VHF FM TRANSCEIVER

TK-7360/7360H

TK-7360H

(

V

SERVICE MANUAL

REVISED

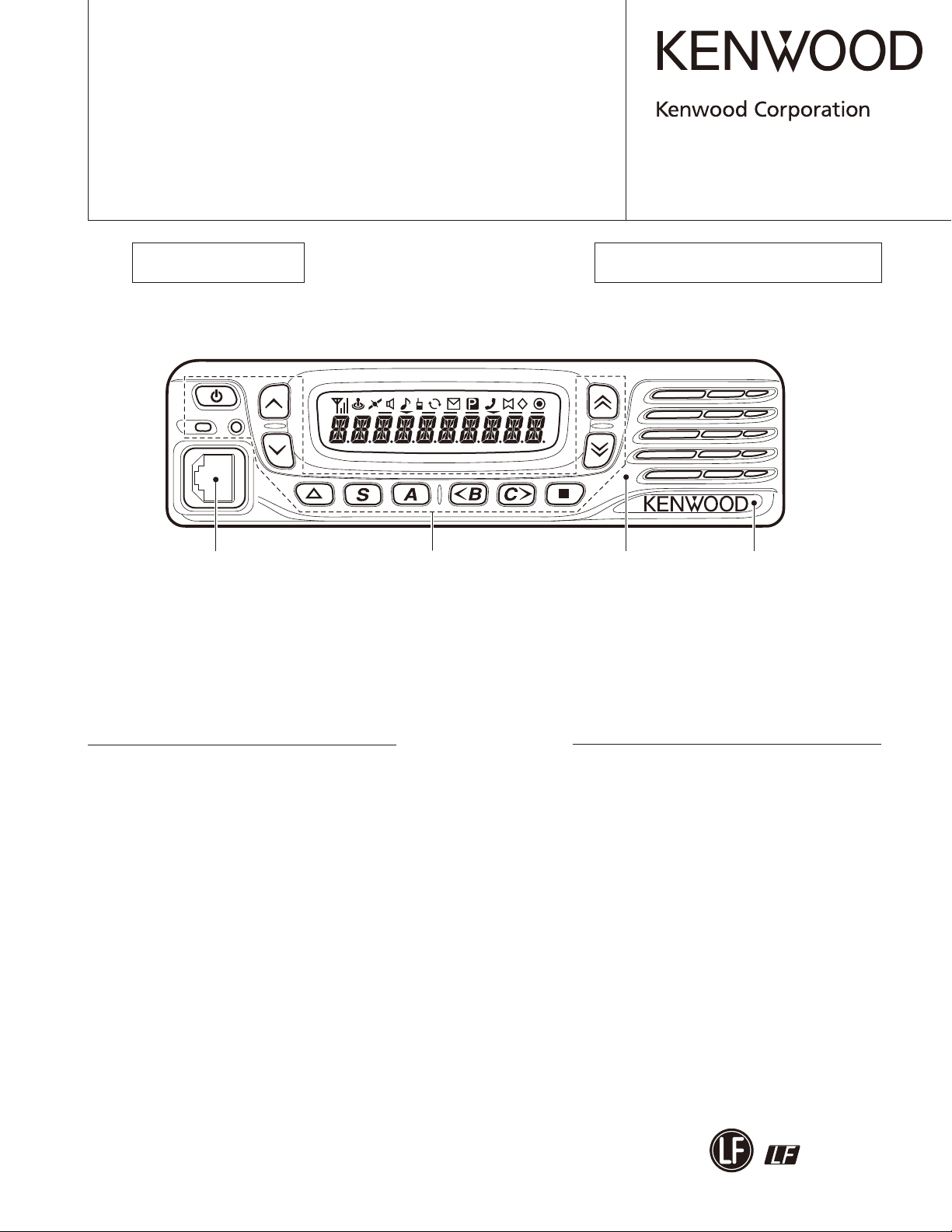

Modular jack

(E58-0535-05)

Key top

(K29-9479-01)

)

© 2011-1 PRINTED IN JA PAN

B51-8952-10 (N) PDF

This service manual added the details of the

panel tuning mode to B51-8952-00.

Panel assy

(A62-1180-13)

Badge

(B43-1650-04)

CONTENTS

GENERAL .....................................................2

SYSTEM SET-UP .........................................4

REALIGNMENT ...........................................4

INSTALLATION ............................................6

DISASSEMBLY FOR REPAIR ....................11

CIRCUIT DESCRIPTION ............................13

SEMICONDUCTOR DATA .........................18

COMPONENTS DESCRIPTION .................19

PARTS LIST ...............................................21

EXPLODED VIEW ......................................31

This product complies with the

directive for the European market.

RoHS

PACKING ....................................................32

ADJUSTMENT ..........................................33

TERMINAL FUNCTION .............................42

PC BOARD

DISPLAY UNIT (X54-3740-20) ...............44

TX-RX UNIT (X57-8020-XX) ..................46

SCHEMATIC DIAGRAM ............................50

BLOCK DIAGRAM .....................................56

LEVEL DIAGRAM ......................................58

SPECIFICATIONS ......................................59

This product uses Lead Free solder.

TK-7360/7360H/7360H(V

)

Document Copyrights

Copyright 2011 by Kenwood Corporation. All rights re-

served.

No part of this manual may be reproduced, translated,

distributed, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, for any purpose without the prior written permission

of Kenwood.

GENERAL

INTRODUCTION

SCOPE OF THIS MANUAL

This manual is intended for use by experienced technicians familiar with similar types of commercial grade com mu ni ca tions equipment. It contains all required service

in for ma tion for the equipment and is current as of the publication date. Changes which may occur after publication

are covered by either Service Bulletins or Manual Revisions.

These are is sued as required.

ORDERING REPLACEMENT PARTS

When ordering replacement parts or equipment information, the full part identifi cation number should be included.

This applies to all parts : components, kits, or chassis. If the

part number is not known, include the chassis or kit number

of which it is a part, and a suffi cient description of the re quired component for proper identifi cation.

PERSONAL SAFETY

The following precautions are recommended for personal

safety:

• DO NOT transmit if someone is within two feet (0.6 me-

ter) of the antenna.

• DO NOT transmit until all RF connectors are secure and

any open connectors are properly terminated.

• SHUT OFF this equipment when near electrical blasting

caps or while in an explosive atmosphere.

• All equipment should be properly grounded before pow-

erup for safe operation.

• This equipment should be serviced by only qualified

technicians.

Disclaimer

While every precaution has been taken in the preparation

of this manual, Kenwood assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained

herein. Kenwood reserves the right to make changes to any

products herein at any time for improvement purposes.

PRE-INSTALLATION CONSIDERATIONS

1. UNPACKING

Unpack the radio from its shipping container and check

for accessory items. If any item is missing, please contact

KENWOOD immediately.

2. LICENSING REQUIREMENTS

Federal regulations require a station license for each

radio installation (mobile or base) be obtained by the equipment owner. The licensee is responsible for ensuring transmitter power, frequency, and deviation are within the limits

permitted by the station license.

Transmitter adjustments may be performed only by a

licensed technician holding an FCC fi rst, second or general

class commercial radiotelephone operator’s license. There is

no license required to install or operate the radio.

3. PRE-INSTALLATION CHECKOUT

3-1. Introduction

Each radio is adjusted and tested before shipment. However, it is recommended that receiver and transmitter operation be checked for proper operation before installation.

3-2. Testing

The radio should be tested complete with all cabling and

accessories as they will be connected in the fi nal installation. Transmitter frequency, deviation, and power output

should be checked, as should receiver sensitivity, squelch

operation, and audio output. Signalling equipment operation

should be verifi ed.

2

GENERAL

TK-7360/7360H/7360H(V

)

4. PLANNING THE INSTALLATION

4-1. General

Inspect the vehicle and determine how and where the

radio antenna and accessories will be mounted.

Plan cable runs for protection against pinching or crush-

ing wiring, and radio installation to prevent overheating.

4-2. Antenna

The favored location for an antenna is in the center of a

large, flat conductive area, usually at the roof center. The

trunk lid is preferred, bond the trunk lid and vehicle chassis

using ground straps to ensure the lid is at chassis ground.

4-3. Radio

The universal mount bracket allows the radio to be

mounted in a variety of ways. Be sure the mounting surface

is adequate to support the radio’s weight. Allow suffi cient

space around the radio for air cooling. Position the radio

close enough to the vehicle operator to permit easy access

to the controls when driving.

4-4. DC Power and wiring

1. This radio may be installed in negative ground electrical

systems only. Reverse polarity will cause the cable fuse

to blow. Check the vehicle ground polarity before instal-

lation to prevent wasted time and effort.

2. Connect the positive power lead directly to the vehicle

battery positive terminal. Connecting the Positive lead

to any other positive voltage source in the vehicle is not

recommended.

3. Connect the ground lead directly to the battery negative

terminal.

4. The cable provided with the radio is suffi cient to handle

the maximum radio current demand. If the cable must be

extended, be sure the additional wire is suffi cient for the

current to be carried and length of the added lead.

5. INSTALLATION PLANNING – CONTROL STATIONS

5-1. Antenna system

Control station. The antenna system selection depends

on many factors and is beyond the scope of this manual.

Your KENWOOD dealer can help you select an antenna system that will best serve your particular needs.

5-2. Radio location

Select a convenient location for your control station radio

which is as close as practical to the antenna cable entry

point. Secondly, use your system’s power supply (which

supplies the voltage and current required for your system).

Make sure suffi cient air can fl ow around the radio and power supply to allow adequate cooling.

SERVICE

This radio is designed for easy servicing. Refer to the

schematic diagrams, printed circuit board views, and alignment procedures contained in this manual.

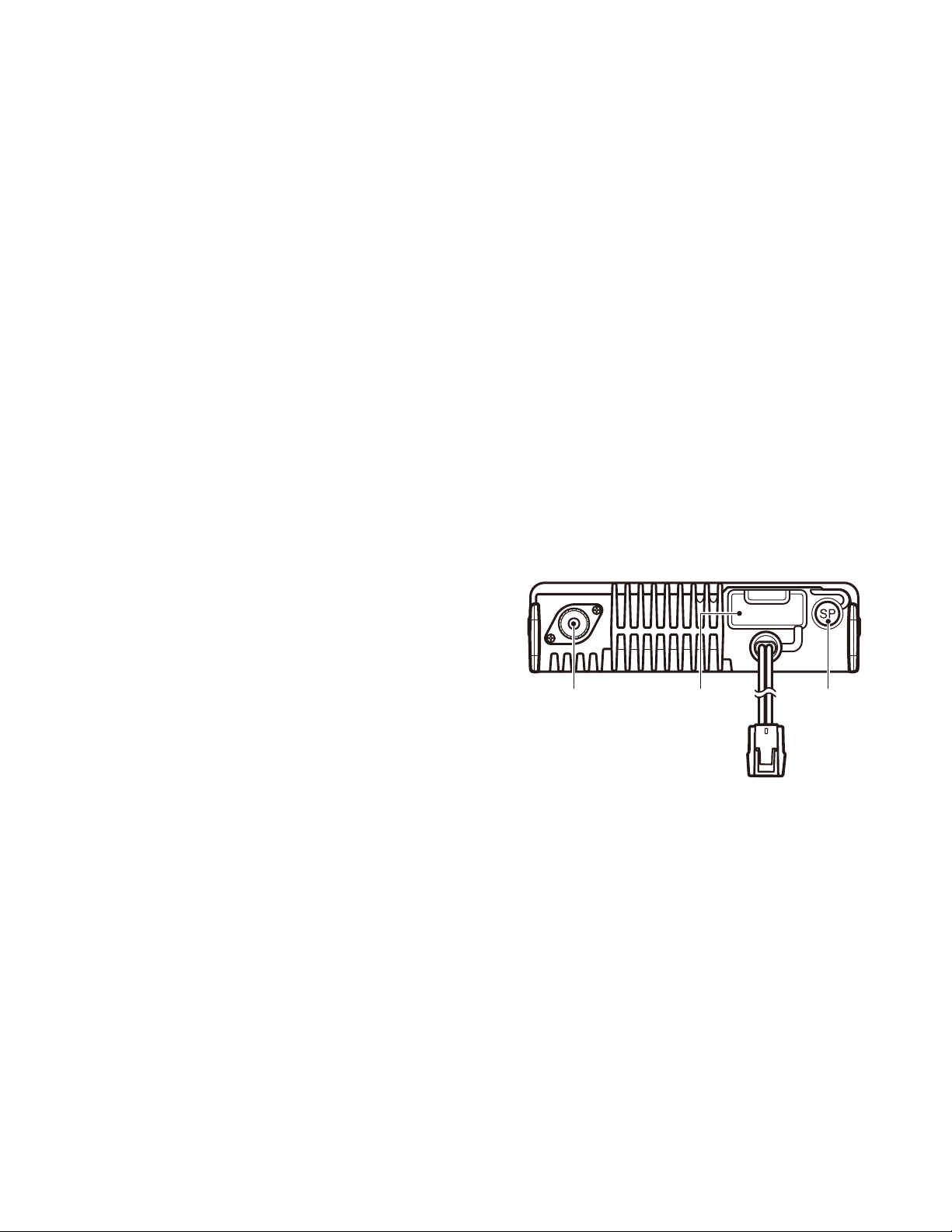

NOTE

If you do not intend to use the speaker 3.5-mm jack and

the D-sub 15-pin connector, fi t the supplied speaker-jack cap

and ACC cap to stop dust and sand from getting in.

