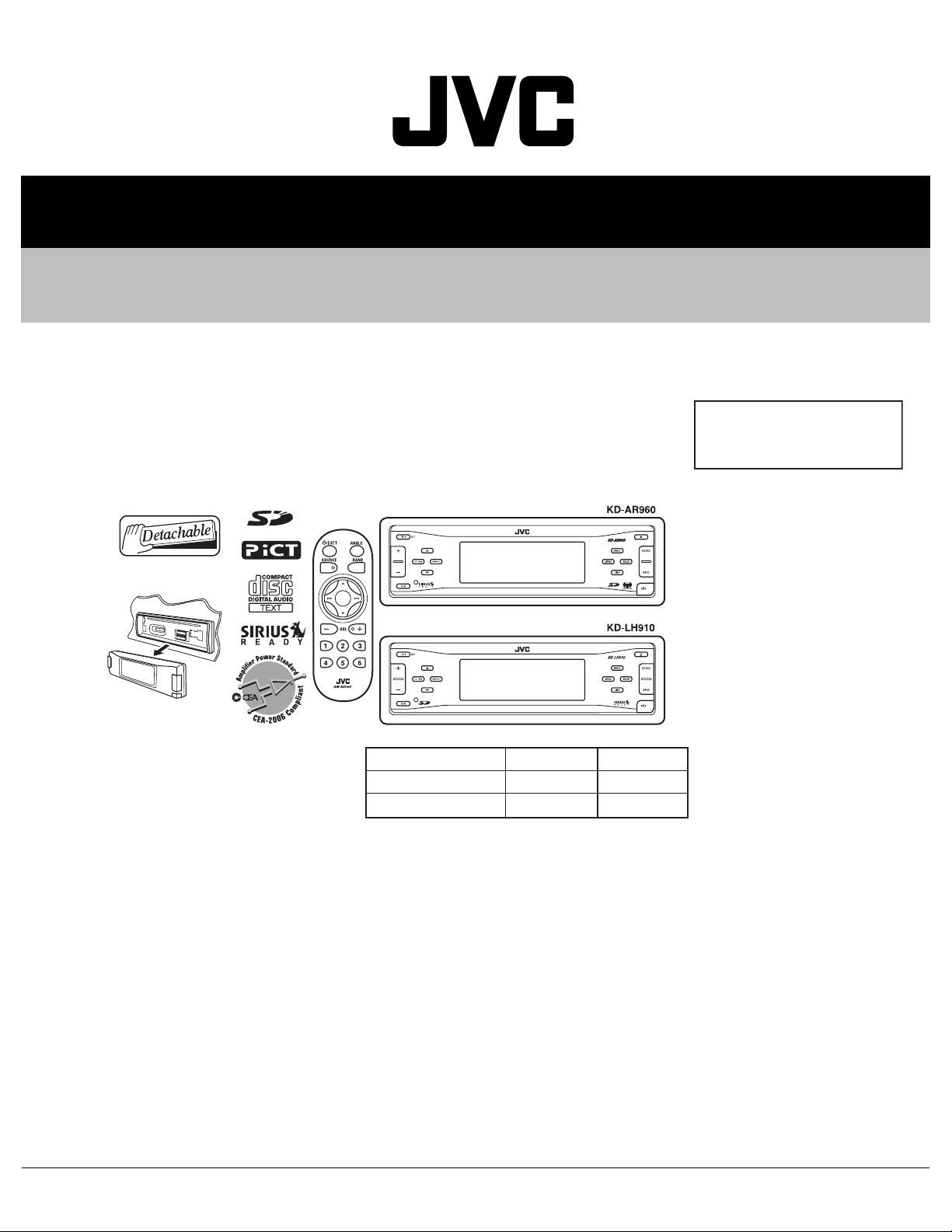

Page 1

SERVICE MANUAL

CD/SD RECEIVER

MA14220052

KD-AR960,KD-LH910

Area suffix

J --------------- Northern America

KD-AR960 KD-LH910

ARSENAL rogo

LINE IN

٤

٤

TABLE OF CONTENTS

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.MA142

2005/2

Page 2

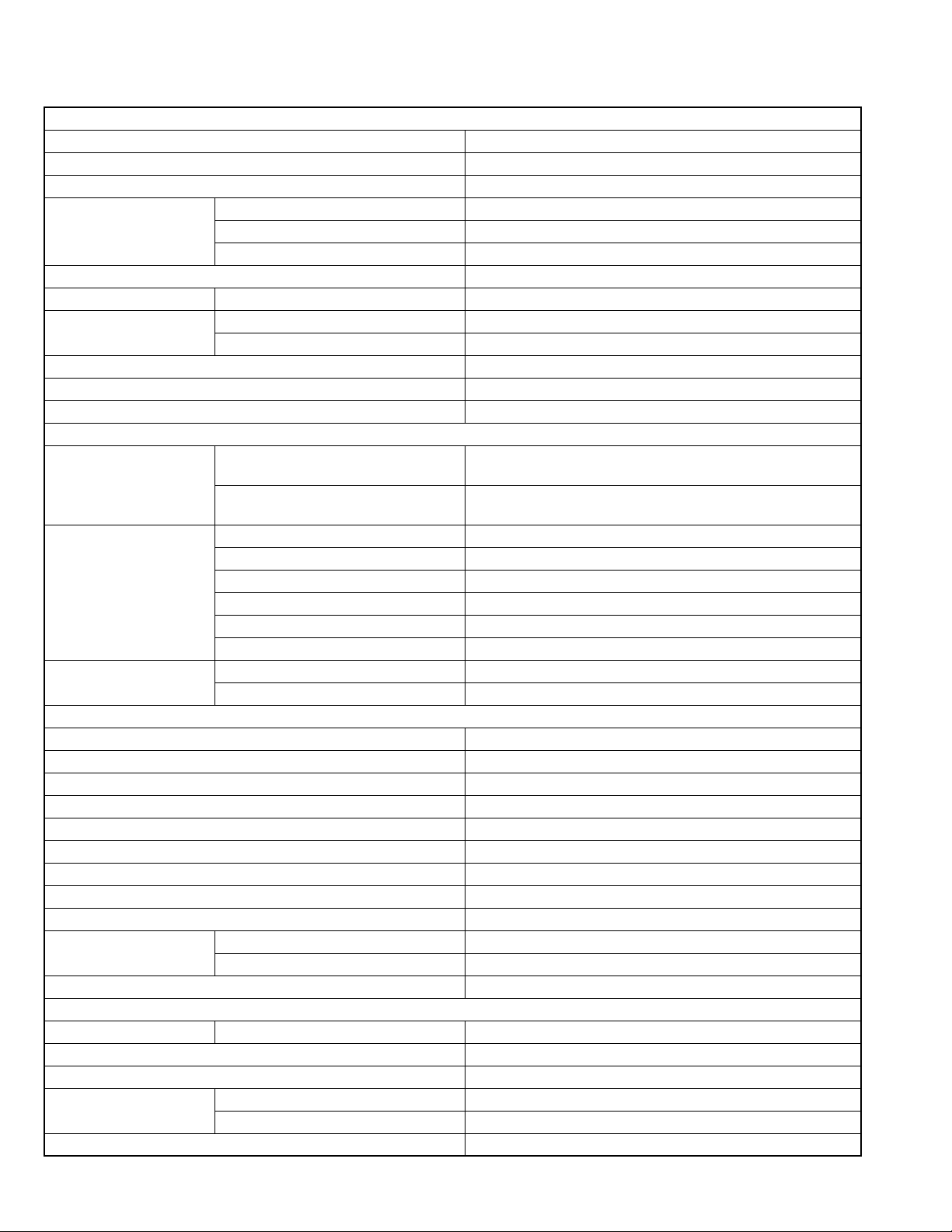

SPECIFICATION

AUDIO AMPLIFIER SECTION

Power Output 20 W RMS × 4 Channels at 4 Ω and

Signal to Noise Ratio 80 dBA (reference: 1 W into 4 Ω)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Low ±12 dB (60 Hz, 80 Hz, 100 Hz, 120 Hz)

Mid ±12 dB (Fix)

High ±12 dB (8 kHz, 10 kHz, 12 kHz, 15 kHz)

Frequency Response 40 Hz to 20 000 Hz

Line-In Level/Impedance KD-AR960 1.5 V/20 kΩ load

Line-Out Level/Impedance KD-AR960 5.0 V/20 kΩ load (full scale)

KD-LH910 4.0 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Subwoofer-Out Level/Impedance 2.0 V/20 kΩ load (full scale)

Other Terminals CD changer, LINE IN (for KD-AR960)

TUNER SECTION

Frequency Range FM 87.5 MHz to 107.9 MHz (with channel interval set to 200 kHz)

87.5 MHz to 108.0 MHz (with channel interval set to 50 kHz)

AM 530 kHz to 1 710 kHz (with channel interval set to 10 kHz)

531 kHz to 1 602 kHz (with channel interval set to 9 kHz)

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

Capture Ratio 1.5 dB

AM Tuner Sensitivity 20 µV

Selectivity 35 dB

CD/SD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 (MPEG1/2 Audio Layer 3) Max. Bit Rate: 320 kbps

WMA (Windows Media Audio) Max. Bit Rate: 192 kbps

Playable SD Card Format Fat 12/16

Storage Up to 512 MB

Playable Audio Format for SD Card MP3/WMA

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C (32°F to 104°F)

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 52 mm × 159 mm (7-3/16" × 2-1/16" × 6-5/16")

Panel Size (approx.) 188 mm × 58 mm × 12 mm (7-7/16" × 2-5/16" × 1/2")

Mass (approx.) 1.7 kg (3.8 lbs) (excluding accessories)

[< or =] 1% THD+N

Design and specifications are subject to change without notice.

