Konica Minolta DF-318, DF-320 Manual

SERVICE MANUAL

Models

DF318/DF-320

APRIL 2004

CSM-DF318/DF320

KONICA MINOLTA BUSINESS SOLUTIONS U.S.A., INC.

DF318/DF320

SERVICE MANUAL

APRIL 2004

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced person servicing this equipment, as well as the risk of damage to the equipment, Konica Minolta Business Solutions U.S.A., Inc. strongly recommends that all servicing be performed by Konica Minolta-trained service technicians only.

Changes may have been made to this equipment to improve its performance after this service manual was printed. Accordingly, Konica Minolta Business Solutions U.S.A., Inc., makes no representations or warranties, either expressed or implied, that the information contained in this service manual is complete or accurate. It is understood that the user of this manual must assume all risks or personal injury and/or damage to the equipment while servicing the equipment for which this service manual is intended.

Corporate Publications Department

© 2004, KONICA MINOLTA BUSINESS SOLUTIONS U.S.A. , INC. All rights reserved.

Printed in U.S.A.

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS

Refer to the 7145/7235/7228/7222 service manual on page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

I OUTLINE

1. DF-318/DF-320 PRODUCT SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 2. CENTER CROSS-SECTIONAL DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3 3. DRIVE SYSTEM DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 3.1 Paper feed drive section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 3.2 Conveyance/Paper exit drive section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 3.3 Reverse drive section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

II UNIT EXPLANATION

1. PAPER FEED/REVERSAL/EXIT SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 1.1 Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 1.2 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 1.2.1 Single sided original mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 1.2.2 Double sided original mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6 1.2.3 Mixed original mode and Z-folded original mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14 1.2.4 Original size detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15 1.2.5 Allowed size combination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15 1.2.6 Control of the verification stamp for FAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

III DISASSEMBLY/ASSEMBLY

1. PAPER FEED/REVERSAL/EXIT SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 1.1 Replacing the paper feed roller and the feed rubber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 1.2 Replacing the double feed prevention roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3 1.3 Replacing the read roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4 1.4 Removing and reinstalling the paper dust removing brush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5 1.5 Replacing the verification stamp for FAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

2. EXTERNAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7 2.1 Removing and reinstalling the RADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

I OUTLINE

III DIS./ASSEMBLY II UNIT EXPLANATION

i

CONTENTS

I OUTLINE

III DIS./ASSEMBLY II UNIT EXPLANATION

Blank page

ii

DF-318/DF-320 PRODUCT SPECIFICATIONS

I OUTLINE

1. DF-318/DF-320 PRODUCT SPECIFICATIONS

A. Type

Type: |

Sheet-through Type reversible DF |

B. Functions

Original size (for metric area): Original size (for inch area):

Original type

Plain paper:

Special paper:

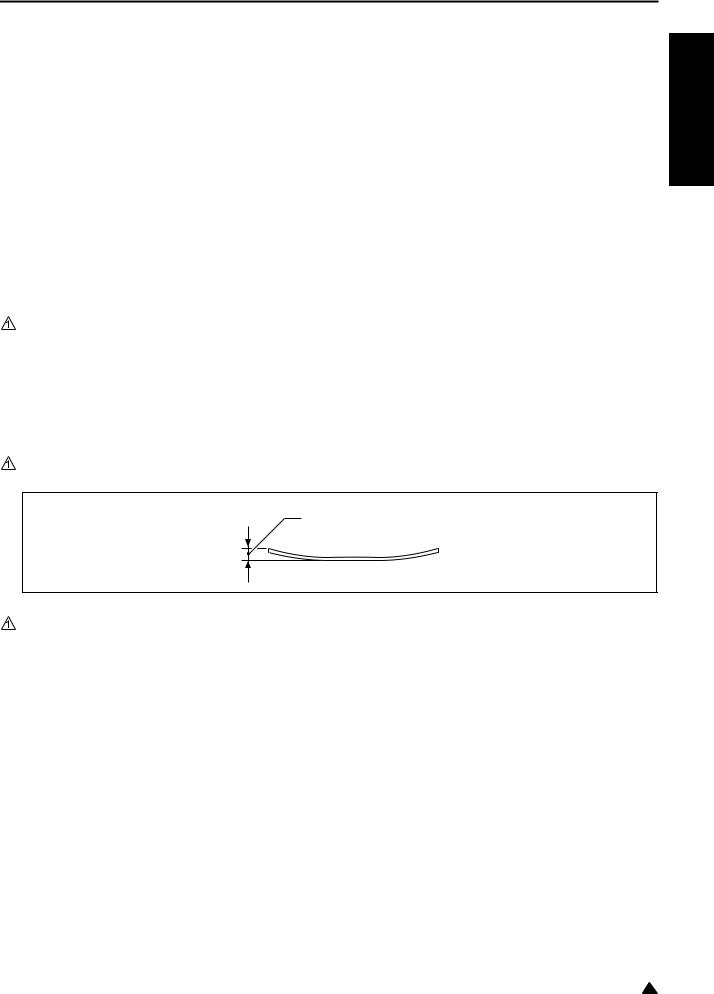

Original Curling (5 sheet):

A3, B4, A4, A4R, B5, B5R, A5, A5R, 11 x 17, 8.5 x 14, 8.5 x 11 11 x 17, 8.5 x 14, 8.5 x 11, 8.5 x 11R, 5.5 x 8.5, 5.5 x 8.5R

A3, B4, A4, B5, B5R, B6R

• Mixing of original size possible.

50g/m2 to 130g/m2 (13lbs to 34lbs), high-quality paper (DF-318) 35g/m2 to 130g/m2 (13lbs to 34lbs), high-quality paper (DF-320) Original feed and conveyance ability may be inferior those of highquality original mentioned above.

The following types of original cannot be used:

• OHP film, Blueprint masters, Offset masters, Bonded original h = 10mm or less (80g/m2 or 20lbs high-quality paper)

h

I OUTLINE

Amount of originals to be stacked: |

50 sheets max. (80g/m2 or 20lbs high-quality paper) |

|

(Original curling: 10mm or less) |

|

80 sheets max. (80g/m2 or 20lbs high-quality paper) |

|

(Original curling: 1mm or less) |

Original scan speed (A4 size): |

Single side mode: 45 sheets/minute |

|

Double side mode: 34 sheets/minute |

Original feed layout: |

Face-up placement, centre standard |

Original image read position: |

At the slit glass section |

C. Machine Data

Power source: |

24VDC/5V (supplied from the main body) |

Power consumption: |

Maximum 100VA |

Weight: |

Approx. 11kg (including about 1.1kg for platen) |

Dimensions: |

576mm (W) x 502mm (D) x 100mm (H) |

|

(Excluding the original feed tray) |

1-1 |

1 |

I OUTLINE

DF-318/DF-320 PRODUCT SPECIFICATIONS

D. Maintenance

Maintenance: Same as the main body

E. Operating Environment

Temperature: |

10°C to 30°C (50°F to 86°F) |

Humidity: |

10% RH to 80% RH |

Note:

• The information herein may be subject to change for improvement without notice.

