Page 1

iSteer™

OPERATOR'S MANUAL

iSteer™

OMPFP11214 ISSUE H1 (ENGLISCH)

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer,

birth defects, and other reproductive harm.

If this product contains a gasoline engine:

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

The State of California requires the above two warnings.

Additional Proposition 65 Warnings can be found in this manual.

John Deere Werke Zweibrücken

European Edition

PRINTED IN GERMANY

Page 2

Foreword

Introduction

This Operator's Manual contains information specic to

the operation of the iSteer Plough, iSteer Side-Shift and

iSteer Steerable Drawbar systems.

Machines equipped with the iSteer system are

accompanied by a manual containing standard machine

operations. READ THIS MANUAL carefully to understand

how to operate and service the iSteer system and the

machine properly. Failure to do so could result in personal

injury and equipment damage.

Pay special attention to the safety information. This is

important for the safe operation of the vehicle.

Trademarks

List of trademarks used through out this Operator’s

Manual.

AutoTrac™

AutoTrac is a trademark of Deere & Company

GreenStar is a trademark of Deere & Company

StarFire is a trademark of Deere & Company

iSteer is a trademark of Deere & Company

IMPORTANT: Use this supplement together with

the StarFire™ iTC and RTK, StarFire™ 3000

and RTK, StarFire™ Mobile RTK and GS3

Guidance Operator's Manuals.

NOTE: For further information, contact your approved

John Deere Dealer.

OUCC002,0003487 -19-05AUG11-1/1

GreenStar™ 3 2630 Display

StarFire™ iTC

iSteer™

OUCC002,0003503 -19-06SEP11-1/1

101311

PN=2

Page 3

Contents

Page

Safety

Recognize Safety Information ............................05-1

Understand Signal Words...................................05-1

Follow Safety Instructions...................................05-1

Practice Safe Maintenance.................................05-2

Handle Electronic Components and

Brackets Safely ..............................................05-2

Avoid High-Pressure Fluids ................................05-3

Operate Implement Automation

Systems Safely .............................................. 05-3

Read the Operator's Manual ..............................05-3

Maintain a Safety Area Around the Implement...05-3

Introduction

Theory of Operation............................................10-1

iSteer™ Basic Requirements .............................10-1

iSteer™ System Basic Operation ....................... 10-2

Connect the iSteer™ System .............................10-3

GS3 Display - iSteer™ Plough

Access iSteer™ Plough......................................15-1

Calibrate the Plough Working Width...................15-2

iSteer™ Plough - RUN Page ..............................15-4

iSteer™ Plough - SETUP Page ..........................15-6

iSteer™ Plough - GPS SETUP Page .................15-9

iSteer™ Plough - Diagnostic Page ...................15-10

GS3 Display - iSteer™ Side-Shift

Access iSteer™ Side-Shift .................................20-1

iSteer™ Side-Shift - RUN Page..........................20-2

iSteer™ Side-Shift - SETUP Page ..................... 20-3

iSteer™ Side-Shift - GPS SETUP Page.............20-5

iSteer™ Side-Shift - Diagnostic Page.................20-6

GS3 Display - iSteer™ Steerable Drawbar

Operate iSteer™ Steerable Drawbar System.....25-1

Sensor Calibration ..............................................25-2

Service

iSteer™ System Service.....................................30-1

Implement Service..............................................30-1

Specications

Metric Bolt and Screw Torque Values .................35-1

EC Declaration of Conformity ............................. 35-2

Original Instructions. All information, illustrations and specications in this

manual are based on the latest information available at the time of publication.

The right is reserved to make changes at any time without notice.

COPYRIGHT © 2011

DEERE & COMPANY

Moline, Illinois

A John Deere ILLUSTRUCTION ® Manual

All rights reserved.

i

101311

PN=1

Page 4

Contents

ii

101311

PN=2

Page 5

Safety

Recognize Safety Information

This is a safety-alert symbol. When you see this symbol

on your machine or in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word—DANGER, WARNING, or CAUTION—is

used with the safety-alert symbol. DANGER identies the

most serious hazards.

DANGER or WARNING safety signs are located near

specic hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

T81389 —UN—07DEC88

DX,ALERT -19-29SEP98-1/1

Follow Safety Instructions

Carefully read all safety messages in this manual and on

your machine safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from your John Deere dealer.

There can be additional safety information contained on

parts and components sourced from suppliers that is not

reproduced in this operator's manual.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machine in proper working condition.

Unauthorized modications to the machine may impair the

function and/or safety and affect machine life.

TS187 —19—30SEP88

DX,SIGNAL -19-03MAR93-1/1

TS201 —UN—23AUG88

If you do not understand any part of this manual and need

assistance, contact your John Deere dealer.

DX,READ -19-16JUN09-1/1

05-1

101311

PN=5

Page 6

Safety

Practice Safe Maintenance

Understand service procedure before doing work. Keep

area clean and dry.

Never lubricate, service, or adjust machine while it is

moving. Keep hands, feet , and clothing from power-driven

parts. Disengage all power and operate controls to relieve

pressure. Lower equipment to the ground. Stop the

engine. Remove the key. Allow machine to cool.

Securely support any machine elements that must be

raised for service work.

Keep all parts in good condition and properly installed.

Fix damage immediately. Replace worn or broken parts.

Remove any buildup of grease, oil, or debris.

On self-propelled equipment, disconnect battery ground

cable (-) before making adjustments on electrical systems

or welding on machine.

On towed implements, disconnect wiring harnesses from

tractor before servicing electrical system components or

welding on machine.

Handle Electronic Components and Brackets Safely

Falling while installing or removing electronic components

mounted on equipment can cause serious injury. Use a

ladder or platform to easily reach each mounting location.

Use sturdy and secure footholds and handholds. Do not

install or remove components in wet or icy conditions.

If installing or servicing a RTK base station on a tower or

other tall structure, use a certied climber.

If installing or servicing a global positioning receiver mast

used on an implement, use proper lifting techniques and

wear proper protective equipment. The mast is heavy and

can be awkward to handle. Two people are required when

mounting locations are not accessible from the ground

or from a service platform.

TS218 —UN—23AUG88

DX,SERV -19-17FEB99-1/1

TS249 —UN—23AUG88

DX,WW,RECEIVER -19-24AUG10-1/1

05-2

101311

PN=6

Page 7

Avoid High-Pressure Fluids

Escaping uid under pressure can penetrate the skin

causing serious injury.

Avoid the hazard by relieving pressure before

disconnecting hydraulic or other lines. Tighten all

connections before applying pressure.

Search for leaks with a piece of cardboard. Protect hands

and body from high-pressure uids.

Safety

If an accident occurs, see a doctor immediately. Any uid

injected into the skin must be surgically removed within

a few hours or gangrene may result. Doctors unfamiliar

with this type of injury should reference a knowledgeable

medical source. Such information is available in

English from Deere & Company Medical Department in

Operate Implement Automation Systems Safely

Do not use implement automation systems on roadways.

Always turn off (disable) implement automation systems

before entering a roadway. Do not attempt to turn

on (activate) an implement automation system while

transporting on a roadway.

Implement automation systems are intended to aid the

operator in performing eld operations more efciently.

The operator is always responsible for the machine path.

Implement automation systems include any application

that automates implement movement. This includes

but may not be limited to iGrade and Active Implement

Guidance.

To prevent injury to the operator and bystanders:

Verify the machine, Implement, and automation systems

•

are set up correctly.

Remain alert and pay attention to the surrounding

•

environment.

Take control of the implement when necessary to

•

avoid eld hazards, bystanders, equipment, or other

obstacles.

Moline, Illinois, U.S.A., by calling 1-800-822-8262 or +1

309-748-5636.

DX,FLUID -19-20AUG09-1/1

Stop operation if poor visibility conditions impair your

•

ability to operate the machine or identify people or

obstacles in the machine path.

CF86321,0000366 -19-25MAY11-1/1

X9811 —UN—23AUG88

PC13793 —UN—25MAY11

Read the Operator's Manual

Before attempting to operate iSteer™ or AutoTrac™,

fully read the Operator's Manual to understand

Maintain a Safety Area Around the Implement

Implement movement and parts in motion can cause

serious injury.

05-3

components and procedures required for safe and

proper operation.