1-2 (No.MA142)

Page 3

1.1 Safety Precautions

SECTION 1

PRECAUTIONS

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

(No.MA142)1-3

Page 4

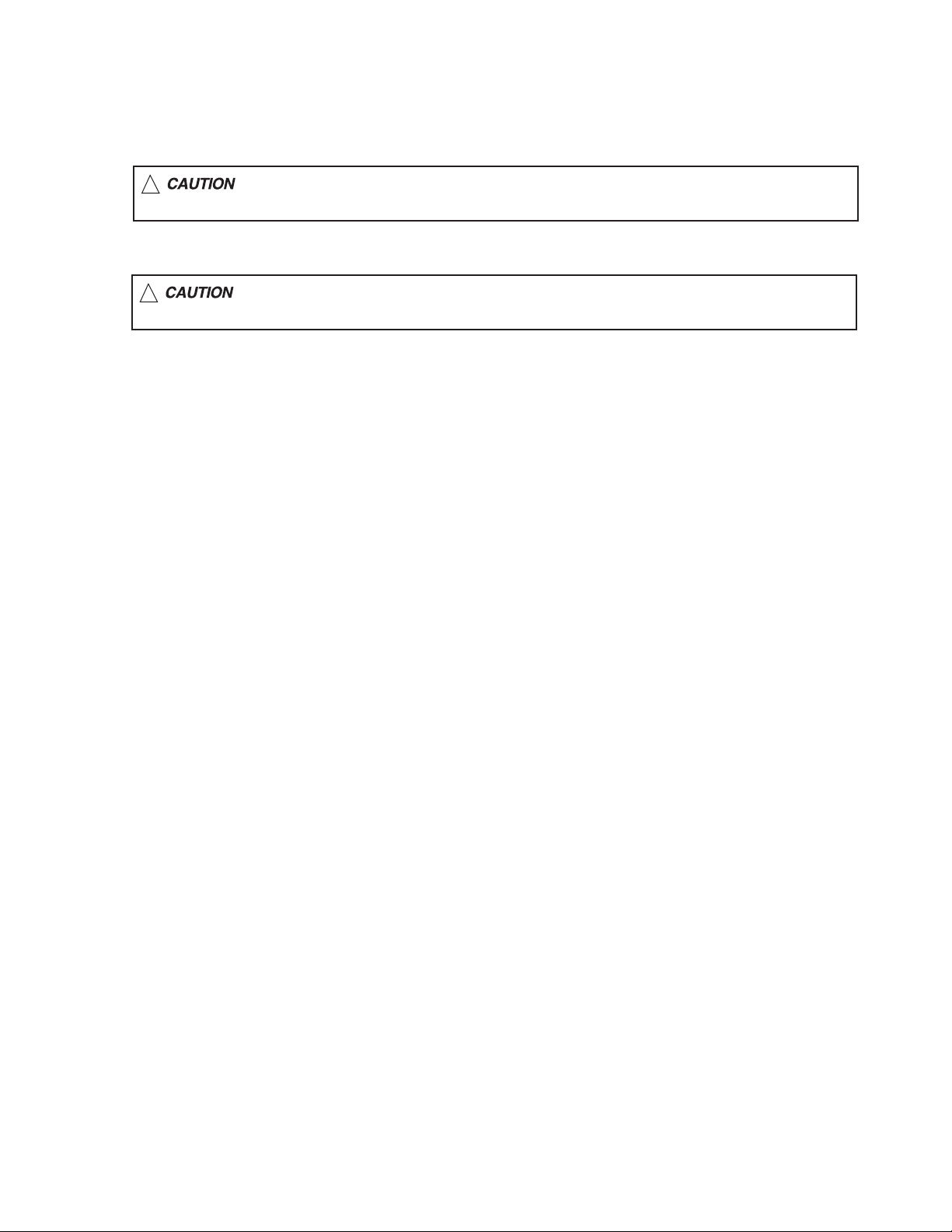

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

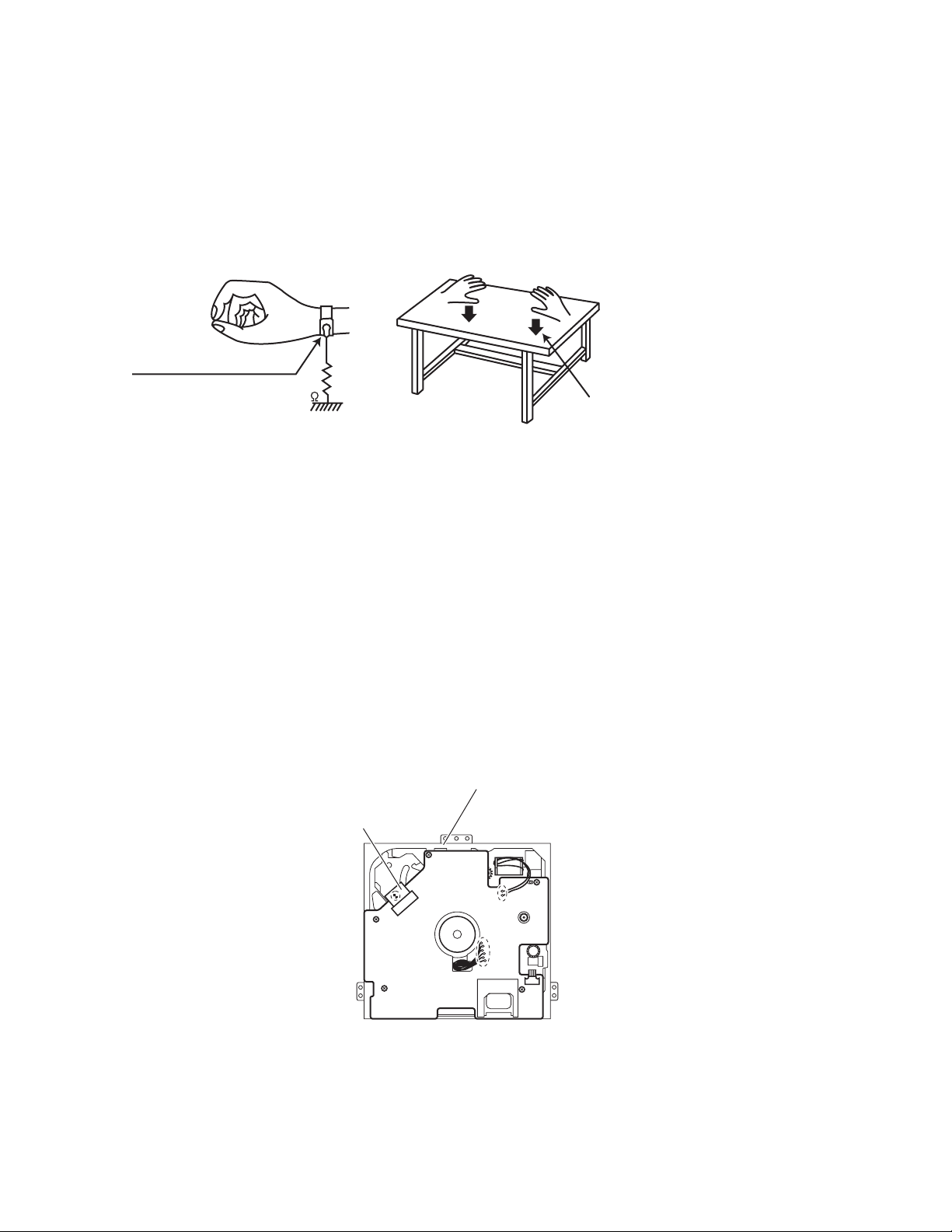

1.4 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the CD pickup unit.

• Apply solder to the short land before the flexible wire is disconnected from the connector on the CD pickup unit.

(If the flexible wire is disconnected without applying solder, the CD pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the flexible wire.

CD mechanism assembly

Flexible wire

1-4 (No.MA142)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.MA142)1-5

Page 6

SECTION 3

DISASSEMBLY

3.1 Main body section

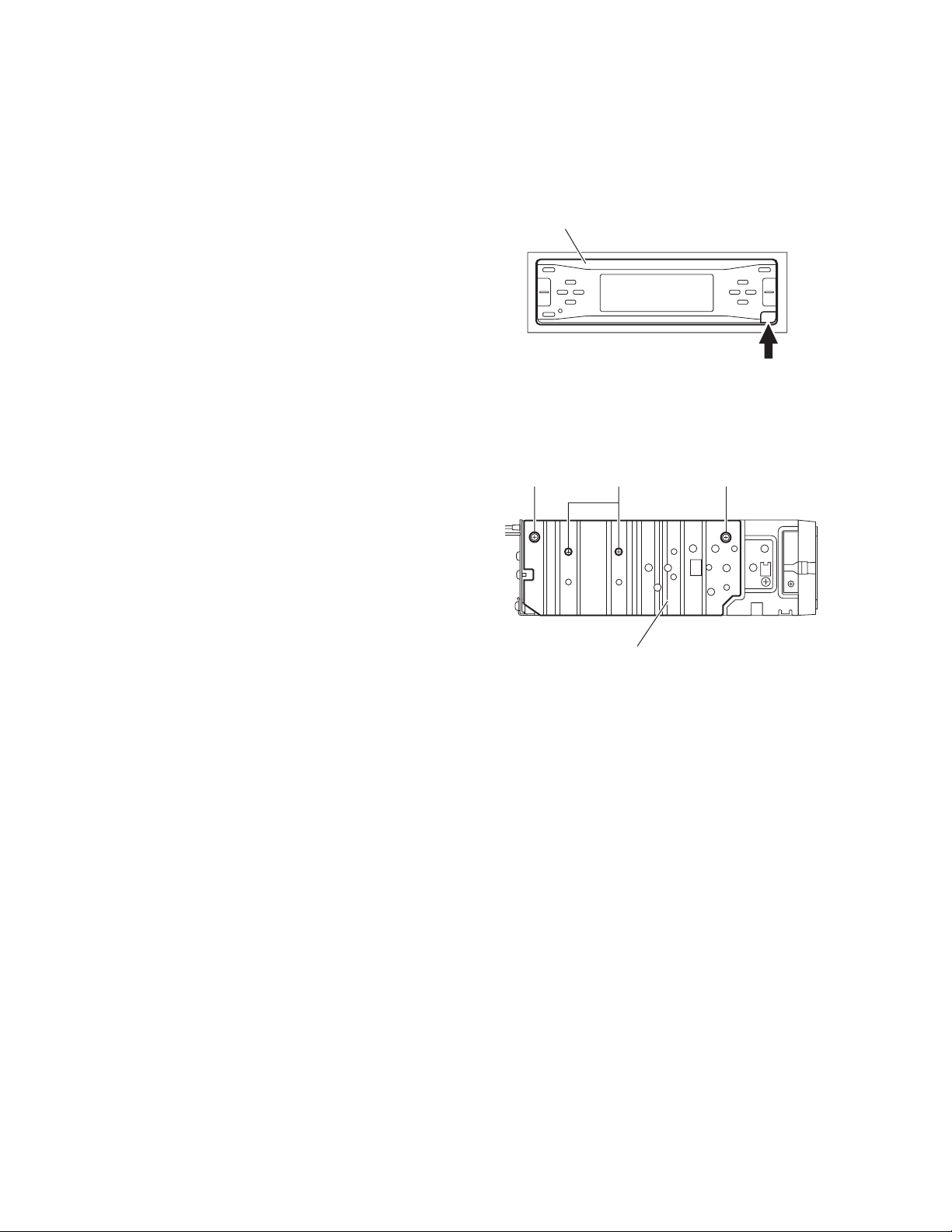

3.1.1 Removing the front panel assembly

(See Fig.1)

(1) Push the detach button in the lower right part of the front

panel assembly.

