Page 1

HR-G1100

Generator

Operator’s Manual 1

Page 2

Introduction

THANK YOU for purchasing a John Deere product.

READ THIS MANUAL carefully to learn how to operate

and service your machine correctly. Failure to do so could

result in personal injury or equipment damage. This manual

and safety signs on your machine may also be available in

other languages. (See your John Deere dealer to order.)

THIS MANUAL SHOULD BE CONSIDERED a permanent

part of your machine and should remain with the machine

when you sell it.

MEASUREMENTS in this manual are given in both

metric and customary U.S. unit equivalents. Use only

correct replacement parts and fasteners. Metric and inch

fasteners may require a specific metric or inch wrench.

RIGHT HAND AND LEFT HAND sides are determined by

facing the control panel end of the machine.

The SERIAL NUMBER is located in the Specification or

Identification Numbers section. Accurately record all the

numbers to help in tracing the machine should it be stolen.

Your dealer also needs these numbers when you order

parts. File the identification numbers in a secure place

off the machine.

WARRANTY is provided from your John Deere dealer for

customers who operate and maintain their equipment as

described in this manual. The warranty is explained on

the warranty certificate shown in this manual.

This warranty provides you the assurance that your

dealer will back products where defects appear within

the warranty period. Should the equipment be abused,

or modified to change its performance beyond the original

factory specifications, the warranty will become void.

2 Operator’s Manual

Page 3

Introduction

NOTICE

FEDERAL EMISSION COMPONENT DEFECT WARRANTY and CALIFORNIA EMISSION CONTROL WARRANTY

are applicable to only those engines / generators complied with EPA (Environmental Protection Agency) and CARB

(California Air Resources Board) emission regulations in the U.S.A.

NOTICE

To the engines / generators exported to and used in the countries other than the U.S.A., warranty service shall be

performed by the distributor in each country in accordance with the standard Robin engine / generator warranty policy

as applicable.

AIR INDEX

To show compliance with California emission regulations, a hang tag has been provided displaying the Air Index level

and durability period of this engine.

The Air Index level defines how clean an engine’s exhaust is over a period of time. A bar graph scaled from “0” (most

clean) to “10” (least clean) is used to show an engine’s Air Index level. A lower Air Index level represents cleaner

exhaust from an engine.

The period of time (in hours) that the Air Index level is measured is known as the durability period. Depending on the

size of the engine, a selection of time periods can be used to measure the Air Index level (see below).

Descriptive Term

Moderate: 50 hours (engine from 0 to 80 cc)

125 hours (engine greater than 80 cc)

Intermediate: 125 hours (engine from 0 to 80 cc)

250 hours (engine greater than 80 cc)

Extended: 300 hours (engine from 0 to 80 cc)

500 hours (engine greater than 80 cc)

Notice: This hang tag must remain on the engine or piece of equipment, and only be removed by the ultimate purchaser

before operation.

Applicable to Emissions Durability Period

Operator’s Manual 3

Page 4

Introduction

FEDERAL EMISSIONS COMPONENT DEFECT WARRANTY

EMISSIONS COMPONENT DEFECT WARRANTY COVERAGE -- This emission warranty is applicable in all States, except the state of

California.

Fuji Heavy Industries Ltd. and Robin America Inc., Wood Dale Illinois, (herein “ROBIN AMERICA”) warrant(s) to the initial retail purchaser and each

subsequent owner, that this Non-road engine (herein “engine”) has been designed, built, and equipped to conform at the time of initial sale to all

applicable regulations of the U.S.

Environmental Protection Agency (EPA), and that the engine is free of defects in materials and workmanship which would cause this engine to fail

to conform with EPA regulations during its warranty period.

For the components listed under PARTS COVERED, the service dealer authorized by ROBIN AMERICA will, at no cost to you, make the necessary

diagnosis, repair, or replacement necessary to ensure that the engine complies with applicable U.S. EPA regulations.

EMISSIONS COMPONENT DEFECT WARRANTY PERIOD

The warranty period for this engine begins on the date of sale to the

initial purchaser and continues for a period of two years.

PARTS COVERED

Listed below are the parts covered by the Emission Components

Defect Warranty. Some of the parts listed below may require scheduled

maintenance and are warranted up to the first scheduled replacement

point for that part.

1. Fuel Metering System

a. Carburetor and internal parts (and / or pressure regulator or fuel

injection system).

b. Air / fuel ratio feedback and control system, if applicable.

c. Cold start enrichment system, if applicable.

d. Regulator assembly (gasoline fuel, if applicable).

2. Air Induction System

a. Intake manifold, if applicable.

b. Air filter.

OWNER’S WARRANTY RESPONSIBILITIES

As the engine owner, you are responsible for the performance of the

required maintenance listed in your owner’s manual. ROBIN AMERICA

recommends that you retain all receipts covering maintenance on

your engine, but ROBIN AMERICA cannot deny warranty solely for

the lack of receipts or for your failure to ensure the performance of all

scheduled maintenance.

As the engine owner, you should however be aware that ROBIN

AMERICA may deny warranty coverage if your engine or a part has

failed due to abuse, neglect, improper maintenance or unapproved

modifications.

You are responsible for the presenting your engine to the nearest service

dealer authorized by ROBIN AMERICA when a problem exists.

If you have any questions regarding your warranty rights and

responsibilities, you should contact the ROBIN AMERICA customer

service department at 1-630-350-8200 for the information.

THINGS YOU SHOULD KNOW ABOUT THE EMISSION

CONTROL SYSTEM WARRANTY MAINTENANCE AND

REPAIRS

3. Ignition System

a. Spark plugs.

b. Magneto or electronic ignition system.

c. Spark advance / retard system, if applicable.

4. Exhaust manifold, if applicable.

5. Miscellaneous items used in above systems.

a. Electronic controls, if applicable.

b. Hoses, belts, connectors, and assemblies.

c. Filter lock assembly (gaseous fuel, if applicable).

OBTAINING WARRANTY SERVICE

To obtain warranty service, take your engine to the nearest authorized

Robin America. Bring your sales receipts indicating date of purchas

for this engine. The service dealer authorized by ROBIN AMERICA

will perform the necessary repairs or a

amount of time and furnish you with a copy of the repair order. Al

and accessories replaced under this warranty become the property of

ROBIN AMERICA.

WHAT IS NOT COVERED

Conditions resulting from tampering, misuse, improper adjustment

(unless they were made by the service dealer authorized by

AMERICA during a warranty repair), alteration, accident, failure to use

the recommended fuel and oil, or not performing required maintenance

services.

The replacement parts used for required maintenance services.

Consequential damages such as loss of time, inconvenience, loss of

use of the engine or equipment, etc.

Diagnosis and inspection charges that do not result in warranty-eligible

service being performed.

Any non-authorized replacement part, or malfunction of authorized

parts due to use of non-authorized parts.

4 Operator’s Manual

djustments within a reasonable

e

l parts

ROBIN

You are responsible for the proper maintenance of the engine. You

should keep all receipts and maintenance records covering the

performance of regular maintenance in the event questions arise.

These receipts and maintenance records should be transferred to each

subsequent owner of the engine. ROBIN AMERICA reserves the right to

deny warranty coverage if the engine has not been properly maintained.

Warranty claims will not be denied, however, solely because of the lack

of required maintenance or failure to keep maintenance records.

MAINTENANCE, REPLACEMENT OR REPAIR OF EMISSION

CONTROL DEVICES AND SYSTEMS MAY BE PERFORMED BY ANY

REPAIR ESTABLISHMENT OR INDIVIDUAL;

HOWEVER, WARRANTY REPAIRS MUST BE PERFORMED BY

A SERVICE DEALER AUTHORIZED BY ROBIN AMERICA. THE

USE OF PARTS THAT ARE NOT EQUIVALENT IN PERFORMANCE

AND DURABILITY TO AUTHORIZED PARTS MAY IMPAIR THE

EFFECTIVENESS OF THE EMISSION CONTROL SYSTEM AND MAY

HAVE A BEARING ON THE OUTCOME OF A WARRANTY CLAIM.

If other than the parts authorized by ROBIN AMERICA are used for

maintenance replacements or for the repair of components affecting

emission control, you should assure yourself that such parts are

warranted by their manufacturer to be equivalent to the parts authorized

by ROBIN AMERICA in their performance and durability.

HOW TO MAKE A CLAIM

All repair qualifying under this limited warranty must be performed by

a service dealer authorized by ROBIN AMERICA. In the event that

any emission-related part is found to be defective during the warranty

period, you shall notify ROBIN AMERICA customer service department

at 1-630-350-8200 and you will be advised of the appropriate warranty

service dealer or service providers where the warranty repair can be

performed.

Page 5

Introduction

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and Fuji Heavy Industries Ltd. (herein “FUJI”) are pleased to explain the emission control system warranty on

your 2005 and later Small Off-Road engine (herein “engine”). In California, new engine must be designed, built and equipped to meet the State’s

stringent anti-smog standards. FUJI must warrant the emission control system on your engine for the periods of time described below, provided

there has been no abuse, neglect or improper maintenance of your engine. Your emission control system may include parts such as the carburetor

or fuel-injection system, and the ignition system. Also included may be hoses, belts, connectors and other emission-related assemblies. Where a

warrantable condition exists, ROBIN AMERICA will repair your engine at no cost to you including diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE:

The 2005 and later engines are warranted for two (2) years. If any emission related part on your engine is defective, the part will be repaired or

replaced by ROBIN AMERICA.

OWNER’S WARRANTY RESPONSIBILITIES:

- As the engine owner, you are responsible for the performance of the required maintenance listed in your Owner’s Manual. ROBIN AMERICA

recommends that you retain all receipts covering maintenance on your engine, but FUJI cannot deny warranty solely for the lack of receipts or

for your failure to ensure the performance of all scheduled maintenance.

- As the engine owner, you should however, be aware that

neglect, improper maintenance or unapproved modifications.

- Your are responsible for presenting your engine to a s

Wood Dale, IL 60191 (herein ROBIN AMERICA) as soon as a problem exists. The warranty repairs should be completed in a reasonable amount

of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should

at 1-630-350-8200.

FUJI may deny you warranty coverage if your engine or a part has failed due to abuse,

ervice dealer or warranty station authorized by ROBIN AMERICA Inc. 940 Lively Blvd.,

contact Robin America Inc. Customer Service Department

LIMITED WARRANTY

on Emission Control Systems

- California Only -

FUJI warrants to the owner of the 2005 and later engine that the engine (1) has been designed, built and equipped so as to conform at the time of

manufacture with the applicable regulations of the California Air Resources Board, and (2) is free from defects in materials and workmanship that

could cause it to fail to conform with those regulations as may be applicable in the terms and conditions stated below.

A. COMMENCEMENT DATE

The warranty period begins on the date the engine is delivered to a

first retail purchaser.

B. LENGTH OF COVERAGE

FUJI warrants to a first retail purchaser and each subsequent purchaser

that the engine is free from defects in materials and workmanship that

cause the failure of a warranted emission-related part for a period of

two (2) years after the date of delivery to the first retail purchaser.

C. WHAT IS COVERED

1. REPAIR OR REPLACEMENT PARTS

Repairs and replacement of any warranted part will be performed at

no charge to you by an authorized service dealer or a warranty

station. You may contact the Robin America Inc. Customer Service

Department at 1-630-350-8200 to obtain the name of the nearest

appropriate location where your warranty repairs are performed.

2. WARRANTY

This warranty continues for a period of two (2) years and applies

only to the repair, replacement or adjustment of the co

parts that are not scheduled for replacement as required

maintenance. Further, component parts w

for regular inspection to the effect of “repair or replace as

necessary” are warranty for the warranty period. Any warranted

part which is scheduled for replacement as required

maintenance is warranted for the period of time up to the first

scheduled replacement point for that part.

3. DIAGNOSIS

You will not be charged for diagnostic labor that leads to the

determination that a warranted part is defective, if the diagnostic

work is performed at an authorized service dealer or warranty

station.

4. DAMAGES

If a warranted part failed causing damage to the engine

components, consult an warranty station.

PERIOD

mponent

hich are scheduled only

D. WHAT IS NOT COVERED

1. This limited warranty does not cover any part which malfunctions,

fails or is damaged due to failure to follow the maintenance and

operating instructions set forth in the 2005 and later Owner’s Manual

including:

a. Improper maintenance of any warranted parts.

b. Improper installation, adjustment or repair of the engine or of

any warranted part unless performed by an authorized service

dealer.

c. Failure to follow recommendations on fuel use contained in the

2005 and later Owner’s Manual.

d. Repairs performed outside of the authorized warranty service

dealers.

e. Use of parts which are not authorized by FUJI.

2. Add-on or modified parts.

This warranty does not cover any part that malfunctions, fails or is

damaged due to alterations by changing, adding to or removing

parts from the engine.

3. Expenses incurred by processing warranty-claims.

FUJI, any authorized service dealer and warranty station

shall not be liable for any loss of use of the engine, for any

alternative usage, for any damage to goods, loss of time or

inconvenience.

E. HOW TO FILE A CLAIM

All repairs qualifying under this Limited Warranty must be performed

by a dealer who sold you the engine or warranty station authorized by

ROBIN AMERICA. In the event that any emission-related part is found

to be defective during the warranty period, you must notify the Robin

America Inc. Customer Service Department at

you will be advised of the appropriate warranty service facilities where

the warranty repair is to be performed.

1-630-350-8200 and

Operator’s Manual 5

Page 6

Introduction

F. WHERE TO OBTAIN WARRANTY SERVICE

It is recommended that warranty service be performed by the authorized

dealer who sold you the engine, although warranty service will be

performed by any authorized service dealers or warranty stations

anywhere in the United States.

When warranty repair is needed, the engine must be brought to an

authorized service dealer or warranty station’s place of business during

normal business hours. In all cases, a reasonable time, not to exceed

30 days, must be allowed for the warranty repair to be completed after

the engine is received by the authorized service dealer or warranty

station.

G. MAINTENANCE, REPLACEMENT AND REPAIR OF

H. PARTS COVERED UNDER THE CALIFORNIA EMISSIONS

WARRAN

1. Fuel Metering System

a. Carburetor and internal parts (and / or pressure regulator or fuel,

b. Air / fuel ratio feedback and control system, if applicable.

c. Cold start enrichment system, if applicable.

d. Regulator assembly (gaseous fuel, if applicable).

2. Air Induction System

a. Intake manifold, if applicable.

b. Air filter.

TY

injection system).

EMISSION-RELATED PARTS

Only warranted engine replacement parts approved by FUJI should

be used in the performance of any warranty maintenance or repairs

on emission-related parts. If other than authorized parts are used for

maintenance, replacement or repair of components affecting emission

control, you should assure yourself that such parts are warranted by

their manufacturer to be equivalent to authorized parts in performance

and durability. FUJI, however, assumes no liability under this warranty

with respect to parts other than authorized parts. The use of nonauthorized replacement parts does not invalidate the warranty on

other components unless the non-authorized parts cause damage to

warranted parts.

3. Ignition System

a. Spark Plug.

b. Magneto or electronic ignition system.

c. Spark advance / retard system, if applicable.

4. Exhaust manifold, if applicable.

5. Miscellan

a. Electronic controls, if applicable.

b. Hoses, belts, connectors, and assemblies.

c. Filter lock assembly (gaseous fuel, if applicable

eous items used in above systems.

).

I. MAINTENANCE STATEMENTS

It is your responsibility to have all scheduled inspection and maintenance services performed at the times recommended in the 2005 and later

Owner’s Manual and to retain proof that inspection and maintenance services are performed at the times when recommended. FUJI will not deny

a warranty claim solely because you have no record of maintenance; however, FUJI may deny a warranty claim if your failure to perform required

maintenance resulted in the failure of warranted part. The proof which you maintain should be given to each subsequent owner of the engine. You are

responsible for performing the scheduled maintenance described below based on the procedures specified in the 2005 and later Owner’s Manual.

The scheduled maintenance below is based on a normal engine operating schedule.

PROCEDURE: INTERVAL:

1. Change engine oil. 1. Initial 20 hours and every 100 hours afterward.

2. Clean air cleaner (element). 2. Every 50 hours.

3. Replace air cleaner element. 3. Every 200 hours.

4. Clean and adjust spark plug and electrodes. 4. Every 200 hours.

NOTE: More frequent maintenance may be necessary under dusty, dirty or severe conditions.

6 Operator’s Manual

Page 7

Contents

Page

Safety ........................................................................ 9

Safety Signs ...........................................................16

Controls ................................................................. 17

Preparing the Generator ........................................ 20

Operation ................................................................ 25

Troubleshooting ..................................................... 31

Service .................................................................... 32

Storage .................................................................... 36

Specifications ......................................................... 37

Wire Diagram ........................................................... 38

Warranty .............................................................39-41

Notes ........................................................................ 42

All information, illustrations and specifications in this manual are based

on the latest information available at the time of publication. The right is

reserved to make changes at any time without notice.

Operator’s Manual 7

Page 8

Contents

8 Operator’s Manual

Page 9

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

Safety

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol

on your machine or in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A signal word--DANGER, WARNING or CAUTION--is used

with the safety-alert symbol. DANGER identifies the most

serious hazards.

DANGER or WARNING safety signs are located near

specific hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual and

safety signs on your machine. Keep safety signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from your John Deere dealer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machine in proper working condition.

Unauthorized modifications to the machine may impair the

function and/or safety and affect machine life.

If you do not understand any part of this manual and need

assistance, contact your John Deere dealer.

Operator’s Manual 9

Page 10

CARBON MONOXIDE - POISONOUS GAS

Use generator outdoors, away from open windows, vents, or

doors. Keep generator at least 1 meter (3 feet) away from any

structure or building during use.

Generator exhaust contains carbon monoxide - a poisonous

gas that can kill you. You CAN

Never use a generator in enclosed or partially-enclosed spaces.

Generators can produce high levels of carbon monoxide very

quickly. When you use a portable generator, remember that you

cannot smell or see carbon monoxide. Even if you can’t smell

exhaust fumes, you may still be exposed to carbon monoxide.

If you start to feel sick, dizzy, or weak while using a generator, get

to fresh air RIGHT AWAY. DO NOT DELAY. The carbon mono

from generators can rapidly lead to full incapacitation and death.

