Page 1

HR-2410GH

Cold Water

Pressure Washer

Operator's Manual 1

Page 2

INTRODUCTION .............................................................................................................................3

IMPORTANT SAFETY WARNINGS.............................................................................................4-7

FEATURES DRAWINGS ................................................................................................................. 8

SAFETY DECALS ........................................................................................................................... 9

INSTALLATION & PREPARATION .........................................................................................10-13

OPERATING INSTRUCTIONS ................................................................................................14-15

STORAGE & MAINTENANCE .................................................................................................16-17

TROUBLESHOOTING .................................................................................................................. 18

TABLE OF CONTENTS

FIRE & VENTILATION PRECAUTIONS ...................................................................................4

SPRAY PRECAUTIONS ...........................................................................................................5

DETERGENT CLEANING PRECAUTIONS ..............................................................................6

MISCELLANEOUS SAFETY PRECAUTIONS ..........................................................................6

ADJUSTMENT PRECAUTIONS ...............................................................................................7

ATTIRE ...................................................................................................................................10

SET-UP ...................................................................................................................................10

ENGINE FUEL TANK .............................................................................................................. 10

NOZZLE REVIEW ................................................................................................................... 11

NOZZLE CONNECTION ......................................................................................................... 11

WATER SUPPLY .....................................................................................................................12

HEAT DUMP VALVE ...............................................................................................................12

PRE-START INSPECTION PROCEDURES ........................................................................... 13

PRIMING THE PUMP ............................................................................................................. 14

START-UP ...............................................................................................................................14

CLEANING WITH DETERGENTS ..........................................................................................15

SHUTDOWN ...........................................................................................................................15

SPECIFIC MAINTENANCE ...................................................................................................16

WINTERIZING ........................................................................................................................17

STATEMENT OF WARRANTY ..................................................................................................... 19

NOTES .....................................................................................................................................20-21

PROTECT YOUR INVESTMENT......

Use only John Deere Fuel Protect

Fuel Stabilizer with Ethanol Protection

TY27534 or TY27535. Developed to

ensure Optimum Performance and

Protection.

IMPORTANT...Use Year Round!

34-1904 012011

Warning: This product contains lead, a

chemical known to the State of California

to cause birth defects or other reproductive

harm.

Wash your hands after handling this product.

2 Operator's Manual

Page 3

INTRODUCTION

Congratulations on the purchase of your John Deere pressure washer! You can be assured your John Deere pressure

washer was constructed with the highest level of precision and accuracy. Each component has been rigorously tested

by technicians to ensure the quality, endurance and performance of this unit.

This operator's manual was compiled for your benet. By reading and following the simple safety, installation, operation,

maintenance and troubleshooting steps described in this manual, you will receive years of trouble free operation from your

John Deere pressure washer. The contents of this manual are based on the latest product information available at the

time of publication. John Deere reserves the right to make changes in price, color, materials, equipment, specications

or models at any time without notice.

! IMPORTANT !

These paragraphs are surrounded by a "SAFETY ALERT BOX". This box is used to designate and

emphasize Safety Warnings that must be followed when operating this pressure washer.

Accompanying the Safety Warnings are "signal words" which designate the degree or level

of hazard seriousness. The "signal words" used in this manual are as follows:

DANGER: Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided MAY

result in minor or moderate injury.

The symbols set to the left of this paragraph are "Safety Alert Symbols". These symbols

are used to call attention to items or procedures that could be dangerous to you or other

persons using this equipment.

ALWAYS PROVIDE A COPY OF THIS MANUAL TO ANYONE USING THIS EQUIPMENT. READ

ALL INSTRUCTIONS BEFORE OPERATING THIS PRESSURE WASHER AND ESPECIALLY

POINT OUT THE "SAFETY WARNINGS" TO PREVENT THE POSSIBILITY OF PERSONAL

INJURY TO THE OPERATOR.

Once the unit has been uncrated, write in the serial number of your unit in the space provided below.

SERIAL NUMBER_________________________________

Inspect for signs of obvious or concealed freight damage. If damage does exist, le a claim with the transportation

company immediately. Be sure that all damaged parts are replaced an that the mechanical and electrical problems are

corrected prior to operation of the unit. If you require service, contact your Customer Service.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

Please have the following information available for all service calls:

1. Model Number

2. Serial Number

3. Date and Place of Purchase

Operator's Manual 3

Page 4

IMPORTANT SAFETY WARNINGS

FIRE & VENTILATION PRECAUTIONS:

1. This unit was designed for outdoor use only. NEVER operate this unit in

an enclosed area. ALWAYS make certain there is adequate air (oxygen)

for combustion as well as ventilation to prevent the presence of poisonous

carbon monoxide gases. Beware of poorly ventilated areas or exhaust fans

which can cause inadequate combustion or engine overheating.

2. NEVER operate this unit in the presence of ammable vapors or combustible

dust, gases or other combustible materials. (A spark may cause an explosion

or re.) When servicing this machine, be especially careful to properly

dispose of any ammable materials. DO NOT spray ammable liquids.

3. ENGINE FUEL TANK:

a. DO NOT SMOKE WHILE FILLING ENGINE FUEL TANK

b. NEVER ll the engine fuel tank while the unit is running or hot. Allow

the engine to cool two minutes before refueling.

c. DO NOT refuel indoors or in a poorly ventilated area.

d. ALWAYS refuel slowly to avoid the possibility of spilled fuel which may

cause a risk of re.

4. DO NOT operate the unit if gasoline is spilled. Wipe unit clean and move

the unit away from the spill. Avoid creating any ignition until the gasoline

has evaporated.

5. DO NOT store the unit near an open ame or any equipment such as a

stove, furnace, water heater, etc., which utilizes a pilot light or devices which

can create a spark.

IMPORTANT

The following is required by California State law, Section 4442 of the California

Public Resources Code. Other states may have similar laws. Federal laws

apply on federal lands.

A spark arrester must be added to the mufer of this engine if it is

to be used on any forest covered, brush covered or grass covered

unimproved land. The arrester must be maintained in effective

working order by the operator.

See your engine or equipment dealer for spark arrester mufer options.

4 Operator's Manual

Page 5

IMPORTANT SAFETY WARNINGS

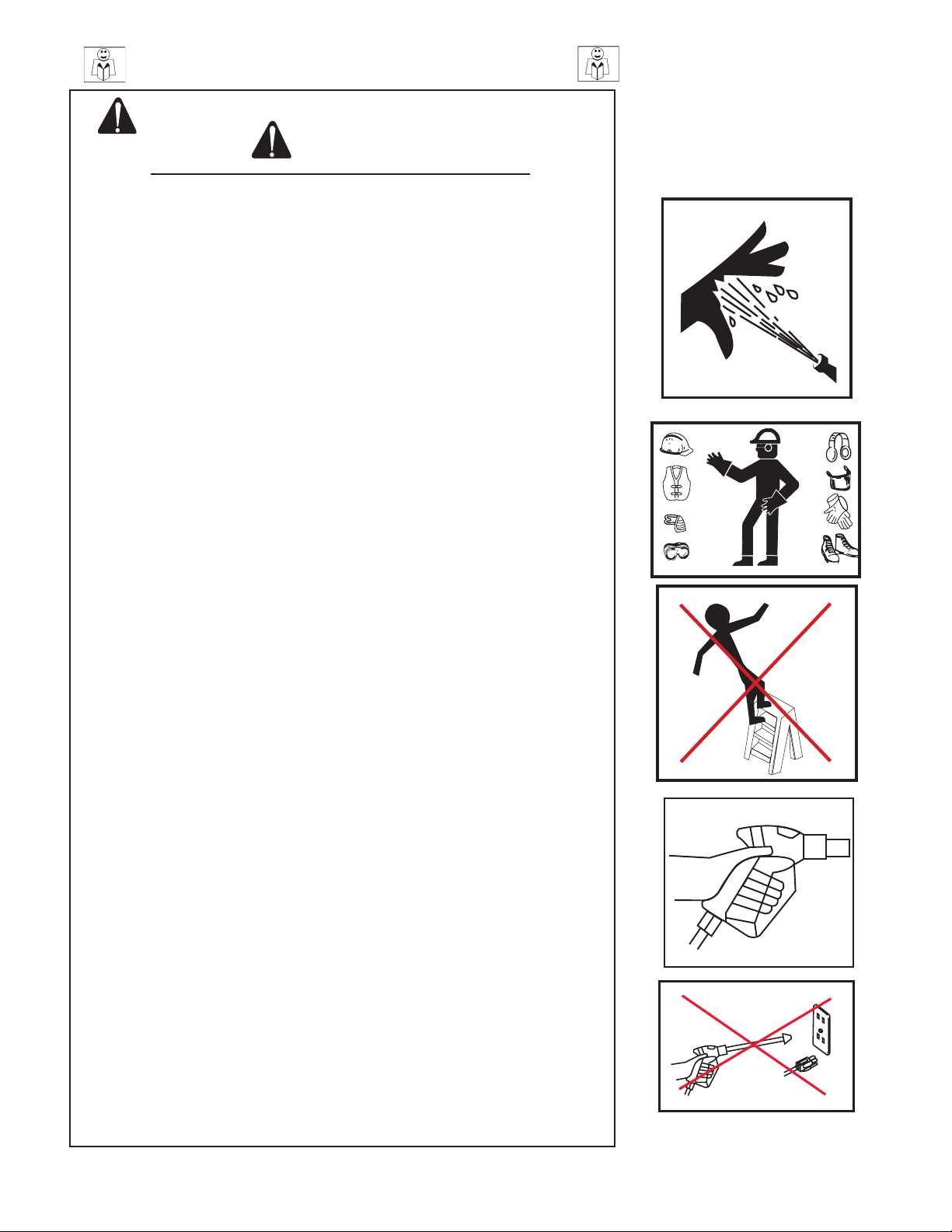

SPRAY PRECAUTIONS:

DANGER

RISK OF INJECTION OR SEVERE CUTTING INJURY

KEEP CLEAR OF NOZZLE

DO NOT DIRECT DISCHARGE STREAM AT PERSONS OR PETS.

