Kenwood DMCJ-7-R Service Manual

General

Power source DC ........................

.............

........................

.......................

.....

...........

3.6 V (rechargeable lithium-ion

battery NB-L10A x 1)

DC 5 V (AC adaptor)

AC 230 V, 50 Hz

DC 3 V Separately available battery case

(commercially available, "AA"

size, alkaline battery x 2)

DC 4.0 V : Separately available car

adaptor, DC-C70

(for cars with a 12-24 V DC

negative earth electrical system)

Power consumption 7 W (AC adaptor)

Output power RMS; 20 mW (10 mW + 10 mW)

(0.2 % T.H.D.)

Charging time Approx. 3.0 hours

(When using the AC adaptor included

with the unit)

Battery life

Note:

The battery case is only sold in certain areas. For more details,

please ask your dealer.

The continuous recording time is for analogue input when the

volume level is set to "VOL 0".

The continuous play time shows the value when the volume level is

set to "VOL 15".

The above values are the standard values when the unit is charged

and used at an ambient temperature of 20

o

C.

The operating time when using alkaline batteries may be different,

depending on the type and manufacturer of the batteries, and on

the operating temperature.

Input sensitivity

Output level

Dimensions Width: 87.0 mm (3-7/16")

Height: 29.4 mm (1-3/16")

Depth: 81.5 mm (3-7/32")

Weight 219 g (0.49 lbs.) with rechargeable

battery

Input socket Line/optical digital, microphone

(powered by the main unit)

Output socket Headphones (impedance: 32

ohms)/remote control unit

MiniDisc Recorder

Type Portable MiniDisc recorder

Signal readout Non-contact, 3-beam semi-coductor

laser pick-up

Audio channels Stereo 2 channels/monaural (long-

play mode) 1 channel

Frequency response 20 - 20,000 Hz (± 3 dB)

Rotation speed Approx 400 - 900 rpm

Error correction ACIRC (Advanced Cross Interleave

Reed-Solomon Code)

Coding ATRAC (Adaptive Transform

Acoustic Coding), 24-bit computed type

Recording method Magnetic modulation overwrite method

Sampling frequency 44.1 kHz (32 kHz and 48 kHz

signals are converted to 44.1 kHz,

and then recorded.)

Wow and flutter Unmeasurable (less than ±0.001% W.peek)

Continuous recording:

Approx. 4.5 hours

Continuous recording:

Approx. 4 hours

Continuous recording:

Approx. 8.5 hours

Continuous play:

Approx. 6.5 hours

Continuous play:

Approx. 8 hours

Continuous play:

Approx. 14.5 hours

Headphones — 10 mW + 32 ohms

10 mW

LINE 300mV (-12dB) — 50 k ohms

Maximum

output level

Specified output

Recording level Reference input level Input impedance

MI C H 0.25 mV 10 k ohms

MIC L 2.5 mV 10 k ohms

LINE 100 mV 20 k ohms

Load

impedance

When using two,

commercially available,

high capacity, "AA" size,

alkaline batteries (in the

separately available battery

case)

When using the rechargeable battery NB-L10A (fully

charged) included with the

unit

When using two, commercially

available, high capacity, "AA"

size batteries with the

rechargeable battery (fully

charged)

....................

............

............

...............

....................

....................

.......................

..........................

...........................

.....................

......................

.......................................

...................................

...................................

DIGITAL EDIT & RECORDING

RECORDING

REC LEVEL

/CURSOR

CHARACTER

AUTO MARK

SYNC/F.PLAY

VOLUME/NAME

PORTABLE MD RECORDER DMC-J7R

BASS/DELETE MODE/INSERT

OPEN

DISP

EDIT

OFF

ENTER

E

J

E

C

T

PORTABLE MD RECORDER

DMC-J7R

SERVICE MANUAL

Transparency cover *

(B10-)

Knob

(K27-2272-08)

Front cabinet

(A02-2808-08)

MD cover

(F07-1638-08)

© 1998-6/B51-5441-00 (K/K) 3163

Upper case assy

(A02-2814-08) : S

(A02-2862-08) : B

Knob base

(A02-2816-08)

Knob

(K29-2270-08)

In compliance with Federal Regulations, following are reproductions of labels on, or inside the product relating to laser product

safety.

SPECIFICATIONS

KENWOOD-Crop. certifies this equipment conforms to DHHS

Regulations No. 21 DFR 1040. 10, Chapter 1, Subchapter J.

DANGER : Laser radiation when open and interlock defeated.

AVOID DIRECT EXPOSURE TO BEAM

* Refer to parts list on page 26. S: Silver, B: Blue

Bottom cabinet *

(A02-)

DMC-J7R

How to reset

When this product is subjected to strong

external interference (mechanical shock,

excessive static electricity, abnormal supply voltage due to lightning, etc.) or if it is

operated incorrectly, it may malfunction. If

such a problem occurs, do the following:

1. Unplug the AC adaptor from the AC

socket.

2. Remove the battery.

3. Leave the unit completely unpowered

for approximately 30 seconds.

4. Plug the AC adaptor back into the AC

socket and retry the operation.

If strange sounds, smell or smoke come

out of the unit or an object is dropped into

the unit, remove the AC adaptor from the

AC socket immediately and contact an authorized KENWOOD service centre.

