Page 1

Safety Light Curtain

DANGER

NOTICE

DANGER

DANGER

96M12000

DANGER

DANGER

DANGER

GL-R Series

Instruction Manual

Detailed information about functions and use of the GL-R series is also described in the "GL-R Series

User's Manual", and the configuration software of "Safety Device Confi gurator" is needed to use all

functions of the GL-R. In order to acquire the "GL-R Series User 's Manual" and "Safety Device

Configurator", download them from the KEYENCE website or call the nearest KEYENCE office.

<KEYENCE website> http://www.keyence.com

This Instruction manual describes handling, operation, and precautionary information for the GL-R

Series Safety Light Curtain ("GL-R").

Read this Instruction manual thoroughly before operating the GL-R in order to understand the device

features, and keep this Instruction manual readily available for reference. Ensure that the end user of this

product receives this manual.

In this Instruction manual, "GL-RF" represents the finger protection type with the detection capability of

14 mm, "GL-RH" represents the hand protection type with the detection capability of 25 mm, "GL-RL"

represents the body protection type with the detection capability of 45 mm and "GL-R" represents all

the models including the GL-RF, GL-RH and GL-RL.

This manual is the original instruction manual.

Symbols

The following symbols alert you to important messages. Be sure to read these messages carefully.

It indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

It indicates a situation which, if not avoided, could result in product damage as well as

property damage.

It indicates additional information on proper operation.

Point

It indicates tips for better understanding or useful information .

Reference

Indicates reference pages in this or another manual.

Safety Information for GL-R Series

General precautions

• You must verify that the GL-R is operating correctly in terms o f functionality and

performance before the start of machine and the operation of the GL-R.

• KEYENCE does not guarantee the function or performance of the GL-R if it is used in a

manner that differs from the GL-R specifications contained in this user's manual or if

the GL-R is modified by the customer.

• When using the GL-R to protect machine operators against a hazard or hazardous zone

or using the GL-R as a safety component for any purpose, always follow the applicable

requirements of the laws, rules, regulations and standards in the country or region

where the GL-R is used. For such regulations, you should directly contact to the

regulatory agency responsible for occupational safety and health in your country or

region.

• Depending on the type of machine on which the GL-R is to be installed, there may be

special safety regulations related to the use, installation, maintenance, and operation of

the safety component. In such a case, you must fulfill such safety regulations. The

responsible personnel must install the GL-R in strict compliance with such safety

regulations.

• The responsible personnel must do the training to the assigned personnel for the

correct use, installation, maintenance, and operation of the GL-R. "Machine operators"

refers to personnel who have received appropriate training from the responsible

personnel and are qualified to operate the machine correctly.

• Machine op erators must have specialized training for the GL-R, and they must

understand and fulfill the safety regulations in the country or region in which they are

using the GL-R.

• When the GL-R fails to operate, machine operators must immediately stop the use of the

machine and the GL-R and report this fact to the responsible personnel.

• The GL -R is designed with the assumption that it would be correctly installed in

accordance with the installation procedures described in this user's manual and

correctly operated according to the instructions in this user's manual. You must

perform an appropriate installation of the GL-R after performing a sufficient risk

assessment for the target machine.

• Be sure to absolutely confirm that there is nobody in the hazardous zone, before you

remove the GL-R from the machine for replacement or disposal.

• When disposing the GL-R, always follow the applicable requirements of the laws, rules,

regulations and standards in the country or region where t he GL-R is used.

• The GL -R should be processed as an industrial waste product when being disposed.

Precaution on use

Operators

• In order to operate the GL-R correctly, the responsible personnel and machine operators

must fulfill all of the procedures described in this user's manual.

• No person other than the responsible personnel and machine operators should be

allowed to install or test the GL-R.

• When performing electrical wiring, always fulfill the electri cal standards and regulations

for the country or region in which the GL-R is used.

Environment of use

• Do n ot use the GL-R in an environment (temperature, humidity, interfering light, etc.)

that does not conform to the specifications contained in this user's manual.

• Be s ure to confirm that the GL-R keeps normal operation when electromagnetic

radiation is generated by wireless devices. (If you use wireless devices such as cellular

phones or transceivers in the vicinity of the GL-R.)

• The GL-R is not designed to be explosion-proof. Never use it in the presence of

flammable or explosive gases or elements.

• Be sure to confirm no deterioration in product quality if you use the GL-R in the

presence of substances, such as heavy smoke, particu late matter, or corrosive chemical

agents.

• Do n ot install the GL-R in areas where the GL-R is exposed to intense in terference light

such as direct sunlight, and direct or indirect light from an inverter-type fluorescent

lamp (rapid-start type lamp, high-frequency operation type lamp, etc).

• Be sure to absolutely confirm that there is nobody in the hazardous zone, before the

interlock is released (i.e. the machine system restarts) by the interlock reset

mechanism. Failure to follow this warning results in significant harm to the machine

operators, including serious injury or death.

• Be sure to absolutely confirm that there is nobody in the hazardous zone before the

override function is activated. Failure to follow this warning results in significant harm

to the machine operators, including serious injury or death.

Tar g et m a chi n e

• The GL-R has not undergone the model certification examination in accordance with

Article 44-2 of the Japanese Industrial Safety and Health Law. The GL-R, therefore,

cannot be used in Japan as a "Safety Device for Press and Shearing machines" as

established in Article 42 of that law.

• The machine on which the GL-R is to be installed must be susceptible to an emergency

stop at all operating points during its operation cycle. Do not use the GL-R for machines

with irregular stop times.

• Do n ot use the GL-R for power presses equipped with full-revolution clutches.

• The GL-R cannot be used as a PSDI because it does not fulfill the requirements of OSHA

1910.217(h). Refer to OSHA 1910.217 for the PSDI mode.

• Do not use the GL-R to control (stop forward motion, etc.) trains, cars and other

transportation vehicles, aircraft, equipment for use in space, medical devices, or

nuclear power generation systems.

• The GL-R is designed to protect people or objects from going into/approaching

detection zone against machine's hazard or hazardous zone. It cannot provide

protection against objects or materials that are expelled from the machine's hazard or

hazardous zone, so you must establish additional safety measures such as installing

safeguards when there is the possibility of such projectiles.

Installation

• The GL-R must be installed only after ensuring the minimum safety distance between

the GL-R and the hazardous zone or hazard as established by the applicable regulations

in the country or region in which the GL-R is used. (e .g. EN ISO13855 (ISO 13855) in EU

countries)

• Cho ose locations for the installation of the GL-R transmitters and receivers so that they

are not subject to the effects of light reflected from glossy surfa ces in the area.

• Corre ct operation and detection is not possible if the receiver has a different beam axis

spacing (detection capability) from that of the transmitter. You must verify that the beam

axis spacing (detection capability) is the same between the transmitter and the receiver

when installing the GL-R.

• The G L-R must be installed so that the machine operator is able to go into or approach

the hazardous zone or hazards only by passing through the detection zone of the GL-R.

Strictly avoid installation that allows the machine operator or a part of the machine

operator's body to go into or approach the hazardous zone or hazards without passing

through the protective zone of the GL-R or to remain in position between the protective

zone of the GL-R and the hazardous zone or hazard. In a case w here you install the GL-R

units in series (series connection), you must always check the installation carefully

whether you follow this warning, especially after installation and maintenance.

• You must always perform the pre-check tests after installing the GL-R in accordance

with the pre-check test procedures, such as items specified in this user's manual, in

order to verify that the test pieces can be detected in all of t he detection zones.

• Inte rlock reset mechanisms (such as switches) must be installed so that the entire

hazardous zone can be checked by the responsible personnel. Interlock reset

mechanisms should not be accessible from within the hazardous zone.

• Mut ing is a function to allow a temporary automatic suspension of the GL-R safety

functions while the GL-R is receiving a signal from muting devices (such as sensors or

switches). Therefore, additional safety measures are required for the machine on which

the GL-R is installed in order to ensure safety while the muting is activated.

• Mut ing devices, the installation of those devices and the procedure to activate the

muting function must fulfill the conditions specified in this user's manual and the

requirements of the laws, rules, regulations and standards in the country or region in

which the GL-R and those devices are used. Failure to follow this warning may result in

significant harm to the machine operators, including serious injury or death .

• When you install muting devices (such as sensors or switches) for muting, the following

conditions must be fulfilled.

(1) Muting devices must be installed so that the muting cannot be activated if the

hazardous zone of the machine is in an unsafe condition or cycle.

(2) Muting devices must be installed so that the muting cannot be activated even if the

personnel is accidentally approaching the detection zone of the GL-R.

• The muting device must be installed such that only responsible personnel have access

to that device to change the installation or orientation. Special tools must be required to

ensure that only responsible personnel are capable of installation, orientation or change

of muting device.

• Only the responsible personnel may be allowed to install or wire the devices to activate

the muting function.

• The installat ion of a muting lamp may be required by the laws, rules, regulations, and

standards in the country or region in which the GL-R is used if you apply the muting

function. It depends on the machine application and/or the result of your risk

assessment. If it is necessary for you to provide a muting lamp, you must fulfill the

requirements because you are fully responsible for installation of the muting lamp.

