Page 1

Supplementary instructions

Supplementary instructions

DK32 DK34

DK32 DK34

DK32 DK34DK32 DK34

Supplementary instructions Supplementary instructions

Variable area flowmeter

with electrical built-ins

Equipment category II 2 G

© KROHNE 11/2012 - 4000422303 AD DK32/34 II2G R03 en

Page 2

CONTENTS

DK32 DK34

1 Safety instructions 3

1.1 General notes ................................................................................................................... 3

1.2 EC conformity ................................................................................................................... 3

1.3 Approval according to the IECEx scheme ........................................................................ 3

1.4 Security information......................................................................................................... 3

2 Device description 4

2.1 Device description ............................................................................................................ 4

2.2 Description code............................................................................................................... 4

2.3 Marking............................................................................................................................. 4

2.4 Flammable products ........................................................................................................ 5

2.5 Equipment category .........................................................................................................5

2.6 Types of protection ........................................................................................................... 5

2.7 Ambient temperature / temperature classes.................................................................. 6

2.8 Electrical data................................................................................................................... 7

3 Installation 8

3.1 Installation........................................................................................................................ 8

4 Electrical connections 9

4.1 General notes ................................................................................................................... 9

4.2 Earthing and equipotential bonding ............................................................................... 10

5 Operation 11

5.1 Start-up........................................................................................................................... 11

5.2 Operation ........................................................................................................................ 11

6 Service 12

6.1 Maintenance ................................................................................................................... 12

6.2 Dismantling .................................................................................................................... 12

7 Notes 13

2

www.krohne.com 11/2012 - 4000422303 AD DK32/34 II2G R03 en

Page 3

DK32 DK34

1.1 General notes

These additional instructions apply to explosion-protected versions of variable area flowmeters

with electrical built-ins and the marking II 2 G. They complement the Installation and Operation

Instructions for the non-explosion protected versions.

The information given in these Instructions contains only the data relevant to Category 2

explosion protection. The technical details given in the Installation and Operation Instructions for

the non-explosion protected versions apply unchanged unless excluded or superseded by these

Instructions.

1.2 EC conformity

The manufacturer declares with the EC Declaration of Conformity on his own responsibility

conformity with the protection goals of Directive 94/9/EC for use in hazardous areas with gas.

The EC Type Examination Certificate of the Physikalisch Technische Bundesanstalt (PTB) forms

the basis of the EC Declaration of Conformity:

SAFETY INSTRUCTIONS 1

PTB 99 ATEX 2191

PTB 99 ATEX 2191

PTB 99 ATEX 2191PTB 99 ATEX 2191

If required the EC Type Test Certificate can be downloaded under www.krohne.com.

1.3 Approval according to the IECEx scheme

Conformity with IECEx standards was tested in accordance with the IECEx Certification Scheme

for Explosive Atmospheres as per IEC 60079-0 and IEC 60079-11. The number of the IEC

certificate is:

IECEx PTB 09.0025

IECEx PTB 09.0025

IECEx PTB 09.0025IECEx PTB 09.0025

1.4 Security information

Assembly, installation, start-up and maintenance may only be performed by personnel trained in

explosion protection!

CAUTION!

The operator respectively his agent is responsible to follow further standards, directives or laws

if required due to operating conditions or place of installation. This applies particularly for the

use of easy detachable process connections such as SMS or Clamp when measuring flammable

mediums.

www.krohne.com11/2012 - 4000422303 AD DK32/34 II2G R03 en

3

Page 4

2 DEVICE DESCRIPTION

2.1 Device description

Variable area flowmeters measure and display the volume flow of flammable and nonflammable gases and liquids. The display houses one or two separately adjustable electrical

limit switches.