CONTENTS / ACCESSORIES / CAUTIONS

Contents

SPECIFICATIONS.........................................Top cover

CONTENTS / ACCESSORIES / CAUTIONS...............2

CONTROLS.................................................................3

DISASSEMBLY FOR REPAIR.....................................4

BLOCK DIAGRAM.......................................................6

CIRCUIT DESCRIPTION.............................................7

TROUBLE SHOOTING................................................8

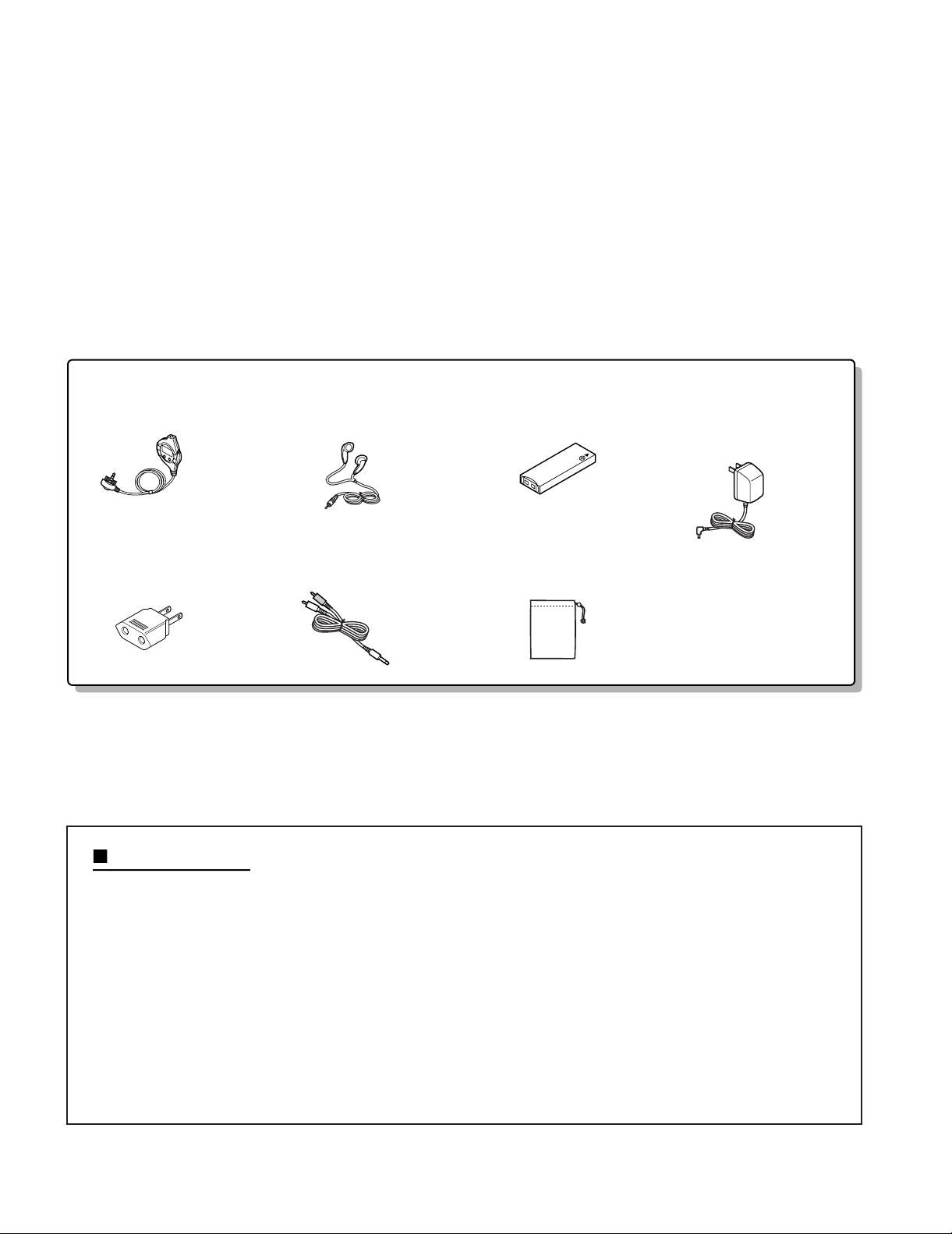

Accessories

NOTE ON SCHEMATIC DIAGRAM...........................14

PARTS DESCRIPTIONS...........................................15

WAVEFORMS OF MD CIRCUIT ...............................16

PC BOARD ................................................................17

SCHEMATIC DIAGRAM............................................21

EXPLODED VIEW .....................................................24

PARTS LIST...............................................................26

Remote control (1)

(A70-1210-08)

AC plug adapter (1)

(E03-0115-05) : M type

Cautions

Stereo headphone (1)

(W01-0941-05) : K,P type

(W01-0948-05) : T,E,E1,M type

Connecting cord (1)

(E30-2836-08)

Rechargeable battery (1)

(W03-5946-08): NB-L10A

Carrying case (1)

(W01-0955-08)

AC adapter (1)

(W08-0669-08) : M type

(W08-0672-08) : E,E1 type

(W08-0673-08) : T type

(W08-0674-08) : K,P type

2

Error messages Meaning Remedy

BATT EMPTY

The battery run down. Charge the rechargeable battery or

replace the alkaline batteries (or use

the AC adaptor for power).

BLANK DISC

Nothing is recorded. Replace the disc with a recorded

disc.

Can't COPY

No copy can be made because of

the SCMS copyright system.

Record using the analogue cable.

Can't EDIT

A track cannot be edited. Change the stop position of the

track and then try editing it.

Can't REC

Recording cannot be performed

correctly due to vibration or shock

in the unit.

Re-record or replace it with another

recordable disc.

Can't WRITE Editing is impossible. Check the number of tracks.

DEFECT

The disc is scratched. If the sound you hear is not right,

try recording again.

Replace the disc with another

recordable disc.

Din UNLOCK Poor connection of the digital cable. Connect the digital cable securely.

DISC ERROR The disc is damaged. Reload the disc or replace it.

DISC FULL

The disc is out of recording space. Replace it with another recordable

disc.

HOLD

The unit is in the safety mode. Return the HOLD switch to its

original position.

LOCKED

LOCK ERROR

The EJECT lever was moved

during recording or editing.

Turn off the power and remove the

MiniDisc.

NO DISC A disc has not been loaded. Load a disc.

PB DISC

PROTECTED

The disc is write protected.

You tried to record on a playbackonly disc.

Move the write protection knob

back to its original position.

Replace it with a recordable disc.

POWER ?

Improper power is being supplied. Use one of the specified power

sources.

SORRY

Since a track number is currently

being located or written to, the unit

cannot accept your command.

Wait for a while and try the

operation again.

SYSTEM ERR

You have come to the conclusion

that the unit is out of order.

To have it repaired, go to the

distributor where you purchased the

unit.

TEMP OVER

The temperature is too high. Turn off the power, and wait for a

while.

TOC ERROR

A large portion of the disc has been

damaged.

Replace it with another recorded

disc.

TOC FULL

There is no space left for recording

character information (track names,

disc names, etc.).

Replace it with another recordable

disc.

Tr. Protect

The track has been protected from

being erased.

Edit the track with the device on

which it was recorded.

U TOC ERROR

A large portion of the disc has been

damaged.

There is an error in the recorded

signal.

Replace it with another recorded

disc.

Erase all of the signal errors, and

then try recording again.

? DISC

A disc which contains data other

than music was played.

There is an error in the signal from

the disc.

A disc which contains non-music

data cannot be played.

Replace it with another recorded

disc.

ERROR MESSAGES

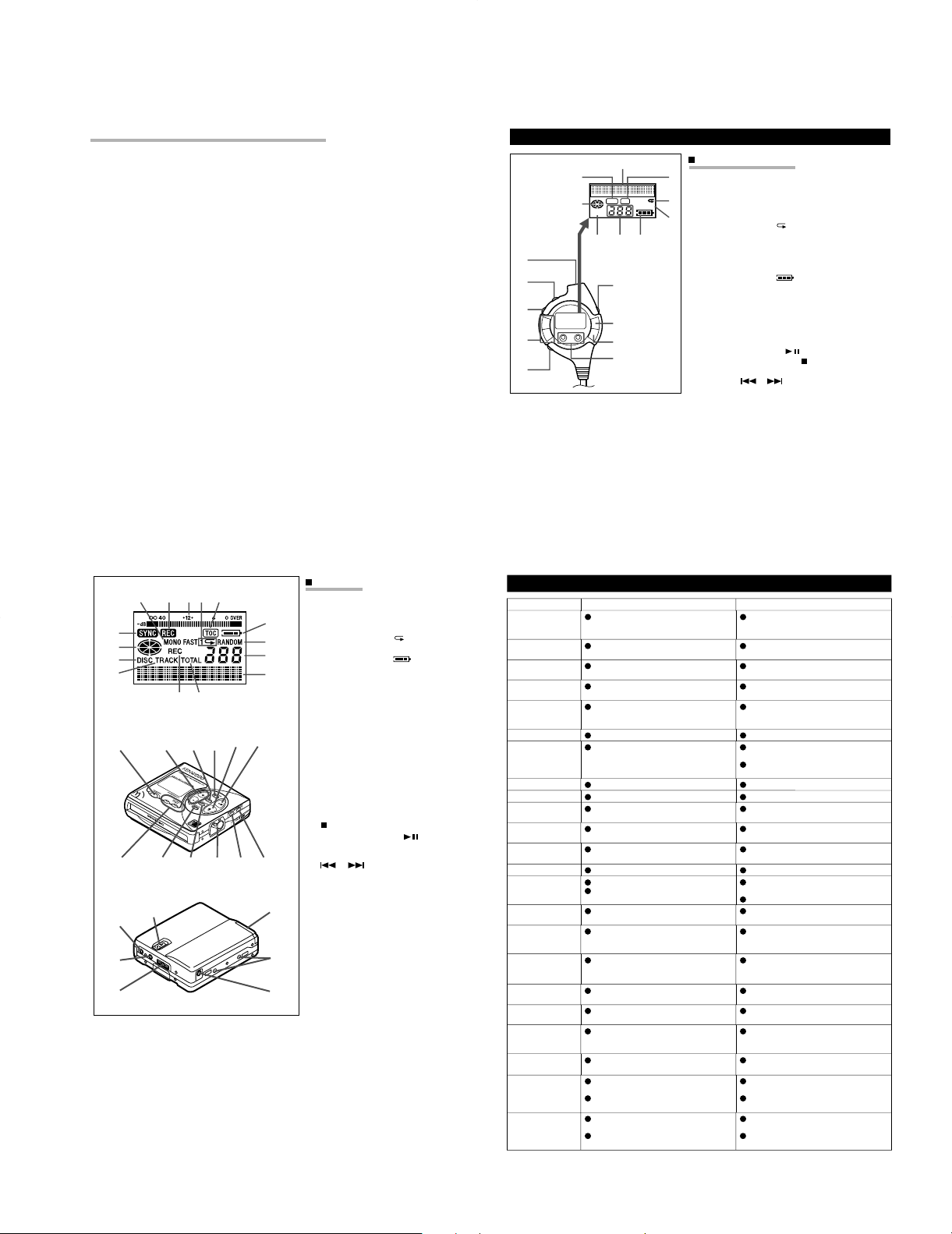

Main Unit

1. Monaural Long-Play Mode Indicator

2. Record Indicator

3. Level Meter

4. Repeat Indicator:

5. TOC Indicator

6. Battery Indicator:

7. Random Indicator

8. Track Number Indicator

9. Character/Time Information Indicator

10. Synchro Recording Indicator

11. Disc Mode Indicator

12. Disc Name Indicator

13. Track Name Indicator

14. Remaining Recording Time Indicator

15. Total Track Number Display

16. Record/Track Mark Button

17. Volume/Name Select Buttons: +, -

18. Display/Lowercase Characters Button

19. Character Button

20. Stop/Power Off/Charge Button:

/OFF

21. Play/Pause Button:

22. Fast Reverse/Fast Forward/Record-

ing LevelControl/Cursor Buttons:

/

23. Enter/Fast Play/Synchro Button

24. Edit/Auto Mark/Time Mark Button

25. Eject Lever

26. Bass/Delete Button

27. Mode/Insert Button

28. Microphone Input Socket

29. Hold Switch

30. Rechargeable Lithium-Ion Battery

Compartment

31. Optical/Line Input Socket

32. Headphones Socket

33. 5V DC Input Socket

34. Battert Case Connection Terminals

12345

6

7

8

9

10

11

12

13

14 15

16 17 18 19 20 21

22

23 24 25 26 27

29

34

30

33

28

31

32

Remote Control Unit

1. Synchro Recording Indicator

2. Character/Time Information

Indicator

3. Record Indicator

4. Repeat Indicator:

5. Random Indicator

6. Disc Mode Indicator

7. Total Track Number Display

8. Track Number Indicator

9. Battery Indicator:

10. Headpones Socket

11. Hold Switch

12. Play Mode Button

13. Volume Buttons: +, -

14. Bass Button

15. Display Button

16. Play/Pause Button:

17. Stop/Power Off Button:

18. Fast Reverse/Fast Forward

Buttons: /

RANDOM

TOTAL

1

REC

SYNC

12

13

14

11

15

16

17

18

10

1

6

2

3

4

5

789

NAMES OF CONTROLS AND INDICATORS

7 Notes about the rechargeable battery

÷ A rechargeable lithium-ion battery is

the only kind that can be used.

Even if the battery supplied with the

unit is not used, you should charge it

at least once every three months

because of the special quality of this

battery.

÷ The rechargeable battery can be

charged approximately 300 times.

÷ Do not use any battery other than

that specified. Use of other batteries maycause malfunctions.

÷ When the operating time is reduced

to about half the normal amount of

time, even after a full charge is performed, replace the battery with a

new one.

÷ When charging or when using the

rechargeable battery, use it within

an ambient temperature range of

5˚C to 35˚C.

÷ If the rechargeable battery is used in

a cold environment, the operating

time will decrease.

Since the rechargeable battery is

vulnerable to damage, please note

the following.

÷ Do not carry the battery in your

pocket or a bag together with metal

objects (keys, coins, jewelry, etc.).

The battery may short out and generate significant amounts of heat.

÷ Do not short-circuit the terminals as

they will become very hot and will

damage the battery.

÷ Do not dip the battery in water, do

not dispose of it in a fire, and do not

take it apart.

To avoid damaging the battery and

shortening its service life, please

note the following.

÷ Do not drop or subject the battery to

shock.

÷ Do not insert objects (metal etc.)

into the battery compartment of this

product or into the rechargeable battery. Do not get the terminals dirty.

If the rechargeable terminals are

dirty, the operating time may be

shortened or it may not be possible

to charge the battery.

÷ After the rechargeable battery is

charged or used, it will get slightly

warm. This is normal.

DMC-J7R

CONTROLS

3

DMC-J7R

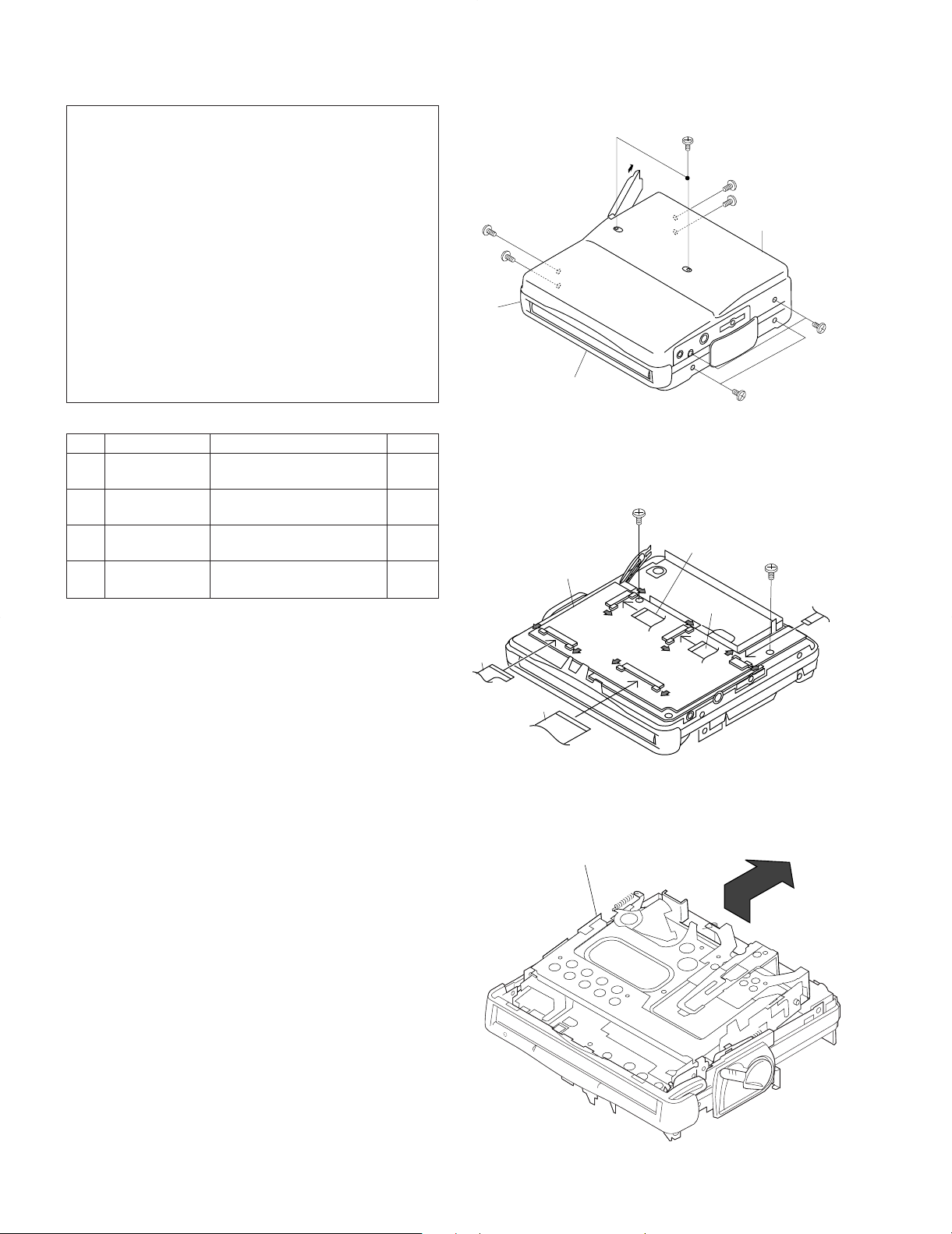

1 Bottom Cabinet 1. Open the battery Lid. 8-1

2. Screw ..................... (A1) x6

2 Top Cabinet 1. Screw ..................... (B1) x4 8-1

2. Flat Cable ...............(B2) x2

3 Main PWB 1. Screw .................... (C1) x2 8-2

2. Flat Cable ...............(C2) x3

4 Mechanism Unit 1. Lift the left side, and remove 8-3

in the arrow direction.

Caution on Disassembly

Follow the below-mentioned notes when disassembling

the unit and reassembling it, to keep it safe and ensure

excellent performance:

1. Take the battery and minidisc out of the unit.

2. When disassembling the machine, be sure to withdraw

the power plug from the socket in advance.

3. When disassemble the parts, remove the nylon band or

wire holder as necessary.

To assemble after repair, be sure to arrange the wires as

they were.

