Page 1

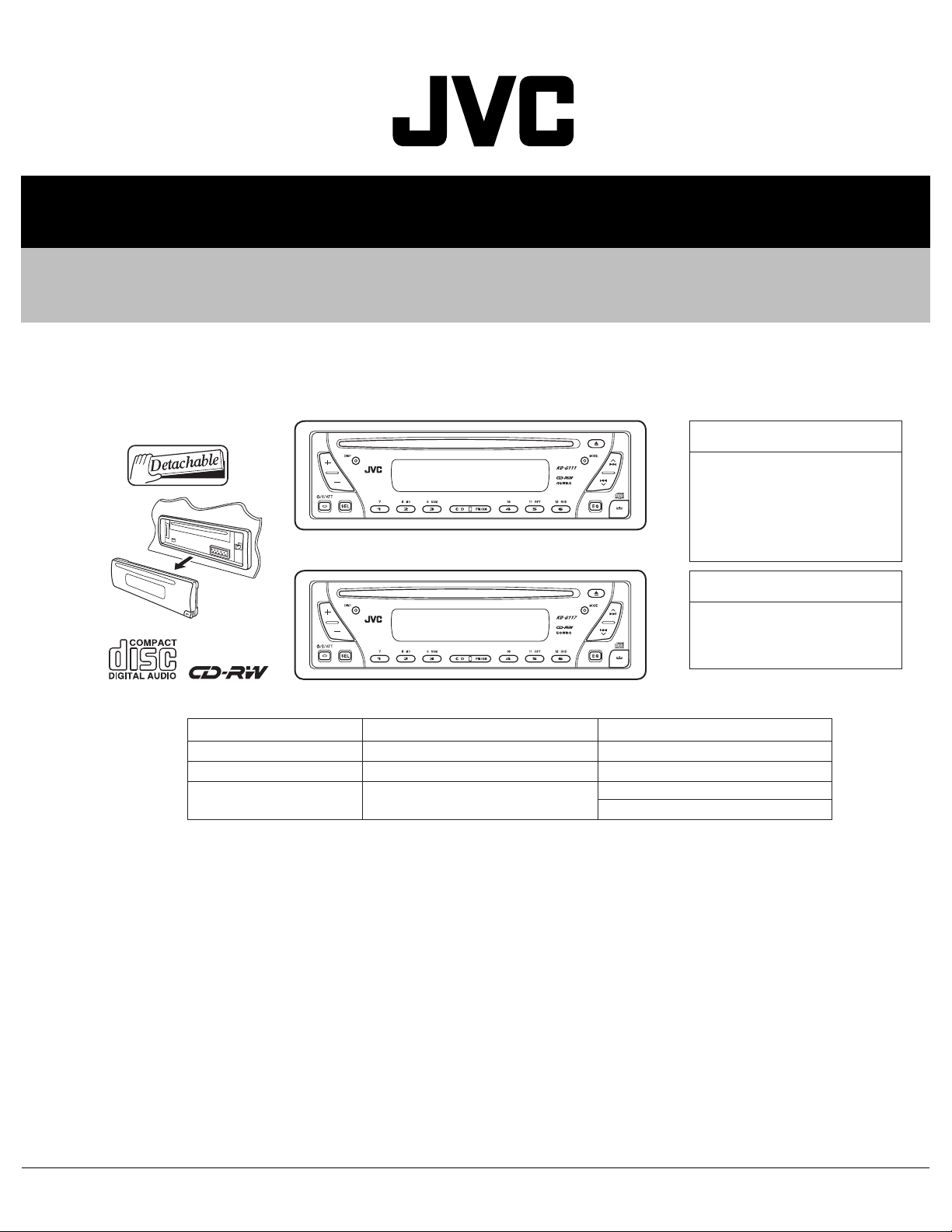

SERVICE MANUAL

CD RECEIVER

MA12520052

KD-G111,KD-G117

KD-G111

KD-G111

Area suffix

E ------------ Southern Europe

EX ------------ Northern Europe

EY ------------- Eastern Europe

KD-G117

EU ------------------------- Turkey

KD-G117

Area suffix

EE -------- Russian Federation

KD-G111 KD-G117

Maximum Power Output

Continuous Power Output

FM Band Cover

87.5 MHz to 108.0 MHz

45 W 50 W

17 W 19 W

FM1/FM2 : 87.5 MHz to 108.0 MHz

FM3 : 65.00 MHz to 74.00 MHz

TABLE OF CONTENTS

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.MA125

2005/2

Page 2

SPECIFICATION

AUDIO AMPLIFIER SECTION

Maximum Power Output Front KD-G111 45 W per channel

KD-G117 50 W per channel

Rear KD-G111 45 W per channel

KD-G117 50 W per channel

Continuous Power Output (RMS) Front KD-G111 17 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

KD-G117 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

Rear KD-G111 17 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

KD-G117 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±10 dB at 100 Hz

Treble ±10 dB at 10 kHz

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-Out Level/Impedance 2.0 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

TUNER SECTION

Frequency Range FM KD-G111 87.5 MHz to 108.0 MHz

KD-G117 FM1/FM2:87.5 MHz to 108.0 MHz

FM3:65.00 MHz to 74.00 MHz

AM (MW) 522 kHz to 1 620 kHz

(LW) 144 kHz to 279 kHz

[FM Tuner] Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 30 dB

Capture Ratio 1.5 dB

[MW Tuner] Sensitivity 20 µV

Selectivity 35 dB

[LW Tuner] Selectivity 50 µV

CD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 52 mm × 150 mm

Panel Size (approx.) 188 mm × 58 mm × 11 mm

Mass (approx.) 1.3 kg (excluding accessories)

Design and specifications are subject to change without notice.

1-2 (No.MA125)

Page 3

1.1 Safety Precautions

SECTION 1

PRECAUTIONS

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

(No.MA125)1-3

Page 4

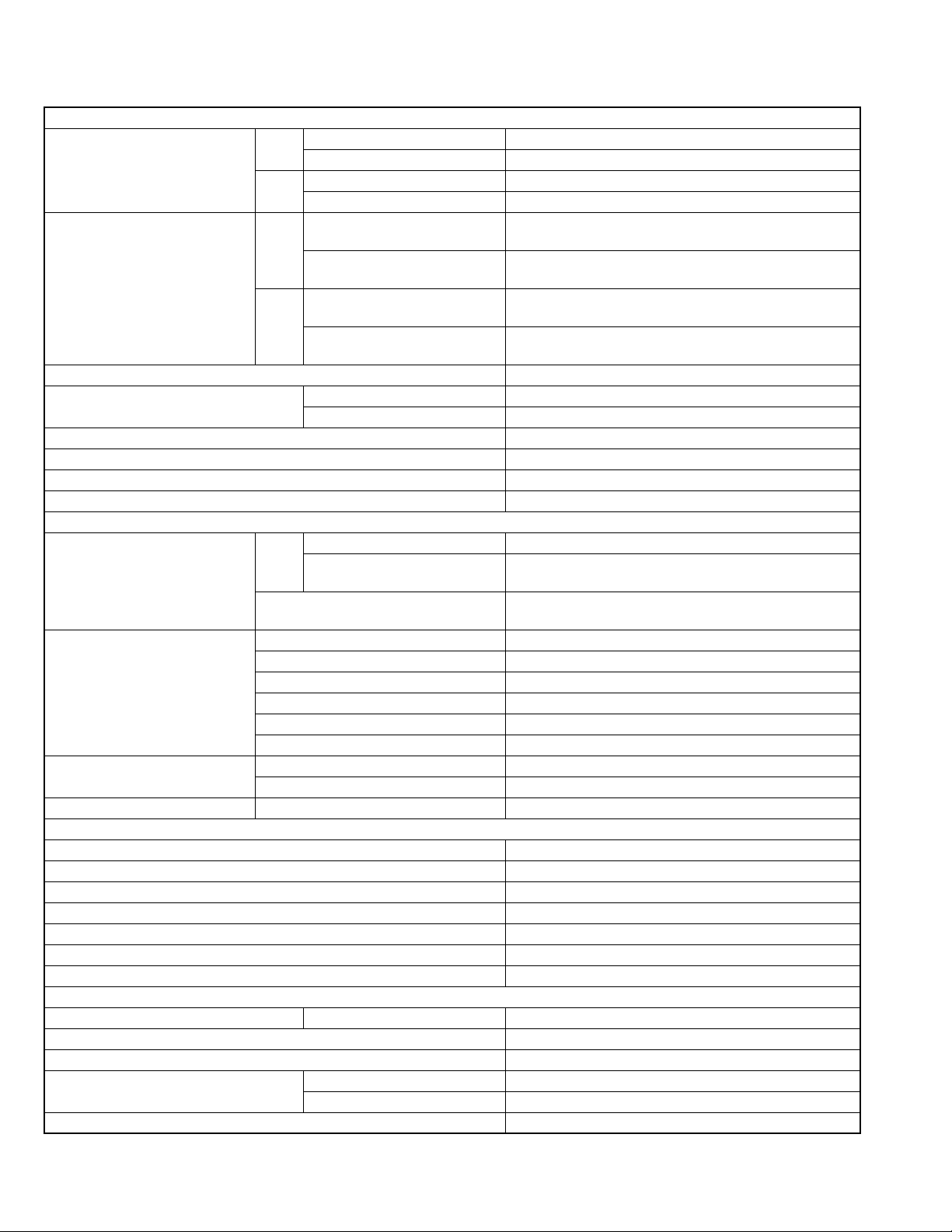

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

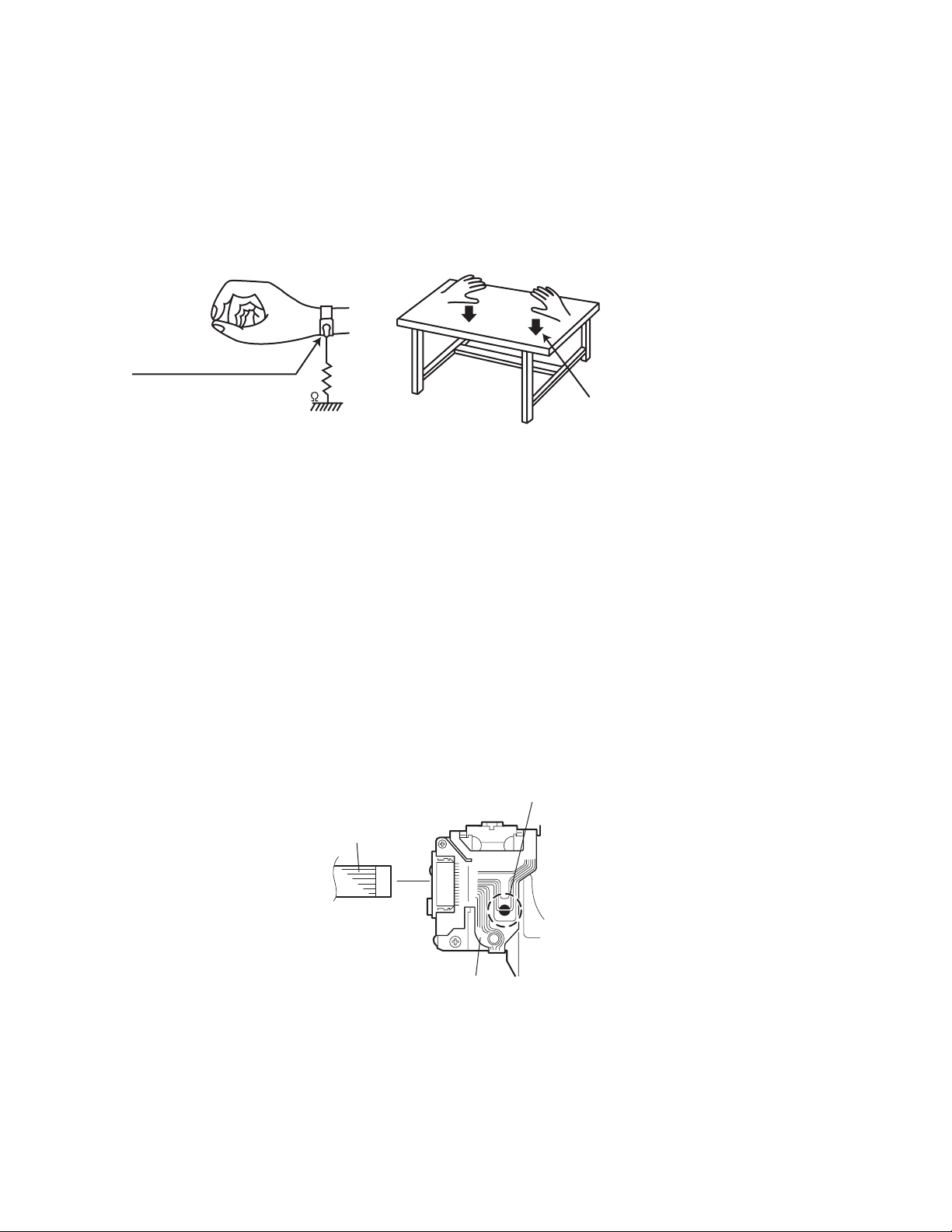

1.4 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the CD pickup unit.

• Apply solder to the short land before the flexible wire is disconnected from the connector on the CD pickup unit.

(If the flexible wire is disconnected without applying solder, the CD pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the flexible wire.

Short-circuit point

(Soldering)

Flexible wire

1-4 (No.MA125)

Pickup

Page 5

1.5 Important for laser products

!

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The CD,MD and DVD player uses invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CAUTION : Visible and Invisible

CLASS 1

LASER PRODUCT

laser radiation when open and

interlock failed or defeated.

AVOID DIRECT EXPOSURE TO

BEAM. (e)

ADVARSEL : Synlig og usynlig

laserstråling når maskinen er

åben eller interlocken fejeler.

Undgå direkte eksponering til

stråling. (d)

VARNING : Synlig och

osynling laserstrålning när

den öppnas och spärren är

urkopplad. Betrakta ej

strålen. (s)

VARO : Avattaessa ja suojalukitus

ohitettuna tai viallisena olet alttiina

näkyvälle ja näkymättömälle

lasersäteilylle. Vältä säteen

kohdistumista suoraan itseesi. (f)

(No.MA125)1-5

Page 6

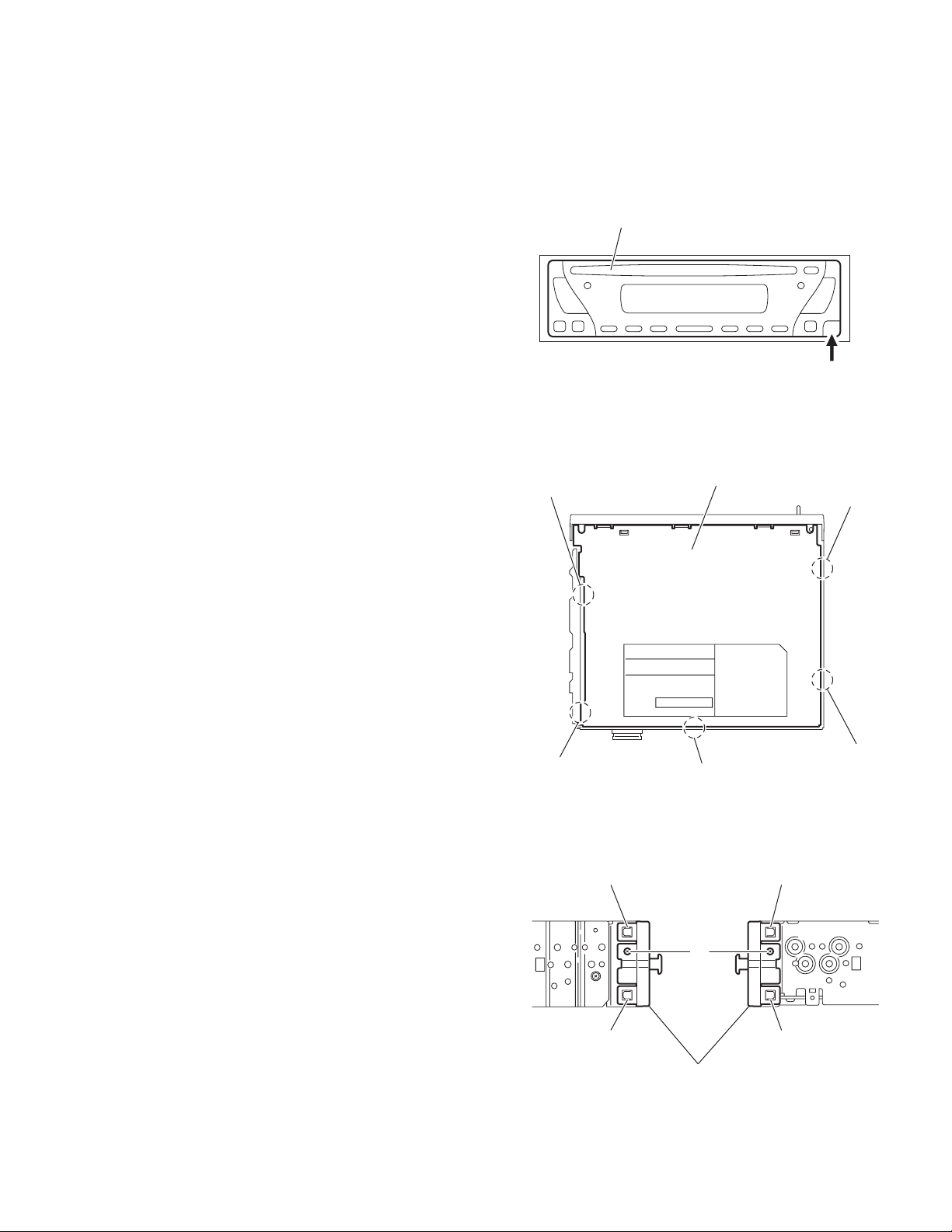

2.1 HOW TO IDENTIFY MODELS

2.1.1 NAME PLATE

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

e

24

XXXXXX

DESTINATION

E2

CD RECEIVER

MODEL NO. KD-G111

DC 12V

SERIAL NO.

Victor Company of Japan, Limited

NEGATIVE GROUND

Discernment sign (as same as KD-G117)

2.1.2 FRONT PANEL BACK SIDE (except KD-G117)

Screw color

E series : SILVER

E2 series : BLACK

for CAR USE

RED

YELLOW

BLACK

BLUE/WHITE LINE

GREEN

GREEN/BLACK LINE

PURPLE

PURPLE/BLACK LINE

WHITE

WHITE/BLACK LINE

GRAY

GRAY/BLACK LINE

:

:

:

REMOTE [MAX 200mA]

:

:

:

:

:

:

:

:

:

Screw

ACCESSORY

BATTERY

GROUND

SPEAKER RL +

SPEAKER RL -

SPEAKER RR +

SPREAKER RR -

SPEAKER FL +

SPEAKER FL -

SPEAKER FR +

SPEAKER FR -

Screw Screw

2.1.3 FRONT CHASSIS ASSEMBLY (except KD-G117)

Panel stopper color

E series : SILVER

E2 series : BLACK

Panel stopper

1-6 (No.MA125)

Page 7

SECTION 3

DISASSEMBLY

3.1 Main body section

3.1.1 Removing the front panel assembly

(See Fig.1)

(1) Push the detach button in the lower right part of the front

panel assembly and remove the front panel assembly.

3.1.2 Removing the bottom cover

(See Fig.2)

(1) Turn the main body up side down.

(2) Insert a screwdriver under the joints to release the two

joints a on the left side, two joints b on the right side and

joint c on the back side of the main body, then remove the

bottom cover from the main body.

Note:

When releasing the joints using a screwdriver, do not damage

the main board.

Front panel assembly

Joint a

Detach button

Fig.1

Bottom cover

Joint b

3.1.3 Removing the front chassis assembly

(See Fig.3)

• Remove the front panel assembly and bottom cover.

(1) Remove the two screws A on the both sides of the main

body.

(2) Release the two joints d and two joints e on the both sides

of the main body, then remove the front chassis assembly

toward the front.