OUCC002,0002BCB -19-29SEP09-1/1

Do not, under any circumstances, operate the implement

with iSteer system when people are in the vicinity.

The transport lock must be engaged.

OUCC002,0002D5F -19-20NOV09-1/1

101311

PN=7

Page 8

Introduction

Theory of Operation

iSteer™ is an active implement guidance system which

keeps the implement on track in case the tractor leaves

its predened track. This is done via a StarFire™ GPS

receiver on the tractor or the implement.

The following criteria are required:

For iSteer™ Plough System

Receiver on tractor. StarFire™ SF1, SF2 or RTK

•

(StarFire™ iTC or StarFire™ 3000)

For iSteer™ Side-Shift/Steerable Drawbar System

Receiver on tractor and implement. RTK signal

•

(StarFire™ iTC or StarFire™ 3000)

iSteer™ Basic Requirements

iSteer™ provides implement steering for vario ploughs,

implements mounted on the three-point hitch and drawbar

steered implements (including offset implements).

For iSteer™ Plough, the plough mounted on the

three-point hitch should have some freedom of lateral

movement.

For iSteer™ Side-Shift, the cylinder must be mounted on

the three-point hitch.

iSteer™ Functional Requirements:

GS3 2630 display mounted in machine.

•

iSteer™ activation.

•

AutoTrac™ activation (AutoTrac™ straight track support

•

with Side-Shift, steerable implement drawbar and

Plough steering).

iSteer™ setup complete (incomplete iSteer™ setup

•

would prevent operator from activating guidance).

The following items need to be included:

Hardware:

Implement harness(es) for receiver (quantity may vary)

•

Implement GPS bracket and receiver

•

Compatible with GreenStar™3 2630 display

•

Software and Settings:

Always use components with the latest software

•

versions (i.e. StarFire™ receiver, control unit).

Receiver setup including offsets and TCM calibration

•

NOTE: For highest accuracy and repeatability

RTK signal is required.

OUCC002,0003504 -19-09SEP11-1/1

Update all components with latest software version

•

available.

iSteer™ control unit installed on implement.

•

Implement mounted steering angle sensor.

•

Hydraulic steering mechanism mounted to implement.

•

For iSteer™ Plough System Only: A John Deere

•

GPS receiver is mounted on the tractor.

For iSteer™ Side-Shift System Only: A John Deere

•

GPS receiver is mounted on the implement and tractor.

IMPORTANT: The GPS receiver should be installed

directly above the cylinder in most cases.

Also, avoid areas of excessive vibration

such as above the PTO.

NOTE: Do not mount implement receiver higher than

4.0 m (13.1 ft.) off the ground.

NOTE: iSteer™ steering mode: Straight Track

guidance mode.

OUCC002,0003505 -19-06SEP11-1/1

10-1

101311

PN=8

Page 9

Introduction

iSteer™ System Basic Operation

iSteer™ Plough System

Basic operation of the iSteer™ Plough system:

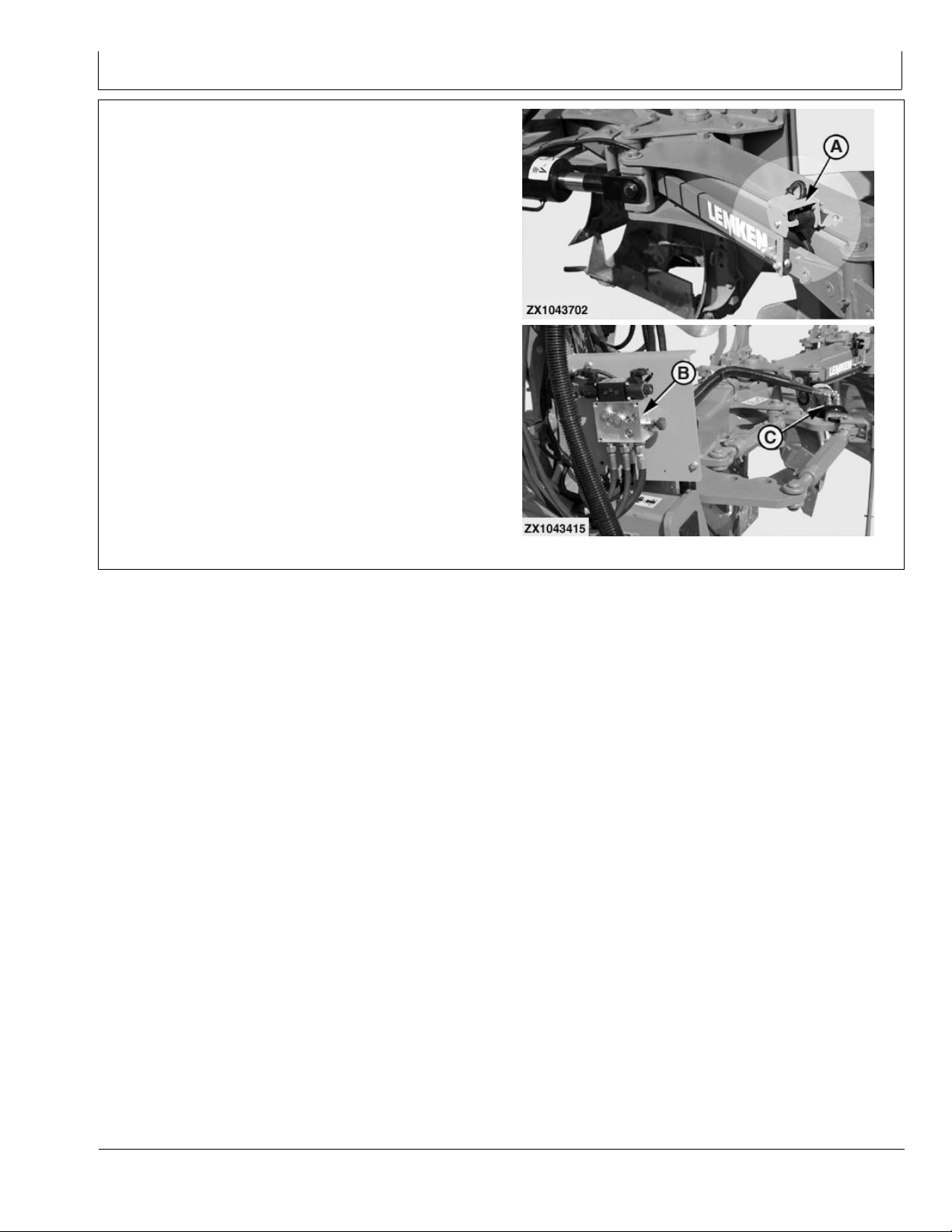

1. A steering angle sensor (A) transmits the current

working width to the iSteer™ Plough control unit.

2. The operator calibrates the iSteer™ Plough control

unit with the information regarding the actual working

width by using the buttons on the display.

3. The StarFire™ 3000 receiver is located on the tractor.

The iSteer™ Plough control unit calculates implement

working width using GPS and AB line values set in the

Guidance screen on the GS3 display.

4. When iSteer™ is enabled and activated and when an

offset of the current AB line is detected, a signal is

sent to the plough control valve (B).

5. The control valve (B) directs hydraulic oil to the plough

hydraulic cylinder (C).

6. The entire procedure is repeated from the rst step

to continually monitor any off-track errors. Constant

adjustments of the variable working width are made to

keep the furrow as straight as the dened AB line.

