Page 1

Cautions to be taken to ensure safety

For those persons involved with the operation/service of your system, including Kawasaki Robot, they must

strictly observe all safety regulations at all times. They should carefully read the manuals and other related

safety documents.

Products described in this catalogue are general industrial robots. Therefore, if a customer wishes to use the

Robot for special purposes, which might endanger operators or if the robot has any problems, please contact

us. We will be pleased to help you.

Be careful as photographs illustrated in this catalogue are frequently taken after removing safety fences and

other safety devices stipulated in the safety regulations from the Robot operation system.

Inquiries

Kawasaki Robotics GmbH Germany

Headquarter Neuss: Tel.

Sperberweg 29 · 41468 Neuss Fax

Munich Ofce: Tel.

Konrad-Zuse-Platz 12 · 81829 München Fax

Osnabrück Ofce: Tel.

Rheiner Str. 195a · 49078 Osnabrück Fax

e-mail: info@kawasakirobot.de · www.kawasakirobot.de

+ 49 - (0)21313426 - 0

+ 49 - (0)21313426 - 22

+ 49 - (0)89 454591- 30

+ 49 - (0)89 454591- 45

+ 49 - (0)541 4069398 - 0

+ 49 - (0)541 4069398 - 11

EUROPE

Kawasaki Robotics (UK) Ltd.

Units 6&7 Easter Court, Europa Boulevard, Westbrook Tel.

Warrington WA5 5ZB · United Kingdom Fax

e-mail: info@kawasakirobot.uk.com · www.kawasakirobot.uk.com

French Ofce:

Parc d‘activites de la clef de Saint-Pierre

Rond Point de l‘Epine des champs Tel.

78996 Elandourt Cedex, France Fax

e-mail: info@kawasakirobot.fr · www.kawasakirobot.fr

Agent

+ 44 - (0)1925 71 3000

+ 44 - (0)1925 71 3001

+ 33- (0)1 30 68 9522

+ 33- (0)1 30 68 9139

printed in Germany Apr. 2008 • GE109 Materials and specications are subject to change without notice.

