Page 1

Safety Light Curtain for Press Machines

GL-RHG Series

User's Manual

237GB

No.981BE124-01

Page 2

Introduction

This user's manual describes handling, operation, and precautionary information for the GL-RHG Series

Safety Light Curtain for Press Machines ("GL-RHG").

Read this user's manual thoroughly before operating the GL-RHG in order to understand the device features, and keep this user's manual readily available for reference. Ensure that the end user of this product

receives this manual.

Symbols

The following symbols alert you to important messages. Be sure to read these messages carefully.

DANGER

NOTICE

Point

Reference

It indicates a hazardous situation which, if not avoided, will result in death or serious injury.

It indicates a situation which, if not avoided, could result in product damage as well as

property damage.

It indicates additional information on proper operation.

It indicates tips for better understanding or useful information.

Indicates reference pages in this or another manual.

Page 3

Safety Information for GL-RHG Series

General precautions

• You must verify that the GL-RHG is operating correctly in terms of functionality and

performance before the start of machine and the operation of the GL-RHG.

• KEYENCE does not guarantee the function or performance of the GL-RHG if it is used in a

manner that differs from the GL-RHG specifications contained in this user's manual or if

the GL-RHG is modified by the customer.

• When using the GL-RHG to protect machine operators against a hazard or hazardous

zone or using the GL-RHG as a safety component for any purpose, always follow the

applicable requirements of the laws, rules, regulations and standards in the country or

region where the GL-RHG is used. For such regulations, you should directly contact the

regulatory agency responsible for occupational safety and health in your country or

region.

• Depending on the type of machine on which the GL-RHG is to be installed, there may be

special safety regulations related to the use, installation, maintenance, and operation of

the safety component. In such a case, you must fulfill such safety regulations. The

responsible personnel must install the GL-RHG in strict compliance with such safety

regulations.

• The responsible personnel must do the training to the assigned personnel for the correct

DANGER

use, installation, maintenance, and operation of the GL-RHG. "Machine operators" refers

to personnel who have received appropriate training from the responsible personnel and

are qualified to operate the machine correctly.

• Machine operators must have specialized training for the GL-RHG, and they must

understand and fulfill the safety regulations in the country or region in which they are

using the GL-RHG.

• When the GL-RHG fails to operate, machine operators must immediately stop the use of

the machine and the GL-RHG and report this fact to the responsible personnel.

• The GL-RHG is designed with the assumption that it would be correctly installed in

accordance with the installation procedures described in this user's manual and correctly

operated according to the instructions in this user's manual. You must perform an

appropriate installation of the GL-RHG after performing a sufficient risk assessment for

the target machine.

• Be sure to absolutely confirm that there is nobody in the hazardous zone, before you

remove the GL-RHG from the machine for replacement or disposal.

• When disposing the GL-RHG, always follow the applicable requirements of the laws,

rules, regulations and standards in the country or region where the GL-RHG is used.

• The GL-RHG should be processed as an industrial waste product when being disposed.

GL-RHG-M-NO0-E

237GB

1

Page 4

Precaution on use

Item Specifications

Ty pe

Press machine equipped with a quick-stopping device and restart prevention mechanism

Pressure capability 50,000 kN or less

Emergency stop time 500 ms or less

Length of strokes Less than (protection height – Die height)

Size range of metal die Less than the bolster width

Item Specifications

Ty pe

Shearing machine (paper cutting machine) equipped with a quick-stopping

mechanism and restart prevention mechanism

Cut thickness 200 mm or less

Cut width 5,000 mm or less

Blade length 5,500 mm or less

Emergency stop time 500 ms or less

Operators

• In order to operate the GL-RHG correctly, the responsible personnel and machine

operators must fulfill all of the procedures described in this user's manual.

DANGER

Environment of use

DANGER

• No person other than the responsible personnel and machine operators should be

allowed to install or test the GL-RHG.

• When performing electrical wiring, always fulfill the electrical standards and regulations

for the country or region in which the GL-RHG is used.

• Do not use the GL-RHG in an environment (temperature, humidity, interfering light, etc.)

that does not conform to the specifications contained in this user's manual.

• Be sure to confirm that the GL-RHG keeps normal operation when electromagnetic

radiation is generated by wireless devices. (If you use wireless devices such as cellular

phones or transceivers in the vicinity of the GL-RHG.)

• The GL-RHG is not designed to be explosion-proof. Never use it in the presence of

flammable or explosive gases or elements.

•

Be sure to confirm no deterioration in product quality if you use the GL-RHG in the presence

of substances, such as heavy smoke, particulate matter, or corrosive chemical agents.

• Do not install the GL-RHG in areas where the GL-RHG is exposed to intense interference

light such as direct sunlight, and direct or indirect light from an inverter-type fluorescent

lamp (rapid-start type lamp, high-frequency operation type lamp, etc).

• Be sure to absolutely confirm that there is nobody in the hazardous zone before the

override function is activated. Failure to follow this warning results in significant harm to

the machine operators, including serious injury or death.

Targ et m ach ine

• When using GL-RHG as a press machine safety device in Japan, press machines other

than those fulfilling the following specifications cannot be used.

•

When using GL-RHG as a shearing machine (paper cutting machine) safety device in Japan, shearing

machines (paper cutting machines) other than those fulfilling the following specifications cannot be used.

DANGER

• The machine on which the GL-RHG is to be installed must be susceptible to an

emergency stop at all operating points during its operation cycle. Do not use the GL-RHG

for machines with irregular stop times.

• Do not use the GL-RHG for power presses equipped with full-revolution clutches.

• The GL-RHG cannot be used as a PSDI because it does not fulfill the requirements of

OSHA 1910.217(h). Refer to OSHA 1910.217 for the PSDI mode.

• Do not use the GL-RHG to control (stop forward motion, etc.) trains, cars and other

transportation vehicles, aircraft, equipment for use in space, medical devices, or nuclear

power generation systems.

• The GL-RHG is designed to protect people or objects from going into/approaching

protective zone against machine's hazard or hazardous zone. It cannot provide protection

2

against objects or materials that are expelled from the machine's hazard or hazardous

zone, so you must establish additional safety measures such as installing safeguards

when there is the possibility of such projectiles.

GL-RHG-M-NO0-E

Page 5

Installation

DANGER

• The GL-RHG must be installed only after ensuring the minimum safety distance between

the GL-RHG and the hazardous zone or hazard as established by the applicable

regulations in the country or region in which the GL-RHG is used. (e.g. EN ISO13855 (ISO

13855) in EU countries)

• Choose locations for the installation of the GL-RHG transmitters and receivers so that

they are not subject to the effects of light reflected from glossy surfaces in the area.

• The GL-RHG must be installed so that the machine operator is able to go into or approach

the hazardous zone or hazards only by passing through the detection zone of the

GL-RHG. Strictly avoid installation that allows the machine operator or a part of the

machine operator's body to go into or approach the hazardous zone or hazards without

passing through the protective zone of the GL-RHG or to remain in position between the

protective zone of the GL-RHG and the hazardous zone or hazard.

• You must always perform the pre-check tests after installing the GL-RHG in accordance

with the pre-check test procedures, such as items specified in this user's manual, in order

to verify that the test pieces can be detected in all of the protective zones.

• Muting is a function to allow a temporary automatic suspension of the GL-RHG safety

functions while the GL-RHG is receiving a signal from muting devices (such as sensors or

switches). Therefore, additional safety measures are required for the machine on which

the GL-RHG is installed in order to ensure safety while the muting is activated.

• Muting devices, the installation of those devices and the procedure to activate the muting

function must fulfill the conditions specified in this user's manual and the requirements

of the laws, rules, regulations and standards in the country or region in which the

GL-RHG and those devices are used. Failure to follow this warning may result in

significant harm to the machine operators, including serious injury or death.

• When you install muting devices (such as sensors or switches) for muting, the following

conditions must be fulfilled.

(1) Muting devices must be installed so that the muting cannot be activated if the

hazardous zone of the machine is in an unsafe condition or cycle.

(2) Muting devices must be installed so that the muting cannot be activated even if

the personnel is accidentally approaching the detection zone of the GL-RHG.

• The muting device must be installed such that only responsible personnel have access to

that device to change the installation or orientation. Special tools must be required to

ensure that only responsible personnel are capable of installation, orientation or change

of muting device.

• Only the responsible personnel may be allowed to install or wire the devices to activate

the muting function.

• The installation of a muting lamp may be required by the laws, rules, regulations, and

standards in the country or region in which the GL-RHG is used if you apply the muting

function. It depends on the machine application and/or the result of your risk assessment.

If it is necessary for you to provide a muting lamp, you must fulfill the requirements

because you are fully responsible for installation of the muting lamp.

• The installation of the indication for override may be required by the laws, rules,

regulations, and standards in the country or region in which the GL-RHG is used if you

ap

ply the ov

your risk assessment. If it is necessary for you to provide the indication for override, you

must fulfill the requirements because you are fully responsible for installation of the

indication for override.

• The customer is fully responsible for complying with the requirements for muting and/or

override. Those who use muting and/or override must fulfill all of the requirements related

to muting and/or override. KEYENCE accepts NO responsibility and NO liability for any

damage or any injury due to the unauthorized installation, usage or maintenance, which

are not specified in this user's manual, and/or due to noncompliance with the laws, rules,

regulations and standards in the country or region in which the GL-RHG is used.

erride function. It depends on the machine application and/or the result of

GL-RHG-M-NO0-E

3

Page 6

DANGER

• When the reduced resolution function is applied, the detection capability varies

according to your configuration. Make sure to accurately calculate the safety distance

according to the detection capability, and install the GL-RHG at a distance greater than or

equal to the minimum safety distance away from the hazardous zone or hazard. The

installation of additional safety measures, such as safeguarding, may be required if the

detection capability varies due to the configuration of reduced resolution. On your own

responsibility, you must perform the risk assessment based on your configuration of

reduced resolution in order to reduce the risk.

• When the fixed blanking function is applied, a hazardous clearance that is not protected

by the GL-RHG may be generated between the obstacle and the GL-RHG. You must install

an additional safety measure such as a safeguard for this clearance.

• The override is a function to allow a temporary manual suspension of the safety functions

of the GL-RHG. Therefore, additional safety measures are required for the whole machine

system on which the GL-RHG is installed in order to ensure safety while the override is

activated.

• Securely tighten mounting brackets and cable connectors used for the installation of the

GL-RHG in accordance with the torque values specified in this user's manual.

• When optical synchronization system is applied and Channel A or B is configured, the

response time is longer than the other case. Make sure to accurately calculate the safety

distance according to the response time, and install the GL-RHG at a distance greater

than or equal to the minimum safety distance away from the hazardous zone or hazard.

Circuit design and wiring

DANGER

• Always turn off the power to the GL-RHG when performing electrical wiring.

• You must fulfill the electrical standards and regulations in the country or region in which

the GL-RHG is being used when you perform the electrical wiring.

• To avoid the risk of electric shock, do not connect any of the GL-RHG inputs to DC power

sources outside of the range of 24 V DC + 20% or to any AC power source.

• To avoid the risk of electric shock, be sure that any hazardous voltage is isolated from all

wiring of the GL-RHG with reinforced insulation or double insulation.

• In order to fulfill the requirements in IEC61496-1, UL61496-1, EN61496-1 and UL508, the

power supply for the GL-RHG must fulfill the conditions listed below.

(a) A rated output voltage of 24 V DC (SELV, Overvoltage Category ) within ±20%.

(b) Double insulation or reinforced insulation between the primary and secondary

circuits.

(c) Output holding time of 20 ms or more.

(d) A power supply must fulfill the requirements of the electrical safety and

electromagnetic compatibility (EMC) regulations or standards in all countries

and/or regions where the GL-RHG is used.

(e) A secondary circuit of power supply (output) must fulfill the requirements for

Class 2 Circuits or Limited Voltage/Current Circuits specified in UL508, if the GL-

R is used in the United States or Canada.

• Do not install the electric wiring of the GL-RHG together with or in parallel with any highvoltage electrical or power lines.

• Both OSSD outputs provided on the GL-RHG must be used to establish a safety-related

machine control system. Establishing a safety-related machine control system with just one

of the OSSD outputs cannot stop the machine due to an OSSD output malfunction and may

result in significant harm to the machine operators, including serious injury or death.

• When using PNP output type cables, do not cause a short-circuit between the OSSD and

+24 V. Otherwise, the OSSDs keep staying at the ON-state and it causes a dangerous

situation.

4

GL-RHG-M-NO0-E

Page 7

DANGER

• When using PNP output type cables, be sure to connect the load between the OSSD and 0 V

to avoid a dangerous situation. If the load is incorrectly connected between the OSSD and

+24 V, the logic of the OSSD operation will be reversed and the OSSD will change to an ON

state when the GL-RHG detects an interruption in the protective zone. This is a dangerous

situation.