1-2

CENTER CROSS-SECTIONAL DIAGRAM

2. CENTER CROSS-SECTIONAL DIAGRAM

[8] |

[9] |

[10] |

[11] |

[12] |

|

|

|

|

IOUTLINE |

[7] |

[6] |

[5] [4] [3] [2] |

[1] |

|

[1] Double feed prevention roller |

[7] |

Conveyance roller |

|

[2] |

Reverse roller |

[8] |

Reverse guide |

[3] |

Paper exit roller |

[9] |

Registration roller |

[4] |

SD303 (Stamp solenoid) |

[10] |

Feed roller |

[5] |

Paper exit guide |

[11] |

Paper feed roller |

[6] |

Read roller |

[12] |

Paper up/down plate |

1-3

I OUTLINE

DRIVE SYSTEM DIAGRAM

3. DRIVE SYSTEM DIAGRAM

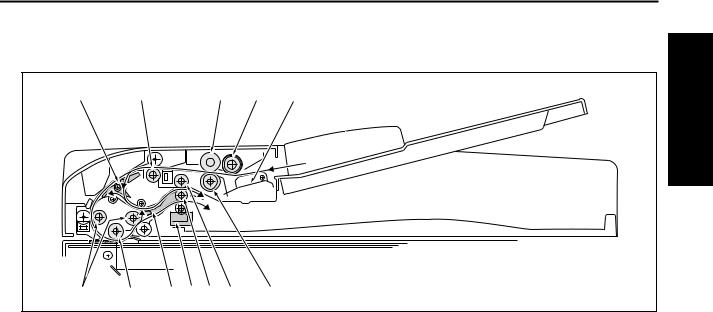

3.1Paper Feed Drive Section

[3] |

[4] |

[5]

[6]

[2]

[1]

[1]

[1] Double feed prevention roller |

[4] |

Feed roller |

|

[2] |

Registration roller |

[5] |

Paper feed roller |

[3] |

M301 (Original feed motor) |

[6] |

Paper up/down plate |

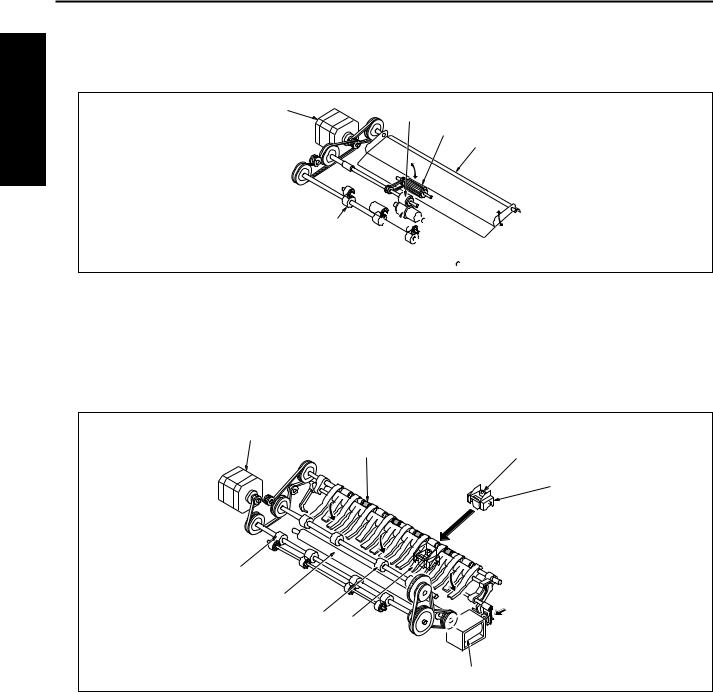

3.2 Conveyance/Paper Exit Drive Section

[7] |

|

[8] |

[9] |

[1]

[6] |

|

[5] |

|

[4] |

[3] |

|

|

|

[2] |

[1] |

SD303 (Stamp solenoid) |

[6] |

Before-read roller |

[2] SD301 (Paper exit solenoid) |

[7] M302 (Original conveyance motor) |

||

[3] |

Paper exit guide |

[8] |

Paper exit roller |

[4] |

After-read roller |

[9] Verification stamp for FAX |

|

[5]Read roller

1-4

DRIVE SYSTEM DIAGRAM

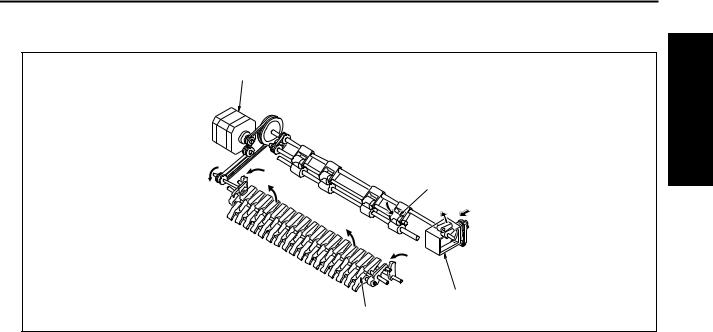

3.3Reverse Drive Section

[3]

[4]

|

|

[1] |

|

|

[2] |

[1] |

SD302 (Pressure roller solenoid) |

[3] M303 (Original reverse motor) |

[2] |

Reverse guide |

[4] Reverse roller |

I OUTLINE

1-5

DRIVE SYSTEM DIAGRAM

I OUTLINE

Blank page

1-6

PAPER FEED/REVERSAL/EXIT SECTION

II UNIT EXPLANATION

1. PAPER FEED/REVERSAL/EXIT SECTION

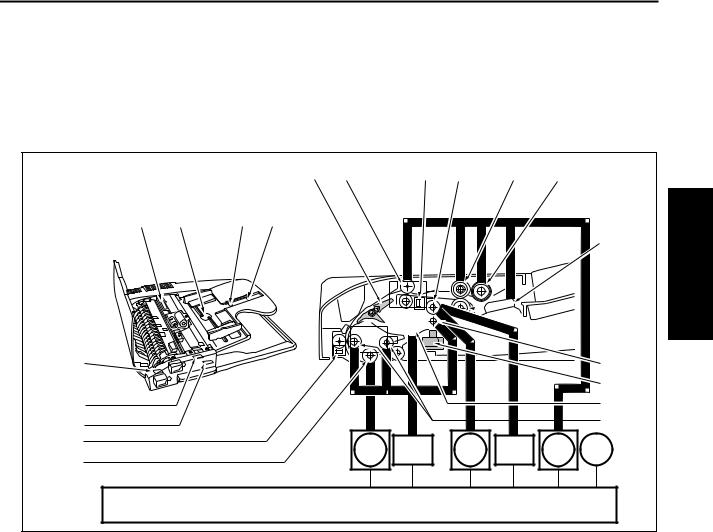

1.1Composition

[16] [17] |

[18] |

[19] |

[20] |

[21] |

[12] |

[13] |

[14] |

[15] |

[1]

[2]

[2]