If a screw of different length is fitted to the MD mecha-

nism (the screw of the part to be fitted to the MD

mechanism chassis), it may contact the optical pickup,

resulting in malfunction.

4. When repairing, pay due attention to electrostatic charges

of IC.

REMOVAL

PROCEDURE

STEP

FIGURE

Figu re 8-1

Figure 8-2

Figure 8-3

Caution:

1. Handle carefully the main PWB and flexible PWB.

After removing the flexible PWB (*1) for optical pickup from

the connector, wrap the front end of flexible PWB in conductive aluminum foil so as to protect the optical pickup from

electrostatic damage.

2. When removing the mechanism from the cabinet or when

installing it, it is advisable to

rotate the unit lock plate to lower the holder section.

DISASSEMBLY FOR REPAIR

(A1)x2

Ø1.4x2mm

(B1)x1

Ø1.4x2mm

Center

Cabinet

(C2)x1

(A1)x1

Ø1.4x2mm

Pull

(C2)x1

Top Cabinet

Main PWB

Pull

Pull

(C1)x1

Ø1.7x2.5mm

Pull

Pull

Pull

Pull

Pull

(C2)x1

(B2)x1

(A1)x1

Ø1.4x2mm

Ø1.4x2mm

Ø1.7x2.5mm

Pull

(B1)x1

Bottom Cabinet

(B1)x2

Ø1.4x2mm

(C1)x1

(A1)x2

Ø1.4x2mm

(B2)x1

Mechanism Unit

4

DISASSEMBLY FOR REPAIR

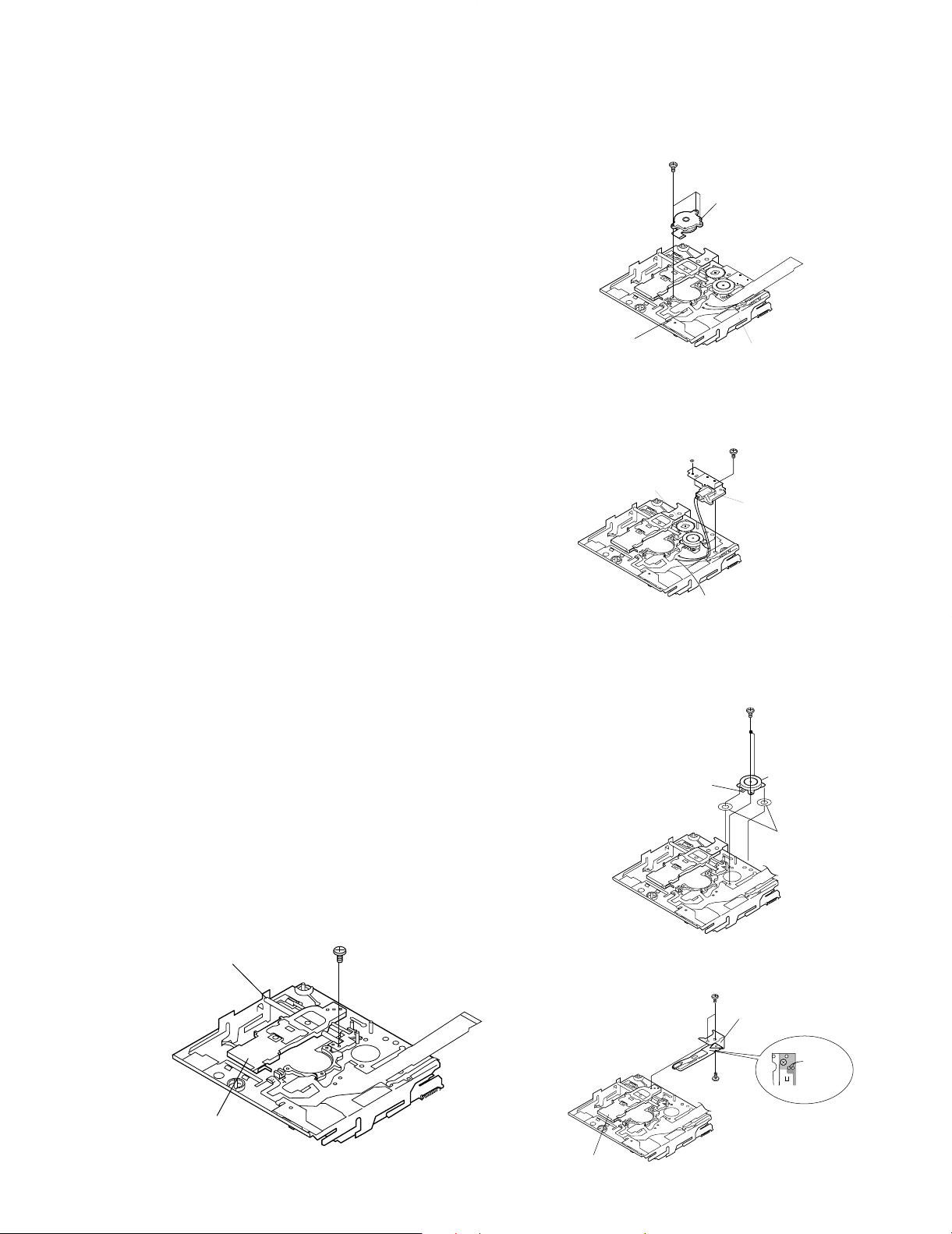

Remove the mechanism according to the disassembling methods 1 to 3. (See Page 8.)

How to remove the spindle motor (See Fig. 9-1.)

1. Remove the solder joint (A1) x 1 of flex PWB.

2. Remove the stop (A2) x 3 pcs. and remove the spindle

motor.

Figure 9-5

Figure 9-1

Figure 9-2

Figure 9-3

How to reinstall the optical pickup unit

(See Fig. 9-5.)

1. Remove the screws (E1) x 1 pcs.

2. Remove the soldering joint (C2) x2 places of flex PWB, and

remove the sled motor.

How to remove the magnetic head

(See Fig. 9-4.)

1. Remove the screw (D1) x 2 pc.

2. Remove the screw (D2) x1 which connects the magnetic

head to the head relay flex PWB, and remove the soldering

joint (D3) x2 pcs.

Note:

Mount carefully so as not to damage the magnetic head.

Figure 9-4

How to remove the lift motor (See Fig. 9-2.)

1. Remove the solder joint (B1) x 2 of slide motor lead wire.

2. Remove the stop washer (B2) x 1 pc., and remove the drive

gear (B3) x 1 PC.

3. Remove the screw (B4) x 1, and remove the lift motor.

Note:

Take care so that the motor gear is not damaged.

(If the gear is damaged, noise is raised in search mode.)

How to remove the sled motor (See Fig. 9-3.)

1. Remove the solder joint (C1) x 2 of slide motor lead wire.

2. Remove the screw (C2) x 2, and remove the sled motor.

Note:

Take care so that the motor gear is not damaged.

(If the gear is damaged, noise is raised in search mode.)

