Kenwood DMCG-7-R Service Manual

POTABLE MD RECORDER

DMC-G7R

SERVICE MANUAL

© 1997-7/B51-5335-00 (K/K) 2740

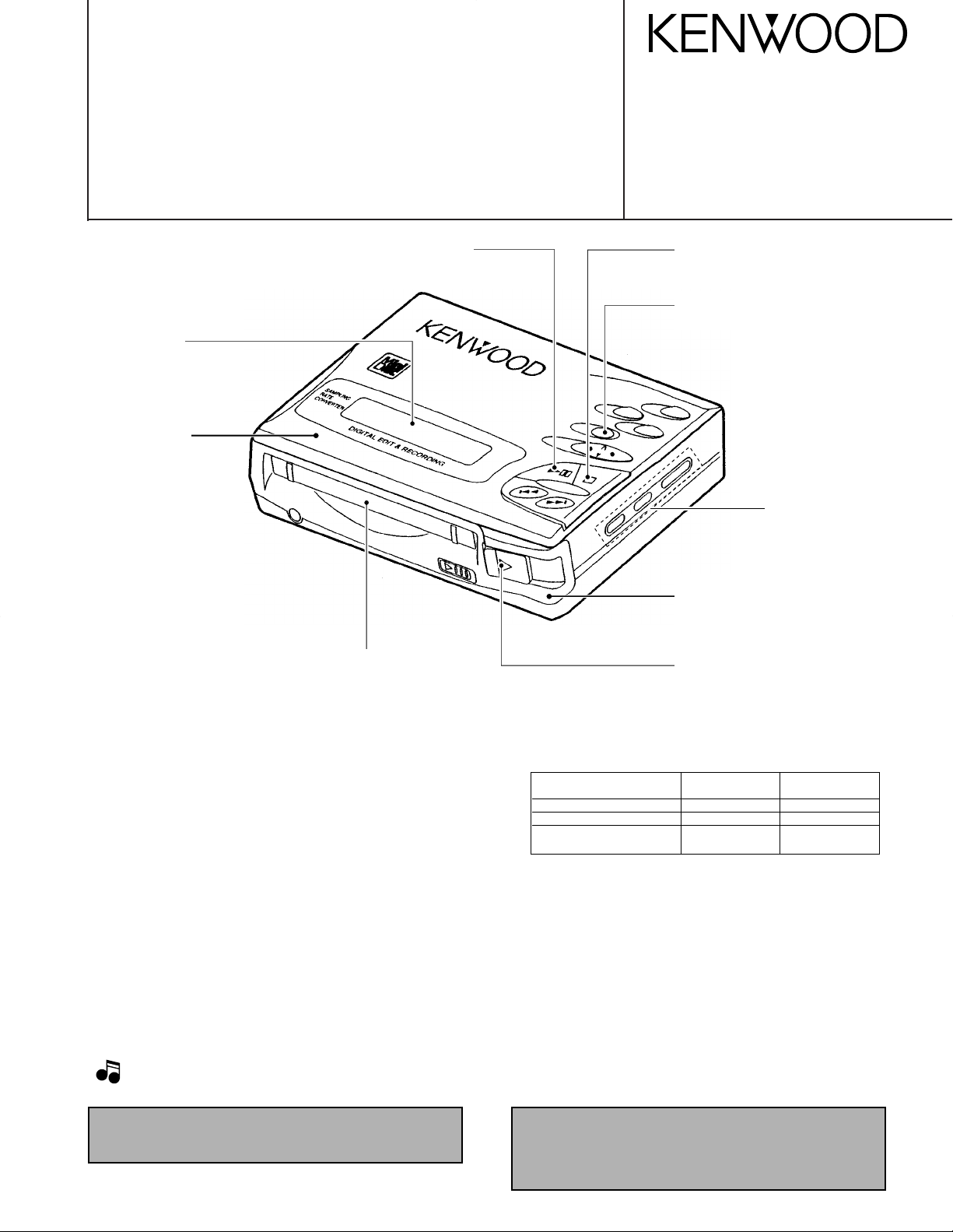

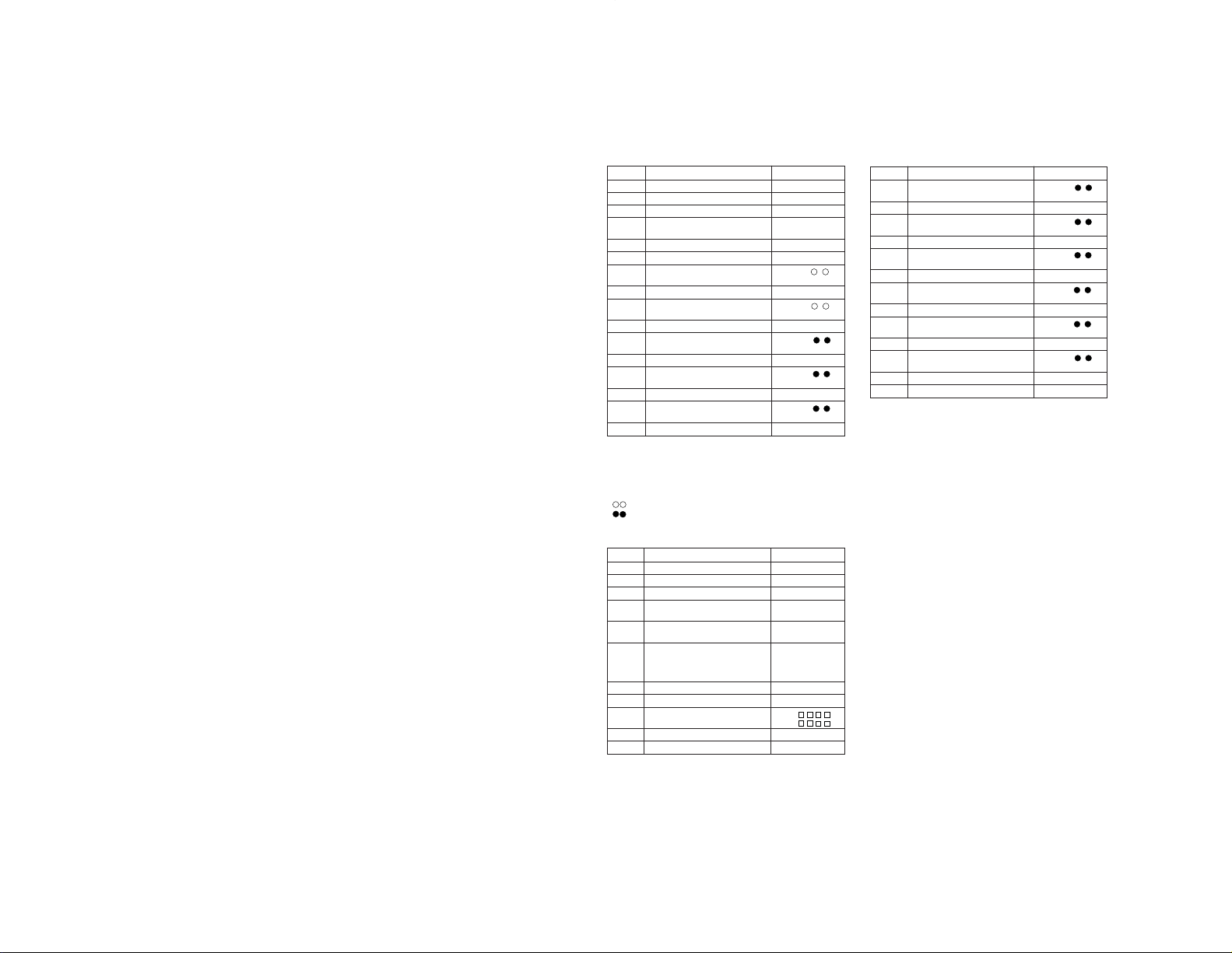

Decoration plate

(B07-2372-08)

Top cover

(F07-0798-08): S

(F07-0799-08): B

S: SILVER, B: BLUE

Knob (PLAY/PAUSE)

(K27-2229-08)

Cover

(F07-1624-08)

Knob (STOP)

(K27-2231-08)

Knob (REC)

(K27-2227-08)

Knob (EDIT MODE)