• The override is a function to allow a temporary manual suspension of the safety

functions of the GL-R. Therefore, additional safety measures are required for the entire

machine system on which the GL-R is installed in order to ensure safety while the

override is activated.

• The override devices, the installation of those devices and the procedures to activate

the override must fulfill the conditions specified in this manual as well as the

requirements of the laws, rules, regulations and standards in the country or region in

which the GL-R and those devices are used. Failure to follow this warning may result in

significant harm to the machine operators, including serious injury or death .

• The override devices, which are used for activation of override, must be manual

operating devices. When installing the devices to activate the override, those devices

must be installed so that the whole hazardous zone can be checked by the responsible

personnel and so that it is not possible for machine operators to operate those devices

in the hazardous zone.

1

E GL-R-IM

Page 2

DANGER

• The installa tion of the indication for override may be required by the laws, rules,

DANGER

DANGER

regulations, and standards in the country or region in which the GL-R is used if you

apply the override function. It depends on the machine application and/or the result of

your risk assessment. If it is necessary for you to provide the indication for override,

you must fulfill the requirements because you are fully responsible for installation of the

indication for override.

• The customer is fully responsible for complying with the requirements for muting and/or

override. Those who use muting and/or override must fulfill all of the requirements

related to muting and/or override. KEYENCE accepts NO responsibility and NO liability

for any damage or any injury due to the unauthorized installation, usage or

maintenance, which are not specified in this user's manual, and/or due to

noncompliance with the laws, rules, regulations and standards in the country or region

in which the GL-R is used.

• W hen the reduced resolution function is applied, the detection capability varies

according to your configuration. Make sure to accurately calculate the safety di stance

according to the detection capability, and install the GL-R at a distance greater than or

equal to the minimum safety distance away from the hazardous zone or hazard. The

installation of additional safety measures, such as safeguarding, may be required if the

detection capability varies due to the configuration of reduced resolution. On your own

responsibility, you must perform the risk assessment based on your configuration of

reduced resolution in order to reduce the risk.

• When the fixed blanking function is applied, a hazardous clearance that is not protected

by the GL-R may be generated between the obstacle and the GL-R. You must install an

additional safety measure such as a safeguard for this clearance.

• S ecurely tighten mounting brackets and cable connectors used for the installation of

the GL-R in accordance with the torque values specified in this user's manual.

• When optical synchronization system is applied and Channel A or B is configured, the

response time is longer than the other c ase. Make sure to accurately calculate the safety

distance according to the response time, and install the GL-R at a distance greater than

or equal to the minimum safety distance away from the hazardous zone or hazard.

Circuit design and wiring

• Always turn off t he power to the GL-R when performing electrical wiring.

• You must fulfill the electrical standards and regulations in the country or region in

which the GL-R is being used when you perform the electrical wiring.

• To avoid the risk of electric shock, do not connect any of the GL-R inputs to DC power

sources outside of the range of 24 V DC + 20% or to any AC power source.

• To avoid the risk of electric shock, be sure that any hazardous voltage is isolated from

all wiring of the GL-R with reinforced insulation or double insulation.

• In order to fulfill the requirements in IEC61496-1, UL61496-1, EN61496-1 and UL508, the

power supply for the GL-R must fulfill the conditions listed below.

(a) A rated output voltage of 24 V DC (SELV, Overvoltage Category ) within ±20%.

(b) Double insulation or reinforced insulation between the primary and secondary

circuits.

(c) Output holding time of 20 ms or more.

(d) A power supply must fulfill the requirements of the electrical safety and

electromagnetic compatibility (EMC) regulations or standards in all countries

and/or regions where the GL-R is used.

(e) A secondary circuit of power supply (output) must fulfill the requirements for

Class 2 Circuits or Limited Voltage/Current Circuits specified in UL508, if the

GL-R is used in the United States or Canada.

• Do not insta ll the electric wiring of the GL-R together with or in parallel with any highvoltage electrical or power lines.

• Bot h OSSD outputs provided on the GL-R must be used to establish a safety-related

machine control system. Establishing a safety-related machine control system with just

one of the OSSD outputs cannot stop the machine due to an OSSD output malfunction

and may result in significant harm to the machine operators, including serious injury or

death.

• W hen using PNP output type cables, do not cause a short-circuit between the OSSD and

+24V. Otherwise, the OSSDs keep staying at the ON-state and it causes a dangerous

situation.

• When using PNP output type cables, be sure to connect the load between the OSSD and

0V to avoid a dangerous situation. If the load is incorrectly connected between th e

OSSD and +24V, the logic of the OSSD operation will be reversed and the OSSD will

change to an ON state when the GL-R detects an interruption in the detection zone. This

is a dangerous situation.

• When using NPN output type cables, do not cause a short-circuit between the OSSD and

0V. Otherwise, the OSSDs keep staying at the ON-state and it causes a dangerous

situation.

• W hen using an NPN output type cable, be sure to connect the loa d between the OSSD

and +24V to avoid a dangerous situation. If the load is incorrectly connected betwe en

the OSSD and 0V, the logic of the OSSD operation will be reversed and the OSSD will

change to an ON state when the GL-R detects the interr uption in the detection zone.

This is a dangerous situation.

• Regardless of whether the cables are PNP or NPN type, you must fulfill the requirements

of Clause 9.4.3 in IEC60204-1: 2005 for protection against maloperation due to earth

fault.

• All outputs, other than OSSDs, are not allowed to be used as safety outputs for a safetyrelated machine control systems. Usage of these functions as safety outputs may result

in significant harm to the machine operators, including serious injury or death.

• The wait input is not allowed to be connected to the output from any components

comprising a part of the safety-related machine control system. If the wait input is

connected to the output of a safety component it may result in significant harm t o the

machine operators, including serious injury or death.

• Th e transmitter and receiver cables must be within the lengths specified in this user's

manual. Usage of cables longer than the specified length may cause the improper

operation of safety functions and may cause a dangerous situation.

Testing and maintenance

• You must always perform the pre-check test in accordance with the checklist, after

maintenance, adjustment or alignment of the target machine or the GL-R and before the

machine startup.

• If the GL-R does not operate properly when you perform a pre-check test in accordance

with the checklist specified in this user's manual, do not operate the machine.

• You must periodically examine the machine to verify that all brakes, other stop

mechanisms, and control devices operate reliably and correctly in addition to checking

the GL-R.

• The responsible personnel must perform maintenance procedures as specified in this

user's manual to ensure safety to the machine and GL-R.

Precautions on regulations and standards

CE Marking

KEYENCE Corporation has confirmed that this product complies with the essential requirements of

the applicable EC Directive, based on the following specifications.

Be sure to consider the following specifications when using this product in a member state of the

European Union.

• Machinery Directive (2006/42/EC)

The GL-R is a safety component as established by the European Union's Machinery Directive

(2006/42/EC) Annex V. The GL-R complies with the following EN Standards and has been certified

by TÜV SÜD Product Service GmbH.

• EN61496-1 Type 4 ESPE

• EN61496-2 Type 4 AOPD

• EN50178

• EN61508, Part 1 to 4 SIL3

• EN62061 SIL CL3

• EN ISO13849-1 Category4, PLe

• EMC Directive (2004/108/EC)

The GL-R complies with the following EN Standards

• EN55011 Class A

• EN61496-1 Type 4 ESPE

These specifications do not give any guarantee that the end-product with this product incorporated

complies with the essential requirements of EMC Directive. The manufacturer of the end-product is

solely responsible for the compliance of the end-product itself according to the EMC Directive.

UL Certificate and North American Regulations

The GL-R complies with the following North American and international standards and has received

UL certification and C-UL certification. (CCN: NIPF/NIPF7, File No:E184802)

• UL61496-1 Type 4 ESPE

• UL61496-2 Type 4 AOPD

• UL508

• UL1998

The GL-R also complies with the following North American regulations.

• FCC Part 15B Class A Digital Device

• ICES-003 Class A Digital Apparatus

Model Certification Examination as a "Safety Devices for Presses and

Shearing Machines"

The GL-R has not obtained the model certification examination in accordance with Article 44-2 of the

Japanese Industrial Safety and Health Law. Therefore, the GL-R cannot be used in Japan as a

"Safety Devices for Presses and Shearing Machines" as established in Article 42 of that law.

Other standards

The GL-R has been designed in consideration of the following standards and regulations. For details

regarding the following standards, contact the third-party certification organization, such as UL or

TÜV.

• EN60204-1

• EN692

• EN693

• OSHA 29 CFR 1910.212

• OSHA 29 CFR 1910.217

• ANSI B11.1 - B.11.19

• ANSI/RIA R15.06 - 1999

• SEMI S2

• "Guidelines for Comprehensive Safety Standards of Machinery", July 31, 2007, number 0731001

issued by Ministry of Health, Labor, and Welfare in Japan.

Standard set

• GL-R transmitter (Transmitter) x 1

• GL-R receiver (Receiver) x 1

• Test piece x 1

GL-RF : With diameter of 14 mm and length of 200 mm

GL-RH : With diameter of 25 mm and length of 200 mm

GL-RL : The test piece (diameter: 45 mm) is not supplied. Please acquire on your own.