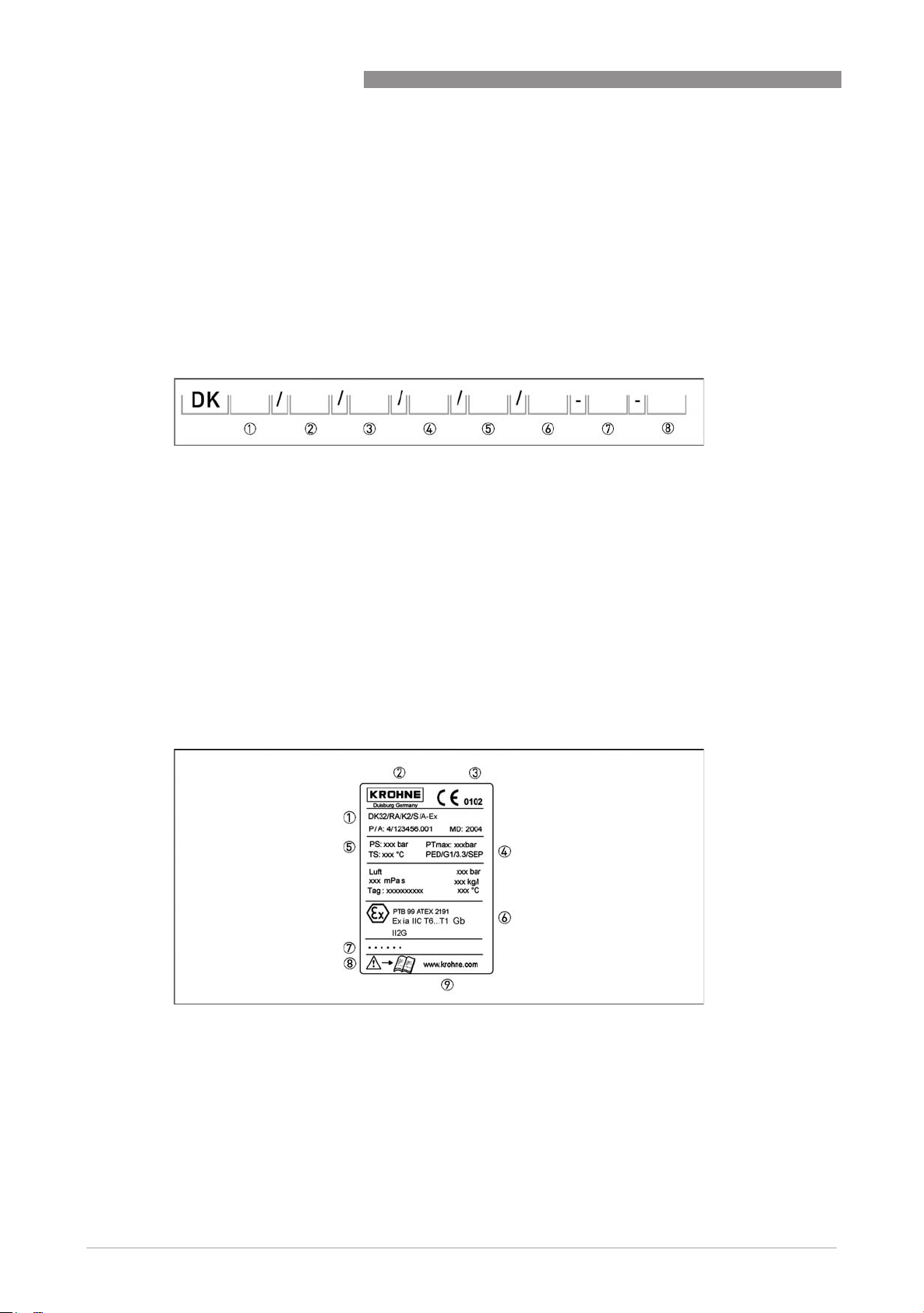

2.2 Description code

The safety description code * consists of the following elements:

1 32 - with valve and horizontal connection / 34 without valve and vertical connection

2 RE - inlet pressure regulator / RA - outlet pressure regulator

3 K1 - one limit switch / K2 - two limit switches

4 S - plug connector / L - cable gland incl. cable

5 HT - high-temperature version

6 A - Limit switch tested for EC type approval or IECEx tested

7 Ex - Explosion-protected equipment

DK32 DK34

* positions which are not needed are omitted (no blank positions)

2.3 Marking

The type marking of the instrument is realized visibly with the rating plate shown below. The

interior of the display has an additional marking with the serial number (P/A).