Joint a

Joint c

Fig.2

Joint d Joint e

A

Joint d

Front chassis assembly

Fig.3

Joint e

Joint b

(No.MA125)1-7

Page 8

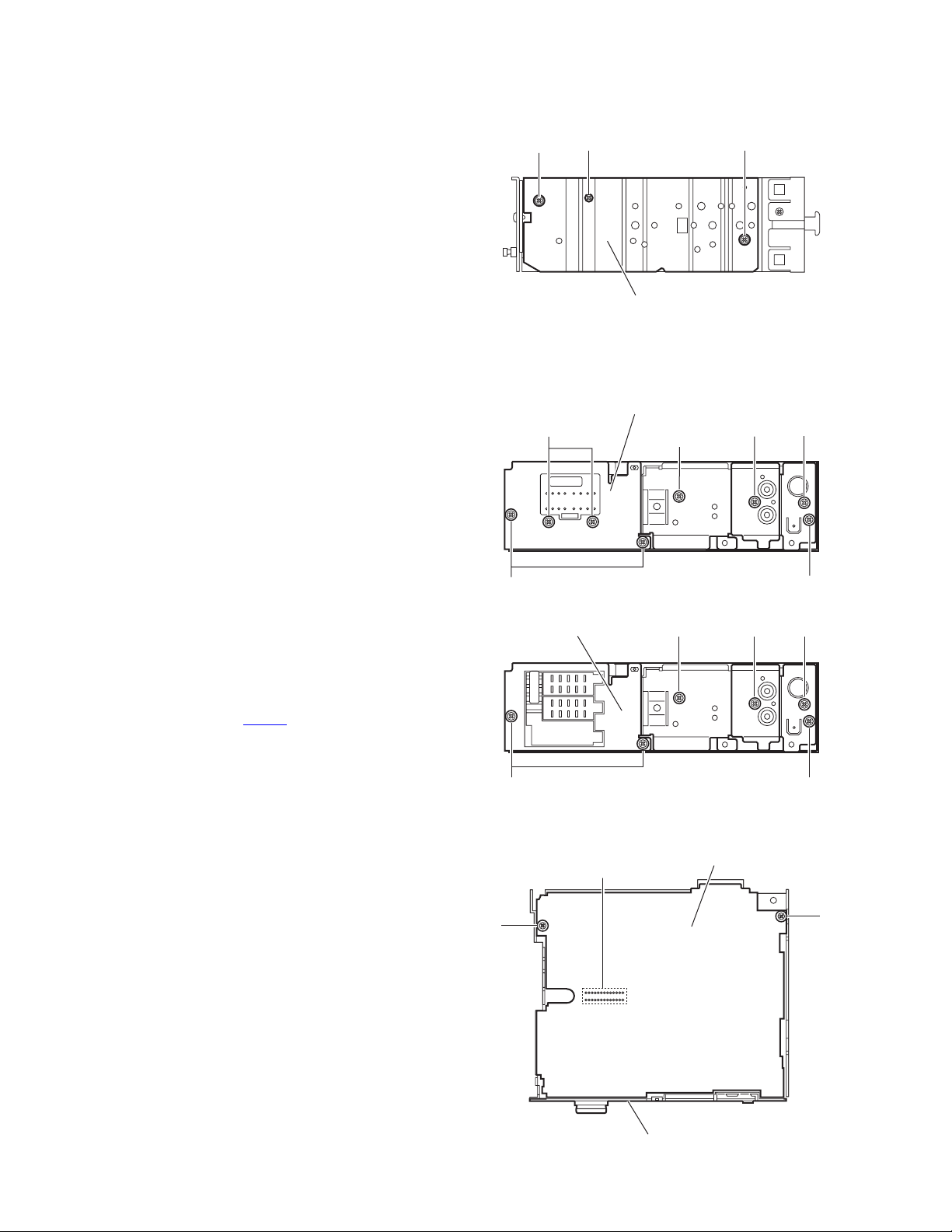

3.1.4 Removing the side panel

(See Fig.4)

Reference:

Remove the front panel assembly as required.

(1) Remove the screw B and two screws C attaching the side

panel on the left side of the main body.

(2) Remove the side panel from the main body.

3.1.5 Removing the rear bracket

(See Fig.5)

• Remove the bottom cover.

(1) For KD-G111, remove the three screws D, three screws E

and two screws F attaching the rear bracket on the back

side of the main body.

(2) For KD-G117, remove the three screws D, screw E and two

screws F attaching the rear bracket on the back side of the

main body.

(3) Remove the rear bracket.

C

B

Side panel

Fig.4

Rear bracket

EF

F

C

E

3.1.6 Removing the main board

(See Figs.5 and 6)

• Remove the front panel assembly, bottom cover and side pan-

el.

Reference:

Remove the front chassis assembly as required.

(1) Remove the three screws D attaching the rear bracket on

the back side of the main body. (See Fig.5.)

(2) Remove the two screws G attaching the main board. (See

Fig.6.)

(3) Disconnect the connector CN501

the main body and take out the main board with the rear

bracket. (See Fig.6.)

Reference:

Remove the rear bracket from the main body as required. (See

"3.1.5 Removing the rear bracket".)

on the main board from

DD

Rear bracket

D

G

CN501

( KD-G111 )

( KD-G117 )

Fig.5

Main board

E

FF

D

G

1-8 (No.MA125)

Rear bracket

Fig.6

Page 9

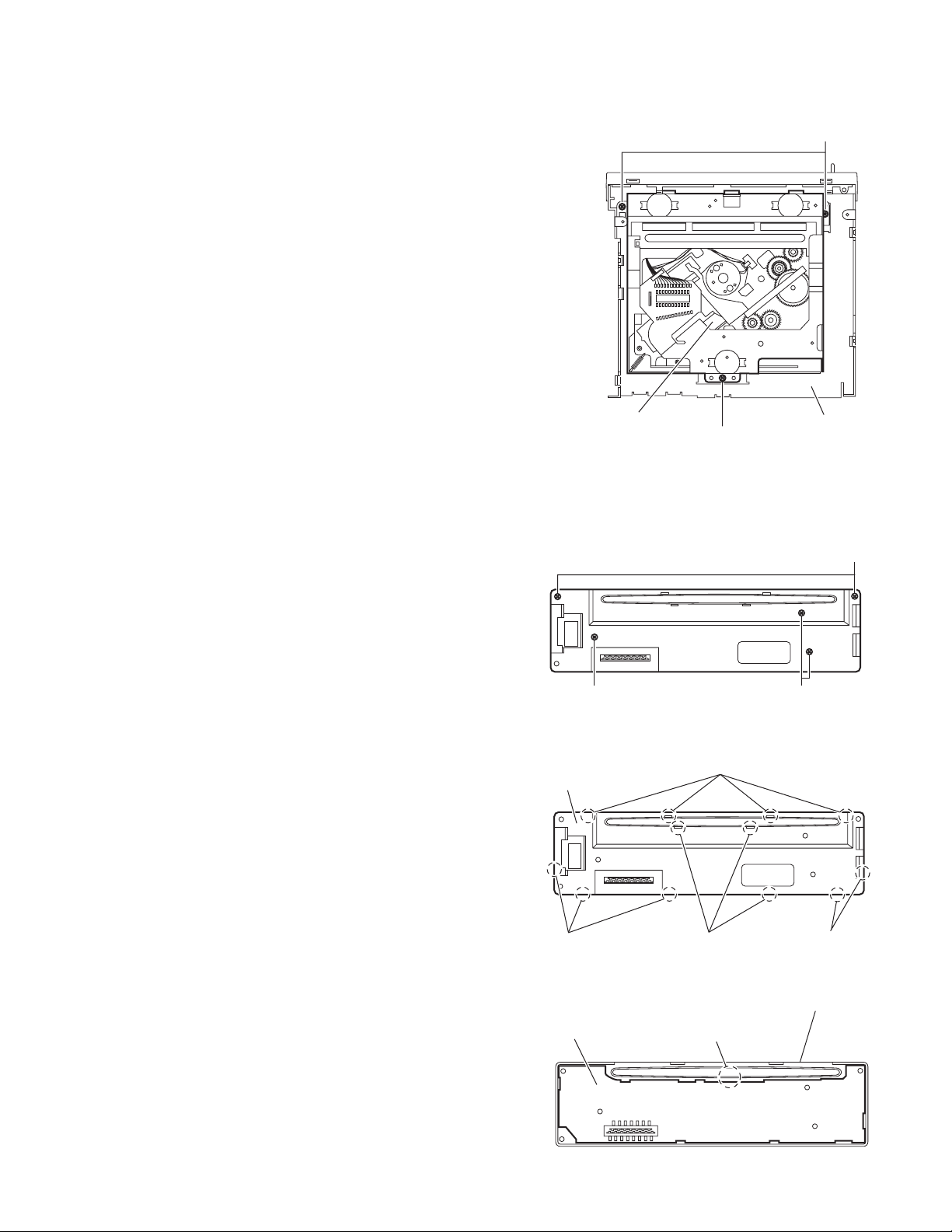

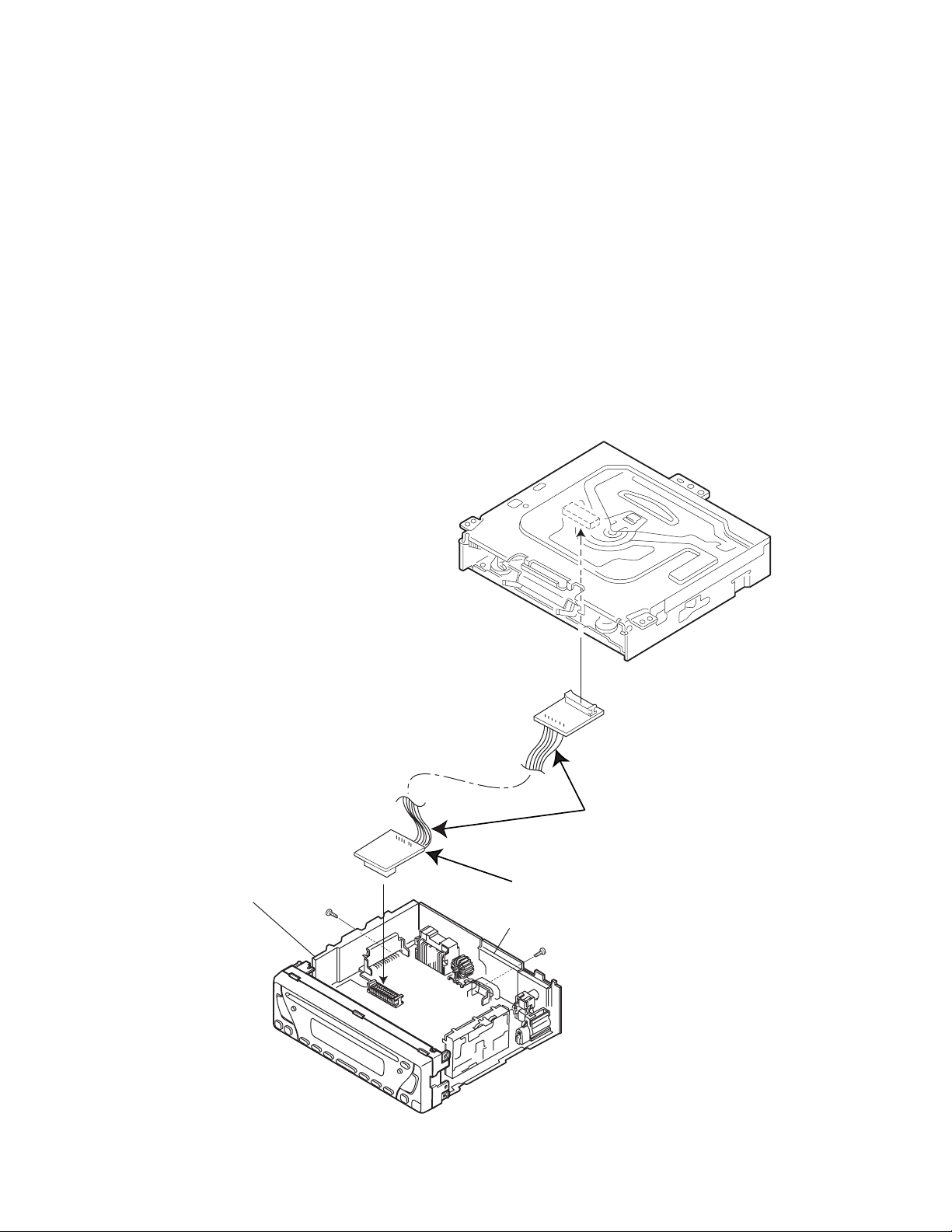

3.1.7 Removing the CD mechanism assembly

(See Fig. 7)

• Remove the front panel assembly, bottom cover, side panel,

rear bracket and main board.

Reference:

Remove the front chassis assembly as required.

(1) Remove the three screws H attaching the CD mechanism

assembly on the top chassis.

(2) Take out the CD mechanism assembly.

H

3.1.8 Removing the front board

(See Figs.8 to 10)

• Remove the front panel assembly.

(1) Remove the five screws J on the back side of the front pan-

el assembly. (See Fig.8.)

(2) Release the twelve joints f and remove the rear cover. (See

Fig.9.)

(3) Release the joint g and take out the front board from the

front panel assembly. (See Fig.10.)

CD mechanism assembly

J

Rear cover

Top chassis

H

Fig.7

J

J

Fig.8

Joints f

Joints f Joints f

Front board

Joints f

Fig.9

Front panel assembly

Joint g

Fig.10

(No.MA125)1-9

Page 10

3.2 CD Mechanism Assembly

A

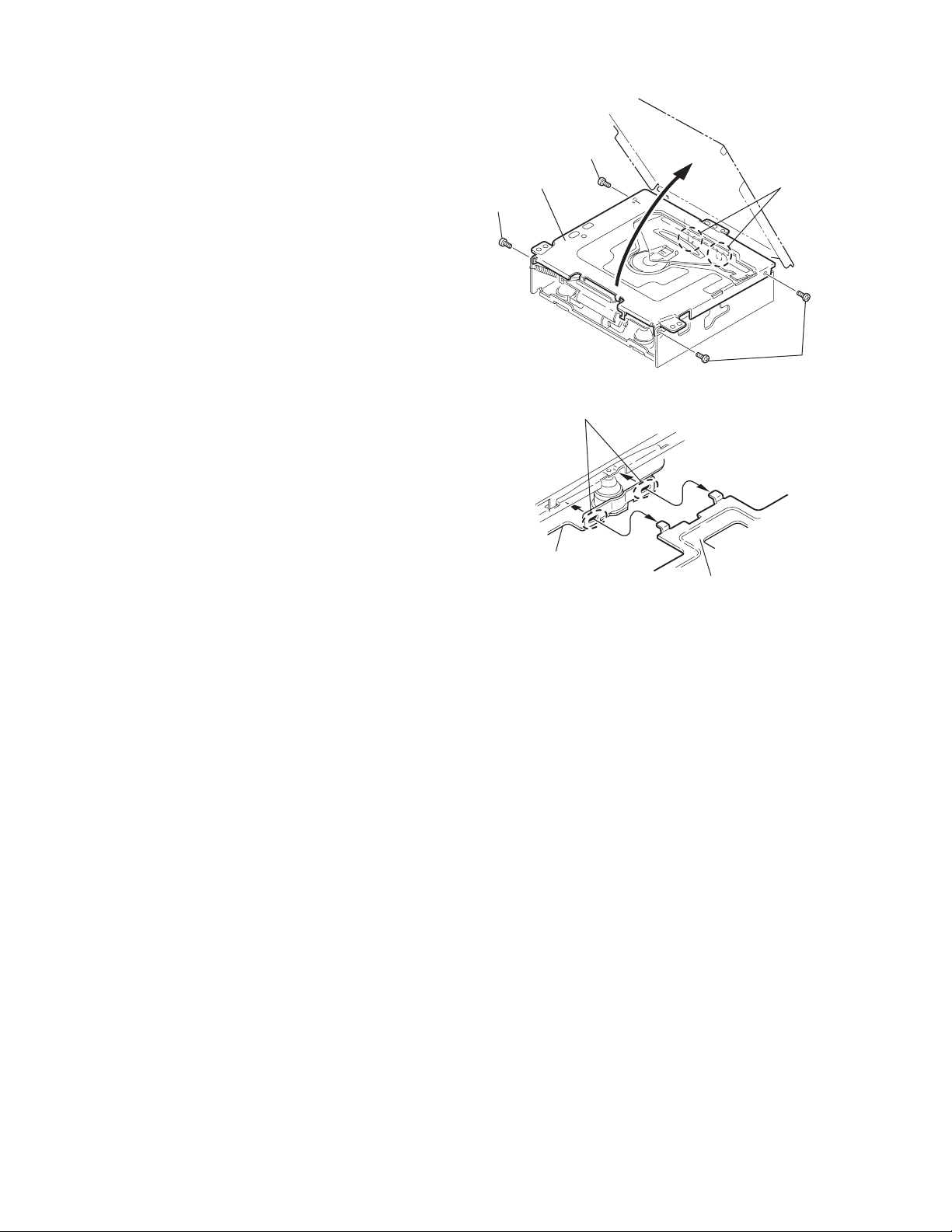

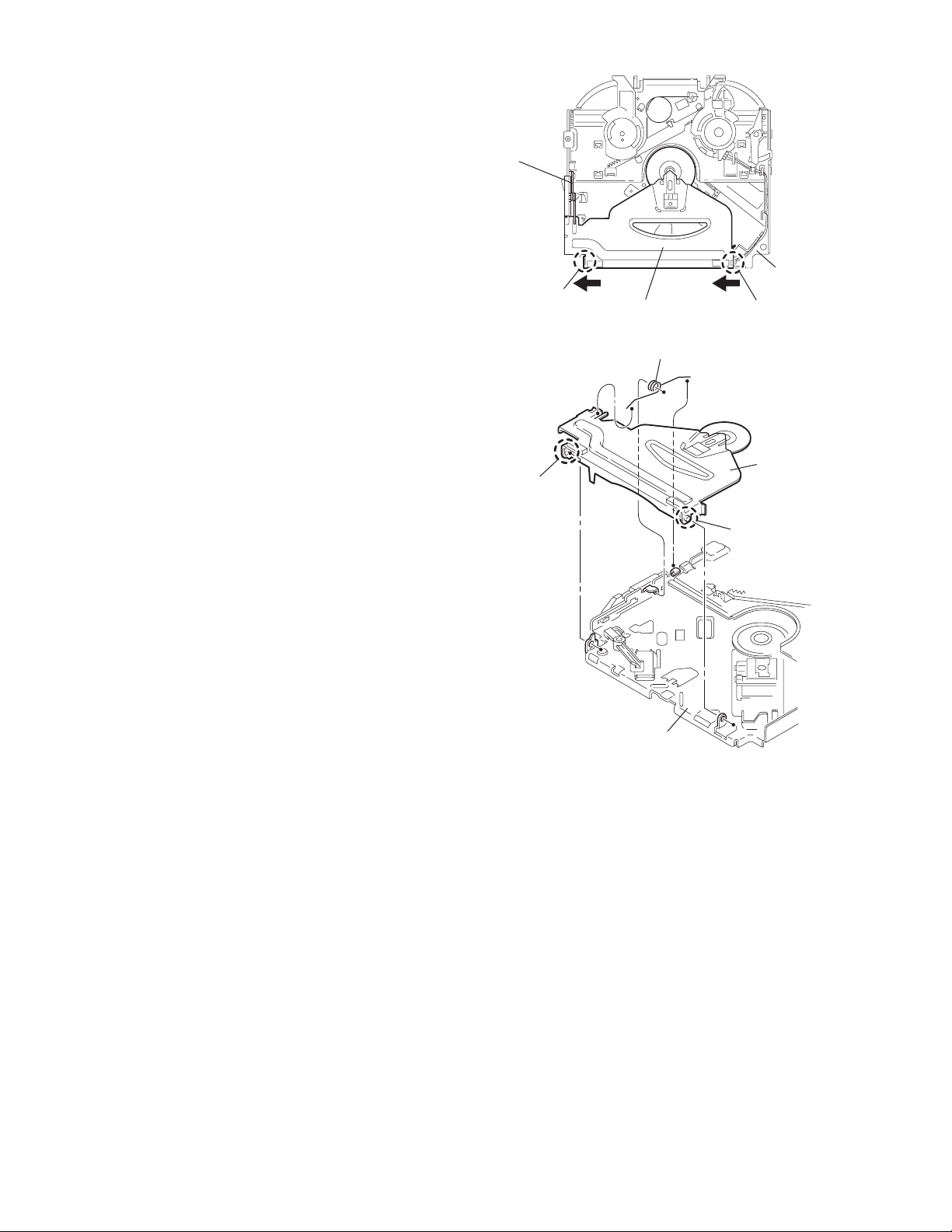

3.2.1 Removing the top cover

(See Figs.1 and 2)

(1) Remove the two screws A on the both side of the body.