• Instruction manual (this document) x 1

E GL-R-IM

2

Page 3

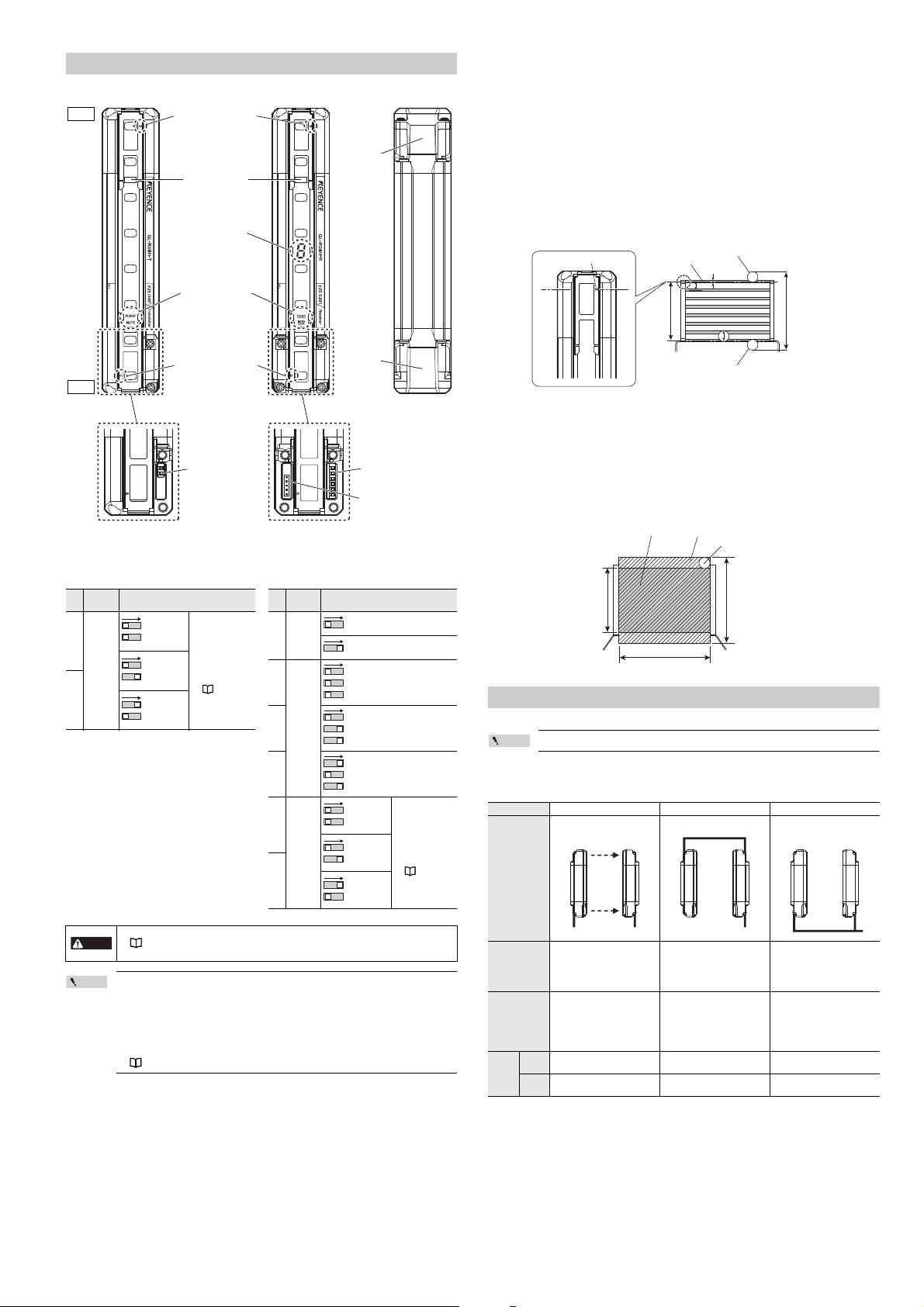

Part Description

Point

DANGER

Transmitter

Beam center-line mark

Receiver Back side

Center Indicators

7-segment display

Function indicators

Beam center-line mark

Setting switch

(2 switches)

Setting switch

(6 switches)

Connector for the

interface unit

(GL-R1UB)

Top

Bottom

End cover

Connector

for the unit

connection

cable

Transmitter Receiver

Switch

No.

Function Configuration

2

Channel

Channel 0

(Not applied)

(Default)

Use Channel for

light interference

prevention when

optical

synchronization

system is applied.

For details, refer to

the "Light

interference

prevention function"

(page 5).

Channel A

1

Channel B

2

Switch

No.

Function Configuration

6

Center

indicator

ON (Green) when all beam axes

are clear (Default)

OFF when all beam axes are clear

(Green OFF)

5

Reduced

resolution

(Safetyrelated

function)

Reduced resolution is not ap plied

(Default).

4

Reduced resolution (one optical

beam) is applied.

3

Reduced resolution (two optical

beams) is applied.

2

Channel

Channel 0

(Not applied)

(Default)

Use Channel for

light interference

prevention when

optical

synchronization

system is applied.

For details, refer to

the "Light

interference

prevention function"

(page 5).

Channel A

1

Channel B

5

43

2

Beam center-line mark

Beam center-line

Specified target detection

capability (position A)

Protection

height

Specified target detection

capability (position B)

Detection

height

a: Beam axis spacing

b: Beam axis diameter

c: Detection capability

a

b

c

Detection zone Protection zone

Specified target detection capability

Detection height Protection height

Operating distance

Beam center-line : An optical path joining the optical center of the emitting element on the transmitter to

Detection height : The height from the top beam center-line to the bottom beam center-line (length).

Protection height : An object approaching the detection zone from the top of the detection height is first

* Refer to the following diagram for an explanation of beam center-line, detection height and protection

height.

the optical center of the corresponding receiving element on the receiver. The GL-R

must be installed so that the beam center-line mark on the transmitter and that on

the receiver face one another and are located at the same height.

detected at point A, which is the distance of the detection capability from the top of

the detection height. The equivalent position on the bottom is called point B. The

height from the top edge of the specified target detection capability that exists at

point A to the bottom edge of the specified target detection capability that exists at

point B is called The "protection height".

The following calculation formula can be defined:

Protection height = "Detection height" + ( 2 x "the specified target detection

capability" ) – "beam axis diameter".

* The side where the end cover has already been installed at shipment is the top side.

Setting switch

2

1

2

1

Detection zone : The zone in which the specified target detection capability can be detected. The

Protection zone : The square area formed with the protection height and the operating distance,

* Refer to the following diagram for detection zone and protection zone.

6

detection zone of the GL-R indicates a square area formed with the detection height

and the operating distance. When an object of the specified target detection

capability is present in this area, the light of the GL-R is blocked, and then the

OSSD goes to OFF state.

which is broader than the detection zone. When an object of the specified target

detection capability is present in this area, the light of the GL-R is blocked, and then

the OSSD goes to OFF state.

Functions and Features

5

43

5

43

2

1

2

1

The functions and features of the GL-R are described in this section.

For more information about these functions, see "GL-R Series User's Manual".

Point

Wiring system

The following three types of wiring systems are available in the GL-R series.

Wiring system Optical synchronization system One-line system Wire synchronization system

Wiring diagram

Transmitter Receiver Transmitter Receiver Transmitter Receiver

• The response time varies according to the configuration of Channel.

"Response time (OSSD)" (page 9)

• The det ection capability varies according to the configuration of reduced res olution.

• The configuration of the setting switch is applied when the power is supplied.

• When th e GL-R is in series connection, the setting switch configuration of the main unit

is applied regardless of the setting switch configuration of the sub unit.

• When th e center indicator and reduced resolution are configured by using the

configuration software, the setting switch must be configured by default. Otherwise an

error occurs.

• When th e GL-R operates in wire synchronization system, the setting switch for Channel

must be configured by default. Otherwise an error occurs.

"Wiring system" (page 3)

• Simplified wiring.

• The unit connection cable is

not needed for the transmitter.

• The input and output functions

on the transmitter are not

available.

• There is a maximum limit for

the total length of cables.

5-core cable

11-core cable

Advantage

Limitation

Applicable

cable

• Wiring is not needed be tween

the transmitter and receiver.

• The Transmitter and the

receiver can operate on

different power supplies.

• The input and output functions

on the transmitter are not

available.

• All indicators other than

"Power" are not available on

the transmitter.

Transmitter

5-core cable Series connection cable

5-core cable

Receiver

11-core cable

3

• All functions of the GL-R are

available.

• Wiring is needed between the

transmitter and the receiver.

