Page 1

iGrade™

*DCY*

*OMPFP13592*

OPERATOR'S MANUAL

OMPFP13592 ISSUE C4 (ENGLISH)

*OMPFP13592*

Proposition 65 Warning

iGrade™

CALIFORNIA

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer,

birth defects, and other reproductive harm.

If this product contains a gasoline engine:

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

The State of California requires the above two warnings.

Additional Proposition 65 Warnings can be found in this manual.

John Deere Ag Management Solutions

PRINTED IN U.S.A.

Page 2

Introduction

www.StellarSupport.com

NOTE: Product functionality may not be fully represented in this document due to product changes occurring after the time of printing. Read the

latest Operator's Manual and Quick Reference Guide prior to operation. To obtain a copy, see your dealer or visit www.StellarSupport.com

OUO6050,0000FB1 -19-10AUG10-1/1

Foreword

WELCOME to the iGrade™ System offered by John

Deere.

READ THIS MANUAL carefully to learn how to operate and

service your system correctly. Failure to do so could result

in personal injury or equipment damage. This manual and

safety signs on your machine may also be available in

other languages. (See your John Deere dealer to order.)

THIS MANUAL SHOULD BE CONSIDERED a permanent

part of your system and should remain with the system

when you sell it.

MEASUREMENTS in this manual are given in both

metric and customary U.S. unit equivalents. Use only

correct replacement parts and fasteners. Metric and inch

fasteners may require a specific metric or inch wrench.

RIGHT-HAND AND LEFT-HAND sides are determined by

facing in the direction of forward travel.

WRITE PRODUCT IDENTIFICATION NUMBERS (P.I.N.)

in the Specification or Identification Numbers section.

iGrade is a trademark of Deere & Company

Accurately record all the numbers to help in tracing

the components should it be stolen. Your dealer also

needs these numbers when you order parts. File the

identification numbers in a secure place off the machine.

WARRANTY is provided as part of John Deere's support

program for customers who operate and maintain their

equipment as described in this manual. The warranty is

explained on the warranty certificate which you should

have received from your dealer.

This warranty provides you the assurance that John

Deere will back its products where defects appear within

the warranty period. In some circumstances, John Deere

also provides field improvements, often without charge

to the customer, even if the product is out of warranty.

Should the equipment be abused, or modified to change

its performance beyond the original factory specifications,

the warranty will become void and field improvements

may be denied.

RW00482,0000266 -19-19FEB14-1/1

031214

PN=2

Page 3

Contents

Page

Safety

Recognize Safety Information ............................05-1

Understand Signal Words...................................05-1

Follow Safety Instructions...................................05-1

Practice Safe Maintenance.................................05-2

Use Steps and Handholds Correctly ..................05-2

Handle Electronic Components and

Brackets Safely ..............................................05-3

Operate Implement Automation

Systems Safely ..............................................05-3

Avoid High-Pressure Fluids ................................05-4

Introduction

Theory of Operation............................................10-1

Activate iGrade™ ............................................... 10-1

iGrade™ Requirements......................................10-2

Machine Controller Compatibility........................10-3

Page

Operation............................................................ 35-3

Grade Control

Theory of Operation............................................40-1

Grade Calculator ................................................ 40-1

Selecting Grade..................................................40-2

Plane Control

Theory of Operation............................................45-1

Control Selection ................................................45-2

Select Active Plane.............................................45-2

Single Slope Plane .............................................45-3

Dual Slope Plane................................................45-4

Plane Calculator .................................................45-5

Dual Scraper.......................................................45-5

Operation............................................................ 45-6

System Components

iGrade™ Components........................................15-1

SCV Setup

Configure SCVs On CommandCen-

ter™ - Auto Mode........................................... 20-1

SCV Operation ................................................... 20-2

Adjust Valve........................................................20-3

Calibrate SCV Thresholds ..................................20-3

Basic Operation

Basic Operation ..................................................25-1

Engage iGrade™................................................25-2

Dual Scrapers.....................................................25-3

Load Limiting ......................................................25-4

Max Cut ..............................................................25-5

Offsets ................................................................25-6

Remote Control—Surface Water Pro™ Plus

Theory of Operation............................................30-1

Control Selection ................................................30-1

Operation............................................................ 30-2

Remote Control—Serial Port

Theory of Operation............................................35-1

Message Definition .............................................35-1

Serial Port Hardware ..........................................35-1

Serial Port Setup ................................................35-2

Control Selection ................................................35-3

Distance Trip

Theory of Operation............................................50-1

Select Distance Trip ...........................................50-1

Distance Trip Setup ............................................50-2

Initiating Trip Cycle .............................................50-3

Adjusting Trip Cycle............................................50-3

Disconnecting iGrade™

Disconnect iGrade™ System .............................55-1

Troubleshooting

Troubleshooting — iGrade™ System.................60-1

Troubleshooting — I/O Voltages Page ...............60-2

Troubleshooting — Machine...............................60-3

Maintenance

iGrade System....................................................65-1

Preseason Checklist...........................................65-1

Daily Checklist ....................................................65-1

Postseason Checklist .........................................65-2

Specifications

EC Declaration of Conformity.............................70-1

Original Instructions. All information, illustrations and specifications in this

manual are based on the latest information available at the time of publication.

The right is reserved to make changes at any time without notice.

COPYRIGHT © 2014

DEERE & COMPANY

Moline, Illinois

A John Deere ILLUSTRUCTION ® Manual

All rights reserved.

i

031214

PN=1

Page 4

Contents

ii

031214

PN=2

Page 5

Safety

Recognize Safety Information

This is a safety-alert symbol. When you see this symbol

on your machine or in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word—DANGER, WARNING, or CAUTION—is

used with the safety-alert symbol. DANGER identifies the

most serious hazards.

DANGER or WARNING safety signs are located near

specific hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

T81389 —UN—28JUN13

DX,ALERT -19-29SEP98-1/1

Follow Safety Instructions

Carefully read all safety messages in this manual and on

your machine safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from your John Deere dealer.

There can be additional safety information contained on

parts and components sourced from suppliers that is not

reproduced in this operator's manual.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machine in proper working condition.

Unauthorized modifications to the machine may impair the

function and/or safety and affect machine life.

TS187 —19—30SEP88

DX,SIGNAL -19-03MAR93-1/1

TS201 —UN—15APR13

If you do not understand any part of this manual and need

assistance, contact your John Deere dealer.

DX,READ -19-16JUN09-1/1

05-1

031214

PN=5

Page 6

Practice Safe Maintenance

Understand service procedure before doing work. Keep

area clean and dry.

Never lubricate, service, or adjust machine while it is

moving. Keep hands, feet , and clothing from power-driven

parts. Disengage all power and operate controls to relieve

pressure. Lower equipment to the ground. Stop the

engine. Remove the key. Allow machine to cool.

Securely support any machine elements that must be

raised for service work.

Keep all parts in good condition and properly installed.

Fix damage immediately. Replace worn or broken parts.

Remove any buildup of grease, oil, or debris.

On self-propelled equipment, disconnect battery ground

cable (-) before making adjustments on electrical systems

or welding on machine.

On towed implements, disconnect wiring harnesses from

tractor before servicing electrical system components or

welding on machine.

Safety

Use Steps and Handholds Correctly

Prevent falls by facing the machine when getting on and

off. Maintain 3-point contact with steps, handholds, and

handrails.

Use extra care when mud, snow, or moisture present

slippery conditions. Keep steps clean and free of grease

or oil. Never jump when exiting machine. Never mount or

dismount a moving machine.

TS218 —UN—23AUG88

DX,SERV -19-17FEB99-1/1

T133468 —UN—15APR13

DX,WW,MOUNT -19-12OCT11-1/1

05-2

031214

PN=6

Page 7

Handle Electronic Components and Brackets

Safely

Falling while installing or removing electronic components

mounted on equipment can cause serious injury. Use a

ladder or platform to easily reach each mounting location.

Use sturdy and secure footholds and handholds. Do not

install or remove components in wet or icy conditions.

If installing or servicing a RTK base station on a tower or

other tall structure, use a certified climber.

Safety

If installing or servicing a global positioning receiver mast

used on an implement, use proper lifting techniques and

wear proper protective equipment. The mast is heavy and

can be awkward to handle. Two people are required when

mounting locations are not accessible from the ground

or from a service platform.

Operate Implement Automation Systems Safely

Do not use implement automation systems on roadways.

Always turn off (disable) implement automation systems

before entering a roadway. Do not attempt to turn

on (activate) an implement automation system while

transporting on a roadway.

Implement automation systems are intended to aid the

operator in performing field operations more efficiently.

The operator is always responsible for the machine path.

Implement automation systems include any application

that automates implement movement. This includes, but

may not be limited to, iGrade™ and Active Implement

Guidance.

To prevent injury to the operator and bystanders:

Verify the machine, implement, and automation systems

•

are set up correctly.

Remain alert and pay attention to the surrounding

•

environment.

Take control of the machine, when necessary, to

•

avoid field hazards, bystanders, equipment, or other

obstacles.

Stop operation if poor visibility conditions impair your

•

ability to operate the machine or identify people or

obstacles in the machine path.