(2) Take out the front panel assembly.

3.1.2 Removing the heat sink

(See Fig.2)

(1) From the left side of the main body, remove the two screws

A and two screws B attaching the heat sink.

(2) Take out the heat sink.

Front panel assembly

Detach button

Fig.1

AAB

Heat sink

Fig.2

1-6 (No.MA142)

Page 7

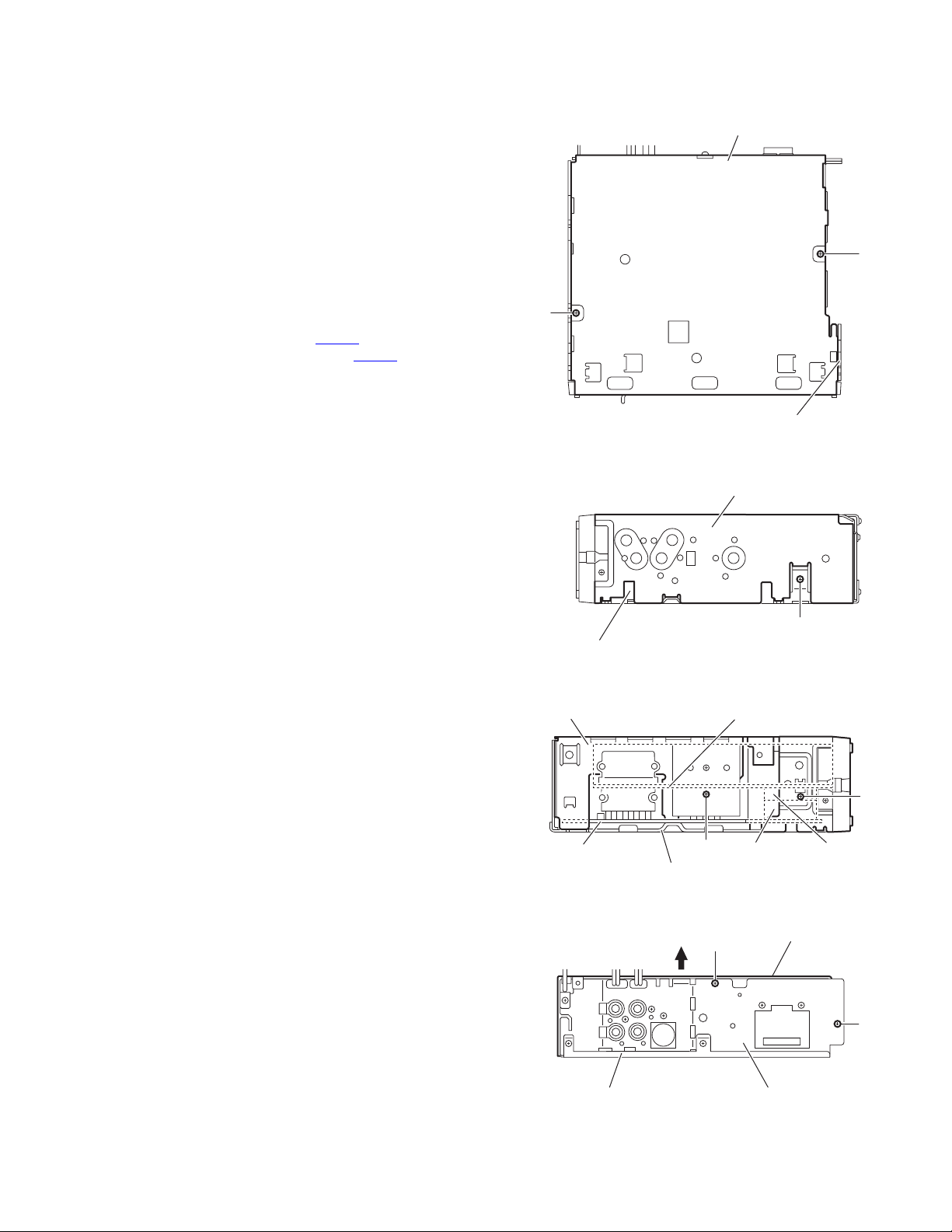

3.1.3 Removing the top chassis assembly

(See Figs.3 to 6)

• Prior to performing the following procedures, remove the heat

sink.

Reference:

Remove the front panel assembly as required.

(1) From the bottom side of the main body, remove the two

screws C attaching the top chassis assembly to the bottom

chassis assembly. (See Fig.3)

(2) From the both and back sides of the main body, remove the

four screws D attaching the top chassis assembly to the

bottom chassis assembly. (See Figs.4 to 6)

(3) From the left side of the main body, remove the screw E at-

taching the top chassis assembly. (See Fig.5)

(4) Lift the top chassis assembly in the direction of the arrow,

and disconnect the connector CN501

nism assembly from the connector CN702

board. (See Figs.5 and 6)

(5) Take out the top chassis assembly from the bottom chassis

assembly.

on the CD mecha-

on the main

Bottom chassis assembly

C

C

Top chassis assembly

Fig.3

Top chassis assembly

Bottom chassis assembly

Top chassis assembly

Main board

Bottom chassis assembly

D

Fig.4

CD mechanism assembly

CN702

E

Fig.5

Top chassis assembly

D

CN501

D

D

Bottom chassis assembly

Rear bracket

Fig.6

(No.MA142)1-7

Page 8

3.1.4 Removing the front chassis

(See Figs.7 and 8)

• Prior to performing the following procedure, remove the front

panel assembly, heat sink and top chassis assembly.

(1) From the both sides of the top chassis assembly, remove

the two screws F attaching the front chassis. (See Figs.7

and 8)

(2) Take out the front chassis forward.

3.1.5 Removing the CD mechanism assembly

(See Fig.9)

• Prior to performing the following procedures, remove the front

panel assembly, heat sink and top chassis assembly.

Reference:

Remove the front chassis as required.

(1) From the inside of the top chassis assembly, remove the

three screws G attaching the CD mechanism assembly.

Reference:

When attaching the screw G, attach it with the mecha

heat sink.

(2) Remove the mecha heat sink from the CD mechanism as-

sembly, and take out the CD mechanism assembly from

the top chassis.

Reference:

When attaching the mecha heat sink, pass the craws of it

through the slots a of CD mechanism assembly.

Top chassis assembly

F

Front chassis

Top chassis

Slots a

Front chassis

Fig.7

Top chassis assembly

Fig.8

Mecha heat sink

G

F

1-8 (No.MA142)

