Page 1

KBWT INSTALLATION INSTRUCTIONS

SAFETY WARNING! — PLEASE READ CAREFULLY

This product should be installed and serviced by a qualified technician, electrician or electrical maintenance person familiar with its operation and the

hazards involved. Proper installation, which includes wiring, mounting in proper enclosure, fusing or other overcurrent protection and grounding, can

reduce the chance of electric shocks, fires or explosion in this product or products used with this product, such as electric motors, switches, coils, solenoids

or relays. Eye protection must be worn and insulated adjustment tools must be used when working with control under power. This product is constructed

of materials (plastics, metals, carbon, silicon, etc.) which may be a potential hazard. Proper shielding, grounding and filtering of this product can reduce

the emiss ion o f radio frequ ency interfere nce (RFI) wh ich m ay adversely affect s ensitive e lectro nic e quipment. If info rma tion is required on th is pro duct,

contact our factory. It is the re spon sibility of the equipment ma nufactu rer and individu al installer to s upply this safety warning to th e ultima te user of this

product. (SW effective 11/92)

This con trol m ay contain elec troni c Start/Stop an d En able circuits that can be used to star t and stop the control. How eve r, these circuits a re ne ver to

be used as safety disconnects since they are not fail-safe. Use only the AC line for this purpose.

The inpu t circu its of this control (ta cho meter, start/stop , inhib it, enable) are n ot iso lated from AC line. Be sure to follow all instructions care fully.

Fire and/or electrocution can resu lt due to improper use of this produc t.

This product complies with all CE directives pertinent at the time of manufacture. Contact factory for detailed installation instructions and Declaration

of Conform ity. Installation o f a CE approved RF I filter (KBRF-200A, KB P/N 994 5C or equivalent) is required. Additional shielded motor cable and/or

AC line cables may be required along with a signal isolator (KBS I-240D, KB P/N 9431 or equivalent).

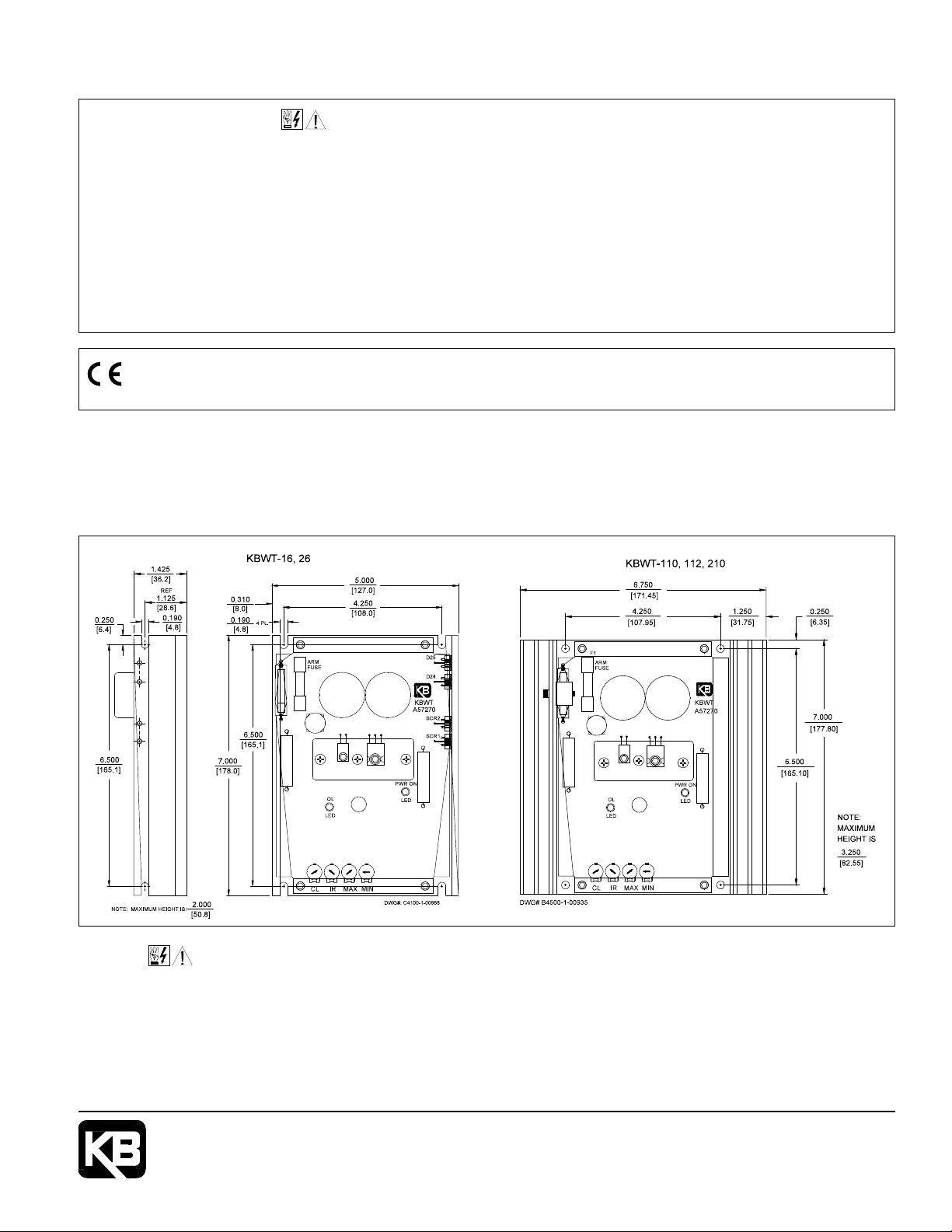

MOUNTING

The KBWT should be mounted on a flat surface and located in an area where it will not be exposed to contaminants such as water, metal chips, solvents