(2) Lift the front side of the top cover and move the top cover

backward to release the two joints a.

Top cover

Joints a

A

Joints a

A

Fig.1

Fig.2

Top cover

1-10 (No.MA125)

Page 11

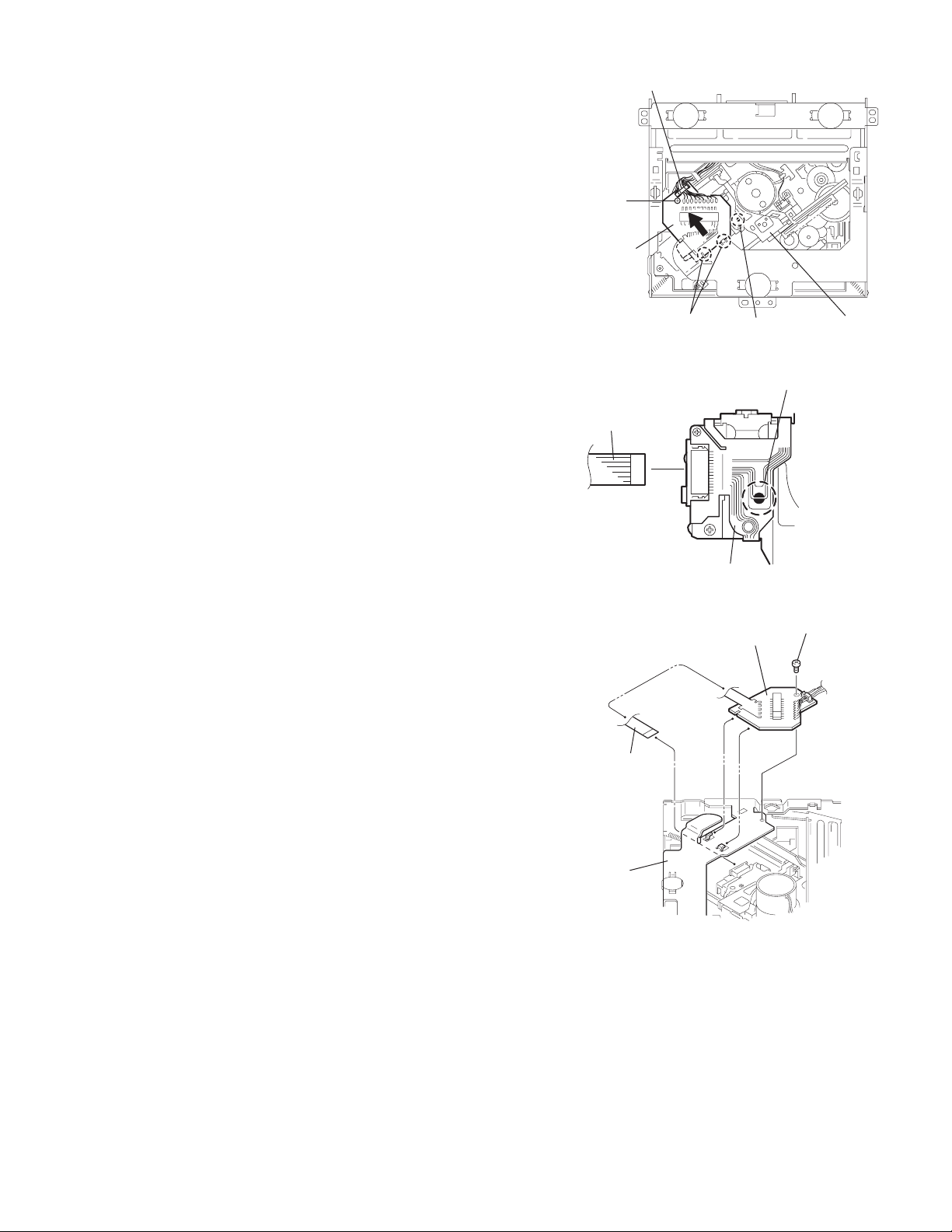

3.2.2 Removing the connector board

(See Figs.3 to 5)

CAUTION:

Before disconnecting the flexible wire from the pickup, solder

the short-circuit point on the pickup. No observance of this in-

struction may cause damage of the pickup.

(1) Remove the screw B fixing the connector board.

(2) Solder the short-circuit point on the connector board.

(3) Disconnect the flexible wire from the pickup.

(4) Move the connector board in the direction of the arrow to

release the two joints b.

(5) Unsolder the wire on the connector board if necessary.

CAUTION:

Unsolder the short-circuit point after reassembling.

B

Connector board

Flexible wire

Wires

Joints b

Short-circuit point

Fig.3

Short-circuit point

(Soldering)

Pickup

Flexible wire

Frame

Pickup

Fig.4

B

Connector board

Fig.5

(No.MA125)1-11

Page 12

3.2.3 Removing the DET switch

(See Figs.6 and 7)

(1) Extend the two tabs c of the feed sw. holder and pull out

the switch.

(2) Unsolder the DET switch wire if necessary.

Connector

board

DET switch

DET switch

Pickup

Fig.6

Tab c

DET switch wire

Tab c

Feed sw. holder

Fig.7

1-12 (No.MA125)

Page 13

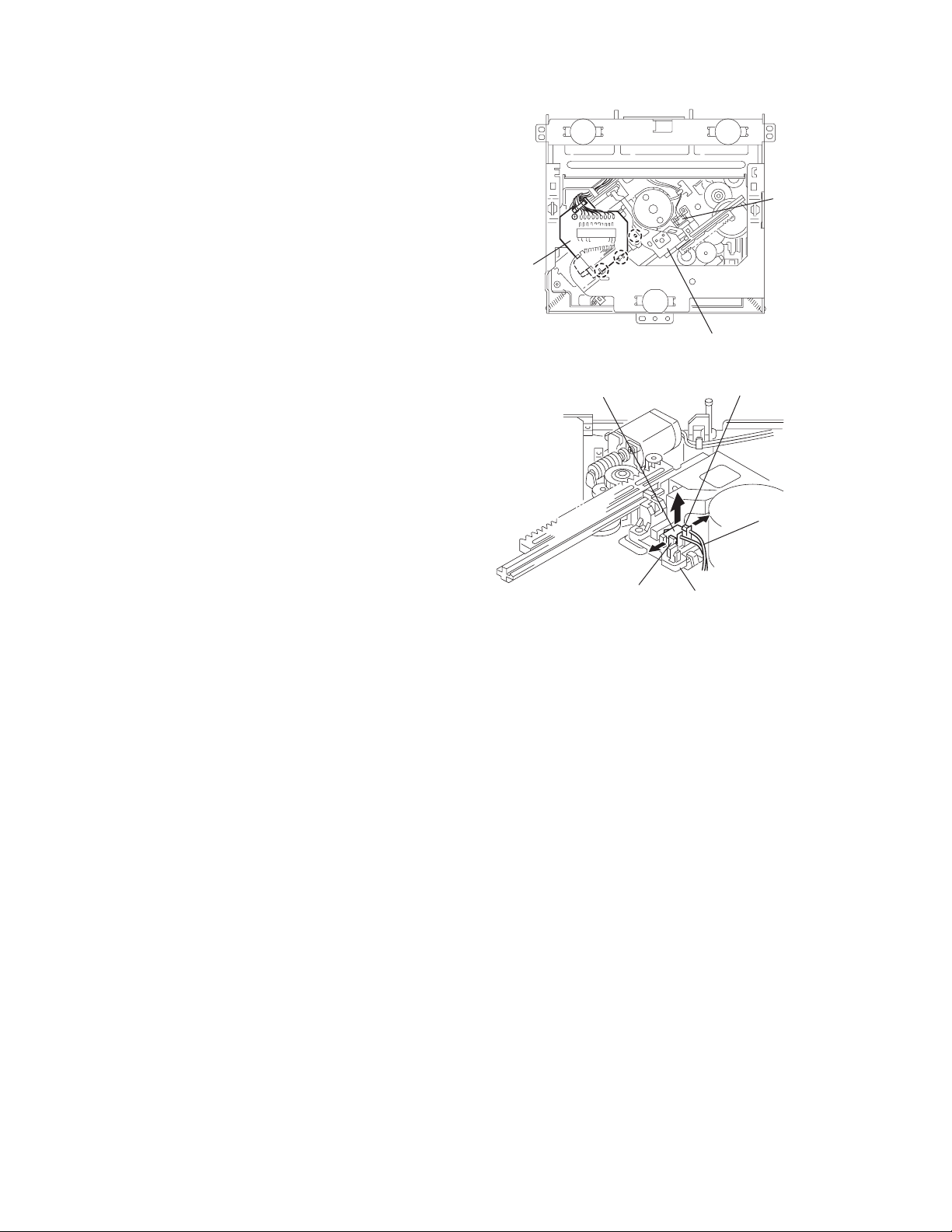

3.2.4 Removing the chassis unit

r

(See Figs.8 and 9)

• Prior to performing the following procedure, remove the top

cover and connector board.

(1) Remove the two suspension springs (L) and (R) attaching

the chassis unit to the frame.

CAUTION:

• The shape of the suspension spring (L) and (R) are different. Handle them with care.

• When reassembling, make sure that the three shafts

on the underside of the chassis unit are inserted to the

dampers certainly.

Suspension spring (R)

Chassis unit

Suspension spring (L)

Frame

Suspension spring (R)

Chassis unit

Shafts

Damper

Damper

Suspension spring (L)

Fig.8

Shaft

Dampe

Frame

Fig.9

(No.MA125)1-13

Page 14

3.2.5 Removing the clamper assembly

(See Figs.10 and 11)

• Prior to performing the following procedure, remove the top

cover.

(1) Remove the clamper arm spring.

(2) Move the clamper assembly in the direction of the arrow to

release the two joints d.

Clamper arm

spring

Joint d

Joint d

Clamper assembly

Fig.10

Clamper arm spring

Chassis rivet

assembly

Joint d

Clamper

assembly

Chassis rivet assembly

Fig.11

Joint d

1-14 (No.MA125)

Page 15

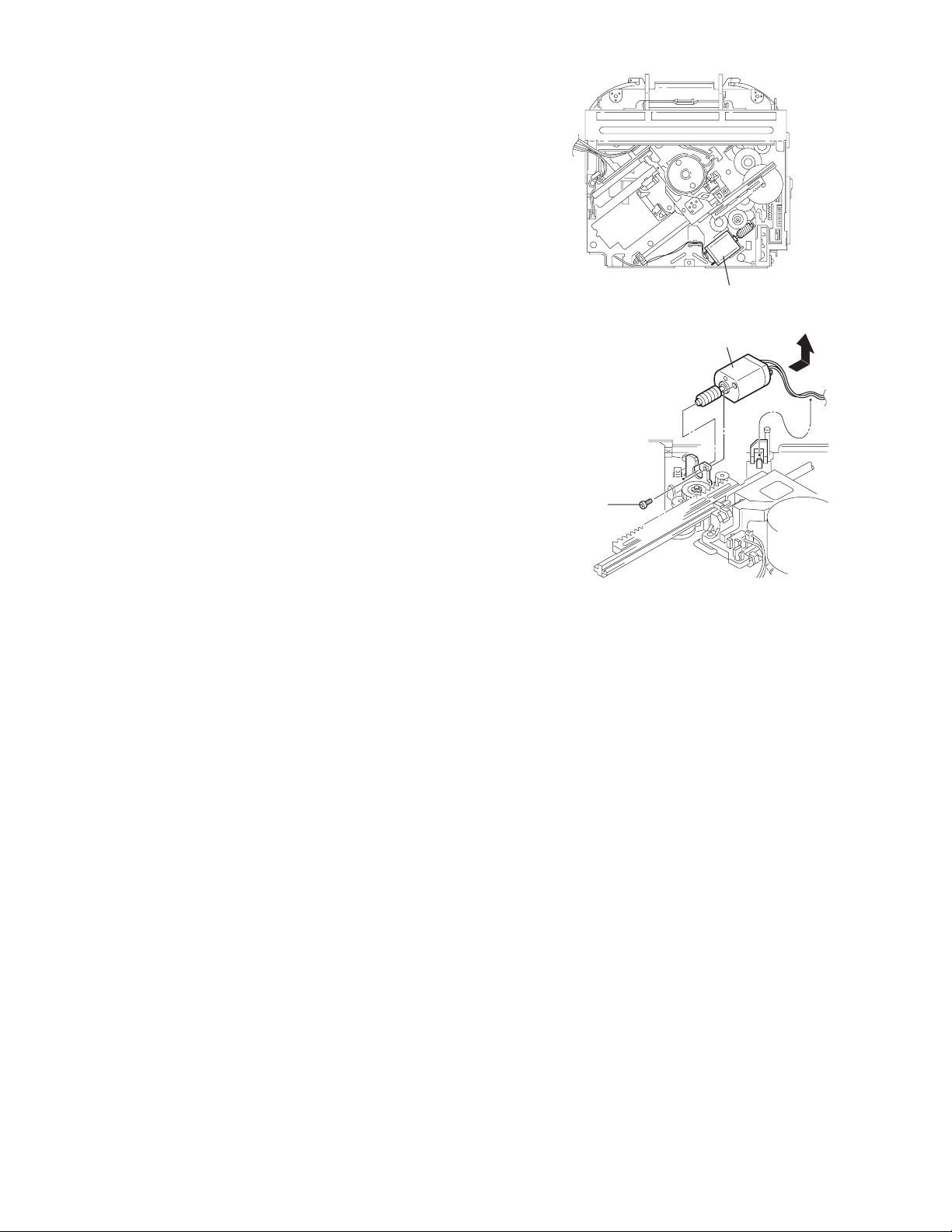

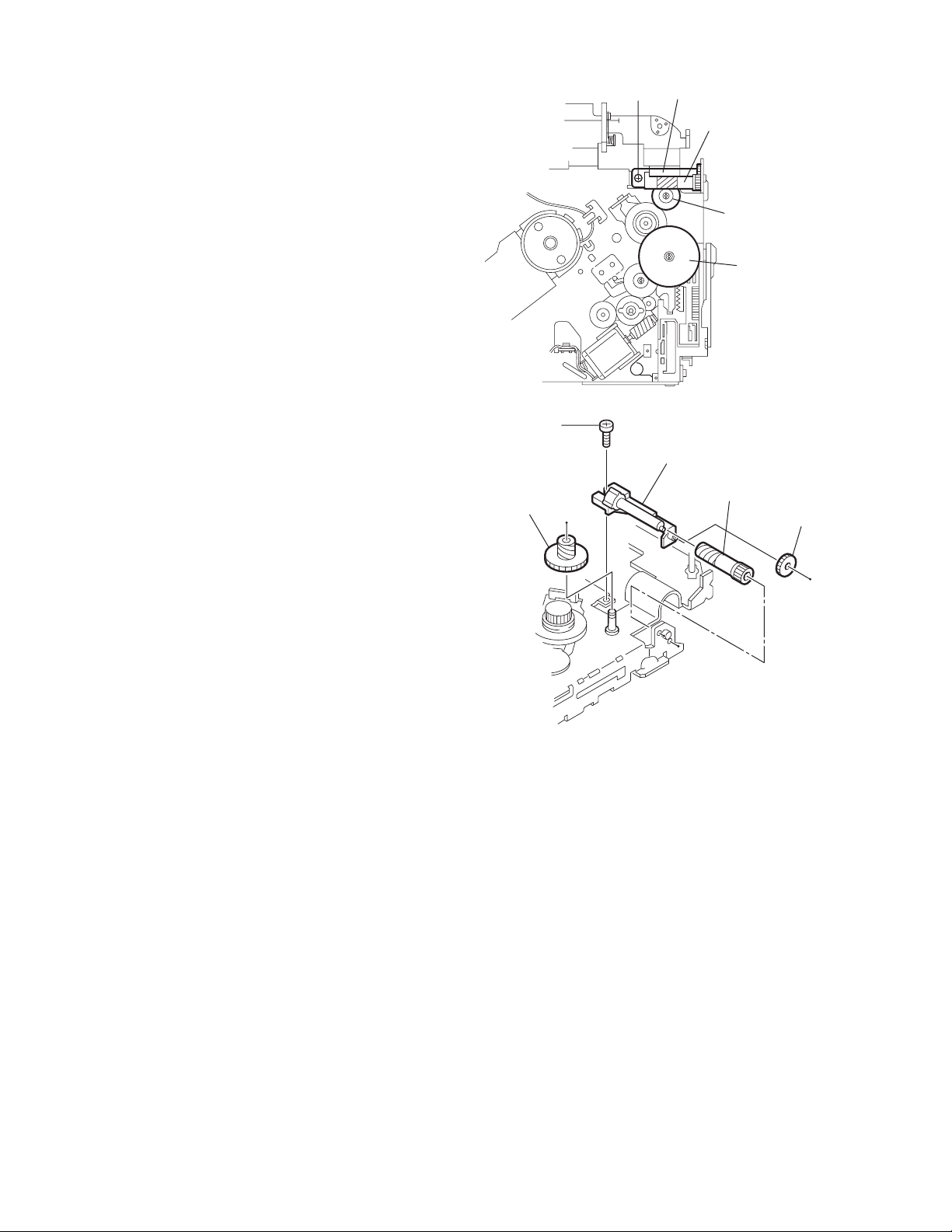

3.2.6 Removing the loading / feed motor assembly

(See Figs.12 and 13)

• Prior to performing the following procedure, remove the top

cover, connector board and chassis unit.

(1) Remove the screw C and move the loading / feed motor

assembly in the direction of the arrow to remove it from the

chassis rivet assembly.

(2) Disconnect the wire from the loading / feed motor assembly

if necessary.

CAUTION:

When reassembling, connect the wire from the loading /

feed motor assembly to the flame as shown in Fig.12.