ONLY TRAINED OPERATORS SHOULD USE THIS PRODUCT.

BASIC PRECAUTIONS SHOULD ALWAYS BE OBSERVED,

INCLUDING THE FOLLOWING:

1. KEEP AWAY FROM THE SPRAY:

a. Because of the high pressure and velocity of the spray, uids can

penetrate the skin, causing serious injury.

b. Never point the gun at yourself or anyone else. Never put your hand,

ngers or body directly over the spray nozzle. Always keep operating

area clear of all persons. Use extreme caution when operating near

children.

c. If an accident does occur and the spray appears to have penetrated

the skin, SEEK EMERGENCY MEDICAL CARE. DO NOT TREAT

AS A SIMPLE CUT. If you are using cleaning agents, be prepared

to tell a physician exactly what kind.

2. ALWAYS wear protective goggles when operating the unit to shield the

eyes from ying debris and detergents. Other protective equipment such

as rubber suits, gloves and respirators are advisable, especially when

using cleaning detergents. Use extreme caution when operating near

children.

3. Stay alert-watch what you are doing. Do not operate the unit when

fatigued or under the inuence of alcohol or drugs.

4. NEVER squeeze the trigger unless securely braced. The thrust from

the water traveling through the nozzle may be powerful enough to cause

the operator to lose balance if unprepared. DO NOT overreach or stand

on unstable support. Wet surfaces can be slippery, wear protective foot

gear and keep good footing and balance at all times. NEVER trigger

the gun while on a ladder or roof.

5. Caution should be used when directing spray toward fragile materials

such as glass. Shattering could result in serious injury.

6. ALWAYS hold on rmly to the gun/wand assembly when starting and

operating the unit. Failure to do so can cause the wand to fall and whip

dangerously. NEVER operate the gun with the trigger wired in the open

position. To prevent accidental discharge, the trigger gun should be

securely locked when not in use.

7. DO NOT direct spray on or into electrical installations of any kind! This

includes electrical outlets, light bulbs, fuse boxes, transformers, etc.

Severe electrical shock may occur.

8. Even after you shut off the unit, there is high pressure water left in the

pump, hose and gun until you release it by triggering the gun. Before

removing the spray nozzle or servicing the unit, ALWAYS shut off the

unit and trigger the gun to release trapped pressure.

Operator's Manual 5

Page 6

IMPORTANT SAFETY WARNINGS

DETERGENT CLEANING PRECAUTIONS:

1. DO NOT use solvents or highly corrosive detergents or acid type cleaners

with this pressure washer. Use only mild detergents.

2. KNOW YOUR DETERGENTS! Be prepared to tell a physician exactly

what you are using in the event of an emergency. Read the Material Safety

Data Sheet (MSDS) provided with your detergent and all detergent labels.

Follow all appropriate instructions regarding preparation, use, safety and

transportation. Keep ALL detergents out of the reach of children.

3. DO NOT use this pressure washer to dispense hazardous detergents.

4. DO NOT alter the detergent injection feature in any manner not prescribed

in this manual. Use only genuine manufacturer replacement parts for

necessary repairs.

MISCELLANEOUS SAFETY PRECAUTIONS:

1. NEVER ALLOW CHILDREN OR ADOLESCENTS TO OPERATE THIS

UNIT!

2. Read and follow all handling, operations, maintenance and safety instructions

listed in this manual and the Engine Operator's manual that accompanies

this unit, and provide such information to ANYONE who will be operating

this unit.

3. In freezing temperatures, the unit must always be warm enough to ensure

there is no ice formation in the pump. DO NOT start this unit if it has been

transported in an open or underheated vehicle without rst allowing the

pump to thaw.

4. When connecting the water inlet to the water supply mains, local regulations

of your water company must be observed. In some areas the unit must not

be connected directly to the public drinking water supply. This is to ensure

that there is no feedback of the detergents into the water supply. (Direct

connection is permitted if a back ow preventer is installed.)

5. DO NOT allow any part of your body or the high pressure hose to make

contact with the mufer. Avoid dragging the hose over an abrasive surface

such as cement. This causes wear and eventual rupturing.

6. High pressure hoses should be inspected daily for signs of wear. If evidence

of failure exists, promptly replace all suspect hoses to prevent the possibility

of injury from the high pressure spray. If a hose or tting is leaking , NEVER

place your hand directly on the leak.

7. DO NOT operate the unit without all protective covers in place.

8. NEVER run the unit with the governor disconnected or operate at excessive

speeds.

9. To reduce the risk of injury, maintain a safe distance for persons while

operating this unit. Close supervision is necessary when operating the unit

near children.

10. DO NOT leave pressurized unit unattended. Shut off the unit and release

trapped pressure before leaving.

11. DO NOT move the unit by pulling on the hose.

6 Operator's Manual

Page 7

IMPORTANT SAFETY WARNINGS

ADJUSTMENT PRECAUTIONS:

1. NEVER alter or modify the equipment, be sure any accessory items and

system components being used will withstand the pressure developed.

Use ONLY genuine manufacturer parts for repair of your pressure washer.

Failure to do so can cause hazardous operating conditions and will void

warranty.

2. NEVER make adjustments to the machinery while it is connected to the

engine without rst removing the ignition cable from spark plug. Turning

the machinery over by hand during adjustment or cleaning might start the

engine and machinery with it, causing serious injury to the operator.

3. Know how to stop the pressure washer and bleed pressures quickly. Be

thoroughly familiar with controls.

4. Before servicing the unit; turn the unit off, relieve the water pressure,

and allow the unit to cool down. Service in a clean, dry, at area. Block

the wheels to prevent the unit from moving.

5. Follow the maintenance instructions specied in this manual.

! SAVE THESE INSTRUCTIONS !

