Page 1

FC2245, FC2245W, CC2245

EN Operator's manual 2-31

Page 2

Contents

Introduction..................................................................... 2

Safety..............................................................................4

Assembly...................................................................... 10

Operation...................................................................... 14

Maintenance................................................................. 21

Troubleshooting............................................................ 26

Introduction

Product description

This product is a brushcutter with a combustion engine.

Work is constantly in progress to increase your safety

and efficiency during operation. Speak to your servicing

dealer for more information.

Intended use

Use the product with a saw blade, a grass blade or a

trimmer head to cut different types of vegetation. Do not

Transportation, storage and disposal........................... 27

Technical data.............................................................. 27

Accessories.................................................................. 29

EC Declaration of Conformity....................................... 31

....................................................................................0

use the product for other tasks than grass trimming,

grass clearing and forestry clearing. Use a saw blade to

cut fibrous types of wood. Use a grass blade or trimmer

head to cut grass.

Note: National or local regulations can regulate the use.

Comply to given regulations.

Only use the product with accessories that are approved

by the manufacturer. Refer to

Accessories on page 29

.

2 1145 - 001 - 09.04.2019

Page 3

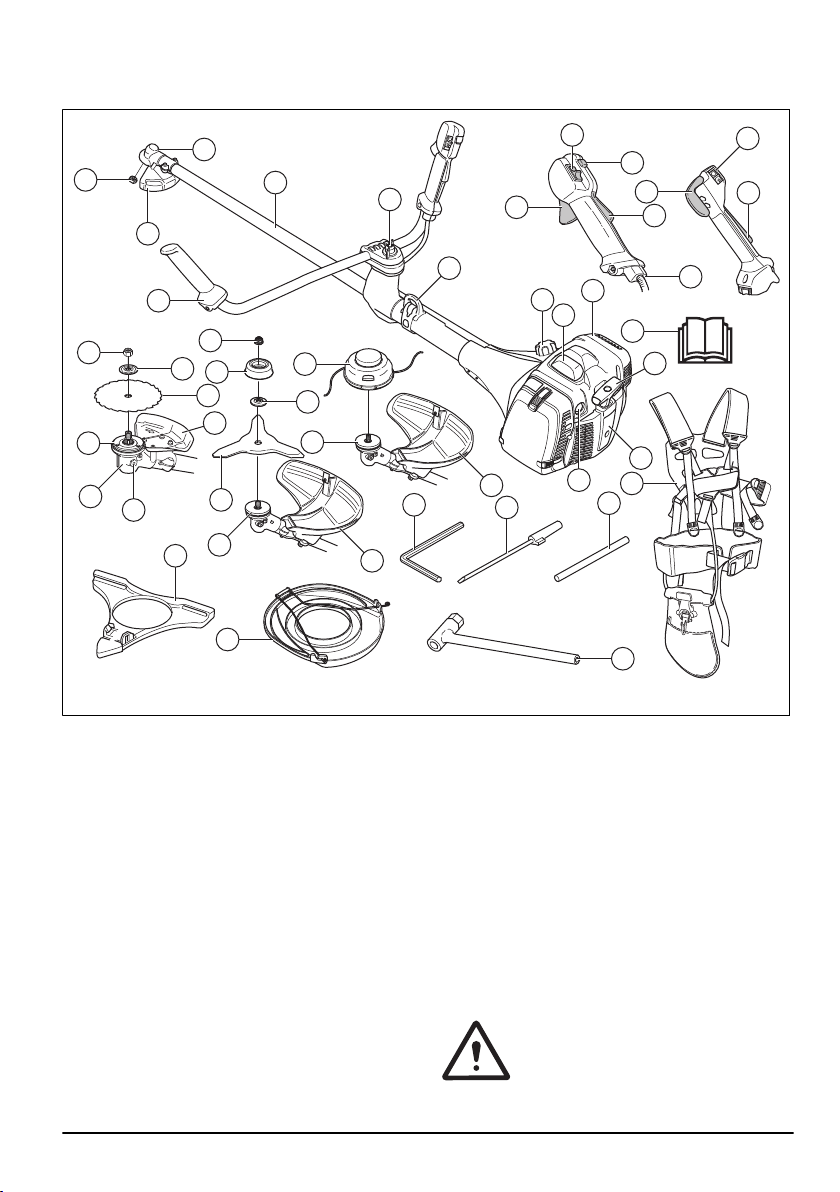

Product overview

CC 2245

FC 2245

5

26

8

9

17

13

29

28

27

11

23

10

8

4

4

35

3

20

1

20

4

31

9

32

24

12

6

21

22

18

19

31

18

26

21

3

21

7

25

30

7

4

1

2

15

1. Saw blade

2. Grease fill cap, bevel gear

3. Bevel gear

4. Cutting attachment guard

5. Shaft

6. Handlebar

7. Throttle trigger

8. Stop switch

9. Throttle trigger lockout

10. Suspension ring

11. Muffler

12. Starter rope handle

13. Fuel tank

14. Choke control

15. Air purge bulb

16. Air filter cover

17. Handle adjustment

18. Locknut

19. Support cup

20. Support flange

21. Drive disc

22. Trimmer head

23. Spark plug cap and spark plug

24. Socket wrench

25. Operator's manual

26. Transport guard

27. Hex key

28. Carburetor screwdriver

29. Locking pin

30. Harness

31. Throttle lock

32. Throttle wire adjustment

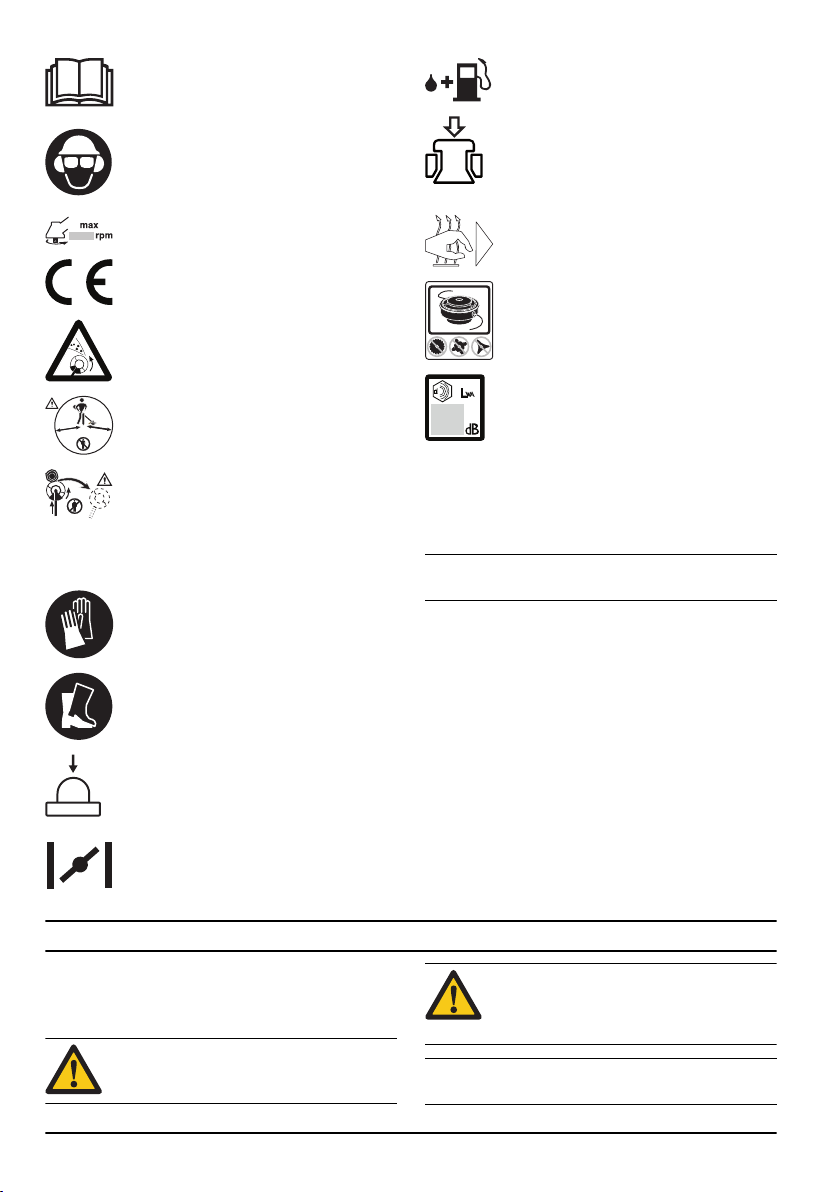

Symbols on the product

Be careful and use the product correctly.

This product can cause serious injury or

death to the operator or others.

1145 - 001 - 09.04.2019 3

Page 4

Read the operator's manual carefully and

5

0

FT

1

5

m

50F

T

15 m

make sure that you understand the

instructions before use.

Use a protective helmet in locations where

objects can fall on you. Use approved

hearing protection. Use approved eye

protection.

Maximum speed of the output shaft.

The product agrees with the applicable EC

directives.

The product can cause objects to eject,

which can cause injury.

Keep a minimum distance of 15 m/49 ft to

persons and animals during operation of the

product.

