Page 1

DDL-9000C-F

INSTRUCTION MANUAL

Page 2

CONTENTS

1. SPECIFICATIONS ............................................................................................................ 1

1-1. Specications of the sewing machine head ..................................................................... 1

1-2. Specications of the control box

2. SET UP .............................................................................................................................2

2-1. Drawing of table ................................................................................................................... 2

2-2. Cautions when setting up the sewing machine

2-2-1. How to carry the sewing machine ............................................................................................ 3

2-2-2. Caution when placing the sewing machine .............................................................................3

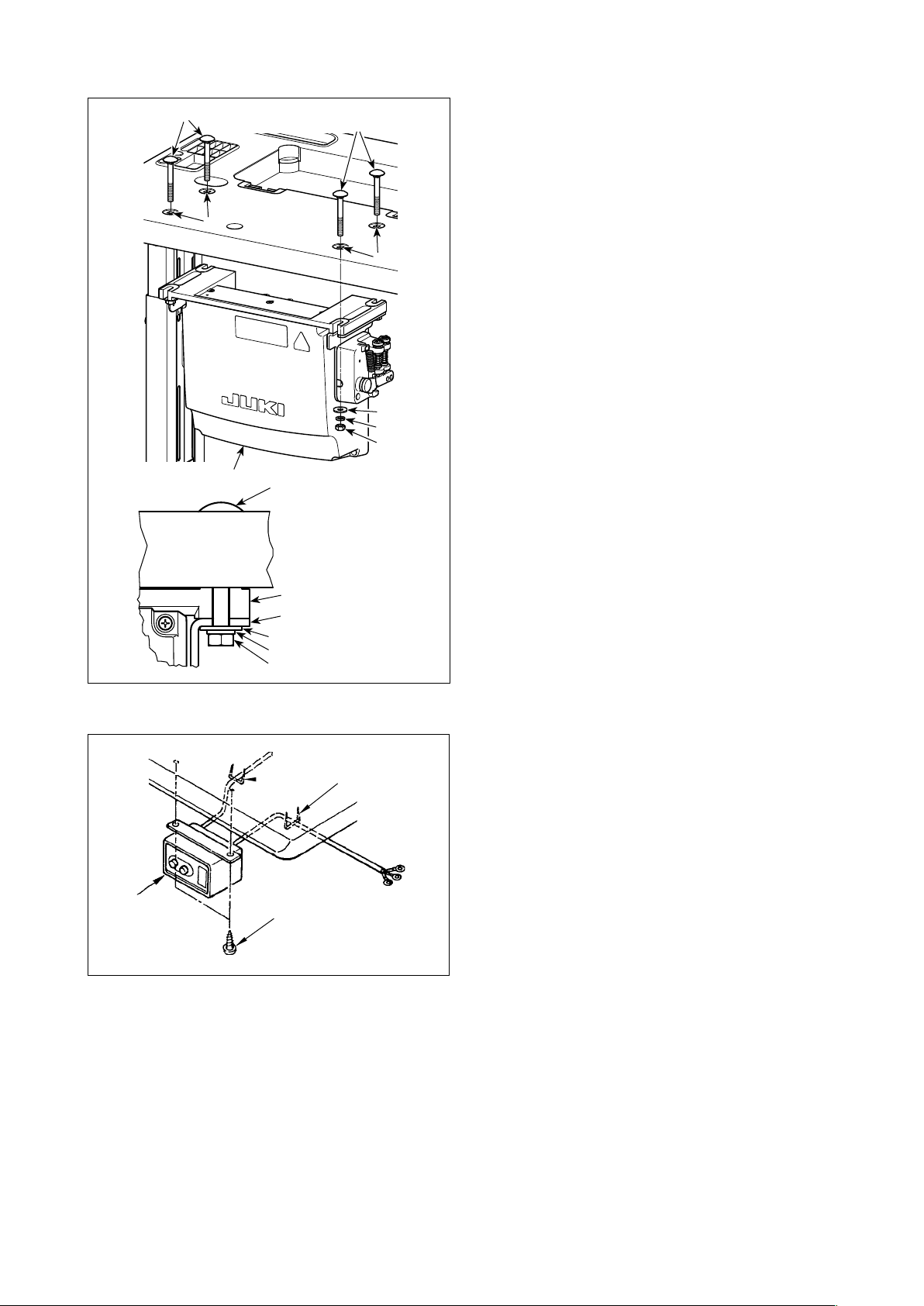

2-3. Installation ............................................................................................................................ 3

2-4. Installing the thread stand

2-5. Installing the electrical box

2-6. Connecting the power switch cable

2-6-1. Installing the power switch ....................................................................................................... 5

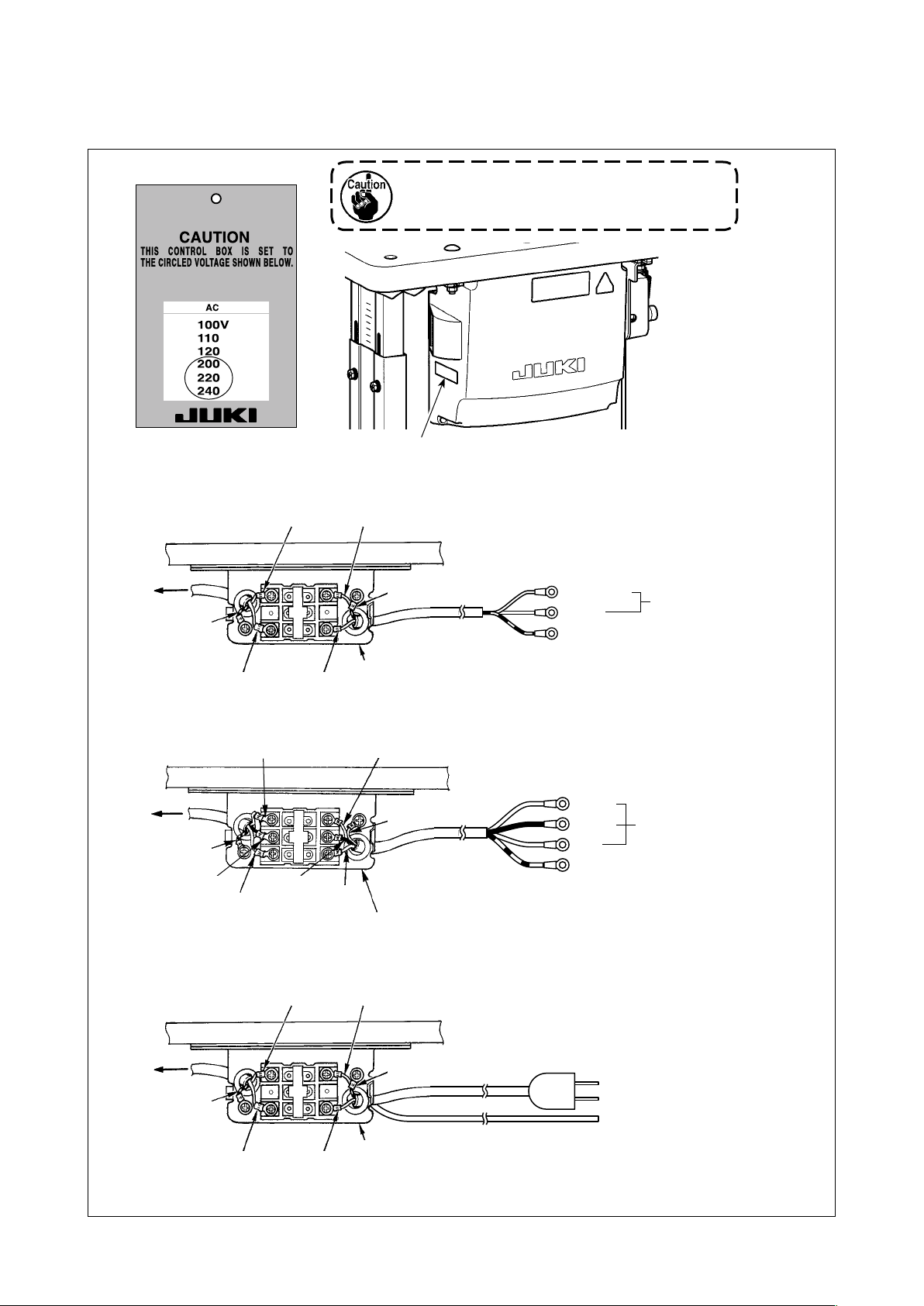

2-6-2. Connecting the power source cord ..........................................................................................6

2-6-3. Installing the reactor box ..........................................................................................................7

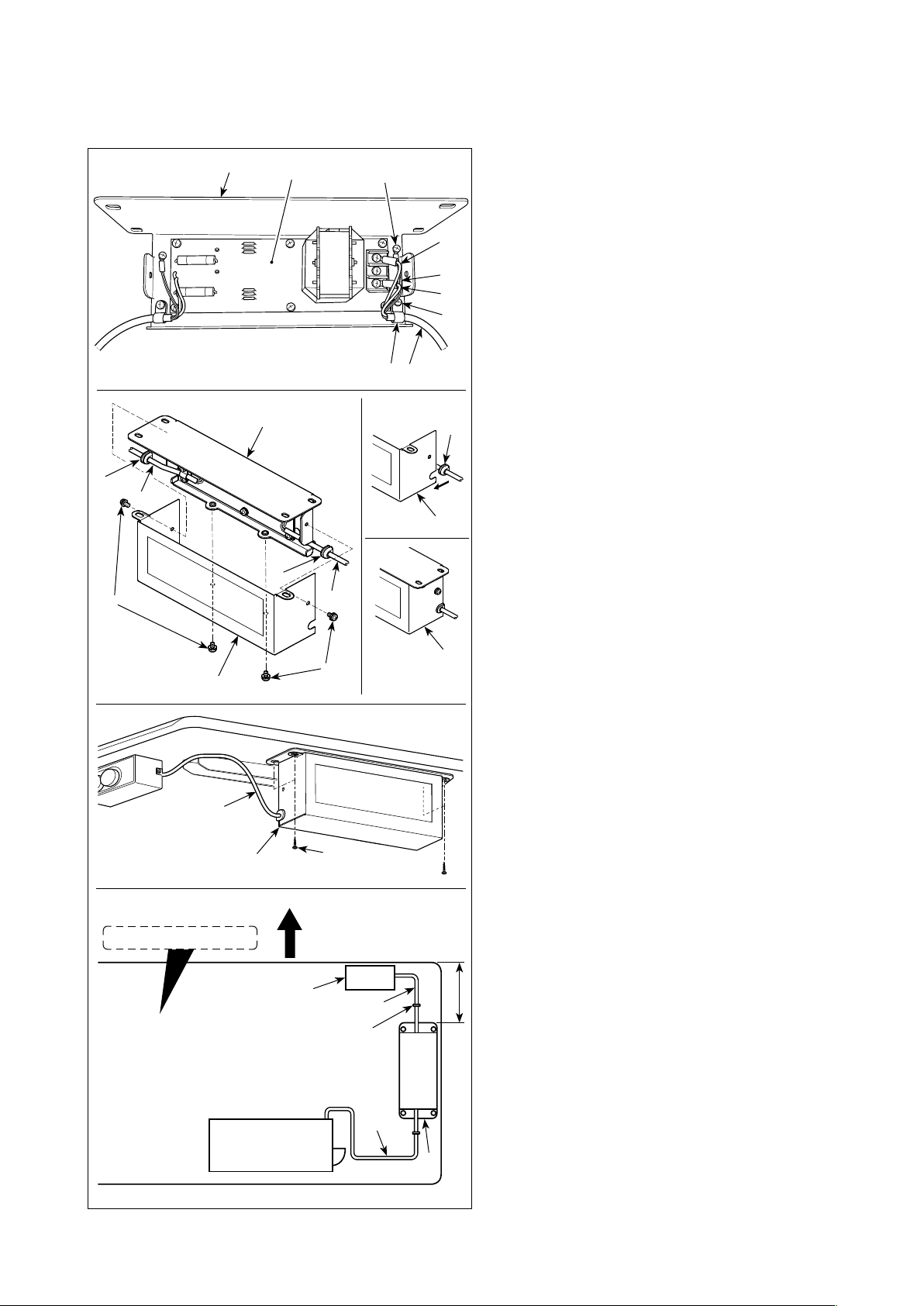

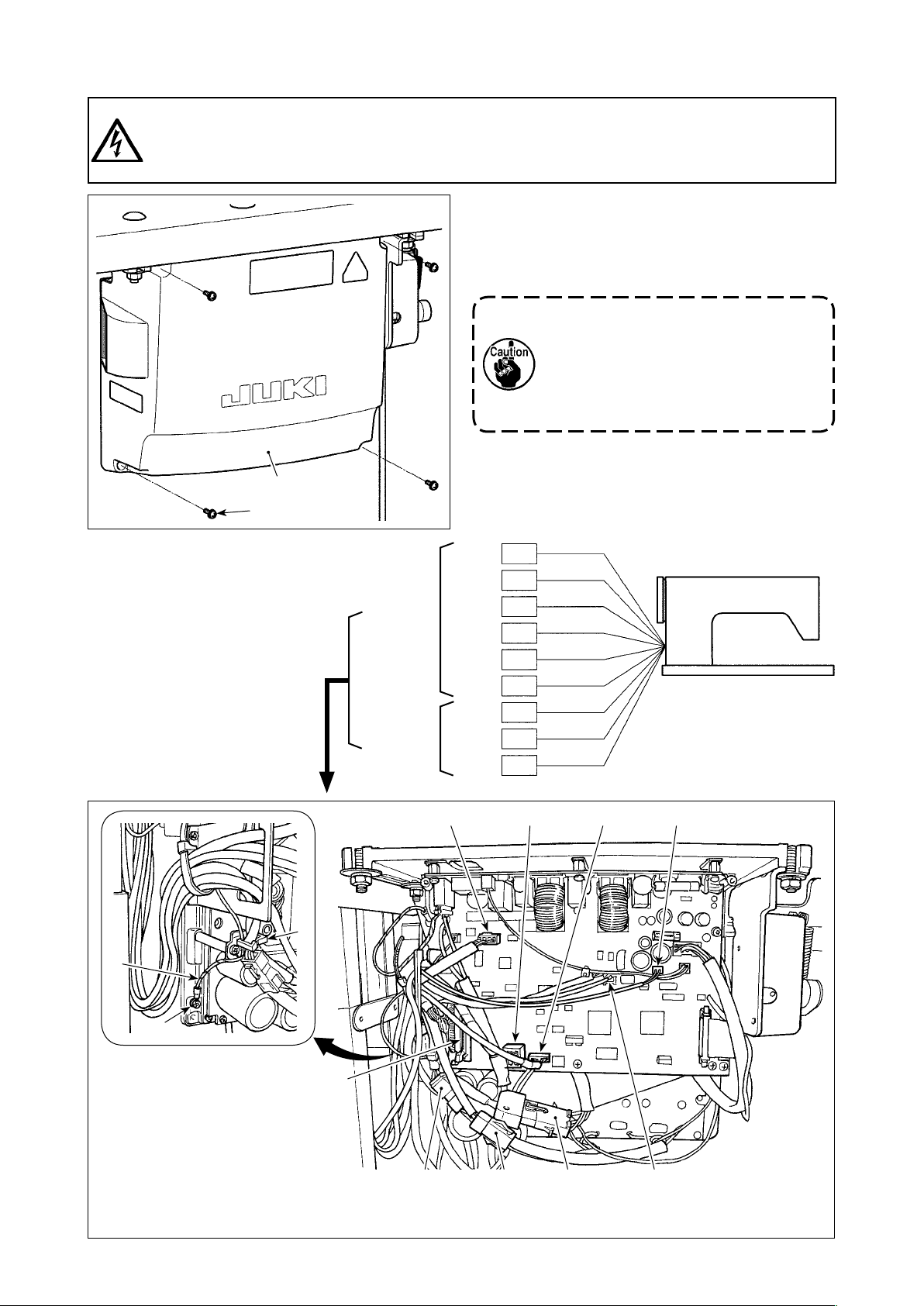

2-7. Connecting the cords .......................................................................................................... 8

2-8. Handling the cords

.............................................................................................................. 9

2-9. Attaching the connecting rod

2-10. Adjustment of the pedal

2-10-1. Installing the connecting rod ................................................................................................ 10

2-10-2. Adjusting the pedal angle .....................................................................................................10

2-11. Pedal operation .................................................................................................................. 10

2-12. Lubrication

......................................................................................................................... 11

2-13. How to use the operation panel (Basic explanation)

2-13-1. Selection of the language (operation to be done at rst) ..................................................12

2-13-2. Names and functions of the panel keys ..............................................................................14

2-13-3. Basic operation ...................................................................................................................... 15

.................................................................................................. 4

.................................................................................................... 10

....................................................................................... 1

................................................................ 3

................................................................................................ 5

.................................................................................. 5

............................................................................................. 9

..................................................... 12

3. PREPARATION BEFORE SEWING .............................................................................. 16

3-1. Attaching the needle ......................................................................................................... 16

3-2. Removing/tting the bobbin case

3-3. Winding the bobbin thread

............................................................................................... 17

3-4. Threading the machine head

3-5. Thread tension

3-5-1. Adjusting the thread tension No. 1 tension ........................................................................... 20

3-5-2. Adjusting the needle thread tension (Active tension) .......................................................... 20

3-5-3. Adjusting the bobbin thread tension .....................................................................................20

................................................................................................................... 20

3-6. Presser foot (Active presser device) ............................................................................... 21

3-6-1. Presser foot pressure .............................................................................................................. 21

3-6-2. Micro-lifter function .................................................................................................................21

3-6-3. Changing the initial value of presser foot pressure ............................................................. 22

3-6-4. Manual lifter .............................................................................................................................. 22

3-7. Adjusting the stitch length ............................................................................................... 23

3-8. Changing the sewing speed

3-9. LED hand light

3-10. Reverse feed stitching

3-11. Custom switch

................................................................................................................... 24

...................................................................................................... 24

................................................................................................................... 25

.................................................................................... 16

............................................................................................ 19

............................................................................................. 23

i

Page 3

3-12. Adjusting the amount of oil (oil splashes) in the hook .................................................. 26

3-12-1. Adjusting the amount of oil in the hook ..............................................................................26

3-12-2. How to conrm the amount of oil (oil splashes) ................................................................. 27

3-12-3. Sample showing the appropriate amount of oil .................................................................. 27

3-13. Adjusting the thread take-up spring and the thread take-up stroke............................. 28

4. HOW TO USE THE OPERATION PANEL .....................................................................29

4-1. Explanation of the sewing screen (when selecting a sewing pattern) ......................... 29

4-2. Sewing patterns

4-2-1. Sewing pattern conguration .................................................................................................33

4-2-2. List of sewing patterns ............................................................................................................ 34

4-2-3. Reverse feed stitching (at start) pattern ................................................................................ 36

4-2-4. Double reverse-feed stitch ...................................................................................................... 41

4-2-5. Editing the sewing patterns .................................................................................................... 42

4-2-6. List of pattern functions .......................................................................................................... 44

4-2-7. Reverse feed stitching (at end) pattern .................................................................................47

4-2-8. Teaching function .................................................................................................................... 48

4-2-9. One-touch utility changeover function .................................................................................. 50

4-2-10. Registration of a new sewing pattern ..................................................................................51

4-2-11. Copying a pattern ...................................................................................................................53

4-2-12. Narrow-down function ........................................................................................................... 54

4-3. Counter function ................................................................................................................ 56

4-3-1. Displaying the sewing screen under the counter display mode ......................................... 56

4-3-2. Types of the counter ................................................................................................................ 56

4-3-3. How to set the counter ............................................................................................................57

4-3-4. How to reset the count-completion state ..............................................................................60

4-4. Simplied chart of panel displays ................................................................................... 61

4-5. List of memory switch data

4-6. List of errors

4-7. Memory switch data

................................................................................................................. 33

.............................................................................................. 62

...................................................................................................................... 67

.......................................................................................................... 71

5. MAIN NEW FUNCTIONS ............................................................................................... 73

5-1. Shorter-thread remaining thread trimming ..................................................................... 73

5-2. Adjusting the feed dog height

5-3. Operating timing of the feed

5-4. Changing the feed locus

.......................................................................................... 76

............................................................................................. 77

................................................................................................... 78

6. CARE ............................................................................................................................. 79

6-1. Maintenance mode ............................................................................................................ 79

6-2. Conrmation of the amount of oil in the hook oil tank

6-3. Cleaning

6-4. Applying grease

............................................................................................................................. 80

................................................................................................................. 80

6-5. Applying grease to the needle bar lower bushing and the presser bar bushing

6-6. Replacing the fuse

............................................................................................................. 82

.................................................. 79

........ 81

7. ADJUSTMENT OF THE MACHINE HEAD (APPLICATION) ........................................83

7-1. Needle-to-hook relationship ............................................................................................. 83

7-2. Adjusting the needle thread presser device

7-3. Adjusting the thread trimmer

7-3-1. For checking of the thread trimming cam timing .................................................................87

7-3-2. Adjustment of the thread trimming cam timing ....................................................................87

7-3-3. Checking of the knife unit ....................................................................................................... 88

........................................................................................... 87

................................................................... 84

ii

Page 4

7-3-4.

