Page 1

AS-2569

KODAK AEROCHROME III MS Film 2427

KODAK AEROCHROME III MS Film 2427 is a very

fine-grain, mediu m-speed color - re vers al aerial camera film.

This film has excellent color rendition and good image

quality.

It has an ESTAR Base with a clear gel backing. The

ESTAR Base has good optical qualities and provides

flexibility, moisture resistance, high tear resistance, and

excellent dimensional stability.

This film can be processed in Process AR-5 using

KODAK EA-5 Chemicals in modern, continuous-processing

machines such as the KODAK Aerial Color Processor,

Model 1611 or the KODAK EKTACHROME RT Processor,

Model 1811. It can also be processed in rewind equipment

such as the Gordon/Morse rewind equipment.

APPLICATIONS

KODAK AEROCHR OME III MS Film 2427 is intended for

low- to medium-altitude mapping and reconnaissance

applications. It provides positive color transparencies

suitable for projection, direct viewing, or making color

prints.

BASE

3.9-mil (0.10 mm) ESTAR Base with a clear gel backing.

EXPOSURE

Aerial Film Speeds (EAFS or ISO A equivalent) should not

be confused with conventional film speeds, which are

designed for roll and sheet films used in pictorial

photography. The characteristics of aerial scenes differ

markedly from those of ordinary pictorial or ground scenes

because of the smaller range in subject luminance,

atmospheric haze conditions, and other factors. Therefore,

different film-speed characteristics are used to relate

aerial-scene characteristics to practical exposure

recommendations.

The KODAK Aerial Exposure Computer, KODAK

Publication AS-10, has been published based on the aerial

film speed criterion.

Nominal speed, daylight (no filter): EAFS or ISO A 32

(based on development in KODAK EA-5 Chemicals)

Note: The Aerial Film Speed given in this publication is

rounded to the nearest cube root of 2 step (equivalent to 1⁄3

stop).

Filters

No color-correction filters are used with this film, although a

haze filter, such as a KODAK WRATTEN Filter HF-3 or

No. 2B may be necessary for reducing the effects of

atmospheric haze.

TOTAL FILM THICKNESS

The nominal total thickness (unprocessed) of this film is

5.44 mils (0.14 mm). This includes emulsion—1.04 mil

(0.03 mm), base—3.9 mils (0.10 mm), and backing—

0.50 mil (0.013 mm).

WEIGHT

The weight of AEROCHROME III MS Film 2427

(unprocessed), conditioned in equilibrium with 50 percent

relative hu midity, is 0.038 lbs/sq ft (0.0172 kg/sq ft).

SPECTRAL SENSITIVITY

This multilayer, color-reversal film is balanced for daylight

exposure.

SAFELIGHT

Total darkness is required.

©Eastman Kodak Company, 2005

Typical Camera Exposure

A typical exposure for this film is approximately 1⁄500

second at f⁄4.7. This exposure is based on a solar altitude of

40 degrees, a clear day, and an aircraft altitude of 5000 feet.

When using an aerial camera equipped with an

antivignetting filter, or other filter, it is important to increase

this typical exposure by the filter factor of the filter used.

IMAGE STRUCTURE

The following data are based on processing in KODAK EA-5

Chemicals, Process AR-5.

