Page 1

Point

Reference

DANGER

NOTICE

DANGER

DANGER

DANGER

96M12530

Dedicated Safety Relay

for the GL-R

GL-T11R

Instruction Manual

Introduction

This instruction manual describes handling, operation, and precautionary

information for the GL-T11R Safety Relay dedicated for use with the GL-R

Series Safety Light Curtain. Read this instruction manual thoroughly along

with the GL-R instruction manual and user manual before operating the

GL-T11R in order to ensure the optimum performance and functionality of

the GL-R and GL-T11R. Keep this manual readily available for reference.

Ensure that the end user of this product receives this manual.

This manual is the original instruction manual.

The GL-T11R can also be used with GL-S Series Safety Light Curtains, but

in this situation there are limitations on the functions that can be used.

Carefully read both the GL-S instruction manual and this instruction

manual to ensure that you fully understand the function limitations before

using this product.

Hereinafter, both the GL-R Series and GL-S Series of safety light curtains

are referred to as GL.

Safety Precautions

General Precautions

• You must verify that the GL-T11R is operating correctly in terms

of functionality and performance before starting the machine.

• KEYENCE does not guarantee the functions and performance

of the GL-T11R if it is used in a manner that differs from the

GL-T11R specifications described in this instruction manual or

if the GL-T11R is modified by the customer.

•

When using the GL-T11R to protect machine operators against a

hazard or hazardous zone or using the GL-T11R as a safety component for any purpose, always follow the applicable requirements of the laws, rules, regulations and standards in the country

or region where the GL-T11R is used. For such regulations, you

should make direct contact with the regulatory agency responsible for occupational safety and health in your country or region.

• Depending on the type of machine on which the GL-T11R is to

be installed, there may be special safety regulations related to

the use, installation, maintenance, and operation of the safety

component, and such safety regulations must be fulfilled. The

responsible personnel must install the GL-T11R in strict compliance with such safety regulations.

•

The responsible personnel must do the training to the assigned

personnel for the correct use, installation, maintenance, and

operation of the GL-T11R. "Machine operators" refers to personnel who have received appropriate training from the responsible

personnel and are qualified to operate the machine correctly.

•

Machine operators must have specialized training for the GL-T11R,

and they must understand and fulfill the safety regulations in the

country or region in which they are using the GL-T11R.

• When the GL-T11R fails to operate, machine operators must

immediately stop the use of the machine and the GL-T11R and

report this fact to the responsible personnel.

•

The GL-T11R is designed with the assumption that it would be correctly installed and operated in accordance with the installation

and operation procedures described in this instruction manual.

You must perform an appropriate installation of the GL-T11R after

conducting a sufficient risk assessment for the target machine.

• When disposing of the GL-T11R, make sure to follow requirements, rules, codes, regulations and laws regarding industrial

wastes in countries or regions where the GL-T11R is used.

• The GL-T11R should be processed as an industrial waste product when being disposed.

Safety Headings

This instruction manual uses the following symbols that alert you to important safety information. Strict adherence to the instructions next to these

heading is required at all times.

It indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

It indicates a situation which, if not avoided, could result in

product damage as well as property damage.

It indicates additional information on proper operation.

It indicates tips for better understanding or useful information.

Indicates reference pages in this or another manual.

Precaution on Use

■ Operators

• In order to operate the GL-T11R correctly, the responsible personnel and machine operators must follow all procedures

described in this instruction manual.

• No person other than the responsible personnel and machine

operators should be allowed to install or test the GL-T11R.

• When performing electrical wiring, always fulfill the electrical

standards and regulations for the country or region in which

the GL-T11R is used.

■ Installation environment

• The GL-T11R is not designed to be explosion-proof. Never use it

in the presence of flammable or explosive gases or elements.

•

When using the GL-T11R in the presence of substances, such as heavy

smoke, particulate matter, or corrosive chemical agents, confirm that

such substances do not induce deterioration in product quality.

• Be sure to confirm absolutely that there is nobody in the

hazardous zone, before the interlock is released (i.e. the

machine system restarts) by the interlock reset mechanism.

Failure to follow this warning may result in significant harm to

the machine operators, including serious injury or death.

• Interlock reset mechanisms (such as switches) must be

installed so that the whole hazardous zone can be checked by

the responsible personnel. Interlock reset mechanisms should

not be accessible from within the hazardous zone.

• Use the GL-T11R within an enclosure of IP54 or higher.

• Ensure there is space around the unit for ventilation.

• Do not install the GL-T11R in the locations listed below:

• Locations with high humidity and a risk of condensation

• Locations where water will splash onto the GL-T11R

• Locations where there are corrosive gases

• Locations where any flammable gases or explosive gases

exist

• Locations where the GL-T11R may be directly subjected to

vibration or impact

• Locations where strong electromagnetic noise may affect the

GL-T11R

1

GL-T11R-IM-E

Page 2

■ Target machine

DANGER

DANGER

DANGER

• The machine on which the GL-T11R is to be installed must be

susceptible to an emergency stop at all operating points during its operation cycle. Do not use the GL-T11R for machines

with irregular stop times.

• Do not use the GL-T11R for power presses equipped with fullrevolution clutches.

• The GL-T11R cannot be used as a PSDI because it does not

fulfill the requirements of OSHA 1910.217(h). Refer to OSHA

1910.217 for the PSDI mode.

• Do not use the GL-T11R to control (stop forward motion, etc.)

trains, cars and other transportation vehicles, aircraft, equipment for use in space, medical devices, or nuclear power generation systems.

■ Circuit design and wiring

• Always turn off the power to the GL-T11R when performing

electrical wiring.

• You must fulfill the electrical standards and regulations in the

country or region in which the GL-T11R is being used when

you perform the electrical wiring.

• Wiring shall be in accordance with IEC60204-1/EN60204-1 so

that short-circuit between adjacent terminals is to be prevented.

• To avoid the risk of electric shock, do not connect any of the

GL-T11R inputs/outputs, except for the FSD, to DC power

sources outside of the range of 24 V DC + 10% or to any AC

power source.