If you experience serious symptoms, get medical attention

immediately. Inform medical staff

is suspected. If you experienced symptoms while indoors, have

someone call the fire department to determine when it is

re-enter the building.

NEVER operate the generator in an explosive atmosphere, near

combustible materials or where ventilation is not sufficient to carry

away exhaust fumes. Exhaust fumes can cause serious injury

or death.

NOT smell or see this gas.

xide

that carbon monoxide poisoning

safe to

NEVER use a generator indoors, including in homes, garages,

basements, crawl spaces, and other enclosed or partially-enclosed

areas, even with ventilation. Opening doors and windows

fans will not prevent carbon monoxide build-up in the home.

Follow the instructions that come with your generator. Locate the

unit outdoors and away from doors, windows, and vents that could

allow the carbon monoxide gas to come indoors.

ONLY run generator outdoors and away from air intakes.

NEVER run generator inside homes, garages, sheds, or other

semi-enclosed spaces. These spaces can trap poisonous gases

EVEN IF you run a fan or open doors and windows.

If you start to feel sick, dizzy, or weak while using the generator,

shut if off and get fresh air RIGHT AWAY. See a doctor. You may

have carbon monoxide poisoning.

Install battery-operated carbon monoxide alarms or plug-in carbon

monoxide alarms with battery back-up in your home, according to

the manufacturer’s installation instructions. The carbon mono

alarms should be certified to the requirements of the la

standards for carbon monoxide alarms. (UL 2034, IAS 6-96, or

CSA 6.19.01).

or using

xide

test safety

Test your carbon monoxide alarm frequently and replace dead

batteries.

10 Operator’s Manual

Page 11

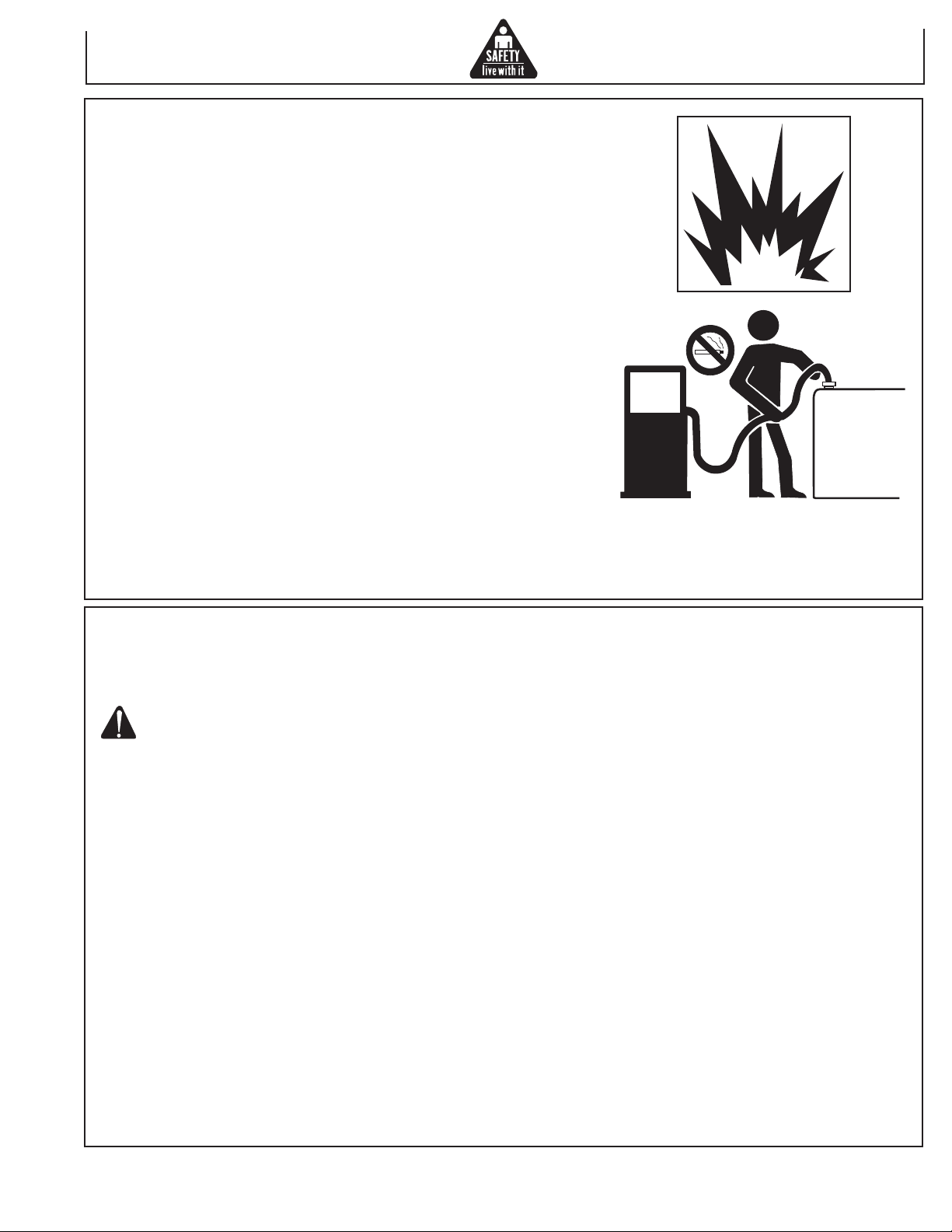

SAFETY WARNING WHEN REFUELING

Gasoline is extremely flammable and its vapors can explode if

ignited.

Observe all safety regulations for the safe handling of fuel. Handle

fuel in safety containers. If the container does not have a spout, use

a funnel.

Do not overfill the fuel tank, leave room for the fuel to expand.

Do not refill fuel tank while the engine is running. Before refueling

the generator, turn it off and let it cool down. Gasoline spilled on hot

engine parts could ignite.

Fill the tank only on an area of bare ground. While fueling the tank,

keep heat, sparks and open flame away. Carefully clean up any

spilled fuel before starting engine.

Always fill fuel tank in an area with plenty of ventilation to avoid

inhaling dangerous fumes.

NEVER store fuel for your generator in the home. Gasoline, pro

kerosene, and other flammable liquids should be stored outside of living

areas in properly-labeled, non-glass safety containers. Do not store

them near a fuel-burning appliance, such as a natural gas water heater

in a garage. If the fuel is spilled or the container is not sealed properly,

invisible vapors from the fuel can travel along the ground and can be

ignited by the appliance’s pilot light or by arcs from electric switches

in the appliance.

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION

These generators are equipped with a GFCI (Ground Fault Circuit

Interrupters) 120V duplex receptacles for protection against the hazards

of electrical shock from defective attachments such as, tools, cords,

and cables.

WARNIN G: The GF CI may not function unless the

ge n e ra t o r i s p r op e r ly g r ou n d ed . F o ll o w

the correct procedure specified in the section

labeled “GROUNDING INSTRUCTIONS”.

A GFCI is a device that interrupts electricity from either the utility or

generator by means of a special type of circuit breaker if a fault current

flow to the ground occurs.

A GFCI can be used only with generators that have the neutral wire

internally bonded to the frame, and the frame properly grounded to the

earth. A GFCI will not work on generators that do not have the neutral

wire bonded to the frame, or on generators which have not been properly

grounded. All John Deere generators have internally bonded ground

wires. A GFCI will not work if the unit is not properly grounded.

pane,

A GFCI may be required by OSHA regulations, the National Electric

Code and/or local and federal codes when operating a generator.

For additional protections against shock hazards due to defective

equipment attached to the twist-lock receptacles, consider the use of

a GFCI on each of these receptacles as well.

GFCI and GFCI protected cord sets and cables may be purchased from

local electrical supply houses.

Operator’s Manual 11

Page 12

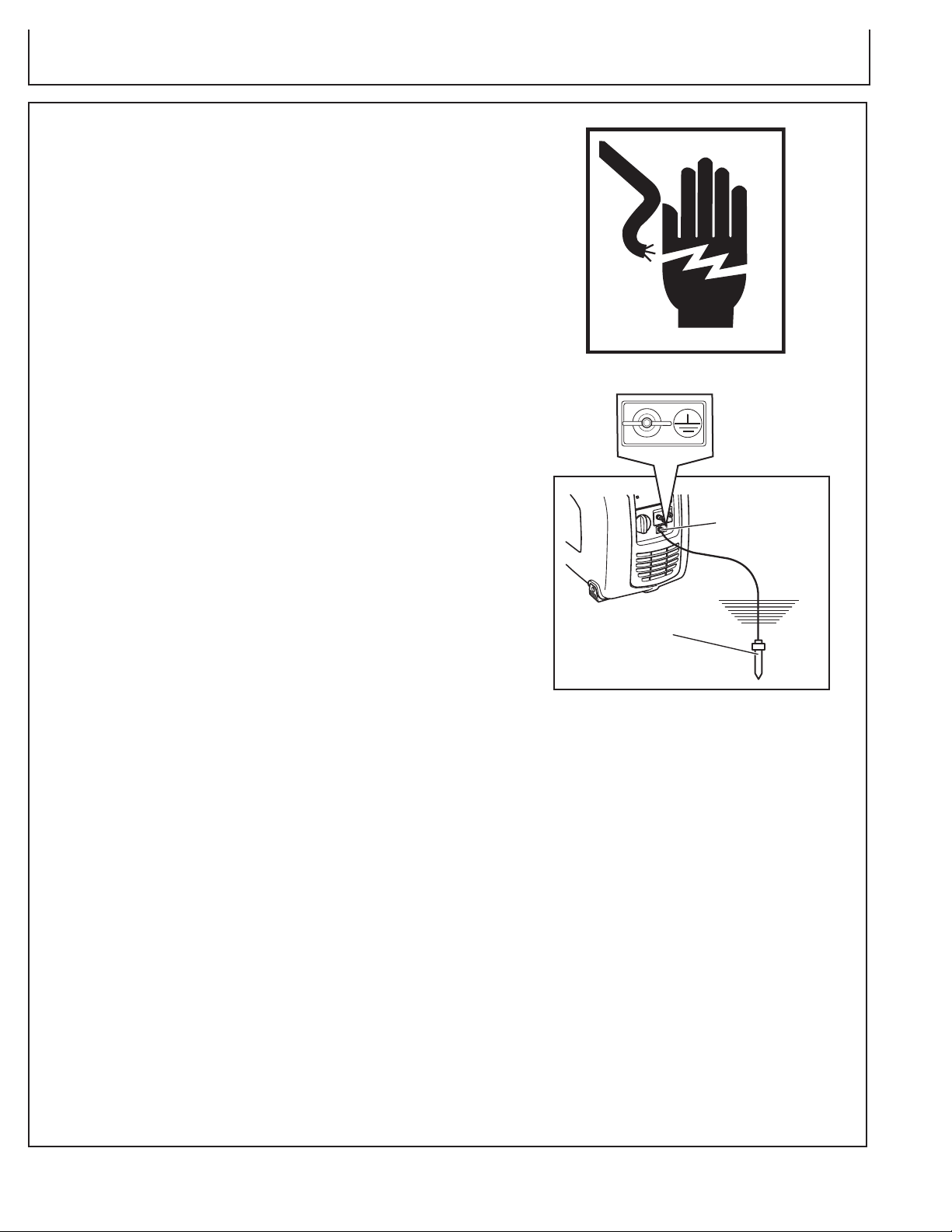

ELECTRICAL HAZARDS

This product must be grounded. If it should malfunction or breakdown,

grounding provides a path of least resistance for electric current to

reduce the risk of electric shock.

DANGER - IMPROPER CONNECTION OF THE EQUIPMENT GROUNDING CONDUCTOR CAN RESULT IN A RISK OF

ELECTROCUTION. CHECK WITH A QUALIFIED

ELECTRICIAN OR SERVICE PERSON IF YOU ARE IN

DOUBT AS TO WHETHER THE UNIT IS PROPERLY

GROUNDED.

This generator is equipped with a grounding terminal for your

protection. Always complete the ground path from the generator to an

external ground source as instructed in the section labeled “Grounding

Instructions” in the Preparation section of this manual.

The generator is a potential source of electrical shock if not kept dry.

Keep the generator dry and do not use in rain or wet conditions. To

protect from moisture, operate it on a dry surface under an open,

canopy-like structure. Dry your hands if wet before touching the

generator.

Plug appliances directly into the generator. Or, use a heavy duty,

outdoor-rated extension cord that is rated (in watts or amps) at least

equal to the sum of the connected appliance loads. Check that the

entire cord is free of cuts or tears and that the plug has all three prongs,

especially a grounding pin.

NEVER try to power the house wiring by plugging the generator into

a wall outlet, a practice known as “back feeding”. This is an extremely

dangerous practice that presents an electrocution risk to utility workers

and neighbors served by the same utility transformer. It also bypasses

some of the built-in household circuit protection devices.

If you must connect the generator to the house wiring to power

appliances, have a qualified electrician install the appropriate equipment

in accordance with local electrical codes. Or, check with your utility

company to see if it can install an appropriate power transfer switch.

For power outages, permanently installed stationary generators are

better suited for providing backup power to the home. Even a properly

connected portable generator can become overloaded. This may result

in overheating or stressing the generator components, possibly leading

to a generator failure.

12 Operator’s Manual

Page 13

IMPORTANT SAFETY INSTRUCTIONS

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

WARNING: To reduce the risk of injury, read this operator’s

manual completely before using. When using this product, the

following basic precautions should always be followed:

1. Read all the instructions before using the product.

2. Do not enclose the generator nor cover it with a

box. The generator has a built-in forced air cooling

system, and may become overheated if it is enclosed.

If generator has been covered to protect if from the

weather during non use, be sure to remove it and keep it

well away from the area during generator use.

3. Operate the generator on a level surface. It is not

necessary to prepare a special foundation for the

generator. However, the generator will vibrate on an

irregular surface, so choose a level place without surface

irregularities.

If the generator is tilted or moved during operation, fuel

may spill and/or the generator may tip over, causing a

hazardous situation.

Proper lubrication cannot be expected if the generator

is operated on a steep incline or slope. In such a case,

piston seizure may occur even if the oil is above the

upper level.

4. Pay attention to the wiring or extension cords from the

generator to the connected device. If the wire is under

the generator or in contact with a vibrating part, it may

break and possibly cause a fire, generator burnout, or

electric shock hazard. Replace damaged or worn cords

immediately.

5. Do not operate in rain, in wet

or damp conditions, or

with wet hands. The operator may suffer severe electric

shock if the generator is wet due to rain or snow.

6. If wet, w

ipe and dry it well before starting. Do not pour

water directly over the generator, nor wash it with water.

7. Be extremely careful that all necessary electrical

grounding procedures are followed during each and

every use. Failure to do so can be fatal.

8. NEVER try to power the house wiring by plugging the

generator into a wall outlet, a practice known as “back

feeding”. This is an extremely dangerous practice that

presents an electrocution risk to utility workers and

neighbors served by the same utility transformer. It

also bypasses some of the built-in household circuit

protection devices.

If you must connect the generator to the house wiring to

power appliances, have a qualified electrician install the

appropriate equipment in accordance with local electrical

codes. Or, check with your utility company to see if it can

install an appropriate power transfer switch.

9. No s

moking while charging a battery. The battery emits

flammable hydrogen gas, which can explode if exposed

to electric arcing or open flame. Keep the area wellventilated and keep open flames / sparks away when

charging a battery.

Operator’s Manual 13

Page 14

IMPORTANT SAFETY INSTRUCTIONS

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

10. Engine becomes extremely hot during and for some time

after operation. Keep combustible materials well away

from generator area. Be very careful not to touch any

parts of the hot engine especially the muffler area or

serious burns may result.

11. Keep children and all bystanders at a safe distance from

work area.

12. It is absolutely essential that you know the safe and

proper use of the power tool or appliance that you intend

to use. All operators must read, understand and follow

the tool / appliance owners manual. Tool and appliance

applications and limitations must be understood. Follow

all directions given on labels and warnings. Keep all

instruction manuals and literature in a safe place for

future reference.

13. Use only “LISTED” extension cords. When a tool or

appliance is used outdoors, use only extension cords

marked “For Outdoor Use”. Extension cords, when not in

use should be stored in a dry and well ventilated area.

14. Always disconnect tools or appliances when not in use,

before servicing, adjusting, or installing accessories and

attachments.

SAVE THESE INSTRUCTIONS

14 Operator’s Manual

Page 15

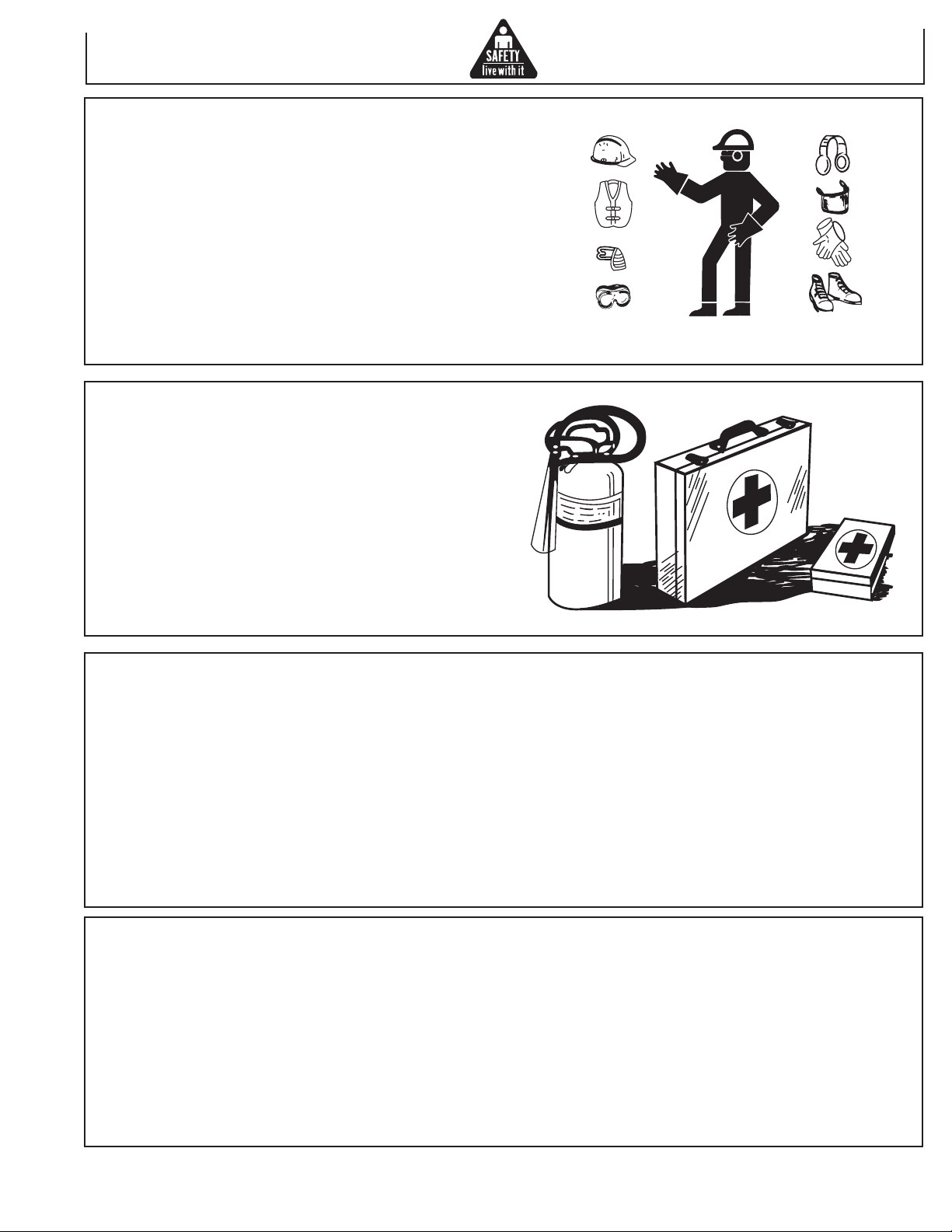

WEAR PROTECTIVE CLOTHING

Wear close fitting clothing and safety equipment

appropriate to the job.

