Page 1

SERVICE MANUAL

MODEL

LT-203

Large Capacity Tray Unit

NOVEMBER 2002

CSM-LT203

Page 2

Page 3

LT-203

SERVICE MANUAL

Used On Model 7145

November 2002

Page 4

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Business Technologies strongly recommends that all servicing be

performed by Konica-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Business Technologies,

Inc., makes no representations or warranties, either

expressed or implied, that the information contained

in this service manual is complete or accurate. It is

understood that the user of this manual must assume

all risks or personal injury and/or damage to the

equipment while servicing the equipment for which

this service manual is intended.

Corporate Publishing Department

© 2002, KONICA BUSINESS TECHNOLOGIES, INC.

All rights reserved.

Printed in U.S.A.

Page 5

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS

Refer to the 7145 service manual on page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

I OUTLINE

1. LT-203 PRODUCT SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. CENTER CROSS-SECTIONAL DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

3. DRIVE SYSTEM DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

3.1 Rear side drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

3.2 Front side drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

II UNIT EXPLANATION

1. PAPER FEED SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1 Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.2 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

1.2.1 Tray up drive control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

1.2.2 Paper feed control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

1.2.3 Remaining paper detection control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

III DISASSEMBLY/ASSEMBLY

1. PAPER FEED SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 Removing the LT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.2 Removing the right, front and rear covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.3 Replacing the feed rubber and the paper feed rubber. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

1.4 Replacing the double feed prevention rubber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

1.5 Replacing the wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

I OUTLINEII UNIT EXPLANATIONIII DIS./ASSEMBLY

iii

Page 6

CONTENTS

I OUTLINEII UNIT EXPLANATIONIII DIS./ASSEMBLY

Blank page

iv

Page 7

I OUTLINE

1. LT-203 PRODUCT SPECIFICATIONS

LT-203 PRODUCT SPECIFICATIONS

A. Type

Type: Side mount type large capacity paper feed tray

B. Functions

Paper size: A4, 8.5 x 11

Applicable copy paper: 60g/m

Maximum tray capacity: 2000 sheets (80g/m

2

to 105g/m2 (16lbs to 24lbs), high-quality paper

2

or 20lbs)

C. Machine data

Power source: 24VDC/5V (supplied from the main body)

Power consumption: Maximum 31VA (with no internal heater used)

Weight: Approx. 13kg

Dimensions: 339mm (W) x 515mm (D) x 299mm (H)

D. Maintenance and life

Maintenance: Same as the main body

Machine service life: Same as the main body

I OUTLINE

E. Operating environment

Temperature: 10°C to 30°C (50°F to 86°F)

Humidity: 10% RH to 80% RH

Note:

• The information herein may be subject to change for improvement without notice.

1-1

Page 8

CENTER CROSS-SECTIONAL DIAGRAM

2. CENTER CROSS-SECTIONAL DIAGRAM

I OUTLINE

[2]

[1]

[5][4][3]