Adjustment of the knife unit ..................................................................................... 89

7-3-5. Adjustment of thread trimming speed ...................................................................................90

7-4. Adjustment of the picker ................................................................................................... 91

7-4-1. Checking the standard adjustment ........................................................................................ 91

7-4-2. Standard adjustment ...............................................................................................................91

7-4-3. Standard adjustment (Adjustment at the tip position) ......................................................... 91

7-5. Active-presser multi-layered section detection function............................................... 92

7-5-1. Multi-layered section detection function ............................................................................... 92

7-5-2. Multi-layered-section detection number of stitches setting function ................................. 94

7-6. Grease shortage alarm ...................................................................................................... 95

7-6-1. Regarding the grease shortage alarm ...................................................................................95

7-6-2. E221 Grease-shortage error ....................................................................................................95

7-6-3. Regarding K118 error resetting procedure ............................................................................96

8. HOW TO USE THE OPERATION PANEL (APPLICATION) ..........................................97

8-1. Management of sewing patterns ...................................................................................... 97

8-1-1. Creation of a new pattern ........................................................................................................ 97

8-1-2. Copying a pattern ....................................................................................................................99

8-1-3. Deleting a pattern ...................................................................................................................100

8-2. Setting up the polygonal-shape stitching ..................................................................... 101

8-2-1. Editing a polygonal-shape stitching pattern ....................................................................... 101

8-2-2. Creating a new polygonal-shape stitching pattern

8-2-3. Setting the step from which polygonal-shape stitching is started ................................... 103

8-3. Cycle pattern .................................................................................................................... 104

8-3-1. Selecting the cycle pattern ...................................................................................................104

8-3-2. Editing cycle sewing data ....................................................................................................105

8-3-3. Creating a new cycle pattern ................................................................................................106

8-3-4. Setting the step from which cycle sewing pattern is started ............................................108

8-4. Custom pitch .................................................................................................................... 109

8-4-1. Selecting a custom pitch .......................................................................................................109

8-4-2. Creating a new custom pitch ................................................................................................ 111

8-4-3. Custom pitch edit function ................................................................................................... 114

8-4-4. Copying/deleting a custom pitch ......................................................................................... 115

8-5. Condensation custom pattern ........................................................................................ 116

8-5-1. Selecting the condensation custom .................................................................................... 116

8-5-2. Creating a new condensation custom ................................................................................. 116

8-5-3. Condensation custom edit function ..................................................................................... 119

8-5-4. Copying/deleting a condensation custom ...........................................................................120

8-6. Simple lock of the screen ............................................................................................... 121

8-7. Version information

8-8. Adjustment of brightness of the LED panel

8-9. Information

8-9-1. Data communication ..............................................................................................................123

8-9-2. USB .........................................................................................................................................126

8-9-3. Production management ....................................................................................................... 128

8-9-4. NFC ..........................................................................................................................................131

....................................................................................................................... 123

......................................................................................................... 121

.................................................................. 122

8-10. Key customization ......................................................................................................... 132

8-10-1. Assignable data....................................................................................................................132

8-10-2. How to assign a function to a key ...................................................................................... 133

.............................................................103

iii

Page 5

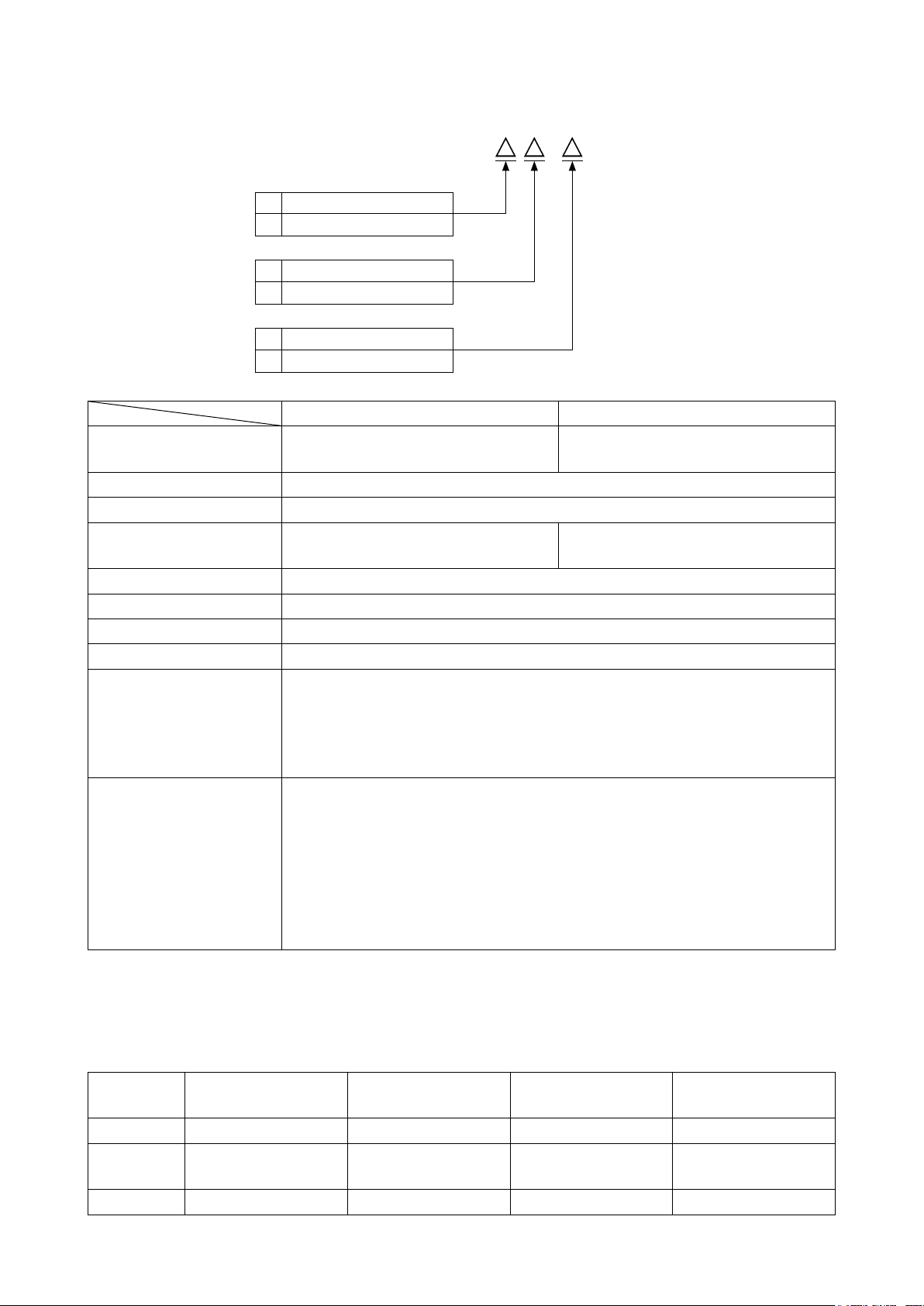

1. SPECIFICATIONS

1-1. Specications of the sewing machine head

DDL-9000C-F - B

Face plate portion lubricating method

M Semi-dry

S Micro-quantity lubrication

Seam specication

S Medium-weight materials

H Heavy-weight materials

Needle thread nipper specication

N With

0 Without

DDL-9000C-FMS DDL-9000C-FSH

Max. sewing speed

(standard locus)

Stitch length 5 mm

Presser foot pressure control Electronic control

Needle

Lubricating oil JUKI NEW DEFRIX OIL No. 1 or JUKI CORPORATION GENUINE OIL 7

Motor AC servo motor

Horizontal feed control Electronic control

Vertical feed control Electronic control

Number of patterns

Noise

*1

Stitch length 0 to 4.00 : 5,000 sti/min

Stitch length 4.05 to 5.00 : 4,000 sti/min

1738 Nm65 to 110 (DB×1 #9 to 18)

134 Nm65 to 110 (DP×5 #9 to 18)

Sewing pattern

Cycle sewing pattern ................... 9 patterns

Custom-pitch pattern ................... 20 patterns

Condensation custom pattern .....9 patterns

FMS ;

- Equivalent continuous emission sound pressure level (LpA) at the workstation:

A-weighted value of 81.5 dBA ; (Includes KpA = 2.5 dBA) ; according to ISO 10821-

C.6.2 -ISO 11204 GR2 at 5,000 sti/min.

FSH ;

- Equivalent continuous emission sound pressure level (LpA) at the workstation:

A-weighted value of 77.5 dBA ; (Includes KpA = 2.5 dBA) ; according to ISO 10821-

C.6.2 -ISO 11204 GR2 at 4,500 sti/min.

............................99 patterns (For the polygonal shape sewing, as

many as 10 patterns can be registered.)

Stitch length 0 to 4.00 : 4,500 sti/min

Stitch length 4.05 to 5.00 : 4,000 sti/min

1738 Nm125 to 160 (DB×1 #20 to 23)

134 Nm125 to 160 (DP×5 #20 to 23)

• The sewing speed will vary depending on the sewing conditions. The sewing speed preset at the time of

shipping is 4,000 sti/min.

*1 : Needle used depends on the destination.

1-2. Specications of the control box

Supply

voltage

Frequency 50Hz/60Hz 50Hz/60Hz 50Hz/60Hz 50Hz/60Hz

Operating

environment

Input 520VA 520VA 520VA 350VA

Single phase

100 to 120V

Temperature : 0 to 35˚C

Humidity : 90% or less

3-phase

200 to 240V

Temperature : 0 to 35˚C

Humidity : 90% or less

– 1 –

Single phase

220 to 240V

Temperature : 0 to 35˚C

Humidity : 90% or less

Single phase

220 to 240V CE

Temperature : 0 to 35˚C

Humidity : 90% or less

Page 6

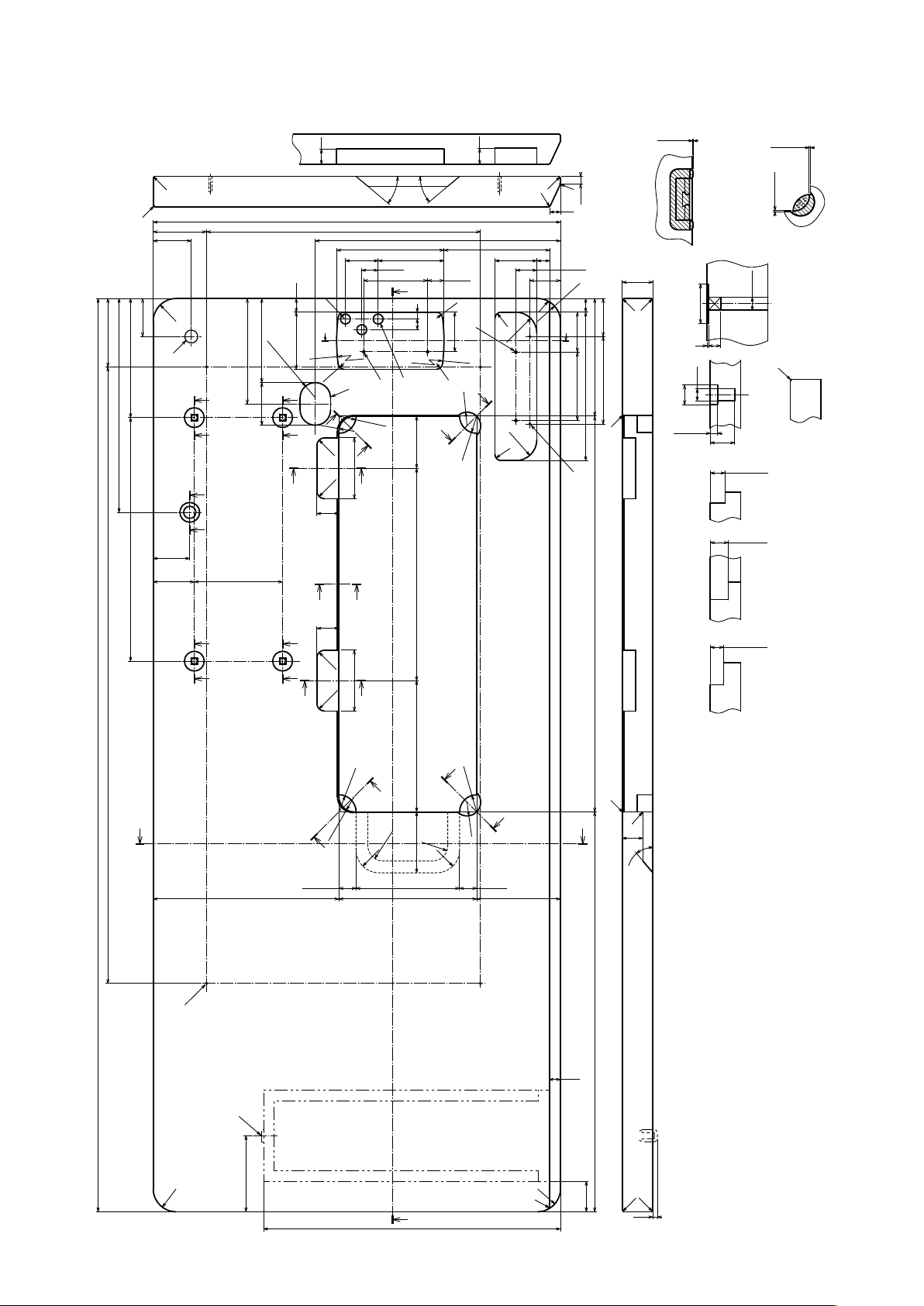

2. SET UP

2-1. Drawing of table

90

810

281

U-U

156.5

320

+0.5

322

Y

R8

52

R242.5

R8

21.5

R18

R22.5

0

21

F

Y

R8

139

55

R8

R27.5

R27.5

R2

R2

R2

X-X

10

14

Rubber cushion

17

27.5

40

R30

R6

18

52.5

S

90

195

installing drawing for

R2

R2

50

154.6

115

C1

H

+0.5

0

S-S

20

R2

R2

70

50

18

R30

50

75

110.5

R242.5

C

(138.5)

56

2×R20

VV

535

360

43

R8

S

R8

G

40°

WW

E

141

21.5

40°

86.5

84

9

14

D

Z

V V

R20

R10

X

R10

29

R22.5

Z

68.5±0.5

80

X

Q Q

48

54

116

T

T

29

VV

V

R10

279±1

1±0.5

Y-Y

reference

X-X部ゴム取付参考図

40

∅26

V-V(1:1)

(4ヵ所)

8

1

∅16

∅26

Q-Q

9.5±1

Z-Z

(2ヵ所)

Y-Y

(2ヵ所)

Y-Y部ゴム取付参考図

Rubber cushion

installing drawing for

∅8.5

32±1

1.2±0.5

reference

I

T-T

19.5±0.5

23.5±0.5

17.5±0.5

1.2±0.5

V

80

R10

X

X

X-X

(2ヵ所)

(2 locations) (2 locations) (2 locations) (4 locations)

W-W

1200

(172.5)

Y

R22.5

Z

U

R20

Z

R30

(244)

(22.5)

R20

80

136

-1

181

0

A

R20

R22.5

Y

R18

R30

22.5

110

U

(525.4) 520

(15)

C1

R2

27

40°

B

R30

100

390

R30

R6

(40)

R2

R2

(6)

Installing position of drawer stopper (on the reverse side)

ø17 drilled hole D 3×ø13 drilled hole

2×ø3.5, depth 10

2×ø3.5, depth 10

Through hole

B

C

E

A 4×ø3.4 on the bottom surface, depth 20 (Drill a hole at the time of set-up.)

F

C1.5 to C2.5 (hinge side only)

G

I

H 2×ø3.4 on the bottom surface, depth 10 (Drill a hole at the time of set-up.)