Operator's Manual 7

Page 8

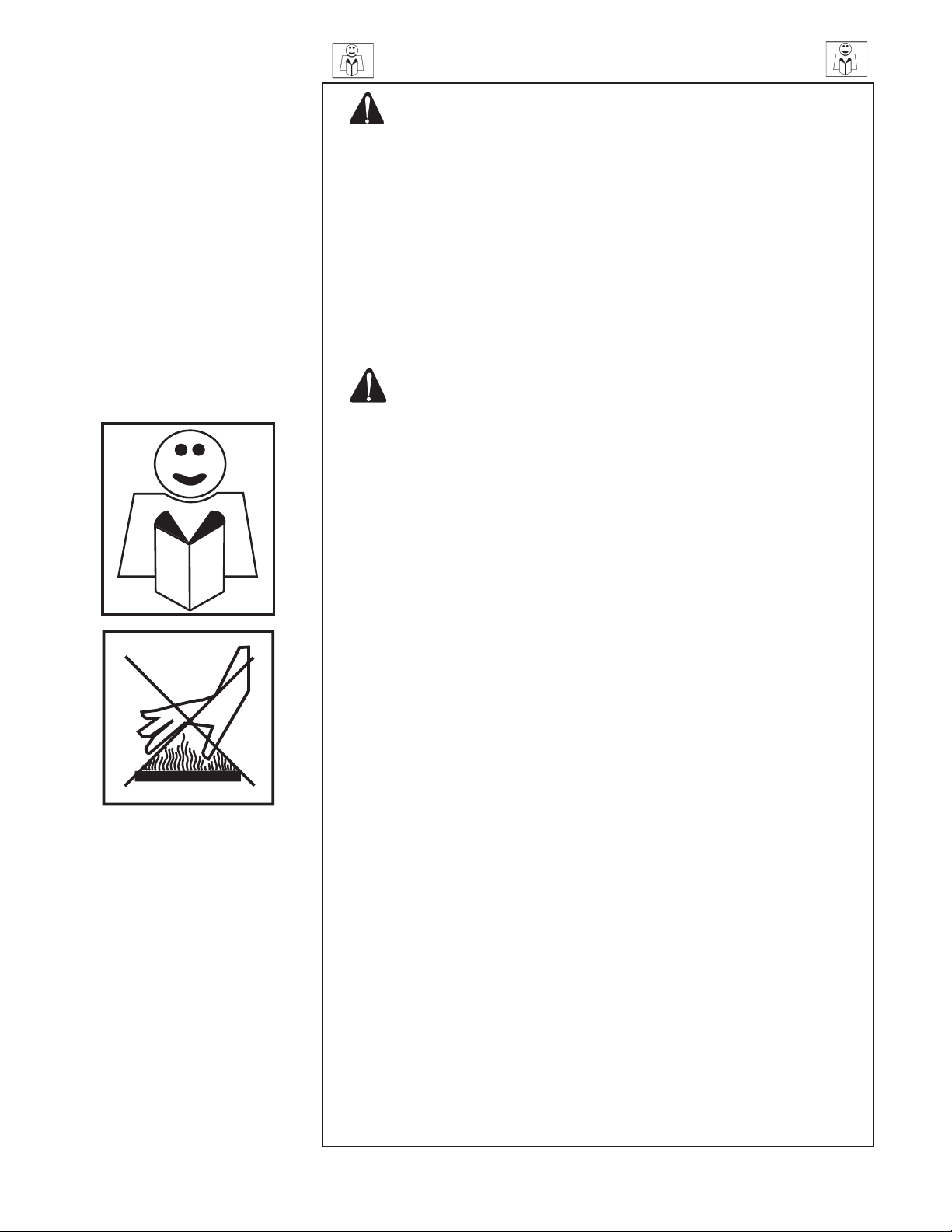

FEATURES

FEATURES LISTING

CV UNITS WITH QC FEATURES 040510

8 Operator's Manual

1. Gun Holder

2. Nozzle Holder

3. Quick Connect Assembly

4. Gun Assembly

5. Engine

6. Chemical Hose

7. High Pressure Hose

8. Unloader

9. Chemical Injection Inlet

10. High Pressure Outlet

11. Thermal Relief Valve

12. Pump

13. Water Supply-Inlet

14. Inlet Filter

Page 9

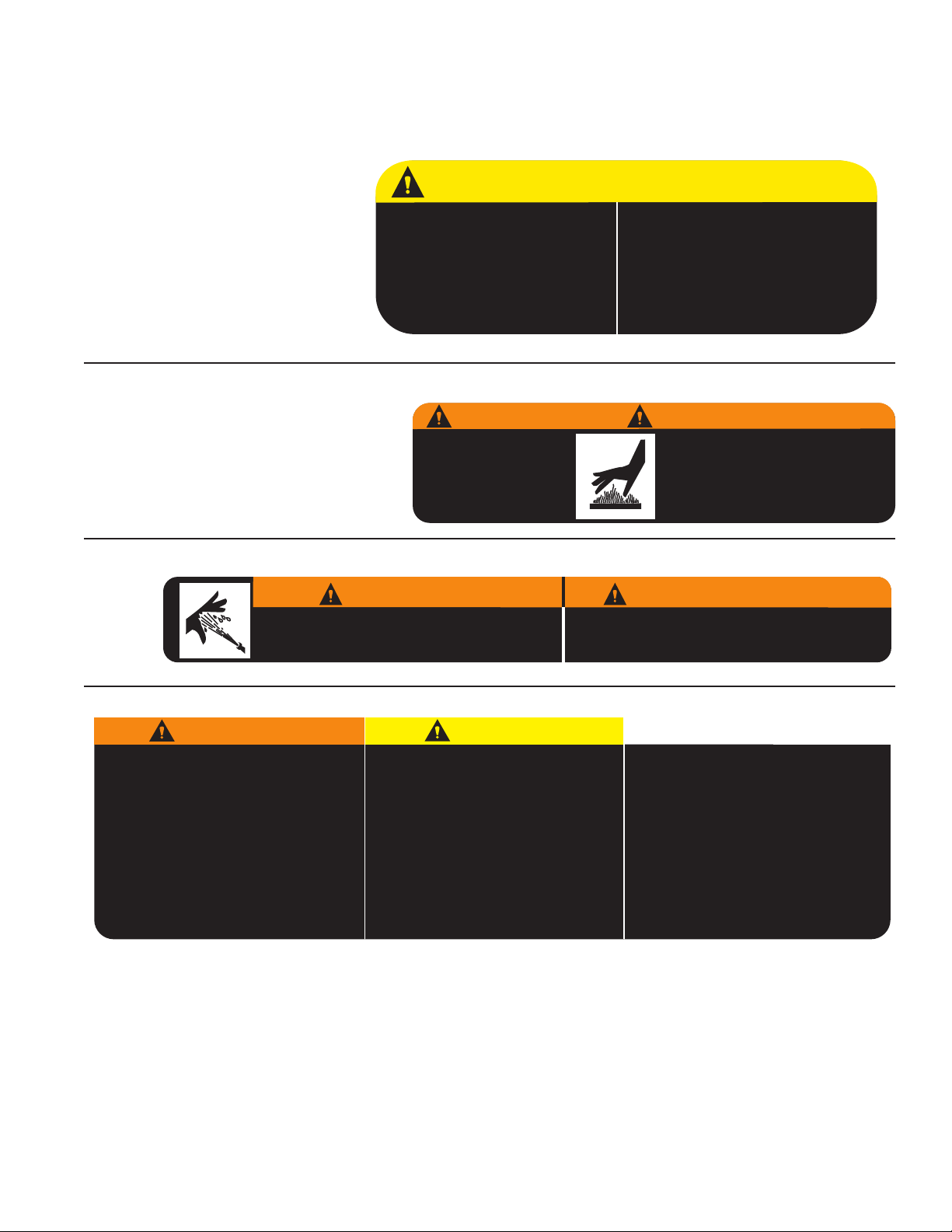

SAFETY DECALS & PLACEMENT FOR HR-2410GH

RISK OF BURNS

MUFFLER AND

ADJACENT AREAS

MAY EXCEED 150°F.

RIESGO DE QUEMAR

EL AMORTIGUADOR Y LAS

AREAS ADYACENTES PUEDEN

TENER TEMPERATURAS POR

ARRIBA DE 150°F.

34-0598-010699-E/S-ENG.

WARNING

ADVERTENCIA

34-0599-E/S-030600-ENG

No ponga combustible cuando

el producto este en operacion.

Permita que el motor se enfrie

por 2 minutos antes de

reablastecer de combustible.

RISK OF FIRE

Do not add fuel when

product is operating. Allow

engine to cool for two (2)

minutes before refueling.

RIESGO DE FUEGE

CAUTION/PRECAUCION

WARNING

CAUTION

• Risk of Injection or Severe Injury: Keep clear of

nozzle. Do not direct spray toward any person or

self.

• Risk of Asphyxiation: Outdoor use only required.

• Risk of Fire: Do not smoke while refueling. Allow to

cool two to three minutes before refueling. Do not

operate while refueling.

• Risk of Electrocution: Do not direct spray toward

any electrical connections, outlets or power lines.

• Risk of Explosion: Do not spray flammable liquids.

• Risk of Injury: Use only properly rated equipment.

• To Reduce Risk of Injury: Read and understand

the operation manual and all instructions before

using.

• Stay Alert: Hold on to gun/wand firmly with both

hands to avoid dangerous kickbacks.

• Always wear eye protection.

• Do not over-reach or stand on unstable support.

Keep good footing and balance at all times.

• Always turn on water supply to pump before

starting.

• Protect pump from freezing.

• Engage trigger safety lock-off when not in use.

OPERATION

• After ensuring all connections are secure, open

inlet water supply completely. Do not operate

without water. Do not use water that is over

70°F/21°C.

• Point gun in a safe direction and adjust nozzle to

low pressure. Brace wand securely to avoid recoil.

Squeeze trigger open and steady the unit while

starting. Start the unit by firmly pulling starter rope.

• After engine is running, adjust the nozzle to

desired setting, squeeze trigger to spray and

release the trigger to stop spray.

• After stopping the engine, always turn off water

supply and squeeze trigger to release trapped

pressure.

34-1883-102506-ENG.

RISK OF INJECTION OR SEVERE INJURY.

Never put your hand, fingers or body directly

over the spray nozzle.

34-1253-030801-ENG.

WARNING

ADVERTENCIA

RIESGO DE INYECCION O LISION SEVERA

Nunca coloque la mano, los dedos o el cuerpo

directamente sobre la boquilla de rocío.

DO NOT REMOVE SAFETY DECALS FROM UNIT

UNLESS REPLACING WITH MOST CURRENT SAFETY DECAL!!!

Reference #2 Decal: Caution-Allow to Cool (Part #34-0599)

Reference #3 Decal: Warning-Mufer Hot (Part #34-0598)

Reference #13 Decal: Warning: Risk of Injection (Part #34-1253)

Reference #4 Decal: Warning/Caution/Operating Instructions (Part #34-1883)

Operator's Manual 9

Page 10

INSTALLATION & PREPARATION

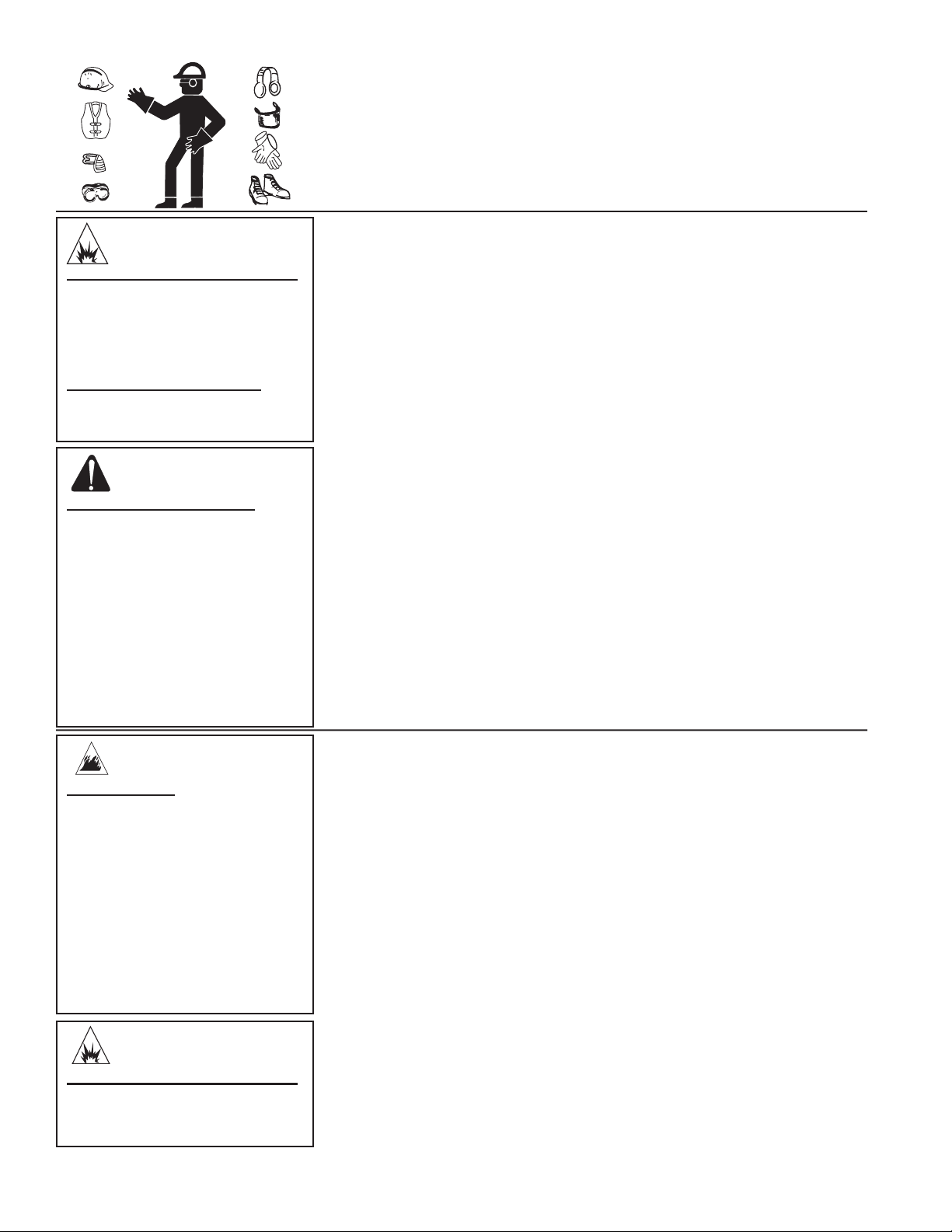

ATTIRE:

Proper attire is essential to your safety. It is advised to utilize whatever means

necessary to protect eyes, ears, and skin. Additional safety attire (such as

respiratory mask) may be required when using detergent cleaning agents with

this washer.

DANGER

RISK OF EXPLOSION OR FIRE!

DO NOT PLACE UNIT IN AN

AREA WHERE FLAMMABLE

GAS VAPORS MAY BE PRESENT.

A SPARK COULD CAUSE AN

EXPLOSION OR FIRE!

RISK OF UNIT BURSTING!

DO NOT STORE/OPERATE UNIT

IN A FREEZING ENVIRONMENT.

WARNING

RISK OF ASPHYXIATION!

-DO NOT O PERATE IN AN

ENCLOSED AREA. USE THIS

PRODUCT ONLY I N WELL

VENTILATED AREAS!

-TH E EXHAUST FROM THE

ENGINE CONTAINS CARBON

MONOXIDE, A POISONOUS,

ODORLESS AND INVISIBLE

GAS. BREATHING THIS GAS

CAN CAUSE SERIOUS INJURY,

ILLNESS & POSSIBLE DEATH.

SET-UP:

1. This unit should only be placed on a level surface to ensure proper lubrication

for the engine and water pump while operating.

2. DO NOT place unit in an area:

a. with insufcient ventilation.

b. where there is evidence of oil or fuel leaks.

c. where ammable gas vapors may be present.

3. Be certain to block the wheels to prevent the unit from moving while operating.

If applicable, attach the handle to the unit and line up the holes in the base

and handle. Locate the two knobs and bolts supplied with your unit. Push

the bolts through the handle holes and tightly screw onto the threaded

knobs.

4. Remove the hose assembly and gun assembly from the carton. If applicable,

screw the male end of the hose into the female end of the gun. Tighten

securely.

5. Do not allow the unit to be exposed to rain, snow or freezing temperatures.

If any part of the unit becomes frozen, excessive pressure may build up in

the unit which could cause it to burst, resulting in possible serious injury to

the operator or bystanders.

DANGER

RISK OF FIRE!

-D O N O T S MO KE W H I L E

FUELING!

-DO NOT FILL THE FUEL TANK

WHILE UNIT IS RUNNING OR

HOT. ALLOW UNIT & ENGINE TO

COOL FOR 2 MINUTES BEFORE

REFUELING!

-DO NOT FILL FUEL TANK TO

POINT OF OVE RFLOWING.

ALLOW 1/4" OF TANK SPACE

FOR FUEL EXPANSION.

WARNING

RISK OF EXPLOSION OR FIRE!

ALWAYS STORE FUEL AWAY

FROM THE WASHER WHILE THE

UNIT IS RUNNING OR HOT.

10 Operator's Manual

ENGINE FUEL TANK:

1. Review "Fire & Ventilation Precautions" pg. 4, before fueling.

2. Locate the Safety Decals on your unit and heed their warnings.

3. On initial start-up, add oil to the engine, (20 oz.). See Engine manual for

proper oil level. The oil level must be checked each time thereafter before

starting the engine.

4. A minimum of 77 octane fuel is recommended for use with this unit. DO

NOT MIX OIL WITH GASOLINE.

5. Purchase fuel in quantities that may be used within 30 days. Use of clean,

fresh lead free gasoline is recommended. Leaded gasoline may be used

if lead-free is unavailable. DO NOT use gasoline containing methanol or

alcohol.

6. Fill the fuel tank according to accompanying engine manual instructions.

7. Review the engine manual accompanying this pressure washer for

correct engine start-up and maintenance procedures.

Page 11

INSTALLATION & PREPARATION

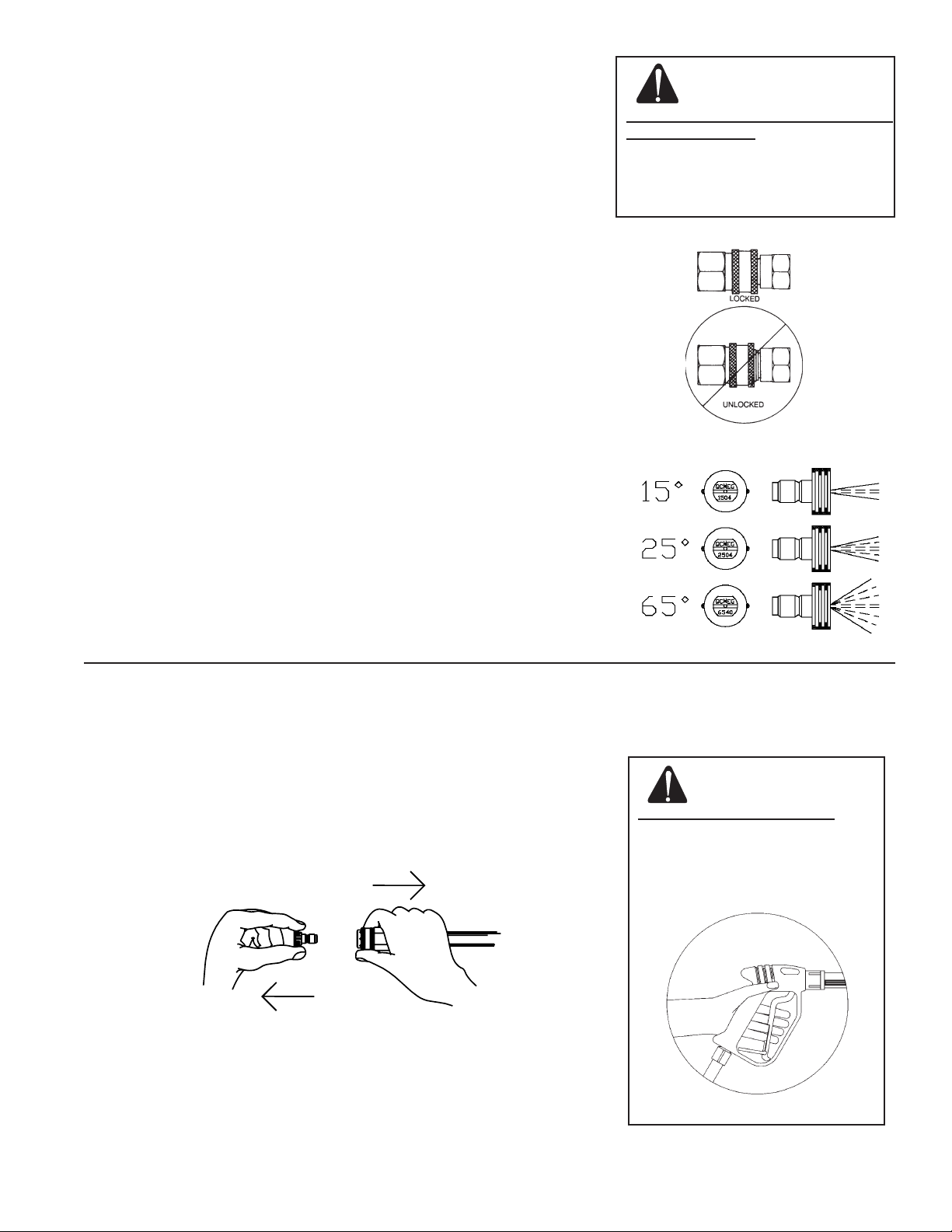

NOZZLE REVIEW:

Various nozzles may be quick-connected into the end of the wand to change the

spray pattern. When using Quick Connects (Q.C.), be certain the connection

is securely locked. If not, the high pressure water may shoot the nozzle from

the wand, causing severe injury or serious damage. To determine spray fan,

refer to the actual number stamped on the nozzle. The rst two digits indicate

the spray fan in degrees, i.e.; 15=15°, 25=25°, 65=65°.

1. The 15° nozzle (YELLOW): This is a chiseling nozzle. The spray

should be directed at a 45° angle to the surface and used like a scraper

to remove paint, grease and dirt. Uses: Surface preparation (removing

mildew stains and paint chips).

2. The 25° nozzle (GREEN): This is a ushing nozzle. This pattern is best

suited for ushing dirt, mud, and grime. Uses: Wet sweeping leaves from

walks, curbs and driveways, cleaning stable oors, washing swimming

pool bottoms, degreasing engines.

3. The 65° nozzle (BLACK): This is a low pressure detergent application

nozzle. This broad spray pattern distributes solution over vast areas

under low pressure. Uses: Detergent application, misting or rinsing.