• To avoid the risk of electric shock, be sure that the hazardous

voltage is isolated from all wiring of the GL-T11R with reinforced insulation or double insulation, except for the FSD.

• In order to fulfill the requirements in IEC61496-1, UL61496-1,

EN61496-1, UL508 and CAN/CSA-C22.2 No. 14, the power supply for the GL-T11R must fulfill the conditions listed below.

(a)The rated output voltage of 24 V DC (SELV, Overvoltage

Category ) within ± 10%

(b)Double insulation or reinforced insulation between the

primary and secondary circuits.

(c)Output holding time of 20 ms or more.

(d)A power supply must fulfill the requirements of the electrical

safety and electromagnetic compatibility (EMC) regulations

or standards in all countries and/or regions where the

GL-T11R is used.

(e)A secondary circuit of power supply (output) must fulfill the

requirements for Class 2 Circuits or Limited Voltage/Current

Circuits specified in UL508 and CAN/CSA-C22.2 No. 14 if the

GL-T11R is used in the United States or Canada.

• Do not install the electric wiring of the GL-T11R together with

or in parallel with high-voltage electrical or power lines.

• Both of the two FSDs provided on the GL-T11R must be used

to establish a safety related machine control system. Establishing a safety related machine control system with just one

of the FSDs cannot stop the machine in the event of an FSD

failure and may result in significant harm to the machine operators including serious injury or death.

• The AUX output, error output, muting state output, alert output,

Clear/Blocked state output and inter-lock-reset-ready output

cannot be used as safety outputs for the safety related control

systems. Usage of these functions as safety outputs may

result in significant harm to the machine operators, including

serious injury or death.

• The wait input is not allowed to be connected to the output

from any components comprising a part of the safety related

machine control system. If the wait input is connected to the

output of a safety component it may result in significant harm

to the machine operators, including serious injury or death.

• Use the GL transmitter cable and receiver cable connected to

the GL-T11R with the length specified in this instruction manual or shorter. Usage of cables longer than the specified length

may cause improper operation of safety functions and may

cause a dangerous situation.

• For connection between GL-T11R and GL, make sure to use

the dedicated cable for GL-T11R for correct connection. If

using a wrong cable or connecting cables for the transmitter

and receiver wrongly, FSD may be always ON. This is dangerous.

Testing and Maintenance

• You must always perform the pre-check test, in accordance

with the pre-check test procedures, after maintenance, adjustment or alignment of the target machine or the GL-T11R and

before the machine startup.

• If the GL-T11R does not operate properly when you perform

the pre-check test according to the pre-check test procedures

specified in this instruction manual, do not operate the

machine.

• You must periodically examine the machine to verify that all

brakes, other stop mechanisms, and control devices operate

reliably and correctly in addition to checking the GL-T11R.

• The responsible personnel must perform maintenance procedures as specified in this instruction manual to avoid any hazardous situation.

• If the GL is in an error condition with the EDM error, the relay

inside the GL-T11R may have a fault. In this case, replace the

relay board according to "Replacing the relay board" of page 6.

Precautions for regulations and standards

■ CE Marking

KEYENCE has confirmed that the GL-T11R complies with the requirements of EC Directives under the conditions that the following requirements are satisfied. Note the following requirements when using the

GL-T11R in EU countries.

● EMC Directive (2004/108/EC)

• Applicable standards

EMI : EN55011, Group 1, Class A

EMS: EN61496-1

However, these requirements do not guarantee that the whole mechanical

device into which the GL-T11R is incorporated satisfies the essential

requirements of EMC Directives. A manufacturer of such a device has the

responsibility to confirm the conformity of the whole mechanical device.

● Machinery Directive (2006/42/EC)

The GL-T11R is a "safety component" defined in the EU Machinery Directive (2006/42/EC) Annex V. The GL-T11R complies with the following EN

standards and has obtained the third-party certificate by TÜV SÜD Product Service GmbH.

• Applicable standards

EN61496-1, Type 4 ESPD

EN50178

EN ISO13849-1, Category 4, PLe

• Use a power supply that provides SELV or PELV output defined in

EN50178.

■ UL Certification and Regulations in North America

The GL-T11R has obtained the following UL/c-UL certifications:

• UL File No. E184802

• Category NIPF/NIPF7

Note the following requirements when using this product as a UL certified

product.

• Use a power supply that provides Class 2 output defined in NEPA70

(NEC: National Electrical Code) in U.S.A.

The GL-T11R also complies with the following regulations in North America.

• FCC Part 15B, Class A Digital Device

• ICES-003, Class A Digital Apparatus

■ Other applicable standards

The GL-T11R has been designed in consideration of the following standards and regulations. For details regarding the following standards, contact the third-party certification organization, such as UL or TÜV.

• EN60204-1

•EN692

•EN693

• OSHA 29 CFR 1910.212

• OSHA 29 CFR 1910.217

• ANSI B11.1 - B.11.19

• ANSI/RIA R15.06 - 1999

• SEMI S2

• "Guidelines for Comprehensive Safety Standards of Machinery", July 31,

2007, number 0731001 issued by Ministry of Health, Labor, and Welfare

in Japan.