iGrade is a trademark of Deere & Company

TS249 —UN—23AUG88

DX,WW,RECEIVER -19-24AUG10-1/1

PC13793 —UN—25MAY11

CF86321,0000366 -19-19DEC13-1/1

05-3

031214

PN=7

Page 8

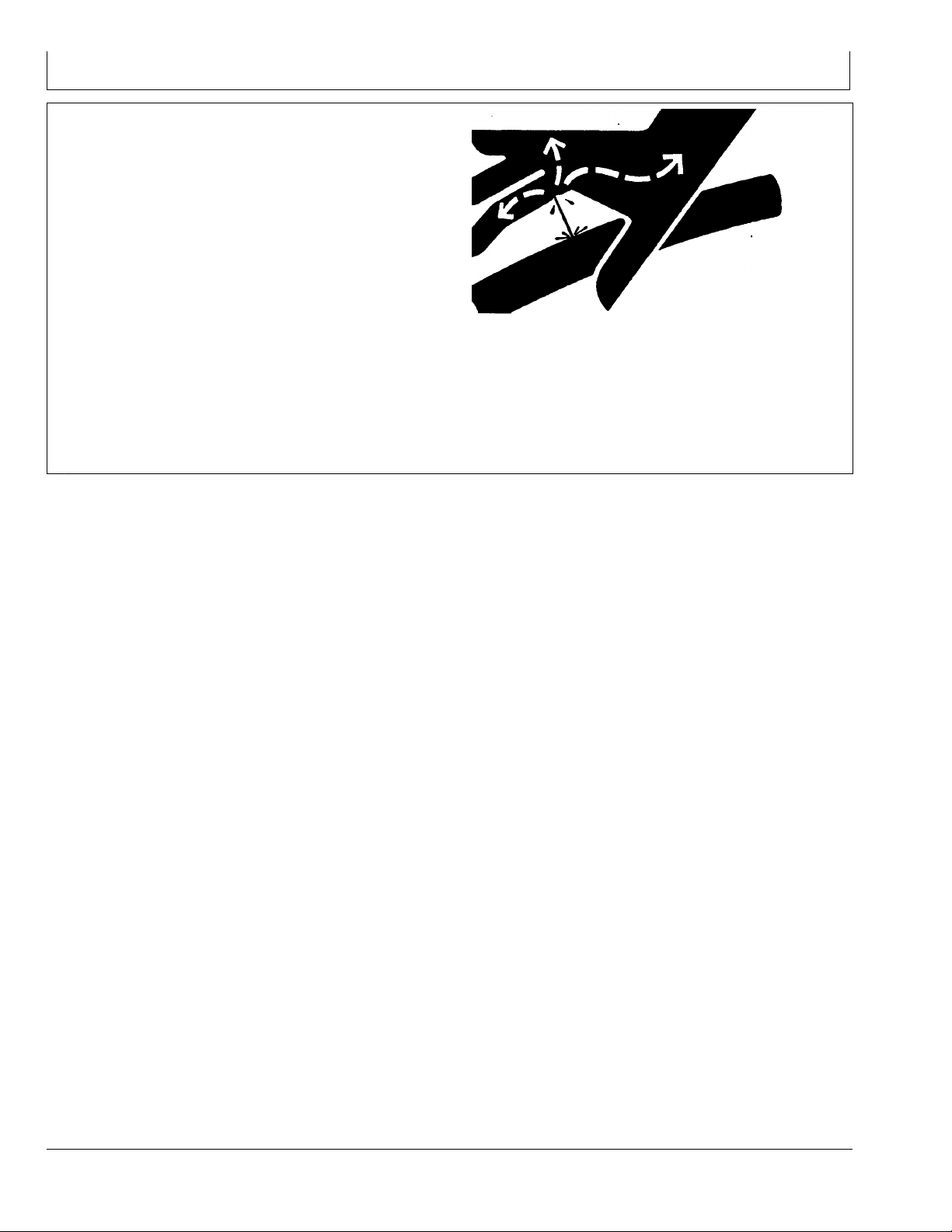

Avoid High-Pressure Fluids

Inspect hydraulic hoses periodically – at least once

per year – for leakage, kinking, cuts, cracks, abrasion,

blisters, corrosion, exposed wire braid or any other signs

of wear or damage.

Replace worn or damaged hose assemblies immediately

with John Deere approved replacement parts.

Escaping fluid under pressure can penetrate the skin

causing serious injury.

Avoid the hazard by relieving pressure before

disconnecting hydraulic or other lines. Tighten all

connections before applying pressure.

Search for leaks with a piece of cardboard. Protect hands

and body from high-pressure fluids.

If an accident occurs, see a doctor immediately. Any fluid

injected into the skin must be surgically removed within

a few hours or gangrene may result. Doctors unfamiliar

Safety

X9811 —UN—23AUG88

with this type of injury should reference a knowledgeable

medical source. Such information is available in

English from Deere & Company Medical Department in

Moline, Illinois, U.S.A., by calling 1-800-822-8262 or +1

309-748-5636.

DX,FLUID -19-12OCT11-1/1

05-4

031214

PN=8

Page 9

Theory of Operation

Introduction

iGrade™ is an active elevation control system which uses

selective control valves (SCVs) to control implement

height based off GPS elevation data.

iGrade™ has four functional modes:

Plane Control – used to create a surface design with

•

either a single slope direction or a dual slope direction.

Grade Control – performs desired slope entered based

•

on actual distance traveled not linear distance. Grade

control is not direction-dependent.

Remote Control – receives elevation data commands

•

from an outside source to control implement height

through SCVs to a desired plane or ditch design.

Distance Trip – allows GPS position to trigger machine

•

hydraulics based on distance traveled. For example,

iGrade is a trademark of Deere & Company

StarFire is a trademark of Deere & Company

Activate iGrade™

To operate iGrade™, a 26-digit activation code is required

for Application Controller 1100.

1. Visit StellarSupport.com or call 1-888-953-3373.

2. Use controller serial number and COMAR order

number to generate an activation code.

using distance trip to create irrigation bays for bedded

crop irrigation.

iGrade™ utilizes StarFire™ Receivers to obtain a

plane or elevation point correlated to a latitude and

longitude position. To function properly, setup is crucial to

performance. Setup including but is not limited to:

SCV thresholds setup

•

SCV flow rates setup

•

TCM calibrations setup

•

Correctly setting a benchmark daily or a zero point for

•

system reference

Correct inputs into system for correct plane design

•

RW00482,000025F -19-19FEB14-1/1

PC14926 —UN—27APR12

PC12961 —UN—29AUG11

Application Controller 1100 Button

3. Select Application Controller 1100 from main menu.

4. Select Setup softkey.

5. Select Activation Entry button.

6. Select activation input box and enter activation code.

If iGrade™ is activated, Activation Entry screen displays:

Distance Trip

•

Remote Control

•

Grade Control

•

Plane Control

•

iGrade is a trademark of Deere & Company

PC17966 —UN—07NOV13

PC17967 —UN—07NOV13

Setup Softkey

Activation Entry Button

Activation Entry Box

RW00482,0000225 -19-19FEB14-1/1

10-1

031214

PN=9

Page 10

Introduction

iGrade™ Requirements

Display:

NOTE: Update software on display.

GreenStar™ 2 2600 Display or GreenStar™ 3 2630

•

Display recommended.

GreenStar™ 2 2100 Display and GreenStar™ 3

•

CommandCenter™ Display are compatible.

Surface Water Pro™ Plus (SWP+) automation requires

•

GS2 2600 Display or GS3 2630 Display.

Receiver:

StarFire™ RTK Receivers installed and functioning on

•

machine and implement.

StarFire™ Receiver and Deluxe Bracket mounted on

•

implement.

NOTE: A StarFire™ 300 Receiver can be used

as a machine receiver to provide speed for

Load Limiting application only.

StarFire™ Receiver mounted on machine for Load

•

Limiting, Max Cut, Distance Trip, AutoTrac™, and

Surface Water Pro™ Plus automation (Remote Control).

TCM turned on and calibrated.

•

Machine receivers (Original StarFire™, StarFire™ iTC,

•

or StarFire™ 3000) require RTK when using Distance

Trip and Max Cut.

Implement receivers (StarFire™ iTC or StarFire™

•

3000) are required to have an RTK signal level.

NOTE: When operating dual scrapers, use same

model of receiver on both implements.

Only use two StarFire™ iTC Receivers or

two StarFire™ 3000 Receivers. Receivers

calculate elevation differently.

When operating Surface Water Pro™, use same

receivers (StarFire™ iTC or StarFire™ 3000) for

collecting elevation data for ditching operation.

Machine receivers can use SF1 or SF2 if Distance Trip

•

is not being used and Max Cut is disabled.

Receiver offsets can be entered for iGrade™. When

•

using multiple implements, install receivers at same

height from blade to receiver. If needed, adjust scraper

offsets for application purposes.

Implement receiver must not be mounted higher than 4

•

m (13.1 ft.) above ground level.

Implement receiver must be connected to machine

•

implement CAN Bus through ISO connector.

Mount receiver mast on center line of implement over

•

control point of implement.

StarFire™ Global Navigation Satellite System (GNSS)

•

antenna is recommended. Implement receivers may

require use of StarFire™ GNSS antenna if operating

iGrade™ in high multipath conditions. High multipath

conditions can occur when satellites are low on horizon

or signal reflects off a surface and intercepted by

receiver.

Additional Hardware:

Application Controller 1100 installed on machine.

•

Various harnesses associated with power supply,

•

controller integration, and receiver installation.

Optional:

Complete AutoTrac™ setup and activate on display.

•

Complete Surface Water setup if using Remote Control

•

for SWP+ automation.

NOTE: iGrade™ does not use an implement

feedback sensor.

GreenStar is a trademark of Deere & Company

Surface Water Pro is a trademark of Deere & Company

AutoTrac is a trademark of Deere & Company

StarFire is a trademark of Deere & Company

iGrade is a trademark of Deere & Company

10-2

RW00482,0000226 -19-11FEB14-1/1

031214

PN=10

Page 11

Introduction

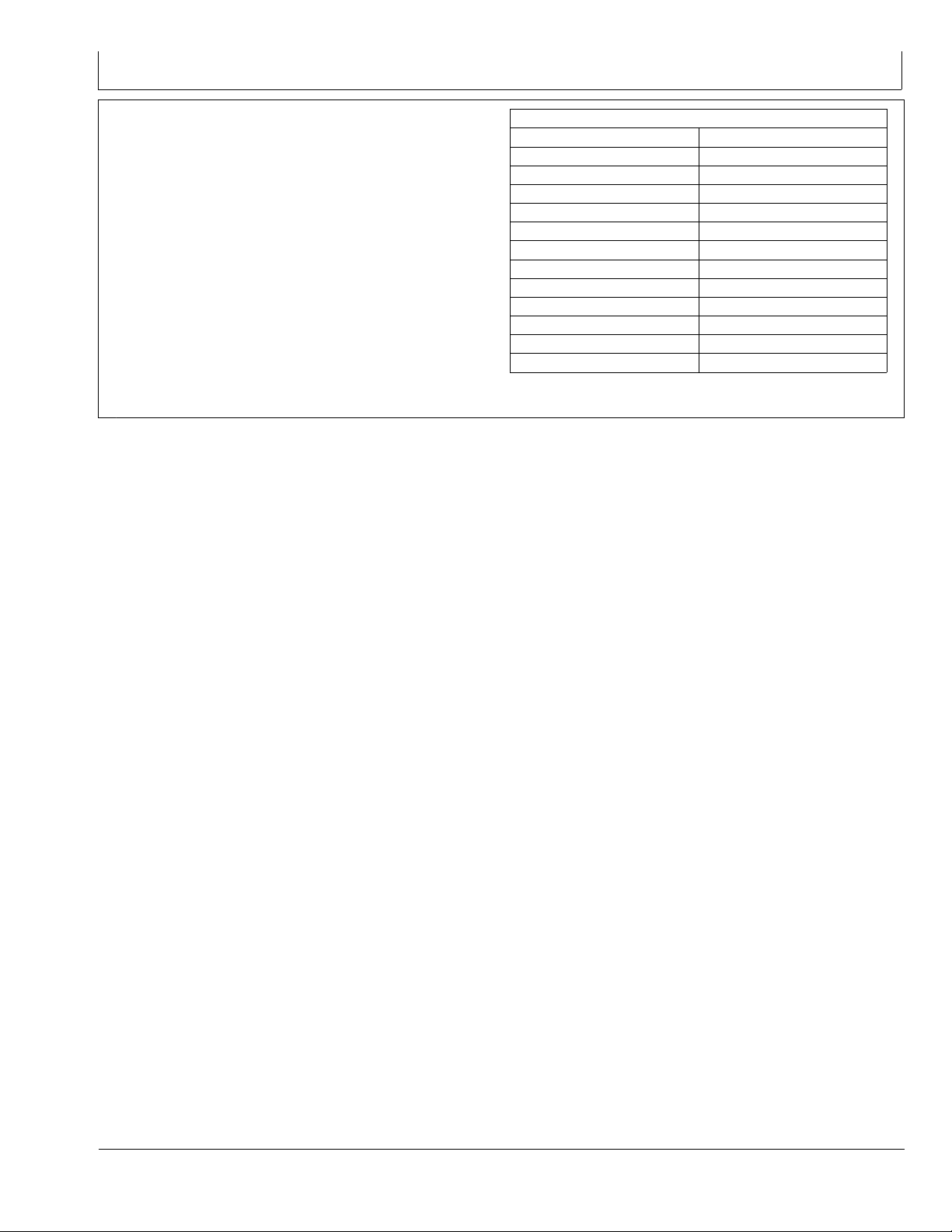

Machine Controller Compatibility

If installing iGrade™ on a machine in serial number

ranges listed in table, contact a John Deere dealer to

determine if any machine controllers require updates

before operating iGrade™.

