Page 1

Using Cameras with a

PLC

Troubleshooting Case Study

Programmable Controller

KV-8000

Series

Page 2

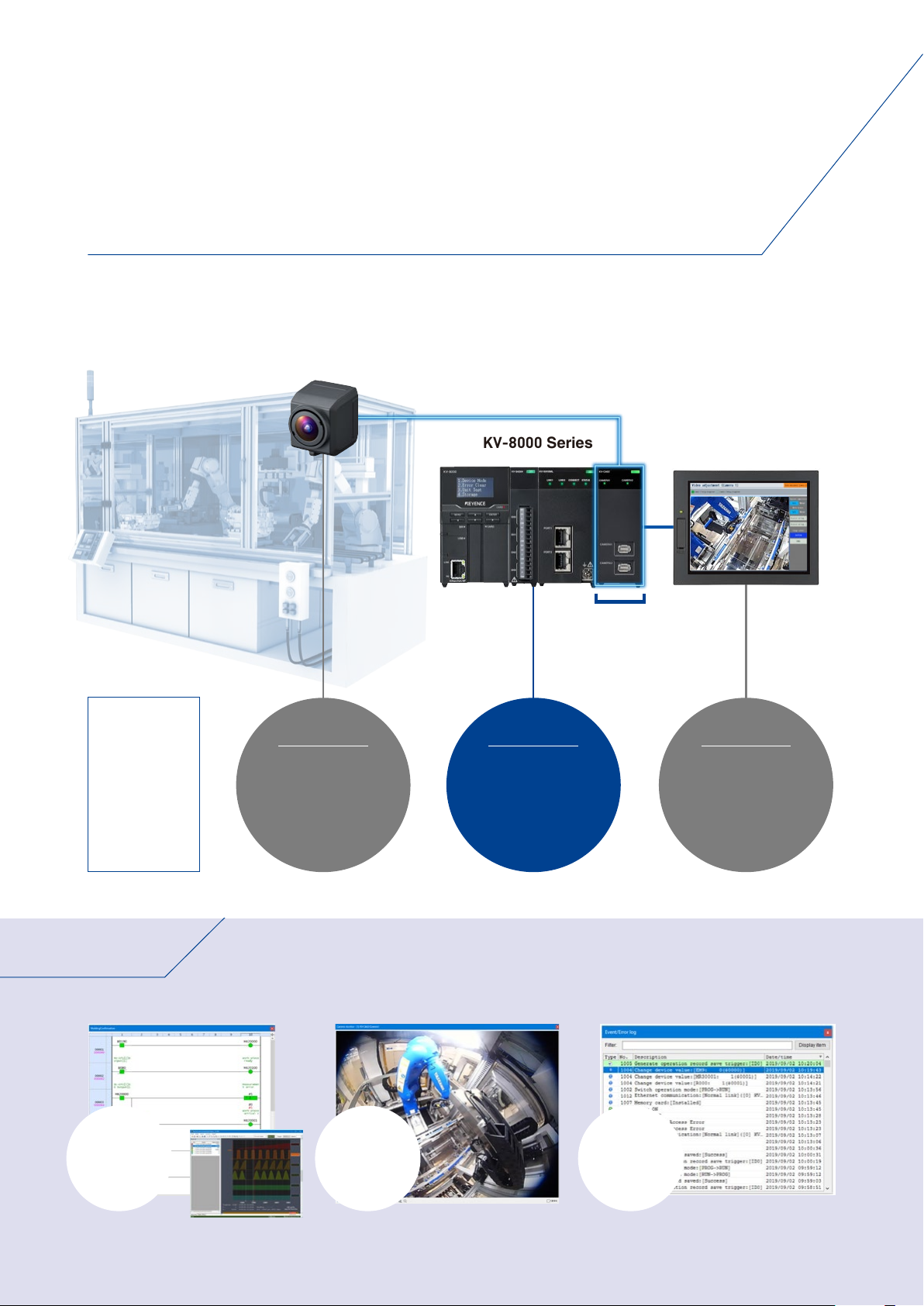

Troubleshooting with equipment

PLCs

Using the Machine Operation Recorder function while

controlling equipment

Equipment problems are recorded (with the Machine Operation Recorder function) at the same time as

equipment is controlled.