[11] |

[3] |

|

|

|

|

|

|

[4] |

|

[10] |

|

|

|

|

|

[5] |

|

[9] |

|

|

|

|

|

[6] |

|

[8] |

M302 |

SD301 |

M303 |

SD302 |

M301 |

FM301 |

|

[7] |

|||||||

|

|

|

|

|

|

||

|

DFDB |

|

|

|

|

|

Symbol |

Name |

Function or method |

[1] |

Paper up/down plate |

Lift the original to the paper feed roller while feeding original |

[2] |

Double feed prevention roller |

Double feed prevention of original |

|

|

Torque limiter method |

|

|

|

[3] |

Paper exit roller |

Original exit |

[4] |

SD303 (Stamp solenoid) |

Affix the verification stamp |

|

|

24VDC drive |

|

|

|

[5] |

Paper exit guide |

Switching-over of the conveyance path original exited |

|

|

SD301 (Paper exit solenoid) open/close method |

|

|

|

[6] |

Conveyance roller |

Original conveyance |

[7] |

Read roller |

Original conveyance |

[8] |

PS309 |

Original detection just before the read section |

|

(Original conveyance sensor) |

|

|

|

|

[9] |

PS301 (No original sensor) |

No paper detection in the paper feed tray |

[10] |

PS304 |

Detection of the open/close of the open/close cover |

|

(Cover open/close sensor) |

|

|

|

|

[11] |

PS303 (DF open/close sensor) |

RADF open/close detection |

[12] |

PS302 (Original exit sensor) |

Detection of original exited |

[13] |

VR301 (Original size VR) |

Detection of original size in the main scanning direction |

[14] |

PS305 (Original size sensor /1) |

Detection of original size in the sub-scanning direction |

[15] |

PS306 (Original size sensor /2) |

Detection of original size in the sub-scanning direction |

II UNIT EXPLANATION

2-1

|

|

PAPER FEED/REVERSAL/EXIT SECTION |

|

|||

|

|

|

|

|

|

|

|

|

|

Symbol |

Name |

Function or method |

|

|

|

|

[16] |

Reverse guide |

Switching-over of the conveyance path for original |

|

|

|

|

[17] |

Registration roller |

Original skew correction, original conveyance |

|

|

|

|

[18] |

PS308 |

Original detection just before the registration roller |

|

|

|

|

|

(Original registration sensor) |

|

|

|

|

|

|

|

||

|

|

|

[19] |

Reverse roller |

Reversal of original |

|

|

|

|

[20] |

Feed roller |

Feeding of original |

|

|

|

|

[21] |

Paper feed roller |

Picking-up of original |

|

|

|

|

DFDB |

DF drive board |

RADF drive board |

|

EXPLANATION |

||||||

|

|

|

|

The control is made by the main body's CB (Main body control |

||

|

|

|

|

|

||

|

|

|

|

|

board). |

|

|

|

|

|

|

|

|

|

|

|

M301 |

Original feed motor |

Driving of original feed section |

|

|

|

|

|

|

24VDC stepping motor |

|

|

|

|

|

|

|

|

UNIT |

|

|

M302 |

Original conveyance motor |

Driving of original conveyance section |

|

|

|

|

|

24VDC stepping motor |

||

|

|

|

|

|

||

|

|

|

|

|

|

|

II |

|

|

M303 |

Original reverse motor |

Driving of original reversal section |

|

|

|

|

|

|

24VDC stepping motor |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

FM301 |

Cooling fan |

Cooling of M302 (Original conveyance motor) |

|

|

|

|

SD301 |

Paper exit solenoid |

Opening/closing of the paper exit guide |

|

|

|

|

|

|

24VDC drive |

|

|

|

|

|

|

|

|

|

|

|

SD302 |

Pressure roller solenoid |

Pressing/releasing of the reverse roller |

|

|

|

|

|

|

24VDC drive |

|

|

|

|

|

|

|

|

1.2Operation

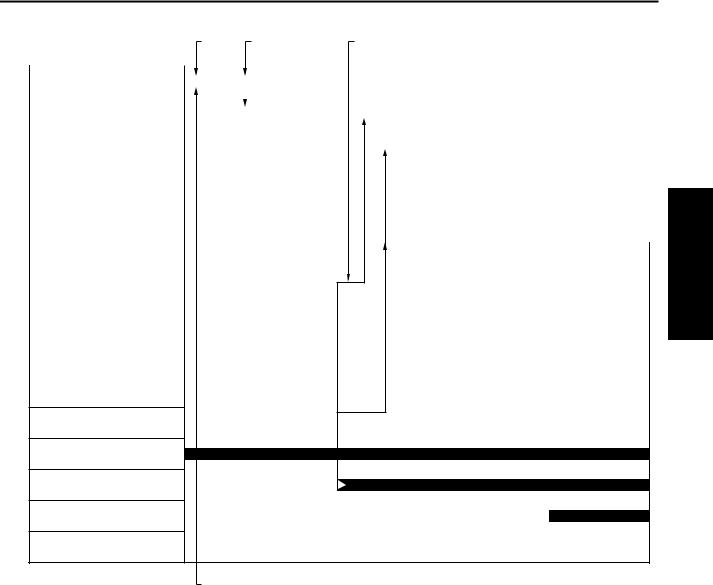

1.2.1Single sided original mode

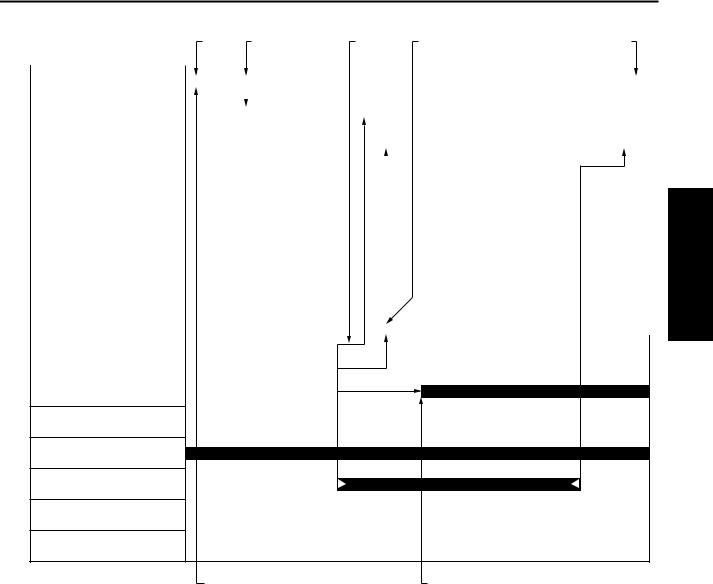

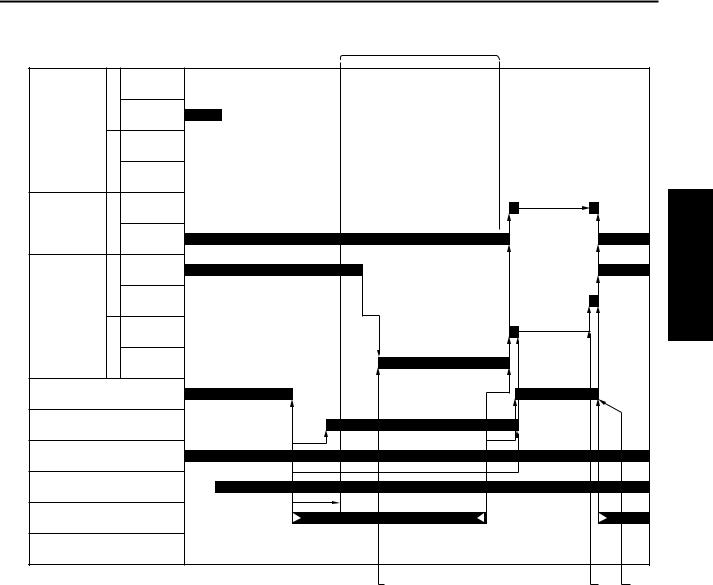

A.The original set in the paper feed tray is pressed against the paper feed roller by the paper up/ down plate, and then struck against the registration roller by the paper feed roller and the feed roller to form a loop. The amount of the loop is controlled according to a value registered by the timer after the leading edge of the original turns on the PS308 (Original registration sensor).