(K27-2230-08)

Front cabinet

(A02-1357-08): S

(A02-1358-08): B

Knob (EJECT)

(K27-2232-08)

SPECIFICATIONS

System.........................................................MiniDisc digital audio system

Read method...Noncontact optical reading system (semiconductor laser)

Rotating speed..........................................................About 400 - 900 rpm

Sampling frequency..............44.1 kHz (32 kHz and 48 kHz are converted

Audio compression...........ATRAC (Adaptive Transform Acoustic Coding)

Number of channels...................................................Stereo : 2 Channels

Recording method.........................Magnetic modulation overwrite system

Error correction method...................................................AC / RC method

Frequency response.......................................20 Hz to 20,000 Hz (±3 dB)

Wow & flutter .............Less than unmeasurable limit (±0.001 % W.PEAK)

Input jack........................Line/optical combined input x 1; microphone x 1

Output jack ..............................Headphone/remote control combined jack

Input sensitivity : MIC H.....................................................0.25 mV/10 kΩ

Output level :phones.....10 mW + 10 mW (Maximum output level/at 16Ω)

Power source...DC 5 V : AC adaptor (AC 120 V, 50/60 HZ)

1. KENWOOD follows a policy of continuous advancements in development, For reason specifications may be changed without notice.

NotesNotes

2. The full performance may not be exhibited in an extremely cold location (under a water-freezing temperature).

In compliance with Federal Regulations, following are reproductions of labels on, or inside the product relating to laser product

safety.

MIC L........................................................2.5 mV/10 kΩ

LINE ........................................................100 mV/20 kΩ

LINE ..................350 mV (at -12dB, standard output/50 kΩ)

DC 3.6 V : Lithium ion battery x 1

DC 5 V : Car battery adaptor (sold separately, DC-C50)

DC 4.5 V : Dry batteries case (sold separately, BC-F5)

to 44.1 kHz and recorded)

Monaural Extended mode : 1 channel

(plug-in power type)

Battery life..................................................................................................

(fully charged batteries)

Type of battery

Rechargeable battery only Approx. 9.5 hours Approx. 7 hours

Alkaline batteries Approx. 24 hours Approx. 17 hours

Rechargeable battery + Approx. 35 hours Approx. 25 hours

Alkaline batteries

(Continuous recording time : based on analog input and recording

monitor volume level of "0"

(Continuous playback time : based on volume level of "VOL 20")

• Time of use may vary depending on battery maker, batter type,

use environment, and temperature.

Dimensions (W) x (H) x (D) ....................109.2 mm x 29.8 mm x 81.3 mm

Weight (Net).................Approx. 270 g (0.59 lb)

Including the accessory rechargeable battery

Approx. 222g (0.49 lb)

not including the accessory rechargeable battery

KENWOOD-Corp. certifies this equipment conforms to DHHS

Regulations No. 21 CFR 1040. 10, Chapter 1, Subchapter J.

DANGER : Laser radiation when open and interlock defeated.

AVOID DIRECT EXPOSURE TO BEAM.

Continuous Continuous

playback time recording time

(4-5/16" x 1-3/16" x 3-3/16")

DMC-G7R

CONTENTS / ACCESSORIES

Contents

SPECIFICATIONS.......................................Front cover

CONTENTS / ACCESSORIES ....................................2

DISASSEMBLY FOR REPAIR.....................................3

TROUBLE SHOOTING................................................5

Accessories

PC BOARD ................................................................19

SCHEMATIC DIAGRAM............................................23

EXPLODED VIEW .....................................................27

PARTS LIST...............................................................29

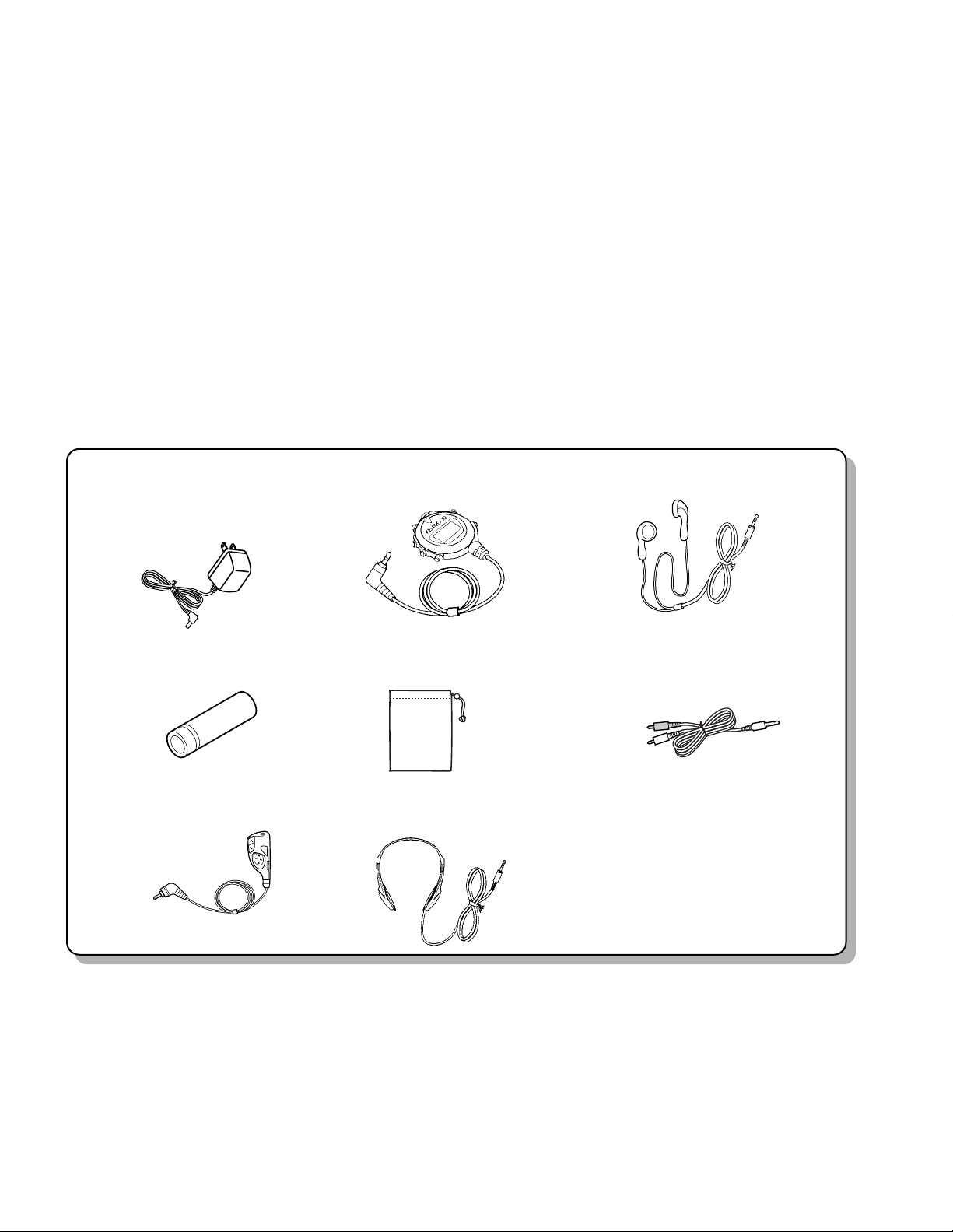

AC adaptor(1)

(W08-0668-08) : K

(W08-0669-08) : M

(W08-0670-08) : E

(W08-0671-08) : T

Rechargeable battery (NB-L5) (1)

(W03-5679-08)

Remote control unit (1)

(A70-1177-05) : KET

Remote control (1)

(A70-1129-05) : M

Carrying case (1)

(W01-0918-08)

Stereo headphone(1)

(W01-0941-15) : K

Stereo headphone(1)

(W01-0920-15) : MET

Patch cord (1)

(E30-2836-08)