ZX1043702 —UN—30NOV09ZX1043415 —UN—30NOV09

A—Steering Angle Sensor

B—Control Valve

C—Hydraulic Cylinder

Continued on next page OUCC002,0003506 -19-08SEP11-1/2

10-2

101311

PN=9

Page 10

Introduction

iSteer™ Side-Shift System

Basic operation of the iSteer™ Side-Shift system:

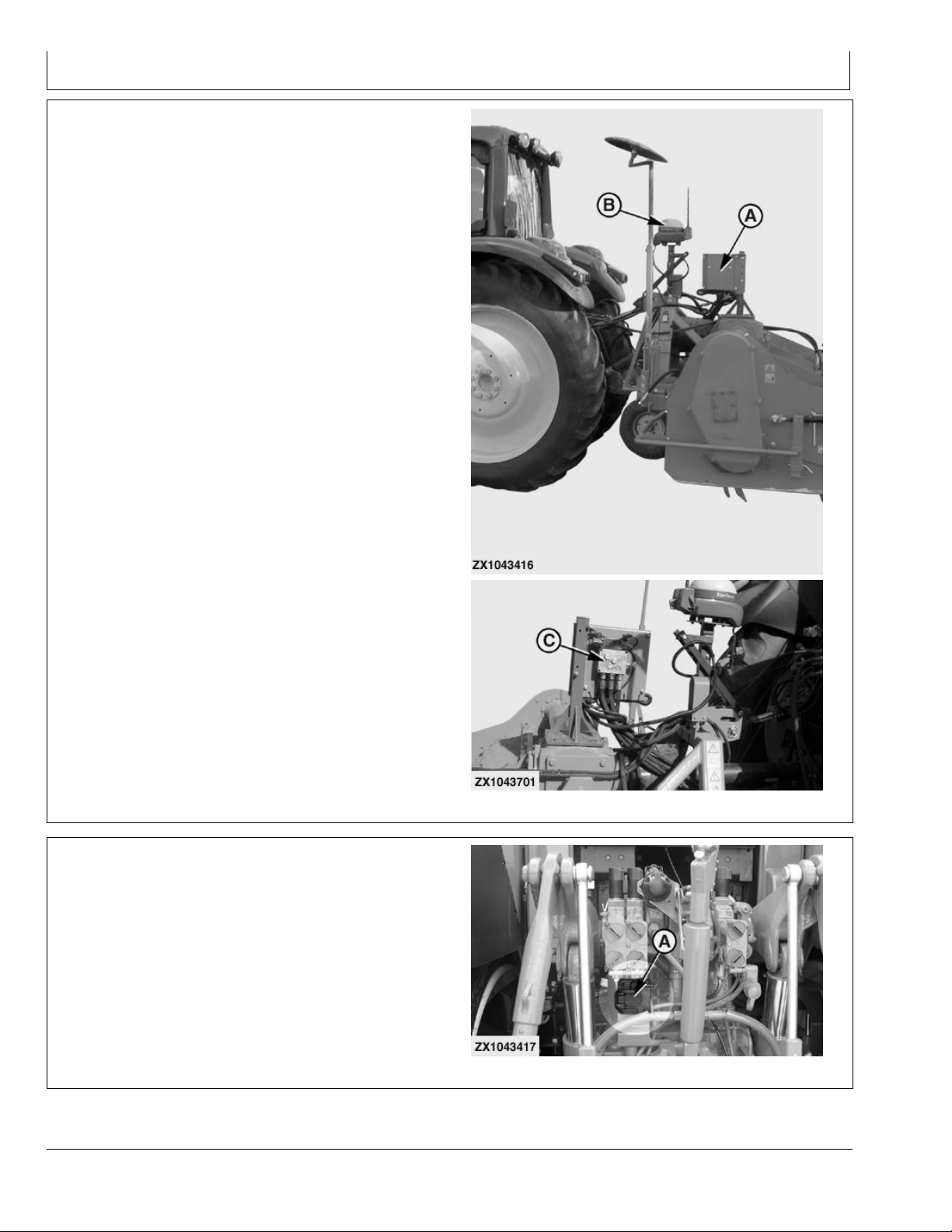

1. A steering angle sensor transmits the location of the

implement to the iSteer™ Side-Shift control unit (A).

2. The operator calibrates the iSteer™ Side-Shift control

unit with this implement information by using the

buttons on the display.

3. The iSteer™ Side-Shift control unit calculates the

implement off-track error using GPS (B) and the AB

line values set in Guidance screen on the GS3 display.

4. When iSteer™ is enabled and activated, and if

implement requires steering adjustment to bring it back

onto AB line, a signal is sent from iSteer™ Side-Shift

control unit to the implement control valve (C).

5. The control valve directs hydraulic oil to the implement

side-shift hydraulic cylinder.

6. The entire procedure is repeated from the rst step

to continually monitor any off-track errors. Constant

adjustments are made to keep the implement steering

towards the currently active AB line.

A—Control Unit

B—GPS Receiver

C—Control Valve

Connect the iSteer™ System

Connect iSteer™ control unit wiring harness to the

ISOBUS connector (A).

Connect all hydraulic hoses to their relevant tractor quick

couplers (see iSteer™ installation instructions).

ZX1043416 —UN—30NOV09ZX1043701 —UN—30NOV09

OUCC002,0003506 -19-08SEP11-2/2

A—ISOBUS Connector

10-3

ZX1043417 —UN—30SEP09

OUCC002,0003507 -19-06SEP11-1/1

101311

PN=10

Page 11

GS3 Display - iSteer™ Plough

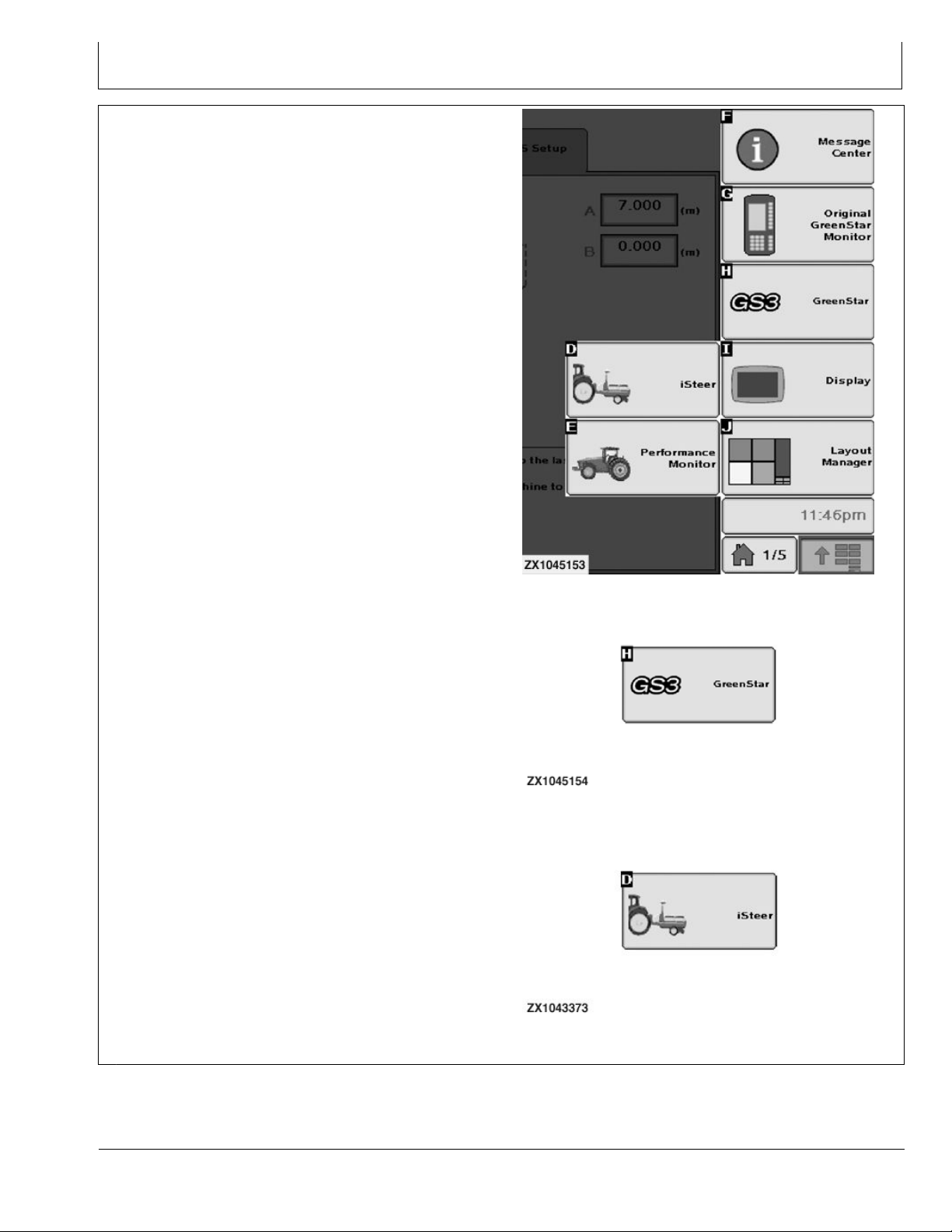

Access iSteer™ Plough

Before accessing iSteer™ Plough, make sure that:

The iSteer™ licence activation is done.