iGrade is a trademark of Deere & Company

Machine Controller Compatibility

Machine Model

8100 -021245

8200 -021030

8300 -021780

8400 -022341

8100T -902028

8200T -902047

8300T -902166

8400T -902636

9100 -10365

9200 -10849

9300 -10928

9400 -10931

Serial Numbers

RW00482,0000261 -19-11FEB14-1/1

10-3

031214

PN=11

Page 12

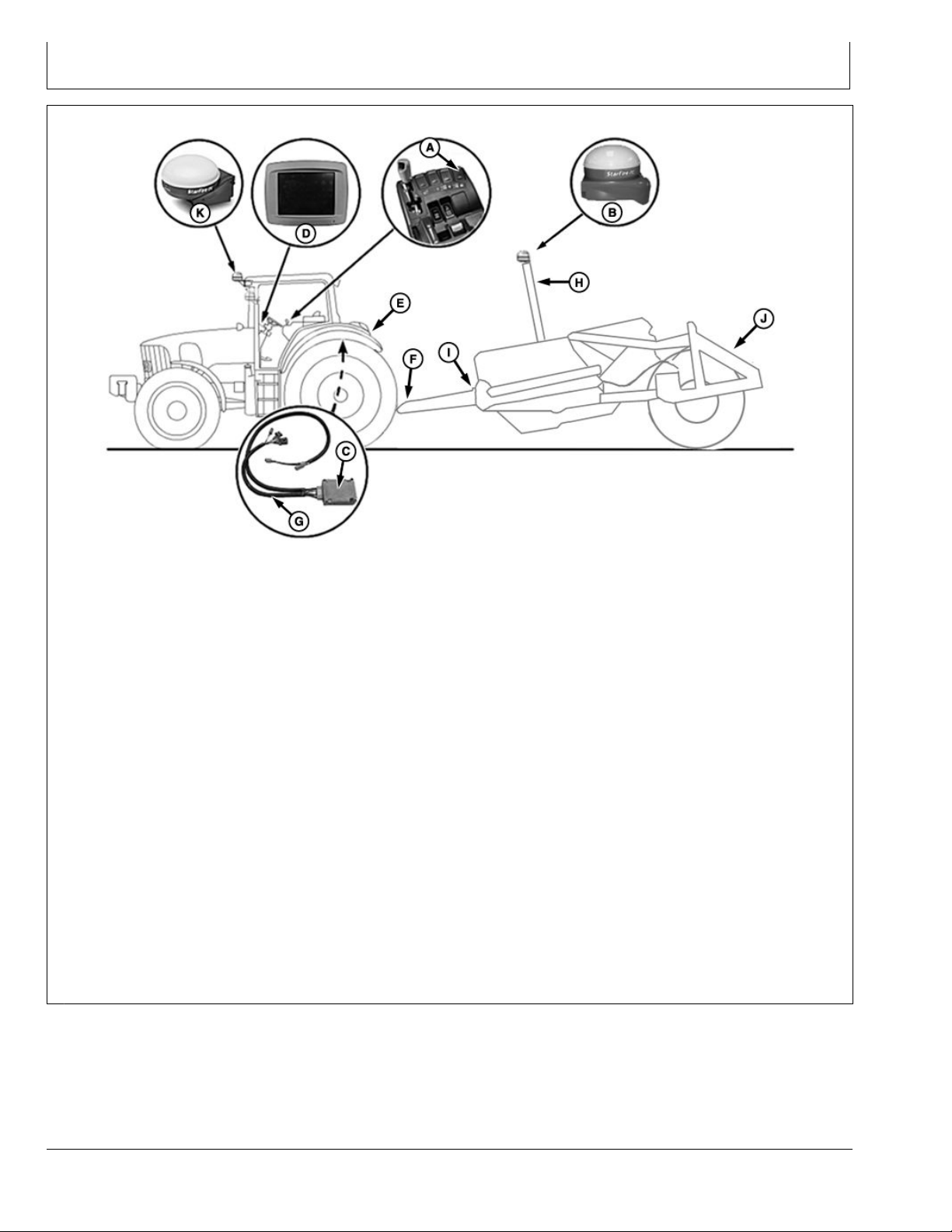

iGrade™ Components

System Components

A—SCV Control Lever

B—StarFire™ RTK Receiver with

Deluxe Shroud

C—Application Controller

Set SCV control lever (A) to AUTO or Actively

•

Controlling (AC) mode.

StarFire™ RTK Receiver (B) communicates elevation

•

of blade height to application controller (C). Receivers

require an RTK activation and radio installed for each

implement receiver and for each machine receiver

using Distance Trip and Max Cut.

Application controller calculates desired elevation

•

information from operator inputs entered in to display

(D).

SCV controller receives instructions from application

•

controller to automate blade height.

Constant adjustments are made to keep height at

•

targeted grade elevation.

Constant power harness (E) connects to convenience

•

outlet. Harness is routed to rear of cab where it

connects to front extension harness (F) and application

controller harnesses (G).

Front extension harness is available in two different

•

lengths 3 m (9.8 ft.) and 10 m (32.8 ft.). Harness

StarFire is a trademark of Deere & Company

D—Display

E—Constant Power Harness

F— Front Extension Harness

G—Application Controller

Harness

H—Implement Receiver

Application Harness

I— Center Extension Harness

J— Rear Extension Harness

connects to constant power harness and ISO implement

connector. Harness is routed along frame of machine

and connects to implement receiver application harness

(H).

If needed, center extension harness (I) extends

•

the distance between front extension harness and

implement receiver application harness. Harness is

available in two lengths 2 m (6.6 ft.) and 8 m (26.2 ft.).

Implement receiver application harness connects to

•

front extension harness and is routed up mast to

implement receiver.

NOTE: If a rear extension harness (J) is not used, a

terminator is needed at end of harness.

Rear extension harness (optional) provides ISO 9-pin

•

connector on rear of scraper.

K—StarFire™ RTK Receiver

RW00482,0000228 -19-11FEB14-1/1

PC18262 —UN—19DEC13

15-1

031214

PN=12

Page 13

SCV Setup

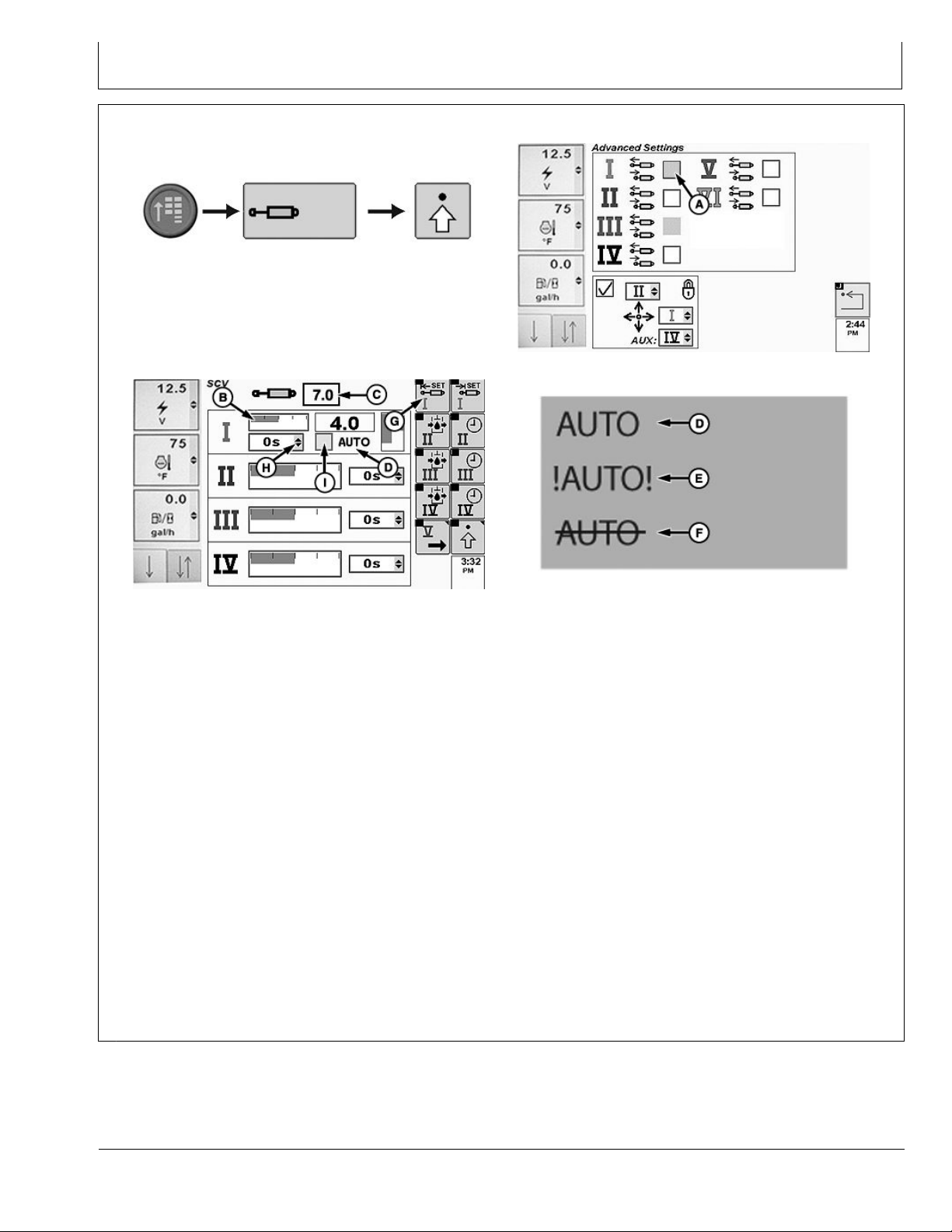

Configure SCVs On CommandCenter™ - Auto Mode

RXA0117610 —UN—10JUN11

CommandARM™ Menu Button > SCV Softkey > Ad-

A—Independent Mode Checkbox

B—Detent Flow Bar Graph

C—Detent Flow Value Box

vanced Settings Softkey

SCV Home Page

D—Auto Status Indicator (Normal

Operation)

E—Auto Status Indicator (Fault

Identified)

To use Auto mode, application controller must be installed

and connected to machine. When connected through

CAN Bus or implement connector, SCV(s) automatically

enter feature mode. SCV Home page with feature option

displays for selected SCVs. On Advanced Settings page,

specified SCV independent mode checkbox (A) is grayed

out.

1. Connect implement to machine.

2. Select Menu button.

3. Select SCV softkey.

SCV Advanced Settings Page

PC18245 —UN—20DEC13

Auto Mode Indicators

F— Auto Status Indicator (Turned

Off)

G—Extend Set Softkey

H—Auto Mode Checkbox

I— Detent Time Drop-down Menu

inoperable. AUTO with a strike through it (F)

indicates auto mode is not active.

5. Select Extend Set softkey (G) to navigate to detent flow

bar graph. Select Confirm button to highlight. Rotate

thumb wheel to adjust flow, then select Confirm button.

NOTE: Detent time drop-down (H) can only be adjusted

when auto mode checkbox (I) is unchecked.

If auto mode checkbox is checked, detent

time cannot be adjusted. Use standard mode

when adjusting detent time.

PC18244 —UN—17DEC13

PC18246 —UN—19DEC13

4. Select Advanced Settings softkey.

NOTE: Bar graph (B) depicts detent flow. Amount of

detent flow is shown in box (C).

AUTO (D) indicates normal auto mode operation.