(A2)x3

ø1.4x2.8mm

Flexible PWB

solder joint

(A1) x1

Stop Washer

Drive Gear

(B3)x1

DMC-J7R

Spindle Motor

MDMechanism

(B4)x1

(B2)x1

ø1.4x2.2mm

Lift Motor

(E1)x1

ø1.7x2.5mm

Shaft

(B1)x2

Remove the solder joint

(C2)x2

Mecha Flexible PWB

solder joint

(D1)x2

Ø1.4x1.8mm

(C1)x2

ø1.4x1.2mm

Sled Motor

Washer x2

Magnetic Head

Pickup Unit

Pickup Unit

(D1)x1

Ø1.4x1.5mm

Solder

joint

(D3)x2

5

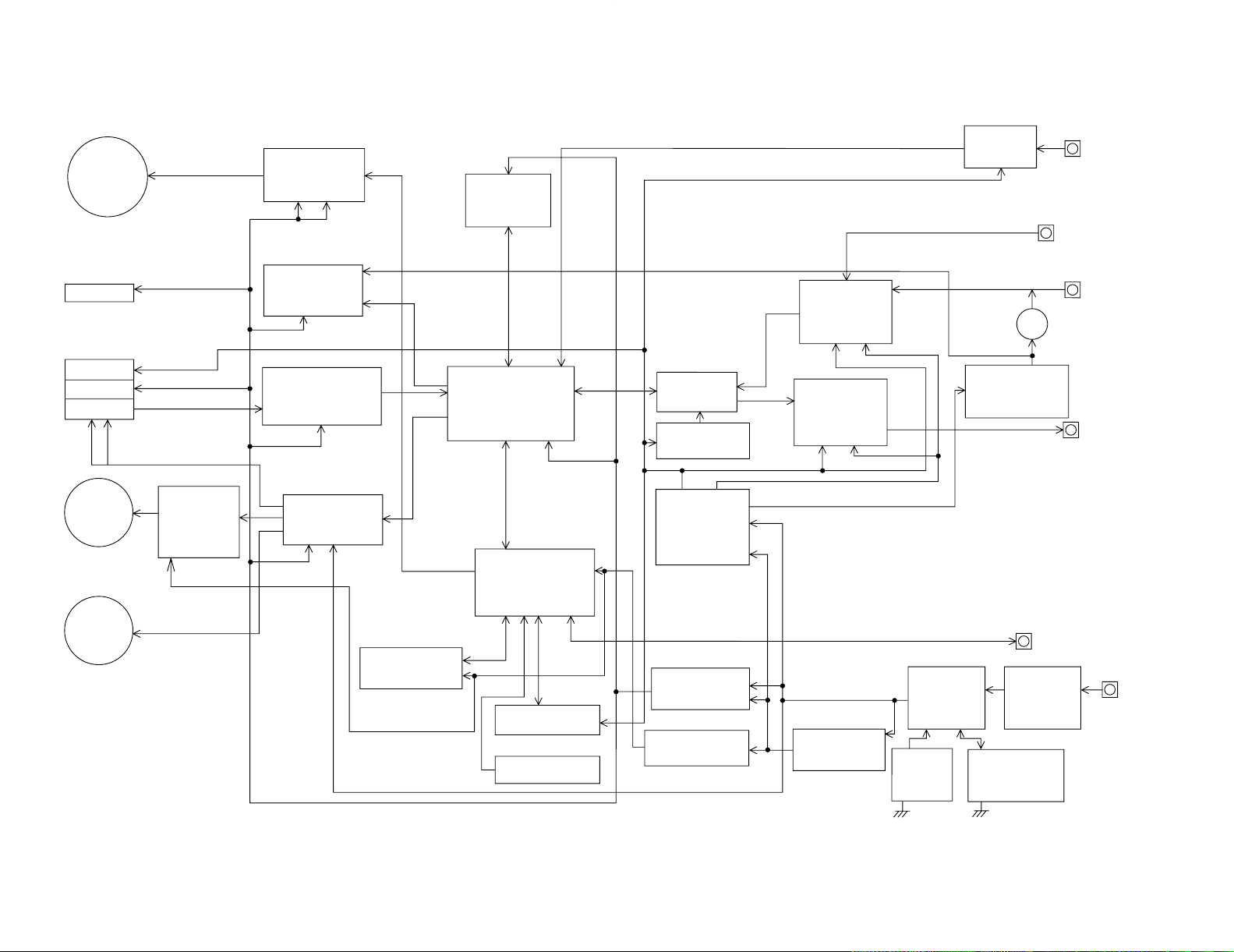

6

LASER

HEAD

LIFT

MOTOR

MOTOR

DRIVER

SPINDLE

MOTOR

SLED

MOTOR

SPINDLE

MOTOR

DRIVER

(BA6965FV)

VCC VS

HEAD

DRIVER

VS

VCC

RF SIGNAL

PROCESSOR

(IR3R55)

PICK COIL

DRIVER

VCC VM

4 M

D-RAM

(IC202)

ENDEC

ATRAC

(LB37648B)

SYSTEM

MICROCOMPUTER

E2-PROM

DISPLAY UNIT

OPERATION UNIT

AD/DA

CONVERTER

POWER

DRIVER

2.5V

REGULATOR

+2.8V

-2.8V

(IR3M09)

VCC

POWER DRIVER

(IR3M09)

2.5V

REGULATOR

(ON/OFF)

(IR3R54N)

AUDIO AMP.

VCC VEE

(IR3R54N)

AUDIO AMP.

VCC VEE

+6~8

DC IN

RIPPLE

FILTER

DIGITAL INPUT

OPTICAL

INPUT UNIT

LINE INPUT

LINE OUT

MIC IN

HEAD PHONES

4.5V

REGULATOR

(ON/OFF)

REMOTE CONTROL

POWER SELECT

N-ch MOS FET

3V

DC/DCONVERTER

BATTERY

VOLTAGE

REGULATOR

CONSTANT

CURRENT DRIVE

RECHARGEABLE

BATTERY

OPIC

POWER SELECT

CHARGE DRIVER

VCC

+2.8

+2.5

F

IC901

+2.5

(LB1638) IC651

+2.5

+2.2

+2.5

+2.5

+2.5

+2.5

+2.5

(74ACT02)

IC351

IC101

IC601

IC201

IC401

+2.5

IC402

+2.8

IC501

+2.5P

IC771

+2.8

IC841

IC821

+2.5

+2.5

IC875

IC701

+2.8V

-2.8V

IC703

+2.8V

-2.8V

J701

+4.5

J701

J702

Q721

IC702

J703

IC801,803,804

+1.8~5.5V

IC871

3~5V

(1.8~3.4V)

IC800,805,Q801

(2.9~4.1V)

J801

DC JACK

(4~5.5V)

