John Deere JD 410 Repair Manual

TECHNICAL MANUAL

ORGANIZATIONAL MAINTENANCE MANUAL

VOLUME 3 OF 3

TM 5-2420-222-20-3

MAINTENANCE

INSTRUCTIONS CONTINUED

PAGE 2-1189

MAINTENANCE

ALLOCATION

CHART (MAC)

PAGE B-1

INDEX

PAGE Index-1

TRACTOR, WHEELED (DED)

LOADER BACKHOE

W/HYDRAULIC IMPACT TOOL AND

HYDRAULIC EARTH AUGER ATTACHMENT

JOHN DEERE MODEL JD 410 (CCE)

WITH BUCKET, IMPACTOR,

AND EARTH DRILL

(NSN 2420-00-567-1035)

APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED

This copy is a reprint which includes current

pages from Change 1.

Change 1 1 SEPTEMBER 1987

HEADQUARTERS, DEPARTMENT OF THE ARMY

TM 5-2420-222-20-3

WARNING

When operating loader backhoe, make sure that all personnel are cleared from vehicle and work

area. Failure to observe this precaution could cause injury to personnel.

WARNING

Do not operate backhoe controls unless you are in operator’s seat facing backhoe. Backhoe

boom cylinder may be accidentally bumped, causing backhoe boom to move suddenly. Failure to

observe this precaution could cause serious injury.

WARNING

Do not attempt to disconnect hydraulic lines and fittings while engine is running or before

hydraulic system pressure has been released. When engine is running, hydraulic system is under

pressure. Hydraulic system pressure should be 0 psi (0 kPa) before lines are disconnected. A line

or fitting disconnected under pressure will blow off with a lot of force and could cause serious

injury to personnel.

WARNING

Be careful when draining hot fluids. Wear gloves to protect your hands from hot parts and fluids

or severe burns could result.

WARNING

Drycleaning solvent P-D-680 is toxic and flammable. Wear protective goggles and gloves and use

only in a well ventilated area. Avoid contact with skin, eyes, and clothes and don’t breathe vapors.

Do not use near open flame or excessive heat. The flashpoint is 100°F to 138°F (38° to 59°C). If

you become dizzy while using cleaning solvent, get fresh air immediately and get medical aid. If

contact with eyes is made, wash your eyes with water and get medical aid immediately.

WARNING

Compressed air used for blowing away chips, dirt, etc., must leave nozzle at less than 30 psi (207

kPa) to prevent personal injury. Be certain that nozzle is rated to provide a maximum of 30 psi

(207 kPa). Be sure to wear safety goggles when using compressed air. Compressed air and

particles moved by compressed air can cause damage to your eyes.

WARNING

Be careful of moving parts when working near engine while it is running. Moving parts could

catch on tools, clothing, or extremities causing serious injury.

WARNING

Keep clear of hydraulic components when raised and not supported. Sudden loss of hydraulic

pressure could cause components to drop without warning.

Change 1 a

TM 5-2420-222-20-3

WARNING

Surge relief valve plug is under strong spring tension. If plug is not supported, parts may fly off

injuring personnel.

WARNING

Valve is under strong spring tension. If valve is not supported when mounting bolts are removed,

parts may fly off injuring personnel.

WARNING

Some parts are heavy. Be careful when handling them. Lifting equipment is needed when parts

weigh over 50 pounds (23 kg) for a single person lift, over 100 pounds (45 kg) for a tw o person lift,

and over 150 pounds (68 kg) for a three or more person lift. Do not try to handle heavy parts

without lifting equipment. Keep clear of heavy parts supported only by lifting equipment. Failure

to observe this precaution could cause serious injury or death of personnel.

Change 1 b

TM 5-2420-222-20-3

C1

CHANGE HEADQUARTERS

DEPARTMENT OF THE ARMY

NO. 1 Washington D.C., 8 April 1992

ORGANIZATIONAL MAINTENANCE MANUAL

TRACTOR, WHEELED,

DED, LOADER BACKHOE:

WITH HYDRAULIC IMPACT TOOL AND

WITH HYDRAULIC EARTH AUGER ATTACHMENT

JOHN DEERE MODEL JD410 (CCE)

WITH BUCKET, IMPACTOR,

AND EARTH DRILL

(NSN 2420-00-567-0135)

TM 5-2420-222-20-3, 1 September 1987, is changed as follows:

1. Cover. The manual title is changed to read as shown above.

2. Remove old pages and insert new pages.

3. New or changed material is indicated by a vertical bar in the margin or by a vertical bar adjacent to the TA number.

Remove Pages Insert Pages

a and b a and b

i and ii i and ii

A-1 and A-2 A-1 and A-2

Appendix B (in its entirety) Appendix B (in its entirety)

C-3 and C-4 C-3 and C-4

Cover 1 and 2 Cover 1 and 2

4. File this change sheet in front of the publication for reference purposes.

Approved for public release; distribution Is unlimited.

1

*TM 5-2420-222-20-3

TECHNICAL MANUAL HEADQUARTERS

DEPARTMENT OF THE ARMY

NO. 5-2420-222-20-3WASHINGTON, D.C.,

ORGANIZATIONAL MAINTENANCE MANUAL

TRACTOR, WHEELED,

DED, LOADER BACKHOE:

WITH HYDRAULIC IMPACT TOOL AND

WITH HYDRAULIC EARTH AUGER ATTACHMENT

JOHN DEERE MODEL JD410 (CCE)

WITH BUCKET, IMPACTOR,

AND EARTH DRILL

(NSN 2420-00-567-0135)

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this manual. If you find any mistakes or if you know of a way to improve the

procedures, please let us know. Mail your letter, DA Form 2028 (Recom m ended Changes to Public ations

and Blank Forms), or DA Form 20282 loc ated in the back of this m anual direct to: Com m ander, US Arm y

Tank-Automotive Command, ATTN: AMSTA-MB, Warren, MI 48397-5000. A reply will be sent to you.

1 September 1987

TABLE OF CONTENTS

VOLUME 3 OF 3

Page

CHAPTER 2 MAINTENANCE INSTRUCTIONS - CONTINUED ......................................................... 2-1189

Section XX. Hydraulic and Fluid Systems........................................................................................... 2-1189

Section XXI. Gages, (Non-Electrical), Weighing and Measuring Devices........................................... 2-1785

Section XXII. Cranes, Shovels, and Earthmoving Equipment Components......................................... 2-1795

Section XXIII. Fire Fighting Equipment Components............................................................................. 2-1851

Section XXIV. Parts Peculiar.................................................................................................................. 2-1855

Section XXV. Preparation for Storage or Shipment .............................................................................. 2-1897

APPENDIX A REFERENCES................................................................................................................ A-1

*This manual supersedes Organizational portion of TM 5-2420-222-14&P1 and TM 5-2420-222-14&P2 dated October

1982, including all changes.

Approved for public release; distribution is unlimited.

Change 1 i

*TM 5-2420-222-20-3

TABLE OF CONTENTS - CONTINUED

VOLUME 3 OF 3 - CONTINUED

Page

APPENDIX B MAINTENANCE ALLOCATION CHART........................................................................ B-1

Section I. Introduction...................................................................................................................... B-1

Section II. Maintenance Allocation Chart ......................................................................................... B-4

Section III. Tools and Test Equipment Requirements....................................................................... B-23

Section IV. Remarks.......................................................................................................................... B-25

APPENDIX C EXPENDABLE SUPPLIES AND MATERIALS LIST....................................................... C-1

Section I. Introduction...................................................................................................................... C-1

Section II. Expendable Supplies and Materials List......................................................................... C-2

APPENDIX D ILLUSTRATED LIST OF MANUFACTURED ITEMS...................................................... D-1

APPENDIX E TORQUE LIMITS ............................................................................................................ E-1

INDEX ........................................................................................................................................ Index-1