!AUTO! (E) indicates a fault and auto mode is

CommandARM is a trademark of Deere & Company

6. To adjust detent, rotate thumb wheel to auto mode

checkbox to left of AUTO, then select Confirm button.

When checkbox is unselected, AUTO displays with a

strike through it.

RW00482,00001D4 -19-11FEB14-1/1

20-1

031214

PN=13

Page 14

SCV Setup

Adjust SCV Flow Rate

CAUTION: Excessive operating speed can cause

damage or injury. Full extension or retraction of

cylinder should take at least 2 seconds.

Adjust rate of operation for each job. Rate should be slow

enough to be safe, yet fast enough to be practical.

Change flow setting as follows:

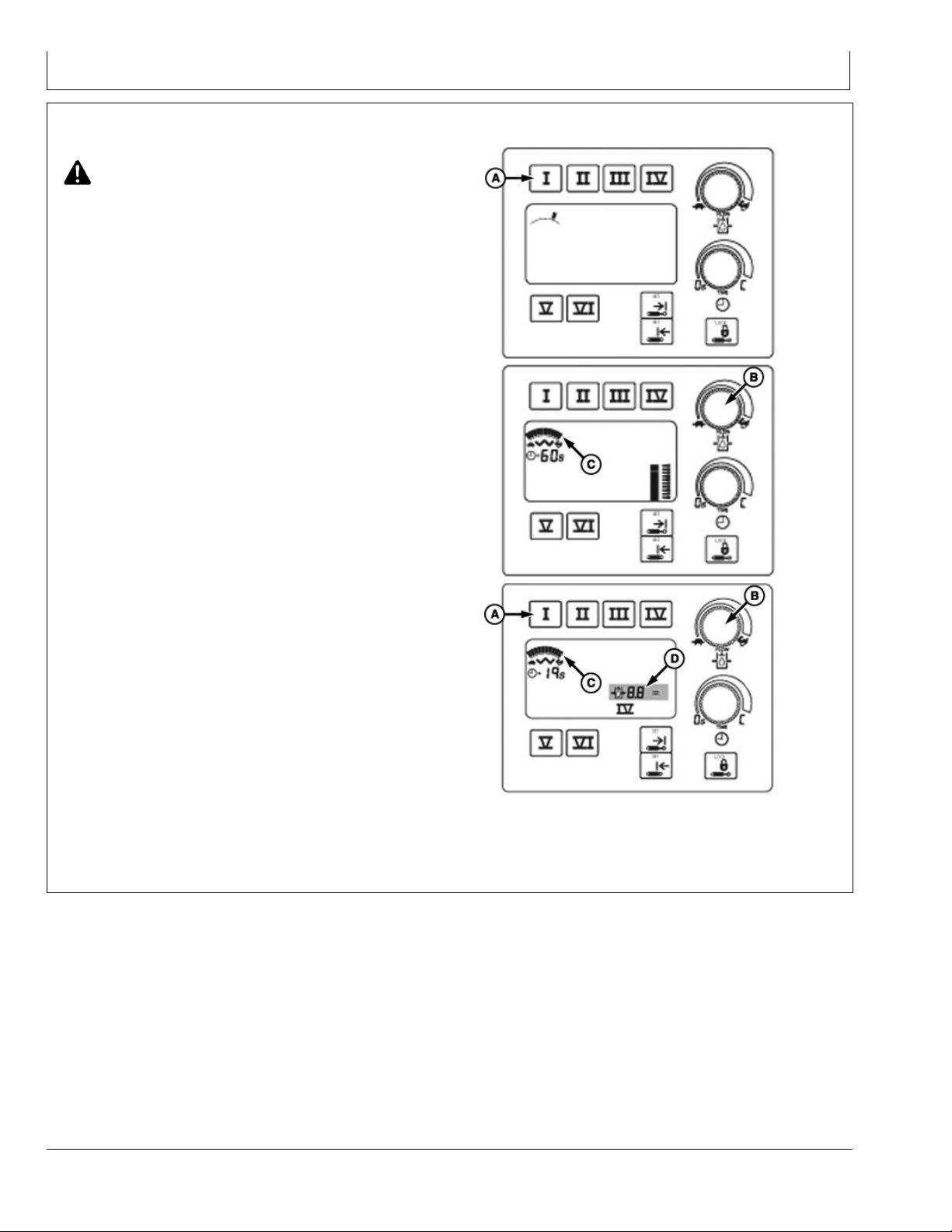

1. Press selected SCV switch (A). Display below touch

switch shows previous rate of flow.

NOTE: To provide operator with additional indication

of command setting, as operator “clicks” flow

knob (B) through the flow settings, the display

will increase or decrease the number of multiple

line increments as the flow changes.

2. Turn flow rate knob clockwise (rabbit) to increase

flow or counterclockwise (turtle) to decrease flow.

Flow setting is shown on bar graph display (C) when

adjustments are made.

NOTE: SCV can be operated to observe flow rate while

in adjustment mode. Reduced cylinder cycle times

and (or) a reduction in motor speed may result if

total flow demand exceeds available pump flow.

SCV FLOW OUTPUT (APPROXIMATE)

Flow

SCV Flow Settings L/min.

a

0.1

1.0 3.6 1.0

2.0 7.2 1.9

3.0 10.2 2.7

4.0 14.4 3.8

5.0 19.2 5.0

6.0 24.0 6.4

7.0 31.2 8.2

8.0 39.6 10.5

9.0 65.4 17.2

a

0.1 = Minimum Flow Setting

10.0 114 30.0

— —

gpm

A—SCV Switch

B—Flow Rate Knob

PC18357 —UN—13JAN14PC18358 —UN—13JAN14PC18359 —UN—13JAN14

C—Bar Graph Display

D—Multiple Dashes

RW00482,0000267 -19-10FEB14-1/1

20-2

031214

PN=14

Page 15

SCV Setup

Adjust Valve

NOTE: Flow rates between 11–30 L/min. (3—8

gpm) are recommended.

If hydraulic flow rate is adjusted, complete

SCV threshold calibration test.

1. Adjust hydraulic flow on machine to operators

preference, then adjust valve.

2. Loosen lock nut (A) on valve cartridge.

3. Use 1/4 turn increments to adjust valve. If implement is:

erratic or moves too fast, turn cartridge clockwise

•

until implement reaches desired operation.

slow or not responsive, turn cartridge

•

counterclockwise until implement reaches desired

operation.

A—Lock Nut

PC14814 —UN—29MAR12

B—Valve Cartridge

NOTE: Torque lock nut to 20—25 N·m (15–18 lb.-ft.).

4. Tighten lock nut on valve cartridge.

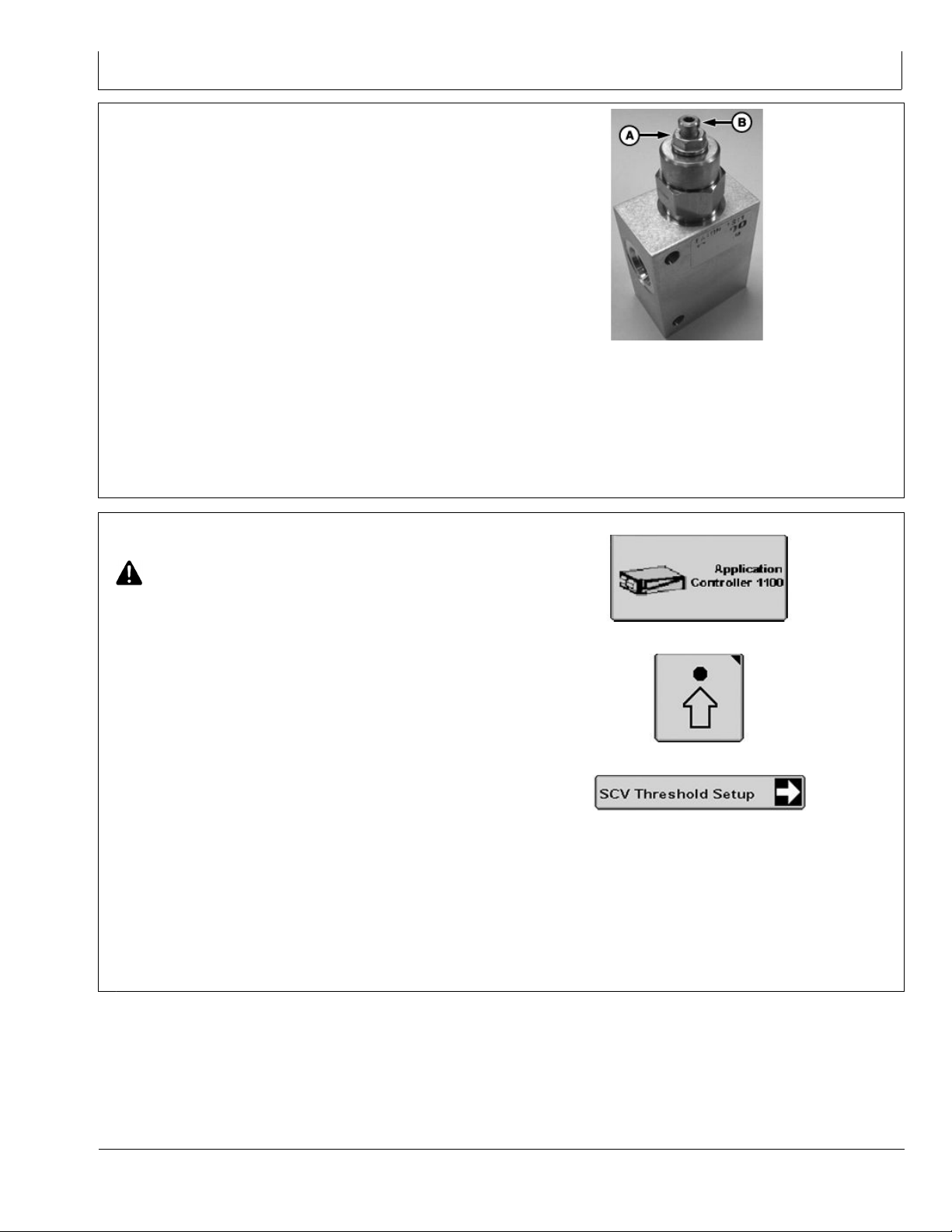

Calibrate SCV Thresholds

CAUTION: To avoid serious injury, keep area

around equipment clear. This procedure

requires machine to move forward.

Implement will move during calibration.

NOTE: Anytime an adjustment to system is made, such

as SCV hydraulic flow rate or counterbalance valve

adjustment, calibrate SCV threshold.

SCV threshold calibration is necessary for optimal

performance. Perform SCV threshold calibration each

time Application Controller with iGrade™ is installed on

a different machine. Without SCV threshold calibration,

scraper may move significantly faster in one direction,

undercompensate, overcompensate, or not perform as

expected due to hydraulic limitations.

To calibrate SCV, machine must move faster than 0.5

km/h (0.3 mph) to initiate hydraulic flow for SCV control.

Select SCV (1 or 3) then AC mode as indicated on SCV

control display. Implement does not need to be in working

(lowered) position to calibrate.

If acceptable performance is not reached after

adjusting valve, adjust hydraulic flow rate on machine

then readjust valve.