• When using NPN output type cables, do not cause a short-circuit between the OSSD and 0 V.

Otherwise, the OSSDs keep staying at the ON-state and it causes a dangerous situation.

• When using an NPN output type cable, be sure to connect the load between the OSSD and

+24 V to avoid a dangerous situation. If the load is incorrectly connected between the

OSSD and 0 V, the logic of the OSSD operation will be reversed and the OSSD will change

to an ON state when the GL-RHG detects the interruption in the protective zone. This is a

dangerous situation.

• Regardless of whether the cables are PNP or NPN type, you must fulfill the requirements

of Clause 9.4.3 in IEC60204-1: 2005 for protection against maloperation due to earth fault.

• All outputs, other than OSSDs, are not allowed to be used as safety outputs for a safetyrelated machine control systems. Usage of these functions as safety outputs may result

in significant harm to the machine operators, including serious injury or death.

• The wait input is not allowed to be connected to the output from any components

comprising a part of the safety-related machine control system. If the wait input is

connected to the output of a safety component it may result in significant harm to the

machine operators, including serious injury or death.

• The transmitter and receiver cables must be within the lengths specified in this user's

manual. Usage of cables longer than the specified length may cause the improper

operation of safety functions and may cause a dangerous situation.

Testing and maintenance

• You must always perform the pre-check test in accordance with the checklist, after

maintenance, adjustment or alignment of the target machine or the GL-RHG and before

the machine startup.

• If the GL-RHG does not operate properly when you perform a pre-check test in

accordance with the checklist specified in this user's manual, do not operate the

DANGER

machine.

• You must periodically examine the machine to verify that all brakes, other stop

mechanisms, and control devices operate reliably and correctly in addition to checking

the GL-RHG.

• The responsible personnel must perform maintenance procedures as specified in this

user's manual to ensure safety to the machine and GL-RHG.

GL-RHG-M-NO0-E

5

Page 8

Precautions on Regulations and Standards

CE Marking

Keyence Corporation has confirmed that this product complies with the essential requirements of the

applicable EC Directive, based on the following specifications.

Be sure to consider the following specifications when using this product in a member state of the European Union.

Machinery Directive (2006/42/EC)

The GL-RHG is a safety component as established by the European Union's Machinery Directive

(2006/42/EC) Annex V. The GL-RHG complies with the following EN Standards and has been certified

by TÜV SÜD Product Service GmbH.

• EN61496-1 Type 4 ESPE

• EN61496-2 Type 4 AOPD

• EN50178

• EN61508, Part 1 to 4 SIL3

• EN62061 SIL CL3

• EN ISO13849-1 Category 4, PL e

EMC Directive (2004/108/EC)

The GL-RHG complies with the following EN Standards

• EN55011 Class A

• EN61496-1 Type 4 ESPE

These specifications do not give any guarantee that the end-product with this product incorporated

complies with the essential requirements of the EMC Directive. The manufacturer of the end-product is

solely responsible for the compliance of the end-product itself according to the EMC Directive.

UL Certificate and North American Regulations

The GL-RHG complies with the following North American and international standards and has received

UL certification and C-UL certification. (CCN: NIPF/NIPF7, File No: E184802)

• UL61496-1 Type 4 ESPE

• UL61496-2 Type 4 AOPD

• UL508

• UL1998

The GL-RHG also complies with the following North American regulations.

• FCC Part 15B Class A Digital Device

• ICES-003 Class A Digital Apparatus

Type examination based on the Chinese standard GB 4584 "压力机用光电保护装置

技术条件"

GL-RHG has passed the type examination based on the Chinese standard GB 4584 "压力机用光电保护装

置技术条件".

• Quality test certificate certificate number: No.20120929

However, if the response time (ON OFF) exceeds 20ms, this product cannot be used as a certified

product. The following two conditions may cause the response time to exceed 20 ms.

• Using GL-RHG in the optical synchronization system and selecting channel A or B

• Make series connection of GL-RHG

"Wiring System" (page 2-2)

"Series connection" (page 2-3)

"Response time (OSSD)" (page 7-5)

6

GL-RHG-M-NO0-E

Page 9

Type examination for "press machine and shearing machine safety device"

GL-RHG has passed the "Type examination" based on the Industrial Safety and Health Law, Article 44-2.

• Type approval certificate number: TA548 (Press machine)

TA552 [Shearing machine (Paper cutting machine)]

Other standards

The GL-RHG has been designed in consideration of the following standards and regulations. For details

regarding the following standards, contact the third-party certification organization, such as UL or TÜV.

• EN60204-1

• EN692

• EN693

• OSHA 29 CFR 1910.212

• OSHA 29 CFR 1910.217

• ANSI B11.1 - B.11.19

• ANSI/RIA R15.06 - 1999

• SEMI S2

• "Guidelines for Comprehensive Safety Standards of Machinery", July 31, 2007, number 0731001

issued by Ministry of Health, Labor, and Welfare in Japan.

GL-RHG-M-NO0-E

7

Page 10

Software License Agreement

The use of [Safety Device Configurator, GL-R configurator, SL-V Configurator] (hereinafter referred to as

[this software]) is subject to the terms outlined in this software license agreement (hereinafter referred to

as [this agreement]) and to the customers consent to this agreement. The customer's use or duplication of

this software, in whole or in part, constitutes the customer's consent to enter into this agreement.

Article 1 (Usage Rights)

1 Contingent of the customer's compliance with the terms of this agreement, KEYENCE Corporation

(hereinafter referred to as KEYENCE) extends to the customer non-exclusive usage rights.

2 The customer may install this software without the limit of the number of the licenses, provided that

this software is used only in the same corporation in order to use our product you have purchased.

Article 2 (Limitations on Duplication)

The customer may make no more than 1 copy of this software for backup purposes only.

Article 3 (Prohibitions)

The customer is prohibited from doing the following with this software.

a. Additions or changes to any or all of the functions of this software. However, installation of updates

or new features provided by KEYENCE is expressly allowed.

b. Reverse compiling or reverse assembling of this software for the purposes of reverse engineering.

c. Sale, transfer, redistribution, license, rental or lease to the third party. This does not include

instances where permission has been obtained from KEYENCE in advance.

Article 4 (Copyright)

The copyrights of this software and all associated documentation are the property of KEYENCE.

Article 5 (Exemption of Liability)

KEYENCE shall not be held liable by the user or third party for any damages arising from the use of

the software.

Article 6 (Support)

Based on this agreement, KEYENCE agrees to provide the customer with technical support in

response to customer questions regarding this software. However, KEYENCE makes no guarantee

that the technical support offered will meet the customer's needs.

Article 7 (Termination of Agreement)

1 Should the customer destroy this software and any backup copies, this agreement will automatically

expire with the customer's cessation of use of this software.

2 KEYENCE reserves the right to unilaterally terminate this agreement should the customer violate

any of the terms of this agreement. In this instance, this software and all copies should be immedi-

ately returned to KEYENCE for destruction.

3 Should KEYENCE be caused damages by the customer's violation of this agreement, the customer

will compensate KEYENCE for those damages.

Article 8 (Basis in Law)

This agreement is to be adjudicated according to Japanese law.

8

GL-RHG-M-NO0-E

Page 11

Table of Contents

Introduction

Symbols

Safety Information for GL-RHG Series ............................................................................... 1

General precautions ....................................................................................................................... 1

Precaution on use ........................................................................................................................... 2

Testing and maintenance ............................................................................................................... 5

Precautions on Regulations and Standards ................................................................................... 6

Software License Agreement .............................................................................................. 8

Table of Contents ................................................................................................................. 9

Chapter 1 Before Use

1-1 Products ................................................................................................................... 1-2

Light curtain unit .......................................................................................................................... 1-2

Cables ......................................................................................................................................... 1-2

Cable protection pipe ................................................................................................................... 1-4

Mounting brackets ....................................................................................................................... 1-5

Antivibration bracket .................................................................................................................... 1-6

Software and Interface Unit ......................................................................................................... 1-7

Dedicated Safety Reley for the GL-R Series (Model: GL-T11R) ................................................. 1-7

1-2 Part Description ....................................................................................................... 1-8

Chapter 2 Functions and Features

2-1 Wiring System ......................................................................................................... 2-2

Wiring system .............................................................................................................................. 2-2

Series connection ........................................................................................................................ 2-3

2-2 Functions ................................................................................................................. 2-4

2-3 OSSD ........................................................................................................................2-5

2-4 External Device Monitoring (EDM Function) ........................................................ 2-6

Wiring .......................................................................................................................................... 2-6

Time chart .................................................................................................................................... 2-6

2-5 Temporary Suspension of Safety Function .......................................................... 2-7

Muting function ............................................................................................................................ 2-7

Devices used for muting function ................................................................................................ 2-8

Detailed operation ....................................................................................................................... 2-8

Example: Muting function with 2 muting devices (Sensors) ...................................................... 2-10

Example: Muting function with 4 muting devices ....................................................................... 2-13

Example: Muting function with 2 muting devices (Switches) ..................................................... 2-17

Override function ....................................................................................................................... 2-20

GL-RHG-M-NO0-E

2-6 Wait Input Function ............................................................................................... 2-22

2-7 Non Safety-Related Outputs ................................................................................. 2-23

AUX (Auxiliary) output (Receiver, red wire) ............................................................................... 2-23

Error output (Transmitter, black wire) ........................................................................................ 2-24

Muting lamp output (The red wire of the transmitter cable) ....................................................... 2-24

9

Page 12

Chapter 3 Installation to a Machine

3-1 Correct Installation Method .................................................................................... 3-2

Transmitter and receiver orientation ............................................................................................ 3-2

Mounting position ........................................................................................................................ 3-3

3-2 Safety Distances ...................................................................................................... 3-4

3-3 Light Interference Prevention Method ................................................................. 3-11

Light Interference Prevention Function ...................................................................................... 3-11

Series connection ...................................................................................................................... 3-11

Interference due to installation .................................................................................................. 3-12

3-4 Installation Distance from Glossy Surfaces ....................................................... 3-13

3-5 Cable Installation ................................................................................................... 3-14

Overview .................................................................................................................................... 3-14

Cable connection to the lower part of the GL-RHG (The unit connection cable and extension cable)

Cable connection to the upper part of the GL-RHG (The series connection cable) .................. 3-15

3-6 Attaching the Cable Protection Pipe ................................................................... 3-16

3-7 Mounting Brackets ................................................................................................ 3-17

Adjustable angle mounting bracket (GL-RB01/GL-RB02) ......................................................... 3-17

Straight mounting bracket (GL-RB11) / L-shaped mounting bracket (GL-RB12) ...................... 3-18

No dead zone mounting bracket (GL-RB21) ............................................................................. 3-19

Antivibration bracket for the adjustable angle mounting bracket (GL-RB32) ............................. 3-20

Antivibration bracket for the straight mounting bracket (GL-RB31) ........................................... 3-21

..... 3-15

3-8 Optical Alignment .................................................................................................. 3-22

Ensure the following prior to optical alignment .......................................................................... 3-22

Alignment procedure ................................................................................................................. 3-22

Chapter 4 Wiring

4-1 Precautions on Wiring and Power Supply ............................................................ 4-2

Power supply ............................................................................................................................... 4-2

4-2 I/O Circuit Diagram .................................................................................................. 4-3

4-3 Cable Color and Pin Position ................................................................................. 4-4

Pin position .................................................................................................................................. 4-4

4-4 Cable Specification ................................................................................................. 4-6

4-5 Examples of Wiring ................................................................................................. 4-7

Symbols ....................................................................................................................................... 4-7

Optical synchronization system ................................................................................................... 4-8

One-line system ......................................................................................................................... 4-10

Wire synchronization system ..................................................................................................... 4-12

10

GL-RHG-M-NO0-E

Page 13

Chapter 5 Indicators

5-1 Function Indicators and 7-segment Display ......................................................... 5-2

Function indicators ...................................................................................................................... 5-2

7-segment display ....................................................................................................................... 5-3

5-2 Center Indicator ....................................................................................................... 5-4

Overview ...................................................................................................................................... 5-4

Changing the Indication Method for the Center indicator ............................................................ 5-4

Chapter 6

6-1 Before Use ............................................................................................................... 6-2

6-2 Installing the configuration software .................................................................... 6-3

6-3 Connecting the GL-RHG Main Unit and PC .......................................................... 6-5

6-4 Main Screen Part Names ........................................................................................ 6-7

6-5 Starting and Exiting the GL-R Configurator ......................................................... 6-9

Monitoring method Using the Configuration Software

About the configuration software ................................................................................................. 6-2

System Requirements ................................................................................................................. 6-2