Loading / feed motor assembly

Fig.12

Loading / feed motor assembly

C

Fig.13

(No.MA125)1-15

Page 16

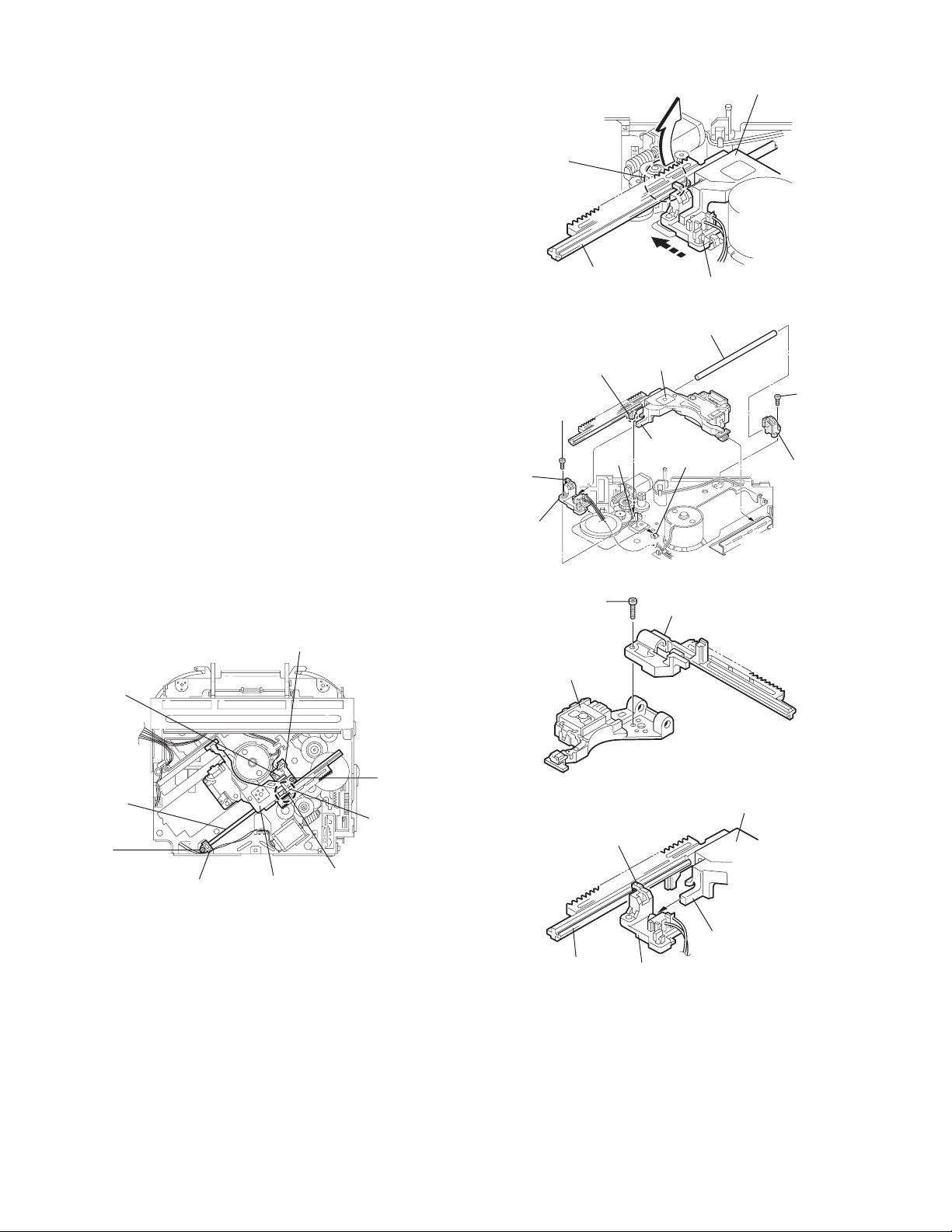

3.2.7 Removing the pickup unit

(See Figs.14 to 18)

• Prior to performing the following procedure, remove the top

cover, connector board and chassis unit.

(1) Remove the screw D and pull out the pu. shaft holder from

the pu. shaft.

(2) Remove the screw E attaching the feed sw. holder.

(3) Move the part e of the pickup unit upward with the pu. shaft

and the feed sw. holder, then release the joint f of the feed

sw. holder in the direction of the arrow. The joint g of the

pickup unit and the feed rack is released, and the feed sw.

holder comes off.

(4) Remove the pu. shaft from the pickup unit.

(5) Remove the screw F attaching the feed rack to the pickup

unit.

3.2.8 Reattaching the pickup unit

(See Figs.14 to 17)

(1) Reattach the feed rack to the pickup unit using the screw F.

(2) Reattach the feed sw. holder to the feed rack while setting

the joint g to the slot of the feed rack and setting the part f

of the feed rack to the switch of the feed sw. holder correctly.

(3) As the feed sw. holder is temporarily attached to the pickup

unit, set to the gear of the joint g and to the bending part of

the chassis (joint h) at a time.

CAUTION:

Make sure that the part i on the underside of the feed

rack is certainly inserted to the slot j of the change lock

lever.

(4) Reattach the feed sw. holder using the screw E.

(5) Reattach the pu. shaft to the pickup unit. Reattach the pu.

shaft holder to the pu. shaft using the screw D.

Feed sw. holder

Joint f

Joint g

Feed sw.

holder

Part e

Feed rack

Part i

E

Pickup unit

Slot j

F

Fig.15

Pu. shaft

Pickup unit

Joint f

Joint h

Fig.16

Feed rack

Pickup unit

Feed sw. holder

D

Pu. shaft

holder

Pu. shaft

D

Pu. shaft holder

1-16 (No.MA125)

Pickup unit

Fig.14

Part e

E

Joint g

Feed rack

Fig.17

Pickup unit

Joint g

Joint f

Feed sw. holder

Fig.18

Page 17

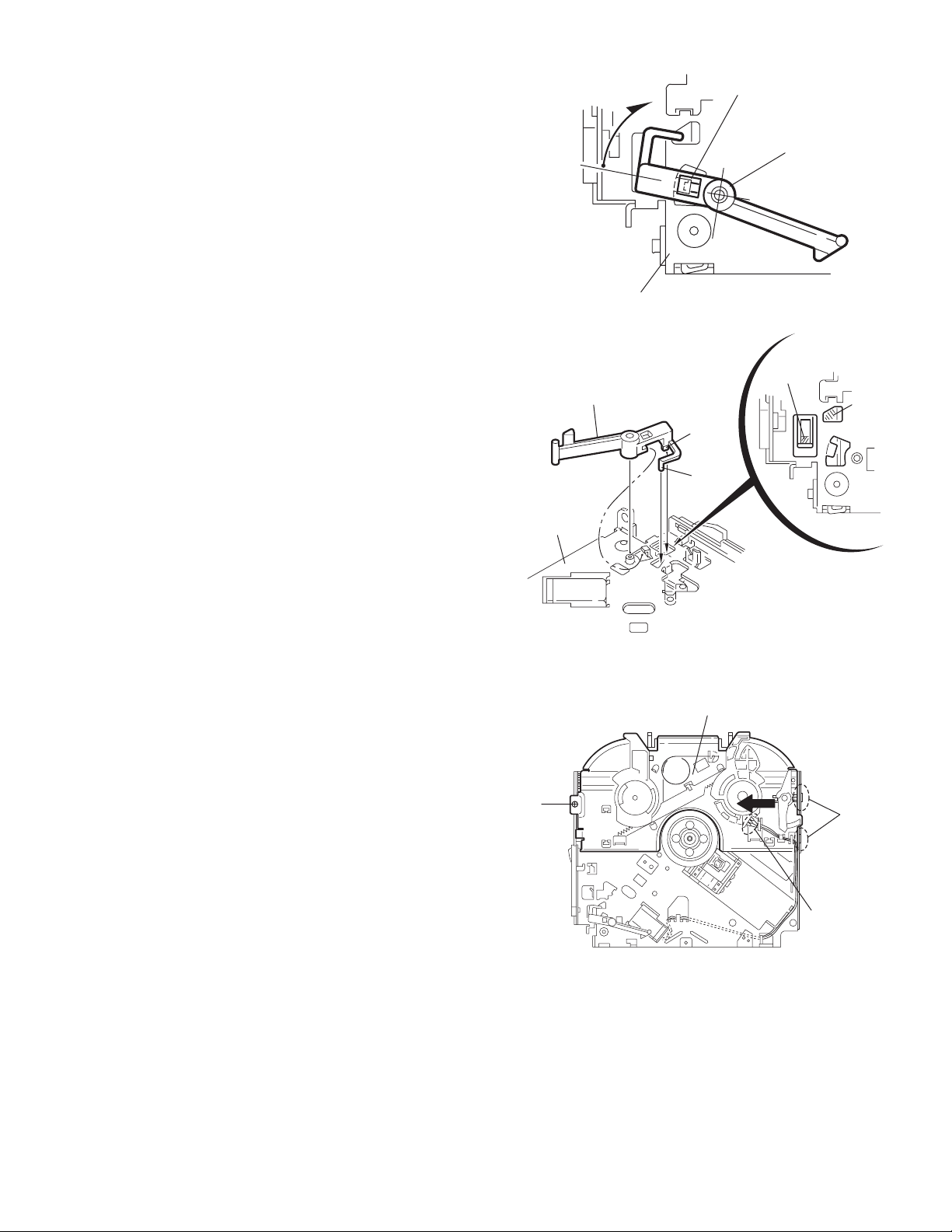

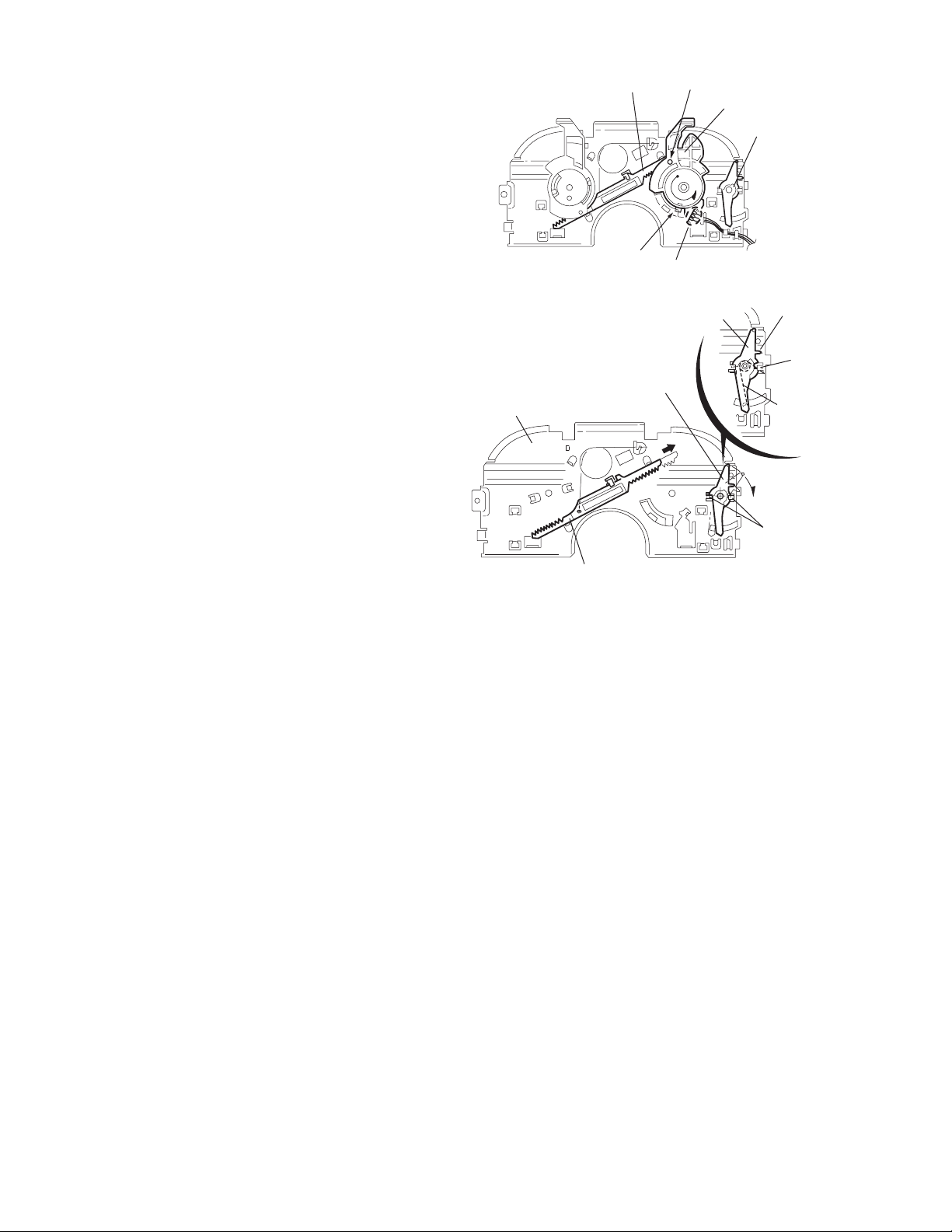

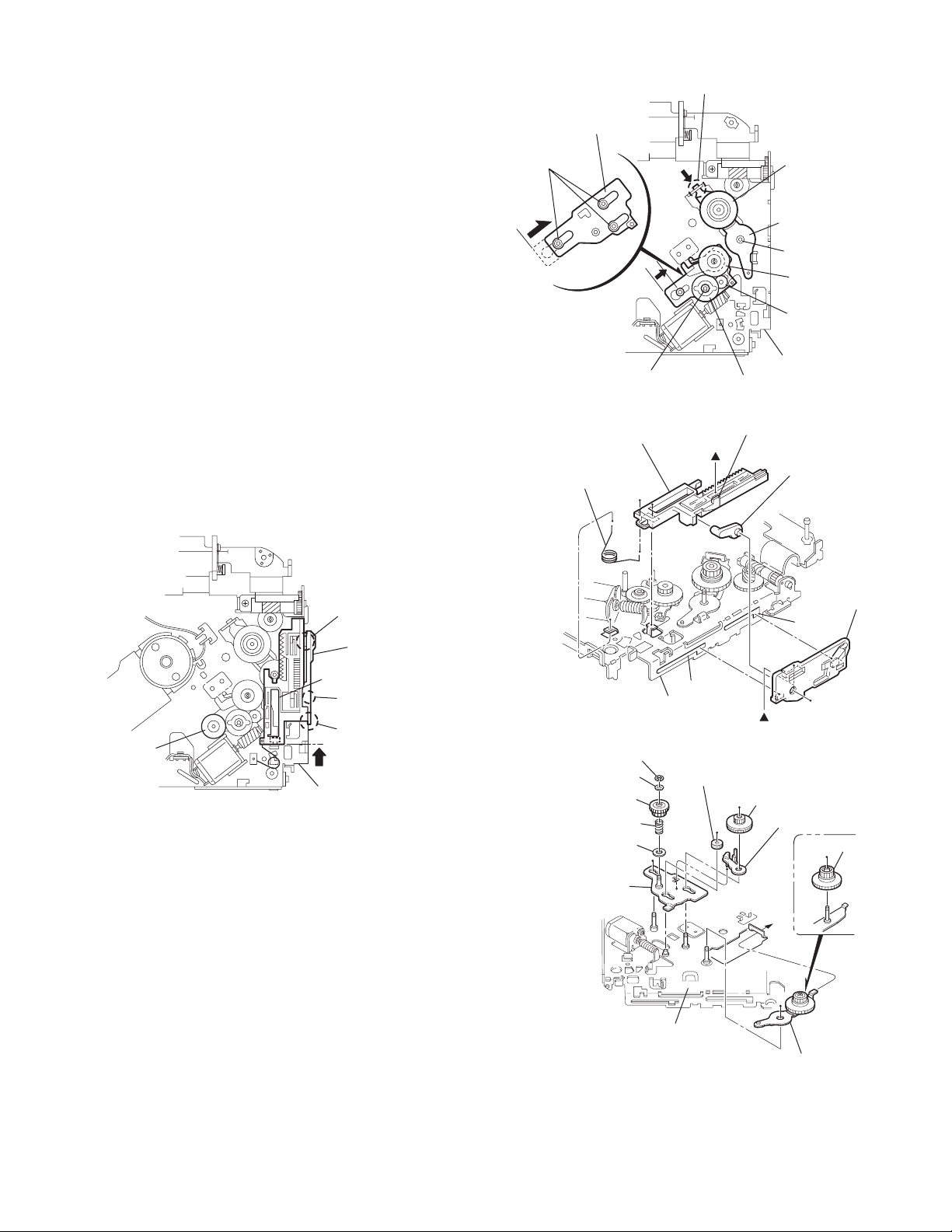

3.2.9 Removing the trigger arm

r

(See Figs.19 and 20)

• Prior to performing the following procedure, remove the top

cover, connector board and clamper unit.

(1) Turn the trigger arm in the direction of the arrow to release

the joint k and pull out upward.

CAUTION:

When reassembling, insert the part m and n of the trigger

arm into the part p and q at the slot of the chassis rivet

assembly respectively and join the joint k at a time.

Chassis rivet assembly

Trigger arm

Chassis rivet

assembly

Joint k

Trigger arm

Fig.19

Part p

Part q

Part m

Part n

3.2.10 Removing the top plate assembly

(See Fig.21)

• Prior to performing the following procedure, remove the top

cover, connector board, chassis unit, and clamper assembly.

(1) Remove the screw H.

(2) Move the top plate assembly in the direction of the arrow to

release the two joints r.

(3) Unsolder the wire marked s if necessary.

H

Fig.20

Top plate assembly

Joints

s

Fig.21

(No.MA125)1-17

Page 18

3.2.11 Removing the mode sw. / select lock arm

(See Figs.22 and 23)

• Prior to performing the following procedure, remove the top

plate assembly.

(1) Bring up the mode sw. to release from the link plate (joint t)

and turn in the direction of the arrow to release the joint u.

(2) Unsolder the wire of the mode sw. marked s if necessary.

(3) Turn the select lock arm in the direction of the arrow to re-

lease the two joints v.

(4) The select lock arm spring comes off the select lock arm at

the same time.

Top plate

Link plate

Joint u

Joint t

s

Fig.22

Select lock arm

Select lock arm

Mode sw.

Select lock arm

Top plate

Hook w

Select lock

arm spring

Link plate

Joints v

Fig.23

1-18 (No.MA125)

Page 19

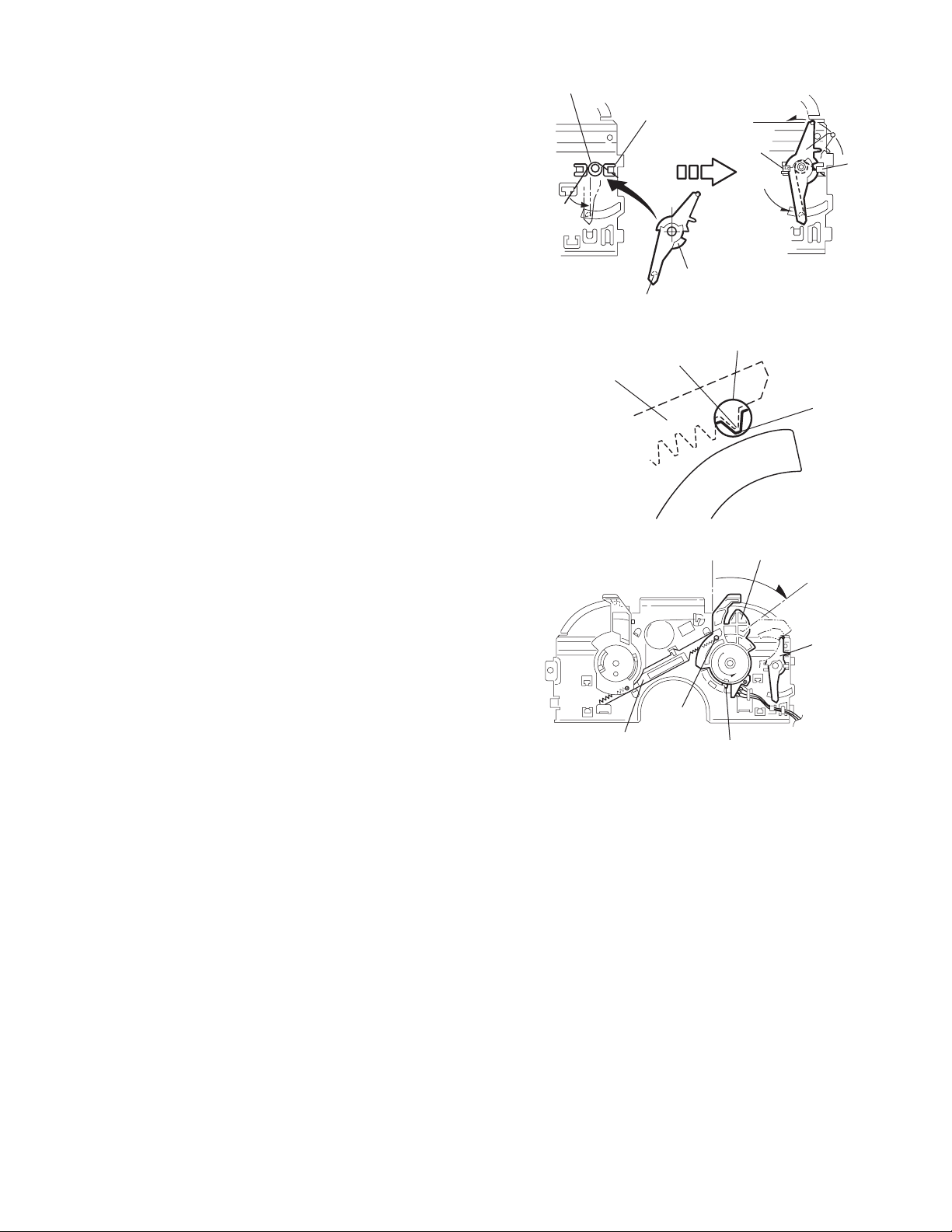

3.2.12 Reassembling the mode sw. / select lock arm

(See Figs.24 to 26)

REFERENCE:

Reverse the above removing procedure.