GL-T11R-IM-E

2

Page 3

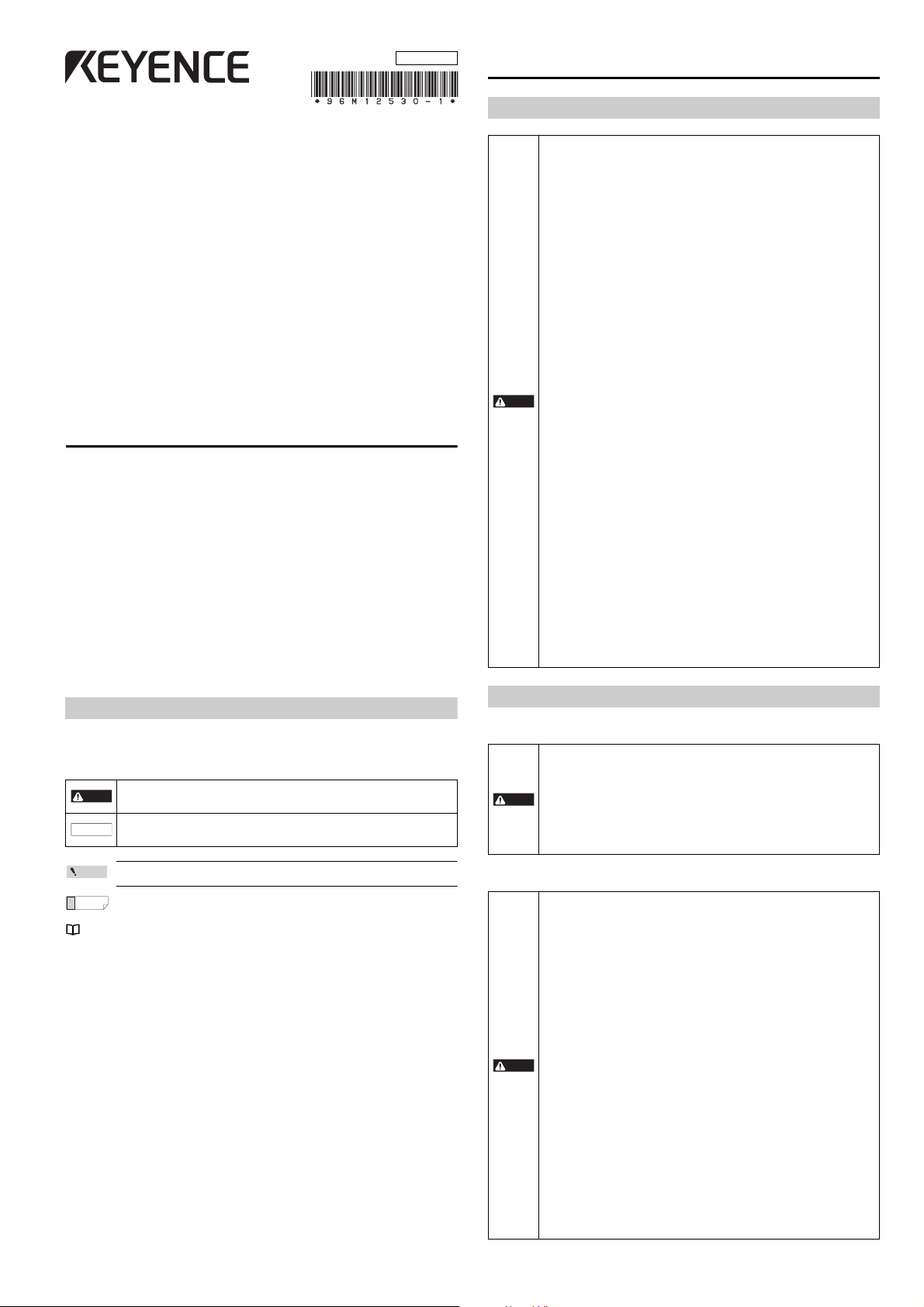

Checking the Package Contents

Point

(Transmitter/receiver set)

M14 connector, male

44

45

φ5.8

φ17φ17

(Transmitter/receiver set)

M14 connector, male

M14 connector, female

45

φ4

φ17

(Transmitter/receiver set)

M14 connector, male

44

45

φ5.8

φ17φ17

(Transmitter/receiver set)

M14 connector, male

M14 connector, female

POWER RESET

FSD-ON

WAIT

FSD-OFF

EDM

ERROR

O-RIDE

MUTE1 MUTE2

Electrical hazard

CAUTION

T R

Transmitter

connector

Indicator

Signal input/output

terminal block

Receiver

connector

Relay output

terminal block

Side Rear

SL-U2 connector

*Covered by tape

at time of

shipment.

SL-U2,

mounting

holes

DIN rail

mating

area

DIN rail

lock pin

(Front View)

Hook B

Hook A

Hook B

* Hook A

latches on

DIN rail

DIN rail

Hook B

* Push the main

unit and latch

hook B.

[Locked state] [Unlocked state]

Hook B

Hook A

*Position hook B so that it is locked.

(Front View)

DIN rail

Hook B

Push down using

a screwdriver.

GL-T11R........................................................×1

Instruction Manual (this document).......... ×1

Cable

Be sure to use the following cables for the connection between

the GL-R and the GL-T11R.

The GL-T11R does not operate when combined with other GL-R

cables.

■ GL-R Series

● Unit connection cable

Shape Model Length

φ5.8

31.5

● Extension cable

Shape Model Length

■ GL-S Series

● Unit connection cable

Shape Model Length

● Extension cable

Shape Model Length

45

GL-RPT03PM 0.3 m

GL-RPT3PM 3 m

φ17

GL-RPT5PM 5 m

GL-RCT10PM 10 m

GL-SPT3P 3 m

GL-SPT5P 5 m

GL-SPT10P 10 m

■ Indicators

Name Light color Description

POWER Green Lights when power is supplied

FSD ON Green Lights when FSD turns ON

FSD OFF Red Lights when FSD turns OFF

ERROR Red Lights when an error condition occurs

MUTE 1 Orange Lights when muting input 1 turns ON

MUTE 2 Orange Lights when muting input 2 turns ON

*1, *2

*1

*1

RESET Orange Lights when reset input turns ON

WAIT Orange Lights when wait input turns ON

*1

EDM Orange Lights when EDM input turns ON

O-RIDE Orange Lights when override input turns ON

*1 When GL-R Series functions are switched using the Safety Device Configurator

setting software, indicators light up according to each function’s input status.

*2 For the GL-S Series, this indicator is fixed to being off.