Before Installation ........................................................................................................................ 6-3

Downloading the configuration Software ..................................................................................... 6-3

Installation Procedure .................................................................................................................. 6-4

Uninstalling each software ........................................................................................................... 6-4

Note for Windows Vista/7 ............................................................................................................ 6-4

Part Names .................................................................................................................................. 6-5

Connection Method ..................................................................................................................... 6-6

Menu bar ..................................................................................................................................... 6-7

Tool bar ....................................................................................................................................... 6-7

Tab .............................................................................................................................................. 6-8

Main area ..................................................................................................................................... 6-8

Starting the <GL-R Configurator> ................................................................................................ 6-9

Exiting the <GL-R Configurator> ............................................................................................... 6-11

GL-RHG-M-NO0-E

6-6 Saving the Configuration Data ............................................................................. 6-12

Saving the configuration data .................................................................................................... 6-12

Opening the saved configuration ............................................................................................... 6-12

6-7 Configuration Tab ................................................................................................. 6-13

6-8 Monitor Tab ........................................................................................................... 6-14

I/O monitoring ............................................................................................................................ 6-15

OFF information ......................................................................................................................... 6-16

Error information ........................................................................................................................ 6-17

6-9 Other Functions ..................................................................................................... 6-18

File (F) ....................................................................................................................................... 6-18

Communication (C) .................................................................................................................... 6-19

Log-in authentication (A) ........................................................................................................... 6-20

Language (L) ............................................................................................................................. 6-20

Help (H) ..................................................................................................................................... 6-20

11

Page 14

Chapter 7 Specifications and Dimensions

7-1 Nomenclature of Model Name ................................................................................ 7-2

Transmitter and receiver unit ....................................................................................................... 7-2

Cable ........................................................................................................................................... 7-2

7-2 Specifications .......................................................................................................... 7-3

Specifications .............................................................................................................................. 7-3

Response time (OSSD) ............................................................................................................... 7-5

Current consumption ................................................................................................................... 7-6

Weight ......................................................................................................................................... 7-6

Packaged items and materials .................................................................................................... 7-8

7-3 Dimensions ............................................................................................................ 7-10

GL-RHG unit .............................................................................................................................. 7-10

Adjustable angle mounting bracket (Model: GL-RB01) ............................................................. 7-11

Adjustable angle mounting bracket (Model: GL-RB02) ............................................................. 7-11

Straight mounting bracket (Model: GL-RB11) ........................................................................... 7-12

L-shaped mounting bracket (Model: GL-RB12) ......................................................................... 7-12

No dead zone mounting bracket (Model: GL-RB21) ................................................................. 7-13

Antivibration bracket for the adjustable angle mounting bracket (Model: GL-RB32) ................. 7-13

Antivibration bracket for the straight mounting bracket (Model: GL-RB31) ............................... 7-14

Interface unit (Model: GL-R1UB) ............................................................................................... 7-15

Appendix

1 Troubleshooting ......................................................................................................A-2

2 Checklist ..................................................................................................................A-7

Error condition .............................................................................................................................A-2

If the device is in the error condition ............................................................................................A-4

If the GL-RHG is not in an error condition ...................................................................................A-6

Checklist before operation ...........................................................................................................A-7

12

GL-RHG-M-NO0-E

Page 15

1

Before Use

1-1 Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Part Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

GL-RHG-M-NO1-E

1-1

Page 16

1

1-1 Products

Brown and blue: AWG22 (nominal cross-sectional area of 0.34 mm2)

Others: AWG26 (nominal cross-sectional area of 0.14 mm2)

Before Use

Light curtain unit

• GL-RHG transmitter (Transmitter) × 1

• GL-RHG receiver (Receiver) × 1

• Test piece Diameter of 25 mm, Length of 200 mm × 1

• Instruction manual

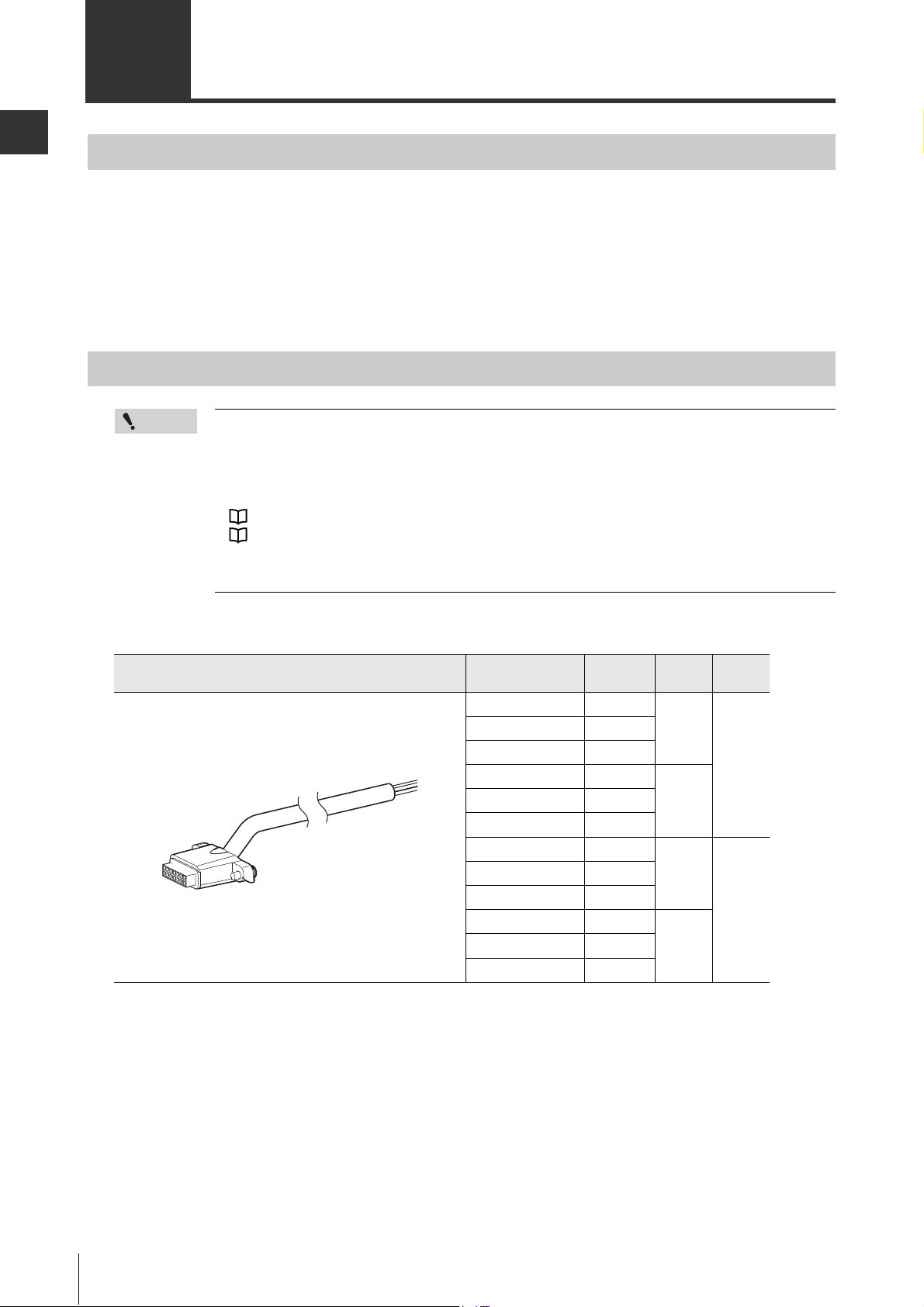

Cables

Point

• Each model is connected to one cable. Therefore, at least two cables are needed as a

system, one for the transmitter and another for the receiver.

• All cables can be used for both the transmitter and receiver.

• The combination of the wiring system and cable determines the functions that can be used.

Different types of cables can be used for the transmitter and receiver.

"2-1 Wiring System" (page 2-2)

"2-2 Functions" (page 2-4)

• Be sure to match the numbers of conductors (core wires) when using the unit connection

cable for extension use and the extension cable.

Unit connection cable

Shape Model

Number

of core

GL-RP5P 5

GL-RP5PS 7

GL-RP5PM 11

GL-RP10P 5

GL-RP10PM 11

GL-RP5N 5

GL-RP5NS 7

GL-RP5NM 11

GL-RP10N 5

GL-RP10NM 11

Length

5 m

10 mGL-RP10PS 7

5 m

10 mGL-RP10NS 7

Output

type

PNP

NPN

1-2

GL-RHG-M-NO1-E

Page 17

1

Unit connection cable (for extension use)

5-core: M12 connector (5 pins, male)

7-core: M12 connector (8 pins, male)

11-core: M14 connector (12 pins, male)

Brown and blue: AWG22 (nominal cross-sectional area of 0.34 mm2)

Others: AWG26 (nominal cross-sectional area of 0.14 mm2)

5-core: M12 connector (5 pins, female)

7-core: M12 connector (8 pins, female)

11-core: M14 connector (12 pins, female)

Two connectors are identical.

Direction of connection is not specified.

Used together with the extension cable.

1-1 Products

Before Use

Shape Model

GL-RPC03P 5

GL-RPC03PM 11

GL-RPC03N 5

GL-RPC03NM 11

Extension cable

Used together with the unit connection cable for extension use.

Shape Model

GL-RC5 5

GL-RC5S 7

GL-RC5M 11

GL-RC10 5

GL-RC10M 11

GL-RC20 5

GL-RC20M 11

Number

of core

Number

of core

Length

0.3 m

Length

5 m

10 mGL-RC10S 7

20 mGL-RC20S 7

Output

type

PNPGL-RPC03PS 7

NPNGL-RPC03NS 7

Output

type

PNP/

NPN

Series connection cable

Used for one-line system or series connection.

"Wiring system" (page 2-2)

"Series connection" (page 2-3)

Shape Model Length

GL-RS008 0.08 m

GL-RS015 0.15 m

GL-RS05 0.5 m

GL-RS1 1 m

GL-RS3 3 m

GL-RS5 5 m

GL-RS10 10 m

Output

type

PNP/

NPN

GL-RHG-M-NO1-E

1-3

Page 18

Before Use

1

DANGER

Outside diameter 20 mm, Inside diameter 15.3 mm Black

1-1 Products

Cable length specification

1. Optical synchronization system, wire synchronization system

The sum of the length of unit connection cable and extension cable must be 30 m or less. This limitation applies separately to the entire transmitter cable setup and the entire receiver cable setup. There

is no limitation for the total length of series connection cables when the GL-RHG is connected in

series.

2. One-line system

The sum of the length for all cables including unit connection cable, extension cable and series connection cable must be 30 m or less.

Cables must be within the lengths specified. Failure to follow this specification may cause

improper operation of safety functions, and may create a dangerous situation.

Cable protection pipe

Point

When using GL-RHG as a press machine and sharing machine (paper cutting machine) safety

device in Japan, make sure to use cable protection pipes.