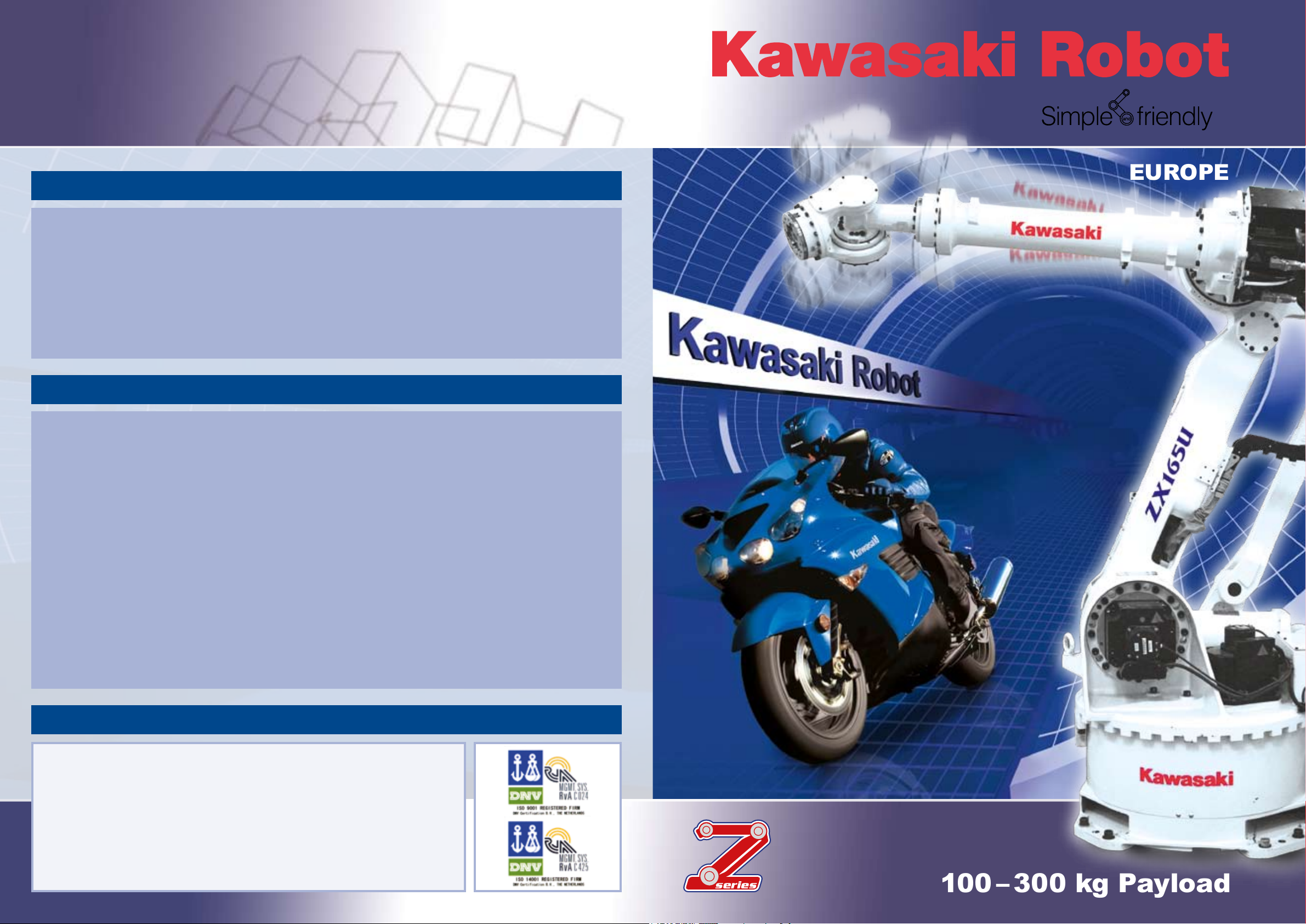

100 – 300 kg Payload

Page 2

Automotive and

General Industries, …

Improved cycle times

A weight-optimised construction, the use of high-speed motors and high-efciency gears permit an

optimisation of the maximum speed and acceleration.

Large working range

and low power consumption

The Z Series has a broad working range thanks to the large reach and small blind angle. Axis 1 can

be pivoted around 360° and has mechanical locks. Through the use of the patented hybrid link con-

guration by Kawasaki the power consumption during the robot movements could be reduced.

Space saving and easy installation

through a small foot print

More space means higher costs. The small base sizes and slim arm prole of the Z Series robot arm

allows a space-saving construction of working cells.

The Kawasaki Z-Series high performance robots provide

exibility as well as the ability, at high payloads and long

reach, to suit all applications, including welding, handling,

tending and much more. With twelve different versions,

divided into three distinct design groups the Z-series can

provide the right model for all future applications.

Whether it‘s the “ZX” for oor mounting, the “ZT” for shelf

mounting or the “ZB” as a compact arm, the Z-series can

do it all. All Z-Series robots are powered by the D-Controller,

exible Controller Unit.

Protective congurations IP65, IP67

Protection class IP65 applies for the robot arm and IP67 for the wrist part. This means that the

Z Series can be used without problems in rough working environments.

Convertability

Simple hardware and software modications allow an optimisation of the ZX165U in terms of reach or

payload. A subsequent adjustment of the robot to different tasks poses no problems and can be car-

ried out at low cost

Spot welding Palletizing Spot welding

Page 3

Specifications Specifications

TYP

Type of arm

Degrees of freedom

Reach

Maximum Payload

JT1

JT2

JT3

Maximum

JT4

stroke

JT5

JT6

JT7

JT1

JT2

JT3

Maximum

JT4

speed

JT5

JT6

JT7

Repeatability

JT4

Moment*

JT5

JT6

JT4

Moment

JT5

of inertia

JT6

Weight

Recommended Controller

Installation

Integrated functions

Optional

Colour

ZB150S ZT130L ZT130U ZT165U ZT200UZB100L

1,655 mm

100 kg

± 160°

+120°~-70°

+100°~-150°

± 360°

± 130°

± 360°

standard 2,000 mm

100°/s

100°/s

90°/s

135°/s

135°/s

210°/s

1,000 mm/s

0 N·m

0 N·m

0 N·m

78.4 kg/m²

78.4 kg/m²

40.18 kg/m²

915 kg

1,500 mm/s

Air Line (12 mm Ø)

Mechanical stopper JT1/JT2/JT3,

special colour.