[4]

[3] [5]

[5]

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[2] |

[1] |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

[1] |

Paper up/down plate |

[4] |

Feed roller |

|||||

[2] |

PS308 (Original registration sensor) |

[5] |

Paper feed roller |

|||||

[3]Registration roller

2-2

PAPER FEED/REVERSAL/EXIT SECTION

[2] |

[3] |

[4] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M301 |

F |

100mm/s |

|

|

|

|

|

|

|

|||

|

(Original |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

feed motor) |

|

|

|

250mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

460mm/s |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

230mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M302 (Original |

F |

230mm/s |

|

|

|

|

|

|

|

|||

|

conveyance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

motor) |

|

|

|

460mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M303 (Original |

F |

230mm/s |

|

|

|

|

|

|

|

|||

|

reverse motor) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

460mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

R |

460mm/s |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

230mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SD302 (Pressure roller solenoid)

SD301 (Paper exit solenoid)

PS301 (No original sensor)

PS308 (Original registration sensor)

PS309 (Original conveyance sensor)

PS302 (Original exit sensor)

[1]

[1] |

START button ON |

[3] |

Pre-feed |

[2] |

Paper up/down plate, pressed down |

[4] |

Loop formation |

II UNIT EXPLANATION

2-3

PAPER FEED/REVERSAL/EXIT SECTION

B. After the loop is formed at the registration roller section, the M301 (Original feed motor) rotates

|

backward and the M302 (Original conveyance motor) re-feeds paper. The original is scanned at |

|||

|

the slit glass section according to a value registered by the timer after the leading edge of the |

|||

|

original turns on the PS 309 (Original conveyance sensor). At this time, if there are originals in |

|||

|

the tray, the next original is pre-fed according to a value registered by the timer after the trail- |

|||

|

ing edge of the preceding original turns off the PS308 (Original registration sensor). When the |

|||

|

trailing edge of the last original turns off the PS309 (Original conveyance sensor), the M301 |

|||

|

goes off. When the PS302 (Original exit sensor) detects the trailing edge of the last original, the |

|||

EXPLANATIONUNITII |

M302 goes off to finish the scanning of the original. |

|

||

|

|

[4] |

[5] |

|

|

|

|

||

|

|

|

[1] |

|

|

|

[3] |

[2] |

|

|

|

|

|

|

[1] |

Paper exit roller |

|

[4] |

Next original |

[2] |

Paper exit guide |

|

[5] |

Paper exit tray |

[3]Slit glass (Original reader)

2-4

PAPER FEED/REVERSAL/EXIT SECTION

|

|

|

[1] [2][3] [4] |

|

[6] |

[7] |

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

M301 |

F |

100mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

(Original |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

feed motor) |

|

|

|

|

250mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

460mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

230mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

M302 (Original |

F |

460mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

conveyance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

motor) |

|

|

|

|

230mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

M303 (Original |

F |

230mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

reverse motor) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

460mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

R |

|

460mm/s |

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

230mm/s |

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SD302 (Pressure roller solenoid)

SD301 (Paper exit solenoid)

PS301 (No original sensor)

PS308 (Original registration sensor)

PS309 (Original conveyance sensor)

PS302 (Original exit sensor)

|

[5] |

|

[8] |

[1] Turning on the START button to press |

[5] Scanning of the 1st paper |

||

|

down the paper up/down plate |

[6] Pre-feeding of the 2nd paper |

|

[2] |

Pre-feeding |

[7] |

Loop formation of the 2nd paper |

[3] |

Loop formation of the 1st paper |

[8] |

Scanning of the 2nd original |

[4]Re-feeding of the 1st paper

II UNIT EXPLANATION

2-5

|

PAPER FEED/REVERSAL/EXIT SECTION |

||

|

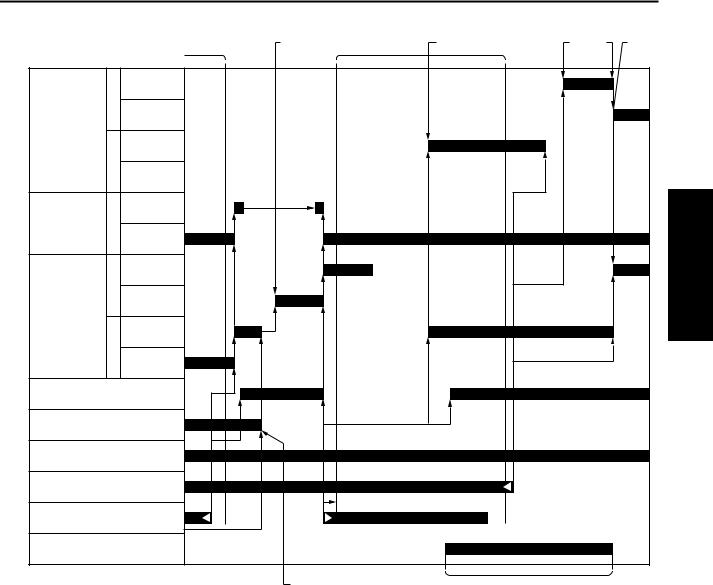

1.2.2 Double sided original mode |

||

|

A. In the double sided original mode, the original is reversed and its back side is scanned first, |

||

|

and then the front side is scanned before being straight ejected. Copying originals in their |

||

|

scanned order may cause the copied sheets to get out of their specified pagination. To avoid |

||

|

this, image processing is used for page alignment. The original set in the paper feed tray is |

||

|

pressed against the paper feed roller by the paper up/down plate, and then struck against the |

||

|

registration roller by the paper feed roller and the feed roller to form a loop. The amount of the |

||

EXPLANATION |

loop is controlled according to a value registered by the timer after the leading edge of the |

||

original turns on the PS308 (Original registration sensor). After the loop is formed at the regis- |

|||

|

|||

|

tration roller section, the M301 (Original feed motor) rotates backward to re-feed paper. Upon |

||

|

backward rotation of the M301, the M303 (Original reverse motor) also rotates backward to |

||

|

open the reverse guide and convey the original to the reverse roller. The reverse roller can |

||

UNIT |

release pressure through the SD302 (Roller pressure solenoid). It turns on the SD302 (Press- |

||

ing by reverse roller) according to the value registered by the timer after the PS308 is turned |

|||

|

|||

II |

on to convey the original to the paper exit tray side. |

||

|

|

||

|

[3] |

[4] |

|

|

|

||

|

|

[5] |

|

|

|

[3] |

|

[1]

[2]

[1] |

Reverse roller |

[3] |

Registration roller |

[2] |

PS308 (Original registration sensor) |

[4] |

M303 (Original reverse motor) |

[3]Reverse guide

2-6

PAPER FEED/REVERSAL/EXIT SECTION

[2] |

[3] |

[4] |

[5] |

[7] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M301 |

F |

100mm/s |

|

|

|

|

|

|

|

|||

|

(Original |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

feed motor) |

|

|

|

250mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

460mm/s |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

230mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M302 (Original |

F |

460mm/s |

|

|

|

|

|

|

|

|||

|

conveyance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

motor) |

|

|

|

230mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M303 (Original |

F |

230mm/s |

|

|

|

|

|

|

|

|||

|

reverse motor) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

460mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

R |

460mm/s |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

230mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SD302 (Pressure roller solenoid)