– 2 –

Page 7

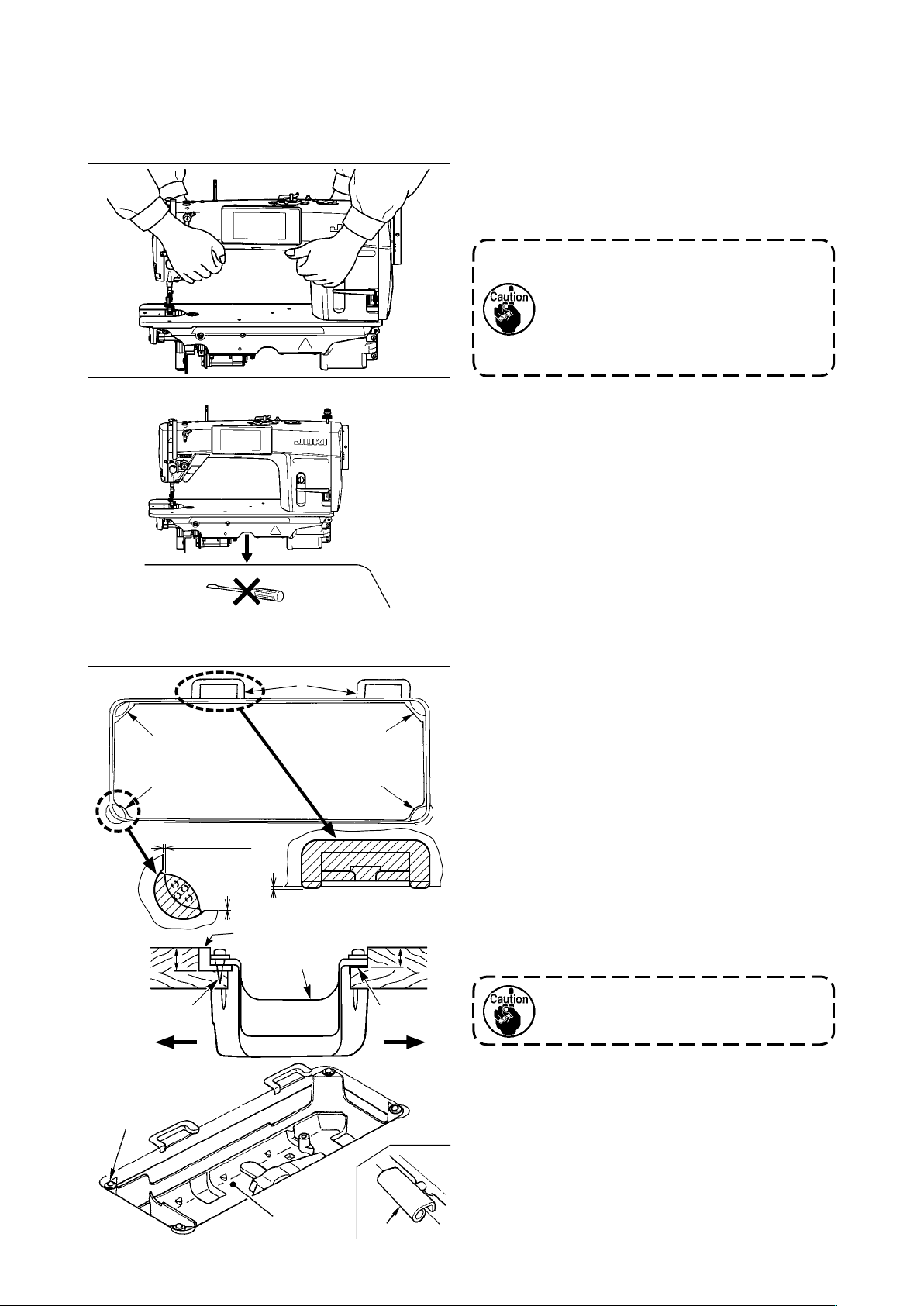

2-2. Cautions when setting up the sewing machine

Thank you very much for the purchase of JUKI Industrial Sewing Machine this time. Make sure of items 2-1

through 2-12 before operating to use this sewing machine with ease.

2-2-1. How to carry the sewing machine

Carry the sewing machine while holding the machine

arm with two persons as shown in the gure.

1. Never hold the handwheel since it

rotates.

2. Be sure to handle the sewing

machine with two persons or more

since the sewing machine weighs

40.5 kg or more.

2-2-2. Caution when placing the sewing ma-

chine

Place the sewing machine on a horizontal and plane

place when placing it and do not place any protrud-

ing thing such as a screwdriver or the like.

2-3. Installation

❸

❶

1.2 ± 0.5 mm

23.5 mm

❷

1 ± 0.5 mm

1.2 ± 0.5 mm

❶

A

❹

❺

❸

❶

19.5 mm

❸

B

1) The under cover ❹ should rest on the four cor-

ners of the machine table groove. Mount rubber

hinge seat ❺ on the table and x it on the table

with a nail.

2) Fix two rubber seats ❶ on side A (operator’s

side) using nails ❷ as illustrated above. Fix two

cushion seats ❸ on side B (hinged side) using a

rubber-based adhesive. Then place under cover

❹ on the xed seats.

3) Fit hinge ❼ into the opening in the machine bed,

and t the machine head to table rubber hinge

seat ❺ before placing the machine head on cushions ❽ on the four corners.

Do not hold the handwheel.

❽

❹

❼

– 3 –

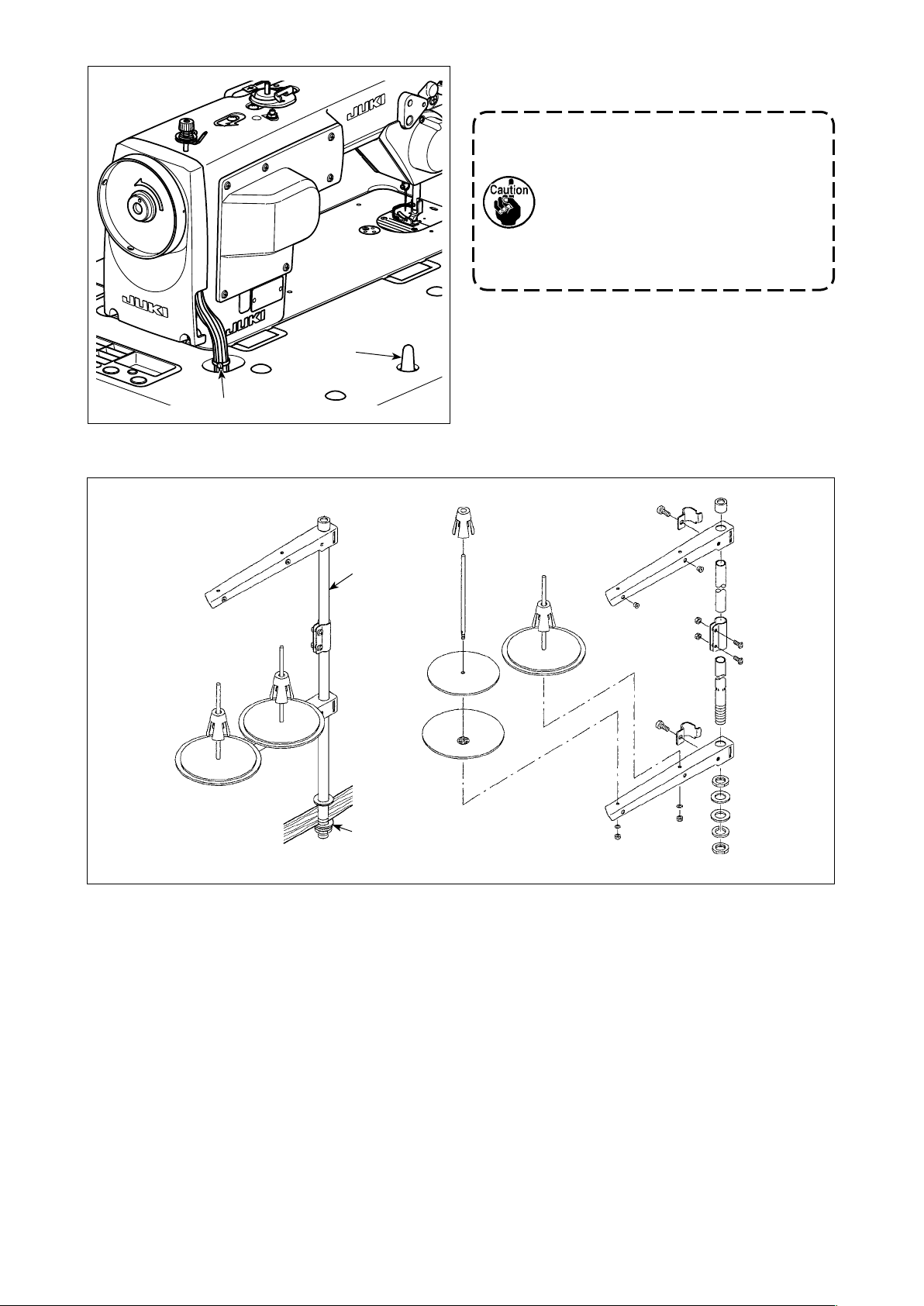

Page 8

❻

2-4. Installing the thread stand

4) Securely attach head support rod ❾ to the table

until it goes no further.

Be sure to mount the machine head

support rod ❾ on the machine table so

that its height from the table surface

becomes 63 to 68 mm. For the sewing

machine provided with the AK device,

be sure to mount the support rod ❾ on

the table so that its height from the table

surface becomes 33 to 38 mm.

5) Bundle cable clip band ❻ supplied as accessories

of the machine head at the root of the cable.

❾

❷

❶

1) Assemble the thread stand unit, and insert it in the hole in the machine table.

2) Tighten nut ❶.

3) For ceiling wiring, pass the power cord through spool rest rod ❷.

– 4 –

Page 9

2-5. Installing the electrical box

❷

a

❶

❷

❷

a

Install control box ❶ on the table using four holes

a in the table. Secure the control box with four bolts

❷, four plain washers ❸, four spring washers ❹

and four hexagonal nuts ❺ supplied with the control

box.

At this time, insert the nut and washer supplied with

the unit as accessories as shown in the gure so

that the control box is securely xed.

❸

❹

❺

Frame

Pedal sensor

❸

❹

❺

2-6. Connecting the power switch cable

❸

❶

❷

2-6-1. Installing the power switch

Fix power switch ❶ under the machine table with

wood screws ❷.

Fix the cable with staples ❸ supplied with the ma-

chine as accessories in accordance with the forms

of use.

– 5 –

Page 10

2-6-2. Connecting the power source cord

Voltage specications at the time of delivery from the factory are indicated on the voltage indication seal.

Connect the cord in accordance with the specications.

Power indication tag

Never use under the wrong voltage and phase.

(For example : In the case of 200V)

• Connecting single phase 220 to 240V

Control box

Green/Yellow

Table

Light blue

Brown

Light blue

Brown

Power switch

• Connecting 3-phase 200 to 240V

White

Table

Control box

Green/Yellow

Black

Red

Black

Red

Power switch

Rating plate

Green/Yellow

White

Green/Yellow

Light blue

Brown

Green/Yellow — GND

White

Black

Red

Green/Yellow — GND

AC220 to 240V

AC200 to 240V

• Connecting single phase 100 to 120V

Control box

Green/Yellow

Table

Light blue

Brown

Light blue

Brown

Power switch

Green/Yellow

– 6 –

Page 11

2-6-3. Installing the reactor box

* For the EU-type models, install the reactor box that is supplied with the sewing machine.

❽

❼

❾

❼

Undersurface of table

❸

❸

❷

❽

❶

❾

Operator's side

❹

❺

❶

A

C

B

❻

❽

1) Connect the terminals of power cord ❶ of the

SC-950(951) to reactor-box PCB asm. ❷ and

to reactor box mounting plate ❸.

Connect brown wire A to the rst connector

and blue wire B to the third connector respec-

tively from the top of terminal block on the

reactor box PCB asm. using screws. Connect

green/yellow wire C to reactor box mounting

plate ❸ with earth setscrew ❹.

2) Attach cable clip ❺ to the power cord of SC-

950(951). Attach the power cord together with

the cable clip to reactor box mounting plate ❸

with cable clip setscrew ❻.

3) Attach cord bushes ❽ to input/output cables

❶ and ❼ of the reactor box. Attach both bush-

es in the same manner.

4) Attach reactor box cover to reactor box

mounting plate ❸ with four reactor-box cover

setscrews ❾.

At this time, x cord bushes ❽ attached to

input/output cables ❶ and ❼ in the concave

section on reactor box cover to eliminate a

gap between reactor box and cover .

5) Install reactor box on the table stand with

four accessory wood screws at the position

that is approximately 200 mm away from the

front end of table stand.

Adjust the installing position according to the

size of table stand so that the reactor box does

not protrude from the edge of table stand.

6) Fix input/output cables ❶ and ❼ of reactor

box on the table stand using accessory cord

staple .

At this time, take care not to cross the input-

and output-cables.

Power box

SC-950(951)

❶

❼

200 mm

– 7 –

Page 12

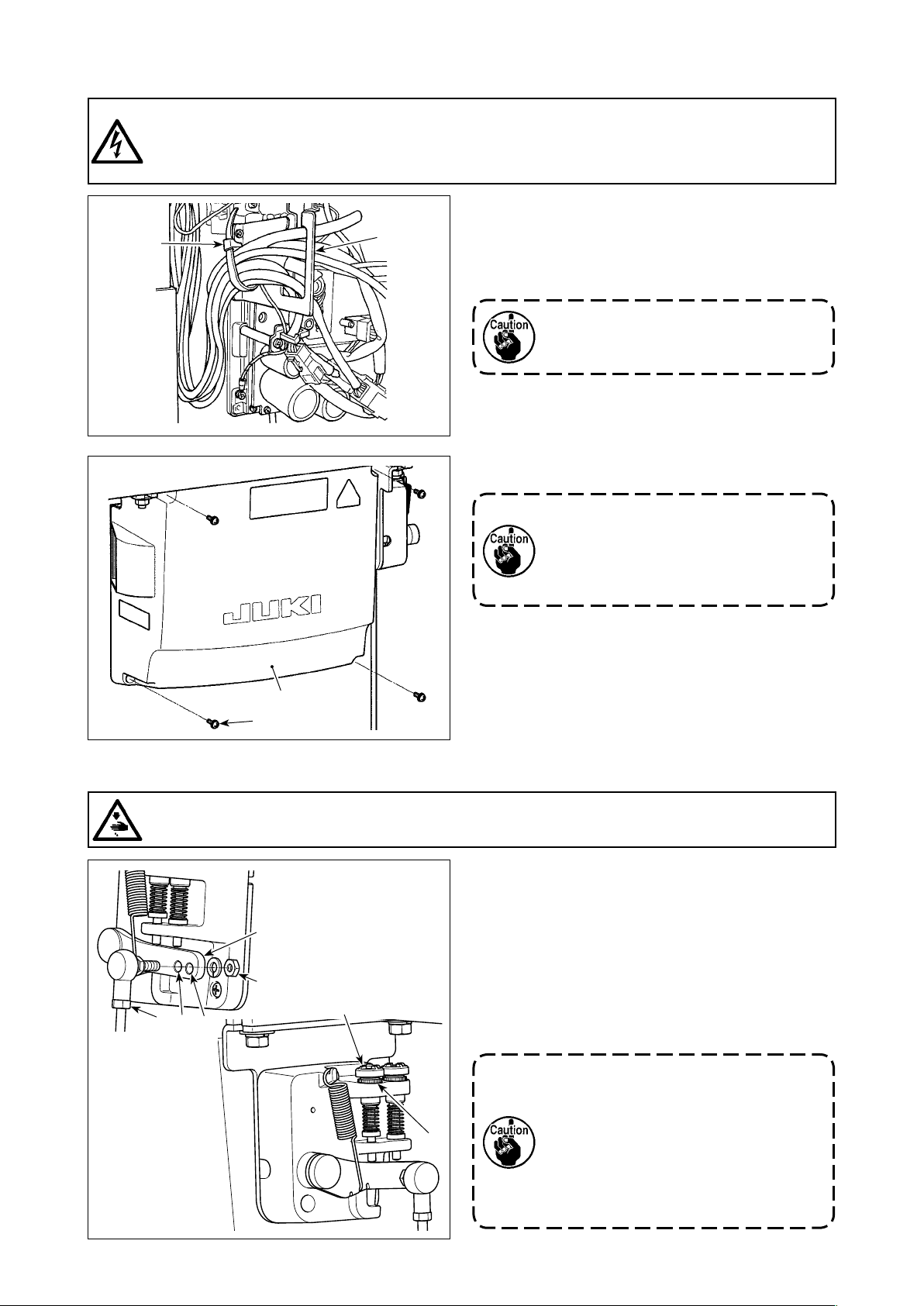

2-7. Connecting the cords

DANGER :

1. To prevent personal injuries caused by electric shock hazards or abrupt start of the sewing

machine, carry out the work after turning OFF the power switch and a lapse of 5 minutes or more.

2. To prevent accidents caused by unaccustomed work or electric shock, request the electric expert

or engineer of our dealers when adjusting the electrical components.

❶

❷

1) Loosen four setscrews ❷ of control box cover ❶.

Remove control box cover ❶.

2) Connect the cords to the respective connectors

on CTL PWB, PWR PWB. (Fig. 1)

Securely x the cords to be connected

to CN20, CN21 and CN22 with cable

clamp ❸.

Check the connector markers of

CN21 and CN22 to prevent improper

connection.

3) Fix the ground wire ❹ on position A of the control

box with a screw. (Fig. 2)

❹

❸

CTL PWB

PWR PWB

CN30

CN32

CN36

CN37

CN38

CN63

CN20

CN21

CN22

CN37

9P

40P

4P

4P

15P

2P

4P

6P

6P

CN30

White

Gray

White

White

White

Black

White

White

White

CN38 CN63

A

Fig. 2

CN32

– 8 –

CN22

CN20CN21

CN36

Fig. 1

Page 13

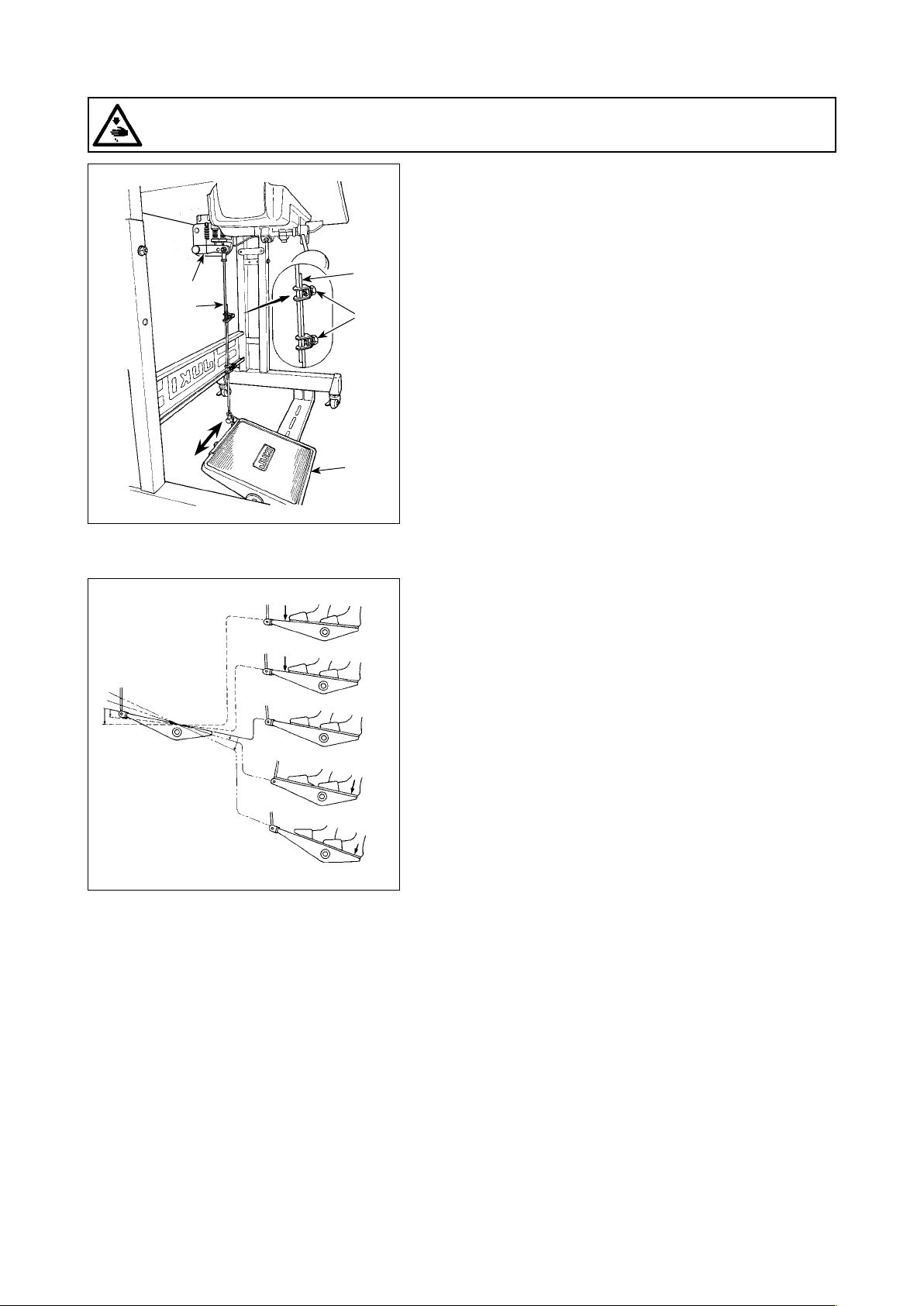

2-8. Handling the cords

DANGER :

1. To prevent personal injuries caused by electric shock hazards or abrupt start of the sewing

machine, carry out the work after turning OFF the power switch and a lapse of 5 minutes or more.