2

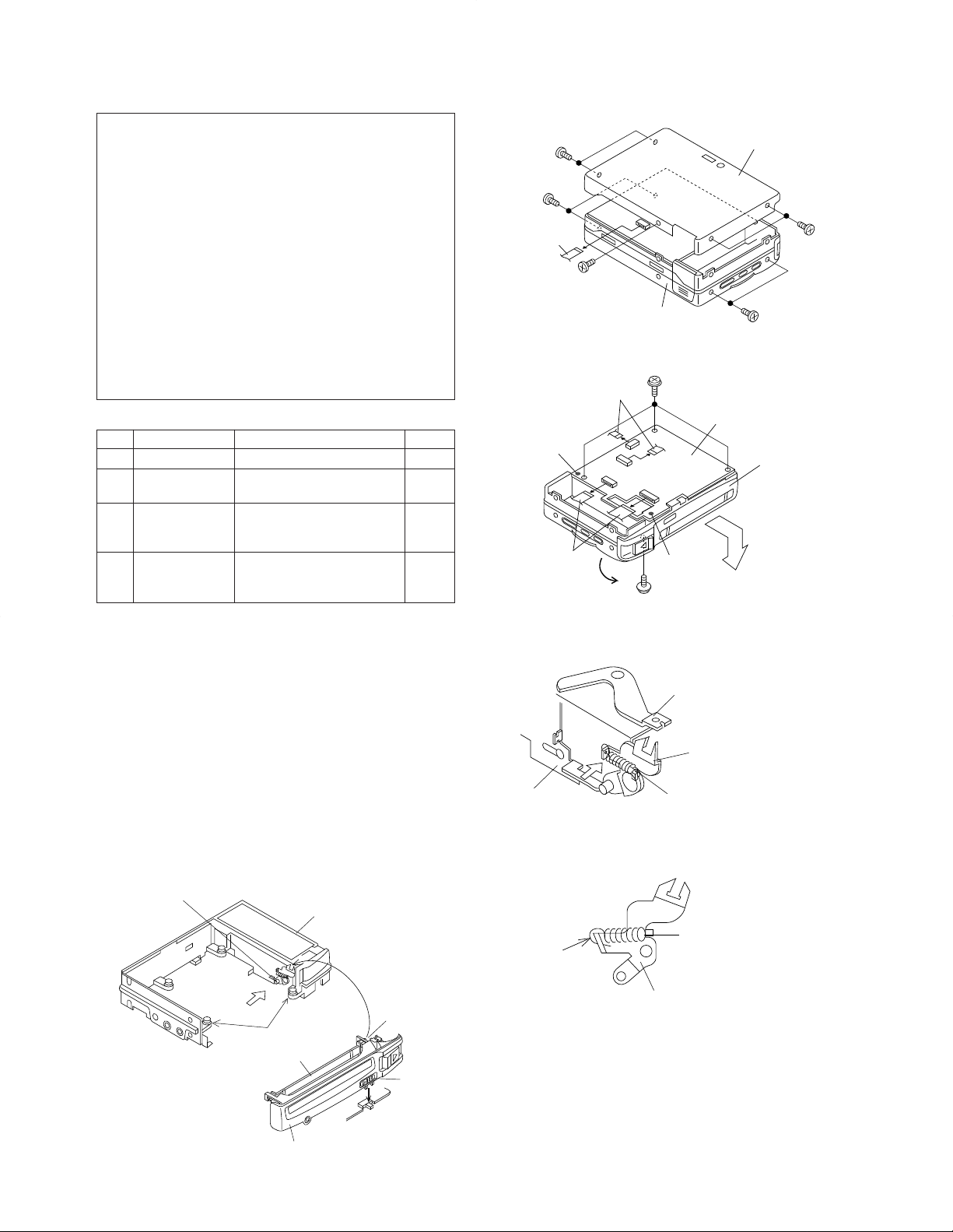

Caution on Disassembly

Follow the below-mentioned notes when disassembling

the unit and reassembling it, to keep it safe and ensure

excellent performance:

1. Take the battery and minidisc out of the unit.

2. When disassembling the machine, be sure to withdraw

the power plug from the socket in advance.

3. When disassemble the parts, remove the nylon band or

wire holder as necessary.

To assemble after repair, be sure to arrange the wires as

they were.

If a screw of different length is fitted to the MD mecha-

nism (the screw of the part to be fitted to the MD

mechanism chassis), it may contact the optical pickup,

resulting in malfunction.

4. When repairing, pay due attention to electrostatic charges

of IC.

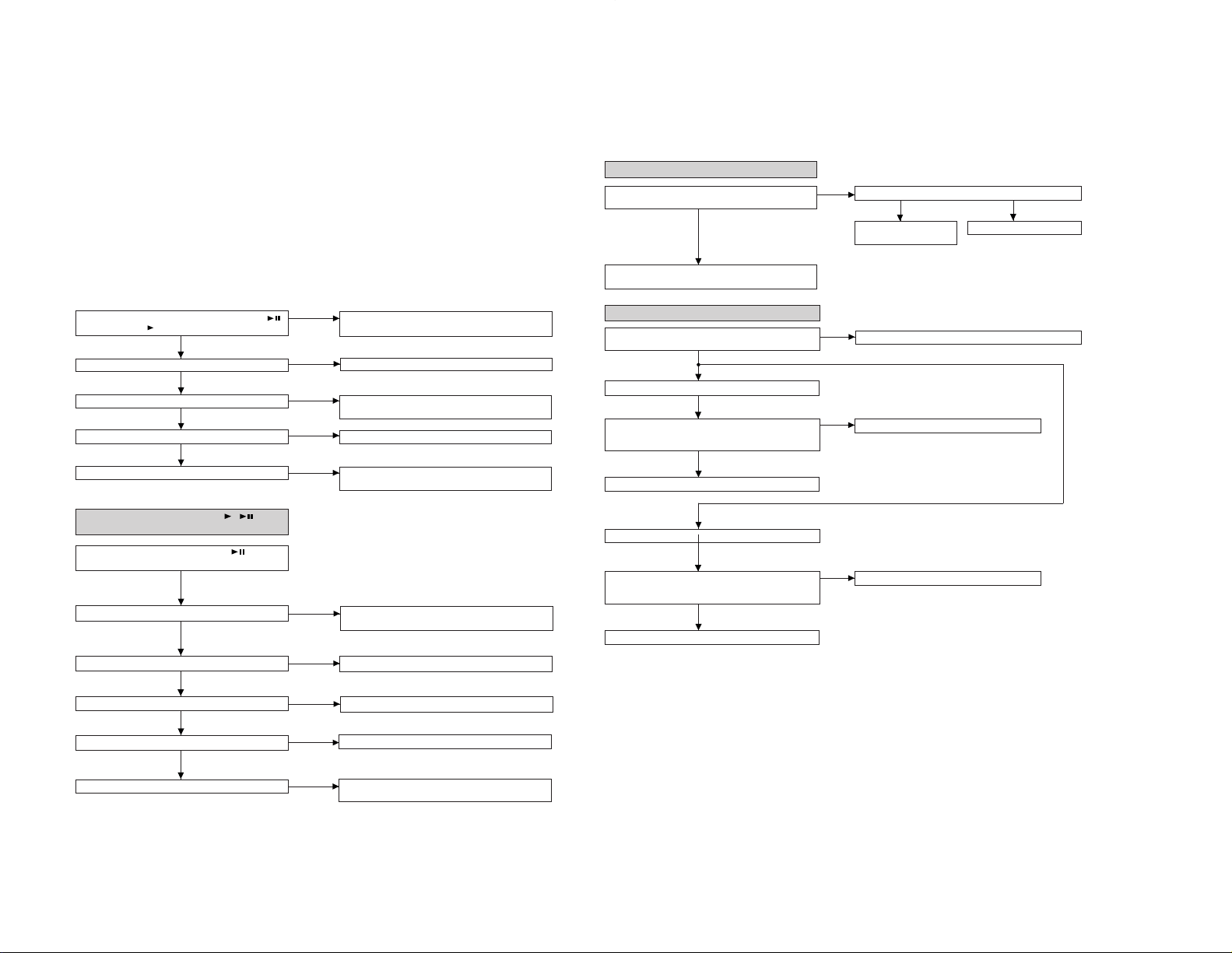

1 Bottom Cover 1. Screw ..................... (A1) x5 7-1

2 Disc Cover 1. Screw..................... (B1) x4 7-1

(Note) 2. Flexible PWB......... (B2) x1

3 Main PWB 1. Screw..................... (C1) x3 7-2

2. Flexible PWB......... (C2) x4

3. Soldering ............... (C3) x2

4 Front Cabinet 1. Screw..................... (D1) x1 7-2

2. Remove the front cabinet in

the arrow direction.