ACC.

Antenna

connector

ACC. cap

Speaker

jack cap

Power input

connector

3

TK-7360/7360H/7360H(V

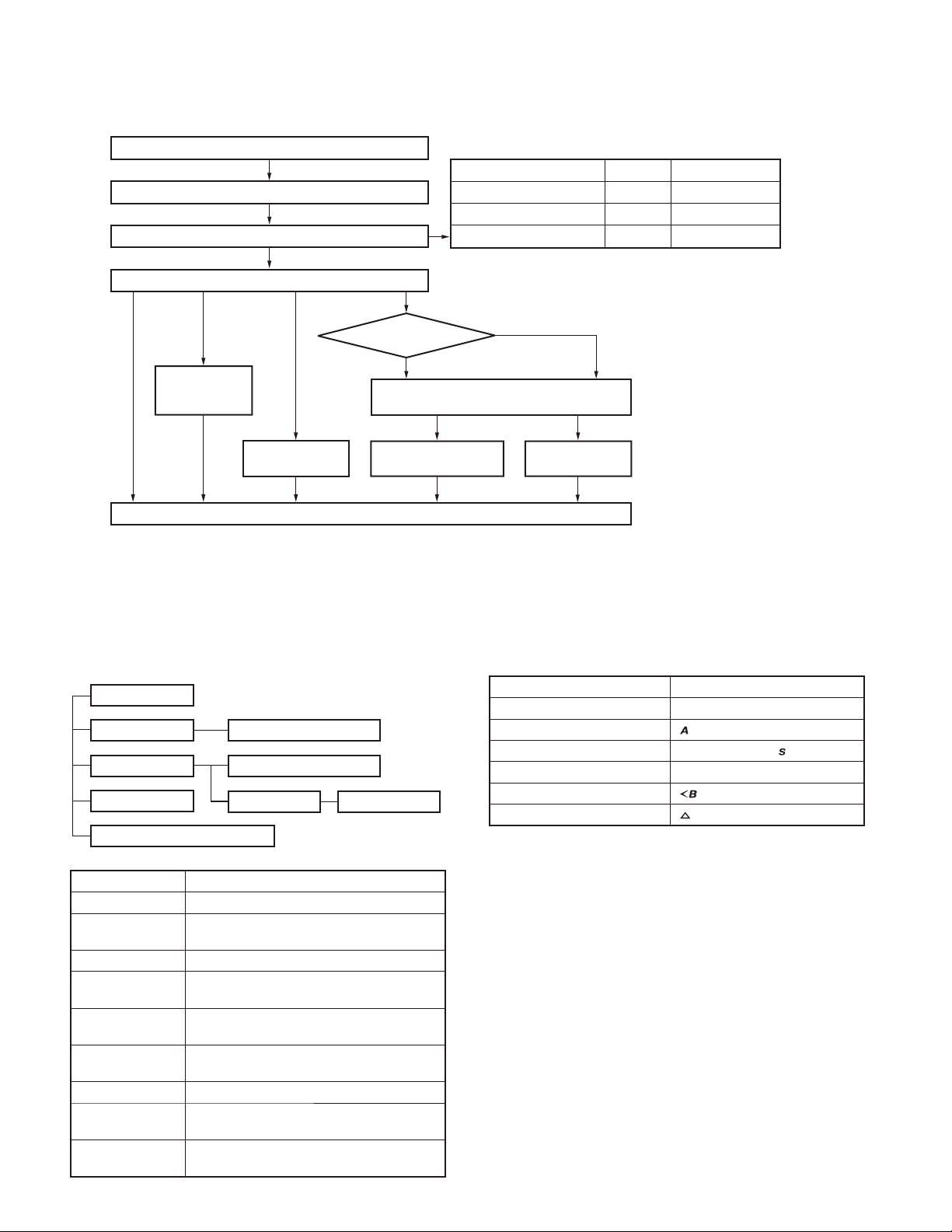

Merchandise received

License and frequency allocated by FCC: K type only

Choose the type of transceiver

)

SYSTEM SET-UP

Frequency range (MHz) RF power

136~174 25W TK-7360 M,M2

136~174

136~174

Type

50W TK-7360H K,M

50W

TK-7360H(V) K

Transceiver programming

VGS-1

Voice guide &

storage unit

See page 9.

1. Modes

User mode

Panel test mode

PC mode

Clone mode

Firmware version information

(Option)

(Option)

KES-3

External speaker

See page 9.

Panel tuning mode

PC programming mode

PC test mode

See page 4.

A personal computer, programming interface (KPG-46/46A),

and FPU (programming software) are required for programming.

KCT-60

Connection cable

KCT-36

Extension cable

(Option)

KCT-18

Ignition sense cable

See page 7. See page 9.

Delivery

REALIGNMENT

2. How to Enter Each Mode

PC tuning mode

(Option)

See page 6.

(Option)

(Option)

KES-5

External speaker

Mode Operation

User mode Power ON

Panel test mode [

Panel tuning mode Panel test mode+[

PC mode Received commands from PC

Clone mode [

Firmware version information [

]+Power ON

]

]+Power ON (One second)

]+Power ON

Mode Function

User mode For normal use.

Panel test mode

Panel tuning mode Used by the dealer to tune the transceiver.

PC mode

PC programming

mode

PC test mode

PC tuning mode Used to tune the transceiver using the PC.

Clone mode

Firmware version

information

Use by the dealer to check the fundamental

characteristics.

Used for communication between the transceiver and PC.

Used to read and write frequency data and

other features to and from the transceiver.

Used to check the transceiver using the PC.

This feature is included in the FPU.

Used to transfer programming data from one

transceiver to another.

Used to confi rm the internal fi rmware version.

4

3. Panel Test Mode

Setting method refer to ADJUSTMENT.

4. Panel Tuning Mode

Setting method refer to ADJUSTMENT.

5. PC Mode

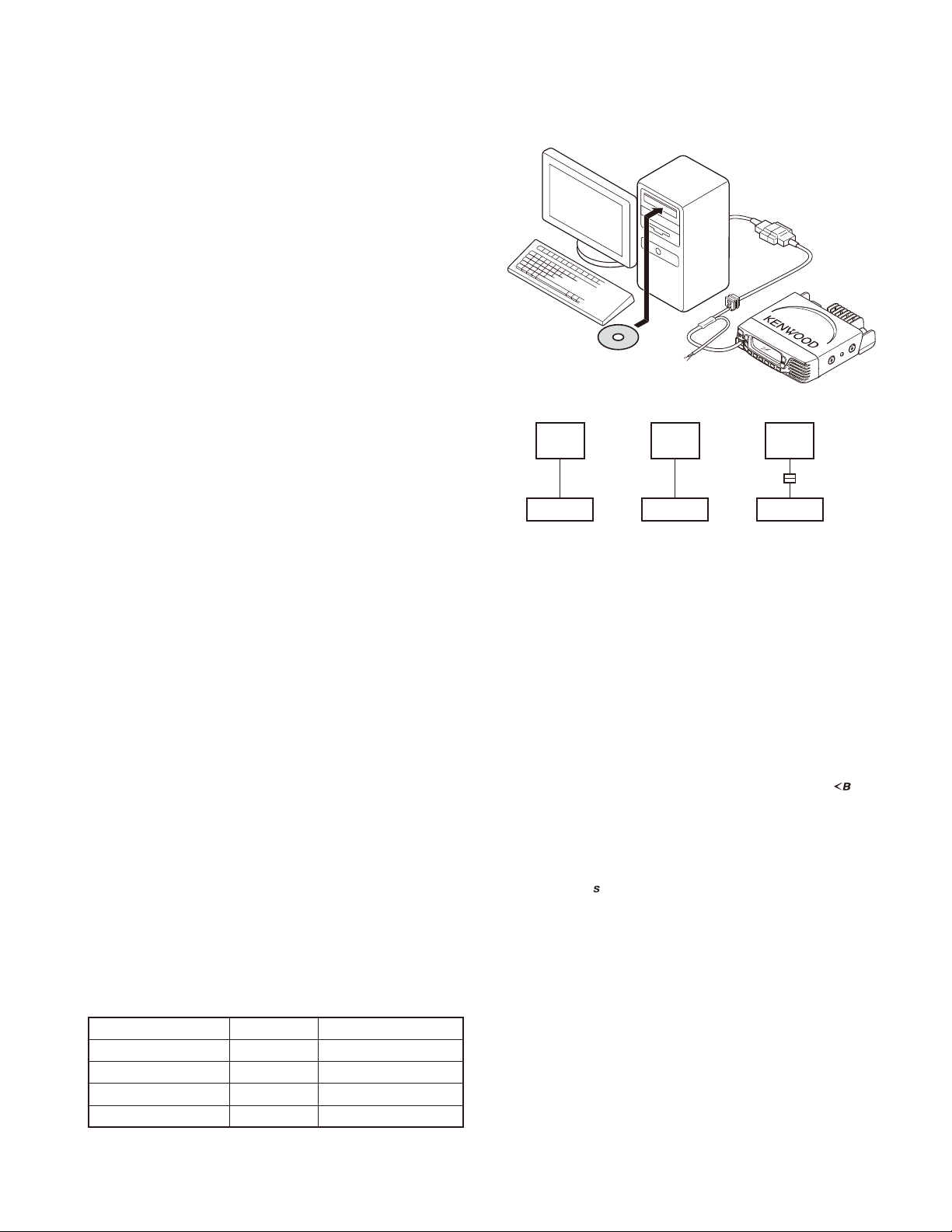

5-1. Preface

The transceiver is programmed using a personal computer, a programming interface (KPG-46/46A, USB adapter

(KCT-53U)) and FPU (programming software).

The programming software can be used with a PC. Figure 1 shows the setup of a PC for programming.

REALIGNMENT

TK-7360/7360H/7360H(V

)

5-2. Connection procedure

1. Connect the transceiver to the computer using the interface cable and USB adapter (When the interface cable is

KPG-46A, the KCT-53U can be used.).

Note:

• You must install the KCT-53U driver in the computer to

use the USB adapter (KCT-53U).

• When using the USB adapter (KCT-53U) for the fi rst time,

plug the KCT-53U into a USB port on the computer with

the computer power ON.

2. When the Power is switched on, user mode can be entered immediately. When the PC sends a command, the

transceiver enters PC mode, and “PROGRAM” is displayed on the LCD.

When data is transmitting from the transceiver, the red

LED blinks.

When data is receiving by the transceiver, the green LED

blinks.