RW00482,00001EB -19-09JAN14-1/1

PC14926 —UN—27APR12

PC12961 —UN—29AUG11

PC18039 —UN—11NOV13

Application Controller 1100 Button

Setup Softkey

SCV Threshold Setup Button

2. Select Setup softkey.

3. Select SCV Threshold Setup button.

1. Select Application Controller 1100 button.

iGrade is a trademark of Deere & Company

Continued on next page RW00482,0000259 -19-06MAR14-1/2

20-3

031214

PN=15

Page 16

SCV Setup

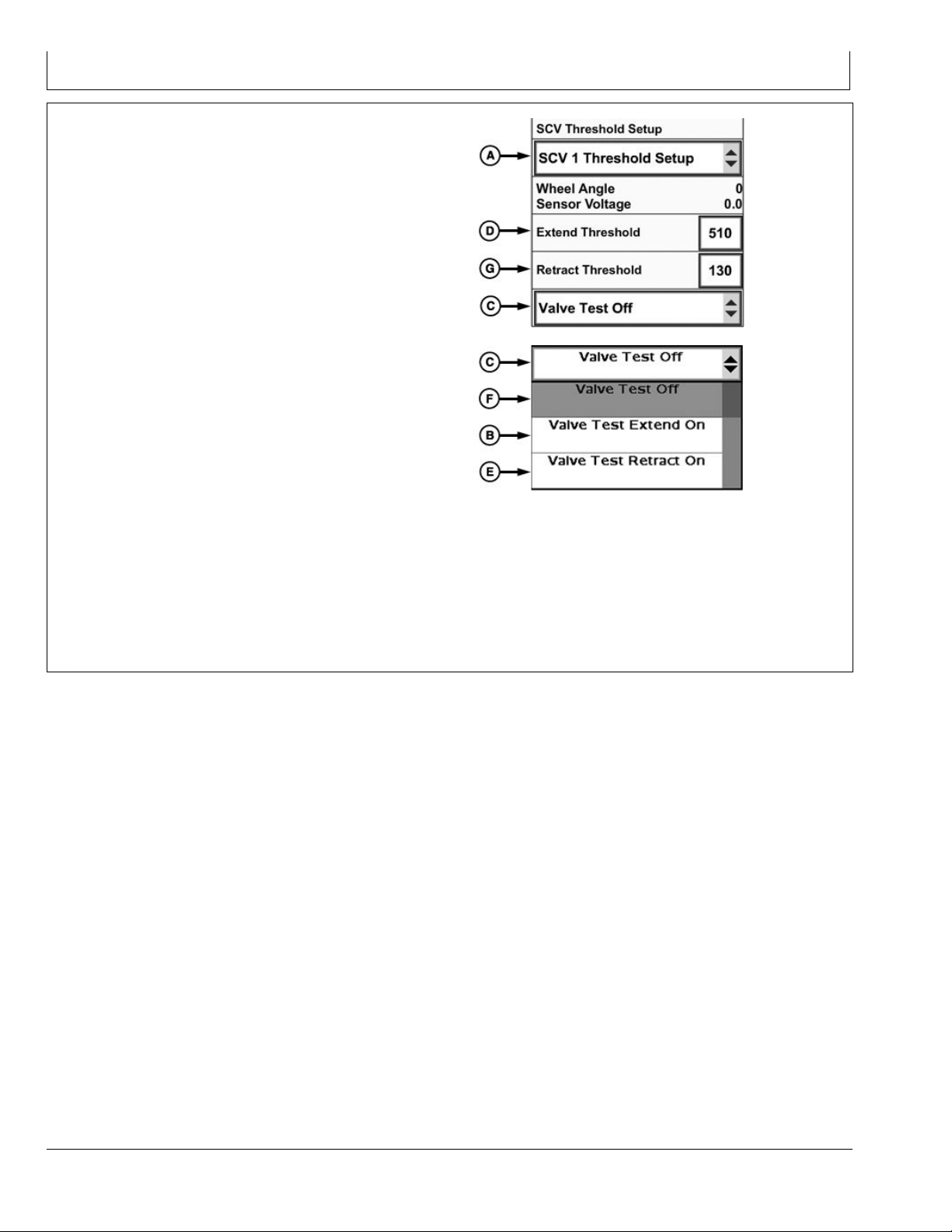

4. Select SCV being used from SCV Threshold Setup

drop-down (A).

5. Select Valve Test Extend On (B) from Valve Test

drop-down menu (C).

6. Place SCV lever into detent.

NOTE: Extend raises implement and retract

lowers implement.

7. Adjust Extend Threshold value (D) to lowest setting

that produces a steady, consistent motion.

If scraper height does not change, increase

•

Extend Threshold value, until minimal movement is

achieved.

If scraper moves quickly or erratically, decrease

•

Extend Threshold.

Repeat procedure as required to obtain a smooth,

•

constant change in scraper height.

Extend and Retract thresholds valves may have

•

different values.

8. Select Valve Test Retract On (E) from drop-down.

9. Repeat adjustment procedures used in Valve Test

Extend calibration.

10. Turn Valve Test Off (F) when calibration is complete.

If SCV flow rate is too high, scraper could be overly

sensitive and cause washboard effect.

SCV Threshold Setup

Valve Test Drop-down Menu

A—SCV Threshold Setup

Drop-down Menu

B—Valve Test Extend On

C—Valve Test Drop-down Menu

D—Extend Threshold

PC18407 —UN—23JAN14

PC18248 —UN—17DEC13

E—Valve Test Retract On

F— Valve Test Off

G—Retract Threshold

If SCV flow rate is too low, control and load limit

functionality could be impaired or limited.

RW00482,0000259 -19-06MAR14-2/2

20-4

031214

PN=16

Page 17

Basic Operation

Basic Operation

SCV controller is set to AC mode (A) by placing SCV

•

into detent position.

iGrade™ calculates elevation error using location of

•

StarFire™ Receiver(s) in relation to a desired elevation

set by operator.

When AUTO control is enabled and activated, and if

•

implement requires height adjustment to bring it back

on desired grade, a signal is sent from iGrade™,

through Application Controller harness, to machine

SCV controller.

SCV controller communicates instructions for sending

•

hydraulic fluid to implement control cylinder.

Entire process returns to first step to continually monitor

•

for any implement elevation error. Constant adjustments

are made to keep implement on desired grade.

NOTE: AUTO (B) indicates normal auto mode

operation. !AUTO! (C) indicates a fault and auto

mode is inoperable. AUTO with a strike through

it (D) indicates auto mode is not active.

If operating a machine with a CommandCenter™

•

display, select AUTO by placing a check in checkbox (E).

PC18217 —UN—05DEC13

SCV Controller Set in AC Mode

A—SCV Controller Set in AC

Mode

B—AUTO Status Indicator

(Turned On)

C—AUTO Status Indicator

(Fault Identified)

D—AUTO Status Indicator

(Turned Off)

E—AUTO Mode Checkbox

iGrade is a trademark of Deere & Company

StarFire is a trademark of Deere & Company

CommandCenter is a trademark of Deere & Company

F— Detent Time Drop-down

Menu

G—Detent Flow Bar Graph

H—Detent Flow Value Box

I— Extend Set Softkey

PC18218 —UN—05DEC13

SCV Homepage

PC18219 —UN—05DEC13

RW00482,000025E -19-20FEB14-1/1

25-1

031214

PN=17

Page 18

Basic Operation

Engage iGrade™

1. Set up control type display.

2. Using SCV controls, place SCV control lever (A) to

forward detent position to activate elevation control.

Engage SCV levers (A and B) if using dual scrapers.

3. Select SCV button on TouchSet™ display.

4. Verify EC on TouchSet™ display changes to AC (C).

If operating a machine with CommandCenter™

display, verify AUTO off (D) changes to AUTO on (E).

(For more information on CommandCenter™ SCV

controls refer to machine Operator's Manual.)

iGrade™ begins acquiring desired elevation immediately

after SCV is placed into forward detent if machine is

moving faster than 0.5 km/h (0.32 mph) and control type

has been properly set up.

A—SCV 1 Control Lever

B—SCV 3 Control Lever

C—AC Mode

D—AUTO Status Indicator

(Turned Off)

E—AUTO Status Indicator

(Turned On)

PC18249 —UN—19DEC13PC18250 —UN—20DEC13PC18251 —UN—20DEC13

TouchSet is a trademark of Deere & Company

CommandCenter is a trademark of Deere & Company

iGrade is a trademark of Deere & Company

25-2

RW00482,000025A -19-11FEB14-1/1

031214

PN=18

Page 19

Basic Operation

Dual Scrapers

Every receiver on CAN Bus is shown in display menu.

Each receiver button contains receiver serial number and

location (machine or implement).

Implement receivers are shown on display when they are

connected to receiver application harness. When using

dual scrapers, two implement receiver buttons are shown.

For dual scraper applications, SCV 1 must control front

scraper and SCV 3 must control rear scraper. Verify on

Implement receiver pages that each implement receiver

correlates to respective SCV movement.

NOTE: It is crucial to system performance to use lowest

serial numbered receiver on front scraper and

highest serial numbered receiver on rear scraper.

Dual scrapers require a receiver mounted on each

•

scraper.

Implement harnesses accommodate multiple receivers.

•

NOTE: Stored planes or grades are same for both

SCVs when using same control type. Setting

benchmark or zero point for front scraper

also sets rear scraper.

For dual scraper applications, threshold

calibrations must be performed for both

SCV 1 and SCV 3.

Selecting same control type for SCV 1 and SCV 3

•

allows dual scrapers to control same plane or grade.

iGrade is a trademark of Deere & Company

StarFire is a trademark of Deere & Company

Dual Scrapers

For best performance:

Mount receiver mast on center line of implement over

•

control point.

Receiver offsets can be entered for iGrade™. When

•

using multiple implements, install receivers at same

height from blade to receiver. If needed, adjust scraper

offsets for application purposes.

NOTE: When operating dual scrapers, use same model

of receiver on both implements. Only use two

StarFire™ iTC Receivers or two StarFire™ 3000

Receivers. Receivers calculate elevation differently.

When operating SWP+, use same receivers

(StarFire™ iTC or StarFire™ 3000) for collecting

elevation data for ditching operation.

RW00482,0000287 -19-11FEB14-1/1

PC17567 —UN—12AUG13

25-3

031214

PN=19

Page 20

Basic Operation

Load Limiting

Load Limiting raises scraper when Engine Speed

Threshold or Slip Threshold are exceeded to protect

machine. StarFire™ Receivers are required on both

machine and implement for full Load Limiting functionality.

Load Limiting auto mode functions with Grade Control,

Remote Control, and Plane Control.

1. Select Application Controller 1100 from main menu.

2. Select Main softkey.

3. Select Plane Control Setup, Remote Control Setup, or

Grade Control Setup button.

4. Select Load Parameter Setup button.

5. Enter Elevation Control Sensitivity.

Elevation Control Sensitivity allows operator to

adjust up and down movement of implement.

Elevation Control Sensitivity defaults to 2000, and

is adjustable between 10—10,001. For slower and

less aggressive up and down implement movement,

decrease value. For faster and more aggressive up

and down implement movement, increase value.

PC14926 —UN—27APR12

PC13072 —UN—16NOV10

PC18047 —UN—12NOV13

PC18049 —UN—12NOV13

PC18050 —UN—12NOV13

Application Controller 1100 Button

Main Softkey

Plane Control Setup Button

Load Parameter Setup Button

Elevation Control Sensitivity

StarFire is a trademark of Deere & Company

6. Select Load Limit Setup button.

7. Enable Load Limiting by selecting Load Limiting On

from drop-down (A). Disable Load Limiting by selecting

Load Limiting Off from drop-down.

8. Enter Engine Speed Threshold (B) and Slip Threshold

(C).

If either threshold is reached, system raises blade

until acceptable conditions are restored. Slip requires

machine receiver to function as ground speed source.