7-core cable

11-core cable

7-core cable

11-core cable

E GL-R-IM

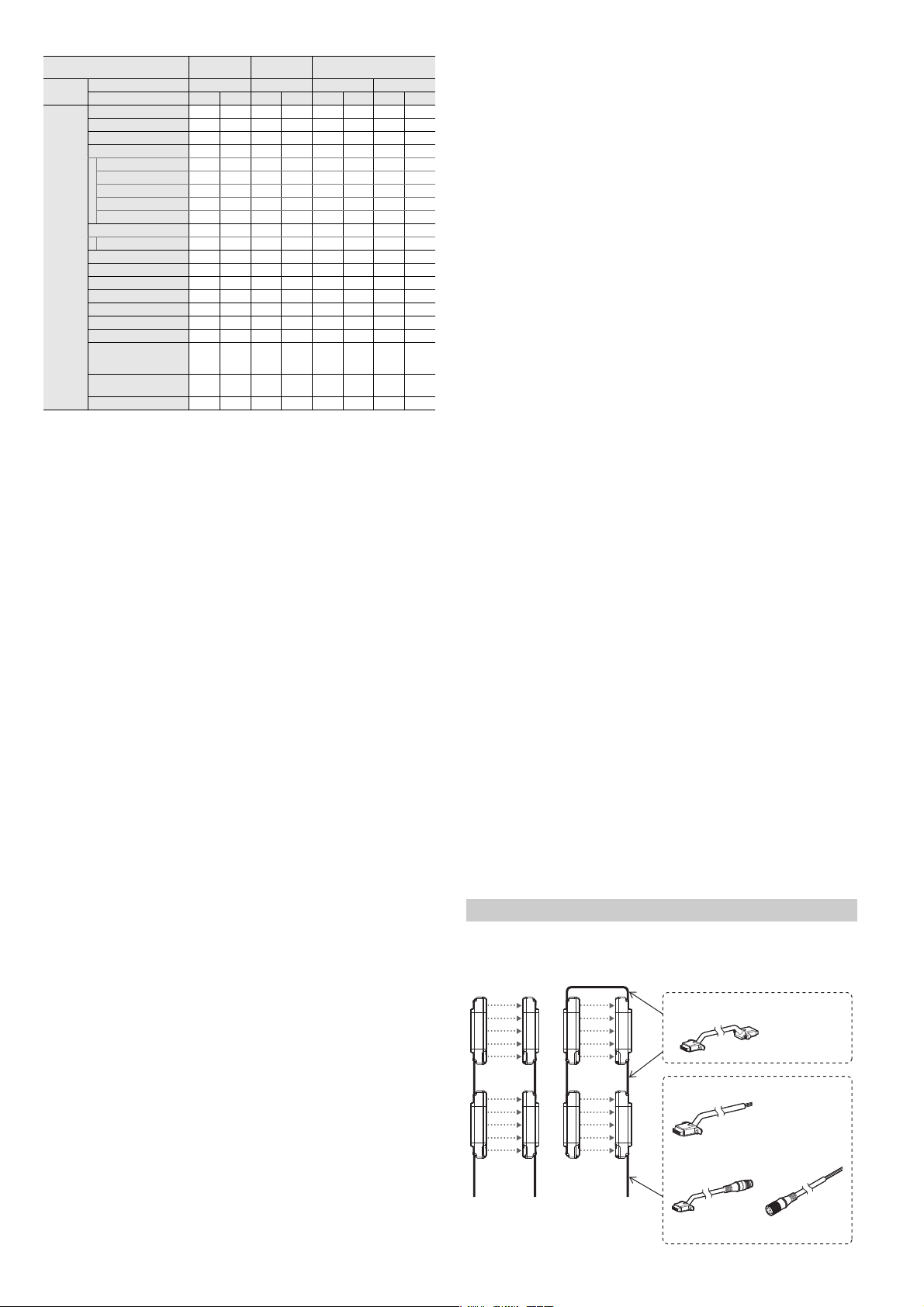

Page 4

Wiring system

Optical/wire

synchronization system

One-line

system

Series connection cable

Unit connection cable

Unit connection cable (for extension

use) + Extension cable

* The unit connection cable can not be

connected on the upper part of the GL-R.

Cable for the transmitter 5-core

Cable

combination

Cable for the receiver

OSSD output

AUX (auxiliary) output

Error output

Muting function

Partial muting function

Muting bank function

Muted condition output

Muting lamp output

Override function () ()

Interlock function () () () ()

Available

function

: Available without the configuration software

: Available with the configuration software

() : Available without the configuratio n software, Functionality can be expanded when using the configuration software.

Interlock-reset-ready output

EDM function () () () ()

Wait input

Alert output

Clear/Block output

Reset input (for error)

Reduced resolution function () () () () () () () ()

Fixed blanking function

Channel configuration

(Light interference

prevention function)

Center indicator

configuration

Monitoring function

Optical

synchronization

5-core 11-core 5-core 11-core 7-core 11-core 7-core 11-core

() () () () () () () ()

One-line Wire synchronization

Series connection

7-core 11-core

Series connection

Up to three GL-R units can be serially connected and used as a single light curtain.

OSSD

The OSSD is a safety-related control output. It connects to an external device (load), such as an FSD or

MPCE. The GL-R generates self-diagnosis signals on its internal control circuit to perform diagnostics on

the output circuit (OSSD). These signals periodically force the OSSD into a temporary OFF state when

no interruption exists in the detection zone.

Interlock function

Interlock is a function that prevents the OSSD from automatically going to the ON state from an OFF

state.

You can prevent the unintended start-up and/or the unintended restart of the machine if an interlock is

applied to the GL-R.

External device monitoring (EDM function)

EDM (External Device Monitoring) is a function of the GL-R that monitors the state of the control devices

which are externally connected to the GL-R. The GL-R can detect a fault, such as welded contacts on

external devices, as long as the EDM function is activated.

This function is available only when connecting the 11-core cable to the receiver.

Fixed Blanking

During normal operation, the OSSD remains in the ON state while the GL-R detects no interruption in the

detection zone, and the OSSD goes to the OFF state when the GL-R detects interruption in the detection zone.

On the other hand, if fixed blanking is enabled on certain beam axes, the OSSD remains in the ON state

as long as the GL-R detects interruption on those beam axes and no interruption elsewhere in the

detection zone.

Reduced resolution

During normal operation, the OSSD goes to the OFF state when the GL-R detects interruption in the

detection zone.

On the other hand, if reduced resolution is enabled on the GL-R with the number of beam axes to be

ignored and not monitored specified, the OSSD remains in the ON state even while the GL-R detects

interruption on certain beam axes as long as the total number of interrupted beam axes is less than or

equal to the number of ignored beams.

Muting Function

The muting function is used to temporarily suspend the GL-R's safety functions while the GL-R receives

a signal from muting devices (such as sensors or switches). Before this function can be used, the outputs

from the muting devices must be connected to the muting input terminal on the GL-R.

In addition, the configuration software provides the user with the opportunity to select the beam axes to

be in the muted condition. You can minimize the number of beam axes to be in the muted condition by

using the configuration software. Therefore, you can reduce the risk of interrupting the hazardous zone.

Muting device

When using the muting device, it must be met with the following conditions.

• The muting device output must be N.O. (normally open).

• Output of the muting device must be the output with contacts, and must be PNP output type if PNP

output type cable is used, or NPN output type if NPN output type cable is used. Also, the muting

device must be capable of 2 to 3 mA current.

• Do not use one muting device with multiple outputs in place of two or more muting devices. (Only

one output per one muting device must be used.)

• If the muting device has a timer function that can adjust the output timing, do not use that function.

Muting lamp

When using the muting lamp, it must meet the following conditions.

For an incandescent lamp : rated 24 V DC, 1 to 5.5 W

For an LED indicator : rated current consumption must be 10 to 230 mA.

Conditions for initiation of muting

Muted condition is initiated if all of the following conditions are met:

• Muting input 2 turns ON within 0.04 to 3 seconds after muting input 1 turns ON

• GL-R detects no interruption in the detection zone

• OSSD is in the ON state and remains for 0.5 seconds or more.

E GL-R-IM

Conditions for termination of muting

Muted condition is terminated if one of the following conditions is met:

• Either of the muting inputs goes to the OFF state for at least 5 ms.

• Light curtain goes into the error condition

• Wait input goes to ON state

• The power supply is interrupted or restored.

• Maximum muting period of approx. 5 minutes has been passed.

Changing of conditions for muting

The following muting conditions can be changed through the configuration software or a special

procedures.

Condition for Initiation of muting

1. Time period specification of 0.04 s to 3 s between muting input 1 and muting input 2 can be option.

2. Sequence specification of muting inputs can be option. (Default sequence: muting input 1 is first,

muting input 2 is second.)

Condition for termination of muting

3. Time period specification form muting input OFF to termination of muted condition. (Default is 0

seconds.)

4. Maximum muting period of approx. 5 minutes can be option.

Condition for muting lamp

5. Error condition can be initiated if muting lamp has some failure.

If you choose these options according to your machine application, password setting and/or password

input is required as a special procedure.

The responsible personnel who intends to apply these options mentioned above from 1 to 4 have to

perform the risk assessment based on the machine application.

Muting bank function

The muting bank function can be activated through the configuration software.

You can configure up to three muting banks on the GL-R. Each muting bank is a group of beam axes that

will go into a muted condition upon activation of muting.

In order to activate a muting bank, you must switch (ON and OFF) the muting bank input.

Override function

During normal operation, the OSSD goes to an OFF state if the muting function is deactivated and an

interruption remains in the detection zone of the GL-R. The OSSD OFF state will remain until the

obstruction is removed.

Override function allows a temporary manual suspension of the GL-R safety functions.