*1

Installation

■ DIN rail Mounting

1 Push hook B down with a screwdriver to release the lock mechanism.

23

Part Names

GL-RCT10PM 10 m

4

Removing from DIN rail

3

GL-T11R-IM-E

Page 4

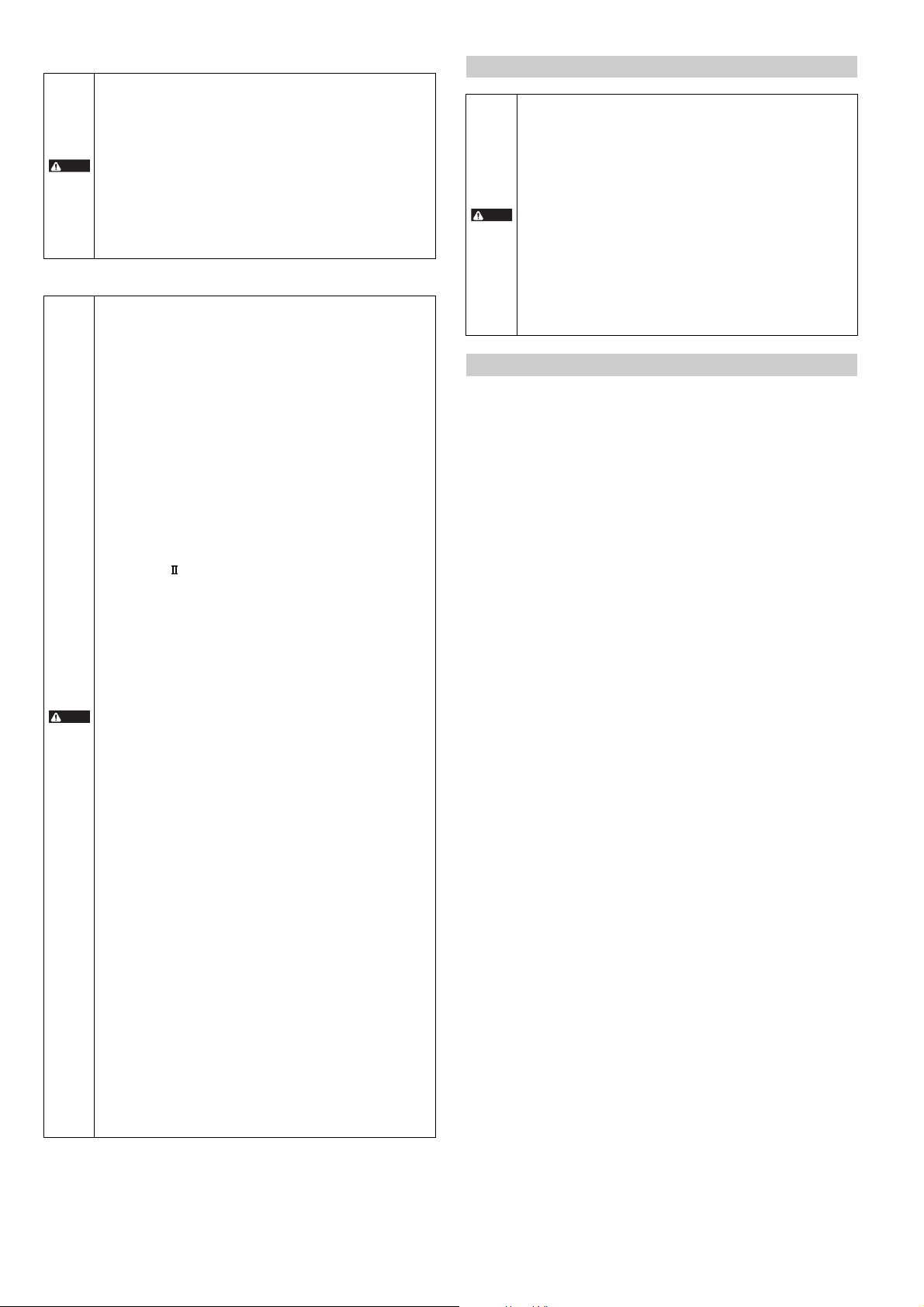

■ Screw Mounting

Point

Reference

2-φ4.2 (mounting hole)

30mm

30mm

30mm

GL-T11R

*Install while

being careful of

the connectors

DANGER

Receiver Connector (black)

Transmitter Connector (grey)

Receiver cable

(Black connector end)

Transmitter cable

(Gray connector end)

Connector end

The two mounting holes are used to install the

GL-T11R with two M4 screws.

(Recommended tightening torque: 0.7 N•m)

124

37

Always leave at least 30 mm of open space between the GL-T11R

and other equipment or walls.

* When using the SL-U2, position the SL-U2 at least 30 mm from

the edge of the cabinet.

Connection to the SL-U2 Recommended Power Supply

The power can be supplied by connecting to the SL-U2 dedicated power

source via the connector on the side.

Connection to the GL

Cable Specification

(1) Cable length

z GL-R Series

When using the main unit connection cable and the extension cable

together, the total length of the combined cables must be 30 m or

less for the transmitter and receiver respectively.

z GL-S Series

When using the main unit connection cable, the extension cable

and the linking cable, the total length of the combined cables must

be 20 m or less for both the transmitter and receiver.

Cables must be within the lengths specified. Failure to follow

this specification may cause improper operation of the safety

functions and may cause a dangerous situation.

(2) Minimum cable bending radius : 5 mm (10 mm for the part where the

connector to the GL-T11R is attached)

1 Remove the seal on the side of the GL-T11R that protects the connector

port.

2 [For DIN rail mounting]

• Mount the GL-T11R and the SL-U2 to the DIN rail, and slide together

to couple the connectors.

[For screw mounting]

• Couple the connector according to the figure above.

3 Slide the SL-U2 connection hook to secure it to the GL-T11R.

When not using the SL-U2, connect a power source to the power input

terminals found on the relay output terminal block.

"Wiring Example" (page 6)

(3) Identification of connector cables

Types can be distinguished by the color of the connector end.

Cables for Transmitter: Gray connector end

Cables for Receiver : Black connector end

Point

Be sure to connect the unit connection cable for the receiver to

the GL receiver and the unit connection cable for the transmitter

to the GL transmitter.