The camera video before and after a problem occurs, all the devices of the PLC for each scan, and the

operation history of the operator are all recorded.

Camera

Device roles

Camera

Video capturing

KV-8000

Equipment

Series

KV-8000

Series

control

Machine

Operation

Recorder

Camera

input

Series

VT5

VT5

Series

Equipment operations

and parameter

settings

Real-time

monitoring of the

camera video

Equipment

PLC

2

Details that can be recorded with the Machine Operation Recorder

function

Ladder operations, camera video, and the operation history can all be linked and played back.

Equipment

PLC ladder/

signals

The behaviour of all devices can

be checked each scan.

Camera

video

Mechanical, target, and human

movements are recorded with two types

of cameras.

HMI

operation

history

The operation history from the HMI and

the inputs from the host PC are recorded.

Page 3

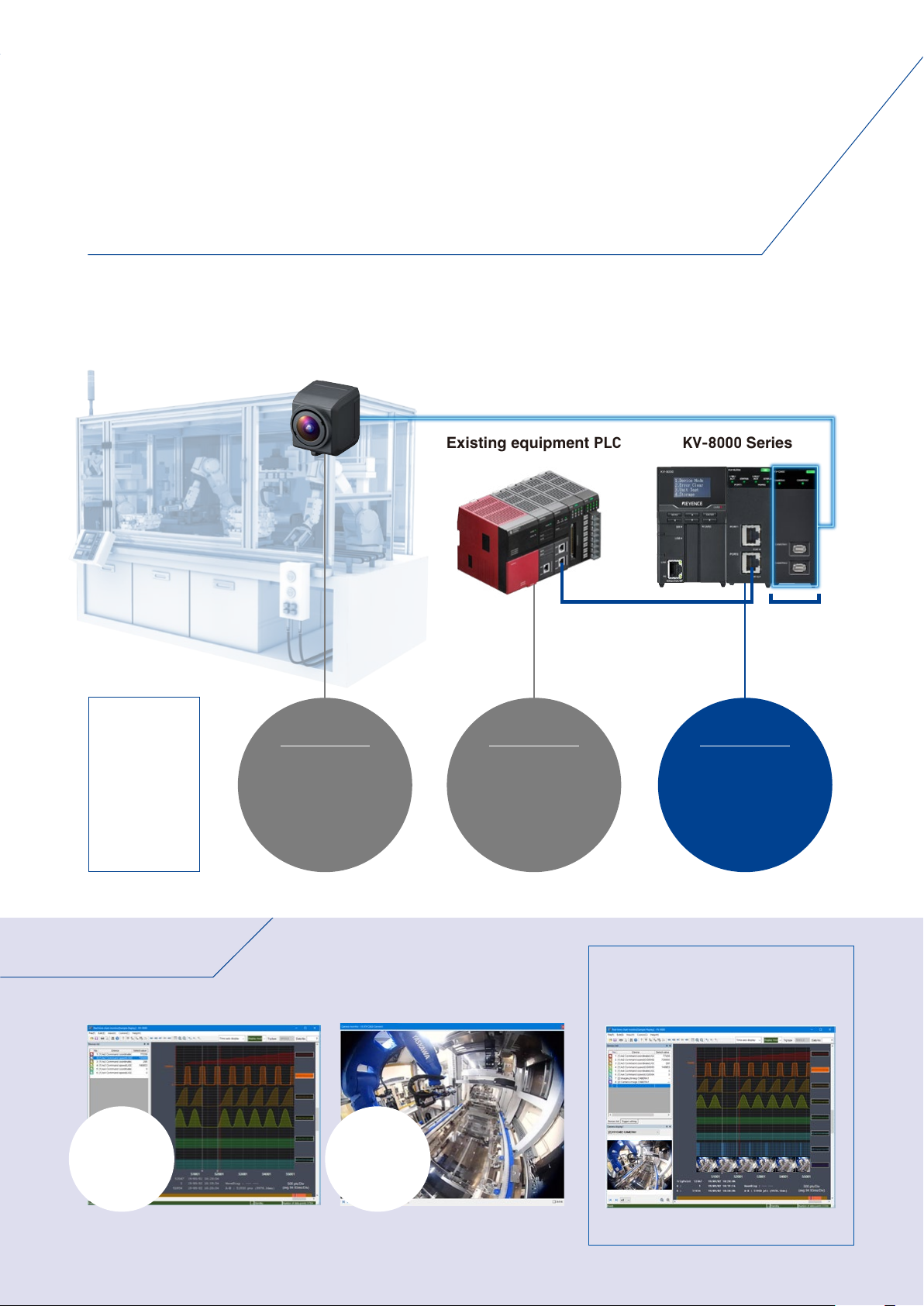

Troubleshooting with PLCs added

to existing installations

Using the Machine Operation Recorder function with it added to

existing equipment

Equipment problems are recorded (with the Machine Operation Recorder function) by acquiring signals from

an existing equipment PLC in a program-less manner.

The camera video before and after a problem occurs and specific devices at each communication cycle are

recorded.

Camera

Device roles

Camera

Video capturing

Existing equipment

Existing

equipment PLC

Equipment control

PLC KV-8000

PLC link

KV-8000

Series

PLC link with an

existing

equipment PLC

Machine

Operation

Recorder

* The KV-XLE02 or KV-XL202/

XL402 is required.

Series

Camera

input

*

PLC added to an

existing installation

Signals from

an existing

equipment

PLC

Linked devices can be checked at each

communication cycle.

Details that can be recorded with the

Machine Operation Recorder function

Changes to specific devices and the camera video

can be linked and played back.

Camera

video

Mechanical, target, and human movements

are recorded with two types of cameras.

