Kia Optima, Magnetis Bodyshop Manual

Body Shop Manual

mashinesoft.com

09120146259

FOREWORD

This Body Shop Manual illustrates body structures and

service procedures for the OPTIMA/MAGENTIS.

This manual illustrates the replacement of major body panels,

plastic parts, body dimensions, sealing treatment etc., in a

systematic manner which is necessary for effective and

lasting body repairs.

You are encouraged to become familiar with this manual

and understand each section in order to perform proper repair

procedures. Keep this manual in a convenient location so

that it is readily available.

All information in this manual including specifications,

data and illustrations is made based on the vehicles built at

the time the manual was printed.

Information regarding the removal/replacement of

components not specifically covered in this manual can be

found in the OPTIMA/MAGENTIS Service Manual.

Information regarding electrical harness routing/

connections, etc. can be found in the OPTIMA/MAGENTIS

Electrical T roubleshooting Manual.

The descriptions and specifications contained in this manual

were in effect at the time this manual was approved for

printing. Kia Motors Corporation reserves the right to

discontinue models at any time, or change specifications

or design without notice and without incurring obligation.

CONTENTS

Title Group

General Information

Body Construction

Body Dimensions

Body Panel Repair Procedure

Body Sealing Locations

Corrosion Protection

Body Modification Tools

Plastic Parts

GI

BC

BD

BP

BS

CP

BT

PP

Kia Motors Corporation

CAUTION :

Severe engine and transaxle damage may result from

the use of poor quality fuels and lubricants that do

not meet Kia specifications. You must always use

high quality fuels and lubricants that meet the

specifications described on the specification section

in the relevant group of the W orkshop Manual.

Copyright c 2005, Kia Motors Corporation

Printed in Korea, September 2005

Pub. No. : A2GB-EG58A (English)

All rights reserved. No part of this publication may be reproduced, stored in an y retrie val system or tr ansmitted in any

form or by any means without the prior written permission of Kia Motors Corporation.

SEOUL, KOREA

IMPORTANT SAFETY NOTICE

mashinesoft.com

09120146259

Proper service methods and repair procedures are essential for safe, reliable operation of all

motor vehicles as well as personal safety of the operator. The service procedures and

descriptions in this shop manual provide general directions for a service and repair.

Procedure, techniques, tools, and parts for service including the skill of the technician vary.

It is impossible to provide advice or caution as to each case in this manual.

Accordingly, anyone who intends to use a replacement part, service procedure, or tool, which is

not recommended by the vehicle manufacturer, must first assure thoroughly that neither their

personal safety nor the safe operation of the vehicle will be first jeopardized by the replacement

part, service procedure, or tool they select.

IN THIS MANUAL

WARNING :

CAUTION :

NOTE :

The following list contains some general WARNINGS that you should follow while working on a

vehicle.

Always wear safety glasses for eye protection.

Use safety stands whenever a procedure requires you to be under the vehicle.

Make sure that the ignition switch is always in the OFF position, unless otherwise required by

the procedure.

Set the parking brake when working on the vehicle. If you have an automatic transaxle, set in

park unless instructed otherwise for a specific operation

Place supporters against the front and rear surfaces of the tires to help prevent the vehicle

from moving

Operate the engine only in a well-ventilated area to avoid the danger of carbon monoxide

poisoning.

Keep yourself and your clothing away from moving parts when the engine is running,

especially the drive belts.

To prevent serious burns, avoid contact with hot metal parts such as the radiator, exhaust

manifold, tail pipe, catalytic converter and muffler.

Do not smoke while working on a vehicle.

To avoid injury, always remove rings, watches, loose hanging jewelry, and loose clothing

before beginning to work on a vehicle.

When it is necessary to work under the hood, keep hands and other objects clear of the

radiator fan blades! Your vehicle may be equipped with a cooling fan that may turn on, even

though the ignition switch is in the OFF position. For this reason care should be taken to

ensure that the radiator fan electric motor is completely disconnected when working under the

hood and the engine is not running.

Remind you to be especially careful in those areas where carelessness can

cause personal injury.

To prevent you from making errors that could damage the vehicle as well as

personal injury.

Gives you added information that will help you complete a particular procedure.

General

mashinesoft.com

09120146259

Information

FUNDAMENTAL PROCEDURES

VEHICLE PROTECTION..................................GI - 2

A WORD ABOUT SAFETY ...............................GI - 2

WELDING PROCEDURES ..............................GI - 3

BOD Y FRAME STRAIGHTENER.....................GI - 3

ELECTRICAL PROCEDURES ........................GI - 3

FOR BEST RESULTS

DISASSEMBLY.................................................GI - 4

PREPARATION OF ASSEMBLY.......................GI - 6

ASSEMBLY.......................................................GI - 7

RUSTPROOF TREA TMENT AFTER

ASSEMBLY.......................................................GI - 8

VEHICLE LIFT (2-SUPPORT TYPE) AND

SAFETY STAND POSITIONS

...................GI - 9

GI

JACK SUPPORT POSITIONS ..................GI - 10

GI-2 GENERAL INFORMATION

mashinesoft.com

09120146259

FUNDAMENT AL PR OCEDURES

VEHICLE PROTECTION

1. Cover the seats before performing any procedure to

keep them from getting dirty.

2. Cover all glasses, seats and mats with a heat resistant

cover when welding.

BVQGI6001

3. Protect moldings, garnishes and ornaments.

A WORD ABOUT SAFETY

1. Wear the appropriate safety equipment that is

necessary for the procedure being performed.

Safety glasses

Mask

Face shield

2. When welding or performing other procedures that

require the use of an open flame near the fuel tank,

disconnect and remove the tank and fuel pipe, and

cap the pipe to prevent fuel leakage.

Ear protectors

Gloves

Safety shoes

BVQGI6002

BVQGI6003

GENERAL INFORMATION GI-3

mashinesoft.com

09120146259

WELDING PROCEDURES

Observe the following tips when welding.

1. Wear appropriate eye protection.

2. Carefully follow the manufacturers operating

instructions for the welding machine you are using.

3. Do not weld, smoke or allow open flames around

volatile chemicals, cleaners or solvents or in any area

where they have just been used.

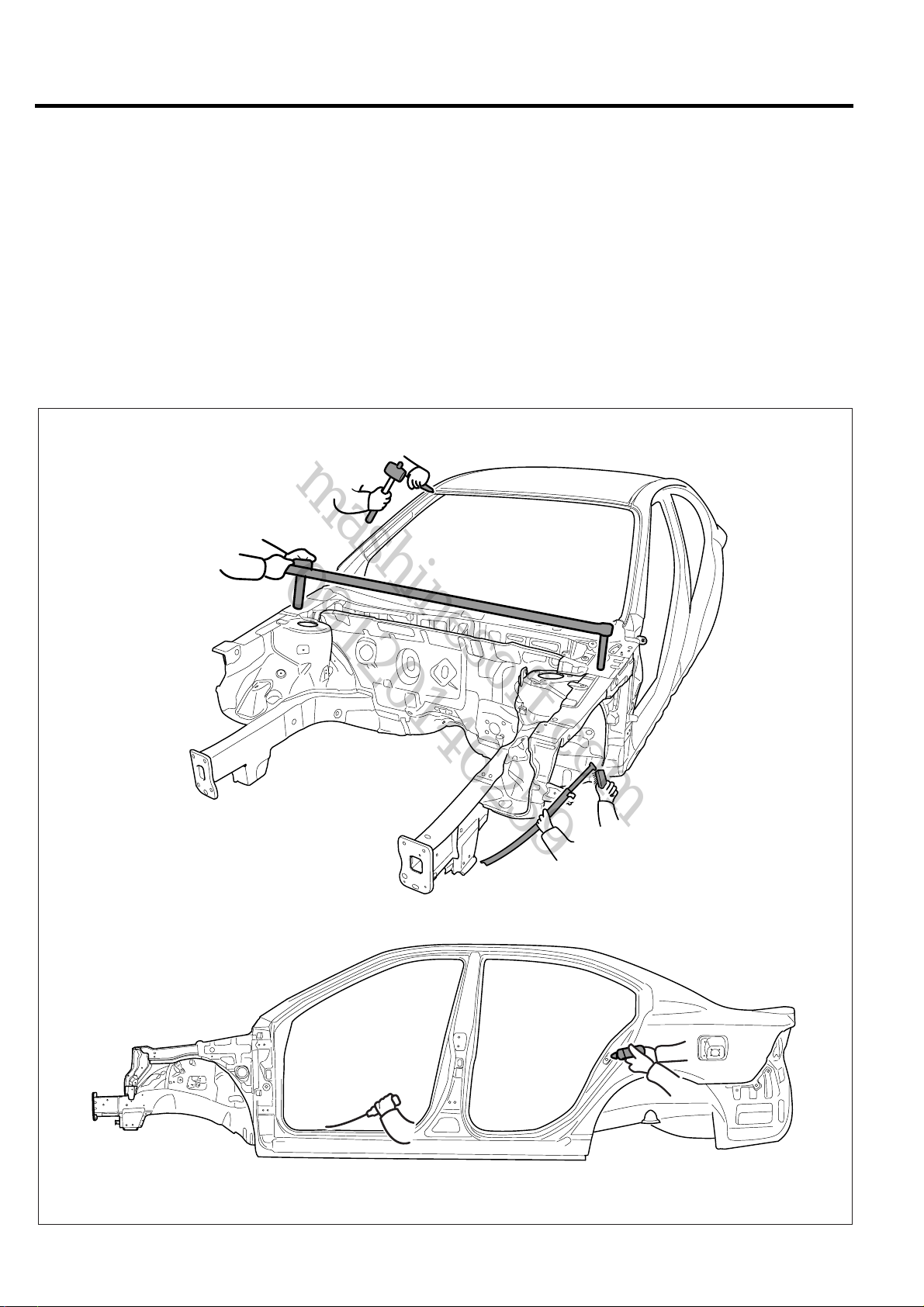

BODY FRAME STRAIGHTENER

When using a frame straightener, do not enter the area

where the body is being straightened by the chain.

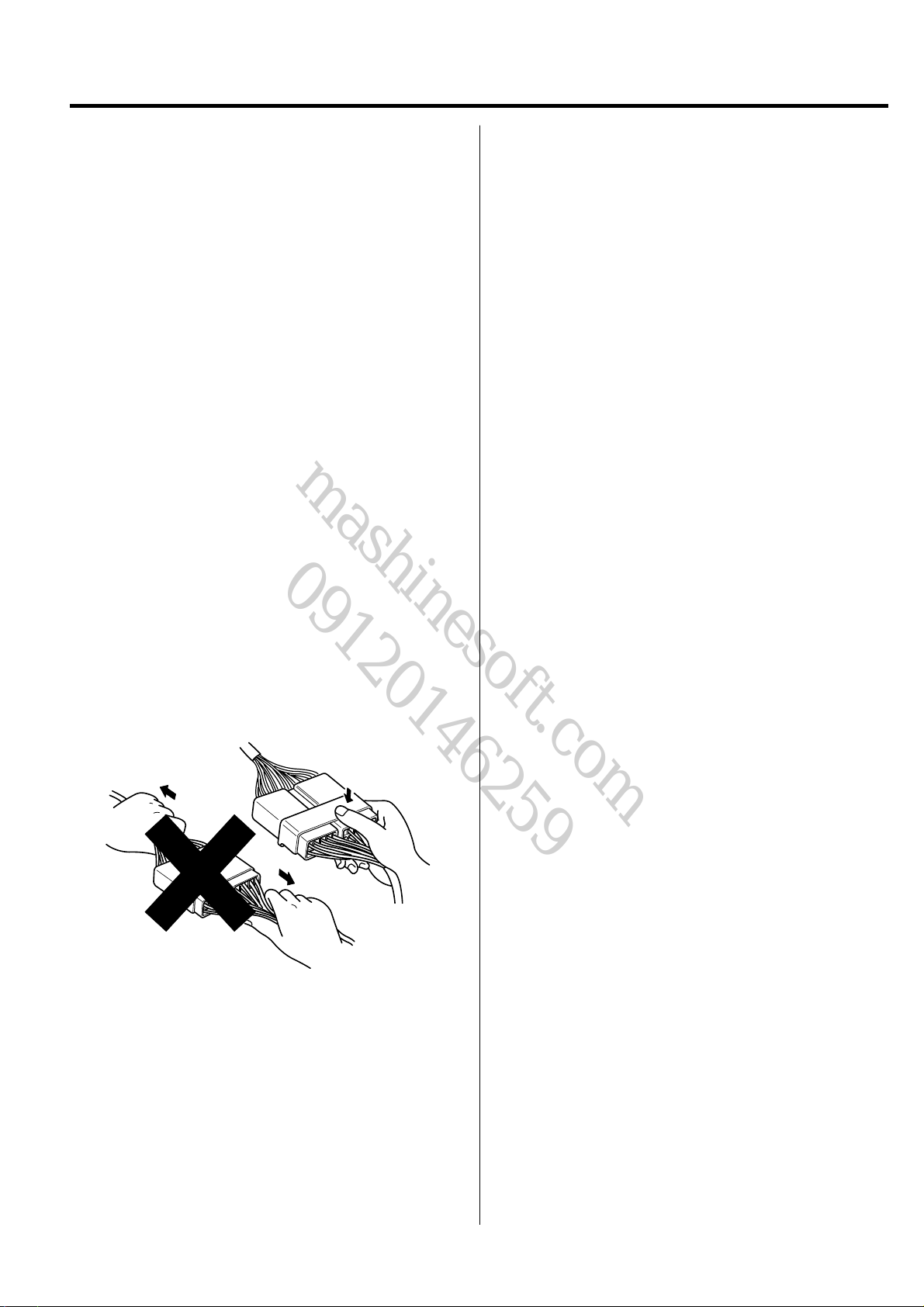

ELECTRICAL PROCEDURES

1. Disconnect the negative battery terminal.

2. Do not pull on wires when disconnecting electrical

connectors. Be careful to hold the connector itself when

disconnecting it.