Risk of blade thrust if the cutting equipment

touches an object that it does not

immediately cut. The product can cut off

body parts. Keep a minimum of 15 m / 49 ft

distance to persons and animals during

operation of the product.

Use approved protective gloves.

Use heavy-duty slip-resistant boots.

Air purge bulb.

Fuel.

Decompression valve.

Heated handles.

Only use a flexible cutting wire. Do not use

metal cutting attachments. Apply this for

grass guard accessory.

Sound power level.

yyyywwxxxx The rating plate shows the

serial number. yyyy is the

production year and ww is

the production week.

Note: Other symbols/decals on the product refer to

certification requirements for other commercial areas.

Product liability

As referred to in the product liability laws, we are not

liable for damages that our product causes if:

• the product is incorrectly repaired.

• the product is repaired with parts that are not from

the manufacturer or not approved by the

manufacturer.

• the product has an accessory that is not from the

manufacturer or not approved by the manufacturer.

• the product is not repaired at an approved service

center or by an approved authority.

Choke.

Safety

Safety definitions

Warnings, cautions and notes are used to point out

specially important parts of the manual.

WARNING: Used if there is a risk of injury or

death for the operator or bystanders if the

instructions in the manual are not obeyed.

4 1145 - 001 - 09.04.2019

Note: Used to give more information that is necessary in

a given situation.

CAUTION: Used if there is a risk of damage

to the product, other materials or the

adjacent area if the instructions in the

manual are not obeyed.

Page 5

General safety instructions

WARNING: Read, understand and obey

these instructions carefully before you use

the product.

Safety instructions for operation

WARNING: Read the warning instructions

that follow before you use the product.

WARNING: This product produces an

electromagnetic field during operation. This

field may under some circumstances

interfere with active or passive medical

implants. To reduce the risk of serious or

fatal injury we recommend persons with

medical implants to consult their physician

and the medical implant manufacturer

before operating this product.

• Do not use the product if you are tired, ill, or under

the influence of alcohol, drugs or medicine, as this

has a negative effect on your vision, alertness,

coordination and judgment.

• Do not operate the product in bad weather, such as

dense fog, heavy rain, strong wind and intense cold.

To operate in bad weather can make you tired and

add risks, such as icy ground and unpredictable

felling direction.

• Always be careful and use your common sense. If

you feel uncertainty about a work situation or the

operating procedures after you read the operator's

manual, speak to a service agent before you

continue.

• Remove the spark plug cap if you let the product out

of view.

Safety instructions for assembly

WARNING:

these instructions carefully before you use

the product.

• Remove the spark plug cap from the spark plug

before you assemble the product.

• Use approved protective gloves.

• When you use a saw blade or a grass blade, make

sure that the correct handlebar, the blade guard and

the harness are attached to the product.

• A defective or incorrect guard can cause injury. Do

not use a cutting attachment that does not have an

approved guard attached.

• Attach the clutch cover and shaft correct before you

start the product to prevent the clutch to fall of.

• Make sure that you assemble the cover and shaft

correct before you start the engine.

• The drive disc and support flange must engage

correctly in the centre hole of the cutting attachment.

A cutting attachment that is attached incorrectly can

cause injury or death.

• To operate the product safely and prevent injury to

the operator or other persons, the product must

always be attached correctly to the harness.

Read, understand and obey

• Learn and understand the difference between

forestry clearing, grass clearing and grass trimming

before you use the product.

• Use personal protective equipment, see

protective equipment on page 6

• Long-term exposure to noise can result in permanent

hearing loss. Always use approved hearing

protection.

• Listen for warning signals and loud voices when you

use hearing protection. Always remove your hearing

protection when the engine stops.

• Never use the product if it is changed or defective.

• Make sure that the spark plug cap and ignition lead

are not damaged to prevent the risk of electrical

shock.

• Look around the work area to make sure that no

persons, animals or objects have a negative effect

on the safety of the operation of the product.

• Look around the work area to make sure that no

persons or animals touch the cutting attachment or

are hit by objects that are ejected from the cutting

attachment.

• Examine the work area. Remove all loose objects,

such as stones, broken glass, nails, steel wire and

string, that can eject or wind around the cutting

attachment.

• Do not use the product in a situation or location

where you can not get aid if an accident occurs.

• Do not use the product without a guard.

• Make sure that persons or animals keep a distance

of a minimum of 15 m during work. Always look

behind you before you turn around with the product.

Stop the product immediately if a person or animal

enters the 15 m safety zone. If more than one

operator does work in the same area, keep a safety

distance of a minimum of 2 times the tree height and

a minimum of 15 m.

• Make sure that you can move safely and have a safe

stance. Examine the area around you for obstacles

Personal

.

1145 - 001 - 09.04.2019

5

Page 6

such as roots, rocks, branch and ditches. Be careful

during work on slopes.

• Do not overreach. Keep a stable position of the feet

and a good balance at all times.

• Before you start the product, put it on a flat surface,

at a minimum ot 3 m from the fuel source and from

where you fill fuel. Make sure that there are no

objects near or touching the cutting attachment.

• If the cutting attachment rotates at idle speed, let a

service agent adjust it. Do not use the product until it

is adjusted or repaired.

• Look out for thrown objects. Always use approved

eye protection and keep away from the cutting

attachment guard. Stones and other small objects

can eject into your eyes and cause blindness or

other injuries.

• Do not put the product down with the engine on

unless you have it in clear view.

• Do not remove the cut material, or let other persons

remove cut material, while the engine is on or the

cutting equipment rotates, as this can result in

serious injury.

• Always stop the engine and make sure that the

cutting equipment does not rotate before you remove

material that is wound around the blade shaft or

caught between the guard and the cutting

attachment.

• Be careful when you remove material from around

the cutting equipment.The bevel gear gets hot during

operation and can cause burn injuries.

• The exhaust fumes from the engine are hot and can

contain sparks. Risk of fire. Be careful around dry

and flammable material.

• Stop the engine before you move to a new work

area. Always attach the transport guard before you

move the equipment.

• Overexposure to vibration can lead to circulatory

damage or nerve damage in persons who have poor

circulation. Speak to your physician if you

experience symptoms of overexposure to vibration.

Such symptoms include numbness, loss of feeling,

tingling, pricking, pain, loss of strength, changes in

skin colour or condition. These symptoms usually

show in the fingers, hands or wrists. The risk

increases at low temperatures.

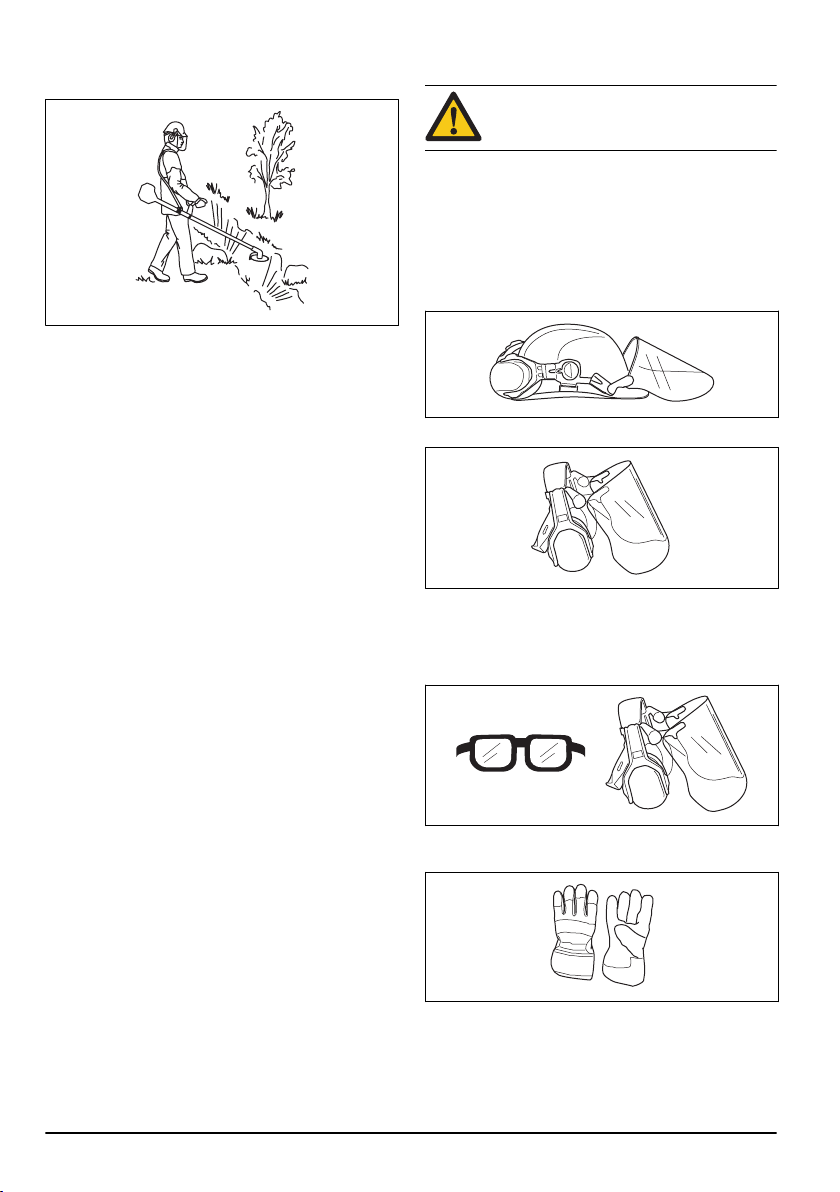

Personal protective equipment

WARNING: Read the warning instructions

that follow before you use the product.