or excessive vibration. When mounting in an enclosure, the air space should be large enough to provide adequate ventilation. The maximum allowable

ambient temperature at full rating is 45°C/113°F. Consult factory if more information is required.

MECHANICAL SPECIFICATIONS – inches/[mm]

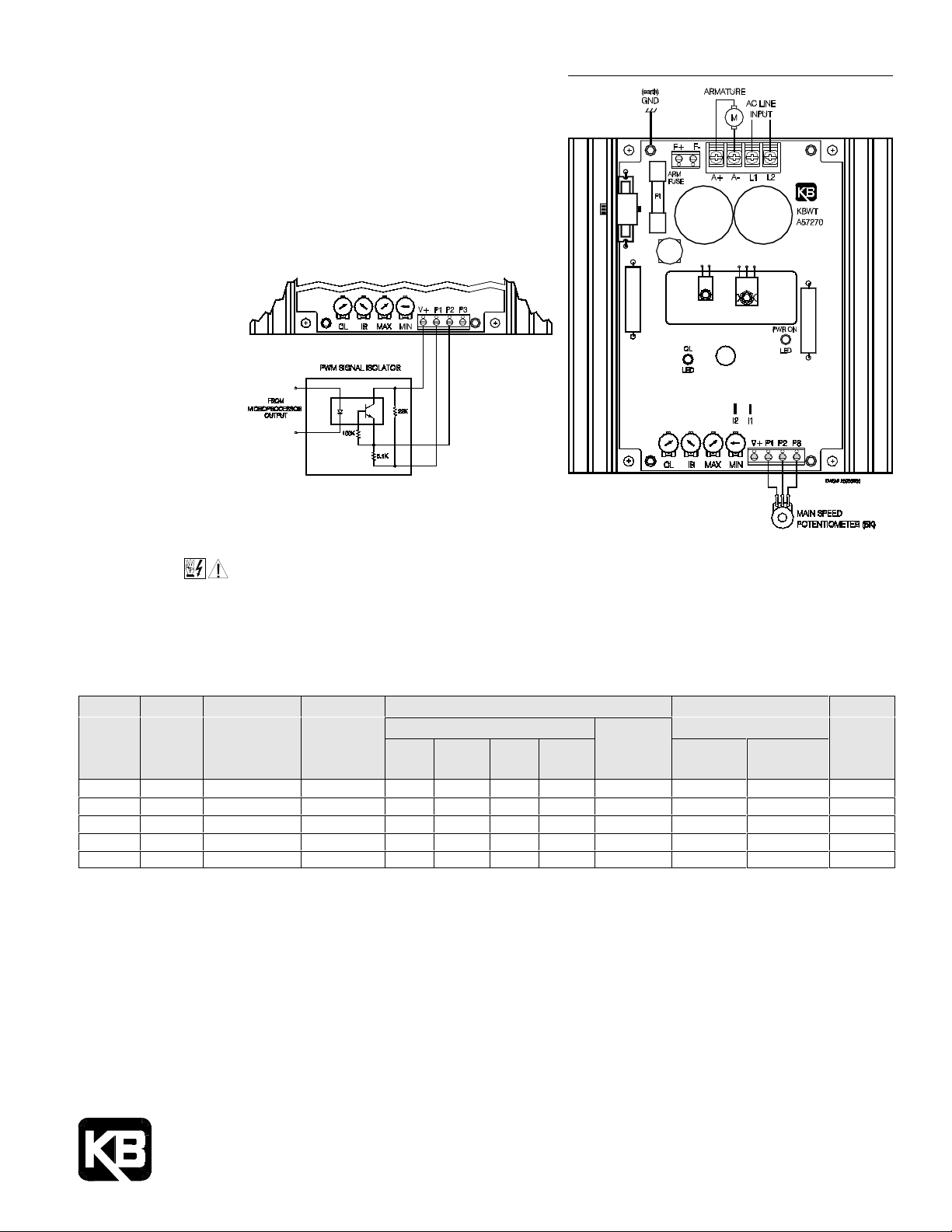

WIRING – Warning! Read Safety Warning before attempting to use this control.

AC Line – Connect AC line to terminals L1 and L2. It is recommended that a line fuse or circuit breaker be installed.

Motor Armature – Connect motor armature to terminals A+ and A!. Be sure motor voltage corresponds to control output voltage range. It is

recommended that a fuse be installed in series with the armature; choose a fuse rating 1.5 times the full load motor rating.