Linked playback even when

added to an existing

installation

Linked playback of waveforms and video

3

Page 4

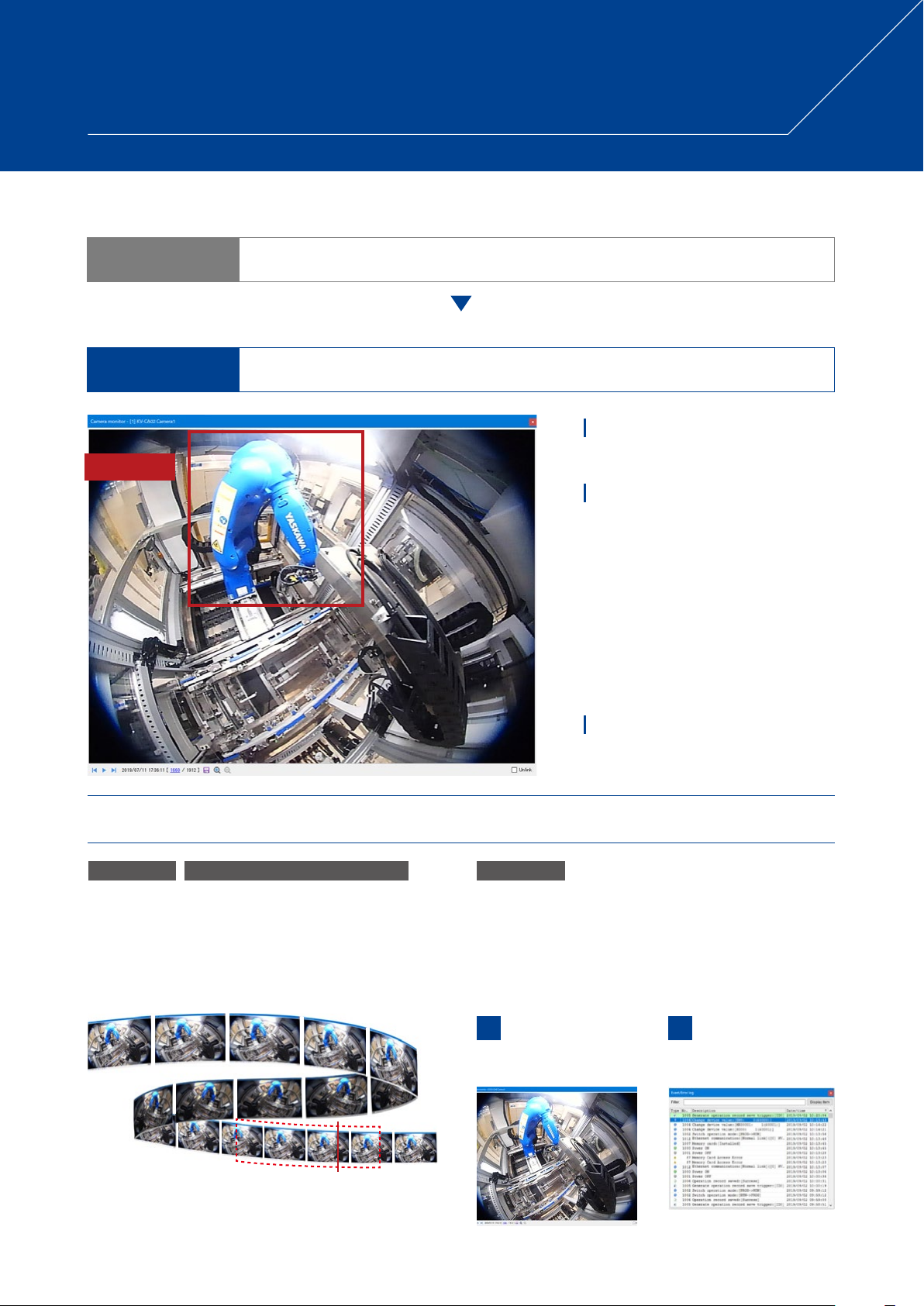

Case

1

Robot path

Conventional

KV-8000

Robots

It is difficult to isolate the causes of problems in processes that use robots.

Solved with the Machine

Operation Recorder function

The behaviour of the robot is recorded, enabling quick identification of the

cause.

Image capturing target

Robot behaviour (path)

Installation results

• Because video of the problem

occurring is recorded, the issue can

be identified immediately even in

situations where operators are not

close to the machine, such as with

unmanned lines.

• The cause—be it the robot, the

operator, or something else—can be

isolated in the initial response to the

problem.

Troubleshooting details

Just the data before and after the

occurrence of a problem is recorded.

The KV-8000 can automatically record just the data before

and after the occurrence of a problem. This makes it

possible to immediately understand the situation by

eliminating the hassle of searching for the scenes to view.

Problem

Automatic recording just before and after the problem

Eliminating the hassle of searching for the scenes to view makes it

possible to understand the situation in the minimal amount of time.

Used camera

Wide field and high-resolution camera

KV-CA1W

EquipmentEquipment Added to existing installation

Judgement is fast during the initial

response to isolate the cause.

The operation history of the operator is retained and is

synchronised with the robot behaviour. This makes it

possible to accurately and quickly isolate the cause

during the initial response to the problem.

Use the camera to

1

check the operation

of the robot.

Isolate the mechanical cause. Isolate the human cause.

Use events to check

2

the operation

history.

4

Page 5

Case

2

Robotic hand

Conventional

KV-8000