Wear a suitable hearing protective device such as

earmuffs or earplugs to protect against objectionable or

uncomfortable loud noises.

Operating equipment safely requires the full attention of

the operator. Do not wear radio or music headphones while

operating machine.

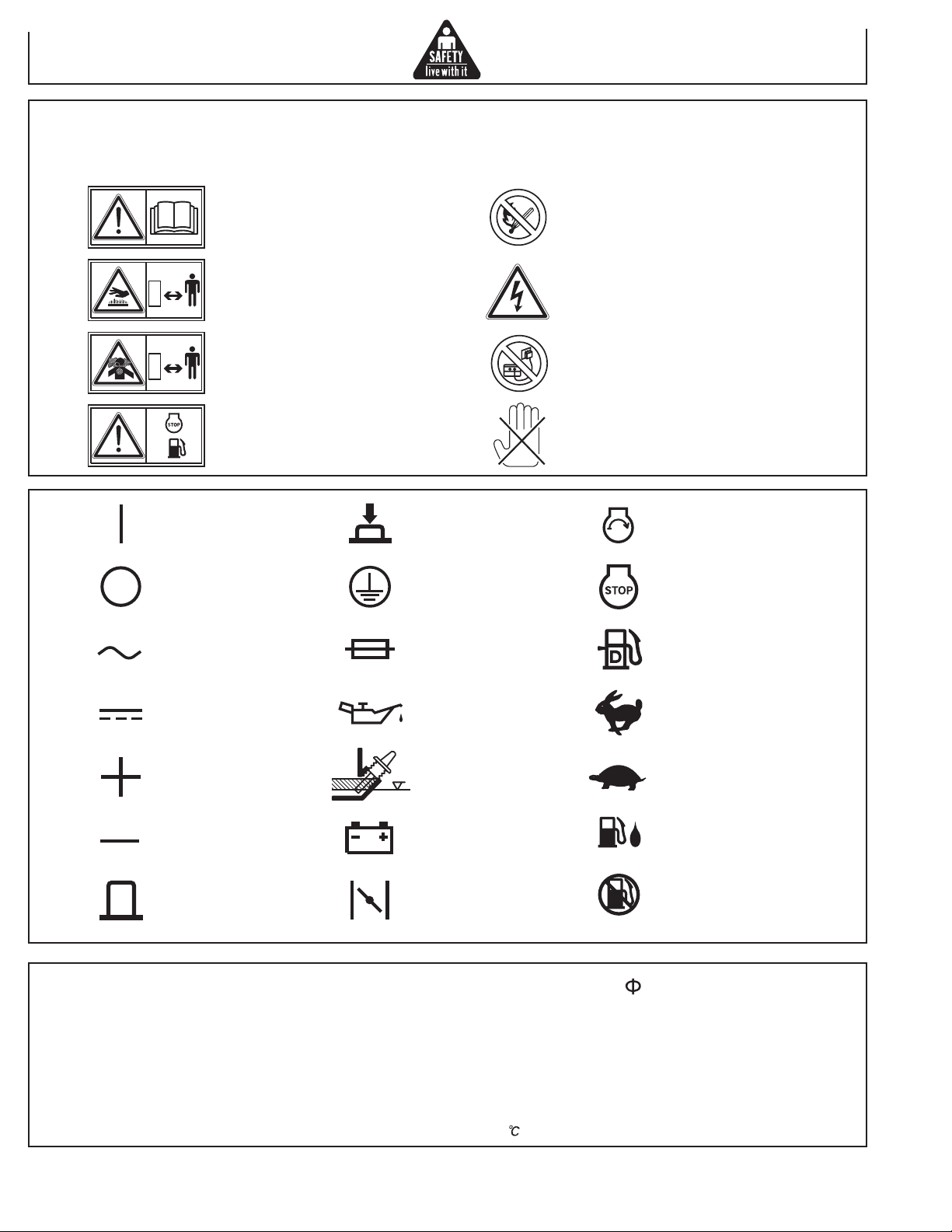

PREPARE FOR EMERGENCIES

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital and fire department near your telephone.

Be prepared if a fire starts.

INSPECT GENERATOR

Be sure all covers, guards and shields are tight and in

place.

Locate all operating controls and safety labels.

Inspect power cord for damage before using. There is a

hazard of electrical shock from crushing, cutting or heat

damage.

SERVICE GENERATOR SAFELY

Before servicing the generator, disconnect all equipment

and allow unit to cool down.

Service generator in a clean dry flat area.

Make sure the engine is stopped before starting any

maintenance servicing or repair.

Operator’s Manual 15

Page 16

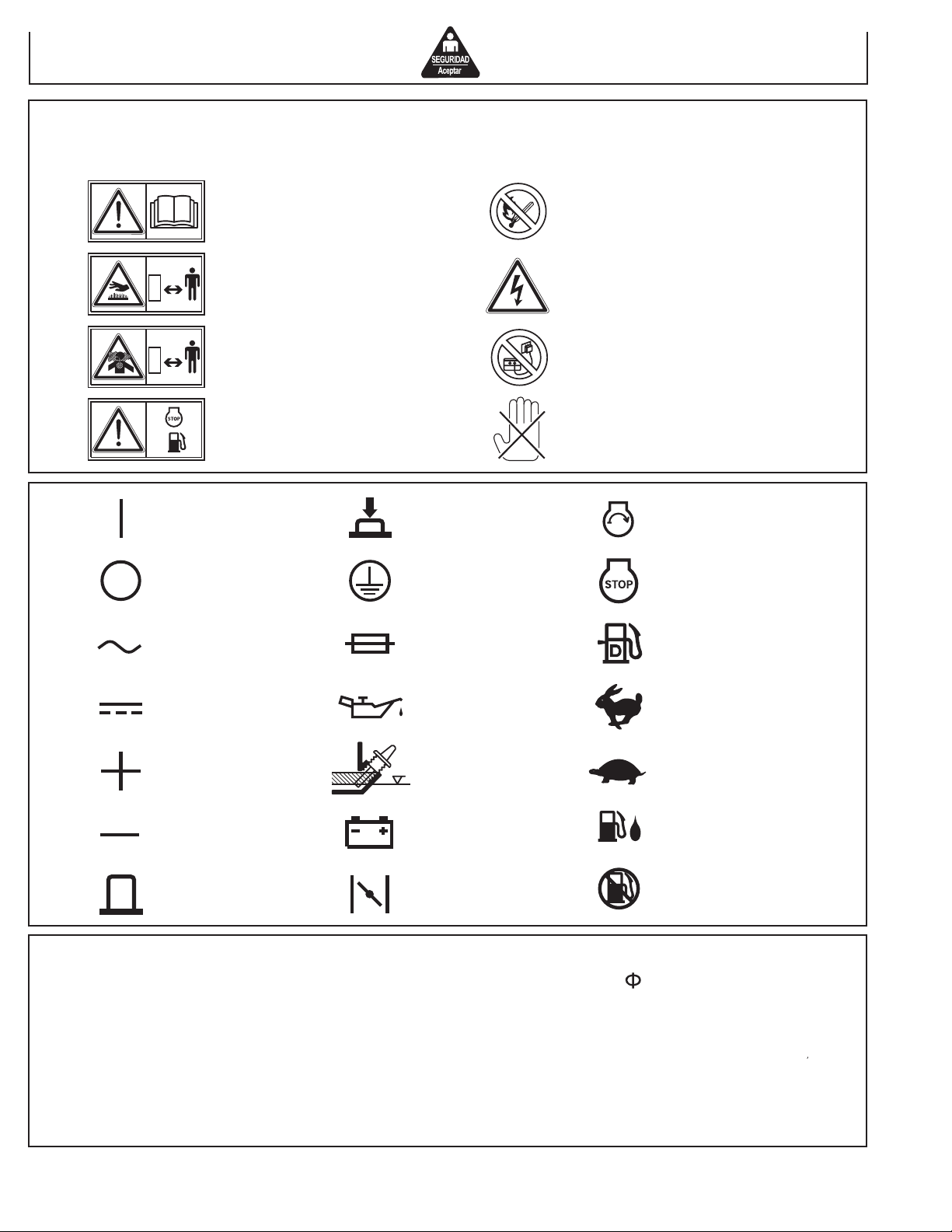

SAFETY SIGNS

Read the operator's instruction manual.

Stay clear of the hot surface.

Exhaust gas is poisonous.

Do not operate in an unventilated room.

Stop the engine before refueling.

Fire, open light and smoking

prohibited.

Caution, risk of electric shock.

Do not connect the generator to

the commercial power lines.

HOT, avoid touching the hot areas.

Engine oil

ON

(power and Engine)

Add oil

Battery charging

condition

OFF

(power and Engine)

Alternating current

Direct current

Plus ;

positive polarity

Minus ;

negative polarity

OUT-position of a

bistable push control

IN-position of a

bistable push control

Protective earth

(ground)

Fuse

Choke ;

cold starting aid

Engine start

(Electric start)

Engine stop

Diesel fuel

Fast

Slow

P r

Rated power (kW)

COP

Continuous power

COS

r

Rated power factor

f r

Rated frequency (Hz)

U r

Rated voltage (V)

I r

Rated current (A)

H max

Maximum site altitude

above sea-level (m)

T max

Maximum ambient

temperature ( )

m

Mass (kg)

Run

Stop

In accordance with the European requirements (eec Directives), the specified symbols as shown in the following table

are used for the products and this instructions manual.

16 Operator’s Manual

Page 17

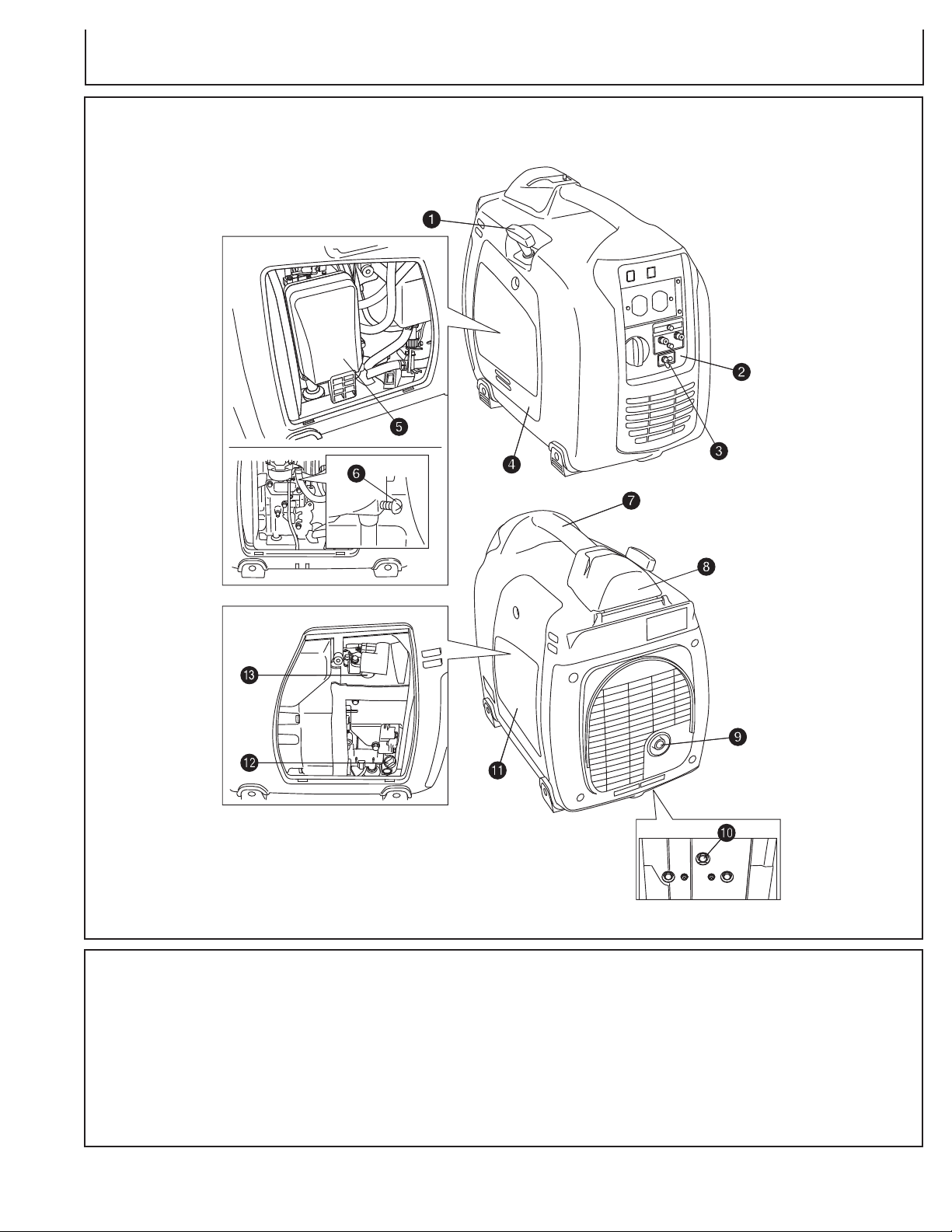

CONTROLS

Controls

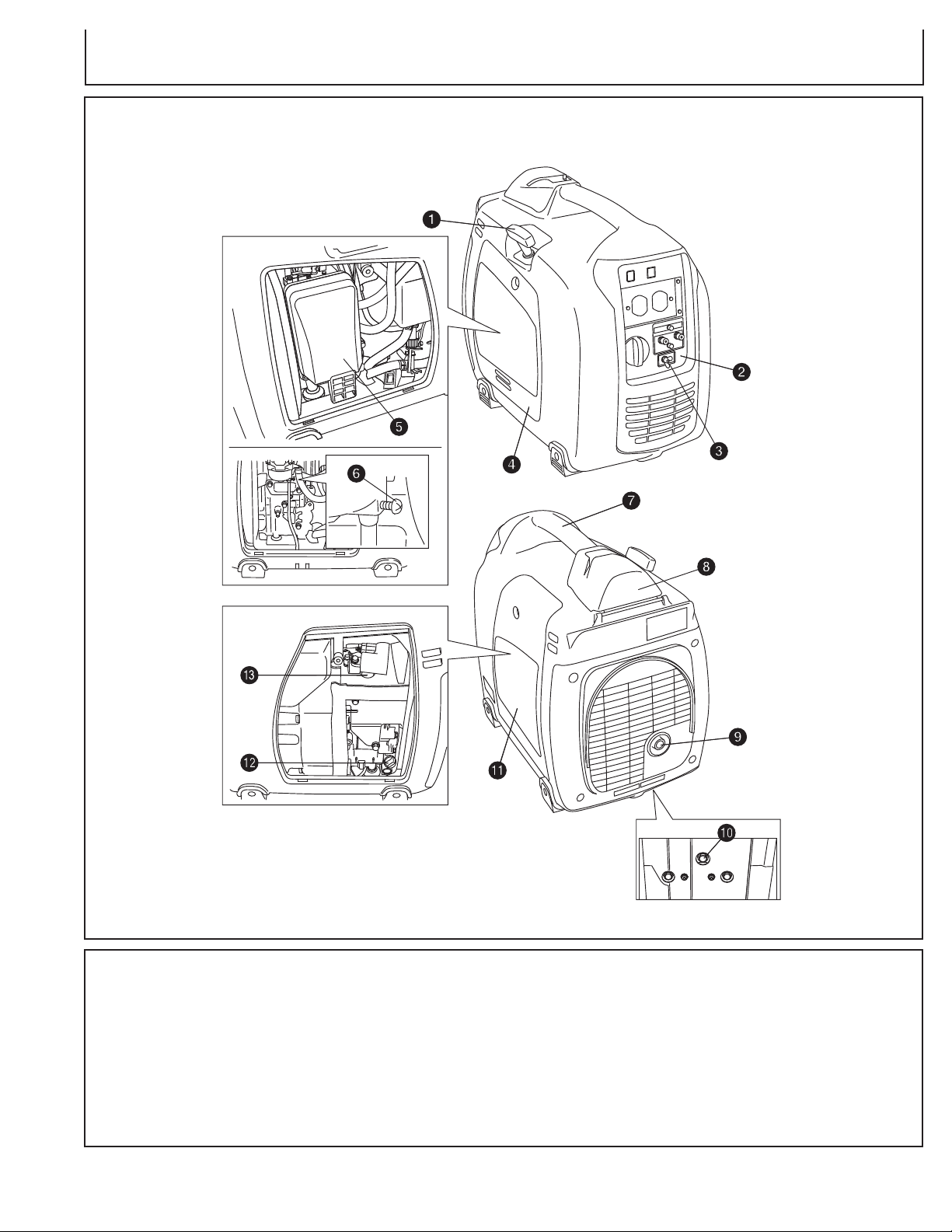

1-- Recoil Starter

2-- Control Panel

3-- Ground Terminal

Operator’s Manual 17

4-- Side Panel (L)