3. Insert the connector until it "licks" when connecting

the connector.

4. Handle all electrical components with care.

BVQGI6004

GI-4 GENERAL INFORMATION

mashinesoft.com

09120146259

FOR BEST RESUL TS

DISASSEMBLY

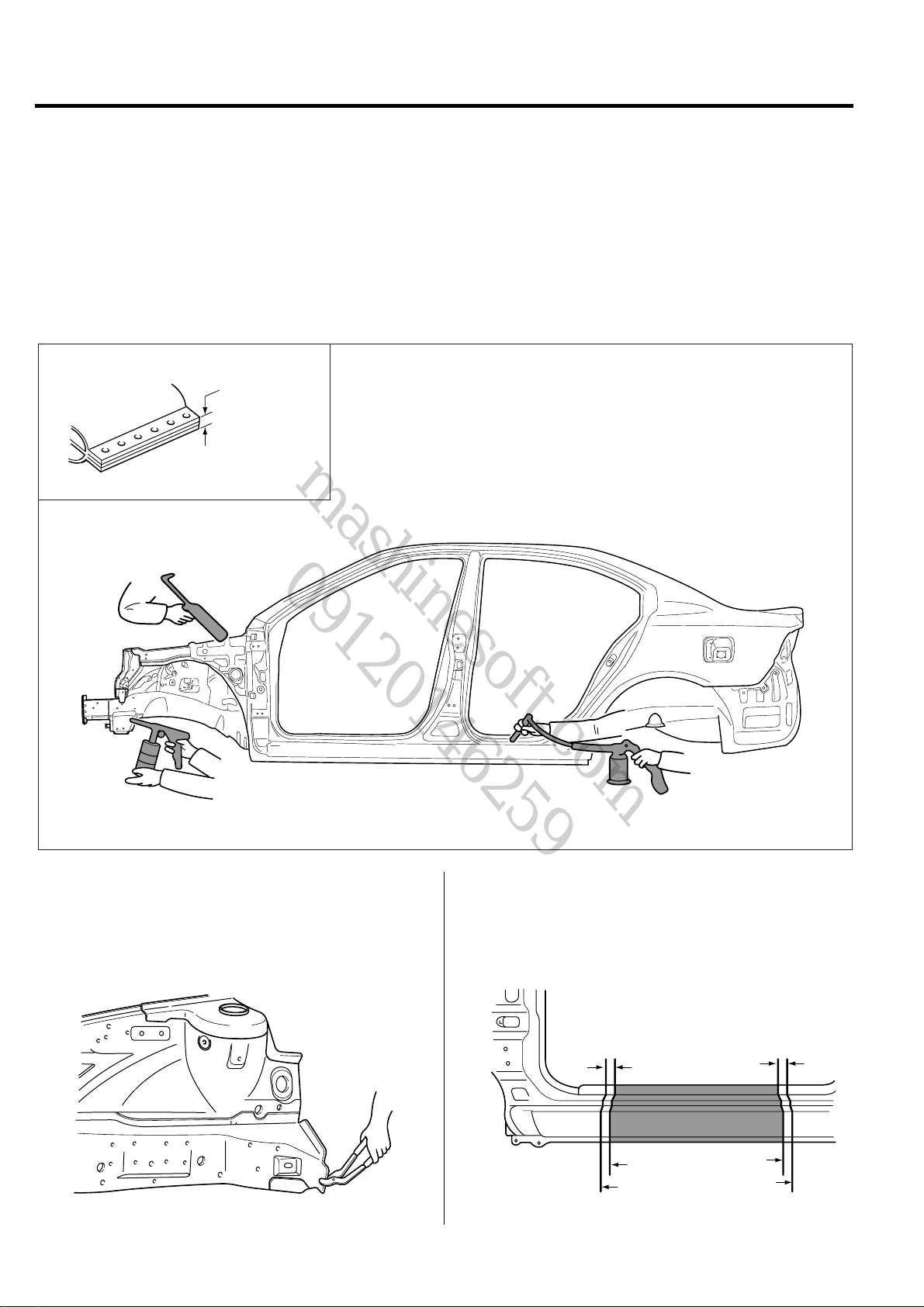

Measuring dimensions before beginning

Measure the dimensions of the damaged area according to the body dimension drawings before disassembling and repairing.

Adjust dimensions with body frame adjuster if deformed.

Selecting cutting area

Select a cutting area that is easily accessible and that is prone to the least amount of distortion when welding.

Select an area that would allow the new part to overlap repair area by 1.2~2.0 in (30~50 mm).

Protecting body from damage

Secure the body with clamps and jacks to prevent damage to the body when working on it.

BMGGI6005

GENERAL INFORMATION GI-5

mashinesoft.com

09120146259

Disassembling related parts

Use caution when removing body molding and trim from

the area to be worked.

Apply masking tape where needed to prevent damage to

the part being removed or to the vehicle body.

Before starting repairs, check if pipes, hoses or electrical

components are present near damaged area.

Wire harness

Repair work area

Cutting area

BVQGI6006

GI-6 GENERAL INFORMATION

mashinesoft.com

09120146259

PREPARATION OF ASSEMBLY

Applying spot sealer

Remove paint from the surf ace of new parts and body to be spot welded, and apply spot sealer for rustproofing.

Selecting a welding method

If the thickness of the area to be welded with the panels overlapped is greater than 0.1 in (3 mm), do plug welding using a

carbon arc welding machine.

Protecting body from damage

Secure the body with clamps and jacks to prevent damage to the body when working on it.

Thicker than

0.1 in (3mm)

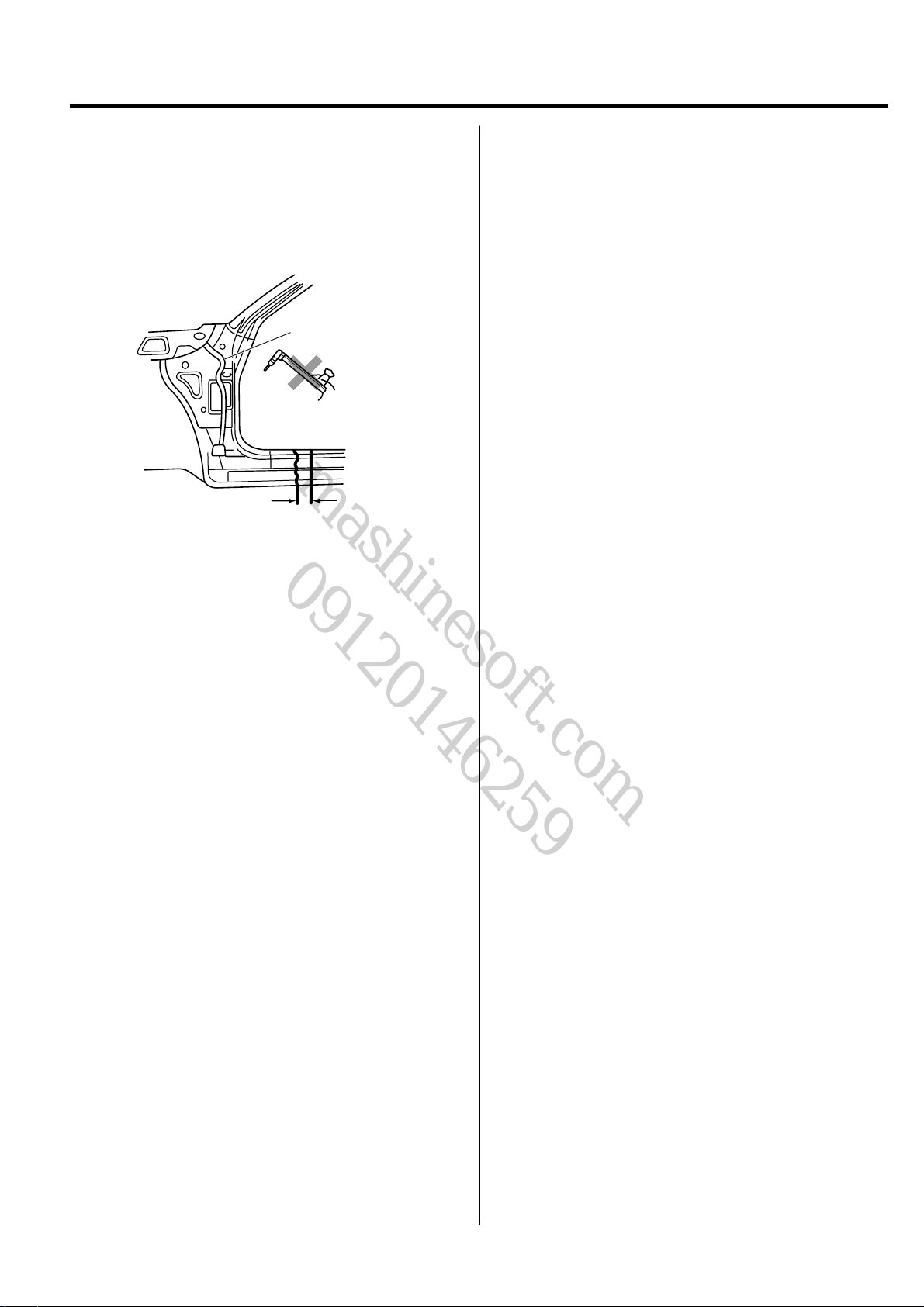

Machining holes for plug welding

Drill a hole of approximately 0.2~0.24 in (5~6 mm) in

diameter in those areas which are not suitable for spot

welding.

BVQGI6008

BMGGI6007

Adjusting a new part

The new part should be cut larger than the repair area,

overlapping the repair area by 1.2~2.0 in (30~50 mm).

1.2~2.0 in

(30~50 mm)

Overlap

body side to modify

new part to modify

1.2~2.0 in

(30~50 mm)