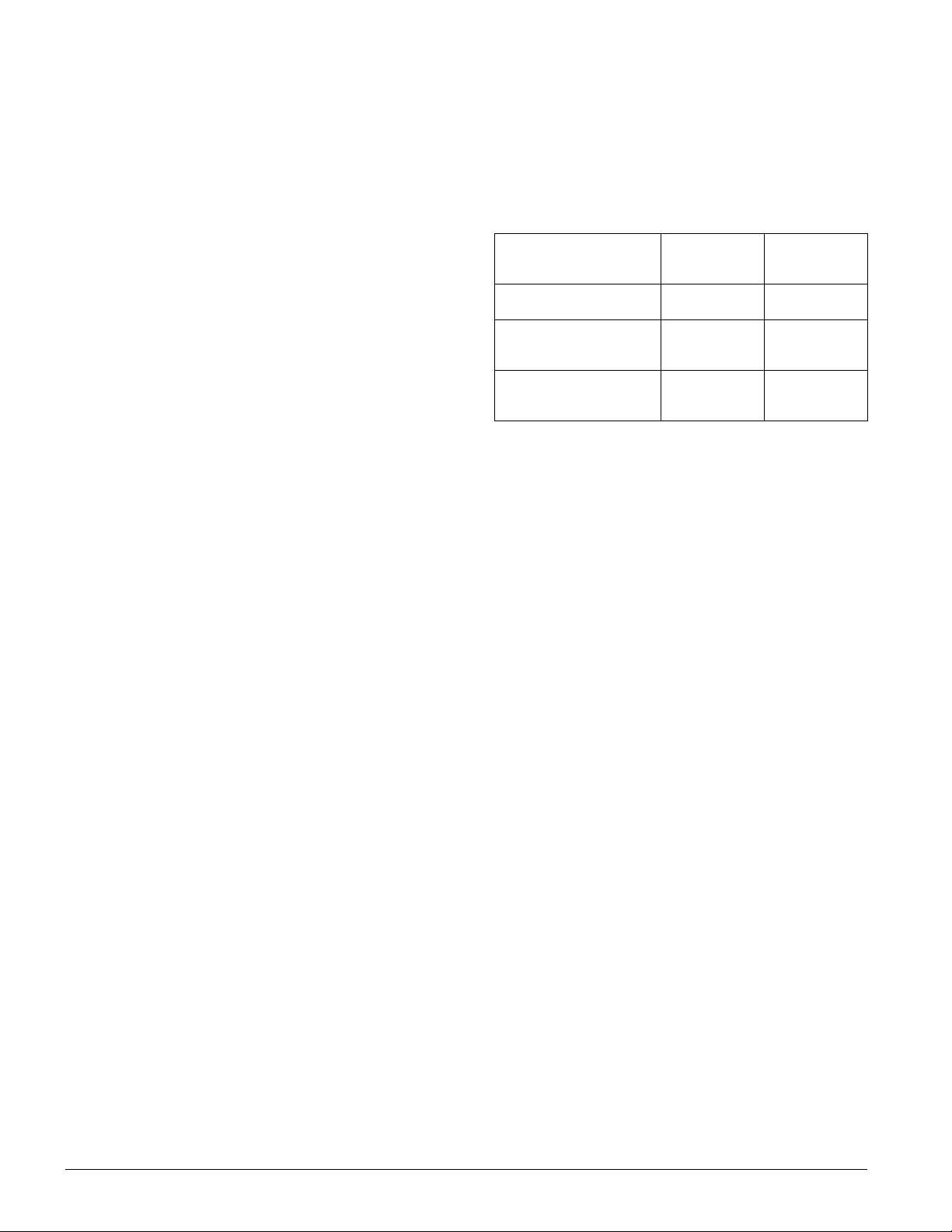

Resolving Power (line pairs/mm)

TOC 1.6:1 TOC 1000:1

80 100 13

*

Granularity values read at a net green diffuse density of 1.0 with a

48-micrometre aperture.

rms Granularity

*

Page 2

STORAGE

For consistent results, all aerial films should be stored under

fairly constant conditions. Kodak aerial films are “usually”

packaged in equilibrium with 40 to 50 percent relative

humidity. High temperatures or high humidity may produce

undesirable changes in the film.

Unexposed Film

Store unexposed film in a refrigerator at 55°F (13°C) or

lower, or freezer at 0 to -10°F (-18to-23°C), in the original

sealed container. If the film is stored in a refrigerator,

remove it about 2 hours before opening; if stored in a freezer ,

remove it about 8 hours before opening. A sufficient

warm-up time is necessary to prevent moisture condensation

on cold film– otherwise, moisture spotting, ferrotyping, or

sticking may occur.

Exposed Film

Keep exposed film cool and dry. Process the f ilm as soon as

possible after exposure to avoid undesirable changes in the

latent image. If it is necessary to hold exposed but

unprocessed film for sev eral days (s uch as o v er a weekend),

it should be resealed and refrigerated at 40°F (4°C) or lower .

Before unsealing and processing exposed film that has been

held in cold storage, follow the warm-up procedures

described for unexposed film described above.

Processed Film

For best keeping, store processed film in a dark, dust -free

area at 50 to 70°F (10 to 21°C) and 30 to 50 percent relative

humidity. Preferably, store negatives on the spool or in

individual KODAK Sleeves. High relative humidity

promotes the growth of mold and causes ferrotyping. Very

low relative humidity causes excessive curl and brittleness.

Avoid storage temperatures over 80°F(27°C).

PROCESSING

The primary recommendation for processing 2427 Film is in

Process AR-5 using mechanized processors. Mechanized

processing in roller-transport processors offers the

advantages of uniform treatment of all portions of the roll,

freedom from banding, and absence of significant density

variations from ends of the roll to the center.