(1) Reattach the select lock arm spring to the top plate and set

the shorter end of the select lock arm spring to the hook w

on the top plate.

(2) Set the other longer end of the select lock arm spring to the

boss x on the underside of the select lock arm, and join the

select lock arm to the slots (joint v). Turn the select lock

arm as shown in the figure.

(3) Reattach the mode sw. while setting the part t to the first

peak of the link plate gear, and join the joint u.

CAUTION:

When reattaching the mode sw., check if the points y and

z are correctly fitted and if each part operates properly.

Select lock arm spring

Hook w

Joint v

Joint v

Select lock arm

Boss x

Fig.24

Joint t

Point y

Link plate

Point z

Link plate

Fig.25

Mode sw.

Select

lock arm

Joint t

Joint u

Fig.26

(No.MA125)1-19

Page 20

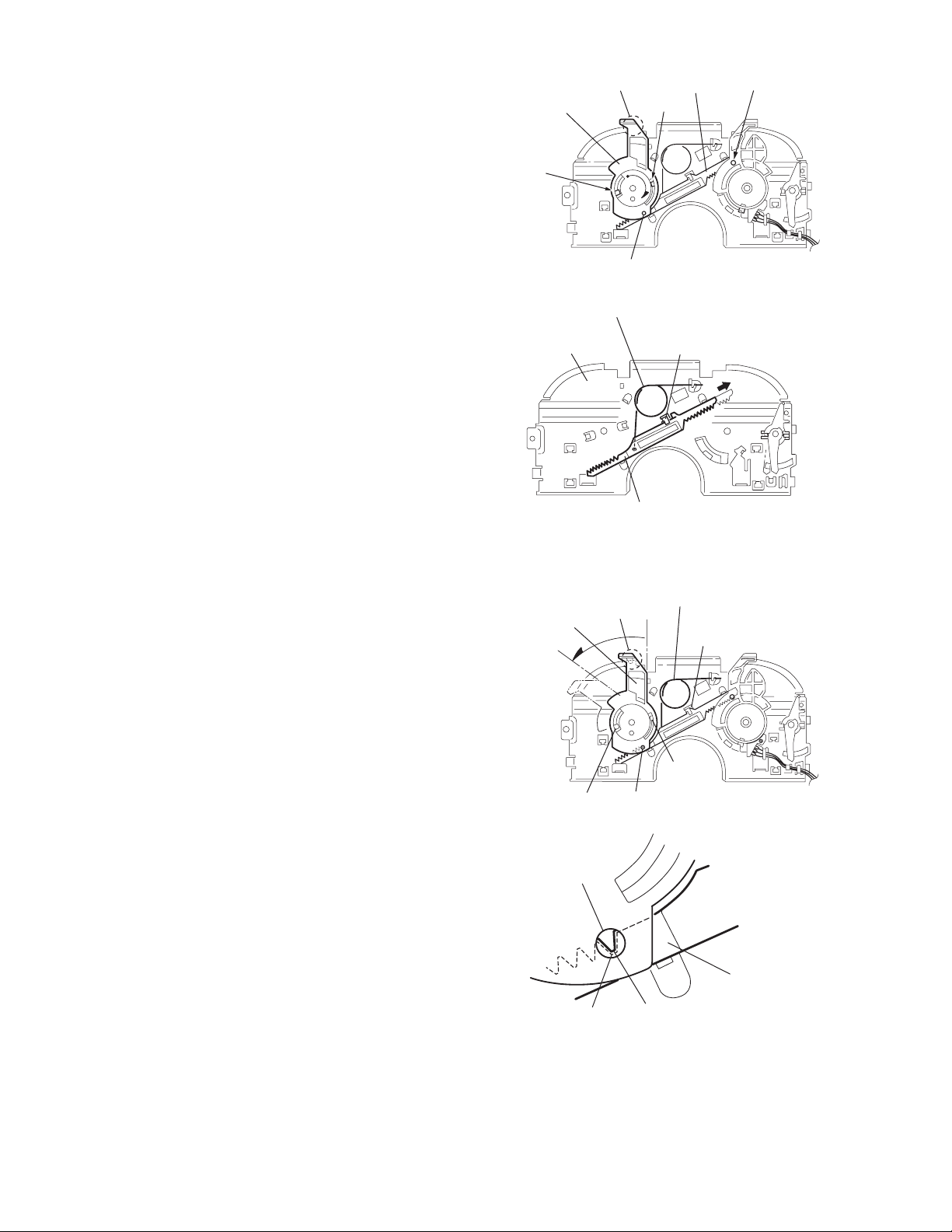

3.2.13 Removing the select arm R / link plate

(See Figs.27 and 28)

• Prior to performing the following procedure, remove the top

plate assembly.

(1) Bring up the select arm R to release from the link plate

(joint a') and turn as shown in the figure to release the two

joints b' and joint c'.

(2) Move the link plate in the direction of the arrow to release

the joint d'. Remove the link plate spring at the same time.

REFERENCE:

Before removing the link plate, remove the mode sw..

Select arm R

Joint b'

Link plate spring

Joint c'

Joint a'

Link plate

Joint b'

Fig.27

Joint r

3.2.14 Reattaching the Select arm R / link plate

(See Figs.29 and 30)

REFERENCE:

Reverse the above removing procedure.

(1) Reattach the link plate spring.

(2) Reattach the link plate to the link plate spring while joining

them at joint d'.

(3) Reattach the joint a' of the select arm R to the first peak of

the link plate while joining the two joints b' with the slots.

Then turn the select arm R as shown in the figure. The top

plate is joined to the joint c'.

CAUTION:

When reattaching the select arm R, check if the points e'

and f' are correctly fitted and if each part operates properly.

Top plate

Select arm R

Joint b'

Joint d'

Link plate

Fig.28

Link plate spring

Joint c'

Joint d'

Joint b'

Joint a'

Fig.29

1-20 (No.MA125)

Joint a'

Point e'

Link plate

Point f'

Fig.30

Page 21

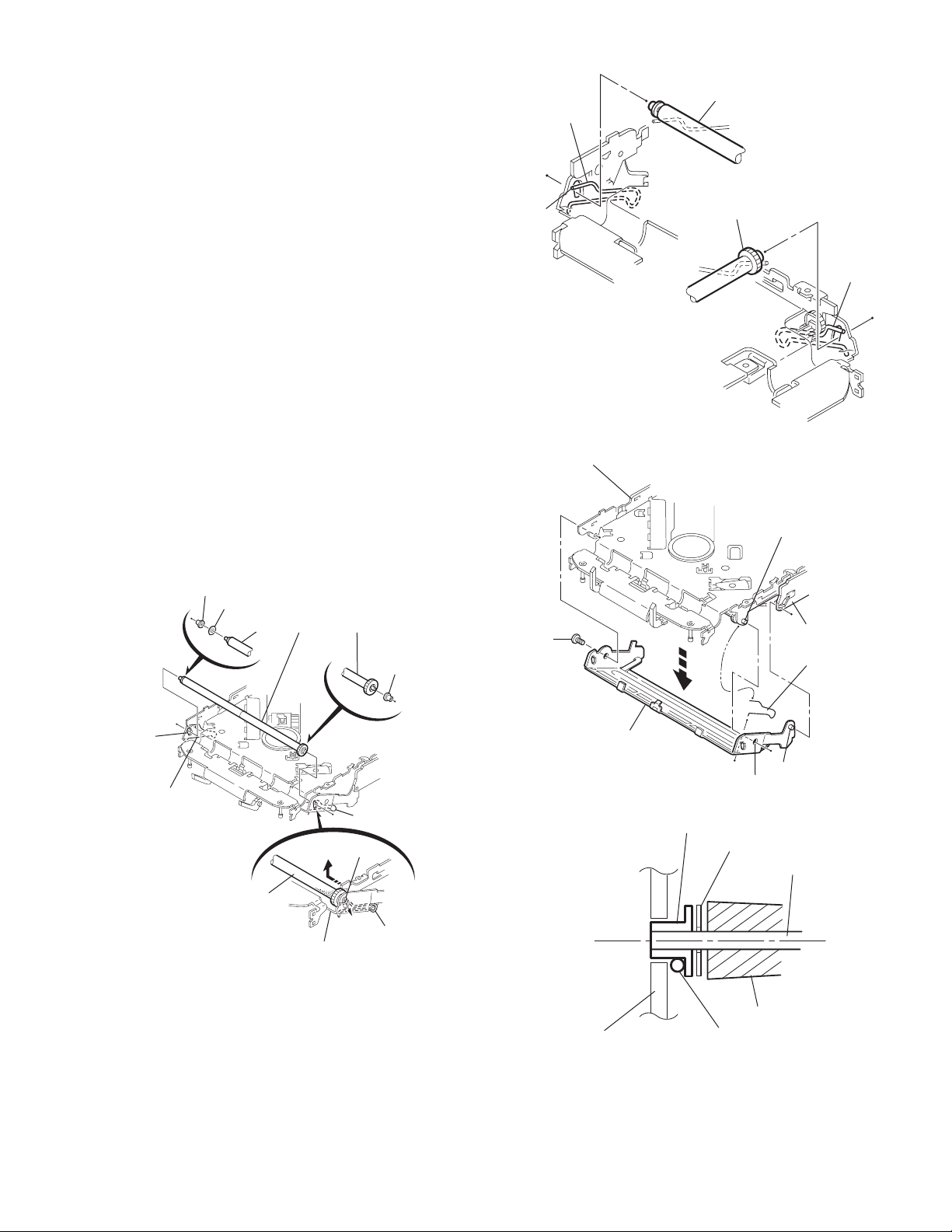

3.2.15 Removing the loading roller assembly

(See Figs.31 to 33)

• Prior to performing the following procedure, remove the

clamper assembly and top plate assembly.

(1) Push inward the loading roller assembly on the gear side

and detach it upward from the slot of the joint g' of the lock

arm rivet assembly.

(2) Detach the loading roller assembly from the slot of the joint

h' of the lock arm rivet assembly.

Roller guide

spring

Part k'

Loading roller assembly

Loading roller assembly

The roller guide comes off the gear section of the loading

roller assembly.

Remove the roller guide and the HL washer from the shaft

of the loading roller assembly.

(3) Remove the screw J attaching the lock arm rivet assembly.

(4) Push the shaft at the joint i' of the lock arm rivet assembly

inward to release the lock arm rivet assembly from the slot

of the L side plate.

(5) Extend the lock arm rivet assembly outward and release

the joint j' from the boss of the chassis rivet assembly. The

roller guide springs on both sides come off at the same

time.

CAUTION:

When reassembling, reattach the left and right roller

guide springs to the lock arm rivet assembly before reattaching the lock arm rivet assembly to the chassis rivet

assembly. Make sure to fit the part k' of the roller guide

spring inside of the roller guide. (Refer to Fig.34.)

Roller guide

HL washer

Loading roller assembly

Roller guide

Chassis rivet assembly

J

Roller guide

spring

Fig.32

Boss

L side plate

Roller guide spring

Joint h'

Roller guide spring

Loading roller assembly

Joint g'

Lock arm rivet assembly

Fig.31

Roller guide spring

Roller guide spring

Lock arm rivet assembly

Lock arm rivet assembly

Joint i'

Part j'

Fig.33

Roller guide

HL washer

Roller shaft assembly

Loading roller

Roller guide spring

Fig.34

(No.MA125)1-21

Page 22

3.2.16 Removing the loading gear 5, 6 and 7

(See Figs.35 and 36)

• Prior to performing the following procedure, remove the top

cover, chassis unit, pickup unit and top plate assembly.

(1) Remove the screw K attaching the loading gear bracket.

The loading gear 6 and 7 come off the loading gear bracket.

(2) Pull out the loading gear 5.

K

Loading gear bracket

K

Loading gear 6

Loading gear 5

Loading gear 3

Fig.35

Loading gear bracket

Loading gear 5

Loading gear 6

Loading gear 7

Fig.36

1-22 (No.MA125)

Page 23

3.2.17 Removing the gears

(See Figs.37 to 40)

• Prior to performing the following procedure, remove the top

cover, chassis unit, top plate assembly and pickup unit.

• Pull out the loading gear 3. (See Fig.35.)

(1) Pull out the feed gear.

(2) Move the loading plate assembly in the direction of the ar-

row to release the L side plate from the two slots m' of the

chassis rivet assembly. (See Fig.37.)

(3) Detach the loading plate assembly upward from the chas-

sis rivet assembly while releasing the joint n'. Remove the

slide hook and loading plate spring from the loading plate

assembly.

(4) Pull out the loading gear 2 and remove the change lock le-

ver.

(5) Remove the E ring and washer attaching the changer gear

2.

(6) The changer gear 2, change gear spring and adjusting

washer come off.

(7) Remove the loading gear 1.

(8) Move the change plate rivet assembly in the direction of the

arrow to release from the three shafts of the chassis rivet

assembly upward. (See Fig.38.)

(9) Detach the loading gear plate rivet assembly from the shaft

of the chassis rivet assembly upward while releasing the

joint p'. (See Figs.38 and 40.)

(10) Pull out the loading gear 4.

Change plate

rivet assembly

Shafts

E ring

Loading plate assembly

Loading plate spring

Joint p'

Loading gear 4

Loading gear plate

rivet assembly

Shaft

Loading gear 2

Loading gear 1

Chassis rivet assembly

Change gear 2

Fig.38

Joint n'

Slide hook

Feed gear

Fig.37

Slot m'

L side plate

Loading plate assembly

Joint n'

Slot m'

Chassis rivet assembly

Chassis rivet assembly

E ring

Washer

Change gear 2

Change gear spring

Adjusting washer

Change plate

rivet assembly

Chassis rivet assembly

L side plate

Slot m'

Slot m'

Fig.39

Loading gear 1

Loading gear 2

Change lock lever

Loading gear 4

Loading gear plate rivet assembly

Fig.40

(No.MA125)1-23

Page 24

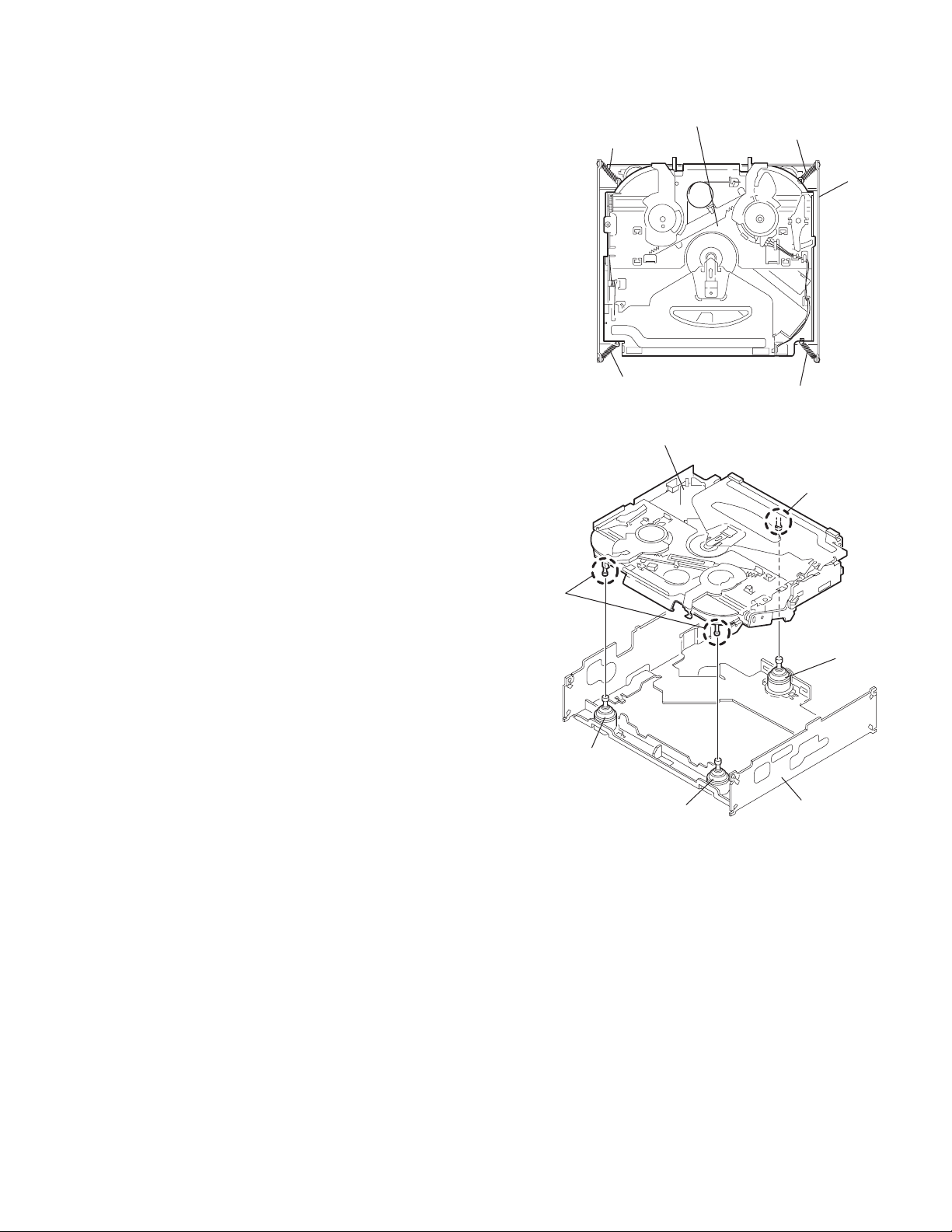

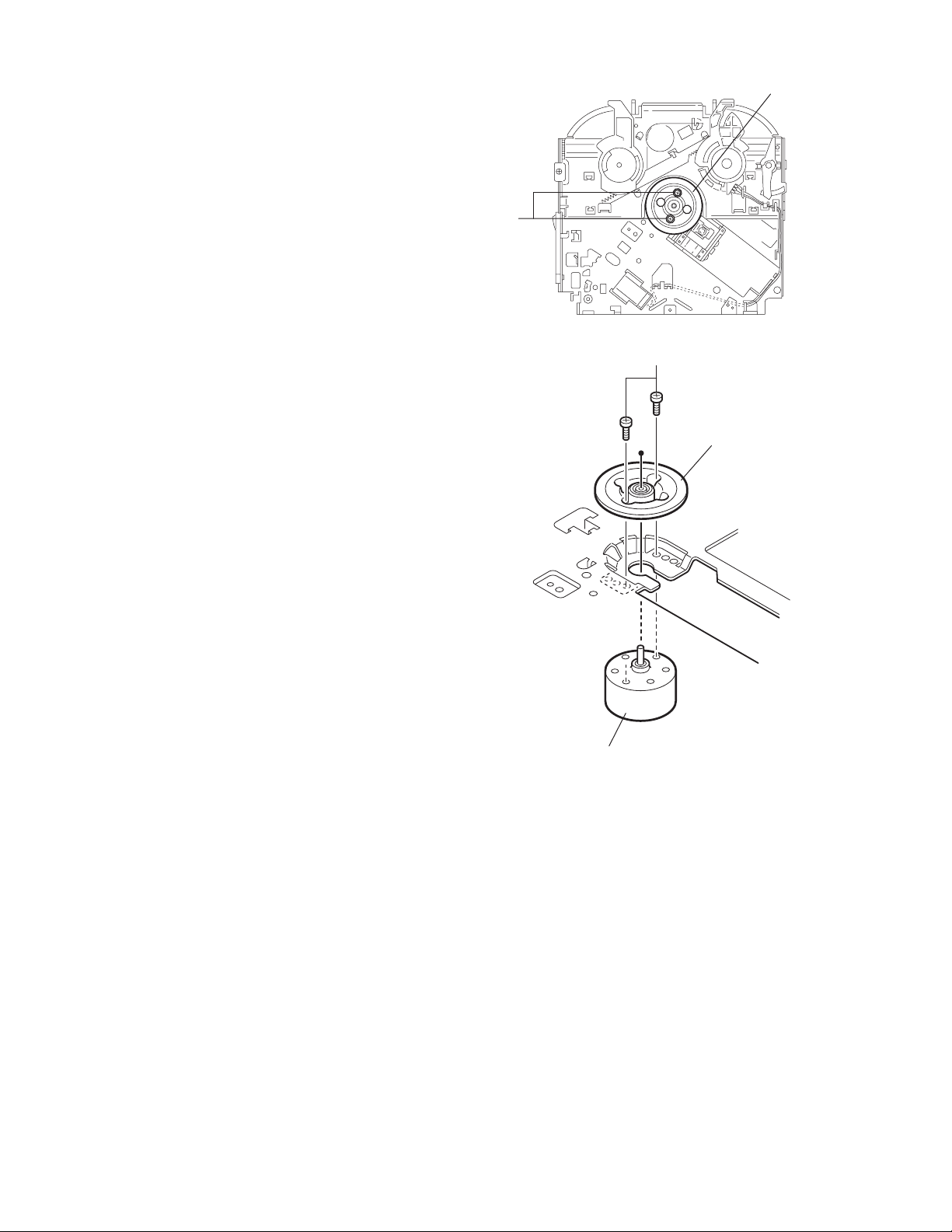

3.2.18 Removing the turn table / spindle motor

(See Figs.41 and 42)

• Prior to performing the following procedure, remove the top

cover, connector board, chassis unit and clamper assembly.