ii

Section XX. HYDRAULIC AND FLUID SYSTEMS

TM 5-2420-222-20-3

Page

Backhoe Bucket Cylinder.............................. 2-1726

Backhoe Control Valve.................................. 2-1260

Backhoe Control Valve Levers and

Linkage (Serial Numbers 235786

thru 235999 Only)....................................... 2-1302

Backhoe Control Valve Levers and

Linkage (Serial Numbers 319995

thru 342573 Only)....................................... 2-1314

Backhoe Control Valve-to-Backhoe

Stabilizer Cylinder Oil Lines........................... 2-1622

Backhoe Control Valve-to-Backhoe

Swing Cylinder Oil Lines............................ 2-1636

Backhoe Control Valve-to-Jaw

Direct Linear Valve Oil Line

(Serial Numbers 319995 thru

342573 Only).............................................. 2-1412

Backhoe Control Valve-to-Manifold

Block Oil lines................................................ 2-1558

Backhoe Control Valve-to-Manifold

Oil Lines (Serial Numbers 235786

thru 235999 Only)....................................... 2-1429

Backhoe Crowd Cylinder............................... 2-1740

Backhoe Stabilizer Cylinders......................... 2-1752

Backhoe Swing Cylinders.............................. 2-1708

Boom-to-Backhoe Control Valve

Hydraulic Impactor Return Oil Line

(Serial Numbers 319995 thru

342573 Only).............................................. 2-1489

Boom-to-Bucket Cylinder Oil Lines

(Serial Numbers 235786 thru

235999 Only).............................................. 2-1598

Boom-to-Bucket Cylinder Oil Lines

(Serial Numbers 319995 thru

342573 Only).............................................. 2-1608

Boom-to-Jaw Cylinder Oil Hose Oil

Lines (Serial Numbers 235786 thru

235999 Only).............................................. 2-1532

Boom-to-Jaw Cylinder Oil Hose Oil

Lines (Serial Numbers 319995 thru

342573 Only).............................................. 2-1538

Boom-to-Manifold Hydraulic Impactor

Return Oil Line (Serial Numbers

235786 thru 235999 Only).......................... 2-1483

Clutch Control Valve-to-Hydraulic

Pump Inlet Oil Line..................................... 2-1352

Hydraulic Accumulator Charging................... 2-1194

Hydraulic Earth Drill Bleed Oil

Line............................................................. 2-1550

Hydraulic Impactor Flow

Regulator.................................................... 2-1237

Page

Hydraulic Impactor Flow Regulator-

to-Boom Oil Line (Serial Numbers

235786 thru 235999 Only).......................... 2-1499

Hydraulic Impactor Flow Regulator-

to-Boom Oil Line (Serial Numbers

319995 thru 342573 Only).......................... 2-1505

Hydraulic Impactor Valve............................... 2-1228

Hydraulic Oil Cooler-to-Clutch

Control Valve Oil Line................................. 2-1361

Hydraulic Oil Filter.......................................... 2-1698

Hydraulic Oil Filter Relief

Valve........................................................... 2-1217

Hydraulic Oil Filter Relief Valve-

to-Clutch Control Valve Adapter

Oil Line........................................................ 2-1346

Hydraulic Pump Pressure Line Tee-

to-Hydraulic Accumulator Oil

Line............................................................. 2-1384

Hydraulic Pump-to-Hydraulic Oil

Cooler Hose (Serial Numbers

319995 thru 342573 Only).......................... 2-1338

Hydraulic Pump-to-Hydraulic Oil

Cooler Oil Line (Serial Numbers

235786 thru 235999 Only).......................... 2-1342

Hydraulic Pump-to-Pressure

Control Valve Oil Line................................. 2-1375

Hydraulic Pump-to-Speed Gear

Assembly (Reverser) Seal Drain

Line............................................................. 2-1369

Hydraulic System Diagram (Serial

Numbers 235786 thru 235999

Only) ........................................................... 2-1779

Hydraulic System Diagram (Serial

Numbers 319995 thru 342573

Only) ........................................................... 2-1782

Hydraulic System Pressure

Release....................................................... 2-1191

Jaw Control (Direct Linear) Valve

Bracket........................................................ 2-1298

Jaw Control (Direct Linear) Valve

Linkage ....................................................... 2-1294

Jaw Control (Direct Linear) Valve-

to-Manifold Block Oil Lines......................... 2-1513

Jaw Control (Direct Linear) Valve

Tubes and Fittings...................................... 2-1391

Jaw Control Valve (Serial Numbers

235786 thru 235999 Only).......................... 2-1242

Jaw Cylinder................................................... 2-1703

Jaw Cylinder Oil Hoses.................................. 2-1544

2-1189

Section XX. HYDRAULIC AND FLUID SYSTEMS - CONTINUED

TM 5-2420-222-20-3

Page

Jaw Direct Linear Valve (Serial

Numbers 319995 thru 342573

Only)........................................................... 2-1250

Jaw Direct Linear Valve-to-

Backhoe Control Valve Oil Line

(Serial Numbers 319995 thru

342573 Only).............................................. 2-1436

Jaw Direct Linear Valve-to-

Hydraulic Impactor Valve Oil Line

(Serial Numbers 319995 thru

342573 Only).............................................. 2-1421

Jaw Direct Linear Valve-to-

Hydraulic Oil filter Relief Valve

Oil Line (Serial Numbers 319995

thru 342573 Only)....................................... 2-1464

Loader Boom Cylinders................................. 2-1770

Loader Bucket Cylinders............................... 2-1760

Loader Control Valve..................................... 2-1285

Loader Control Valve Handle and

Linkage.......................................................... 2-1324

Loader Control Valve Mounting

Bracket....................................................... 2-1282

Loader Control Valve-to-Hydraulic

Oil Filter Relief Valve Oil

Line............................................................. 2-1653

Loader Control Valve-to-Loader

Boom Cylinder Head End Oil

Lines........................................................... 2-1679

Loader Control Valve-to-Loader

Boom Cylinder Rod End Oil Lines.............. 2-1688

Loader Control Valve-to-Loader

Bucket Cylinder Head End Oil

Lines........................................................... 2-1661

Loader Control Valve-to-Loader

Bucket Cylinder Rod End Oil

Lines........................................................... 2-1670

Manifold Block............................................... 2-1270

Manifold Block-to-Boom Bucket

Cylinder Oil Lines....................................... 2-1590

Manifold Block-to-Boom Jaw Control

Oil Hoses (Serial Numbers 235786

thru 235999 Only)....................................... 2-1522

Page

Manifold Block-to-Boom Jaw Control

Oil Tubes (Serial Numbers 319995

thru 342573 Only)....................................... 2-1526

Manifold Block-to-Crowd Cylinder

Oil Lines (Serial Numbers 235786

thru 235999 Only........................................ 2-1570

Manifold Block-to-Crowd Cylinder

Oil Lines (Serial Numbers 319995

thru 342573 Only)....................................... 2-1578

Manifold Block-to-Head End Boom

Cylinder Oil Line.......................................... 2-1565

Manifold-to-Hydraulic Oil Filter

Relief Valve Oil Line (Serial

Numbers 235786 thru 235999

Only) ........................................................... 2-1450

Manifold-to-Hydraulic Impactor

Valve Oil Line (Serial Numbers

235786 thru 235999 Only).......................... 2-1440

Manifold-to-Jaw Control Valve Oil

Lines (Serial Numbers 235786 thru

235999 Only) .............................................. 2-1456

Pressure Control Valve.................................. 2-1200

Pressure Control Valve-to-Jaw

Direct Linear Valve Oil Line

(Serial Numbers 319995 thru

342573 Only) .............................................. 2-1405

Pressure Control Valve-to-Loader

Control Valve Oil Line................................. 2-1647

Pressure Control Valve-to-Manifold

Oil Line (Serial Numbers 235786

thru 235999 Only)....................................... 2-1400

Pump Stroke Control Valve Filter

Element....................................................... 2-1196

Quick Coupler-to-Boom Oil Lines

(Serial Numbers 235786 thru 235999

Only) ........................................................... 2-1472

Quick Coupler-to-Boom Oil Lines

(Serial Numbers 319995 thru

342573 Only) .............................................. 2-1477

2-1190

HYDRAULIC SYSTEM PRESSURE RELEASE

This task covers:

Hydraulic System Pressure Release (page 2-1191)

INITIAL SETUP

Personnel Required

One

LOCATION ITEM REMARKS

HYDRAULIC SYSTEM PRESSURE RELEASE

TM 5-2420-222-20-3

ACTION

NOTE

Hydraulic system pressure must be released before disconnecting hydraulic lines and fittings. A

line or fitting disconnected under pressure will blow off with a lot of force and could cause injury

to personnel.

When engine is running, hydraulic system is under pressure. In order to release hydraulic system

pressure, engine must be shut down.

There are three ways to release hydraulic system pressure. Perform any one of the following three

steps to release hydraulic system pressure.