•

NOTE: When iSteer™ control unit is connected, the

Straight Track guidance mode is automatically

preselected. This mode in the GS3 Guidance

settings is then grayed out.

The farm, eld, and client setup is done.

•

The initial path (AB line) has been set.

•

The plough working width has been calculated correctly

•

(sensor calibrated). See Calibrate the Plough Working

Width in this Section.

Press GreenStar 3 Pro button and refer to 2630

GreenStar Display Operator's Manual to proceed .

Press iSteer™ button to operate the iSteer™ Plough

system. The iSteer™ main page appears and displays

three tabs.

Refer to:

iSteer™ Plough - RUN Page,

•

iSteer™ Plough - SETUP Page or

•

iSteer™ Plough - GPS SETUP Page in this Section.

•

GreenStar 3 Pro Button

iSteer™ Button

ZX1045153 —UN—19AUG11ZX1045154 —UN—19AUG11

ZX1043373 —UN—17SEP09

15-1

OUCC002,0003508 -19-06SEP11-1/1

101311

PN=11

Page 12

GS3 Display - iSteer™ Plough

Calibrate the Plough Working Width

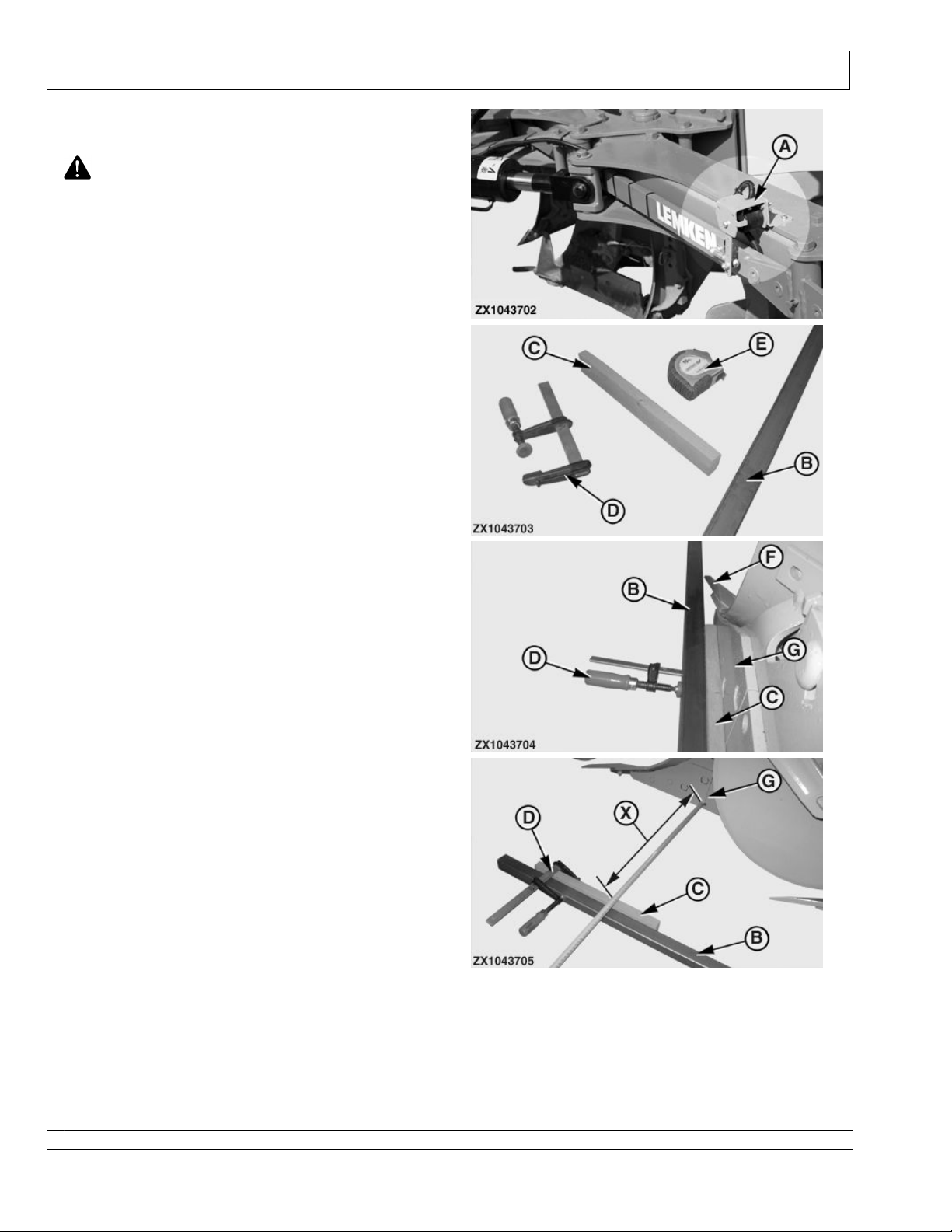

CAUTION: Ensure there are no bystanders near

the implement during calibration.

To obtain accurate working width measurement results

from the plough control unit, it is essential to calibrate

the working width sensor (A) after its installation on the

plough frame.

NOTE: Inaccurate measurement causes the ploughing

width to be wider or narrower than calculated by

the control unit. As a result, the tractor always

drives beside its line on the GS3 display.

To calibrate the sensor (A), proceed as follows :

Requirements:

A +/- 3 m (10 ft.) straight iron bar (B).

•

Two equally thick slats (C).

•

Two clamps (D).

•

A measuring tape (E).

•

1. Mounting the bar to the plough:

Put the plough on a at surface. Clamp the bar (B) to

the side cap (G) of the plough element and let the bar

extend to the front.

ZX1043702 —UN—30NOV09ZX1043703 —UN—30NOV09ZX1043704 —UN—30NOV09ZX1043705 —UN—30NOV09

IMPORTANT: The bar (B) must be mounted exactly

parallel to the side cap of the plough element.

Because the edge of the share (F) is wider

than the side cap (G), the bar (B) must be

mounted with a slat (C) in between .

2. Measuring the plough:

Adjust the width of the plough to its narrowest

(contract) position.

3. Measure the distance (X) between the side cap (G)

and the second slat (C) which is clamped to the bar (B).

4. Convert the measured width (X) to the total ploughing

width. To do this, divide the measured width (X) by the

number of measured elements. Multiply the result with

the total number of elements.

Example for a three-element plough: Adjust the

plough to its minimum width.

a. Measure the working width of two elements.

b. To calculate the total ploughing width, the measured

width is divided by 2 and the value obtained is then

multiplied by 3. If the measured width is for instance

58 cm (23 in.), the minimum total ploughing width

is: 58 / 2 x 3 = 87 cm (34 in.).

5. Measure and calculate the maximum ploughing width

in the same way.

IMPORTANT: If the plough has four elements or more,

it is recommended to measure the distance

between at least three elements.

A—Sensor

B—Bar

C—Slat

D—Clamp

Continued on next page OUCC002,0003509 -19-06SEP11-1/2

E—Measuring Tape

F— Share

G—Side Cap

X—Distance to measure

15-2

101311

PN=12

Page 13

GS3 Display - iSteer™ Plough

Check if measured widths (X) (narrow and wide) are equal

to those displayed in the graph on the iSteer™ Plough

- RUN Page on the GS3 display (see iSteer™ Plough -

RUN Page). If they are not equal, the sensor (A) must

be readjusted accordingly.