Note:

The data stored in the computer must match the “Model

Name” when it is written into the EEPROM.

5-3. KPG-46/KPG-46A description

(PC programming interface cable: Option)

The KPG-46/46A is required to interface the transceiver

to the computer. It has a circuit in its D-sub connector (KPG46: 25-pin, KPG-46A: 9-pin) case that converts the RS-232C

logic level to the TTL level.

The KPG-46/46A connects the 8-pin microphone connec-

tor of the transceiver to the RS-232C serial port of the computer.

5-4. KCT-53U description (USB adapter: Option)

The KCT-53U is a cable which connects the KPG-46A to

a USB port on a computer.

When using the KCT-53U, install the supplied CD-ROM

(with driver software) in the computer. The KCT-53U driver

runs under Windows 2000, XP or Vista (32-bit).

5-5. FPU (Programming Software) description

The FPU is the programming software for the transceiver

supplied on a CD-ROM. This software runs under Windows

XP, Vista or 7 on a PC.

The data can be input to or read from the transceiver and

edited on the screen. The programmed or edited data can

be printed out. It is also possible to tune the transceiver.

List of FPU for transceiver

Model Type FPU

TK-7360 M,M2 KPG-135D(M)

TK-7360H K KPG-135D(K)

TK-7360H M KPG-135D(M)

TK-7360H(V) K KPG-135D(K)

PC

D-SUB

(25-pin)

KPG-46

Transceiver

PC

FPU

PC

D-SUB

(9-pin)

KPG-46A

Transceiver

KPG-46 or KPG-46A or

KPG-46A + KCT-53U +

Tuning cable

(E30-3383-05)

PC

USB

KCT-53U

KPG-46A

Transceiver

Fig. 1

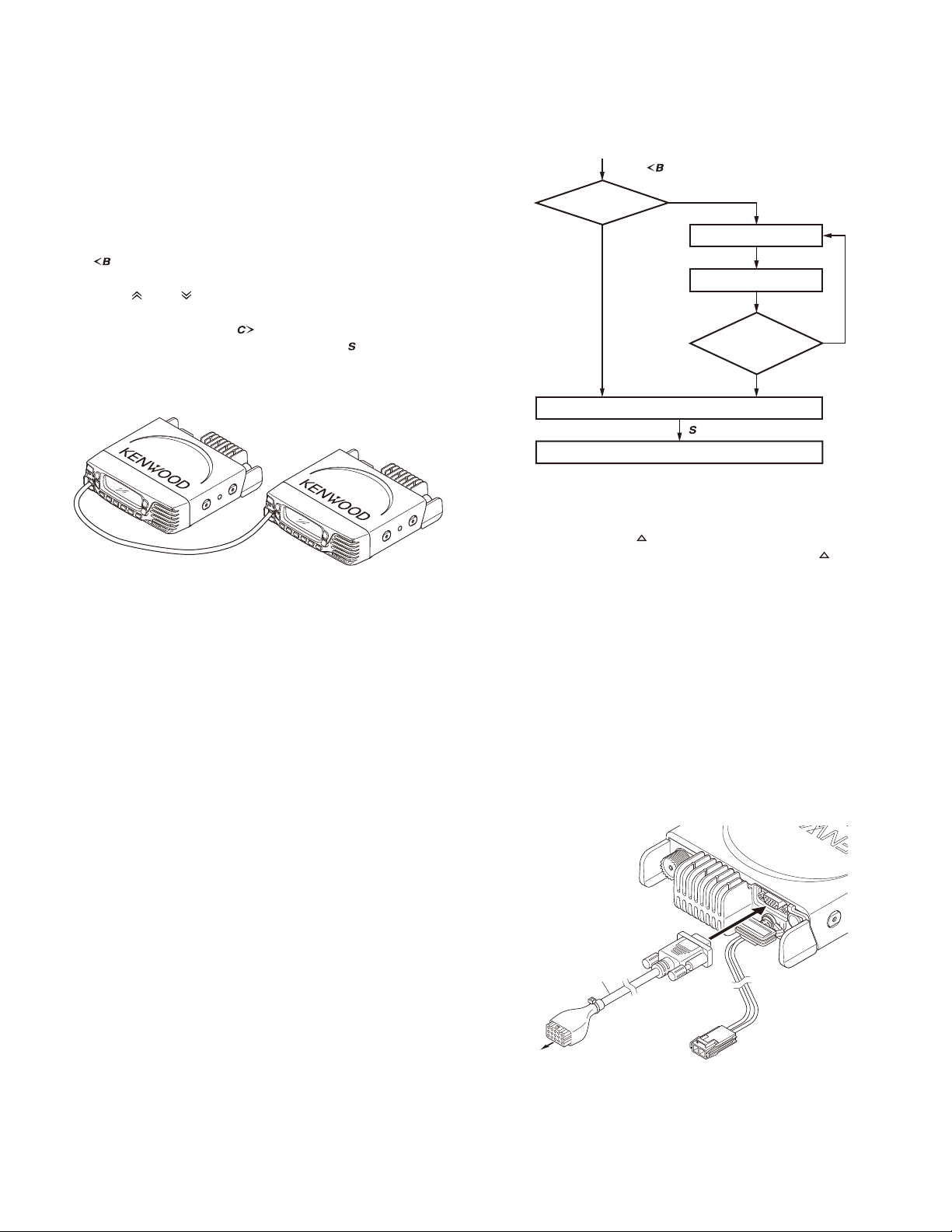

6. Clone Mode

Programming data can be transferred from one transceiver to another by connecting them via their modular

microphone jacks. The operation is as follows (the transmit

transceiver is the source and the receive transceiver is a target).

Note :

Clone mode should be enabled.

1. Turn the source transceiver power ON with the [

held down (1 second), “CLONE MODE” is displayed on

the LCD.

2. Power on the target transceiver.

3. Connect the cloning cable (No. E30-3382-05) to the mod-

ular microphone jacks on the source and target.

4. Press the [

The data of the source is sent to the target. While the

source is sending data, red LED blinked. While the tar-

get is receiving the data, “PROGRAM” is displayed and

green LED blinked. When cloning of data is completed,

the source displays “END”, and the source red LED

turned off, and the target automatically operates in the

User mode. The target can then be operated by the

same program as the source.

5. The other target can be continuously cloned. Carry out

the operation in step 2 to 4.

] key on the source transceiver.

] key

5

TK-7360/7360H/7360H(V

)

REALIGNMENT

6-1. Adding the data password

If the read authorization password is set in the optional

feature menu, you must enter the password (Source transceiver) to activate a clone mode.

You can use 0~9 to confi gure the password. The maximum length of the password is 6 digits.

1. [

]+Power ON.

2. “CLONE LOCK” is displayed on the LCD.

3. If the [

is displayed, numbers (0 to 9) are displayed flashing.

When you press the [

number is determined. If you press the [

tering the password in this procedure, “CLONE MODE”

is displayed if the entered password is correct. If the

password is incorrect, “CLONE LOCK” is redisplayed.

] and [ ] keys is pressed while “CLONE LOCK”

] key, the currently selected

] key after en-

Cloning cable

(E30-3382-05)

Fig. 2

6-2. Flow chart (Source transceiver)

Press [ ] key + Power ON for 1 second

password*

* Read

Authorization

password

Is

set?

No

Start the clone funnction

Yes

Shows CLONE LOCK

Clone mode

[ ]

Enter password

Is entered

password

correct?

Yes

7. Firmware Version Information

Press and hold the [ ] key while turning the transceiver

power ON and then keep pressing and holding the [

the fi rmware version information appears on the LCD.

No

] key,

INSTALLATION

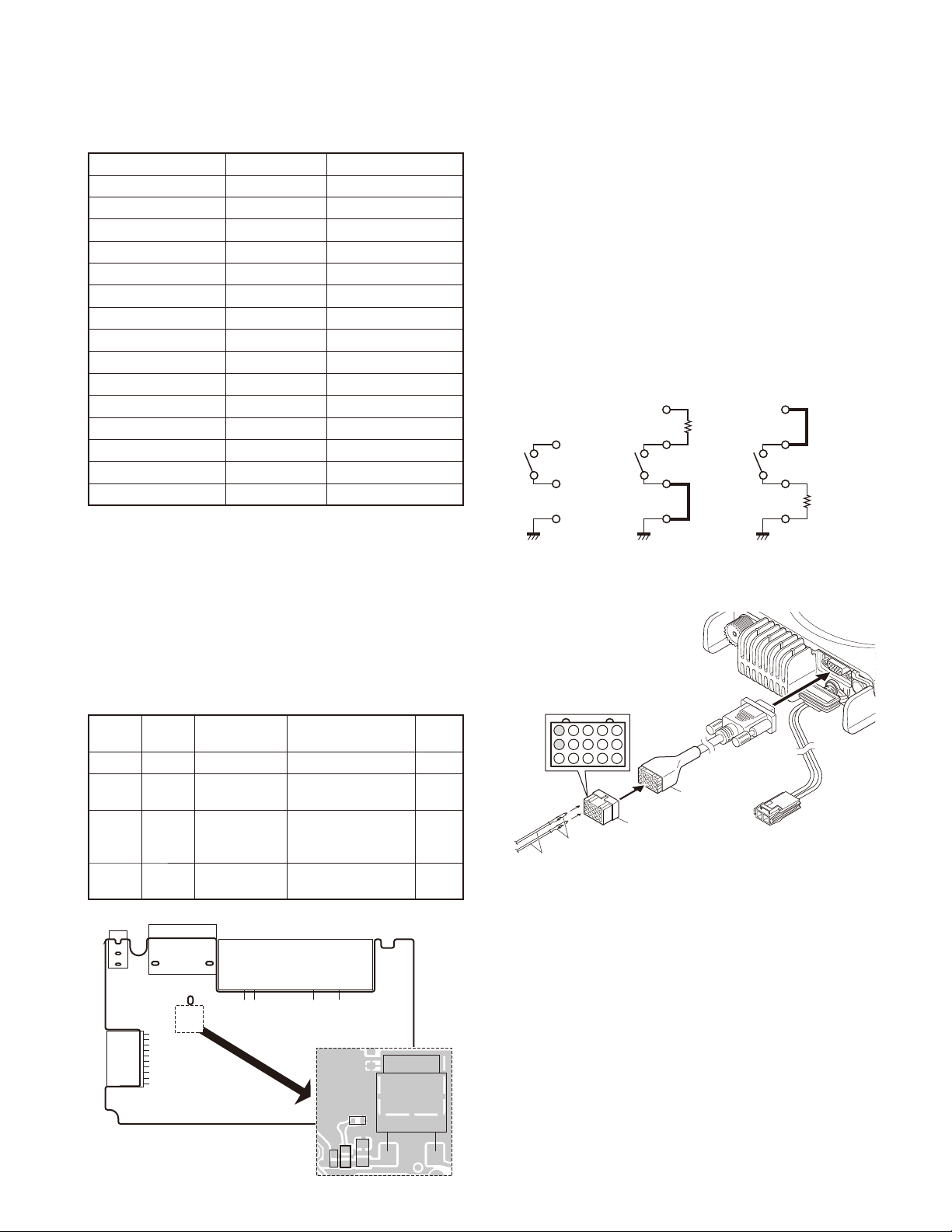

1. Connection Cable (KCT-60: Option)

The KCT-60 connection cable kit is used to connect the

transceiver to a Horn alert cable, KCT-18 (Ignition sense

cable), KES-5 (External speaker), or through the KCT-36 extension cable.

1-1. Installing the KCT-60 (Connection cable) in the

transceiver

1. Remove the ACC. cap on the rear of the transceiver.

2. Connect the D-sub connector of the KCT-60 to the D-sub

15-pin terminal of the transceiver.

3. Connect the 15-pin connector of the KCT-60 to a Horn

alert cable, KCT-18, KES-5, or through a KCT-36 extension

cable.

Note: You must setup using the KPG-135D(K) or KPG135D(M).