This makes it possible to remove the obstruction remaining in the detection zone of the GL-R. (Machine

is able to be manually operated on a temporary basis because the safety function of the GL-R is

temporarily suspended.)

Conditions for initiation of override

Override function is initiated if all of the following conditions are met and the wait input goes to the ON

state within 0.04 s to 1 s after the override input turns ON state.

• GL-R is not in the error condition.

• GL-R detects interruption in the detection zone. (One or more beam axis is blocked.)

• OSSD is OFF state. (including interlock condition)

• Either of muting inputs, or both, turns ON state

Conditions for termination of override

Override function is terminated if one of the following conditions is met:

• All of muting inputs turn OFF.

• Either the override input or wait input, or both, turn OFF.

• Light curtain goes to into the error condition

• Maximum override period of approx. 60 seconds has been passed.

Changing of the condition for override

The following condition can be changed through the configuration software.

Conditions that deactivate the override condition

• Maximum override period of approx. 60 seconds can be option.

If you choose this option according to your machine application, password setting and/or password input

is required. The responsible personnel must securely manage the password. The responsible personnel

who intends to apply this option must perform the risk assessment based on the machine application.

Installation

Overview

4

Page 5

z

z

z

z

Cable installation

• Do not remove the black gasket installed on the connector. Without this gasket the

requirement of IP65 and IP67 cannot be fulfilled.

• Secure ly tighten the cable connector and end cover with the screw in accordance with

DANGER

the torque values specified in this user's manual. Without proper installation, the

requirement of IP65 and IP67 cannot be fulfilled.

• Connect the unit connection cable to the connector port on the lower part of the GL-R.

Removing the end cover on the upper part of the GL-R and connecting the unit

NOTICE

Cable connection to the lower part of the GL-R (The unit connection cable

connection cable may result in GL-R damage.

• The end cover must be connected to the connector except when the series cable is

connected. If both the end cover and series cable are not connected to the connector, an

error occu rs.

and extension cable)

The unit connection cable and extension cable can be used for both the transmitter and

Reference

receiver.

Ensuring proper GL-R installation near a glossy surface

If there is a glossy surface around the GL-R, the GL-R may be affected and may not detect an

interruption in the detection zone.

To avoid this problem, installation must be done according to the following:

Safe

A=2.5°

Approaching direction

A

A

Transmitter

Glossy surface

Area surrounding the

hazardous zone

Transmitter

Object

(Interruption)

A

A

Receiver

Receiver

Dangerous

A=2.5°

Approaching direction

A

A

Transmitter

Glossy surface

Area surrounding the

hazardous zone

Transmitter

Object

(Interruption)

A

A

Receiver

Receiver

M3 cross slot screws (Recommended tightening torque of 0.3 N•m )

Cable connection to the upper part of the GL-R (The series connection

cable)

The series connection cable can be used on both the transmitter and receiver.

Reference

1

M3 cross slot screws

End cover

When the GL-R units are wired by the one-line system, the end cover re moved from the

upper part of the GL-R must be secured to the lower part with the screw. (Recommended

DANGER

tightening torque of 0.3 N•m)

Without the end cover, the requirement of IP65 and IP67 cannot be fulfilled.

Installation of the GL-R unit

Connect all cables to the GL-R before installing the mounting bracket to the GL-R unit.

Point

The installation method differs according to the type of mounting bracket.

For details, see the manual included in the package of mounting bracket or "GL-R Series User's Manual".

Light interference prevention method

Light interference prevention function

• When wire synchronization system is applied

The light interference prevention function automatically reduces mutual interference between GL-R

units.

• When optical synchronization system is applied

The light interference prevention function is applied according to Channel configuration.

The mutual interference is reduced between GL-R units with Channel A and Channel B.

The mutual interference is not reduced between GL-R units with Channel 0 and Channel 0, GL-R

units with Channel 0 and Channel A, or GL-R units with Channel 0 and Channel B.

Channel is configured by using the setting switch at the lower part of front side of GL-R units.

Configure the same Channel to the setting switch on both the transmitter and receiver.

For more information about the setting switch, see also "Part Description" (page 3).

When the GL-R is in series connection, the setting switch configuration of the main unit is

applied regardless of the setting switch configuration of the sub unit.

The response time varies according to the configuration of Channel.

DANGER

"Wiring system" (page 3)

Series connection

Connecting GL-R in series can prevent mutual interference.

"Response time (OSSD)" (page 9)

2

M3 cross slot screws

(Recommended tightening torque of 0.3 N•m)

Object (Interruption)

AA

Glossy surface

Area surrounding the

hazardous zone

When determining a specific installation distance, refer to the following values including the installation

tolerance.

X

Transmitter

Glossy surface

Operating distance "X" Minimum installation distance "Y"

Less than 3 m 0.13 m

3 m or more X/2 x tan5° = 0.0437 X

Receiver

Y

Object (Interruption)

AA

Glossy surface

Area surrounding the

hazardous zone

X

Transmitter Receiver

5°

Y

Glossy surface

Wiring

• Each model is connected to one cable. Therefore, at least two cables are needed as a

Point

system, one for the transmitter and another for the receiver.

• All cables can be use d for both the transmitter and receiver.

• The combination of the wiring sy stem and cable determines the functions that can be

used. Different types of Cables can be used for the transmitter and receive r.

"Wiring system" (page 3)

• Be sure to match the numbers of conductors (core wires) when using the unit connection

cable for extension use and the extension cable.

Cable specification

(1) Cable length

1. Optical synchronization system, wire synchronization system

The sum of the length for the unit connection cable and extension cable must be 30 m or less.

This limitation applies separately to the entire transmitter cable setup and the entire receiver

cable setup.

2. One-line system

The sum of the length for all of the unit connection cables, extension cables and series cables

must be 30 m or less.

• Cables must be within the lengths specified. Failure to follow this specification may

cause improper operation of safety functions, and may create a dangerous situation.

• The ser ies connection cable cannot be cut or extended. If the cable is cut or extended,

DANGER

safety features may not operate properly. Do not allow this to happen as it is extremely

dangerous.

(2) Minimum cable bending radius : 5 mm

(3) Identification of connector cables

Connector

Connector colors

PNP output type cables or series connection cables : Black connectors

NPN output type cables : Grey connectors

PNP output type cables and NPN output type cables cannot be used at the same time

Point

(mixed wiring is not possible). One type of cable must be chosen based on the application.

5

E GL-R-IM

Page 6

Cable color and pin position

Output circuit (PNP type cable) Output circuit (NPN type cable)

Main

circuit

+24 V

Black or White

0 V

+24 V

Black or White

0 V

Main

circuit

Blue

Brown

Blue

Brown

External device

External device

Input circuit (PNP type cable)

+24 V

0 V

(Input line)

(Input line)

+24 V

0 V

Blue

Brown

Blue

Brown

Input circuit (NPN type cable)

Main

circuit

Main

circuit

NOTICE

Transmitter

(FE) Grey

(0V) Blue

(Not in use) White

(Not in use) Black

(+24V) Brown

(+24V) Brown

(OSSD1) Black

(OSSD2) White

(0V) Blue

(FE) Grey

Receiver

(FE) Grey

(0V) Blue

(Not in use) White

(Not in use) Black

(+24V) Brown

(+24V) Brown

(OSSD1) Black

(OSSD2) White

((0V) Blue

(FE) Grey

Transmitter

Receiver

(+24V) Brown

(OSSD1) Black

(OSSD2) White

(0V) Blue

(FE) Grey

(AUX output) Red

(EDM input) Red/Black

(Reset input) Yellow

(Interlock mode selection input) Pink

(FE) Grey

(0V) Blue

(Not in use) White

(Not in use) Black

(+24V) Brown

Orange (Not in use)

K1

K2

S1

K3

K1 K2

Orange/Black (Not in use)

Transmitter

Receiver

(+24V) Brown

(OSSD1) Black

(OSSD2) White

(0V) Blue

(FE) Grey

(AUX output) Red

(EDM input) Red/Black

(Reset input) Yellow

(Interlock mode selection input) Pink

(FE) Grey

(0V) Blue

(Not in use) White

(Not in use) Black

(+24V) Brown

K3

K1 K2

Orange (Not in use)

Orange/Black (Not in use)

K1

K2

S1

Transmitter

Receiver

• When the synchronization wire 1 is wired between the transmitter and rec eiver, and the

Reference

5-core cable

7-core cable

11-core cable

synchronization wire 2 is wired in the same manner, the GL-R operates in wire synchronization

system.

• When the synchronization wire 1 or 2 is not connected, the GL-R operates in optical

synchronization system.

• When optical synchronization system or one-line system is applied, the input and output

functions on the transmitter are not available.

• The func tions assigned to the input and output may differ according to the configuration when

setting through the configuration software.