OUCC002,0003509 -19-06SEP11-2/2

15-3

101311

PN=13

Page 14

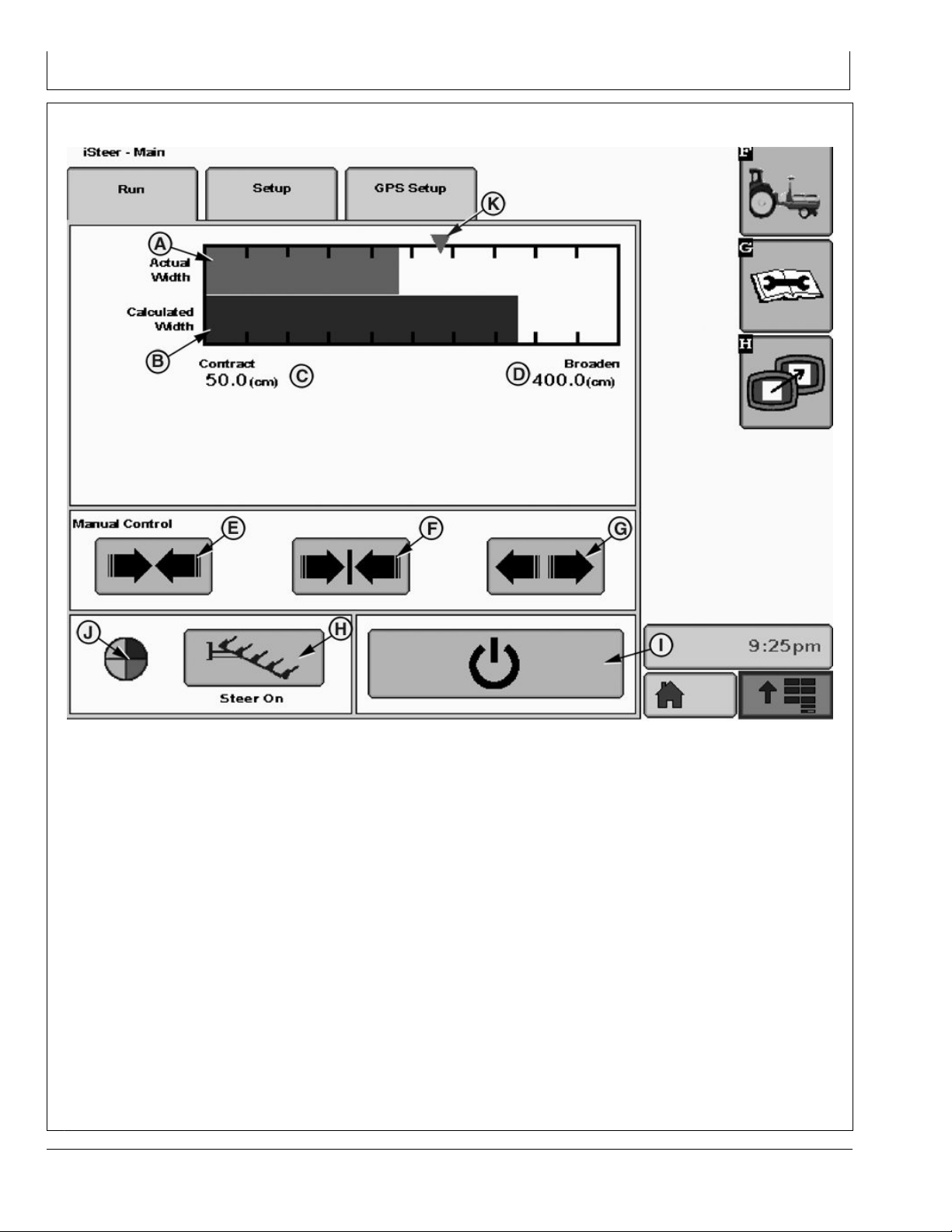

iSteer™ Plough - RUN Page

GS3 Display - iSteer™ Plough

A—Actual Width

B—Calculated Width

C—Contract - element minimum

limit when contracted

D—Broaden - element maximum

limit when broadened

E—Manual Contract Button

F— Manual Set to Working Width

Button

The RUN page allows the operator to:

Visually check the plough width by referencing the bar

•

graph actual width display (A) and calculated width

display (B) between the plough contract position (C),

broaden position (D) and desired working width (K), as

shown.

NOTE: In case of erratic movements of the bar

graph, check sensor.

NOTE: Desired working width cursor (K) position

corresponds to the value entered in the

implement setup on the GS3 display.

Manually control the plough width using Contract button

•

(E), Set to Working Width button (F) or Broaden button

(G).

G—Manual Broaden Button

H—Enable iSteer™ Button

I— Activate iSteer™ Button

Enable the iSteer™ Plough system using Enable button

•

J— iSteer™ Status Pie

K—Desired Working Width

Cursor

(H).

Activate the iSteer™ Plough system when ploughing

•

using Activate button (I).

Visually check iSteer™ Plough status by referencing

•

status pie (J). Press Diagnostic softkey G to display the

diagnostic page. Refer to iSteer™ Plough - Diagnostic

Page in this Section.

Prior to operating the plough with iSteer™ Plough system,

make sure:

1. All required plough settings and sensor calibration

were performed correctly. Refer to iSteer™ Plough SETUP Page in this Section.

2. GPS settings have been checked. Refer to iSteer™

Plough - GPS SETUP Page in this Section.

Continued on next page OUCC002,000350A -19-06SEP11-1/2

15-4

ZX1045155 —UN—19AUG11

101311

PN=14

Page 15

GS3 Display - iSteer™ Plough

3. Press Enable iSteer™ button (H) and set the initial

path. Refer to GS3 Guidance Operator's Manual to

set the initial path.

IMPORTANT: Only straight track mode is allowed.

Create AB line as explained in relevant

guidance Operator's Manual.

4. Press Activate iSteer™ button (I) to start implement

guidance.

IMPORTANT: When iSteer™ is activated all other

GreenStar Pro modules are deactivated.

OUCC002,000350A -19-06SEP11-2/2

15-5

101311

PN=15

Page 16

iSteer™ Plough - SETUP Page

GS3 Display - iSteer™ Plough

A—Element Limits (cm)

B—User Limits (cm)

C—Number of Elements

D—Working Width (cm)

E—Auto-Width Check Box

F— One direction plough

G—On-Land Plough

H—Activation AutoTrac + iSteer

The SETUP page allows the operator to:

Set plough element limits (A) between 20 and 80 cm

•

(7 and 31.5 in.)

Set plough element user limits (B) which can be the

•

same as or within the range of the element limits (A).

Set the number of plough elements (C) between 3 and

•

15 (default value is 3).

NOTE: The values of the plough element limits (A), (B)

and the number of elements (C) must be consistent

with the working width (D) which corresponds to

the track spacing dened on the Guidance screen.

Check Auto-Width box (E) whenever the plough needs

•

to move to working width upon iSteer™ deactivation.

NOTE: A ground speed of at least 0.5 km/h is

necessary for Auto-Width to function.

I— Calibrate Button

J— Manual Control

K—Invert Steering Check Box

L— Plough Direction Button

Check One direction plough box (F) if this kind of plough

•

M—Desired Working Width

Cursor

is used.

Check On-Land Plough box (G) if tractor drives beside

•

the furrow.

Check Activation AutoTrac + iSteer box (H) to activate

•

AutoTrac™ and iSteer™ simultaneously.

NOTE: This box appears only if On-Land Plough

box (G) has been checked.

Calibrate (I) sensor contract and broaden positions

•

each time a new plough is operated. See Sensor

Calibration hereafter.

Manually control (J) the plough position (contract and

•

broaden).

Continued on next page OUCC002,000350B -19-06SEP11-1/5

15-6

ZX1045156 —UN—06SEP11

101311

PN=16

Page 17

GS3 Display - iSteer™ Plough

IMPORTANT: Use manual control (J) to install

the sensor correctly on the plough. During

manual control operation, oversteering

the cylinder to the left or right position

may damage the sensor.

Check whether the illustration of the plough direction

•

(L) corresponds to the real tractor position in the furrow.

If it does not correspond to the actual position, press

Plough Direction button (L) to adjust tractor position.

Plough direction (A) is displayed with the following

message:

- Place the tractor in the furrow. Make sure the last

movement was in the forward direction. Is your

current situation the same as the picture below?

Press the Toggle button (B), if necessary, then press

the Enter button (D) to conrm or press the Cancel

button (C).

Sensor Calibration

CAUTION: Ensure there are no bystanders near

the implement during calibration.

Check Invert Steering box (K) to invert hydraulic valve

•

direction in case of reversed valve connection.