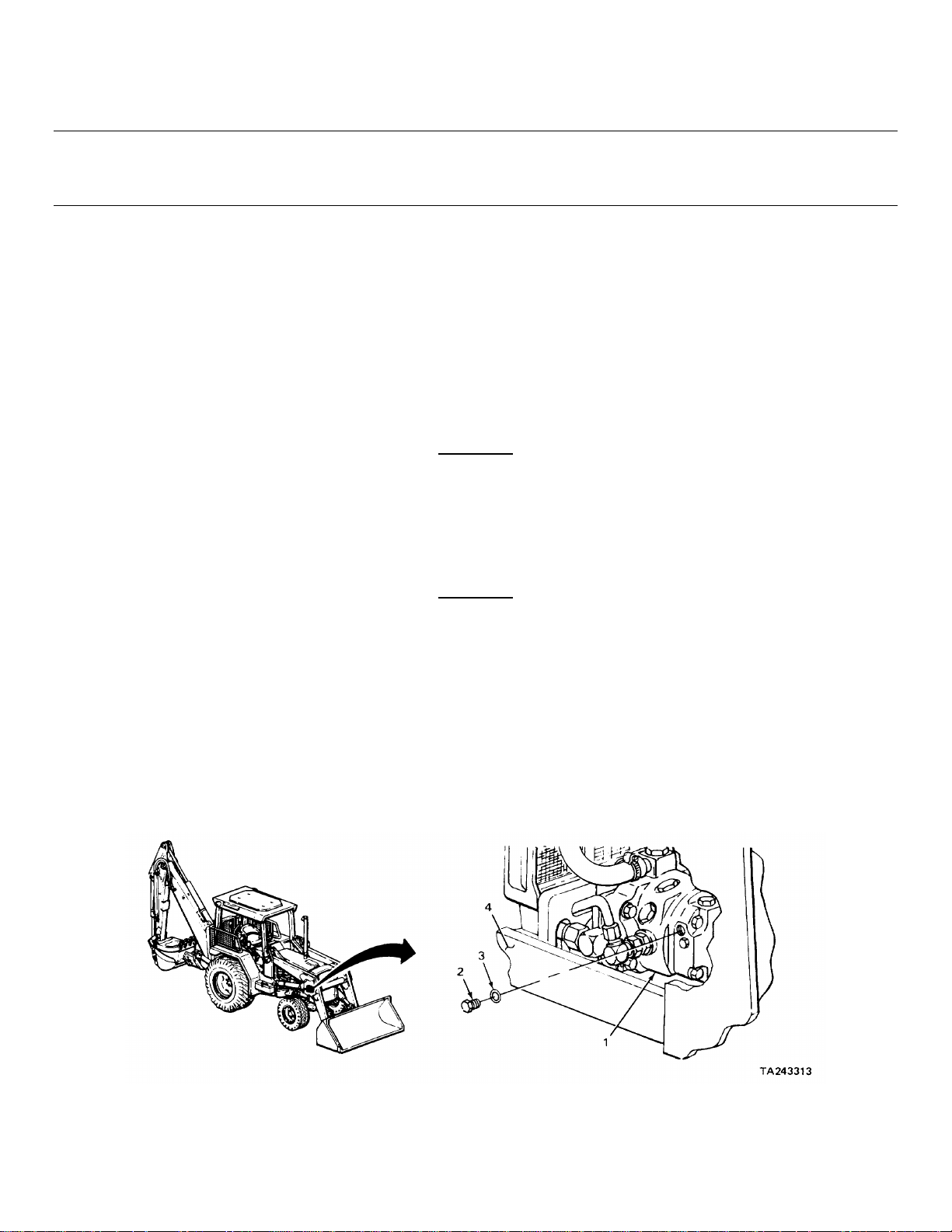

2-1191

TM 5-2420-222-20-3

HYDRAULIC SYSTEM PRESSURE RELEASE - CONTINUED

ACTION

LOCATION ITEM REMARKS

HYDRAULIC SYSTEM PRESSURE RELEASE - CONTINUED

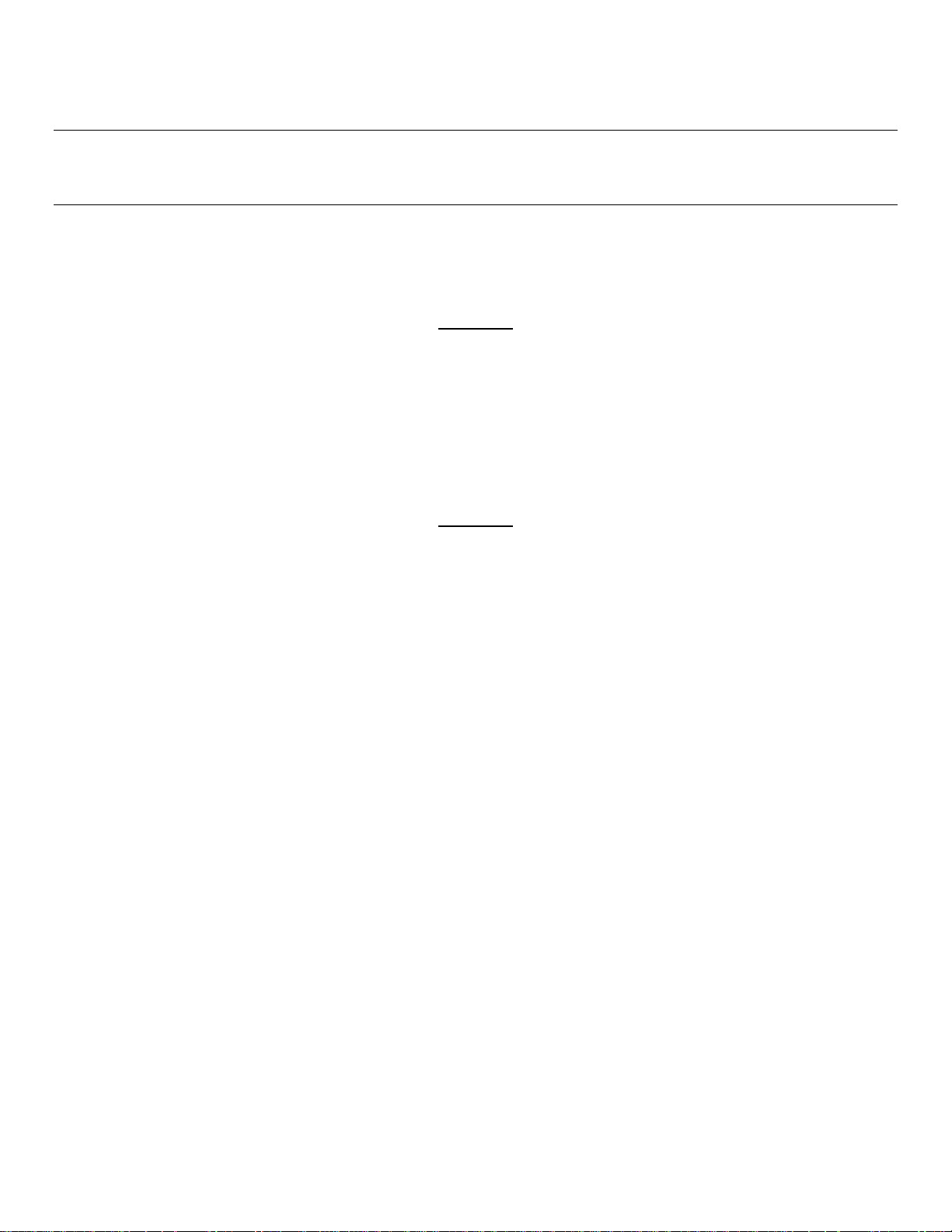

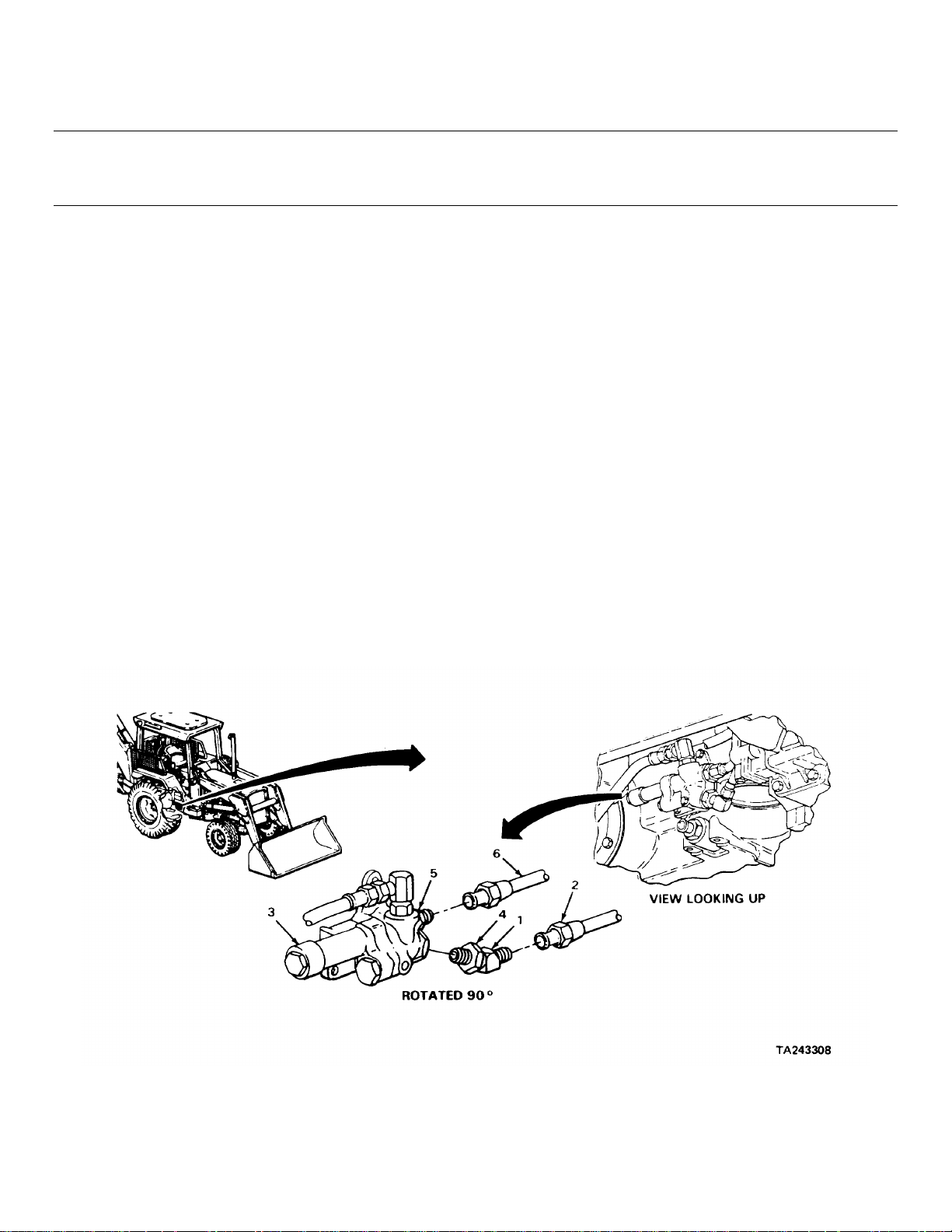

1. Operator’s Steering wheel (1) Turn from side to side until steering is

compartment hard.

WARNING

When operating loader backhoe, make sure that all personnel are cleared from vehicle and work

area. Failure to observe this precaution could cause injury to personnel.

2. Loader bucket a. Pull back until loader bucket (3) stops

control lever (2) raising.

b. Push forward until loader bucket (3)

rests on ground.

WARNING

Do not operate backhoe controls unless you are in operator’s seat facing backhoe. Backhoe

boom cylinder may be accidentally bumped, causing backhoe boom to move suddenly. Failure to

observe this precaution could cause serious injury.

3. Backhoe boom a. Pull back until boom (5) stops

control lever (4) raising.

b. Push forward until backhoe bucket (6)

rests on ground.

2-1192

HYDRAULIC SYSTEM PRESSURE RELEASE - CONTINUED

TM 5-2420-222-20-3

TASK ENDS HERE

TA243304

2-1193

HYDRAULIC ACCUMULATOR CHARGING

This task covers:

Charging (page 2-1194)

INITIAL SETUP

Tools Materials/Parts

Charging kit, accumulator, Nitrogen, technical (item 17, Appendix C)