Process AR-5 Cycle Times

Processor Transport

KODAK Aerial Color

Processor, Model 1611

KODAK EKTACHROME

RT Processor , Model 1811

(with Quick-Change)

KODAK EKTACHROME

RT Processor , Model 1811

(Standard Configuration)

Speed (feet

per minute)

3.5 17.4 min

3.5 17.2 min

5.3 13.6 min

In each case, the film is fed emulsion side down into the

processor.

This publication provides general information regarding

the KODAK Aerial Color Processor, Mode 1611, and the

KODAK EKTACHROME RT Processor, Model 1811.

Refer to the operating manuals for additional set-up

information.

Note: For a list of firms equipped to offer machine

processing of 2427 Film, write to Eastman Kodak Company,

Aerial Imaging, Rochester, New York 14653-7128.

Chemicals

Process AR-5 uses the following KODAK EA-5 Chemicals:

KODAK EA-5 First Developer *

KODAK EA-5 First Developer Replenisher

KODAK EA-5 First and Second Stop Bath and

Replenisher

KODAK EA-5 Color Developer

KODAK EA-5 Color Developer Replenisher

KODAK EA-5 Bleach and Replenisher

KODAK Aerial Color Fixer and Replenisher

KODAK EA-5 Stabilizer and Replenisher

The first developer working solution is prepared by

combining one part first developer with two parts first

developer replenisher.

Dry-to-Dry

Processing

Time

Notice: Observe precautionary information on product labels and on

the Material Safety Data Sheets.

2 KODAK AEROCHROME III MS Film 2427 • AS-2569

Page 3

Processing Sequence—3.5 fpm

Replenishment and Wash Rates—3.5 fpm

KODAK Aerial Color Processor, Model 1611

Solution/

Step

SKIP

TANKS

First

Developer

Tank

No.

Time

(Seconds)

Solution Temperature

1, 2, 3 21.3 —

4, 5 141.6 (49.4 ± 0.3°C) 121 ± 0.5°F

First Stop 6 70.5 (46 ± 3°C) 115 ± 5°F

Wash 7 71.3 (49 ± 3°C) 120 ± 5°F

Color

Developer

Second

Stop

8, 9 140.7 (49 ± 0.6°C) 120 ± 1°F

10 71.1 (49 ± 3°C) 120 ± 5°F

Wash 11 70.5 (49 ± 3°C) 120 ± 5°F

Bleach 12 70.3 (49 ± 3°C) 120 ± 5°F

Fixer 13 71.3 (49 ± 3°C) 120 ± 5°F

Final Wash

*

14, 15,

16

211.3 (49 ± 3°C) 120 ± 5°F

Dryer — 106.5 (63 ± 3°C) 145 ± 5°

*

Inject EA-5 Stabilizer and Replenishe r into ta nk 16 of the fina l wa sh at a

rate of 50 mL/min for all film widths.

KODAK EKTACHROME RT Processor, Model 1811,

Quick-Change

Solution/

Step

SKIP

TANKS

First

Developer

Tank

No.

Time

(Seconds)

Solution Temperature

1 - 6 39.3 —

7, 8 141.3 (49.4 ± 0.3°C) 121 ± 0.5°F

First Stop 9 70.3 (46 ± 3°C) 115 ± 5°F

Wash 10 71.3 (49 ± 3°C 120 ± 5°F)

Color

Developer

Second

Stop

11, 12 140.7 (49 ± 0.6°C) 120 ± 1°F

13 70.3 (49 ± 3°C) 120 ± 5°F

Wash 14 71.3 (49 ± 3°C) 120 ± 5°F

Bleach 15 70.5 (49 ± 3°C) 120 ± 5°F

Fixer 16 71.1 (49 ± 3°C) 120 ± 5°F

Final Wash

Dryer

*

Inject EA-5 Stabilizer and Replenisher into tank 18 of the final wash at a

rate of 50 mL/min for all film widths.

†

Set air damper control knobs at 8. The te mperature of the dryer may

require adjustment depending on the ambient temperature and humidity

conditions in the processing area.

