Page 1

AS-75

KODAK DOUBLE-X AEROGRAPHIC Film 2405

KODAK DOUBLE-X AEROGRAPHIC Film 2405 is a

panchromatic, negative aerial camera film with good contrast

for easier interpretation from negatives, high resolution, and

wide exposure latitude. Its extended red sensitivity permits

greater speed with the filters used for the reduction of

atmospheric-haze effects.

The ESTAR Base provides flexibility, moisture

resistance, high tear resistance, and excellent dimensional

stability. This film has a thin, highly hardened, and

abrasion-resistant emulsion that permit high-temperature

rapid processing in modern continuous-processing

machines.

This film can be processed in the KODAK VERSAMAT

Film Processor, Model 11 or 1140, with KODAK

VERSAMAT 885 Chemicals, KODAK VERSAMAT

641 Chemicals, or KODAK VERSAMAT Chemicals,

Type A. KODAK DOUBLE-X AEROGRAPHIC

Film 2405 can also be processed at normal temperatures in

conventional rewind equipment, such as the Gordon/Morse

M-10 Developing Outfit (Military Designator: B-5) using a

variety of Kodak black-and-white developers

APPLICATIONS

KODAK DOUBLE-X AEROGRAPHIC Film 2405 is a

medium- to high-speed film for aerial mapping, charting, and

general aerial photography.

SAFELIGHT

Total darkness is required.

EXPOSURE

Aerial film speeds (ISO A or EAFS) should not be con fused

with conventional film speeds which are designed for roll

and sheet films used in pictorial ph otography. The

characteristics of aerial scenes differ markedly from those of

ordinary pictorial or ground scenes because of the smaller

range in subject luminances, atmospheric haze conditions,

and other factors. Therefore, different film-speed parameters

are used to relate aerial-scene characteristics to practical

exposure recommendations. The KODAK Aerial Exposure

Computer, KODAK Publication AS-10 has been published

based on the aerial film speed criterion.

Nominal speed, daylight (no filter): EAFS or ISO A 400

Other suggested aerial film speeds for processing this film

in the KODAK VERSAMAT Film Processor, Models 11 or

1140, using VERSAMAT 885 Chemicals, 641 Chemicals

and Type A Chemicals can be found in the sensitometric data

tables.

Note: The aerial film speeds given in this publication were

obtained by rounding the calculated values to the nearest

cube root of 2 step (equivalent to 1⁄3 stop).

BASE

3.9-mil (0.10 mm) ESTAR Base with a dyed-gel backing

TOTAL FILM THICKNESS

The nominal total thickness (unprocessed) of this film is

4.50 mils (0.114 mm). This includes emulsion—0.40 mil

(0.010 mm), base—3.9 mils (0.10 mm), and backing—

0.20 mil (0.005 mm).

WEIGHT

The weight of 2405 Film (unprocessed), conditioned in

equilibrium with 50 percent relative humidity, is 0.035 lbs⁄ft

(0.0159 kg/ft

2

).

SPECTRAL SENSITIVITY

Panchromatic, with extended red sensitivity.

©Eastman Kodak Company, 2005

Filters

KODAK PROFESSIONAL WRATTEN Gelatin Filter

No. 3 No. 8 No. 12 No. 15 No. 25

Filter Factor 1.5 2 2 2.5 4

Typical Camera Exposure

A typical exposure for this film is approximately 1⁄750

second at f⁄8. This exposure is based on a solar altitude of 40

degrees, a clear day, an aircraft altitude of 5,000 feet, and a

speed of ISO A 400, using a 2X antivignetting filter.

Reciprocity Characteristics

2

No exposure or development time adjustments are required

for exposure times from 1⁄1,000 second to 1⁄10 second; at

1⁄10,000 second, increase the development time by 10

percent.