[1] Double feed prevention roller [4] Paper feed roller

[2] Conveyance roller [5] Paper lift plate

[3] Feed roller

1-2

Page 9

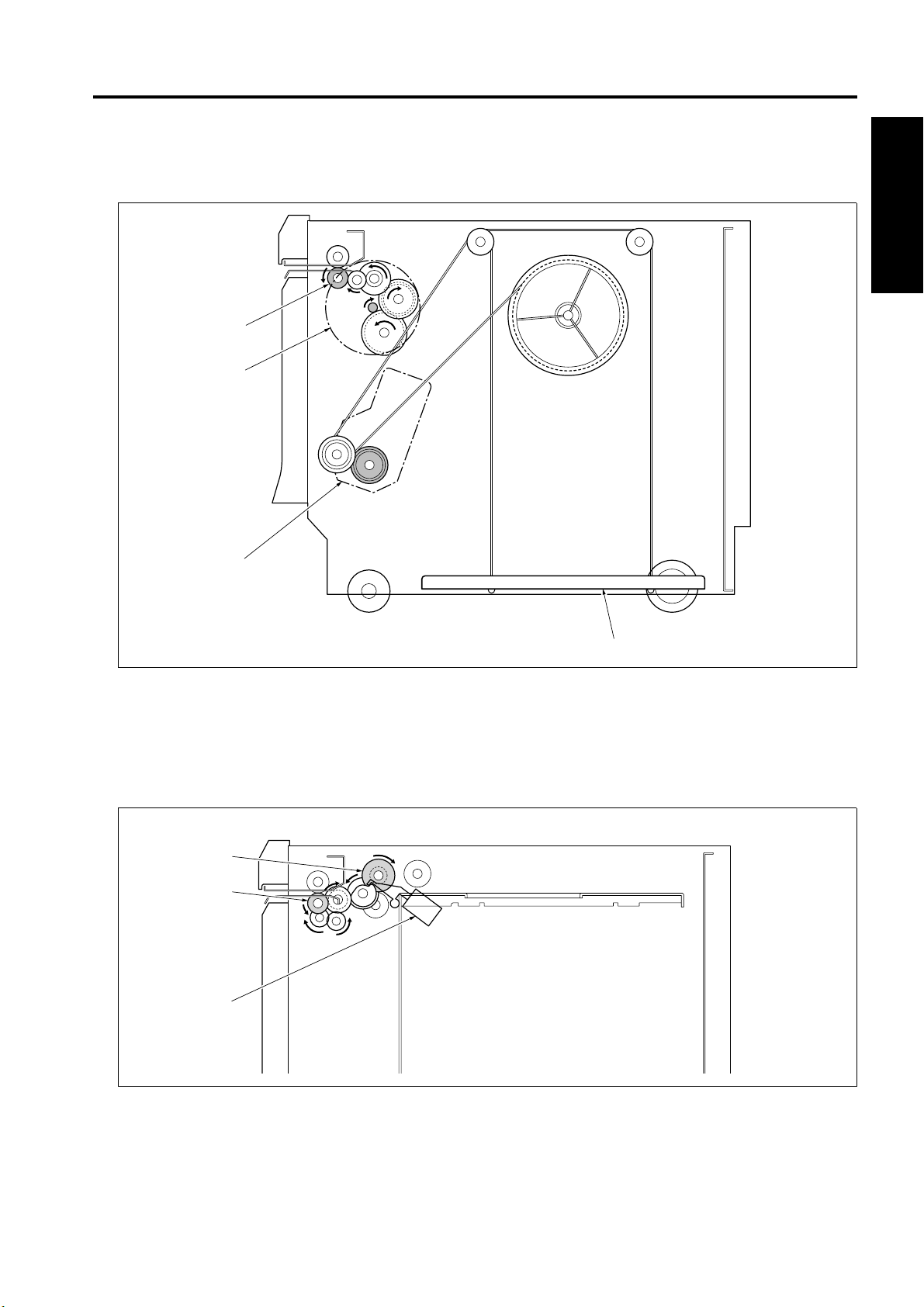

3. DRIVE SYSTEM DIAGRAM

3.1 Rear side drive

[4]

[3]

DRIVE SYSTEM DIAGRAM

I OUTLINE

[2]

[1]

[1] Paper lift plate [3] M150 (LT paper feed motor)

[2] M151 (Tray up drive motor) [4] Conveyance roller

3.2 Front side drive

[3]

[2]

[1]

[1] SD151 (LT paper feed solenoid) [3] Feed roller

[2] Conveyance roller

1-3

Page 10

DRIVE SYSTEM DIAGRAM

I OUTLINE

Blank page

1-4

Page 11

II UNIT EXPLANATION

1. PAPER FEED SECTION

1.1 Composition

PAPER FEED SECTION

LTDB

[8]

M150

SD151

[10] [11] [12][9]

[13]

[1]

II UNIT EXPLANATION

[2]

[3]

[7]

[6] [4] , [5]

Symbol Name Function or method

[1] MS151 (Interlock switch) Turns ON and OFF the 24VDC power source in interlock-

ing with the tray cover.