GL-T11R-IM-E

4

Page 5

Wiring

Point

Reference

Reference

POWER RESET

FSD-ON

WAIT

FSD-OFF

EDM

ERROR

O-RIDE

MUTE1 MUTE2

Electrical hazard

CAUTION

Signal input/output

terminal block

Relay output

terminal block

NOTICE

Push in the orange projection

using the flat-head screwdriver.

Insert the cable.

10 mm

Insert the cable.

Insert the flat-head screwdriver

to the square hole.

10 mm

GL-R main unit

Receiver

No.

Name

1 OSSD2

2 Not used

3 OSSD1

4 Reset input

*1

5

Synchronization 1 (RS485+)

6

Synchronization 2 (RS485-)

7 24V

8 AUX output

*1

9 EDM input

10 0V

11

Interlock selection input

*1

12 FE

*1

Transmitter

No.

Name

1 Wait input

*1

2 Not used

3 Override input

*1

4 Error output

*1

5

Synchronization 1 (RS485+)

6

Synchronization 2 (RS485-)

7 24V

8

Muting lamp output

*1

9 Muting input 2

*1

10 0V

11 Muting input 1

*1

12 FE

*1

Relay unit

Relay output terminal block

No.

Name

1

FSD1

2

3

FSD2

4

5FE

*1

60V

7 24V (input)

8 EDM input (24V)

9 EDM input

Signal input/output terminal block*1

No.

Name

10 Reset input (24V)

11 Reset input

12

Interlock selection input (24V)

13

Interlock selection input

14 AUX output

15 Error output

16 Muting lamp output

17 Muting input 1

18 Muting input 2

19 Wait input

20 Override input

21 0V

6

10

11 12

3

4

5

21

9

8

7

6

10

12 11

9

8

7

12

3

4

5

Under factory default settings, shorting bars are connected between terminals 8 and 9, and terminals 10 and 11.

■ GL-R Series

The GL-R Series operates with the following settings under the factory

default settings.

• Interlock function: Not used (Auto reset mode)

• EDM function: Not used

If a setting change is not necessary, use as it is. For details of each function, refer to the "GL-R User’s Manual".

■ GL-S Series

The GL-S Series operates with the following settings under the factory

default settings.

• EDM function: Not used

Not all of the input/output functions assigned to the signal input/output terminals can be used. Use the signal input/output terminals with the factory

default settings.

■ Wiring method

(1) Wiring the Relay Output Terminal Block

• Connectable cable : AWG24 to 12 (single wire, stranded wire)

• Connectable wire ferrule diameter: 1.3 - 2.6mm

• Cable strip length:

(2) Wiring the Signal Input/Output Terminal Block

■ Input/Output assignment

Signal input/output terminal block

(GL-R Series only)

No.

10 Reset input (24V) 1

11 Reset input 2

12 Interlock selection input (24V) 3

13 Interlock selection input 4

14 AUX output 5 FE

15 Error output 6 0V

16 Muting lamp output 7 24V (input)

17 Muting input 1 8 EDM input (24V)

18 Muting input 2 9 EDM input

19 Wait input

20 Override input

21 0V

For the GL-R Series, the functions are switched to different

functions according to the settings configured with the "Safety

Device Configurator" PC setting software.

When the settings are changed, check the wiring referring to the

internal circuit diagram in the next section.

For the GL-R Series, the power source can be supplied to the muting

device or muting lamp from each 24V terminal. (The total supply

current is 95mA or less. The voltage decreases by approx. 1V from the

voltage input to GL-T11R.)

Relay output terminal block

Name No. Name

FSD1

FSD2

*

* Power supply terminal for GL-T11R.

Do not connect when the SL-U2

power source is connected to the

side of GL-T11R.

• Connectable cable : AWG24 to 12 (single wire, stranded wire)

• Connectable wire ferrule diameter: 1.3 - 2.1mm

• Cable strip length:

Do not perform pre-tinning on the cable end.

Internal circuit diagram

K2

K1

*1 These functions cannot be used with the GL-S.