6

KCT-60

Horn alert cable,

KCT-18, KES-5 or through

KCT-36 extension cable

INSTALLATION

TK-7360/7360H/7360H(V

)

1-2. Terminal function

D-sub 15-pin Pin No. Function Molex 15-pin Pin No.

1SB1

2 IGN 2

3PA12

4DO4

5DI5

6 FNC1 9

7 FNC2 11

8 FNC3 7

9 FNC4 6

10 FNC5 8

11 FNC6 10

12 5C -

13 HR1 13

14 HR2 14

15 GND 3

2. Horn Alert Function

The Horn alert function (max. 2A drive) is enabled by in-

stalling the KCT-60 in the transceiver.

2. Remove the ACC. cap on the rear of the transceiver.

3. Connect the D-sub connector of the KCT-60 to the D-sub

15-pin terminal of the transceiver.

4. Insert the two crimp terminals of the Horn alert cable to

pins 13 and 14 of the square plug.

5. Connect the square plug to the 15-pin connector of the

KCT-60.

6. Connect the remaining two Horn alert cables to your car

Horn alert signal control.

The internal FET switch can be controlled by turning the

HA function on/off and by using a signaling decode output. The maximum current of HA is 2A. This FET switch

is the open drain circuit. Therefore, a DC power supply is

necessary to use the HR1. The voltage range is from 5V

to 16V.

1. SB

13. HR1

14. HR2

3. GND

More

than 8

Ω

(Default)

13. HR1

14. HR2

3. GND

1. SB

13. HR1

14. HR2

3. GND

More

than 8

Ω

Note: You must set up using the KPG-135D(K) or KPG135D(M).

2-1. Installation Procedure

1. Remove the chip resistor R863 (4.7kΩ) on the TX-RX unit

before installing the KCT-60 in the transceiver.

Combination of Horn alert function and Ignition function

R863 KCT-18

Present Absent Always inactive Inactive Default

Absent Present

Absent Absent Always active

Present Present

Horn alert

function

Active when

ignition is off

Do not use this

confi guration

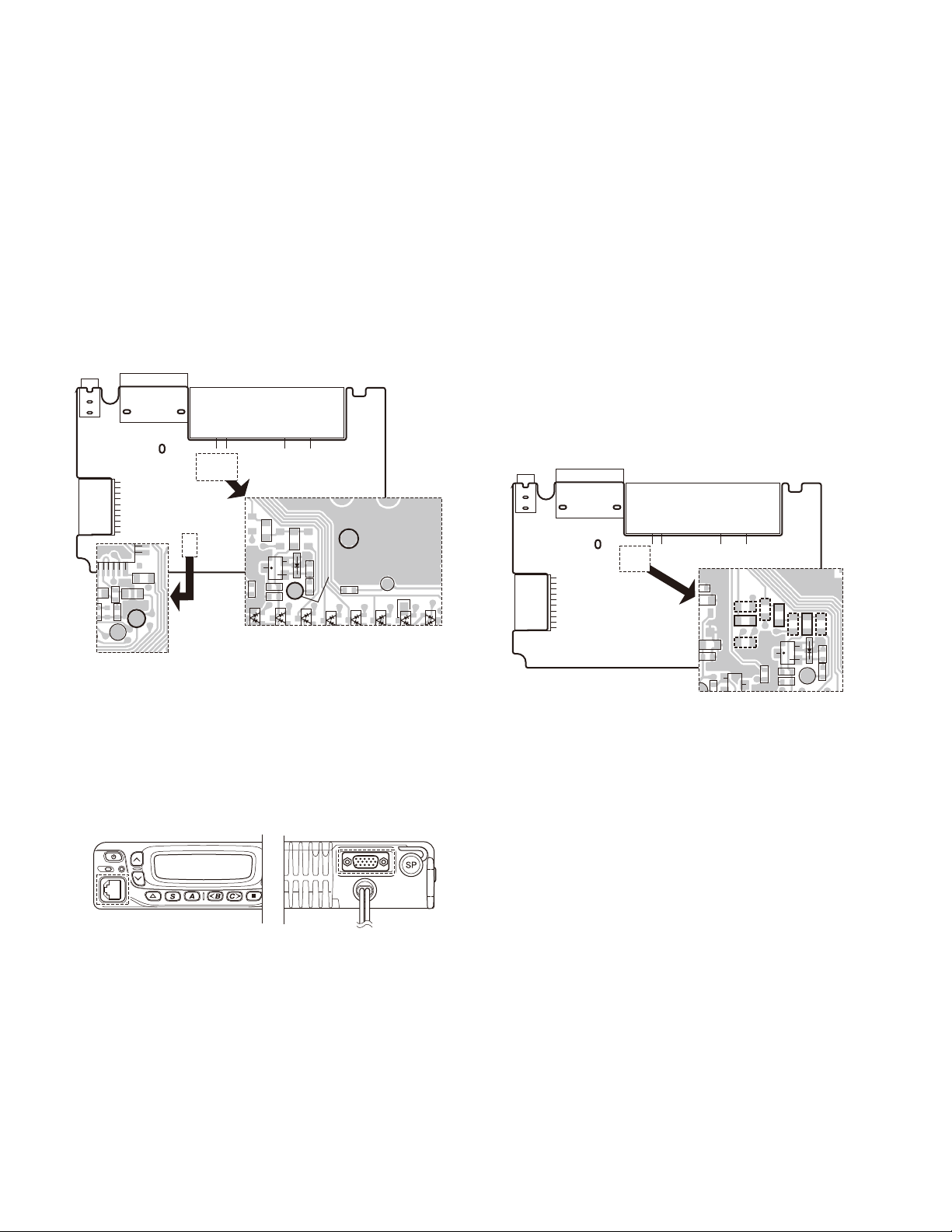

TX-RX unit

Component side

Ignition function

Active

Transceiver cannot be

turned on if the igni-

tion function is set

Do not use this con-

fi guration

R863

13

10

7

4

14

15

13

Crimp terminal

Horn alert cable

1

11

8

5

2

12

9

6

3

KCT-60

14

Square plug

3. Ignition Sense Cable (KCT-18: Option)

The KCT-18 is an optional cable for enabling the ignition

function. The ignition function lets you turn the transceiver

power on and off with the car ignition key.

3-1. Installing the KCT-18 (Ignition sense cable) in

the transceiver

1. The KCT-18 can be installed in the transceiver by the fol-

lowing two methods (Method A, Method B).

Method A: The KCT-18 is soldered to the “IGN” pad on

the TX-RX unit.

Method B: The KCT-18 is connected to the 15-pin con-

nector of the KCT-60 connected to the transceiver.

7

TK-7360/7360H/7360H(V

)