[2] PS154 (Remaining paper sensor /1) Remaining paper detection

[3] PS151 (Remaining paper sensor /2) Remaining paper detection

[4] PS153 (No paper sensor) Detection of the presence of paper

[5] PS152 (Tray upper limit sensor) Paper upper limit detection

[6] Double feed prevention roller Prevent double feed of paper, Torque limiter

[7] M151 (Tray up drive motor) Tray drive, 24VDC brush motor

[8] Actuator LT set detection actuator

[9] PS155 (Paper feed sensor) Detection of the presence of paper

[10] Conveyance roller Paper conveyance

[11] Feed roller Paper conveyance

[12] Paper feed roller Paper conveyance

[13] Paper lift plate Lifting up of paper

2-1

Page 12

PAPER FEED SECTION

Symbol Name Function or method

M150 LT paper feed motor Driving of the 1st paper feed system, 24VDC brushless

SD151 LT paper feed solenoid Transmission of the 1st paper feed driving force

1.2 Operation

1.2.1 Tray up drive control

When the tray cover is closed, the tray up drive coupling projects to interlock with the M151 (Tray up drive

motor). Also, the tray cover turns on the MS151 (Interlock switch) to supply a 24VDC power to the drive

system. As a result, the M151 goes on to lift the paper lift plate.

When the PS152 (Tray upper limit sensor) is turned on to detect the paper upper limit, the M151 goes off.

When paper is fed and the PS152 is turned off, the M151 lifts the paper lift plate until the PS152 is turned

on again. When the tray cover is opened, the cover wire is pulled to release the tray up drive coupling.

II UNIT EXPLANATION

Then, the paper lift plate goes down to the position where the weight of paper is balanced with the tension

of the wire fixing spring.

motor PLL control

1.2.2 Paper feed control

The paper feed system is driven by the M150 (LT paper feed motor). When the SD151 (LT paper feed

solenoid) is turned on, the 1st paper feed section feeds paper to the registration section.

2-2

Page 13

PAPER FEED SECTION

1.2.3 Remaining paper detection control

The remaining paper quantity is detected by the PS151 (Remaining paper sensor /2) and the PS154

(Remaining paper sensor /1). The paper lift plate goes up gradually as the quantity of paper in the tray is

getting reduced. Interlocking with the paper lift plate that goes up, the actuator at the rear of the tray

rotates. The remaining paper quantity is detected by the PS151 and the PS154 when they are turned on

and off by the actuator.

No paper detection is made by the PS153 (No paper sensor).

Remaining paper in the tray PS151 PS154

Full !

Medium !!

Low !

!: Sensor on

[5]

[4]

[3]

[1]

[2]

[1] Actuator [4] Rotating direction when the tray goes up

[2] PS151 (Remaining paper sensor /2) [5] PS153 (No paper sensor)

[3] PS154 (Remaining paper sensor /1)