REMOVAL

PROCEDURE

STEP

FIGURE

Bottom Cover

(B1) x2

Ø2x2mm

(B1) x2

Ø2x2mm

(A1) x2

Ø2x2mm

(A1) x2

Ø2x2mm

(A1) x1

Ø2x2mm

(B2) x1

Disc Cover

Figu re 7-1

Figure 7-2

Figure 7-3

Figure 7-4

Note:

When removing the upper lid, at first turn the operation knob

side in the arrow direction to remove.

Installing the front cabinet (See Fig. 7-3.)

1. Make sure that the lid opening and closing spring has been

engaged at the upper side as shown in Figure < A > .

2. Fit the MD lid right pin into the lid opening and closing lever

to install it.

Note:

• Take care since the antivibration rubber may come off.

• If the main PWB has been installed previously, fit the knob to

the HOLD switch shown in Figure < B > .

• If the mechanism has been installed, the antivibration rubber

may come off from the center cabinet fitting part when the

front part of center cabinet is widened.

DISASSEMBLY FOR REPAIR

Lid opening and closing lever

<A>

Antivibration rubber

Center Cabinet

MD lid

SW

MD lid right pin

HOLD knob

<B>

(C3) x1

(C2) x2

Eject lever

Engage the spring

at the upper side.

<A>

Figure <A>

(C2) x2

DMC-G7R

(C1) x3

Ø2x2.5mm

Main PWB

Front Cabinet

(C3) x1

(D1) x1

Ø2x2.5mm

Eject knob lever

Lid opening and closing lever

Lid opening and closing spring

Lid opening and closing spring

Lid opening and closing lever

Front Cabinet

3

DMC-G7R

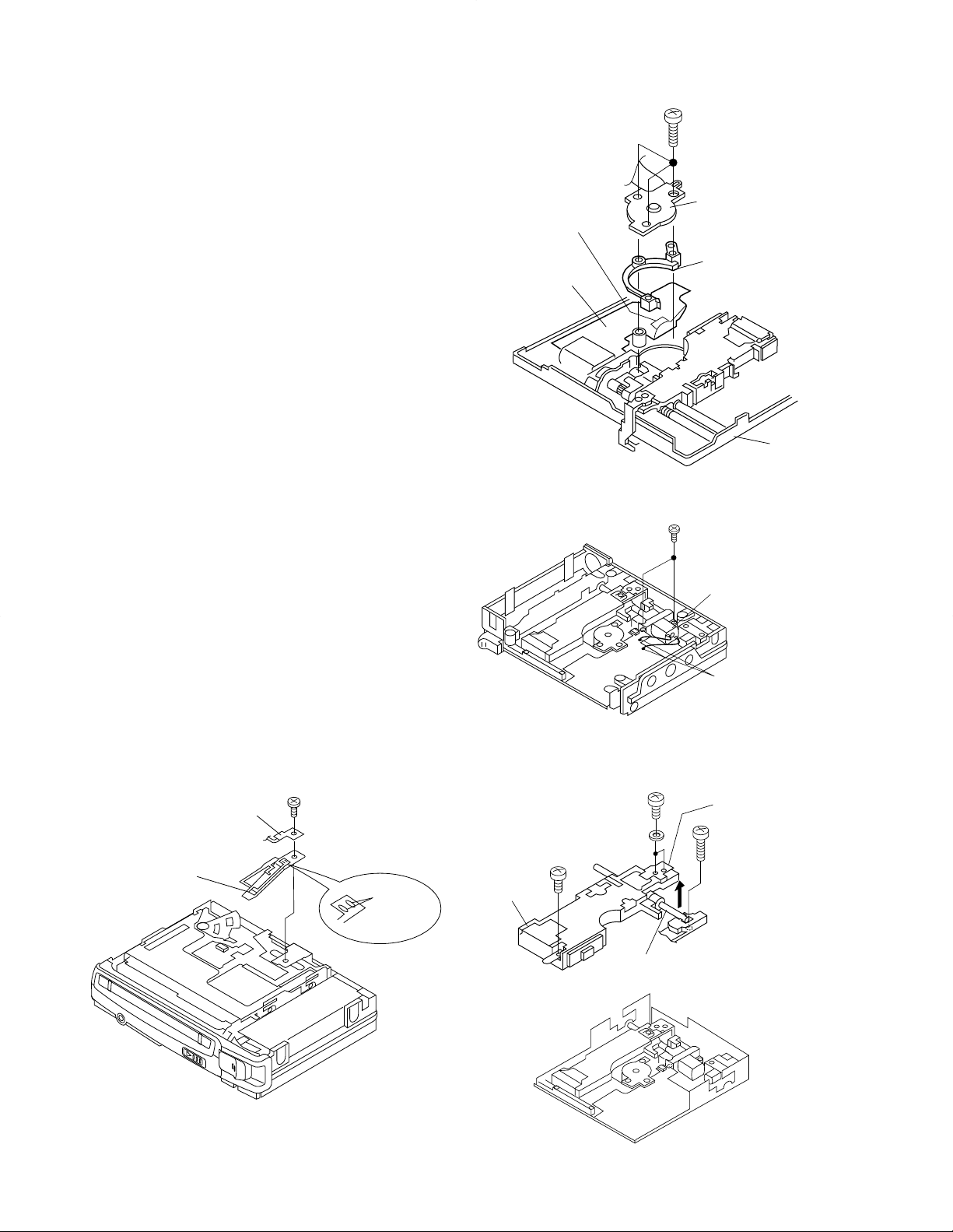

Remove the mechanism according to the disassembling methods 1 to 4. (See Page 7.)

How to remove the disc motor (See Fig. 8-1.)

1. Remove the solder joint (A1) x 1 of flex PWB.

2. Remove the screws (A2) x 3 pcs. and remove the disc

motor.

Take care so that the turnrable is not damaged.

Figure 8-4

(A2) x 3

Ø1.4 x 4.5mm

Flexible PWB

solder joint

(A1) x1

Disc Motor

Motor Spacer

Mechanism PWB

Mechanism

Figure 8-1

(B2) x2

Ø1.4x2.2mm

(B1) x2

Remove the solder joint.

Slide Motor

Figure 8-2

Figure 8-3

How to remove the slide motor (See Fig. 8-2.)

1. Remove the solder joint (B1) x 1 of slide motor lead wire.

2. Remove the screw (B2) x 1, and remove the slide motor.

Note:

Take care so that the motor gear is not damaged.

(If the gear is damaged, noise is raised in search mode.)

How to reinstall the optical pickup unit

(See Fig. 8-3.)

1. Remove the screws (C1) x 5 pcs.

2. Remove the magnetic fielt arm block from the pickup, and

move the magnetic field arm block outwards.

Note:

Take due care so that the magnetic head is not damaged.

3. Withdraw a little the slide motor side shaft (C2) x 1 pcs., and

slowly raise the optical pickup.

How to remove the magnetic head

(See Fig. 8-4.)

1. Remove the screw (D1) x 1 pc.

2. Remove the unsolder (D2) x 2 pcs. which connects the

magnetic head and the head hookup flex.

Note:

Mount carefully so as not to damage the magnetic head.