2. To prevent accidents caused by unaccustomed work or electric shock, request the electric expert

or engineer of our dealers when adjusting the electrical components.

❷

➡

A

❶

1) Bring the cords under the table into the control

box.

2) Put the cord brought into the control box through

cord exit plate ❶ and x cable clip band ❷.

Arrange the cord so that it is not tensed

or hitched even when the machine head

is tilted. (See A section.)

3) Install control box cover ❸ with four setscrews ❹.

For the purpose of preventing the cord

breakage, take care not to allow the

cords to be caught between the control

box and control box cover ❸ when

attaching the latter.

❸

❹

2-9. Attaching the connecting rod

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and a lapse of 5 minutes or more.

❷

❸

❶

B

A

❹

❺

1) Fix connecting rod ❶ to installing hole B of pedal

lever ❷ with nut ❸.

2) Installing connecting rod ❶ to installing hole A

will lengthen the pedal depressing stroke, and the

pedal operation at a medium speed will be easier.

3) The pressure increases as you turn reverse depressing regulator screw ❹ in, and decreases as

you turn the screw out.

1. If the screw is excessively loosened,

the spring will come off. Loosen the

screw to such an extent that the top

of the screw can be observed from

the case.

2. Whenever you have adjusted the

screw, be sure to secure the screw by

tightening metal nut ❺ to prevent the

screw from loosening.

– 9 –

Page 14

2-10. Adjustment of the pedal

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

2-10-1. Installing the connecting rod

1) Move pedal ❸ to the right or left as illustrated by the

arrows so that motor control lever ❶ and connecting rod

❷ are straightened.

❶

❷

2-11. Pedal operation

❸

❷

❹

E

A

B

C

D

2-10-2. Adjusting the pedal angle

1) The pedal tilt can be freely adjusted by changing the

length of the connecting rod ❷.

2) Loosen adjust screw ❹, and adjust the length of connecting rod ❷.

The pedal is operated in the following four steps :

1) The machine runs at low sewing speed when you lightly

depress the front part of the pedal. B

2) The machine runs at high sewing speed when you further

depress the front part of the pedal. A (If the automatic

reverse feed stitching has been preset, the machine runs

at high speed after it completes reverse feed stitching.)

3) The machine stops (with its needle up or down) when you

reset the pedal to its original position. C

4) The machine trims threads when you fully depress the

back part of the pedal. E

* When the auto-lifer (AK device) is used, one more op-

erating switch is provided between the sewing machine

stop switch and thread trimming switch.

The presser foot goes up when you lightly depress the

back part of the pedal D, and if you further depress the

back part, the thread trimmer is actuated.

When starting sewing from the state that the presser foot

has been lifted with the Auto-lifter and you depress the

back part of the pedal, the presser foot only comes down.

• If you reset the pedal to its neutral position during the au-

tomatic reverse feed stitching at seam start, the machine

stops after it completes the reverse feed stitching.

• The machine will perform normal thread trimming even

if you depress the back part of the pedal immediately

following high or low speed sewing.

• The machine will completely perform thread trimming

even if you reset the pedal to its neutral position immedi-

ately after the machine started thread trimming action.

– 10 –

Page 15

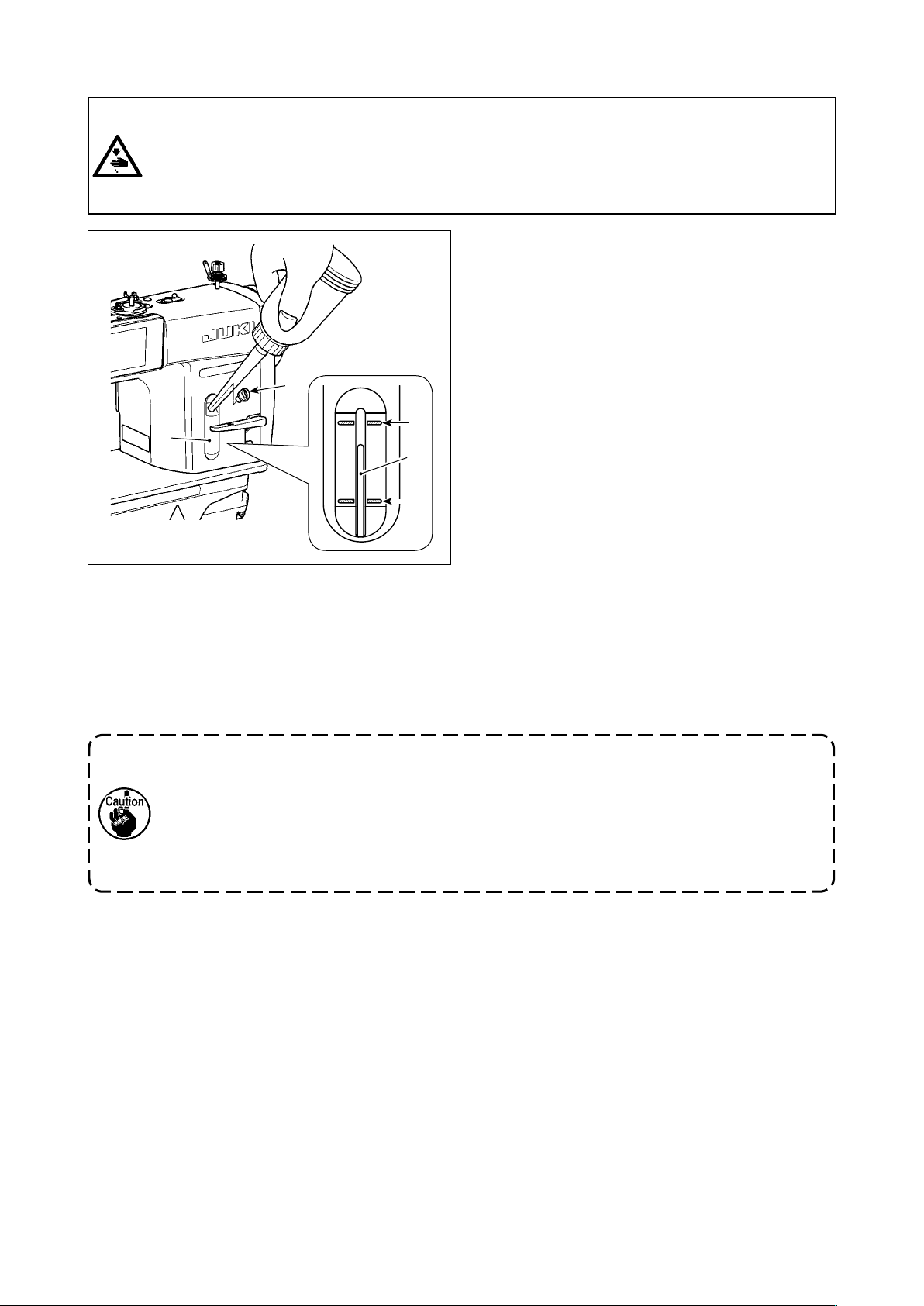

2-12. Lubrication

WARNING :

1. Do not connect the power plug until the lubrication has been completed so as to prevent accidents

due to abrupt start of the sewing machine,

2. To prevent the occurrence of an inammation or rash, immediately wash the related portions if oil

adheres to your eyes or other parts of your body.

3. If oil is mistakenly swallowed, diarrhea or vomitting may occur. Put oil in a place where children

cannot reach.

❷

❶

A

❸

B

Fill the oil tank with oil for hook lubrication before

operating the sewing machine.

1) Remove oil hole cap ❶ and ll the oil tank with

JUKI NEW DEFRIX OIL No.1 (part number : MD-

FRX1600C0) or JUKI CORPORATION GENUINE

OIL 7 (part number : 40102087) using the oiler

supplied with the machine.

2) Fill the oil tank with the oil until the top end of

oil amount indicating rod ❸ comes between the

upper engraved marker line A and the lower

engraved marker line B of oil amount indicating

window ❷.

If the oil is lled excessively, it will leak from the

air vent hole in the oil tank or proper lubrication

will be not performed. In addition, when the oil is

vigorously lled, it may overow from the oil hole.

So, be careful.

3) When you operate the sewing machine, rell oil if

the top end of oil amount indicating rod ❸ comes

down to the lower engraved marker line B of oil

amount indicating window ❷.

1. When you use a new sewing machine or a sewing machine after an extended period of

disuse, use the sewing machine after performing break-in at 2,000 sti/min or less.

2. For the oil for hook lubrication, purchase JUKI NEW DEFRIX OIL No. 1 (part number :

MDFRX1600C0) or JUKI CORPORATION GENUINE OIL 7 (part number : 40102087).

3. Be sure to lubricate clean oil.

4. Do not operate the machine with the oil hole cap ❶ removed. Never remove cap ❶ from the

oil inlet in any case other than oiling. In addition, take care not to lose it.

– 11 –

Page 16

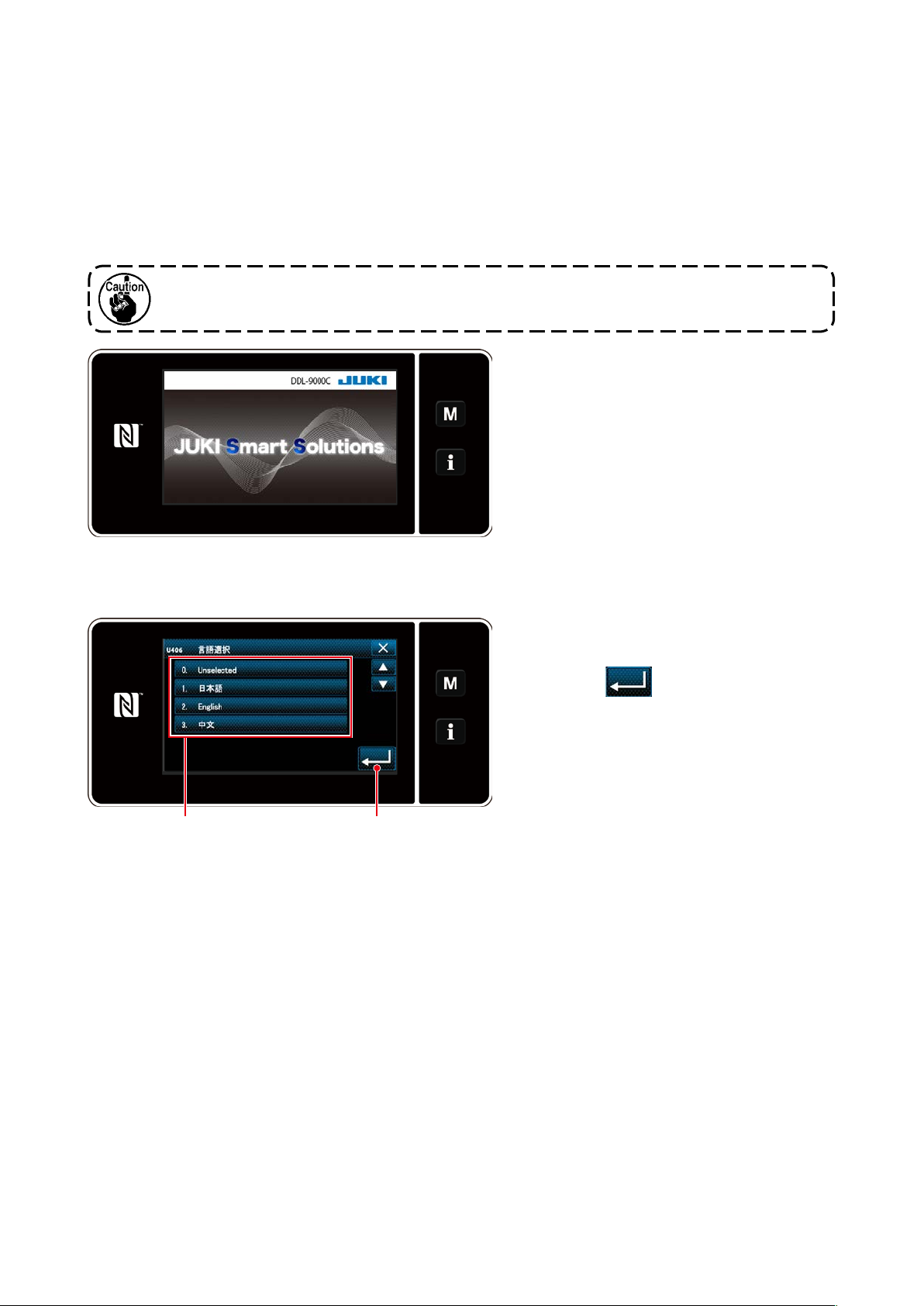

2-13. How to use the operation panel (Basic explanation)

2-13-1. Selection of the language (operation to be done at rst)

Select the language to be displayed on the operation panel when you turn ON the power to your sewing

machine for the rst time after the purchase. Note that, if you turn the power OFF without selecting the

language, the language selection screen will be displayed every time you turn ON the power to the sew-

ing machine.

Turning ON the power switch

①

Be aware that the needle bar moves automatically. The needle bar can also be set so that it

does not move automatically. Refer to "4-5. List of memory switch data" p. 62 for details.

Firstly, the welcome screen is displayed

on the panel. Then, the language selection

screen is displayed.

<Welcome screen>

Selecting the language

②

Select the language you want to use and

press corresponding language button ❶.

Then, press

❷

.

This determines the language to be dis-

played on the panel.

❷❶

<Language selection screen>

The language to be displayed on the operation panel can be changed using the memory switch U406.

Refer to "4-5. List of memory switch data" p. 62 for details.

– 12 –

Page 17

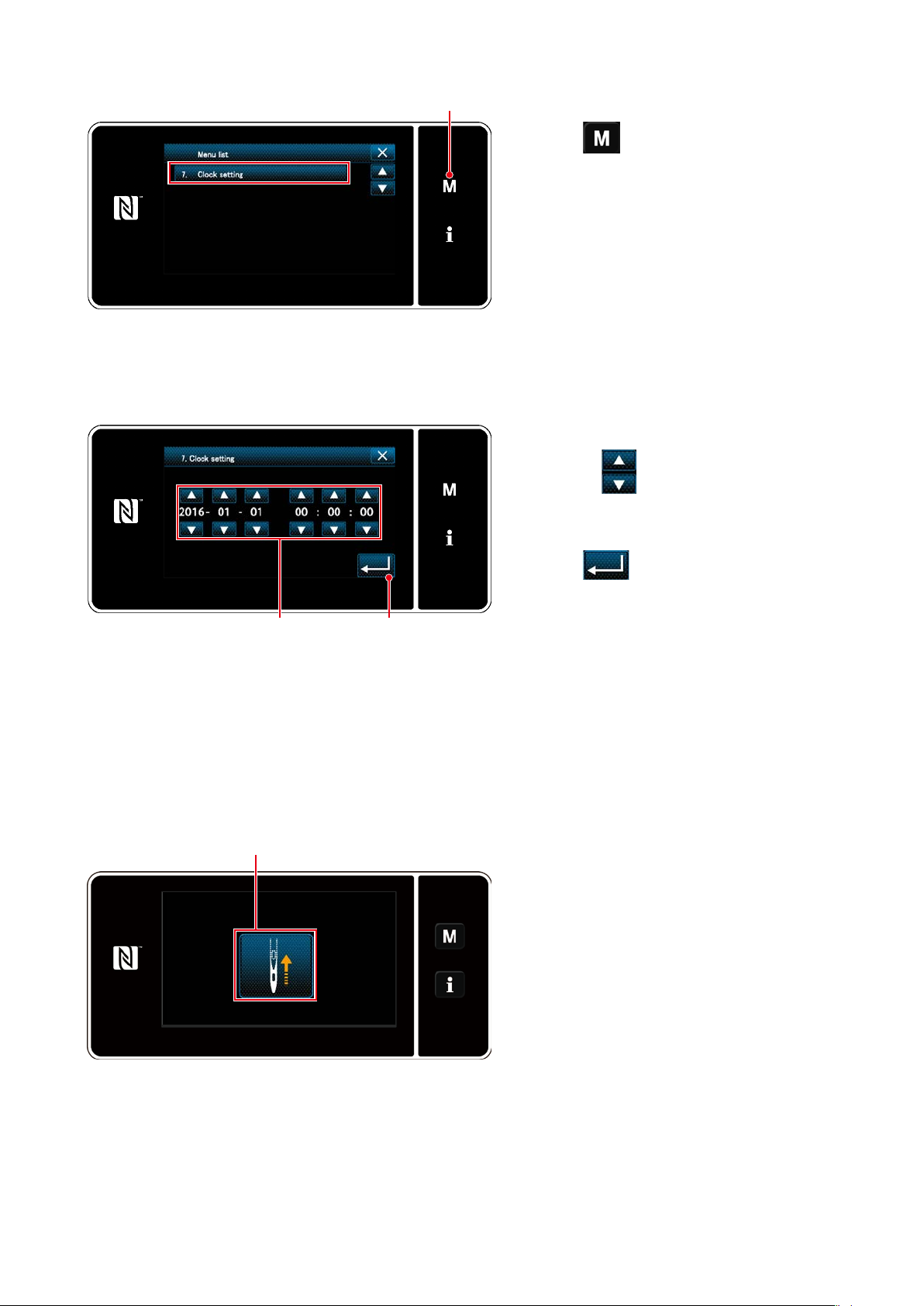

Setting the clock

③

❸

<Mode screen>

1. Press

❸

.

The "mode screen" is displayed.

2. Select the "7. Clock setting".

The "clock setting screen" is displayed.

3. Enter year/month/day/hour/minute/sec-

ond with

❹

.

The time entered is displayed in 24-hour

notation.

4. Press

to conrm the clock set-

❺

<Clock setting screen>

Retrieval of the origin

④

❻

ting. Then, the current screen returns to

❺❹

the previous screen.

Press ❻ to bring the origin retrieval needle

bar to its upper position.

* In the case "U090 Initial operation upper

position stop function" is set to "1", the

screen shown on the left is not displayed,

but the needle bar automatically goes up

to its upper position.