INSTALLATION

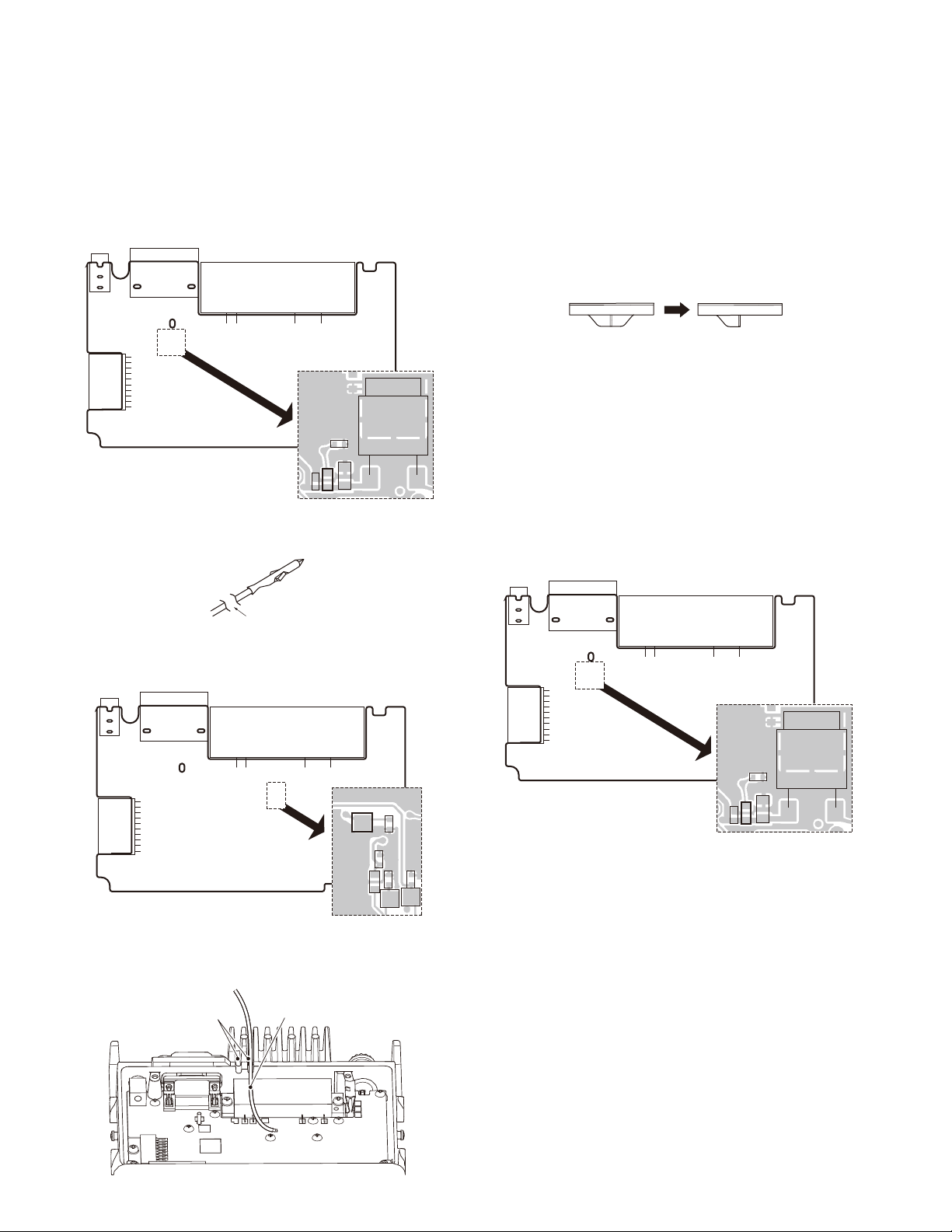

Installation Procedure: Method A

■

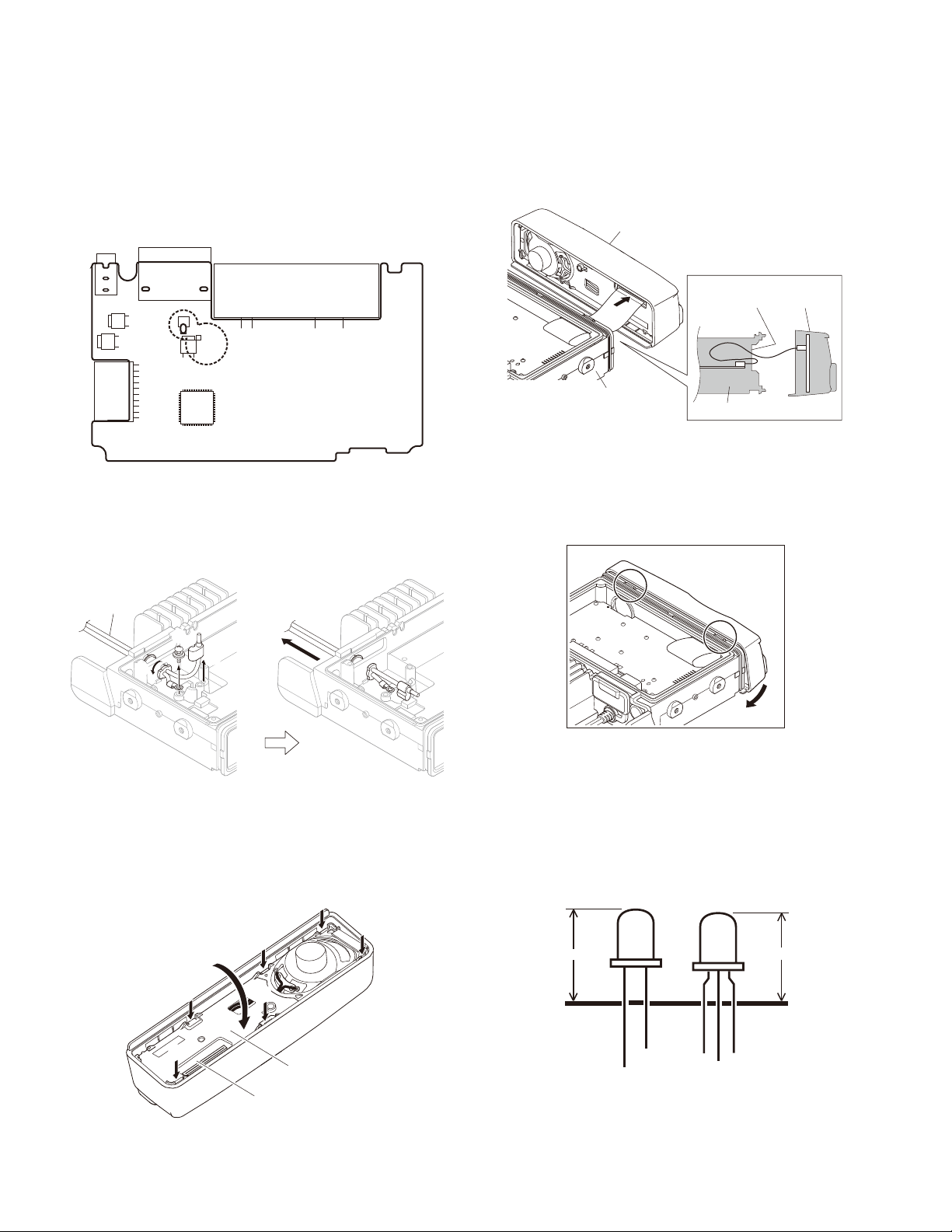

1. Remove the two screws on both the right and left sides

of the transceiver, then remove the cabinet and top packing from the transceiver.

2. Remove the chip resistor R863 (4.7kΩ) on the TX-RX

unit.

TX-RX unit

Component side

R863

3. Cut the crimp terminal side of the KCT-18 using a pair of

nippers or similar tool.

6. Cut off the projection of the top packing using a pair of

nippers or similar tool.

If the KCT-18 cable is dressed to be routed through the

indentations on the right side in step 5, the right side of

the projection needs to be cut off. If the KCT-18 cable is

dressed to be routed through the indentations on the left

side, the left side of the projection needs to be cut off.

Following is a fi gure presenting an example for when the

right side of the projection is cut off.

7. Reinstall the top packing. Check the correct fi tting of the

top packing, then reinstall the cabinet and two screws

for the right and left sides.

8. Connect the other side of the KCT-18 to the ignition line

of the car.

Installation Procedure: Method B

■

1. Remove the two screws on both the right and left sides

of the transceiver, then remove the cabinet and top packing from the transceiver.

2. Remove the chip resistor R863 (4.7kΩ) on the TX-RX

unit.

Cut

4. Solder the cable side cut in the above step 3 to the “IGN”

pad on the TX-RX unit.

IGN

TX-RX unit

Component side

5. Dress the KCT-18 cable as shown in the fi gure. The KCT18 cable needs to pass through one of two indentations

located on the rear panel of the transceiver.

Indentation part

KCT-18

TX-RX unit

Component side

R863

3. Remove the ACC. cap on the rear of the transceiver.

4. Connect the D-sub connector of the KCT-60 to the D-sub

15-pin terminal of the transceiver.

5. Insert the crimp terminal side of the KCT-18 to pin 2 of

the square plug.

6. Connect the square plug to the 15-pin connector of the

KCT-60.

7. Connect the other side of the KCT-18 to the ignition line

of the car.

Note: You must set up using the KPG-135D(K) or KPG135D(M).

8

TK-7360/7360H/7360H(V

)

INSTALLATION

Note:

You must set up using the KPG-135D(K) or KPG-135D(M).

Before the external speaker can be used, you must as-

sign one of the keys as “External Speaker”, using the

KPG-135D(K) or KPG-135D(M).

1

4

7

10

13

14

15

2

5

8

11

3

6

9

12

KCT-18

Ignition

line of the car

2

KCT-60

Square plug

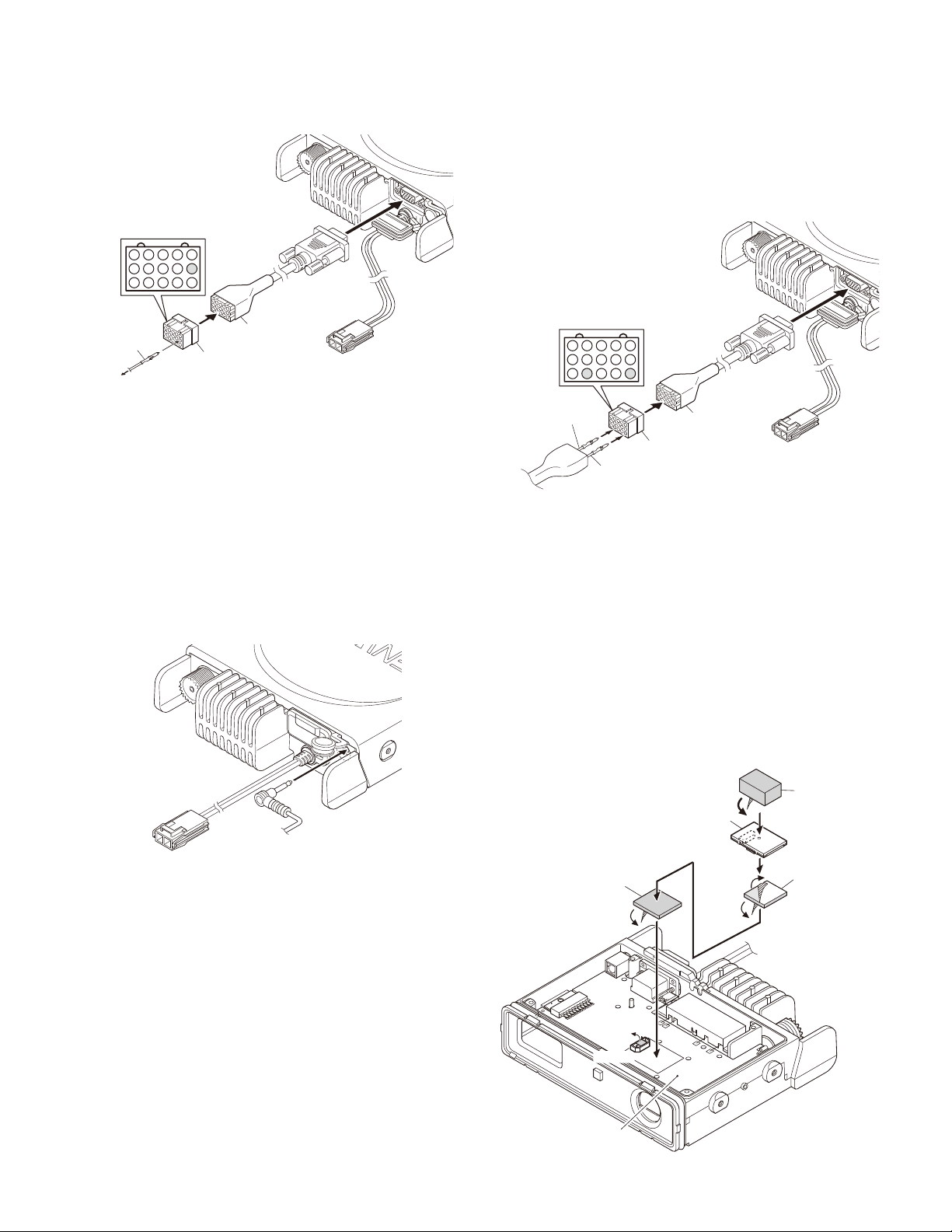

4. External Speaker (Option)

4-1. KES-3

The KES-3 is an external speaker for the 3.5-mm-diameter

speaker jack.

Connection procedure

■

1. Remove the speaker-jack cap on the rear of the transceiver.

2. Connect the KES-3 to the 3.5-mm-diameter speaker jack

on the rear of the transceiver.

13

10

7

4

11

8

12

9

12

Black lead

1

5

2

6

3

3

KCT-60

Square plug

14

15

Black/

White lead

5.

Voice Guide & Storage Unit (VGS-1: Option)

5-1. Installing the VGS-1 unit in the transceiver

1. Remove the two screws on both sides of the transceiver, then remove the cabinet and top packing from the

transceiver.

2. Remove the cover fi tted into the TX-RX unit connector

(CN700).

3. Attach two cushions to VGS-1

4. Insert the VGS-1 connector (CN1) into the TX-RX unit

connector (CN700).

Note: You must set up using the KPG-135D(K) or KPG135D(M).

Cushion

(G13-1994-04)

VGS-1

20x30x12mm

4-2. KES-5

External speaker KES-5 can be installed for KCT-60.

Connection procedure

■

1. Remove the ACC. cap on the rear of the transceiver.

2. Connect the D-sub connector of the KCT-60 to the D-sub

15-pin terminal of the transceiver.

3. Insert the two crimp terminals of the KES-5 to pins 3 and

12 of the square plug.

4. Connect the square plug to the 15-pin connector of the

KCT-60.

Cushion

(G13-1994-04)

20x30x1.0mm

Cover

CN700

TX-RX PCB

Cushion

(G13-1974-04)

21x21x1.0mm

9

TK-7360/7360H/7360H(V

)

INSTALLATION

6. GPS Receiver Connection

6-1. Installing the GPS receiver

1. Solder each cable of the connector cables to the TX-RX

unit.

• Red cable

The red cable needs to be connected to the solder pad

(5M) on the TX-RX unit.

• Yellow cable

The yellow cable needs to be connected to the solder

pad GPS (RS-232C-RXD) on the TX-RX unit.

• Black cable

The black cable needs to be connected to the solder pad

(GND) on the TX-RX unit.

TX-RX unit

Component side

5M

Red

Black

GND

Yellow

GPS (RS-232C-RXD)

8. Changing Serial Port Level

8-1. Change FNC2 (RXD) of D-SUB 15-pin connec-

tor from TTL level to RS-232C level

FNC2 (RXD) of D-SUB 15-pin connector is confi gured at

the TTL level as the default value. But you can change this

serial port level to RS-232C level by confi guring the port.

Remove the R726 chip jumper and solder the clip jumper

to R727.

8-2.

Change FNC1 (TXD) and FNC2 (RXD) of D-SUB

15-pin connector from TTL level to RS-232C level

FNC1 (TXD) and FNC2 (RXD) of D-SUB 15-pin connector

are confi gured at the TTL level as the default value. But you

can change these serial port level to RS-232C level through

the RS-232C level converter IC (IC700) by confi guring the

port.

Remove the R760 and R761 chip jumpers and solder the

chip jumpers to R752, R753, R767 and R768.

R760

R768

R726

R727

R752

TX-RX unit

Component side

R761

R753

R767

Note: You must set up using the KPG-135D(K) or KPG135D(M).

7. Extended Function: COM Port 0 and COM Port 1

Location of COM Port 0 and COM Port 1 of the trans-

ceiver is shown below.

COM Port 1

COM Port 0

You must configure the transceiver COM Port 0 and

COM Port 1 using the KPG-135D(K) or KPG-135D(M).

When you set as “Data”, the Function port 1 and 2 will

be automatically fi xed as Input ports. The reason for this is

because function port 1 (TXD) and 2 (RXD) share the same

circuit path of TXD and RXD line.

In the case of 8-1.

■

[TTL level]

R726,R760 and R761: 0Ω chip jumper.

R727, R752, R753, R767 and R768: open.

[RS-232C level]

R727, R760 and R761: 0Ω chip jumper.

R726, R752, R753, R767 and R768: open.