"Attaching the Cable Protection Pipe" (page 3-16)

Shape Model Length

OP-87700 1 m

OP-87701 5 m

OP-87702 20 m

1-4

GL-RHG-M-NO1-E

Page 19

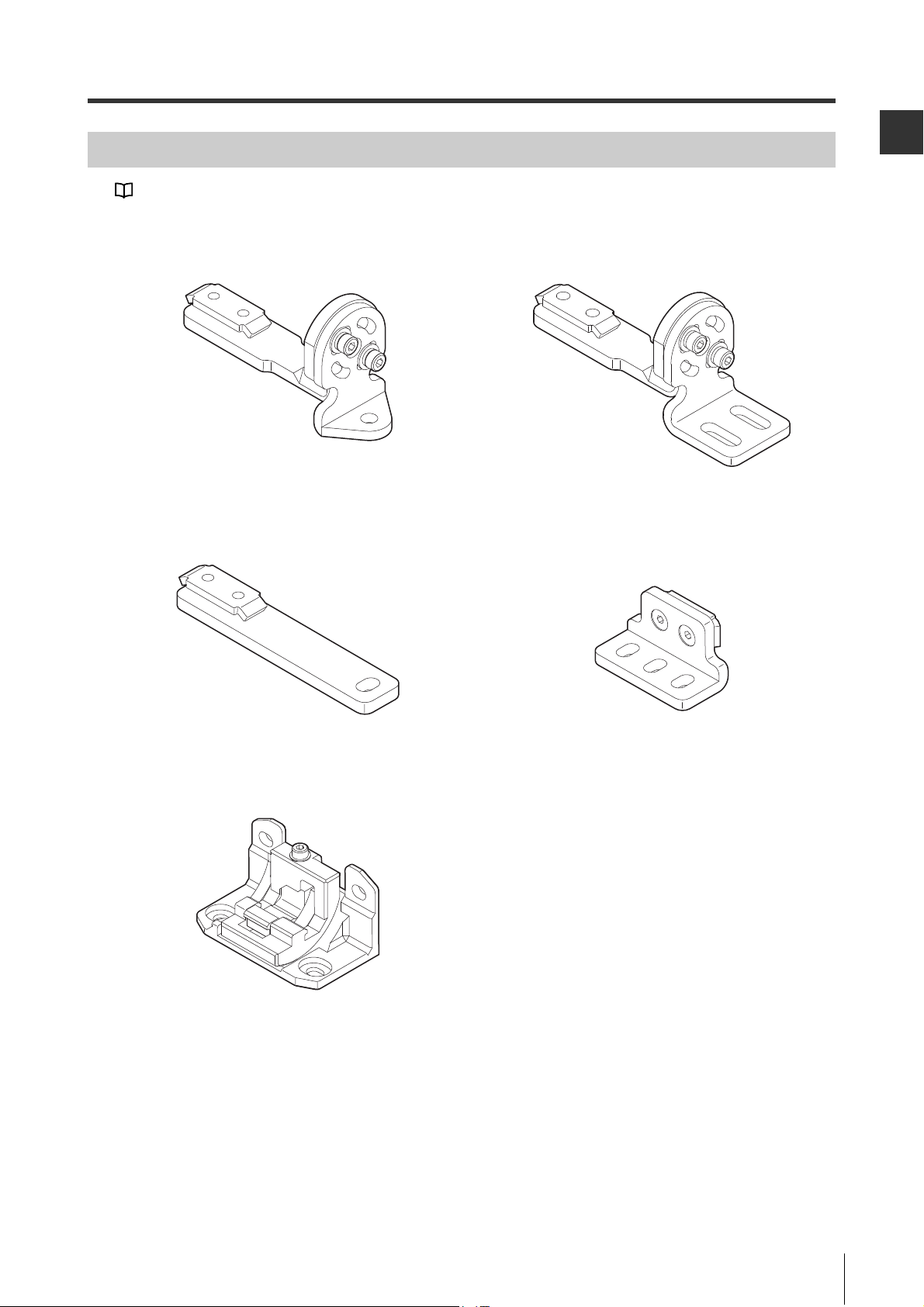

1-1 Products

1

Mounting brackets

"3-7 Mounting Brackets" (page 3-17)

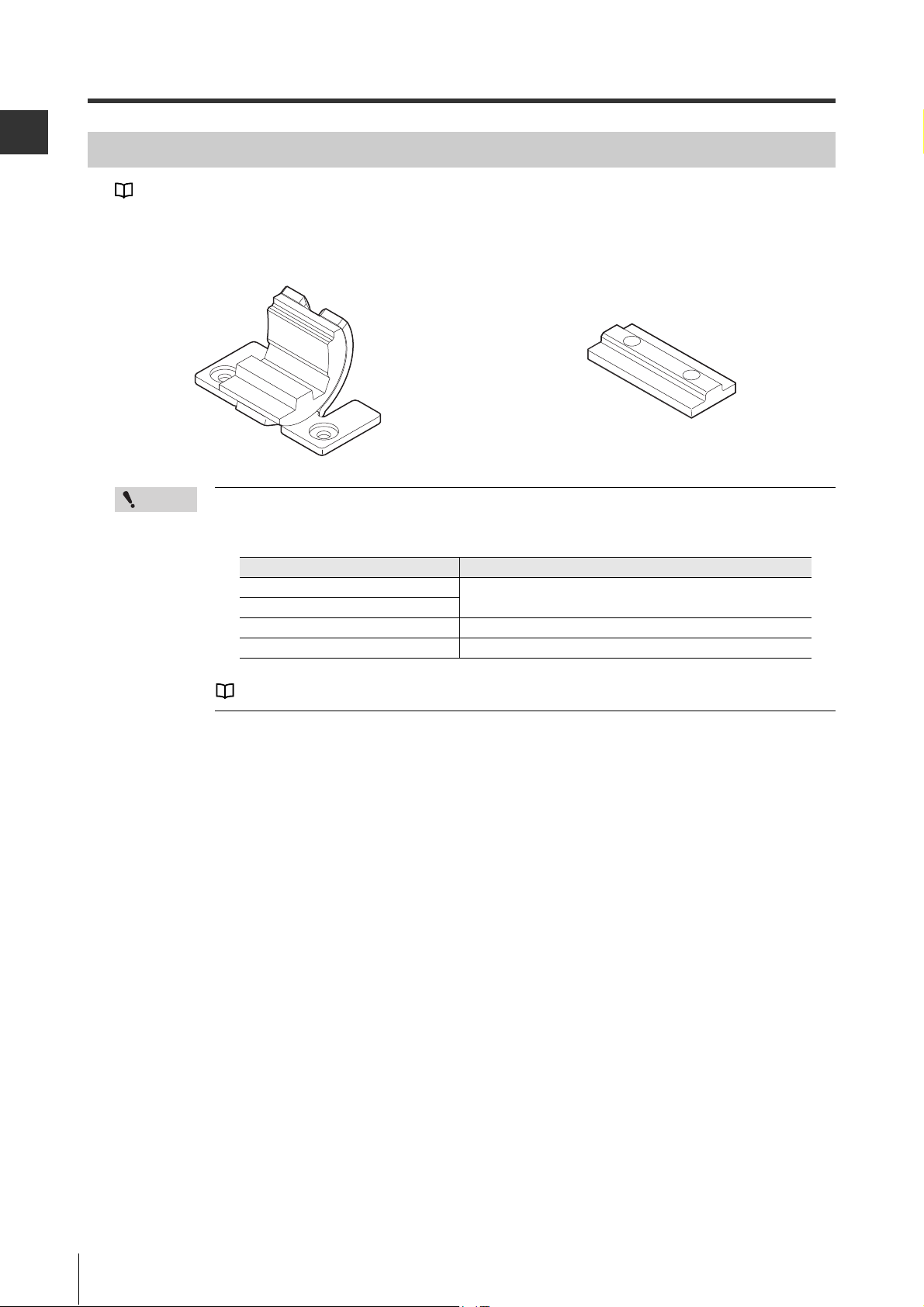

Adjustable angle mounting bracket

(GL-RB01)

Materials: SPHC

Straight mounting bracket

(GL-RB11)

Materials: SPHC

Adjustable angle mounting bracket

(GL-RB02)

Materials: SPHC

L-shaped mounting bracket

(GL-RB12)

Materials: SPHC

Before Use

No dead zone mounting bracket

(GL-RB21)

Materials: Zinc die-cast

GL-RHG-M-NO1-E

1-5

Page 20

1-1 Products

1

Before Use

Antivibration bracket

"3-7 Mounting Brackets" (page 3-17)

Antivibration bracket for the adjustable

angle mounting bracket (GL-RB32)

Materials: SPHC, EPDM

Point

If the length for a single GL-RHG unit is 1280 mm or greater, use the following antivibration

bracket additionally as an intermediate support bracket. The antivibration bracket must be

selected according to the mounting bracket and installed on the center of the GL-RHG unit.

Mounting bracket Antivibration bracket

Adjustable angle mounting bracket

No dead zone mounting bracket

Straight mounting bracket Antivibration bracket for the straight mounting bracket

L-shaped mounting bracket L-shaped mounting bracket

Antivibration bracket for the straight

mounting bracket (GL-RB31)

Materials: EPDM

Antivibration bracket for the adjustable angle mounting bracket

For more information about the mounting position of the antivibration brackets, see

"Dimensions" (page 7-10).

1-6

GL-RHG-M-NO1-E

Page 21

1-1 Products

1

Relay terminal to convert control output to contact relay. Connection

between GL-RHG and GL-T11R is made using the dedicated connector

cable.

Each I/O line of GL-RHG is assigned to each terminal block of GL-T11R.

For details, refer to "GL-T11R Instruction Manual".

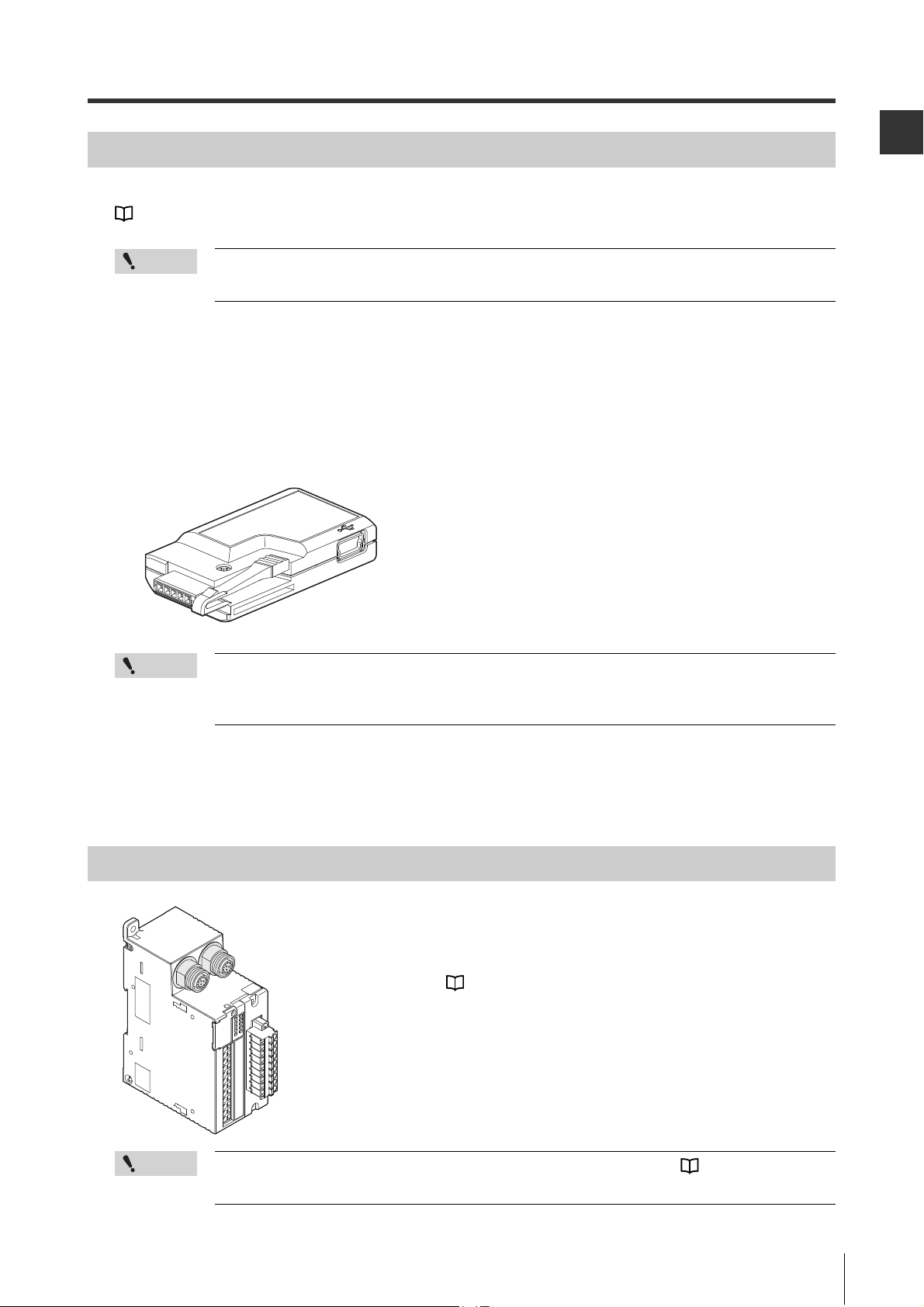

Software and Interface Unit

Required options when monitoring GL-RHG on a PC

"Chapter 6 Monitoring method Using the Configuration Software" (page 6-1)

Point

Configuration software <Safety Device Configurator>

The configuration software can be downloaded from the KEYENCE website.

http://www.keyence.com

If you can not access the internet, call the nearest KEYENCE office.

Interface unit (GL-R1UB)

Configuration data created by the configuration software cannot be uploaded to GL-RHG.

The configuration software can only monitor GL-RHG.

Before Use

Point

USB cable to connect the interface unit and the personal computer is not supplied. Please

acquire [A: miniB] type USB cable on yourself.

(You can also use the following option USB cables)

USB cable 2 m (OP-51580)

USB cable 5 m (OP-86941)

Dedicated Safety Reley for the GL-R Series (Model: GL-T11R)

Point

For connection between GL-RHG and GL-T11R, the cable shown on "Cables" (page 1-2)

cannot be used.