1 Device type

2 Manufacturer

3 Notified ATEX body

4 PED data

5 Sizing data: temperature & pressure rating

6 Ex-data according to PTB 99 ATEX 2191 and IECEx PTB 09.0025

7 Built-in equipment

8 Note manual

9 KROHNE website

4

www.krohne.com 11/2012 - 4000422303 AD DK32/34 II2G R03 en

Page 5

DK32 DK34

2.4 Flammable products

Atmospheric conditions:

Atmospheric conditions:

Atmospheric conditions:Atmospheric conditions:

An explosive atmosphere is a mixture of air and flammable gases, vapours, mists or dusts under

atmospheric conditions. The following values define it

= -20...+60°C / -4...+140°F and P

T

atm

Outside of this range, no key data are available as to ignition behaviour for most mixtures.

Installation condititions:

Installation condititions:

Installation condititions:Installation condititions:

Variable area flowmeters operate outside of atmospheric conditions, which means that

explosion protection according to Directive 94/9/EC (ATEX) – regardless of the zone assignment

– is fundamentally not applicable due to the lack of key safety data for the interior of the

measuring section.

WARNING!

Operation with flammable products is only permitted as long as no explosive fuel/air mixture

builds up on the inside of the flowmeter under operating conditions. The operator is responsible

for ensuring that the flowmeter is operated safely as regards the temperature and pressure of

the products used. In case of operation with flammable products the measuring units must be

included in the periodic pressure tests of the system. When using the device version H250/C...

(PTFE-liner, nonconductive) the min. conductivity of the medium must be 10

avoid the electrostatic charge.

= 0.8...1.1 bar.

atm

DEVICE DESCRIPTION 2

-8

S/m, in order to

2.5 Equipment category

The flowmeters are designed in Category II 2G according to EN 60079-0 and EN 60079-11 for use

in Zone 1.

2.6 Types of protection

The variable-area flowmeter is designed in Intrinsic Safety type of protection, protection level

“ia“ according to EN 60079-11.

The marking refering to ATEX is: II 2G Ex ia IIC T6 Gb

The marking refering to IECEx is: Ex ia IIC T6 Gb

The marking contains the following information:

The marking contains the following information:

The marking contains the following information:The marking contains the following information:

II

II Explosion protection Group II

IIII

2222 Device category 2

GGGG Gas explosion protection

ia

ia Intrinsic Safety type, protection level “ia“

iaia

IIC

IIC suitable for gas group IIC, IIB and IIA

IICIIC

T6

T6 suitable for temperature class T6 ... T1

T6T6

Gb

Gb EPL, suitable for zone 1

GbGb

II 2G Ex ia IIC T6 Gb

II 2G Ex ia IIC T6 GbII 2G Ex ia IIC T6 Gb

Ex ia IIC T6 Gb

Ex ia IIC T6 GbEx ia IIC T6 Gb

www.krohne.com11/2012 - 4000422303 AD DK32/34 II2G R03 en

5

Page 6

2 DEVICE DESCRIPTION

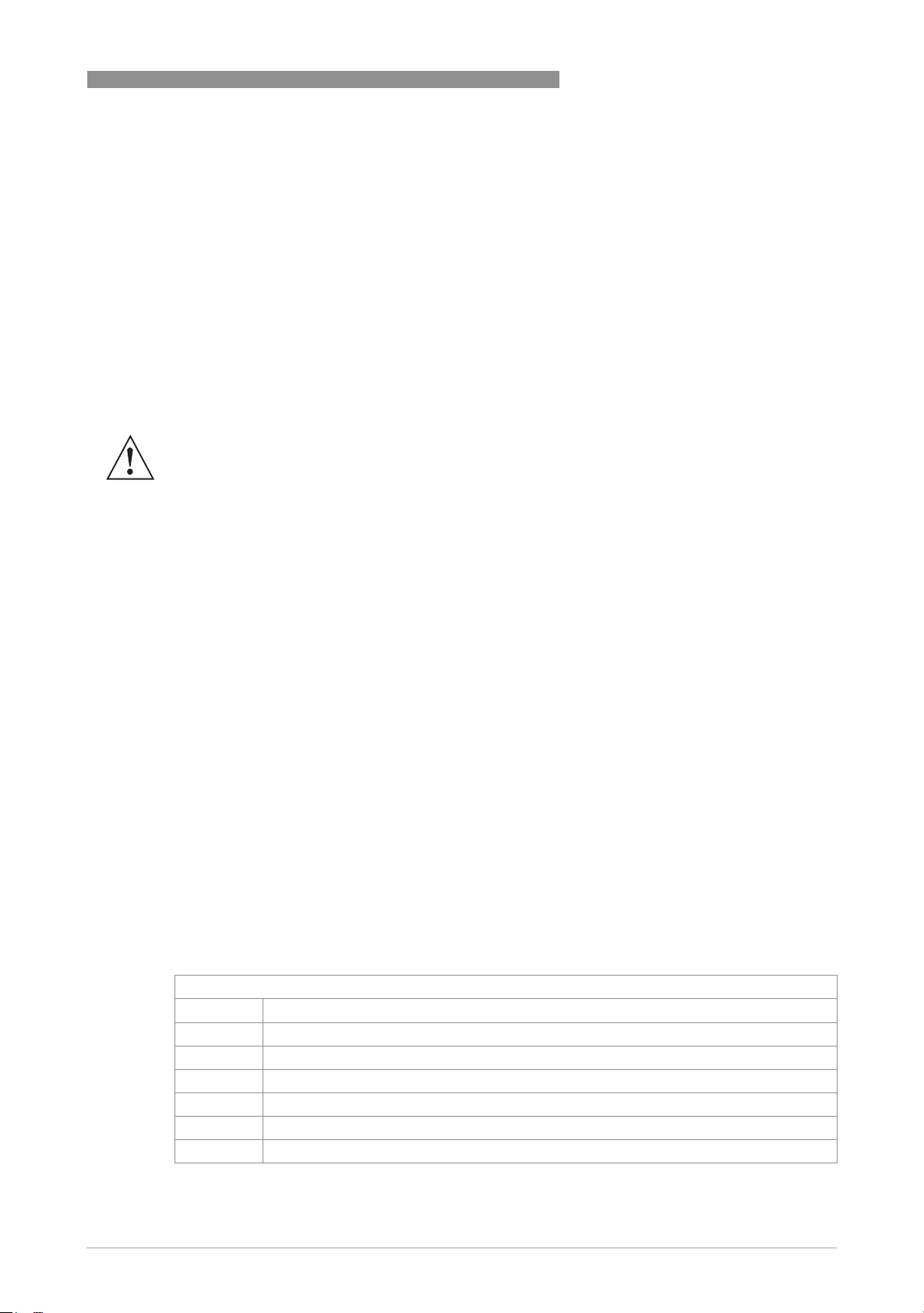

2.7 Ambient temperature / temperature classes

Due to the influence of the product temperature, variable area flowmeters with built-in electrical

equipment (electric variants) are not assigned to any fixed temperature class. The temperature

class of these devices is rather a function of the product temperature and ambient temperature

that is present and the specific device version. Please see the following tables for the

assignments.

The tables take into account the following parameters:

• Ambient temperature T

• Product temperature T

INFORMATION!

The maximum permissible product temperatures listed in the tables are valid under

the following conditions:

•

The measuring device is installed and operated in accordance with the installation

instructions in the installation and operating manual.