OUCC002,000350B -19-06SEP11-2/5

Calibrate sensor contract and broaden positions as

follows:

A—Plough Direction

B—Toggle Button

C—Cancel Button

D—Enter Button

ZX1043377 —UN—21NOV09

Continued on next page OUCC002,000350B -19-06SEP11-3/5

15-7

101311

PN=17

Page 18

GS3 Display - iSteer™ Plough

Sensor Calibration - Step 1/2

A—Sensor Setup - 1/2

B—Contract Button

C—Contract Position Value (V)

D—Invert Steering Check Box

E—Next Button

F— Sensor Setup - 2/2

1.

Press the Calibrate button on the RUN page.

2. Sensor setup 1/2 (A) is displayed with the following

message:

”Contract the plough to its most narrow position using

the button below. If the plough broadens, press the

invert steering check box. Then press the next button.”

3. Press and hold Contract button (B) until the desired

voltage level (C) is reached. The limit that can be set

by the operator is 0.75 V or 4.25 V depending on the

sensor mounting location.

NOTE: If the plough broadens instead of contracts,

check the Invert Steering box (D).

4. Press Next button (E) to continue sensor position

calibration process.

ZX1043378 —UN—21NOV09

Sensor Calibration - Step 2/2

ZX1043381 —UN—17SEP09

G—Broaden Button

H—Broaden Position Value (V)

I— Accept Button

J— Alarm Message

K—Alarm Message

L— Cancel Button

5. Sensor setup 2/2 (F) is displayed with the following

message:

”Broaden the plough to its widest position using the

button below. Then press the accept button.”

6. Press and hold Broaden button (G) until the desired

voltage level (H) is reached. The limit that can be set

by the operator is 0.75 V or 4.25 V depending on the

sensor mounting location.

NOTE: Alarm messages ”Sensor value too close to

previous setting.” (J) or ”Sensor value outside valid

range. Consider a different mounting position.” (K)

may appear while pressing Contract or Broaden

button (B, G). The difference between the voltage

settings must be at least 1 V. Follow message

instructions then press Accept button (I).

ZX1043379 —UN—21NOV09

ZX1043382 —UN—17SEP09

Continued on next page OUCC002,000350B -19-06SEP11-4/5

15-8

101311

PN=18

Page 19

GS3 Display - iSteer™ Plough

7. Once calibration is nished, press Accept (I) to

validate calibration.

iSteer™ Plough - GPS SETUP Page

OUCC002,000350B -19-06SEP11-5/5

The GPS SETUP page allows the operator to:

A - Input in-line distance from the GPS receiver to the

•

last plough body.

B - Input lateral distance from center-line of machine

•

to GPS receiver.

NOTE: The receiver height has to be entered in

StarFire™ Settings for correct positioning.

Press Toggle button (C) to select the right tractor/GPS

receiver conguration as shown on illustration and then

input distance A and B values.

C—Toggle Button

15-9

ZX1045157 —UN—19AUG11

ZX1043412 —UN—30SEP09

OUCC002,000350C -19-08SEP11-1/1

101311

PN=19

Page 20

iSteer™ Plough - Diagnostic Page

GS3 Display - iSteer™ Plough

A—Status Pie B—Conditions C—State D—Status

The status pie (A) displayed on the RUN page allows the

operator to view the stage iSteer™ is in.

When iSteer™ is enabled and all conditions (B) are

•

met, the status pie (A) is fully green.

When iSteer™ is activated (active steering of the plough

•

Depending on the conditions (B), the state (C) of the

iSteer™ status pie (A) reects the status (D) to help in

diagnosing the system. Refer to the following chart for

conditions and status description:

and ground speed is above 0.5 km/h) iS is displayed.

iSteer™ Status Pie Conditions/Status Description

State Conditions Status

iSteer Activation Yes/No

1/4 of pie

2/4 of pie

Implement Type Plough

GS3 Ready for iSteer Yes/No

Differential Mode Vehicle SF1/SF2/RTK

AutoTrac Not Active

AB Line Dened Yes/No

Track Spacing Valid Yes/No

No iSteer Trouble Codes Yes/No

Valid iSteer Conguration Yes/No

Sensor Calibration Valid Yes/No

Continued on next page OUCC002,000350D -19-08SEP11-1/2

SF1/SF2/RTK

15-10

ZX1045158 —UN—06SEP11

101311

PN=20

Page 21

GS3 Display - iSteer™ Plough

iSteer™ Status Pie Conditions/Status Description

State Conditions Status

3/4 of pie Steer On/Off Button On/Off

Speed Within Range Yes/No

a

Within 20 Degrees of AB Line Yes/No4/4 of pie with iS

a

If ground speed is above 0.5 km/h

Within 40 % Tracking Width Yes/No

OUCC002,000350D -19-08SEP11-2/2

15-11

101311

PN=21

Page 22

GS3 Display - iSteer™ Side-Shift

Access iSteer™ Side-Shift

Before accessing iSteer™ Side-Shift, make sure that:

The iSteer™ licence activation is done.

•

NOTE: When iSteer™ control unit is connected, the

Straight Track guidance mode is automatically

preselected. This mode in the GS3 Guidance

settings is then grayed out.

The farm, eld, and client setup is done.

•

The initial path (AB line) has been set.

•

Press GreenStar 3 Pro button and refer to 2630

GreenStar Display Operator's Manual to proceed .

Press iSteer™ button to operate the iSteer™ Side-Shift

system. The iSteer™ main page appears and displays

three tabs.

Refer to:

iSteer™ Side-Shift - RUN Page,

•

iSteer™ Side-Shift - SETUP Page or

•

iSteer™ Side-Shift - GPS SETUP Page in this Section.

•

GreenStar 3 Pro Button

iSteer™ Button

ZX1045153 —UN—19AUG11ZX1045154 —UN—19AUG11

ZX1043373 —UN—17SEP09

20-1

OUCC002,000350E -19-06SEP11-1/1

101311

PN=22

Page 23

iSteer™ Side-Shift - RUN Page

GS3 Display - iSteer™ Side-Shift

A—Lateral Offset Graph

B—Cylinder Position

C—Manual Left Side-Shift Button

D—Manual Set to Offset Position

Button

The RUN page allows the operator to:

Visually check the lateral offset (A) and cylinder position

•

(B).

NOTE: In case of erratic movements of the bar

graph or cylinder, check sensor.

NOTE: The graph accuracy (arrow distance) default

is set to 10 cm (3.94 in.) and is adjustable

under Guidance Settings tab (see GS3

Guidance Operator's Manual).

Manually control the cylinder position using Left

•

Side-Shift button (C), Set to Offset Position button (D)

or Right Side-Shift button (E).

NOTE: With manual offset to 0 the implement is

centered (no lateral offset).

E—Manual Right Side-Shift

Button

F— Enable iSteer™ Button

Enable the iSteer™ Side-Shift system using Enable

•

G—Activate iSteer™ Button

H—iSteer™ Status Pie

button (F).

Activate the iSteer™ Side-Shift system using Activate

•

button (G).

Visually check iSteer™ Side-Shift status by referencing

•

the status pie (H). Press Diagnostic softkey G to display

the diagnostic page. Refer to iSteer™ Side-Shift Diagnostic Page in this Section.

Prior to operating the implement with the iSteer™

Side-Shift system, make sure:

1. All requested iSteer™ Side-Shift settings and sensor

calibration were performed correctly. Refer to iSteer™

Side-Shift - SETUP Page in this Section.

2. GPS settings have been checked. Refer to iSteer™

Side-Shift - GPS SETUP Page in this Section.

IMPORTANT: Correct receiver height is critical

to proper operation. This value is entered

in the StarFire™ setup page.

Continued on next page OUCC002,000350F -19-06SEP11-1/2

20-2

ZX1045162 —UN—19AUG11

101311

PN=23

Page 24

GS3 Display - iSteer™ Side-Shift

3. Press Enable iSteer™ button (F) and set the initial

path. Refer to GS3 Guidance Operator's Manual to

set the initial path.

IMPORTANT: Only straight track mode is allowed.

Create AB line as explained in relevant

guidance Operator's Manual.

iSteer™ Side-Shift - SETUP Page

4. Press Activate iSteer™ button (G) to start implement

guidance.

IMPORTANT: When iSteer™ is activated all other

GreenStar Pro modules are deactivated.

OUCC002,000350F -19-06SEP11-2/2

A—Steer Sensitivity

B—Pulse Length (s)

C—Auto-Center Check Box

D—Activation AutoTrac+iSteer

The SETUP page allows the operator to:

Set cylinder steering sensitivity (A) between 50 and 150

•

(default value is 100).