5-- Air Cleaner

6-- Fuel Drain Screw

7-- Carrying Handle

8-- Tank Cap Cover

9-- Exhaust Outlet

10-- Oil Drain Plug

11-- Side Panel (R)

12-- Oil Gauge

13-- Spark Plug Cap

Page 18

Controls

OUT

PUT

CONTROLS

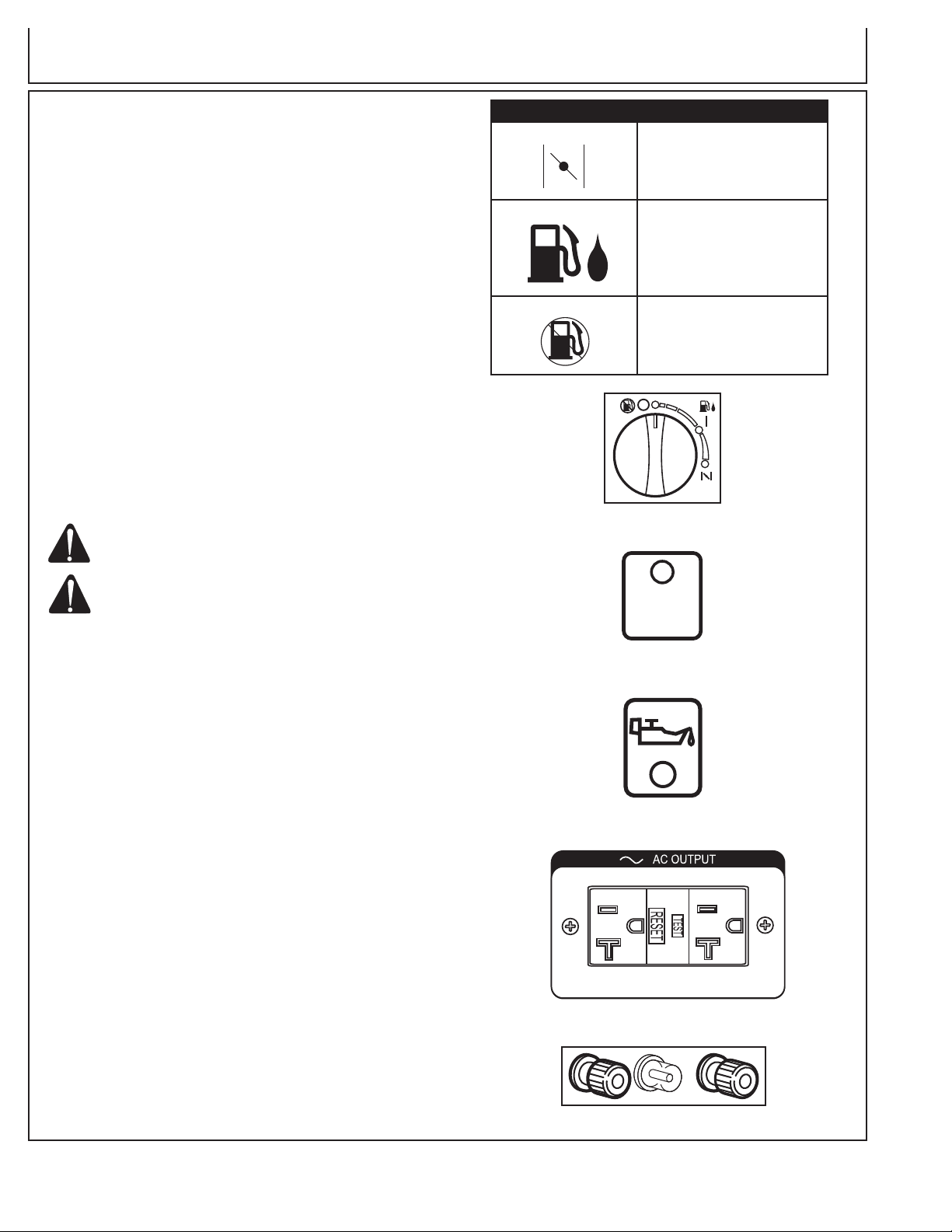

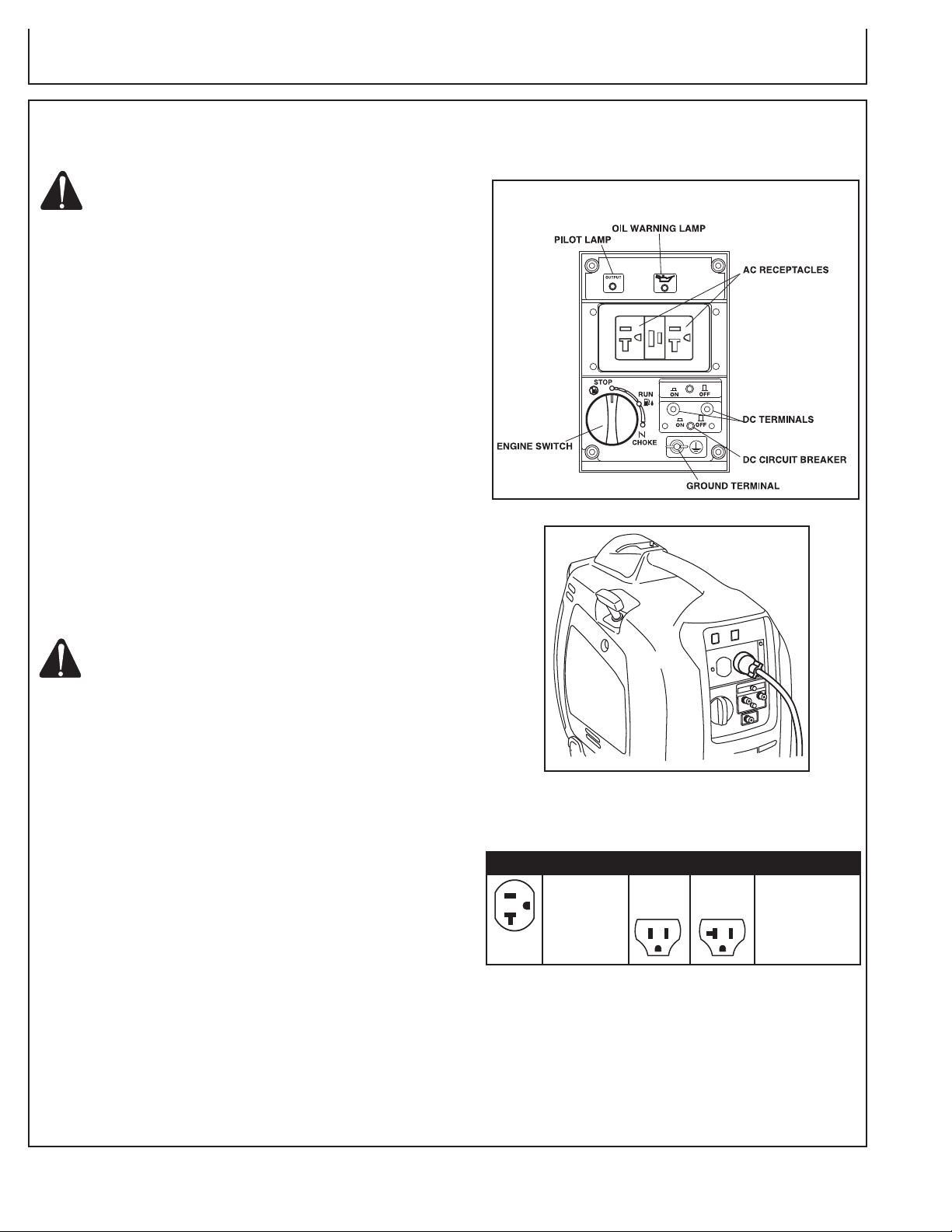

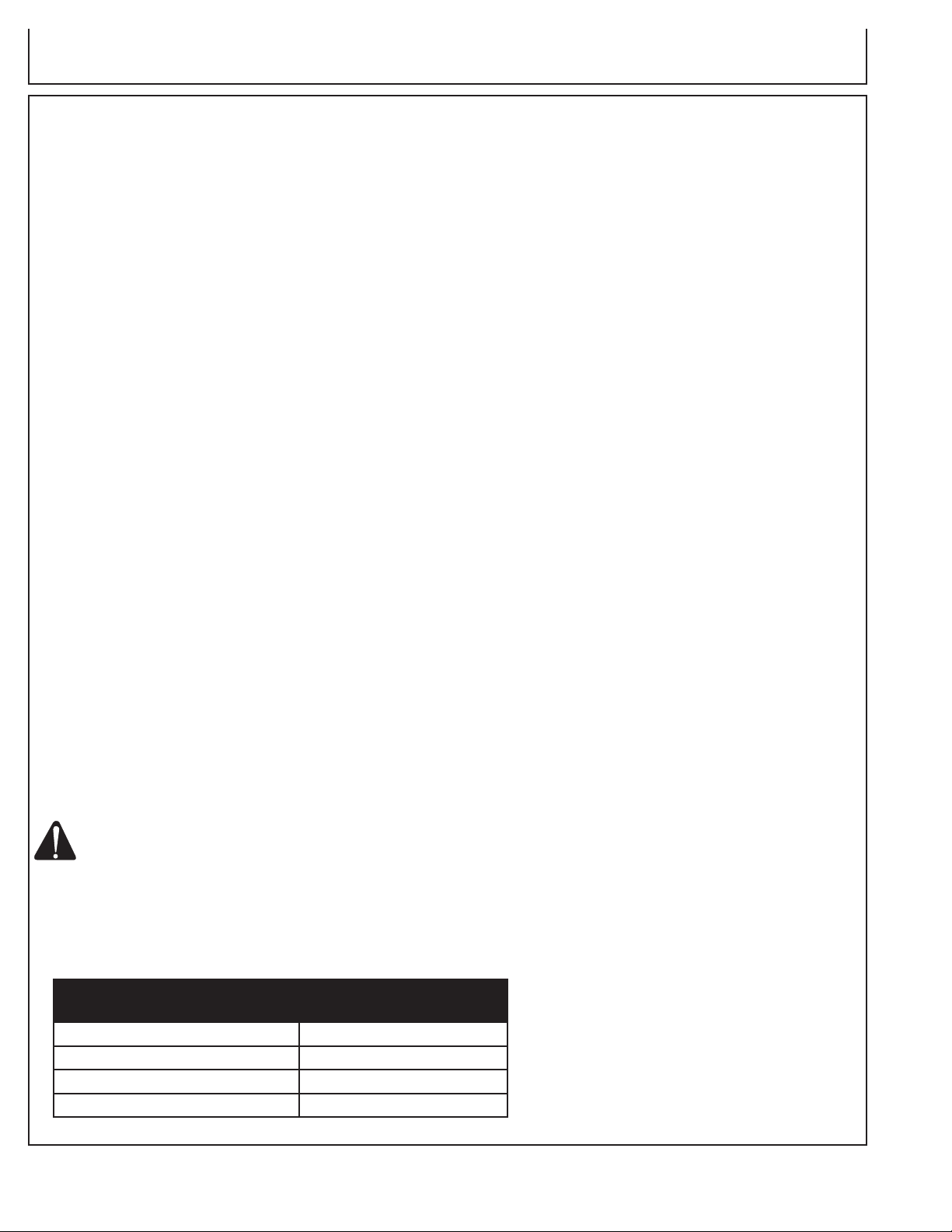

ENGINE SWITCH: (Fig. 15)

The engine switch is designed for easy operation with the

interlocking mechanism between the fuel valve and the

choke.

OUTPUT LAMP:

These lamps are turned on in the following conditions:

Output Lamp (Green) --- The lamp is turned on while

generating properly.

Oil Sensor Lamp --- (Fig. 17)

When the level of the engine oil falls below the prescribed

value, the alarm lamp lights up and the engine stops

automatically. When the engine stops due to oil shortage, it

can not be started anymore even by pulling the recoil starter

(just the alarm lamp flickers). In such a case, replenish

engine oil. See “Pre-Operation; Engine Oil” on page 21.

AC RECEPTA

AC electric power is available through this receptacle. Use

a grounding type plug as shown on page 26, Table 1.

WARNING: DO NOT PUT FOREIGN OBJECTS

INTO THE PLUG RECEPTACLE.

CAUTION: DO NOT PLUG MORE THAN TWO

APPLIANCES INTO THE GENERATOR

AT A TIME.

(Fig. 16)

CLES: (Fig. 18)

ENGINE SWITCHES

CHOKE To start the engine, turn the

knob to the position. (Choke

valve is closed.)

RUN Keep the knob in this

position after the engine

starts. (The engine can be

started with the knob at the

position when the engine is

warm.

STOP To stop the engine, return

the knob to the position.

(The fuel cock is closed as

well.)

(Fig. 15)

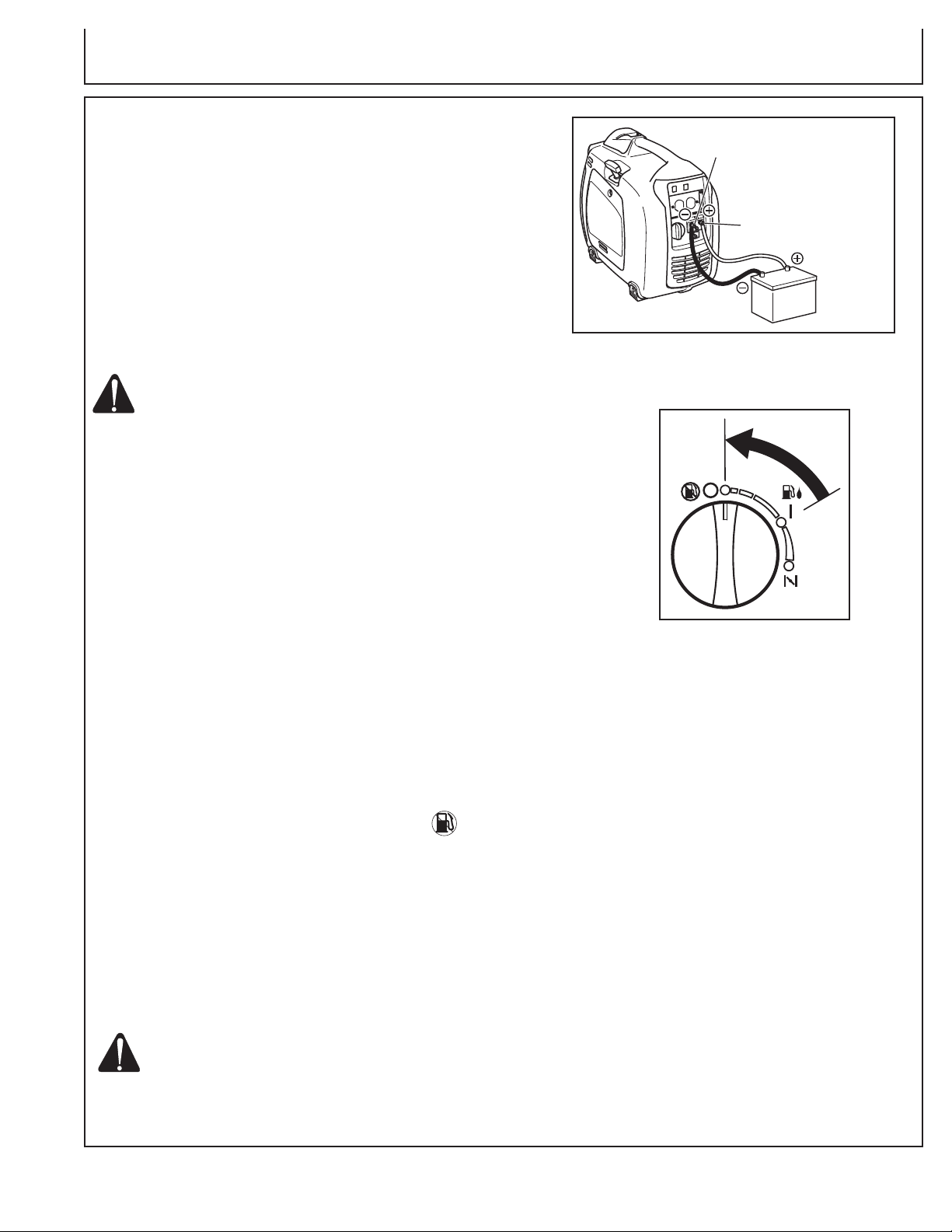

DC TERMINAL: (Fig. 19)

DC electric power for battery charging is available.

- Red is positive (+) terminal.

- Black is negative (-) terminal.

(Fig. 16)

(Fig. 17)

(Fig. 18)

(Fig. 19)

18 Operator’s Manual

Page 19

Controls

" "

" "

Button

Knob

IN (ON)

OUT (OFF)

Recoil Starter

Handle

Fuel Tank Cap

Fuel Filter Screen

Tank Cap Cover

CONTROLS

DC CIRCUIT BREAKER: (Fig. 20)

DC circuit breaker shuts off electric current when the current

exceeds its limit.

Check for e

xcessive current consumption or defects in the

appliance. After making sure everything is in order, push

the button to the “ON” position.

CAUTION: IF CIRCUIT BREAKER CONTINUES

TO TRIP, CHECK APPLIANCE FOR DEFECT.

IF GENERATOR IS MALFUNCTIONING,

SEE YOUR AUTHORIZED JOHN DEERE

SERVICE CENTER OR DEALER.

NEVER INTERFERE WITH THE OPERATION

OF THE CIRCUIT BREAKER KNOB OR

KE EP PUS H IN G I T IN TH E “ ON ”

POSITION.

RECOIL STARTER:

(Fig. 21)

Pull this handle to start the generator.