M14 connector male pin array M14 connector female pin array

K1

K2

5

GL-T11R-IM-E

Page 6

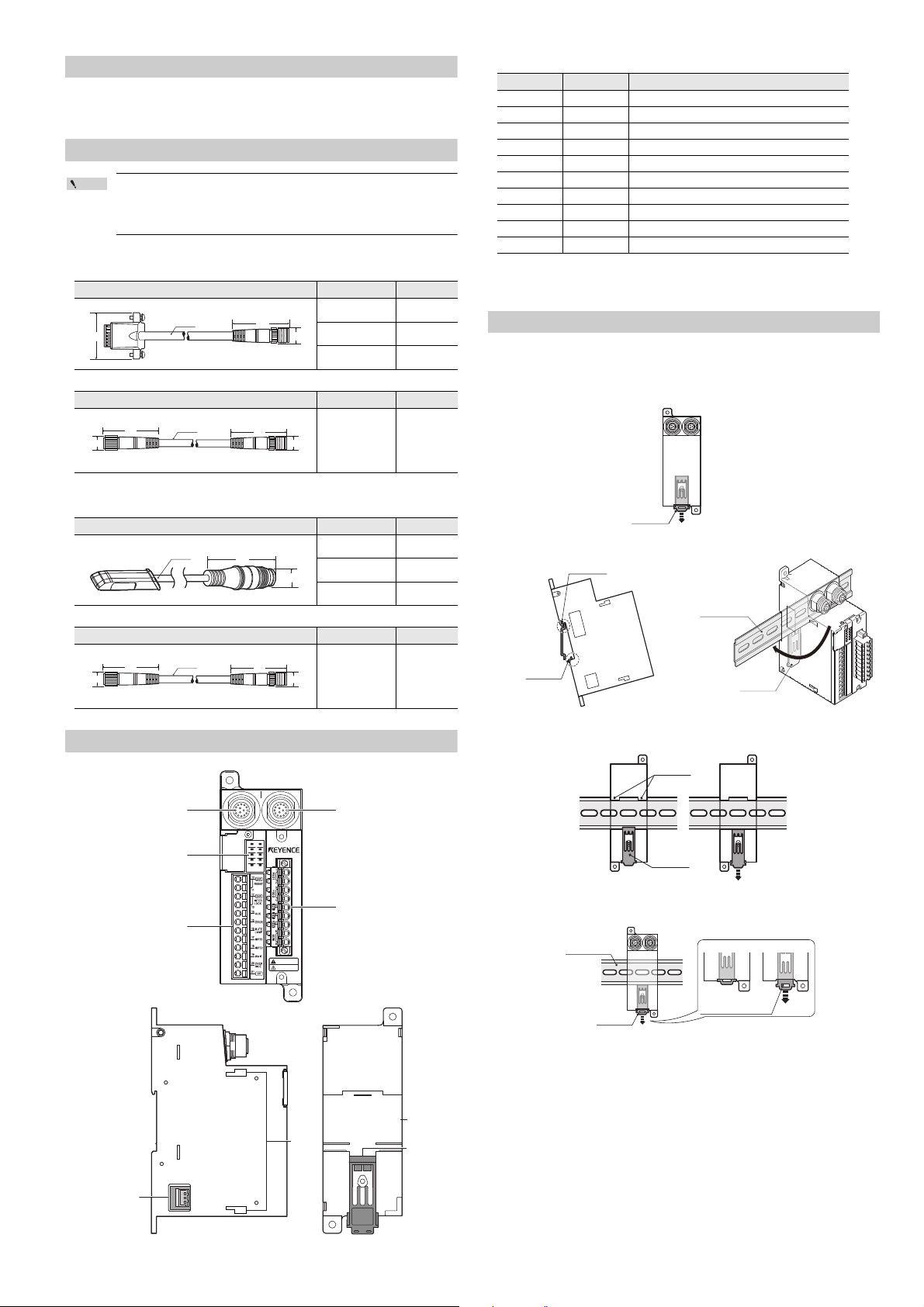

Wiring Example

Point

K3

K3

F1

F2

K4

K3

K4

M

K4

Relay output terminal block

Name No.

FSD1

1

2

FSD2

3

4

FE 5

0V

*1

6

24V (input)

*1

7

EDM input (24V)

*2

8

EDM input

*2

9

PLC IN

P1

L1

S2

S3

P2

S1

Signal input/output terminal block

Name No.

Reset input (24V)

*3

10

Reset input

*3

11

Interlock selection input (24V) 12

Interlock selection input 13

AUX output 14

Error output 15

Muting lamp output 16

Muting input 1 17

Muting input 2 18

Wait input 19

Override input 20

0V 21

Black

Black

Blue

Brown

Brown

Blue

K3

K3

F1

F2

K4

K3

K4

M

K4

Relay output terminal block

Name No.

FSD1

1

2

FSD2

3

4

Not used 5

0V

*1

6

24V (input)

*1

7

EDM input (24V)

*2

8

EDM input

*2

9

Relay output terminal block

Relay board for the GL-T11R

2xφ4.2

(112)

35.9 49.8

3.5

83.8

(100.7) (16)

37

135

124

23

23

11

48

Replacing the Relay Board

■ GL-R Series

This wiring example illustrates the case of the following settings.

• Interlock function: Used (Manual reset mode)

• EDM function: Used

• Muting function: Used

The relay used for the FSD of the GL-T11R can be replaced without rewiring the connection terminal.

1 Prepare the relay board for the GL-T11R (OP-87682).

2 Turn off the power to the GL-T11R and all the devices connected to the

GL-T11R.

3 Loosen the two terminal replacement screws, and remove the relay

output terminal block.

4 Loosen the two relay board replacement screws and remove the cur-

rent relay board from the GL-T11R.

■ GL-S Series

■ Meaning of symbols

F1, F2 : Fuse

K3, K4 : External device (Magnet contactor, etc.)

S1 : Switch for reset (N.O.)

S2 : Switch for wait input (N.O.)

S3 : Switch for override (N.O.)

L1 : Muting lamp (Incandescent lamp or LED lamp)

P1, P2 : Muting device

(Photoelectric sensors with built-in amplifiers such as PZ (PNP

output), etc.)

M : 3-phase motor

PLC : For monitoring use. This is a NON-SAFETY RELATED system.

S2 and PLC are NON-SAFETY RELATED systems.

*1 No. 6 and No. 7 do not need to be wired when the SL-U2 is connected.

*2 If it is not necessary to perform error detection for K3 and K4 (when

EDM input is not used), use the shorting bar between No. 8 and No.

9.

*3 In the auto reset mode, use the shorting bar between No. 10 and No.

11. To release the error condition of a GL-R through the reset input,

connect a N.C. switch.

• For the GL-R Series, the functions are switched to different

functions according to the settings configured with the "Safety

Device Configurator" PC setting software. When the settings

are changed, check the wiring referring to the internal circuit

diagram in the previous section.

• The total electric current supplied from each 24 V terminal of

the GL-T11R must be 95 mA or less.

GL-T11R-IM-E

5 Install the new relay board in the GL-T11R and tighten the relay board

replacement screws. (Recommended tightening torque: 0.3 N•m)

6 Attach the relay output terminal block to the relay board and tighten the

terminal replacement screws. (Recommended tightening torque: 0.3

N•m)

7 Check the operation according to the checklist.

External Dimensions Diagram

6

Page 7

Specifications

OSSD of GL

FSD

10ms 32ms

Specified

period of time

0.3 s*

Error condition

OSSD of GL

FSD

EDM input

10ms 32ms 10ms

Specified

period of time

0.3 s*

Response Time for Combination Between GL and GL-T11R

Model GL-T11R

Supported model GL-R Series/GL-S Series

Relay

output

Response

time

Life-span

Non-safety

output

External

input

Power

source

Environment

resistance

Material Main unit case Polycarbonate

Weight Approx. 310 g

Applicable

standard

FSD1, 2

ON → OFF GL + 10 ms

OFF → ON GL + 32 ms

Electrical lifespan

AUX output*

Error output*

Muting lamp

1

output*

EDM input [GL-R Series]

Wait input*

Reset input*

Muting input 1,

1

2*

Override input*

Power source

voltage

Consumption

current

Enclosure rating

Pollution degree 2

Overvoltage

category

Ambient

temperature

Storage

ambient

temperature

Ambient

humidity

Storage

ambient

humidity

Elevation 2000 m or less

Vibration

Shock

EMS EN61496-1, UL61496-1, IEC61496-1

EMC

EMI

Safety

250 V AC, 6 A 30 V DC, 6 A (Resistance load)

240 V AC, 2 A (COSφ=0.3) (Inductive load)

24 V DC, 1 A (COSφ=0.3) (Inductive load)

100,000 cycles or more with 250 V AC, 6 A

(Open/Close frequency 20 times/min.)