PICK

T

DMC-J7R

BLOCK DIAGRAM

66 P52 RCLAT Output Record audio

67 P53 PBOPON Output Audio IC output stage control output

68 P54 MCPGIN Input Mic plug insertion detection input

69 P55 INPGIN Input Line/digital plug insertion detection

70 P56 INPGCK Input Line/digital plug type detection

71 P57 RCPCNT Output Record circuit power control output

72 VSS VSS Output Ground potential

73 P60 EMPHO Output Audio emphasis control output 0

74 P61 HPLAY Input Main unit PLAY key operation detection input

75 P62 HREC Input Main unit REC key operation detection input

76* P63 RTCCE Output Clock IC chip enable control output

77* P64 RTCWR Output Clock IC read/write control output

78 P65 CEDT In/Output Clock/EEPROM serial data input/output

79 P66 CECK Output Clock/EEPROM serial data input/output

80 P67 EPCS Output EEPROM chip selection output

81 VDD VDD Output Positive power supply

82 T15 SPIN Inout Spindle motor FG pulse detection input

83* P101 P101 Output Spare for sled motor control

84* P102 TEST0 Input Test mode setting input 0

85* P103 TEST1 Input Test mode setting input 1

86 P30 PSLINN Output Built-in battery power selection output

87 P31 PSLDCI Output DC jack power selection output

88 P32 PSLDRY Output Dry cell power selection output

89* P33 P33 Output Spare for sled motor control

90 P34 ELON Output Remote controller EL light control output

91 T100 CIN Input Truck cross signal detection input

92 P36 PHOLD Output Dry cell power ON holding output

93 P37 PCNT1 Output Power IC VREF feed control output

94 TEST/VPP VPP Output Test/R-ROM write power input

95 P90 PCNT2 Output Power IC VCC feed control output

96 P91 CKSTP Output Main clock stop control output

97 P92 DISCIN Input Disk insertion detection input

98 P93 INNSW Input Mechanism inner SW position detection input

99 P94 DISCPR Input Record enable/disable switch detection input

100 P95 PDCNT Output PD current control output for inner detection

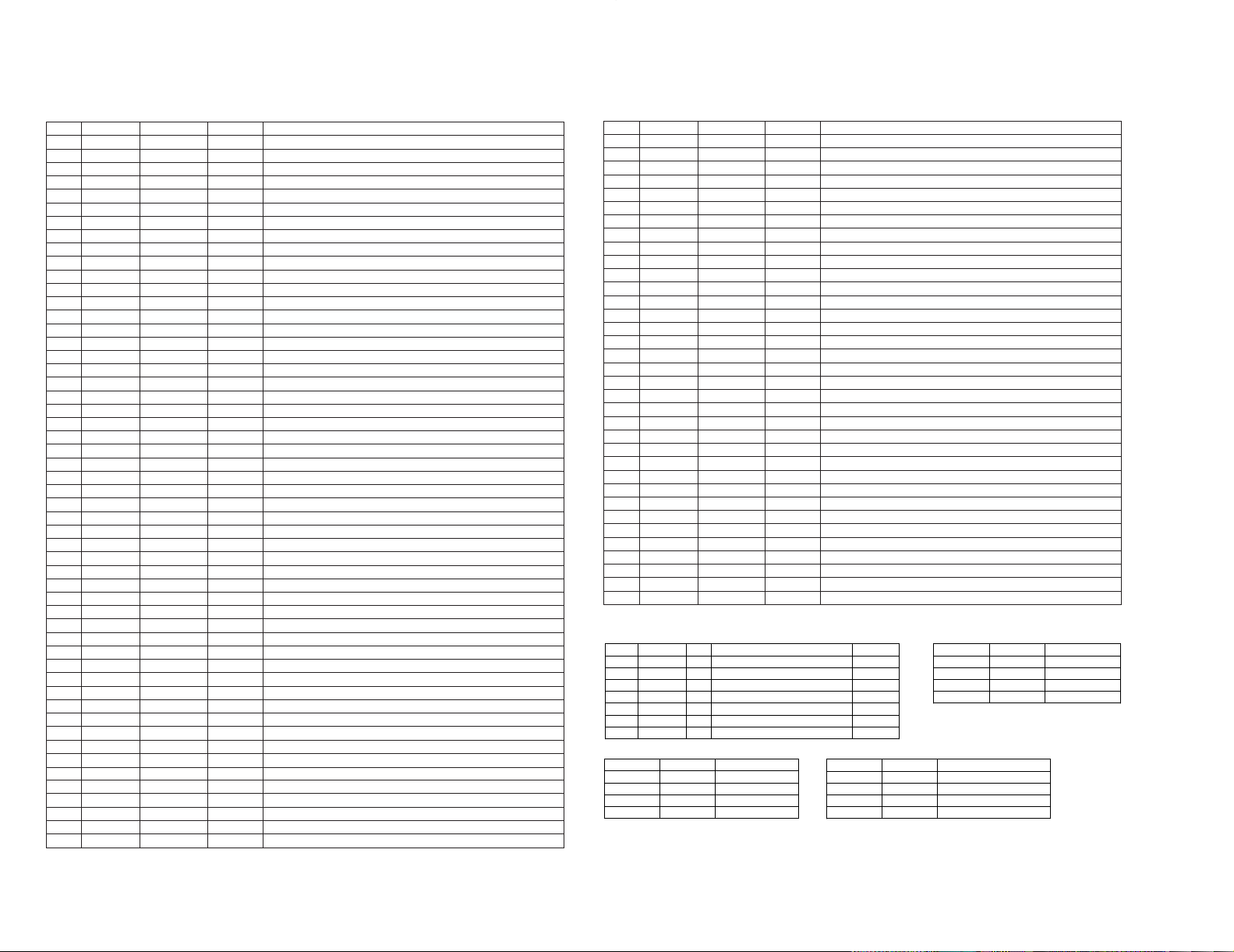

Pin No.

FunctionPort Name Terminal Name

Input/Output

In this unit, the terminal with asterisk mark (*) is (open) terminal which is not connected to the outside.

Table1: TEST PORT

Table2: EMPHASIS PORT

TEST1 TEST0 Description

EMPH1 EMPH0 Description

H H Normal mode

H H fs: 32kHz ON

H L No adjustment

H L fs: 48kHz ON

L H Test mode

L H fs: 48kHz OFF

L L Prohibition

L L fs: 44.1kHz ON

Table3: LDCNT PORT

EMPH1 EMPH0 Description

H H Brake

HL UP

L H DOWN

L L OFF

SYSTEM LSI EXTENSION PORT(IC:201/LR37648)

Pin No. Port Name I/O Descriptions Remarks

52,53 LDCNT1,2 O Recording head up/down control port. table3

54 - O No use open

55 EMPH1 O Audio emphasis control port. table2

56 DCNT1 O Mechanism driver enable port. H= enable

57 OPTCNT O Power on/off for optical input circuitry. H= on

58 DAPON O D/A converter control port H=work

59 ADPON O A/D converter control port H=work

1 P120 SWP UP Output Asterisk input Output for pull-up

2*~7* P121~P126 P121~P126 Output Not used

8 P127 OEM Input Product brand ID input

9 VDD VDD Input Positive power supply

10* X2 X2 Input Not used

11 X1 X1 Input Main system clock input

12 VSS VSS Input Ground potential

13* XT2 XT2 Input Not used

14 XT1 XT1 Input Subsystem clock input

15 RESET RESET Input Microcomputer hard reset input

16 INPUT0 DINT Input System LSI interruption request input

17 P01 SENSE Input System LSI servo sense input

18 P02 FOK Input Focus OK signal input

19 P03 XRST Outout System LSI hard reset output

20* P04 P04 Output Not used

21 P05 HDON Output Record head current control output

22 P06 VLIM Intput Volume limiting switch input

23 AVDD AVDD Input A/D converter analog positive power

24 AVREF0 AVREF0 Input A/D converter reference voltage input

25 ANI0 PLVINN Input Built-in battery voltage detection input

26 ANI1 PLVDCI Input DC jack voltage detection input

27 ANI2 PLVDRY Input Dry cell voltage detection input

28 ANI3 RKEY Input Remote controller key operation detection input

29 ANI4 HKEY1 Input Main unit key operation detection input 1

30 ANI5 HKEY2 Input Main unit key operation detection input 2

31 ANI6 TEMP Input Ambient temperature detection input

32 ANI7 CNTRY Intput Product destination ID input

33 AVSS AVSS Intput A/D converter ground potential

34 ANO0 LDVAR Output P.U. laser power set output

35* ANO1 MDOUT Output Internal motion mode output

36 AVREF1 AVREF1 Output D/A converter reference voltage input

37 P70 SYWR Output System LSI write enable output

38 P71 SYRD Output System LSI read enable output

39 P72 SYRS Output System LSI register selection output

40 P20 - Output Not used

41 SO1 RMDAT Output Remote controller display data output

42 P22 - Output

43 P23 HSTOP Input Main unit STOP key operation detection input

44 P24/BUZ BEEP Output Beep tone pulse output

45 P25 DSPSTB Output Main unit display control strobe output

46 SO0 DSPDAT Output Main unit display control serial data output

47 SCK0 DSPSCK Output Main unit display control serial clock output

48~55 P80~P87 SYD0~SYD7 In/Output System LSI parallel data bus

56 P40 EJECT Input Eject lever operation detection input *

57 P41 KHOLD Input Main unit key hold switch input

58 P42 RPLAY Input Remote controller PLAY key operation detection input

59* P43 HFON Output P.U. high frequency superposition control output

IC401 RH-iX2680AF03(IX2680AF):System Microcomputer

Pin No.

Function

Port Name

Terminal Name Input/Output

In this unit, the terminal with asterisk mark (*) is (open) terminal which is not connected to the outside.