DISASSEMBLY FOR REPAIR

(D1) x1

Head intervening flexible PWB

Magnetic head

Ø1.4x2mm

Unsolder

(D2) x2

Pickup Unit

(C1) x 1

Ø1.4 x 2.5mm

(C1) x 2

Ø1.4 x 3mm

Magnetic field arm block

(C1) x 1

Ø2 x4.5mm

Shaft (C2) x 1

4

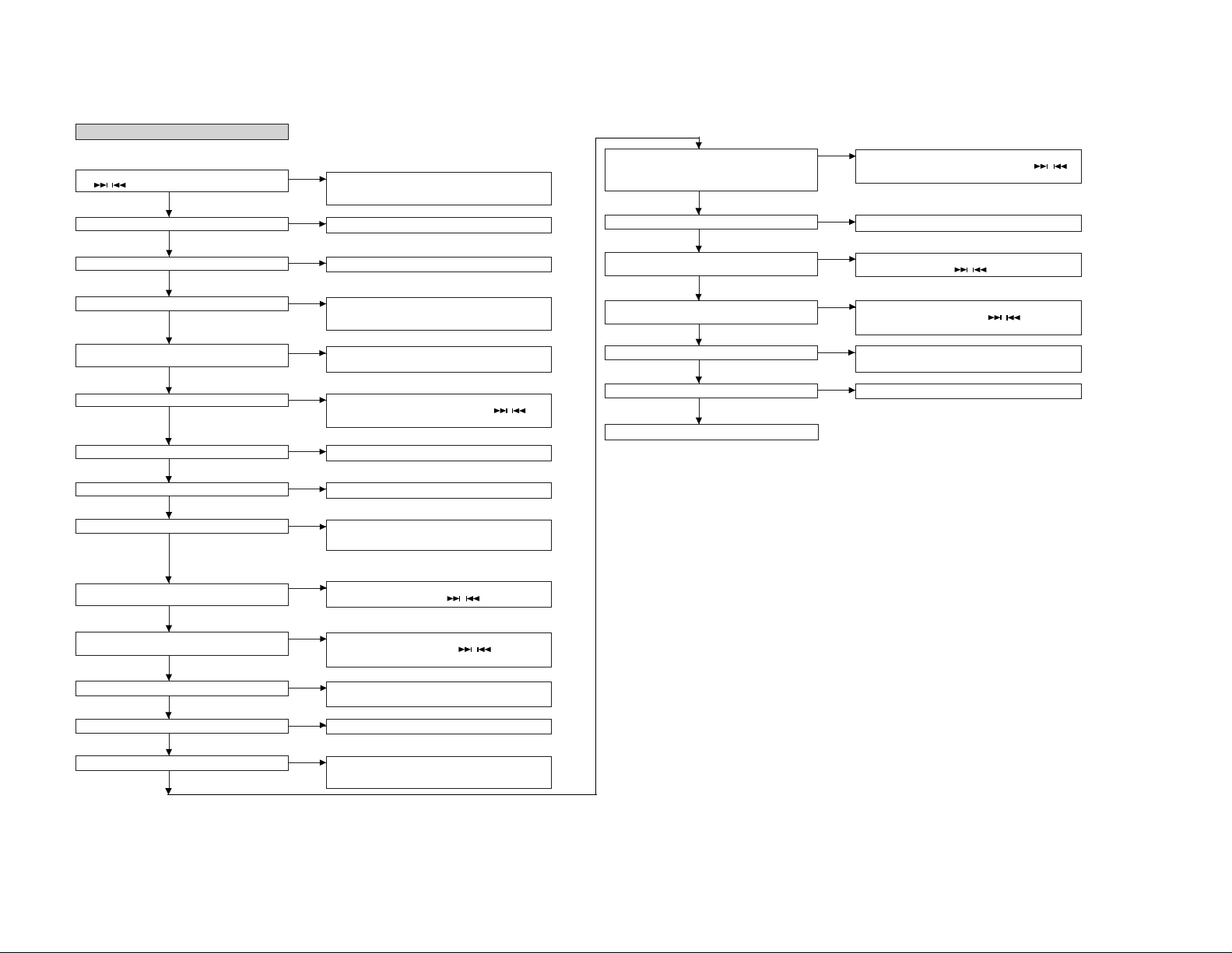

• Abnormal display

No

Yes

Is waveform output from IC 401 pins 13 to 15?

Check for pattern breakage of flexible PWB, check for

defects of display microcomputer (replace the display unit).

Is waveform output from CNS 402 pins 1 to 3?

Are the pin7 (VCC) and pin 6 (GND) normal?

• Playback state cannot be set

Is playback state unsettable for high reflection disc and low

reflection disc?

Yes

Check between IC401 and

CNS402.

No

Check the periphery of IC401.

Proceed to "Test mode check".

Yes

Only the low reflection disc cannot be played back.

Only the high reflection disc cannot be played back.

Yes

Is the pin 46 of IC401 in L state when the high reflection disc

is inserted?

Is the pin 51 of IC401 and pin 23 of IC101 in L state?

Check SW902, mechanism flexible PWB and CN601.

No

Proceed to "Test mode check".

Yes

No

Yes

Is the pin 46 of IC401 in L state when the high reflection disc

is inserted?

Is the pin 51 of IC401 and pin 23 of IC101 in L state?

No

Proceed to "Test mode check".

Yes

Check SW902, mechanism flexible PWB and CN601.

It is advisable to use the TEST mode (refer to Error Data Display Mode, P15) indicating the causes of troubles before

starting repair. Causes of operation errors (up to 10 errors) are recorded as error codes. This information is useful

for repair.

When does not function

When the CD section does not operate When the objective lens of the optical pickup is dirty,this section may not operate.Clean

the objective lens,and check the playback operation.When this section does not operate even after the above step is taken,check

the following items.

Remove the cabinet and follow the troubleshooting instructions.

"Track skipping and/or no TOC(Table Of Contents) may be caused by build up of dust other foreign matter on the laser pickup lens.

Before attempting any adjustment make certain that the lens is clean. If not, clean it as mentioned below."

Turn the power off.

Gently clean the lens with a lens cleaning tissue and a small amount of isopropyl alcohol.

Do not touch the lens with the bare hand.

Is the power supply turned on when the remote control

button or main unit button is pressed?

No

Perform the check stated in item "Power is not turned on

when the PLAY button is pressed".

Perform the check stated in item "Abnormal display".

No

Yes

Does the display operate normally?

Is playback state set?

Yes

Perform the check stated in item "Playback state connot be

set".

No

Is audio output normal?

Yes

Perform the check stated in item "Audio playback circuit".

No

Is recording/playback operation normal?

Yes

Perform the check stated in item "Recording/playback

operation".

No

• Power is not turned on when the / button

is pressed.

No

No

Yes

Check the periphery of remote controller and main unit

headphone terminal (J703) and IC401.

No

Is the pin 26 of IC401 in H state?

Is operation normal when the main body button is pressed?

Check the position of Hold switch.

Is power turned on when the remote control button is

pressed?

No

Are IC401 pin 50 set to "L"?

Check the DISC IN (SW904) switch of mechanism PWB.

Yes

Yes

Is clock supplied to the pins 83 and 86 of IC401?

No

Check that voltage is applied to the periphery of IC403.

Yes

Is 2.5V applied to TP201?

No

Check whether there is solder touch of part connected to

the +2.5V line.