(1) Remove the two screws L attaching the spindle motor as-

sembly through the slot of the turn table on top of the body.

(2) Unsolder the wire on the connector board if necessary.

Turn table

L

Fig.41

L

Turn table

1-24 (No.MA125)

Spindle motor

Fig.42

Page 25

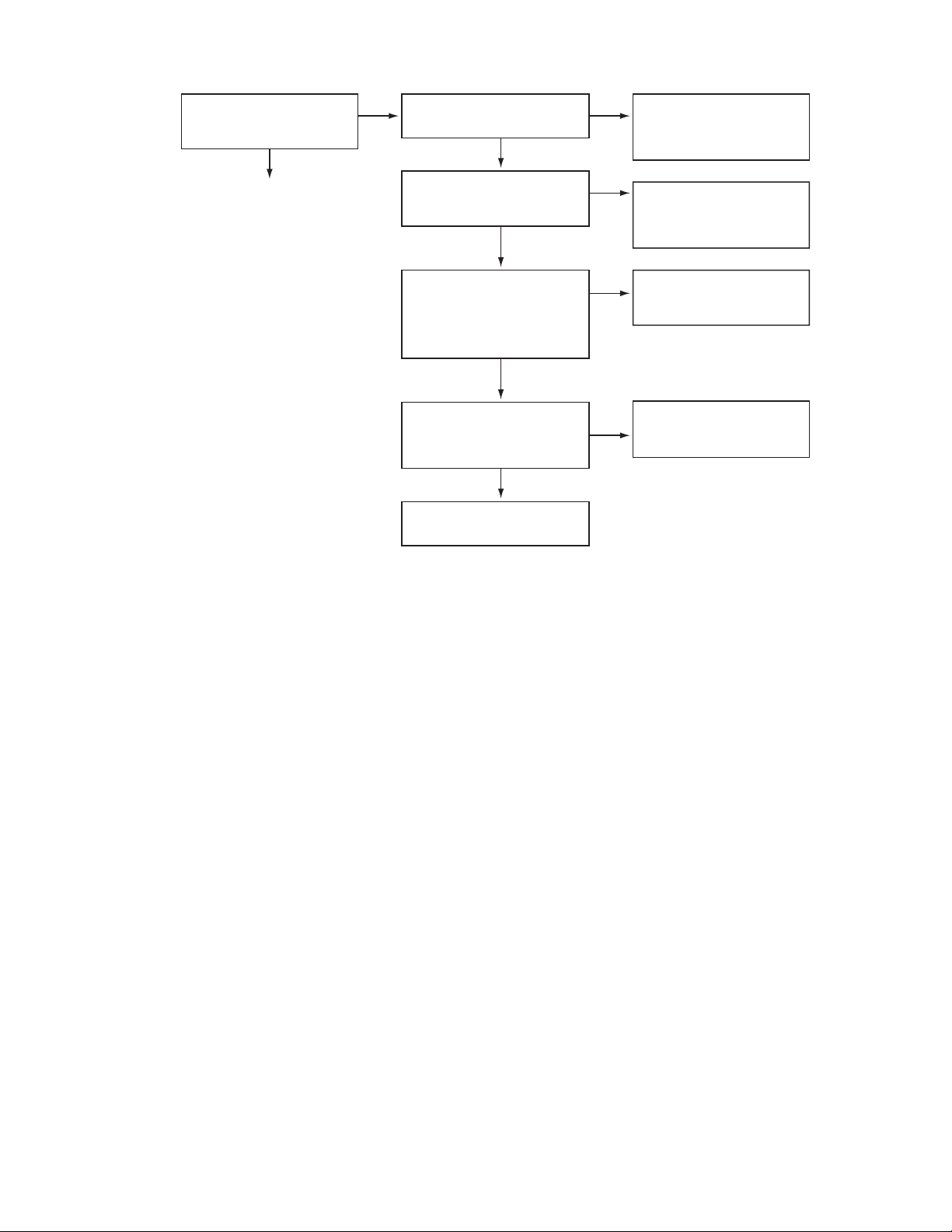

SECTION 4

ADJUSTMENT

4.1 Adjustment method

Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Electric voltmeter

(3) Digital tester

(4) Tracking offset meter

(5) Test Disc JVC :CTS-1000

(6) Extension cable for check

EXTSH002-22P × 1

Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

How to connect the extension cable for adjusting

Caution:

Be sure to attach the heat sink and rear bracket onto the power amplifier IC and regulator IC respectively, before supply the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

Standard measuring conditions

Power supply voltage DC14.4V(10.5 to 16V)

Load impedance 20KΩ(2 Speakers connection)

Output Level Line out 2.0V (Vol. MAX)

Dummy load

Exclusive dummy load should be used for AM,and FM. For FM

dummy load,there is a loss of 6dB between SSG output and

antenna input.The loss of 6dB need not be considered since

direct reading of figures are applied in this working standard.

Heat sink

Extension cable

EXTSH002-22P

Rear bracket

(No.MA125)1-25

Page 26

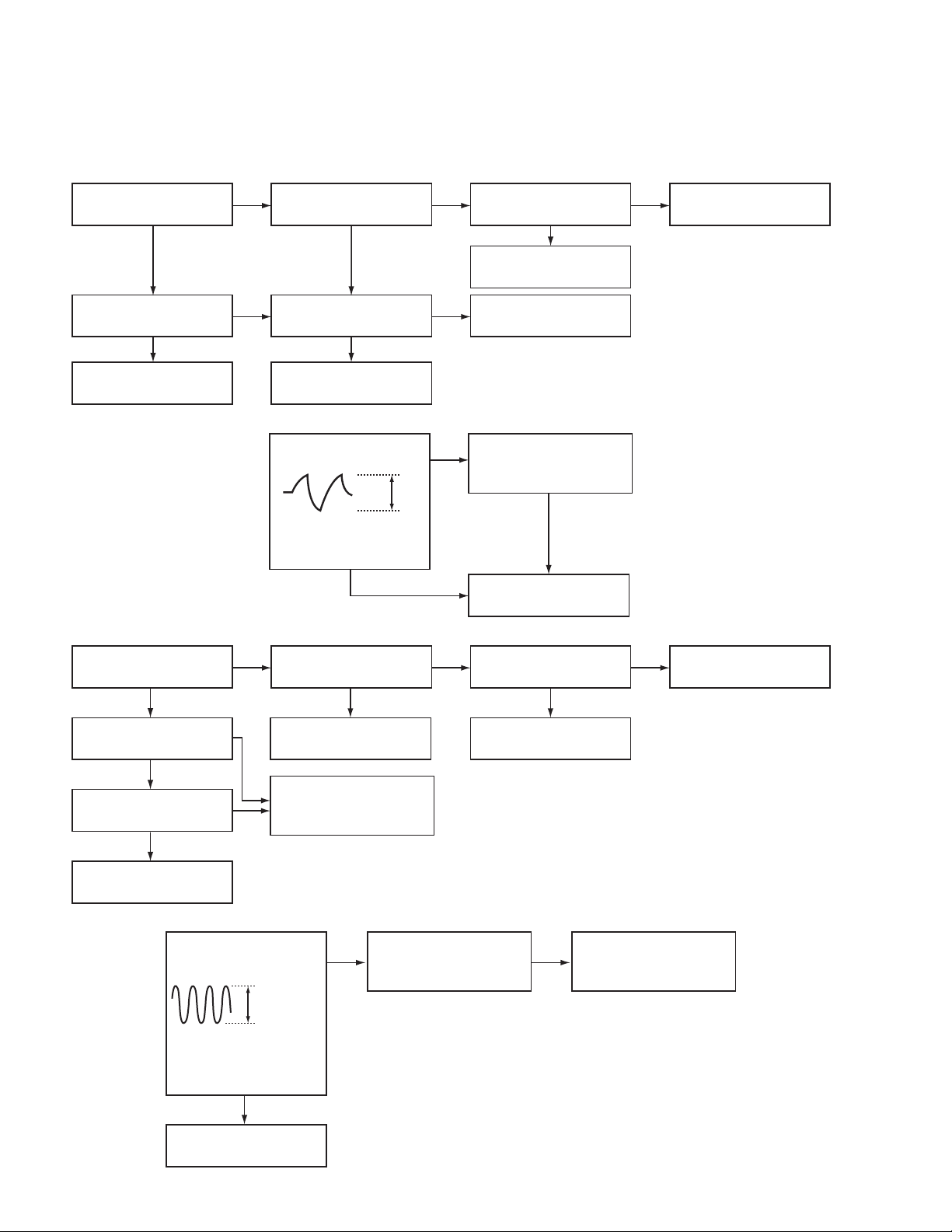

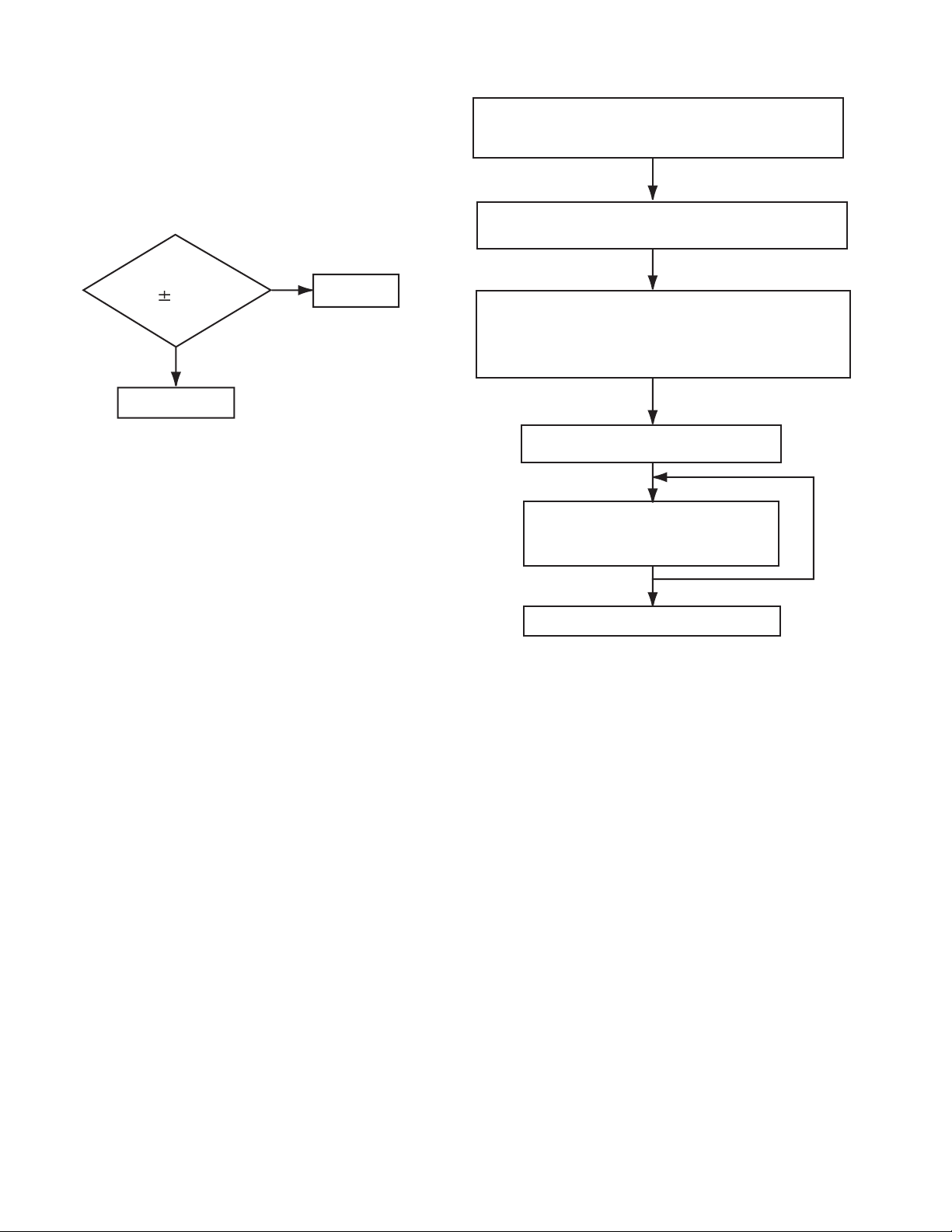

5.1 KD-G111 E,EX,EY,EU version model

5.1.1 Feed section

NO

Is the voltage output at

IC561 pin 22 5V or 0V

YES

Is the wiring for IC561

pin 22 correct?

SECTION 5

TROUBLESHOOTING

YES

NO

Is 5V present at IC541

pin 27?

Check the vicinity of

IC561.

NO

Check CD 8V.

YES

Is 4V present at both

sides of the feed motor?

YES

Check the feed motor.

5.1.2 Focus section

5.1.3 Spindle section

Is the disk rotated?

YES

Does the RF signal

appear at TP RF?

NO

Is 6V or 2V present at

IC541 pins 4 and 5?

Check IC541.

When the lens is

moving:

Does the S-search

waveform appear at

IC541 pins 8 and 9?

NO

Is 4V present between

IC541 pins 6 and 7?

Check the spindle motor

and its wiring.

NO

YES

YES

4V

YES

NO

Check the feed motor

connection wiring.

Check the circuits in

the vicinity of IC541

pins 15 and 16.

Check the pickup and

its connections.

NO

Is 4V present at IC561

pins 24 and 25?

Check the vicinity of

IC541

YES

NO

Check IC561.

YES

YES

Is the RF waveform

at TP RF distorted?

YES

Proceed to the Tracking

section

5.1.4 Tracking section

When the disc is rotated

at first:

Is the tracking error

signal output at TP TE?

1-26 (No.MA125)

NO

NO

Approx. 1.2V

YES

Check IC561.

Check the circuits in

the vicinity of IC501

or the pickup.

NO

Check the circuits in

the vicinity of IC501

pins 25 and 26.

NO

Check the pickup and

its connections.

Page 27

5.1.5 Signal processing section

Is the sound output from

both channels (L, R)?

YES

Normal

No sound from either

channel.

YES

Is 9V present at IC301 pin

31?

YES

NONO

Compare the L-ch and

R-ch to locate the

defective point.

NO

Check the vicinity of the

Q321 audio power

supply.

Is the audio signal

(including sampling output

components) output to

IC151 pins 1 and 7 during

playback?

YES

Is the audio signal output

at IC301 pins 3 and 30

during playback?

YES

Check the muting circuit.

NO

NO

Check IC151 and its

peripheral circuits.

Check IC301 and its

peripheral circuits.

(No.MA125)1-27

Page 28

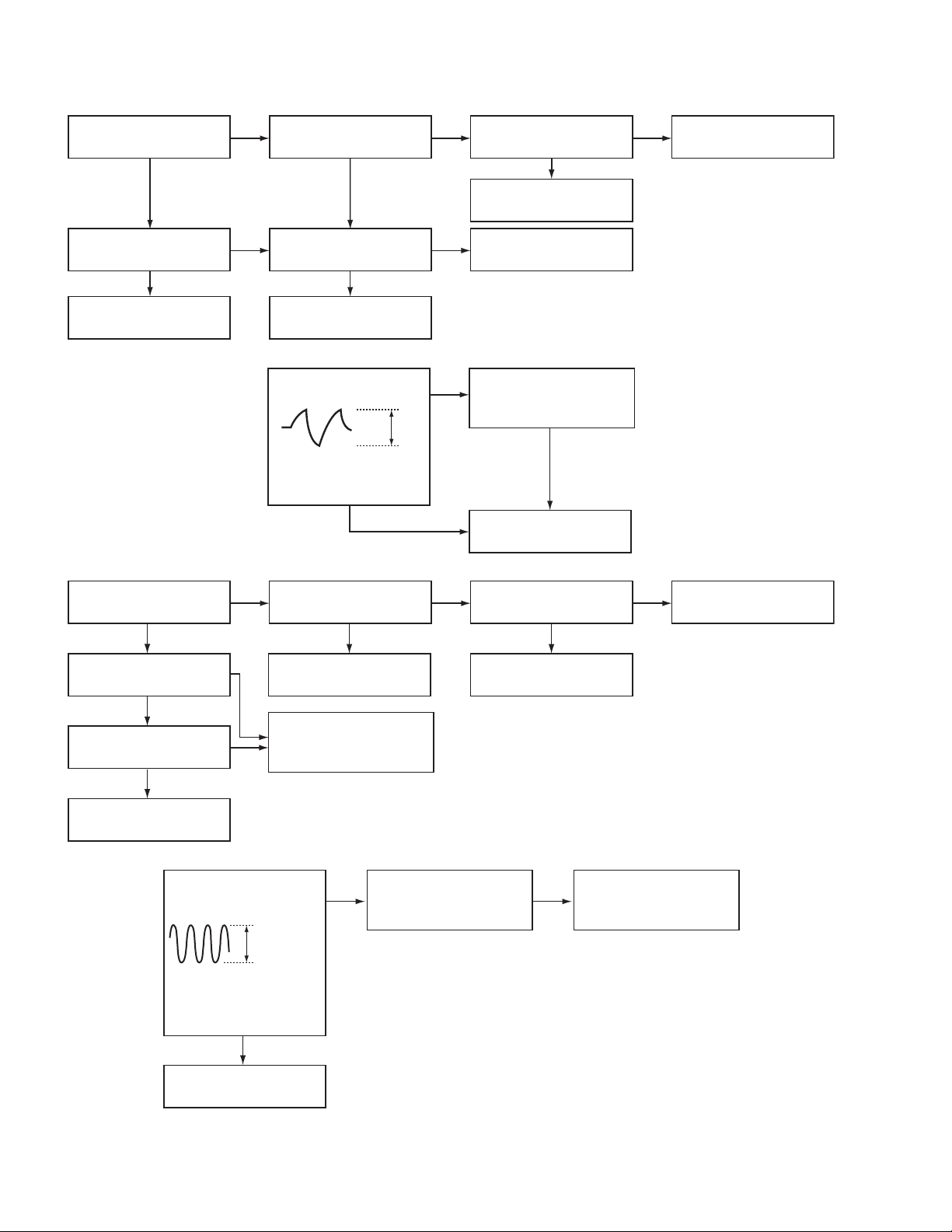

5.2 KD-G111 E2,EX2,EY2,EU2 and KD-G117 EE,EE2 version model

5.2.1 Feed section

Is the voltage output at

IC521 pin 40, 5V or 0V

YES

Is 4V present at both

sides of the feed motor?