Nudie ND-925-0 (-W) Packing, plug

Connector, John Deere R40617

Hose, John Deere AR47753 Personnel Required

Knife, pocket

Wrench, box, 5/8-inch One

LOCATION ITEM REMARKS

TM 5-2420-222-20-3

ACTION

CHARGING

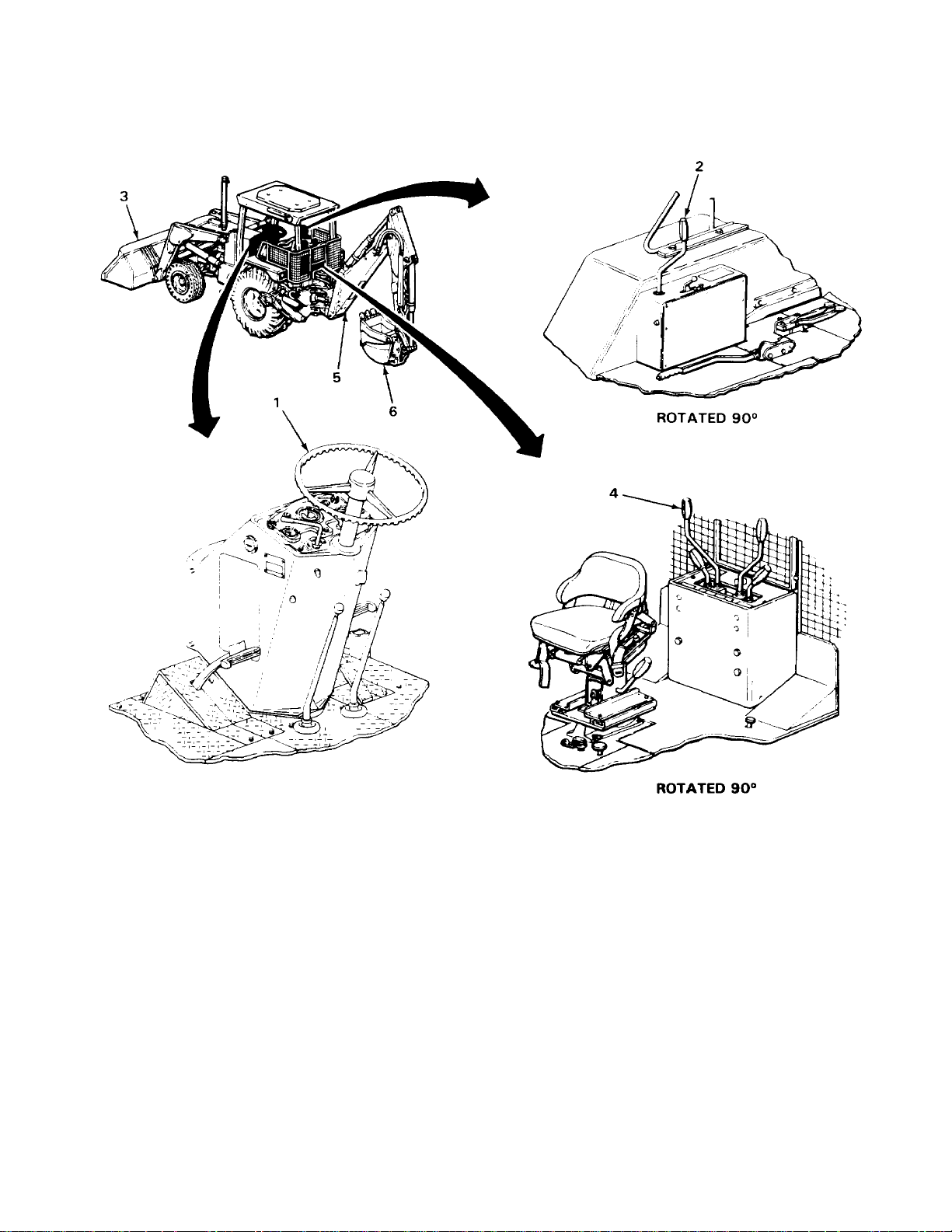

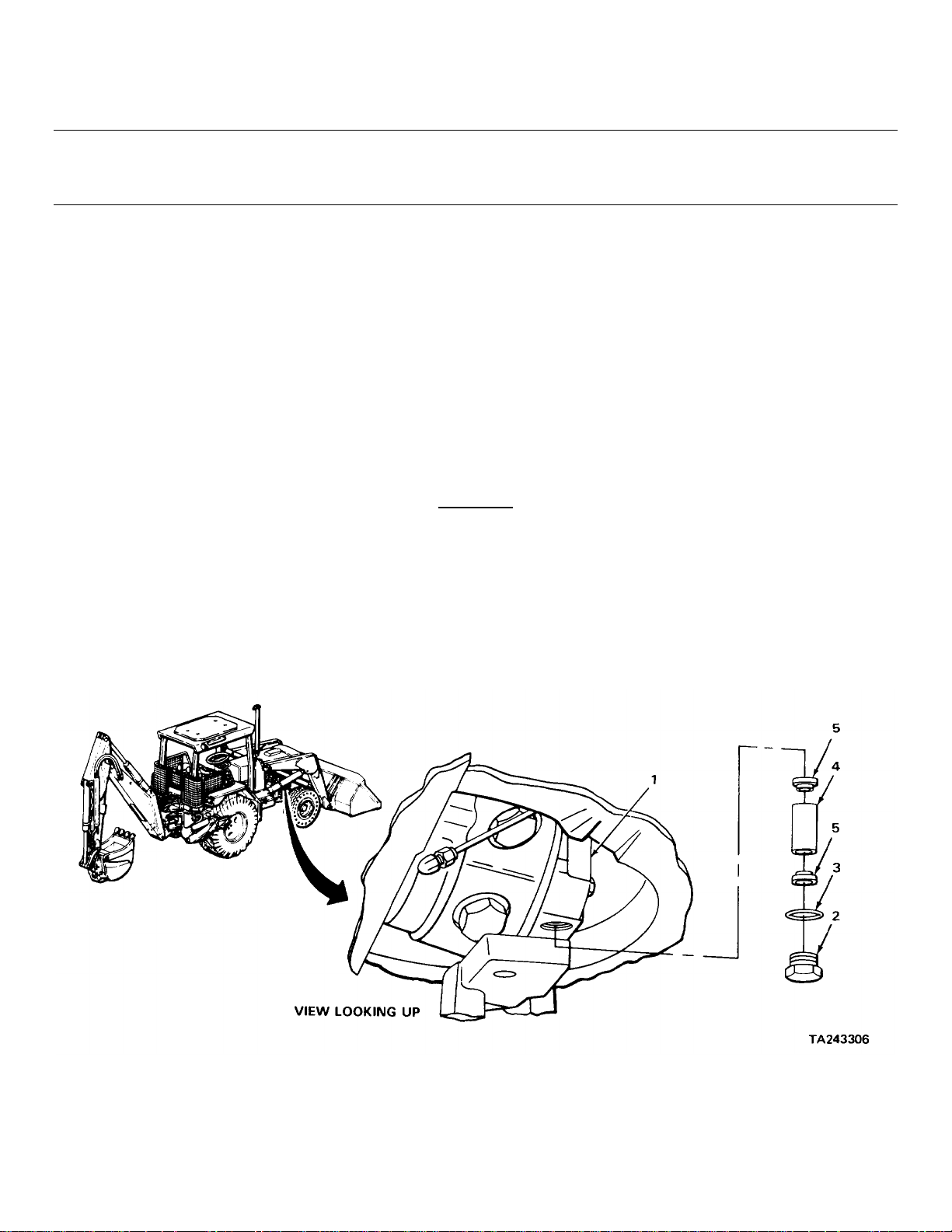

1 Accumulator (1) Plug (2) with assem- Using 5/8-inch box wrench, unscrew and

bled packing (3) take out.

2 Plug (2) Packing (3) a Using pocket knife, take off.

b Get rid of.

CAUTION

Use only dry nitrogen to charge hydraulic accumulator. Using air or any combustible gas may

cause damage to internal parts.

When charging accumulator, be careful not to exceed specified pressure or damage to internal

parts may occur.

3 Bracket (4) and Accumulator (1) a Using Nuday ND925-0 (-W) accumu-

clamp (5) lator charging kit, John Deere R40617

connector, and John Deere AR47753

hose connected to charging port,

charge.

Accumulator is charged when gage

on charging kit reads 475 to 525 psi

(3275 to 3620 kPa).

b. If overcharged, use Nuday ND925-0 (-W)

accumulator charging kit with gage and

valve disconnected from technical nitrogen

tank to bleed off any excess pressure.

2-1194

TM 5-2420-222-20-3

HYDRAULIC ACCUMULATOR CHARGING - CONTINUED

ACTION

LOCATION ITEM REMARKS

c Disconnect Nuday ND925-0 (-W)

accumulator charging kit, John Deere

R40617 connector, and John Deer

AR47753 hose.

4 Plug (2) New packing (3) Place in position.

5 Accumulator (1) Plug (2) with assem- Screw in and tighten using 5/8-inch box

bled packing (3) wrench.

TASK ENDS HERE

TA243305

2-1195

PUMP STROKE CONTROL VALVE FILTER ELEMENT

This task covers:

a. Removal (page 2-1196) c. Inspection/Replacement (page 2-1198)

b. Cleaning (page 2-1197) d. Installation (page 2-1198)

INITIAL SETUP

Tools Materials/Parts - Continued

Knife, pocket Rags, wiping (item 21, Appendix C)

Pan, drain Solvent, drycleaning (item 28, Appendix C)

Screwdriver, flat-tip, 1/8-inch

Wrench, box and open-end, Personnel Required

combination, 1 1/4 - inch

Two

Materials/Parts

Equipment Condition

Filter element

Packing, filter element 1. Hydraulic system pressure released

(two required (page 2-1191)

Packing, filter plug 2. Right side grille removed

(TM 5-2420-222-10)

TM 5-2420-222-20-3

ACTION

LOCATION ITEM REMARKS

REMOVAL

WARNING

Do not attempt to disconnect hydraulic lines and fittings while engine is running or before

hydraulic system pressure has been released. When engine is running, hydraulic system is under

pressure. Hydraulic system pressure should be 0 psi (0 kPa) before lines are disconnected. A line

or fitting disconnected under pressure will blow off with a lot of force and could cause serious

injury to personnel.

Be careful when draining hot fluids. Wear gloves to protect your hands from hot parts and fluids

or severe burns could result.