Overlap

BVQGI6009

GENERAL INFORMATION GI-7

mashinesoft.com

09120146259

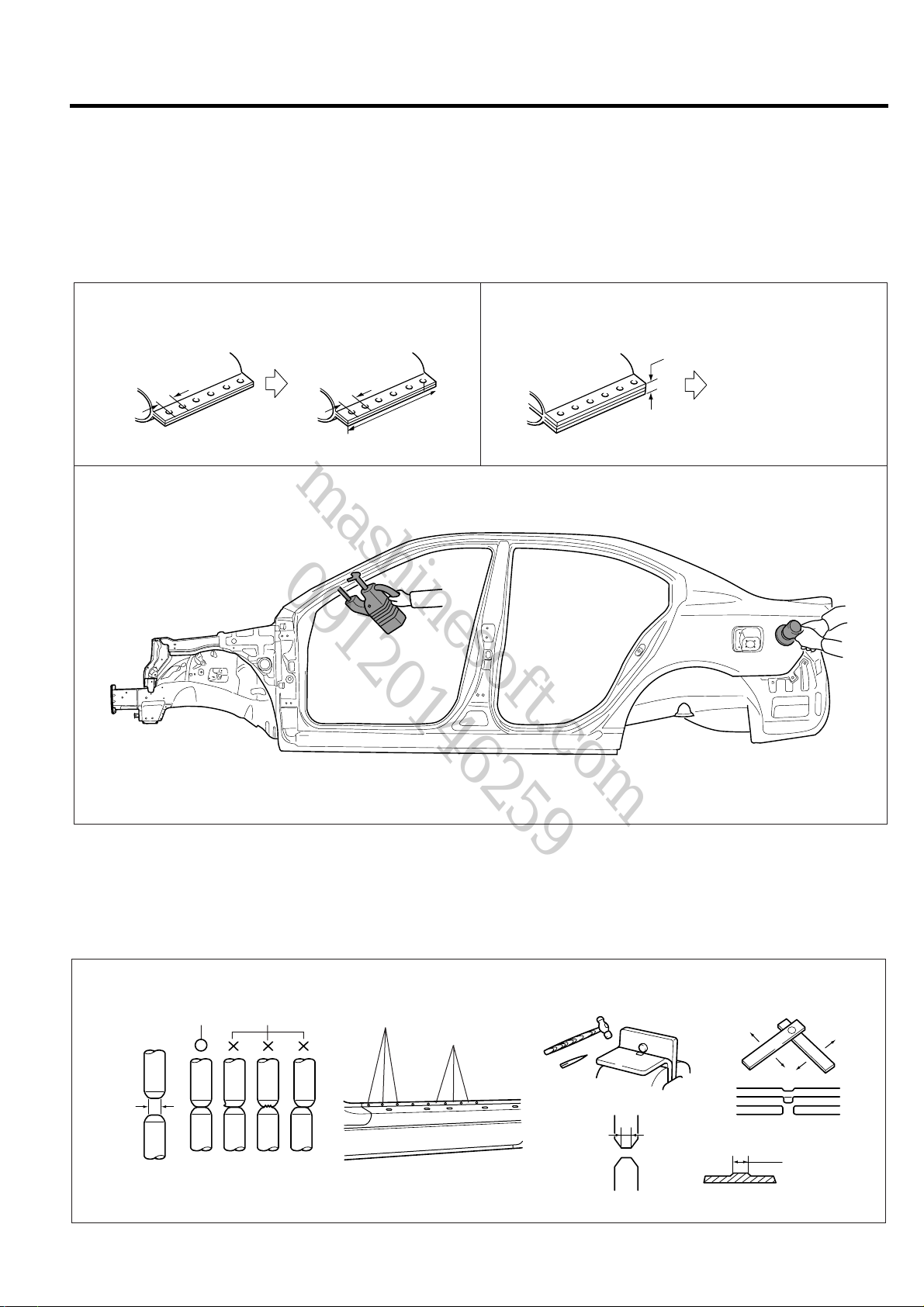

ASSEMBLY

Measuring dimensions before welding

When assembling a new part, assemble it according to the body dimensions given in Section 31, and start welding after

checking the gaps with nearby parts.

Caution when welding

The number of welding points should be determined based on the criteria below:

Spot welding Plug welding

Pitch:

2.0 in (50 mm)

Old part

Increase the number of

spot welds by 30%.

Pitch:

1.4 in (35 mm)

Repair part

Pitch: Same number of

welds as original part.

Repair part

more than

0.1 in (3 mm)

Caution when spot welding

The tip of the spot welding machine should be maintained to a minimum of 0.1 in (3 mm) because it greatly affects welding

strength. When possib le, spot welding should be done between the existing spot w elded points.

Before and after spot welding, weld a test piece(test pin) of the same material as the body panel, and check the welding

strength.

Good

0.1 in

(3 mm)

No good

Existing welded spots

New welded spots

Using a hammer and a chisel

0.1 in

(3 mm)

Center

diameter

BMGGI6010

Using a test piece(test pin)

Nugget diameter

to be 4/5 of chip

diameter

BVQGI6011

GI-8 GENERAL INFORMATION

mashinesoft.com

09120146259

RUSTPROOF TREATMENT AFTER ASSEMBLY

Body sealing

Apply body sealer where necessary.

Applying rustproof material

Apply rustproofing material(wax, oil, etc.) behind welded area.

Applying undercoat

Apply undercoat on the body where necessary.

BMGGI6012

GENERAL INFORMATION GI-9

mashinesoft.com

09120146259

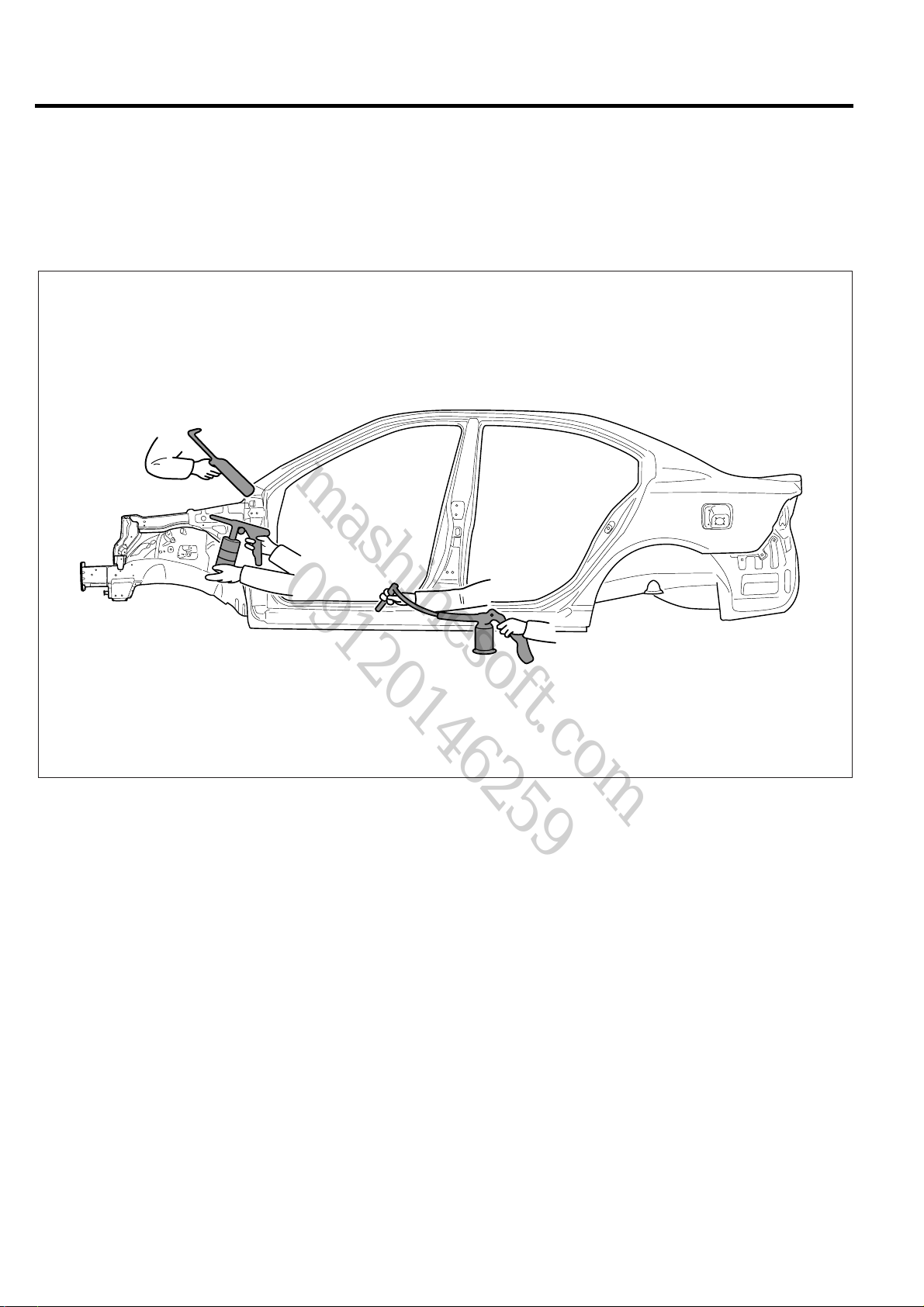

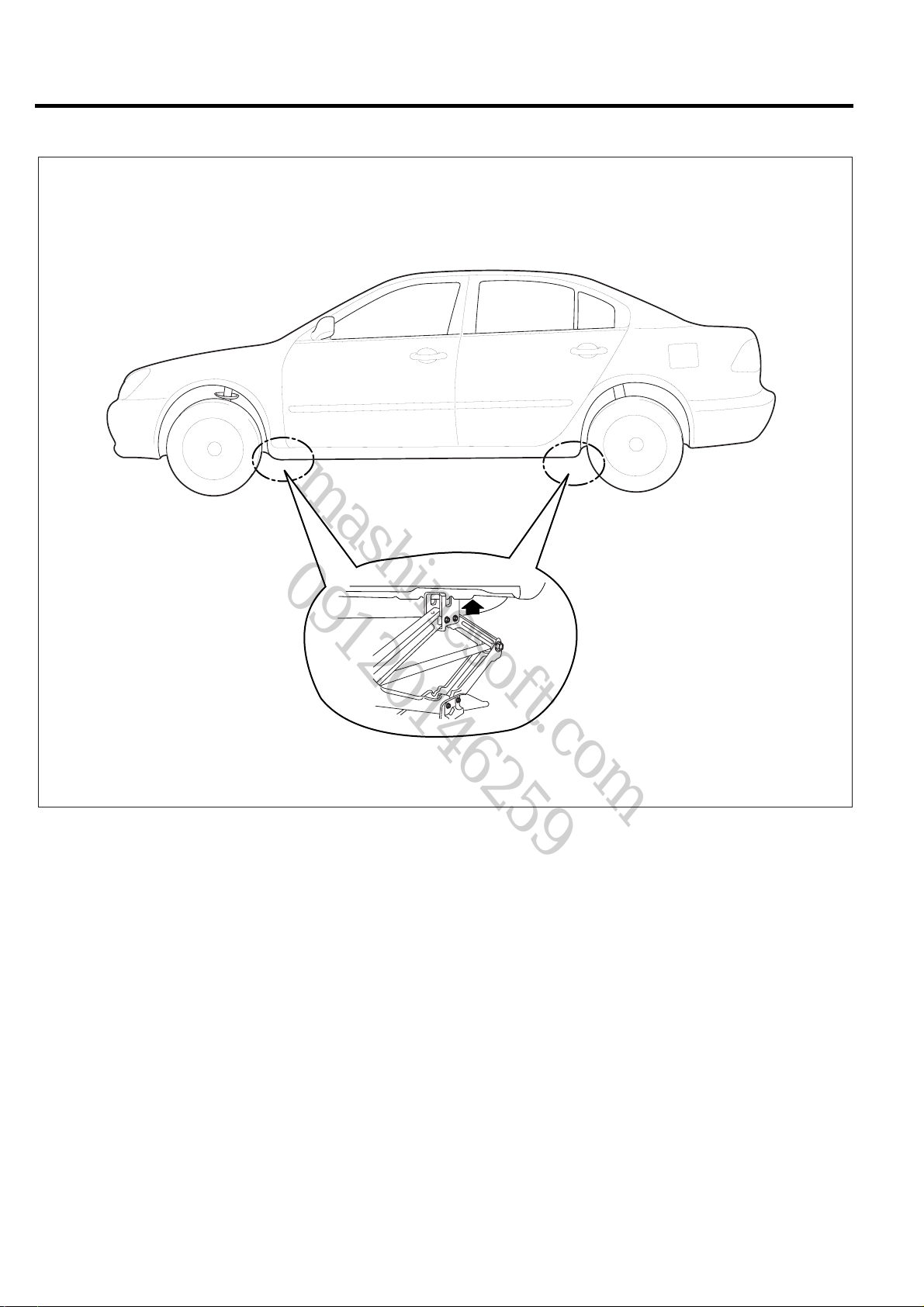

VEHICLE LIFT (2-SUPPORT TYPE) AND SAFETY STAND POSITIONS

1. Place the lift blocks under the support points as shown in the illustration

2. Raise the hoist a few inches and rock the v ehicle to be sure it is firmly supported.

3. Raise the hoist to full height to inspect the lift points for secure support.

Lift Block

[Front]

Lift Block

[Rear]