"Wiring system" (page 3)

Pin No Wire Color

Transmitter Receiver

Assigned function

1 Brown +24 V +24 V

2 White (Not in use) OSSD2

3Blue 0 V 0 V

4 Black (Not in use) OSSD1

5Grey FE FE

M12 connector male pin assignment M12 connector female pin assignment

Reference

2

1

5

3

4

Pin No Wire Color

Transmitter Receiver

Assigned function

1 White Wait input OSSD2

2 – (Not in use) (Not in use)

3 Black Error output OSSD1

4 Brown +24 V +24 V

5 Orange Synchronization 1 (RS485_+) Synchronization 1 (RS485_+)

6 Orange/Black Synchronization 2 (RS485_–) Synchronization 2 (RS485_–)

7Blue 0 V 0 V

8Grey FE FE

M12 connector male pin assignment M12 connector female pin assignment

Reference

2

1

83 7

4

6

5

Pin No Wire Color

Transmitter Receiver

Assigned function

1 White Wait input OSSD2

2 – (Not in use) (Not in use)

3 Black Error output OSSD1

4 Yellow Override input RESET input

5 Orange Synchronization 1 (RS485_+) Synchronization 1 (RS485_+)

6 Orange/Black Synchronization 2 (RS485_–) Synchronization 2 (RS485_–)

7Blue 0 V 0 V

8 Red Muting lamp output AUX (auxiliary) output

9 Red/Black Muting input 2 EDM input

10 Brown +24 V +24 V

11 Pink Muting input 1 Interlock selection input

12 Grey FE FE

Examples of Wiring

The functions assigned to the input and output may differ according to the configuration

when configuring through the configuration software.

For more information, see the "GL-R Series user's Manual".

Symbols

R1, R2 : External device (Safety PLC, Safety relay unit, etc)

K1, K2 : External device (Force guided relay, magnet contactor, etc)

K3 : Solid state contactor

S1 : Switch used for reset input

S2 : Switch used for wait input

S3 : Switch used for override input

S4, S5, S6 : Switch used for muting bank inputs

L1 : Muting lamp (Incandescent lamp or LED lamp)

P1, P2 : Muting device (Self-contained photoelectric sensors, etc.)

M : 3-phase motor

PLC : For NON SAFETY-RELATED system control use

*1 These are NON SAFETY-RELATED components.

Optical synchronization system

1

2

5

4

3

1

2

87 3

6

4

5

Transmitter: 5-core cable, Receiver: 5-core cable

(1) PNP output cable

(2) NPN output cable

Transmitter: 5-core cable, Receiver: 11-core cable

When using the EDM function and interlock function

(1) PNP output cable

*1

*1

*1

R1 R2

R1 R2

M14 connector male pin assignment M14 connector female pin assignment

Reference

12

10

3

9

12 11

4

8

5

7

6

I/O circuit diagram

Reference

E GL-R-IM

• Grey wire (FE) is electrically-connected to the light cur tain body case.

•

The light curtai n body case and internal power signal lines are couple d by capacitor (3 kV, 100 pF).

21

10

9

3

11 12

8

7

5

6

4

M

K2K1

OUT IN

PLC

(2) NPN output cable

K2K1

OUT IN

M

PLC

6

Page 7

z

z

z

z

z

One-line system

• The series connection cable must be used to connect the transmitter and receiver.

• The unit connection cable is not needed for the transmitter.

• The wiring for the receiver is the same as optical synchronization system.

Transmitter: Series connection cable, Receiver: 5-core cable

(1) PNP output cable

Transmitter

Receiver

(0V) Blue

(OSSD1) Black

R1 R2

(FE) Grey

(OSSD2) White

(+24V) Brown

(2) NPN output cable

Transmitter

Wire synchronization system

Transmitter: 7-core cable, Receiver: 7-core cable

Receiver

(0V) Blue

(OSSD1) Black

R1 R2

(FE) Grey

(OSSD2) White

(+24V) Brown

(1) PNP output cable

Transmitter

Orange (Synchronization 1)

Orange/Black (Synchronization 2)

(0V) Blue

(FE) Grey

(+24V) Brown

(Wait input) White

(Error output) Black

S2

Receiver

(0V) Blue

(OSSD1) Black

R1 R2

(FE) Grey

(OSSD2) White

(+24V) Brown

Indicators

Transmitter

7-segment display

Function indicator

Function indicators

Name Indicator Description

POWER

(Orange)

MUTE

(Orange)

* When optical synchronization system is

applied, only the "POWER" indicator turns ON

on the transmitter.

"Wiring system" (page 3)

7-segment display

Upon power-up

Wire synchronization

During normal operation

Applying the reduced resolution function or fixed blanking function.

Wait input is activated.

Transmitter

Light ON Power ON (Transmitter)

Light OFF Power OFF (Transmitter)

Muted condition or

Light ON

Override condition

Blinking

Muting input 1 ON

slowly

Muting input 2 ON or

Blinking

Muting input 1 ON and

Muting input 2 ON

Muting input 1 OFF and

Light OFF

Muting input 2 OFF

Channel 0 Channel A Channel B

Condition Display

Muting input 1 is activated.

Optical synchronization

Receiver

Name Indicator Description

OSSD

(Red/

Green)

INTERLOCK

(Yellow)

Receiver

Light in

OSSD OFF

red

Light in

OSSD ON

green

Amount of received light is

Blinking in

unstable.

green

(Alert output OFF)

Light OFF Power OFF (Receiver)

Light ON Interlock condition

Interlock reset ready condition

Blinking

(Interlock reset ready output ON)

Light OFF No interlock or error co ndition

PLC

(2) NPN output cable

Transmitter

Orange/Black (Synchronization 2)

(0V) Blue

(FE) Grey

(Wait input) White

(Error output) Black

S2

PLC

Orange (Synchronization 1)

(+24V) Brown

Muting input 2 is activated.

Muting input 1 and 2 are both

Receiver

Applying the muting

function or override

function.

(0V) Blue

(OSSD1) Black

R1 R2

(FE) Grey

(OSSD2) White

Other than those above. Turn OFF

*1 When not in the muted condition because conditions for initiation of muting are not met.

*2 When not in the override condition because conditions for initiation of override are not met.

Error condition

When an error occurs, the OSSD goes to the OFF-state and the GL-R goes to the error condition.

For the 7-segment display in the error condition, refer to "Troubleshooting" (page 10).

(+24V) Brown

*1

activated

.

Muted condition

Override input is activated

Override condition.

*2

.

7

E GL-R-IM

Page 8

Center indicator

GL-RH

Beam axis

Center

indicator

(Upper)

Center

indicator

(Middle)

Center

indicator

(Lower)

Dimensions

Center indicator (Upper) : indicates whether interruption is present in the top

Center indicator (Middle) :

Center indicator (Lower) : indicates whether interruption is present in the bottom

Center

Light OFF red light green light

indicator

Top beam axis

Upper

is blocked

Top beam axis

or Bottom

beam axis is

blocked

Bottom beam

Lower

axis is blocked

* The center indicator on the transmitter is OFF when optical synchronization

system is applied.

beam axis or not. (clear or blocked)

indicates whether the middle axis beams are

interrupted or not.

beam axis or not. (clear or blocked)

Although the top beam axis is

unblocked, the others are

blocked

Although the top and bot tom

beam axis are unblocked, the

middle beams are blocked

Although the bottom bea m

axis is unblocked, the others

are blocked

No interruption is

present in

detection zone of

the GL-R. (clear)

Blinking red

light

Error conditionMiddle

Units: mm

Transmitter and Receiver

38

32

F

E10

B

A

C

GL-RH

Units: mm

Model

Beam axes

GL-R08H 8 160 140 185

GL-R12H 12 240 220 265 120

GL-R16H 16 320 300 345 160

GL-R20H 20 400 380 425 200

GL-R24H 24 480 460 505 240

GL-R28H 28 560 540 585 280

GL-R32H 32 640 620 665 320

GL-R36H 36 720 700 745 360

GL-R40H 40 800 780 825 400

GL-R44H 44 880 860 905 440

GL-R48H 48 960 940 985 480

GL-R52H 52 1040 1020 1065 520

GL-R56H 56 1120 1100 1145 560

GL-R60H 60 1200 1180 1225 600

GL-R64H 64 1280 1260 1305 640

GL-R72H 72 1440 1420 1465 720

GL-R80H 80 1600 1580 1625 800

GL-R88H 88 1760 1740 1785 880

GL-R96H 96 1920 1900 1945 960

GL-RL

A: Length

B: Detection height C: Protection height D: Beam axis pitch

20 10 22.5

E F G

Units: mm

Model

Beam axes

GL-R04L 4 160 120 205

GL-R06L 6 240 200 285 120

GL-R08L 8 320 280 365 160

GL-R10L 10 400 360 445 200

GL-R12L 12 480 440 525 240

GL-R14L 14 560 520 605 280

GL-R16L 16 640 600 685 320

GL-R18L 18 720 680 765 360

GL-R20L 20 800 760 845 400

GL-R22L 22 880 840 925 440

GL-R24L 24 960 920 1005 480

GL-R26L 26 1040 1000 1085 520

GL-R28L 28 1120 1080 1165 560

GL-R30L 30 1200 1160 1245 600

GL-R32L 32 1280 1240 1325 640

A: Length

B: Detection height C: Protection height D: Beam axis pitch

40 30 42.5

E F G

80

80

G

D

32.9

Setting switchesInterface unit connector

Antivibration bracket for the Adjustable angle

mounting bracket

Antivibration bracket for the straight mounting

bracket

(only receiver)

If the length for a single GL-R unit is 1280 mm or greater, use the following antivibration

mounting bracket additionally as an intermediate support bracket. The antivibration

mounting bracket must be selected according to the mounting bracket and installed on the

center of the GL-R unit indicated as position "G".