GL-RHG-M-NO1-E

1-7

Page 22

Before Use

1

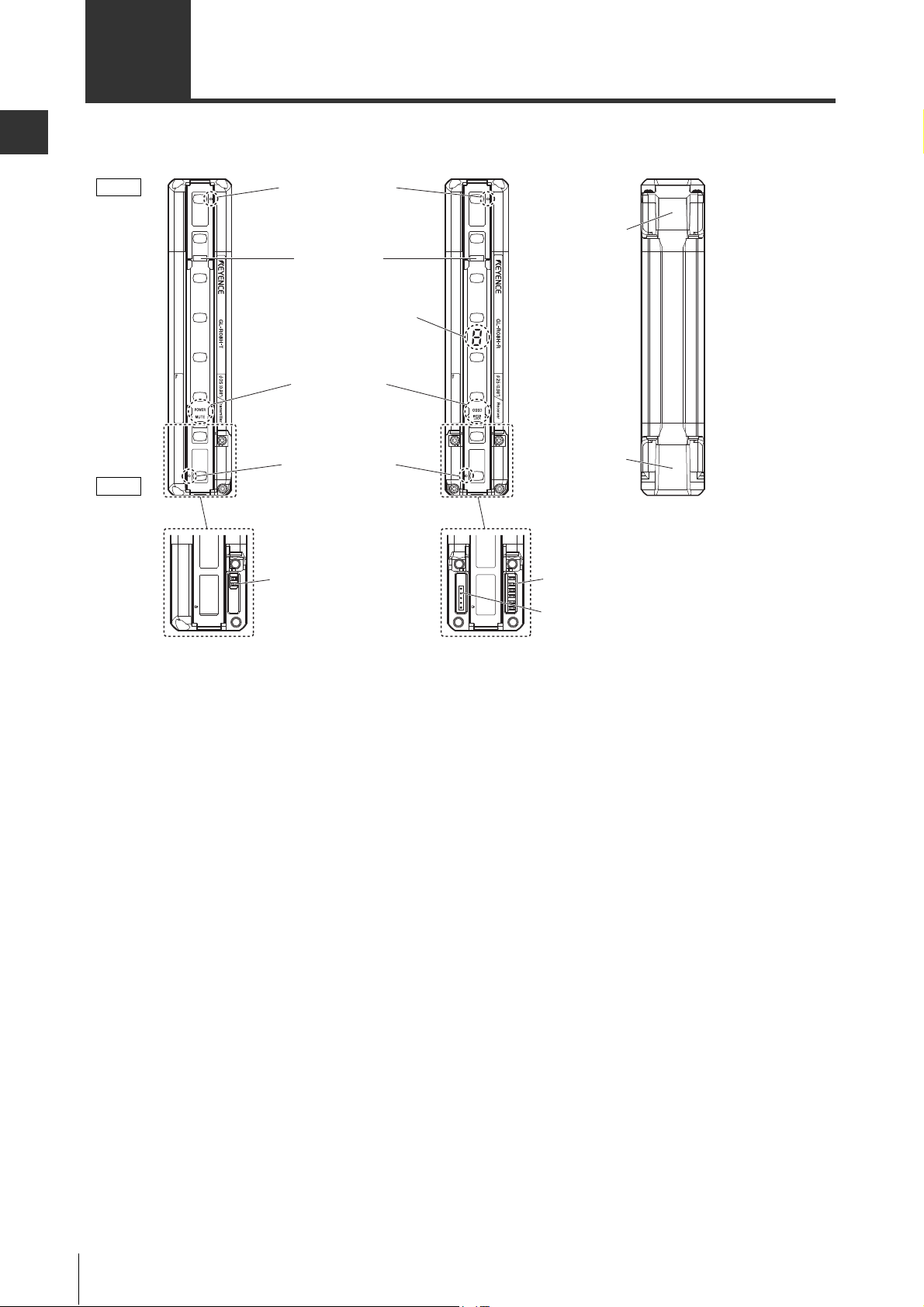

Transmitter Receiver Back side

End cover

Connector for the

unit connection

cable

Setting switch

(2 switches)

Setting switch

(6 switches)

Connector for the interface unit

(GL-R1UB)

To p

Beam center-line mark

Center Indicators

7-segment display

Function indicators

Beam center-line mark

Bottom

1-2 Part Description

*1 The side where the end cover has already been installed at shipment is the top side.

1-8

GL-RHG-M-NO1-E

Page 23

1

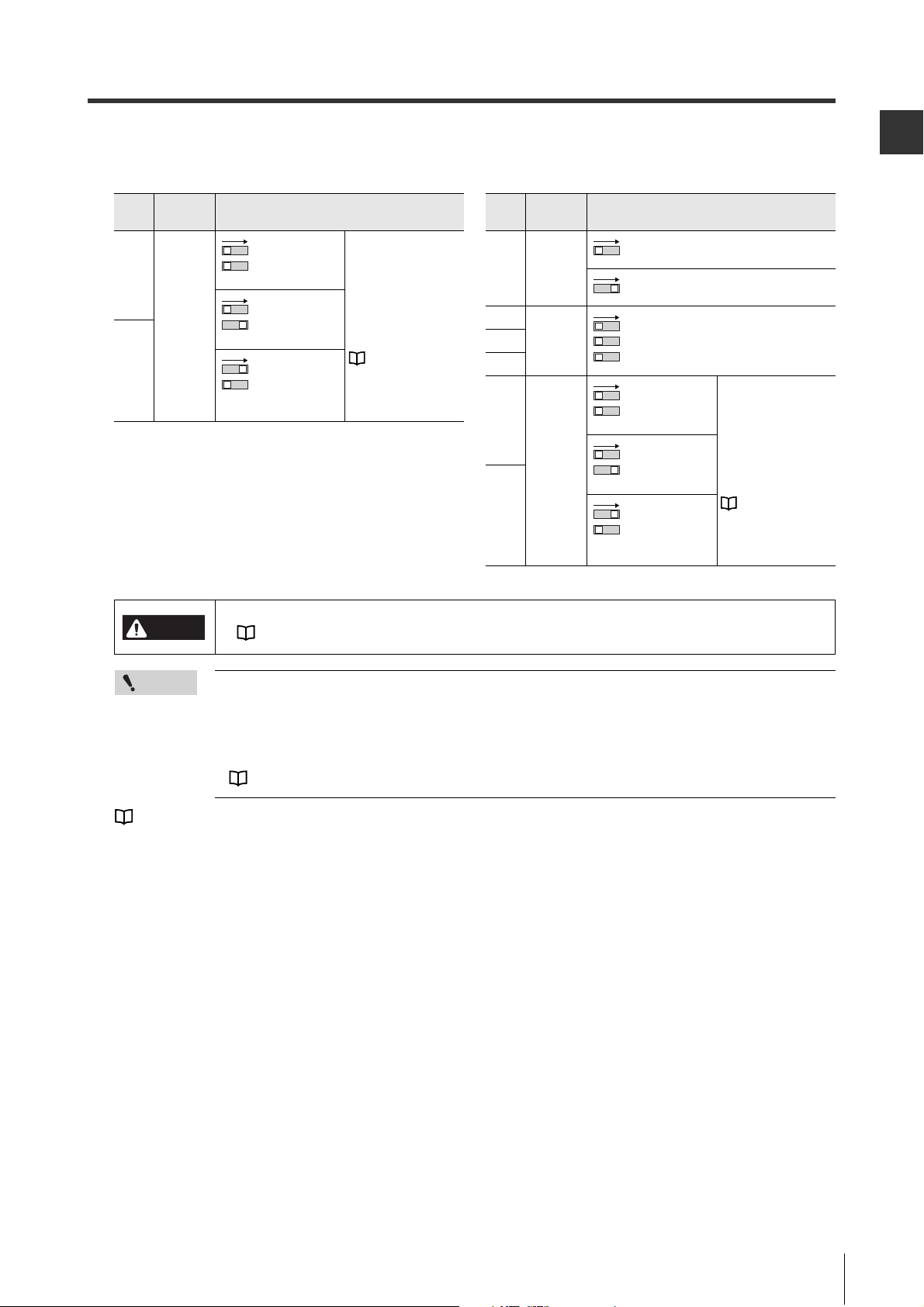

Setting switch

Transmitter Receiver

Switch

No.

Function Configuration

2

Channel

Channel 0

(Not applied)

(Default)

Use Channel for light

interference

prevention when

optical

synchronization

system is applied.

For details, refer to

"Light

Interference

Prevention Function"

(page 3-11)

Channel A

1

Channel B

2

Switch

No.

Function Configuration

6

Center

indicator

ON (Green) when all beam axes are

clear (Default).

OFF when all beam axes are clear.

(Green OFF)

5

Not in use

Do not change from the default

position.

4

3

2

Channel

Channel 0

(Not applied)

(Default)

Use Channel for light

interference

prevention when

optical

synchronization

system is applied.

For details, refer to

"Light

Interference

Prevention Function"

(page 3-11)

Channel A

1

Channel B

1-2 Part Description

Before Use

DANGER

Point

2

1

2

1

66

5

43

2

1

2

1

2

1

• The response time varies according to the configuration of Channel.

"Response time (OSSD)" (page 7-5)

• The configuration of the setting switch is applied when the power is supplied.

• When the GL-RHG is in series connection, the setting switch configuration of the main unit

is applied regardless of the setting switch configuration of the sub unit.

• When the GL-RHG operates in wire synchronization system, the setting switch for Channel

must be configured by default. Otherwise an error occurs.

"Wiring System" (page 2-2)

"Center Indicator" (page 5-4)

GL-RHG-M-NO1-E

1-9

Page 24

Before Use

1

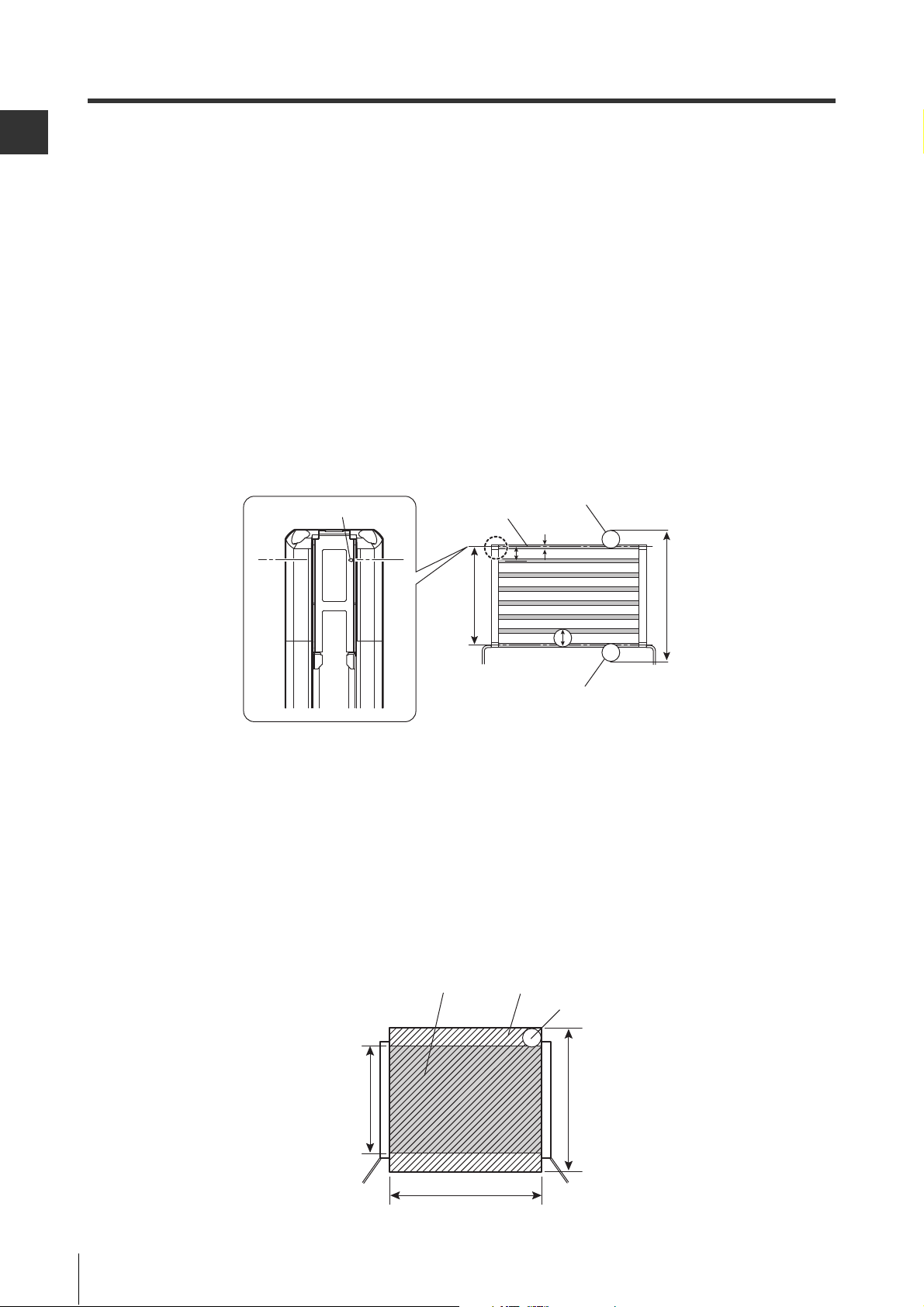

Beam center-line mark

Beam center-line

Specified target detection

capability (position A)

Specified target detection

capability (position B)

Protective

height

a: Beam axis spacing

b: Beam axis diameter

c: Detection capability

a

b

c

Detection

height

Protective zone Detection zone

Specified target detection capability

Protective height Detection height

Operating distance

1-2 Part Description

Beam center-line: An optical path joining the optical center of the emitting element on the transmitter to

the optical center of the corresponding receiving element on the receiver. The

GL-RHG must be installed so that the beam center-line mark on the transmitter and

that on the receiver face one another and are located at the same height.