BMGGI6013

GI-10 GENERAL INFORMATION

mashinesoft.com

09120146259

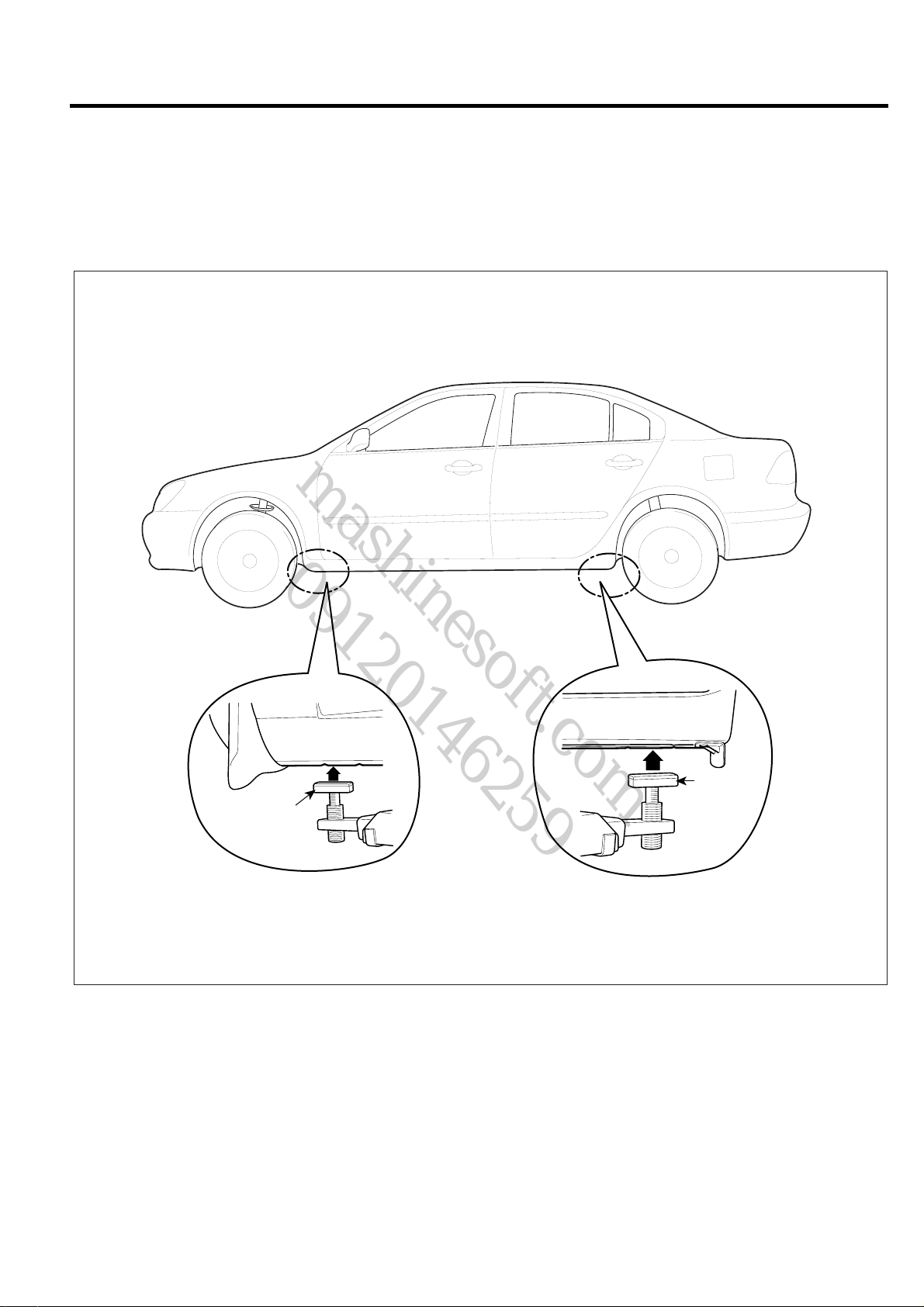

JACK SUPPORT POSITIONS

BMGGI6013

Body

mashinesoft.com

09120146259

Construction

BODY COMPONENTS .................................BC - 2

ZINC-GALVANIZED STEEL PANELS ....BC - 4

HIGH STRENGTH STEEL PANELS .......BC - 6

BC

BC-2 BODY CONSTRUCTION

mashinesoft.com

09120146259

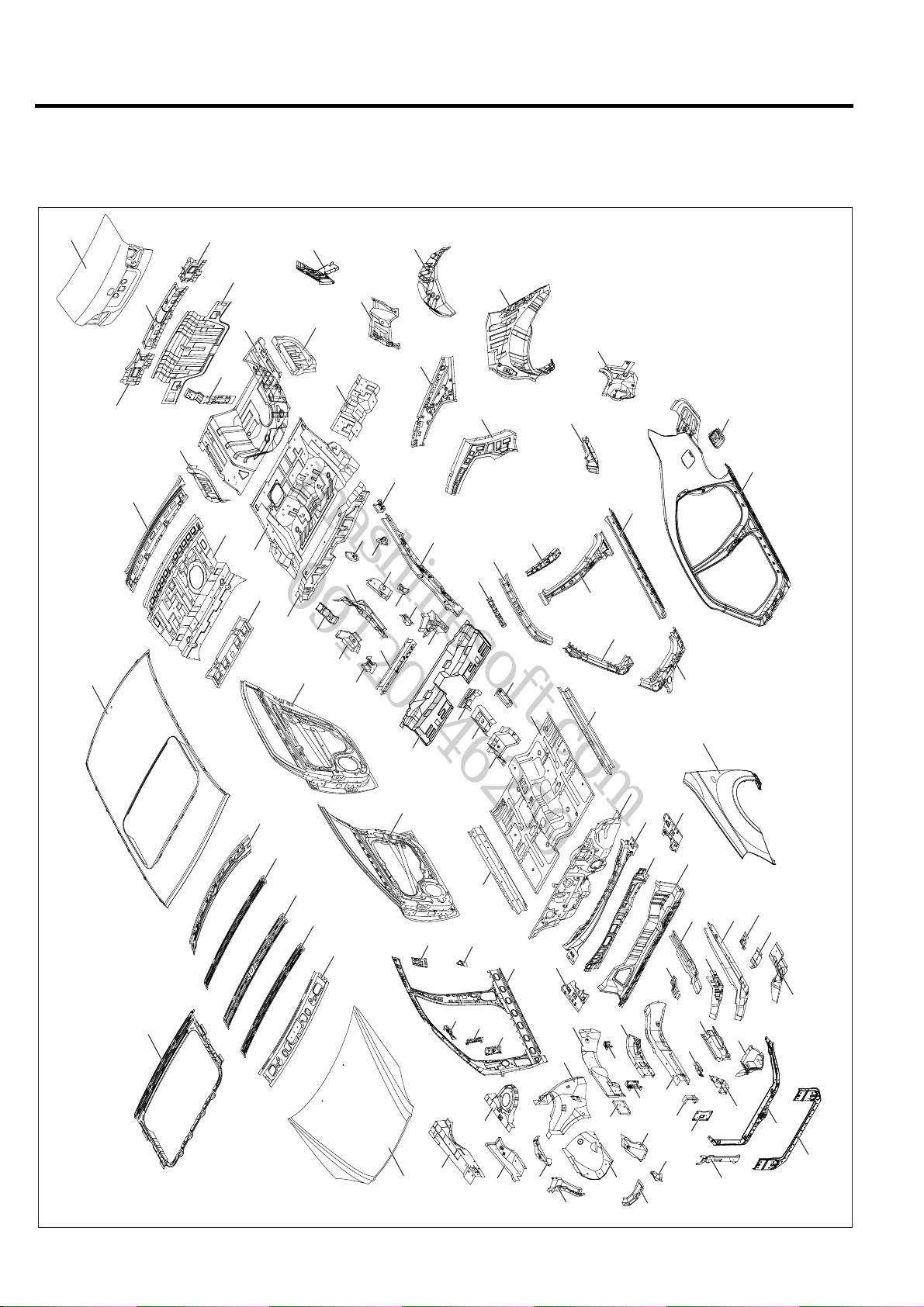

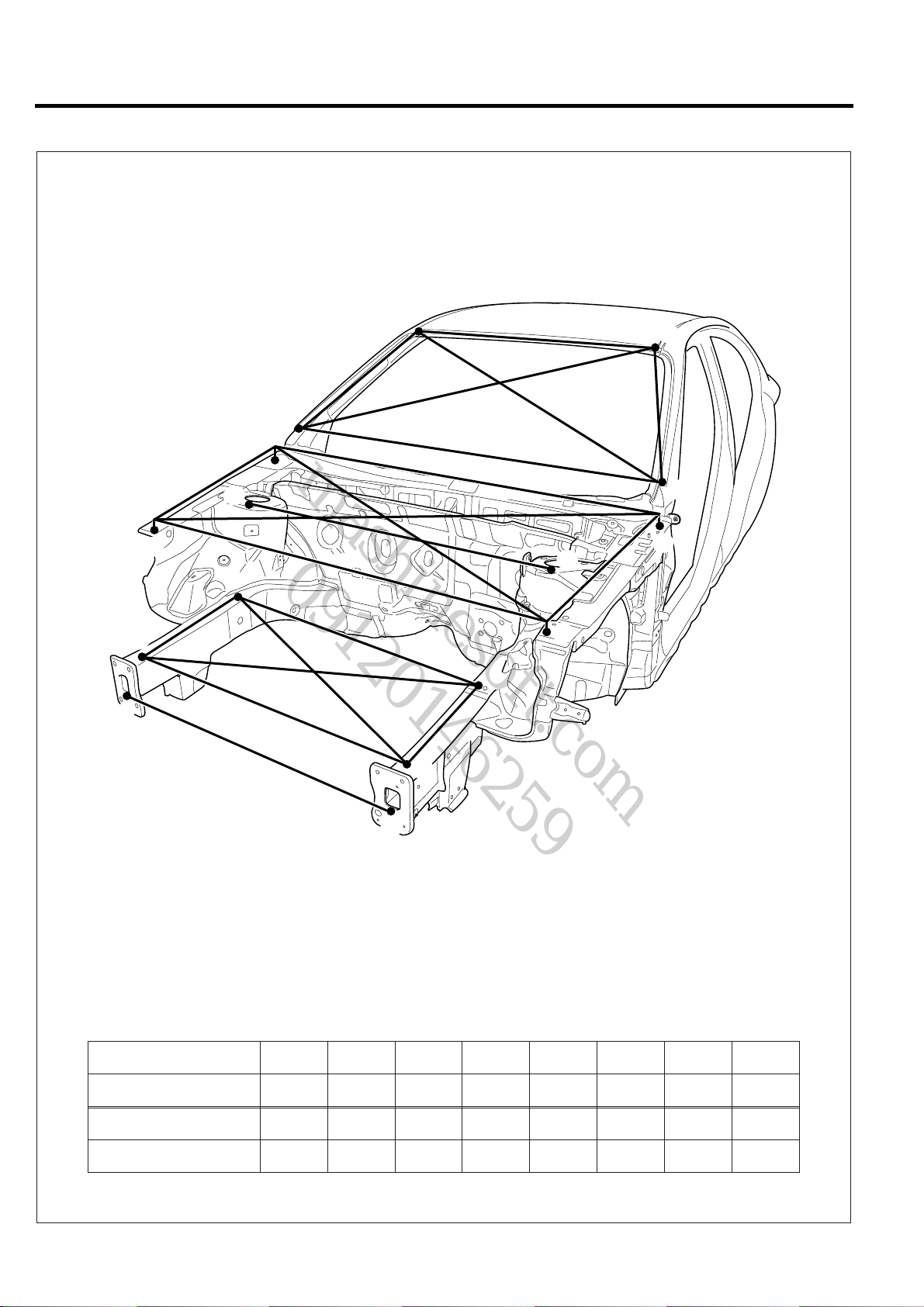

BOD Y COMPONENTS

Body construction will sometimes differ depending on specifications and country of destination. Theref ore, please k eep in

mind that the information contained herein is based on vehicles for general destination.