G GCD mechanism assembly

Fig.9

Page 9

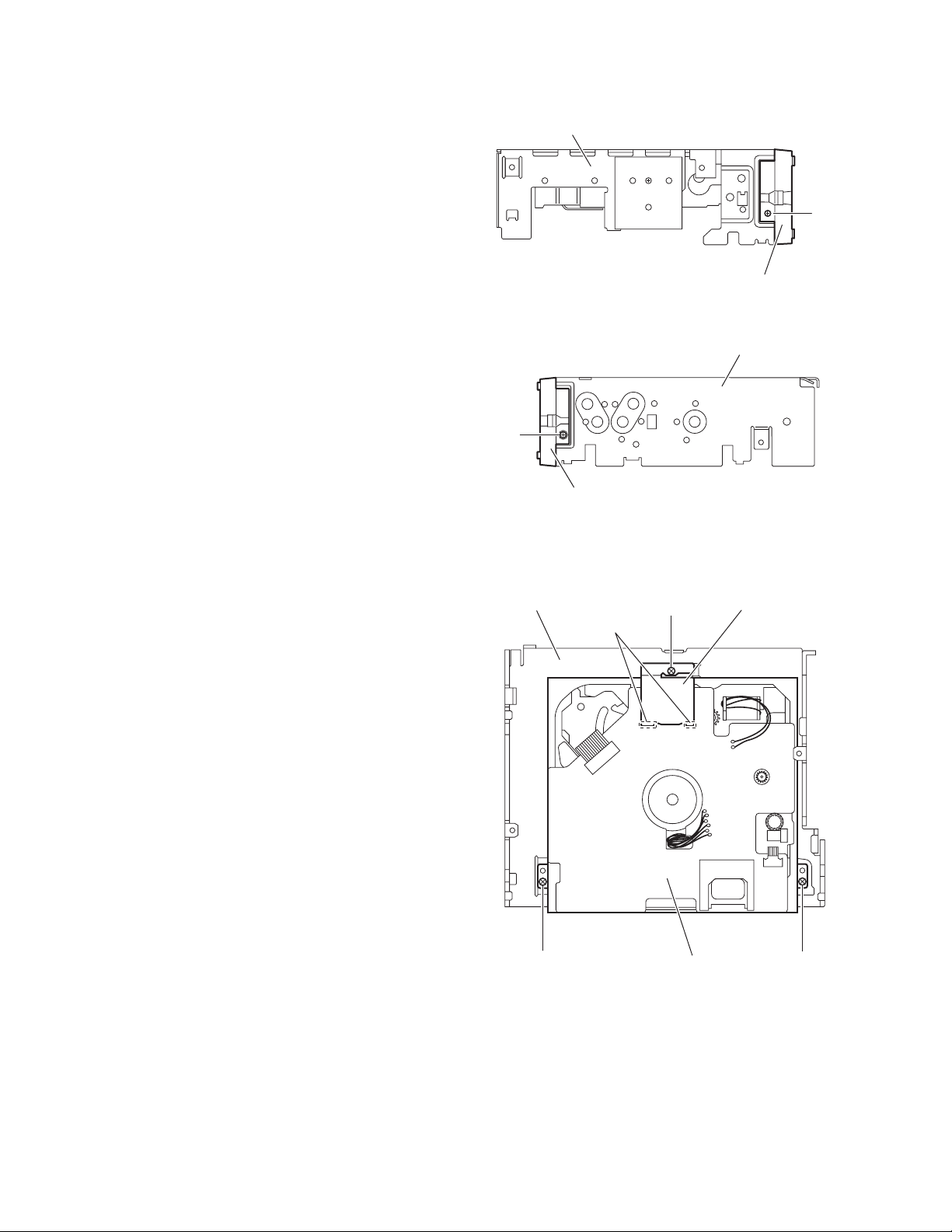

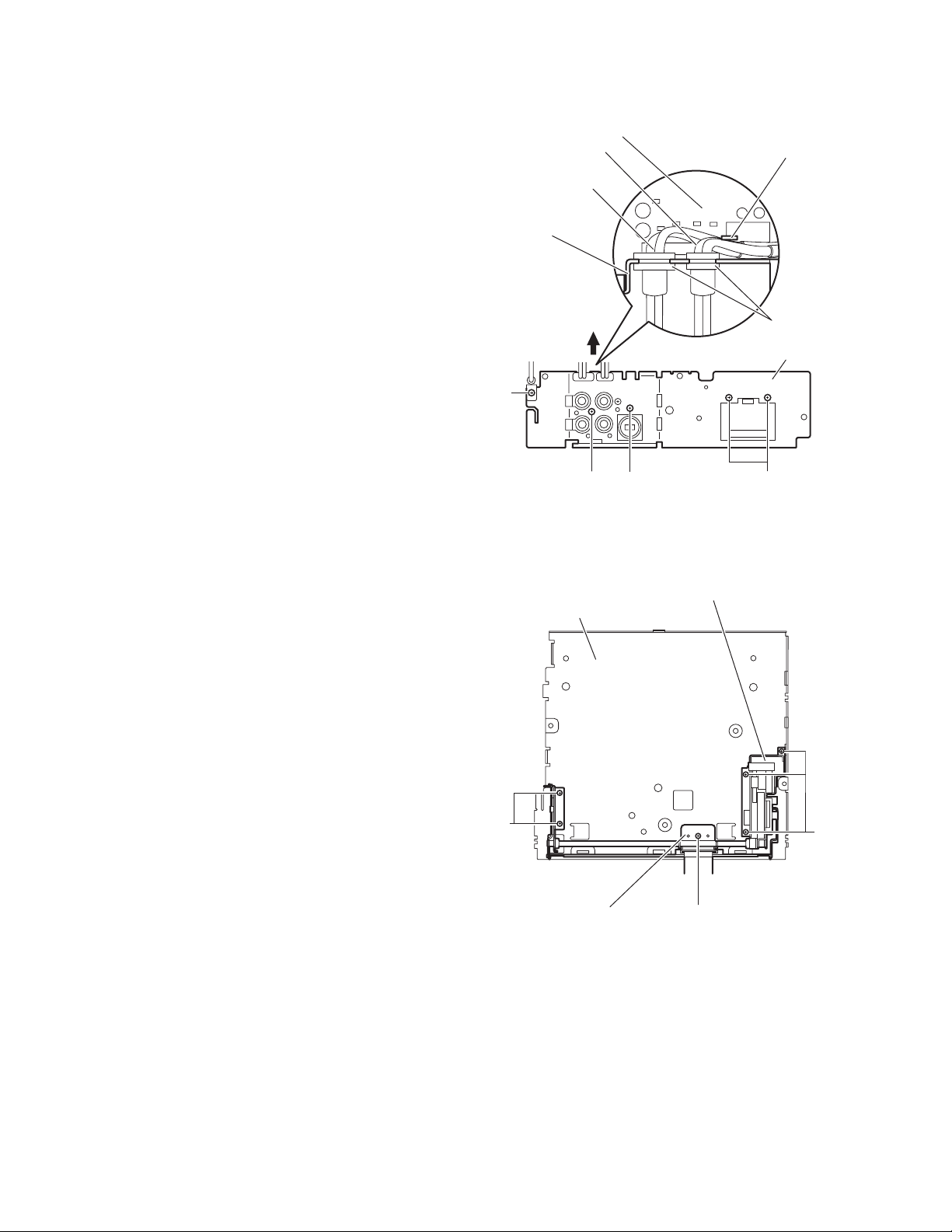

3.1.6 Removing the main board

(See Figs.10 and 11)

• Prior to performing the following procedures, remove the front

panel assembly, heat sink and top chassis assembly.

(1) From the back side of the bottom chassis assembly, re-

move the two screws H attaching the rear bracket to the

bottom chassis assembly. (See Fig.10)

(2) From the top side of the bottom chassis assembly, remove

the two screws J attaching the main board to the bottom

chassis assembly. (See Fig.11)

(3) Release the stopper of the connector CN701

board in an upward direction, disconnect the card wire from

the connector CN701

(4) Disconnect the wire from the connector of the front door

mechanism assembly. (See Fig.11)

(5) Disconnect the wire from the connector CN951

board. (See Fig.11)

Reference:

After connecting the wires, fix the wires with the wire

clamp.

(6) Take out the main board with the rear bracket from the bot-

tom chassis assembly.

. (See Fig.11)

on the main

on the main

H

Front door mechanism assembly

Connector

Card wire

Bottom chassis assembly

Fig.10

Bottom chassis assembly

CN701

Stopper

Rear bracket

J

J

Main board

CN951

Fig.11

Wire clamps

(No.MA142)1-9

Page 10

3.1.7 Removing the rear bracket

(See Fig.12)

• Prior to performing the following procedures, remove the front

panel assembly, heat sink, top chassis assembly and main

board.

(1) From the back side of the main board, remove the wires

from the rear bracket in the direction of the arrow.

(2) Remove the screw K, three screws L and screw M attach-

ing the rear bracket to the main board.

Reference:

After attaching the rear bracket to the main board, pass

the wires through the wire holder and insert them into the

slots of the rear bracket.

(3) Take out the rear bracket from the main board.

Wire

Wire (KD-AR960)

Rear bracket

M

Main board

Wire holder

Slots

Rear bracket

3.1.8 Removing the front door mechanism assembly

(See Fig.13)

• Prior to performing the following procedures, remove the front

panel assembly, heat sink, top chassis assembly and main

board.

(1) From the top side of the bottom chassis assembly, remove

the screw N attaching the FPC guide to the bottom chassis.

(2) Remove the five screws P attaching the front door mecha-

nism assembly to the bottom chassis.

Reference:

When attaching the screws N and P, apply a locking

agent them.

(3) Take out the front door mechanism assembly from the bot-

tom chassis.

Bottom chassis

P

L K

Front door mechanism assembly

FPC guide

L

Fig.12

P

N

1-10 (No.MA142)

Fig.13

Page 11

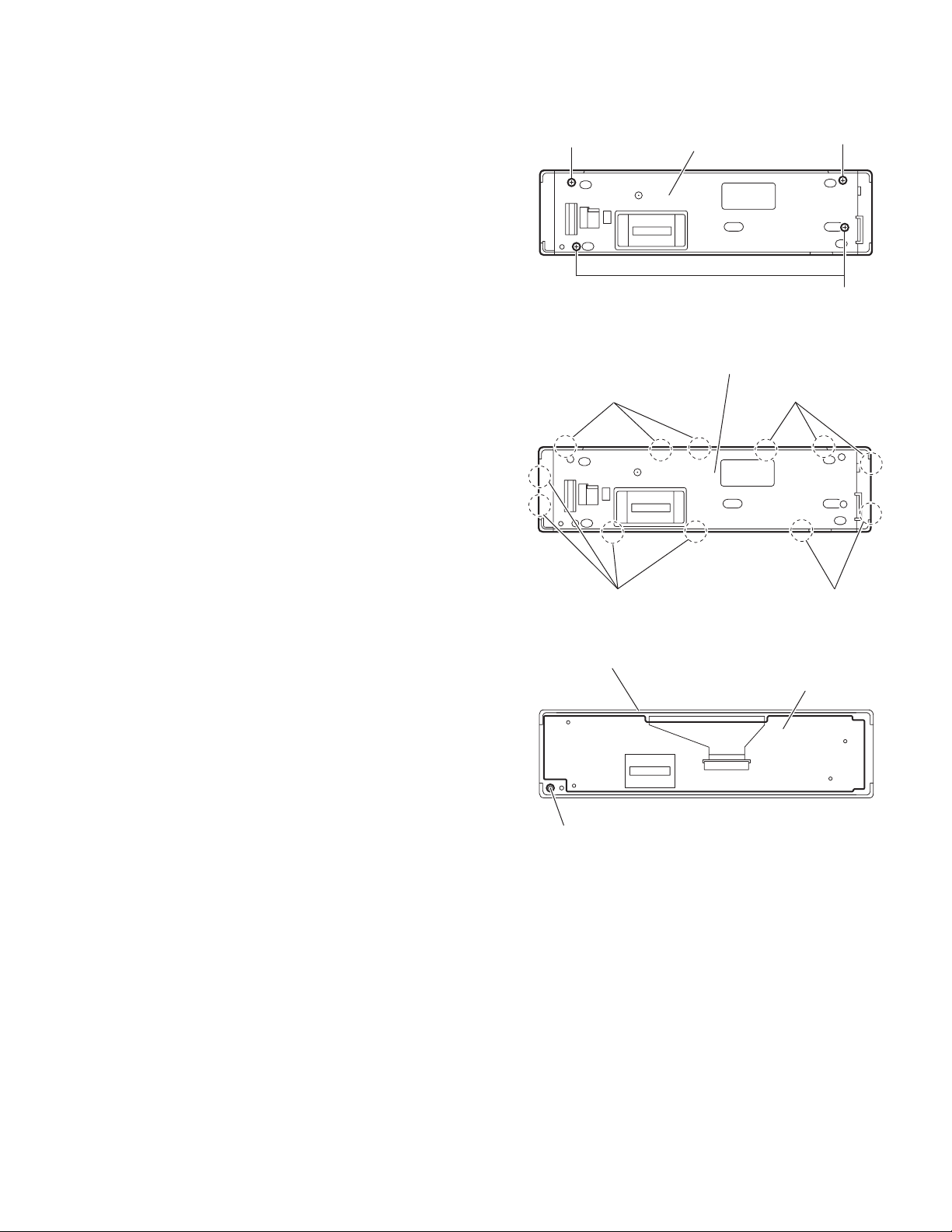

3.1.9 Removing the switch board

(See Figs.14 to 16)