Set cylinder pulse length (B) between 0.1 and 2

•

seconds (default value is 0.3 s).

Check Auto-Center box (C) whenever the implement

•

needs to be moved to the offset position upon iSteer™

deactivation.

E—Calibrate Button

F— Manual Control

Check Activation AutoTrac+iSteer box (D) to activate

•

G—Invert Steering Check Box

AutoTrac and iSteer™ simultaneously.

Calibrate (E) cylinder sensor left and right positions

•

each time a new implement is operated. See Sensor

Calibration hereafter.

Manually control (F) implement position (to the left or

•

right).

Check Invert Steering box (G) to invert hydraulic valve

•

direction in case of reversed valve connection.

Continued on next page OUCC002,0003510 -19-06SEP11-1/3

20-3

ZX1045161 —UN—06SEP11

101311

PN=24

Page 25

Sensor Calibration

GS3 Display - iSteer™ Side-Shift

Sensor Calibration - Step 1/3

CAUTION: Ensure there are no bystanders near

the implement during calibration.

Calibrate sensor left and right positions as follows:

1. Press the Calibrate button on the RUN page.

2. Sensor setup 1/3 (A) is displayed with the following

message:

”Move the side shift cylinder to left position using the

button below. If the cylinder moves to the right, press

the invert steering check box. Press next to continue.”

3. Press and hold Left button (B) until the desired voltage

level (C) is reached. The limit that can be set by the

operator is 0.75 V or 4.25 V.

NOTE: If the cylinder moves to the right instead of to

the left, check the Invert Steering box (D).

4. Press Next button (E) to continue sensor position

calibration process.

5. Sensor setup 2/3 (F) is displayed with the following

message:

”Move the side shift cylinder to right position using the

button below. Press next to continue.”

6. Press and hold Right button (G) until the desired

voltage level (H) is reached. The limit that can be set

by the operator is 0.75 V or 4.25 V.

ZX1043386 —UN—30SEP09

Sensor Calibration - Step 2/3

Sensor Calibration - Step 3/3

A—Sensor Setup - 1/3

B—Left Button

C—Left Position Value (V)

D—Invert Steering Check Box

E—Next Button

F— Sensor Setup - 2/3

ZX1043387 —UN—30SEP09

ZX1043388 —UN—30SEP09

G—Right Button

H—Right Position Value (V)

I— Sensor Setup - 3/3

J— Center Button

K—Accept Button

L— Cancel Button

7. Press Next button (E) to continue sensor position

calibration process.

8. Sensor setup 3/3 (I) is displayed with the following

message:

”Dene Cylinder Offset Position.”

9. Press Left, Center or Right button (B, J or G) to

dene cylinder offset position using cylinder position

illustration, as shown.

Continued on next page OUCC002,0003510 -19-06SEP11-2/3

20-4

101311

PN=25

Page 26

GS3 Display - iSteer™ Side-Shift

10. Once calibration is nished press Accept (K) to

validate calibration.

iSteer™ Side-Shift - GPS SETUP Page

OUCC002,0003510 -19-06SEP11-3/3

The GPS SETUP page allows the operator to:

Input in-line distance from the connection point to GPS

•

receiver (A).

Input lateral distance from the connection point to GPS

•

receiver (B).

Press Toggle button (C) to select the right tractor/GPS

receiver conguration as shown on illustration and then

input distance A and B values.

C—Toggle Button

20-5

ZX1045160 —UN—19AUG11

ZX1043413 —UN—30SEP09

OUCC002,0003511 -19-06SEP11-1/1

101311

PN=26

Page 27

GS3 Display - iSteer™ Side-Shift

iSteer™ Side-Shift - Diagnostic Page

A—Status Pie B—Conditions C—State D—Status

The status pie (A) displayed on the RUN page allows the

operator to view the stage iSteer™ is in.

When iSteer™ is enabled and all conditions (B) are

•

met, the status pie (A) is fully green.

When iSteer™ is activated (active steering of the plough

•

Depending on the conditions (B), the state (C) of the

iSteer™ status pie (A) reects the status (D) to help in

diagnosing the system. Refer to the following chart for

conditions and status description:

and ground speed is above 0.5 km/h) iS is displayed.

iSteer™ Status Pie Conditions/Status Description

State Conditions Status

iSteer Activation Yes/No

1/4 of pie

2/4 of pie

Implement Type

GS3 Ready for iSteer Yes/No

Differential Mode Vehicle

Differential Mode Implement

AB Line Dened Yes/No

Track Spacing Valid Yes/No

No iSteer Trouble Codes Yes/No

Valid iSteer Conguration Yes/No

Sensor Calibration Valid Yes/No

Continued on next page OUCC002,0003512 -19-06SEP11-1/2

Side-Shift

RTK

RTK

20-6

ZX1045159 —UN—06SEP11

101311

PN=27

Page 28

GS3 Display - iSteer™ Side-Shift

iSteer™ Status Pie Conditions/Status Description

State Conditions Status

3/4 of pie Steer On/Off Button On/Off

Speed Within Range Yes/No

a

Within 20 Degrees of AB Line Yes/No4/4 of pie with iS

a

If ground speed is above 0.5 km/h

Within 40 % Tracking Width Yes/No

OUCC002,0003512 -19-06SEP11-2/2

20-7

101311

PN=28

Page 29

GS3 Display - iSteer™ Steerable Drawbar

Operate iSteer™ Steerable Drawbar System

Refer to information given in GS3 Display - iSteer™

Side-Shift Section to access and operate the iSteer™

Steerable Drawbar system.

OUCC002,0003513 -19-06SEP11-1/1

25-1

101311

PN=29

Page 30

Sensor Calibration

GS3 Display - iSteer™ Steerable Drawbar

Sensor Calibration - Step 1/3

CAUTION: Ensure there are no bystanders near

the implement during calibration.

Calibrate sensor left and right positions as follows:

1. Press the Calibrate button on the RUN page.

2. Sensor setup 1/3 (A) is displayed with the following

message:

”Move the side shift cylinder to left position using the

button below. If the cylinder moves to the right, press

the invert steering check box. Press next to continue.”

3. Press and hold Left button (B) until the desired voltage

level (C) is reached. The limit that can be set by the

operator is 0.75 V or 4.25 V.

NOTE: If the cylinder moves to the right instead of to

the left, check the Invert Steering box (D).

4. Press Next button (E) to continue sensor position

calibration process.

5. Sensor setup 2/3 (F) is displayed with the following

message:

”Move the side shift cylinder to right position using the

button below. Press next to continue.”

6. Press and hold Right button (G) until the desired

voltage level (H) is reached. The limit that can be set

by the operator is 0.75 V or 4.25 V.

ZX1043386 —UN—30SEP09

Sensor Calibration - Step 2/3

Sensor Calibration - Step 3/3

A—Sensor Setup - 1/3

B—Left Button

C—Left Position Value (V)

D—Invert Steering Check Box

E—Next Button

F— Sensor Setup - 2/3

ZX1043387 —UN—30SEP09

ZX1043418 —UN—30SEP09

G—Right Button

H—Right Position Value (V)

I— Sensor Setup - 3/3

J— Center Button

K—Accept Button

L— Cancel Button

7. Press Next button (E) to continue sensor position

calibration process.

8. Sensor setup 3/3 (I) is displayed with the following

message:

”Dene Cylinder Offset Position.”

9. Press Left, Center or Right button (B, J or G) to

dene cylinder offset position using cylinder position

illustration, as shown.

Continued on next page OUCC002,0003514 -19-06SEP11-1/2

25-2

101311

PN=30

Page 31

GS3 Display - iSteer™ Steerable Drawbar

NOTE: For applications requiring no offset, make sure

cylinder is centered by pressing the Center button (J).

10. Once calibration is nished press Accept (K) to

validate calibration.

OUCC002,0003514 -19-06SEP11-2/2

25-3

101311

PN=31

Page 32

Service

iSteer™ System Service

General: Due to the use of an electronic control unit,

there is minimal service required to maintain performance

levels. However, periodic software updates may be

required. To maintain optimum performance, these

updates should be loaded.