• Always use approved personal protective equipment

when you use the product. Personal protective

equipment cannot fully prevent injury but it

decreases the degree of injury if an accident does

occur. Let your dealer help you select the right

equipment.

• Use a helmet if the trees in the work area have a

height of more than 2 m.

• Use approved hearing protection.

• Use approved eye protection. If you use a visor, you

must also use approved protective goggles.

Approved protective goggles must comply with the

ANSI Z87.1 standard in the USAs or EN 166 in EU

countries.

• Use gloves when necessary, for example when you

attach, examine or clean the cutting equipment.

6

1145 - 001 - 09.04.2019

Page 7

• Use protective boots with steel toes and non-slip

A

A

B

B

soles.

• Use clothing made of a strong fabric. Always use

heavy, long pants and long sleeves. Do not use

loose clothing that can catch on twigs and branches.

Do not wear jewelry, short pants, sandals or go with

bare feet. Put your hair up safely above shoulder

level.

• Keep first aid equipment close at hand.

Safety devices on the product

For information about where to find the safety devices,

see

Product overview on page 3

WARNING: Read the warning instructions

that follow before you use the product.

.

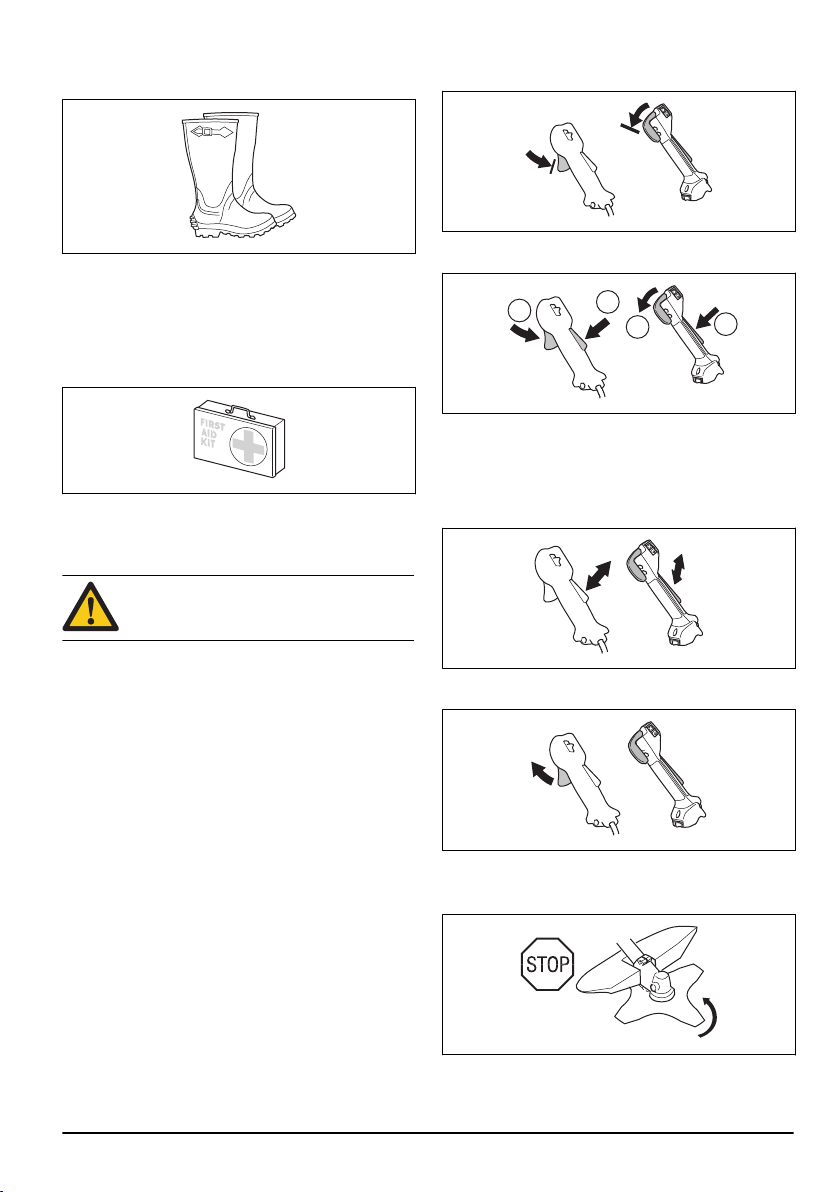

1. Press the throttle trigger (B) and make sure that it is

locked.

2. Press the throttle trigger lockout (A). Make sure that

the throttle trigger (B) is released.

3. Release the handle and make sure that the throttle

trigger lockout (A) and the throttle trigger (B) go back

to their initial positions.

4. Press the throttle trigger lockout (A) and make sure

that it goes back to its initial position when you

release it.

• Do not use a product with defective safety devices.

Do a check of and do maintenance on the safety

devices regularly. If the safety devices are defective,

speak to your JONSERED service agent.

• Do not make changes to safety devices. Do not use

the product if protective covers, safety switches or

other protective devices are not attached or are

defective.

• For all service and repair work on the product,

especially for the safety devices, special training is

necessary. If the safety devices fail the checks given

in this operator's manual, you must let a service

agent help you. We guarantee that professional

repairs and service is available. If your dealer is not

a service agent, speak to them for information about

the nearest service agent.

• Do not use a cutting attachment without an approved

and correctly attached cutting attachment guard. See

To assemble the cutting equipment on page 11

To do a check of the throttle trigger lockout

The throttle trigger lockout locks the throttle trigger at the

idle position.

1145 - 001 - 09.04.2019

.

5. Press the throttle trigger (B) and make sure that it

goes back to its initial position when you release it.

6. Start the engine and apply full throttle.

7. Release the throttle trigger and make sure that the

cutting attachment stops.

7

Page 8

To do a check of the stop switch

1. Start the engine.

2. Move the stop switch to the stop position and make

sure that the engine stops.

To do a check of the cutting attachment guard

The cutting attachment guard stops objects that ejects in

the direction of the operator. It also prevents injuries that

occur if you touch the cutting attachment.

1. Stop the engine.

2. Do a visual check for damages, for example cracks.

3. Replace the cutting attachment guard if it is

damaged.

To do a check of the vibration damping system

The vibration damping system decreases vibration in the

handles to a minimum which makes the operation

easier.

1. Stop the engine.

2. Do a visual check for deformation and damage for

example, cracks.

3. Make sure you attach the elements of the vibration

damping system are correctly.

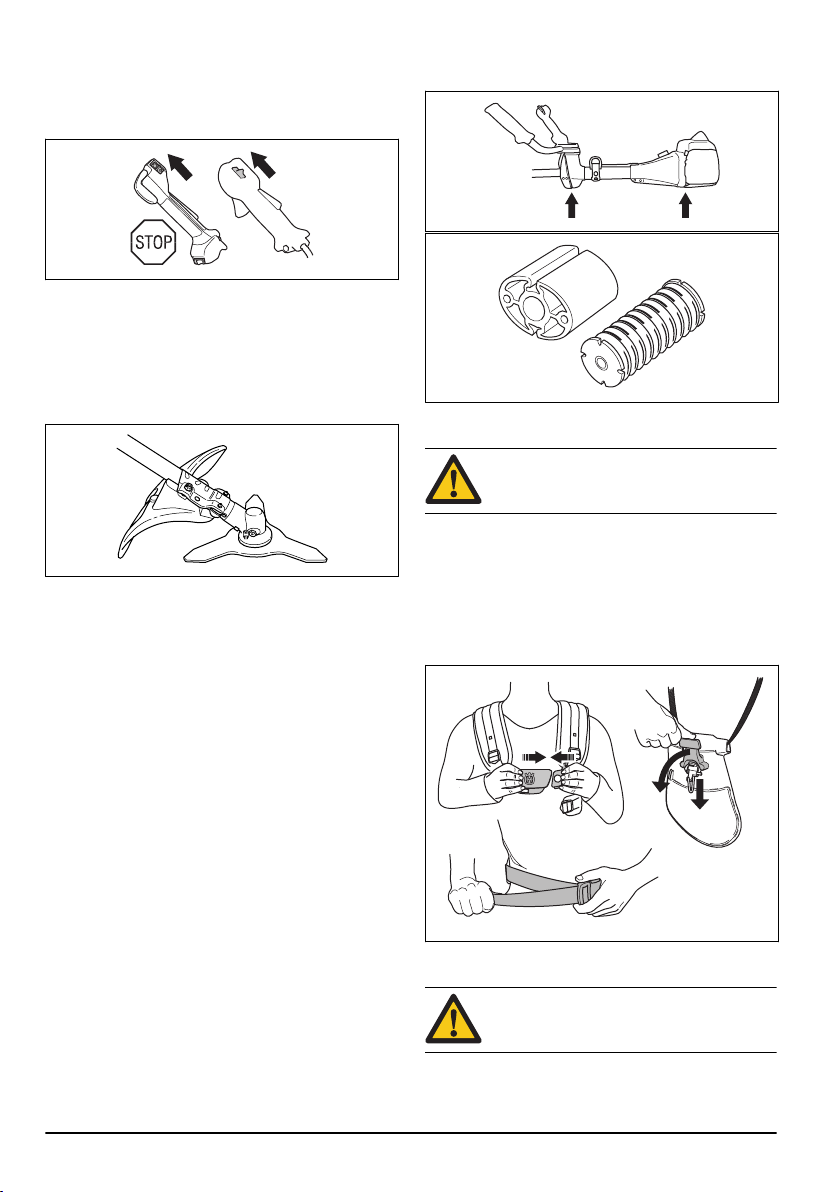

To do a check of the safety-release mechanism

WARNING: Do not use a harness with a

defective safety-release mechanism.