Protective height: The height from the top beam center-line to the bottom beam center-line (length).

Detection height:

An object approaching the protective zone from the top of the protective height is first

detected at point A, which is the distance of the detection capability from the top of the

protective height. The equivalent position on the bottom is called point B. The height from

the top edge of the specified target detection capability that exists at point A to the bottom

edge of the specified target detection capability that exists at point B is called the "detec-

tion height".

The following calculation formula can be defined:

Detection height = "Protective height" + (2 × "specified target detection capability") –

"beam axis diameter".

*

Refer to the following diagram for an explanation of beam center-line, protective height and detection height.

Protective zone: The zone in which the specified target detection capability can be detected. The detec-

tion zone of the GL-RHG indicates a square area formed with the protective height and

the operating distance. When an object of the specified target detection capability is

present in this area, the light of the GL-RHG is blocked, and then the OSSD goes to

OFF state.

Detection zone:

The square area formed with the detection height and the operating distance, which is

broader than the protective zone. When an object of the specified target detection capabil-

ity is present in this area, the light of the

OFF state.

* Refer to the following diagram for protective zone and detection zone.

GL-RHG

is blocked, and then the OSSD goes to

1-10

GL-RHG-M-NO1-E

Page 25

2

Functions and Features

2-1 Wiring System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-3 OSSD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-4 External Device Monitoring (EDM Function). . . . . . . . . . . . 2-6

2-5 Temporary Suspension of Safety Function . . . . . . . . . . . . 2-7

2-6 Wait Input Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2-7 Non Safety-Related Outputs. . . . . . . . . . . . . . . . . . . . . . . . 2-23

GL-RHG-M-NO2-E

2-1

Page 26

2

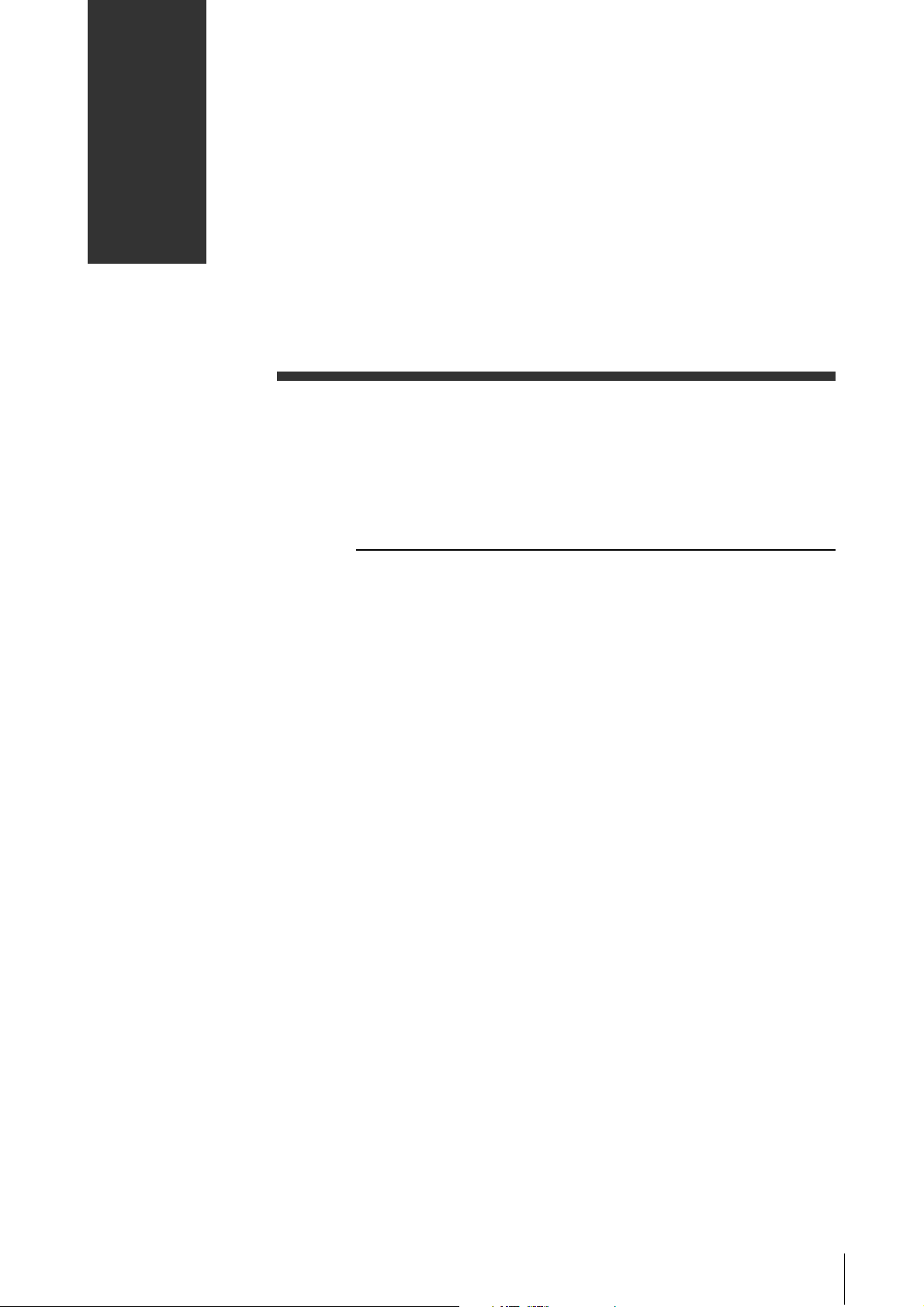

2-1 Wiring System

The following three types of wiring systems and the series connection are available in the GL-RHG series.

Functions and Features

Wiring system

Wiring system Optical synchronization system One-line system Wire synchronization system

Wiring diagram

Advantage

Limitation

Applicable

cable

Transmitter 5-core cable Series connection cable

Receiver

Transmitter Receiver Transmitter Receiver Transmitter Receiver

• Wiring is not needed between

the transmitter and receiver.

• The Transmitter and the

receiver can operate on

different power supplies.

• The input and output

functions on the transmitter

are not available.

• All indicators other than

"Power" are not available on

the transmitter.

5-core cable

11-core cable

• Simplified wiring.

• The unit connection cable is

not needed for the transmitter.

• The input and output

functions on the transmitter

are not available.

• There is a maximum limit for

the total length of cables.

5-core cable

11-core cable

• All functions of the GL-RHG

are available.

• Wiring is needed between the

transmitter and the receiver.

7-core cable

11-core cable

7-core cable

11-core cable

Reference

Available functions are determined according to the combination of the wiring system and cables.

Refer "2-2 Functions" (page 2-4) for the available function and select the wiring system and

cables.

"Cables" (page 1-2)

"2-2 Functions" (page 2-4)

"4-5 Examples of Wiring" (page 4-7)

2-2

GL-RHG-M-NO2-E

Page 27

2

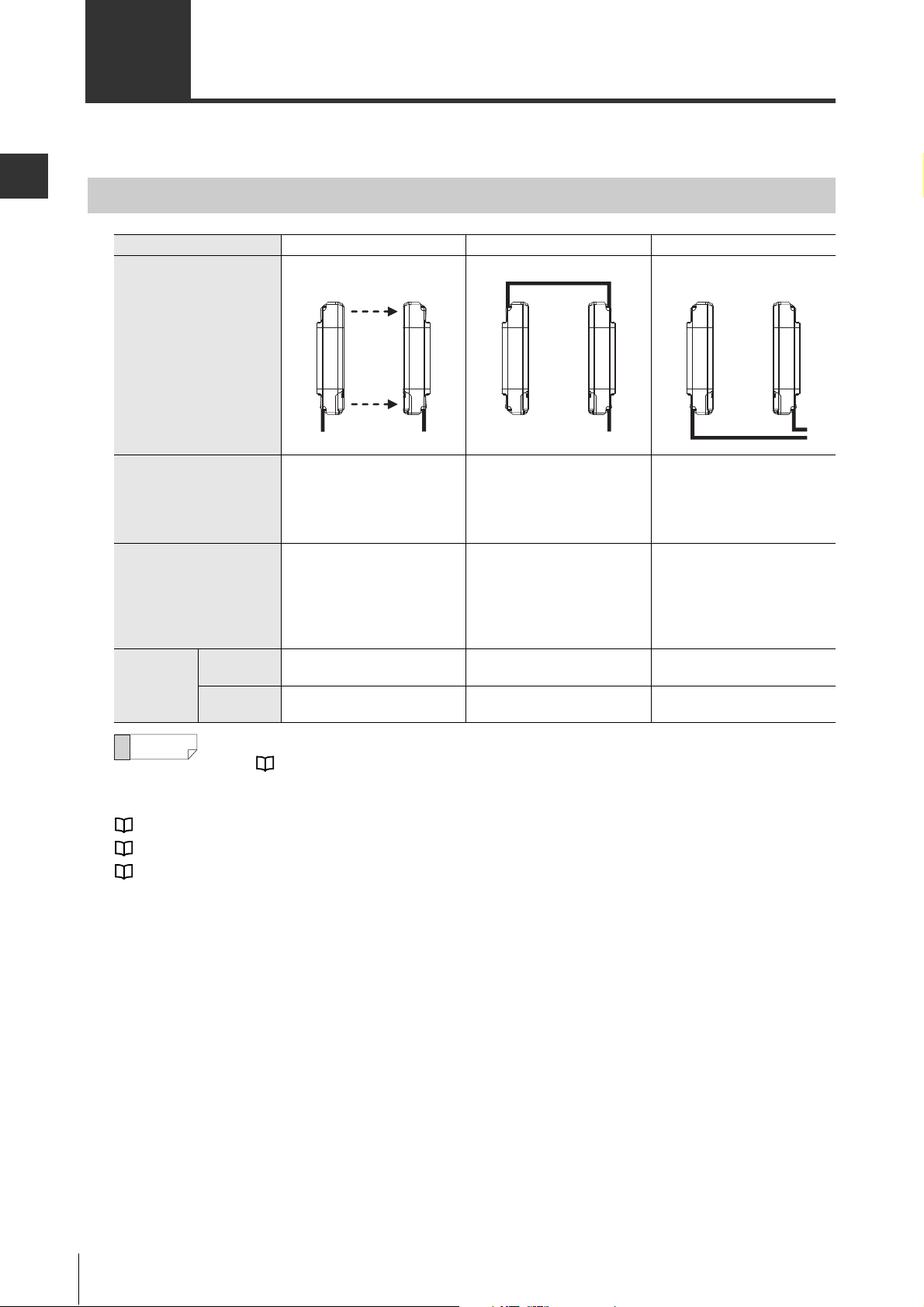

Series connection

Example of use with 3 units in series connection

Series connection

cable

Series connection

cable

Unit connection cable

Sub unit 2

Sub unit 1

Main unit

Transmitter Transmitter Transmitter

Receiver Receiver Receiver

2-1 Wiring System

Up to three GL-RHG units can be serially connected and used as a single light curtain. The series connection is available in all wiring system. The series connection cables that KEYENCE provides as an

optional part. ( "Series connection cable" (page 1-3))

Benefits

Functions and Features

• Prevents light interference between the connected GL-RHGs

• Simplified wiring

Limitations

• Up to 3 units

• Up to 240 total number of beam axes (Up to 228 total number of beam axes when channel A or B is set

by selecting the optical synchronization system)

• When one-line wiring system is applied, the total length of unit connection cable, extension cable and

series connection cables must be 30 m or less.