Robotic hand

Transferring defects/quality defects occur with unknown causes in a process

that uses a robot.

Solved with the Machine

Operation Recorder function

The status of both the robotic hand and the ladder execution are known,

so the cause investigation is quick.

Image capturing target

• The robotic hand as it grips the target

• The welding status

• The target assembly status

Installation results

•

The program execution status and the

operation of the robotic hand at the time of

the problem can be linked and played back,

which makes it easy to investigate the cause.

•

The original video is retained, so the

operation can be checked without needing

teaching pendant operations and other such

work that requires specialised knowledge.

Used camera

Wide field and high-resolution camera

KV-CA1W

Troubleshooting details

Equipment Added to existing installation

Quickly investigate the cause with

linked playback.

The robot operations and the ladder execution status can be

checked in the same chronological order. The status before and

after the problem occurs can be checked with video and

waveforms, which leads to quick identification of the cause.

Ladder execution status

Problem

occurrence

(Cycle changes before and

after the problem)

These can be linked and

played back in the same

chronological order.

Robot operations

(Robot operations before and

after the problem)

5

Page 6

Case

Mechanical mechanisms

3

Conventional

• After a problem has occurred, it is not possible to judge whether the issue was a

mechanical mechanism.

• The system needs to be restored quickly, but it is not possible to tell whether the

mechanical status is such that it is OK to restart the system.

Solved with the Machine Operation Recorder function

KV-8000

It is possible to determine whether the cause of the problem was the mechanical

mechanisms without having to wait for the problem to occur again.