<Origin retrieval screen>

– 13 –

Page 18

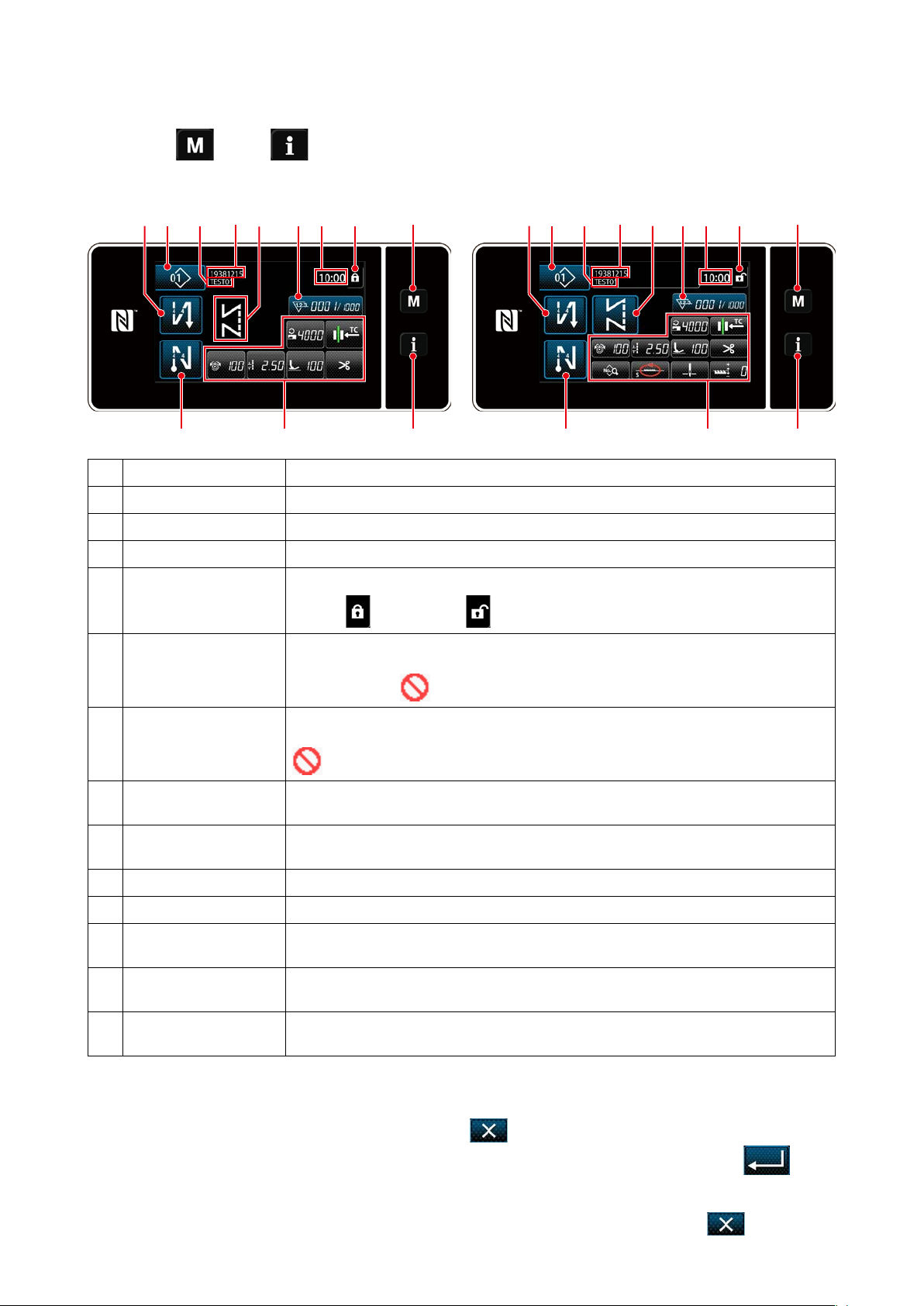

2-13-2. Names and functions of the panel keys

Changeover between the operator mode and the maintenance personnel mode is carried out by

*

pressing

❶

and

simultaneously.

❷

<Operator mode> <Maintenance personnel mode>

❺ ❼

❽ ❾ ❹ ❶❸

Switch/display Description

Mode key This switch is used for displaying the menu screen.

❶

Information key This switch is used for displaying the information screen.

❷

Sewing pattern No. button

❸

Simplied screen lock

❹

button

This switch is used for displaying the number of the sewing pattern.

This button is used for displaying the simplied lock status of the screen on it.

Locked:

❹ ❶❸

❷❻

Unlocked:

❺ ❼

❽ ❾

❷❻

Sewing-start re-

❺

verse-feed stitch button

Sewing-end re-

❻

verse-feed stitch button

Part number In the case the part number/process display is selected with U404, the part number is

❼

Process/comment In the case the part number/process display is selected with U404, the process is dis-

❽

Clock display The time set on the sewing machine is displayed in this eld in 24-hour system.

❾

Sewing pattern display The selected sewing pattern is displayed in this eld.

Customization button 1 A selected function can be allocated to and registered with this button. Initially, the

Customization buttons 2

- 7

Customization buttons 2

- 11

This switch is used for changing the ON/OFF status of the reverse feed stitching at the

beginning of sewing. When reverse feed stitching at the beginning of sewing is placed

in the OFF state,

This switch is used for changing the ON/OFF status of reverse feed stitching at the end

of sewing. When reverse feed stitching at the end of sewing is placed in the OFF state,

mark is displayed at the upper left of the button.

displayed. In the case the comment display is selected, the comment is displayed.

played. In the case the comment display is selected, the comment is displayed.

sewing counter has been factory-allocate and -registered.

A selected function can be allocated to and registered with this button.

A selected function can be allocated to and registered with this button.

mark is displayed at the upper left of the button.

* Conrmation of data

To change the pattern number, press Sewing pattern No. button ❸.

Select the sewing pattern you want to use. Then, press

to conrm your choice.

For the setting items of the Memory switch or sewing pattern, change the target data and press

conrm the change.

After the setting data on the number of stitches of reverse-feed stitching or the number of stitches of

multi-layer stitching has been changed, the changed setting data is conrmed by pressing .

– 14 –

to

Page 19

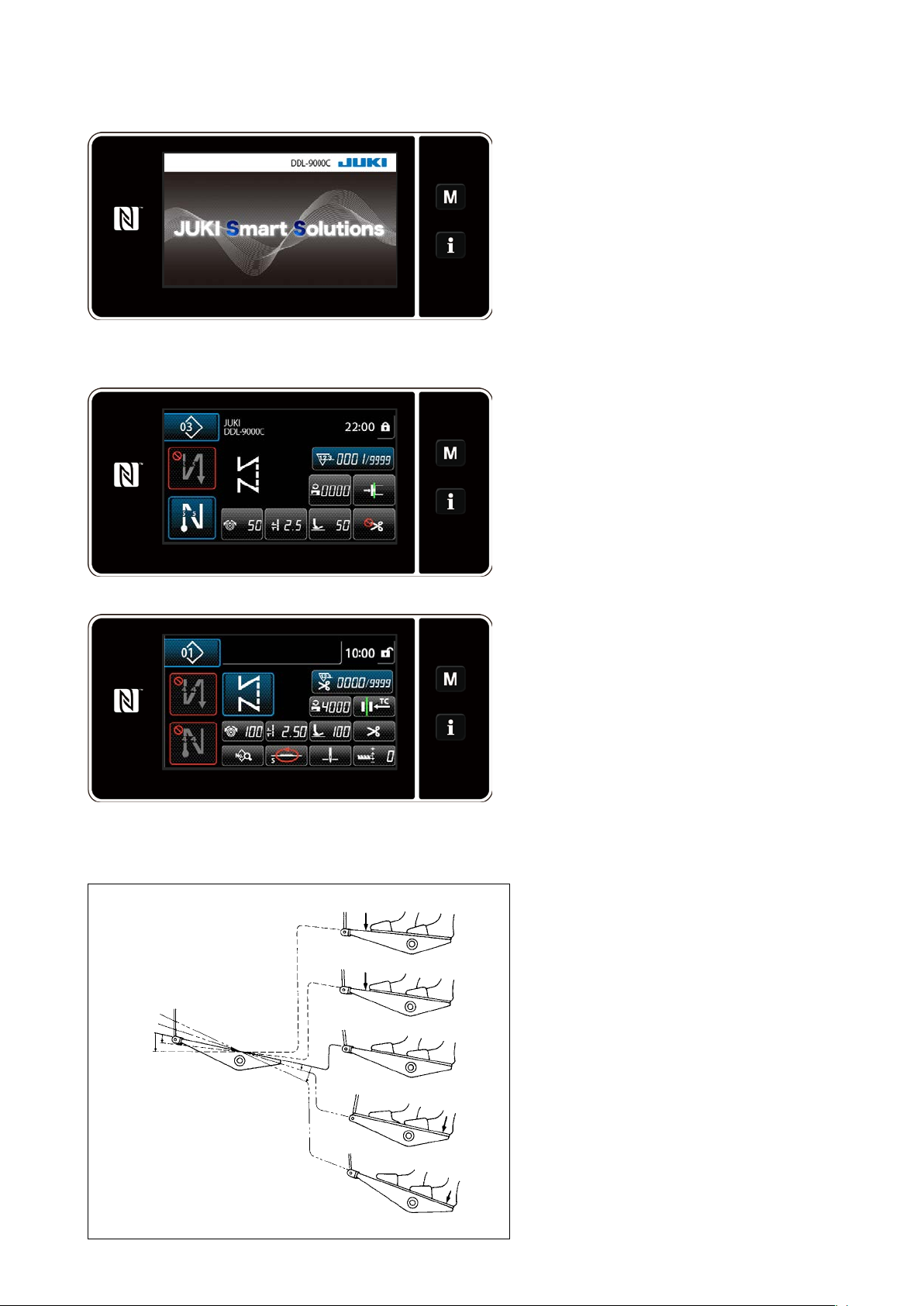

2-13-3. Basic operation

Turning ON the power switch

①

Selecting a sewing pattern

②

<Sewing screen (Operator mode)>

When you turn ON the power switch, the

welcome screen is displayed.

The sewing screen is displayed.

Select a sewing pattern.

・

Refer to

"4-2. Sewing patterns" p. 33

for details.

Congure settings of each function which

・

is assigned according to "8-10. Key cus-

tomization" p. 132.

Set up functions for the selected sewing

・

pattern.

Refer to

"4-2-5. Editing the sewing

patterns" p. 42 and "4-2-6. List of

pattern functions" p. 44 for details.

<Sewing screen (Maintenance personnel mode)>

Starting sewing

③

When you depress the pedal, the sewing

machine starts sewing.

Refer to "2-11. Pedal operation" p. 10.

– 15 –

Page 20

3. PREPARATION BEFORE SEWING

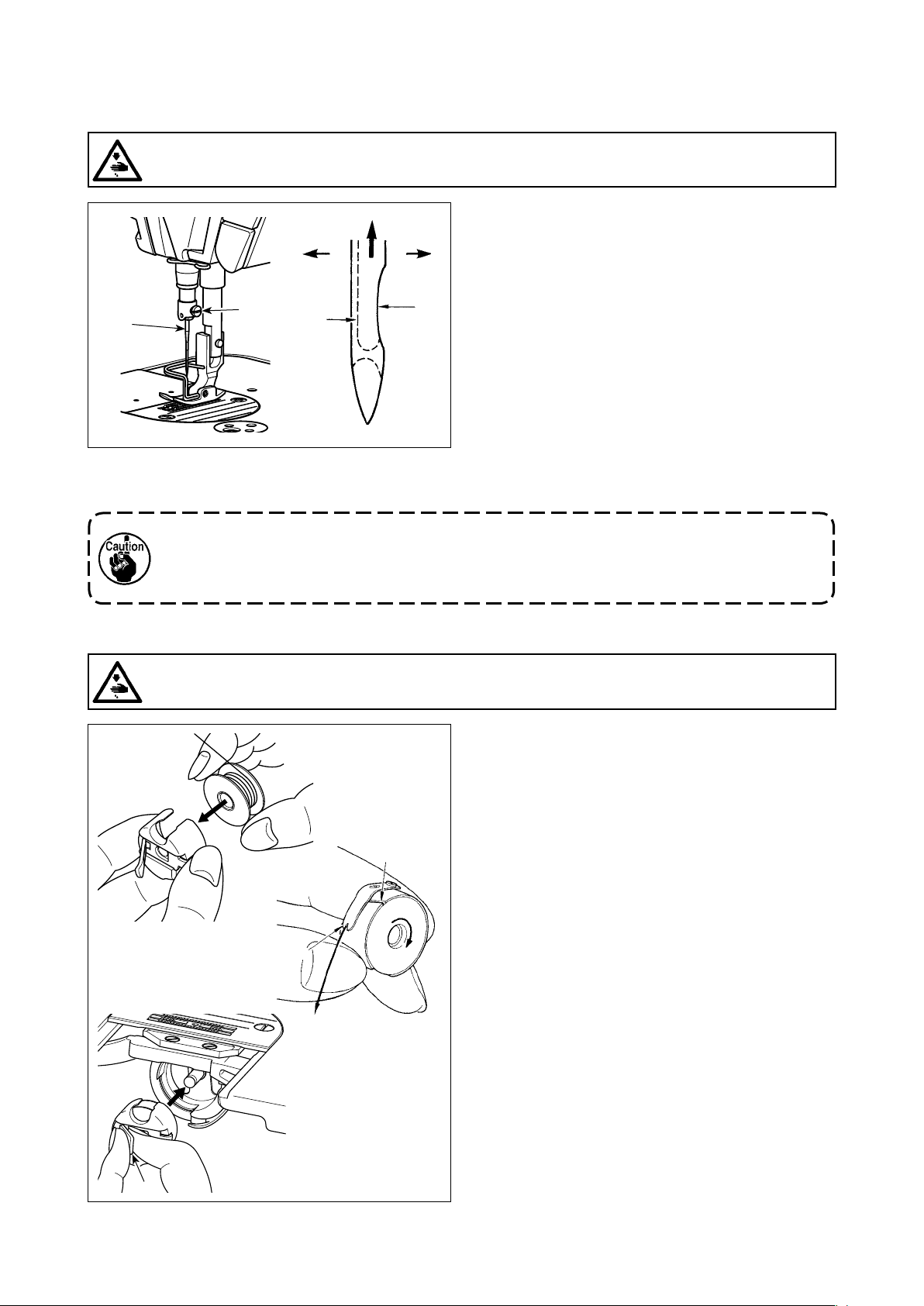

3-1. Attaching the needle

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

Use the specied needle for the machine. Use the

proper needle in accordance with the thickness of

D

❶

❷

C

4) Securely tighten screw ❷.

5) Check that long groove C of the needle is facing exactly to the left in direction D.

When polyester lament thread is used, if the indented part of the needle is tilted toward

operator's side, the loop of thread becomes unstable. As a result, hangnail of thread or thread

breakage may occur. For the thread that such phenomenon is likely to occur, it is effective to

attach the needle with its indented part slightly slanting on the rear side.

B

A

thread used and the kinds of the materials.

1) Turn the handwheel until the needle bar reaches

the highest point of its stroke.

2) Loosen screw ❷, and hold needle ❶ with its in-

dented part A facing exactly to the right in direction B.

3) Insert the needle fully into the hole in the needle

bar in the direction of the arrow until the end of

hole is reached.

3-2. Removing/tting the bobbin case

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

A

B

C

1) Turn the handwheel to lift the needle above the

throat plate.

2) Install the bobbin in the bobbin case so that the

thread wound direction is clockwise.

3) Pass the thread through thread slit A of the bobbin case, and pull the thread in direction C. By

so doing, the thread will pass under the tension

spring and come out from notch B.

4) Check that the bobbin rotates in the direction of

the arrow when thread is pulled.

5) Pinching latch D of the bobbin case with ngers,

t the bobbin case in the hook.

D

– 16 –

Page 21

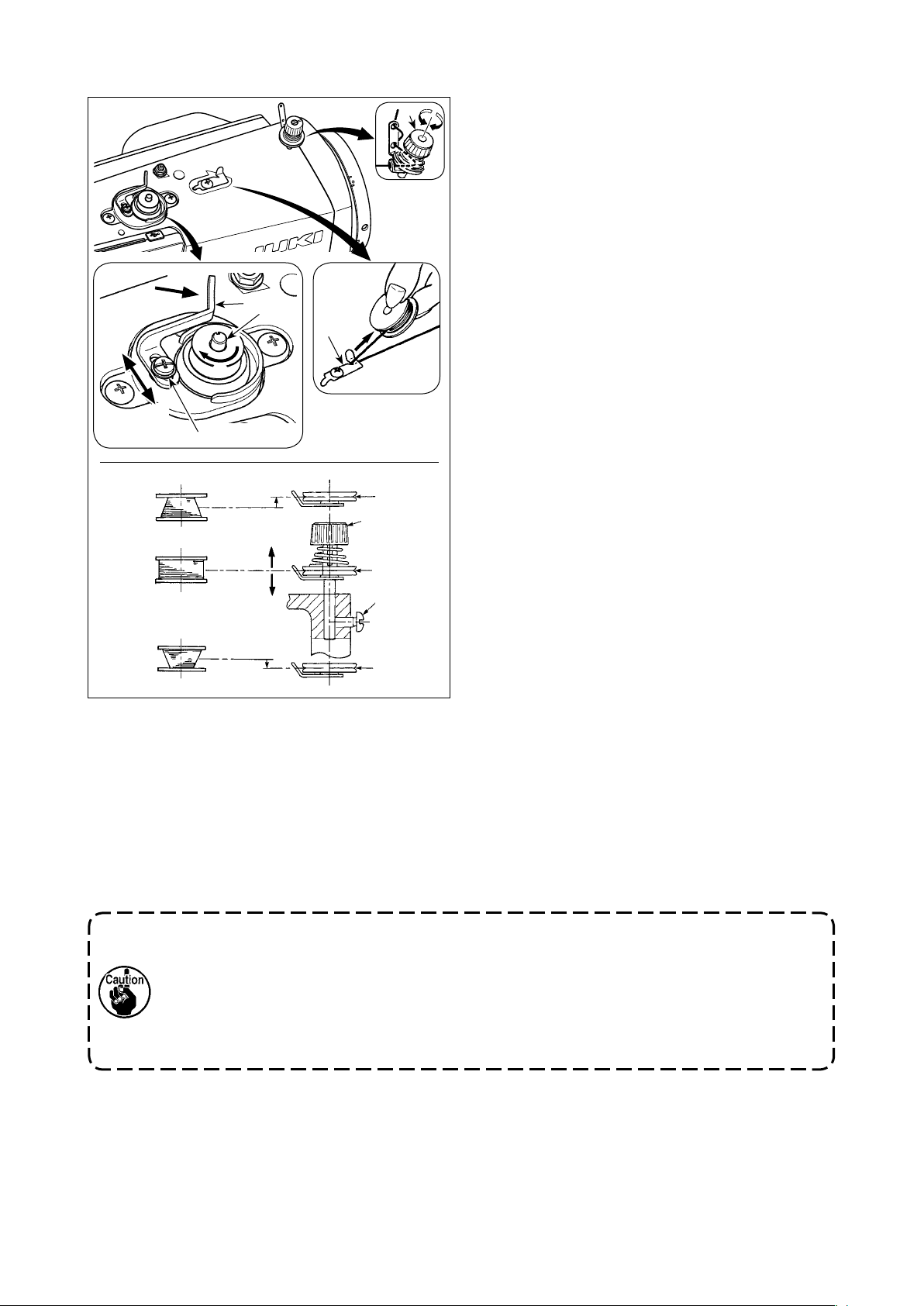

3-3. Winding the bobbin thread

D

C

A

❹

B

❷

❶

E

F

❸

❼

❻

❻

❺

❻

❽

1) Insert the bobbin deep into the bobbin winder

spindle ❶ until it will go no further.

2) Pass the bobbin thread pulled out from the spool

rested on the right side of the thread stand fol-

lowing the order as shown in the gure on the

left. Then, wind clockwise the end of the bobbin

thread on the bobbin several times. (In case of

the aluminum bobbin, after winding clockwise the

end of the bobbin thread, wind counterclockwise

the thread coming from the bobbin thread ten-

sion several times to wind the bobbin thread with

ease.)