1,365 mm

150 kg

± 160°

+120°~-70°

+100°~-150°

± 360°

± 130°

± 360°

standard 2,000 mm

100°/s

100°/s

90°/s

135°/s

135°/s

210°/s

1,000 mm/s

911.4 N·m

911.4 N·m

450.8 N·m

78.4 kg/m²

78.4 kg/m²

40.18 kg/m²

900 kg

1,500 mm/s

ZX130U ZX165L ZX165U ZX200U ZX300SZX130L

Articulated arm

6 axes (optional 7 axes)

3,530 mm

130 kg

± 180°

+60°~-75°

+165°~-95°

± 360°

± 130°

± 360°

standard 2,000 mm

105°/s

105°/s

105°/s

140°/s

135°/s

230°/s

1,000 mm/s

735 N·m

735 N·m

421 N·m

51.9 kg/m²

51.9 kg/m²

27.4 kg/m²

1,565 kg

2,500 mm/s

Air lines (12 mm Ø x 2), wiring for the solenoid valves of the grab (A.C. 24V)

Mechanical stopper JT1/JT2/JT3, special colour, internal wiring for end effector,

twin solenoid valve 1/2, single solenoid valve 1/2, twin solenoid valve 1 + single

solenoid valve 1, 1 lter control unit, internal hoses for welding gun cooling water

Munsell 10GY9/1 or equivalent Munsell 10GY9/1 or equivalent

± 0,3mm

3,230 mm

130 kg

± 180°

+60°~-75°

+165°~-95°

± 360°

± 130°

± 360°

standard 2,000 mm

105°/s

105°/s

105°/s

140°/s

135°/s

230°/s

1,000 mm/s

735 N·m

735 N·m

421,4 N·m

51.9 kg/m²

51.9 kg/m²

27.44 kg/m²

1,550 kg

2,500 mm/s

D42

Floor

3,230 mm

165 kg

± 180°

+60°~-75°

+165°~-95°

± 360°

± 130°

± 360°

standard 2,000 mm

105°/s

105°/s

105°/s

135°/s

135°/s

210°/s

1,000 mm/s

911,4 N·m

911,4 N·m

450,8 N·m

78.4 kg/m²

78.4 kg/m²

40.18 kg/m²

1,550 kg

2,500 mm/s

3,230 mm

200 kg

± 180°

+60°~-75°

+165°~-95°

± 360°

± 130°

± 360°

standard 2,000 mm

90°/s

90°/s

90°/s

120°/s

115°/s

180°/s

1,000 mm/s

980 N·m

980 N·m

490 N·m

93.1 kg/m²

93.1 kg/m²

46.1 kg/m²

1,550 kg

2,500 mm/s

2,951 mm

130 kg

± 180°

+75°~-60°

+250°~-120°

± 360°

± 130°

± 360°

standard 2,000 mm

110°/s

110°/s

110°/s

140°/s

135°/s

230°/s

1,000 mm/s

7.35 N·m

7.35 N·m

221.4 N·m

51.94 kg/m²

51.94 kg/m²

27.44 kg/m²

1,400 kg

2,500 mm/s

twin solenoid valve 1/2, single solenoid valve 1/2, twin solenoid valve 1 + single solenoid valve 1,

2,651 mm

130 kg

± 180°

+75°~-60°

+250°~-120°

± 360°

± 130°

± 360°

standard 2,000 mm

110°/s

110°/s

110°/s

140°/s

135°/s

230°/s

1,000 mm/s

7.35 N·m

7.35 N·m

221.4 N·m

51.94 kg/m²

51.94 kg/m²

27.44 kg/m²

1,350 kg

2,500 mm/s

Air lines (12 mm Ø x 2), wiring for the solenoid valves of the grab (A.C. 24V)

Mechanical stopper JT1/JT2/JT3, special colour, internal wiring for end effector,

1 lter control unit, internal hoses for welding gun cooling water

+250°~-120°

standard 2,000 mm

1,000 mm/s

40.18 kg/m²

2,500 mm/s

Articulated arm

6 axes (optional 7 axes)