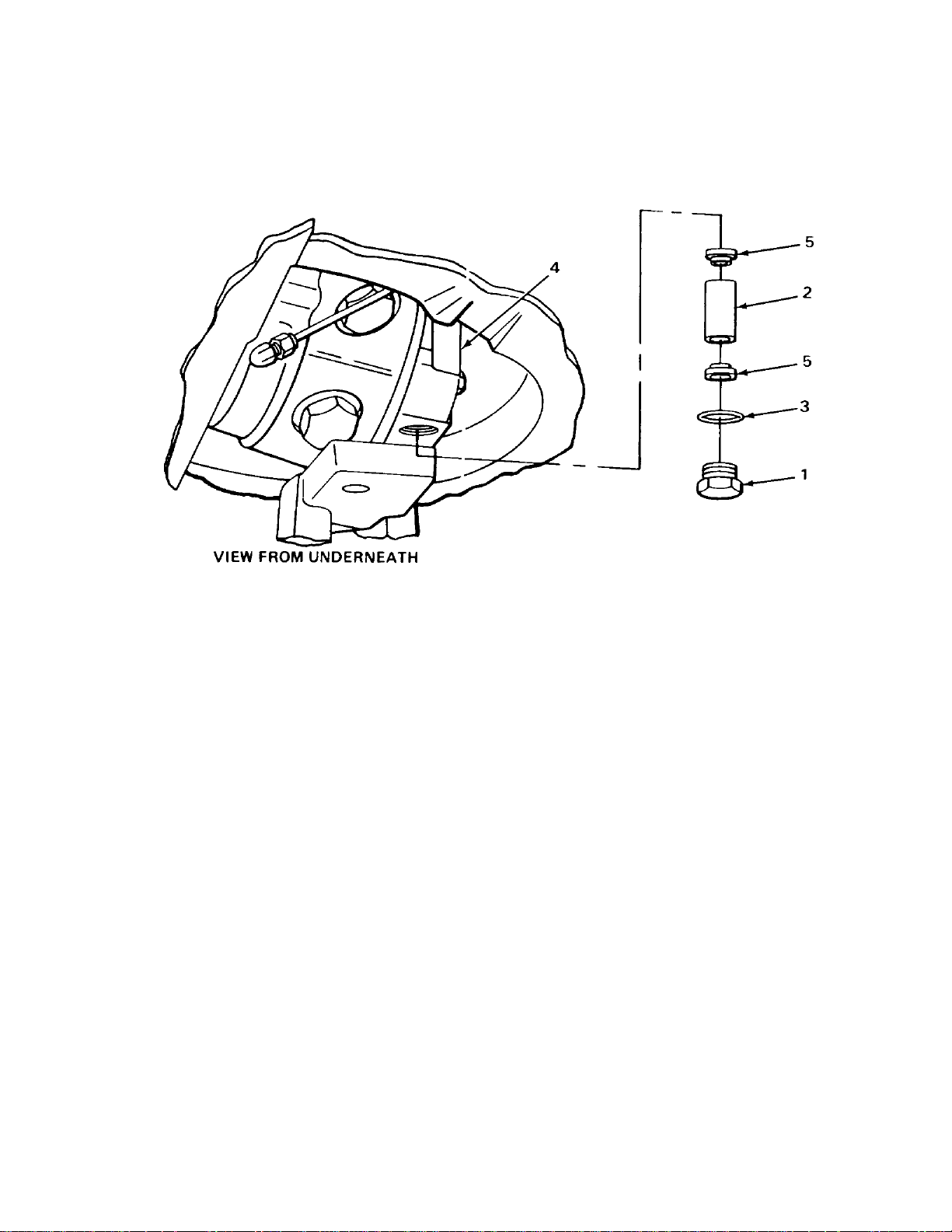

1. Housing (1) Plug (2) with a. Place drain pan underneath to catch

assembled draining fluid.

packing (3) b. Using 1 1/4-inch combination box and

open-end wrench, unscrew and take

out.

2-1196

TM 5-2420-222-20-3

PUMP STROKE CONTROL VALVE FILTER ELEMENT - CONTINUED

ACTION

LOCATION ITEM REMARKS

2. Filter element (4) a. Using 1/8-inch flat-tip screwdriver,

and two packings (5) take out.

b. Get rid of packing (5).

c. Plug housing (1) (page 2-137).

d. Get rid of drained fluid (page 2-137).

3. Plug (2) Packing (3) a. Using pocket knife, take off.

b. Get rid of.

CLEANING

NOTE

For more information on how to clean parts, go to General Maintenance Instructions (page 2-137).

WARNING

Drycleaning solvent P-D-680 is toxic and flammable. Wear protective goggles and gloves and use

only in a well ventilated area. Avoid contact with skin, eyes, and clothes and don’t breathe vapors.

Do not use near open flame or excessive heat. The flashpoint is 100°F to 138°F (38° to 59°C). If

you become dizzy while using cleaning solvent, get fresh air immediately and get medical aid. If

contact with eyes is made, wash your eyes with water and get medical aid immediately.

4. Plug (2) and a. Clean in drycleaning solvent.

filter element (4) b. Using clean, dry rags, wipe dry.

2-1197

TM 5-2420-222-20-3

PUMP STROKE CONTROL VALVE FILTER ELEMENT - CONTINUED

ACTION

LOCATION ITEM REMARKS

INSPECTION/REPLACEMENT

NOTE

For more information on how to inspect parts, go to General Maintenance Instructions (page 2-

137).

Replace defective parts as needed.

5. Plug (1) a. Look for cracks and breaks.

b. Look for damaged threads.

6. Filter element (2) a. Look for cracks, breaks, bends, and

dents.

b. Look for plugged wire mesh which cannot

be cleaned.

c. Look for enlarged holes in wire mesh.

INSTALLATION

7. Plug (1) New packing (3) Place in position.

8. Housing (4) Filter element (2) a. Unplug housing (4).

and two new b. Place in position.

packings (5)

9. Plug (1) with Screw in and tighten using 1 1/4-inch

assembled combination box and open-end wrench.

packing (3)

10. Loader backhoe Transmission Check fluid level and add proper amount

and grade (TM 5-2420-222-10).

11. Engine Start and run at high idle

(TM 5-2420-222-10).

12. Housing (4) Plug (1) a. Check for leaks.

b. If leaking, tighten using 1 1/4-inch

combination box and open-end wrench.

c. If leaking does not stop, shut down

engine (TM 5-2420-222-10) and

replace defective packing or plug as

outlined in this task.

d. If found leaking, repeat steps 10

thru 12.

13. Loader backhoe Engine If still running, shut down

(TM 5-2420-222-10).

2-1198

PUMP STROKE CONTROL VALVE FILTER ELEMENT - CONTINUED

TM 5-2420-222-20-3

TASK ENDS HERE

NOTE

FOLLOW-ON MAINTENANCE: Install right side grille (TM 5-2420-222-10).

