 VDC

Signal output [mA]

Signal output [mA]Signal output [mA]

www.krohne.com11/2018 - 4000282606 - TD DK32-34-37 R07 en

11

Loading...

Loading...