"1-2 Part Description" (page 1-8)

"4-4 Cable Specification" (page 4-6)

Point

• Series connection is required for secure light interference prevention. When not connecting

the GL-RHG units in series, install the units by referring to "Light Interference

Prevention Method" (page 3-11)

• If the response time (ON OFF) exceeds 20 ms, this unit cannot be used as a certified

product based on the Chinese standard GB 4584 "压力机用光电保护装置技术条件".

"Response time (OSSD)" (page 7-5)

GL-RHG-M-NO2-E

2-3

Page 28

2

2-2 Functions

The wiring system and the type of cable used with the GL-RHG determine the functions that can be used.

Functions and Features

Wiring system

Cable

combination

Available

function

: Available without the configuration software

: Available with the configuration software

Output a signal when an error occurs. Error output function 2-24

Output a signal for monitoring by the PLC. AUX output function 2-23

Suspend the GL-RHG's safety functions temporarily while the workpiece is passing

through the detection area.

Suspend the GL-RHG's safety functions temporarily in order to activate the machine

while the workpiece remains in the detection area.

Separate the power supplies for the transmitter and receiver which are located far

away from each other.

Make sure whether the beam axes are optically aligned. Monitoring function 6-14

Cable for the transmitter 5-core

Cable for the receiver 5-core

OSSD output 2-5

AUX (auxiliary) output 2-23

Error output 2-24

Muting function 2-7

Muting lamp output 2-24

Override function 2-20

EDM function 2-6

Wait input 2-22

Reset input (for error) A-4

Channel configuration

(Light interference prevention

function)

Center indicator configuration 5-4

Monitoring function 6-14

Requirement Function Page

Optical

synchronization

11-core

3-11

One-line Wire synchronization

Series

connection

5-core

11-core

7-core 11-core

7-core

11-core

Muting function 2-7

Override function 2-20

Optical synchronization 2-2

7-core

11-core

Page

2-4

GL-RHG-M-NO2-E

Page 29

2

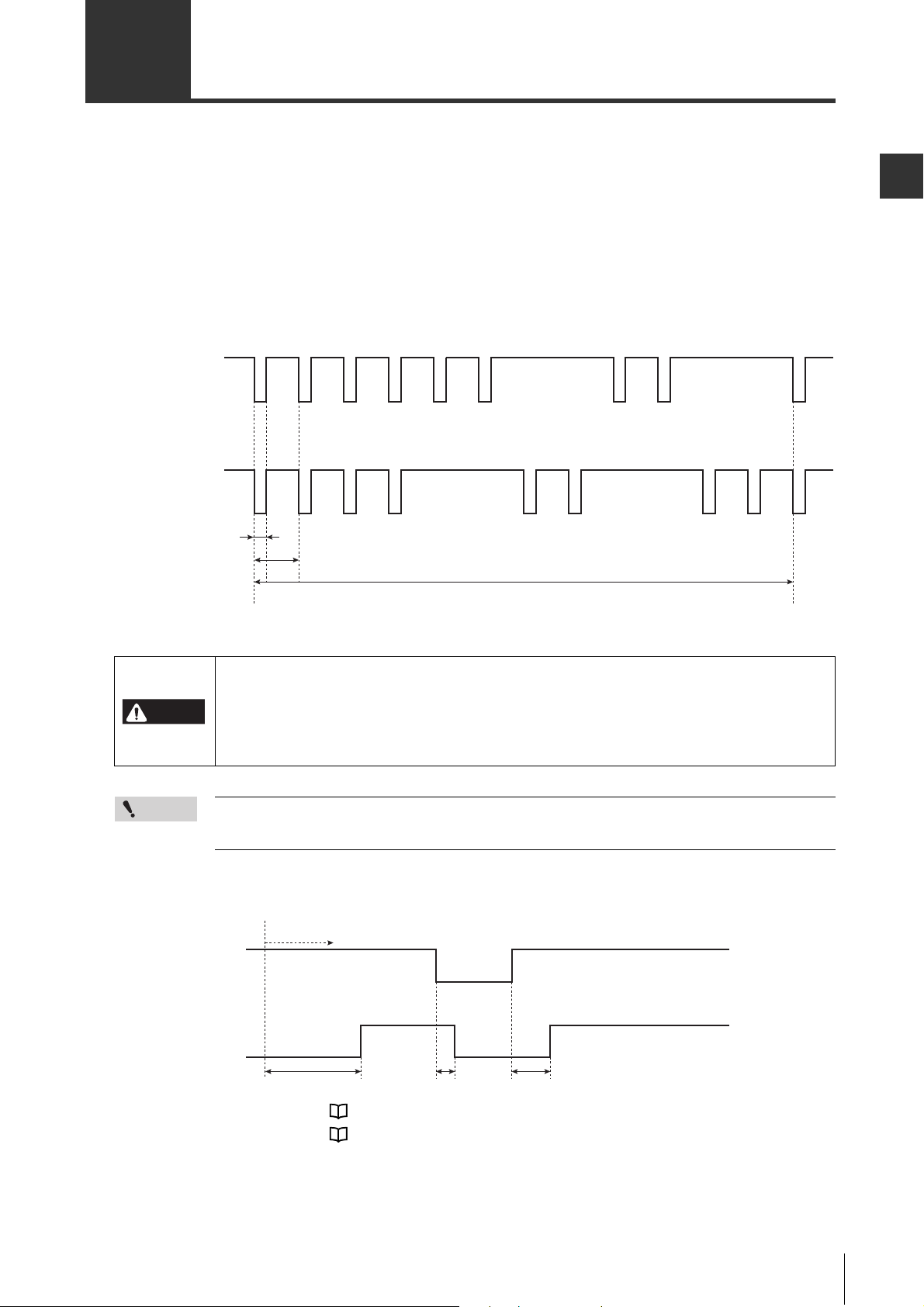

2-3 OSSD

OSSD 1

ON

640 to 940ms

A

OFF

A : 50 to 250s

B : 53 to 79ms

OSSD 2

ON

OFF

B

GL-R

OSSD

Clear

ON

OFF

Approx. 3 sec.

Start-up

Blocked

T1 T2

The OSSD is a safety-related control output. It connects to an external device (load), such as an FSD or

MPCE. The GL-RHG generates self-diagnosis signals on its internal control circuit to perform diagnostics

on the output circuit (OSSD). These signals periodically force the OSSD into a temporary OFF state when

no interruption exists in the protective zone.

If the internal control circuit receives a feed-back signal (OFF signal) based on the self-diagnosis, the

GL-RHG determines that its output circuit is operating normally. If this OFF signal is not returned to the

internal control circuit, the GL-RHG determines that there is a problem in its output circuit or wiring and

goes to the error condition.

Functions and Features

For the wiring between the GL-RHG and the safety-related part of a machine control system,

both OSSD 1 and OSSD 2 must always be wired to a safety-related part of the machine

DANGER

control system in order to ensure safety. If only one OSSD is wired to the safety-related part

of a machine control system, it results in significant harm to the machine operators,

including serious injury or death, if OSSD malfunction were to occur.

Point

The devices connected to the OSSD, such as safety relay or contactor, should not respond to

these temporary, self-diagnostic OFF-signals.

Time chart

T1: ON to OFF Response time "Response time (OSSD)" (page 7-5)

T2: OFF to ON Response time "Response time (OSSD)" (page 7-5)

GL-RHG-M-NO2-E

2-5

Page 30

Functions and Features

2

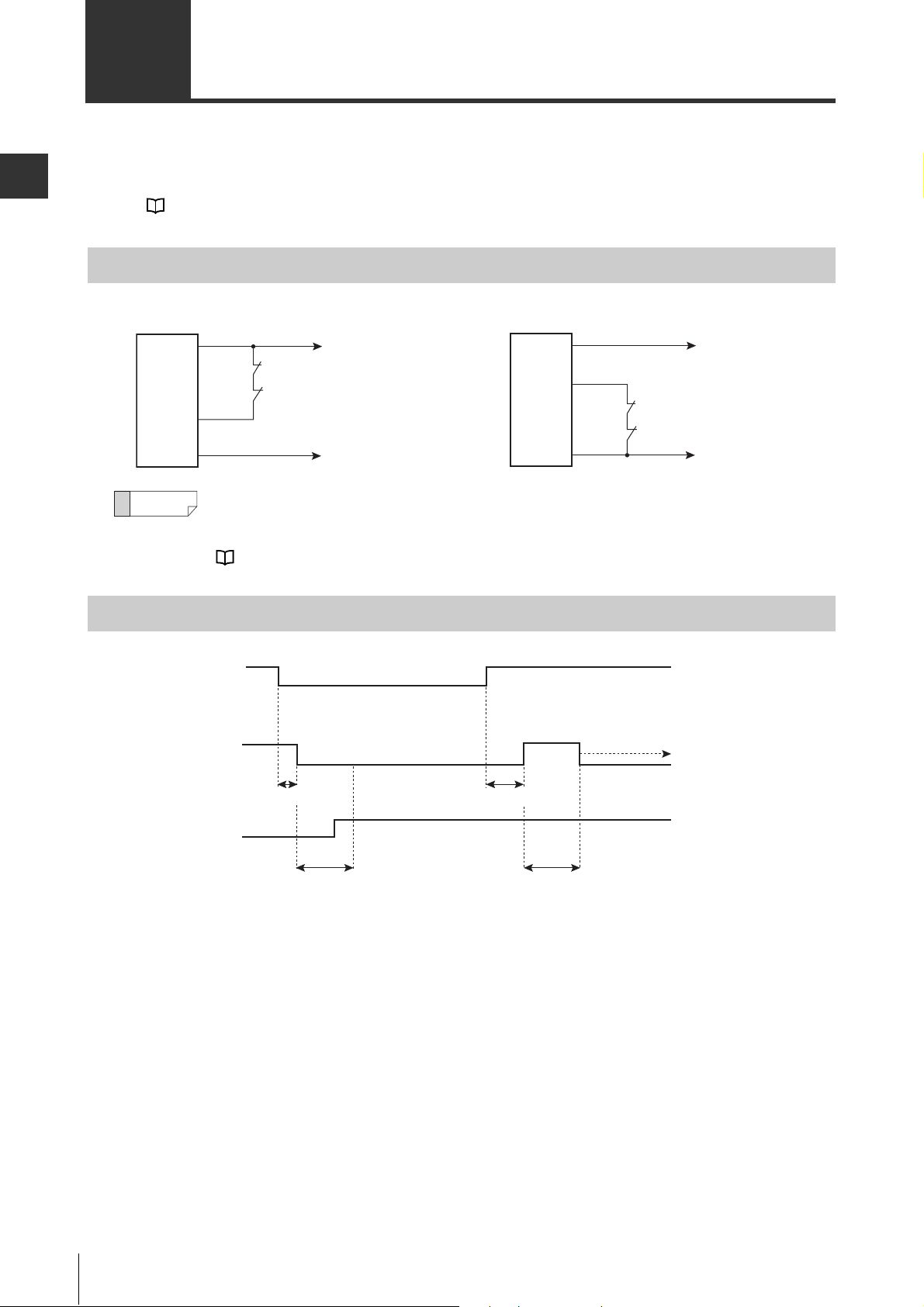

When using a PNP output type cable When using an NPN output type cable

Brown

Red/Black

Blue

GL-RHG

Receiver

+24 V

0 V

Device 1

Device 2

Short-circuit current: 10 mA

Brown

Red/Black

Blue

GL-RHG

Receiver

+24 V

0 V

Device 1

Device 2

Short-circuit current: 10 mA

GL-RHG

OSSD

External device

(B contact)

Response time (ON to OFF) Response time (ON to OFF)

Error condition

Specified

period of time

0.3 s

Specified

period of time

0.3 s

(1) (2)

Clear

Blocked

ON

OFF

ON

OFF

2-4

External Device Monitoring (EDM Function)

EDM (External Device Monitoring) is a function of the GL-RHG that monitors the state of the control

devices which are externally connected to the GL-RHG. The GL-RHG can detect a fault, such as welded

contacts on external devices, as long as the EDM function is activated.

See "Functions" (page 2-4) for the information of wiring system and cable type to activate this function.

Wiring

Reference

When using the 11-core cable and not using the EDM function, short-circuit the EDM input to AUX

output (Red wire on the receiver).

"4-5 Examples of Wiring" (page 4-7)

Time chart

(1) If the GL-RHG detects the operation of the external devices within the specified period of time (0.3 s)

after the operation of OSSD (ON to OFF, or OFF to ON), the GL-RHG continues normal operation.

(2) Unless the GL-RHG detects the operation of an external device within the specified period of time

(0.3 s) after the operation of OSSD (ON to OFF, OFF to ON), the GL-RHG goes into an error condition due to an EDM error.