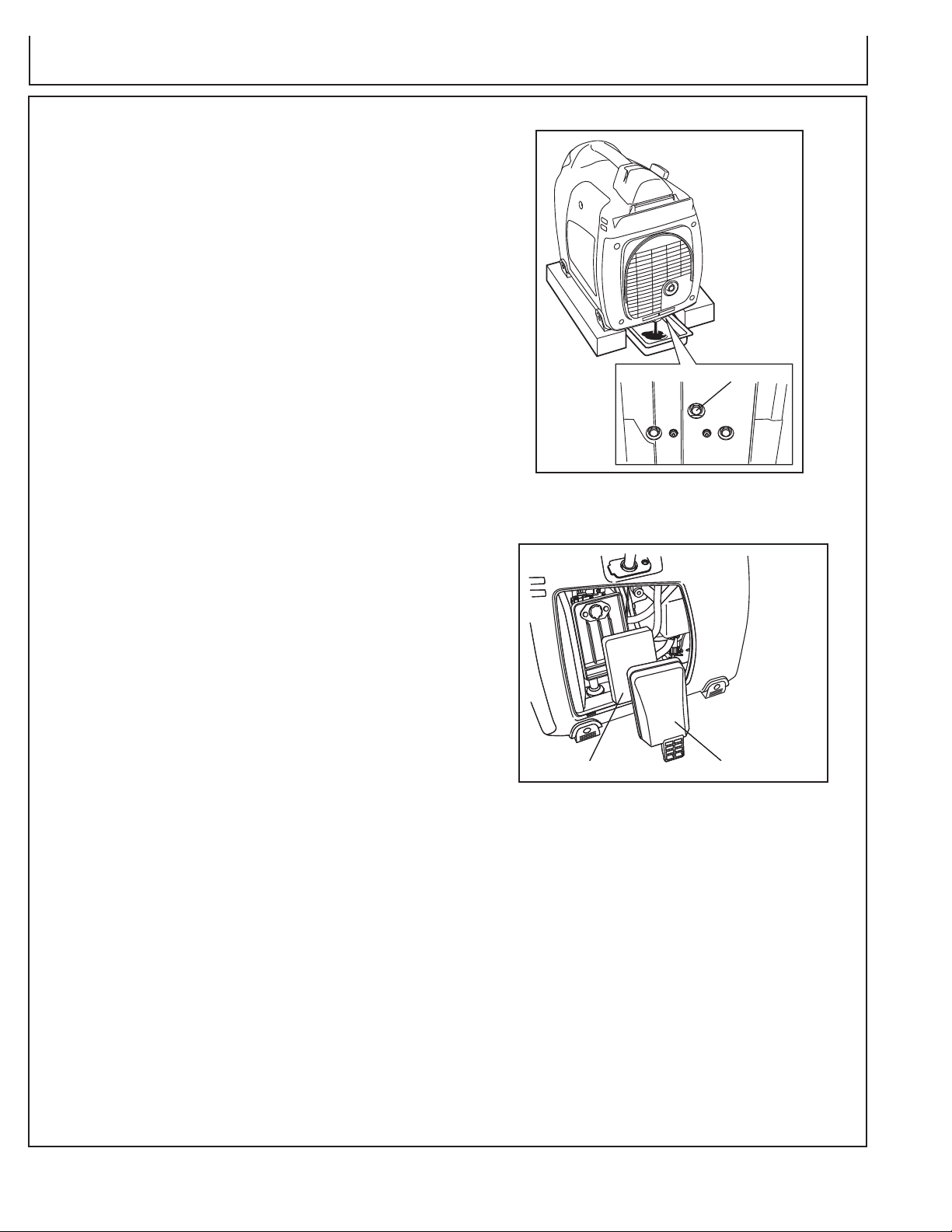

GROUND TERMINAL: (Fig. 22)

Terminal for grounding the generator.

FUEL TANK CAP

: (Fig. 23)

The fuel tank cap is located under the cover. To open

the cover, lift up and towards the muffler end as shown

in the illustration. Remove the fuel tank cap by turning

counterclockwise.

(Fig. 20)

(Fig. 21)

(Fig. 22)

Operator’s Manual 19

SIDE COVER: (Fig. 24)

To access the following items for servicing, take the

applicable side cover out by removing the screw with a

screwdriver.

LH-Side Cover - Air cleaner, etc.

RH-Side Cover - Oil level gauge, Ignition Coil,

Spark Plug, etc.

(Fig. 23)

(Fig. 24)

Page 20

Preparing the Generator

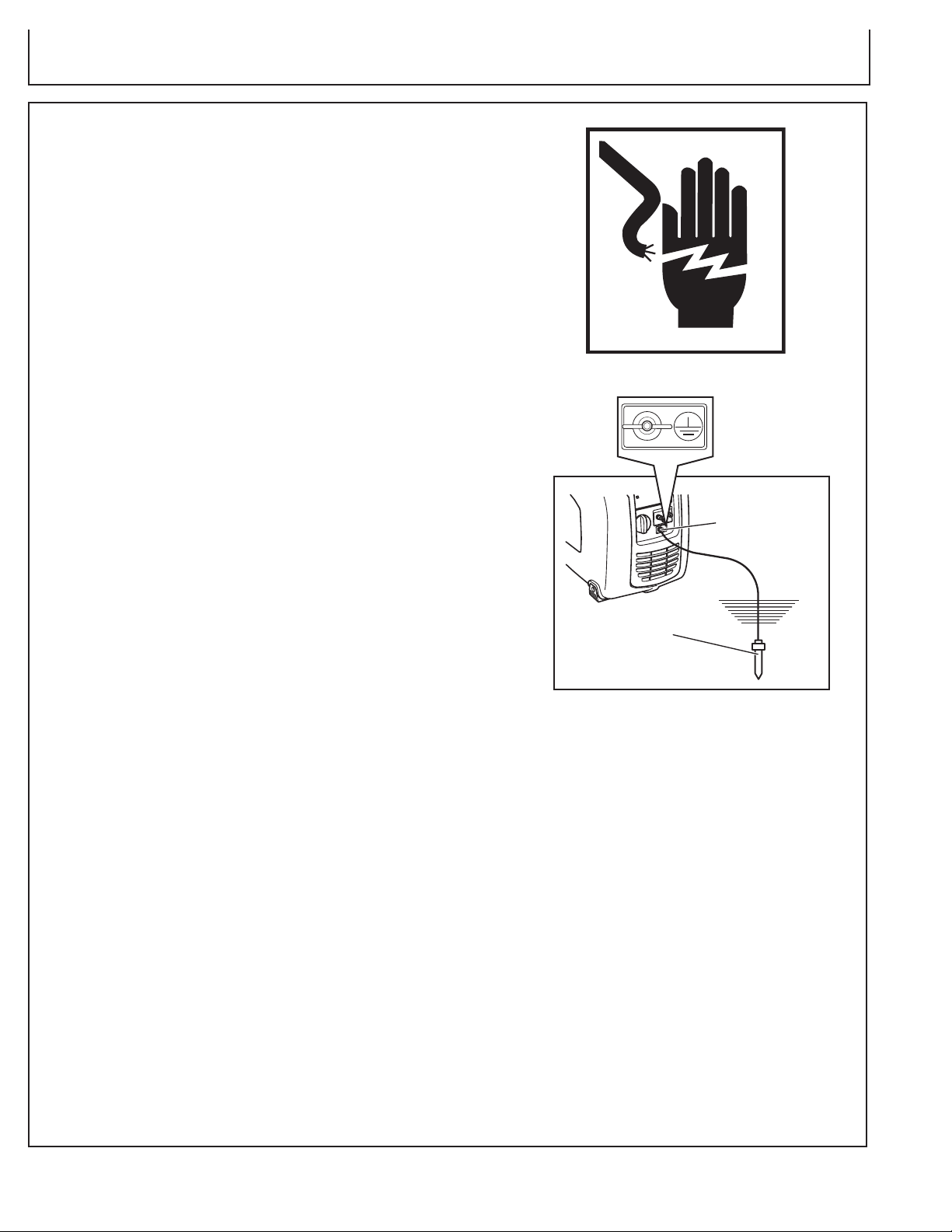

Ground Terminal

Grounding Rod

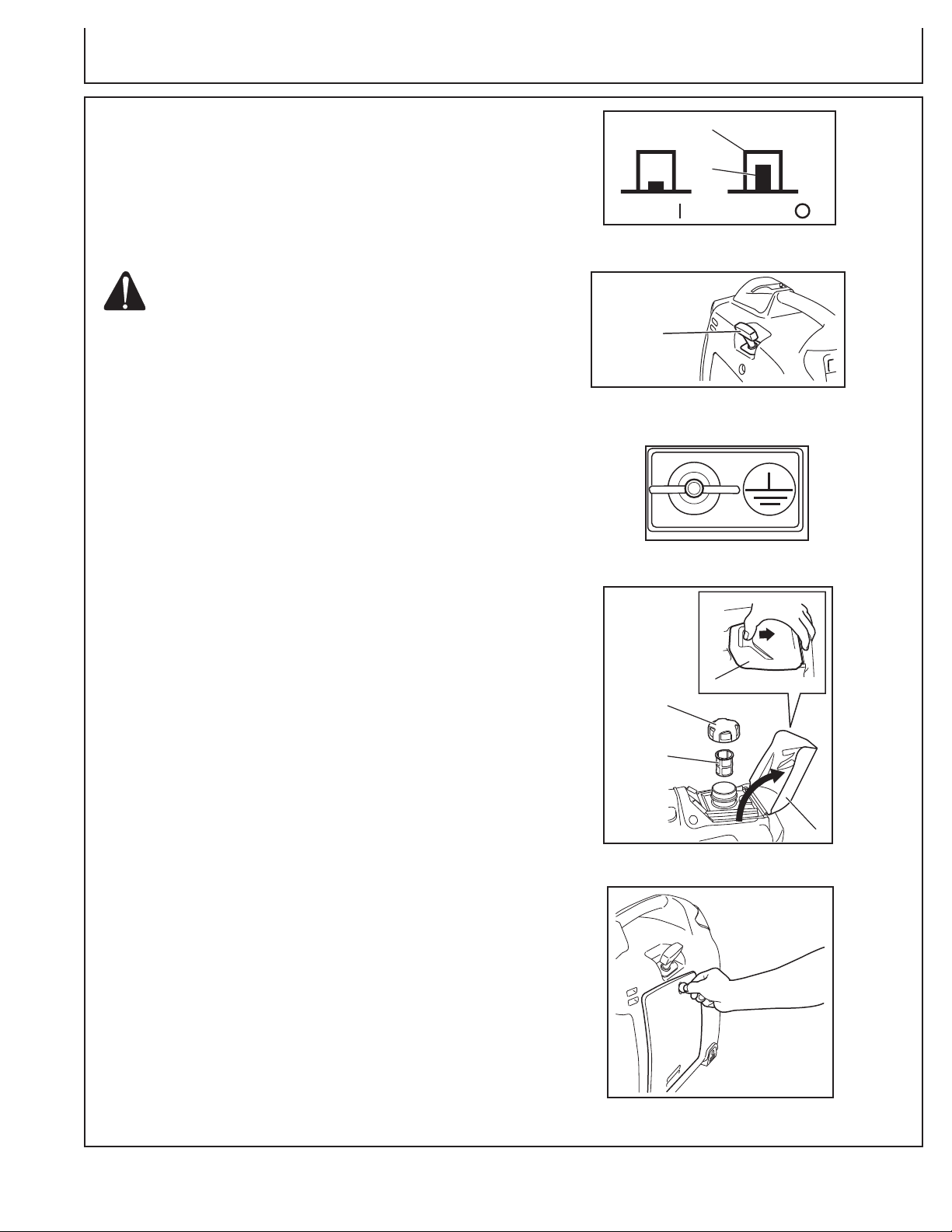

GROUNDING INSTRUCTIONS

This product must be grounded. If it should malfunction or

breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric shock.

DANGER - IMPROPER CONNECTION OF THE

EQUIPMENT-GROUNDING CONDUCTOR CAN

RESULT IN A RISK OF ELECTROCUTION.

CHECK WITH A QUALIFIED ELECTRICIAN OR

SERVICE PERSON IF YOU ARE IN DOUBT AS

TO WHETHER THE UNIT IS PROPERLY

GROUNDED.

The ground terminal on the frame must always be used to

connect the generator to a suitable ground source. The ground

path should be made with #8 size wire. Connect the grounding

wire securely to the ground terminal. Connect the other end of

the wire securely to a suitable ground source. (Fig. 1)

The National Electric Code contains several practical ways in

which to establish a good ground source. Examples given below

illustrate a few of the ways in which a good ground source may

be established.

A metal underground water pipe in direct contact with the earth

for at least 10 feet can be used as a grounding source. If an pipe

is unavailable, an 8 foot length of pipe or rod may be used as the

ground source. The pipe should be 3/4 inch trade size or larger

and the outer surface must be noncorrosive. If a steel or iron rod

is used it should be at least 5/8 inch diameter and if a nonferrous

rod is used it should be at least 1/2 inch diameter and be listed

as material for grounding. Drive the rod or pipe to a depth of 8

feet. If a rock bottom is encountered less than 4 feet down, bury

the rod or pipe in a trench. All electrical tools and appliances

operated from this generator, must be properly grounded by use

of a third wire or be “Double Insulated”.

It is recommended to:

1. Use electrical devices with 3 prong power cords.

2. Use an extension cord with a 3 hole receptacle and a 3

prong plug at the opposite ends to ensure continuity of

the ground protection from the generator to appliance.

We strongly recommend that all applicable federal, state and

local regulations relating to grounding specifications be checked

and followed.

LINE TRANSFER SWITCH

If this generator is used for standby service, it must have

a transfer switch between the utility power service and the

generator. The transfer switch not only prevents the utility

power form feeding into the generator, but is also prevents the

generator form feeding out into the utility company’s lines. This

is intended to protect the serviceman who may be working on

a damaged line.

(Fig. 1)

THIS INSTALLATION MUST BE DONE BY A LICENSED

ELECTRICIAN AND ALL LOCAL CODES MUST BE

FOLLOWED.

20 Operator’s Manual

Page 21

Preparing the Generator

Engine Oil Dipstick

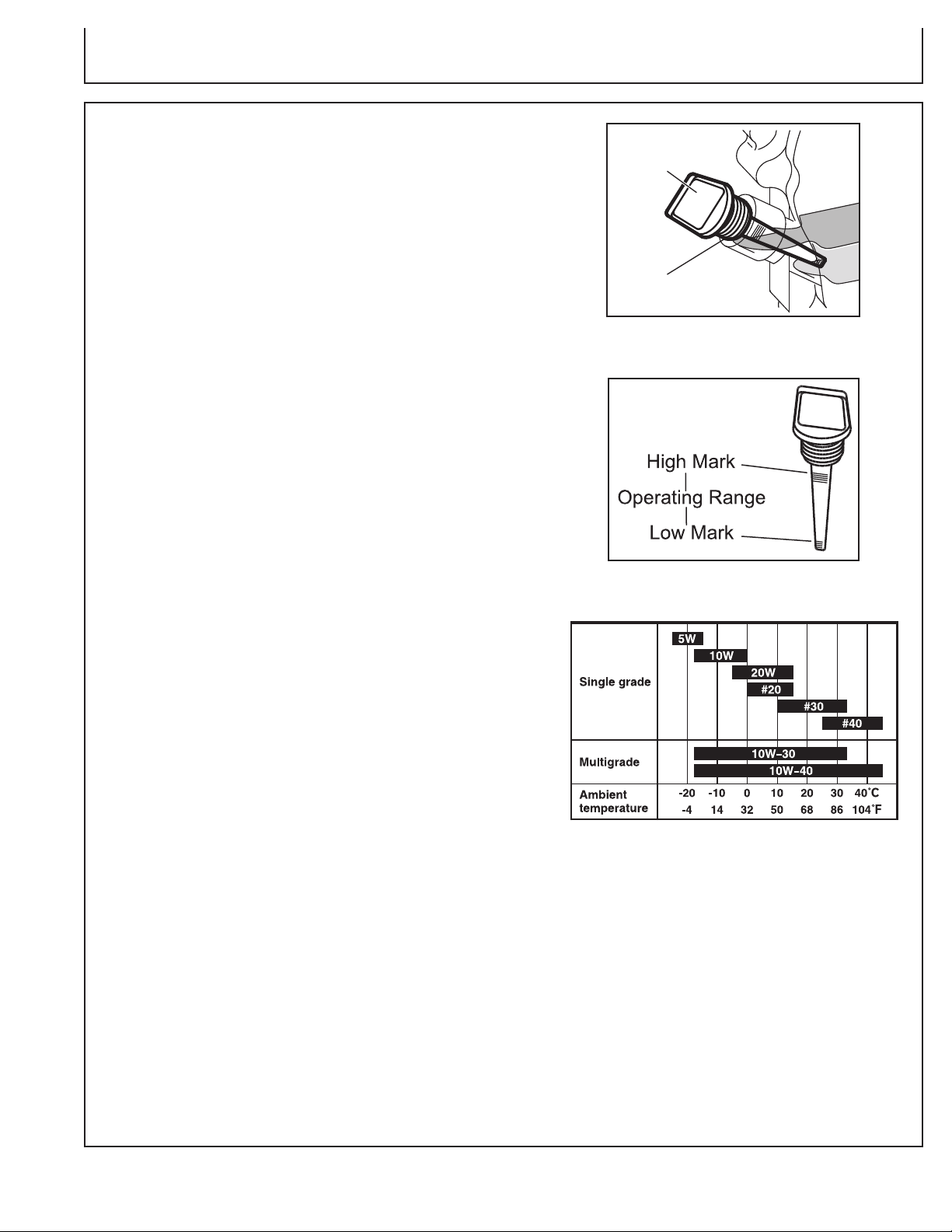

PRE-OPERATION

ENGINE OIL:

Before checking or refilling oil, be sure generator is located on

stable and level surface with engine stopped.

1. Remove oil dipstick and check the engine oil level. (Fig. 2)

2. If oil level is below the lower level line, refill with suitable

oil to upper level line. Do not screw in the oil dipstick when

checking oil level. (Fig. 3)

3. Change oil if contaminated. (See “Maintenance Schedule;

Changing Engine Oil” page 34.)