72

64

76

79

74

81

76

75

77

73

80

82

78

69

84

92

55

98

81

83

99

100

91

56

103

97

90

101

94

96

54

85

104

52

102

93

95

86

87

47

53

88

46

51

89

62

44

49

50

43

63

42

45

61

57

48

40

41

4

59

68

67

66

65

70

71

39

58

60

63

27

38

34

59

37

36

35

7

9

10

17

6

8

11

22

16

18

19

14

5

12

28

15

26

30

24

20

21

13

33

25

32

31

29

23

2

1

3

BMGBC6001

BODY CONSTRUCTION BC-3

mashinesoft.com

09120146259

1. Radiator support lower member

2. Radiator support upper member

3. Radiator support center member

4. Fender panel

5. Fender apron inner panel

6. Front shock absorber housing panel

7. Shock absorber cover

8. Shock absorber housing reinforcement

9. Fender apron upper outer panel

10. Fender apron upper inner panel

11. Fender apron front upper reinforcement

12. Fender apron front lower reinforcement

13. Transaxle side mounting bracket

14. Engine mounting support

15. Front side inner member

16. Front side member inner reinforcement

17. Front side outer member

18. Engine mounting rear bracket

19. Engine mounting front bracket

20. Front end module mounting reinforcement

21. Front end module mounting bracket

22. Front side member outer extension

23. Front side member outer front extension

24. Sub frame mounting front support

25. Front side rear lower member

26. Front side member rear lower reinforcement

27. Front side inner rear reinforcement

28. Front side rear upper reinforcement

29. Front side member rear lower extension

30. Side sill inner front extension

31. Sub frame rear mounting bracket

32. Sub frame rear mounting reinforcement

33. Sub frame rear mounting support

34. Side inner panel

35. Cowl cross member front bracket

36. Cowl cross member rear bracket

37. Front pillar upper extension

38. Front seatbelt reel mounting bracket

39. Center pillar inner reinforcement

40. Side outer panel

41. Front pillar outer lower reinforcement

42. Front pillar outer upper reinforcement

43. Center pillar outer reinforcement

44. Center pillar outer upper reinforcement

45. Side sill outer reinforcement

46. Roof side outer reinforcement

47. Roof side outer rail

48. Fuel filler mounting

49. Side outer rear extension

50. Rear combination lamp housing panel

51. Quarter inner lower panel

52. Quarter inner upper panel

53. Quarter panel reinforcement

54. Wheel house inner panel

55. Rear package tray side front panel

56. Rear package tray side rear panel

57. Cowl top upper reinforcement

58. Cowl top lower reinforcement

59. Shock absorber housing gusset assembly

60. Cowl top panel assembly

61. Dash panel assembly

62. Center floor panel assembly

63. Side sill inner panel

64. Roof panel

65. Roof front rail assembly

66. Roof center NO.1 rail

67. Roof center rail assembly

68. Roof center NO.3 rail

69. Roof rear rail assembly

70. Sun roof reinforcement ring

71. Hood panel assembly

72. Trunk lid panel assembly

73. Back panel

74. Rear transverse member

75. Trunk lid striker suppor t

76. Rear transverse extension

77. Rear package tray center panel

78. Rear package tray front lower member

79. Rear window opening outer frame

80. Rear floor rear panel assembly

81. Rear floor side panel assembly

82. Rear floor front panel

83. Rear seat mounting bracket

84. Rear floor front extension

85. Rear floor front cross member assembly

86. Rear floor front cross reinforcement

87. Center floor side member rear extension

88. Rear floor front filler assembly

89. Center floor side member rear extension assembly

90. Rear floor center cross member assembly

91. Rear floor center cross center reinforcement

92. Rear door panel assembly

93. Rear floor center cross member extension

94. Rear suspension mounting upper bracket

95. Rear floor side member assembly

96. Rear floor side rear member assembly

97. Rear suspension spring sheet reinforcement

98. Trailing arm mounting upper bracket

99. Rear tie down reinforcement

100. Side sill inner rear panel

101. Trailing arm mounting upper bracket assembly

102. Side sill inner rear reinforcement

103. Trailing arm mounting lower bracket assembly

104. Front door panel assembly

BC-4 BODY CONSTRUCTION

mashinesoft.com

09120146259

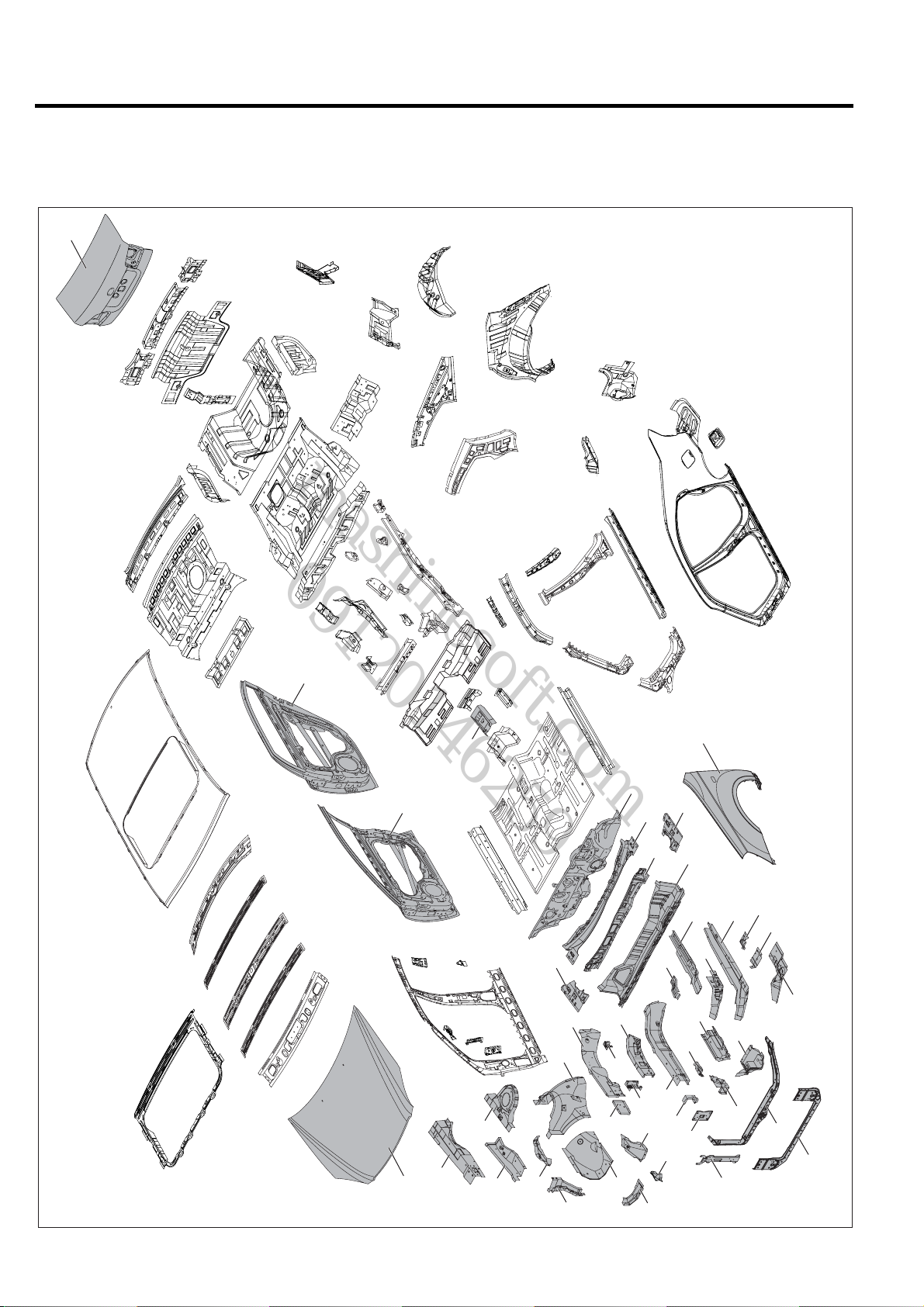

ZINC-GAL VANIZED STEEL PANELS

Becavanized steel panel has excellent resistance, it tis used in areas which have a high possibility of painting deficiency

below.

72

92

104

71

12

58

28

15

13

20

24

59

21

60

27

30

4

33

25

32

26

31

29

23

2

1

3

BMGBC6002

87

61

57

59

11

22

16

18

19

14

5

17

6

7

9

10

8

BODY CONSTRUCTION BC-5

mashinesoft.com

09120146259

1. Radiator support lower member

2. Radiator support upper member

3. Radiator support center member

4. Fender panel

5. Fender apron inner panel

6. Front shock absorber housing panel

7. Shock absorber cover

8. Shock absorber housing reinforcement

9. Fender apron upper outer panel

10. Fender apron upper inner panel

11. Fender apron front upper reinforcement

12. Fender apron front lower reinforcement

13. Transaxle side mounting bracket

14. Engine mounting support

15. Front side inner member

16. Front side member inner reinforcement

17. Front side outer member

18. Engine mounting rear bracket

19. Engine mounting front bracket

20. Front end module mounting reinforcement

21. Front end module mounting bracket

22. Front side member outer extension

23. Front side member outer front extension

24. Sub frame mounting front support

25. Front side rear lower member

26. Front side member rear lower reinforcement

27. Front side inner rear reinforcement

28. Front side rear upper reinforcement

29. Front side member rear lower extension

30. Side sill inner front extension

31. Sub frame rear mounting bracket

32. Sub frame rear mounting reinforcement

33. Sub frame rear mounting support

34. Side inner panel

35. Cowl cross member front bracket

36. Cowl cross member rear bracket

37. Front pillar upper extension

38. Front seatbelt reel mounting bracket

39. Center pillar inner reinforcement

40. Side outer panel

41. Front pillar outer lower reinforcement

42. Front pillar outer upper reinforcement

43. Center pillar outer reinforcement

44. Center pillar outer upper reinforcement

45. Side sill outer reinforcement

46. Roof side outer reinforcement

47. Roof side outer rail

48. Fuel filler mounting

49. Side outer rear extension

50. Rear combination lamp housing panel

51. Quarter inner lower panel

52. Quarter inner upper panel

53. Quarter panel reinforcement

54. Wheel house inner panel

55. Rear package tray side front panel

56. Rear package tray side rear panel

57. Cowl top upper reinforcement

58. Cowl top lower reinforcement

59. Shock absorber housing gusset assembly

60. Cowl top panel assembly

61. Dash panel assembly

62. Center floor panel assembly

63. Side sill inner panel

64. Roof panel

65. Roof front rail assembly

66. Roof center NO.1 rail

67. Roof center rail assembly

68. Roof center NO.3 rail

69. Roof rear rail assembly

70. Sun roof reinforcement ring

71. Hood panel assembly

72. Trunk lid panel assembly

73. Back panel

74. Rear transverse member

75. Trunk lid striker suppor t

76. Rear transverse extension

77. Rear package tray center panel

78. Rear package tray front lower member

79. Rear window opening outer frame

80. Rear floor rear panel assembly

81. Rear floor side panel assembly

82. Rear floor front panel

83. Rear seat mounting bracket

84. Rear floor front extension

85. Rear floor front cross member assembly

86. Rear floor front cross reinforcement

87. Center floor side member rear extension

88. Rear floor front filler assembly

89. Center floor side member rear extension assembly

90. Rear floor center cross member assembly

91. Rear floor center cross center reinforcement

92. Rear door panel assembly

93. Rear floor center cross member extension

94. Rear suspension mounting upper bracket

95. Rear floor side member assembly

96. Rear floor side rear member assembly

97. Rear suspension spring sheet reinforcement

98. Trailing arm mounting upper bracket

99. Rear tie down reinforcement

100. Side sill inner rear panel

101. Trailing arm mounting upper bracket assembly

102. Side sill inner rear reinforcement

103. Trailing arm mounting lower bracket assembly

104. Front door panel assembly

BC-6 BODY CONSTRUCTION

mashinesoft.com

09120146259

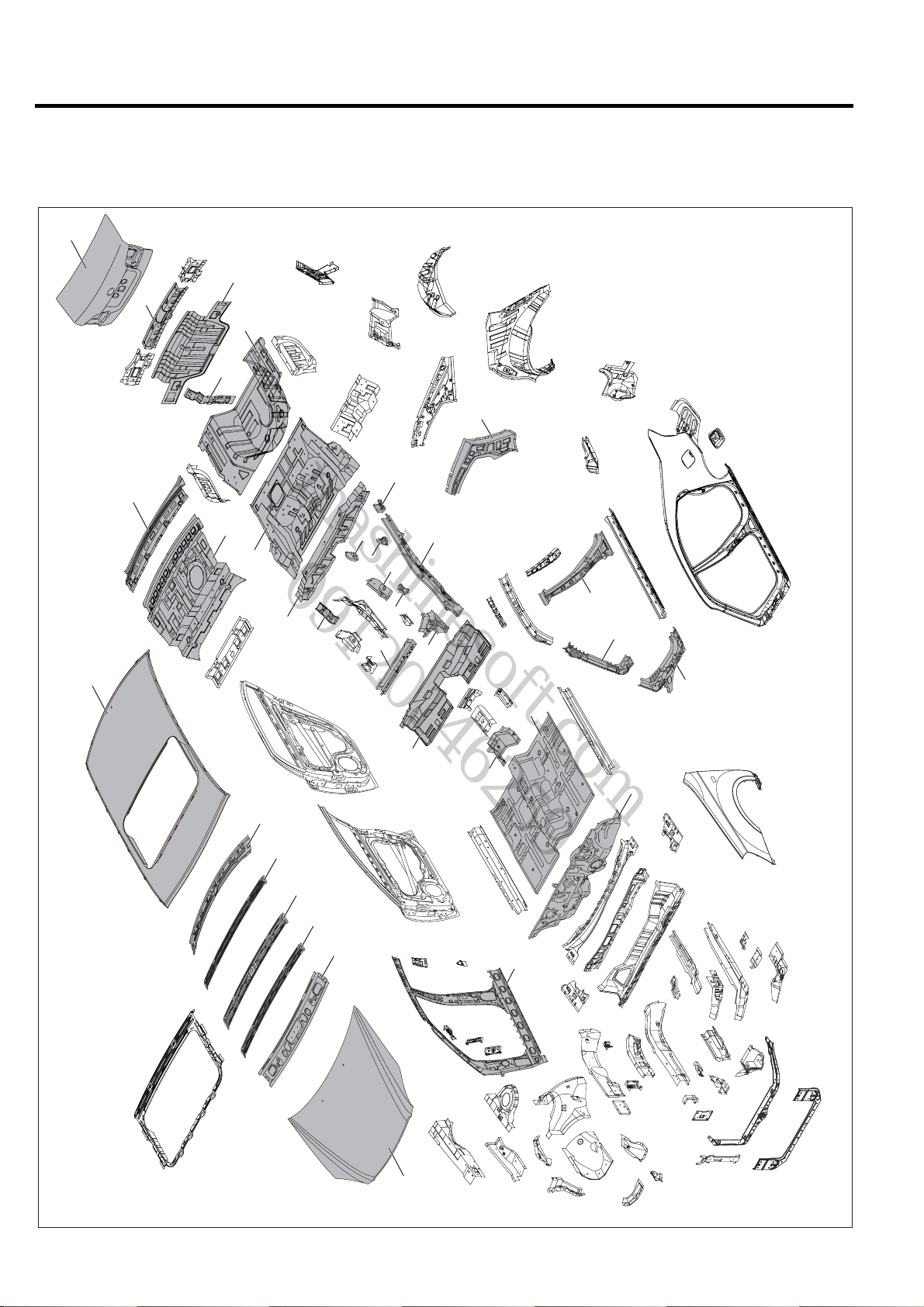

HIGH STRENGTH STEEL P ANELS

Because high strength steel panel has excellent resistance, it is used in areas which have a high posibility of painting

deficiency below.