YES

Check the feed motor.

5.2.2 Focus section

5.2.3 Spindle section

Is the disk rotated?

NO

Is the wiring for IC521

pin 40 correct?

NO

Is 6V or 2V present at

IC561 pins 4 and 5?

Check IC561.

When the lens is

moving:

Does the S-search

waveform appear at

IC561 pins 8 and 9?

NO

Is 4V present between

IC561 pins 6 and 7?

NO

NO

YES

4V

YES

Is 5V present at IC561

pins 3,12,21?

Check the vicinity of

IC521.

YES

Check the feed motor

connection wiring.

NO

Check the circuits in

the vicinity of IC561

pins 8 and 9.

Check the pickup and

its connections.

NO

Is 4V present at IC521

pin 41?

NO

Check CD 8V.

YES

YES

NO

Check IC521.

YES

Does the RF signal

appear at TP RF?

YES

Is the RF waveform

at TP RF distorted?

YES

Proceed to the Tracking

section

5.2.4 Tracking section

When the disc is rotated

at first:

Is the tracking error

signal output at TP TE?

Check the spindle motor

and its wiring.

NO

NO

Approx. 1.2V

YES

Check IC521.

YES

Check the circuits in

the vicinity of IC501

or the pickup.

NO

Check the circuits in

the vicinity of IC501

pins 2 and 7.

YES

Check the vicinity of

IC561

NO

Check the pickup and

its connections.

1-28 (No.MA125)

Page 29

5.2.5 Signal processing section

Is the sound output from

both channels (L, R)?

YES

Normal

No sound from either

channel.

YES

Is present at IC161 pin

31?

YES

NONO

Compare the L-ch and

R-ch to locate the

defective point.

NO

Check the vicinity of the

IC901 audio power

supply.

Is the audio signal

(including sampling output

components) output to

IC571 pins 1 and 7 during

playback?

YES

Is the audio signal output

at IC161 pins 3 and 30

during playback?

YES

Check the muting circuit.

NO

NO

Check IC571 and its

peripheral circuits.

Check IC161 and its

peripheral circuits.

(No.MA125)1-29

Page 30

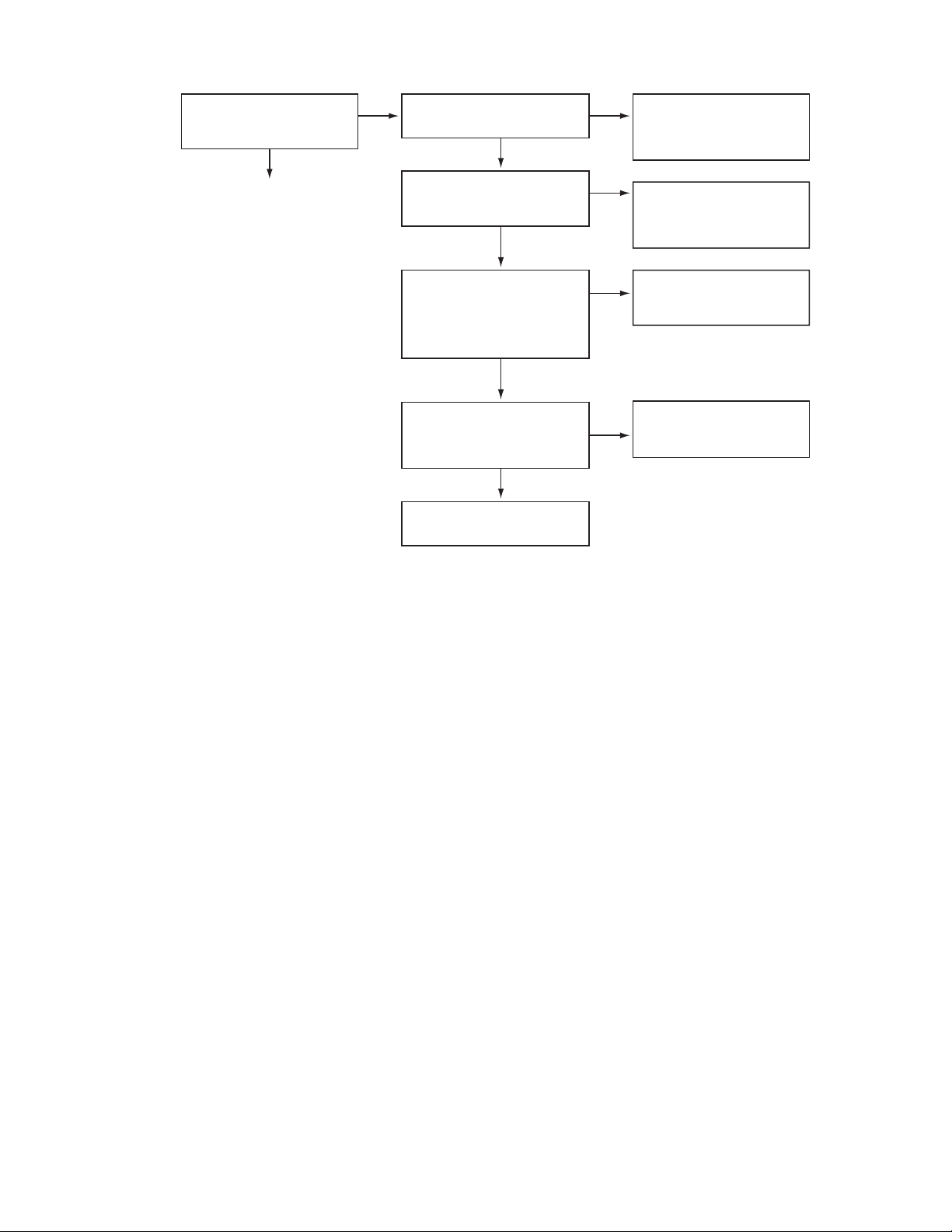

5.3 Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to clean the lens

with a alcohol soaked cotton swab.

(2) Life of the laser diode

When the life of the laser diode has expired, the following

symptoms will appear.

• The level of RF output (EFM output: amplitude of eye

pattern) will be low.

5.4 Replacement of laser pickup

Turn of the power switch and, disconnect the

power cord.

Replace the pickup with a normal one. (Refer

to "Removing the pickup unit" on the previous page.)

Is RF output

1.3 0.4Vp-p?

NO

Replace it.

YES

OK

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board

which is attached to the pickup is used to adjust the laser

power.Since this adjustment should be performed to match

the characteristics of the whole optical block, do not touch

the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup should

be replaced. If the semi-fixed resistor is adjusted while the

pickup is functioning normally, the laser pickup may be

damaged due to excessive current.

Plug the power cord in, and turn the power on.

At this time, check that the laser emits for about

seconds and the objective lens moves up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at

RF test point or

ARF test point.

Finish.

1-30 (No.MA125)

Page 31

5.5 16 PIN CORD DIAGRAM (KD-G111)

BK

8

7

6

5

4

3

2

1

RD

NC

BL/WH

WH

GN

VI

GY

B1

A1

A2

B3

A3

B4

A4

YL

NC

NC

NC

WH/BK

GN/BK

VI/BK

GY/BK

RR+

10 VI/BK

RR-

FR-

FL+

FL-

16

13

12

10

2 VI

15

14

11

9

1 GYB2 FR+

9 GY/BK

12 WH/BK

RL+

RL-

4 WH

3 GN

11 GN/BK

BK

RD

BL

Black

Red

Blue

WH White

7 RD

16 YL

5 BL/WH

8 BK

GN

Green

VI Violet

GY

YL

MEMORY

REMOTE

GND

Gray

Yellow

ACC

B4

A2

B3

A4

B1

B2

B3

B4

RR

FR

FL

RL

VI

GY

WH

GN

Rear Right

Front Right

Front Left

Rear Left

VI/BK

GY/BK

WH/BK

GN/BK

A1

A2

A3

A4

REMOTE

ACC

MEMORY

GND

B1

NC

NC

B2

BL/WH

B3

RD

B4

Remote out

ACC Line

Memory Backup Battery+

Ground

NC

YL

NC

BK

A1

A2

A3

A4

(No.MA125)1-31

Page 32

5.6 16 PIN CORD DIAGRAM (KD-G117)

10

12

14

16

NC

YL

NC

BK

NC

NC

BL/WH

RD

9

11

13

15

1

2

3

4

5

6

7

8

VI

VI/BK

GY

GY/BK

WH

WH/BK

GN

GN/BK

2

4

6

8

VI/BK

GY/BK

WH/BK

GN/BK

RR+

RR-

FR+

FR-

FL+

FL-

RL+

RL-

VI

GY

WH

GN

1

3

5

BK

RD

BL

WH

Black

Red

Blue

White

7

GN

VI

GY

YL

Green

Violet

Gray

Yellow

RR

FR

FL

RL

REMOTE

YL

12

BL/WH

13

RD

15

16

BK

Rear Right

Front Right

Front Left

Rear Left

Remote

MEMORY

REMOTE

ACC

GND

ANT

ACC

TEL

GND

MEMORY

MEMORY BACKUP

DIRECT TO BATTERY

+12Volt

ACC + 12Volt

GROUND

Auto Antenna

ACC Line

Telephone Muting

Ground

Memory Backup Battery+

1-32 (No.MA125)

Page 33

(No.MA125)1-33

Page 34

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY CAR ELECTRONICS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA125)

Printed in Japan

VPT

Page 35

CD RECEIVER

RECEPTEUR CD

KD-G111

For canceling the display demonstration, see page 7.

Pour annuler la démonstration des affichages, référez-vous à la page 7.

ENGLISH

FRANÇAIS

For installation and connections, refer to the separate manual.

Pour l’installation et les raccordements, se référer au manuel séparé.

INSTRUCTIONS

MANUEL D’INSTRUCTIONS

GET0253-003A

[EX/EU]

Page 36

Thank you for purchasing a JVC product.

Please read all instructions carefully before operation, to ensure your complete understanding and

to obtain the best possible performance from the unit.

ENGLISH

IMPORTANT FOR LASER PRODUCTS

1. CLASS 1 LASER PRODUCT

2. CAUTION: Do not open the top cover. There are no user serviceable parts inside the unit; leave

all servicing to qualified service personnel.

3. CAUTION: Visible and invisible laser radiation when open and interlock failed or defeated.

Avoid direct exposure to beam.

4. REPRODUCTION OF LABEL: CAUTION LABEL, PLACED OUTSIDE THE UNIT.

Warning:

If you need to operate the receiver while

driving, be sure to look ahead carefully or

you may be involved in a traffic accident.

How to forcibly eject a disc

If a disc cannot be recognized by the

receiver or cannot be ejected, ejects the disc

as follows.

How to reset your unit

• If this does not work, try to reset your

receiver.

• This will reset the microcomputer. Your

preset adjustments will also be erased.

• If a disc is loaded, it will eject. Be careful

not to drop the disc.

Note: Only for [EX] model users in UK and European countries

For security reasons, a numbered ID card is provided with this receiver, and the same ID number is

imprinted on the receiver’s chassis. Keep the card in a safe place, as it will help the authorities to

identify your unit if stolen.

2

• Be careful not to drop the disc when it

ejects.

Page 37

Contents

How to reset your unit ........................... 2

How to forcibly eject a disc................... 2

How to read this manual........................ 4

How to use the MODE button ............... 4

Control panel — KD-G111 ......... 5

Parts identification................................. 5

Getting started....................... 6

Basic operations........................... 6

Canceling the display demonstrations ... 7

Setting the clock .................................... 7

Radio operations ................... 8

Listening to the radio........................... 8

Storing stations in memory.................... 9

Listening to a preset station................... 9

Disc operations ...................... 10

Playing a disc ..................................... 10

Selecting the playback modes................ 11

Sound adjustments ................ 12

Selecting preset sound modes

(C-EQ: custom equalizer) .................. 12

Adjusting the sound............................... 13

ENGLISH

General settings — PSM ......... 14

Basic procedure ..................................... 14

Detaching the control panel.... 15

Maintenance .......................... 16

More about this receiver ........ 17

Troubleshooting ..................... 18

Specifications ......................... 19

*For safety....

• Do not raise the volume level too much, as

this will block outside sounds, making driving

dangerous.

• Stop the car before performing any

complicated operations.

*Temperature inside the car....

If you have parked the car for a long time in

hot or cold weather, wait until the temperature

in the car becomes normal before operating the

unit.

3

Page 38

How to read this manual

The following methods are used to made the

explanations simple and easy-to-understand:

• Some related tips and notes are explained in

ENGLISH

“More about this receiver” (see page 17).

• Button operations are mainly explained with

the illustrations as follows:

Press briefly.

Press repeatedly.

Press either one.

Press and hold until

your desired response

begins.

How to use the MODE button

If you press MODE, the receiver goes into

functions mode, then the number buttons work

as different function buttons.

Ex.: When number button 2 works as

MO (monaural) button.

Time countdown indicator

To use these buttons for original functions

again after pressing MODE, wait for

5 seconds without pressing any of these buttons

until the functions mode is cleared.

• Pressing MODE again also clears the

functions mode.

Press and hold both

buttons at the same

time.

4

Page 39

Control panel — KD-G111

Parts identification

Display window

1 +/– buttons

2 DISP (display) button

3 Loading slot

4 Display window

5 MODE button

6 0 (eject) button

7

¢/4 buttons

8

9 SEL (select) button

p MO (monaural) button

q SSM (Strong-station Sequential Memory)

w CD button

e FM/AM button

r RPT (repeat) button

t RND (random) button

y EQ (equalizer) button

u

i Number buttons

(standby/on/attenuator) button

button

(control panel release) button

Display window

o Tuner reception indicators

MO (monaural), ST (stereo)

; CD indicator

a RND

s RPT (repeat) indicator

d LOUD (loudness) indicator

f EQ (equalizer) indicator

g Sound mode (C-EQ: custom equalizer)

indicators

ROCK, CLASSIC, POPS, HIP HOP, JAZZ,

USER

•

h Main display

j Source display

Volume level indicator

(disc random) indicator

also works as the time countdown

indicator.

ENGLISH

5

Page 40

Getting started

ENGLISH

Basic operations

~

Ÿ

You cannot select “CD” as the playback

source if there is no disc in the loading

slot.

!

Volume level appears.

Volume level indicator

To drop the volume in a moment (ATT)

To restore the sound, press it

again.

To turn off the power

Caution on volume setting:

Discs produce very little noise compared

with other sources. Lower the volume

before playing a disc to avoid damaging

the speakers by the sudden increase of the

output level.

⁄ Adjust the sound as you want.

(See pages 12 and 13.)

6

Page 41

Canceling the display

demonstrations

If no operations are done for about 20 seconds,

display demonstration starts.

[Initial: DEMO ON]—see page 14.

1

2

3

Setting the clock

1

2

Set the hour and minute.

1 Select “CLOCK H” (hour), then

adjust the hour.

2 Select “CLOCK M” (minute),

then adjust the minute.

3 Finish the procedure.

To check the current clock time when the

power is turned off

ENGLISH

Finish the procedure.

4

To activate the display demonstration

In step 3 above...

7

Page 42

Radio operations

Listening to the radio

ENGLISH

~

Lights up when receiving an FM stereo

broadcast with sufficient signal strength.

Selected band appears.

Ÿ Start searching for a station.

2 Select the desired station frequencies.

When an FM stereo broadcast is hard to

receive

1

When a station is received, searching

stops.

To stop searching, press the same

button again.

To tune in to a station manually

In step Ÿ above...

1

8

2

Lights up when monaural mode is activated.

Reception improves, but stereo effect will

be lost.

To restore the stereo effect, repeat the same

procedure so that the MO indicator goes off.

Page 43

Storing stations in memory

You can preset six stations for each band.

FM station automatic presetting —

SSM (Strong-station Sequential

Memory)

Select the FM band (FM1 – FM3)

1

you want to store into.

2

2

ENGLISH

3

Preset number flashes for a while.

3

“SSM” flashes, then disappears when

automatic presetting is over.

Local FM stations with the strongest signals are

searched and stored automatically in the FM

band.

Manual presetting

Ex.: Storing FM station of 92.5 MHz into the

preset number 4 of the FM1 band.

1

Listening to a preset station

1

2 Select the preset station (1 – 6) you

want.

To check the current clock time while

listening to an FM or AM station

9

Page 44

Disc operations

ENGLISH

Playing a disc

All tracks will be played repeatedly until you

stop playback.

Total playing time of

the inserted disc

Elapsed playing

time

Total track number

of the inserted disc

Current track

number

To stop play and eject the disc

To fast-forward or reverse the track

Fast-forwards.

Reverses.

To go to the next or previous tracks

To the following

tracks.

To the beginning of the current track, then

the previous tracks.

To go to a particular track directly

To select a number from 01 – 06:

10

To select a number from 07 – 12:

Page 45

Prohibiting disc ejection

You can lock a disc in the loading slot.

To cancel the prohibition, repeat the same

procedure.

To check the current clock time while

listening to a disc

Selecting the playback modes

You can use only one of the following playback modes at a time.

1

2 Select your desired playback mode.

ENGLISH

Repeat play

Ex.: When “TRK RPT” is selected

Random play

Ex.: When “DISC RND” is selected

Mode Plays repeatedly

TRK RPT: The current track.

• RPT lights up.

RPT OFF: Cancels repeat play.

Mode Plays at random

DISC RND: All tracks of the current disc.

• RND

RND OFF: Cancels random play.

lights up.

11

Page 46

Sound adjustments

Selecting preset sound modes (C-EQ: custom equalizer)

ENGLISH

You can select a preset sound mode suitable to

the music genre.

~

Ex.: When “ROCK” is selected

Indication pattern for each sound mode:

Indication For:

USER (Flat sound) 00 00 OFF

ROCK Rock or disco

music

CLASSIC Classical

music

POPS Light music +04 +01 OFF

HIP HOP Funk or rap

music

JAZZ Jazz music +02 +03 OFF

1

*

BAS: Bass

2

*

TRE: Treble

3

*

LOUD: Loudness

1

TRE

*

2

LOUD

*

BAS

+03 +01 ON

+01 –02 OFF

+02 00 ON

Preset values

3

*

12

Page 47

Adjusting the sound

You can adjust the sound characteristics to your

preference.

1

Ex.: When “TRE” is selected

2

Indication pattern changes as

you adjust the level.

Indication To do: Range

BAS*1

(bass)

TRE*

(treble)

FAD*

(fader)

BAL

(balance)

LOUD*

(loudness)

VOL*3

(volume)

Adjust the bass. –06 (min.)

1

Adjust the treble. –06 (min.)

2

Adjust the front

and rear speaker

balance.

Adjust the left

and right speaker

balance.

1

Boost low and

high frequencies

to produce a wellbalanced sound at

low volume level.

Adjust the

volume.

to

+06 (max.)

to

+06 (max.)

R06 (Rear

only)

to

F06 (Front

only)

L06 (Left

only)

to

R06 (Right

only)

LOUD ON

LOUD OFF

00 (min.) to

30 or 50

(max.)*

ENGLISH

J

4

*1 When you adjust the bass, treble, or

loudness, the adjustment you have made is

stored for the currently selected sound mode

(C-EQ) including “USER.”

2

*

If you are using a two-speaker system, set

the fader level to “00.”