SD301 (Paper exit solenoid)

PS301 (No original sensor)

PS308 (Original registration sensor)

PS309 (Original conveyance sensor)

PS302 (Original exit sensor)

|

[1] |

|

[6] |

[1] |

START button ON |

[5] Switching of the reverse guide to the |

|

[2] Paper up/down plate, pressed down |

|

reverse section side |

|

[3] |

Pre-feed |

[6] |

Pressing by the reverse roller |

[4] |

Loop formation |

[7] |

Pressing of the 2nd original up/down plate |

II UNIT EXPLANATION

2-7

II UNIT EXPLANATION

PAPER FEED/REVERSAL/EXIT SECTION

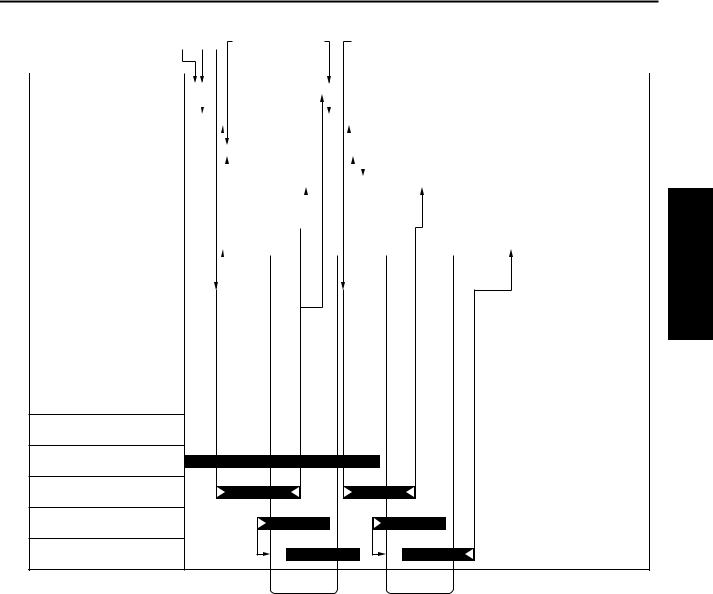

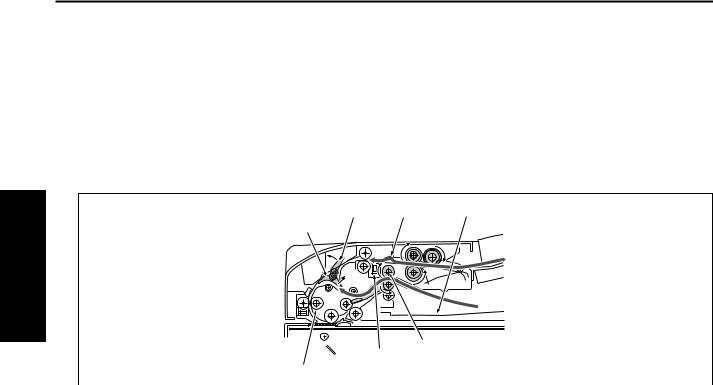

B.According to the value registered by the timer after the PS308 (Original registration sensor) detects the trailing edge of the original, the M302 (Original conveyance motor) and the M303 (Original reverse motor) rotate forward to reverse the original and convey the back side to the slit glass section. The reverse guide is closed by the forward rotation of the M303 and the flapper[4] is opened by the rigidity of the original. As a result, the original is guided to the conveyance roller. At this time, if there is a succeeding original in the tray, it is pre-fed according to the value registered by the timer after the trailing edge of the preceding original turns off the PS308 (Original registration sensor).

[5] |

[6] |

[7] |

[4]

|

|

[2] |

[1] |

|

|

[3] |

|

|

|

|

|

|

|

|

|

|

|

|

|

[1] |

Reverse roller |

|

[5] |

Reverse guide |

[2] PS308 (Original registration sensor) |

|

[6] |

Next original |

|

[3] |

Conveyance roller |

|

[7] |

Paper exit tray |

[4]Flapper

2-8

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PAPER FEED/REVERSAL/EXIT SECTION |

||||

|

|

|

[1] |

[2] |

[4] |

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

M301 |

F |

100mm/s |

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

||||||||||||

|

|

(Original |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

feed motor) |

|

|

|

250mm/s |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

R |

|

460mm/s |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

230mm/s |

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

M302 (Original |

F |

460mm/s |

|

|

|

|

|

|

|

||||||||

|

|

conveyance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

motor) |

|

|

|

230mm/s |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

M303 (Original |

F |

230mm/s |

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

||||||||||||

|

|

reverse motor) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

460mm/s |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

R |

|

460mm/s |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

230mm/s |

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SD302 (Pressure roller solenoid)

SD301 (Paper exit solenoid)

PS301 (No original sensor)

PS308 (Original registration sensor)

PS309 (Original conveyance sensor)

PS302 (Original exit sensor)

|

|

[3] |

[5] |

[1] |

Pressing of the 2nd original up/down plate |

[4] |

Loop formation of the 2nd original |

[2] |

Pre-feeding of the 2nd original |

[5] |

Scanning of the back of the 1st original |

[3]Reversing of the 1st original (from front to back)

II UNIT EXPLANATION

2-9

II UNIT EXPLANATION

PAPER FEED/REVERSAL/EXIT SECTION

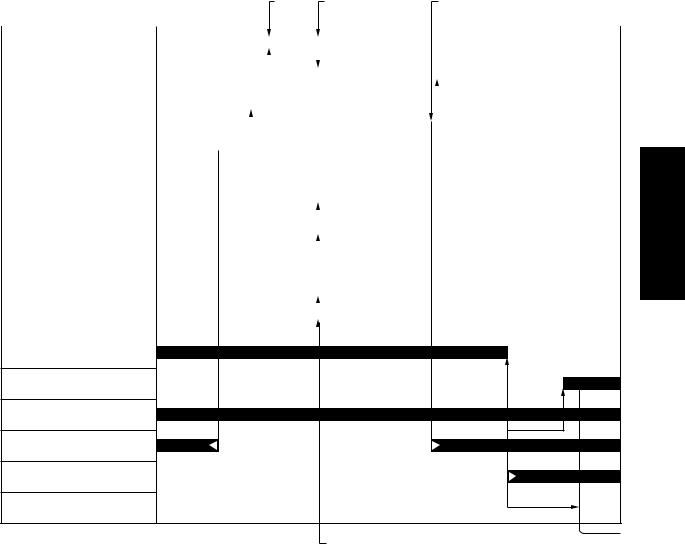

C.According to a value registered by the timer after the leading edge of the original turns on the PS 309 (Original conveyance sensor), the back side of the original is scanned at the slit glass section. At this time, the SD301 (Paper exit solenoid) is turned on to close the paper exit guide, and a original the back side of which has been scanned is conveyed to the reverse roller. The SD301 is turned on according to a value registered by the timer after the leading edge of the original turns on the PS309. Paper conveyed to the reverse roller switches back and conveys again an original to the conveyance roller, thus replacing the back side of the original with its front side. Since the leading and trailing edges of an original larger than B5R is overlapped each other while in switching back at this reversal section, the SD302 (Roller pressure solenoid) is turned off to release the pressure of the reverse roller.