*

17, 18 140.7 (49 ± 3°C) 120 ± 5°F

†

— 147.3 (60 ± 3°C) 140 ± 5°F

*

9 1/2-in

(mL/min)

Solution/

Step

First

Developer

Models 1611 and 1811 with Quick-Change

Basic

Rate

(mL/sq ft)

70 mm

(mL/min)

Film Width

5-in

(mL/min)

150 120 220 415

First Stop 200 160 290 555

Was h —2 gal /mi n—

Color

Developer

Second

Stop

250 200 365 695

200 160 290 555

Wash —2 gal/min (Model 1611 only)—

Bleach 90 75 130 250

Fixer 100 80 145 275

Final

†

Wash

*

These rates have been rounded to the nearest usable increment.

†

Inject EA-5 Stabilizer and Replenishe r into tank 16 (Mod el 1611) or tank

18 (Model 1811) of the final wash at a rate of 50 mL/min for all film

widths. In the Model 1611, this w as flows counterc urrent to tanks 15 and

14. In the Model 1811, this wash overflows from tank 17 into tank 14.

—2 gal/min—

Processing Sequence—5.3 fpm

KODAK EKTACHROME RT Processor, Model 1811

Solution/

Step

SKIP

TANKS

First

Developer

First Stop 7 46.9 (46 ± 3°C) 115 ± 5°F

Wash 8 46.9 (49 ± 3°C) 120 ± 5°F

Color

Developer

Second

Stop

Wash 14 46.9 (49 ± 3°C) 120 ± 5°F

Bleach 15 46.9 (49 ± 3°C) 120 ± 5°F

Fixer 16 46.9 (49 ± 3°C) 120 ± 5°F

Wash 17 46.9 (49 ± 3°C) 120 ± 5°F

Stabilizer 18 46.9 —Equilibrium—

Dryer

(V ents set

†

at 8)

*

No temperature controlling device is provided; solution temperature

attains “equilibrium” depending on temperature of replenisher and

surrounding conditions.

†

Set air damper control knob at 8. The dryer temperature may require

adjustment depending on the ambien t temperature and humidity

conditions in the processing area.

Tank

No.

Time

(Seconds)

Solution Temperature

1, 2, 3 14.6 —

4, 5, 6 140.3 (49.4 ± 0.3°C) 121 ± 0.5°F

9, 10,

11, 12

187.5 (49 ± 0.6°C) 120 ± 1°F

13 46.9 (49 ± 3°C) 120 ± 5°F

*

— 97.8 (60 ± 3°C) 140 ± 5°F

KODAK AEROCHROME III MS Film 2427 • AS-2569 3

Page 4

Replenishment and Wash Rates—5.3 fpm

Model 1811, Standard Configuration

Solution/

Step

First

Developer

First Stop 200 245 440 840

Wash —2 gal/min—

Color

Developer

Second

Stop

Bleach 90 110 200 380

Fixer 100 120 220 420

†

Wash

Stabilizer 120 145 265 505

*

These rates have been rounded to the nearest usable increme nt.

†

This wash overflows from tank 17 into tank 14.

Basic

Rate

(mL/sq ft)

150 185 330 630

250 305 550 1050

200 245 440 840

70 mm

(mL/min)

Film Width

5-in

(mL/min)

—2 gal/min—

*

9 1/2-in

(mL/min)

Bleach Regeneration

Regeneration of used EA-5 Bleach will reduce processing

solution costs and substantially reduce the amount of bleach

discarded to the sewer. Collection and treatment tanks for

bleach overflow solution and chemical testing capability are

required. A detailed laboratory procedure is available from

Eastman Kodak Company.

REWIND PROCESSING

Note: This is not a primary recommendation.

KODAK AEROCHROME III MS Film 2427 yields

optimum results with modern, high-temperature,

continuous-processing machines. It can be processed in

rewind equipment, although this method is not a primary

processing recommendation. Eastman Kodak Company no

longer offers packaged chemicals for such processing.

Customers wishing to use rewind equipment such as the

Gordon/Morse M-10 Developing Outfit (Military

Designator: B-5) may contact Aerial Imaging for

information on exposure, processing chemicals, process

cycles, and general recommendations.

PROCESS CONTROL

KOD AK Control Strips, Process AR-5, are available and are

recommended for monitoring the processing of 2427 Film

and several other color aerial films in KODAK

roller-transport processors using EA-5 chemicals. For

detailed information on process con trol and

trouble-shooting, refer to “Using Processes AR-5 and AN-5

for KODAK Color Aerial Films,” KODAK

Publication Z-200.

PRINTING TRANSPARENCIES

Y ou can reproduce images made on AER OCHR OME III MS

Film by using a variety of Kodak materials.