In the case of 8-2.

■

[TTL level]

R726,R760 and R761: 0Ω chip jumper.

R727, R752, R753, R767 and R768: open.

[RS-232C level]

R726, R752, R753, R767 and R768: 0Ω chip jumper.

R727, R760 and R761: Open.

10

TK-7360/7360H/7360H(V

DISASSEMBLY FOR REPAIR

)

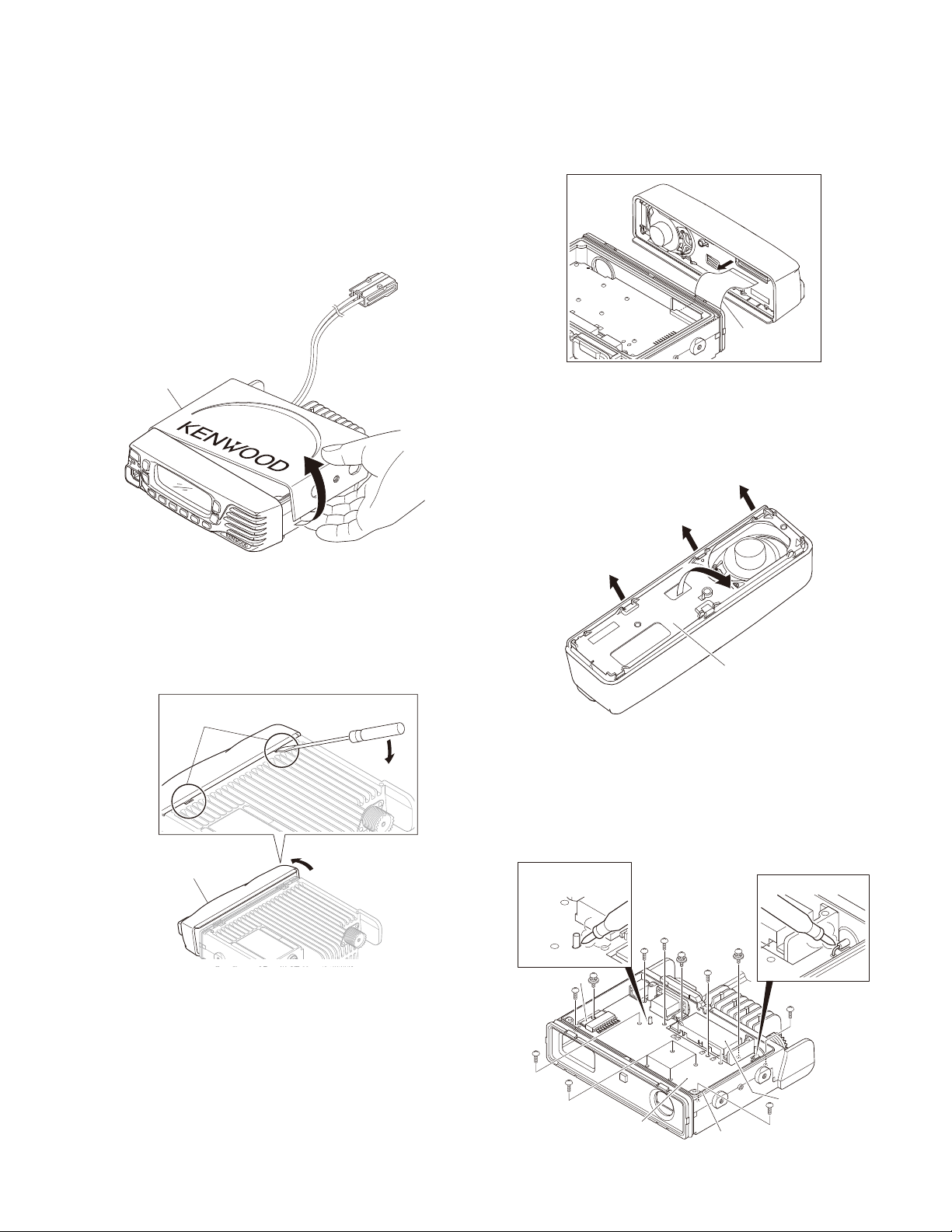

1. Disassembly Procedure

1. When removing the cabinet, fi rst remove the two screws

from the right and left with a phillips screwdriver.

Then, hook your fi nger on the edge of the cabinet and

pull it out until it is over the chassis protrusion. Remove

the cabinet by prying the cabinet as shown below.

Cabinet

3. Disconnect the fl at cable from connector of the panel assembly.

Flat cable

4. Hook the finger to hole and while pulling the speaker

holder to this side, expand the panel side of q to e, and

remove the speaker holder from the front panel.

@

:

.

2. To remove the panel assembly, fi rst turn the transceiver

upside down.

Then, insert a fl at-head screwdriver into the holes of the

chassis and tilt it in the direction as shown by the arrow.

Holes

Panel assembly

Speaker holder

5. When removing the TX-RX PCB, first remove the top

packing.

Then, remove the solder of the antenna hot pin and posi-

tive terminal of the DC cord.

Remove the 15 screws from the TX-RX PCB, power

module, and audio amp.

Positive terminal

of the DC cord

Audio amp

Antenna hot pin

TX-RX PCB

Power module

Top packing

11

TK-7360/7360H/7360H(V

DISASSEMBLY FOR REPAIR

)

Note:

When you supply power to the TX-RX PCB after remov-

ing the TX-RX PCB from the chassis, solder the positive

and ground terminals of the DC cord (Recommendation:

E30-3448-25) to the + and GND terminals of the TX-RX

PCB.

+

GND

TX-RX PCB

Component side

6. Pull it out behind the chassis by rotating the bush e of

the DC cord 90 degrees in the direction of the arrow after the screw q in the negative terminal is removed, and

the positive terminal w is removed from the chassis.

2. When mounting the panel assembly, pass the fl at cable

through the hole of the chassis as shown below then

connect the fl at cable to connector of the panel assembly.

Panel assembly

Hole of

the chassis

Chassis

Chassis

3. Fit the panel assembly into the two tabs of the chassis

top side fi rst.

Then, fit the panel assembly into the two tabs of the

chassis bottom side by turning the panel assembly.

Panel

assembly

DC cord

:

.

@

2. Precautions for Reassembly

1. The tab from q to e is applied the front panel fi rst. And,

to y tabs inside the front panel is pushed.

r

@

:

.

B

;

Speaker holder

=

3. Correspondence when replacing the LED (D22 and D23)

When replacing the LED (D22 and D23), it makes it to

length.

LED

D22

13mm

LED

D23

12mm

12

Display PCB

TK-7360/7360H/7360H(V

CIRCUIT DESCRIPTION

)

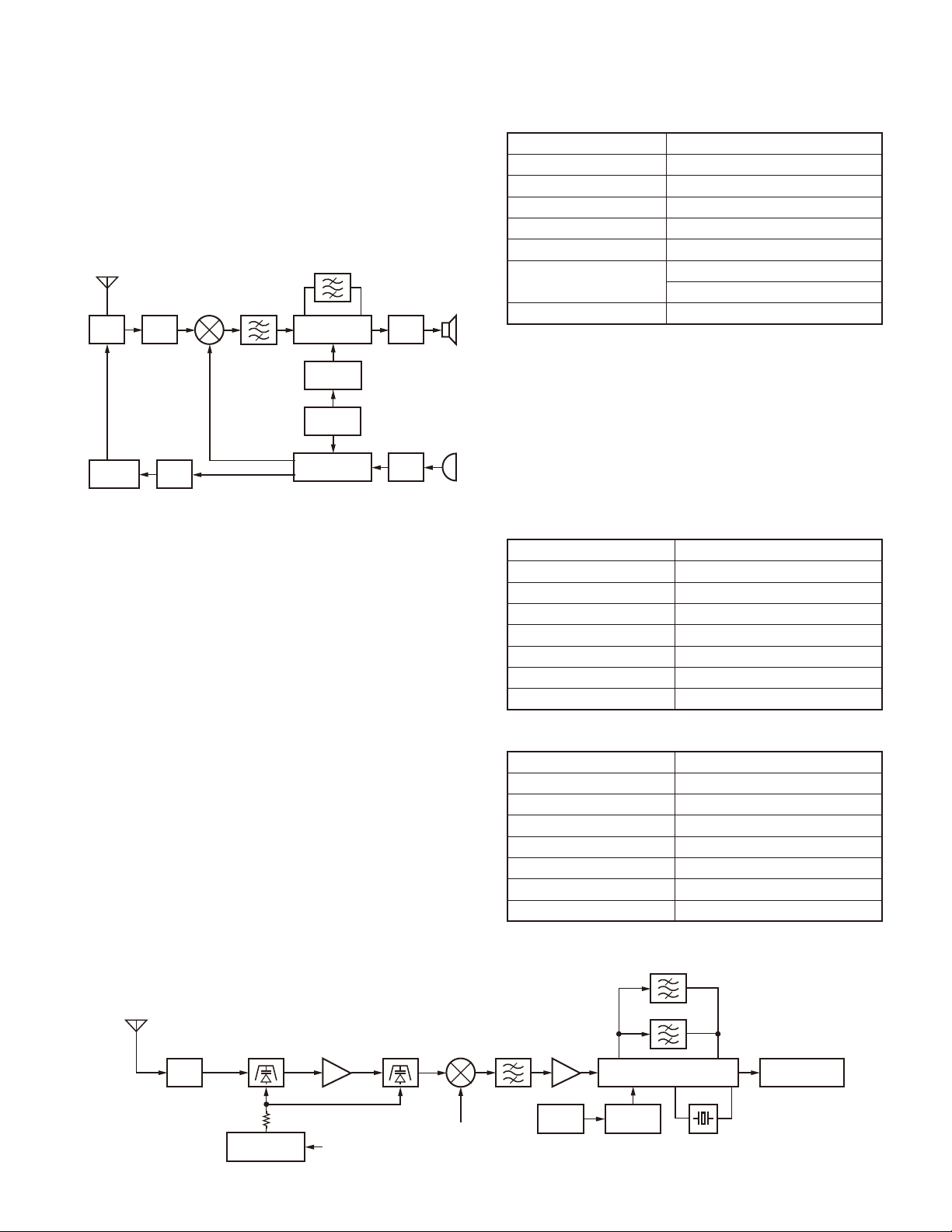

1. Frequency Confi guration

The receiver utilizes double conversion. The first IF is

38.85MHz and the second IF is 450kHz. The fi rst local oscillator signal is supplied from the PLL circuit.

The PLL circuit in the transmitter generates the neces-

sary frequencies. Figure 1 shows the frequencies.

RX

TX

CF 450kHz

IF SYSTEM

38.4MHz

X2

multiply

TCXO

PLL/VCO

SP

AF

PA

19.2MHz

MIC

MIC

AMP

ANT

ANT

SWRFAMP

POWER

AMP

RF

AMP

1st

MIX

MCF

38.85MHz

Fig. 1 Frequency confi guration

2. Receiver System

The receiver is a double conversion superheterodyne.

The frequency confi guration is shown in Figure 1.

2-1. Front-end RF Amplifi er

An incoming signal from the antenna is applied to an RF

amplifi er (Q511) after passing through the transmit/receive

switch circuit (D303, D304, D307 and D308) and bandpass

fi lter (L518, L519 and varactor diodes: D506, D507).

After the signal is amplifi ed (Q511), the signal is fi ltered

by the bandpass (L513 and varactor diodes: D504, D505) to

eliminate unwanted signals before it is passed to the fi rst

mixer.

The voltage of these diodes are controlled by tracking

the MCU (IC704) center frequency of the bandpass filter.

(See Figure 2)

2-2. First Mixer

The signal from the RF amplifi er is heterodyned with the

fi rst local oscillator signal from the PLL frequency synthesizer circuit at the fi rst mixer (Q507) to create a 38.85MHz

fi rst intermediate frequency (1st IF) signal. The fi rst IF signal

is then fed through one pair of monolithic crystal fi lters (MCF:

XF500) to further remove spurious signals.