TA 243307

2-1199

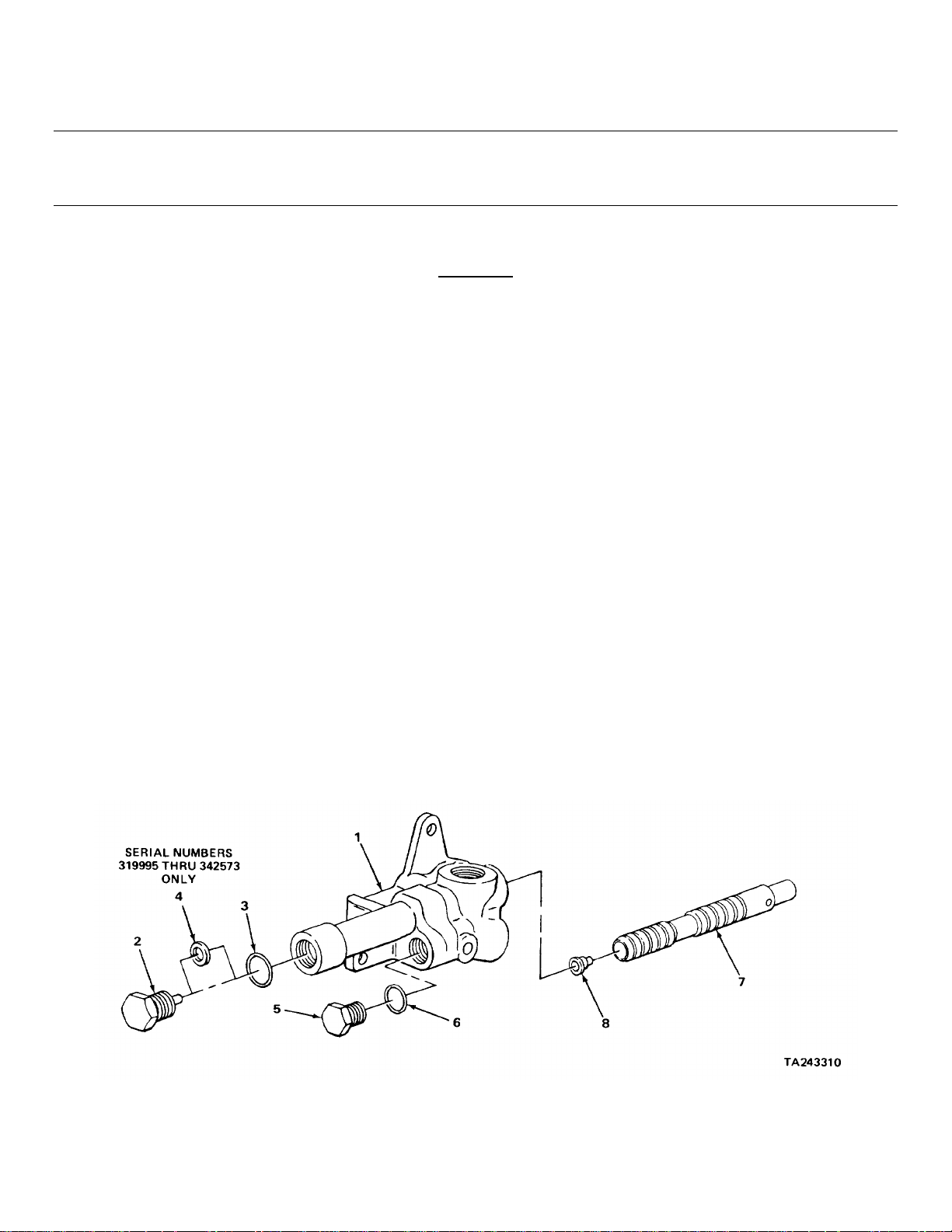

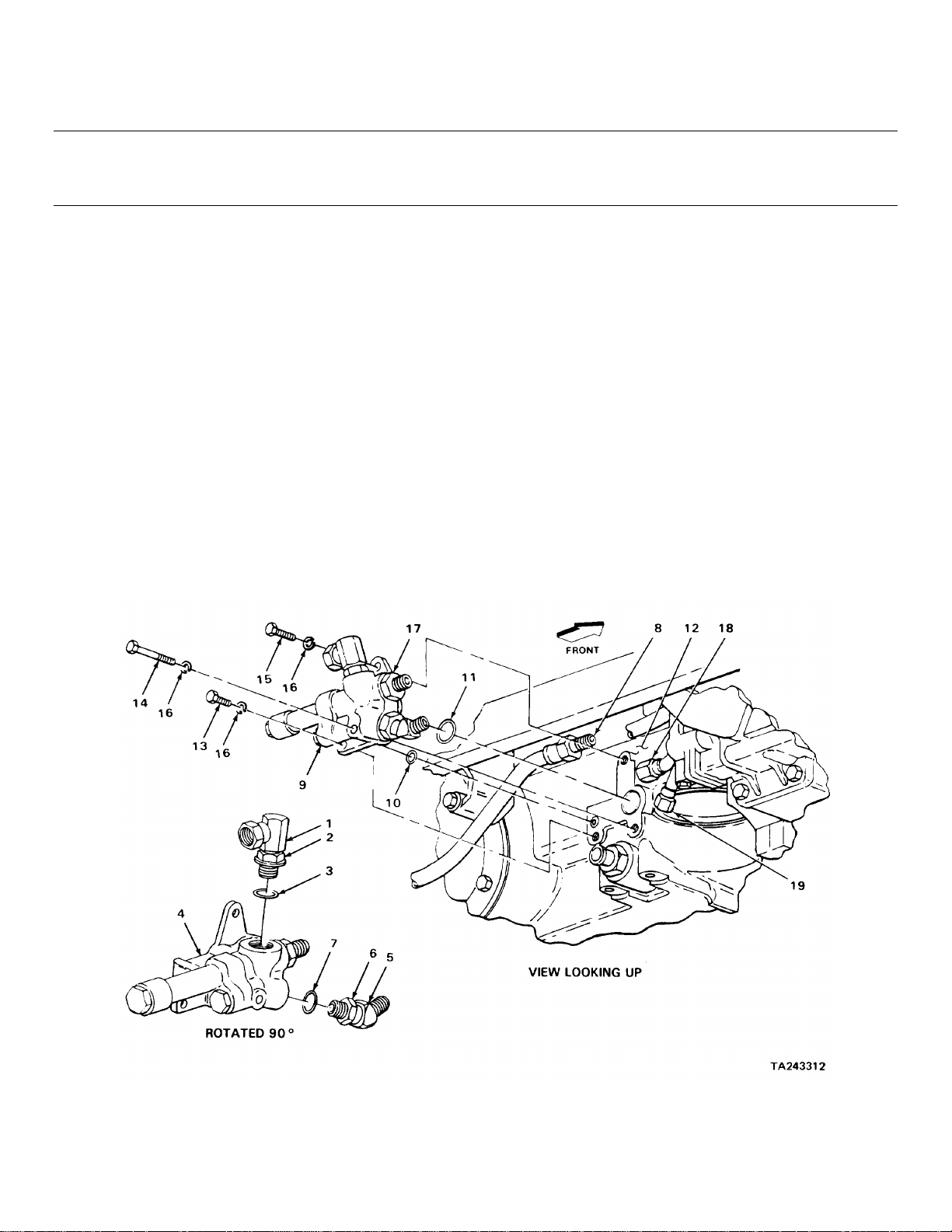

PRESSURE CONTROL VALVE

This task covers:

a. Removal (page 2-1200) e. Repair (page 2-1206)

b. Disassembly (page 2-1202) f. Assembly (page 2-1206)

c. Cleaning (page 2-1204) g. Installation (page 2-1208)

d. Inspection/Replacement(page 2-1205) h. Adjustment (page 2-1210)

INITIAL SETUP

Tools Tools - Continued

Caliper, micrometer, outside, Wrench, open-end, 1 1/4-inch (two required)

0 to 1-inch Wrench, open-end, 1 3/8-inch

Caps, vise jaw (pair) Wrench, torque, 1/2-inch drive,

Compressor, reciprocating air 0 to 150 foot-pound capacity

Extension, 3/8-inch drive, 5-inch

Fitting kit, tube and pipe Materials/Parts

Gage, multi-range, pressure

Gun, air blow Lockwasher, valve screw (three required)

Handle, ratchet, 3/8-inch drive Packing, adapter union-to-valve

Hose, air compressor Packing, connector-to-valve

Knife, pocket Packing, elbow-to-valve

Pan, drain Packing, plug-to-pump

Pliers, long roundnose Packing, plug-to-valve

Press, arbor Packing, plug-to-valve

Remover and installer, 0.250-inch Packing, valve-to-transmission case

outside diameter Packing, valve-to-transmission case

Socket, 3/8-inch drive, 1/2-inch Solvent, drycleaning (item 28, Appendix C)

Socket, 3/8-inch drive, 9/16-inch Tags, marking (item 30, Appendix C)

Tester, spring, 4 to 400-pound

capacity Personnel Required

Thread set, pipe

Vise, machinist’s Two

Universal-joint, 3/8-inch drive

Wrench, open-end, 9/16-inch Equipment Condition

Wrench, open-end, 7/8-inch

Wrench, open-end, 1-inch Right side grille removed

Wrench, open-end, 1 1/16-inch (TM 5-2420-222-10)

TM 5-2420-222-20-3

ACTION

LOCATION ITEM REMARKS

REMOVAL

1. Loader backhoe Hydraulic oil filter Remove (page 2-1217).

relief valve

2-1200

TM 5-2420-222-20-3

PRESSURE CONTROL VALVE - CONTINUED

ACTION

LOCATION ITEM REMARKS

2. Transmission oil Remove (page 2-836).

filter

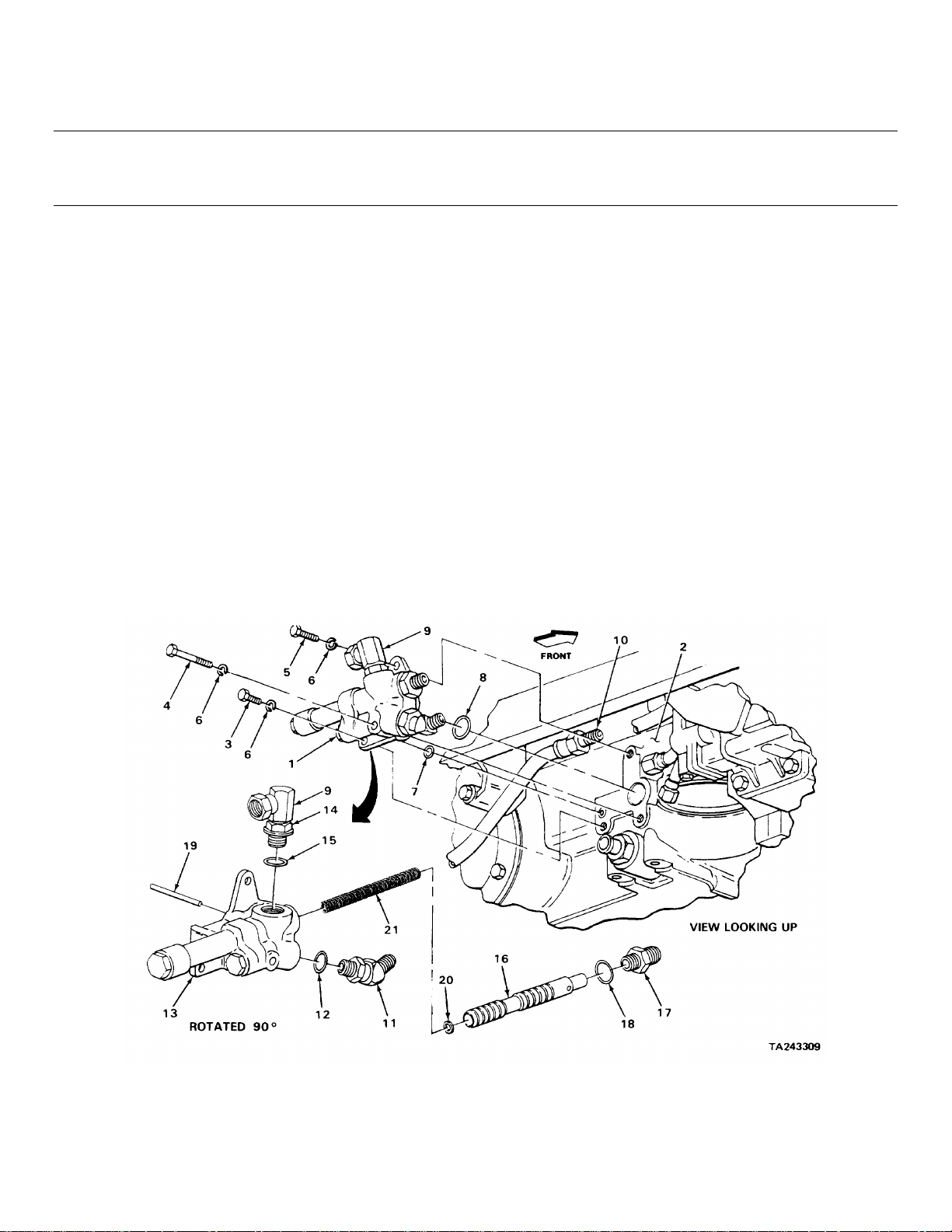

3. Elbow (1) Line (2) a. Place drain pan underneath to catch

draining fluid.

b. Using 1-inch open-end wrench,

unscrew and take off.

c. Cap (page 2-137).

d. Tag (page 2-137).

4. Valve assembly (3) Nut (4) Using 1 1/16 and 1 1/4-inch open-end

and elbow (1) wrenches, loosen.

5. Valve assembly (3) Elbow (1) with a. Note relative position for proper

assembled parts placement during installation.

b. Using 1 1/16-inch open-end wrench,

unscrew and take out.

6. Connector (5) Line (6) a. Place drain pan underneath to catch

draining fluid.

b. Using 1 3/8-inch open-end wrench,

unscrew and take off.

c. Cap (page 2-137).

d. Tag (page 2-137).

2-1201

TM 5-2420-222-20-3

PRESSURE CONTROL VALVE - CONTINUED

ACTION

LOCATION ITEM REMARKS

REMOVAL - CONTINUED

NOTE

Pressure control valve mounting screws are three different lengths. Note position of screws for

proper placement during installation.