3) Press the bobbin winding lever ❷ in the direction

of A and start the sewing machine. The bobbin

rotates in the direction of B and the bobbin thread

is wound up. The bobbin winder spindle ❶ auto-

matically as soon as the winding is nished.

4) Remove the bobbin and cut the bobbin thread

with the thread cut retainer ❸.

5) When adjusting the winding amount of the bobbin thread, loosen setscrew ❹ and move bobbin

winding lever ❷ to the direction of C or D. Then

tighten setscrew ❹.

To the direction of C : Decrease

To the direction of D : Increase

6) In case that the bobbin thread is not wound evenly on the bobbin, remove the handwheel, loosen screw ❺

and adjust the height of bobbin thread tension ❽.

• It is the standard that the center of the bobbin is as high as the center of thread tension disk ❻.

• Adjust the position of thread tension disk ❻ to the direction of E when the winding amount of the bobbin

thread on the lower part of the bobbin is excessive and to the direction F when the winding amount of

the bobbin thread on the upper part of the bobbin is excessive.

After the adjustment, tighten screw ❺.

7) To adjust the tension of the bobbin winder, turn the thread tension nut ❼.

1. When winding the bobbin thread, start the winding in the state that the thread between the

bobbin and thread tension disk ❻ is tense.

2. When winding the bobbin thread in the state that sewing is not performed, remove the

needle thread from the thread path of thread take-up and remove the bobbin from the hook.

3. There is the possibility that the thread pulled out from the thread stand is loosened due to

the inuence (direction) of the wind and may be entangled in the handwheel. Be careful of

the direction of the wind.

– 17 –

Page 22

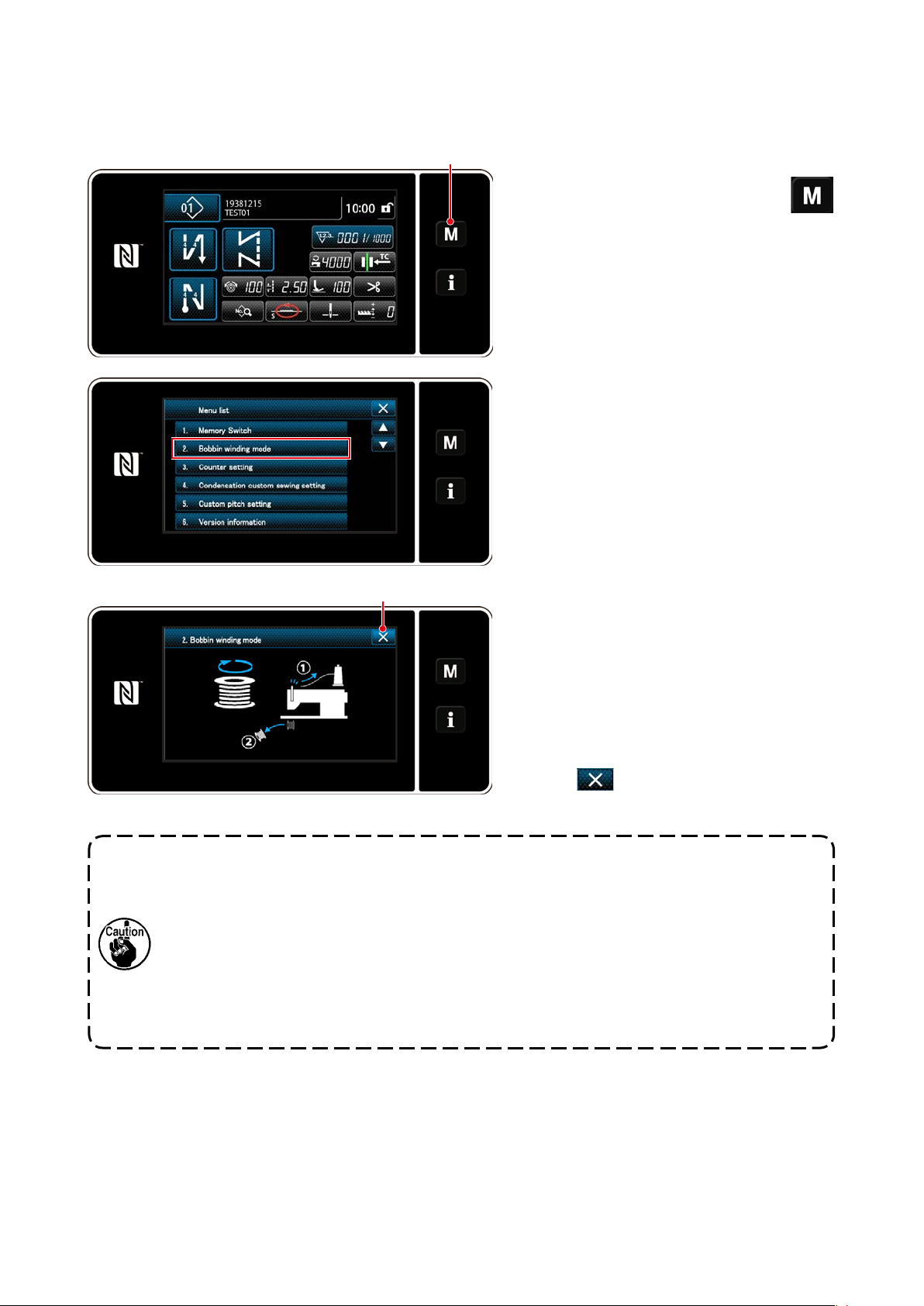

[Bobbin winding mode]

To wind a bobbin only or to check the oil quantity in the hook, the bobbin winding mode should be used.

Depress the pedal to start winding a bobbin.

❶

1) Display the mode screen by pressing

❶.

2) Select the "2. Bobbin winding mode".

❷

3) The sewing machine mode is changed over

to the "Bobbin winding mode".

The sewing machine runs with its presser

foot up when the pedal is depressed. In this

state, a bobbin can be wound. The sewing

machine runs only as long as the pedal is

depressed.

When ❷ is pressed, the sewing ma-

chine exits from the "Bobbin winding mode".

1. When winding the bobbin thread, start the winding in the state that the thread between the

bobbin and thread tension disk ❻ is tense.

2. Remove the needle thread from the thread path of thread take-up and remove the bobbin

from the hook.

3. There is the possibility that the thread pulled out from the thread stand is loosened due to

the inuence (direction) of the wind and may be entangled in the handwheel. Be careful of

the direction of the wind.

4. The speed of the sewing machine under the bobbin winding mode is equal to the one which

has been set for the machine head.

– 18 –

Page 23

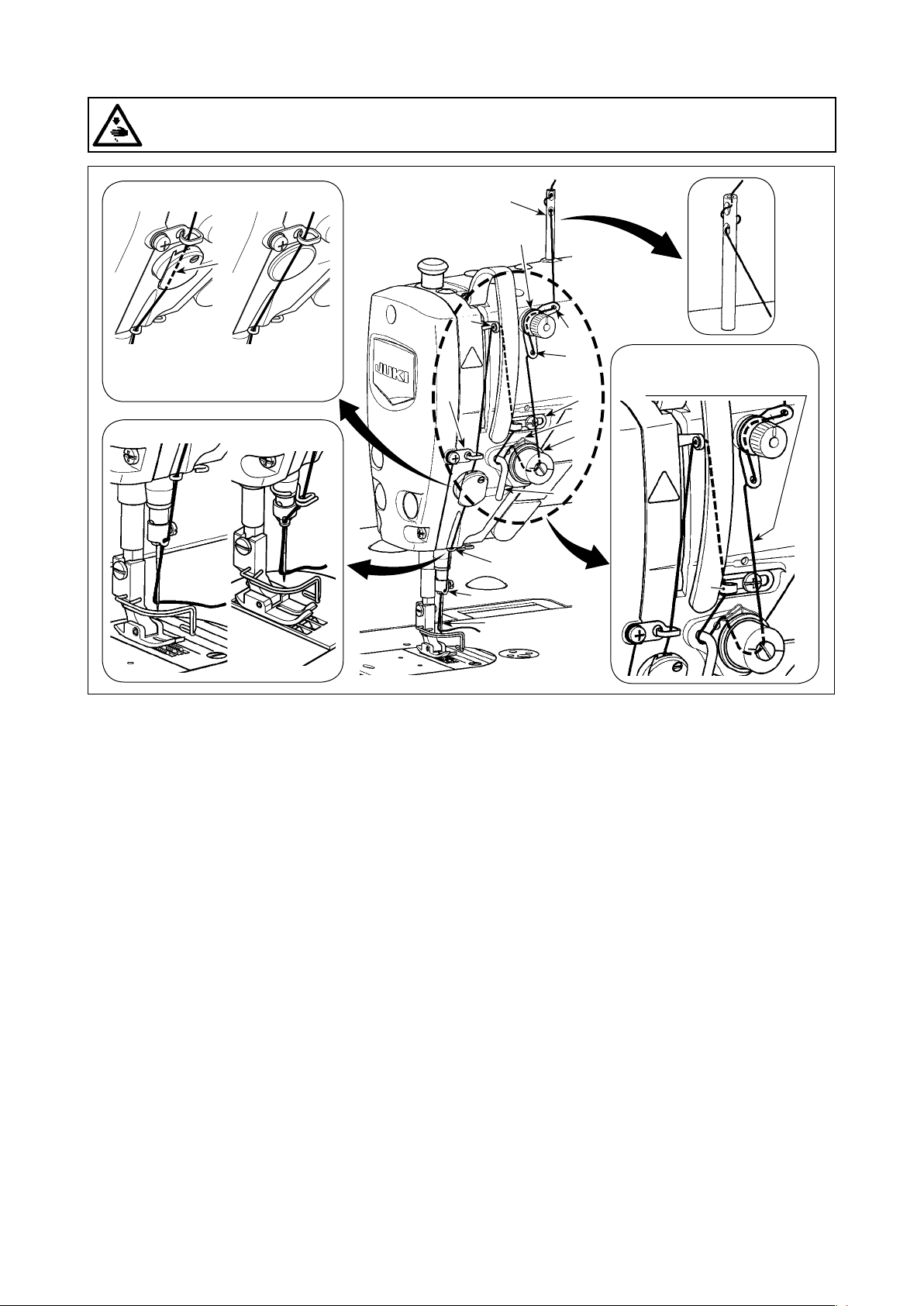

3-4. Threading the machine head

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

"NB type" "0B type"

B

(Note)

Be sure to pass the thread

through the section B.

"S type" "H type"

❾

❶

❸

❼

❹

❷

(Note)

Do not pass this thread

through section A.

❽

❻

❺

A

– 19 –

Page 24

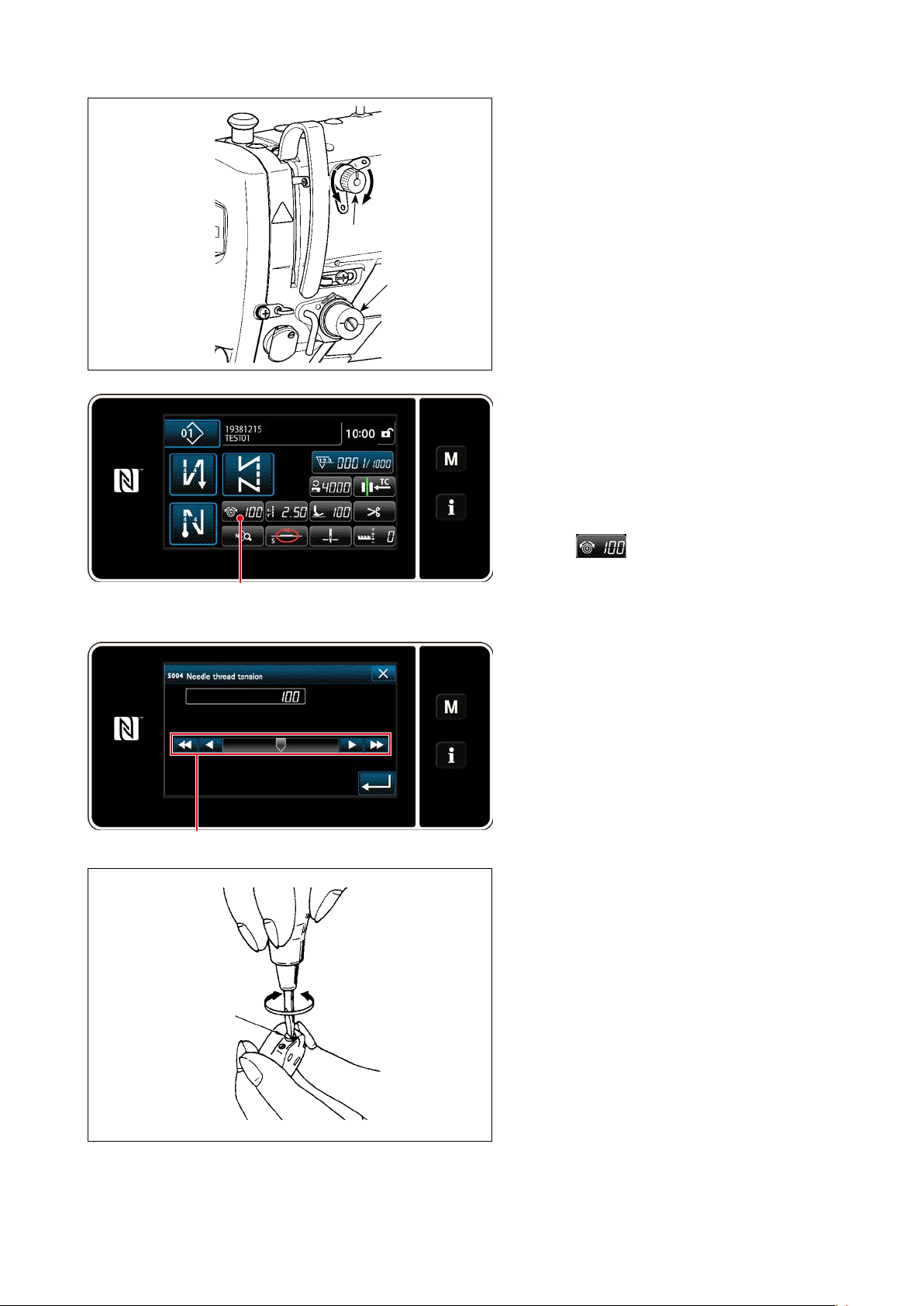

3-5. Thread tension

❸

B

❶

A

3-5-1. Adjusting the thread tension No. 1

tension

1) Turn thread tension No. 1 nut ❶ clockwise

(in direction A), to shorten the thread length

remaining on the needle after thread trimming or counterclockwise (in direction B),

to lengthen the thread length.

❷

3-5-2. Adjusting the needle thread ten-

sion (Active tension)

Active tension ❷ permits setting of the needle

thread tension on the operation panel accord-

ing to each sewing condition. In addition, the

data can be stored in memory.

1) Press ❸ to display the needle

thread tension input screen. (The numeric

value displayed on the screen is the current

needle thread tension value.)

❹

❺

C

D

2) Change the needle thread tension as desired by pressing ❹.

3) There is a setting range of 0 to 200.

When the set value is increased, the ten-

sion becomes higher.

* When the set value is 60 at the time of stan-

dard delivery, the thread tension is adjusted

to 0.59 N (spun thread #60). (Reference)

(When thread tension No. 1 is released.)

3-5-3. Adjusting the bobbin thread ten-

sion

1) Turn tension adjusting screw ❺ clockwise

(in direction C) to increase or counterclockwise (in direction D) to reduce the bobbin

thread tension.

– 20 –

Page 25

3-6. Presser foot (Active presser device)

WARNING :

Do not place anything under the presser foot when turning the power ON. If the power is turned ON

while placing something under the presser foot, the sewing machine displays E910.

If the power to the sewing machine is turned ON while the material, etc. is placed under the

presser foot, the presser stepping motor will generate a specic sound during origin retrieval.

It should be noted that this phenomenon is not a fault.

❶ A

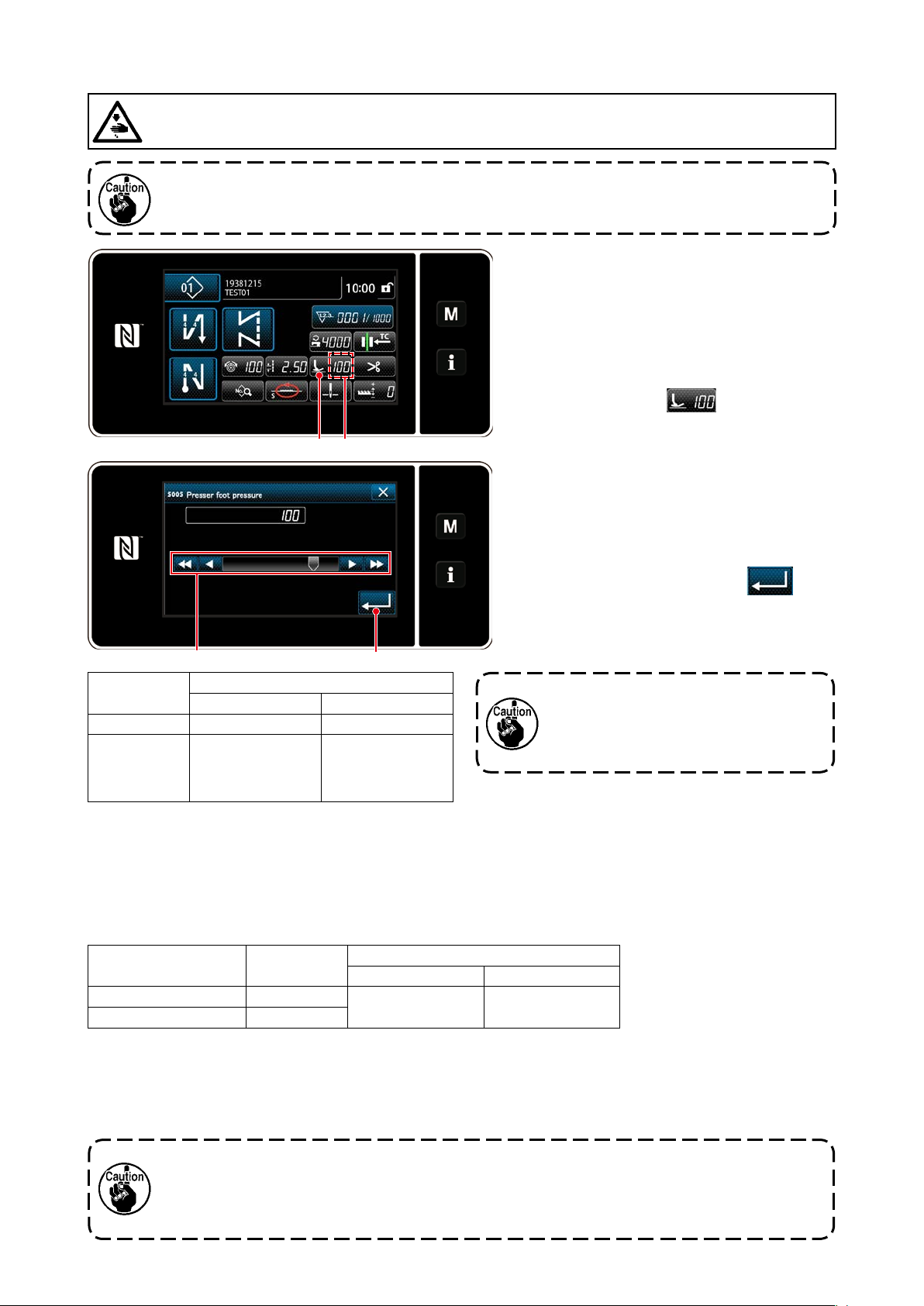

3-6-1. Presser foot pressure

The presser foot pressure is displayed in

section A on the panel. (Example of display :

100)

[How to change]

1) Display the presser foot pressure entry

screen by pressing ❶.