Page 2

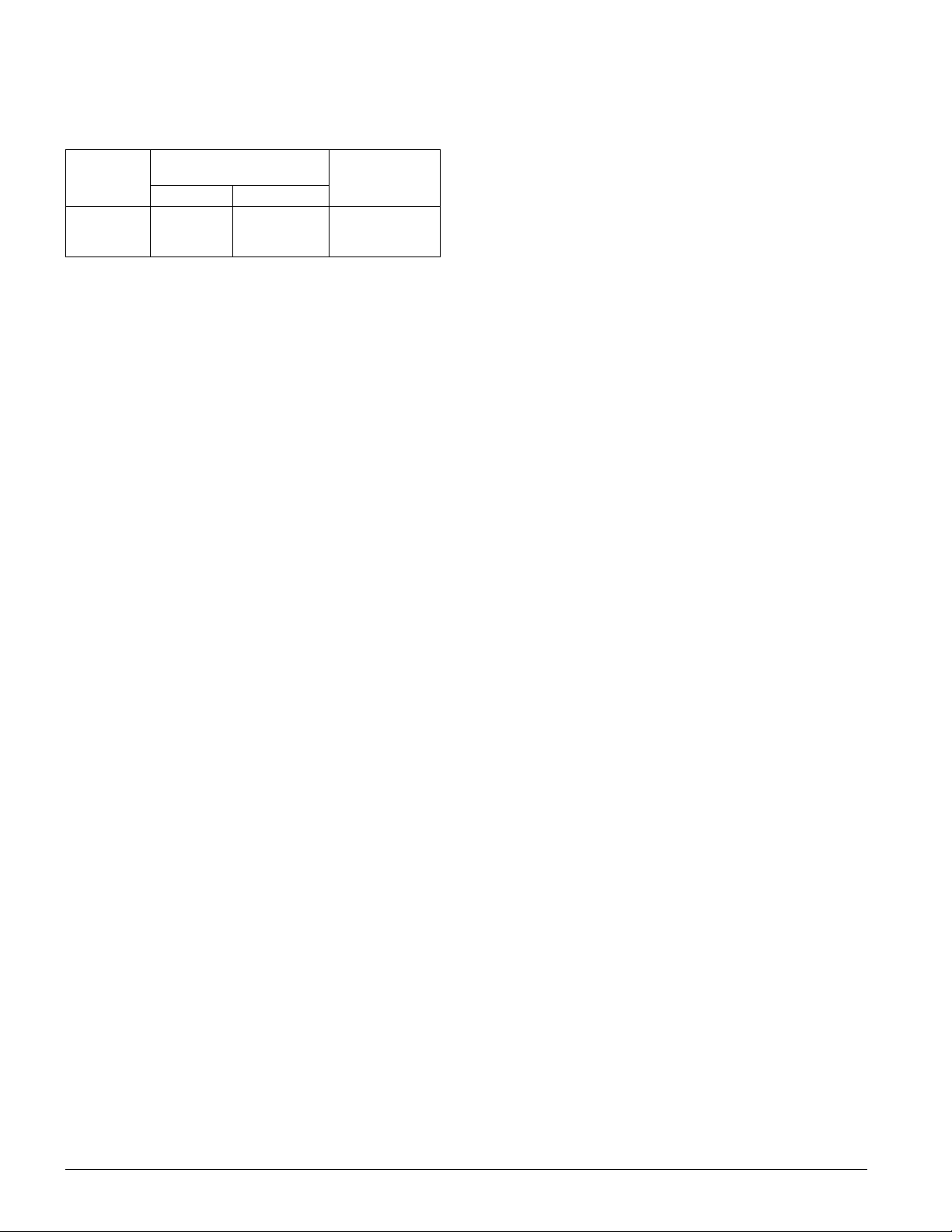

IMAGE STRUCTURE

The following data are based on processing in KODAK

VERSAMAT Film Processors, Model 11, using KODAK

VERSAMAT Chemicals at the conditions noted.

Resolving Power

Developer

885

641

Type A

*

Granularity values read at a net diffuse density of 1.0 with a

48-micrometre aperture.

(line pairs/mm)

TOC 1.6:1 TOC 1000:1

50

40

38

125

125

94

rms Granularity

26

26

42

Process conditions to achieve above values:

885 Chemicals:15 fpm, 85°F (29.5°C), process gamma 1.10

641 Chemicals: 5 fpm, 85°F (29.5°C), process gamma 1.30

Type A Chemicals: 10 fpm, 90°F (32°C), process gamma

1.65

STORAGE

For consistent results, all aerial films should be stored under

fairly constant conditions. Kodak aerial films are “usually”

packaged in equilibrium with 40 to 50 percent relative

humidity. High temperatures or high humidity may produce

undesirable changes in the film.

Unexposed Film

Store unexposed film in a refrigerator at 55°F (13°C) or

lower, or freezer at 0 to -10°F (-18 to -23°C), in the original

sealed container. If the f ilm is stored in a refrigerator, remov e

it about 2 hours before opening; if stored in a freezer, remove

it about 8 hours before opening. A sufficient warm-up time

is necessary to prevent moisture condensation on cold film -otherwise, moisture spotting, ferrotyping, or sticking may

occur.

Exposed Film

Keep exposed film cool and dry. Process the film as soon as

possible after exposure to avoid undesirable changes in the

latent image. If it is necessary to hold exposed but

unprocessed film for sev eral days (s uch as o v er a weekend),

it should be resealed and refrigerated at 40°F (4°C) or lower.