TROUBLE SHOOTING

DMC-G7R

5

6

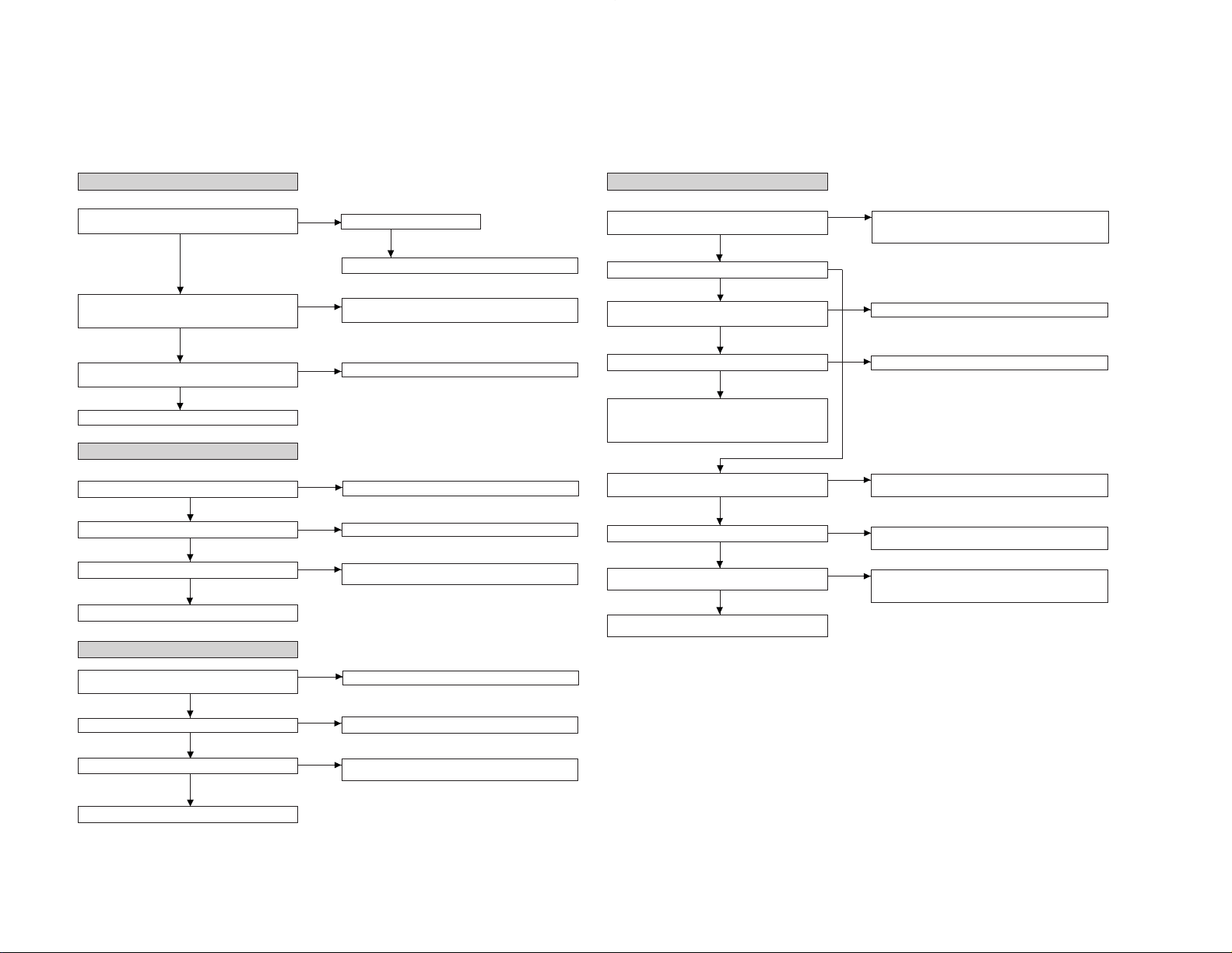

Continued from the preceding page

In case of high reflection disc, proceed to the item "normal

playback".In case of low reflection disc, check whether

adjustment is within allowable range in the TOTAL level

adjustment step.

Check whether values of pins 10, 11, 14, and 15 of IC201 and

pins 30 and 32 of IC101 (TP143) change when the /

button is pressed.

No

Doesn't the disc motor run at high speed in the same step?

Check ADIP waveform of pin 4 of IC201.

No

Yes

Is tracking gain adjustment within allowable range in the

same step?

Check whether values of pins 16 to 19 of IC201 and TP144

(TEOUT) change when the / button is pressed.

No

Yes

Is adjustment within allowable range in tracking error

balance adjustment step?

Check whether value of pin 20 of IC201 and TP144(TEOUT)

changes or DC shift occurs when the / button is

pressed.

No

Yes

Is tracking servo applied in focus gain fine adjustment step?

Check waveforms of pins 54 and 55 of IC201, pins 18, 19, 21,

and 23 of IC601, pins 4 and 6 of CNS101.

No

Yes

Is slide servo applied in continuous playback step?

Replace IC201.

No

Yes

Yes

Check item "Normal Playback".

• Test mode check

Insert a high reflection (low reflection) disc, and once perform automatic adjustment in AUTO mode, and then check in MANUAL mode.

Simultaneously observe waveforms of EFM(TP145), FEOUT(TP143), and TEOUT(TP144).

Does the optical pickup move to outer/inner periphery when

the / button is pressed?

Check the pins 56 and 57 of IC201, the pins 25, 27, 29 and 30

of IC601, the pins 10 and 11 of CNS601, and the slide motor

terminal.

No

Is tracking error offset measurement within allowable range?

Yes

Check Vref values of pins 3 and 4 of IC101 and pin 22 of IC201.

No

Is focus error offset measurement within allowable range?

Yes

Check Vref values of pins 3 and 4 of IC101 and pin 22 of IC201.

No

Yes

Is laser power normal when laser lights?

Check the pins 21 and 22 of IC101, the pins 6 and 52 of IC401,

the periphery of Q101, Q102, and Q103, CNS101, and pickup

flexible PWB insertion.

No

Yes

Does focus access occur in focus gain rough adjustment

step?

Check the pins 52 and 53 of IC201, the pins 10, 12, 14, and 15

of IC601,and the pins 5 and 7 of CNS101.

No

Yes

Is adjustment out of allowable range?

Check whether values of pins 10, 11, 14, and 15 of IC201, pins

30 and 32 of (IC101) (TP143) change when the / button

is pressed.

No

Does the disc motor rotate in the same step?

Check as stated in item "The disc motor does not rotate".

No

Is focus servo applied in tracking gain adjustment step?

Check timing of pins 91 and 92 of IC401 and TP144(TEOUT).

No

Yes

Yes

Doesn't the disc motor rotate at high speed in the same step?

No

Check EFM waveform of pin 23 of IC201 in case of high

reflection.

Check ADIP waveform of pin 4 of IC201 in case of low reflection.

Yes

Is tracking gain adjustment within allowable range in the

same step?

Check whether values of pins 16 to 19 of IC201 and

TP144(TEOUT) change when the / button is pressed.

No

Yes

Is adjustment within allowable range in tracking error

balance adjustment step?

Check whether value of pin 20 of IC201 and TP144(TEOUT)

changes or DC shift occurs when the / button is

pressed.

No

Yes

Is tracking servo applied in focus gain fine adjustment step?

Check waveforms of pins 54 and 55 of IC201, pins 18, 19, 21,

and 23 of IC601, pins 4 and 6 of CNS101.

No

Yes

Is slide servo applied in continuous playback step?

Replace IC201.

No

Yes

Is cluster address counted up continuously in the same step?

Check waveforms of pins 53 to 56 of IC101 and pins 23 to 25 of

IC201. (In case of low reflection check also the waveform of pin

4 of IC201.)

No

Yes

Yes

Continued on the next page.

DMC-G7R

TROUBLE SHOOTING

• Recording/playback operation

Insert a low reflection disc, and ascertain audio output by normal playback, and then set TEST REC mode.

Yes

Does the head move down, failing to start record even

when the continuous record mode is set after address?

Check voltage of pins 56 and 57 of IC401, pins 2, 4, 7, and 9 of

IC851, pins 12 and 13 of CNS601. Check whether disc is

record-inhibited.

No

Is RF waveform output TP145 in recording/playback mode?

Does level of pins 6 and 54 of IC401 and pin 22 of IC101

change depending on record and playback?

Is RF pattern output from IC201 pin 60 and CNS201 pin 2?

Yes

No

Check for soldering failure of IC201 and CNS201.

No

Check periphery of IC401 and IC101.

Check whether there is any damage in IC101, periphery of

Q101, and laser diode.

Yes

Check for defects of IC351 in head drive flexible PWB,

Q351 to 354, head, flexible PWB.

No

Yes

Yes

Is audio monitor output given in normal mode LINE IN

record?

Check waveforms of pins 111, 12, 14, 15 of IC501, pins 76 to

79 of IC201.

Is waveform obtained on IC501 pins 3 and 5?

No

Yes

Check whether the pin 24 of IC501 and the pin 75 of IC401 are

in H state.

No

No

Check whether the pin 8 of IC701 is in H state. Check whether

voltage of pins 13 to 15 of IC701 changes when the Record

Volume Up/Down button is pressed

Is audio waveform observed on the pins 18 and 19 of

IC703?

Yes

Check whether input waveform is observed on the pins 5

and 6 of IC703.

No

• Normal playback

Is initialization performed normally in case of high reflection

disc normal playback?

When the address up to the sector address has been proved to be normal in the test mode.

Yes

No

Does the playback time display act?

Check IC201 and IC202 connection line.

Is an attempt tp read repeatebly the TOC section of low

reflection disc made?

No

Check whether the disc is new one.

Yes

Position check in INNER mode

Yes

• Audio playback circuit

Although the playback time display is acting, no sound is given during playback in the normal mode.

No

Is audio waveform output from IC501 pins 26 and 27?