2,810 mm

165 kg

± 180°

+75°~-60°

± 360°

± 130°

± 360°

standard 2,000 mm

100°/s

105°/s

95°/s

135°/s

135°/s

210°/s

911.4 N·m

911.4 N·m

450.8 N·m

78.4 kg/m²

78.4 kg/m²

1,355 kg

D42

Floor

2,651 mm

165 kg

± 180°

+75°~-60°

+250°~-120°

± 360°

± 130°

± 360°

110°/s

110°/s

110°/s

135°/s

135°/s

210°/s

1,000 mm/s

911.4 N·m

911.4 N·m

450.8 N·m

78.4 kg/m²

78.4 kg/m²

40.18 kg/m²

1,355 kg

2,500 mm/s

2,651 mm

200 kg

± 180°

+75°~-60°

+250°~-120°

± 360°

± 130°

± 360°

standard 2,000 mm

95°/s

95°/s

95°/s

120°/s

115°/s

180°/s

1,000 mm/s

± 0,3mm

980 N·m

980 N·m

490 N·m

93.1 kg/m²

93.1 kg/m²

46.1 kg/m²

1,350 kg

2,500 mm/s

2,501 mm

300 kg

± 180°

+75°~-60°

+250°~-120°

± 360°

± 120°

± 360°

standard 2,000 mm

100°/s

85°/s

85°/s

90°/s

90°/s

150°/s

1,000 mm/s

1,715 N·m

1,715 N·m

862.4 N·m

166.6 kg/m²

166.6 kg/m²

107.8 kg/m²

1,400 kg

2,500 mm/s

Type of arm

Degrees of freedom

Reach

Maximum Payload

JT1

JT2

JT3

JT4

JT5

JT6

JT7

JT1

JT2

JT3

JT4

JT5

JT6

JT7

Repeatability

JT4

JT5

JT6

JT4

JT5

JT6

Weight

Recommended Controller

Installation

Integrated functions

Optional

Colour

TYP

Maximum

stroke

Maximum

Speed

Moment*

Moment

of inertia

ZT130LZB150S ZX300SZX130U

ZT130U

ZT165U

ZT200U

ZX130LZB100L

ZX165U

ZX200U

Page 4

Motion Range & DimensionsMotion Range & Dimensions

:Unnecessary

to tighten bolts

Ø0.04

X

YXØ0.15

Y

X

ISO FLANGE

OPTION FLANGE

* Dimension:228

X YØ0.15

Ø0.04

X

Y

X

* Dimension:244

A

VIEW

Ø9H7 Depth12

6–M10 Depth 16

60

°

30

°

Ø160

Ø55H7

Depth 12

Ø9

2

30

°

30

°

Ø160

6–M10 Depth 12

2–Ø10H7 Depth 12

Ø80H7

Depth 8

Ø125

JT5±130°

JT6±360°

JT4±360°

A

JT1

JT3

JT1

JT3

JT3

JT2

JT2

Point P

Working range

based on point P

Point P

100

°

150

°

300

410

50 50

5050

700

25

650

25

700

6557065

4-Ø22

4-Ø40

23

427

195

1,315

565

474

545

565

545

*

850 250

70

°

120

°

150

°

160

°

160

°

587.5 1,960

2,547.5

1,665 1,131

957 708

329

Installations Dinensions

:Unnecessary

to tighten bolts

Ø0.04 X

YXØ0.15

Y

X

ISO FLANGE

OPTION FLANGE

* Dimension:228

X YØ0.15

Ø0.04

X

Y

X

* Dimension:244

A

VIEW

Ø9H7

+0.015

0

Depth 12

6-M10 Depth 16

60

°

30

°

Ø160

Ø55H7

+0.030

0

Depth 12

Ø9

2

30

°

30

°

Ø160

6–M10 Depth 12

2-Ø10H7

+0.015

0

Depth 12

Ø80H7

+0.030

0

Depth 8

Ø125

* TOOL, HAND, etc. may interfere

with robot arm depending on

angle of wrist axes.