WARNING

RISK OF INJECTION CAUSING

SEVERE INJURY!

-NEVER LOOK DIRECTLY AT THE

NOZZLE ORIFICE UNLES S IT

IS DISCONNECTED FROM THE

GUN/WAND ASSEMBLY!

CONNECTION OF Q.C. NOZZLES

QUICK-CONNECT (Q.C.)

NOZZLE CONNECTION:

1. Be certain the trigger gun is locked in the “OFF” position. See WARNING

at right.

2. The nozzle assembly should be disconnected from the gun assembly

at this time by retracting the locking ring on the quick-connect tting to

remove the nozzle.

QUICK-CONNECTION

WARNING

RISK OF SEVERE INJURY!

THE TRIGGER GUN SHOULD

ALWAYS BE LOCKED IN THE OFF

POSITION WHEN NOT IN USE!

Operator's Manual 11

Page 12

CHECK WATER INLET STRAINER

INSTALLATION & PREPARATION

WATER SUPPLY:

1. Select a water supply hose which is a quality grade of garden hose measuring

at least 3/4" ID and no longer than 50 feet.

2. Check the water inlet lter to ensure it is clean and free of any obstructions.

Periodic cleaning of the water lter will help prevent pump problems. As

a lter becomes obstructed, it restricts proper ow of water to the pump.

This can result in cavitations which will cause premature failure of pump

packings. Using a screwdriver, remove the strainer from the unit. Clean,

or replace if necessary.

3. Connect the hoses:

a. Connect one end of the water supply hose to the water inlet of the

unit.

b. Connect the other end of the hose to your pressurized water supply.

Do not use a non-pressurized water supply (i.e. from a pond or well)

with this unit.

c. Connect the high pressure discharge hose to the water outlet of the

unit.

d. High Pressure Discharge Hose to Gun. (If Applicable)

4. Follow the incoming water requirements listed below:

a. Water pressure must be a minimum of 20 pounds per square inch (PSI)

and a maximum of 125 PSI. (A typical outdoor faucet will generally

supply this PSI if turned completely "ON".)

b. Incoming GPM must be approximately one gallon more than the outgoing

GPM stated on the pressure washer nameplate. (You can check GPM

by timing how long it takes to ll a 5 gallon container.)

c. Incoming water temperature must not exceed 125°F. Excessive pump

damage may result if the water temperature exceeds this acceptable

level.

5. Never allow the unit to operate without the incoming water line attached and

the water supply completely turned on.

HEAT DUMP VALVE:

To ensure the water temperature does not exceed acceptable levels, never allow

the pressure washer to operate in the bypass mode (with the unit running and

the trigger gun closed) for more than three minutes.

Your unit is provided with a heat dump valve. The heat dump valve will be

located opposite the water inlet on your pump. The heat dump valve may begin

to open and release water if the water temperature in the pump has exceeded

140°F. This will allow fresh, cool water to enter the system.

12 Operator's Manual

Page 13

INSTALLATION & PREPARATION

PRE-START INSPECTION PROCEDURES:

Before starting the unit, perform the following procedures:

1. Check the oil level in the pump and engine.

2. Inspect the water inlet lter. Clean or replace if necessary. See "Water

Supply", #2, pg. 12.

3. Check all hose connections to ensure they are securely tightened. See

"Water Supply", #3, pg. 12.

4. Inspect for system fuel leaks. If a fuel leak is found, DO NOT START

UNIT! See "Fire & Ventilation Precautions", #2 and #4, pg. 4. Be sure

that all damaged parts are replaced and that the mechanical problems

are corrected prior to operation of the unit. If you require service, contact

Customer Service.

5. Inspect high pressure hoses for kinking, cuts and leaks. If a cut or leak

is found, DO NOT USE HOSE! Replace hose before starting unit. See

"Miscellaneous Safety Precautions" #6, pg. 6. Be sure that all damaged

parts are replaced and that the mechanical problems are corrected

prior to operation of the unit. If you require service, contact Customer

Service.

END OF PREPARATION INSTRUCTIONS

WARNING

THE FOLLOWING PAGES CONTAIN OPERATING AND

MAINTENANCE INSTRUCTIONS

DO NOT ATTEMPT TO OPERATE THIS PRESSURE WASHER

UNTIL YOU HAVE READ AND UNDERSTOOD ALL SAFETY

PRECAUTIONS AND INSTRUCTIONS LISTED IN THIS MANUAL.

INCORRECT OPERATION OF THIS UNIT CAN CAUSE SERIOUS

INJURY!!

DO NOT ALTER OR MODIFY THIS EQUIPMENT IN ANY MANNER!

Operator's Manual 13

Page 14

CAUTION

RISK OF UNIT DAMAGE.

BE CERTAIN THE NOZZLE IS

NOT CONNECTED TO THE UNIT

WHILE PRIMING THE PUMP.

PRIMING ALLOWS MINERAL

DEPOSITS TO BE RELEASED

FROM THE SYSTEM WHICH

WOULD OBSTRUCT OR DAMAGE

THE NOZZLE ASSY. RESULTING

IN COSTLY REPAIRS.

DANGER

RISK OF INJECTION CAUSING

SEVERE INJURY!

-KEEP CLEAR OF NOZZLE! NEVER

PLACE HAND OR FINGERS IN

FRONT OF NOZZLE!

-DO NOT DIRECT DISCHARGE

STREAM AT PEOPLE OR PETS!

-BE CERTA IN THE NOZZLE

IS SECURELY CONNECTED

TO THE WAND TO PREVENT

ACCIDENTAL DISCHARGE!

CAUTION

RISK OF DAMAGE.

DO NOT ALLOW SPRAY PATTERN

TO REMAIN ON A FIXED AREA

FOR AN EXTENDED PERIOD OF

TIME. POSSIBLE DAMAGE MAY

OCCUR TO THE AREA.

OPERATING INSTRUCTIONS

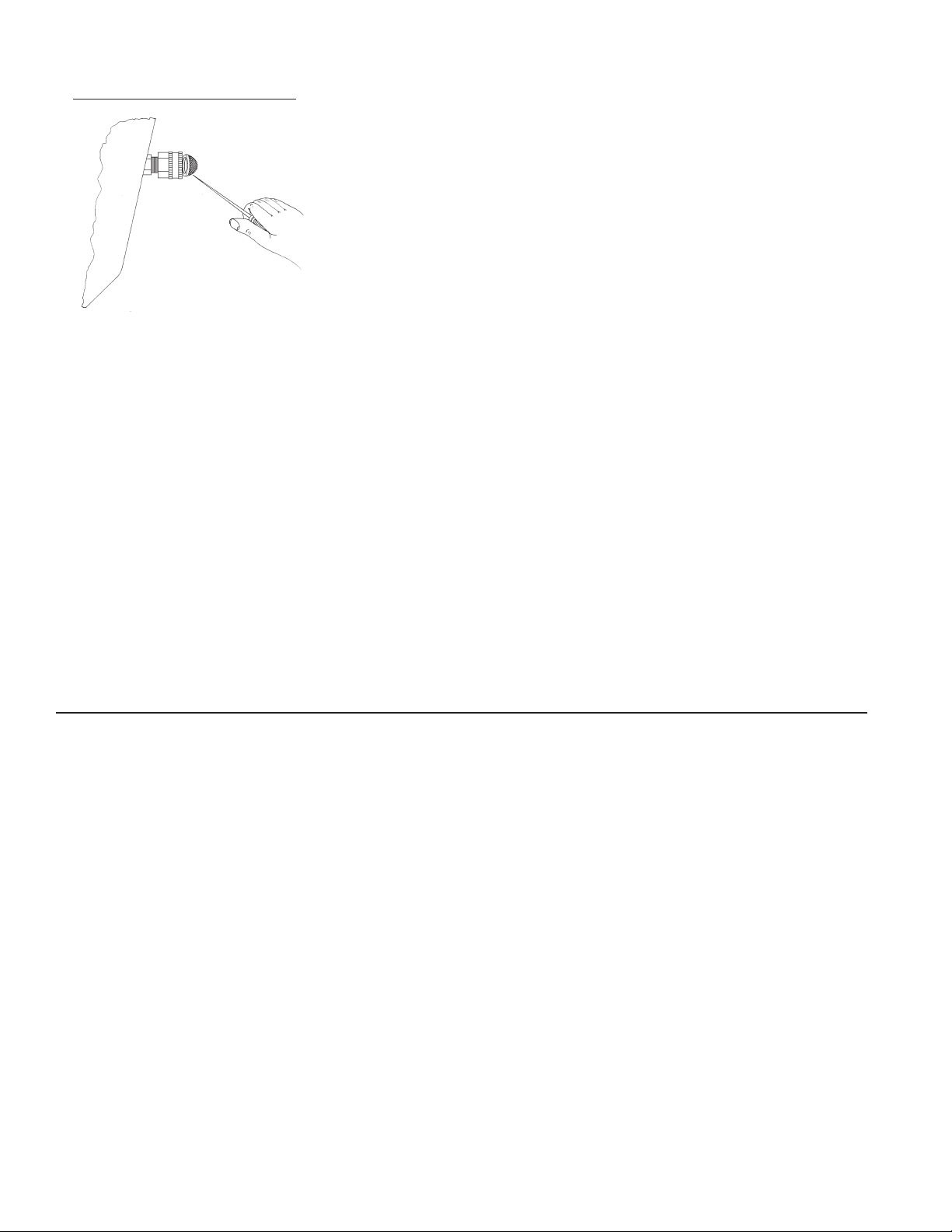

PRIMING THE PUMP:

1. It is essential to prime the pump on initial start-up and each time the water

supply is disconnected from the unit after initial use.

2. Lay the high pressure hose out to remove any loops. Water ow will constrict

the hose, creating tight loops if the hose is not straight.