Yes

Is audio waveform output from IC703 pins 18 and 19.

No

Check the pins 5 and 6 of IC703.

Yes

Is audio waveform output from J703 pins 4 and 5.

No

Check whether there is defective solder joint of audio signal line

between IC703 and J703.

Check headphones jack,and periphery of headphone.

Yes

• The disc motor fails to rotate.

No

Check the periphery of IC201.

Is waveform observed on the pins 58 and 59 of IC201 in

focus gain rough adjustment step?Is audio waveform Is

Yes

waveform observed on the pins 21 of IC601?

Replace IC601.

Yes

No

Check solder joints of L607, IC201, IC901, CNS601, and flexible

PWB.

No

Check the lead-in switch SW901, solder joint of mechanism

PWB, and the pin 8 of CNS601.

No

Is the read-in switch turned on when the optical pickup is

moved to the innermost periphery in NORMAL mode?

(Is the pin 48 of IC401 on L level?)

Check IC201 pins 76 to 78, pin 80 and IC501 pins 11, 12, 13, 15.

Do the pins 16 and 21 of IC901 waveform observe?

Replace the disc motor.

Yes

TROUBLE SHOOTING

DMC-G7R

7

8

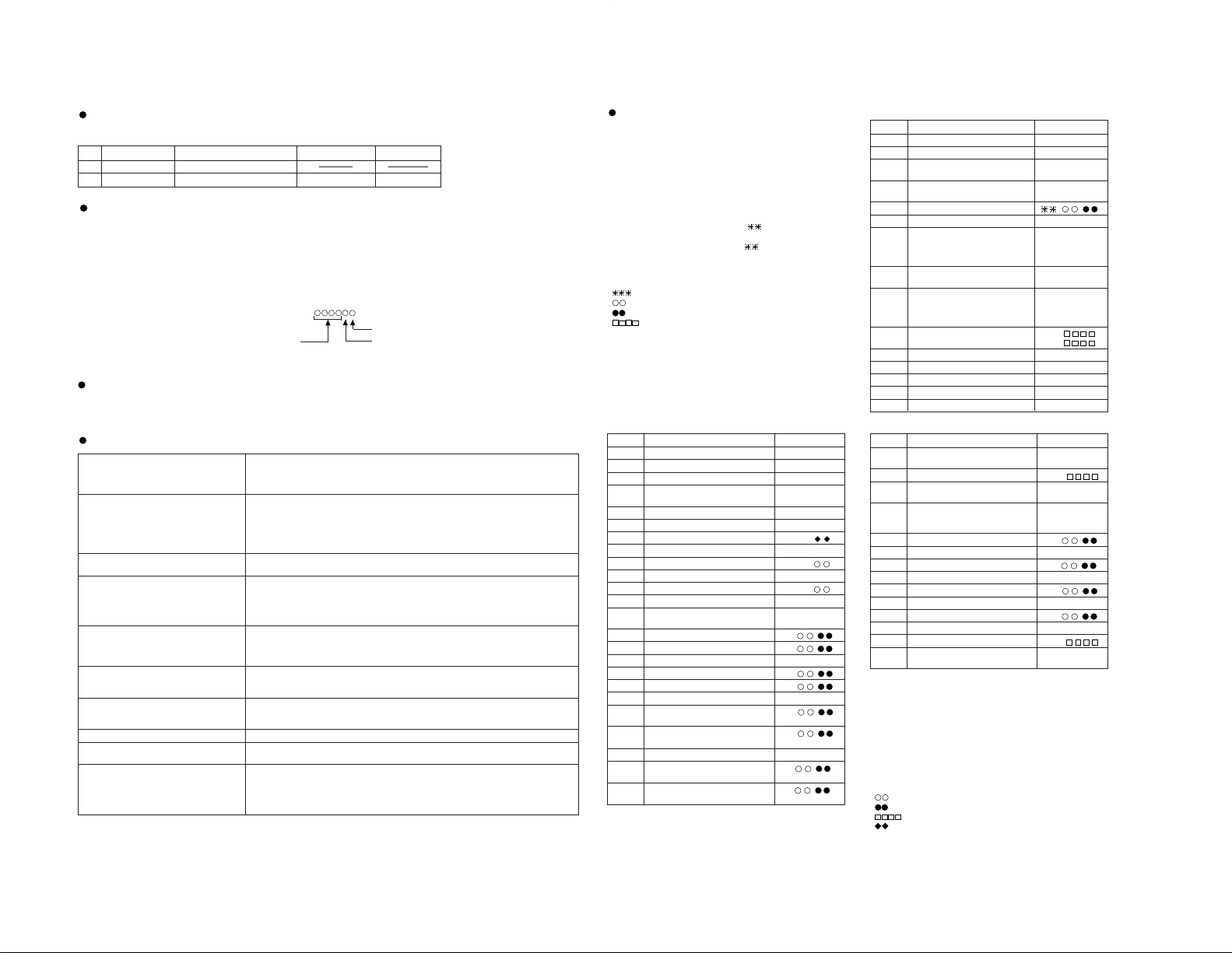

1. AUTO Mode

• When the STOP button is pressed while the AUTO menu

appears or during automatic adjustment, the mode changes to

the TEST mode stop state. At this time the adjustment value is

not output.

• As for operation during continuous playback refer to [Explanation

of TEST-PLAY mode].

• Adjustment NG: If the measurement value of adjustment FEO is

out of range,focus ON failure occurs or adjustment error or TZC

error occurs.

• When the high reflection disc is used, changes as follows.

TEO — FEO — Hf — Hg — Hb — Hf

• When the low reflection disc is used, changes as follows.

TEO — FEO — If — Lg — Lb — Lf — Gl — Gg — Gb — Lf

• Grating adjustment: When the focus servo and spin servo are

ON.

• : Adjustment name

• : Measurement value

• : Set value

• : Address

Operation in each TEST mode

Step No.

Operation and state

Display

Step 1 Test mode STOP state [ T E S T ]

Step 2 BASS button.

Step 3 AUTO menu. [ A U T O ]

Step 4 PLAY button -->

Slide shift to innermost periphery

Step 5 Automatic adjustment [ ]

Step 6 End of adjustment

Step 7 When adjustment is OK, the

process proceeds to (8).

When adjustment is NG, the

process proceeds to (13).

Step 8 Grating adjustment, adjustment [ A D J . O K ]

value output

Step 9 When the PLAY button is pressed,

the process proceeds to (10).

When the STOP button is pressed,

the process proceeds to (12).

Step 10 Continuous playback (pit section) [ S Q ]

Continuous playback (groove section) [ A P ]

Step 11 STOP button

Step 12 Test mode STOP state [ T E S T ]

Step 13 Adjustment value output [ A D J . N G ]

Step 14 STOP button

Step 15 Test mode STOP state [ T E S T ]

2. MAMUAL Mode

Step 1 Test mode STOP state [ T E S T ]

Step 2 BASS button

Step 3 AUTO menu [ A U T O ]

Step 4 SKIP UP button x 1 times

(Or SKIP DOWN button x 9 times)

Step 5 MANUAL menu [ M A N U A L ]

Step 6 PLAY button

Step 7 Temperature measurement [ T M P : ]

Step 8 SKIP UP button

Step 9 Tracking error offset measurement [ T E O : ]

Step 10 SKIP UP button

Step 11 Focus error offset measurement [ F E O : ]

Step 12 SKIP UP button—Laser lighting [ L O N : _ _ ]

Step 13 SKIP UP button—

Slide shift to innermost periphery

Step 14-a

Focus gain rough adjustment (high reflection)

[ H f ]

Step 14-b

Focus gain rough adjustment (low reflection)

[ L f ]

Step 15 SKIP UP button

Step 16-a

Pit:Tracking gain adjustment (high reflection)

[ H g ]

Step 16-b

Pit:Tracking gain adjustment (low reflection)

[ L g ]

Step 17 SKIP UP button

Step 18-a Pit: [ H b ]

Tracking balance adjustment (high reflection)

Step 18-b Pit: [ L b ]

Tracking balance adjustment (low reflection)

Step 19 SKIP UP button

Step 20-a Pit: [ H f ]

Focus gain adjustment (high reflection)

Step 20-b Pit: [ L f ]

Focus gain adjustment (low reflection)

Step No.