7. Valve assembly (1) Three screws (3, a. Place drain pan underneath to catch

and transmission 4, and 5) and three draining fluid.

case (2) lockwashers (6) b. Using 9/16-inch, 3/8-inch drive

socket, 5-inch extension, universal

joint, ratchet handle, and 9/16-inch

open end wrench, unscrew and take

out.

c. Get rid of lockwashers (6).

8. Transmission Valve assembly (1) a. Take off.

case (2) with assembled parts b. Allow to drain in drain pan.

9. Valve assembly (1) Two packings a. Using pocket knife, take off.

(7 and 8) b. Get rid of.

10. Union adapter (9) Hose (10) a. Position over drain pan to catch

draining fluid.

b. Using 1 1/16-inch and 1 1/4-inch open-

end wrenches, unscrew and take out.

c. Cap (page 2-137).

d. Tag (page 2-137).

e. Get rid of drained fluid (page 2-137).

11. Elbow (11) Packing (12) a. Using pocket knife, take off.

b. Get rid of.

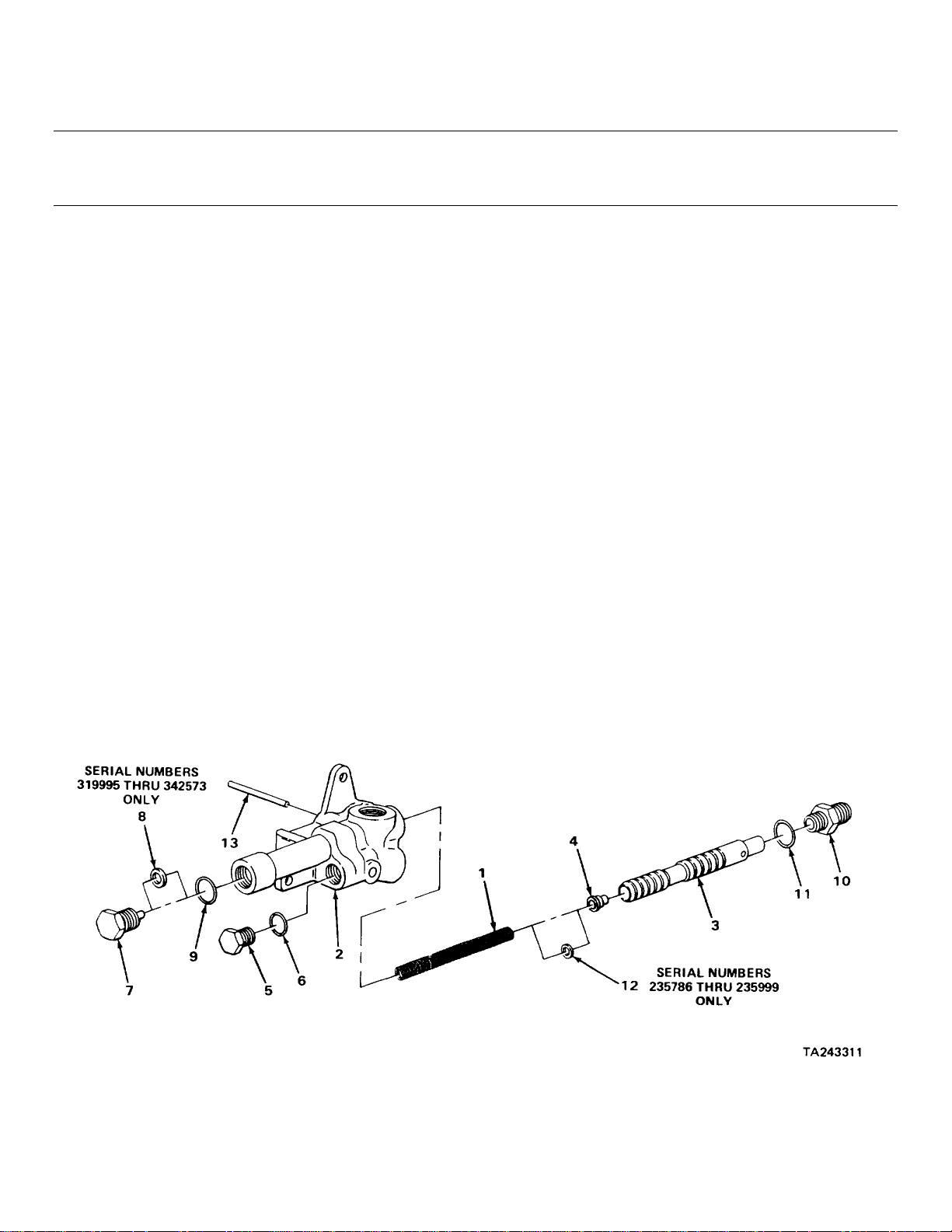

DISASSEMBLY

12. Pressure housing Nut (14) a. Place housing (13) in machinist’s vise

(13) and union with vise jaw caps.

adapter (9) b. Using two 1 1/4-inch open-end

wrenches, loosen.

13. Pressure Union adapter (9) a. Note relative position for proper

housing (13) with assembled parts placement during assembly.

b. Using 1 1/4-inch open-end wrench,

unscrew and take out.

14. Union adapter (9) Packing (15) a. Using pocket knife, take off.

b. Get rid of.

2-1202

TM 5-2420-222-20-3

PRESSURE CONTROL VALVE - CONTINUED

ACTION

LOCATION ITEM REMARKS

15. Pressure housing Connector (17) with Using 1 3/8-inch open-end wrench,

(13) and valve (16) assembled unscrew and take out.

packing (18)

16. Connector (17) Packing (18) a. Using pocket knife, take off.

b. Get rid of.

17. Pressure housing Pin (19) a. Depress valve (16) by hand to relieve

(13) and valve (16) spring tension.

b. Using long roundnose pliers, take out.

NOTE

Loader backhoes with Serial Numbers 235786 thru 235999 use one or more washers between

spring and orifice. Loader backhoes with Serial Numbers 319995 thru 342573 do not use washers

in this position.

18. Pressure Valve (16), washers a. Take out.

housing (13) (20), if present, b. If found, note quantity of washers (20)

and spring (21) so same number can be used during

assembly.

2-1203

TM 5-2420-222-20-3

PRESSURE CONTROL VALVE - CONTINUED

ACTION

LOCATION ITEM REMARKS

DISASSEMBLY - CONTINUED

19. Pressure Plug (2) with Using 1-inch open-end wrench, unscrew

housing (1) assembled parts and take out.

20. Plug (2) Packing (3) a. Using pocket knife, take off.

b. Get rid of.

21. Washers (4) a. On loader backhoes with Serial Numbers

319995 thru 342573 only, take off.

b. Note number of washers used for proper

spacing of plug (2) during assembly.

22. Pressure Plug (5) with a. Using 7/8-inch open-end wrench,

housing (1) assembled unscrew and take out.

packing (6) b. Take housing (1) out of machinist’s

vise.

23. Plug (5) Packing (6) a. Using pocket knife, take off.

b. Get rid of.

CAUTION

Do not remove orifice from pressure control valve unless inspection shows need for replacement.

Removal will damage parts.

24. Valve (7) Orifice (8) Using 0.250-inch remover and installer

and arbor press, press out.

CLEANING

NOTE

For more information on how to clean parts, go to General Maintenance Instructions (page 2-137).

WARNING

Drycleaning solvent P-D-680 is toxic and flammable. Wear protective goggles and gloves and use

only in a well ventilated area. Avoid contact with skin, eyes, and clothes and don’t breathe vapors.

Do not use near open flame or excessive heat. The flashpoint is 100°F to 138°F (38° to 59°C). If

you become dizzy while using cleaning solvent, get fresh air immediately and get medical aid. If

contact with eyes is made, wash your eyes with water and get medical aid immediately.

2-1204

TM 5-2420-222-20-3

PRESSURE CONTROL VALVE - CONTINUED

ACTION

LOCATION ITEM REMARKS

CLEANING - CONTINUED

WARNING

Compressed air used for blowing away chips, dirt, etc., must leave nozzle at less than 30 psi (207

kPa) to prevent personal injury. Be certain that nozzle is rated to provide a maximum of 30 psi

(207 kPa). Be sure to wear safety goggles or lenses when using compressed air. Compressed air

and particles moved by compressed air can cause damage to your eyes.

25. All parts a. Clean in drycleaning solvent.

b. Using reciprocating air compressor, air

compressor hose, and air blow gun,

blow dry.

INSPECTION/REPLACEMENT

NOTE

For more information on how to inspect parts, go to General Maintenance Instructions (page 2-

137).

Replace defective parts which cannot be repaired.

26. Valve (7) a. Look for cracks, breaks, grooves,

pits, and deep scratches.

b. Using 0 to 1-inch outside micrometer

caliper, measure outside diameter at

front and rear.

Outside diameter at front should be

0.7497 to 0.7503 inch (19.0424 to

19.0576 mm). Outside diameter at

rear should be 0.7257 to 0.7263 inch

(18.4328 to 18.4480 mm).

2-1205

TM 5-2420-222-20-3

PRESSURE CONTROL VALVE - CONTINUED

ACTION

LOCATION ITEM REMARKS

INSPECTION/REPLACEMENT - CONTINUED

27. Spring (1) a. Look for cracks, breaks, and abnormal

bends.

b. Using 4 to 400-pound capacity spring

tester, measure free length.

Free length should be approximately

4.625 inches (117.475 mm).

c. Using 4 to 400-pound capacity spring

tester and 0 to 150 foot-pound

capacity, 1/2-inch drive torque wrench,

apply 50 foot-pounds (68 N•m) torque

and measure compressed length.

Compressed length should be

approximately 3.5 inches (88.9 mm).

28. Pressure housing (2) a. Look for cracks and breaks.

b. Look for grooves, pits, and deep

scratches in valve bore.

29. All other parts Look for cracks and breaks.

30. All threaded parts Look for damaged threads.

REPAIR

31. Pressure housing (2) If threads are damaged, using pipe thread

set, restore threads.

ASSEMBLY

CAUTION

Be careful not to damage orifice during assembly. Damaged orifice may cause pressure control

valve to operate improperly.

32. Valve (3) Orifice (4) If removed, using 0.250-inch outside

diameter remover and installer and arbor

press, press in.