|

|

|

[7] |

[8] |

|

|

|

|

|

|

|

|

|

[6] |

|

|

|

|

|

[5] |

|

|

|

|

|

|

|

[2] |

[1] |

|

|

[4] |

|

|

|

|

|

[3] |

|

|

|

|

|

|

|

|

|

[1] |

Reverse roller |

|

|

[5] PS309 (Original conveyance sensor) |

|

[2] |

Paper exit guide |

|

|

[6] |

Conveyance roller |

[3] |

Read roller |

|

|

[7] |

Flapper |

[4] |

Slit glass |

|

|

[8] |

Next original |

2-10

PAPER FEED/REVERSAL/EXIT SECTION

|

|

[1] |

|

M301 |

F 100mm/s |

|

|

(Original |

250mm/s |

|

|

feed motor) |

|

|

|

|

|

|

|

|

R 460mm/s |

|

|

|

230mm/s |

|

|

M302 (Original |

F 460mm/s |

|

EXPLANATION |

conveyance |

230mm/s |

|

|

motor) |

|

||

|

|

||

M303 (Original |

F 230mm/s |

|

|

reverse motor) |

|

|

|

460mm/s |

|

II UNIT |

|

|

|

||

|

R 460mm/s |

|

|

|

230mm/s |

|

|

SD302 (Pressure roller solenoid) |

|

|

|

SD301 (Paper exit solenoid) |

|

|

|

PS301 (No original sensor) |

|

|

|

PS308 (Original registration sensor) |

|

|

|

PS309 (Original conveyance sensor) |

|

|

|

PS302 (Original exit sensor) |

|

|

|

|

[2] |

[3] |

[4] |

[1]Scanning of the back of the 1st original

[2]Switching-back of the 1st original

[3]Reversing of the 1st original (from back to front)

[4]SD302 (Roller pressure solenoid) release

2-11

II UNIT EXPLANATION

PAPER FEED/REVERSAL/EXIT SECTION

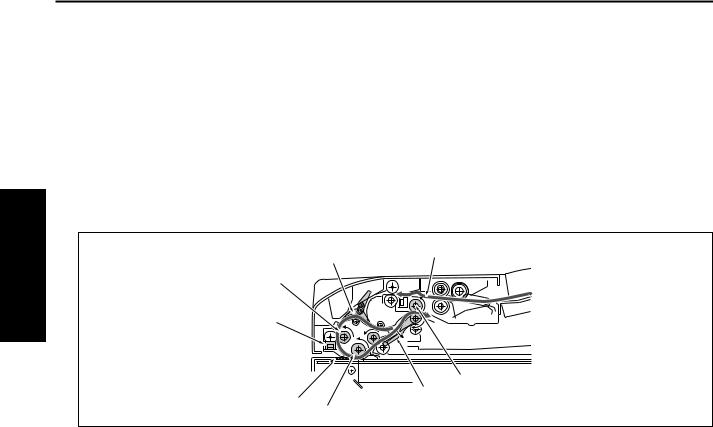

D.According to a value registered by the timer after the leading edge of the original turns on the PS309 (Original conveyance sensor), the scanning of the back of the original is made at the slit glass section. Since the SD301 (Paper exit solenoid) is off at this time, the paper exit guide is left open and the original the front of which has been scanned is conveyed to the paper exit roller to be exited. While the back of the original is being scanned, the SD301 goes off according to a value registered by the timer after the leading edge of the original turns on the PS309.

[5] [6] |

[7] |

[4] |

|

|

[3] |

[1] |

|

[2] |

||

|

[1] |

Paper exit roller |

[5] |

Next original |

[2] |

Paper exit guide |

[6] |

Reverse roller |

[3] |

Slit glass |

[7] |

Paper exit tray |

[4]PS309 (Original conveyance sensor)

2-12

PAPER FEED/REVERSAL/EXIT SECTION

|

[1] |

[3] |

[4] |

[5] |

[7] [8] |

[9] |

M301 |

F 100mm/s |

|

|

|

|

|

(Original |

250mm/s |

|

|

|

|

|

feed motor) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R 460mm/s |

|

|

|

|

|

|

230mm/s |

|

|

|

|

|

M302 (Original |

F 460mm/s |

|

|

|

|

EXPLANATION |

conveyance |

230mm/s |

|

|

|

|

|

motor) |

|

|

|

|

||

|

|

|

|

|

||

M303 (Original |

F 230mm/s |

|

|

|

|

|

reverse motor) |

|

|

|

|

|

|

460mm/s |

|

|

|

|

II UNIT |

|

|

|

|

|

|

||

|

R 460mm/s |

|

|

|

|

|

|

230mm/s |

|

|

|

|

|

SD302 (Pressure roller solenoid) |

|

|

|

|

|

|

SD301 (Paper exit solenoid) |

|

|

|

|

|

|

PS301 (No original sensor) |

|

|

|

|

|

|

PS308 (Original registration sensor) |

|

|

|

|

|

|

PS309 (Original conveyance sensor) |

|

|

|

|

|

|

PS302 (Original exit sensor) |

|

|

|

|

|

|

|

|

[2] |

|

|

[6] |

|

[1]Scanning of the back of the 1st original

[2]Switching of the paper exit guide in the direction of the paper exit

[3]Reversing of the 1st original (from back to front)

[4]Scanning of the front of the 1st original

[5]Re-feeding of the 2nd original

[6]Exiting of the 1st original

[7]Pressing of the 3rd original up/down plate

[8]Pre-feeding of the 3rd original

[9]Reversing of the 2nd original (from front to back)

2-13

II UNIT EXPLANATION

PAPER FEED/REVERSAL/EXIT SECTION

1.2.3Mixed original mode and Z-folded original mode

The mixed original mode supports both the same series original and the different series original. The operation of the original conveyance in the mixed original mode is the same as that of the normal double sided original mode, regardless of a single sided mode or double sided mode.

Although the detection of original size in the normal mode is made at the time when the original is set in the paper feed tray, the size detection in the mixed original mode, however, is made based on the length of time when the original passes through the PS308 (Original registration sensor) while the original is being sent from the paper feed tray to the reverse roller. The original detection like this is applicable to all originals.

In the Z-folded original mode, the same detection operation as that for the mixed original sizes mode is made only on the first original to determine the original size. However, the normal operation of original conveyance is made for originals on and after the 2nd original.

[1]

[2]

[1] Reverse roller |

[2] PS308 (Original registration sensor) |

2-14

PAPER FEED/REVERSAL/EXIT SECTION

1.2.4Original size detection

A. Normal copy mode

(1)Main scanning direction

Detected by the value of resistance of the VR301 (Original size VR) that is interlocked with the position of the guide plate above the paper feed tray.

(2)Sub-scanning direction

Detected by the combination of the PS305 (Original size sensor /1) and the PS306 (Original size sensor 2/) when they are turned on and off.

B. Mixed original mode and Z-folded original mode

(1)Main scanning direction

The width of the largest original of the mixed original sizes is detected by the value of resistance of the VR301 (Original size VR) that is interlocked with the position of the guide plate above the paper feed tray.

(2)Sub-scanning direction

Detection is made based on the length of time when the original passes through the PS308 (Original registration sensor).