JT5±130°

JT6±360°

JT4±360°

A

JT1

JT3

JT1

JT3

JT3

JT2

JT2

Installation Dimensions

Point P

Working range

based on point P

Point P

100

°

150

°

300

410

50 50

5050

700

25 650 25

700

6557065

4–Ø22

4-Ø40

467

23

427

195

1,315

565

287.5

474

539

216

1,947.5

1,115832.5

8311,365

545

565

545

*

550 250

7

0°

120

°

150

°

826

160

°

160

°

Ø0.05

JT1 180°

JT1 180°

A

JT3

JT3

JT2

JT2

JT4±360°

JT6±360°

JT5±130°

B

370

75

125

125

125

500100 100

500 100

100

770

770

125

2–Ø25G8

300

300300

8–Ø22

30

173.05

4,571

530

1,100

300

600

78 1,300

2,103

80

3,230

24.40600.5210

00

9090

80

58

95

°

16

5

°

60

°

75

°

24.401,300

395510150

1.30

90

142

5 x 2–M10–20/25

10 x 2–M6–12/18

Y

X

Ø0.04

X

Ø0.15

YX

Depth 8

Ø1

2

5

2–Ø10H7

+0.015

0

Depth 12

6–M10 Depth 12

Ø1

60

30

°

30

°

Unnecessary

for standard spec.

Ø80H7

+0.030

0

• ISO 9409-1 Series 2 (Ø125)

for 130S/165U

JT3

JT2

JT3

JT2

JT4±360˚

JT6±360˚

JT5±130˚

JT1

JT1

A

288

60

˚

75

˚

70

˚

120

˚

3,340

3,415

1,965 2,651

1,490

1,225

670 1,100 270

1,300 244

395510150

13

90

142

370

75

125

125 125

500 100100

500 100

2–Ø25G8

Ø0.05

100

770

770

125

300

Installation Dimensions

300 300

9090

80

58

8–Ø22

R517

180

˚

180

˚

R1,289

1,199

600.5210

30

Y

X

X

YX

ISO FLANGE

30

˚

30

˚

5 x 2–M10–20/25

10 x 2–M6–12/18

6–M10 Depth 12

Ø0.15

Ø

160

Ø

12

5

Ø0.04

2

–Ø10H7

Depth 12

Ø80H7

Depth 8

* Dimension:228

ZB100L

ZT130U

ZT165U

ZT200U

ZB150S

ZX130U

ZX165U

ZX200U

Page 5

Motion Range & DimensionsMotion Range & Dimensions

Unnecessary

to tighten bolts

YX

Ø0.15

Y

X

ISO FLANGE

OPTION FLANGE

*Dimension:228

X Y

Ø0.15

Ø0.04

X

Y

X

* Dimension:244

Ø0.04

X

VIEW A

2–Ø9H7

Depth 12

6–M10 Depth 16

60

°

30

°

Ø160

Ø55H7

Depth 12

Ø92

30

°

30

°

Ø160

6–M10 Depth 12

2–Ø10H7

Depth 12

Ø80H7

Depth 8

Ø

125

JT3

JT2

JT3

JT2

Ø0.05

JT4±360°

JT6±360°

JT5±130°

JT1

JT1

A

Inter feren ce rad ius a round

the r otati onal a xis

Rear side

Interference area

Installation Dimensions

Point P

Point P

Work ing r ange

base d on point P

ISO FLANGE

OPTION FLANGE

* Dimension

228

244

8–Ø22

30

*

288

60

°

75

°

70

°

120

°

1,490

1,459

270

1,100

670

395669

150

13

90

142

370

75

125

125 125

500

100100

500

100100

770

770

125

2–Ø25G8

300

300 300

10 x 2–M6–12/18

5 x 2–M10–20/25

9090

80

58

R517

180°

180°

LINK H

1,199

R1,289

600.5

210

3,499

3,733

1,225

2,124

2,810

LINK H

Ø0.05

JT4±360°

JT6±360°

JT5±120°

JT1 180°

JT1

Int erf ere nc e r adi us ar oun d

the ro tat io nal ax is

A

JT2

JT3

JT2

JT3

1,150 248

395360150

13

90

142

370

75

125

125 125

500 100100

500 100100

770

770

125

2–Ø25G8

300

300 300

9090

80

58

5 x 2–M10–20/25

10 x 2–M6–12/18

8–Ø22

R

5

1

7

Link H

Link H

1,199

30

288

250.05

3,190

1,490

1,225

70

°

1

2

0

°

75

°

6

0

°

1,815

3,115

2701,100670

600.5210

R1,289

Rear side interference area

X

Ø0.15

X

Ø0.04

XYY

Depth 8

X

Ø0.15

Ø0.04

XYY

X

• Conventional Type (Ø113)

Unnecessary

for standard spec.