Operation and state

Display

Step 21 Step (24) when SKIP UP button,

Step (22) when PLAY button.

Step 22 Pit section continuous playback [ S Q ]

Step 23 When the P-MODE button is pressed,

the process proceeds to (20-a) or (20-b).

Step 24 The high reflection disc is not accepted.

When the low reflection disc is used, the

process proceeds to (25).

Step 25 TOTAL signal level adjustment [ G l ]

Step 26 SKIP UP button

Step 27 Groove: Tracking gain adjustment [ G g ]

Step 28 SKIP UP button

Step 29 Groove: Tracking balance adjustment [ G b ]

Step 30 SKIP UP button

Step 31 Focus gain adjustment [ L f ]

Step 32 PLAY button

Step 33 Groove section continuous playback [ A P ]

Step 34 When the P-MODE button is pressed,

the process to (31).

Step No.

Operation and state

Display

• Reversing when the SKIP DOWN button is pressed.

• When the VOL UP button is pressed during adjustment, the set value

increases, and the new set value is output.

• When the VOL DOWN button is pressed during adjustment, the set

value reduces, and the new set value is output.

• When the VOL UP/DOWN button is held down, the setting changes

continuously, one cycle being 100 ms.

• When the STOP button is pressed while the MANUAL menu

appears, or during measurement or adjustment, the mode changes

to the TEST mode stop state.

• As for operation during continuous playback refer to [Explanation of

TEST-PLAY mode].

• : Measurement value

• : Set value

• : Address

• : Temperature code

Test disc

MD adjustment needs two types of disc, namely recording disc (low reflection disc) and playback-only disc (high

reflection disc).

Type

Test disc

Parts No.

Price Code

1 High reflection disc ESYA 1014 (SONY)

2 Low reflection disc Recording minidisc UDSKM0001AFZZ AZ

Note: Use the low reflection disc on which music has been recorded.

Microcomputer version

EEPROM version

Destination

Entering the TEST mode

1. Setting at port (in standby state, disc-free state or power nonconnected state)

(1) Set the port as follows.

TEST1 : "Low"

TEST0 : "High"

(2) Press the PLAY button in the standby state (it is allowed to insert the disc or to connect the power supply).

(3) Test Mode STOP [ _ T E S T _ ]

2. Setting by special button operation (in standby state)

(1) Holding down the DISP button and ENTER button, press the PLAY button.

(2) Normal mode setting initialization (BASS setting, VOL setting, etc.)

(3) Indication of microcomputer version for one second [ ]

(4) Whole LCD lighting for 2 seconds

(5) Test Mode STOP [ _ T E S T _ ]

*When the PLAY button is pressed during indication (3) and (4), the process proceeds to (5).

Leaving the TEST mode

(1) Press the STOP button in the TEST mode stop state or version indicating state or whole LCD lighting state.

(2) EEPROM rewrite-enable area updating, adjustment error setting (so as to adjust all the items when the power supply is turned

on in the normal mode)

(3) Change to standby state

Test Mode

1. AUTO Mode • Automatic adjustment is performed. (After adjustment the grating adjustment mode is set.)

• Continuous playback is performed (Error rate indication, jump test).

• The temperature correction is performed only when servo start is performed, but the

posture correction is not performed.

2. MANUAL Mode • Temperature is displayed. (Updating in real time)

• Seeing the displayed measurement value/set value, make manualadjustment to set values

within the allowable range.

• Continuous playback is performed (error rate display, jump test).

• The temperature correction is performed only when servo start is performed, but the

posture correction is not performed.

3. RESULT Mode • Adjustment value is indicted.

• Adjustment value is changed manually. (in servo OFF state).

4. TEST-PLAY Mode • Continuous playback from the specified address is performed.

• 1 line, 10 lines or 400 lines manual jump is performed.

• C1 error rate display (pit section), ADIP error rate display (groove section)

• The temperature correction is performed only when servo start is performed, but the

posture correction is not performed during continuous playback.

5. TEST-REC Mode • Continuous record from the specified address is performed.

• Change of record laser output(servo gain is also changed according to laser output).

• The temperature correction is performed only when servo start is performed, but the

posture correction is not performed during continuous recording.

6. INNER Mode • Determine the position where the INNER switch is turned on.(only high reflection disc).

• The temperature correction is performed only when servo start is performed, but the

posture correction is not performed.

7. NORMAL Mode • The mode is changed from the TEST mode to the normal mode without adjustment.

• In the normal mode the internal operation mode, memory capacity, etc. areindicated.

• In the normal mode both temperature correction and posture correction are performed.

8. Digital input display Mode • Digital input information is displayed.

9. Error data display Mode • Error information is displayed.

• Error information is initialized.

10. E2-PROM setting mode • Factors of digital servo are changed manually. (Each servo is turned on individually.)

• Cut-off frequency of BASS1, BASS2 and BASS3 is selected manually.

• Temperature detection terminal voltage is measured, and the reference value is set.

• Defaults are selected and set.

• Setting of EEPROM protect area is updated. (In case of protect releasing)

DMC-G7R

TROUBLE SHOOTING

Step 1 Test mode STOP state [ T E S T ]

Step 2 BASS button

Step 3 AUTO menu [ A U T O ]

Step 4 SKIP UP button x 2 times

(Or SKIP DOWN button x 8 times)

Step 5 RESULT menu [ R E S U L T ]

Step 6 PLAY button

Step 7 Indication of measurement value: [ T E O : ]

Tracking error offset

Step 8 SKIP UP button

Step 9 Indication of measurement value: [ F E O : ]

Focus error offset

Step 10 SKIP UP button

Step 11 Indication of measurement value: [ H f _ _ ]

High reflection focus gain

Step 12 SKIP UP button

Step 13 Indication of measurement value: [ H g _ _ ]

High reflection pit tracking gain

Step 14 SKIP UP button

Step 15 Indication of measurement value: [ H b _ _ ]

High reflection pit tracking balance

Step 16 SKIP UP button

Step No.

Operation and state

Display

3. RESULT Mode

Step 17 Indication of measurement value: [ L f _ _ ]

Low reflection focus gain

Step 18 SKIP UP button

Step 19 Indication of measurement value: [ L g _ _ ]

Low reflection tracking gain

Step 20 SKIP UP button

Step 21 Indication of measurement value: [ L b _ _ ]

Low reflection pit tracking balance

Step 22 SKIP UP button

Step 23 Indication of measurement value: [ G l _ _ ]

Low reflection TOTAL signal level

Step 24 SKIP UP button

Step 25 Indication of measurement value: [ G g _ _ ]

Low reflection groove tracking gain

Step 26 SKIP UP button

Step 27 Indication of measurement value: [ G b _ _ ]

Low reflection groove tracking balance

Step 28 STOP button

Step 29 Test mode STOP state [ T E S T ]

Step No.

Operation and state

Display

• Reversing when the SKIP DOWN button is pressed

• When the VOL UP button is pressed during set value indication, the set value increases, and the new set value is stored in RAM.

• When the VOL DOWN button is pressed during set value indication, the set value decreases, and the new set value is stored in RAM.

• When the VOL UP/DOWN button is held down, the setting changes continuously, one cycle being 100 ms.

• When the STOP button is pressed while the RESULT menu appears, or during measurement value or set value indication, the mode

changes to the TEST mode stop state.

• : Measurement value

• : Set value

7. TEST/PLAY Mode

Step 1 Test mode STOP state [ T E S T ]

Step 2 BASS button

Step 3 AUTO menu [ A U T O ]

Step 4 SKIP UP button x 3times

(Or SKIP DOWN button x 7 times)

Step 5 TEST-PLAY menu [ T _ P L A Y ]

Step 6 When the DISP button is pressed, the

process proceeds to (7).

When the PLAY button is pressed, the

process proceeds to (9).

Step 7 TEST-PLAY mode [ A d 0 0 5 0 ]

Step 8 PLAY button

Step 9 Continuous playback (pit section) [ S Q ]

Continuous playback (groove section) [ A P ]

Step 10 STOP button

Step 11 Test mode STOP state [ T E S T ]

Operation and state

Step No. Display

TROUBLE SHOOTING

DMC-G7R

9

Loading...

Loading...