60 P44 LDON Output P.U. laser ON/OFF control output

61 P45 OPICGA Output P.U. detection sensitivity selection output

62 P46 RFLAT Output RF amp. IC data latch output

63 P47 RACLK Output RF/audio IC data clock output

64 P50 RADAT Output RF/audio IC serial data output

65 P51 PBLAT Output Playback audio IC data latch output

7

CIRCUIT DESCRIPTION

DMC-J7R

8

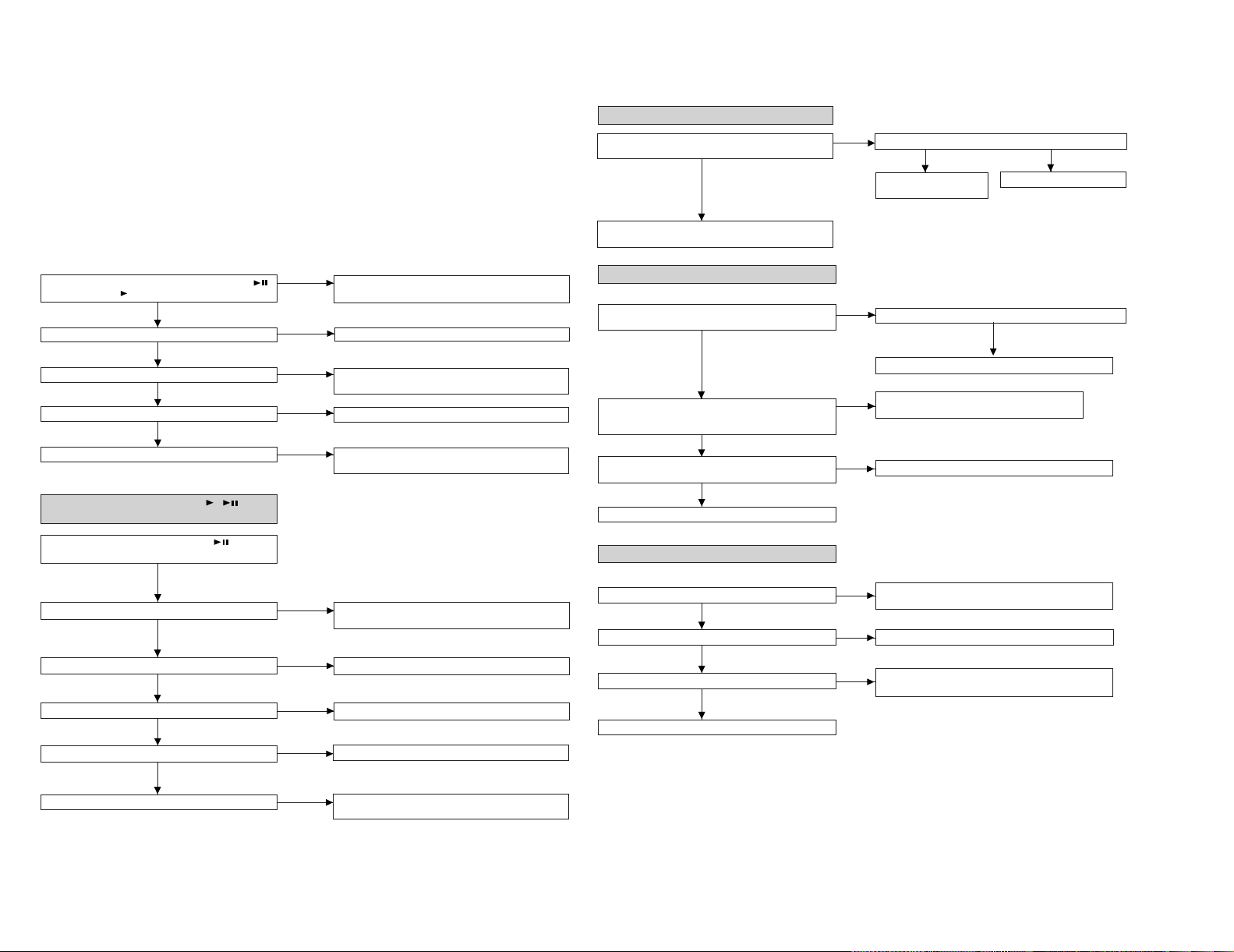

Yes

Check whether there is defective solder joint of audio signal

line between IC703 and J703

No

Yes

Is audio wavefrom output from J703 pins 3 and 4.

Check the pins 5 and 6 of IC703.

No

Yes

Is audio wavefrom output from IC703 pins 18 and 19.

Check IC201 pins 70 to 72, pin 74 and IC501 pins 9, 10, 11,

15

No

• Abnormal display

No

Yes

Is waveform output from IC 401 pins 45 to 47?

Check for pattern breakage of flexible PWB, check for

defects of display microcomputer (replace the display unit).

Is waveform output from CNS 482 pins 1 to 3?

Are the pin7 (VCC) and pin 6 (GND) normal?

• Playback state cannot be set

Is initialization performed normally in case of high- reflection

disc playback?

Yes

Check between IC401 and

CNS482.

No

Check the periphery of IC401.

Does the playback time display advance?

Yes

Position check in INNER mode

Check IC201 and IC202 connection line.

Is the lead-in photointerrupter set to OFF when the optical

pickup moves to the innermost periphery in NORMAL mode?

(Is TP660 in H level?).

Check the lead-in photointerrupter, mechanical flex

PWB soldering and CNS601 connection.

No

Ia an attempt to repeat repeatedly the TOC part performed

on the low-reflection disc?

Yes

No

No

Replace the disc.

No

• Audio playback clrcult

When it has been ascertained that the address up to cluster address is normal in the TEST mode.

Yes

Is audio wavefrom output from IC501 pins 19 and 20?

Check headphones jack,and periphery of headphone.

Although the playback time display is acting., no sound is given during playback in the normal mode.

It is advisable to use the TEST mode (refer to Error Data Display Mode, P15) indicating the causes of troubles before

starting repair. Causes of operation errors (up to 10 errors) are recorded as error codes. This information is useful

for repair.

When does not function

When the CD section does not operate When the objective lens of the optical pickup is dirty,this section may not operate.Clean

the objective lens,and check the playback operation.When this section does not operate even after the above step is taken,check

the following items.

Remove the cabinet and follow the troubleshooting instructions.

"Track skipping and/or no TOC(Table Of Contents) may be caused by build up of dust other foreign matter on the laser pickup lens.

Before attempting any adjustment make certain that the lens is clean. If not, clean it as mentioned below."

Turn the power off.

Gently clean the lens with a lens cleaning tissue and a small amount of isopropyl alcohol.

Do not touch the lens with the bare hand.

Is the power supply turned on when the remote control

button or main unit button is pressed?

No

Perform the check stated in item "Power is not turned on

when the PLAY button is pressed".

Perform the check stated in item "Abnormal display".

No

Yes

Does the display operate normally?

Is playback state set?

Yes

Perform the check stated in item "Playback state connot be

set".

No

Is audio output normal?

Yes

Perform the check stated in item "Audio playback circuit".

No

Is recording/playback operation normal?

Yes

Perform the check stated in item "Recording/playback

operation".

No

• Power is not turned on when the / button

is pressed.

No

No

Yes

Check the periphery of remote controller and main unit

headphone terminal (J703) and IC401.

No

Is the pin 57 of IC401 in H state?

Is operation normal when the main body button is pressed?

Check the position of Hold switch.

Is power turned on when the remote control button is

pressed?

No

Are IC401 pin 97 set to "L"?

Check the DISC IN (SW901) switch of mechanism PWB.

Yes

Yes

Is clock supplied to the pins 11 and 14 of IC401?

No

Check that voltage is applied to the periphery of IC403.

Yes

Is 2.5V applied to TP811?

No

Check whether there is solder touch of part connected to

the +2.5V line.