The safety-release mechanism lets the operator remove

the product quickly from the harness if there is an

emergency.

1. Stop the engine.

2. Do a visual check for damages, such as cracks.

3. Release and attach the safety-release mechanism to

make sure that it operates correctly.

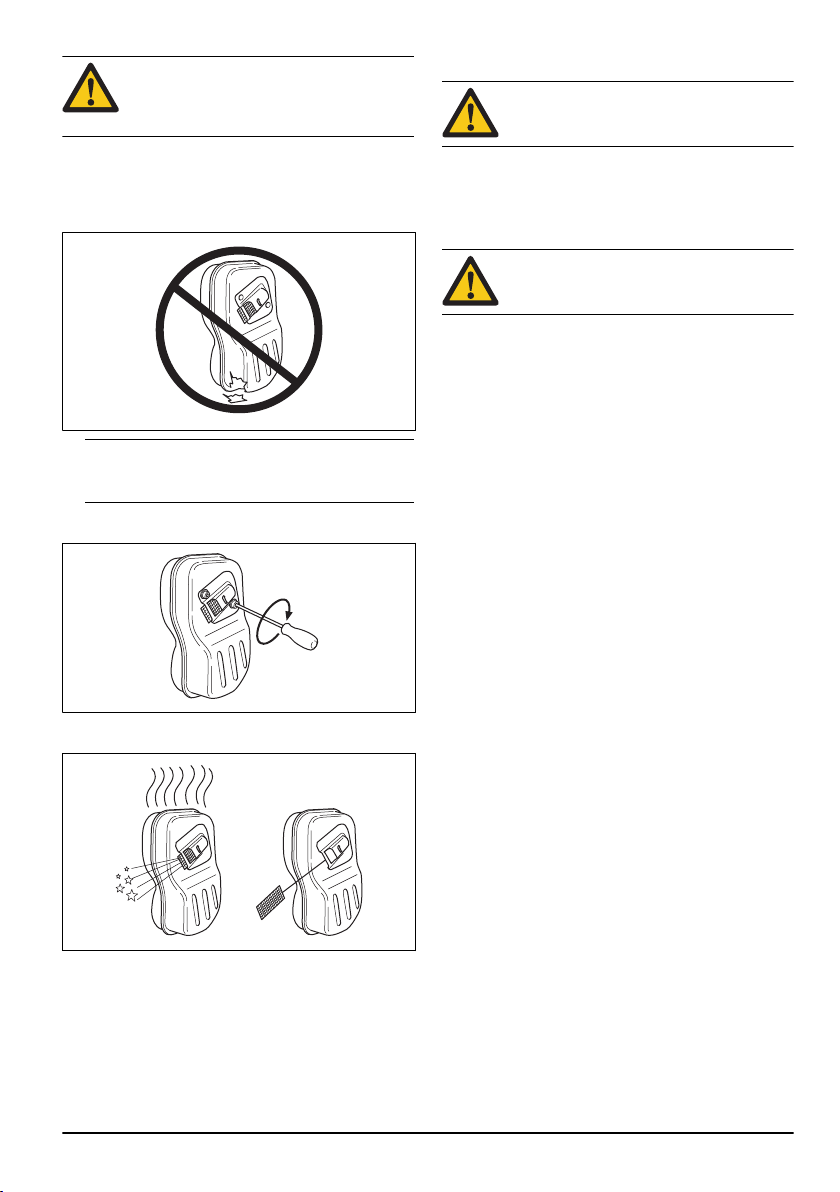

To do a check of the muffler

WARNING: Do not use a product with a

defective muffler.

8 1145 - 001 - 09.04.2019

Page 9

WARNING: The mufflers become very hot

during and after operation, also at idle

speed. Use protective gloves to prevent

burn injuries.

The muffler keeps noise levels to a minimum and sends

exhaust fumes away from the operator.

1. Stop the engine.

2. Do a visual check for damage and deformation.

Note: The inner surfaces of the muffler contain

chemicals that can cause cancer. Be careful not to

touch these elements if the muffler is damaged.

3. Make sure that the muffler is correctly attached to

the product.

4. If the muffler on your product has a spark arrester

screen, do a visual check.

To do a check of the locknut

WARNING: Stop the engine, use protective

gloves and be careful around the sharp

edges of the cutting attachment.

• Make sure that the locknut is attached and tightened

correctly. Refer to

on page 24

To attach and remove the locknut

.

Cutting attachment

WARNING: Read the warning instructions

that follow before you use the product.

• Do the regular maintenance. Let an approved

service center regularly examine the cutting

attachment to do adjustments or repairs.

• The performance of the cutting attachment

increases.

• The life of the cutting attachment increases.

• The risk of accidents decreases.

• Only use an approved cutting attachment guard.

Refer to

• Do not use a damaged cutting attachment.

Accessories on page 29

Grass trimmer head

• Make sure that you wind the grass trimmer line

tightly and equally around the drum to decrease the

vibration.

• Use only the approved grass trimmer heads and

grass trimmer lines. Refer to

29

.

• Use a correct length of the grass trimmer line. A long

grass trimmer line uses more engine power than a

short grass trimmer line.

• Make sure that the cutter on the cutting attachment

guard is not damaged.

• Soak the grass trimmer line in water for 2 days

before you attach the grass trimmer line to the

product. This increases the life of the grass trimmer

line.

• Refer to the instructions for the cutting attachment to

use the correct procedure to load the cord and the

correct cord diameter.

.

Accessories on page

a) Replace the spark arrester screen if it is

damaged.

b) Clean the spark arrester screen if it is blocked.

See

To clean the muffler on page 22

information.

1145 - 001 - 09.04.2019

for more

Saw blade and grass blade

• Use correctly sharpened blades. An incorrectly

sharpened or damaged blade increases the risk of

injury.

• Use correctly set blades. Correct blade set is 1 mm.

An incorrectly set blade increases the risk of injury

and damage.

• To sharpen and set the blade correctly, refer to the

instructions that come with the blade.

9

Page 10

Fuel safety

WARNING: Read the warning instructions

that follow before you use the product.

• Do not mix the fuel indoor or near a heat source.

• Do not start the product if there is fuel or engine oil

on the product. Remove the unwanted fuel/oil and let

the product dry. Remove unwanted fuel from the

product.

• If you spill fuel on your clothing, change clothing

immediately.

• Do not get fuel on your body, it can cause injury. If

you get fuel on your body, use a soap and water to

remove the fuel.

• Do not start the engine if you spill oil or fuel on the

product or on your body.

• Do not start the product if the engine has a leak.

Examine the engine for leaks regularly.

• Be careful with fuel. Fuel is flammable and the fumes

are explosive and can cause injuries or death.

• Do not breathe in the fuel fumes, it can cause injury.

Make sure that there is a sufficient airflow.

• Do not smoke near the fuel or the engine.

• Do not put warm objects near the fuel or the engine.

• Do not add the fuel when the engine is on.

• Make sure that the engine is cool before you refuel.

• Before you refuel, open the fuel tank cap slowly and

release the pressure carefully.

• Do not add fuel to the engine in an indoor area. Not

sufficient airflow can cause injury or death because

of asphyxiation or carbon monoxide.

• Tighten the fuel tank cap carefully or a fire can

occur.

• Move the product at a minimum of 3 m (10 ft) from

the position where you filled the tank before a start.

• Do not put too much fuel in the fuel tank.

• Make sure that a leak cannot occur when you move

the product or fuel container.

• Do not put the product or a fuel container where

there is an open flame, spark or pilot light. Make

sure that the storage area does not contain an open

flame.

• Only use approved containers when you move the

fuel or put the fuel into storage.

• Empty the fuel tank before long-term storage. Obey

the local law on where to dispose fuel.

• Clean the product before long-term storage.

• Remove the spark plug cap before you put the

product into storage to make sure that the engine

does not start accidentally.

Safety instructions for maintenance

WARNING: Read the warning instructions

that follow before you use the product.

• Stop the engine, make sure that the cutting

attachment stops. Remove the cylinder cover and

disconnect the spark plug cap before you do the

maintenance.

• The exhaust fumes from the engine contain carbon

monoxide, an odourless, poisonous and very

dangerous gas that can cause death. Do not run the

product indoors or in closed spaces.

• The exhaust fumes from the engine are hot and can

contain sparks. Do not run the product indoors or

near flammable material.