100,000 cycles or more with 30 V DC, 6 A

(Open/Close frequency 20 times/min.)

500,000 cycles or more with 250 V AC, 1 A

(Open/Close frequency 30 times/min.)

500,000 cycles or more with 30 V DC, 1 A

(Open/Close frequency 30 times/min.)

AC15: 100,000 cycles or more with 240 V AC, 2 A

(Open/Close frequency 20 times/min., cosφ=0.3)

DC13: 100,000 cycles or more with 24 V DC, 1 A

(Open/Close frequency 20 times/min., L/R=48ms)

1

1

1

1

(Connectable to PNP/NPN input device)*

50mA or less, Residual voltage 2.5 V or less

Incandescent lamp (24 V DC, 1 to 5.5 W)

Connectable to LED lamp (Load current 10 to 230 mA)

ON voltage: [Power source voltage - 5 V] to

[Power source voltage]

OFF voltage: Open or 0 to 3 V

Short-circuit current: Approx. 2.5 mA

(EDM input only approx. 10 mA)

[GL-S Series]

1

Short-circuit current (EDM input): Approx. 1 mA

24 V DC ± 10%, Ripple (P-P) 10% or less, Class2

100mA or less (at 24 V DC, GL-T11R alone)

IP20 (IEC60529) Install inside a control panel of

10 to 55 Hz 0.7 mm compound amplitude,

20 sweeps each in X, Y, and Z directions

100 m/s

1,000 times each in X, Y, and Z directions

EN55011 ClassA, FCC Part15B ClassA,

EN61496-1, UL61496-1, IEC61496-1 (Type 4 ESPE)

Resistance load

Resistance load

Resistance load

Resistance load

Inductive load

Inductive load

Transistor output

(When the cable length

between GL-R and GL-T11R is 5 m)

IP54 or greater

-10 to +55 °C (No freezing)

-25 to 60 °C (No freezing)

15 to 85% RH (No condensation)

15 to 95% RH

2

(Approx. 10 G) 16 ms pulse,

ICES-003 ClassA

EN ISO13849-1: 2008 (Cat4 PL e)

UL508, EN50178

2

* For operations of each function and detailed specifications, refer to the

"GL-R User’s Manual" or "GL-S User’s Manual".

*1 When connected to the GL-S Series, these functions cannot be used.

*2 The output operation is the same as that when the PNP output type

cable is used.

The following are the response times for the combination between GL and

GL-T11R.

A) Maximum response time when the FSD goes to the OFF state after the

GL detects an interruption in the detection zone.

The response time* (ON to OFF) of the GL connected to GL-T11R +

10 ms

B) Maximum response time when the FSD goes back to the ON state after

the GL detects no interruption in the detection zone.

The response time* (OFF to ON) of the GL connected to GL-T11R +

32 ms

* For details on the response time, refer to the GL-R user's manual

or the GL-S user's manual.

The following are examples of total response times in cases where the

GL-T11R is connected to the GL with the series-connection cable.

When connecting the GL-R32H (32 beam axes), GL-R24H (24 beam

axes), and GL-R12L

unit is 7.9 ms, 7.0 ms, and 6.6 ms respectively

(12 beam axes) in series, the response time of each

. The response time (ON to

OFF) is 7.9 + 7.0 + 6.6 - 4.2* + 10 = 27.3 ms and the response time (OFF

to ON) is 50.6 + 49.3 + 48.7 - 84* + 32 = 96.6 ms

* When calculating the response time of the GL-R using two con-

nected sub units, sum the response time of all three GL-R and

then subtract 4.2 ms (ON to OFF) or 84 ms (OFF to ON). For more

detail, refer to the GL-R user’s manual.

■ Time Chart

FSD

ON

OFF

ON

OFF

When EDM input is used

ON

OFF

ON

OFF

ON

OFF

(1) The normal operation continues because FSD operates within the per-

missible time (0.3 sec.) according to the OSSD operation of GL.

(2) The GL enters an error condition as "EDM error" because FSD does not

operates within the permissible time (0.3 sec.).

* For the GL-R Series, the time can be changed using the Safety Device

Configurator.

7

GL-T11R-IM-E

Page 8

Checklist

2013

12530E 1053-1 96M12530

When the installation and wiring of the GL and the GL-T11R are completed,

the responsible personnel must verify operations in accordance with the

checklist shown below. The following checklist covers the minimum requirements for the GL-T11R. The check items required may vary depending on the

machine where the GL-T11R is installed, and the laws, rules, regulations and

standards in the country or region in which the GL-T11R will be used. KEYENCE strongly recommends that other necessary check items should be

added by the responsible personnel for the use of the GL-T11R.

This checklist only lists the items related to the GL-T11R, so refer to the GL-R

instruction manual or the GL-S instruction manual to create a checklist that

also covers the GL.

■ Inspection after installation

When the installation of the GL-T11R is completed, the responsible personnel

must verify the operation of the GL-T11R in accordance with the checklist

shown below.

The checklist below covers the minimum requirements for the GL-T11R. The

check items required may vary depending on the machine on which the GLT11R is installed and the laws, rules, regulations and standards in the country

or region in which the GL-T11R will be used. KEYENCE strongly recommends

that other necessary check items should be added by the responsible personnel for the use of the GL-T11R.

(1) Pre-check for installation condition

❑

The machine on which the GL-T11R is installed can stop when it

receives the FSD output from the GL-T11R.