Oil Capacity ...................... 0.106 gal. / 0.4 liters

Recommended engine oil:

John Deere PLUS-4® oil is the preferred oil to use. If John

Deere PLUS-4® oil is not available, use 4-stroke automotive

detergent oil of API service class SE or higher grade (SG, SH

or SJ is recommended). If single viscosity oil is used, select

the appropriate viscosity for the average temperature in your

area. (Fig. 4)

(Fig. 2)

(Fig. 3)

Operator’s Manual 21

(Fig. 4)

Page 22

Red

Marking

Fuel Tank Cap

Fuel Filter Screen

Tank Cap Cover

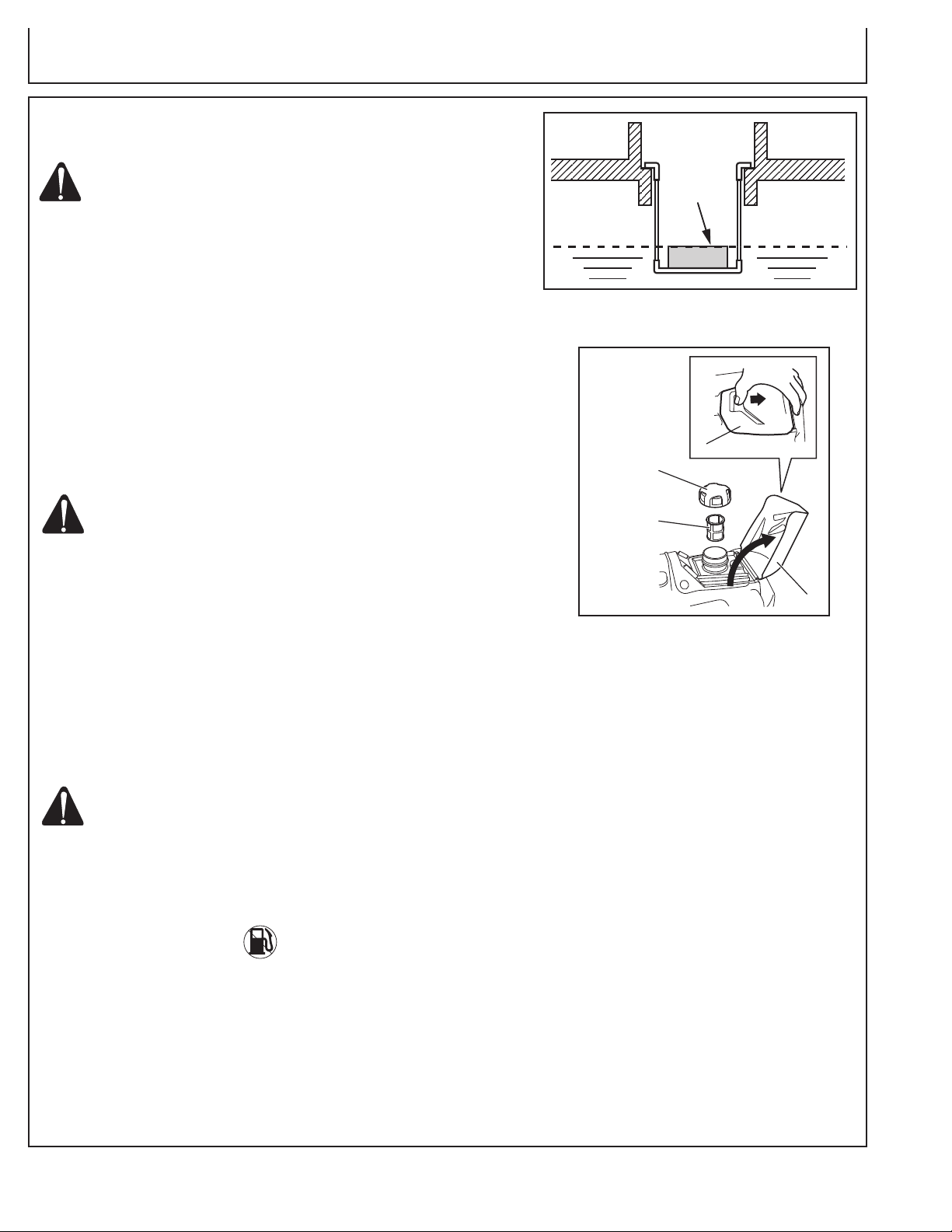

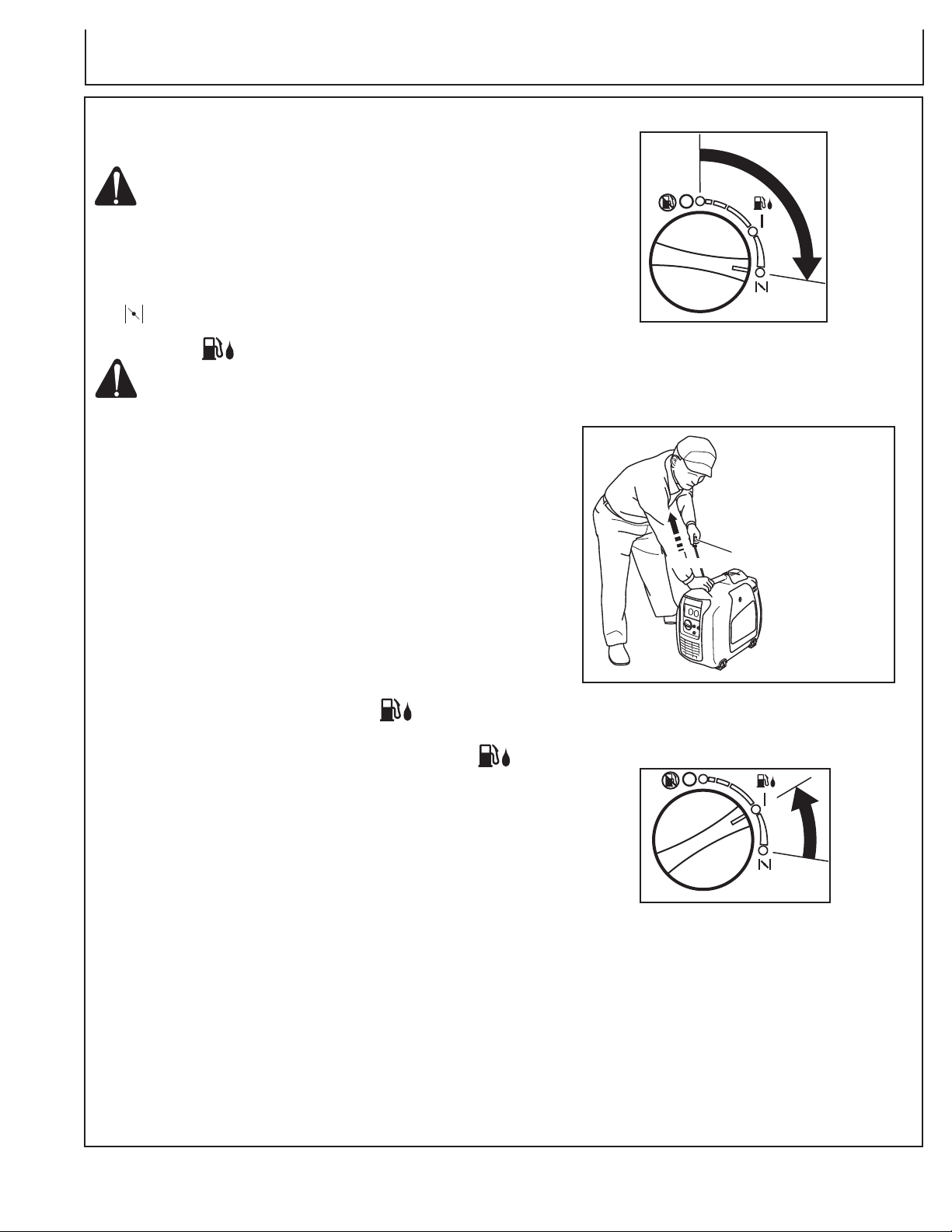

PRE-OPERATION

FUELING:

Preparing the Generator

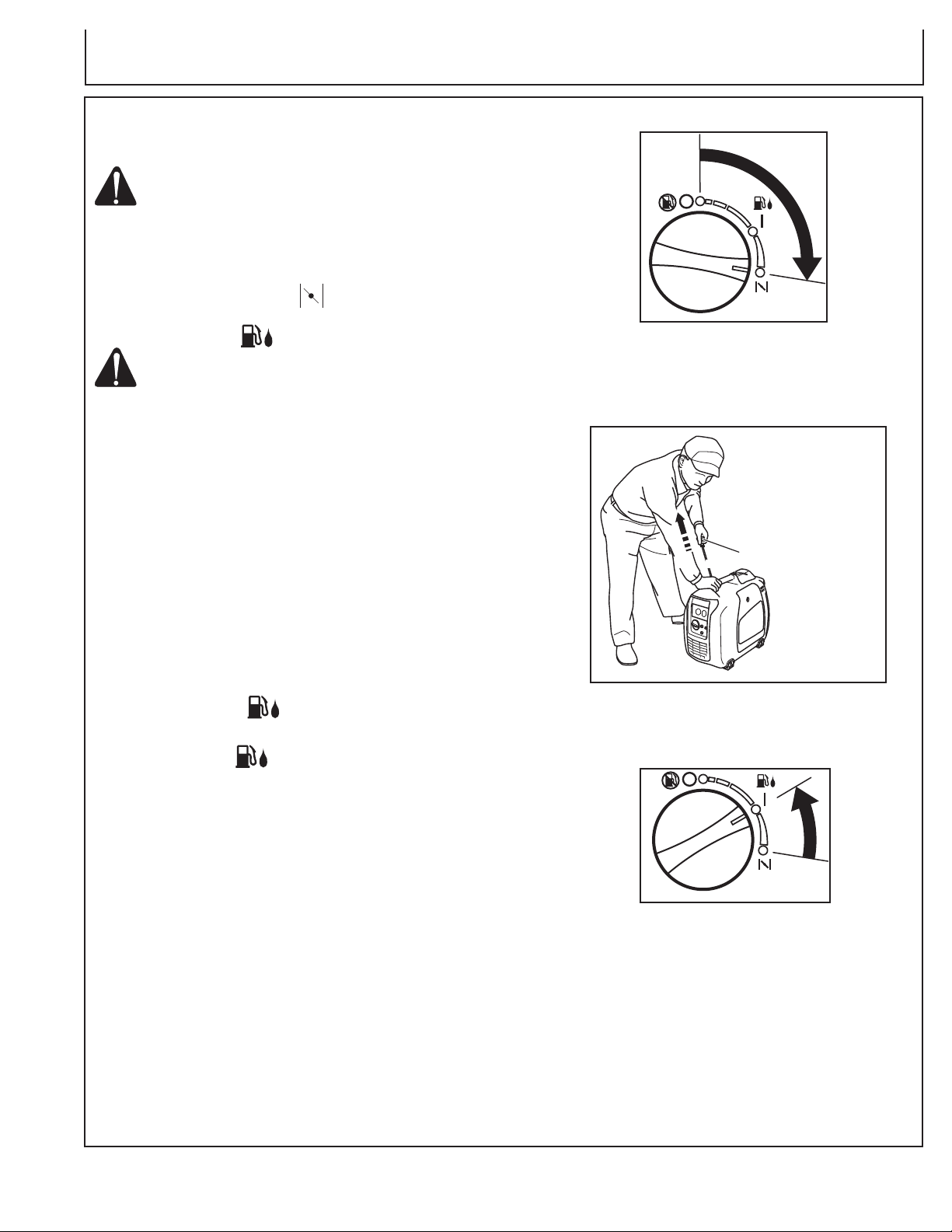

WARNING: WARNING: EXPLOSIVE FUEL! GASOLINE IS

EXTREMELY FLAMMABLE AND ITS VAPORS CAN

EXPLODE IF IGNITED.

STORE GASOLINE ONLY IN APPROVED

CONTAINERS, IN WELL VENTILATED,

UNOCCUPIED BUILDINGS AND AWAY FROM

SPARKS OR FLAMES.

DO NOT FILL THE FUEL TANK WHILE THE

ENGINE IS HOT OR RUNNING, SINCE SPILLED

FUEL COULD IGNITE IF IT COMES IN CONTACT

WITH HOT PARTS OR SPARKS FROM IGNITION.

DO NOT START THE ENGINE NEAR SPILLED

FUEL.

NEVER USE GASOLINE AS A CLEANING AGENT.

WARNING: DO NOT OVERFILL THE FUEL TANK, LEAVE

ROOM FOR THE FUEL TO EXPAND.

1. If fuel level is low, refill with unleaded automotive gasoline.

2. Fuel level should never go over the RED marking at the inlet portion.

(Fig. 5)

3. Be sure to use the fuel filter screen on the fuel filter neck. (Fig. 6)

(Fig. 5)

(Fig. 6)

Fuel Tank Capacity ...................... 0.92 gal. / 3.5 liters

4. When using the generator for the first time or stopping due to the

fuel running out, pull the recoil handle several times after filling the

fuel up to the RED marking at the inlet portion of the fuel tank.

WARNING: MAKE SURE YOU REVIEW EACH WARNING

IN ORDER TO PREVENT FIRE HAZARD.

DO NOT REFILL TANK WHILE ENGINE IS RUNNING

OR HOT.

BEFORE FILLING FUEL, TURN THE ENGINE

SWITCH TO “ “ (STOP) POSITION.

BE CAREFUL NOT TO ADMIT DUST, DIRT, WATER

OR OTHER FOREIGN OBJECTS INTO FUEL.

WIPE OFF SPILT FUEL THOROUGHLY BEFORE

STARTING ENGINE.

KEEP OPEN FLAMES AWAY.

22 Operator’s Manual

Page 23

Preparing the Generator

PRE-OPERATION

FUELING (continued):

General Recommendations

• Purchase gasoline in small quantities and store in clean,

approved containers.

• To minimize gum deposits in your fuel system and to

insure easy starting, do not use gasoline left over from

the previous season.

• Do not add oil to the gasoline.

Fuel Type

• For best results use only clean, fresh, unleaded gasoline

with a pump sticker octane rating of 87 or higher.

• Unleaded gasoline is recommended as it leaves less

combustion chamber deposits.

GASOLINE/ALCOHOL BLENDS:

Gasohol (up to 10% ethyl alcohol, 90% unleaded gasoline by

volume) is approved, as a fuel. Other gasoline/alcohol blends

are not approved.

GASOLINE/ETHER BLENDS:

Methyl Tertiary Butyl Ether (MTBE) and unleaded gasoline

blends (up to a maximum of 15% MTBE by volume) are approved

as a fuel. Other gasoline/ether blends are not approved.

Operator’s Manual 23

Page 24

Preparing the Generator

PRE-OPERATION

CHECK COMPONENT PARTS:

Check following items before starting engine:

1. Fuel leakage from fuel hose, etc.

2. Bolts and nuts for looseness.

3. Components for damage or breakage.

4. Generator not resting on or against any adjacent wiring.

CHECK GENERATOR SURROUNDINGS:

When listening to the radio near the generator, the radio sound may

be disturbed on account of the radio wave condition and the radio

performance.

Make sure you review each warning in order to prevent fire

hazard.

WARNING: KEEP AREA CLEAR OF FLAMMABLES OR

OTHER HAZARDOUS MATERIALS.

KEEP GENERATOR AT LEAST 3 FEET (1 METER) AWAY

FROM BUILDINGS OR OTHER STRUCTURES.

ONLY OPERATE GENERATOR IN A DRY, WELL VENTILATED

AREA.

KEEP EXHAUST PIPE CLEAR OF FOREIGN OBJECTS.

KEEP GENERATOR AWAY FROM OPEN FLAME.

NO SMOKING!

KEEP GENERATO R ON A STA BLE AND LE VEL

SURFACE.

DO NOT BLOCK GENERATOR AIR VENTS WITH PAPER OR

OTHER MATERIAL.

24 Operator’s Manual

Page 25

Operation

Recoil Starter Handle

Pull Briskly

OPERATION

STARTING THE GENERATOR:

CAUTION: CHECK THE OIL LEVEL BEFORE EACH

OPERATION AS OUTLINED ON PAGE 21.

1. Make sure all appliances are disconnected from the

generator.

2. Turn engine switch to the “ “ (CHOKE) position (Fig. 7).

(When the engine is warm or temperature is high, start engine

with the switch at “ “ (RUN) position).

CAUTION: DO NOT CONNECT APPLIANCES WITH

DEFECTIVE LINES AND/OR PLUGS.

BE SURE APPLIANCES ARE NOT CONNECTED

TO GENERATOR WHEN STARTING UP.

STARTING THE GENERATOR WITH AN

APPLIANCE CONNECTED COULD RESULT IN

DAMAGE TO THE GENERATOR AND/OR

APPLIANCE AND PERSONAL INJURY.

(Fig. 7)

3. Pull the recoil starter handle slowly until passing the

compression point (resistance will be felt), then return the

handle to its original position and pull briskly. (Fig. 8)

4. After starting, allow the recoil starter handle to return to its

original position with the handle still in your hand.

NOTE: If the engine fails to start after several attempts, repeat

the starting procedures mentioned above with the engine

switch placed at “ “ (RUN) position.

5. After 20 to 30 seconds of warm-up is completed, turn the

engine switch to “ “ (RUN) position. (Fig. 9)

6. Make sure the output lamp is on. This indicates that the

generator is properly operating.

NOTE: Please consult with an authorized John Deere Dealer

if the output lamp is off during the proper operation.

7. Test the GFCI receptacle on the unit. Push the test button. The

reset button should pop out and there should be no power at

the receptacle. Apply a test load or lamp to each receptacle

to verify. IF THE RESET BUTTON DOES NOT POP OUT, DO

NOT USE THE RECEPTACLE. SEE DEALER FOR SERVICE

IMMEDIATELY.

8. If GFCI receptacle test correctly, firmly push the reset button

to restore power. A distinctive click should be heard or felt

when this is complete. IF THE RECEPTACLE DOES NOT

RESET PROPERLY, DO NOT USE THE RECEPTACLE. SEE

DEALER FOR SERVICE IMMEDIATELY.

(Fig. 8)

(Fig. 9)

Operator’s Manual 25

Page 26

OPERATION

USING ELECTRIC POWER:

Operating the Generator

WARNING: MAKE SURE THAT THE APPLIANCE IS

SWITCHED OFF BEFORE CONNECTING IT TO

THE GENERATOR.

DO NOT MOVE THE GENERATOR WHILE IT IS

RUNNING.

BE SURE TO GROUND THE GENERATOR.

FAILURE TO

GROUND UNIT MAY LEAD TO

ELECTRICAL SHOCK.