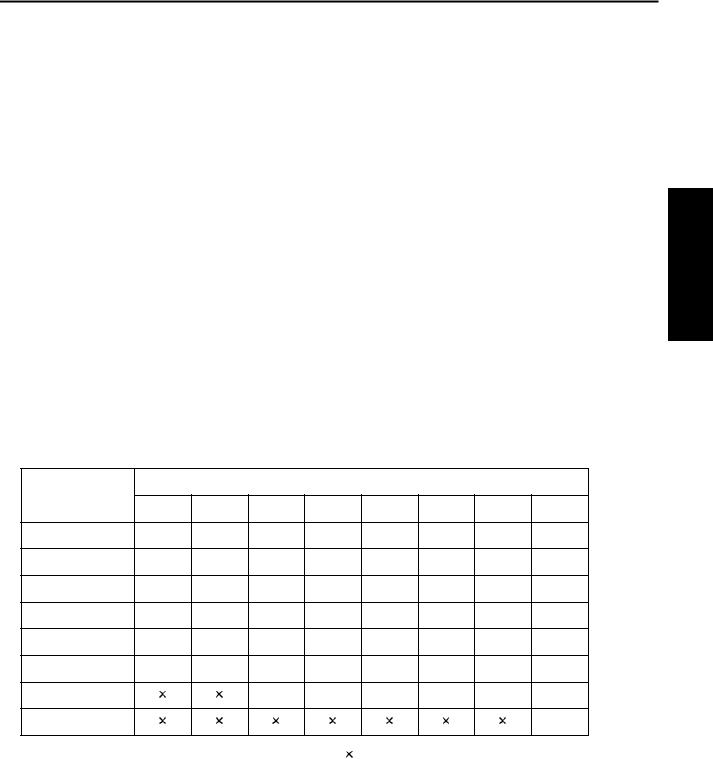

1.2.5Allowed size combination

A. For metric area

Other originals |

Standard originals (the maximum original size detected by the guide plate) |

|||||||

|

A3 |

A4 |

B4 |

B5 |

A4R |

A5 |

B5R |

A5R |

A3 |

|

{ |

— |

— |

— |

— |

— |

— |

A4 |

{ |

|

— |

— |

— |

— |

— |

— |

B4 |

~ |

~ |

|

{ |

— |

— |

— |

— |

B5 |

~ |

~ |

{ |

|

— |

— |

— |

— |

A4R |

~ |

~ |

~ |

~ |

|

{ |

— |

— |

A5 |

~ |

~ |

~ |

~ |

{ |

|

— |

— |

B5R |

|

|

~ |

~ |

~ |

~ |

|

— |

A5R |

|

|

|

|

|

|

|

|

( : same size, {: same series, ~: different series, |

: no mixed loading, —: not supported) |

|||||||

II UNIT EXPLANATION

2-15

II UNIT EXPLANATION

PAPER FEED/REVERSAL/EXIT SECTION

B. For inch area

Other originals |

Standard originals (the maximum original size detected by the guide plate) |

|||||

|

|

|

|

|

|

|

|

11 x 17 |

8.5 x 11 |

8.5 x 14 |

8.5 x 11R |

5.5 x 8.5 |

5.5 x 8.5R |

|

|

|

|

|

|

|

11 x 17 |

|

{ |

— |

— |

— |

— |

|

|

|

|

|

|

|

8.5 x 11 |

{ |

|

— |

— |

— |

— |

|

|

|

|

|

|

|

8.5 x 14 |

~ |

~ |

|

{ |

{ |

— |

|

|

|

|

|

|

|

8.5 x 11R |

~ |

~ |

{ |

|

{ |

— |

|

|

|

|

|

|

|

5.5 x 8.5 |

~ |

~ |

{ |

{ |

|

— |

|

|

|

|

|

|

|

5.5 x 8.5R |

— |

— |

— |

— |

— |

|

|

|

|

|

|

|

|

( : same size, {: same series, ~: different series,  : no mixed loading, —: not supported)

: no mixed loading, —: not supported)

1.2.6Control of the verification stamp for FAX

A.Operation of the verification stamp for FAX

In the FAX mode, a stamp showing that the original has been scanned is affixed on the original face that has been scanned (for the double sided original mode, a stamp is affixed on front side only). The stamp is driven by the SD303 (Stamp solenoid) and stamping is made when the original passes through the paper exit roller. At this time, the M302 (Original conveyance motor) is turned off temporarily to stop the original.

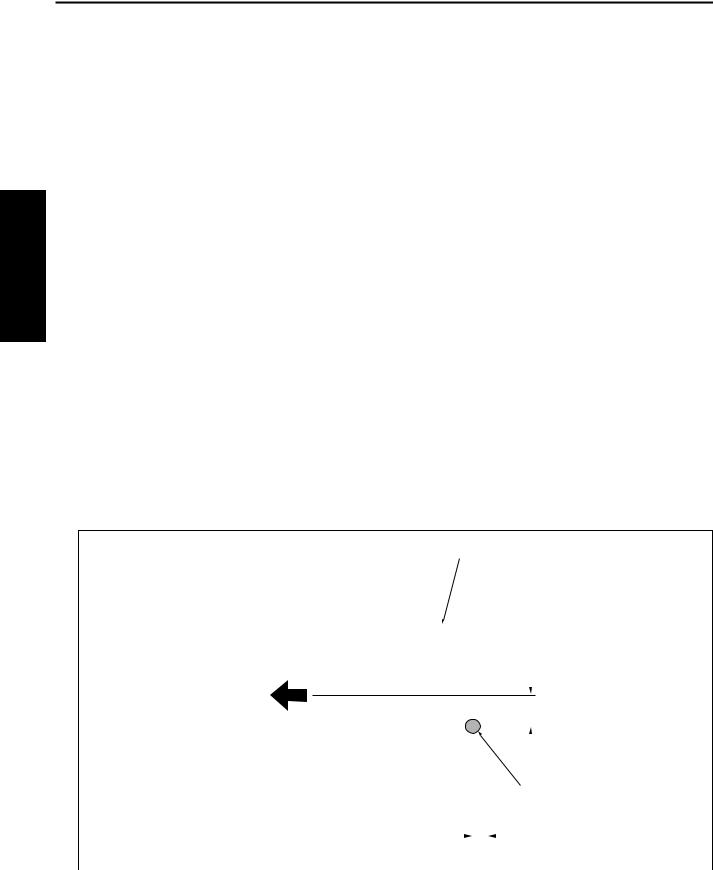

B.Stamping position

[5]

|

|

[4] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[1] |

|||||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[2] |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[3] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

||||||||||

[1] |

51mm ± 5mm |

|

[4] Direction of original conveyance |

||||||||||

[2] |

Stamping position |

|

[5] Front of the original |

||||||||||

[3]10mm ± 2mm

2-16

PAPER FEED/REVERSAL/EXIT SECTION

III DISASSEMBLY/ASSEMBLY

Caution:

Caution:

•Make sure the power cord of the copier is unplugged from the power outlet before disassembly or assembly.