DMC-J7R

TROUBLE SHOOTING

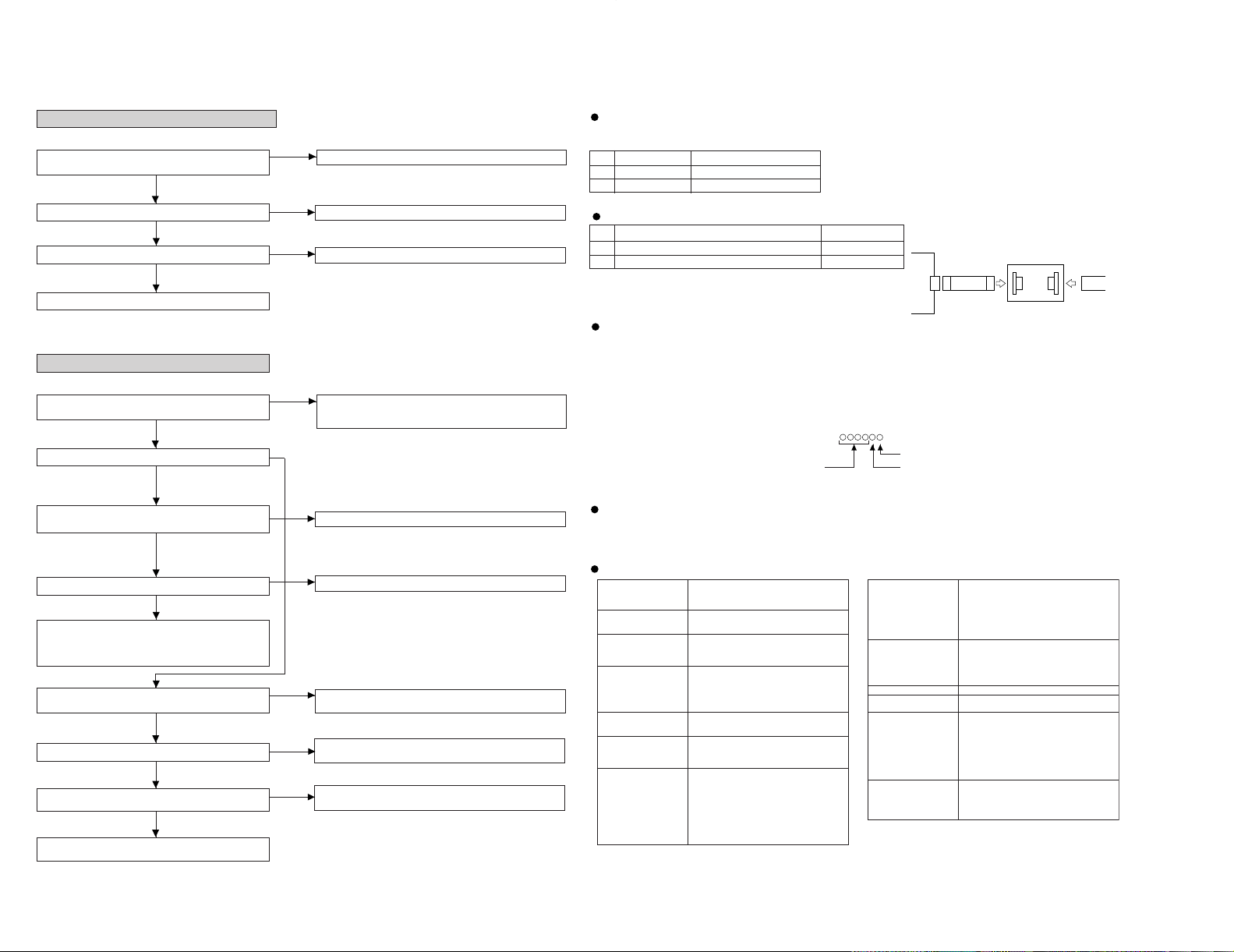

1 High reflection disc TG YS-1 (SONY)

2

Low reflection disc Recording minidisc

Test disc

MD adjustment needs two types of disc, namely recording disc (low reflection disc) and playback-only disc (high

reflection disc).

Type

Test disc

Note: Use the low reflection disc on which music has been recorded.

EEPROM version

Destination

Leaving the TEST mode

(1) Press the STOP button in the TEST mode stop state or version indicating state or whole LCD lighting state.

(2) EEPROM rewrite-enable area updating, adjustment error setting (so as to adjust all the items when the power supply is turned

on in the normal mode)

(3) Change to standby state

Test Mode

1. AUTO 1 Mode • Perform preliminary automatic adjustment.

• If the combination of mechanism and pickup

PWB has been changed, be sure to start from

AUTO1.

2. AUTO 2 Mode • Perform ATT (attenuator) automatic adjustment.

• Perform continuous playback (error rate display,

jump test)

3.

✻

✻

✻

✻

✻

✻

✻

✻

MANUAL 1 Mode • Temperature is displayed. (Updating in realtime)

• Seeing the displayed adjustment value, perform

preliminary manual adjustment.

(Error rate indication, jump test)

4. MANUAL 2 Mode • Temperature is displayed. (Updating in realtime)

• Seeing the displayed adjustment value

perform manfully the preliminary adjustment.

(Error rate indication, jump test)

• Continuous playback is performed

(error rate display, jump test).

5. RESULT 1 Mode • The value adjusted in AUTO1 or MANUAL1 is

indicated.

• (Execution in servo "OFF" state").

6. RESULT 2 Mode • The value adjusted in AUTO 2 or MANUAL 2 is

indicated.

• Adjustment value is changed manually.

(error rate display, jump test).

7. TEST-PLAY Mode • Continuous playback from the specified address

is performed.

• 1 line, 10 lines or 400 lines manual jump is

performed.

• C1 error rate display (pit section), ADIP error

rate display (groove section)

• The temperature correction is performed only

when servo start is performed, but the posture

correction is not performed duringcontinuous

playback.

Microcomputer version

Entering the TEST mode

1. Setting at port (in standby state, disc-free state or power nonconnected state)

(1) Set the port as follows.

TEST1 : "Low"

TEST0 : "High"

(2) Press the PLAY button in the standby state (it is allowed to insert the disc or to connect the power supply).

(3) Test Mode STOP [ _ T E S T _ ]

2. Setting by special button operation (in standby state)

(1) Holding down the DISP button and ENTER button, press the PLAY button.

(2) Normal mode setting initialization (BASS setting, VOL setting, etc.)

(3) Indication of microcomputer version for one second [ ]

(4) Whole LCD lighting for 2 seconds

(5) Test Mode STOP [ _ T E S T _ ]

*When the PLAY button is pressed during indication (3) and (4), the process proceeds to (5).

8. TEST-REC Mode • Continuous record from the specified address is

performed.

• Change of record laser output(servo gain is also

changed according to laser output).

• The temperature correction is performed only

when servo start is performed, but the posture

correction is not performed during continuous

recording.

9. NORMAL Mode • The mode is changed from the TEST mode to

the normal mode without adjustment.

• In the normal mode the internal operation mode,

memory capacity, etc. areindicated.

• In the normal mode both temperature correction

and posture correction are perfomed.

10. DIGITAL INPUT mode • Digital input information is displayed.

11.

ERROR INFORMATION

• Error information is displayed.

Mode • Error information is initialized

12. E2-PROM Mode • Factors of digital servo are changed manually.

(Each servo is turned on individually.)

• Cut-off frequency of BASS1, BASS2 and BASS3

is selected manually.

• Temperature detection terminal voltage is

measured, and the reference value is set.

• Defaults are selected and set.

• Setting of EEPROM protect area is updated.

(In case of protect releasing)

13. INNER

These modes are not used for service.

Mode • Determine the position where the INNER switch

is turned on. (only high reflection disc).

• The temperature correction is performed only

when servo start is performed, but the posture

correction is not performed.

Type

Parts No.

1 Flat Cable for servicing 16Pin QCNWK0110AFZZ

2 Extension Connector for Service 16Pin RUNTK0460AFZZ

Extension Cable (See Fig.10)

Figure 10

Mecha Flexible PWB

16 pin

16 PIn

CN601

QCNWK0110AFZZ

16pin Flat Cable

RUNTK0460AFZZ

Extension PWB for servicing 16pin

PWB side

• The spindle motor fails to run.Does the head move

No

Does the waveform appear on the IC201 pins 24 and 25 after

TEST mode AUTO2 completion and in this state?

Check the IC201 periphery.

Yes

Does waveform appear on the IC601 pin 13?

Does waveform appear on IC901 pins 1, 19 and 20?

Replace the spindle motor.

Yes

No

L608, IC201, IC901, CN601 and flex, etc. soldering check

No

Replace. IC601

Yes

• Recording/playback operation

Insert a low reflection disc, and ascertain audio output by normal playback, and then set TEST REC mode.

Yes

Does the head move down, failing to start record even

when the continuous record mode is set after address?

Check voltage of pins 52 and 53 of IC201, pins 2, 4, 7, and 9 of

IC651, pins 3 and 4 of CNS601. Check whether disc is recordinhibited.

No

Does the RF waveform of TP201 appear when playback is

Does level of pins 34 of IC401 and pin 17 of IC101 change

depending on record and playback?

Is RF pattern output from IC201 pin 50?

Yes

No

Check for soldering failure of IC201 .

No

Check periphery of IC401 and IC101.

Check whether there is any damage in IC101, periphery of

laser diode.

Yes

Check for defects of IC351 in head drive flexible PWB,

Q351 to 354, head, flexible PWB.

No

Yes

Is audio monitor output given in normal mode LINE IN

record?

Check waveforms of pins 9 to 12 of IC501, pins 70 to 73 of

IC201.

Is waveform obtained on IC501 pins 3 and 6?

No

Yes

Check whether the pin 7 of IC501 and the pin 59 of IC201 are in

H state.

No

No

Does voltage on the IC701 pins 13 to 15 change in case of

record VOLUME UP/DWN?

Is audio waveform observed on the pins 18 and 19 of

IC703?

Yes

Check whether input waveform is observed on the pins 5

and 6 of IC703.

Yes

9

TROUBLE SHOOTING

DMC-J7R

Loading...

Loading...