2) Change the presser foot pressure as desired by pressing ❷. (Range of input values

on the panel is from -350 to 200.)

* Refer to the following for a rough indica-

tion of the input value on the panel and

the presser foot pressure.

3) Conrm your entry by pressing ❸.

Then, the sewing screen is displayed.

❷

Input value on

the panel

0 Approx. 10 N (1 kg) Approx. 30 N (3 kg)

100

(Factory-set-

ting at the time

of shipment)

Presser foot pressure (Reference)

S type H type

Approx. 40 N (4 kg) Approx. 60 N (6 kg)

❸

1. To avoid personal injury, never put

your ngers under the presser foot.

2. Be aware that the presser foot

pressure varies when the presser

foot or the throat plate is changed.

3-6-2. Micro-lifter function

Sewing while lifting the presser foot by very small amount is enabled by inputting a negative value on the

panel. The micro-lifter function helps reduce slippage and damage of the material in the case of sewing

raised fabric such as velvet.

* Refer to the table shown below for a rough indication of the relation among the value input on the panel,

the presser foot height and the presser foot pressure.

Input value on the panel

0 0 mm

-350 Approx. 4 mm

*1 The presser foot height 0 mm means the state the sole of presser foot comes in contact with the top surface

of throat plate.

*2 The presser foot pressure becomes constant by inputting a negative value on the panel.

*3 The presser foot pressure varies when the presser foot or the throat plate is changed.

*4 Range of input values on the panel is from -350 to 200.

Presser foot

height

Presser foot pressure (Reference)

S type H type

Approx. 10 N (1 kg) Approx. 30 N (3 kg)

1.

Be sure to input a positive value on the operation panel in the case the micro-lifter function is not

used. If not, the presser foot is slightly raised and the feed dog is unable to provide a sufcient

efciency of feed.

2.

In the case of using the micro-lifter function, the efciency of feed is likely to be insufcient. To

achieve the sufcient efciency of feed, reduce the sewing speed or help feed the material by hand.

– 21 –

Page 26

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

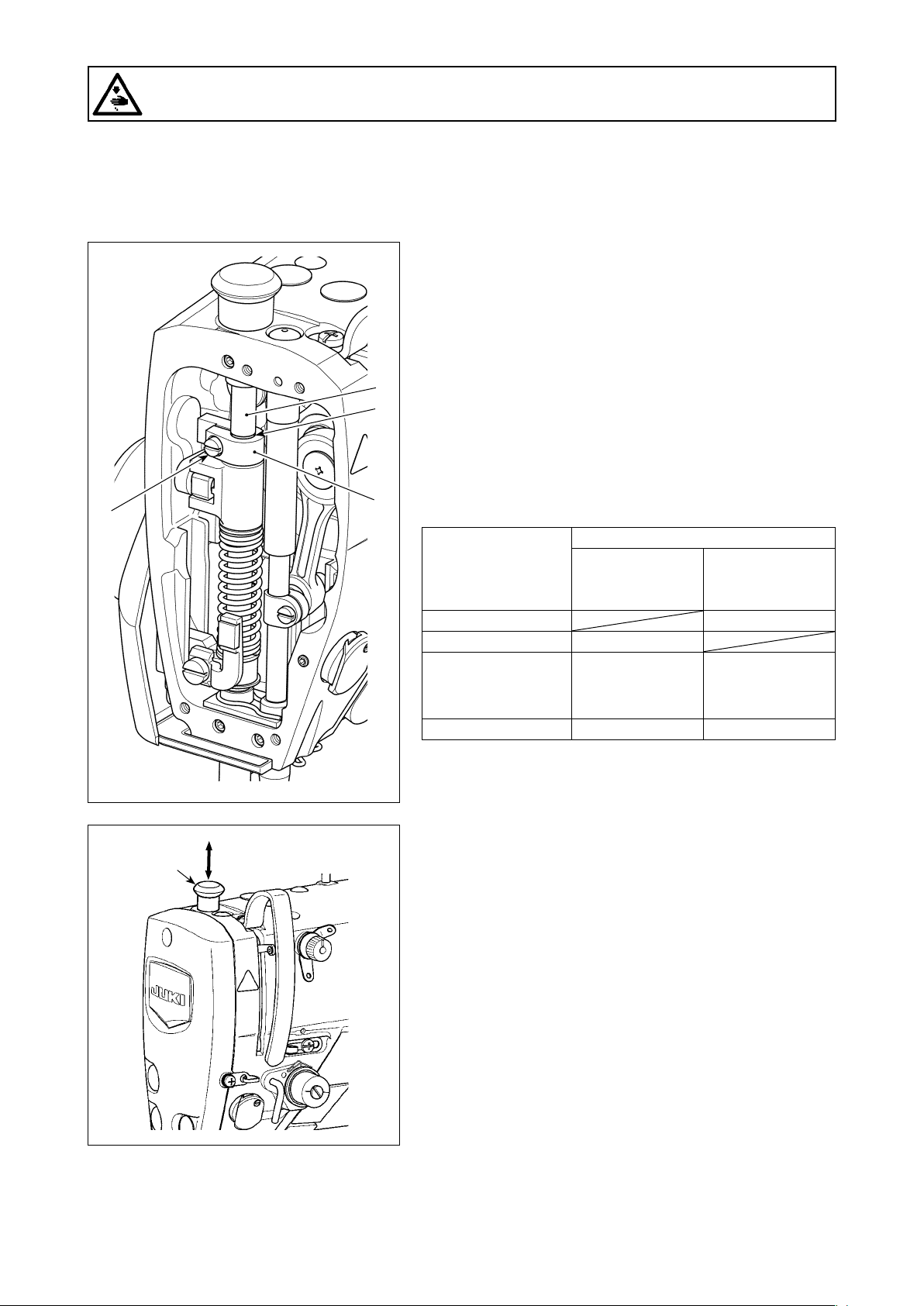

3-6-3. Changing the initial value of presser foot pressure

If you want to change the initial value of presser foot pressure, it is possible to change the initial presser foot

pressure by changing the mounting position of presser bar position bracket (upper) ❹.

Carry out adjustment according to the sewing process as needed basis.

[How to adjust]

1) Turn OFF the power to the sewing machine.

2) Remove the face plate.

3) Loosen presser bar position bracket (upper) clamping

screw ❺. Adjust the vertical position of presser bar position bracket (upper) ❹ using marker line B on presser

❻

B

bar ❻ as reference.

* Adjust the orientation of presser bar position bracket

(upper) ❹ so that it is in parallel with the face plate.

4) After the completion of adjustment, tighten presser bar

position bracket (upper) clamping screw ❺ and attach

❺

❹

the face plate.

❻

Position of presser bar

position bracket (upper) ❹ with respect

to marker line B on

presser bar ❻

4 mm above Approx. 0 N (0 kg)

1 mm above Approx. 0 N (0 kg)

0 (just beneath the

marker line)

(Factory-setting at the

time of shipment)

1 mm below Approx. 20 N (2 kg) Approx. 40 N (4 kg)

Presser foot pressure (Reference)

S type H type

Approx. 10 N (1 kg) Approx. 30 N (3 kg)

3-6-4. Manual lifter

The presser foot can be manually lifted/lowered by moving

presser bar cap ❻ up and down while the power to the sew-

ing machine is in the OFF state.

Use this manual lifting feature when replacing the gauge or

adjusting the needle entry area.

– 22 –

Page 27

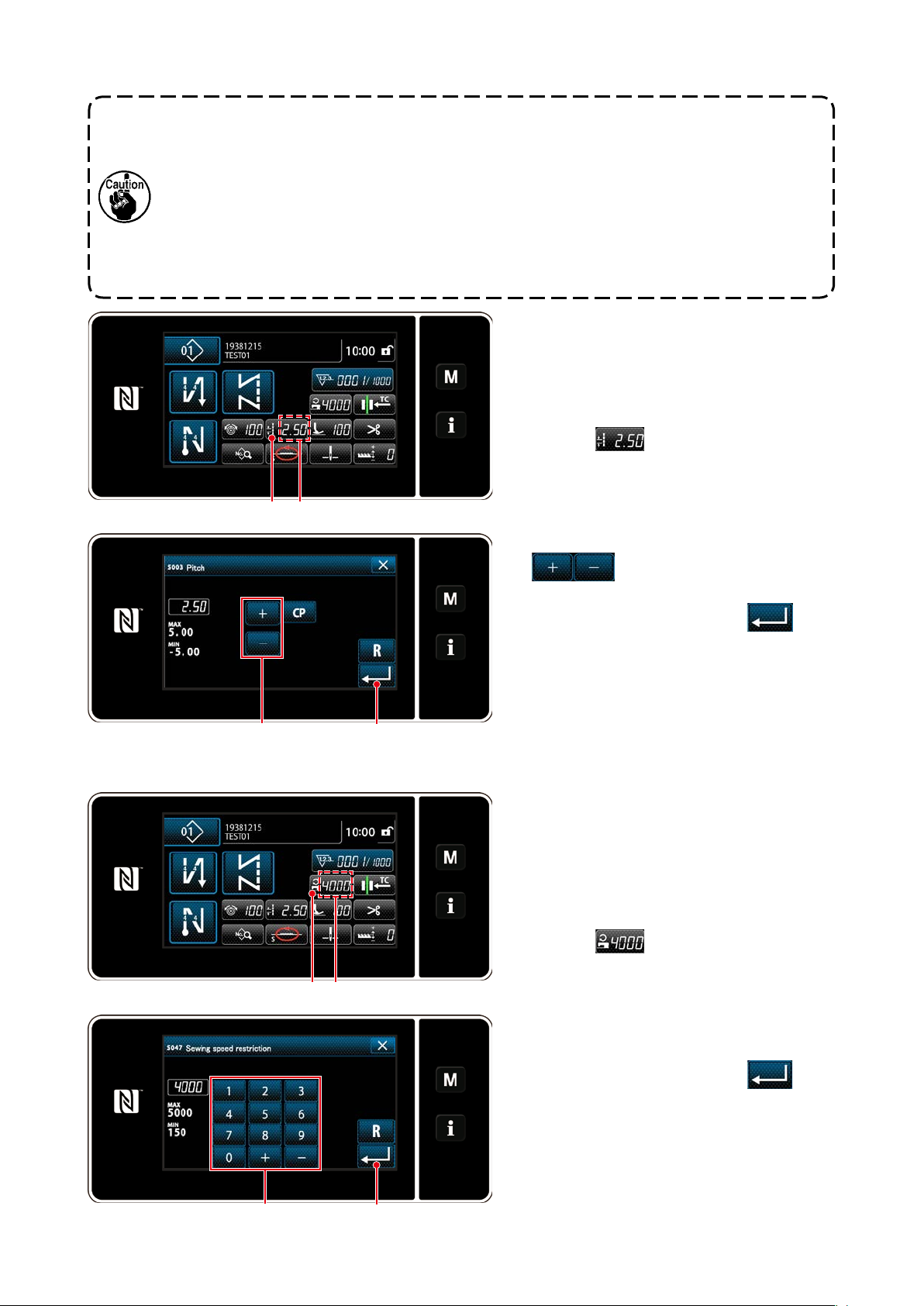

3-7. Adjusting the stitch length

1. There may be the cases where the feed amount of the operation panel and the actual sewing

pitch are different from each other in case of the use in the state other than the standard

delivery or material used. Compensate the pitch in accordance with the sewing product.

2. Be aware that interference between the throat plate and feed dog can occur depending on

the gauge used. Be sure to check the clearance in the gauge to be used. (The clearance

must be 0.5 mm or more.)

3. When you have changed the stitch length, feed dog height or feed timing, run the sewing

machine at a low speed to make sure that the gauge does not interfere with the changed

part.

❶ A

Stitch length is displayed in section A on the

panel. (Example of display : 2.50 mm)

[How to adjust]

1) Display the stitch pitch entry screen by

pressing ❶.

❷ ❸

3-8. Changing the sewing speed

❶ A

2) The value displayed is changed by pressing

❷. (In increments of 0.05 mm ;

Input range : -5.00 to 5.00)

3) Conrm your entry by pressing ❸.

Then, the sewing screen is displayed.

The sewing speed is displayed in section A

on the panel. (Example of display : 4,000 sti/

min)

[How to change]

1) Display the sewing speed entry screen by

pressing ❶.

2) Change the sewing speed as desired by

pressing ten keys ❷.

3) Conrm your entry by pressing ❸.

Then, the sewing screen is displayed.

❸❷

– 23 –

Page 28

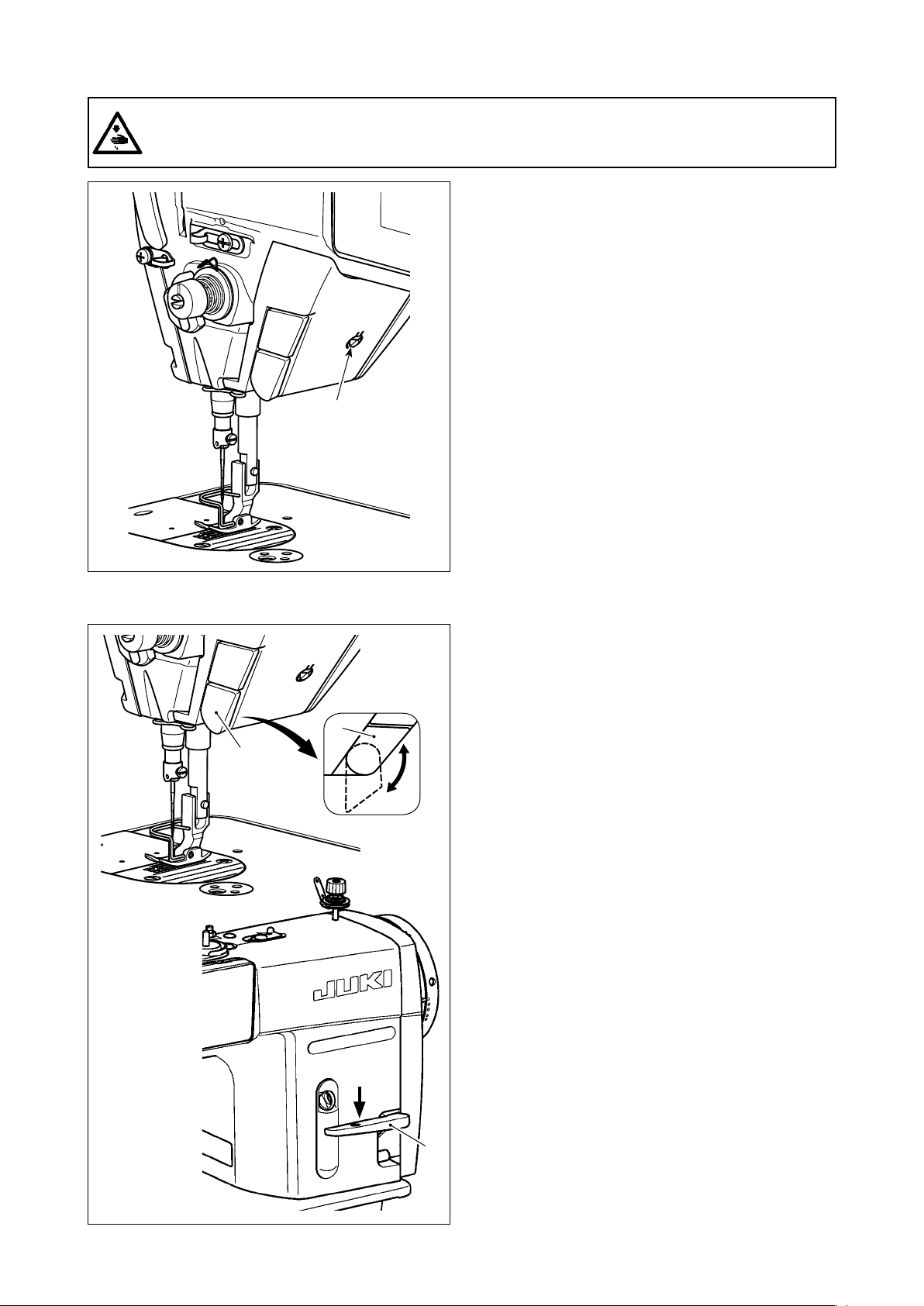

3-9. LED hand light

WARNING :

In order to protect against personal injury due to unexpected start of the sewing machine, never

bring hands near the needle entry area or place foot on the pedal during the adjustment of intensity

of the LED.

❶

* This LED is intended to improve operability

of the sewing machine and is not intended for

maintenance.

The sewing machine is provided as standard with an

LED light which illuminates the needle entry area.

Intensity adjustment and turn-off of the light is carried out by pressing switch ❶. Every time the switch

is pressed, the light is adjusted in intensity in ve

steps and is turned off in turn.

[Change of intensity]

1

Bright⇒...... Dim⇒O

⇒

...... 4

⇒

5

1

⇒

ff⇒Bright

In this way, every time the switch ❶ is pressed, the

hand lamp status is changed in repetition.

3-10. Reverse feed stitching

❶

❶

Fig. 1

[One-touch type reverse feed stitching mecha-

nism]

The one-touch type reverse feed switch ❶ is

pressed, the machine performs reverse feed stitch-

ing.

The machine resumes normal feed stitching the

moment the switch lever is released.

[Reverse feed stitching by means of the reverse

feed lever]

Length of the seam sewn by feeding the material in

the normal or reverse direction of feed can be controlled by operating reverse feed lever ❷.