72

73

74

80

75

53

96

79

77

82

84

98

64

69

68

67

66

103

97

90

65

95

101

94

93

85

88

43

42

41

62

61

34

71

BMGBC6003

BODY CONSTRUCTION BC-7

mashinesoft.com

09120146259

1. Radiator support lower member

2. Radiator support upper member

3. Radiator support center member

4. Fender panel

5. Fender apron inner panel

6. Front shock absorber housing panel

7. Shock absorber cover

8. Shock absorber housing reinforcement

9. Fender apron upper outer panel

10. Fender apron upper inner panel

11. Fender apron front upper reinforcement

12. Fender apron front lower reinforcement

13. Transaxle side mounting bracket

14. Engine mounting support

15. Front side inner member

16. Front side member inner reinforcement

17. Front side outer member

18. Engine mounting rear bracket

19. Engine mounting front bracket

20. Front end module mounting reinforcement

21. Front end module mounting bracket

22. Front side member outer extension

23. Front side member outer front extension

24. Sub frame mounting front support

25. Front side rear lower member

26. Front side member rear lower reinforcement

27. Front side inner rear reinforcement

28. Front side rear upper reinforcement

29. Front side member rear lower extension

30. Side sill inner front extension

31. Sub frame rear mounting bracket

32. Sub frame rear mounting reinforcement

33. Sub frame rear mounting support

34. Side inner panel

35. Cowl cross member front bracket

36. Cowl cross member rear bracket

37. Front pillar upper extension

38. Front seatbelt reel mounting bracket

39. Center pillar inner reinforcement

40. Side outer panel

41. Front pillar outer lower reinforcement

42. Front pillar outer upper reinforcement

43. Center pillar outer reinforcement

44. Center pillar outer upper reinforcement

45. Side sill outer reinforcement

46. Roof side outer reinforcement

47. Roof side outer rail

48. Fuel filler mounting

49. Side outer rear extension

50. Rear combination lamp housing panel

51. Quarter inner lower panel

52. Quarter inner upper panel

53. Quarter panel reinforcement

54. Wheel house inner panel

55. Rear package tray side front panel

56. Rear package tray side rear panel

57. Cowl top upper reinforcement

58. Cowl top lower reinforcement

59. Shock absorber housing gusset assembly

60. Cowl top panel assembly

61. Dash panel assembly

62. Center floor panel assembly

63. Side sill inner panel

64. Roof panel

65. Roof front rail assembly

66. Roof center NO.1 rail

67. Roof center rail assembly

68. Roof center NO.3 rail

69. Roof rear rail assembly

70. Sun roof reinforcement ring

71. Hood panel assembly

72. Trunk lid panel assembly

73. Back panel

74. Rear transverse member

75. Trunk lid striker suppor t

76. Rear transverse extension

77. Rear package tray center panel

78. Rear package tray front lower member

79. Rear window opening outer frame

80. Rear floor rear panel assembly

81. Rear floor side panel assembly

82. Rear floor front panel

83. Rear seat mounting bracket

84. Rear floor front extension

85. Rear floor front cross member assembly

86. Rear floor front cross reinforcement

87. Center floor side member rear extension

88. Rear floor front filler assembly

89. Center floor side member rear extension assembly

90. Rear floor center cross member assembly

91. Rear floor center cross center reinforcement

92. Rear door panel assembly

93. Rear floor center cross member extension

94. Rear suspension mounting upper bracket

95. Rear floor side member assembly

96. Rear floor side rear member assembly

97. Rear suspension spring sheet reinforcement

98. Trailing arm mounting upper bracket

99. Rear tie down reinforcement

100. Side sill inner rear panel

101. Trailing arm mounting upper bracket assembly

102. Side sill inner rear reinforcement

103. Trailing arm mounting lower bracket assembly

104. Front door panel assembly

Body

mashinesoft.com

09120146259

Dimensions

GENERAL

MEASUREMENT METHOD .......................BD - 2

PROJECTED DIMENSIONS ............................BD - 2

ACTUAL-MEASUREMENT DIMENSIONS......BD - 3

MEASUREMENT POINT..................................BD - 3

FRONT BODY .................................................BD - 4

SIDE BODY ......................................................BD - 6

INTERIOR A .....................................................BD - 8

INTERIOR B .....................................................BD - 10

INTERIOR C .....................................................BD - 12

REAR BODY ....................................................BD - 14

UNDER BODY

(PROJECTED DIMENSIONS)

UNDER BODY

(STRAIGHT-LINE DIMENSIONS)

.........................................................BD - 2

...................BD - 16

............BD - 18

BD

BD-2 BODY DIMENSIONS

mashinesoft.com

09120146259

GENERAL

1. Basically, all measurements in this manual are taken

with a tracking gauge.

2. When a measuring tape is used, check to be sure there

is no elongation, twisting or bending.

3. For measuring dimensions, both projected dimension

and actual-measurement dimension are used in this

manual.

MEASUREMENT METHOD

PROJECTED DIMENSIONS

1. These are the dimensions measured when the

measurement points are projected into the reference

plane, and are the reference dimensions used for body

alterations.

2. If the length of the tracking gauge probes are

adjustable, make the measurement by lengthening one

probe by the amount equivalent to the difference in

height of the two surfaces.

Height

Projected Dimension

BMCBD6001

BODY DIMENSIONS BD-3

N

mashinesoft.com

09120146259

ACTUAL-MEASUREMENT DIMENSIONS

1. These dimensions indicate the actual linear distance

between measurement points, and are the reference

dimensions for use if a tracking gauge is used for

measurement.

2. Measure by first adjusting both probes to the same

length (A=A')

CAUTIO

Check the probes and gauge itself to make sure

there is no free play.

A

Actually-Measured Dimension

A'

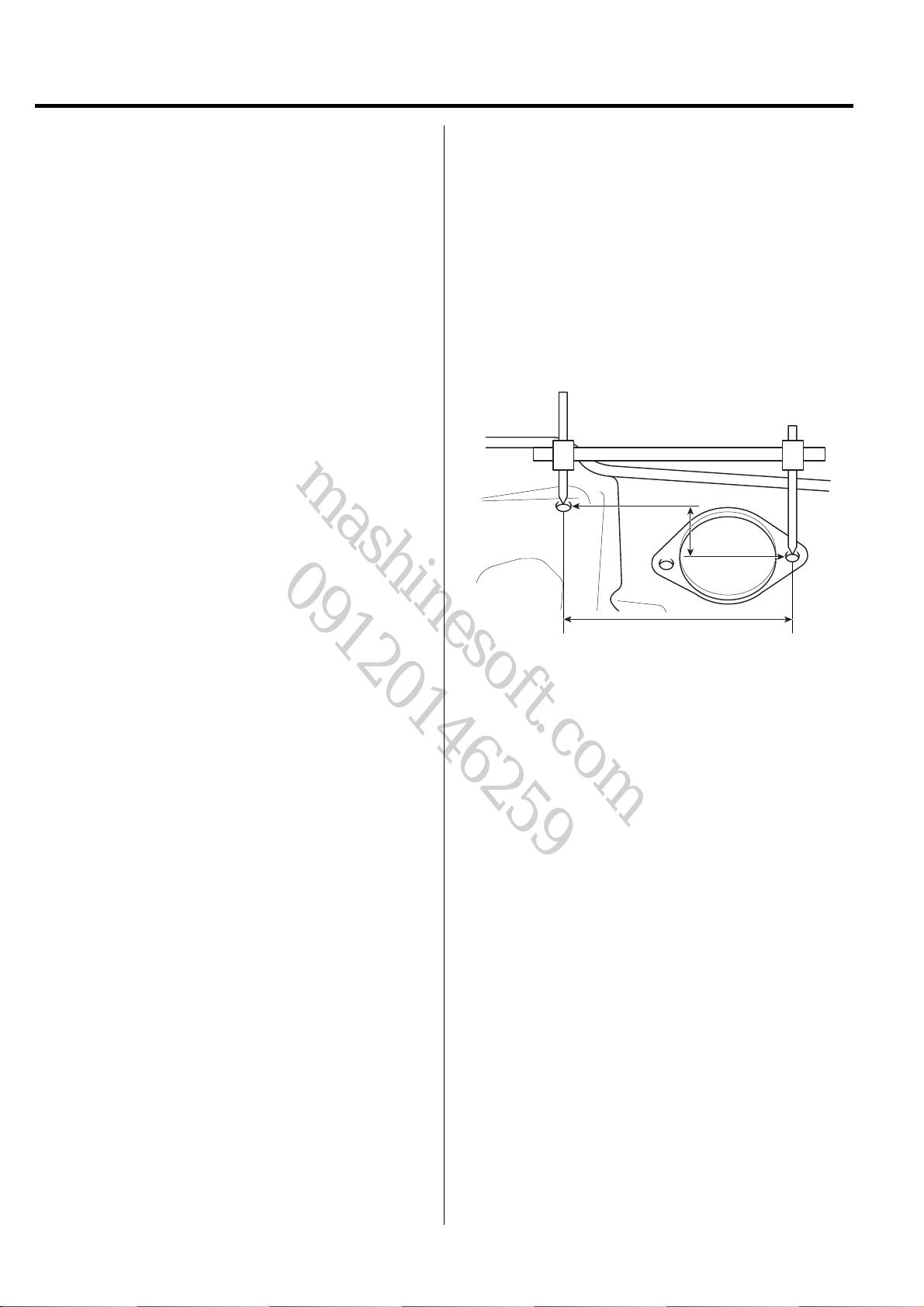

MEASUREMENT POINT

1. Measurements should be taken at the hole center.

Hole Center

BMCBD6003

BMCBD6002

BD-4 BODY DIMENSIONS

mashinesoft.com

09120146259

FRONT BODY

H

H'

G

B

C

A

D

E

D'

F

E'

F'

* These dimensions indicated in this figure are actual-measurement dimensions.

G'

B'

C'

A'

BMGBD6001

Point symbol

Length(mm)

Point symbol

Length(mm)

A-A'

1416

D'-E'

390

A-B

709

D'-E

1054

A-B'

1660

E-E'

980

B-B'

1585

F-F'

984

C-C'

1178

G-G'

1505

D-D'

978

G-H

747

D-E

390

G-H'

1476

D-E'

1054

H-H'