33. Plug (5) New packing (6) Place in position.

34. Pressure Plug (5) with a. Place housing (2) in machinist's vise

housing (2) assembled with vise jaw caps.

packing (6) b. Screw in and tighten using 7/8-inch

open-end wrench.

2-1206

TM 5-2420-222-20-3

PRESSURE CONTROL VALVE - CONTINUED

ACTION

LOCATION ITEM REMARKS

35. Plug (7) Washer (8) On loader backhoes with Serial Numbers

319995 thru 342573 only, place same number

as removed during disassembly in position.

36. New packing (9) Place in position.

37. Pressure Plug (7) with Screw in and tighten using 1-inch open-

housing (2) assembled parts end wrench.

38. Connector (10) New packing (11) Place in position.

39. Valve (3) Washers (12) On loader backhoes with Serial Numbers

235786 thru 235999 only, place same

number as removed during disassembly

in position.

40. Spring (1) Place in position.

41. Pressure Valve (3) with Place in position.

housing (2) assembled parts

42. Pressure housing Pin (13) a. Using long roundnose pliers, depress

(2) and valve (3) valve (3) until aligned with hole in

housing (2).

b. Place in position.

43. Pressure housing Connector (10) with Screw in and tighten using 1 3/8-inch

(2) and valve (3) assembled open-end wrench.

packing (11)

2-1207

TM 5-2420-222-20-3

PRESSURE CONTROL VALVE - CONTINUED

ACTION

LOCATION ITEM REMARKS

ASSEMBLY - CONTINUED

44. Union adapter (1) Nut (2) Screw on all the way.

45. New packing (3) Place in position.

46. Pressure Union adapter (1) Screw in and tighten to position noted

housing (4) with assembled parts during disassembly using 1 1/4-inch

open-end wrench.

47. Union adapter (1) Nut (2) a. Tighten until seated against housing

and pressure (4) using two 1 1/4-inch open-end

housing (4) wrenches.

b. Take housing (4) out of machinist’s

vise with vise jaw caps.

INSTALLATION

48. Elbow (5) Nut (6) Screw in all the way.

49. New packing (7) Place in position.

50. Union adapter (1) Hose (8) a. Uncap.

b. Take off tag.

c. Screw in and tighten using 1 1/16-inch

and 1 1/4-inch open-end wrenches.

51. Valve assembly (9) Two new packings Place in position.

(10 and 11)

52. Transmission Valve assembly (9) Place in position.

case (12) with attached parts

NOTE

Pressure control valve mounting screws are three different lengths. Install each screw in position

as noted during removal.

53. Transmission case Three screws (13, Screw in and tighten using 9/16-inch,

(12) and valve 14, and 15) and 3/8-inch drive socket, 5-inch extension,

assembly (9) three new universal-joint, ratchet handle, and

lockwashers (16) 9/16-inch open-end wrench.

2-1208

TM 5-2420-222-20-3

PRESSURE CONTROL VALVE - CONTINUED

ACTION

LOCATION ITEM REMARKS

54. Connector(17) Line (18) a. Uncap.

b. Takeoff tag.

c. Screw in and tighten using 1 3/8-inch

open-end wrench.

55. Valve assembly (9) Elbow (5) with Screw in and tighten to position noted

assembled parts during removal using 1 1/16-inch

open-end wrench.

56. Valve assembly (9) Nut (6) Tighten until seated against valve

and elbow (5) assembly (9) using 1 1/16-inch and

1 1/4-inch open-end wrenches.

57. Elbow (5) Line (19) a. Uncap.

b. Take off tag.

c. Screw in and tighten using 1-inch

open-end wrench.

58. Loader backhoe Transmission oil Install (page 2-836).

filter

2-1209

TM 5-2420-222-20-3

PRESSURE CONTROL VALVE - CONTINUED

ACTION

LOCATION ITEM REMARKS

INSTALLATION - CONTINUED

59. Loader backhoe Hydraulic oil filter Install (page 2-1217).

relief valve

60. Transmission Check fluid level and add proper amount

and grade (TM 5-2420-222-10).

Do not shut down engine at this time.

61. Engine Run at high idle (TM 5-2420-222-10).

62. Pressure control a. Raise and lower loader bucket

valve (TM 5-2420-222-10) and check for leaks.

b. If leaking at any connection, tighten

using 7/8-inch, 1 3/8-inch, 1 1/4inch, or two 1 1/4-inch open-end

wrenches or 1 1/16-inch and 1 1/4inch open-end wrenches.

c. If leaking does not stop, shut down

engine (TM 5-2420-222-10) and

replace leaking connection packing or

fitting or valve component as outlined

in this task.

d. If found leaking, repeat steps 60

thru 62).

63. Engine If still running, shut down

(TM 5-2420-222-10).

ADJUSTMENT

WARNING

Do not attempt to disconnect hydraulic lines and fittings while engine is running or before

hydraulic system pressure has been released. When engine is running, hydraulic system is under

pressure. Hydraulic system pressure should be 0 psi (0 kPa) before lines are disconnected. A line

or fitting disconnected under pressure will blow off with a lot of force and could cause serious

injury to personnel.

64. Hydraulic system Release pressure (page 2-1191).

WARNING

Be careful when draining hot fluids. Wear gloves to protect your hands from hot parts and fluids

or severe burns could result.

2-1210

TM 5-2420-222-20-3

PRESSURE CONTROL VALVE - CONTINUED

ACTION

LOCATION ITEM REMARKS

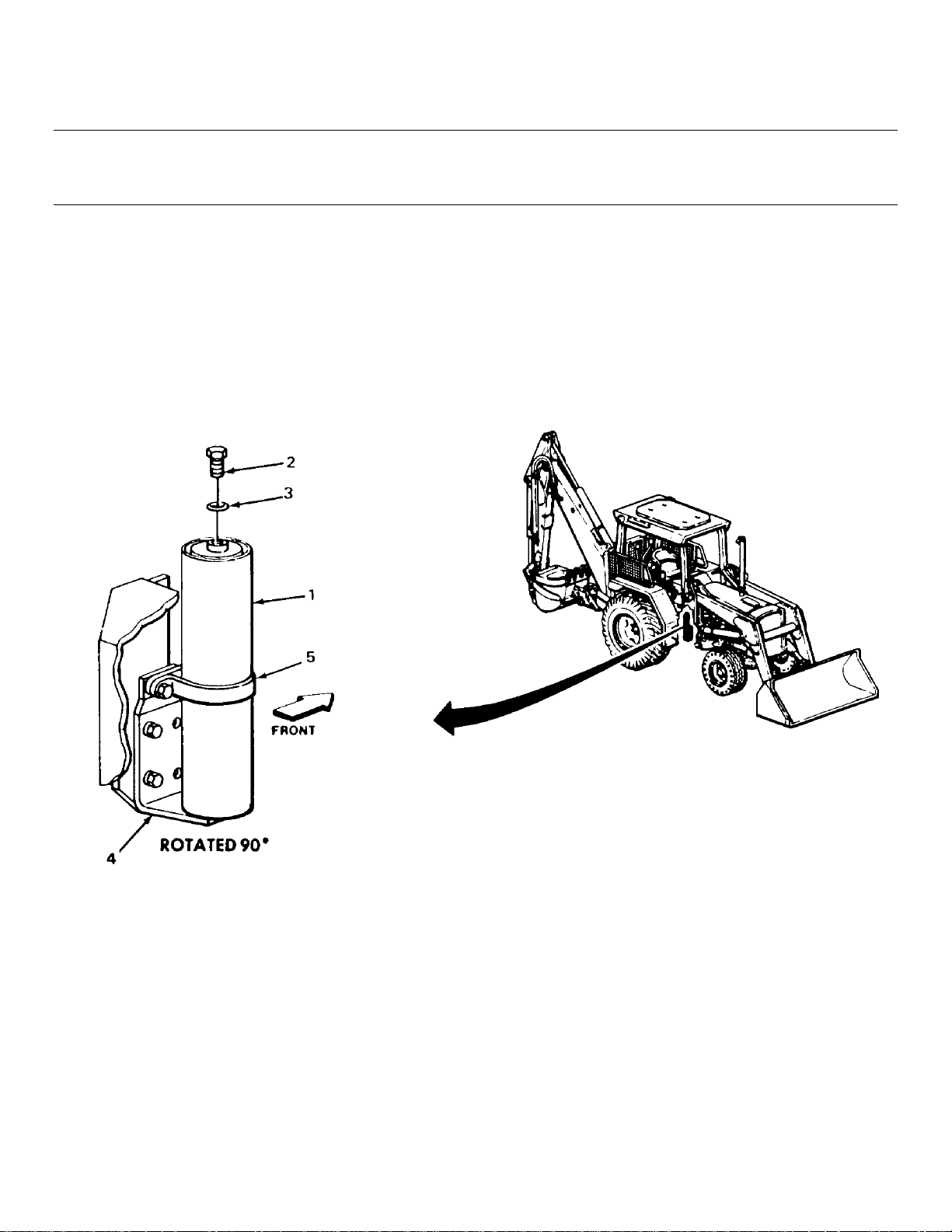

65. Hydraulic pump (1) Plug (2) a. Place drain pan under pump (1) to

with assembled catch draining fluid.

packing (3) b. Using 1/2-inch, 3/8-inch drive

socket, 5-inch extension, and ratchet

handle, unscrew and take out.’

66. Plug (2) Packing (3) a. Using pocket knife, take off.

b. Get rid of.

67. Front support (4) Hydraulic pump (1) Using tube and pipe fitting kit fittings,

connect multi-range pressure gage.

WARNING

Be careful of moving parts when working near engine while it is running. Moving parts could

catch on tools, clothing, or extremities causing serious injury.

68. Loader backhoe Engine Have assistant start and run at

1250 rpm (TM 5-2420-222-10).

WARNING

Keep clear of hydraulic components when raised and not supported. Sudden loss of hydraulic

pressure could cause components to drop without warning.

69. Loader bucket While assistant raises (TM 5-2420-222-

10), note multi-range pressure reading.

Reading should be 1700 to 1800 psi

(11721 to 12411 kPa), pressure control

valve setting.

70. Engine Have assistant shut down

(TM 5-2420-222-10).

2-1211

Loading...

Loading...