NOTICE

Adjustable angle mounting bracket

No dead zone mounting bracket

Straight mounting bracket

L-shaped mounting bracket L-shaped mounting bracket

Mounting bracket Antivibration bracket

GL-RF

Units: mm

Model

Beam axes

GL-R23F 23 240 220 244

A: Length

GL-R31F 31 320 300 324 160

GL-R39F 39 400 380 404 200

GL-R47F 47 480 460 484 240

GL-R55F 55 560 540 564 280

GL-R63F 63 640 620 644 320

GL-R71F 71 720 700 724 360

GL-R79F 79 800 780 804 400

GL-R87F 87 880 860 884 440

GL-R95F 95 960 940 964 480

GL-R103F 103 1040 1020 1044 520

GL-R111F 111 1120 1100 1124 560

GL-R119F 119 1200 1180 1204 600

GL-R127F 127 1280 1260 1284 640

B: Detection height C: Protection height D: Beam axis pitch

10 10 12

E F G

120

E GL-R-IM

8

Page 9

Specifications

Specifications

Beam axis spacing/Lens diameter 10 mm/4 20 mm/5 40 mm/5

Detection capability 14 mm 25 mm 45 mm

Operating distance 0.2 to 10 m

Effective aperture angle Max. ±2.5° (When operating distance is 3 m (9.84 ft.) or more)

Light source Infrared LED (870 nm)

Response time

OSSD operation Turns on when no interruptions are present in the detection zone

Synchronization between the transmitter

and receiver

Light interference prevention function

Control output

(OSSD)

Supplemental

output

(Non-safetyrelated output)

Input

Power suppl y

Protection circuit

Environmental

resistance

Material

Weight see "Weight" (page 10)

Approved

standard

Parameter for

IEC61508

*1 When the option front protection cover is installed on the one of transmitter or receiver, the Operating

*2 When the GL-R is used under surrounding air temperatures between 50 to 55°C, the Maximum load

*3 For PFHd of each GL-R, contact your nearest KEYENCE office.

Model GL-RF GL-RH GL-RL

*1

Optical synchronizati on (Channel 0) or Wire synchronization: 6.6 to 18.1 ms

Optical synchronization (Channel A or B): 6.9 to 27.4 ms

Optical synchronizat ion or Wire synchronization

Prevents mutual interference in up to two GL-R systems.

Optical synchronization: prevented by Channel A and B with setting switch

Output

Max. load current 500 mA

Residual voltage (during

ON)

OFF state voltage Max. 2.0 V (with a cable length of 5 m (16.4 ft.))

Leakage current Max. 200 A

Max. capacitive load 2.2 F

Load wiring resistance Max. 2.5

AUX Transistor outputs. (Compatible with bo th PNP and NPN)

Error output

Muting lamp output

EDM input

Wait input

Reset input

Muting input 1, 2

Override input

Power voltage DC24 V ± 20% (Ripple P-P 10% or less, Class2)

Current consumption Transmitter: 37 to 81 mA, Receiver: 66 to 91 mA

Enclosure rating IP65 / IP67 (IEC60529)

Overvoltage category

Ambient temperature -10 to +55°C (No freezing)

Storage ambient

temperature

Relative humidity 15% to 85%RH (No condensation)

Storage relative humidity 15% to 95%RH

Ambient light White incandescent lamp: 3,000 lx or less, Sunlight: 20,000 lx or less

Vibration

Shock

Main unit case Aluminum

Upper case/Lower case Nylon (GF30%)

Front cover Polycarbonate, SUS304

EMS IEC61496-1, EN61496-1, UL61496-1

EMC

EMI EN55011 ClassA, FCC Part15B ClassA, ICES-003 ClassA

Safety

T1 (Proof test interval) 20 years

PFHd (average frequency

of a dangerous failure per

hour)

Hardware fault toleranc e 1

Type of element Type B

Failure response time Within a response time

Safe state OSSDs are in OFF-state

distance is shorten by 0.5 m. When the front covers are installed on both of the transmitter and

receiver, the Operating distance is shorten by 1.0 m.

Load current: Max. 50 mA, Residual voltage: Max. 2.5 V

LED lamp (load current :10 to 230 mA) can be connected

< with PNP cable >

ON-voltage: 10 to 30 V

OFF-voltage: Open or 0 to 3 V

Short-circuit current:

Approx. 2.5 mA

(Approx. 10 mA for EDM)

Reverse current protection, sho rt-circuit protection for each outpu t, surge protection for each output

10 to 55 Hz, 0.7 mm compound amplitude, 20 sweeps each in X, Y and Z directions

100 m/s2 (Approx. 10 G) 16 ms pulse in X, Y and Z directions 1,000 times each axis

IEC61508, EN61508 (SIL3), IEC62061, EN62061 (SIL CL3)

(Determined by wiri ng)

Wire synchronization: prevented automatically

2 transistor outputs.

(PNP or NPN is determined by the cable type)

Max. 2.5 V (with a cable length of 5 m (16.4 ft.))

(with a cable length of 5 m (16.4 ft.))

Incandescent lamp (24 VDC, 1 to 5.5 W) or

-25 to +60°C (No freezing)

IEC61496-1, EN61496-1, UL61496-1 (Type 4 ESPE)

IEC61496-2, EN61496-2, UL61496-2 (Type 4 AOPD)

EN ISO13849-1:2008 (Category 4, PL e)

1.78×10

UL508

UL1998

-9

to 5.14×10

*2

*1

0.2 to 15 m

< with NPN cable >

ON-voltage: 0 to 3 V

OFF-voltage: Open or

10 V to Power voltage

Short-circuit current:

Approx. 2.5 mA

(Approx. 10 mA for EDM)

-9

current should not exceed 350 mA.

Response time (OSSD)

GL-RF

Model

GL-R23F 6.9 49.2 64.4 9.3 5 2.7 74.0

GL-R31F 7.8 50.5 67.9 10.7 54.8 79.5

GL-R39F 8.6 51.8 71.3 12.1 56.9 85.1

GL-R47F 9.5 53.1 74.8 13.5 59.0 90.7

GL-R55F 10.4 54 .3 78.3 14.9 61.1 96.3

GL-R63F 11.2 55.6 81.7 16.3 63.2 101.8

GL-R71F 12.1 56.9 85.2 17.6 65.3 107.4

GL-R79F 13.0 58.2 88.6 19.0 67.4 113.0

GL-R87F 13.8 59.5 92.1 20.4 69.4 118.5

GL-R95F 14.7 60.8 95.5 21.8 71.5 124.1

GL-R103F 15.5 62.1 99.0 23.2 73.6 129.7

GL-R111F 16.4 63.4 102.4 24.6 75.7 135.2

GL-R119F 17.3 64.7 105.9 26.0 77.8 140.8

GL-R127F 18.1 66.0 109.4 27.4 79.9 146.4

Wire synchronization, One-line or

Optical synchronization system (Channel 0)

ONOFF OFFON *1All blockedON *2ONOFF OFFON *1All blockedON

Response time (OSSD)

Optical synchronization system

(Channel A or B)

GL-RH

Model

GL-R08H 6.6 48.7 63.1 6.9 49.1 64.2

GL-R12H 6.6 48.7 63.1 7.4 49.9 66.3

GL-R16H 6.6 48.7 63.1 8.1 50.9 69.1

GL-R20H 6.6 48.7 63.1 8.8 52.0 71.9

GL-R24H 7.0 49.3 64.9 9.5 53.0 74.7

GL-R28H 7.4 50.0 66.6 10.2 54.0 77.5

GL-R32H 7.9 50.6 68.3 10.9 55.1 80.2

GL-R36H 8.3 51.3 70.0 11.6 56.1 83.0

GL-R40H 8.7 51.9 71.8 12.3 57.2 85.8

GL-R44H 9.2 52.6 73.5 12.9 58.2 88.6

GL-R48H 9.6 53.2 75.2 13.6 59.3 91.4

GL-R52H 10.0 53.9 77.0 14.3 60.3 94 .2

GL-R56H 10.5 54.5 78.7 15.0 61.4 96 .9

GL-R60H 10.9 55.2 80.4 15.7 62.4 99 .7

GL-R64H 11.3 55.8 82.1 16.4 63.4 102.5

GL-R72H 12.2 57.1 85.6 17.8 65.5 108.1

GL-R80H 13.1 58.4 89.1 19.2 67.6 113.7

GL-R88H 13.9 59.7 92.5 20.6 69.7 119.2

GL-R96H 14.8 61.0 96.0 22.0 71.8 124.8

Wire synchronization, One-line or

Optical synchronization system (Channel 0)

ONOFF OFFON *1All blockedON *2ONOFF OFFON *1All blockedON

Response time (OSSD)

Optical synchronization system

(Channel A or B)

GL-RL

Model

GL-R04L 6.6 48 .7 63.1 6. 9 49. 1 64.2

GL-R06L 6.6 48 .7 63.1 6. 9 49. 1 64.2

GL-R08L 6.6 48 .7 63.1 6. 9 49. 1 64.2

GL-R10L 6.6 48 .7 63.1 7. 0 49. 3 64.9

GL-R12L 6.6 48 .7 63.1 7. 4 49. 9 66.3

GL-R14L 6.6 48 .7 63.1 7. 7 50. 4 67.7

GL-R16L 6.6 48 .7 63.1 8. 1 50. 9 69.1

GL-R18L 6.6 48 .7 63.1 8. 4 51. 4 70.5

GL-R20L 6.6 48 .7 63.1 8. 8 52. 0 71.9

GL-R22L 6.8 49 .0 64.0 9. 1 52. 5 73.3

GL-R24L 7.0 49 .3 64.9 9. 5 53. 0 74.7

GL-R26L 7.2 49 .6 65.7 9. 8 53. 5 76.1

GL-R28L 7.4 50.0 66.6 10.2 54.0 77.5

GL-R30L 7.7 50.3 67.5 10.5 54.6 78.9

GL-R32L 7.9 50.6 68.3 10.9 55.1 80.2

*1 If the interruption is present in the detection zone for less than 80 ms, the response time (OFF to

ON) will be 80 ms or more to ensure that the OSSD maintains the OFF state for more than 80 ms.