3. Securely connect the gun assembly to the high pressure hose.

NOTE: The nozzle assembly should NOT be connected to the gun assembly

at this time. See “Nozzle Connection”)

4. With the trigger gun locked in the “OFF” position, turn the water supply

completely on. Pointing the gun in a safe direction, unlock the trigger gun

and squeeze the trigger.

5. Low pressure water will begin owing from the hose/gun assembly. This

allows the unit to prime and purge any air from the system. The unit is

primed when water ow is uninterrupted by air.

6. Once the unit is primed, release the trigger and lock the gun in the “OFF”

position. Securely connect the nozzle assembly. (See “Nozzle Connection”)

START-UP:

1. Refer to the "Safety Precautions" pgs. 4-7 before starting the unit.

2. Locate the Safety Decals on your unit and heed their warnings.

3. With the gun locked in the "OFF" position, Point the trigger gun away from

yourself or anyone else. Ensure the water supply is completely turned

on.

4. Disengage the safety lock-off on the gun and squeeze the trigger. Low

pressure water will begin owing from the nozzle.

5. BE CERTAIN the trigger gun remains in an open position while starting

the engine. Brace yourself as the gun will kickback from the high pressure

created by the pump once the engine has started.

6. Steady the unit during engine start-up. (Refer to the engine manual

accompanying this pressure washer for the correct procedures needed to

start the engine.)

7. Once the engine has started, perform the following procedures with the gun

open:

a. Inspect for system oil leaks and fuel leaks. If a fuel leak is found, TURN

UNIT OFF IMMEDIATELY! See "Fire & Ventilation Precautions", #2 and

#4, pg. 4. Be sure that all damaged parts are replaced and that the

mechanical problems are corrected prior to operation of the unit.

If you require service, contact Customer Service.

b. Inspect high pressure hoses for kinking, cuts and leaks. If a cut

or leak is found, DO NOT TOUCH HOSE AT LEAK!!! TURN UNIT

OFF IMMEDIATELY! Replace hose before restarting the unit. See

"Miscellaneous Safety Precautions" #6, pg. 6. Be sure that all damaged

parts are replaced and that the mechanical problems are corrected

prior to operation of the unit. If you require service, contact Customer

Service.

8. Trigger the gun several times and try adjusting the spray pattern. Be certain

to LOCK the trigger gun in the "OFF" position whenever adjusting the spray

pattern. NEVER look directly into the nozzle! High pressure water creates

a risk of severe injury!

9. Do not allow unit to operate in bypass mode (with trigger closed) for more

than three minutes without triggering the gun. Failure to follow this simple

rule can cause premature failure of pump packing seals, resulting in costly

pump repair.

10. Because your pressure washer delivers a high pressure spray and a variety

of spray patterns, there are many cleaning jobs that can be done without

the use of detergents. If a cleaning agent is required, see "Cleaning With

Detergents" pg. 15 for the correct procedures.

14 Operator's Manual

Page 15

OPERATING INSTRUCTIONS

CLEANING WITH DETERGENTS:

1. Refer to "Detergent Cleaning Precautions" pg. 6. Be certain to wear

protective safety attire as stated on pg. 10.

2. Prepare detergent solution according to label directions. Never pump

acids, akalines abrasive uids or solvents thru the unit.

3. Connect the detergent hose to the unit as shown on page 8. The detergent

ratio is preset and cannot be adjusted.

4. Immerse the detergent strainer into the detergent solution to allow

detergent to siphon.

5. With the trigger gun locked in the "OFF" position, move the nozzle cover

at the end of the wand away from the trigger gun.

NOTE: This injection system is designed to apply detergents under low

pressure only. It will not allow detergent solutions to be introduced into

the system unless the nozzle cover at the end of the wand is moved

away from the trigger gun in the low pressure detergent mode.

6. To apply solution, unlock the trigger gun and squeeze the trigger. In a

few moments a detergent/water mixture will exit the low pressure nozzle.

Start spraying the lower portion of the surface being cleaned and move

up, using long overlapping strokes. Applying from the bottom up helps

avoid streaking. Allow to soak briey. (Avoid working on hot surfaces or

in direct sunlight to minimize the chances of the detergent drying, which

may result in damaging painted surfaces.) Be certain to rinse a small

section at a time.

7. To rinse; lock the trigger gun in the "OFF" position, pull the nozzle cover

at the end of the wand toward the trigger gun. Unlock the trigger gun

and spray. It will take about 30 seconds to purge all detergent from the

line. For best rinsing results, start at the top and work down.

8. Siphon a gallon of water through the low pressure detergent injection

system after each use. This prevents the possibility of corrosion or

detergent residue causing mechanical problems during the next use.

LOW PRESSURE DETERGENT

SHUTDOWN:

1. Turn engine "OFF" as directed in the Engine Manual.

2. Turn the water supply "OFF".

3. Pointing the gun in a safe direction, trigger gun momentarily to relieve

any trapped pressure.

4. Once pressure is relieved, disconnect the nozzle assembly.

5. Disconnect and drain gun, wand and hoses.

6. Wipe unit clean and store with gun, wand and hoses in a safe, nonfreezing area.

Operator's Manual 15

Page 16

STORAGE & MAINTENANCE

SPECIFIC MAINTENANCE:

ENGINE: The engine instructions that accompany your unit detail specic

procedures for maintenance of the engine. Following the engine

manufacturer’s recommendations will extend engine work life.

PUMP: Factory sealed system. Contact customer service with system

problems.

NOZZLES: Water ow through the spray nozzle will erode the orice, making

it larger, resulting in a pressure loss. Nozzles should be replaced

whenever pressure is less than 85% of the maximum. The frequency

of replacement will depend upon such variables as mineral content

in the water and number of hours the nozzle is used.

QUICK COUPLERS: There is an o-ring seal inside the female quick coupler.

This o-ring will deteriorate or, if the unit is allowed to pump without

the high pressure hose or nozzle attached, the o-ring may be blown

out occasionally. Simply insert a replacement o-ring to correct the

leak. (Additional o-rings can be purchased from your dealer.)

16 Operator's Manual

Page 17

WINTERIZING:

32˚F 0˚C

For storage and transportation purposes in subfreezing ambient temperatures, it

will be necessary to winterize this unit. This unit must be protected to the lowest

incurred temperature for the following reasons:

1. If any part of the pumping system becomes frozen; excessive pressure may

build up in the unit which could cause the unit to burst resulting in possible

serious injury to the operator or bystanders.

2. The pumping system in this unit may be permanently damaged if frozen.

FREEZE DAMAGE IS NOT COVERED BY WARRANTY.

If you must store your unit in an area where the temperature may fall below 32°F,

you can protect your unit by following the procedure outlined below.

1. Gather the following items:

a. Two 5 gallon containers.

b. One gallon of antifreeze. (Mi-T-M® recommends an environmentally safe

antifreeze.)

c. Water supply.

d. Three foot hose, 1/2-3/4 I.D. with a 3/4 inch male garden hose tting.

2. Procedure:

a. To start winterizing, unit must be run and primed according to the “Start-

up Procedures” listed on page 14.

b. After running and priming, shut off the unit and water supply.

c. Relieve system pressure by pointing the trigger gun in a safe direction

and squeezing the trigger until water ow ceases to exit the nozzle.

d. Lock the trigger gun in an OFF position and remove the nozzle.

e. In one 5 gallon container, mix the antifreeze and water according to

manufacturer’s recommendations for the temperature to which you are

winterizing.

NOTE: Proper winterizing is based on the recommended manufacturer’s

instructions listed on the “Protection Chart” shown on the back label of

most antifreeze containers.

f. Remove the water supply hose from the unit and attach the 3 foot

hose securely to the inlet connection. Submerge the other end into the

antifreeze solution.

g. Point the wand into the empty container and start the unit.

h. Trigger the gun until the antifreeze begins to exit the wand. Release

the trigger for 3 seconds, then trigger the gun for 3 seconds. Continue

cycling the gun several times until all the antifreeze mixture is siphoned

from the container.

i. Stop the unit.

j. Detach the 3 foot hose from the unit and drain any excess antifreeze back

into the 5 gallon container.

k. Disconnect the hose/gun/wand assembly from the unit and drain any

excess antifreeze back into the 5 gallon container.

l. Store the hose, gun and wand with the unit in a safe, non-freezing area.

m. Store antifreeze solution for next use or dispose of according to state EPA

laws.

3. Optional Procedure:

a. Shut the unit and water supply off.

b. Relieve system pressure by pointing the trigger gun in a safe direction

and squeezing the trigger until water ow ceases to exit the nozzle.

c. Disconnect and drain the hose, gun and wand.

d. Start the unit and allow it to run until all the water exits the unit. Once the

water has stopped owing from the unit, turn the unit off.

NOTE: When using this procedure, caution should be used as ice chips can form

from drops of water which could cause the unit to burst if starting before

completely thawed.

WARNING

RISK OF UNIT BURSTING!

DO NOT STORE/OPERATE UNIT

IN A FREEZING ENVIRONMENT!

Operator's Manual 17

Page 18

TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE REMEDY

Engine will not start. Various engine problems. Refer to the Engine Manual

accompanying your unit.

Unit components are frozen. Allow to thaw. If any part of the unit

becomes frozen; excessive pressure

may build up in the unit which could

cause the unit to burst resulting in

possible serious injury to the operator or

bystanders.

No discharge at nozzle when Inadequate water supply. Ensure hose is 3/4" diameter and

trigger mechanism is squeezed. incoming water supply is turned on.

Kink in water inlet hose. Remove kink.

Low or uctuating pressure. Kink in high pressure discharge hose. Replace hose.

Water inlet lter obstructed. Remove screen, clean or replace.

Pump sucking air. (Prime eliminated) Tighten all water intake connections

Eliminate leaks in intake line.