AC APPLICATION:

1. Make sure the output lamp is turned on.

2. Turn off the switch(es) of the electrical appliance(s) before

connecting to the generator.

3. Insert the plug(s) of the electrical appliance(s) into the

receptacle. (Fig. 10)

• Using Table 1, check appliance plug for compatibility with

the generator receptacle.

• Be sure that the total wattage of all connected appliances

does not exceed the rated output of the generator, see

specifications on page 37.

WARNING: BE SURE TO GROUND THE

GENERATOR IF THE CONNECTED ELECTRICAL

DEVICE IS GROUNDED.

CONTROL PANEL

NOTE: The generator is equipped with an overload. If the

generator shuts off during operation, the generator may

be overloaded or the appliance may be defective.

Stop the generator immediately, check the appliance

(Fig. 10)

and/or generator for overloading, and have repaired as

necessary by an authorized John Deere Dealer.

4. Turn on the switch of the appliance.

Style Receptacle AC plug Description

NEMA

5-20R

NEMA

5-15P

NEMA

5-20P

GFCI (Ground

Fault Circuit

Interrupter)

Receptacle,

duplex

Table 1

26 Operator’s Manual

Page 27

Operating the Generator

Positive Terminal (Red)

Negative Terminal (Black)

OPERATION

DC APPLICATION:

The DC terminal is used only for charging 12 volt batteries. It

provides up to 12V - 8.3A (100W) of maximum power. (Fig. 11)

CONNECTION OF CABLE:

Connect positive terminal (red) on generator to positive (+) terminal

on battery.

Connect negative terminal (black) on generator to negative (-)

terminal on battery.

Both AC and DC output can be used at the same time if the total

output is within rated output of the generator.

SAFETY PRECAUTIONS WHILE CHARGING:

WARNING: AN EXPLOSIVE HYDROGEN GAS IS

DISCHARGED THROUGH VENT HOLES IN

THE BATTERY DURING THE CHARGING

PROCESS. DO NOT ALLO W SPARK OR

OPEN FLAME AROUND THE GENERATOR

OR BATTE RY DURI NG THE CHA RGING

PROCESS.

ELECTROLYTE FLUID CAN BURN EYES

AND CLOTHING. BE EXTREMELY CAREFUL

TO AVOID CONTACT. IF INJURED, WASH

TH E A F F EC T ED AR E A I MM E DI AT ELY

WITH LARGE QUANTITIES OF WATER AND

CONSULT A DOCTOR FOR TREATMENT.

(Fig. 11)

When charging a large capacity battery or totally discharged

battery, excessive current may force the DC breaker to turn off.

Battery defects may cause the DC breaker to trip. Check the

battery before resetting the DC breaker.

STOPPING THE GENERATOR:

1. Turn off the power switch of the electric equipment and unplug

the cord from receptacle of the generator.

2. Allow the engine about 3 minutes to cool down at no load before

stopping.

3. Turn the engine switch to the position “ “ (STOP).

(See Fig. 12)

OIL SENSOR:

The oil sensor detects the fall in oil level in the crankcase and

automatically stops the engine when the oil level falls below a

predetermined level.

When the engine has stopped automatically, turn off the generator,

and check the oil level. Refill engine oil to the upper level as

instructed on page 21 and restart the engine.

If the engine does not start by usual starting procedures, check

the oil level.

CAUTION: DO NOT REMOVE OIL SENSOR PROBE

WHEN REFILLING WITH OIL.

(Fig. 12)

REMOVE OIL FILLER CAP ON THE OPPOSITE

SIDE OF CARBURETOR.

Operator’s Manual 27

Page 28

Operating the Generator

OPERATION

WATTAGE INFORMATION:

Some appliances need a “surge” of energy when starting. This means

that the amount of electrical power needed to start the appliance may

exceed the amount needed to maintain its use.

Electrical appliances and tools normally come with a label indicating

voltage, cycles / Hz, amperage (amps) and electrical power needed to

run the appliance or tool.

Check with your nearest dealer or service center with questions

regarding power surge of certain appliances or power tools.

• Electrical loads such as incandescent lamps and hot plates require

the same wattage to start as is needed to maintain use.

• Loads such as fluorescent lamps require 1.2 to 2 times the indicated

wattage during start-up.

• Loads for mercury lamps require 2 to 3 times the indicated wattage

during start-up.

• Electrical motors require a large starting current. Power requirements

depend on the type of motor and its use. Once enough “surge” is

attained to start the motor, the appliance will require only 30% to 50%

of the wattage to continue running.

• Most electrical tools require 1.2 to 3 times their wattage for running

under load during use.

• Loads such as submersible pumps and air compressors require a

very large force to start. They need 3 to 5 times the normal running

wattage in order to start.

NOTE: The following wattage chart is general guide only. Refer to your

specific appliance for correct wattage.

To determine the total wattage required to run a particular electrical

appliance or tool, multiply the voltage figure of the appliance / tool by

the amperage (amps) figure of same. The voltage and amperage (amps)

information can be found on a name plate which is normally attached

to electrical appliances and tools.

CAUTION: IF AN ELECTRIC MOTOR FAILS TO START OR

REACH RUNNING SPEED, TURN OFF THE

APPLIANCE OR TOOL IMMEDIATELY TO AVOID

EQUIPMENT DAMAGE. ALWAYS CHECK THE

REQUIREMENTS OF THE TOOL OR APPLIANCE

BEING USED COMPARED TO THE RATED OUTPUT

OF THE GENERATOR.

Applications Applicable Wattage (W)

60 Hz

Incandescent Lamp, Heater approx. 900

Fluorescent Lamp, Electric Tool

Mercury Lamp approx. 250

Compressor Pump approx. 200

approx. 450

28 Operator’s Manual

Page 29

Operating the Generator

OPERATION

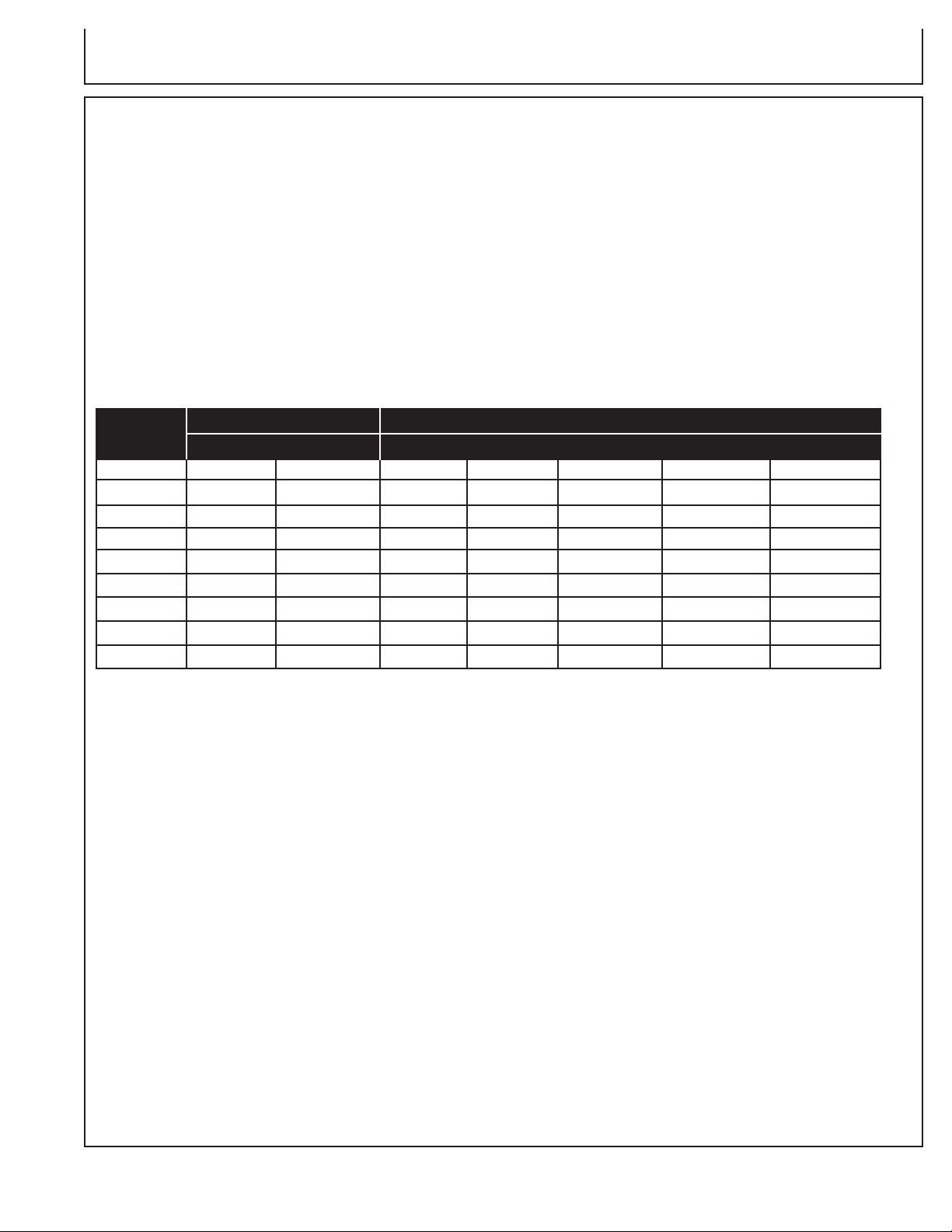

CABLE SIZE:

When a long electric extension cord is used to connect an appliance or

tool to the generator, a certain amount of voltage drop or loss occurs in

the extension cord which reduces the effective voltage available for the

appliance or tool. The chart below has been prepared to illustrate the

approximate voltage loss when an extension cord of 300 feet (approx.

100 meters) is used to connect an appliance or tool to the generator.

Equipment damage can result from low voltage. Therefore, to prevent

excessive voltage drop between the generator and the equipment,

the cable should be of adequate gauge for the length used. The cable

selection chart gives the maximum cable lengths for various gauges of

wire which can adequately carry the loads shown.

CURRENT LOAD IN WATTS MAXIMUM CABLE LENGTH (FEET)

IN AMPS 120 VOLTS 240 VOLTS #8 WIRE #10 WIRE #12 WIRE #14 WIRE #16 WIRE

2.5 300 600 1000 600 375 250

5 600 1200 500 300 200 125

7.5 900 1800 350 200 125 100

10 1200 2400 250 150 100 50

15 1800 3600 150 100 65

20 2400 4800 175 125 75 50

25 3000 6000 150 100 60

30 3600 7200 125 65

40 4800 9600 90

Operator’s Manual 29

Page 30

Operating the Generator

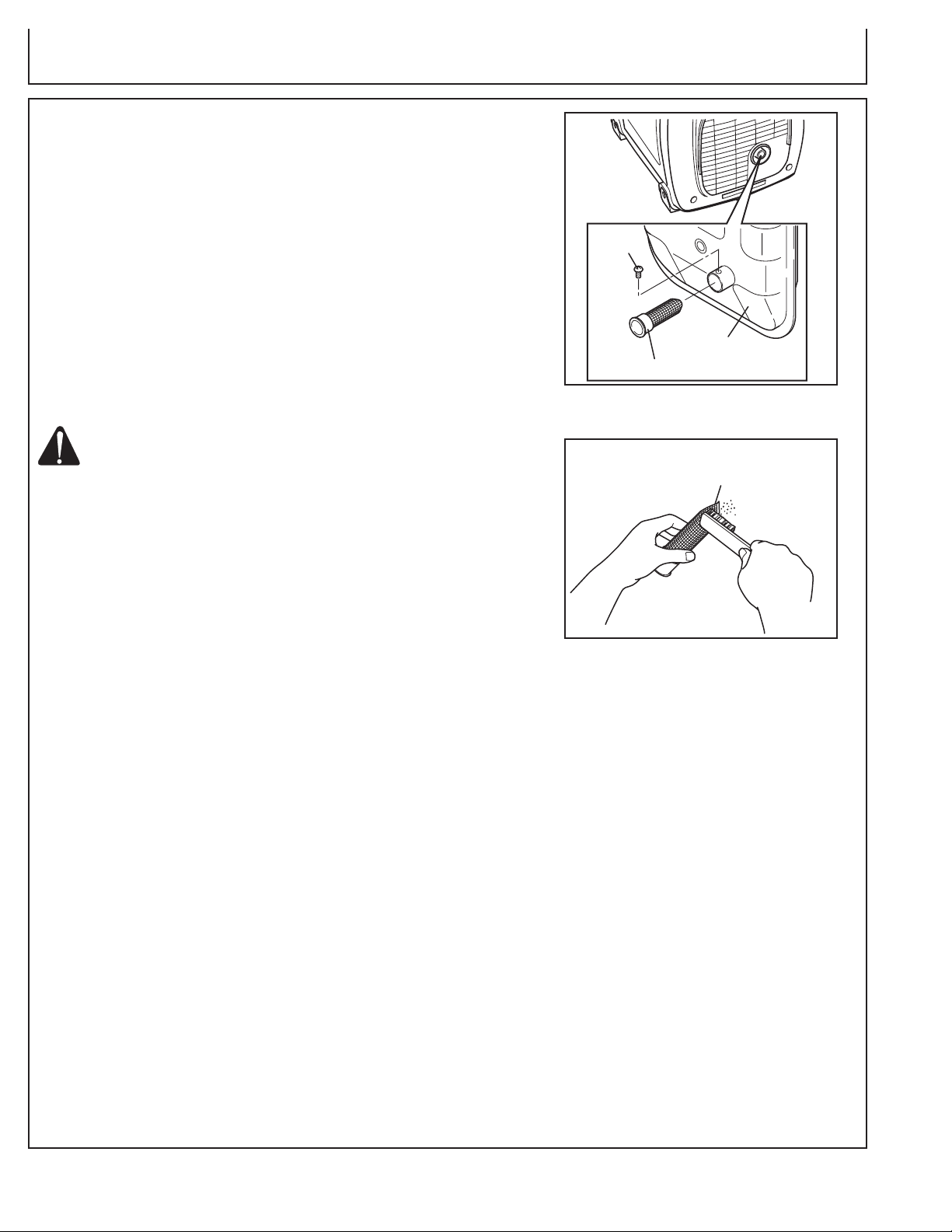

SPARK ARRESTER SCREEN

SPARK

ARRESTER

SCREEN

SCREW

MUFFLER

OPERATION

SPARK ARRESTER:

In a dry or wooded area, it is recommended to use the product with a

spark arrester. Some areas require the use of a spark arrester. Please

check your local laws and regulations before operating your product.

The spark arrester must be cleaned regularly to keep it functioning as

designed.

A clogged spark arrester :

• Prevents the flow of exhaust gas

• Reduces engine output

• Increases fuel consumption

• Makes starting difficult

(Fig. 13)

CAUTION: IF THE ENGINE HAS BEEN RUNNING, THE

M U F F L E R A N D T H E S PA R K A R R E S T E R

WILL BE VERY HOT. ALLOW THE MUFFLER TO COOL

BEFORE CLEANING THE SPARK ARRESTER.

How to remove the spark arrester (Fig. 13):

1. Remove the flange bolts from the muffler cover and remove the

muffler cover.

2. Remove the special screw from the spark arrester and remove the

spark arrester from the muffler.

Clean the spark arrester screen (Fig. 14):

1. Use a brush to remove carbon deposits from the spark arrester screen.

Be careful to avoid damaging the screen.

2. The spark arrester must be free of breaks and holes. Replace the

spark arrester if it is damaged.

3. Install the spark arrester, and muffler protector in the reverse order

of disassembly.

(Fig. 14)

30 Operator’s Manual

Page 31

Troubleshooting

When generator engine fails to start after several attempts, or if no electricity is available at the output socket, check

the following chart. If your generator still fails to start or generate electricity, contact your nearest John Deere dealer or

service shop for further information or corrective procedures.

Symptom Problem Solution

Engine will not start. Check if engine switch is off. Turn engine switch to the “ “

(CHOKE)

Fuel Tank empty. Fill tank making sure not to overfill.

position.

Check to make sure generator is not If connected,

connected to an appliance. on the connected appliance and

unplug.

Check spark plug for loose spark If loose, push spark plug cap back

plug cap. into place.

Check spark plug for contamination. Remove spark plug and clean

electrode.

Check engine oil level. If the engine oil level is low, add oil

per “Pre-Operation; Engine Oil” on

page 21.

Generator has no output. Check the AC and DC breakers. Depress the circuit breaker into the ON

(Output Lamp is ON) Check if the DC circuit breaker is position, after making sure the electric

turned off. power level is proper and the electric

appliance (s) are in the normal

condition.

Check to see if the engine was started Turn off the appliance, and disconnect

with appliances already connected to cable from receptacle. Reconnect

the generator. after the generator has been started

properly.

turn off the power switch

Low power. Carbon brushes are excessively worn,

contact an authorized John Deere

Service Center or Dealer.

Generator has no output. Contact an authorized John Deere

(Output Lamp is OFF) Service Center or Dealer.

Operator’s Manual 31

Page 32

Service

MAINTENANCE SCHEDULE

Maintenance, replacement or repair of the emission control devices and

systems must be performed by an authorized John Deere Service Center

or Dealer.

DAILY INSPECTION:

Before running the generator, check the following service items:

• Leakage of gasoline and engine oil.

• AC receptacles and DC terminals for damage.

• Excessive vibration, noise.

• Loose or broken bolts, nuts or shields.

• Clean air element.

PERIODIC MAINTENANCE:

Periodic maintenance is vital to safe and efficient operation of your

generator.

Check the Periodic Maintenance Table for periodic maintenance

intervals.

NOTE: REPLACEMENT, REPAIR AND ADJUSTMENT OF THESE

COMPONENTS MUST BE PERFORMED BY AN AUTHORIZED

JOHN DEERE SERVICE CENTER OR DEALER.

The emission control system consists of the following parts:

• Carburetor and internal parts

• Cold start enrichment system, if applicable

• Intake manifold, if applicable

• Air cleaner element

• Spark plug

• Magneto or electr

• Spark advance / retard sys

• Exhaust manifold, if applicable

• Hoses, belts, connectors, and assemblies

onic ignition system

tem, if applicable

32 Operator’s Manual

Page 33

Service

MAINTENANCE SCHEDULE

PERIODIC MAINTENANCE TABLE:

The maintenance schedule indicated in the table is based on the normal generator operation. Should the

generator be operated in extremely dusty condition or in heavier loading condition, the maintenance intervals

must be shortened depending on the contamination of oil, clogging of filter elements, wear of parts, and so on.