II UNIT EXPLANATION

2-3

Page 14

PAPER FEED SECTION

II UNIT EXPLANATION

Blank page

2-4

Page 15

III DISASSEMBLY/ASSEMBLY

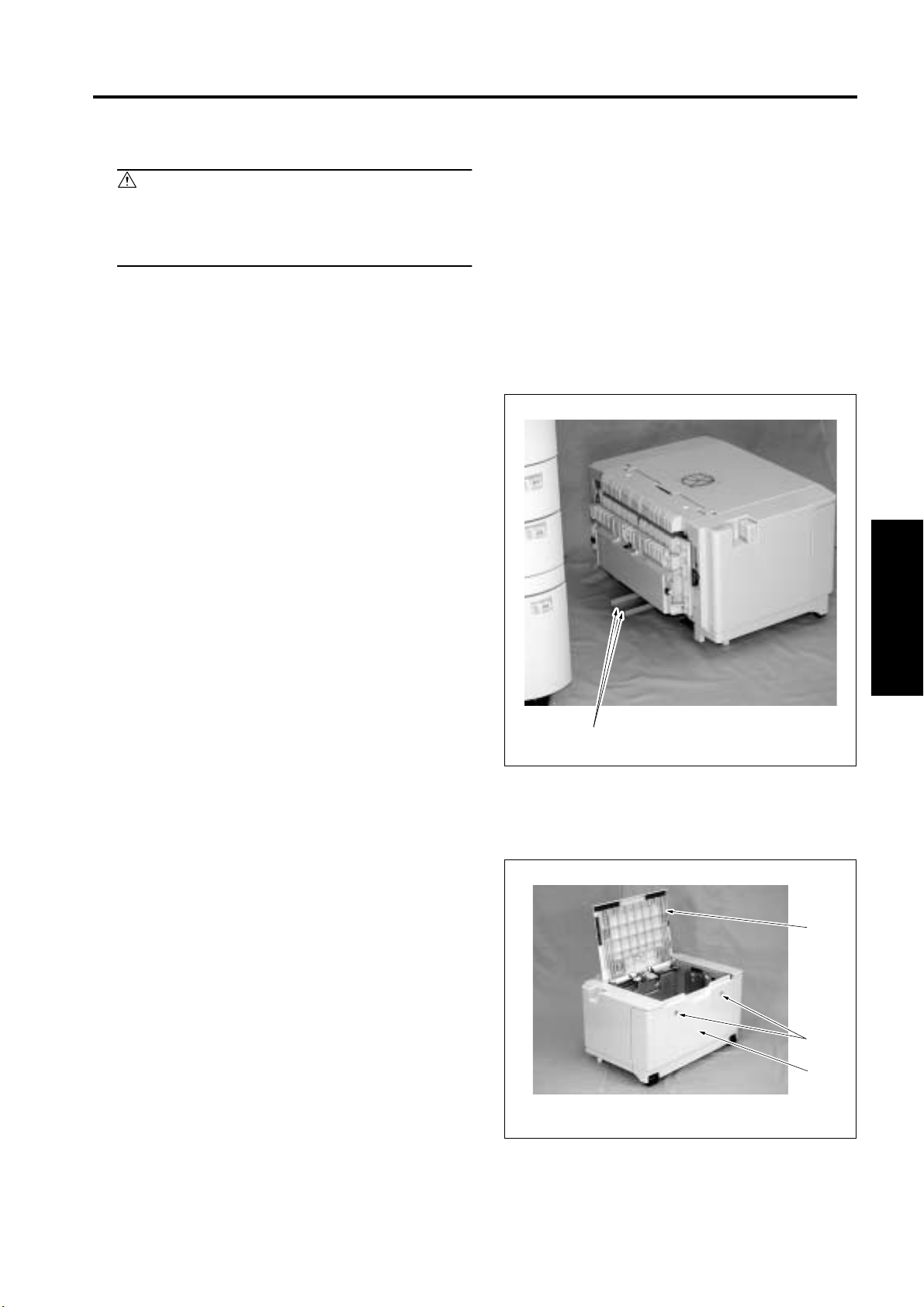

Caution:

• Make sure the power cord of the copier is

unplugged from the power outlet before dis-

assembly or assembly.

1. PAPER FEED SECTION

1.1 Removing the LT

1. Pull the LT out of the main body.

2. Remove the 2 screws [1], and remove the LT

from the main body.

PAPER FEED SECTION

1.2 Removing the right, front and rear covers

1. Pull out the LT from the main body.

2. Open the top cover [1], remove the 2 screws [2]

and remove the right cover [3].

III DIS./ASSEMBLY

[1]

[1]

[2]

[3]

3-1

Page 16

PAPER FEED SECTION

3. Remove the 4 screws [1], and remove the front

cover [2].

4. Remove the 3 screws [1] and remove the cable

cover [2].

5. Remove the 4 screws [3], and remove the rear

cover [4].

6. Reinstall the above parts following the removal

steps in reverse.

[1]

[2]

[1]

[4]

[3]

III DIS./ASSEMBLY

[3]

Note:

• Install the right cover so that the casters [1] (front

and rear) on the right side turn in the direction

shown in the drawing.

[1][2]

[1]

3-2

Page 17

1.3 Replacing the feed rubber and the paper feed rubber

A. Periodically replaced parts/cycle

• Feed rubber: Every 240,000 copies (once for

every 200,000 copies for actual durable count)

• Paper feed rubber: Every 240,000 copies (once

for every 200,000 copies for actual durable

count)

B. Procedure

1. Open the tray cover [1].

2. Remove the 2 stop rings [2]. Slide the bearing

on the front [3] and that on the rear [4] to the

outside and remove the paper feed roller unit

[5].

PAPER FEED SECTION

[1][2]

3. Remove the 2 stop rings [1] and remove the

actuator [2] and the bearing [3].

4. Pull out the feed shaft [4].

5. Remove the feed rubber [6] from the feed roller

[5].

6. Remove the stop ring [7] and pull out the paper

feed shaft [8].

7. Remove the paper feed rubber [10] from the

paper feed roller [9].