• Prior to performing the following procedures, remove the front

panel assembly.

(1) From the back side of the front panel assembly, remove the

four screws Q attaching the rear cover assembly to the

front panel assembly. (See Fig.14)

(2) Release the twelve joints b of the front panel assembly and

remove the rear cover assembly. (See Fig.15)

(3) Take out the switch board from the front panel assembly.

(See Fig.16)

Note:

When removing the rear cover assembly and switch board, be

careful not to lose the comp. spring. (See Fig.16)

Q

Joints b Joints b

Rear cover

Fig.14

Rear cover assembly

Q

Q

Joints b

Front panel assembly

Comp. spring

Joints b

Fig.15

Switch board

Fig.16

(No.MA142)1-11

Page 12

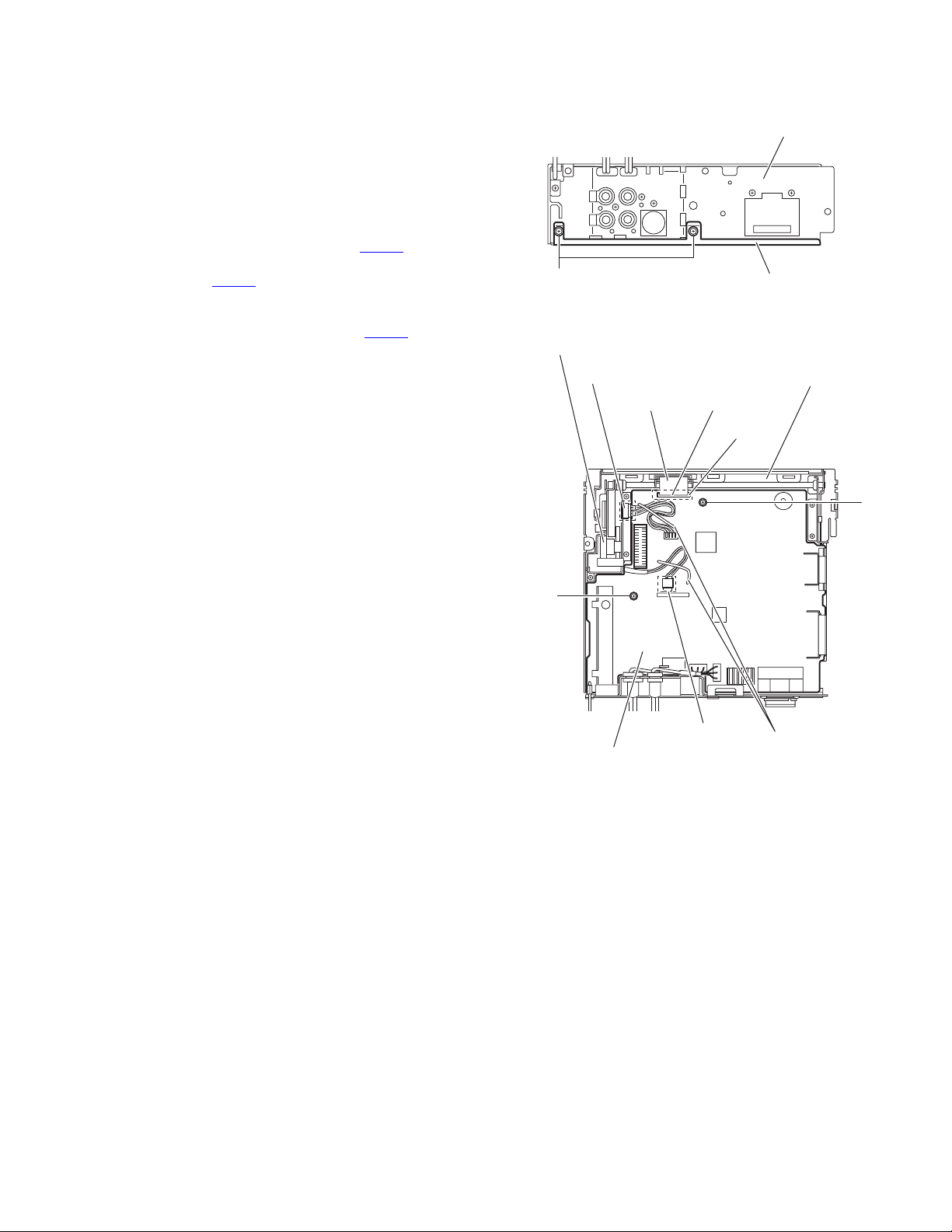

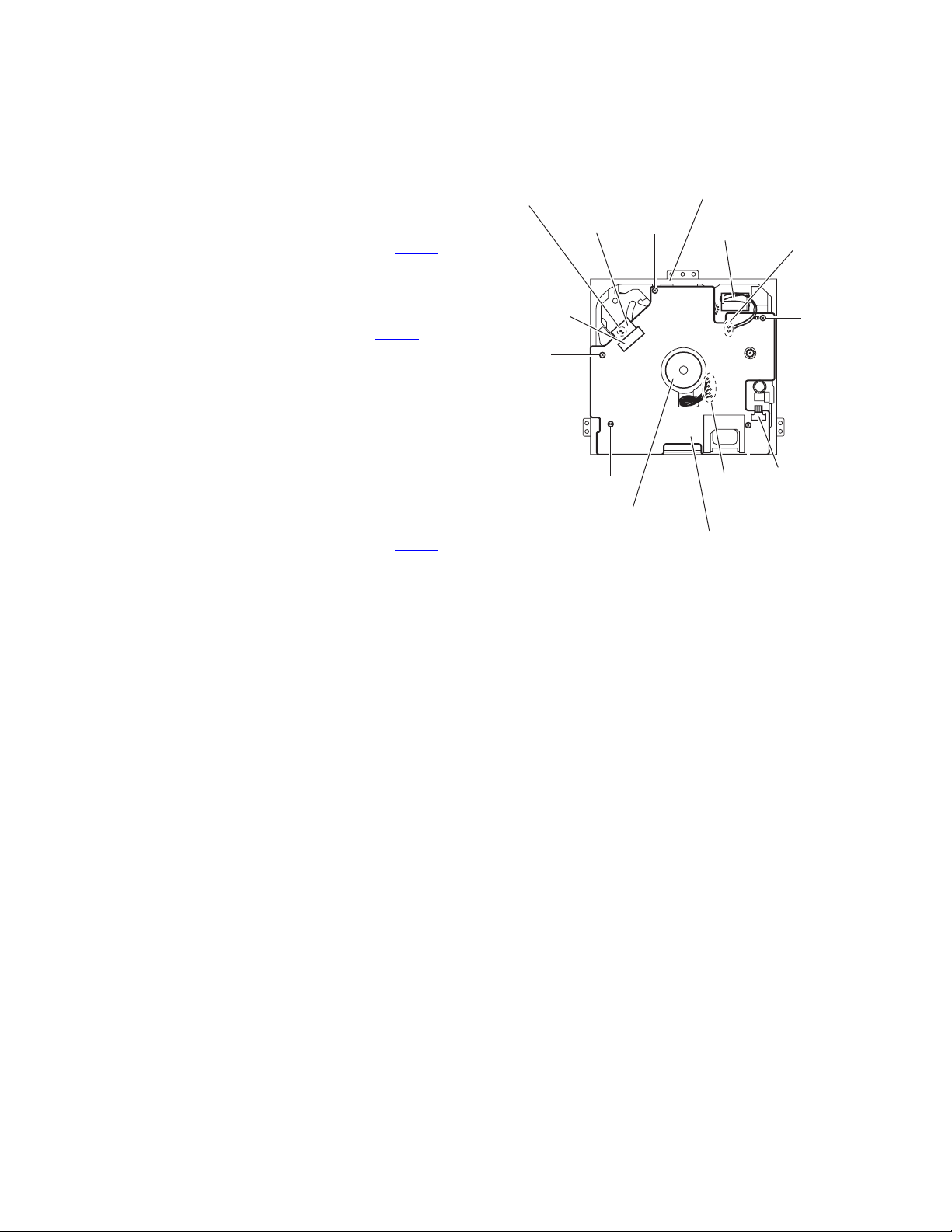

3.2 CD mechanism assembly section

• Remove the CD mechanism assembly from the main body.

(See "3.1.5 Removing the CD mechanism assembly".)

3.2.1 Removing the mechanism control board

(See Fig.1)

(1) From the bottom side of the CD mechanism assembly, sol-

der the short sections on the flexible wire.

Caution:

Solder the short sections on the flexible wire before disconnecting the flexible wire from the connector CN601

on the mechanism control board. If you do not follow this

instruction, the CD pickup may be damaged.