2-6

GL-RHG-M-NO2-E

Page 31

2

2-5

DANGER

Temporary Suspension of Safety Function

Muting function

The muting function is used to temporarily suspend the GL-RHG's safety functions while the GL-RHG system meet the specified condition for muting. Before this function can be used, the outputs from the muting

devices must be connected to the muting input terminal on the GL-RHG.

In addition, the configuration software provides the user with the opportunity to select the beam axes to be in

the muted condition.

See "Functions" (page 2-4) for the information of wiring system and cable type to activate this function.

Point

For more specific examples of operations or for information about installation when using the

muting function. "Example: Muting function with 2 muting devices (Sensors)" (page 2-10)

• Since the muting function temporarily suspends the safety functions of the GL-RHG,

additional safety measures are required for the entire machine on which the GL-RHG is

installed. This is to ensure safety while the muting function is activated.

• The muting devices, the installation of those devices and the procedure to activate the

muting function must fulfill the conditions specified in this user's manual and the

requirements of the laws, rules, regulations, and standards in the country or region in

which the GL-RHG and those devices are used. Failure to follow this warning may result

in significant harm to the machine operators, including serious injury or death.

• When you install the muting devices (such as sensors or switches), the following

conditions must be fulfilled.

(1) Muting devices must be installed so that the muting function cannot be activated if the

machine that the GL-RHG is on is in the middle of a hazardous cycle or period.

(2) Muting devices must be installed so that the muting function cannot be activated by

personnel approaching the protective zone of the GL-RHG.

• Only responsible personnel should be allowed to install or wire the muting function or

muting devices.

• The muting devices must be installed in such a way that only responsible personnel can

change the installation or orientation by requiring special tools or keys to access the

devices.

• The whole responsibility for use of the muting function must rest with the customer.

Those who use the muting function must fulfill all of the requirements related to muting

functions. KEYENCE accepts NO responsibility or liability for any damage or injury due to

unauthorized installation, unauthorized usage or maintenance methods that are not

specified in this user's manual and/or due to noncompliance with the laws, rules,

regulations and standards set fourth by the country or region in which the GL-RHG is

used.

• The installation of a muting lamp may be required by the laws, rules, regulations, and

standards in the country or region in which the GL-RHG is used if you apply the muting

function. It depends on the machine application and/or the result of your risk assessment.

If it is necessary for you to provide the muting lamp, you must fulfill the requirements

because you are fully responsible for installation of the muting lamp.

Functions and Features

GL-RHG-M-NO2-E

2-7

Page 32

2-5 Temporary Suspension of Safety Function

2

Devices used for muting function

Functions and Features

Muting device

• The muting device output must be N.O. (normally open).

• A PNP output muting device is required when using the PNP output type cable and an NPN output mut-

ing device is required when using the NPN output type cable. The muting device must be capable of 2 to

3 mA current.

• Do not use one muting device with multiple outputs in place of two or more muting devices. (Only one

output per one muting device must be used.)

• If the muting device has a timer function that can adjust the output timing, do not use that function.

Muting lamp

When using the muting lamp, it must meet the following conditions.

For an incandescent lamp : rated 24 V DC, 1 to 5.5 W

For an LED indicator : rated current consumption must be 10 to 230 mA.

Detailed operation

Conditions for initiation of muting

Muted condition is initiated if all of the following conditions are met:

• Muting input 2 turns ON within 0.04 to 3 seconds after muting input 1 turns ON

• GL-RHG detects no interruption in the protective zone

• OSSD is in the ON state and remains for 0.5 seconds or more.

Conditions for termination of muting

Muted condition is terminated if one of the following conditions is met.

• Either of the muting inputs goes to the OFF state for at least 5 ms.

• Light curtain goes to an error condition

• Wait input goes to ON state

• The power supply is interrupted or restored.

• Maximum muting period of approx. 5 minutes has been passed.

Reference

When the GL-RHG is interrupted, the GL-RHG cannot go to the muted condition. In this case, you

can apply override function to suspend the safety functions temporarily. "Override function" (page

2-20)

2-8

GL-RHG-M-NO2-E

Page 33

2

Time chart

Muting input 1

Muting input 2

Muted condition

Not muted condition

Muting lamp

GL-RHG

OSSD

T1 T1No limit 5 ms max.

5 ms max.

90 ms max.

Within 5 min

90 ms max. 90 ms max.

Within 5 min

90 ms max.

Response time (ON to OFF) Response time (OFF to ON)

Clear

Blocked

ON

OFF

ON

OFF

ON

OFF

Light OFF

Light ON

T1: 0.04 to 3 seconds

2-5 Temporary Suspension of Safety Function

Functions and Features

Point

Reference

• If muting input 2 turns on outside the T1 range after muting input 1 turns on, the GL-RHG

will not mute and remains in normal operation. (The GL-RHG does not go into an error

condition.)

• If only muting input 1 or muting input 2 turn OFF and back ON, the GL-RHG will not return to

the muted condition. To return to the muted condition, both muting inputs 1 and 2 must first

turn OFF and the muting conditions must be met again.

• If the GL-RHG power is turned ON while the GL-RHG is in the muted condition or either

muting input 1 or 2 is on, the GL-RHG will not go to a muted condition. In this case, both

muting inputs must be turned OFF and the muting conditions must be met again.

• The function indicators and 7-segment display indicate each condition.

"Function Indicators and 7-segment Display" (page 5-2)

• If the GL-RHG does not go to muted condition when both muting input 1 and 2 are ON, all muting

condition are not met. The configuration software can show the conditions which are not met.

"I/O monitoring" (page 6-15)

GL-RHG-M-NO2-E

2-9

Page 34

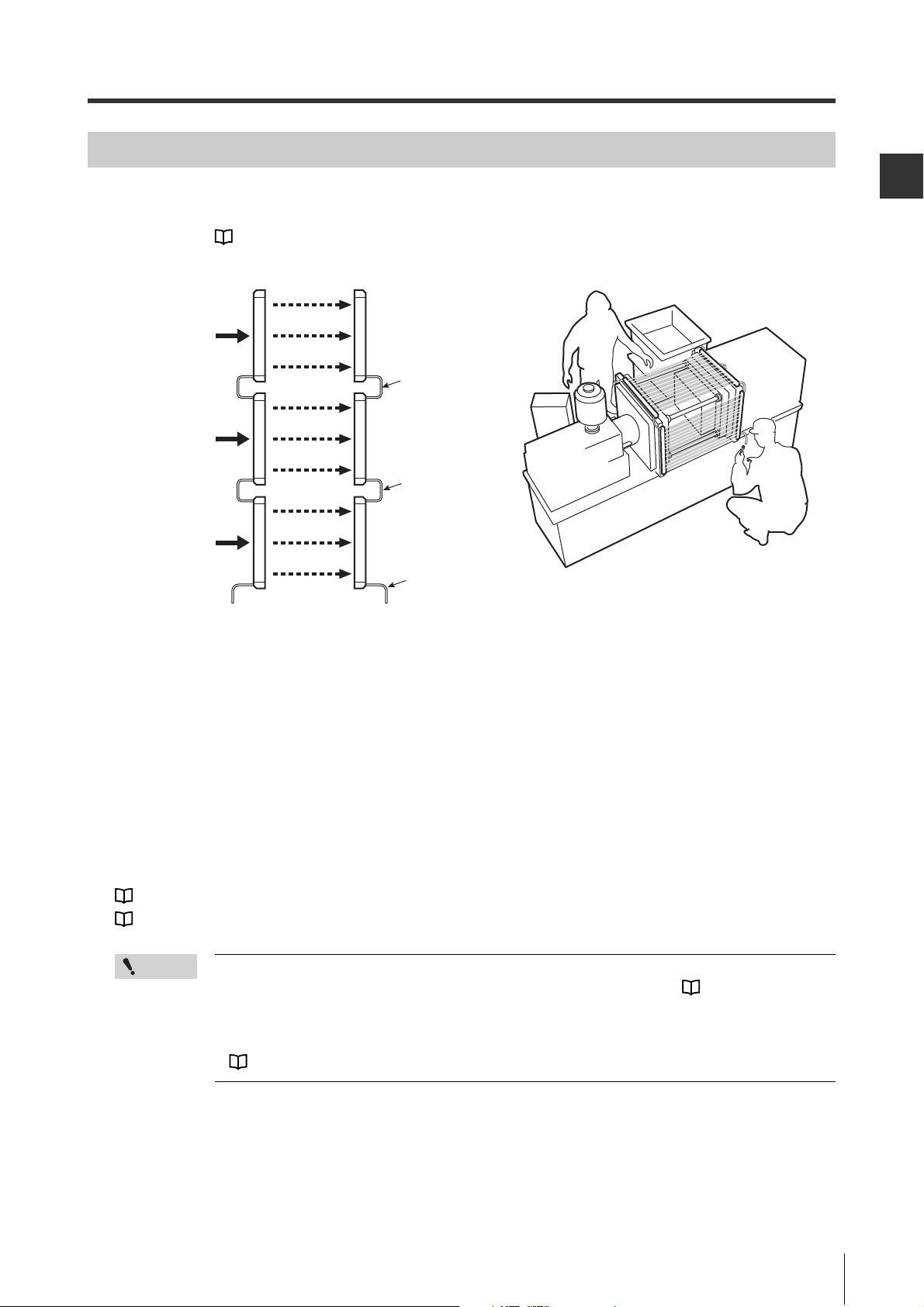

2-5 Temporary Suspension of Safety Function

2

Workpiece

Sensor A2

Safety zone Hazardous zone

Receiver

Reflector

ReflectorSensor A1

Beam axis

Transmitter

GL-RHG

The beams from sensor

A1 and A2 must intersect

each other within the

hazardous zone.

L

V

D

Example: Muting function with 2 muting devices (Sensors)

Functions and Features

The following is an example of the muted condition while the workpiece is passing through the detection

area of the GL-RHG. In this example, 2 retro-reflective photoelectric sensors are used as the muting

devices (ON when the beam from the sensor is blocked).

Conditions for installation of muting devices

All 4 of the following conditions must be met in order to ensure a continuous muted condition while the

workpiece is passing through the detection area.

L (mm) : Length of the workpiece

D (mm) : Displacement distance between the point where the workpiece first interrupts each beam.

V (mm/s) : Workpiece speed

The activation time of muting input 1 and that of muting input 2 must be between 0.04 to 3 seconds.

(1) 0.04 < D / V < 3

(2) D < L

(3) Both sensor A1 and sensor A2 must be installed so that their beams intersect in the hazardous area.

(4) Both sensor A1 and sensor A2 must turn ON when the beam is blocked (Dark ON).

2-10

GL-RHG-M-NO2-E

Page 35

2

Explanation

(1) The workpiece is approaching the

protective zone but the GL-RHG

does not go into the muted condition because both muting input 1

and 2 are OFF. At this point, the

GL-RHG continues normal operation and OSSD goes OFF if the

GL-RHG gets interrupted.

Sensor A2

Safety zone Hazardous zone

Receiver

Reflector

ReflectorSensor A1

Beam axis

Transmitter

GL-RHG

Workpiece

Movement

(2)

The workpiece interrupts the beam

from sensor A1 first, and then interrupts the beam from sensor A2. The

GL-RHG then goes into the muted

condition and the OSSD does not

turn off even if the GL-RHG detects

an interruption.

Sensor A2

Safety zone Hazardous zone

Receiver

Reflector

ReflectorSensor A1

Beam axis

Transmitter

GL-RHG

Workpiece

Movement

(3) The GL-RHG goes back to nor-

mal operation (not muted) if either

sensor A1 or sensor A2 turns off

as the workpiece passes.

Sensor A2

Safety zone Hazardous zone

Receiver

Reflector

ReflectorSensor A1

Beam axis

Transmitter

GL-RHG

Workpiece

Movement

2-5 Temporary Suspension of Safety Function

Functions and Features

GL-RHG-M-NO2-E

2-11

Page 36

Functions and Features

2

When using the PNP output cable

Brown

Pink

(Muting input 1)

Blue

GL-RHG

Transmitter

+24 V

0 V

Sensor A1

Sensor A2

Red/Black

(Muting input 2)

Short-circuit current: 2.5 mA

When using the NPN output cable

Brown

Pink

(Muting input 1)

Blue

GL-RHG

Transmitter

+24 V

0 V

Sensor A1

Sensor A2

(Muting input 2)

Red/Black

Short-circuit current: 2.5 mA

Sensor A1

Sensor A2

Muting lamp

OSSD

Muted condition

Within approx. 5 min.

Within 0.04

to 3 s

90 ms max.90 ms max.

GL-RHG

ON

OFF

ON

OFF

ON

OFF

Clear

Blocked

Light ON

Not muted condition

Light OFF

2-5 Temporary Suspension of Safety Function

Wiring the muting inputs

Point

Time chart

Output type of the switch or sensor used as the muting device must be the same as the cable

used.