Note:

• Be sure to install the feed rubber [6] so that the

paint mark [11] turns in the direction shown in the

drawing.

[3] [4][5]

[5]

[4]

III DIS./ASSEMBLY

[11]

[6]

[1]

[3]

[2]

[7]

[10]

[9][8]

3-3

Page 18

PAPER FEED SECTION

8. Reinstall the above parts following the removal

steps in reverse.

Note:

• When installing the paper feed roller unit, be sure

to put the paper feed shaft [1] securely into the

ring [3] of the actuator on the front side after

passing it under the paper feed roller release arm

[2].

• Install the paper feed roller unit so that the hook

[4] of the paper feed roller holder comes above

the paper feed roller release arm [2].

• Be sure to put the feed shaft [5] securely into the

coupling shaft [6].

[5]

[4]

[6]

[2]

[1]

[3]

III DIS./ASSEMBLY

3-4

Page 19

1.4 Replacing the double feed prevention rubber

A. Periodically replaced parts/cycle

• Double feed prevention rubber: Every 240,000

copies (once for every 200,000 copies for actual

durable count)

B. Procedure

1. Pull out the LT from the main body.

2. Open the tray cover [1].

3. Remove the 2 screws [2], and remove the cover

[3].

PAPER FEED SECTION

[1]

4. Remove the screw [1] from the left side.

[2][3]

[1]

III DIS./ASSEMBLY

3-5

Page 20

PAPER FEED SECTION

5. Pushing the knobs [1] on both sides with your

fingers and remove the double feed prevention

roller unit [2].

[1][2][1]

6. Pull out the shaft [1] while pressing the lever of

the shaft [1].

7. Remove the double feed prevention rubber [3]

from the double feed prevention roller [2].

III DIS./ASSEMBLY

Note:

• Be sure to install the double feed prevention rub-

ber [3] so that the paint mark [4] turns in the direc-

tion as shown in the drawing.

[4]

[3]

[2]

[1]

3-6

Page 21

8. Reinstall the above parts following the removal

steps in reverse.

PAPER FEED SECTION

Note:

• When installing the double feed prevention roller

unit, be sure to align the upper section of the claw

[1] with the center (the longest scale) of the mark-

ing [2] impressed on the plate for leveling.

[2]

[1]

III DIS./ASSEMBLY

3-7

Page 22

PAPER FEED SECTION

1.5 Replacing the wire

Wire length

Wire/A : 707.2mm

Wire/B : 585.7mm

Wire/C : 558.7mm

Wire/D : 680.2mm

Assist wire : 706.3mm

Detection wire : 609.6mm

A. Removing wires

1. Pull out the LT from the main body.

2. Remove the right, front and rear covers.

3. Remove the 3 connectors [1].

4. Remove the 2 screws [2], and remove the cable

[3].

[1]

III DIS./ASSEMBLY

[2] [3]

5. Remove the 6 screws [1] and remove the LT

drive board unit [2].

[1] [2]

[1]

3-8

Page 23

6. Remove the 2 washers [1].

Note:

• Since the washers may have stuck to the

removed LT drive board unit side, don’t lose

them.

PAPER FEED SECTION

[1]

7. Remove the 3 screws [1], and remove the M151

(Tray up drive motor) [2].

8. Remove the 4 screws [1], and remove the wire

drive shaft bracket [2].

[2]

[1]

III DIS./ASSEMBLY

[2]

3-9

[1]

[1]

Page 24

PAPER FEED SECTION

9. Remove the E-ring [1], and remove the wire

stopper [2].

10. Remove the assist wire [4] from the spring [3].

Note:

• Be careful that the paper lift plate [5] comes down

by its own weight.

11. Peel off the seal [7] from the detection reel [6].

12. Rotate the detection reel [6] clockwise as seen

from the rear side, and remove the detection

wire [8] from the reel.

[8][6]

[7]

C

D

B

A

[3]

[4]

[5]

[2]

[1]

III DIS./ASSEMBLY

3-10

Page 25

13. Remove the 2 E-rings [1] and the 2 wire stop-

pers [3].

14. Remove the 4 E-rings [4] and remove the 4

upper pulleys [5].

[1]

[2]

PAPER FEED SECTION

[2]

[1]

C

D

B

A

15. Remove the E-ring [1] and the drive pulley [2],

then remove the assist wire [3], the wire A [4]

and the wire B [5].