Image capturing target

• Mechanical parts of the target

processing section

• Suctioned transfer

Mechanical mechanisms

• Sensor installation status

Installation results

• The mechanical mechanisms can be

recorded, which enables prompt

analysis without the need to wait

on-site for the problem to occur again.

•

The status of the mechanical mechanisms

when a problem occurs can be recorded

automatically, so there is no need to stop

equipment in order to investigate the cause.

Used camera

Compact standard camera

KV-CA1H

Troubleshooting details

Equipment Added to existing installation Equipment Added to existing installation

Automatic recording enables prompt

analysis.

The problem can be recorded automatically, so analysis

can be started without having to wait for the problem to

reoccur. This eliminates the time and effort spent in

waiting for a reoccurrence and leads to prompt solutions.

Conventional

method

KV-8000

6

Problem

occurrence

Recording

Problem

occurrence

Waiting for

problem

reoccurrence

Analysis

Problem

occurrence

Analysis can be

started without having

to wait for the problem

to reoccur.

Analysis

The cause can even be investigated

during operation.

The mechanical status when a problem occurs is recorded,

so it is possible to judge whether the system can be

restarted. The cause can be investigated without having to

stop the equipment, which maintains the operation rate.

There are no

mechanical problems,

so operation can be

restarted while the

cause is investigated in

the office.

The mechanical status

is recorded before and

after the problem.

Page 7

Case

4

Overall equipment

Conventional

KV-8000

• It is not possible to predict where problems will occur.

• Operators cannot notice changes in the locations that are normally difficult to see.

A wide field and high-resolution camera makes it possible to check the overall

equipment as well as the locations that are difficult to see.

Preprocessing mechanical mechanisms

Solved with the Machine

Operation Recorder function

Image capturing target

From the unloader to the preprocessing

Installation results

• Operators can notice changes in the

locations where it is difficult for people

to enter or where it is difficult to

perform visual checks.

• If it is not possible to predict the

locations where problems will occur,

overall equipment changes can be

captured with a wide field camera.

Conveyor direction

Used camera

Wide field and high-resolution camera

KV-CA1W

Troubleshooting details

Equipment EquipmentAdded to existing installation Added to existing installation

Record the locations that are difficult to see.

A wide field and high-resolution camera makes it

possible to record (with high resolution) the overall

device as well as the locations that are normally difficult

to see. This is useful in detecting problems that cannot

be anticipated in advance.

Even when zoomed

in, the target and the

Target

mechanical

mechanisms can be

checked sufficiently.

Real-time monitoring is possible.

By installing cameras, the locations that are difficult for

operators to see can be checked in real time with video

on the HMI. A sample screen is also available and can

be put to use immediately.

On the HMI screen,

settings such as

the image quality

and exposure can

be fine-tuned.

KV-CA1W

VT5 Series

7

Page 8

Case

5

Operator line of flow

Conventional

KV-8000

It is not possible to check whether the operator line of flow is optimal when a

problem occurs.

Solved with the Machine

Operation Recorder function

The operator line of flow when a problem occurs is known.

Image capturing target

Operator line of flow

Installation results

• The operator line of flow when a

problem, for which recovery takes a

long time, occurs is known. This

makes it possible to implement

countermeasures such as changing

the equipment layout.

• The record data can be converted into

a video file, which makes it easy to

Operator line

of flow

share this data with and deploy this

data to other workers.

Used camera

Wide field and high-resolution camera

KV-CA1W

Troubleshooting details

Equipment

To increase the operation rate, it is important to reduce the time and effort spent handling problems for which recovery takes a

long time. By subcategorising alarms and recording the operator line of flow when the corresponding alarm occurs, it is possible

to consider countermeasures. Furthermore, recorded videos can be output as .AVI files, so videos containing lines of flow after

countermeasures have been implemented can be shared with other operators to prompt them to improve their own lines of flow.

Use a Pareto alarm chart to

1

subcategorise the problems

that take time to recover from.

Increase the operation rate by improving the line of flow.

Record the operator line of flow

2

when the corresponding

problem occurs, analysing the

cause of the long recovery time.

Generate an .AVI file of the line

3

of flow after implementing

countermeasures and share

this file with other operators as

an improvement procedure.

avi

Sharing

8

Page 9

Case

6

Operator countermeasure

Conventional

KV-8000

Operator

countermeasure

It is difficult to accurately grasp the countermeasure details when a problem

occurs.