3

*

Normally the +/– buttons work as the

volume control. So you do not have to select

“VOL” to adjust the volume level.

4

*

Depending on the amplifier gain control

setting. (See page 14 for details.)

13

Page 48

General settings — PSM

Basic procedure

3 Adjust the PSM item selected.

You can change PSM (Preferred Setting Mode)

items listed on the table that follows.

ENGLISH

1

4 Repeat steps 2 and 3 to adjust the

other PSM items if necessary.

Select a PSM item.

2

Ex.: When you select “AMP GAIN”

Indications Selectable settings, [reference page]

5 Finish the procedure.

DEMO

Display demonstration

CLOCK H

Hour adjustment

CLOCK M

Minute adjustment

AMP GAIN

Amplifier gain control

14

DEMO ON: [Initial]; Display demonstration will be activated

automatically if no operation is done for about

20 seconds, [7].

DEMO OFF: Cancels.

0 – 23, [7]

[Initial: 0 (0:00)]

00 – 59, [7]

[Initial: 00 (0:00)]

You can change the maximum volume level of this receiver.

LOW PWR: VOL 00 – VOL 30 (Select this if the maximum power

of the speaker is less than 45 W to prevent them from

damaging the speaker.)

HIGH PWR: [Initial]; VOL 00 – VOL 50

Page 49

Detaching the control panel

When detaching or attaching the control panel,

be careful not to damage the connectors on

the back of the control panel and on the panel

holder.

Detaching the control panel

Before detaching the control panel, be sure to

turn off the power.

Attaching the control panel

ENGLISH

15

Page 50

Maintenance

How to clean the connectors

Frequent detachment will deteriorate the

connectors.

To minimize this possibility, periodically wipe

ENGLISH

the connectors with a cotton swab or cloth

moistened with alcohol, being careful not to

damage the connectors.

Connector

Moisture condensation

Moisture may condense on the lens inside the

CD player in the following cases:

• After starting the heater in the car.

• If it becomes very humid inside the car.

Should this occur, the CD player may

malfunction. In this case, eject the disc and

leave the receiver turned on for a few hours

until the moisture evaporates.

To keep discs clean

A dirty disc may not play correctly.

If a disc does become dirty, wipe

it with a soft cloth in a straight line

from center to edge.

• Do not use any solvent (for

example, conventional record cleaner, spray,

thinner, benzine, etc.) to clean discs.

To play new discs

New discs may have some rough

spots around the inner and outer

edges. If such a disc is used, this

receiver may reject the disc.

To remove these rough spots, rub the edges

with a pencil or ball-point pen, etc.

How to handle discs

When removing a disc from

its case, press down the center

holder of the case and lift the

disc out, holding it by the

edges.

• Always hold the disc by the edges. Do not

touch its recording surface.

When storing a disc into its case, gently insert

the disc around the center holder (with the

printed surface facing up).

• Make sure to store discs into the cases after

use.

Do not use the following discs:

Wrap disc

16

Center holder

Sticker

Sticker

residue

Disc

Stick-on

label

Page 51

More about this receiver

Basic operations

Turning off the power

• If you turn off the power while listening to a

disc, disc play will start from where playback

has been stopped previously, next time you

turn on the power.

Tuner operations

Storing stations in memory

• During SSM search...

– All previously stored stations are erased and

stations are stored newly.

– Received stations are preset in No. 1 (lowest

frequency) to No. 6 (highest frequency).

– When SSM is over, the station stored in

No. 1 will be automatically tuned in.

• When storing a station manually, a previously

preset station is erased when a new station is

stored in the same preset number.

Disc operations

General

• This receiver has been designed to reproduce

CDs, and CD-Rs (Recordable)/CD-RWs

(Rewritable) in audio CD (CD-DA) format.

• When a disc has been loaded, selecting “CD”

for the playback source starts disc play.

Inserting a disc

• When a disc is inserted upside down, the disc

automatically ejects.

• Do not insert 8 cm discs (single CD) and

unusual shape discs (heart, flower, etc) into

the loading slot.

• Some CD-Rs or CD-RWs may not play

back on this receiver because of their disc

characteristics, and for the following causes:

– Discs are dirty or scratched.

– Moisture condensation occurs on the lens

inside the receiver.

– The pickup lens inside the receiver is dirty.

– CD-R or CD-RW on which the files are

written with “Packet Write” method.

– There are improper recording conditions

(missing data, etc.) or media conditions

(stain, scratch, warp, etc.).

• CD-RWs may require a longer readout time

since the reflectance of CD-RWs is lower

than that of regular CDs.

• Do not use the following CD-Rs or

CD-RWs:

– Discs with stickers, labels, or protective seal

stuck to the surface.

– Discs on which labels can be directly

printed by an ink jet printer.

Using these discs under high temperatures

or high humidity may cause malfunctions or

damage to discs.

Changing the source

• If you change the source, playback also stops

(without ejecting the disc).

Next time you select “CD” for the playback

source, disc play starts from where it has been

stopped previously.

Ejecting a disc

• If the ejected disc is not removed within

15 seconds, the disc is automatically inserted

again into the loading slot to prevent it from

dust. (Disc will not play this time.)

ENGLISH

Playing a CD-R or CD-RW

• Use only “finalized” CD-Rs or CD-RWs.

• This receiver can play back multi-session

discs; however, unclosed sessions will be

skipped while playing.

General settings—PSM

• If you change the “AMP GAIN” setting from

“HIGH PWR” to “LOW PWR” while the

volume level is set higher than “VOL 30,” the

receiver automatically changes the volume

level to “VOL 30.”

17

Page 52

Troubleshooting

What appears to be trouble is not always serious. Check the following points before calling a service

center.

ENGLISH

• Sound cannot be heard

General

• The receiver does not

• SSM automatic presetting

• Static noise while listening

FM/AM

• Disc automatically ejects. Disc is inserted upside

• CD-R/CD-RW cannot be

• Tracks on the CD-R/

• Disc can be neither played

Symptoms Causes Remedies

from the speakers.

work at all.

does not work.

to the radio.

played back.

CD-RW cannot be

skipped.

back nor ejected.

The volume level is set to

the minimum level.

Connections are incorrect. Check the cords and

The built-in microcomputer

may have functioned

incorrectly due to noise, etc.

Signals are too weak. Store stations manually.

The aerial is not connected

firmly.

down.

CD-R/CD-RW is not

finalized.

Disc is locked. Unlock the disc (see page

Adjust it to the optimum

level.

connections.

Reset the receiver (see page

2).

Connect the aerial firmly.

Insert the disc correctly.

• Insert a finalized CD-R/

CD-RW.

• Finalize the CD-R/

CD-RW with the

component which you

used for recording.

11).

18

Disc playback

• Disc sound is sometimes

interrupted.

• “NO DISC” appears on

the display.

The CD player may have

functioned incorrectly.

You are driving on rough

roads.

Disc is scratched. Change the disc.

Connections are incorrect. Check the cords and

No disc in the loading slot. Insert a disc into the loading

Disc is inserted incorrectly. Insert the disc correctly.

Eject the disc forcibly (see

page 2).

Stop playback while driving

on rough roads.

connections.

slot.

Page 53

Specifications

AUDIO AMPLIFIER SECTION

Maximum Power Output:

Front: 45 W per channel

Rear: 45 W per channel

Continuous Power Output (RMS):

Front: 17 W per channel into 4 Ω, 40 Hz

to 20 000 Hz at no more than 0.8%

total harmonic distortion.

Rear: 17 W per channel into 4 Ω, 40 Hz

to 20 000 Hz at no more than 0.8%

total harmonic distortion.

Load Impedance: 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range:

Bass: ±10 dB at 100 Hz

Treble: ±10 dB at 10 kHz

Frequency Response: 40 Hz to 20 000 Hz

Signal-to-Noise Ratio: 70 dB

Line-Out Level/Impedance:

2.0 V/20 kΩ load (full scale)

Output Impedance: 1 kΩ

TUNER SECTION

Frequency Range:

FM: 87.5 MHz to 108.0 MHz

AM: (MW) 522 kHz to 1 620 kHz

(LW) 144 kHz to 279 kHz

CD PLAYER SECTION

Type: Compact disc player

Signal Detection System: Non-contact optical

pickup (semiconductor laser)

Number of channels: 2 channels (stereo)

Frequency Response: 5 Hz to 20 000 Hz

Dynamic Range: 96 dB

Signal-to-Noise Ratio: 98 dB

Wow and Flutter: Less than measurable limit

GENERAL

Power Requirement:

Operating Voltage:

DC 14.4 V (11 V to 16 V allowance)

Grounding System: Negative ground

Allowable Operating Temperature:

0°C to +40°C

Dimensions (W × H × D):

Installation Size (approx.):

182 mm × 52 mm × 150 mm

Panel Size (approx.):

188 mm × 58 mm × 11 mm

Mass (approx.):

1.3 kg (excluding accessories)

ENGLISH

[FM Tuner]

Usable Sensitivity: 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity:

16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz): 65 dB

Frequency Response: 40 Hz to 15 000 Hz

Stereo Separation: 30 dB

Capture Ratio: 1.5 dB

[MW Tuner]

Sensitivity: 20 µV

Selectivity: 35 dB

[LW Tuner]

Sensitivity: 50 µV

Design and specifications are subject to change

without notice.

19

Page 54

Having TROUBLE with operation?

Please reset your unit

Refer to page of How to reset your unit

Vous avez des PROBLÈMES de fonctionnement?

Réinitialisez votre appareil

Référez-vous à la page intitulée Comment réinitialiser votre appareil

EN, FR

© 2004 Victor Company of Japan, Limited

1004DTSMDTJEIN

Page 55

KD-G111

Installation/Connection Manual

Manuel d’installation/raccordement

GET0253-010A

[EX/EU]

ENGLISH

This receiver is designed to operate on 12 V DC, NEGATIVE ground electrical systems. If

your vehicle does not have this system, a voltage inverter is required, which can be purchased

at JVC IN-CAR ENTERTAINMENT dealers.

Parts list for installation and connection

The following parts are provided for this receiver.

After checking them, please set them correctly.

A / B

Hard case/Control panel

Etui de transport/Panneau de

commande

F

Washer (ø5)

Rondelle (ø5)

G

Lock nut (M5)

Ecrou d’arrêt (M5)

C

Sleeve

Manchon

H

Mounting bolt (M5 x 20 mm)

Boulon de montage (M5 x 20 mm)

INSTALLATION (IN-DASH MOUNTING)

The following illustration shows a typical installation. If you have any questions or require

information regarding installation kits, consult your JVC IN-CAR ENTERTAINMENT dealer or a

company supplying kits.

• If you are not sure how to install this receiver correctly, have it installed by a qualified

technician.

1004DTSMDTJEIN

EN, FR

FRANÇAIS

Cet appareil est conçu pour fonctionner sur des sources de courant continu de 12 V à masse

NEGATIVE. Si votre véhicule n’offre pas ce type d’alimentation, il vous faut un convertisseur de tension,

que vous pouvez acheter chez un revendeur d’autoradios JVC.

Liste des pièces pour l’installation et raccordement

Les pièces suivantes sont fournies avec cet appareil.

Après vérification, veuillez les placer correctement.

D

Trim plate

Plaque d’assemblage

I

Rubber cushion

Amortisseur en caoutchouc

E

Power cord

Cordon d’alimentation

J

Handles

Poignées

INSTALLATION (MONTAGE DANS LE TABLEAU DE BORD)

L’illustration suivante est un exemple d’installation typique. Si vous avez des questions ou avez besoin

d’information sur des kits d’installation, consulter votre revendeur d’autoradios JVC ou une compagnie

d’approvisionnement.

• Si l’on n’est pas sûr de pouvoir installer correctement cet appareil, le faire installer par un technicien

qualifié.

*1 When you stand the receiver, be careful

not to damage the fuse on the rear.

1

*

Lorsque vous mettez l’appareil à la

verticale, faire attention de ne pas

endommager le fusible situé sur l’arrière.

Removing the receiver / Retrait de l’appareil

Before removing the receiver, release the rear section.

Avant de retirer l’appareil, libérer la section arrière.

Insert the two handles, then

pull them as illustrated so

that the receiver can be

removed.

Insérez les deux poignées, puis

tirez de la façon illustrée de

façon à retirer l’appareil.

Do the required electrical connections.

Réalisez les connexions électriques.

When using the optional stay / Lors

de l’utilisation du hauban en option

Stay (option)

Fire wall

Cloison

Dashboard

Tableau de

bord

Install the receiver at an

angle of less than 30˚.

Installez l’appareil avec un

angle de moins de 30˚.

Hauban (en option)

Screw (option)

Vis (en option)

Bend the appropriate tabs to hold the

sleeve firmly in place.

Tordez les languettes appropriées pour

maintenir le manchon en place.

When installing the receiver without using the sleeve / Lors de

l’installation de l’appareil scans utiliser de manchon

In a Toyota for example, first remove the car radio and install the receiver in its

place.

Par exemple dans une Toyota, retirer d’abord l’autoradio et installer l’appareil à la

place.

Flat type screws

(M5 x 8 mm)*

Vis à tête plate

(M5 x 8 mm)

Note : When installing the receiver on the mounting bracket, make

Remarque : Lors de l’installation de l’appareil sur le support de montage,

Bracket*

*

Support*

Pocket

Poche

sure to use the 8 mm-long screws. If longer screws are

used, they could damage the receiver.

s’assurer d’utiliser des vis d’une longueur de 8 mm. Si des vis plus

longues sont utilisées, elles peuvent endommager l’appareil.

Bracket*

Support*

Not included with this

*

receiver.

*

Non fourni avec cet appareil.

Flat type screws

(M5 x 8 mm)*

Vis à tête plate

(M5 x 8 mm)

*

PRECAUTIONS on power supply and speaker

connections:

• DO NOT connect the speaker leads of the power cord to

the car battery; otherwise, the receiver will be seriously

damaged.

• BEFORE connecting the speaker leads of the power cord to the

speakers, check the speaker wiring in your car.

PRECAUTIONS sur l’alimentation et la connexion

des enceintes:

• NE CONNECTEZ PAS les fils d’enceintes du cordon

d’alimentation à la batterie; sinon, l’appareil serait

sérieusement endommagé.

• AVANT de connecter les fils d’enceintes du cordon d’alimentation aux

enceintes, vérifiez le câblage des enceintes de votre voiture.

TROUBLESHOOTING

• The fuse blows.

* Are the red and black leads connected correctly?

• Power cannot be turned on.

* Is the yellow lead connected?

• No sound from the speakers.

* Is the speaker output lead short-circuited?

• Sound is distorted.

* Is the speaker output lead grounded?

* Are the “–” terminals of L and R speakers grounded in common?

• Noise interfere with sounds.

* Is the rear ground terminal connected to the car’s chassis using shorter and thicker cords?

• Receiver becomes hot.

* Is the speaker output lead grounded?

* Are the “–” terminals of L and R speakers grounded in common?

• This receiver does not work at all.

* Have you reset your receiver?

EN CAS DE DIFFICULTES

• Le fusible saute.

* Les fils rouge et noir sont-ils racordés correctement?

• L’appareil ne peut pas être mise sous tension.

* Le fil jaune est-elle raccordée?

• Pas de son des enceintes.

* Le fil de sortie d’enceinte est-il court-circuité?

• Le son est déformé.

* Le fil de sortie d’enceinte est-il à la masse?

* Les bornes “–” des enceintes gauche et droit sont-elles mises ensemble à la masse?

• Interférence avec les sons.

* La prise arrière de mise à la terre est-elle connectée au châssis de la voiture avec un cordon court et

épais?

• L’appareil devient chaud.

* Le fil de sortie d’enceinte est-il à la masse?

* Les bornes “–” des enceintes gauche et droit sont-elles mises ensemble à la masse?

• Cet appareil ne fonctionne pas du tout.

* Avez-vous réinitialisé votre appareil?

1

Page 56

ENGLISH FRANÇAIS

ELECTRICAL CONNECTIONS

To prevent short circuits, we recommend that you disconnect the battery’s negative terminal and

make all electrical connections before installing the receiver.

• Be sure to ground this receiver to the car’s chassis again after installation.

Notes:

• Replace the fuse with one of the specified rating. If the fuse blows frequently, consult your JVC

IN-CAR ENTERTAINMENT dealer.

• It is recommended to connect to the speakers with maximum power of more than 45 W (both

at the rear and at the front, with an impedance of 4 Ω to 8 Ω). If the maximum power is less

than 45 W, change “AMP GAIN” setting to prevent the speakers

from being damaged (see page 14 of the INSTRUCTIONS).

• To prevent short-circuit, cover the terminals of the UNUSED

leads with insulating tape.

• The heat sink becomes very hot after use. Be

careful not to touch it when removing this receiver.

If your car is equipped with the ISO connector / Si

A

votre voiture est équippée d’un connecteur ISO

• Connect the ISO connectors as illustrated.

• Connectez les connecteurs ISO comme montré sur l’illustration.

From the car body

De la carrosserie de la

voiture

ISO connector of the supplied power cord

Connecteur ISO pour le cordon d’alimentation

fourni

View from the lead side

Vue à partir du côté des fils

Dissipateur de chaleur

Heat sink

For some VW/Audi or Opel (Vauxhall) automobile / Pour certaine voiture VW/Audi ou Opel (Vauxhall)

You may need to modify the wiring of the supplied power cord as illustrated.

• Contact your authorized car dealer before installing this receiver.

Vous aurrez peut-être besoin de modifier le câblage du cordon d’alimentation fourni comme montré sur l’illustration.

• Contactez votre revendeur automobile autorisé avant d’installer l’appareil.

Original wiring / Câblage original

ISO connector

Connecteur ISO

RACCORDEMENTS ELECTRIQUES

Pour éviter tout court-circuit, nous vous recommandons de débrancher la borne négative de la batterie et

d’effectuer tous les raccordements électriques avant d’installer l’appareil.

• Assurez- vous de raccorder de nouveau la mise à la masse de cet appareil au châssis

de la voiture après l’installation.

Remarques:

• Remplacer le fusible par un de la valeur précisée. Si le fusible saute souvent, consulter votre revendeur

d’autoradios JVC.

• Il est recommandé de connecter des enceintes avec une puissance de plus de 45 W (les enceintes arrière

et les enceintes avant, avec une impédance comprise entre 4 Ω et 8 Ω). Si la puissance maximum est

inférieure à 45 W, changez “AMP GAIN” pour éviter d’endommager vos enceintes (voir page 14 du

MANUEL D’INSTRUCTIONS).

• Pour éviter les court-circuits, couvrir les bornes des fils qui ne sont PAS UTILISÉS avec de la bande

isolante.

• Le dissipateur de chaleur devient très chaud après usage. Faire attention de ne pas le toucher en retirant

cet appareil.

Modified wiring 1 / Câblage modifié 1

Modified wiring 2 / Câblage modifié 2

Use modified wiring 2 if the

receiver does not turn on.

Utilisez le câblage modifié 2 si l’appareil

ne se met pas sous tension.

Y: Yellow

Jaune

R: Red

Rouge

Connections without using the ISO connectors / Connexions sans l’utilisation des connecteurs ISO

B

Before connecting: Check the wiring in the vehicle carefully. Incorrect connection may cause

serious damage to this receiver.

The leads of the power cord and those of the connector from the car body may be different in

color.

1 Cut the ISO connector.

2 Connect the colored leads of the power cord in the order specified in the illustration below.

3 Connect the aerial cord.

4 Finally connect the wiring harness to the receiver.

Rear ground terminal

Borne arrière de masse

15 A fuse

Fusible 15 A

Aerial terminal

Borne de l’antenne

*2 Before checking the operation of this receiver

prior to installation, this lead must be connected,

otherwise power cannot be turned on.

*2 Pour vérifier le fonctionnement de cet appareil avant

installation, ce fil doit être raccordé, sinon l’appareil

Line out (see diagram )

Sortie de ligne

(voir le diagramme

)

Black

Noir

2

Yellow*

2

Jaune*

Red

Rouge

Blue with white stripe

Bleu avec bande blanche