VIEW A

6–M10 Depth 12

3

0

°

3

0

°

Ø160

2–Ø10H7

+0.015

0

Depth 12

• ISO 9409-1 Series 1 (Ø160)

+0.035

0

Ø100H7

Ø2

0

0

10–M10 Depth 17

3

0

°

3

0°

2–Ø10H7

+0.015

0

Depth 17

Ø2

0

0

Ø1

1

3

Depth 12

+0.030

0

Ø68H7

180°

Dimensions for Base

JT3

JT2

JT3

JT2

Ø0.05

JT4±360°

JT6±360°

JT5±130°

Dimensions for Base

JT1

180°

A

288

6

0

°

75

°

7

0

°

1

2

0

°

1,490

670 1,100 270

1,600

695510150

13

90

142

370

75

125

125 125

500 100100

500 100100

770

770

125

2–Ø25G8

300

300 300

9090

80

58

5 x 2–M10–20/25

10 x 2–M6–12/18

8–Ø22

R

5

1

7

180

°

Link H

Link H

R1,289

1,199

Rear side interference area

600.5210

30

3,640

4,015

2,951

1,225

2,265

Y

X

Ø0.04

X

Ø0.15

YX

Depth 8

X

Depth 12

Y

Ø0.15

YX

X

Ø0.04

Y

Ø1

2

5

2–Ø10H7

+0.015

0

Depth 12

6–M10 Depth 12

Ø1

6

0

30

°

30

°

Ø9

2

+0.030

0

Ø55H7

Ø

16

0

30

°

6

0

°

6–M10 Depth 16

Ø9H7

+0.015

0

Depth 12

Interference radius around

the rotational axis

JT1

Ø80H7

• ISO 9409-1 Series 2 (Ø125)

Unnecessary

for standard spec.

• Conventional Type (Ø92)

ZX130L

ZX300S

ZX165L

Page 6

Controller

‚q‚d‚o‚d‚`‚s‚s‚d‚`‚b‚g

‚d‚q‚q‚n‚q

?@‚o‚n‚v‚d‚q

‚b‚n‚m‚s‚q‚n‚k

SIDE VIEW

FRONT VIEW

SIDE VIEW

REAR VIEW

1,200

550

600

470

160

‚q‚t‚m

‚b‚x‚b‚k‚d

‚r‚s‚`‚q‚s

‚g‚n‚k‚c

‚l‚n‚s‚n‚q

‚o‚n‚v‚d‚q

‚q‚d‚r‚d‚s

‚d‚q‚q‚n‚q

Ergonomic operation

• Optimised work at the teach pendant

The Teach Pendant (TP) is a combination of control

keyboard and an easy-read, 6.4 inch colour LCD touchscreen. A new hardware structure for the TP reduces the

key response time and the ergonomic arrangement of

the keys helps the operator achieve optimised inputs and

programming. The workow is optimised and the TP becomes an ergonomic user platform for operating the robot.

Special software

combined with standards

Applications Software Modules facilitate programming for

a wide range of applications such as palletizing, handling,

spot welding, bonding and arc welding. The simplied

block programming and Kawasaki‘s high level robot

language (AS-language) provide enormous possibilities

for innovative movement- and process control. Using the

available options – such as servo-welding, network support and a high-performance visualisation system –

a platform is created to nd exible solutions for even

the most complex of applications.

High performance through

modern control technology

A RISC, 64-bit high-speed dual processor provides the

computing power. The use of a fully digitally controlled

servo-system has signicantly improved operating performance, cycle time and path accuracy. In addition, system

errors have been reduced to a minimum through collision

detection/automatic stop and path recovery after an emergency stop.