Item Rating

Nominal center frequency 38.85MHz

Pass bandwidth ±6.0kHz or more at 3dB

40dB stop bandwidth ±25.0kHz or less

Ripple 1.0dB or less

Insertion loss 4.0dB or less

Guaranteed attenuation

Terminal impedance 610Ω// 3.0pF// Coupling Cap 13.0pF

75dB (–900kHz); 50dB (+900kHz)

Spurious: 40dB or more within fo±1MHz

Table 1 Crystal fi lter (L71-0659-05): XF500

2-3. IF Amplifi er Circuit

The fi rst IF signal is amplifi ed by Q504, and enters IC500

(FM processing IC). The signal is heterodyned again with

a second local oscillator signal within IC500 to create a

450kHz second IF signal. The second IF signal is then fed

through a 450kHz ceramic filter (Wide: CF500, Narrow:

CF501) to further eliminate unwanted signals before it is

amplifi ed and demodulated by the quadrature detector with

the ceramic discriminator (CD500).

Item Rating

Nominal center frequency 450kHz

6dB bandwidth ±6.0kHz or more

50dB bandwidth ±12.5kHz or less

Ripple 2.0dB or less

Insertion loss 6.0dB or less

Guaranteed attenuation 35.0dB or more within fo±100kHz

Terminal impedance 2.0k

Ω

Table 2 Ceramic fi lter (L72-0993-05): CF500

Item Rating

Nominal center frequency 450kHz

6dB bandwidth ±4.5kHz or more

50dB bandwidth ±10.0kHz or less

Ripple 2.0dB or less

Insertion loss 6.0dB or less

Guaranteed attenuation 60.0dB or more within fo±100kHz

Terminal impedance 2.0k

Ω

Table 3 Ceramic fi lter (L72-0999-05): CF501

CF500 (Wide)

ANT

D303,D304

D307,D308

ANT

SW

L518,L519

D506,D507

BPF

IC501

DC OP AMP

Q511

RF AMP

TV

TVC &

APCC

L513

D504,D505

BPF

Q507

MIX

1st local

OSC (VCO/PLL)

XF500

MCF

Fig. 2 Receiver System

Q504

IF AMP

X1

TCXO

CF501 (Narrow)

IC500

FM system IC

Q500

Doubler

CD500

IC702

Baseband IC

13

TK-7360/7360H/7360H(V

CIRCUIT DESCRIPTION

)

2-4. Wide/Narrow Switching Circuit

The Wide port (pin 99) and Narrow port (pin 98) of the

MCU is used to switch between ceramic fi lters. When the

Wide port is high, the ceramic fi lter switch diodes (D500,

D501) cause CF500 to turn on to receive a Wide signal.

When the Narrow port is high, the ceramic fi lter switch

diodes (D500, D501) cause CF501 to turn on to receive a

Narrow signal.

IC500

FM System IC

IF_IN MIX_O

CF500

(Wide)

CF501

D500 D501

Narrow

IC704

pin98

(Narrow)

R506

R505

R507

R508

Wide

IC704

pin99

Fig. 3 Wide/Narrow switching circuit

2-5. AF Signal System

The detection signal from the FM IC (IC500) goes to the

baseband IC (IC702) DISC input (pin 16) for characterizing

the signal.

The AF signal output from IC702 is input to the audio

power amplifi er (IC706). The AF signal from IC706 switches

between the internal speaker and the speaker jack (J701)

output.

IC500

FM IC

IC702

Baseband

IC

IC706 SP

AF PA

Fig. 4 AF signal system

The electric fi eld strength of the receive signal can be

known before the SQIN voltage is input to the MCU, and

the scan stop speed is improved.

D502

Noise DET

SQIN

RSSI

IC704

MCU

IC500

FM IC

FIL_OUT

RSSI

Q505

Noise

AMP

Fig. 5 Squelch circuit

3. Transmitter System

3-1. Outline

The transmitter circuit produces and amplifies the desired frequency directly. It FM-modulates the carrier signal

by means of a varicap diode.

3-2. Power Amplifi er Circuit

The transmit output signal from the VCO passes through

the transmission/reception selection diode (D17) and amplified by Q300. The amplified signal goes to the RF power

module (IC300) through a low-pass fi lter. The lowpass fi lter

removes unwanted high-frequency harmonic components,

and the resulting signal goes through the antenna terminal.

3-3. APC Circuit

The automatic transmission power control (APC) circuit

detects part of a fi nal amplifi er output with a coupler circuit

and applies a voltage to IC301. IC301 compares the APC

control voltage (PC) generated by the baseband IC (IC702)

and DC amplifi er (IC501) with the detection output voltage.

IC301 generates the voltage to control IC300 and stabilizes

transmission output.

The APC circuit is confi gured to protect over current of

Q300 and IC300 due to fl uctuations of the load at the antenna end and to stabilize transmission output at voltage and

temperature variations.

Q300 IC300

D17

DRIVE

AMP

RF POWER

module

D303,D304

ANT

SW

ANT

LPF

2-6. Squelch Circuit

The detection output from the FM IC (IC500), a voltage

is applied to the MCU (IC704). The MCU controls squelch

according to the voltage (SQIN) level.

The signal from the RSSI pin of IC500 is monitored.

IC701MIC

MIC

AMP

Q712

SW

MIC key

input

IC702

Baseband

IC

MCU

IC704

TCXO

19.2MHz

Fig. 6 Transmitter system

14

X1

Q6

TX

VCO

PLL IC

IC2

APCC

IC702

pin32

Q12

BUFF

AMP

RF

AMP

Q3

DC

AMP

IC501

APC

control

IC301

Coupler

circuit

Fig. 7 APC circuit

Q13

RF

AMP

Q300 IC300

DRIVE

AMP

ANT

RF POWER

module

TK-7360/7360H/7360H(V

CIRCUIT DESCRIPTION

)

4. PLL Frequency Synthesizer

The PLL circuit generates the fi rst local oscillator signal

for reception and the RF signal for transmission.

4-1. PLL Circuit

The frequency step of the PLL circuit is 5, 6.25, 7.5, 10,

12.5 or 15kHz.

A 19.2MHz reference oscillator signal is divided at IC2

by a fi xed counter to produce the reference frequency. The

voltage controlled oscillator (VCO) output signal is buffer

amplifi ed by Q12, then multiplied by using a doubler and divided by a programmable counter in IC2.

The divided signal is compared in phase with the refer-

ence signal in the phase comparator in IC2. The output

signal from the phase comparator is fi ltered through a low-

IC2: PLL IC

1/N

LPF

ASTC

Charge

pump

IC3

voltage

OP

AMP

Fig. 8 PLL circuit

PLL

DATA

19.2MHz

REF

OSC

Phase

comparator

1/M

Assist

pass fi lter and passed to the VCO to control the oscillator

frequency.

4-2. VCO Circuit

The operating frequency is generated by Q6 in transmit

mode and Q8 in receive mode. The oscillator frequency is

controlled by applying the VCO control voltage, obtained

from the phase comparator to the varactor diodes (D6 and

D7 in transmit mode and D8 and D9 in receive mode) and

assist voltage to the (D10, D12 and D13 in transmit mode

and D11, D14 and D15 in receive mode).

The TX/RX pin is set high in receive mode causing Q7 to

turn off, and turn Q10 on. The TX/RX pin is set low in transmit mode. The outputs from Q8 and Q6 are amplified by

Q12 and sent to the RF amplifi ers.

D10,D12,D13

Q3

Doubler

AMP

D6,D7

D8,D9

Q6

TX VCO

Q12

BUFF

AMP

Q8

RX VCO

Q7,Q10

T/R SW

D11,D14,D15

4-3. Unlock Circuit

During reception, the 9RC signal goes high, the 9TC signal goes low, and Q400 turns on. Q402 turns on and a voltage is applied to the collector (9R). During transmission, the

9RC signal goes low, the 9TC signal goes high and Q401

turns on. Q403 turns on and a voltage is applied to 9T.

The MCU in the control unit monitors the PLL (IC2) LD

signal directly. When the PLL is unlocked during transmission, the PLL LD signal goes low. The MCU detects this

signal and makes the 9TC signal low. When the 9TC signal

goes low, no voltage is applied to 9T, and no signal is transmitted.

9C

9R 9T

Q402

SW

Q400

SW

9RC

IC704

MCU

Q403

SW

Q401

SW

LD

9TC

IC2

PLL

PLL lock

: LD “H”

Fig. 9 Unlock circuit

5. Control Circuit

The MCU carries out the following tasks:

1) Controls the WIDE, NARROW, TX/RX outputs.

2) Controls the Baseband IC (IC702).

3) Controls the PLL (IC2).

4) Controls the display unit.

IC2

PLL

PLLE

PLDT

PLCK

UL

BLED CDATA

GLED

RLED

MBL

BLC

Display unit

IC704

MCU

LCDDI

LCDDO

IC1

LCD driver

Fig. 10 Control circuit

LCDCL

LCDCE

SCLK

RD ATA

IRQ

CSN

Baseband IC

IC702

15

TK-7360/7360H/7360H(V

CIRCUIT DESCRIPTION

)

5-1. Memory Circuit

The transceiver has a 512k-bit EEPROM (IC705). The EEPROM contains adjustment data. The MCU (IC704) controls

the EEPROM through three serial data lines.

EEPC

IC704

MCU

EEPD

EEPS

EEPQ

IC705

EEPROM

Fig. 11 Memory circuit

5-2. Display Circuit

The MCU (IC704) controls the LCD display and LEDs.

When power is on, the MCU will use the MBL line and

the BLC line to control the key backlight LEDs and LCD

backlight LEDs.

When the transceiver is busy, the GLED line goes high,

Q6 turns on and the green LED (D23) lights after Q5 turns

on. In transmit mode, the RLED line goes high, Q3 and Q4

turn on and the red LED (D23) lights.

BLED will be set high when the function select (FPU setting) is on, Q2 turns on and the blue LED (D22) lights.

The LCD driver (IC1) controls the functions of the LCD

through the LCDDI, LCDDO, LCDCL, LCDCE lines from the

MCU.

LCDDI

IC704

MCU

LCDDO

LCDCL

LCDCE

BLC

MBL

GLED

RLED

BLED

Q10

SW

Q8

SW

Q6

SW

Q3

SW

IC1

LCD

driver

SW

SW

SW

SW

SW

LCD backlight

Q9

Key backlight

Q7

Q5

Q4

Q2

LCD

Display

D5~D9

D23

D22

Fig. 12 Display circuit

IC1

LCD

driver

KMO1

KMO2

KMO3

KMI3

KMI2

KMI1

B

VOL DN

CH DN

C

S

CH UP

■

A

VOL UP

Fig. 13 Key matrix circuit

6. Signaling Circuit

6-1. Encode

Low-speed data (QT, DQT)

■

Low-speed data is output from pin 26 (LSDO) of the

MCU (IC704). The signal passes through a low-pass CR

fi lter. The signal is mixed with the audio signal and goes to

the VCO and TCXO (X1) modulation input after signal processing in the baseband IC (IC702).

High-speed data (2-tone)

■

High-speed data (HSD) is output from pin 2 (HSDO) of

the MCU.

The signal passes through a low-pass CR fi lter. TX deviation making an adjustment by MCU is applied to the baseband IC (IC702). The signal is mixed with the audio signal

and goes to the VCO and TCXO.

The RX tone is audio output of the baseband IC (IC702)

at the same time to audio power amplifi er and then to the

speaker.

LSDO

QT/DQT

IC704

MCU

HSDO

2-TONE

IC702

Baseband IC

DTMF/

MSK

Fig. 14 Encode

MSK / DTMF

■

MSK and DTMF signal is self generated by the baseband

IC (IC702).

The TX deviation adjustment is done by the output gain

of the baseband IC (IC702), and is routed to the VCO. When

encoding MSK/DTMF, the microphone-input signal is muted.