Before unsealing and processing exposed film that has been

held in cold storage, follow the warm-up procedures

described for unexposed film described above.

Processed Film

For best keeping, store processed film in a dark, dust-free

area at 50 to 70°F (10 to 21°C) and 30 to 50 percent relative

humidity. Preferably, store negatives on the spool or in

individual KOD AK PROFESSION AL Sleeves. High relative

humidity promotes the growth of mold and causes

*

ferrotyping. V ery low relativ e humidity causes excessive curl

and brittleness. Avoid storage temperatures over 80°F

(27°C).

PROCESSING

KODAK DOUBLE-X AEROGRAPHIC Film 2305 can be

processed in KODAK VERSAMAT Film Processor, Models

11 and 1140, with KODAK VERSAMAT 885 Chemicals,

KODAK VERSAMAT 641 Chemicals, or KODAK

VERSAMAT Chemicals, Type A.

Mechanized processing in roller-transport processors

offers the advantages of uniform treatment of all portions of

the roll, freedom from banding, and absence of significant

density variations from ends of the roll to the center. Refer to

the operator’s manual for the processor set-up information,

but in all cases, the fixer replenisher should be introduced

into tank No. 5 of the processor with a countercurrent flow

to tank No. 3, where it overflows to a collection or recovery

system.

General instructions for setting the machine dryer

temperature are included in these pages. However, the

temperature of the dryer may require some further

adjustment, depending upon the ambient temperature

conditions in the processing area. Usually it is best to set the

temperature approximately 3°F (2°C) above that required to

dry unexposed, processed film.

Chemicals

The following KODAK VERSAMAT Chemicals may be

used in both the Model 11 and Model 1140 VERSAMAT

Processors.

KODAK VERSAMAT 885 Developer Starter

KODAK VERSAMAT 885 Developer Replenisher

KODAK VERSAMAT 885 Fixer and Replenisher

KODAK VERSAMAT 641 Developer Starter

KODAK VERSAMAT 641 Developer Replenisher

KODAK VERSAMAT 641 Fixer and Replenisher

KODAK VERSAMAT Developer Starter, Type A

KODAK VERSAMAT Developer Replenisher, Type A

KODAK VERSAMAT Fixer and Replenisher, Type A

Notice: Observe precautionary information on product labels and on

the Material Safety Data Sheets.

2 KODAK DOUBLE-X AEROGRAPHIC Film 2405 • AS-75

Page 3

Replenishment Rates

Basic developer and fixer replenishmen t rat e s, in millilitres

per square inch of film processed, vary depending upon the

type of chemicals used. The following rates apply to

processing in the VERSAMAT Processor, Models 11 and

1140.

Basic Replenishment Rates (mL/in2)

KODAK VERSAMAT Chemicals

885 641 Type A

Developer 0.29 0.31 0.20

Fixer 0.45 0.68 0.34

Processing Sequence (All Recommended

Chemicals)

KODAK VERSAMAT Processor, Model 11

Processing

Step

Develop

Fix 3

Wash 2

Dry —

*

Use 90°F (32°C) for KODAK VERSAMAT Chemicals, Type A.

No. of

Racks

*

1 or 2

Path

Length

1.2 or 2.4 m

(4 or 8 ft)

3.6 m

(12 ft)

2.4 m

(8 ft)

2.4 m

(8 ft)

Temperature

85 ± 0.5°F

(29.5 ± 0.3°C)

85°F (29.5°C), nominal

2 to 6°F (1 to 3°C) below

developer temperature

135 to 145°F (57 to 63°C)

Model 11, KODAK VERSAMAT 641 Chemicals

Machine

Speed

(fpm)

5 1.05 320 0.12 1.70 500 0.21

10 0.85 160 0.10 1.10 320 0.13

15 0.65 80 0.13 0.95 250 0.13

20 0.60 50 0.13 0.85 160 0.15

25 0.50 32 0.12 0.80 125 0.14

1 Developer Rack 2 Developer Racks

Average

Gamma

85°F (29.5°C)

ISO A D-min

Average

Gamma

ISO A D-min

Fixing: Adequate fixing is obtained at machine speeds up

to and including 10 feet per minute.

Washing: To be determined.

Drying: Adequate drying is obtained at machine speeds

up to and including 12 feet per minute.