• Accessories and changes to the product that are not

approved by the manufacturer, can cause serious

injury or death. Do not change the product. Always

use original accessories.

• If the maintenance is not done correctly and

regularly, there is an increased risk of injury and

damage to the product.

• Only do the maintenance as this operator's manual

recommends. Let an approved JONSERED service

agent do all other servicing.

• Let an approved JONSERED service agent do

servicing on the product regularly.

• Replace damaged, worn or broken parts.

Assembly

Introduction

WARNING: Before you assemble the

product, you must read and understand the

safety chapter.

WARNING: Remove the spark plug cable

from the spark plug before you assemble the

product.

10 1145 - 001 - 09.04.2019

To attach the throttle handle

Note: For some models the throttle handle is attached at

the factory.

1. Remove the nut and screw at the bottom of the

throttle handle.

Page 11

2. Put the throttle handle onto the right side of the

handlebar.

3. Align the screw hole in the throttle handle with the

hole in the handlebar.

4. Put the screw into the hole at the bottom of the

throttle handle and through the handlebar.

5. Install and tighten the nut.

To assemble the handlebar

1. Remove the knob and attach the handlebar as given

in the illustration.

To set the handlebar in transport position

1. Loosen the knob.

2. Turn the handlebar clockwise until the throttle handle

touches the battery.

3. Turn the handlebar around the shaft.

4. Tighten the knob.

To assemble the cutting equipment

The cutting equipment includes a cutting attachment and

a cutting attachment guard.

WARNING: Use protective gloves.

WARNING: Always use the cutting

attachment guard that is recommended for

the cutting attachment. See

page 29

.

Accessories on

2. Tighten the knob lightly.

3. Put on the harness and hang the product from the

suspension point.

4. Adjust the handle to put the product in a correct work

position.

5. Tighten the knob fully.

1145 - 001 - 09.04.2019

WARNING: An incorrectly attached cutting

attachment can result in injury or death.

To attach the guard extension

CAUTION:

you use a trimmer head/plastic blade. Do

not use the guard extension when you use a

grass blade.

1. Put the guard extension in the groove of the cutting

attachment guard.

2. Put the guard extension into position on the cutting

attachment guard with the 4 locking hooks.

Use the guard extension when

11

Page 12

To remove the guard extension

A

G

F

D

B

C

A

E

A

B

B

C

D

F

A

E

• Release the locking hooks with the spark plug

wrench.

To attach the grass blade and the grass blade guard/combination guard

1. Put the blade guard/combination guard (A) onto the

shaft and tighten the bolt to attach it.

6. Make sure that the drive disc and support flange

engages correctly in the centre hole of the grass

blade.

7. Attach the nut (G).

8. Tighten the nut with the socket wrench. Hold the

shaft of the socket wrench near the blade guard.

Tighten in the opposite direction to how the cutting

attachment rotates. Tighten it to a torque of 35-50

Nm.

2. Make sure that the guard extension is removed.

3. Turn the output shaft to align one of the holes in the

drive disc (B) with the related hole in the gear

housing.

4. Put the locking pin (C) in the hole to lock the shaft.

5. Put the grass blade (D), the support cup (E) and the

support flange (F) on the output shaft.

12

To attach the saw blade guard (FC2245, FC2245W)

• Attach the saw blade guard (A) with the 4 screws

(B).

To attach the saw blade guard (CC2245)

1. Attach the holder (A) and bracket (B) with 2 bolts (C)

on the gear housing (D).

2. Attach the saw blade guard (E) with 4 bolts (F) in the

holder (A).

1145 - 001 - 09.04.2019

Page 13

To attach the saw blade (CC2245)

D

E

C

A

B

L

A

M

C

B

H

P

C

1. Put the drive disc (A) on the output shaft.

2. Turn the output shaft to align one of the holes in the

drive disc with the related hole in the gear housing.

3. Put the locking pin (B) in the hole to lock the shaft.

4. Put the saw blade (C) and the support flange (D) on

the output shaft.

5. Make sure that the drive disc and support flange

engages correctly in the center hole of the grass

blade.

6. Attach the nut (E).

7. Tighten the nut with the socket wrench. Hold the

shaft of the socket wrench near the blade guard.

Tighten in the opposite direction to how the cutting

attachment rotates. Tighten it to a torque of 35-50

Nm.

3. Put the locking pin (C) in the groove on the bolt head

and tighten the bolt fully.

To attach a trimmer head or plastic blade

1. Put the drive disc (B) on the output shaft.

2. Align the metal cup (P) with the center of the blade

guide on the drive disc.

3. Turn the output shaft to align one of the holes in the

drive disc with the related hole in the gear housing.

4. Put the locking pin (C) in the hole to lock the shaft.

5. Turn the trimmer head/plastic blades (H)

counterclockwise to attach.

To adjust the Balance XT harness

Refer to

Product overview on page 3

the harness.

1. Stop the engine.

2. Push the safety-release mechanism down to release

the product from the harness.

3. To adjust the harness to the operator's height:

a) Push the spring loaded lock.

b) Turn the shoulder strap harness.

c) Move the shoulder strap harness to an applicable

hole on the back plate.

for an overview of

To attach the trimmer guard or combination guard for trimmer head and plastic blades

1. Hang the trimmer guard/combination guard (A) onto

the two hooks on the plate holder (M).

2. Bend the guard around the shaft and attach it with

the bolt (L) on the opposite side of the shaft.

1145 - 001 - 09.04.2019

13

Page 14

4. Attach the strap (A) in correct position for grass

A

B

clearing or forestry clearing.

9. Tighten the elastic strap (B) to move more load from

the shoulder strap to the hip strap.

5. Tighten the hip strap tightly. Make sure that the hip

strap aligns with the hip.

6. Push the 2 parts of the breastplate together as

shown.

7. Attach the side belt to the breastplate.

8. To decrease the pressure on the rib cage and

shoulders, connect the side strap with the strap to

the hip pad. Recommended for women.

10. Adjust the shoulder strap to make the product weigh

equally on your shoulders.

11. Adjust the side straps around the rib cage until the

breastplate is aligned with the center of your chest.

12. Adjust the height of the suspension point. Refer to

Correct balance of the product on page 16

forestry clearing, the correct height of the

suspension is approximately 10 cm/4 in below your

hip.

. For

Operation

Introduction

WARNING: Before you operate the product,

you must read and understand the safety

chapter.

14 1145 - 001 - 09.04.2019

Before you operate the product

• Examine the work area to make sure that you know

the type of terrain, the slope of the ground and if

there are obstacles such as stones, branches and

ditches.

• Do an overhaul inspection of the product.

Page 15

• Do the safety inspections, maintenance and

servicing that are given in this manual.

• Make sure that all covers, guards, handles and the

cutting equipment are correctly attached and not

damaged.

• Make sure that there are no cracks at the bottom of

the saw blade or grass blade teeth or by the center

hole of the blade. Replace the blade if it is damaged.

• Examine the support flange for cracks. Replace the

support flange if it is damaged.

• Make sure that the locknut can not be removed by

hand. If you can remove it by hand, it does not lock

the cutting attachment sufficiently and you must

replace it.

• Examine the blade guard for damages or cracks.

Replace the blade guard if it has been hit or if it has

cracks.

• Examine the trimmer head and cutting attachment

guard for damages or cracks. Replace the trimmer

head and cutting attachment guard if they have been

hit or if they have cracks.

Fuel

This product has a two-stroke engine.

CAUTION: Incorrect type of fuel can result in

engine damage. Use a mixture of gasoline

and two-stroke oil.

Premixed fuel

• Use JONSERED premixed alkylate fuel of a good

quality, for best performance and extension of the

engine life. This fuel contains less harmful chemicals

compared to regular fuel, which decreases harmful

exhaust fumes. The quantity of remains after

combustion is lower with this fuel, which keeps the

components of the engine more clean.

To mix fuel

Gasoline

• Use good quality unleaded gasoline with a maximum

of 10% ethanol contents.

CAUTION: Do not use gasoline with an

octane grade less than 90 RON/87 AKI.

Use of a lower octane grade can cause

engine knocking, which causes engine

damages.

• We recommend that you use gasoline of a higher

octane grade for work with continuously high rpm.

Two-stroke oil

• For best results and performance use JONSERED

two-stroke oil.

• If JONSERED two-stroke oil is not available, use a

two-stroke oil of good quality for air-cooled engines.

Speak to your servicing dealer to select the correct

oil.

CAUTION:

water-cooled outboard engines, also

referred to as outboard oil. Do not use oil

for four-stroke engines.

To mix gasoline and two-stroke oil

Gasoline, liter Two-stroke oil,

5 0.10

10 0.20

15 0.30

20 0.40

Do not use two-stroke oil for

liter

2% (50:1)

1145 - 001 - 09.04.2019 15

Page 16

CAUTION: Small errors can influence the

C

B

A

ratio of the mixture drastically when you mix

small quantities of fuel. Measure the quantity

of oil carefully and make sure that you get

the correct mixture.

1. Fill half the quantity of gasoline in a clean container

for fuel.

2. Add the full quantity of oil.

3. Shake the fuel mixture.

4. Add the remaining quantity of gasoline to the

container.