[Adjusting the position of one-touch type reverse

feed switch]

One-touch type reverse feed switch ❶ can be used

at two different positions by turning it. (Fig. 1)

❷

– 24 –

Page 29

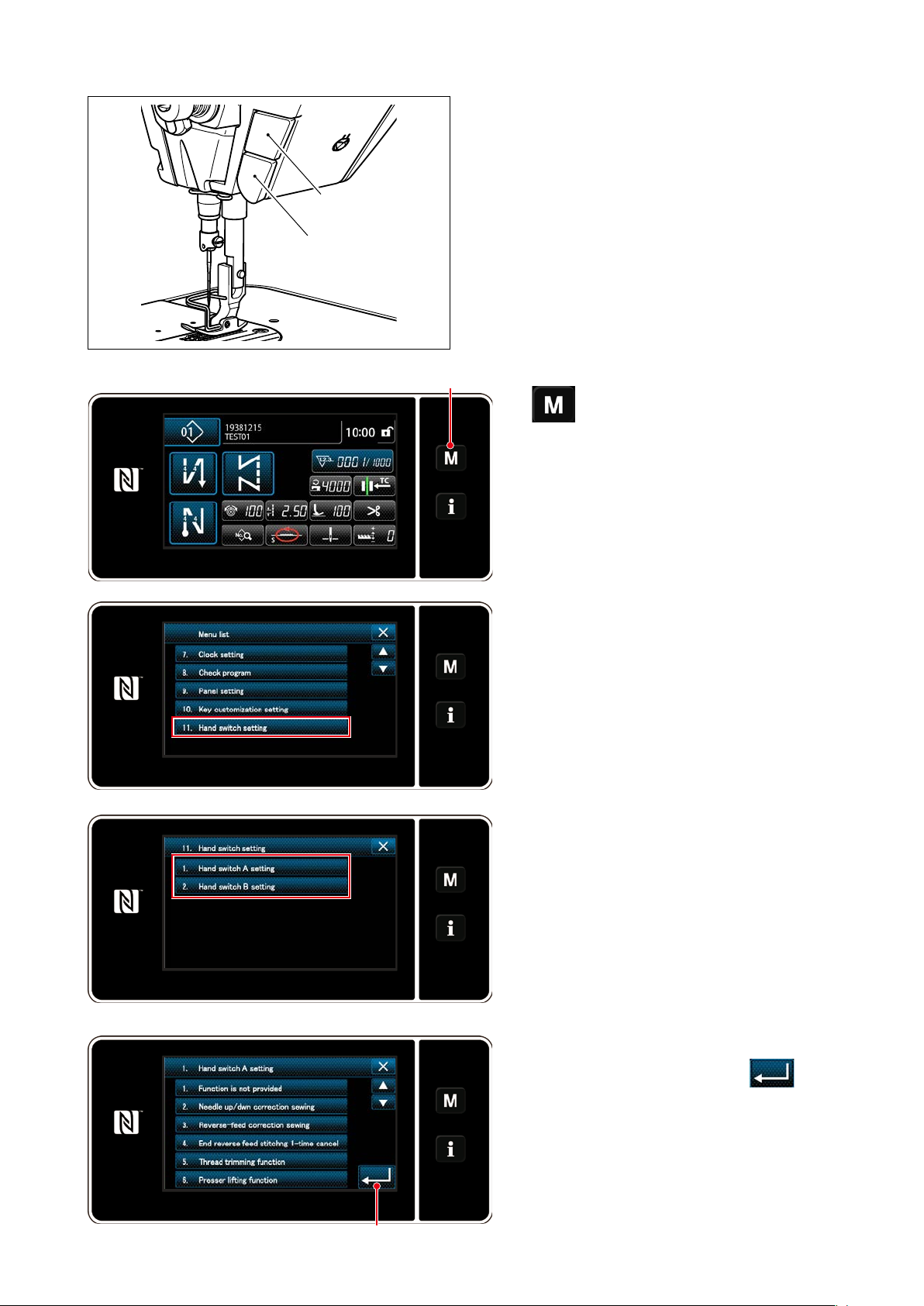

3-11. Custom switch

Various operations can be carried out by operating

custom switch B.

* It is also possible to assign an operation to custom

B

A

switch A.

The initial values are as follows:

Custom switch A

: Input of reverse feed

stitching switch

Custom switch B

: One-touch changeover

switch

❶

1)

The "mode screen" is displayed.

held pressed for three second.

❶

2) Select the "11. Hand switch setting".

3) Select the switch to be set.

4) Select the function item which is to be as-

❷

– 25 –

signed to the switch, and press

❷.

Page 30

[Description of operations of the custom switch]

Function item

1 Optional input function is not provided

2 Needle up / down compensating stitching

3 Back compensating stitching

4 Function of canceling once reverse feed stitching at

the end of sewing

5 Thread trimming function

6 Presser foot lifting function

7 One stitch compensating stitching

8 Material edge sensor input

9 Function of prohibiting depressing front part of pedal

10 Function of prohibiting thread trimming output

11 Low speed command input

12 High speed command input

13 Needle lifting function

14 Reverse feed stitching switch input

15 Soft start switch input

16 One-shot speed command switch input

17 Backward one-shot speed command switch input

18 Safety switch input

19 Automatic reverse feed stitching cancellation/addition

switch

20 Sewing counter input

21 One-touch type changeover switch

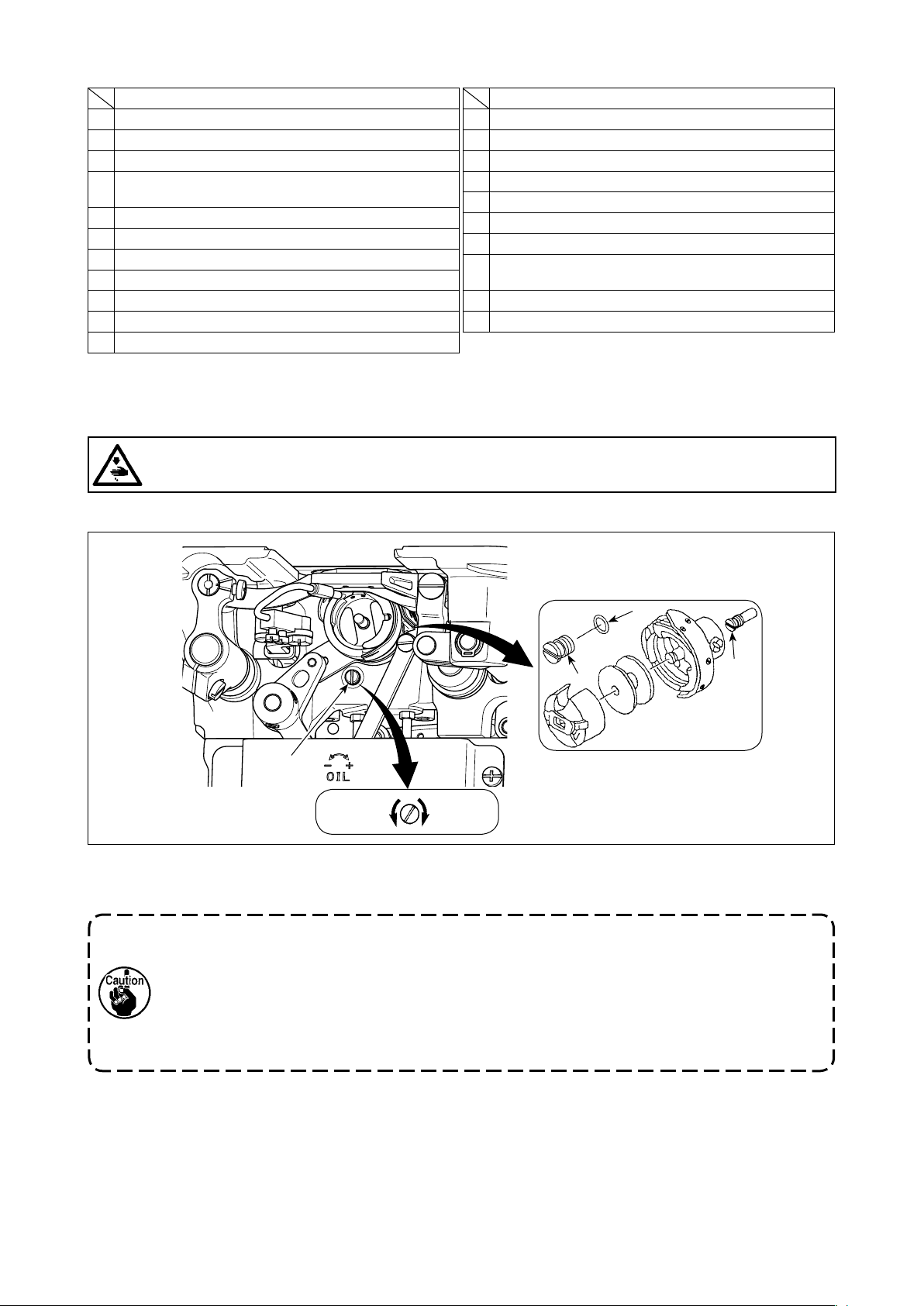

3-12. Adjusting the amount of oil (oil splashes) in the hook

WARNING :

Be extremely careful about the operation of the machine since the amount of oil has to be checked

by turning the hook at a high speed.

3-12-1. Adjusting the amount of oil in the hook

Function item

❹

❷

❶

Decrease

❸

Increase

Tighten (turn clockwise) oil amount adjustment screw ❶ to increase the amount of oil in the hook, or loosen

(turn counterclockwise) to decrease it.

"When using RP hook (hook for dry head) for DDL-9000C-FMS type"

1. Remove hook driving shaft oil wick setscrew ❷ and attach hook driving shaft stopper screw

❸ (part number : 11079506) and rubber ring ❹ (part number : RO036080200).

2. Loosen oil amount adjustment screw ❶ up to the minimum so as to reduce the oil amount in

the hook. However, do not completely stop the oil and be careful not to allow oil adjustment

screw ❶ to come off.

3. Never drain the oil in the oil tank even when RP hook (hook for dry head) is used.

– 26 –

Page 31

3-12-2. How to conrm the amount of oil (oil splashes)

Position to conrm the amount of oil (oil splashes)Amount of oil (oil splashes) conrmation paper

25 mm

Approx.

Hook

Hook driving shaft front bushing

Approx. 70 mm

* Use any paper available regardless of

the material.

3 to 10 mm

Bed

Oil splashes

conrmation paper

Closely t the paper against

the wall surface of the bed.

* Place the amount of oil (oil splashes) conrmation

paper under the hook and keep it from the hook by

3 to 10 mm to conrm the amount.

* In the case of measuring the oil quantity in the hook, measure it under the "Bobbin winding mode".

Refer to "3-3. Winding the bobbin thread [Bobbin winding mode]" p.18 for the bobbin winding

mode.

* When carrying out the procedure described below in 2), conrm the state that the needle thread

from the thread take-up lever to the needle and the bobbin thread are removed, the presser foot is

lifted and the slide plate is removed. At this time, take extreme caution not to allow your ngers to

come in contact with the hook.

1) If the machine has not been sufciently warmed up for operation, make the machine run idle for approxi-

mately three minutes. (Moderate intermittent operation)

2) Place the amount of oil (oil splashes) conrmation paper under the hook while the sewing machine is in

operation.

3) Conrm that oil exists in the oil tank.

4) Conrmation of the amount of oil should be completed in ve seconds. (Check the period of time with a

watch.)

3-12-3. Sample showing the appropriate amount of oil

Appropriate amount of oil (small) Appropriate amount of oil (large)

Splashes of oil from the hook

• DDL-9000C-FMS : 0.5 to 1 mm

• DDL-9000C-FSH : 1 to 3 mm

Splashes of oil from the hook

• DDL-9000C-FMS : 1 to 1.5 mm

• DDL-9000C-FSH : 2 to 4 mm

1) The state given in the gure above shows the appropriate amount of oil (oil splashes). It is necessary

to nely adjust the amount of oil in accordance with the sewing processes. However, do not excessively

increase/decrease the amount of oil in the hook. (If the amount of oil is too small, the hook will be seized

(the hook will be hot). If the amount of oil is too much, the sewing product may be stained with oil.)

2) Check the oil amount (oil splashes) three times (on the three sheets of paper), and adjust so that it should

not change.

– 27 –

Page 32

3-13. Adjusting the thread take-up spring and the thread take-up stroke

"DDL-9000C-FMS" "DDL-9000C-FSH"

❾

❽

A

B

❻

C

D

❶

❸

❷

❽

❻

A

B

❾

❶

❸

❷

F

❺

❶

❹

E

G

H

(1) Adjusting the stroke of thread take-up spring ❶

1) Loosen setscrew ❷.

2) Turn tension post ❸ clockwise (in direction A), the stroke of the thread take-up spring will be increased,

and turn the post ❸ counterclockwise (in direction B), the stroke will be decreased.

(2) Adjusting the pressure of thread take-up spring ❶

1) Loosen setscrew ❷, and remove thread tension (asm.) ❺.

2) Loosen tension post setscrew ❹.

3) Turn tension post ❸ clockwise (in direction A), the pressure will be increased, and turn the post ❸ counterclockwise (in direction B), the pressure will be decreased.

* Standard state of the thread take-up spring ❶

The engraved marker line ❻ on the machine arm is almost aligned with the top of thread take-up spring. (It is

necessary to adjust in accordance with materials and processes.)

To check how the thread take-up spring works, draw out the needle thread in direction F after

having adjusted the thread take-up spring pressure to check whether the thread take-up spring

exerts force to the thread up to the last moment (state G) just before the thread comes out

from E. If the spring fails to exert force to the spring until the last moment (state H), decrease

the thread take-up spring pressure. In addition, the stroke of the thread take-up spring is

excessively small, the spring does not work properly. For the general fabrics, a stroke of 10 to

13 mm is proper.

(3) Adjusting the thread take-up stroke

1) When sewing heavy-weight materials, move thread guide ❽ to the left (in direction C) to increase the

length of thread pulled out by the thread take-up.

2) When sewing light-weight materials, move thread guide ❽ to the right (in direction D) to decrease the

length of thread pulled out by the thread take-up.

* Standard state of the thread guide

• DDL-9000C-FMS : Marker line ❾ on the thread guide aligns with the center of the setscrew.

• DDL-9000C-FSH : Marker line ❾ on the thread guide aligns with the center of the marker line on the ma-

chine arm.

– 28 –

Page 33

4. HOW TO USE THE OPERATION PANEL

4-1. Explanation of the sewing screen (when selecting a sewing pattern)

On the sewing screen, the shape and set values of the currently-sewn sewing pattern are displayed.

The display and button operation differ according to the selected sewing pattern.

Note that the sewing screen shows two different displays, i.e., the sewing pattern display and the counter display.

Refer to "4-3. Counter function" p. 56 for the description of the counter display.

There are two different screen display modes; i.e., <Operator mode> and <Maintenance personnel

mode>.

The mode can be changed over between the operator mode and the maintenance personnel mode by

simultaneously pressing

❶

and

❷

.

(1) Sewing screen (when selecting a sewing pattern)

A sewing pattern can be selected with

. Four different stitch shapes are available as

shown below.

<Operator mode>

❺ ❼❽ ❾

Free stitching pattern

(Operator mode)

❹ ❶❸

❷❻

<Maintenance personnel mode>

❺ ❾

Constant-dimension sewing pattern

(Operator mode)

❹ ❶❸

❷❻

Multi-layer stitching pattern

(Operator mode)

– 29 –

Polygonal-shape stitching pattern

(Operator mode)

Page 34

Free stitching pattern

(Maintenance personnel mode)

Constant-dimension sewing pattern

(Maintenance personnel mode)

Multi-layer stitching pattern

(Maintenance personnel mode)

Polygonal-shape stitching pattern

(Maintenance personnel mode)

Switch/display Description

Mode key This switch is used for displaying the menu screen.

❶

Level 1 is displayed by pressing this switch in the normal manner. Level 2 or

Level 3 is displayed by keeping this switch held pressed for three seconds or

more for the former or six seconds or more for the latter.

The mode is changed over between the operator mode and maintenance

personnel mode by pressing the Mode key and the Information key simultaneously.

Information key This switch is used for displaying the information screen.

❷

Level 1 or Level 2 is displayed by pressing this switch in the normal manner

for the former or by keeping it held pressed for three seconds or more for the

latter.

The mode is changed over between the operator mode and maintenance

personnel mode by pressing the Information key and the Mode key simultaneously.

Sewing pattern No.

❸

button

Simplied screen

❹

lock button

Sewing pattern list screen is displayed. The currently-selected sewing pattern

number is displayed on this button. (P01 – P99)

This is button is used for changing over the operation status of buttons displayed on the screen between enable and disable.

This button is used for displaying the simplied lock status of the screen on it.

Locked:

Unlocked:

Once the button operation is locked using the simplied screen lock button,

operation of the buttons displayed on the screen, excluding this button will be

disabled.

– 30 –

Page 35

Switch/display Description

Sewing-start re-

❺

verse-feed stitch

button

Sewing-end re-

❻

verse-feed stitch

button

Part number The part number is displayed in this eld.

❼

Process/comment The process or comment is displayed in this eld.

❽

Clock display The time set on the sewing machine is displayed in this eld in 24-hour sys-

❾

* Pattern shape button Selected sewing pattern is displayed on this screen.

* Sewing data list but-

ton

Customization button A selected function can be allocated to and registered with this button.

Customization button A selected function can be allocated to and registered with this button.

Customization button A selected function can be allocated to and registered with this button.

* Customization button A selected function can be allocated to and registered with this button.

* Customization button A selected function can be allocated to and registered with this button.

* Customization button A selected function can be allocated to and registered with this button.

Customization button A selected function can be allocated to and registered with this button.

Customization button A selected function can be allocated to and registered with this button.

This switch is used for changing the ON/OFF status of the reverse feed stitching at the beginning of sewing. When reverse feed stitching at the beginning

of sewing is placed in the OFF state,

of the button.

The reverse feed stitching (at start) edit screen is displayed by keeping this

key held pressed for one second.

This button is displayed for free stitching, constant-dimension sewing or

→

polygonal-shape stitching.

This switch is used for changing the ON/OFF status of reverse feed stitching

at the end of sewing. When reverse feed stitching at the end of sewing is

placed in the OFF state,

The reverse feed stitching (at end) edit screen is displayed by keeping this

key held pressed for one second.

This button is displayed for free stitching, constant-dimension sewing or

→

polygonal-shape stitching.

tem.

Four different sewing patterns are available, i.e., free stitching pattern,

constant-dimension sewing pattern, multi-layer stitching pattern and polygonal-shape stitching pattern.

The shape selection screen is displayed by pressing this button.

A selected function can be allocated to and registered with this button.

In the initial state, "sewing data edit screen" is displayed.

Refer to "4-2-6. List of pattern functions" p. 44.

This button has been initially set to the "sewing counter".

Refer to "4-2-6. List of pattern functions" p. 44.

This button has been initially set to the "pitch".

Refer to "4-2-6. List of pattern functions" p. 44.

This button has been initially set to the "sewing speed".

Refer to "4-2-6. List of pattern functions" p. 44.

This button has been initially set to the "correction of feed dog height ".

Refer to "4-2-6. List of pattern functions" p. 44.

This button has been initially set to the "feed locus".

Refer to "4-2-6. List of pattern functions" p. 44.

This button has been initially set to the "stop position of needle bar".

Refer to "4-2-6. List of pattern functions" p. 44.

This button has been initially set to the "needle thread tension".

Refer to "4-2-6. List of pattern functions" p. 44.

This button has been initially set to the "presser foot pressure".

Refer to "4-2-6. List of pattern functions" p. 44.

mark is displayed at the upper left of the button.

mark is displayed at the upper left

– 31 –

Page 36

Switch/display Description

Customization button A selected function can be allocated to and registered with this button.

This button has been initially set to the "prohibition of thread trimming".

Refer to "4-2-6. List of pattern functions" p. 44.

Customization button A selected function can be allocated to and registered with this button.

This button has been initially set to the "feed timing".

Refer to "4-2-6. List of pattern functions" p. 44.

Multi-layer stitching

button

The multi-layer stitching setting screen is displayed by keeping this button

held pressed for one second.

Refer to "4-2-5. Editing the sewing patterns" p. 42.

This button is displayed when multi-layer stitching is selected.

→

Number of stitches This button is used for displaying the number of stitches of constant-dimen-

sion sewing or the number of stitches registered for each step of polygonal-shape stitching.

This button is displayed when constant-dimension sewing or polygo-

→

nal-shape stitching is selected.

Display of the

number of steps of

a polygonal-shape

This button is displayed when constant-dimension sewing or polygonal-shape

stitching is selected (1 to 20).

This button is displayed when polygonal-shape stitching is selected.

→

stitching pattern

* Only in the case the maintenance personnel mode is selected.

– 32 –

Page 37

4-2. Sewing patterns

Patterns which are frequently sewn can be registered as sewing patterns.

Once the patterns are registered as sewing patterns, the desired sewing pattern can be called up only

by selecting its sewing pattern number.