(2) Disconnect the flexible wire from the connector CN601

the mechanism control board.

(3) Disconnect the flexible wire from the connector CN602

the mechanism control board.

(4) Remove the solders from the soldered sections a on the

mechanism control board and remove the wires of the feed

motor.

(5) Remove the solders from the soldered sections b on the

mechanism control board, and remove each wire of the

spindle motor and other parts.

(6) Remove the five screws A attaching the mechanism con-

trol board.

Caution:

When reassembling, remove the solders from the short sections after connecting the flexible wire to the connector CN601

on the mechanism control board.

on

on

Short sections

Flexible wire

CN601

A

CD mechanism assembly

A

A

Spindle motor

Mechanism control board

Fig.1

Feed motor

b

A

a

A

CN602

1-12 (No.MA142)

Page 13

3.2.2 Removing the top cover

r

(See Fig.2)

(1) From the back side of the CD mechanism assembly, re-

move the two screws B attaching the top cover.

(2) Take out the top cover in an upward direction.

Reference:

When attaching the top cover, set the sections c of the top cover under the bending sections d of the chassis base.

3.2.3 Removing the mechanism section

(See Figs.2 to 4)

• Remove the mechanism control board and top cover.

(1) From the front side of the CD mechanism assembly, re-

move the two screws C attaching the right and left stoppers. (See Fig.2)

(2) Remove the two floating springs on the bottom side of the

CD mechanism assembly. (See Fig.3)

(3) Take out the mechanism section in an upward direction

and remove the three damper springs from the dampers.

(See Fig.4)

Caution:

• When reassembling the mechanism section, reattach the

damper springs to the dampers respectively and insert the

three shafts on the bottom of the mechanism section to the

dampers. (See Fig.4)

• Before inserting the shaft to the dampers, apply IPA to the

hole of damper.

Floating spring

Fig.3

Mechanism section

C

Stopper

Top cover

Stopper

C

Fig.2

B

d

c

Chassis base

B

Damper

spring(F)

(Green)

Damper

(Black)

Damper

spring(F)

(Green)

Damper

spring(R)

(Red)

Dampe

(Yellow)

Damper

(Black)

Fig.4

(No.MA142)1-13

Page 14

3.2.4 Removing the clamper unit

(See Figs.5 and 6)

• Remove the mechanism control board, top cover and mecha-

nism section.

(1) From the bottom side of the mechanism section, remove

the clamper 2 spring. (See Fig.5)

(2) Release section e of the clamper spring from the bending

section of the chassis base. (See Fig.6)

(3) Move the clamper unit in the direction of the arrow and re-

lease the joints (f, g). (See Fig.5)

(4) Take out the clamper unit in an upward direction. (See

Fig.5)

3.2.5 Reattaching the clamper unit

(See Figs.5 to 9)

(1) From the bottom side of the mechanism section, attach the

clamper spring to the clamper unit. (See Figs.5 and 9)

(2) Move the clamper unit to set the joints (f, g) to each projec-

tion of the chassis base. (See Fig.5)

(3) Make sure that section h of the clamper unit is inserted to

the notch of the chassis base. (See Figs.5 and 8)

(4) Move the clamper spring to the outside of the bending part

of the chassis base. (See Fig.6)

Caution:

When reattaching the clamper unit, temporarily hook the

end of the clamper spring as shown in the figure to make

the work easy. (See Fig.9.)

(5) Attach the clamper 2 spring to the chassis base and

clamper unit. (See Figs.5 and 7.)

Clamper spring

f

Chassis base

Clamper 2 spring

Clamper unit

h

g

Fig.5

Clamper spring

Chassis base

e

Fig.6

1-14 (No.MA142)

Page 15

Clamper 2 spring

Clamper unit

Chassis base

Clamper unit

Fig.7

Clamper spring

Fig.9

Clamper unit

Notch

h

Fig.8

(No.MA142)1-15

Page 16

3.2.6 Removing the front unit

(See Figs10 to 12)

• Remove the mechanism control board, top cover and mecha-

nism section.

(1) From the bottom side of the mechanism section, remove

the double-stick tape fixing the flexible wire. (See Fig.10.)

(2) From the top side of the mechanism section, remove the

screw D attaching the front unit. (See Figs.11 and 12.)

(3) Move the front unit toward the front to release the joint i.

(See Figs.11 and 12.)

(4) Release two joints j and k on the right side of the chassis

base. (See Fig.12)

(5) Take out the front unit in an upward direction.

(6) Remove the double-stick tape fixing the flexible wire and

remove the two screws E attaching the switch wire. (See

Fig.12)

Reference:

You can remove the switch wire only without removing the

front unit.

Flexible wire

Double-stick

tape

Fig.10

Double-stick tape

Flexible

wire

Front unit

E

D

i

Fig.11

Switch wire

D

Front unit

1-16 (No.MA142)

j

k

Chassis base

i

Fig.12

Page 17

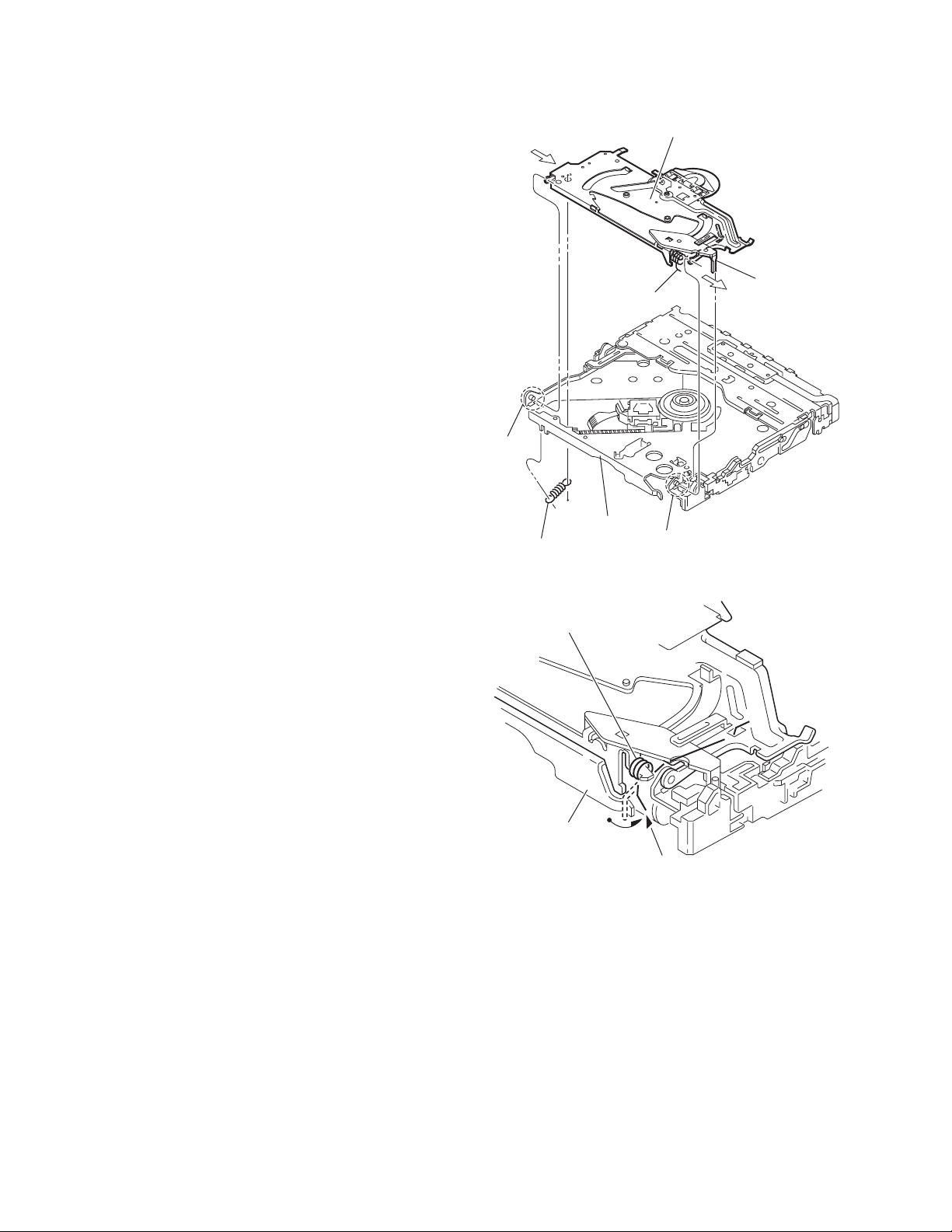

3.2.7 Removing the loading arm assembly

(See Figs.13 and 14)

• Remove the mechanism control board, top cover, mechanism

section and front unit.

(1) From top side of the mechanism section, move the loading

arm assembly in the direction of the arrow. (See Fig.13)

(2) Release the projections from the right and left joints (m, n)

of the chassis base. (See Figs.13 and 14)

(3) Release the projection from notch p of the connect arm on

the right side of the mechanism section and release the

projection from notch q of the slide cam assembly on the

left side. (See Figs.13 and 14.)

Loading arm assembly

n

Chassis base

p

m

Fig.13

Loading arm assembly

Side cam

assembly

q

n

Chassis base

Fig.14

m

p

Connect arm

(No.MA142)1-17

Page 18

3.2.8 Removing the rod (L), rod (R) and roller assembly

(See Figs.15 and 16)

• Remove the mechanism control board, top cover, mechanism

section, front unit and loading arm assembly.

(1) From the bottom side of the loading arm assembly, release

the rod (L) and (R) from the joints r. (See Fig.15)

(2) Remove the roller assembly from the loading arm assem-

bly. (See Fig.16)

(3) Remove the two collars and washer from the roller assem-

bly. (See Fig.16)

Caution:

After attaching the roller assembly to the loading arm assembly, attach the rod (L) and (R). Then attach the rods to the right

and left collars of the roller assembly. (See Fig.15)

Collar

Rod(R) Rod(L)

r

Rod(R)

Roller assembly

Loading arm assembly

r

Collar

Rod(L)

r

r

Fig.15

Rod(L)

Collar

Washer

Roller assembly

Rod(R)

Collar

Loading arm assembly

Fig.16

1-18 (No.MA142)

Page 19

3.2.9 Removing the CD pickup

(See Figs.17 to 19)

• Remove the mechanism control board.