Solved with the Machine

Operation Recorder function

The countermeasure details are maintained as a video, so the situation can

be understood accurately.

Image capturing target

Operator countermeasure details

Installation results

• Operators can accurately grasp the

countermeasure without having to ask

questions.

• The appropriateness of the operations

directly before the problem and of the

countermeasure details after the

problem can be checked.

Used camera

Compact standard camera

KV-CA1H

Troubleshooting details

Equipment Added to existing installation

Operators can accurately grasp the operation

details without having to ask questions.

The countermeasure details when a problem occurs can

be recorded as a video, which makes it possible to

accurately grasp the situation. Furthermore, the HMI

operation history can be recorded in the same

chronological order, which is useful in troubleshooting.

Operation history

Countermeasure video

Linked

Equipment Added to existing installation

The operation details before and after

the problem are understood.

Information can be recorded both before and after a

problem occurs: were operations related to the trouble

occurrence performed in advance, were the

countermeasures after the problem occurred

appropriate?

Recording time

Operations directly before

the problem

File saving trigger

Countermeasure after

the problem

9

Page 10

Camera sample images

Wide field and high-resolution camera KV-CA1W

Robot close-up

Equipment outer appearance

Equipment top view

Equipment rear view

Through an acrylic sheet

10

Equipment bottom view

Page 11

Compact standard camera KV-CA1H

Target close-up

Equipment outer appearance

Hand close-up

Equipment rear view

Mechanism bird’s-eye view

Horizontal view

11

Page 12

Lineup

CPU

Camera input Camera

CPU unit

KV-8000

■ LD instruction execution speed: 0.96μs

■ Program capacity: 1500ksteps maximum

■ Machine Operation Recorder function

■ EtherNet/IP™ port

Camera input unit

KV-CA02

■ Maximum number of connected units per

system: 4

■ Number of camera input ports: 2

■ Camera hot swapping supported

Compact standard camera

KV-CA1H

■ Resolution: 640 (H)×480 (V)

■ Frame rate: 10/30/120fps

■ Viewing angle: • Horizontal viewing angle:

Approximately 60°

• Vertical viewing angle:

Approximately 47°

SD card

Shared camera options

Industrial SD card

KV-M16G/M4G

■ SLC standard

■ Recording capacity: 16GB/4GB

Camera cable

KV-C5/C10/C20

■ Cable length: 5m/10m/20m

Mounting adapter

OP-88386

■ For mounting on a stand

(The stand must be prepared

separately.)

Wide field and high-resolution camera

KV-CA1W

■ Resolution: 1280 (H)×960 (V)

■ Frame rate: 10/30fps

■ Viewing angle: • Horizontal viewing angle:

• Vertical viewing angle:

GLOBAL NETWORK

AUSTRIA

BELGIUM

BRAZIL

CANADA

CHINA

The information in this publication is based on KEYENCE’s internal research/evaluation at the time of release and is subject to change without notice.

Company and product names mentioned in this catalogue are either trademarks or registered trademarks of their respective companies. Unauthorised reproduction of this catalogue is strictly prohibited.

Copyright © 2019 KEYENCE CORPORATION. All rights reserved.

CONTAC T YOUR NE ARES T OFFI CE FOR RE LEA SE STATUS

CZECH REPUBLIC

FRANCE

GERMANY

HONG KONG

HUNGARY

Approximately 180°

Approximately 150°

Please visit:

INDIA

INDONESIA

ITALY

JAPAN

KOREA

www.keyence.com

MALAYSIA

MEXICO

NETHERLANDS

PHILIPPINES

POLAND

ROMANIA

SINGAPORE

SLOVAKIA

SLOVENIA

SWITZERLAND

KV8Troubleshootingexamples-WW-TG-GB 1109-1

Adjustable bracket

OP-88387

■ For mounting on a pole

(Separately prepare a support pole

with a diameter of 12 mm.)

SAFET Y INFORMATION

Please read the instruction manual carefully in

order to safely operate any KEYENCE product.

TAIWAN

THAILAND

UK & IRELAND

USA

VIETNAM

WW11-1039

600V85

Loading...

Loading...