Not in high pressure mode. Pull the nozzle cover toward gun.

Obstructed or worn spray nozzle. Remove, clean or replace.

Damaged or obstructed valve assy. Remove, inspect, clean or replace.

on pump.

Pump packings worn. Replace packings.

Unloader valve not operating correctly. Repair or replace.

Oil leaking from unit. DO NOT USE!!!!! Contact Customer Service.

Detergent will not siphon into Detergent strainer is not completely Check, submerge if necessary.

Low Pressure Detergent mode. submerged in detergent solution.

Detergent strainer obstructed. Inspect, clean or replace.

Detergent hose cut, obstructed or Inspect, clean or replace.

kinked.

Not in low pressure mode. Push nozzle cover away from gun.

Nozzle assembly is plugged. Clean or replace.

Too many high pressure hose Use one extension maximum.

extensions attached to the water outlet.

Ball & Spring in Venturi stuck. Remove, clean or replace.

Water ows back into detergent Ball & Spring in Venturi reversed, Remove, clean or replace.

container. missing or corroded.

Water ows from the nozzle when the Gun is malfunctioning. Repair or replace.

trigger gun is locked in the "OFF"

position.

18 Operator's Manual

Page 19

STATEMENT OF WARRANTY

John Deere warrants all parts, (except those referred to below), of your new pressure washer

to be free from defects in materials and workmanship during the following periods:

For One (1) Year from the date of original purchase:

Cart Assembly Plumbing

High Pressure Pump GFCI

For Ninety (90) days from the date of original purchase:

Trigger Gun High Pressure Hose

Strainer/Filters On/Off Switch

Unloader Valve

Defective parts not subject to normal wear and tear will be repaired or replaced at our

option during the warranty period. In any event, reimbursement is limited to the purchase

price paid.

EXCLUSIONS

1. The Engine is covered under separate warranty by its respective manufacturer and

is subject to the terms set forth therein.

2. Normal wear parts:

Pump Packings Spray Nozzles

Pump Valves Detergent Valves

Quick Connects/Screw Connects O-rings

3. This warranty does not cover parts damaged due to normal wear, misapplication,

misuse, operation at other than recommended speeds, pressures or temperature. Parts

damaged or worn because of the use of caustic liquids or by operation in abrasive or

corrosive environments or under conditions causing pump cavitation are not warranted.

Failure to follow recommended operating and maintenance procedures also voids

warranty.

4. The use of other than Genuine John Deere Repair Parts will void warranty.

5. Warranty will be void if used in any application other than consumer/homeowner. Parts

returned, prepaid to our factory or to an Authorized Service Center will be inspected

and replaced free of charge if found to be defective and subject to warranty. There

are no warranties which extend beyond the description of the face hereof. Under no

circumstances shall the manufacturer bear any responsibility for loss of use of the unit,

loss of time or rental, inconvenience, commercial loss or consequential damages.

For Service or Warranty Consideration, contact

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

Operator's Manual 19

Page 20

NOTES

20 Operator's Manual

Page 21

NOTE

Manual del Operador 21

Page 22

TABLA DE MATERIAS

INTRODUCCION ...........................................................................................................................23

ADVERTENCIAS IMPORTANTES DE SEGURIDAD ..............................................................24-27

PRECAUCIONES CONTRA INCENDIO Y DE VENTILACION ........................................24

PRECAUCIONES PARA ROCIADO .................................................................................25

PRECAUCIONES PARA LIMPIEZA CON DETERGENTES .............................................26

PRECAUCIONES MISCELANEAS DE SEGURIDAD ......................................................26

PRECAUCIONES DE AJUSTE ......................................................................................... 27

ILUSTRACION DE LOS ELEMENTOS Y COMPONENTES ........................................................28

CALCOMANIAS DE SEGURIDAD ...............................................................................................29

INSTALACION Y PREPARACION ...........................................................................................30-33

VESTIMENTA ...................................................................................................................30

PREPARACION ................................................................................................................ 30

TANQUE DE COMBUSTIBLE DEL MOTOR ....................................................................30

BOQUILLA AJUSTABLE ...................................................................................................31

CONEXION DE LA BOQUILLA ......................................................................................... 31

SUMINISTRO DE AGUA ...................................................................................................32

VALVULA DE DESCARGA TERMICO ..............................................................................32

PROCEDIMIENTOS DE INSPECCION ANTES DEL ARRANQUE ..................................33

INSTRUCCIONES DE OPERACION .......................................................................................34-36

CEBADO DE LA BOMBA .................................................................................................. 34

ARRANQUE .................................................................................................................34-35

LIMPIEZA CON DETERGENTES .....................................................................................35

APAGADO ........................................................................................................................36

ALMACENAMIENTO Y MANTENIMIENTO ............................................................................36-37

MANTENIMIENTO ESPECIFICO .....................................................................................36

PREPARACION PARA EL INVIERNO .............................................................................. 37

LOCALIZACION DE FALLAS ......................................................................................................38

DECLARACION DE GARANTIA ..................................................................................................39

PROTECT YOUR INVESTMENT......

Use only John Deere Fuel Protect

Fuel Stabilizer with Ethanol Protection

TY27534 or TY27535. Developed to

ensure Optimum Performance and

Protection.

IMPORTANT...Use Year Round!

34-1904 012011

ADVERTENCIA: Este producto tiene

plomo, una sustancia química conocida

al Estado de California a causar cáncer

y defectos de nacimiento u otro daño

reproductivo.

Lávese las manos despues de usar este producto.

22 Manual del Operador

Page 23

INTRODUCCION

¡Felicitaciones por la compra de su nueva lavadora a presión! Puede estar seguro que su lavadora a presión fue construida

con el nivel más alto de precisión y exactitud. Cada componente ha sido probado rigurosamente por técnicos para asegurar

la calidad, la resistencia y el rendimiento de esta unidad.

Este manual del operador fue compilado para su benecio. Leyendo y siguiendo los pasos simples de seguridad, instalación,

operación, mantenimiento y localización de fallas descritos en este manual ayudará a prolongar aun más la operación

libre de fallas que usted puede esperar de su nueva lavadora a presión. El contenido de este manual está basado en la

información actualizada disponible al momento de la publicación. Fabricante se reserva el derecho de efectuar cambios

en precio, color, materiales, equipo, especicaciones o modelos en cualquier momento sin previo aviso.

¡IMPORTANTE!

Estos párrafos están rodeados por una “CASILLA DE ALERTA DE SEGURIDAD”. Esta

casilla se usa para designar y enfatizar las Advertencias de Seguridad que deben seguirse

al operar esta lavadora a presión. Acompañando a las Advertencias de Seguridad están las

“palabras de alerta” que designan el grado o nivel de seriedad de riesgo. Las “palabras de

alerta” usadas en este manual son las siguientes:

PELIGRO: Indica una situación inminente riesgosa la cual, si no se evita,

RESULTARA en la muerte o en lesiones graves.

ADVERTENCIA: Indica una situación potencialmente riesgosa la cual, si no se evita,

PODRIA resultar en la muerte o en lesiones graves.

PRECAUCION: Indica una situación potencialmente riesgosa la cual, si no se evita

PUEDE resultar en lesiones menores o moderadas.

El símbolo indicado a la izquierda de este párrafo es el “Símbolo de Alerta de Seguridad”.

Este símbolo se usa para alertarlo acerca de artículos o procedimientos que podrían ser

peligrosos para usted u otras personas usando este equipo.

PROVEA SIEMPRE UNA COPIA DE ESTE MANUAL A CUALQUIER PERSONA QUE USE

ESTE EQUIPO. LEA TODAS LAS INSTRUCCIONES ANTES DE OPERAR ESTA LAVADORA A

PRESION, OBSERVANDO EN PARTICULAR LAS “ADVERTENCIAS DE SEGURIDAD” PARA

EVITAR LA POSIBILIDAD DE LESIONES PERSONALES AL OPERADOR.

Escriba el número de serie de su unidad en el espacio provisto abajo, una vez que la unidad haya sido desempacada.

NUMERO DE SERIE___________________________

Inspeccione por daño el contenido de la caja. Si algo parece dañado, NO LA DEVUELVA AL LUGAR DE COMPRA.

Llame a su representante de servicio al cliente.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

Telefono: 1-877-JD-KLEEN

Telefone gratis en los EE. UU.: 877-535-5336 / Fax 563-556-1235

Lunes - Viernes 8:00 a.m. - 5:00 p.m. CST

Por favor tenga disponible la información siguiente para todas las llamadas de servicio:

1. Número de modelo

2. Número de serie

3. Fecha y lugar de compra

Manual del Operador 23

Page 24

ADVERTENCIAS IMPORTANTES DE SEGURIDAD

PRECAUCIONES CONTRA INCENDIO Y DE VENTILACION:

1. Esta unidad fue diseñada para uso al aire libre solamente. NUNCA opere esta

unidad en un área cerrada. SIEMPRE asegúrese que haya aire (oxígeno)

adecuado para la combustión así también como ventilación adecuada para

evitar la presencia de gases venenosos de monóxido de carbono. Esté alerta

en áreas mal ventiladas o con ventiladores aspiradores que pueden causar

una combustión inadecuada o sobrecalentamiento del motor.

2. NUNCA opere esta unidad en la presencia de vapores inamables o polvo,

gases combustibles u otros materiales combustibles. (Una chispa puede causar

una explosión o incendio.) Tenga cuidado de descartar apropiadamente los

materiales inamables. NO rocíe líquidos inamables.