Engine Speed defaults to 1500 and Slip defaults to

15%.

A—Load Limiting Drop-down

Menu

B—Engine Speed Threshold

C—Slip Threshold

D—Load Limit Diagnostics

E—Back Button

RW00482,0000284 -19-11FEB14-1/2

PC18059 —UN—12NOV13

Load Limit Setup Button

PC18060 —UN—12NOV13

Load Limit Settings

RW00482,0000284 -19-11FEB14-2/2

25-4

031214

PN=20

Page 21

Basic Operation

Max Cut

NOTE: If using SF2 signal on machine receiver, Distance

Trip does not function and Max Cut must be disabled.

Max Cut allows operator to set a maximum amount of

cut implement takes in a single pass. Max Cut requires

machine and implement to have a StarFire™ Receiver

with RTK signal.

1. Select Application Controller 1100 button.

2. Select Main softkey.

3. Select Plane Control Setup, Remote Control Setup, or

Grade Control Setup button.

4. Select Load Parameter Setup button.

StarFire is a trademark of Deere & Company

PC14926 —UN—27APR12

PC13072 —UN—16NOV10

PC18047 —UN—12NOV13

PC18049 —UN—12NOV13

Application Controller 1100 Button

Main Softkey

Plane Control Setup Button

Load Parameter Setup Button

RW00482,0000285 -19-11FEB14-1/2

5. Enter Elevation Control Sensitivity.

Elevation Control Sensitivity allows operator to

adjust up and down movement of implement.

Elevation Control Sensitivity defaults to 2000, and

is adjustable between 10—10,001. For slower and

less aggressive up and down implement movement,

decrease value. For faster and more aggressive up

and down implement movement, increase value.

6. Select Max Cut Setup button.

7. Enable Max Cut by selecting Max Cut Enabled from

drop-down (A). Disable Max Cut by selecting Max Cut

Disabled from drop-down.

8. Operate implement manually to desired Max Cut

depth and select Set Max Cut Here button (B). Select

Shift Max Cut Down button (C) or Shift Max Cut Up

button (D) to increase or decrease maximum cut depth

in increments of 2 cm (0.79 in.).

A—Max Cut Drop-down Menu

B—Set Max Cut Here

C—Set Max Cut Down

D—Shift Max Cut Up

E—Back Button

PC18061 —UN—12NOV13

PC18062 —UN—12NOV13

Elevation Control Sensitivity

Max Cut Setup Button

PC18063 —UN—12NOV13

Max Cut Settings

RW00482,0000285 -19-11FEB14-2/2

25-5

031214

PN=21

Page 22

Basic Operation

Offsets

iGrade™ allows user to preset step size for shifting offsets

for Remote Control and Plane Control. For dual scraper,

setting offsets step size changes step size for both SCV 1

and SCV 3.

1. Select Application Controller 1100 button.

2. Select Main softkey.

3. Select Remote Control Setup or Plane Control Setup

for SCV 1. If using dual scrapers, selecting SCV 1 or

SCV 3 sets the same step size for both SCVs.

4. For Plane Control, select Parameter Setup. For

Remote Control, skip this step.

5. Select Offsets Setup.

6. Enter Offsets Step Size (A).

7. For dual scrapers, scraper 2 offset may be set higher

or lower than scraper 1.

1. Enter Scraper 2 Offset (B).

2. Select Scraper 2 Higher or Scraper 2 Lower from

drop-down menu (C).

A—Offsets Step Size

B—Scraper 2 Offset

C—Scraper 2 Drop-down Menu

PC14926 —UN—27APR12

PC13072 —UN—16NOV10

PC18047 —UN—12NOV13

PC18471 —UN—10FEB14

PC18474 —UN—10FEB14

PC18473 —UN—10FEB14

Application Controller 1100 Button

Main Softkey

Plane Control Setup Button

Remote Control Setup Button

Parameter Setup Button

iGrade is a trademark of Deere & Company

Offsets Setup Button

PC18472 —UN—10FEB14

Offsets

RW00482,0000286 -19-18FEB14-1/1

25-6

031214

PN=22

Page 23

Remote Control—Surface Water Pro™ Plus

Theory of Operation

SWP+ is an advanced ditching program that generates a

“best fit drain.” SWP+ calculates the most effective drain in

a field while moving the least amount of soil. Information

is generated from vertical GPS signals calculated from

the StarFire™ Receiver. SWP+ requires an RTK enabled

receiver on implement and SF2 or RTK enabled receiver

on machine.

StarFire is a trademark of Deere & Company

Apex is a trademark of Deere & Company

Control Selection

1. Select Setup softkey.

2. Select Control Selection button.

3. Select Remote Control from SCV 1 Control Type

drop-down.

NOTE: Remote Control can utilize dual scrapers. When

utilizing dual scraper functionality, use SCV 1 for

front scraper and SCV 3 for rear scraper.

4. Select Back button.

Remote Control feature automatically controls blade

height to a desired elevation calculated from ditches

created in Apex™ or by SWP+ software on the display.

NOTE: If using SF2 signal on machine receiver, Distance

Trip does not function and Max Cut must be disabled.

RW00482,000024C -19-11FEB14-1/1

PC12961 —UN—29AUG11

PC17972 —UN—07NOV13

PC18065 —UN—12NOV13

Setup Softkey

Control Selection Button

PC17974 —UN—07NOV13

SCV 1 Control Type Drop-down Menu

Back Button

RW00482,00001F1 -19-09JAN14-1/1

30-1

031214

PN=23

Page 24

Remote Control—Surface Water Pro™ Plus

Operation

NOTE: Separate offsets can be placed in Remote Control

Main and on SWP+ Create/Edit Drain page. If

system is not cutting to grade, check both offsets.

Offsets are based on designed ditch, not ground level

(distance off grade, not a maximum cut limit).

(Refer to Surface Water Pro™ Operator Manual for

in-depth information on SWP.)

1. Select Main softkey.

2. Select Remote Control Main button.

After SCV(s) have been placed in detent and AC enabled,

iGrade™ controls blade height to grade.

Offsets are changed in increments.

•

Set Offset—Zero Error (A) takes current error and

•

applies it as an offset to the designed ditch.

Shift offsets are useful when implement is attempting to

•

control an elevation that machine cannot attain. Shift

Offset Up (B) to achievable cut and Shift Offset Down

(C) back to 0 over subsequent passes.

A—Set Offset—Zero Error

B—Shift Offset Up

C—Shift Offset Down

PC13072 —UN—16NOV10

PC18066 —UN—12NOV13

Main Softkey

Remote Control Main Button

PC18067 —UN—12NOV13

Remote Control Main

Surface Water Pro is a trademark of Deere & Company

iGrade is a trademark of Deere & Company

30-2

PC12524 —UN—23MAR10

SWP+ Create/Edit Drain Page

RW00482,00001F2 -19-19FEB14-1/1

031214

PN=24

Page 25

Remote Control—Serial Port

Theory of Operation

The John Deere Application Controller allows the ability

to connect with 3rd Party Software through the use of

a serial connection. This functionality may be useful

if you currently use an additional software package to

provide capabilities such as cut/fill mapping and would

like the John Deere Application Controller to connect and

communicate with this software. After a serial connection

Message Definition

The John Deere Application Controller can use two types

of command messages.

Elevation Setpoint

The 3rd Party software can send a commanded elevation

to the Application Controller. The implement will be

controlled such that the implement receiver elevation

attempts to match the setpoint elevation. The message

protocol is as follows:

$JD,ELEV, 274.32 Carriage Return

Where the elevation value is in meters and can handle

two decimal places. Ensure that there are no spaces and

that the carriage return ends the message.

is established, the 3rd Party Software can send setpoint

commands that the Application Controller will use to

automatically control elevation on an implement. This is

accomplished using the serial port on the controller and

the operation specific message protocols. The controller

is also capable of retransmitting GPS data to the third

party software using the same serial port, eliminating the

need for an additional connection.

JS56696,00009A2 -19-25APR11-1/1

Depth Setpoint

The 3rd Party software can send a commanded depth to

the Application Controller. The implement will be controlled

such that the implement receiver elevation attempts

to match the setpoint depth. When using this mode a

machine receiver will be needed to calculate the elevation

of the ground surface. Offsets will need to be used to

account for height differences between the machine and

implement receivers. The message protocol is as follows:

$JD,DEPTH, 1.54 Carriage Return

Where the depth value is in meters and can handle two

decimal places. Ensure that there are no spaces and that

the carriage return ends the message.

CZ76372,0000236 -19-15NOV10-1/1

Serial Port Hardware

Remote Control harnesses for third-party software must

follow these guidelines.

NOTE: Contact your John Deere dealer to order parts.

Harness does not come assembled.

Part Number Description

57M9804

57M8164

—

—

Mating Connector to Controller Harness

Pins for 57M9804

DB9 Plug Connector Assembly

2.5 m (8 ft.) of 0.5 mm

2

(20 AWG) wire

PC17350 —UN—06NOV13

Serial Port Wiring Pinouts

Quantity

1

3

1

3

RW00482,00001EC -19-11FEB14-1/1

35-1

031214

PN=25

Page 26

Remote Control—Serial Port

Serial Port Setup

1. Select Setup softkey.

2. Select Serial Port Setup button.

NOTE: Baud Rate is the data transfer rate used

for commands from third-party software as

well as GPS position data going to third-party

software, if applicable.

3. Select Baud Rate from drop-down menu (A).

4800

•

9600

•

19200

•

38400

•

4. If utilizing Application Controller to retransmit

StarFire™ implement position data through serial

port, select National Marine Electronics Association

(NMEA) messages needed by third-party software

from drop-down (B).

NOTE: If not using Application Controller to send

StarFire™ implement position data through

serial port, select NMEA Off.

NO NMEA

•

NMEA GGA

•

NMEA GGA, GSA

•

NMEA GGA, GSA, RMC

•

NMEA ALL

•

5. If utilizing Application Controller to retransmit

StarFire™ implement position data though serial port,

select data frequency needed by third-party software

from drop-down (C).

1 Hz

•

5 Hz

•

6. If utilizing third-party software to show an as applied

map, Last Altitude allows a third receiver on last

StarFire is a trademark of Deere & Company

PC12961 —UN—29AUG11

PC18252 —UN—17DEC13

A—Baud Rate Drop-down

Menu

B—NMEA Message Drop-down

Menu

C—NMEA Rate Drop-down

Menu

Setup Softkey

Serial Port Setup Button

Serial Port Setup

D—Last Altitude Drop-down

Menu

E—Back Button

implement for elevation data. John Deere does

not have an approved setup for this application.

Customer must determine best installation setup for

this application.

RW00482,00001ED -19-11FEB14-1/1

PC18071 —UN—13NOV13

35-2

031214

PN=26

Page 27

Remote Control—Serial Port

Control Selection

1. Select Setup softkey.

2. Select Control Selection button.

NOTE: Remote Control can utilize dual scrapers. SCV

1 must be used for front scraper and SCV 3

for rear scraper. When utilizing dual scraper

functionality, change SCV Control Type for both

SCV 1 and SCV 3 to Remote Control.

3. Select Remote Control from SCV 1 control type

drop-down (A).

4. Select Back button (B).

A—SCV 1 Control Type

Drop-down Menu

B—Back Button

PC12961 —UN—29AUG11

PC17972 —UN—07NOV13

Setup Softkey

Control Selection Button

PC18072 —UN—10DEC13

Control Selection

RW00482,00001F3 -19-28JAN14-1/1

Operation

Offsets are based on desired command from third-party

software, not ground level (distance off grade, not a

maximum cut limit).