Maintenance Items Every 8

hours (Daily)

Clean generator and

check bolts and nuts.

Check and refill

engine oil.

AC receptacles

DC terminal

Engine switch

Clean air element.

Clean spark plug.

Change engine oil. *

Spark arrester

Replace air element.

Clean fuel filter.

Clean and adjust spark

plug and electrodes.

Replace spark plug.

Remove carbon from

cylinder head. **

Check and adjust valve

clearance. **

Clean and adjust

carburetor. **

Clean and replace carbon

brushes.**

Overhaul engine **

Rotor **

Stator **

Replace engine mount **

Replace fuel lines ** Yearly

•

(Refill daily up to upper level)

•

•

•

•

Every 20

hours

(Initial)

• •

Every 50

hours (Weekly)

•

•

Every 100

hours

•

Every 200

hours (Monthly)

•

•

•

Every 500

hours

•

•

•

•

•

Every 1000

hours

•

•

•

•

* NOTE: Initial oil change should be performed after the first twenty (20) hours of operation. Thereafter, change oil every

hundred (100) hours. Before changing oil, check for a suitable way to dispose of old oil. Your local zoning or

environmental regulations will give you more detailed instructions on proper disposal.

**NOTE: As to the procedures for these items, contact your authorized John Deere Service Dealer.

Operator’s Manual 33

Page 34

Service

Oil Drain Plug

Element

Air Cleaner Cover

MAINTENANCE SCHEDULE

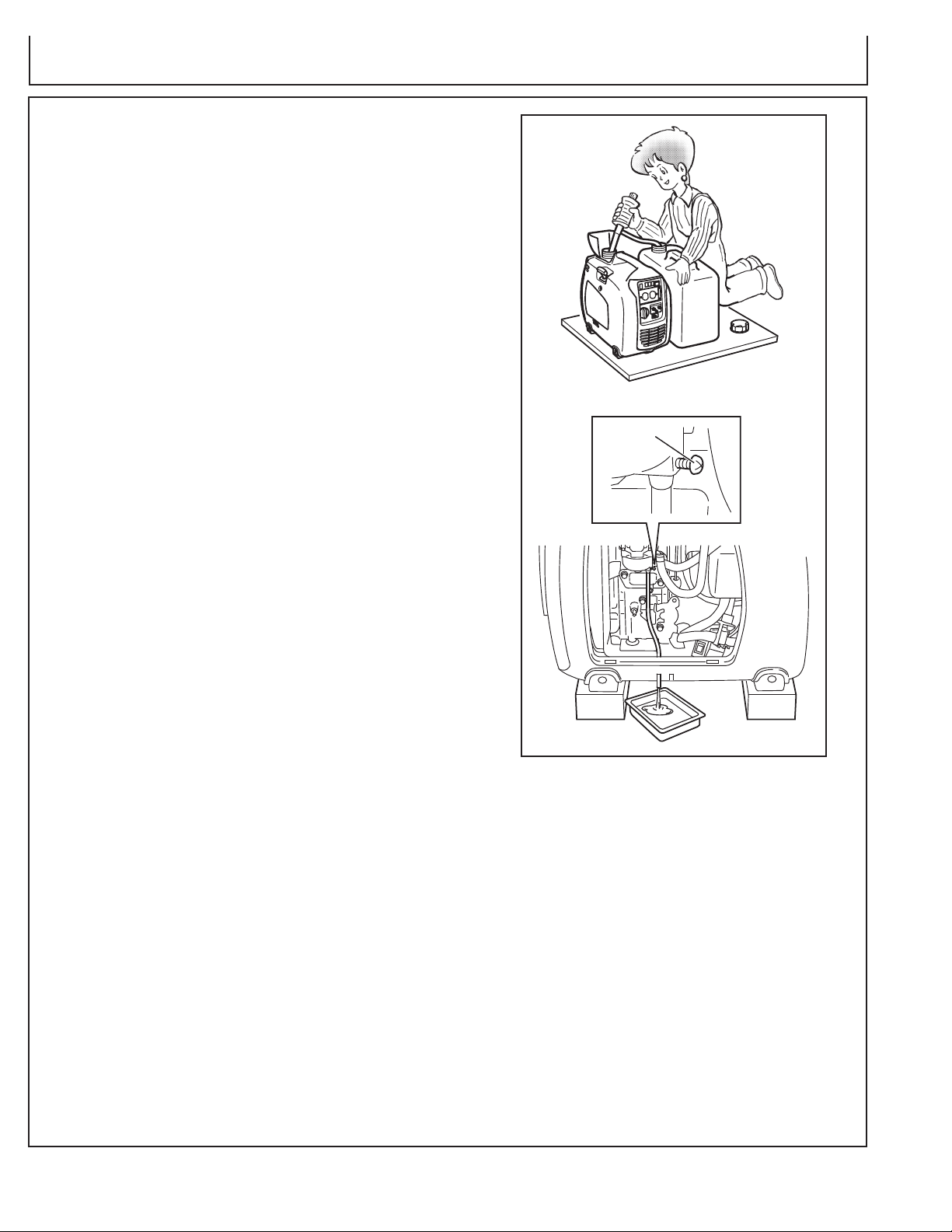

CHANGING ENGINE OIL:

Change oil after the first 20 hours of operation. Thereafter

it should be changed every 100 hours.

1. Drain oil by removing the drain plug and the oil filler

cap while the engine is warm. (Fig. 15)

2. Reinstall the drain plug and fill the engine with oil until

it reaches the upper level on the oil filler cap.

NOTE: John Deere PLUS-4® oil is the preferred oil to use.

If John Deere PLUS-4® oil is not available, use 4stroke automotive detergent oil of API service class

SE or higher grade (SG, SH or SJ is recommended).

If contaminated or deteriorated oil is used or the

quantity of the engine oil is not sufficient, the

engine damage will result and its life will be greatly

shortened.

3. Dispose of used oil according to local zoning or

environmental regulations.

SERVICING THE

AIR CLEANER:

Maintaining an air cleaner in proper condition is very

important. Dirt induced through improperly installed,

improperly serviced or inadequate elements damages

and wears out engines. Always keep the element clean.

(Fig. 16)

1. Unhook the cover and remove the cleaner element.

2. Urethane foam: Wash the element with fresh water.

Squeeze out the water then dry the element. (Do not

twist.)

(Fig. 15)

(Fig. 16)

34 Operator’s Manual

Page 35

Service

Spark Plug

Plug Wrench

0.024 - 0.028 in

MAINTENANCE SCHEDULE

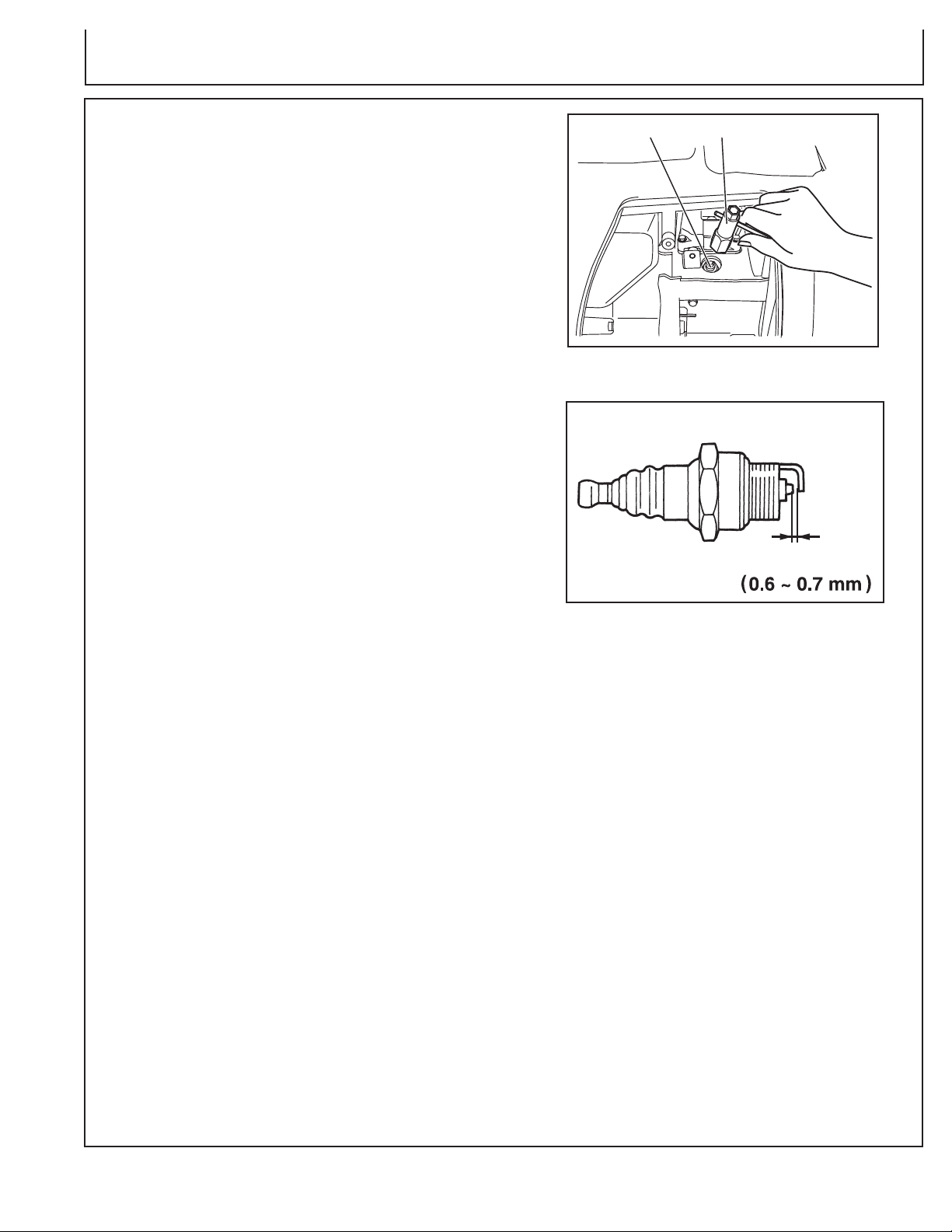

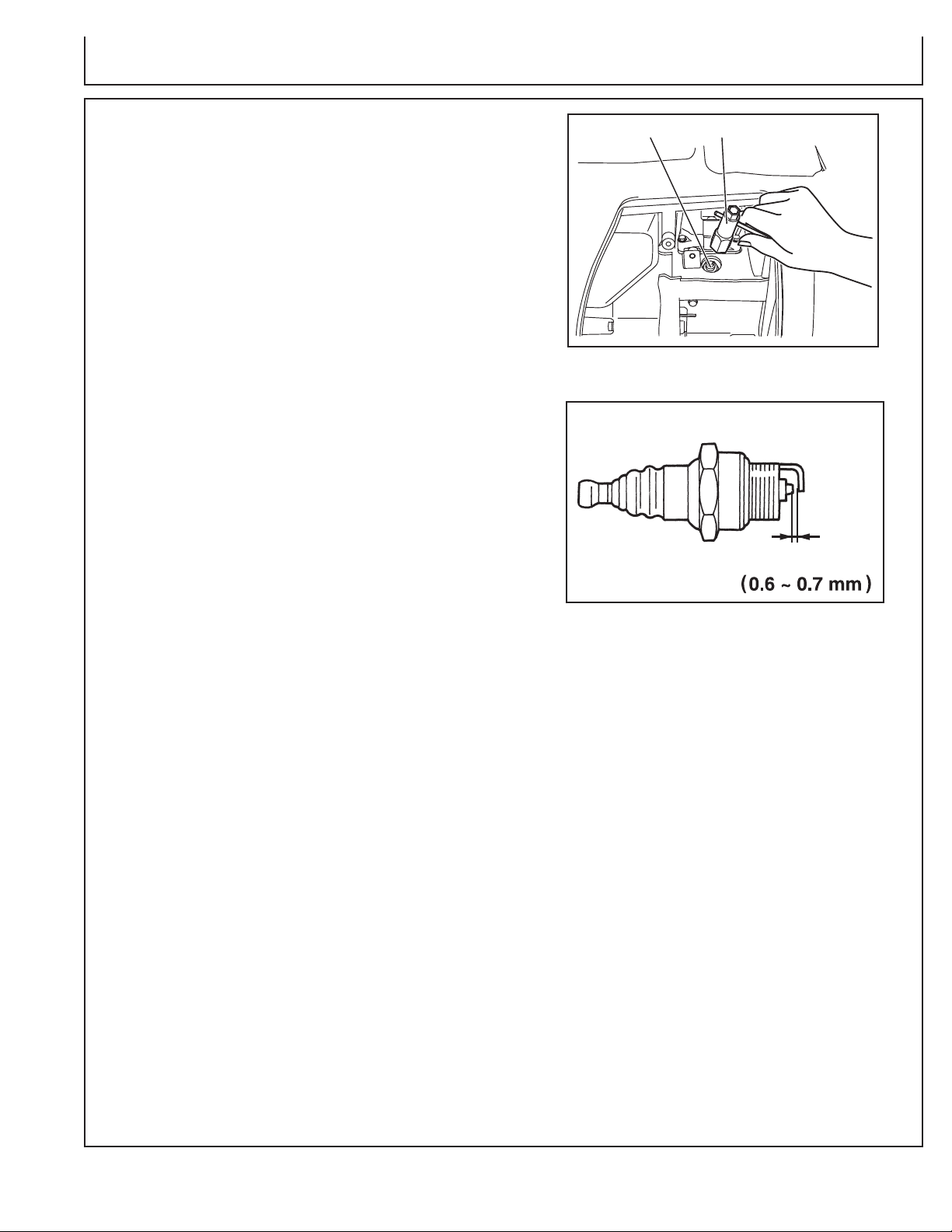

CLEANING AND GAPPING SPARK PLUG:

If the plug is contaminated with carbon, remove the carbon

using a plug cleaner or wire brush. (Fig. 17)

Adjust the electrode gap to 0.6 to 0.7 mm (0.024 to

0.028 in). (Fig. 18)

Recommended Spark Plug:

Spark Plug .................NGK BMR4A Champion

(Fig. 17)

(Fig. 18)

Operator’s Manual 35

Page 36

Storage

Drain Screw

PREPARATION FOR STORAGE

The following procedures should be followed prior to

storage of your generator for periods of 6 months or

longer.

1. Drain fuel from fuel tank carefully by disconnecting the

fuel line. Gasoline left in the fuel tank will eventually

deteriorate making engine-starting difficult.

2. When draining fuel from the fuel tank, it is best use a

hand pump and set it into the refilling port. Do not tip

unit over to empty fuel.

3. Remove the drain screw of the carburetor. (Fig. 19)

4. Change engine oil.

5. Check for loose bolts and screws, tighten them if

necessary.

Service

6. Clean generator thoroughly with clean cloth.

USE WATER TO CLEAN GENERATOR!

7. Pull recoil starter handle until resistance is felt, leaving

handle in that position.

8. Store generator in a well ventilated, low humidity

area.

NEVER

(Fig. 19)

36 Operator’s Manual

Page 37

Specifications

SPECIFICATIONS

ITEM SPECIFICATION

ALTERNATOR ...............................................................2-pole, Revolving Field, Self Exciting, Single Phase,

AVR Brush Type

Frequency ..................................................................... 60 Hz

Rated voltage ............................................................... AC 120V

Rated output ................................................................900 VA (0.9 kVA)

Rated Amperage .......................................................... 7.5 A

Rated power factor ...................................................... 1.0

DC output ..................................................................... 12V @ 8.3A

Over current protector .................................................. Circuit Breaker

GROUND SYSTEM ....................................................... Neutral Ground

ENGINE ......................................................................... Forced air-cooled, 4-cycle, OHV Gasoline Engine

Displacement ............................................................... 5.24 cu. in. (85.8 mL)

Fuel .............................................................................. Automotive Unleaded Gasoline

Fuel tank capacity (gal./L) ............................................ 0.93 / 3.5

Rated continuous operation ......................................... 3.5 hours (approx.)

Starting system ............................................................ Recoil starter

DIMENSION ................................................................... Length: 19.3 in (490 mm)

Width: 11.6 in (295 mm)

Height: 17.5 in (445 mm)

DRY WEIGHT ................................................................ 56.1 lb. (25.5kg)

VALVE CLEARANCE

(Intake & Exhaust) (in / mm) ........................................ 0.0039 0.0012 / 0.1 0.03

Note: Adjust the valve clearance while the engine is cold.

EMISSIONS DURABILITY PERIOD .............................. 250 hours

(California Only)

+

-

+

-

RECORD SERIAL NUMBER

Write you model number, machine serial number (see

serial number tag in illustration) and date of purchase in the

spaces provided below. Your dealer needs this information

when ordering parts.

Model No. ______________________________________________

Machine Serial No. _______________________________________

Date of Purchase ________________________________________

(To be filled in by purchaser)

Operator’s Manual 37

Page 38

Wire Diagram

38 Operator’s Manual

Page 39

Warranty

STATEMENT OF WARRANTY

The John Deere warrants all parts, (except those referred to below), of your new generator

to be free from defects in materials and workmanship during the following periods:

For Two (2) Years from the date of original purchase.

Defective parts not subject to normal wear and tear will be repaired or replaced at our

option during the warranty period. In any event, reimbursement is limited to the purchase

price paid.

ExcluSiONS

1. Engine/Motor and Generator are covered under separate warranty by its respective

manufacturer and is subject to the terms set forth therein.

2. This warranty does not cover parts damaged due to normal wear, misapplication, misuse,

operation at other than recommended . Failure to follow recommended operating and

maintenance procedures also voids warranty.

3. The use of other than genuine manufacturer repair parts will void warranty.

4. Parts returned, prepaid to our factory or to an Authorized John Deere Service Center

will be inspected and replaced free of charge if found to be defective and subject

to warranty. There are no warranties which extend beyond the description of the

face hereof. Under no circumstances shall the manufacturer bear any responsibility

for loss of use of the unit, loss of time or rental, inconvenience, commercial loss or

consequential damages.