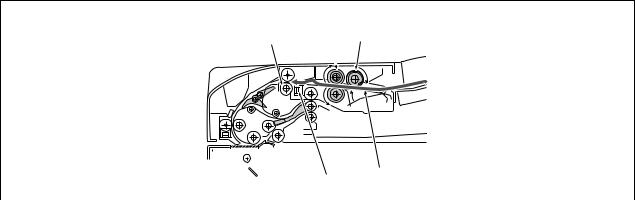

1.PAPER FEED/REVERSAL/ EXIT SECTION

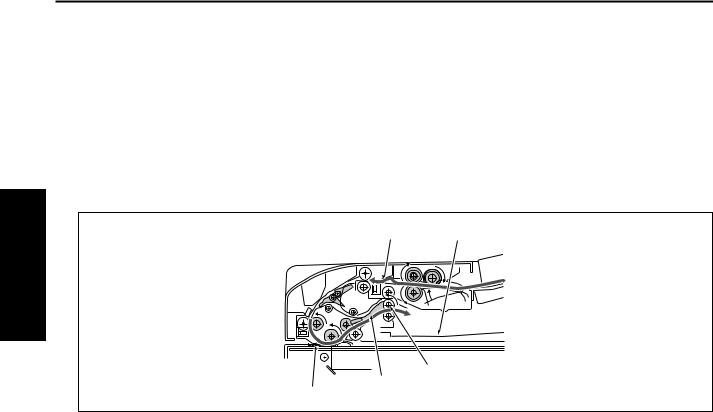

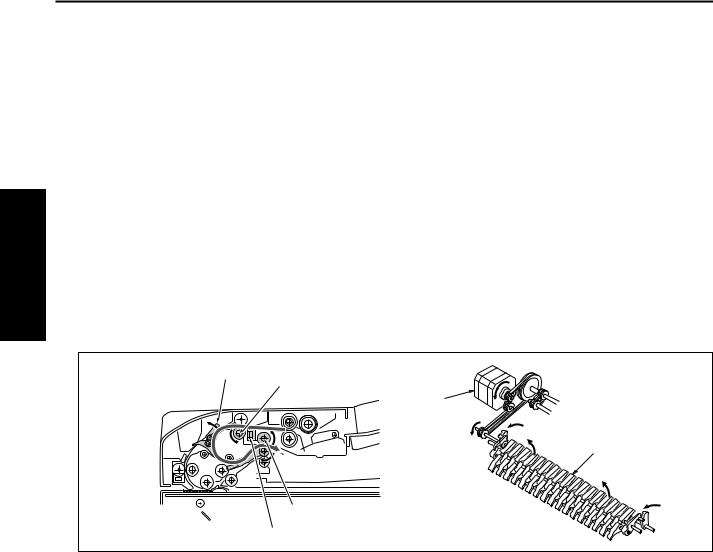

1.1Replacing the Paper Feed Roller and the Feed Rubber

A. Periodically replaced parts/cycle

A. Periodically replaced parts/cycle

•Paper feed roller: Every 1,200,000 copies (once for every 300,000 copies for actual durable count) (7145)

•Paper feed roller: Every 1,000,000 copies (once for every 300,000 copies for actual durable count) (7235/7228/7222)

•Feed rubber: Every 960,000 copies (once for every 250,000 copies for actual durable count) (7145)

•Feed rubber: Every 1,000,000 copies (once for every 250,000 copies for actual durable count) (7235/7228/7222)

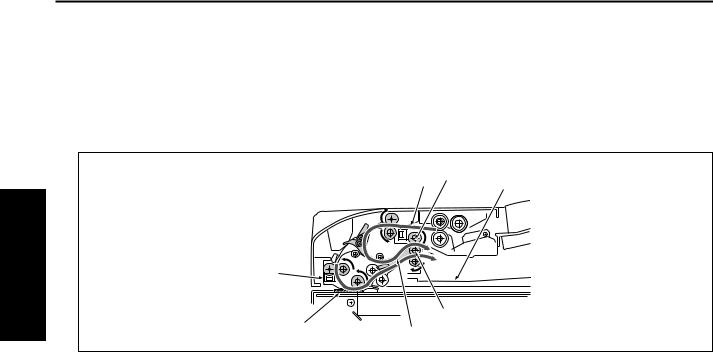

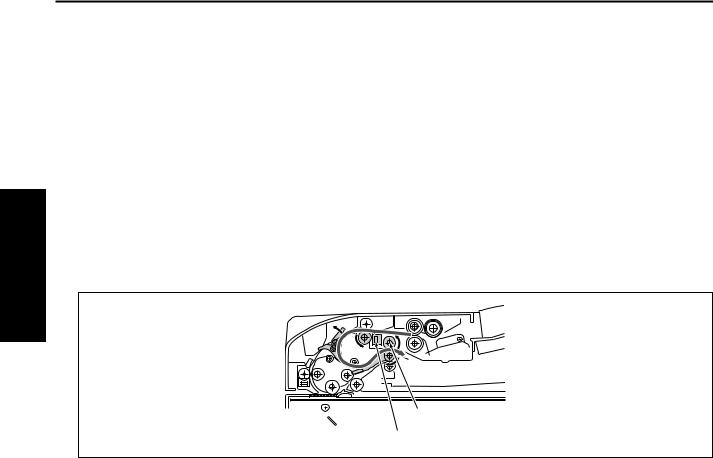

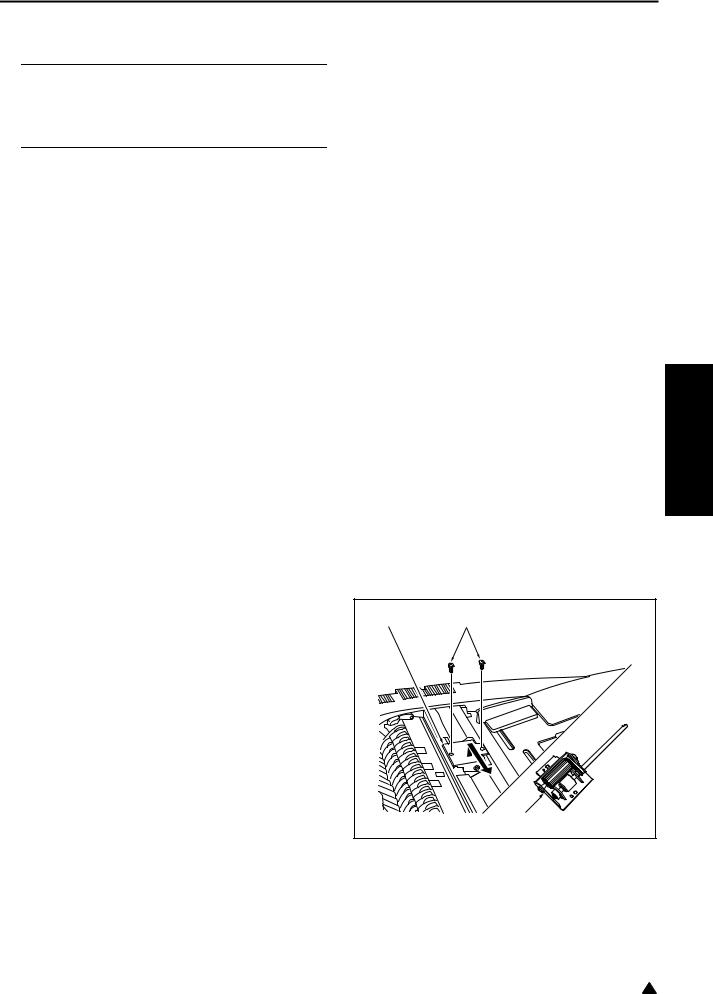

B. Procedure

1.Open the open/close cover.

2.Remove the 2 screws [1] and remove the paper feed unit [2].

[2] |

[1] |

|

[2] |

III DIS./ASSEMBLY

3-1 |

1 |

Loading...

Loading...