Model 11, KODAK VERSAMAT Chemicals, Type A,

Machine

Speed

(fpm)

5 1.20 400 0.11 2.15 500 0.13

10 1.00 160 0.09 1.65 320 0.11

15 0.85 80 0.09 1.20 250 0.10

20 0.75 64 0.09 1.05 160 0.10

1 Developer Rack 2 Developer Racks

Average

Gamma

90°F (32°C)

ISO A D-min

Average

Gamma

ISO A D-min

Sensitometric Data

Model 11—KODAK VERSAMAT 885 Chemicals

Machine

Speed

(fpm)

5 1.25 500 0.21 — — —

10 0.90 250 0.12 1.30 500 0.22

15 0.80 160 0.11 1.10 400 0.16

20 0.70 100 0.10 1.00 250 0.14

25 0.65 64 0.10 0.85 200 0.13

1 Developer Rack 2 Developer Racks

Average

Gamma

Fixing: Adequate fixing is obtained at machine speeds up

to and including 20 feet per minute.

Washing: LE-100 keeping quality is obtained at machine

speeds up to and including 10 feet per minute with one

developer rack and up to 5 feet per minute with two

developer racks. (LE = Life Expectancy)

Drying: Adequate drying is obtained at machine speeds

up to and including 20 feet per minute.

85°F (29.5°C)

ISO A D-min

Average

Gamma

ISO A D-min

Fixing: Adequate fixing is obtained at machine speeds up

to and including 10 feet per minute.

Washing: To be determined.

Drying: Adequate drying is obtained at machine speeds

up to and including 10 feet per minute.

Processing Sequence (All Recommended

Chemicals)

KODAK VERSAMAT Processor, Model 1140

Processing

Step

Develop 1 or 2

Fix 3

Wash 2

Dry —

No. of

Racks

Path

Length

1.2 or 2.4 m

(4 or 8 ft)

3.6 m

(12 ft)

2.4 m

(8 ft)

2.4 m

(8 ft)

Temperature

99 or 104 ± 0.5°F

(37 or 40 ± 0.3°C)

99 or 104°F

(37 or 40°C), Nominal

2 to 6°F (1 to 3°C) below

developer temperature

Up to 149°F (65°C)

KODAK DOUBLE-X AEROGRAPHIC Film 2405 • AS-75 3

Page 4

Sensitometric Data

Model 1140 -- KODAK VERSAMAT 885 Chemicals

Machine

Speed

(fpm)

10 1.50 500 0.28 — — —

20 0.90 320 0.18 1.65 500 0.32

30 0.75 200 0.13 1.10 400 0.25

40 0.65 125 0.12 0.90 320 0.19

10 1.60 500 0.34 — — —

20 0.85 320 0.20 — — —

30 0.80 250 0.16 1.40 500 0.34

40 0.75 200 0.15 1.05 400 0.28

Model 1140 -- KODAK VERSAMAT 641 Chemicals

Machine

Speed

(fpm)

10 1.20 400 0.15 2.20 500 0.37

20 0.80 250 0.11 1.20 400 0.16

30 0.70 125 0.10 1.00 320 0.13

40 0.60 80 0.14 0.85 250 0.16

10 1.50 500 0.20 — — —

20 0.90 320 0.12 1.55 500 0.24

30 0.70 160 0.10 1.10 400 0.16

40 0.60 100 0.14 0.95 320 0.18

1 Developer Rack 2 Developer Racks

Average

Gamma

Average

Gamma

ISO A D-min

99°F (37°C)

104°F (40°C)

1 Developer Rack 2 Developer Racks

ISO A D-min

99°F (37°C)

104°F (40°C)

Average

Gamma

Average

Gamma

ISO A D-min

ISO A D-min

DIMENSIONAL STABILITY

The dimensional stability of aerial films is of particular

interest and importance in accurate mapping and in the

reproduction of maps.

Dimensional stability is an all-inclusive term. In

photography, it applies to size changes caused by changes in

humidity and in temperature, and by processing and aging.

The absence of solvent in ESTAR Base is one of the reasons

why ESTAR Base films show excellent dimensional

stability. The dimensional properties of ESTAR Base may

vary slightly in different directions within a sheet; the

differences that may exist, however, are not always between

the length and width directions.

Temporary Dimensional Changes

Thermal Coefficient of Linear Expansion:

0.001% per degree F of change

0.0018% per degree C of change

Humidity Coefficient of Linear Expansion (Unprocessed):

0.002% per 1% change in relative humidity

Permanent Dimensional Changes

Processing Dimensional Change:

-0.03% to +0.01% shrinkage to swell

Aging Shrinkage of Processed Film:

0.03% 1 week at 120°F (49°C), 20% RH

0.03% 1 year at 78°F (25.5°C), 60% RH

Model 1140 -- KODAK VERSAMAT Chemicals,

Type A

This is not a primary processing recommendation, although

satisfactory results can be obtained at processor speeds up to

10 feet per minute. Refer to the processing conditions and

sensitometric data for the KODAK VERSAMAT Processor,

Model 11, above.