TCXO

MOD

VCO

MOD

X1

TCXO

IC2

PLL

VCO

5-3. Key Matrix Circuit

The front panel has function keys. Each of them is connected to a cross point of a matrix of the KMI1 to KMO3

ports of the LCD driver. The KMO1 to KMO3 ports are always high, while the KMI1 to KMI3 ports are always low.

The LCD driver monitors the status of the KMI1 to

KMO3 ports. If the state of one of the ports changes, the

LCD driver assumes that the key at the matrix point corresponding to that port has been pressed.

16

6-2. Decode

Low-speed data (QT, DQT)

■

The demodulated signal from the FM IC (IC500) will input

to the baseband IC (IC702) to remove frequencies of 300Hz

or more.

The signal is input to pin 88 (LSDI) of the MCU. The

MCU digitizes this signal, performs processing such as DC

restoration, and decodes the signal.

CIRCUIT DESCRIPTION

High-speed data (2-tone)

■

The demodulated signal from the FM IC (IC500) is amplified by the baseband IC and passes through a band pass

fi lter and a comparator (IC709) to detect the signal to the

MCU. The MCU digitizes this signal and decodes the signal

after receiving the signal at pin 5 (HSDI).

MSK/ DTMF

■

The demodulated signal from the FM IC (IC500) will input to the baseband IC (IC702), then the baseband IC will

decode and send the decoded information to the MCU by

the data line.

The MCU then processes the decoded information.

REPLAY data

DTMF/MSK

decode data

LSDI

QT/DQT

HSDI

2-TONE

IC704

MCU

IC500

FM IC

IC702

Baseband IC

DTMF/MSK

decode

IC709

BPF/COMP

Fig. 15 Decode

TK-7360/7360H/7360H(V

7. Power Supply Circuit

When the power switch on the display unit is pressed,

the power port on the display unit which is connected to

port 17 (POWER), goes low, then port 52 (SBC) goes high,

Q406 turns on, SB switch (Q407) turns on and power (SB) is

supplied to the transceiver.

When the DC power is supplied to the transceiver, voltage regulator IC (IC401, IC402) will supply into the MCU

VDD and reset the voltage detect IC (IC404). IC404 will

generate signal (RESET) into the reset terminal on the MCU

(IC704) to carry out a power on reset. Also, MCU (IC704) is

checking on port 91 (BATT). If DC power is less than about

8.5V, the transceiver is unable to power on.

When the DC power voltage deceases from normal voltage, the INT voltage detector IC (IC403) will set to high on

MCU port 18 (INT). If B line becomes less than about 8.5V,

MCU will send the backup data to EEPROM (IC705) and go

into STOP mode.

This circuit has an overvoltage protection circuit. If a DC

voltage of 16V or higher is applied to the base of Q717, this

voltage turns Q717 on and sets port 18 (INT) to low. As a result port 78 (SBC) is low, and turns Q406 and Q407 (SB) off.

)

SB

IGN

R792

R793

POWER

SW

Q407

SW

Q714

BATT

POWER

IC704

MCU

INT

SW

IGN

SBC

5M

3.3M

RESET

Q406

SW

IC401

AVR

IC404

V-DET

Fig. 16 Power supply circuit

IC402

AVR

Q717

SW

IC403

V-DET

B

D715

R411R412

17

TK-7360/7360H/7360H(V

SEMICONDUCTOR DATA

)

MCU: F3650TDFBKEBA (TX-RX unit IC704)

Pin No.

10 RESET I Reset

11 XOUT O 11.0592MHz clock output

12 VSS - GND

13 XIN I 11.0592MHz clock input

14 VCC1 - +5V

15 5CC O 5C control

16 MKEY I/O Mic key detect

17 POWKEY I Power key detect

18 INT I MCU stop

19 ASTSW O Assist speed up switch control

20 BEEP O Beep for side tone

21 FNC8 I/O Function port 8

22 FNC7 I/O Function port 7 (REC/SRC)

23 FNC6 I/O Function port 6

24 FNC5 I/O Function port 5

25 FNC4 I/O Function port 4

26 LSDO O Low speed data output

27 SI I Serial data input for VGS

28 SO O Serial data output for VGS

29 FNC1 I/O Function port 1 (TXD to COM port 1)

30 FNC2 I/O Function port 2 (RXD from COM port 1)

31 ECLK - SCLK for emulator

32 FNC3/EBSY I/O Function port 3 / BUSY for emulator

33 TXD I/O TXD to FPU

34 RXD I/O RXD from FPU

35 HOOK I Hook

36 PTT I PTT

37 BSFT O Beat shift (L: beat shift ON)

38 LPOSW O No use

39 EPM - EPM for emulator

40 PLLE O PLL lock enable

41 PLDT O PLL data output

42 PLCK O PLL clock output

Name I/O Function

1 FREQ O Frequency alignment

2 HSDO O High speed data output

3 LCDDO O LCD data output

4 LCDCE O LCD enable

5 HSDI I High speed data input

6 E - GND (Only for bus control)

7 CNVSS I CNVSS for emulator (H: boot mode)

8 LCDDI I LCD data input

9 LCDCL O LCD clock output

Pin No.

43 PA O Public address control

44 CE - CE for emulator

45 CDATA O Command data output for baseband IC

46 RDATA I Reply data input for baseband IC

47 SCLK O Serial clock output for baseband IC

48 CSN1 O Chip select for baseband IC

49 SP MUTE O Speaker mute control

50 9RC O 9R control

51 9TC O 9T control

52 SBC O SB control

53 3CC O 3C control

54 PLPS O Sleep mode function for PLL IC

55 EEPS O EEPROM chip select

56 AMPSW O

57 EEPQ I EEPROM serial data input

58 EEPD O EEPROM serial data output

59 EEPC O EEPROM serial clock output

60 VCC2 - +3.3V

61 SCRSW O Scrambler switch control (Audio path)

62 VSS - GND

63 NC - No connection

64 TXRX O TX/RX (H: RX / L: TX)

65 BLC O LCD backlight control

66 MBL O Panel and mic key backlight control

67 NC - No connection

68 DST I Destination

69 NC - No connection

70 NC - No connection

71 STSW O

72 IGN I Ignition

73 IRQ1 I Interrupt request for baseband IC

74 RLED O Red LED for TX

75 GLED O Green LED for busy

76 BLED O Blue LED for VGS writing and signaling

77 VGSRX O VGS recording switch control for RX

78 NC - No connection

79 NC - No connection

80 EMG I Emergency key detect

81 NC - No connection

82 NC - No connection

83 UL I PLL unlock detect

84 DMUTE O Det mute control

Name I/O Function

AF AMP switch control

(L: enable / H: disable)

Side tone switch control for VGS playback

18

TK-7360/7360H/7360H(V

SEMICONDUCTOR DATA

)

Pin No.

85 MIC1MUTE O Internal mic mute control

86 MIC2MUTE O External mic mute control

87 HSDI I No use

88 LSDI I Low speed data input: QT/DQT/(LTR)

89 TEMP2 I Temperature 2 data input

90 TEMP1 I Temperature 1 data input

91 BATT I Battery voltage input

92 RSSI I RSSI input

Name I/O Function

Pin No.

93 SQIN I Squelch input

94 AVSS - GND

95 CV I VCO lock voltage detect

96 VREF - +5V

97 AVCC - +5V

98 NARROW O Wide/Narrow control (Hi: Narrow)

99 WIDE O Wide/Narrow control (Hi: Wide)

100 HORN O Horn alert switch control

Name I/O Function

COMPONENTS DESCRIPTION

Display unit (X54-3740-20)

Ref. No. Part Name Description

IC1 IC LCD driver

Q2 Transistor Indication LED (BLUE) switch

Q3 Transistor TX LED switch control

Q4 Transistor TX LED switch

Q5 Transistor BUSY LED switch

Q6 Transistor BUSY LED switch control

Q7 Transistor KEY backlight switch

Q8 Transistor KEY backlight switch control

Q9 Transistor LCD backlight switch control

Q10 Transistor LCD backlight switch

D1 Zener diode Surge protection

D2 Diode Voltage protection

D5~9 LED KEY backlight

D10 Diode Voltage protection

D11~21 LED LCD backlight

D22 LED Indication (BLUE)

D23 LED TX/BUSY indication

D24 LED LCD backlight

TX-RX unit (X57-8020-XX)

Ref. No. Part Name Description

IC1 IC DC AMP (frequency)

IC2 IC PLL IC

IC3 IC Assist fi lter

IC300 IC Power module

IC301 IC DC AMP (APC)

IC400 IC Voltage regulator (9V)

IC401 IC Voltage regulator (3.3V)

IC402 IC Voltage regulator (5V)

IC403 IC Voltage detection (INT)

IC404 IC Voltage detection (reset)

IC500 IC FM SYSTEM IC

IC501 IC RX BPF/ APC DC AMP

IC700 IC RS-232C driver

IC701 IC MIC MOD AMP

IC702 IC Baseband IC

IC703 IC Voltage regulator (3.3V)

IC704 IC MCU

IC705 IC EEPROM

19

TK-7360/7360H/7360H(V

COMPONENTS DESCRIPTION

)

Ref. No. Part Name Description

IC706 IC AF power AMP

IC707,708 IC Option setting switch

IC709 IC HSD BPF/COMP

IC710 IC MOD/ Option setting switch

Q1 Transistor Buffer AMP (PLL IC clock)

Q2 Transistor Fin fi lter control

Q3 Transistor Doubler

Q4 FET Assist fi lter switch

Q5 FET Assist fi lter switch control

Q6 FET TX VCO

Q7 Transistor TX/RX VCO switch

Q8 FET RX VCO

Q10 Transistor T/R VCO switch

Q11 Transistor Ripple fi lter

Q12 Transistor Buffer AMP

Q13 Transistor RF AMP

Q300 Transistor TX drive AMP

Q400 Transistor 9R switch control

Q401 Transistor 9T switch control

Q402 Transistor 9R switch

Q403 Transistor 9T switch

Q404 FET 5C switch

Q405 FET 3.3C switch

Q406 Transistor SB switch

Q407 FET SB switch control

Q500 Transistor Doubler (2nd local)

Q502 Transistor W/N switch

Q503 Transistor W/N switch control

Q504 Transistor IF AMP

Q505 Transistor Squelch noise AMP

Q506 Transistor Squelch input switch

Q507 FET 1st mixer

Q508 Transistor Squelch input switch

Q511 FET RF AMP

Q700 Transistor RS-322C RXD buffer

Q702 FET Horn alert switch

Q703 Transistor MIC mute switch

Q704 FET MIC mute switch

Q705 Transistor Horn alert switch control

Q708 Transistor DET AMP (D-SUB)

Ref. No. Part Name Description

Q709 FET TX/RX switch

Q710 Transistor Baseband IC clock AMP

Q712 FET Option switch

Q713 FET DET mute switch

Q714 Transistor IGN switch

Q715 Transistor Beet shift switch

Q716,717 Transistor Over voltage detect switch

Q718,719 FET SP mute switch

Q720 Transistor AF AMP switch

D1 Diode PLL unlock detect

D2~4 Diode Fin fi lter switch

D6,7

D8,9

D10

D11

D12,13

D14,15

D16

D17,18 Diode TX/RX RF switch

D300 Zener diode Voltage protection

D301 Diode TX power control

D302 Diode Reverse power detection

D303,304 Diode ANT switch

D305,306 Diode RF power detection

D307,308 Diode ANT switch

D309,310 Zener diode Voltage protection

D400 Surge absorber Voltage protection

D500,501 Diode W/N CF switch

D502 Diode Squelch detection

D504~507

D700~711 Diode Surge protection

D712,713 Diode MIC AGC detection

D715 Zener diode Voltage drop

D716 Diode Speed up (DET mute)

Variable capacitance diode

Variable capacitance diode

Variable capacitance diode

Variable capacitance diode

Variable capacitance diode

Variable capacitance diode

Variable capacitance diode

Variable capacitance diode

TX VCO frequency

RX VCO frequency

RX VCO assist

TX VCO assist

RX VCO assist

TX VCO assist

Modulation

RF BPF tuning

20

Loading...

Loading...