*2 "All blocked" means the situation where the GL-R operates in optical synchronization system and

the transmitter and receiver is not synchronized (top and bottom beam axes are both blocked). In

this situation, the response time is longer because the GL-R synchronizes the transmitter and

receiver first and then determines the clear or blocked.

Point

Wire synchronization, One-line or

Optical synchronization system (Channel 0)

ONOFF OFFON *1All blockedON *2ONOFF OFFON *1All blockedON

• When the GL-R units are connected in series, the response ti me is calculated

according to the following steps;

1. Sum up the response time of all unit.

2. Subtract the following time from the result of previous step.

ON to OFF

One sub unit: 2 ms

Two sub unit: 4.2 ms

(When Optical synchronization system and Channel A or B)

One sub unit : 2.7 ms

Two sub unit: 5.7 ms

OFF to ON

One sub unit: 42 ms

Two sub unit: 84 ms

When connecting the GL-R32H (32 beam axes), GL-R24H (24 beam axes) , and GLR12L (12 beam axes) in series for one-line system, the response time of each unit is

7.9 ms, 7.0 ms, and 6.6 ms respectively, and the response time (ON to OFF) is 7.9 ms +

7.0 ms + 6.6 ms - 4.2 ms = 17.3 ms.

the response time (OFF to ON) is 50.6 ms + 49.3 ms + 48.7 ms - 84 ms = 64.6 ms.

• 2.0 m/s is the maximum object detection speed of the GL-R series.

Response time (OSSD)

Optical synchronization system

(Channel A or B)

Units: ms

Units: ms

Units: ms

*2

*2

*2

9

E GL-R-IM

Page 10

Current consumption

Units: mA Units: mA Units: mA

Model

Current

consumption (Max.)

Transmitter

Receiver

GL-R23F 50 70

GL-R31F 54 71

GL-R39F 57 72

GL-R47F 60 74

GL-R55F 62 75

GL-R63F 64 77

GL-R71F 66 78

GL-R79F 67 80

GL-R87F 69 81

GL-R95F 71 83

GL-R103F 72 84

GL-R111F 74 85

GL-R119F 76 87

GL-R127F 78 89

Model

Current

consumption (Max.)

Transmitter

Receiver

GL-R08H 43 66

GL-R12H 46 68

GL-R16H 50 69

GL-R20H 53 71

GL-R24H 57 72

GL-R28H 59 73

GL-R32H 61 74

GL-R36H 63 75

GL-R40H 65 76

GL-R44H 66 77

GL-R48H 68 79

GL-R52H 69 80

GL-R56H 71 81

GL-R60H 72 82

GL-R64H 73 83

GL-R72H 75 85

GL-R80H 77 87

GL-R88H 79 89

GL-R96H 81 91

Model

Current

consumption (Max.)

Transmitter

Receiver

GL-R04L 37 66

GL-R06L 39 67

GL-R08L 41 68

GL-R10L 43 69

GL-R12L 46 70

GL-R14L 48 71

GL-R16L 50 72

GL-R18L 52 73

GL-R20L 54 75

GL-R22L 56 75

GL-R24L 57 76

GL-R26L 59 77

GL-R28L 60 78

GL-R30L 61 79

GL-R32L 62 80

Units: g Units: g Units: g

Model

Weight

Transmitter

Receiver

GL-R23F 320 330

GL-R31F 430 440

GL-R39F 550 550

GL-R47F 660 670

GL-R55F 780 780

GL-R63F 890 900

GL-R71F 1000 1010

GL-R79F 1200 1200

GL-R87F 1300 1300

GL-R95F 1400 1400

GL-R103F 1500 1500

GL-R111F 1600 1600

GL-R119F 1700 1700

GL-R127F 1800 1900

Model

Weight

Transmitter

Receiver

GL-R08H 210 210

GL-R12H 320 330

GL-R16H 430 440

GL-R20H 550 550

GL-R24H 660 660

GL-R28H 770 770

GL-R32H 880 890

GL-R36H 1000 1000

GL-R40H 1110 1110

GL-R44H 1220 1220

GL-R48H 1330 1340

GL-R52H 1440 1450

GL-R56H 1560 1560

GL-R60H 1670 1680

GL-R64H 1780 1790

GL-R72H 2010 2010

GL-R80H 2230 2240

GL-R88H 2450 2460

GL-R96H 2680 2690

Model

Weight

Transmitter

Receiver

GL-R04L 210 210

GL-R06L 320 330

GL-R08L 430 440

GL-R10L 550 550

GL-R12L 660 660

GL-R14L 770 770

GL-R16L 880 890

GL-R18L 1000 1000

GL-R20L 1110 1110

GL-R22L 1220 1220

GL-R24L 1330 1340

GL-R26L 1440 1450

GL-R28L 1560 1560

GL-R30L 1670 1680

GL-R32L 1780 1790

*1 The above current consumption does not include the current consumed via OSSD output.

*2 If inputs other than EDM input turn on, consumption current per input increases by 2.5 mA.

Weight

Troubleshooting

If the GL-R is not functioning normally, check the GL-R indicators first.

The GL-R is in an error condition under the following situations.

• The center indicators blink in red.

• The 7-segment display indicates "".

If the GL-R does not demonstrate the above situations, the GL-R is not in an error condition.

If the GL-R is in an error condition

Indication Error name Cause Check and corrective action

E GL-R-IM

Wiring error

The end cover on the

receiver is not connected.

The unit connection cable

is connected to the upper

part of the GL-R.

Transmitter and receiver

are not the same model.

When the GL-R operates in wire synchronization system

The synchronization wire is

not wired correctly or

disconnected.

When the GL-R operates in one-line system

The unit connection cable

is connected to the

transmitter.

The series connection

cable is connected to the

lower part of the GL-R.

When the GL-R is in series connection.

The sub unit is not

connected correctly.

The sub unit is broken.

When the error is cleared by restarting the GL-R.

The synchronization wire is

affected by external noise.

Check that the end cover is installed on the receiver

correctly.

"Cable installation" (page 5)

Connect the unit connection cable to the lower part of

the GL-R.

"Cable installation" (page 5)

Check that all transmitter and receiver models are

paired correctly.

Check the wiring of the synchronization wire.

"Cable color and pin position" (page 6)

• Connect the unit connection cable to the receiver.

• Do not connect the unit connection cable to the

transmitter.

"Cable installation" (page 5)

Connect the series connection cable to the upper part

of the transmitter and receiver.

"Cable installation" (page 5)

• Check for the direction of the sub unit installation.

• Check whether the receiver o f sub unit is connected

to the transmitter of main unit.

• Check whether the total numbe r of beam axes is

more than 240.

"Series connection" ( page 4)

Check that the sub unit operates correctly when not in

series connection.

Check for noise source (inverter, servomotor, etc.)

around the GL-R installatio n location and cables.

Indication Error name Cause Check and corrective action

Setting switch error

Configuration error

Interlock error

EDM error

Receiver error

Transmitter error

OSSD1 error

OSSD2 error

Sub unit error

Communication error

Muting lamp

disconnection error

Muting lamp over

current error

Synchronization beam

axis error

System error

:

*1 All indicators on the transmitter may turn OFF.

*2 This error occurs only when the muting lamp error is configured to cause error condition by using the

configuration software.

The configuration of the

setting switch is out of

specification.

The setting switch is

configured to something

other than Channel 0 in

wire synchronization

system.

The configuration of the

setting switch overlaps the

configuration uploaded

from the configuration

software.

The unit configuration is

different from the

configuration uploaded

from the software.

The upload of configuration

has not been completed

correctly when using the

configuration software.

Interlock mode selection

input or reset input are

wired incorrectly.

EDM input is not

connected correctly.

There is a welded contact

on the external device.

The receiver is affected by

ambient light.

The transmitter is broken. Replace the transmitter.

When the error is cleared by restarting the GL-R.

The transmitter is affected

by external noise.

When the error is cleared by restarting the GL-R.

OSSD is affected by

external noise.

There is a voltage surge

affecting the OSSD due to

an inductive load.