•

It must be ensured that the flowmeter is not heated by the effects of additional

heat radiation (sunshine, neighbouring system components) and

thus operated above the permissible ambient temperature range.

•

Insulation must be limited to the piping.

Unobstructed ventilation of the indicator part must be ensured.

amb.

m

DK32 DK34

DK3./../.././../A–Ex permissible medium and ambient temperatures

Temperature

class

T6 -20...+40 -4...+104 75 167 80 176

T5 -20...+40 -4...+104 100 212 100 212

T4 -20...+40 -4...+104 135 275 135 275

T3...T1 -20...+40 -4...+104 135 275 150 302

Ambient

temperature

Maximum permissible medium temperature

with connector (S) or cable gland (L)

Type DK32 Type DK34

[°C] [°F] [°C] [°F] [°C] [°F]

-20...+50 -4...+122 70 158 70 158

-20...+60 -4...+140 60 140 60 140

-20...+50 -4...+122 95 203 100 212

-20...+60 -4...+140 85 185 90 194

-20...+50 -4...+122 130 266 135 275

-20...+60 -4...+140 120 248 130 266

-20...+90 -4...+194 90 194 90 194

-20...+50 -4...+122 130 266 140 284

-20...+60 -4...+140 120 248 130 266

-20...+90 -4...+194 90 194 90 194

6

www.krohne.com 11/2012 - 4000422303 AD DK32/34 II2G R03 en

Page 7

DK32 DK34

2.8 Electrical data

The electronic signal output may only be connected to intrinsically safe circuits. Depending on

the instrument design, the following maximum values apply per circuit:

Design DK3./../.././../A–Ex

DEVICE DESCRIPTION 2

U

i

I

i

P

i

16 VDC

25 mA

64 mW

Irrespective of the instrument design the following values are to be observed for each

intrinsically safe circuit in case of interconnection:

C

i

L

i

150 nF

150 µH

www.krohne.com11/2012 - 4000422303 AD DK32/34 II2G R03 en

7

Page 8

3 INSTALLATION

3.1 Installation

Installation and setup must be carried out according to the applicable installation installation

standards (e.g. EN 60079-14) by qualified personnel trained in explosion protection. The

information given in the Installation and Operation Instructions and the Supplementary

Installation and Operation Instructions must always be observed.

Variable area flowmeters must be installed in such a way that

• There is no danger from mechanical impact effects.

• There are no external forces affecting the indicator part.

• The device is accessible for any visual inspections that are necessary, and can be viewed from

all sides.

• The nameplate is clearly visible.

• It can be operated from a location with secure footing.

CAUTION!

The manufacturer is not liable for any damage resulting from improper use or use other than the

intended purpose. This applies in particular to hazards due to insufficient corrosion resistance

and suitability of the materials in contact with product.

DK32 DK34

8

www.krohne.com 11/2012 - 4000422303 AD DK32/34 II2G R03 en

Page 9

DK32 DK34

4.1 General notes

For version DK3./../../S/../A-Ex (plug), the separate intrinsically safe signal circuits with level of

protection "ia" or "ib" are electrically connected in the terminal compartment of the plug

housing and for version DK3./../../L/../A-Ex (connecting cable) it is the connecting cable as

illustrated in the connection diagram. Permissible maximum values (electrical data) must be

observed.

Connecting cable

The connecting cables must be selected according to prevailing installation standards (e.g.

EN 60079-14). The outer diameter of the connecting cable must be within the sealing range of

the cable entry. The connecting cables must be fixed and laid in such a way as to be sufficiently

protected against damage.

All cores that are not used must be securely connected to the earth potential of the hazardous

area or carefully insulated against each other and against earth (test voltage ≥ 500 V

Cable entries / Blanking plugs

The DK3./../../S/../A-Ex variable area flowmeter is equipped with a connector. The connector

guarantees protection from foreign bodies and water (protection category) IP65 as per EN 60529.