5. Carefully shake the fuel mixture.

CAUTION: Do not mix fuel for more than 1

month at a time.

To fill the fuel tank

1. Clean the area around the fuel tank cap.

• Keep body parts away from the hot surfaces.

• Keep body parts away from the cutting attachment.

Correct balance of the product

For forestry clearing, the product is correctly balanced

when it freely hangs horizontally from the suspension

point. With correct balance, the risk of hitting stones if

you release the handlebar is decreased.

For grass clearing, the product is correctly balanced

when the blade is at cutting height near the ground.

2. Shake the container and make sure that the fuel is

fully mixed.

3. Tighten the fuel tank cap carefully.

4. Move the product 3 m/10 ft or more away from the

refueling area and fuel source before starting.

To see where the fuel tank is on your product,

Note:

refer to

Introduction on page 2

.

Work position

• Hold the product with 2 hands.

• Hold the product on the right side of your body.

• Keep the cutting attachment below waist level.

• Always keep the product attached to the harness.

16

To start a cold engine

1. Pull the choke control (A) up.

2. Push the decompression valve (B).

The decompression valve moves to the initial

Note:

position when the product starts.

3. Push the air purge bulb (C) about 6 times or fuel until

fuel starts to fill the bulb. It is not necessary to fill the

air bulb fully.

1145 - 001 - 09.04.2019

Page 17

4. Hold the body of the product on the ground with your

E

D

B

F

A

C

CC 2245 FC 2245

left hand.

6. Pull the starter rope handle quickly and with force.

Pull the starter rope handle until the engine starts.

To stop the engine

• Move the stop switch to the stop position.

CAUTION: Do not step on the product.

5. Pull the starter rope handle slowly until you feel

some resistance. When you feel resistance, pull the

starter rope handle quickly and with force.

Note: Do not twist the starter rope around your hand.

6. Continue pull the starter rope handle until the engine

starts.

CAUTION: Do not pull the starter rope to

full extension and do not let go of the

starter rope handle. Release the starter

rope slowly. If you do not obey these

instructions it can cause damage to the

engine.

7. Set the choke control to the run position and apply

full throttle.

To start a warm engine

1. Set the stop switch (A) to the start position.

2. Push the throttle lockout (B) and the throttle trigger

(C).

3. Push the start throttle button (D) while you engage

the throttle trigger (C).

4. Release the throttle lockout and the throttle trigger.

5. Press the air purge bulb (E) about 6 times or until

fuel starts to fill the bulb. It is not necessary to fill the

air purge bulb fully.

Heated handles (FC2245W)

The product has heating elements in the handles. The

ON/OFF switch is on the throttle handle. The heating

elements automatically keep a temperature of 70° when

the heat is on.

Blade thrust

A blade thrust is when the product moves to the side

quickly and with force. A blade thrust occurs when the

grass blade or saw blade hits or catches on an object

that cannot be cut. A blade thrust can eject the product

or operator in all directions. There is a risk of injury to

the operator and bystanders.

The risk increases in areas where it is not easy to see

the material that is cut.

Do not cut with the area of the blade that is shown in

black. The speed and movement of the blade can cause

blade thrust. The risk increases with the thickness of the

branch that is cut.

Do not use the decompression valve (F).

Note:

1145 - 001 - 09.04.2019

17

Page 18

General work instructions

WARNING: Be careful when you cut a tree

that is in tension. It can spring back to its

normal position before or after the cut and

hit you or the product, and cause injury.

• Clear an open space at one end of the work area,

and start the work from there.

• Move in a regular pattern across the work area.

• Move the product fully to the left and right, to clear a

width of 4–5 m on each turn.

• Clear a length of 75 m before you turn and go back.

Move the fuel can along with you as you continue.

• Move in a direction where you do not go across

ditches and obstacles more than necessary.

• Move in a direction where the wind makes the cut

vegetation fall in the cleared area.

3. Tilt the saw blade and push it with force diagonally

down to the right. At the same time, push the tree

with the blade guard.

To fell a tree to the right

To fell to the right, push the bottom of the tree to the left.

1. Apply full throttle.

2. Put the saw blade against the tree as given in the

picture.

3. Tilt the saw blade and push it with force diagonally

up and to the right. At the same time, push the tree

with the blade guard.

• Move along slopes, not up and down.

Forestry clearing with a saw blade

To fell a tree to the left

To fell to the left, push the bottom of the tree to the right.

1. Apply full throttle.

2. Put the saw blade against the tree as given in the

picture.

18

To fell a tree forward

To fell forward, push the bottom of the tree rearward.

1. Apply full throttle.

2. Put the saw blade against the tree as given in the

picture.

3. Pull the saw blade forward with a fast movement.

To fell large trees

Large trees must be cut from 2 sides.

1. Examine in which direction the tree will fall.

2. Apply full throttle.

1145 - 001 - 09.04.2019

Page 19

3. Do the first cut on the side of the tree to which it will

fall.

• For groups of thin trees:

4. Cut through the tree from the other side.

CAUTION: If the saw blade becomes

blocked, do not pull the product with a

sudden movement. That can cause damage

to the saw blade, bevel gear, shaft or

handlebar. Release the handles, hold the

shaft with 2 hands and carefully pull the

product.

Note: Use more cutting pressure fo fell small trees. Use

less cutting pressure to fell large trees.

Brush cutting with a saw blade

To fell to the left, push the bottom of the tree to the right.

• Cut down thin trees and brush.

• Move the product from side to side.

• Cut many trees in one movement.

a) Cut the outer trees high up.

b) Cut the outer trees to the correct height.

c) Cut from the center. If you cannot get access to

the center, cut the outer trees high up and let

them fall. This decreases the risk that the saw

blade becomes blocked.

Grass clearing with a grass blade

CAUTION: Do not use grass blades and

grass knives on wood. Use grass blades

and grass knives for long or heavy grass

only.

• Move the product from side to side.

• Start the movement from right to left when you cut.

Move the product to the right before you cut again.

• Cut with the left side of the grass blade.

• Angle the grass blade to the left to make the grass

fall in a line. This makes it easy to collect the grass.

• Keep a stable position with your feet apart.

• Move forward after each right movement and make

sure that you have a stable position again before you

cut again.

• Keep the support cup with a light pressure against

the ground to make sure that the grass blade does

not hit the ground.

• Obey these instructions to decrease the risk that cut

material winds around the grass blade:

a) Apply full throttle.

1145 - 001 - 09.04.2019

19

Page 20

b) Do not move the grass blade through cut

material when you move the product from left to

right.

• Before you collect the cut material, stop the engine

and remove the product from the harness. Put the

product down on the ground.

Grass trimming with a trimmer head

To trim the grass

1. Hold the trimmer head immediately above the

ground at an angle. Do not push the trimmer line into

the grass.

2. Decrease the length of the trimmer line by 10-12

cm / 4-4.75 in.

3. Decrease the engine speed to decrease the risk of

damage to plants.

4. Use 80 % throttle when you cut grass near objects.

7. Reduce the risk of material wrapping around the

blade by always work at full throttle and avoid the

previously cut material during the return stoke.

8. Stop the engine, unclip the harness and place the

machine on the ground before you start to collect the

cut material.

To cut the grass

1. Make sure that the trimmer line is parallel to the

ground when you cut the grass.

2. Do not push the trimmer head to the ground. This

can cause damage to the product.

3. Move the product from side to side when you cut

grass. Use full speed.

To clear grass with a grass blade

1. Grass blades and grass cutters must not be used on

woody stems.

2. A grass blade is used for all types of tall or coarse

grass.

3. The grass is cut down with a sideways, swinging

movement, where the movement from right-to-left is

the clearing stoke and the movement from left-toright is the return stoke. Let the left-hand side of the

blade (between 8 and 12 o'clock) do the cutting.

4. if the blade is angled to the left when clearing grass,

the grass will collect in a line, which makes it easier

to collect, e.g. by raking.

5. Try to work rhythmically. Stand firmly with your feet

apart. Move forward after the return stoke and stand

firmly again.

6. Let the support cup rest lightly against the ground. It

is used to protect the blade from hitting the ground.

20 1145 - 001 - 09.04.2019

To sweep the grass

The airflow from the rotating trimmer line can be used to

remove cut grass from an area.

1. Hold the trimmer head and the trimmer line parallel

to the ground and above the ground.

2. Apply full throttle.

3. Move the trimmer head from side to side and sweep

the grass.

WARNING:

each time you assemble new trimmer line to

prevent unbalance and vibrations in the

handles. Also do a check of the other parts

of the trimmer head and clean it if

necessary.

Clean the trimmer head cover

Page 21

Maintenance

Introduction

WARNING: Before you do maintenance, you

must read and understand the safety

chapter.

Maintenance schedule

Maintenance Daily Weekly Monthly

Clean the external surface. X

Examine the harness for damages. X

Examine the quick-release mechanism on the harness for damages and make

sure that it operates correctly.

Do a check of the throttle trigger lockout and the throttle trigger. Refer to

check of the throttle trigger lockout on page 7

Make sure that the cutting attachment does not rotate at idle speed. X

Do a check of the stop switch. Refer to

8

.