Main Potentiometer – The control can be operated from a remote potentiometer, or from an isolated analog voltage for voltage following.

Remote Potentiometer – Connect remote potentiometer wires to terminals P1, P2 and P3, so that the "high" side of the potentiometer connects to P3,

the "wiper" to P2 and the "low" side to P1.

KB ELECTRONICS, INC.

www.kbelectronics.com

“The Right Control

for Your Application”

12095 NW 39th Street, Coral Springs, FL 33065-2516 ! (954) 346-4900 ! Fax (954) 346-3377

Ou tside F lorid a C all TOLL FREE (800) 221-6570 ! E-m ail – info@kbelectronics.com

Page 2

This control may contain a potentiometer safety reset circuit. When power is first

CONNECTION DIAGR AM

applied, you must rotate the main speed potentiometer fully CCW or adjust your analog

input signal to 0 VDC, then increase setting to desired speed. To disable this feature,

you can remove the D20 Diode from the circuit board.

Warning! This control has be en Hi-Pot te st ed at th e f actory. If you choose to

perform another Hi-Pot test on the control, there is a risk that the control can be

damaged. Please consult factory for more information.

Analog Input – An isolated 0-5 VDC analog voltage can also be used to drive the

control. Note: If an isolated signal voltage is not available, an optional signal isolator

can be installed (Model KBSI-240D, P/N 9431). Connect the isolated input voltage to

terminal P2 (positive) and P1 (negative).

Microprocessor Input – An

TYPICAL MICROPROCESSOR CONNECTION

isolated PWM signal from a

microprocessor can be used

to operate the control. The

output frequency should be

200 Hz or greater and

should be derived from an

optocoupler with a transistor or

operational amplifier

signal output.

INHIBIT

The control can be electronically

stopped and started with the Inhibit

circuit. To "Stop" the control, terminals

I1 & I2 must be shorted via a contact. The control can be restarted by opening the contact. Note: The Inhibit should not

be used as a safety disconnect. Use only the AC line for that purpose. The Inhibit Circuit is not isolated. Do not

earth ground inhibit leads.

OPERATION – WARNING! Read Safety Warning before attempting to operate the control or severe injury or electrocution can

result.

After the control has been set up properly and the wiring has been completed, the start-up procedure can begin. If AC power has been properly

connected to the control, the "ON" LED indicator will illuminate. Before starting, be sure the main potentiometer is in the minimum position. To start

the control, the potentiometer knob should be rotated clockwise; the motor should begin to rotate. Note: If the motor rotates in the incorrect

direction, it will be necessary to disconnect the main AC power and reverse the armature wires.

ELECTRICAL RATINGS

MAXIMUM DC OUTPUT CURRENT

Model No.

KBWT-16 8614 115 10.0 6.0 90 6.0 130 10.0 0.75 (0.5) 1.5 (1.1) 15

KBWT-26 8615 230 10.0 6.0 180 6.0 260 10.0 1.5 (1.1) 3.0 (2.0) 15

KBWT-110 8603 115 15.0 10.0 90 8.5 130 17.0 1.2 (0.9) 2.0 (1.5) 20

KBWT-112 8612 115 18.0 12.0 90 10.5 130 25.0 1.5 (1.1) 2.5 (1.9) 25

KBWT-210 8610 230 15.0 10.0 180 8.5 260 17.0 2.2 (1.7) 4.0 (3.0) 20

KB Part

No.

AC Line Voltage

(VAC) !10%,+15%

(50/60 Hz)

Maximum

AC Line Current

(Amps RMS)

CONTINUOUS DUTY RATING

AmpsDC@ Output

Voltage

AmpsDC@ Output

Voltage

Current Limit

Max. Setting

(Amps DC)

Maximum Motor Horsepower

Continuous

Duty

(KW)

Intermittent

Duty

(1 minute)

(Optional)

Armature

Fuse Rating

(Amps)

TRIMPOT ADJUSTMENTS

The control contains trimpots which have been factory adjusted for most applications. The connection diagram illustrates the location of the trimpots

and their approximate adjustment positions. Some applications may require readjustment of the trimpots in order to tailor the control to exact

requirements.

FUNCTION INDICATOR LAMPS

The control contains two LED indicator lamps that reflect operational status.

A. Power On Indicator (PWR ON) – This lamp will glow GREEN when the AC line is connected to the control.

B. Overload Indicator (OL) – When the motor is loaded to the current limit (CL) setpoint (CL is established by the setting of the CL trimpot), this lamp

will glow RED. If the control is allowed to stay in CL and then “times out” in Timed Current Limit, the CL LED will remain illuminated, until the control

is restarted with the On/Off or Inhibit Switch. If the OL LED remains illuminated during control operation, a fault condition may exist.

KB ELECTRONICS, INC.

12095 NW 39th Street, Coral Springs, FL 33065 • (954) 346-4900 • Fax (954) 346-3377

Ou tside F lorid a C all TOLL FREE (800) 221-657 0 • E-m ail – info@kbelectronics.com

www.kbelectronics.com (A40130) – Rev. A – 6/99

Loading...

Loading...