The controller is of course fully downwardly compatible.

This means that the D controller can be integrated in existing old systems with no problems.

Teach Pendant

• Large LCD colour monitor with

touchscreen functions.

• Ergonomically arranged cursor keys.

• The key layout has been optimised

with respect to the frequency of use

by the operator.

Modular and

exible control design

• Connection of peripheral equipment

Standard I/O connections and a number of eld bus interfaces such as Interbus, Probus, CC-Link and DeviceNet

etc. are available as interfaces to the peripheral equipment. The peripheral equipment is connected directly

and permits the system‘s high exibility.

Furthermore, K-Logic (integrated software PLC) allows

the creation of a highly complex Integrated system at a

minimum cost

• Network communication

The controller also supports network communication via

Ethernet to communicate with a host computer and for

an easy upload and download of the programs to be run.

Furthermore, the status of the robot can be monitored

per remote access via an Intranet/Internet connection.

• Extension with aditional axes

A further two axes can be integrated in the standard

controller without any problems and without an additional housing. Three or more additional axes are available

by selecting SSCNET-compatible motors. This allows

multi-axial systems to be easily congured to match the

customer‘s requirements.

User-friendly design

A reduction of the robot‘s internal wiring and the use of

modular assemblies facilitates servicing and ensures

shorter working times when repairing or replacing parts

with no long and costly downtimes.

What‘s more, supporting service functions

such as data storage help the user locate

the causes of existing problems. The

service software includes restoration

procedures* in the event of system

errors (Z Series) and an Ethernet

interface allows a remote system

diagnosis.

* In the event of system er rors th e serv ice and su ppor t

function of t he Z Seri es offe rs proc edures t o display:

possible so urces of error s and probabiliti es as well

as diagnosis , replac ement instructions and t imes to

remedy faults.

Specifications

MODEL

Design

Number of controlled axes

Servomotor

Position detection

Drive system

Programming

Coordinates Systems

Types of motion control

Ext. control signals

Multi-

purpose

Input signals

signals

Output signals

Storage capacity

External memory

PC, network, etc.

Data com-

munication

Field bus

interface

Teach pendant

Control panel

Teach Pendant

Cable

length

Robot controller

Dimensions (WxDxH)

Weight

Necessary

power supply

Own earthing of the robot

temperature/humidity

Colour

*

¹ Please c ontact us if you use 7 a xes or mor e.

teach lock switch, deadman‘s switch, 58 hardware keys

(keys for manual operation of the robot, cursor keys, etc.)

Basic switch: motor voltage on, cycle star t, error reset,

0-45° C, 35-85% humidity without dew formation and frost

External View & Dimensions

D42

Fully digitally controlled servo -system

Movement with axis, linear and circle interpolation

1 MB: approx. 10,000 program steps

6.4 “ TFT LCD touchscreen, 640x480 VGA, “E-Stop”,

“E-Stop”, run/hold, teach/repeat, etc.

A.C. 380/400/415/440/460/480 V ± 10%,

< 100 Ω; maximum leakage current 100 mA

STANDARD

Standalone main housing

6 axes

A.C. servomotor

Absolute encoder

Block teaching or AS language

Axis, basis, tool

Motor voltage Off, Hold

32 channels

32 channels

PCMCIA card slot

RS232C, Ethernet

10 m

10 m

600 mm x 550 mm x 1,200 mm

130 kg

50/60 Hz, 3 phases, 11,4 KVA

Munsell 10GY9/1 or equivalent

D 42

OPTION

Maximum 16 axes*¹

Fixed tool point

64/96/128 channels

64/96/128 channels

2/4/8 MB: approx. 20,000/40,000/80,000 program steps

RS485

CC-Link, DeviceNet, Probus-DP,

ControlNET, AB Remote I/O, Interbus

5 m, 15 m, 20 m, 25 m, 30 m

5 m, 15 m, 20 m, 25 m, 30 m, 35 m, 40 m

approx. 200 kg (with transformer)

A.C. 200/220 V ± 10%,

50/60 Hz, 3 phases, 11,4 KVA

< 100 Ω; max. leakage current 100 mA (with transformer)

• Deadman‘s switch with three positions

on rear.

Loading...

Loading...