1. Select Main softkey.

2. Select Remote Control Main button.

After SCV(s) have been placed in detent and AC enabled,

iGrade™ controls blade height to grade.

Set Offset—Zero Error (A) takes current error and

•

applies it as an offset to desired command.

Shift offsets are useful when implement is attempting to

•

control an elevation that machine cannot attain. Shift

Offset Up (B) to achievable cut and Shift Offset Down

(C) back to 0 over subsequent passes.

When setting zero point in Remote Control a value is

displayed next to Offset. This value represents difference

between surveyed receiver elevation and elevation of

front implement receiver when zeroing error.

A—Set Offset—Zero Error

B—Shift Offset Up

iGrade is a trademark of Deere & Company

C—Shift Offset Down

PC13072 —UN—16NOV10

PC18066 —UN—12NOV13

Main Softkey

Remote Control Main Button

PC18067 —UN—12NOV13

Remote Control Main

RW00482,00001D6 -19-11FEB14-1/1

35-3

031214

PN=27

Page 28

Grade Control

Theory of Operation

Grade Control automatically controls scraper to a defined

slope over a GPS distance. Grade may be defined by the

Grade Calculator or operator inputs (slope and direction)

at point of origin on slope. Slope direction is calculated

based on GPS logic. North corresponds to an angle of 0°

and 360°. Angles increase clockwise in degrees with a full

circle equaling 360°. Direction of travel does not affect

grade and system automatically fills or cuts during uphill

or downhill operation. The slope causes an increase in

elevation over a given distance for uphill operations and

decreases in elevation for downhill operations.

PC18421 —UN—28JAN14

A—Point of Origin (Start Point)

B—Starting Grade

C—Finished Grade

D—Slope %

E—Area Cut (Dirt Removed)

F— Area Filled (Dirt Added)

G—North = 0°/360°

H—East = 90°

I— South = 180°

J— West = 270°

K—Slope Direction (Degrees)

Grade Calculator

1. Select Setup softkey.

2. Select Control Selection button.

3. Select Grade Control for SCV 1 (or SCV 1 and SCV

3 for dual scrapers).

4. Select Main softkey.

5. Select Grade Control Setup button.

PC12961 —UN—29AUG11

PC17972 —UN—07NOV13

PC18075 —UN—13NOV13

PC13072 —UN—16NOV10

RW00482,0000271 -19-11FEB14-1/1

Setup Softkey

Control Selection Button

Grade Control Drop-down Menu

PC18076 —UN—13NOV13

Continued on next page RW00482,0000218 -19-11FEB14-1/2

Main Softkey

Grade Control Setup Button

40-1

031214

PN=28

Page 29

Grade Control

6. Enter Slope (A) if known or use Grade Calculator (B)

to calculate slope.

NOTE: Use front scraper as SCV 1 to define grade

when utilizing dual scrapers.

Grade Calculator (B) records a series of points and

calculates slope to connect end points of recorded path.

Select Start Grade Calculator (C) to reset Grade

•

Calculator, clear any previous data, and take start

position.

Drive to end position and select Stop Grade Calculator.

•

Grade Statistics are displayed on screen.

•

If data appears correct, select Set as Grade Control

•

Slope (D).

Operator must drive same path during operation recorded

with Grade Calculator. If same path is not driven, final

elevation may not match desired or recorded elevation

due to a different distance traveled. Make sure that

scraper remains in a constant position during data

collection (for example: in up position).

PC18077 —UN—10DEC13

Grade Control Setup

A—Slope

B—Grade Calculator

C—Start/Stop Grade Calculator

D—Set as Grade Control Slope

Selecting Grade

After entering desired grade, go to start point for grade

and lower cutting edge.

1. Select Main softkey.

2. Select Grade Control Main button.

3. Select Grade Direction (A) machine will travel (uphill

or downhill).

NOTE: Uphill is a positive slope and downhill is

a negative slope.

4. Select Start Grade (B).

Front scraper sets grade. For dual scrapers, raise front

pan when full and place rear pan into auto mode. If pan(s)

are full before grade is complete, select Pause button (C)

to stop grade and empty pan(s). Return to spot grade

was paused and lower front scraper cutting edge back to

desired grade. Select Resume and continue grade. Pause

and resume as needed until desired grade is completed.

PC13072 —UN—16NOV10

PC18409 —UN—24JAN14

PC18078 —UN—10DEC13

Grade Calculator

RW00482,0000218 -19-11FEB14-2/2

Main Softkey

Grade Control Main Button

A—Grade Direction

B—Start Grade

C—Pause/Resume

40-2

PC18410 —UN—24JAN14

Grade Control Main

RW00482,000026C -19-19FEB14-1/1

031214

PN=29

Page 30

Plane Control

Theory of Operation

Plane Control automatically controls scraper to cut to

defined plane. Defined planes can be a single sloped

plane or a dual sloped plane. Planes may be defined by the

Plane Calculator or operator inputs (slope and direction)

for a set origin point on plane. Slope direction is calculated

based on GPS logic and in the down slope direction. North

corresponds to an angle of 0° and 360°. Angles increase

clockwise in degrees with a full circle equaling 360°. The

system allows operator to set up two independent planes

that can be used as a cut and a fill plane.

The Plane Calculator can create a best fit plane based

on recorded elevation data. Once all data has been

collected, a best fit plane is created.

A—North = 0°/360°

B—East = 90°

C—South = 180°

D—West = 270°

E—Slope 0.12%, Down Slope

Direction 160°

F— Slope1 0.12%, Down Slope

Direction1 270°

G—Slope2 0.14%, Down Slope

Direction2 180°

PC18420 —UN—28JAN14

Slope Direction

Single Slope

Dual Slope

PC18411 —UN—12FEB14

PC18412 —UN—28JAN14

RW00482,000026D -19-12FEB14-1/1

45-1

031214

PN=30

Page 31

Plane Control

Control Selection

1. Select Setup softkey.

2. Select Control Selection Button.

3. Select Plane Control from SCV 1 Control Type

drop-down menu.

NOTE: For ease of instruction, this manual uses SCV 1

for the iGrade™ system. Turn other SCV Controls

to OFF unless using dual scrapers.

iGrade is a trademark of Deere & Company

Select Active Plane

1. Select Main softkey.

2. Select Plane Control Setup button.

PC12961 —UN—29AUG11

PC17972 —UN—07NOV13

PC18413 —UN—27JAN14

SCV Control Type Drop-down Menu

PC13072 —UN—16NOV10

Setup Softkey

Control Selection Button

RW00482,0000262 -19-12FEB14-1/1

3. Select active plane from Plane Control Setup

drop-down menu.

NOTE: Both SCVs control same active plane if same

control type is selected for both SCVs.

PC18047 —UN—12NOV13

PC18414 —UN—27JAN14

Plane Control Setup Drop-down Menu

Main Softkey

Plane Control Setup Button

RW00482,000026E -19-26JAN14-1/1

45-2

031214

PN=31

Page 32

Plane Control

Single Slope Plane

1. Select plane to define from Plane Control Setup

drop-down menu.

2. Select Single Slope Entry button.

3. Enter plane Slope (A) and Slope Direction (B) if

known, or use Plane Calculator.

4. Drop scraper on point of origin and select Set Plane

Origin (C).

NOTE: If running dual scrapers, use front scraper

(SCV1) to set plane origin.

A—Slope

B—Slope Direction

C—Set Plane Origin Button

D—North = 0°/360°

E—East = 90°

F— South = 180°

G—West = 270°

H—Slope 0.12%, Down Slope

Direction 160°

PC18414 —UN—27JAN14

PC18415 —UN—27JAN14

Plane Control Setup Drop-down Menu

Single Slope Entry Button

PC18416 —UN—28JAN14

Single Slope Entry

Single Slope

PC18423 —UN—28JAN14

RW00482,000026F -19-12FEB14-1/1

45-3

031214

PN=32

Page 33

Plane Control

Dual Slope Plane

1. Select plane to define from Plane Control Setup

drop-down menu.

2. Select Dual Slope Entry button.

3. Select Dual Slope Input button.

4. Enter plane Slope1 (A), Down Slope Direction1 (B),

plane Slope2 (C), and Down Slope Direction2 (D) if

known, or use Plane Calculator.

NOTE: Slope direction allows operators to define desired

direction of slopes in relation to each other. Slope

directions can be at any angle to one another.

5. Select Dual Slope Setup button to return to Dual Slope

Entry page to set plane origin.

6. Drop scraper to a point on the plane and press Set

Plane Origin button. The plane is created at the

elevation of the set origin.

NOTE: If running dual scrapers, use front scraper

(SCV1) to set plane origin.

A—Slope1

B—Down Slope Direction1

C—Slope2

D—Down Slope Direction2

E—Back Button

F— North = 0°/360°

G—East = 90°

H—South = 180°

I— West = 270°

J— Slope1 0.12%, Down Slope

Direction1 270°

K—Slope2 0.14%, Down Slope

Direction2 180°

PC18414 —UN—27JAN14

PC18417 —UN—27JAN14

PC18419 —UN—27JAN14

Plane Control Setup Drop

Dual Slop Entry Button

Dual Slope Input Button

PC18418 —UN—04FEB14

Dual Slope Input

45-4

PC18422 —UN—28JAN14

Dual Slope

RW00482,0000270 -19-12FEB14-1/1

031214

PN=33

Page 34

Plane Control

Plane Calculator

Theory of Operation

Plane calculator records a series of elevation points

(approximately every 1.5 m [5 ft.]) and stores elevation

data. When data collection is turned off, iGrade™

generates a best fit plane and displays calculated slope

and direction. If given slope and direction look realistic,

select Save to Active Plane button (A). Start (Stop) Data

Collection (B) can continuously record by leaving data

collection on or only record desired points of interest

by turning data collection on and off between points to

generate the best fit plane.

If calculated plane does not appear correct, collect and

save more data points to active plane, or plane data

can be cleared and collection restarted. Plane created

displays in both Single and Dual Sloped Entries pages.

Tips

Use front scraper as SCV 1 to define plane, if utilizing

•

dual scrapers.

Collecting more points results in better accuracy.

•

Scatter data points (do not drive in straight line unless

•

collecting data from the entire area).

Clear plane data at start of every new plane. Uncleared

•

data is applied to current plane.

Edit calculated plane information, if needed, through

•

Single or Dual Slope entry pages after saving created

plane to active plane.

Ensure that scraper remains in a constant position

•

during data collection (for example, in up position).

Plane Calculator assumes a 1:1 cut-fill ratio.

•

Plane Calculator calculates a plane origin based on

•

height of implement receiver during data collection.

Origin can be shifted to an actual on-grade point by

selecting Set Plane Origin button in either Single Slope

or Dual Slope Entry pages or by using offsets.

iGrade is a trademark of Deere & Company

PC18084 —UN—13NOV13

Plane Calculator Button

Plane Calculator

A—Save to Active Plane

B—Start (Stop) Data Collection

1. Select Plane Calculator.

2. If new plane, clear Plane Data (C).

3. Select Start Data Collection to gather data.

4. Turn off data collection and review calculated slope

and heading.

5. If correct, select Save to Active Plane to accept and

enter plane information in both Single and Dual Slope

Entry pages for selected active plane.

C—Clear Plane Data

D—Back Button

RW00482,000021B -19-12FEB14-1/1

PC18365 —UN—13JAN14

Dual Scraper

Dual Scrapers can be used with Plane Control or Grade

•

Control.