1077

BODY DIMENSIONS BD-5

mashinesoft.com

09120146259

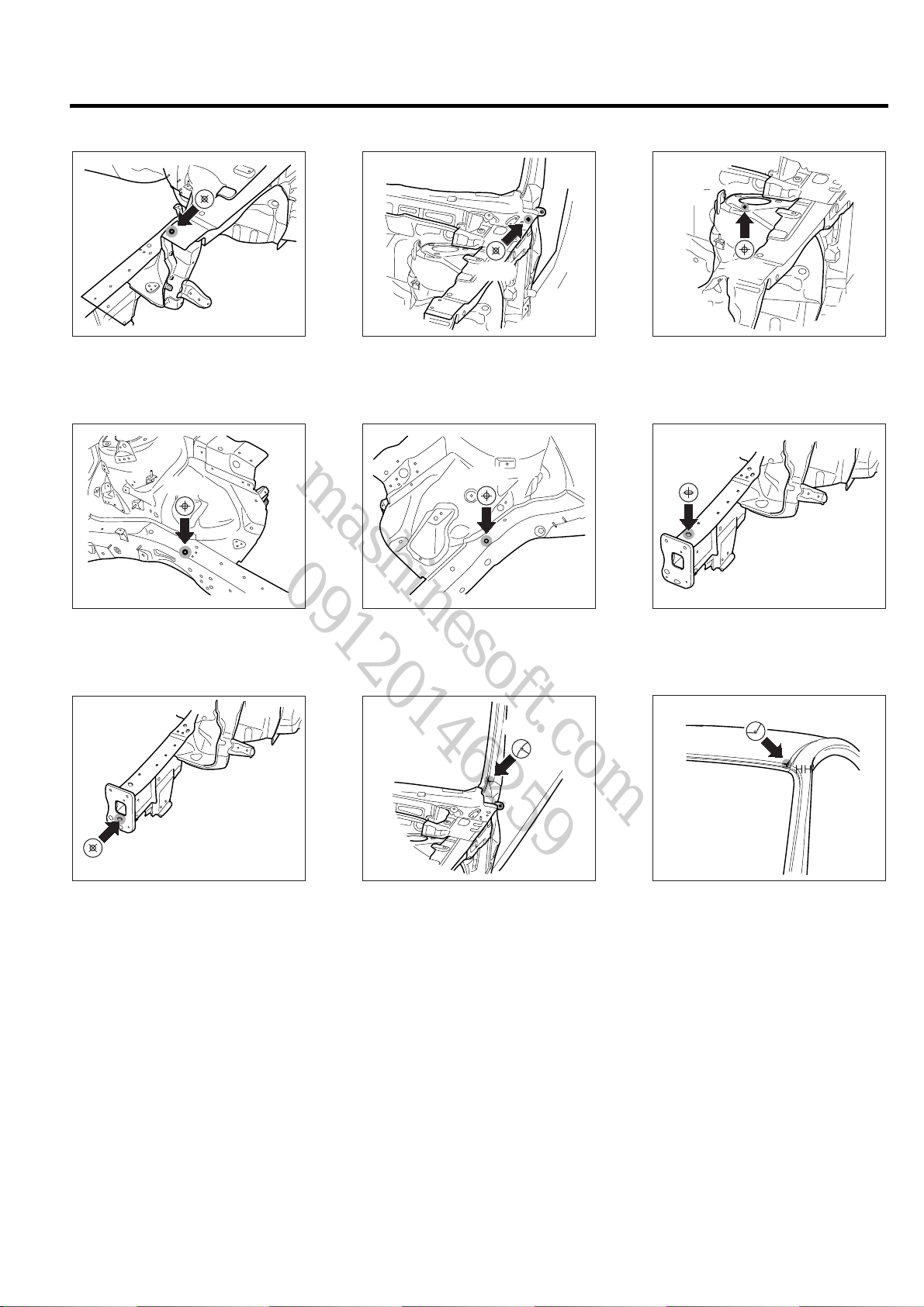

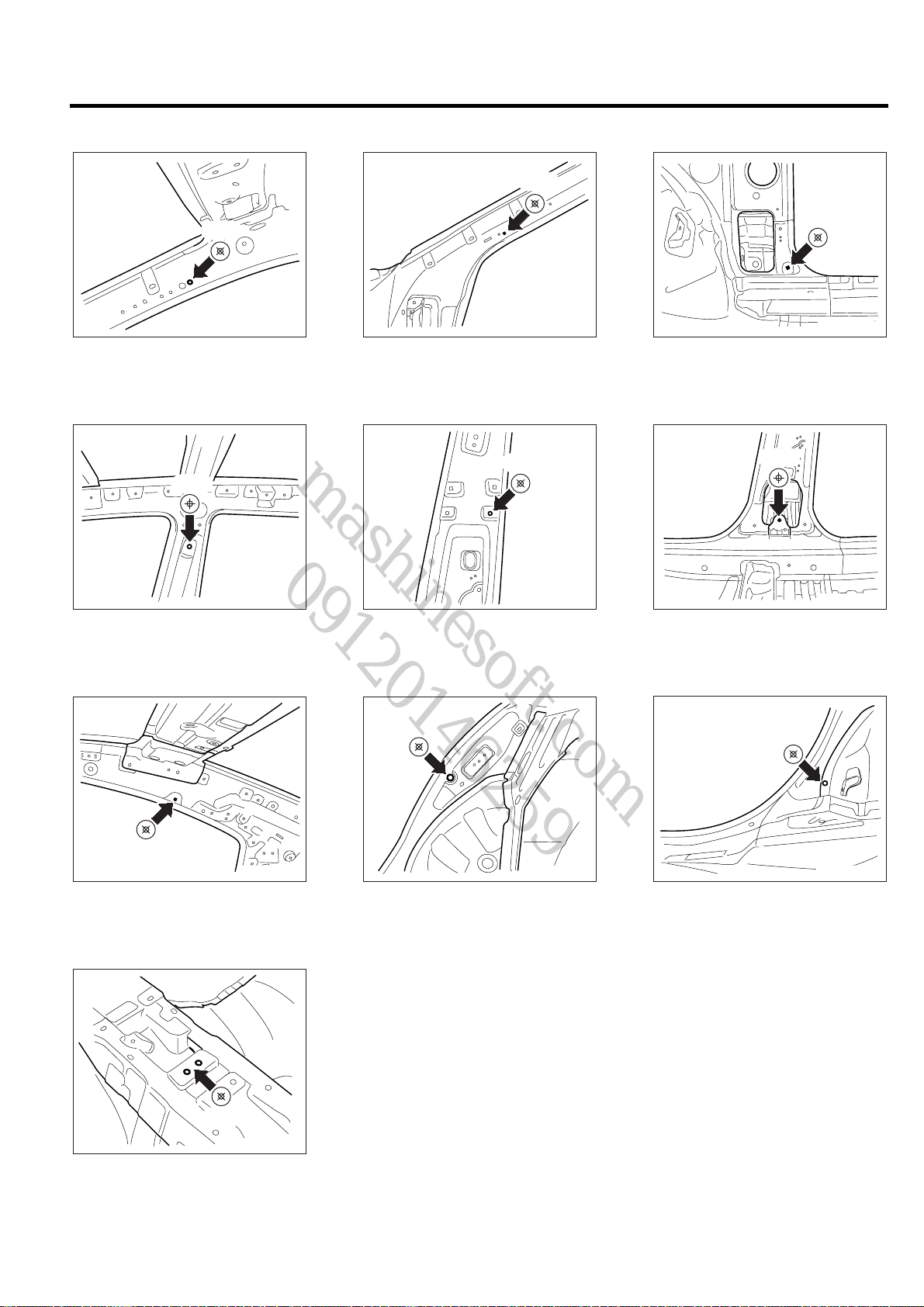

A,A'

BMGBD6002

Front end module mounting hole

(ø9)

D

BMGBD6005

Engine bracket mounting hole

(ø15)

B,B'

BMGBD6003

Hood hinge mounting hole (ø11)

D'

BMGBD6006

Transaxle bracket mounting hole

(ø15)

G,G'

C,C'

BMGBD6004

Tooling hole (ø11)

E,E'

BMGBD6007

Wiring mounting hole (S7x12)

H,H'

F,F'

Tooling hole (ø8)

BMGBD6007A

Front side outer edge

BMGBD6008

BMGBD6009

Front roof edge

BD-6 BODY DIMENSIONS

mashinesoft.com

09120146259

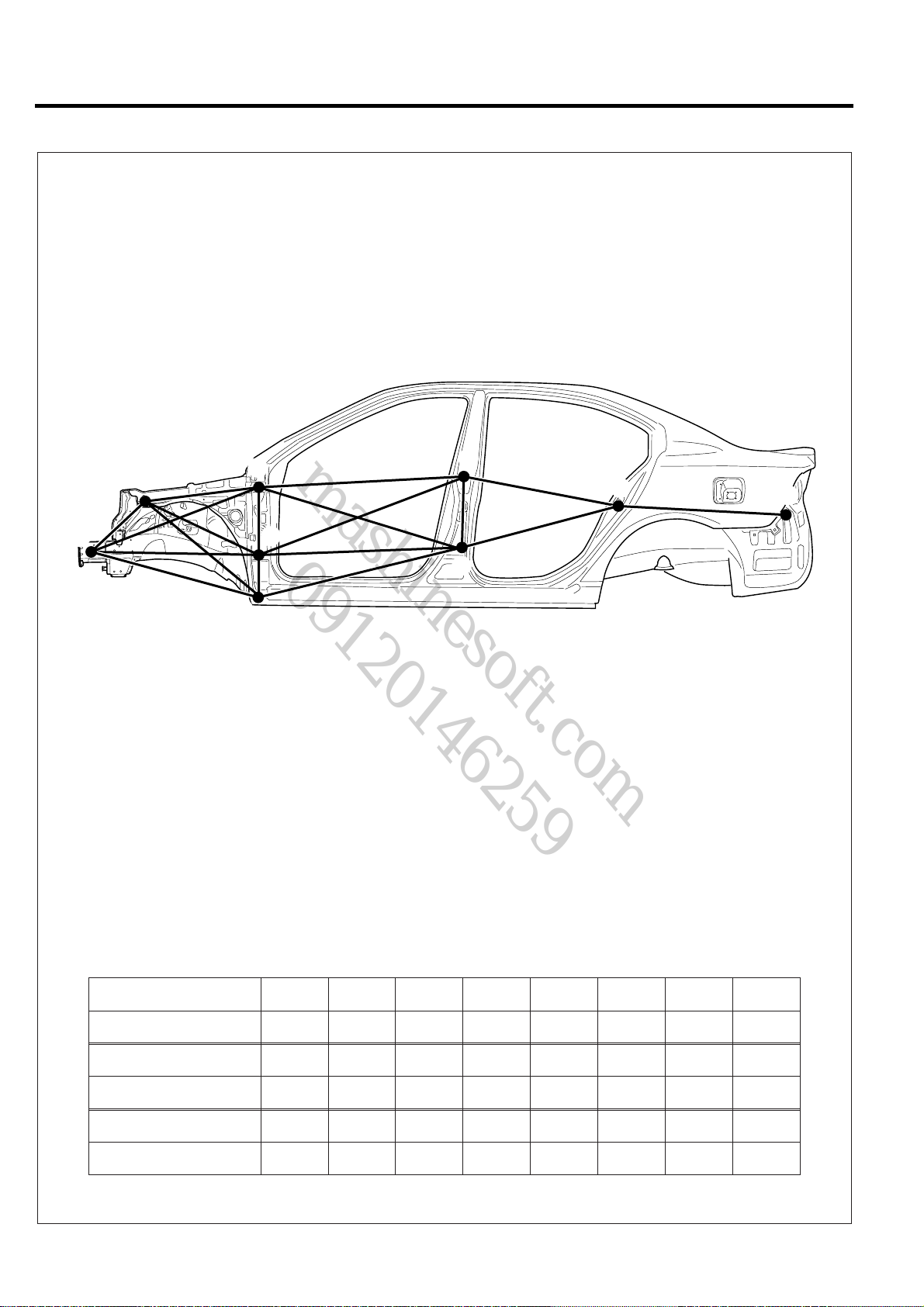

SIDE BODY

B

A

* These dimensions indicated in this figure are actual-measurement dimensions.

C

D

E

F

H

G

K

BMGBD6101

Point symbol

Length(mm)

Point symbol

Length(mm)

Point symbol

Length(mm)