16. Remove the E-ring [6] and the drive pulley [7],

then remove the detection wire [8], the wire D

[9] and the wire C [10].

[1]

[2]

[3]

[4]

[4]

[5]

[4]

[5]

III DIS./ASSEMBLY

C

D

B

A

[10]

[5]

A

B

[9]

D

C

[8]

[7]

[6]

3-11

Page 26

PAPER FEED SECTION

B. Stringing wires

1. Pass the wire A [1], the wire B [2], the wire C [3]

and the wire D [4] through the paper lift plate [5].

2. There are 2 upper pulleys and 2 lower pulleys

provided. Run the wire A [6] and the wire B [7]

through each of the upper pulleys [8] and the

lower pulleys [9], and then through the adjust-

ment part [10].

3. Tighten the 2 upper pulleys [8] with the 2 E-rings

[11].

4. Install the wire stopper [12] to each of the 2

lower pulleys [9] in the direction as shown in the

drawing. And then fasten it with the E-ring [13].

5. Run the wire C [14] and the wire D [15] through

the groove of the pulley [16].

6. Tighten the 2 pulleys [16] with the 2 E-rings [17].

[6]

AA

[6][7]

B

[11][8][11]

[10]

B

[2]

[1]

[8]

[14] [15] [15]

C

[17][16]

C

[3]

A

DD

[17][16]

[4]

D

[5]

[9]

[12]

[13]

[9]

[12]

[13]

III DIS./ASSEMBLY

7. After putting the assist wire [1], the wire A [2]

and the wire B [3] into the holes in the front sec-

tion of the drive shaft [4], install the drive pulley

[5] and tighten it with the E-ring [6].

8. After putting the detection wire [7], the wire D [8]

and the wire C [9] into the holes in the rear sec-

tion of the drive shaft [4], install the drive pulley

[10] and tighten it with the E-ring [11].

B

C

D

A

[9]

[6]

[1]

[5]

[2]

[3]

A

B

[8]

D

C

[7]

[10]

[11]

[4] [4]

3-12

Page 27

9. From the left side of the LT, hold the drive pulley

[1] and the drive pulley [2] with both hands and

rotate them to the front side (counterclockwise

as seen from the front) until there are no slacks

found in the wires A, B, C, and D.

10. Rotate the coupling shaft [3] on the rear side to

lift the paper lift plate [4] to the upper limit.

PAPER FEED SECTION

[7]

[9]

[10]

[3]

[2]

Note:

• Be sure to wind the wires from the inside of the LT

to the outside.

At this time, the assist wire [5] and the detection

wire [11] should not have been wound around the

drive pulleys [6] and [12].

11. Wind the assist wire [5] about half turn counter-

clockwise around the drive pulley [6].

12. Wind the assist wire [5] a full turn clockwise

around the pulley [7] and install it to the spring

[8].

13. Install the wire stopper [9] to the pulley [7] in the

direction as shown in the drawing, and tighten it

with the E-ring [10].

14. With the paper lift plate [4] lifted fully up to the

upper limit, wind the detection wire [11] about

half turn clockwise around the drive pulley /R

[12].

15. Set the wire attaching notch [2] at the right

above position with no tension applied on the

detection reel [1], and wind the detection wire [3]

a turn counterclockwise around the detection

reel [1] starting at the top side.

[1]

[5]

[6]

[8]

C

D

B

A

[4]

[11][5]

[12]

III DIS./ASSEMBLY

[2]

Note:

• Be sure to wind the wire from the inside of the LT

to the outside.

16. Rotate the detection reel [1] clockwise to apply

tension. After rotating about 3/4 turns, install the

detection wire [3].

17. Stick the seal [4] to the detection reel [1].

18. For reinstallation, follow Steps 1 to 8 in “A.

Removing the wire” in reverse order.

3-13

[1]

[4] [3]

Page 28

PAPER FEED SECTION

Note:

• After finishing wire replacement or rewiring, move

the paper lift plate up and down by hand to con-

firm that moves smoothly.

• Make sure that the wires do not cross each other,

or a wire does not run on another wire.

• After installing the wires, adjust “LT tray tilt adjust-

ment”.

III DIS./ASSEMBLY

3-14

Loading...

Loading...