Select the same control type for each SCV.

•

Plane setup can be completed with either SCV control.

•

Only one plane is used for both scrapers.

Front scraper (SCV 1) must be used for Plane and

•

Grade Calculators and to set plane origins.

A—SCV 1 Main

B—SCV 1 Setup

C—SCV 3 Main

D—SCV 3 Setup

E—Version Information

45-5

PC18088 —UN—13NOV13

Plane Control — Dual Scraper

RW00482,000021C -19-09JAN14-1/1

031214

PN=34

Page 35

Plane Control

Operation

1. Select Active Plane (A).

2. Use Shift Offset Up (B) and Shift Offset Down (C) to

adjust designed plane.

When pan cut is too aggressive, select Shift Offset

•

Up button to obtain an achievable cut. Shift offset

back to 0.00 on subsequent passes.

When pan cut is not aggressive enough, select Shift

•

Offset Down button to obtain an achievable cut. Shift

offset back to 0.00 on subsequent passes.

Plane shift offsets are based on previously designed

•

plane, not ground level. Offsets shift entire plane

up or down.

iGrade™ cuts to active plane as long as machine is in AC

(A) or AUTO mode (B) and moving faster than 0.5 km/h

(0.3 mph). When scraper is full, raise scraper and unload.

Place machine back in AC or AUTO mode and iGrade™

returns blade elevation to active plane.

Plane Control Main

A—Active Plane Drop-down

B—Shift Offset Up

PC18089 —UN—13NOV13

C—Shift Offset Down

RW00482,00001EE -19-26JAN14-1/2

A—SCV Controller Set in AC

Mode

B—AUTO Status Indicator

C—AUTO Mode Checkbox

D—Detent Time Drop-down

Menu

E—Detent Flow Bar Graph

F— Detent Flow Value Box

G—Extend Set Softkey

PC12522 —UN—31MAR10

SCV Controller Set in AC Mode

PC18264 —UN—20DEC13

SCV Homepage

RW00482,00001EE -19-26JAN14-2/2

45-6

031214

PN=35

Page 36

Distance Trip

Theory of Operation

Distance Trip collects GPS distance and cycles SCV

controller based off a predetermined interval. Controller

calculates where trip needs to occur based off a furrow

heading in degrees and distance between furrows. This

Select Distance Trip

NOTE: If using SF2 signal on machine receiver, Distance

Trip does not function and Max Cut must be disabled.

1. Select Setup softkey.

2. Select Control Section button.

NOTE: Distance Trip is only available on SCV 1.

3. On Control Selection drop-down for SCV 1, select

Distance Trip. Select OFF for all other SCV(s).

calculation allows direction of travel to be at varying

angles to furrow. Distance Trip operation requires RTK

enabled machine and implement receivers. Distance Trip

works off GPS distance, not elevation.

RW00482,000025B -19-12FEB14-1/1

PC12961 —UN—29AUG11

PC17972 —UN—07NOV13

PC18093 —UN—13NOV13

Control Selection Drop-down Menu

Setup Softkey

Control Selection Button

RW00482,000025C -19-12FEB14-1/1

50-1

031214

PN=36

Page 37

Distance Trip

Distance Trip Setup

1. Select Main softkey.

2. Select Distance Trip Setup button.

Furrow Heading (A) – Angle or heading of furrows (rows)

in reference to North (0°). To determine furrow heading,

center machine over furrow and obtain heading from

display.

Interval Distance (B) – Distance between parallel furrows.

GPS Offsets to Implement (C) – Distance from machine

receiver and working point of implement.

Implement Width (D) – Distance between furthest

working points of an implement.

Trip Time (E) – Time in seconds SCV completes a cycle.

A—Furrow Heading

B—Interval Distance

C—GPS Offset to Implement

D—Implement Width

E—Trip Time

PC13072 —UN—16NOV10

PC18094 —UN—13NOV13

Main Softkey

Distance Trip Setup Button

PC18095 —UN—13NOV13

Distance Trip Setup

50-2

PC18424 —UN—28JAN14

Distance Trip Setup

RW00482,00001EF -19-12FEB14-1/1

031214

PN=37

Page 38

Distance Trip

Initiating Trip Cycle

1. Select Main softkey.

2. Select Distance Trip Main button.

Trigger First Trip (A) – Cycles SCV controller and sets

current locations as origin point to calculate distance.

Manual Trip (B) – Cycles SCV without distance setup or

setting current point as origin.

Left or Right Furrow Position (C) – Allows iGrade™ to

calculate correct GPS distance based off which side of

implement furrow is located to trip implement.

A—Trigger First Trip

B—Manual Trip

iGrade is a trademark of Deere & Company

C—Furrow Position

PC13072 —UN—16NOV10

PC18425 —UN—28JAN14

Main Softkey

Distance Trip Main Button

PC18426 —UN—28JAN14

Distance Trip Main

RW00482,0000272 -19-12FEB14-1/1

Adjusting Trip Cycle

Stop Tripping (A) – Stops measuring distance and

tripping SCV.

Trip Earlier (B) – Shifts preset trip interval to occur sooner

but does not decrease interval distance.

Trip Later (C) – Shifts preset trip interval to occur later but

does not increase interval distance.

Each press of Trip Earlier or Trip Later buttons changes

trip distance by 5 cm (2 in.).

A—Stop Tripping

B—Trip Earlier

C—Trip Later

PC18427 —UN—28JAN14

Distance Trip Main

RW00482,0000263 -19-28JAN14-1/1

50-3

031214

PN=38

Page 39

Disconnecting iGrade™

Disconnect iGrade™ System

NOTE: If an electronic failure occurs, hydraulic control

can be set to operate in normal, manual mode.

Without electronic control, automatic implement

height adjustments are not possible.

Disconnection procedure for changing machine or

implement:

1. Shut off machine, set parking brake, and remove key.

2. Disconnect implement receiver harness at ISO 9-pin

connector (A).

3. Disconnect constant power harness.

NOTE: Once completed, machine SCV control

reverts to normal manual operation.

4. Disconnect lighting connector (B) and all other

implement connections related to releasing equipment

from machine.

Disconnection procedure for electronic failure:

On Application Controller Setup menu, select Control

•

Selection.

On Control Selection drop-down, select Off.

•

After Off has been selected, cycle machine power and

•

iGrade™ will be disabled.

Disconnection procedure for permanent removal:

Shut off machine, set parking brake, and remove key.

•

Disconnect application controller from rear ISO

•

connector.

iGrade is a trademark of Deere & Company

Rear View of Machine

A—ISO Connector B—Lighting Connector

Remove controller and components following

•

procedures in Application Controller installation

instructions.

RW00482,000024D -19-12FEB14-1/1

PC12191 —UN—05OCT09

55-1

031214

PN=39

Page 40

Troubleshooting

Troubleshooting — iGrade™ System

A—Status Code Location

Status Code

No GPS

Cycle Power

No RTK

Update GPS SW

OK

Symptom Problem Solution

No GPS correction available. Ensure StarFire™ Receiver on implement and

Controller must be restarted to communicate with new

function.

No RTK correction received from selected StarFire™

Receiver, or RTK not currently available.

Incompatible software loaded. Update software on implement StarFire™ Receiver(s)

System is ready to be operated. Any faults still

occurring are likely to be independent of iGrade™

control system.

Monitor screen not readable on

hookup to machine

Description

No communications with implement

controller.

PC18096 —UN—13NOV13

Grade Control Setup Screen

machine are connected and functioning properly.

Shut OFF machine and start again.

Activate RTK on implement StarFire™ Receiver and

(or) machine StarFire™ Receiver.

to compatible version.

System is working properly.

Shut off power, check connections,

and power up to reboot system.

Check 4-pin DEUTSCH® connector

at back of ISO implement connector

on machine for cleanliness and proper

attachment.

Solution

Paused

Shows current state of Grade Control. Grade Control is currently paused.

No remote commands Display is not set up to send proper

elevation error from Surface Water

Pro™ Plus.

StarFire is a trademark of Deere & Company

iGrade is a trademark of Deere & Company

DEUTSCH is a trademark of Deutsch Co.

Surface Water Pro is a trademark of Deere & Company

Verify connector at head of implement

is seated and tight.

Either restart or resume operation.

Make sure that display software is

up-to-date or that Surface Water

Pro™ Plus is set up correctly.

RW00482,00001D7 -19-12FEB14-1/1

60-1

031214

PN=40

Page 41

Troubleshooting — I/O Voltages Page

Description Reading

Analog In Pin 1 (Pin G2)

Analog In Pin 2 (Pin K2)

Analog Out Pin 1 (Pin H1)

Analog Out Pin 2 (Pin J1)

5 Volt Out Supplied voltage 0–5 V for system.

Sense Volt

Digital In 1 (Pin G1)

Digital In 2 (Pin K1)

Line Count Not applicable for iGrade™ system.

Wheel angle sensor voltage reading:

Wheel angle sensor voltage reading:

Command SCV 1 voltage value 0–5 V,

Command SCV 3 voltage value 0–5 V,

with 9-pin implement feedback harness

with paddle pot connected = 0 V and

Troubleshooting

SCV 1 = 0–5 V,

2.5 V = neutral (center)

SCV 2 = 0–5 V,

2.5 V = neutral (center)

2.5 V = neutral

2.5 V = neutral

Sense voltage 0–5 V:

connected = 5 V,

changes with command

External valve paddle pot:

0 = no command,

1 = command

Value displays a 1

System Definitions

Not applicable for iGrade™ system.

When set up for SCV 1, voltage commanded

to hydraulics controller, or current command

voltage of respective SCV when not

in Auto mode.

When set up for SCV 3, voltage commanded

to hydraulics controller, or current command

voltage of respective SCV when not

in Auto mode.

Voltage supplied to the system, should

read close to 5 V.

Voltage coming from hydraulic controller

system, should read approximately 5 V.

Not applicable for iGrade™ system.

iGrade is a trademark of Deere & Company

RW00482,00001F0 -19-12FEB14-1/1

60-2

031214

PN=41

Page 42

Troubleshooting

Troubleshooting — Machine

Symptom Problem Solution

AC not showing on TouchSet™

display.

Machine is not adjusting to desired

grade.

Loss of display and operation of

implement.

Washboarding — scraper overly

sensitive and causes washboard

effect.

Dirty or loose 10-pin connector at rear

of machine.

Power down machine and disconnect

all iGrade™ components. Clean all

connectors and check for lose or

dirty pins. Reconnect all iGrade™

components and power up machine.

Verify correct control type and SCV

are selected in iGrade™ setup and

power has cycled.

EC displayed on SCV display. Push correct SCV control lever into

detent to bring up AC mode.

Dirty or loose 4-pin connection at rear

of machine.

GreenStar™ harness improperly

connected.

Clean connectors and reconnect

tightly.

Power down machine and system,

then disconnect harness, clean, and

install properly.

Electrical short in harness.

Check electrical wiring for breaks,

shorts, and damage.

SCV’s flow rate is too high. Adjust SCV flow rate down.

Counterbalance valve improperly

adjusted.

Readjust counterbalance valve

cartridges and perform threshold

calibration.

Control and load limit functionality

impaired or limited.

TouchSet is a trademark of Deere & Company

iGrade is a trademark of Deere & Company

GreenStar is a trademark of Deere & Company

SCV’s flow rate is too low. Adjust SCV flow rate up.

RW00482,00001D8 -19-12FEB14-1/1

60-3

031214

PN=42

Page 43

Maintenance

iGrade System