GS3 Display: For the GS3 system, updating is

accomplished when you perform a ”live update”

Implement Service

Contact the manufacturer of the implement steering

module for servicing procedures.

using a connection to the Stellar Support website

(www.stellarsupport.com). Once downloaded, the updates

must be loaded onto your USB device. After updating

the USB device, the operating system will prompt you

that updates are available the next time you insert the

card into your GS3.

Implement Control Unit: Contact your control unit

manufacturer to keep control unit software up to date.

OUCC002,00034A2 -19-06SEP11-1/1

OUCC002,0002BCC -19-17AUG09-1/1

30-1

101311

PN=32

Page 33

Specications

4.84.8 8.8 9.8 10.9

12.9

12.9

12.9

12.9

10.9

9.8

8.8

4.8

Metric Bolt and Screw Torque Values

TS1670 —UN—01MAY03

Bolt or Screw

Size Lubricated

Class 4.8 Class 8.8 or 9.8 Class 10.9 Class 12.9

a

Dry

b

Lubricated

a

Dry

b

Lubricated

a

Dry

b

Lubricated

a

N·m lb.-in. N·m lb.-in. N·m lb.-in. N·m lb.-in. N·m lb.-in. N·m lb.-in. N·m lb.-in. N·m lb.-in.

M6 4.7 42 6 53 8.9 79 11.3 100 13 115 16.5 146 15.5 137 19.5 172

N·m lb.-ft. N·m lb.-ft. N·m lb.-ft. N·m lb.-ft.

M8 11.5 102 14.5 128 22 194 27.5 243 32 23.5 40 29.5 37 27.5 47 35

N·m lb.-ft. N·m lb.-ft. N·m lb.-ft.

M10 23 204 29 21 43 32

N·m

lb.-ft.

M12 40 29.5 50 37

75 55

55

40 63 46 80 59

95 70 110 80 140 105 130 95 165 120

75 55

M14 63 46 80 59 120 88 150 110 175 130 220 165 205 150 260 190

M16 100 74 125 92 190 140 240 175 275 200 350 255 320 235 400 300

M18 135 100 170 125 265 195 330 245 375 275 475 350 440 325 560 410

M20 190 140 245 180 375 275 475 350 530 390 675 500 625 460 790 580

M22 265 195 330 245 510 375 650 480 725 535 920 680 850 625 1080 800

M24 330 245 425 315 650 480 820 600 920 680 1150 850 1080 800 1350 1000

M27 490 360 625 460 950 700 1200 885 1350 1000 1700 1250 1580 1160 2000 1475

M30 660 490 850 625 1290 950 1630 1200 1850 1350 2300 1700 2140 1580 2700 2000

M33 900 665 1150 850 1750 1300 2200 1625 2500 1850 3150 2325 2900 2150 3700 2730

M36 1150 850 1450 1075 2250 1650 2850 2100 3200 2350 4050 3000 3750 2770 4750 3500

Torque values listed are for general use only, based on the strength of

the bolt or screw. DO NOT use these values if a different torque value or

tightening procedure is given for a specic application. For stainless steel

fasteners or for nuts on U-bolts, see the tightening instructions for the

specic application. Tighten plastic insert or crimped steel type lock nuts

by turning the nut to the dry torque shown in the chart, unless different

instructions are given for the specic application.

Shear bolts are designed to fail under predetermined loads. Always

replace shear bolts with identical property class. Replace fasteners with

the same or higher property class. If higher property class fasteners are

used, tighten these to the strength of the original. Make sure fastener

threads are clean and that you properly start thread engagement. When

possible, lubricate plain or zinc plated fasteners other than lock nuts,

wheel bolts or wheel nuts, unless different instructions are given for the

specic application.

a

“Lubricated” means coated with a lubricant such as engine oil, fasteners with phosphate and oil coatings, or M20

and larger fasteners with JDM F13C, F13F or F13J zinc ake coating.

b

“Dry” means plain or zinc plated without any lubrication, or M6 to M18 fasteners with JDM F13B, F13E or F13H zinc ake coating.

DX,TORQ2 -19-12JAN11-1/1

b

Dry

95 70

35-1

101311

PN=33

Page 34

Specications

EC Declaration of Conformity

Deere & Company

Moline, Illinois U.S.A

The person named below declares that

The iSteer™ System

Model: Plough, Side-Shift and Steerable Drawbar

fullls all relevant provisions and essential requirements of the following directives:

DIRECTIVE

Electromagnetic Compatibility 2004/108/EC Self certied, per Annex II of the Directive

Name and address of the person in the European Community authorized to compile the technical construction le:

Brigitte Birk

Deere & Company European Ofce

John Deere Strasse 70

Mannheim, Germany D-68163

EUConformity@JohnDeere.com

Place of declaration: D-66482 Zweibrücken,

Germany

Date of declaration: 01 August 2009 Title: Engineering Manager AMS Europe

Manufacturing unit: John Deere AMS Europe

NUMBER

CERTIFICATION METHOD

Name: John H. Leinart

DXCE01 —UN—28APR09

OUCC002,0003515 -19-06SEP11-1/1

35-2

101311

PN=34

Page 35

Index

B

Bolt and screw torque values

Metric ...................................................................... 35-1

C

Calibrating

Plough Working Width ............................................ 15-2

H

Hardware torque values

Metric ...................................................................... 35-1

I

iSteer Plough

Accessing................................................................ 15-1

Calibrating............................................................... 15-2

Diagnostic Page.................................................... 15-10

GPS SETUP Page.................................................. 15-9

Operating ....................................................... 15-2, 15-9

iSteer™ Plough

Operating ................................................................ 15-4

RUN Page............................................................... 15-4

Setting..................................................................... 15-6

SETUP Page........................................................... 15-6

iSteer Side-Shift

Setting..................................................................... 20-3

SETUP Page........................................................... 20-3

iSteer™ Side-Shift

Accessing................................................................ 20-1

Diagnostic Page...................................................... 20-6

GPS SETUP Page.................................................. 20-5

Operating ....................................................... 20-2, 20-5

RUN Page............................................................... 20-2

iSteer Steerable Drawbar

Operating ................................................................ 25-1

Setting..................................................................... 20-3

SETUP Page........................................................... 20-3

iSteer™ Steerable Drawbar

Accessing................................................................ 20-1

Diagnostic Page...................................................... 20-6

GPS SETUP Page.................................................. 20-5

Operating ....................................................... 20-2, 20-5

RUN Page............................................................... 20-2

Page

Page

T

Torque charts

Metric ...................................................................... 35-1

M

Metric bolt and screw torque values ........................... 35-1

S

Service........................................................................ 30-1

Index-1

101311

PN=1

Page 36

Index

Index-2

101311

PN=2

Page 37

John Deere Service Keeps You On The Job

John Deere Parts

We help minimize downtime by putting genuine John

Deere parts in your hands in a hurry.

That’s why we maintain a large and varied inventory—to

stay a jump ahead of your needs.

The Right Tools

Precision tools and testing equipment enable our Service

Department to locate and correct troubles quickly . . . to

save you time and money.

TS100 —UN—23AUG88

DX,IBC,A -19-04JUN90-1/1

Well-Trained Technicians

School is never out for John Deere service technicians.

Training schools are held regularly to be sure our

personnel know your equipment and how to maintain it.

Result?

Experience you can count on!

Prompt Service

Our goal is to provide prompt, efcient care when you

want it and where you want it.

We can make repairs at your place or at ours, depending

on the circumstances: see us, depend on us.

JOHN DEERE SERVICE SUPERIORITY: We'll be around

when you need us.

TS101 —UN—23AUG88

DX,IBC,B -19-04JUN90-1/1

TS102 —UN—23AUG88

DX,IBC,C -19-04JUN90-1/1

IBC-1

TS103 —UN—23AUG88

DX,IBC,D -19-04JUN90-1/1

101311

PN=37

Page 38

John Deere Service Keeps You On The Job

IBC-2

101311

PN=38

Page 39

John Deere Service Keeps You On The Job

IBC-3

101311

PN=39

Page 40

John Deere Service Keeps You On The Job

IBC-4

101311

PN=40

Page 41

John Deere Service Keeps You On The Job

IBC-5

101311

PN=41

Page 42

Page 43

Page 44

Loading...

Loading...