A-B

568

C-F

1103

G-H

895

A-C

1217

C-G

1128

H-K

935

A-D

1164

D-E

308

A-E

1117

D-F

1174

B-C

726

D-G

1082

B-D

788

E-G

1196

B-E

889

F-G

365

C-D

360

F-H

850

BODY DIMENSIONS BD-7

mashinesoft.com

09120146259

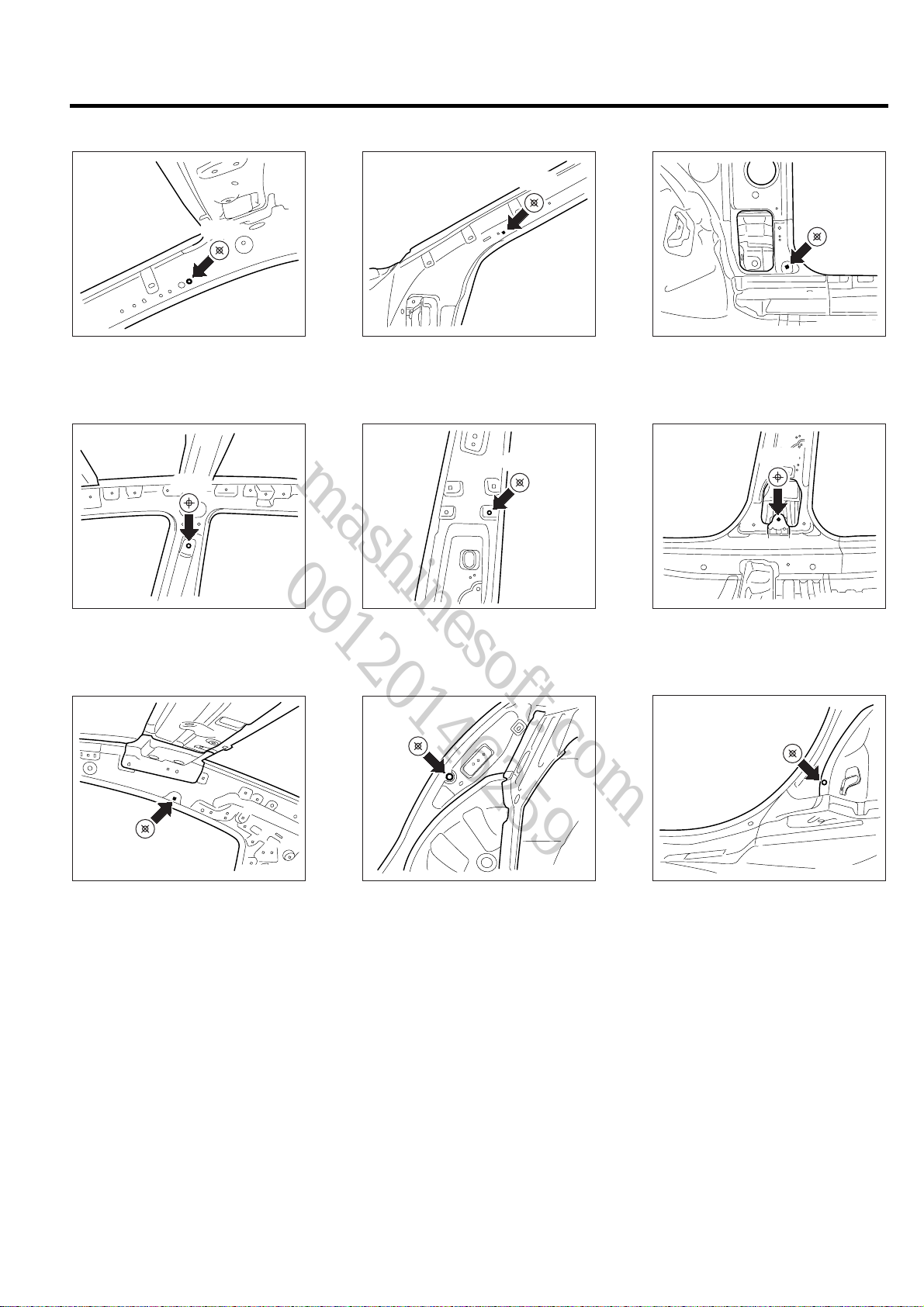

B

C

A

BMGBD6102

BMGBD6103

BMGBD6104

Tooling hole (ø10)

D

BMGBD6105

Front door lower hinge mounting

hole (ø13)

Wiring mounting hole (S7x12)

E

BMGBD6105A

Fender mounting hole (ø10)

H

Front door upper hinge mounting

hole (ø13)

F

BMGBD6106

Rear door upper hinge mounting

hole (ø13)

K

G

BMGBD6107

Rear door lower hinge mounting

hole (ø13)

Door switch mounting hole (ø17)

BMGBD6108

BMGBD6109

Rear bumper mounting hole

(S6.5x8)

BD-8 BODY DIMENSIONS

mashinesoft.com

09120146259

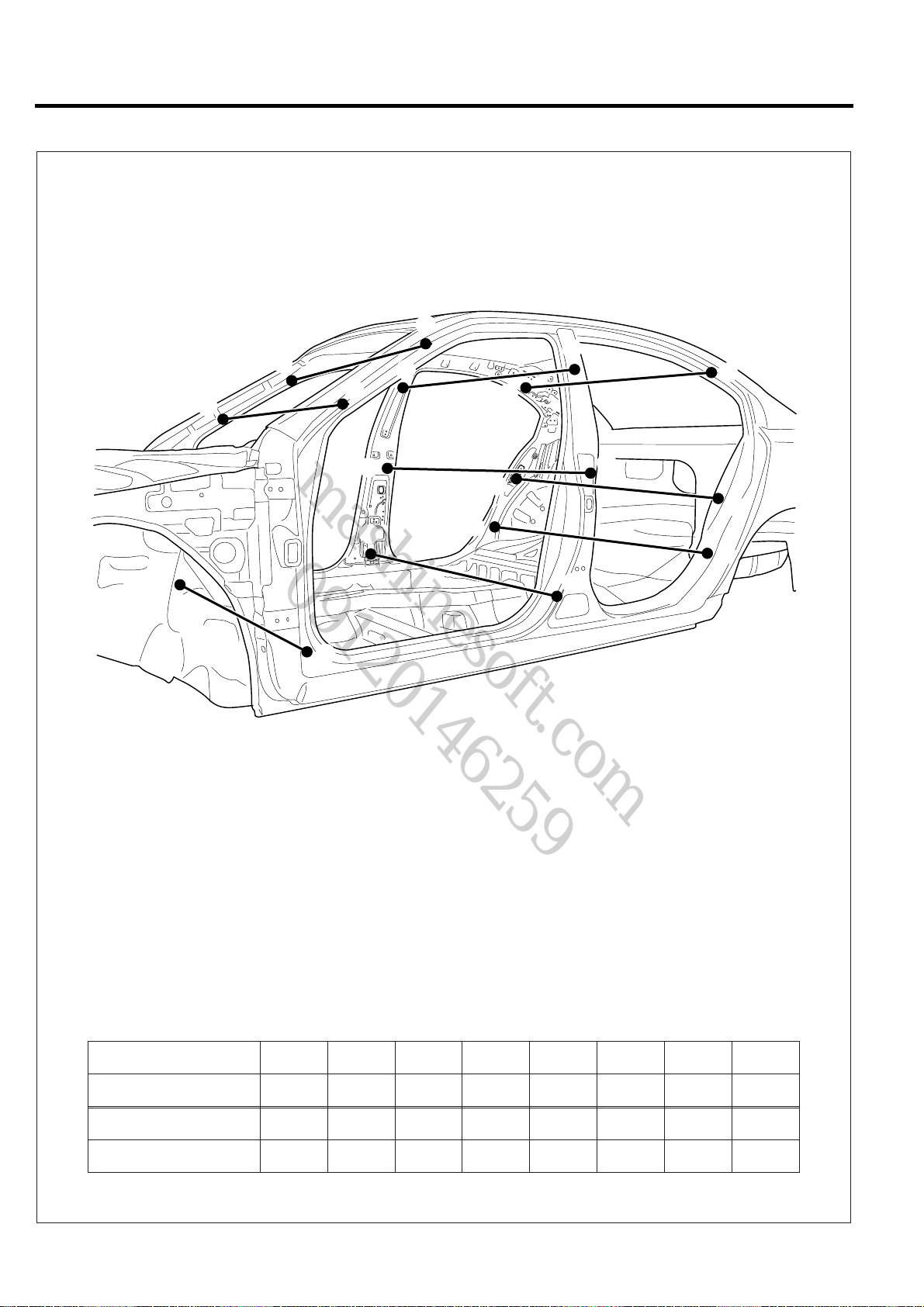

INTERIOR A

A'

A

B'

B

D

G

D'

G'

E

H

F

C

C'

* These dimensions indicated in this figure are actual-measurement dimensions.

K

E'

F'

H'

K'

BMGBD6201

Point symbol

Length(mm)

Point symbol

Length(mm)

A-A'

1222

K-K'

1457

B-B' C-C' D-D' E-E' F-F' G-G' H-H'

1389 1450 1235 1429 1423 1205 1456

BODY DIMENSIONS BD-9

mashinesoft.com

09120146259

B,B'

A,A'

BMGBD6202

Front trim mounting hole (ø8.5)

D,D'

BMGBD6205

Front seatbelt mounting hole

(ø16)

BMGBD6203

Front cab mounting hole (ø6.6)

E,E'

BMGBD6206

Center pillar lower trim mounting

hole (ø8.5)

C,C'

BMGBD6204

Front cowl side trim mounting

hole (ø8.5)

F,F'

BMGBD6207

Front seatbelt retractor mounting

hole (ø12.2)

H,H'

G,G'

BMGBD6208

Cab guide bracket mounting hole

(ø6.6)

Rear door switch mounting hole

BMGBD6209

(ø17)

K,K'

BMGBD6210

Tooling hole (ø10)

BD-10 BODY DIMENSIONS

mashinesoft.com

09120146259

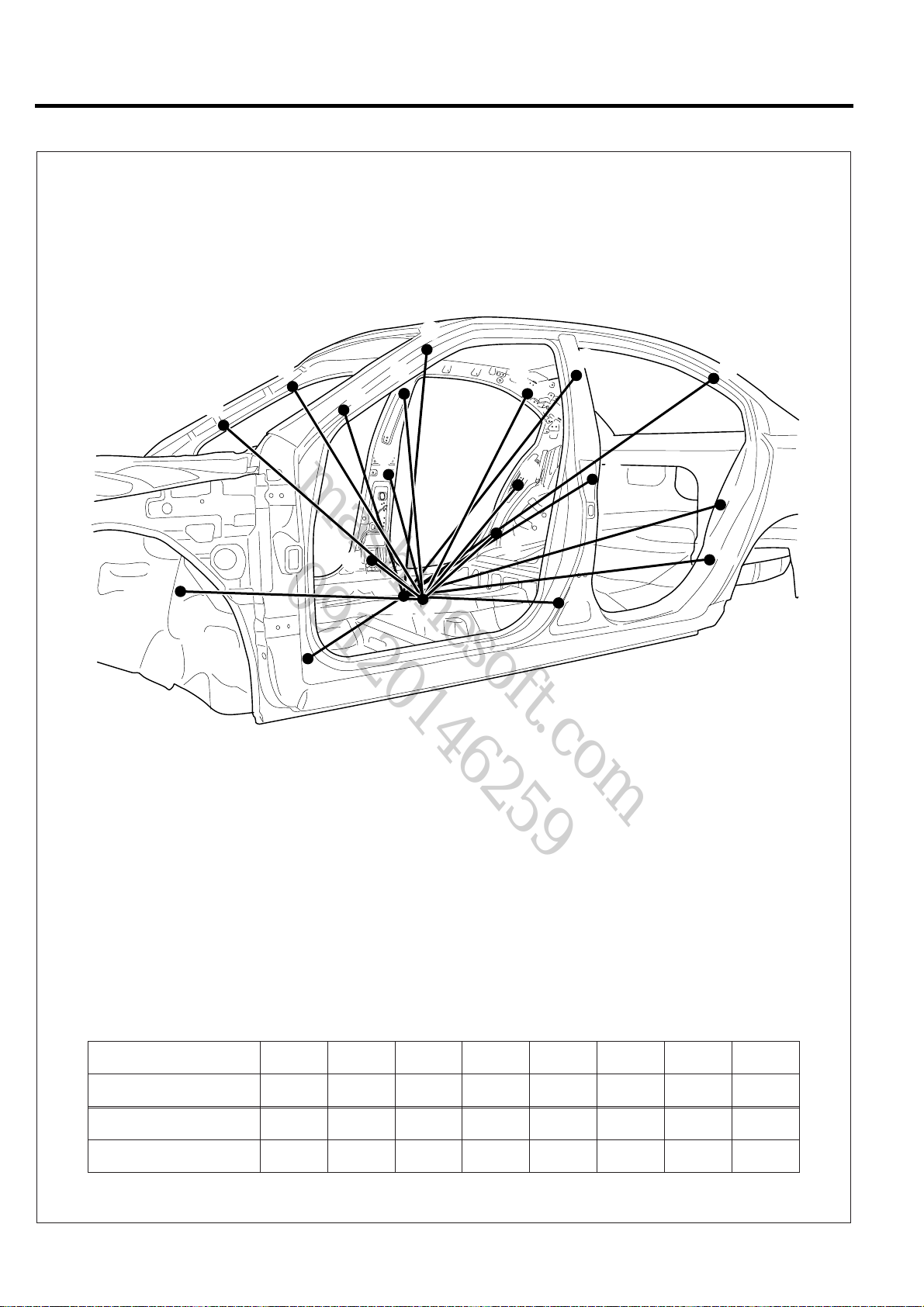

INTERIOR B

A'

F'

D'

G'

E'

H'

K'

BMGBD6301

A

B

C

C'

B'

F

D

E

M

M'

G

H

K

* These dimensions indicated in this figure are actual-measurement dimensions.

Point symbol

Length(mm)

Point symbol

Length(mm)

M-A'

1111

M-K'

1244

M-B' M-C' M-D' M-E' M-F' M-G' M-H'

1147 1021 1144 927 738 1565 1393

BODY DIMENSIONS BD-11

mashinesoft.com

09120146259

B,B'

A,A'

BMGBD6202

Front trim mounting hole (ø8.5)

D,D'

BMGBD6205

Front seatbelt mounting hole

(ø16)

BMGBD6203

Front cab mounting hole (ø6.6)

E,E'

BMGBD6206

Center pillar lower trim mounting

hole (ø8.5)

C,C'

BMGBD6204

Front cowl side trim mounting

hole (ø8.5)

F,F'

BMGBD6207

Front seatbelt retractor mounting

hole (ø12.2)

H,H'

G,G'

BMGBD6208

Cab guide bracket mounting hole

(ø6.6)

Rear door switch mounting hole

M,M'

BMGBD6302

Brake lever mounting hole (ø9)

BMGBD6209

(ø17)

K,K'

BMGBD6210

Tooling hole (ø10)

Loading...

Loading...