REWIND OR SPIRAL REEL PROCESSING

KODAK DOUBLE-X AEROGRAPHIC Film 2405 yields

optimum results with modern, high-temperature,

continuous-processing machines. It can be processed in

rewind equipment or on spiral reels, although these methods

are not primary processing recommendations. Customers

wishing to use spiral reels or rewind equipment such as the

Gordon/Morse M-10 Developing Outfit (Military

Designator: B-5) may contact Aerial Systems for

information on exposure, processing chemicals, process

cycles, and general recommendations.

4 KODAK DOUBLE-X AEROGRAPHIC Film 2405 • AS-75

Page 5

SIZE DATA AND ORDERING

0

0

INFORMATION

Information on available sizes and minimum order

quantities of this film is available on the web at

www.kodak.com/go/aerial. You can also write or call:

Aerial Imaging

Eastman Kodak Company

343 State Street

Rochester, New York 14650-0505

(585) 724-4688

Toll-free in the US: (877) 909-4280

Note: The Kodak materials described in this publication

used with KODAK DOUBLE-X AEROGRAPHIC Film

2405 are available from those dealers normally supplying

Kodak products. Other materials may be used, but equivalent

results may not be obtained.

CURVES

3.0

2.0

1.0

Log Sensitivity*

0.0

1.0

250 350 550

4.0

3.0

Spectral Sensitivity

D = 0.3 above gross fog

D = 1.0 above gross fog

450

Wavelength (nm)

Characteristic Curves

Exposure: Daylight 1/100 sec

ODAK VERSAMAT

Process: K

K

ODAK VERSAMAT

2 developer racks; 85

Densitometry: Diffuse visual

Film Processor, Model 11;

°F (29.5°

885 Chemicals;

C)

Exposure: 1.4 seconds

Process: Recommended

Densitometry: Diffuse visual

650

75

2.0

Density

1.0

0.0

–4 -2

–3

Log Exposure (lux seconds)

10 fpm

15 fpm

20 fpm

25 fpm

-1

KODAK DOUBLE-X AEROGRAPHIC Film 2405 • AS-75 5

Page 6

KODAK DOUBLE-X AEROGRAPHIC Film 2405

3

1000

100

641 Chemicals

Aerial Film Speed (ISO A)

10

0

Gamma vs. Machine Speed

4

3

2

Gamma

1

0

010

F002_1115AC

ISO A vs. Gamma

885 Chemicals

Type A Chemicals

Exposure: Daylight 1/100 sec

ODAK VERSAMAT

Process: K

ODAK VERSAMAT

K

K

ODAK VERSAMAT

1 and 2 developer racks; 85

K

ODAK VERSAMAT

1 and 2 developer racks; 90

1

GAMMA

KODAK VERSAMAT Film Processor,

MODEL 11, 85F (29.5C)

KODAK VERSAMAT 885 Chemicals

Machine Speed (fpm)

Film Processor, Model 11;

885 Chemicals;

641 Chemicals;

°

F (29.5°C)

Chemicals, Type A;

°

F (32

°

2

1 developer rack

2 developer racks

ISO A vs. Machine Speed

1200

1000

800

600

C)

400

Aerial Film Speed (ISO A)

200

0

F002_1107AC

100

KODAK VERSAMAT 885 Chemicals,

KODAK VERSAMAT Film Processor,

Model 11, 85F (29.5C)

1 developer rack

2 developer racks

20 30 40 50

Machine Speed (fpm)

Modulation Transfer Function

200

100

70

50

30

20

10

7

5

RESPONSE (%)

KODAK VERSAMAT 885 Chemicals

3

KODAK VERSAMAT Film Processor,

2

2 racks, 85F (29.5C), 10 fpm; Diffuse visual

1

50403020

F002_1096AC

SPATIAL FREQUENCY (cycles/mm)

60020050201054321 100

NOTICE: While the sensitometric data in this publication are typical of production coatings, they do not represent

standards which must be met by Kodak. Varying storage, exposure, and processing conditions will affect results.

The company reserves the right to change and improve product characteristics at any time.

KODAK DOUBLE-X

AEROGRAPHIC Film 2405

KODAK Publication No. AS-75

TI 0912

Aerial Imaging

EASTMAN KODAK COMPANY • ROCHESTER, NY 14650-0505

Kodak, Aerographic, Double-X, Estar, Versamat, and Wratten are trademarks

Revised 11-05

Printed in U.S.A.

Loading...

Loading...