(1) From the bottom side of the CD mechanism assembly, turn

the feed gear in the direction of the arrow to move the CD

pickup assembly outwards. (See Fig.17)

(2) Remove the screw F and remove the thrust spring. (See

Fig.17)

(3) Remove the CD pickup assembly in an upward direction

from the side of L.S. gear and release the CD pickup assembly from joint s of the sub guide. (See Fig.18)

(4) Move the lead screw of the CD pickup assembly in the di-

rection of the arrow to release at joint t. (See Fig.18)

(5) Remove the screw G attaching the rack spring and rack

plate on the CD pickup assembly. (See Fig.19)

(6) Pull out the lead screw. (See Fig.19)

Caution:

• When attaching the CD pickup assembly, attach the CD

pickup assembly at joint s of sub guide first, and attach the

lead screw to the joint t on the L.S.holder 2. (See Fig.18)

• Perform electric adjustment after replacing the pickup.

CD mechanism assembly

CD pickup assembly

Thrust spring

Feed gear

F

Fig.17

L.S.holder 2

Sub guide

s

Rack spring

Rack plate

t

Lead screw

Fig.18

G

CD Pickup assembly

L.S. Gear

Lead screw

CD Pickup

Fig.19

(No.MA142)1-19

Page 20

3.2.10 Removing the spindle motor

r

r

(See Fig.20)

• Remove the mechanism control board, top cover, mechanism

section and clamper unit.

(1) From the top side of the mechanism section, remove the

T.table assembly and washer from the spindle motor.

(2) Remove the two screws H attaching the spindle motor.

(3) Take out the spindle motor from the bottom side of the

mechanism section.

Caution:

Perform adjustment when reattaching the spindle motor.

3.2.11 Removing the feed motor

(See Figs.21 and 22)

• Remove the mechanism control board.

(1) From the bottom side of the CD mechanism assembly, re-

move the F.T.spring. (See Fig.21)

(2) Remove the two screws J attaching the feed motor assem-

bly. (See Fig.21)

(3) Remove the slit washer from the motor H.assembly and

pull out the worm wheel. (See Fig.22)

(4) Remove the two screws K attaching the feed motor. (See

Fig.22)

T. table assembly

F.T.Spring

Washer

H

Spindle moto

Fig.20

J

Feed motor assembly

1-20 (No.MA142)

Fig.21

Slit washer

Worm wheel

Feed moto

K

Motor H.assembly

Fig.22

Page 21

3.2.12 Removing the SW board and rest SW board

(See Fig.23)

• Remove the mechanism control board.

(1) From the bottom side of the CD mechanism assembly, re-

move the screw L attaching the SW board.

(2) Remove the screw M attaching the rest SW board.

CD mechanism assembly

ML

SW boardRest SW board

Fig.23

(No.MA142)1-21

Page 22

SECTION 4

ADJUSTMENT

4.1 Adjustment method

Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Electric voltmeter

(3) Digital tester

(4) Tracking offset meter

(5) Test Disc JVC :CTS-1000

(6) Extension cable for check

EXTGS004-26P × 1

Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

How to connect the extension cable for adjusting

Caution:

Be sure to attach the heat sink and rear bracket onto the power amplifier IC and regulator IC respectively, before supply the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

Standard measuring conditions

Power supply voltage DC14.4V(11 to 16V)

Load impedance 20KΩ(2 Speakers connection)

Output Level KD-AR960 Line out 5.0V (Vol. MAX)

KD-LH910 Line out 4.0V (Vol. MAX)

Dummy load

Exclusive dummy load should be used for AM,and FM. For FM

dummy load,there is a loss of 6dB between SSG output and

antenna input.The loss of 6dB need not be considered since

direct reading of figures are applied in this working standard.

Extension cable: EXTGS004-26P

CN702

Heat sink

Rear bracket

1-22 (No.MA142)

Page 23

4.2 Service mode

4.2.1 Service mode setting

(1) Push POWER BOTTON (Power ON)

(2) Set to service mode

By pushing and holding "DISP" button and "VOLUME +" button sequentially.

(3) Select the menu with "CURSOR" button, and decide it with "OK" button.

(4) When the "BACK" button is pushed, it returns to the former menu.

"VOLUME +" button

"OK" button "DISP" button

"CURSOR" button

Service Mode (MENU)

Service Mode

Running Mode

Data Clear

RDS Service Mode

Service Mode

VERSION

ERROR READ

CD DATA READ

"BACK" button

Version

MAIN

CD V

CH V

V

Error Read

ERROR READ

OK:Function

CD Error Read

CD Error Read

E1 E3

E2

1 4

2 5

3

CH Error Read

CH Error Read

E1 E3

E2

1 4

2 5

3

Panel Mecha Error Read

Panel Mecha Error Read

E1 E3

E2

1 4

2 5

AB

3

(No.MA142)1-23

Page 24

AB

f

f

CD Data Read

CD Data Read

OK:Read

Running Mode

RUNNING PANEL MECHA 2

RUNNING PANEL MECHA 3

RUNNING CD

ADJ NOW

FEB FEO TEB RFG

FGA TEO TGA

ADJ INT

FEB FEO TEB RFG

FGA TEO TGA

OTHERS

IOP TEMP IOP INT

TEMP MIX P TOTAL H

Running Panel Mecha 2

RUNNING PANEL MECHA 2

COUNT :

ERROR :

Running Panel Mecha 3

RUNNING PANEL MECHA 3

COUNT :

ERROR :

ADJ NOW

The auto adjustment value o

survo at now

ADJ INT

The auto adjustment value o

survo at initial

Data Clear

EPROM Clear

Name Clear

CD Error Clear

CH Error Clear

Panel Mecha Error Clear

Picture Clear

Running CD

RUNNING CD

COUNT :

ERROR :

EPROM Clear

NOW

EPROM CLEAR

Name Clear

NOW

NAME CLEAR

C D

1-24 (No.MA142)

Page 25

C

D

CD Error Clear

NOW

CD ERROR CLEAR

CH Error Clear

NOW

CH ERROR CLEAR

Panel Mecha Error Clear

NOW

PANEL MECHA ERROR CLEAR

Picture Clear

NOW

PICTURE CLEAR

RDS Service Mode

VER=

SPI =

PTY=

AF

PS =

PTY= CLOCK=00:00

Freq=87.5MHz

PI =

SM=

SQ=

ONLY USED WITH RDS MODEL

TP/TA=

MS/DI=

(No.MA142)1-25

Page 26

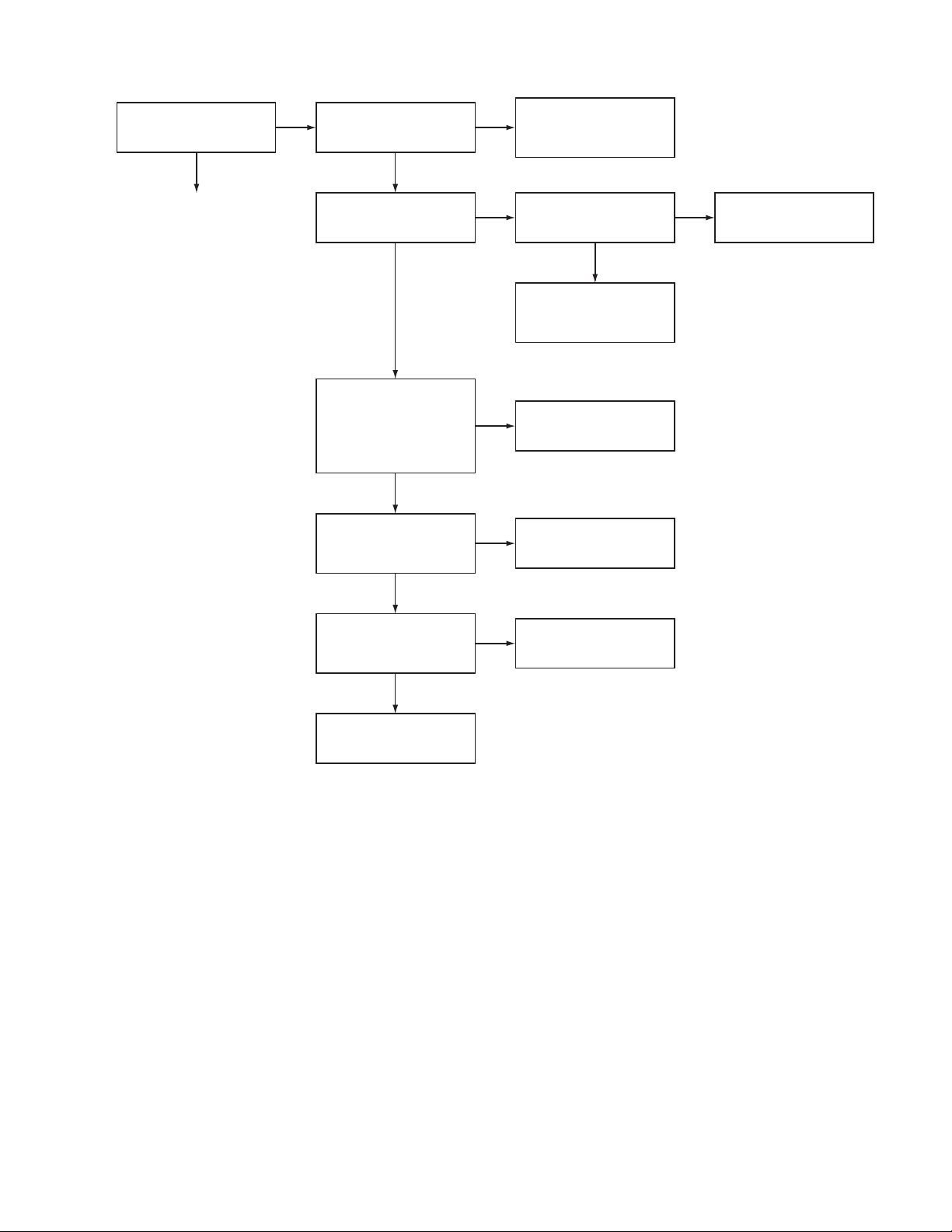

5.1 Feed section

SECTION 5

TROUBLESHOOTING

Is 5V or 0V at IC601

pin 63?