Color Transparencies

You can make duplicates directly on KODAK

PROFESSIONAL EKTACHROME Duplicating Film

EDUPE. Or, you could scan your image to a file or have an

internegative made, and print it on KODAK

PROFESSIONAL ENDURA Clear Display Material.

Color Prints

You could scan your image to a file or have an internegativ e

made, and print it on—

KODAK PROFESSIONAL PORTRA, SUPRA, and

ULTRA ENDURA Papers

KODAK PROFESSIONAL ENDURA Transparency

Display Material

KODAK PROFESSIONAL ENDURA Metallic Paper

4 KODAK AEROCHROME III MS Film 2427 • AS-2569

Page 5

DIMENSIONAL STABILITY

The dimensional stability of aerial films is of particular

interest and importance in accurate mapping and in the

reproduction of maps.

Dimensional stability is an all-inclusive term. In

photography, it applies to size changes caused by changes in

humidity and in temperature, and by processing and aging.

The absence of solvent in ESTAR Base is one of the reasons

why ESTAR Base films show excellent dimensional

stability. The dimensional properties of ESTAR Base may

vary slightly in different directions within a sheet; the

differences that may exist, however, are not always between

the length and width directions.

Temporary Dimensional Changes

Thermal Coefficient of Linear Expansion:

0.001% per degree F of change

0.0018% per degree C of change

Humidity Coefficient of Linear Expansion (Unprocessed):

0.0025% per 1% change in relative humidity

Permanent Dimensional Changes

SIZE DATA AND ORDERING

INFORMATION

Information on available sizes and minimum order

quantities of this film is available on the web at

www.kodak.com/go/aerial. You can also write or call:

Aerial Imaging

Eastman Kodak Company

343 State Street

Rochester, New York 14650-0505

(585) 724-4688

Toll-free in the US: (877) 909-4280

Note: The Kodak materials described in this publication

used with KODAK AEROCHROME III MS Film 2427 are

available from those dealers normally supplying Kodak

products. Other materials may be used, but equivalent

results may not be obtained.

Processing Dimensional Change:

-0.03 to +0.02% shrinkage to swell

Aging Shrinkage of Processed Film:

0.06% 1 week at (49°C) 120°F , 20% RH

0.03% 1 year at (25.5°C) 78°F , 60% RH

KODAK AEROCHROME III MS Film 2427 • AS-2569 5

Page 6

KODAK AEROCHROME III MS Film 2427

y

S

S

C

S

)

)

4.0

0

S

O

S

CURVES

Spectral Sensitivity

2.0

1.0

*

0.0

LOG SENSITIVITY

1.0

Effective Exposure:

Process:

Density:

2.0

250 300 350 400 450 500 550 600 650 750700

Yellow-

Forming

Layer

Exposure

AR-5

1.0, Equivalent Neutral Density (END)

Magenta-

Forming

Layer

WAVELENGTH (nm)

*Sensitivity = reciprocal of exposure (erg/cm ) required

to produce specified densit

Spectral Dye Density

1.4

Normalized Dyes to form a visual neutral density of

1.0 for a viewing illuminant of 5000 K

1.2

ITY

1

0.8

TRAL DEN

PE

0.6

E

0.4

DIFFU

0.2

0.0

400

Process:

Yellow

AR-5

Magenta

500

WAVELENGTH (nm

Visual Neutral

600

Cyan-

Forming

Layer

2

Cyan

700

DENSITY

200

100

70

50

30

20

E (%)

N

10

P

RE

1

3.0

2.0

1.0

0.0

7

5

3

2

Characteristic Curves

Exposure:

3.0

Process:

R

Densitometry:

G

B

2.0

LOG EXPOSURE (lux-seconds

AR-5 / 2427

1.0 0.0

Modulation Transfer Function

Exposure:

Process:

Daylight

AR-5

SPATIAL FREQUENCY (cycles/mm)

Daylight

Status A

1.

B

G

R

60020050201054321 100

NOTICE: While the sensitometric data in this publication are typical of production coatings, they do not represent

KODAK AEROCHROME III MS

Film 2427

standards which must be met by Kodak. Varying storage, exposure, and processing condtions will affect results.

The company reserves the right to change and improve product characteristics at any time.

Aerial Imaging

EASTMAN KODAK COMPANY • ROCHESTER, NY 14650-0505

Kodak, Aerochrome, Estar, Ektachrome, and Wratten are trademarks.

Revised 11-05

Printed in U.S.A.

KODAK Publication No. AS-2569

TI2569

Loading...

Loading...