Examine the cutting attachment guard for damages and cracks. X

Make sure that the saw blade or grass blade is attached correctly. Make sure

that the saw blade or grass blade is sharp and not damaged.

Examine the support flange for damages and cracks. Replace it if it is damaged. X

Examine the trimmer head for damages and cracks. Replace it if it is damaged. X

Examine the handle and the handlebar for damages and make sure that they are

attached correctly.

Tighten the locking screw fully for cutting attachments with a support cup. X

Tighten the locknut fully for cutting attachments with a locknut. X

Examine the transport guard for damage and make sure that it can be attached

correctly.

Examine the engine, the fuel tank and the fuel lines for leaks. X

Clean the air filter. Replace it if it is damaged. X

Tighten nuts and screws. X

Examine the starter and the starter rope for damages. X

Examine the vibration damping units for damages and cracks.

Examine the spark plug. Refer to

Clean the cooling system. X

Clean or replace the spark arrester screen. X

To examine the spark plug on page 25

.

To do a check of the stop switch on page

For all servicing and repair work on the product, special

training is necessary. We guarantee the availability of

professional repairs and servicing. If your dealer is not a

service agent, speak to them for information about the

nearest service agent.

X

To do a

1

. X

X

X

X

X

X

X

1

Replace the vibration damping unit after each season or at a minimum of one time each year.

1145 - 001 - 09.04.2019 21

Page 22

Maintenance Daily Weekly Monthly

A

5 mm

Clean the external surface of the carburetor and the area around it. X

Make sure that the bevel gear is filled to ¾ with grease. X

Examine the fuel filter for contamination and the fuel hose for cracks and other

defects. Replace if it is necessary.

Examine all cables and connections. X

Examine the clutch, clutch springs and clutch drum for wear. Replace it if it is

necessary.

Replace the spark plug. X

Clean or replace the spark arrester screen. X

Lubricate the drive shaft.

2

X

X

X

To adjust the idle speed

Your JONSERED product is made to specifications that

decrease harmful emissions.

1. Make sure that the air filter is clean and the air filter

cover is attached before you adjust the idle speed.

2. Adjust the idle speed with the idle speed screw T

which is identified with "T" mark.

a) Turn the idle speed screw T clockwise until the

cutting attachment starts to rotate.

b) Turn the idle speed screw T counterclockwise

until the cutting attachment stops.

WARNING: If the cutting attachment

does not stop when you adjust the idle

speed, speak to your servicing dealer.

Do not use the product until it is correctly

adjusted or repaired.

3. The idle speed is correct when the engine operates

smoothly in all positions. The idle speed must be

below the speed when the cutting attachment starts

to rotate.

Refer to

Note:

recommended idle speed.

Technical data on page 27

for the

To adjust the start throttle speed (CC2245)

1. Apply idle speed to the product.

2. Push the start throttle lock. Refer to

the throttle trigger lockout on page 7

3. If the start throttle speed is less than 4000 rpm, turn

the adjuster screw (A) clockwise. When the cutting

attachment starts to rotate, turn the adjuster screw

(A) ½ turn clockwise.

4. If the start throttle speed is more than 6500 rpm, turn

the adjuster screw (A) counterclockwise. When the

cutting attachment starts to rotate, turn the adjuster

screw (A) ½ turn counterclockwise.

To do a check of

.

To clean the muffler

WARNING:

and after operation, also at idle speed. Risk

of fire and burn injuries.

The muffler gets very hot during

2

At an interval of 3 months.

22 1145 - 001 - 09.04.2019

Page 23

1. If the muffler on your product has a spark arrester

A

B

E

C

D

screen, clean it weekly with a steel brush. Replace

the spark arrester screen if it is damaged.

CAUTION: A blocked spark arrester screen

causes the engine to become too hot and

results in damage to the cylinder and piston.

CAUTION: If the spark arrester screen is

frequently blocked, let your service agent

examine the muffler.

To clean the cooling system and starter pawls

The cooling system includes:

• The air intake on the starter (A)

• The fins on the flywheel (B)

• The cooling fins on the cylinder (C)

• The cylinder cover (D)

• The starter pawls (E) that are found on the flywheel

Air filter

Remove dust and dirt from the air filter to keep it clean in

order to prevent:

• Carburettor malfunctions.

• Starting problems.

• Loss of engine power.

• Unnecessary wear to engine parts.

• Too much fuel consumption.

Clean the air filter at an interval of 25 hours, or more

regularly if conditions are unusually dusty.

To do a check of a paper air filter (CC2245)

1. Remove the air filter cover.

2. Open the 2 snap locks that hold the filter frame.

3. Remove the filter frame and the air filter.

4. Examine and clean the air filter housing with a brush.

5. Examine the air filter. Replace the air filter if it is dirty

or damaged.

CAUTION:

as this can cause damage to the air filter.

Replace a damaged air filter.

Do not bend of fold the air filter

Clean the cooling system weekly or more frequently if it

is necessary.

1. Remove the starter cover and the cylinder cover.

2. Clean the cooling system with a brush.

3. Examine the starter pawls and area around them for

dirt.

4. Clean around the starter pawls with a brush, to make

sure that they can move freely.

1145 - 001 - 09.04.2019

To clean a nylon air filter (FC2245, FC2245W)

1. Remove the air filter cover.

2. Release the snap locks that hold the air filter.

3. Remove the air filter.

4. Examine and clean the air filter housing with a brush.

5. Examine the air filter. Clean the air filter with warm

soap water.

23

Page 24

CAUTION: Replace an air filter that is

damaged.

Bevel gear

The bevel gear is filled to ¾ with grease at the factory.

Before use, make sure that the grease level has not

changed. Use JONSERED special grease if it is

necessary to fill up. Do not change the grease in the

bevel gear. Let servicing personnel do the repair of the

bevel gear.

Drive shaft

Lubricate the drive shaft at an interval of 3 months. Let a

service agent help you if you are not sure about the

procedure.

To attach and remove the locknut

WARNING: Stop the engine, use protective

gloves and be careful around the sharp

edges of the cutting attachment.

Use the locknut to attach some types of cutting

attachments. The locknut has a left thread.

• Use a socket wrench with a shaft that is sufficiently

long to let you keep your hand behind the cutting

attachment guard. The arrow in the illustration shows

the area where you can safely operate the socket

wrench.

• To attach, tighten the locknut in the opposite

direction to how the cutting attachment rotates.

• To remove the locknut, turn it in the same direction

as how the cutting attachment rotates.

• Keep count when you remove and attach the

locknut. Replace the locknut after approximately 10

times.

Make sure that you can not turn the locknut by

Note:

hand. Replace the locknut if the nylon lining does not

have a resistance of a minimum of 1.5 Nm.

To sharpen the grass knife and grass blade

WARNING: Stop the engine. Use protective

gloves.

• To sharpen the grass knife or grass blade correctly,

refer to the instructions that come with the cutting

attachment.

• Sharpen all edges equally to keep the balance.

• Use a single-cut flat file.

24

1145 - 001 - 09.04.2019

Page 25

WARNING: Always discard a blade that is

15˚

damaged. Do not try to make a bent or

twisted blade straight and use it again.

To sharpen the saw blade

WARNING: Stop the engine. Use protective

gloves.

• To sharpen the blade correctly, refer to the

instructions that come with the blade.

• Make sure that the product and blade has sufficient

support when you sharpen it.

• Use a 5.5 mm round file with a file holder.

• Adjust the blade set to 1 mm with the recommended

setting tool. Refer to the instructions that come with

the blade.

WARNING: Always discard a blade that is

damaged. Do not try to make a bent or

twisted blade straight and use it again.

To examine the spark plug

CAUTION: Always use the recommended

spark plug type. Incorrect spark plug type

can cause damage to the product.

• Examine the spark plug if the engine is low on

power, is not easy to start or does not operate

correctly at idle speed.

• To decrease the risk of unwanted material on the

spark plug electrodes, obey these instructions:

a) Make sure that the idle speed is correctly

adjusted.

b) Make sure that the fuel mixture is correct.

c) Make sure that the air filter is clean.

• If the spark plug is dirty, clean it and make sure that

the electrode gap is correct, refer to

on page 27

.

Technical data

• Hold the file at an angle of 15°.

• Sharpen one tooth of the saw blade to the right and

the next tooth to the left, see the illustration.

Sharpen the edges of the teeth with a flat file if

Note:

the blade is heavily worn. Continue to sharpen with a

round file.

• Sharpen all edges equally to keep the blade

balanced.

1145 - 001 - 09.04.2019

• Replace the spark plug if it is necessary.

To adjust the product for cold environments

If the temperature is 5° or colder, adjustments are

necessary to prevent operation problems.

25

Page 26

• Attach the air duct as shown in the illustration. Make

sure that the arrow points in the direction of the

winter mode symbol.

• Replace the air filter cover with the winter mode air

filter cover.

• If you operate the product in snow, attach a cover on

top of the starter.

• For (FC2245W), make sure that the wire is

lubricated when you operate the product in cold

environments.

• If the temperature is more than 5°, use the regular

air filter cover. Remove the cover on top of the

starter and adjust the air duct to the initial position.

Make sure that the arrow points in the direction of

the summer mode symbol.