❑

The interlock reset mechanisms (such as switches) are installed so that

the whole hazardous zone can be checked by the responsible personnel and that operations of the interlock reset mechanisms are not possible within the hazardous zone.

❑

The GL-T11R is installed in an enclosure of IP54 or greater.

❑

The DIN rail is fixed on the control panel (enclosure) with adequate

strength to support the weight of the GL-T11R.

❑

Space is ensured around the GL-T11R for ventilation or heat release as

specified in this manual.

❑

The installation of the GL-T11R fulfills conditions specified in this

instruction manual and the requirements of the laws, rules, regulations

and standards in the country or region where the GL-T11R is used.

(2) Pre-check for wiring

❑

To supply power to the GL-T11R, the SL-U2 power supply recommended by KEYENCE is used, or a different 24 VDC power supply that

satisfies the power supply conditions specified in this instruction manual is used.

❑

The cable for transmitter (Gray M14 connector end) is connected to the

cable connector for transmitter, and the cable for receiver (Black M14

connector end) is connected to the cable connector for receiver.

❑

The safety related machine control system is established by using both

of the safety outputs provided on the GL-T11R.

❑

The polarity is correct for connection to the power supply.

❑

The wait input is not connected to the output from the safety components comprising a part of the safety related machine control system.

❑

Non-safety related outputs are not used as a part of the safety related

control system.

❑

Wiring is performed in a manner that complies with the requirements of

Clause 9.4.3 in IEC60204-1:2005 in order for the protection against

malopeation due to earth fault.

■ Regular (periodical) inspection

The responsible personnel must perform a regular inspection.

It is recommended to perform a regular inspection at least once every six

months.

Note that the following inspection items comprise only a bare minimum

inspection. KEYENCE Corporation strongly recommends including the necessary checking items into this checklist based on the judgment of the responsible personnel since additional criteria may be necessary depending on both

the machine to which the GL-T11R is installed and the laws, rules, regulations

and standards in the country or region in which the GL-T11R is used/installed.

The result of this inspection must be kept on record along with the machine

log.

❑

Conductive contamination does not occur due to oil or dust adherence.

❑

The response time of the whole machine control system is below the

design value and normal.

❑

Devices with a finite lifetime such as switches, relays or contactors are

still functional.

❑

Wiring is correctly performed and no modifications or connection

changes are made that may adversely affect the safety related system

of the equipment.

❑

There are no disconnected or loose wires on the connection terminal.

❑

The open/close cycle of the FSD is within the lifespan. If needed,

replace it by referring to "Replacing the Relay Board".

GL-T11R-IM-E

■ Inspection as needed

In the following cases, perform inspection for all items.

• When the unit is installed for the first time

• When the parts and wires relating to this system are replaced or changed

• When an abnormal operation is found

WARRANTIES AND DISCLAIMERS

(1) KEYENCE warrants the Products to be free of defects in materials and

workmanship for a period of one (1) year from the date of shipment. If any

models or samples were shown to Buyer, such models or samples were used

merely to illustrate the general type and quality of the Products and not to

represent that the Products would necessarily conform to said models or

samples. Any Products found to be defective must be shipped to KEYENCE

with all shipping costs paid by Buyer or offered to KEYENCE for inspection

and examination. Upon examination by KEYENCE, KEYENCE, at its sole

option, will refund the purchase price of, or repair or replace at no charge any

Products found to be defective. This warranty does not apply to any defects

resulting from any action of Buyer, including but not limited to improper

installation, improper interfacing, improper repair, unauthorized modification,

misapplication and mishandling, such as exposure to excessive current, heat,

coldness, moisture, vibration or outdoors air. Components which wear are not

warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various Products.

They are only suggestions, and it is Buyer's responsibility to ascertain the

fitness of the Products for Buyer’s intended use. KEYENCE will not be

responsible for any damages that may result from the use of the Products.

(3) The Products and any samples ("Products/Samples") supplied to Buyer are not

to be used internally in humans, for human transpor tation, as safety devices or

fail-safe systems, unless their written specifications state otherwise. Should any

Products/Samples be used in such a manner or misused in any way, KEYENCE

assumes no responsibility, and additionally Buyer will indemnify KEYENCE and

hold KEYENCE harmless from any liability or damage whatsoever arising out of

any misuse of the Products/Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE

PROVIDED WITH NO OTHER WARRANTIES WHATSOEVER. ALL

EXPRESS, IMPLIED, AND STATUTORY WARRANTIES, INCLUDING,

WITHOUT LIMITATION, THE WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF

PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED.

IN NO EVENT SHALL KEYENCE AND ITS AFFILIATED ENTITIES BE

LIABLE TO ANY PERSON OR ENTITY FOR ANY DIRECT, INDIRECT,

INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES

(INCLUDING, WITHOUT LIMITATION, ANY DAMAGES RESULTING FROM

LOSS OF USE, BUSINESS INTERRUPTION, LOSS OF INFORMATION,

LOSS OR INACCURACY OF DATA, LOSS OF PROFITS, LOSS OF

SAVINGS, THE COST OF PROCUREMENT OF SUBSTITUTED GOODS,

SERVICES OR TECHNOLOGIES, OR FOR ANY MATTER ARISING OUT

OF OR IN CONNECTION WITH THE USE OR INABILITY TO USE THE

PRODUCTS, EVEN IF KEYENCE OR ONE OF ITS AFFILIATED ENTITIES

WAS ADVISED OF A POSSIBLE THIRD PARTY’S CLAIM FOR DAMAGES

OR ANY OTHER CLAIM AGAINST BUYER. In some jurisdictions, some of

the foregoing warranty disclaimers or damage limitations may not apply.

BUYER'S TRANSFER OBLIGATIONS:

If the Products/Samples purchased by Buyer are to be resold or delivered to a

third party, Buyer must provide such third party with a copy of this document,

all specifications, manuals, catalogs, leaflets and written information provided

to Buyer pertaining to the Products/Samples.

E 1101-3

Document Control No. 981BE151-01

8

Loading...

Loading...