YES

Is 4V present at both

sides of the feed motor?

YES

Check the feed motor.

5.2 Focus section

5.3 Spindle section

NO

Is the wiring for IC601

pin 63 correct?

NO

Is 6V or 2V present at

IC681 pins 26 and 27?

Check IC681.

When the lens is

moving:

Does the S-search

waveform appear at

IC681 pins 10 and 11?

NO

NO

YES

4V

YES

YES

Is 5V present at IC681

pin 19?

Check the vicinity of

IC601.

Check the feed motor

connection wiring.

NO

Check the circuits in

the vicinity of IC681

pins 13 and 14.

Check the pickup and

its connections.

NO

Check CD8V.

YES

YES

Is the disk rotated?

YES

Does the RF signal

appear at RF test point?

YES

Is the RF waveform

at

RF test point

Proceed to the Tracking

section

5.4 Tracking section

distorted?

YES

When the disc is rotated

at first:

Is the tracking error

signal output at IC601

pin 57?

NO

Is 4V present between

IC681 pins 6 and 7?

Check the spindle motor

and its wiring.

NO

Check the circuits in

the vicinity of IC601

or the pickup.

NO

NO

Approx. 1.2V

YES

NO

YES

Check the circuits in

the vicinity of IC601

pins 41 to 49.

Is 4V present at IC601

pin 64?

YES

Check the vicinity of

IC681.

NO

Check the pickup and

its connections.

NO

Check IC601.

1-26 (No.MA142)

Check IC601.

Page 27

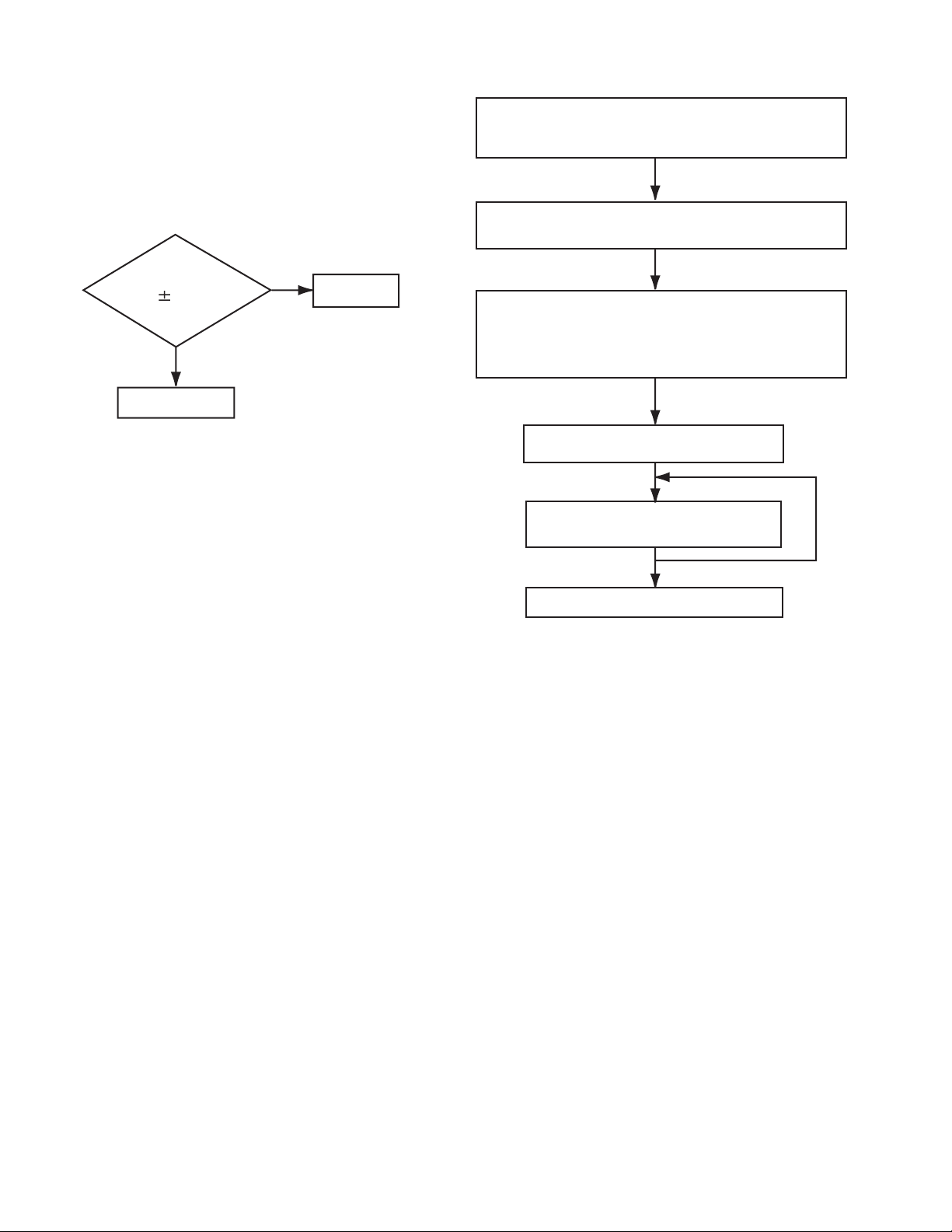

5.5 Signal processing section

Is the sound output from

both channels (L, R)?

YES

Normal

NO

No sound from either

channel.

Is 9V present at IC161

pin 40?

Is the audio signal

(including sampling

output components)

output to IC410 pins 1

and 7 during playback?

Is the audio signal

output at IC161 pins 36

to 39 during playback?

YES

YES

YES

Compare the L-ch and

NO

R-ch to locate the

defective point.

NO

Is 9V present at IC901

pin 10?

Check the connection

between IC901 pin10

and IC161 pin 40.

NO

Check IC410 and its

peripheral circuits.

NO

Check IC161 and its

peripheral circuits.

YES

NO

Check IC901 and its

peripheral circuits.

YES

Is the audio signal output

at IC361/IC381 pins 12

and 13 during playback?

YES

Check the power amp.

IC301.

NO

Check IC361/IC381 and

its peripheral circuits.

(No.MA142)1-27

Page 28

5.6 Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to clean the lens

with a alcohol soaked cotton swab.

(2) Life of the laser diode

When the life of the laser diode has expired, the following

symptoms will appear.

• The level of RF output (EFM output: amplitude of eye

pattern) will be low.

5.7 Replacement of laser pickup

Turn of the power switch and, disconnect the

power cord.

Replace the pickup with a normal one. (Refer

to "Removing the pickup unit" on the previous page.)

Is RF output

1.3 0.4Vp-p?

NO

Replace it.

YES

OK

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board

which is attached to the pickup is used to adjust the laser

power.Since this adjustment should be performed to match

the characteristics of the whole optical block, do not touch

the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup should

be replaced. If the semi-fixed resistor is adjusted while the

pickup is functioning normally, the laser pickup may be

damaged due to excessive current.

Plug the power cord in, and turn the power on.

At this time, check that the laser emits for about

seconds and the objective lens moves up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at

RF test point.

Finish.

1-28 (No.MA142)

Page 29

5.8 16 PIN CORD DIAGRAM (KD-AR960)

8

7

6

5

4

3

2

1

BK

RD

NC

BL/WH

WH

GN

VI

GY

YL

OR/WH

NC

BR

WH/BK

GN/BK

VI/BK

GY/BK

16 YL

8 BK

7 RD

15 OR/WH

13 BR TEL

5 BL/WH

3 GN

16

15

14

13

12

11

10

9

MEMORY

GND

ACC

ILL

REMOTE

RL+

BK

RD

BL

WH

BR

CAUTION!

REMOTE

ONLY

OUTPUT

Black

Red

Blue

White

Brown

GN

VI

GY

YL

OR

Green

Violet

Gray

Yellow

Orange

GND

11 GN/BK

10 VI/BK

12 WH/BK

RR

FR

FL

RL

TEL

2 VI

4 WH

1 GY

9 GY/BK

Rear Right

Front Right

Front Left

Rear Left

Telephone muting

RL-

RR+

RR-

FL+

FL-

FR+

FR-

REMOTE

ACC

MEMORY

GND

ILL

Remote out

ACC Line

Memory Backup Battery +

Ground

Illuminations Control

(No.MA142)1-29

Page 30

5.9 16 PIN CORD DIAGRAM (KD-LH910)

8

7

6

BL/WH

5

4

3

2

1

BK

RD

NC

WH

GN

VI

GY

YL

OR/WH

NC

NC

WH/BK

GN/BK

VI/BK

GY/BK

16 YL

8 BK

7 RD

15 OR/WH

5 BL/WH

3 GN

16

15

14

13

12

11

10

9

MEMORY

GND

ACC

ILL

REMOTE

RL+

BK

RD

BL

WH

REMOTE

CAUTION!

ONLY

OUTPUT

Black

Red

Blue

White

GN

VI

GY

YL

OR

Green

Violet

Gray

Yellow

Orange

GND

11 GN/BK

2 VI

10 VI/BK

4 WH

12 WH/BK

1 GY

9 GY/BK

RR

FR

FL

RL

Rear Right

Front Right

Front Left

Rear Left

RL-

RR+

RR-

FL+

FL-

FR+

FR-

REMOTE

ACC

MEMORY

GND

ILL

Remote out

ACC Line

Memory Backup Battery +

Ground

Illuminations Control

1-30 (No.MA142)

Page 31

(No.MA142)1-31

Page 32

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY CAR ELECTRONICS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA142)

Printed in Japan

VPT

Loading...

Loading...