CAUTION:

temperatures of more than than 5° if it is

adjusted for winter mode. The engine

becomes too hot and can be damaged.

Do not operate the product at

To lubricate the wire

CC2245

Note: The wire is lubricated at the factory. Lubricate the

wire monthly.

1. Remove the protective cover.

2. Remove the cylinder cover to get access to the

rubber bellows on the wire.

3. Remove the plug on the grease nipple.

4. Use antifreeze spray with a 2 mm spray tube. Spray

in short intervals.

5. Examine the rubber bellows on the wire to make

sure that it does not expand.

6. Attach the cylinder cover and the protective cover.

Troubleshooting

The engine does not start

Check Possible cause Procedure

Stop switch. The stop switch is in the stop posi-

tion.

Starter pawls. The starter pawls cannot move free-

ly.

Fuel tank. Incorrect fuel type. Drain the fuel tank and fill with cor-

Carburetor Incorrect adjustment of the idle

speed

26 1145 - 001 - 09.04.2019

Let an approved servicing dealer replace the stop switch.

Remove the starter cover and clean

around the starter pawls. Refer to

To

clean the cooling system and starter

pawls on page 23

Let an approved servicing dealer

help you.

rect fuel.

Adjust the idle speed with the idle

speed screw T.

.

Page 27

Check Possible cause Procedure

Spark plug. The spark plug is dirty or wet. Make sure that the spark plug is dry

The spark plug electrode gap is incorrect.

The spark plug is loose. Tighten the spark plug.

Fuel filter The fuel filter is clogged. Replace the fuel filter.

and clean.

Clean the spark plug. Make sure that

the electrode gap is correct. Make

sure that the spark plug has a supressor.

Refer to

Technical data on page 27

for correct electrode gap.

The engine starts but stops again

Check

Fuel tank Incorrect fuel type. Empty the fuel tank and fill it with cor-

Fuel filter The fuel filter is clogged. Replace the fuel filter.

Carburetor The idle speed is not correctly adjus-

Air filter The air filter is clogged. Clean the air filter.

Possible cause Procedure

rect fuel.

ted.

Adjust the idle speed with the idle

speed screw T.

Transportation, storage and disposal

Transportation and storage

• Let the product cool before transportation or storage.

• Remove the spark plug cap before long-term

storage.

• Attach the product during transportation. Make sure

that it cannot move.

• Make sure that there is no risk of fuel leaks, fuel

fumes, sparks or flames during transportation and

storage.

• Attach the transport guard during transportation and

storage.

• Clean and do servicing on the product before longterm storage.

Technical data

/2.0 Technical data

FC2245 FC2245W CC2245

Engine

Cylinder displacement, cm

Idle speed, rpm 2700 2700 2700

Speed of output shaft, rpm 10100 10100 8800

3

45.7 45.7 45.7

1145 - 001 - 09.04.2019 27

Page 28

FC2245 FC2245W CC2245

Max. engine power, according to ISO 8893,

2.2/3.0 @ 9000 2.2/3.0 @ 9000 2.1/2.8 @ 9000

kW/hp @ rpm

Catalytic converter muffler - - No

Ignition system

Spark plug NGK CMR6H NGK CMR6H NGK CMR6H

Electrode gap, mm 0.5 0.5 0.5

Fuel

Fuel tank capacity, l/cm

3

0.9/900 0.9/900 0.9/900

Weight

Weight, kg 8.2 8.4 8.7

Noise emissions

3

Sound power level, measured dB (A) 113 113 115

Sound power level, guaranteed LWA dB (A) 114 114 117

Sound levels

4

Equivalent sound pressure level at the operator’s ear, measured according to EN ISO 11806 and ISO 22868, dB(A):

Equipped with trimmer head (original) 100 - 99

Equipped with grass blade (original) 100 - 100

Equipped with saw blade (original) 100 100 100

Vibration levels

Equivalent vibration levels (a

Equipped with trimmer head (original), left/

5

) at handles, measured according to EN ISO 11806 and ISO 22867, m/s2:

hv,eq

- - 3.1/2.9

right

Equipped with grass blade (original), left/right - - 2.7/3.5

Equipped with saw blade (original), left/right 2.3/3.0 2.3/3.0 2.8/3.6

3

Noise emissions in the environment measured as sound power (LWA) in conformity with EC directive 2000/14/

EC. Reported sound power level for the machine has been measured with the original cutting attachment that

gives the highest level. The difference between guaranteed and measured sound power is that the guaranteed sound power also includes dispersion in the measurement result and the variations between different

machines of the same model according to Directive 2000/14/EC.

4

Reported data for equivalent sound pressure level for the machine has a typical statistical dispersion (standard deviation) of 1 dB(A).

5

Reported data for equivalent vibration level has a typical statistical dispersion (standard deviation) of 1 m/s2.

28 1145 - 001 - 09.04.2019

Page 29

Accessories

Accessories (FC2245, FC2245W)

Approved accessories Accessory type Cutting attachment guard, art. no.

Centre hole in blades/knives, Ø 25.4mmOutput shaft thread M12

Grass blade/grass cutter Multi 255-3 (Ø 255, 3 teeth) 537 29 74-02 / 544 46 43-01

Multi 275-4 (Ø 275, 4 teeth) 537 29 74-02 / 544 46 43-01

Multi 300-3 (Ø 300 3 teeth) 537 29 74-02 / 544 46 43-01

Saw blade Scarlet 200-22 (Ø 200, 22 teeth) 537 21 71-01

Scarlet 225-24 (Ø 225, 24 teeth) 502 03 94-06

Plastic blades Polytrim Ø 300 mm (Separate blades

have part number 531 01 77-15)

Trimmer head Trimmy S II (Ø 2.4–3.3 mm cord) 537 29 73-02 / 544 46 43-01

Auto 55 (Ø 2.7-3.3 mm cord) 537 29 73-02 / 544 46 43-01

Tap-N-Go 45 Spin (Ø 2.7–3.3 mm

cord)

Support cup Fixed

With ball bearing

537 29 74-02 / 544 46 43-01

537 29 73-0 / 544 46 43-01

Accessories (CC2245)

Approved accessories

Centre hole in blades/knives, Ø 25.4mmOutput shaft thread M12

Grass blade/grass cutter Multi 255-3 (Ø 255, 3 teeth) 537 28 85-02 / 544 46 43-01

Saw blade Scarlet 200-22 (Ø 200, 22 teeth) 537 31 09-01

Plastic blades Polytrim Ø 300 mm (Separate blades

Trimmer head Trimmy S II (Ø 2.4–3.3 mm cord) 503 95 43-04 / 544 46 43-01

1145 - 001 - 09.04.2019 29

Accessory type Cutting attachment guard, art. no.

Multi 275-4 (Ø 275, 4 teeth) 537 28 85-02 / 544 46 43-01

Multi 300-3 (Ø 300 3 teeth) 537 28 85-02 / 544 46 43-01

have part number 531 01 77-15)

Auto 55 (Ø 2.7-3.3 mm cord) 503 95 43-04 / 544 46 43-01

Tap-N-Go 45 Spin (Ø 2.7–3.3 mm

cord)

537 28 85-02 / 544 46 43-01

503 95 43-04 / 544 46 43-01

Page 30

Approved accessories Accessory type Cutting attachment guard, art. no.

Support cup Fixed

With ball bearing

30 1145 - 001 - 09.04.2019

Page 31

EC Declaration of Conformity

EC Declaration of Conformity

Husqvarna AB, SE-561 82 Huskvarna, Sweden, tel:

+46-36-146500, declares that the brush cutters

JONSERED FC2245, FC2245W, CC2245 with serial

numbers dating from 2016 onwards (the year is clearly

stated on the rating plate, followed by the serial

number), comply with the requirements of the

COUNCIL’S DIRECTIVE:

• of May 17, 2006 ”relating to machinery” 2006/42/EC

• of February 26, 2014 ”relating to electromagnetic

compatibility” 2014/30/EU

• of May 8, 2000 ”relating to the noise emissions in the

environment” 2000/14/EC. Conformity assessment

according to Annex V. For information relating to

noise emissions, see the

chapter.

• of June 8, 2011 ”on the restriction of the use of

certain hazardous substances in electrical and

electronic equipment” 2011/65/EU.

The following standards have been applied:

EN ISO 12100:2010, EN ISO 11806-1:2011, ISO

14982:1998, CISPR 12:2007, EN 50581:2012

RISE SMP Svensk Maskinprovning AB, Box 7035,

SE-750 07 Uppsala, Sweden, has performed voluntary

type examination on behalf of Husqvarna AB. The

certificates are numbered: SEC/11/2310 - FC2245,

FC2245W, SEC/11/2309 - CC2245.

RISE SMP Svensk Maskinprovning AB has also verified

agreement with appendix V of the council’s directive

2000/14/EG.

The certificate has the number: 01/164/077 - FC2245,

FC2245W, 01/164/076 - CC2245.

Huskvarna March 30, 2016

Technical data on page 27

Per Gustafsson, Development Manager (Authorized

representative for Husqvarna AB and responsible for

technical documentation)

1145 - 001 - 09.04.2019

31

Page 32

www.jonsered.com

Original instructions

1157545-26

2019-05-08

Loading...

Loading...