The cable entry is closed with a plug. The plug is to be replaced with a suitable connecting cable

(nominal diameter range 6...9mm).

ELECTRICAL CONNECTIONS 4

).

eff

Connection diagrams

Contact connection Cable colors of assembled cable

1 Min minus white

2 Min plus yellow

3 Max minusMax minus green

4 Max plus brown

5 Lift slot

6 Fastening screw of connection box

www.krohne.com11/2012 - 4000422303 AD DK32/34 II2G R03 en

9

Page 10

4 ELECTRICAL CONNECTIONS

4.2 Earthing and equipotential bonding

If the device is not sufficiently electrostatically grounded via the process cables, an additional

earth connection must be established using the earth screw 1. The position of the ground

terminal is illustrated below. The connection guarantees only an electrostatic connection of the

device and does not comply with the requirements of an equipotential bonding connection.

DK32 - DK34

DK32 DK34

10

www.krohne.com 11/2012 - 4000422303 AD DK32/34 II2G R03 en

Page 11

DK32 DK34

5.1 Start-up

Start-up is only permitted when the variable area flowmeter:

• is correctly installed in the system and connected.

• has been checked for the proper state with regard to its installation and connection

requirements.

The user of the system must have it checked before start-up in compliance with the national

regulations for checks before startup.

5.2 Operation

Setting of the limit switches may be carried out during operation. Remove the housing cover to

this purpose. The housing cover has to be closed immediately after the limit switches have been

set.

OPERATION 5

www.krohne.com11/2012 - 4000422303 AD DK32/34 II2G R03 en

11

Page 12

6 SERVICE

6.1 Maintenance

Maintenance work of a safety-relevant nature within the meaning of explosion protection may

only be carried out by the manufacturer, his authorised representative or under the supervision

of authorised inspectors.

For systems in hazardous areas, regular tests are required in order to maintain the proper

condition.

The following checks are recommended:

• Checking the housing, the cable entries and the feed lines for corrosion and/or damage.

• Checking the measuring unit and the piping connections for leakage.

The cover is to be closed following maintenance work on the display unit.

6.2 Dismantling

Replacing the display part

Due to the modular design of the variable area flowmeter, it is possible to replace a complete

display with an identical spare part in accordance with safety guidelines.

DK32 DK34

CAUTION!

There may be a loss of measuring accuracy!

Exchanging the entire device

Removal and installation is the user's responsibility.

Any replacement and removal should take place in a de-energized state if possible. If that is not

possible, the basic conditions for intrinsic safety (e.g. no grounding or connection of different

intrinsically safe circuits to one another) must be observed during dismantling.

CAUTION!

•

Pressurized pipes must be depressurized before removing the measuring section.

•

In the case of environmentally critical or hazardous products, appropriate safety precautions

must be taken with regard to residual liquids in the measuring unit.

•

New seals must be used when re-installing the device in the piping.

12

www.krohne.com 11/2012 - 4000422303 AD DK32/34 II2G R03 en

Page 13

DK32 DK34

NOTES 7

www.krohne.com11/2012 - 4000422303 AD DK32/34 II2G R03 en

13

Page 14

7 NOTES

DK32 DK34

14

www.krohne.com 11/2012 - 4000422303 AD DK32/34 II2G R03 en

Page 15

DK32 DK34

NOTES 7

www.krohne.com11/2012 - 4000422303 AD DK32/34 II2G R03 en

15

Page 16

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

• Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature meters

• Pressure meters

• Analysis products

• Products and systems for the oil & gas industry

• Measuring systems for the marine industry

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg (Germany)

Tel.:+49 (0)203 301 0

Fax:+49 (0)203 301 10389

info@krohne.de

The current list of all KROHNE contacts and addresses can be found at:

© KROHNE 11/2012 - 4000422303 AD DK32/34 II2G R03 en - Subject to change without notice.

www.krohne.com

Loading...

Loading...