3. TANQUE DE COMBUSTIBLE DEL MOTOR

a. NO FUME MIENTRAS LLENA EL TANQUE DE COMBUSTIBLE DEL

MOTOR

b. NUNCA llene el tanque de gasolina mientras el motor está funcionando o

está caliente. Permita que el motor se enfríe durante dos minutos antes

de cargar combustible.

c. NO cargue gasolina en un ambiente cerrado o en un área mal

ventilada.

d. SIEMPRE cargue combustible lentamente para evitar la posibilidad de

combustible derramado que puede ocasionar un riesgo de incendio.

4. NO opere la unidad si hay combustible derramado. Limpie la unidad y aléjela

del área del derrame. Evite crear cualquier encendido hasta que se haya

evaporado la gasolina.

5. NO almacene la unidad cerca de una llama abierta ni de ningún equipo tal

como cocina, horno, calentador de agua, etc., que utilice una llama piloto o

mecanismos que puedan crear una chispa.

IMPORTANTE

Lo siguiente es requerido por la ley del estado de California, sección 4442 del

Código de Recursos Públicos de California. Otros estados pueden tener leyes

similares. Las leyes federales se aplican en las tierras federales.

Si este motor se usará en tierras no mejoradas cubiertas de

bosques, cubiertas de matorrales o grama, debe agregarse un

supresor de chispas al silenciador. El supresor debe ser mantenido

en condiciones efectivas de trabajo por el operador.

Para opciones del supresor de chispas del silenciador consulte con su distribuidor de motores o equipo.

24 Manual del Operador

Page 25

ADVERTENCIAS IMPORTANTES DE SEGURIDAD

PRECAUCIONES PARA ROCIADO:

PELIGRO

RIESGO DE INYECCION O DE LESION GRAVE DE CORTE

MANTENGASE ALEJADO DE LA BOQUILLA

NO DIRIJA LA CORRIENTE DE DESCARGA A LAS PERSONAS NI A

LOS ANIMALES DOMESTICOS.

SOLO LOS OPERADORES ENTRENADOS DEBEN USAR ESTE

EQUIPO.

DEBEN OBSERVARSE SIEMPRE LAS PRECAUCIONES BASICAS,

INCLUYENDO LAS SIGUIENTES:

1. MANTENGASE ALEJADO DEL ROCIADO

a. Los uidos pueden penetrar la piel, causando lesiones graves, a

causa de la alta presión y velocidad del rociado.

b. Nunca apunte la pistola hacia usted ni hacia otra persona. Nunca

coloque su mano, dedos o cuerpo directamente sobre la boquilla

de rociado. Mantenga siempre el área de operación despejada de

todas las personas. Ejerza una precaución extrema al operar cerca

de niños.

c. REQUIERA CUIDADO MEDICO DE EMERGENCIA si ocurriera un

accidente y el rocío parece haber penetrado la piel. NO LO TRATE

COMO UN CORTE SIMPLE. Si usted está usando agentes limpiadores,

esté preparado a informar a su médico exactamente de qué clase.

2. SIEMPRE use antiparras protectoras al operar la unidad, para proteger los

ojos contra desechos despedidos y detergentes. Otros equipos protectores

tales como trajes de goma, guantes y respiradores son recomendables,

especialmente al usar detergentes de limpieza. Ejerza una precaución

extrema al operar cerca de niños.

3. Esté alerta - observe lo que hace. No opere la unidad cuando esté fatigado

o bajo la inuencia de alcohol o drogas.

4. NUNCA accione el gatillo a menos que la unidad esté rmemente sujeta.

El empuje del agua recorriendo la boquilla puede ser lo sucientemente

poderoso como para causar que el operador pierda el equilibrio si no

está preparado. NO SE INCLINE ni se pare sobre un apoyo inestable.

Las supercies húmedas pueden ser resbalosas, use equipo protector

de calzado y manténgase bien parado y en equilibrio en todo momento.

NUNCA accione el gatillo de la pistola mientras esté en una escalera o

en el techo.

5. NO dirija el rociado hacia materiales frágiles tales como vidrio. El astillado

podría resultar en lesiones graves.

6. SIEMPRE sujete rmemente el conjunto de pistola/vara al arrancar y

operar la unidad. El no hacerlo puede causar que la vara caiga y azote

peligrosamente. NUNCA opere la pistola con el gatillo conectado en la

posición abierta. La pistola a gatillo debería estar bien asegurado cuando

no se usa, para evitar una descarga accidental.

7. ¡NO dirija el rociado de agua hacia o dentro de ninguna instalación eléctrica!

Esto incluye tomacorrientes, lámparas eléctricas, transformadores, la

unidad misma, etc. Puede ocurrir un choque eléctrico grave.

8. Aun después que apague la unidad, hay agua a alta presión en la bomba,

manguera y pistola hasta que la elimine accionando el gatillo. SIEMPRE

apague la unidad y accione el gatillo para liberar la presión interna, antes

de sacar la boquilla de rociado o reparar la unidad.

Manual del Operador 25

Page 26

ADVERTENCIAS IMPORTANTES DE SEGURIDAD

PRECAUCIONES PARA LIMPIEZA CON DETERGENTES:

1. NO use solventes ni detergentes altamente corrosivos, ni limpiadores de

tipo ácido con esta lavadora a presión. Use detergentes mild solamente.

2. ¡CONOZCA SUS DETERGENTES! En el caso de una emergencia, esté

preparado a informar al médico exactamente lo que usted está usando.

Lea La Hoja de Datos de Seguridad del Material (MSDS) provista con

su detergente y todas las etiquetas de los detergentes. Observe todas

las instrucciones apropiadas acerca de la preparación, uso, seguridad y

transporte. Mantenga TODOS los detergentes fuera del alcance de los

niños.

3. NO use esta lavadora a presión para dispensar detergentes riesgosos.

4. NO altere de ninguna manera no recomendada en este manual la

característica de inyección de detergente. Para las reparaciones necesarias

use piezas genuinas de repuesto fabricante solamente.

PRECAUCIONES MISCELANEAS DE SEGURIDAD:

1. ¡NUNCA PERMITA QUE LOS NIÑOS O ADOLESCENTES OPEREN ESTA

UNIDAD!

2. Lea y observe todas las instrucciones de manejo, funcionamiento,

mantenimiento y seguridad incluidas en este manual y en el manual del

operador del motor que acompañan a esta unidad, y provea tal información

a CUALQUIERA que opere esta unidad.

3. La unidad debe estar sucientemente caliente como para asegurar que no

haya formación de hielo en la bomba, a temperaturas de congelación. NO

arranque esta unidad, si ha sido transportada en un vehículo abierto o sin

suciente calefacción, sin permitir primero que la bomba se descongele.

4. Deben observarse los reglamentos locales de su compañía de agua, al

conectar la entrada de agua a las cañerías maestras de agua. En algunas

áreas la unidad no debe conectarse directamente al suministro público de

agua potable. Esto es para asegurar que no haya realimentación de los

detergentes al suministro de agua. (Se permite la conexión directa si se

instala un supresor de ujo de retroceso.)

5. NO permita que ninguna parte de su cuerpo ni de la manguera de alta

presión toque el silenciador. Evite arrastrar la manguera sobre una supercie

abrasiva tal como cemento. Esto causa desgaste y eventual ruptura.

6. Las mangueras de alta presión deberían inspeccionarse diariamente por

señas de desgaste. Si existe evidencia de falla, reemplace rápidamente

todas las mangueras sospechosas para evitar la posibilidad de lesiones

causadas por rociado a alta presión. Si una manguera o adaptador pierden,

NUNCA coloque su mano directamente sobre la pérdida.

7. No opere la unidad sin todas las cubiertas protectoras en su sitio.

8. NUNCA haga funcionar la máquina con el gobernador desconectado ni la

opere a velocidades excesivas.

9. Mientras opere esta unidad, mantenga una distancia segura para las

personas, para reducir el riesgo de lesiones. Al operar la unidad cerca de

niños se requiere una supervisión estrecha.

10. NO deje desatendida la unidad presurizada. Apague la unidad y descargue

la presión interna antes de alejarse.

11. NO mueva la unidad tirando de la manguera.

26 Manual del Operador

Page 27

ADVERTENCIAS IMPORTANTES DE SEGURIDAD

PRECAUCIONES DE AJUSTE:

1. NUNCA altere ni modique el equipo, asegúrese que todos los artículos

accesorios y los componentes del sistema que se usan resistirán la

presión desarrollada. Use SOLO piezas genuinas fabricante para reparar

su lavadora a presión. El no hacerlo puede causar condiciones operativas

riesgosas y cancelará la garantía.

2. NUNCA efectúe ajustes a la máquina mientras esté conectada al motor,

sin sacar primero el cable de encendido de la bujía. El girar la máquina a

mano durante el ajuste o la limpieza podría arrancar el motor y la máquina,

lo que causará lesiones graves al operador.

3. Sepa cómo detener la lavadora a presión y purgar las presiones

rápidamente. Esté completamente familiarizado con los controles.

4. Apague la unidad, elimine la presión de agua, y permita que la unidad

se enfríe, antes de repararla. Preste servicio en un área limpia, seca y

plana. Para evitar que la unidad se mueva, bloquee las ruedas.

5. Observe las instrucciones de mantenimiento especicadas en este

manual.

¡GUARDE ESTAS INSTRUCCIONES!

Manual del Operador 27

Page 28

CARACTERÍSTICAS

CV UNITS WITH QC FEATURES 040510

LISTA DE CARACTERÍSTICAS

1. Sostenedor de la pistola

2. Sostenedor de la boquilla variable

3. Aprisa Conecte

4. Ensamble de la pistola

5. Motor

6. Manguera del detergente

7. Manguera de descarga de alta presión

28 Manual del Operador

8. Bomba

9. Chemical Injection Inlet

10. Salida de agua

11. Válvula De Descarga Termal

12. Pistón Axial De la Bomba

13. Entrada de agua

14. Filtro de entrada de agua

Page 29

CALCOMANIAS DE SEGURIDAD Y UBICACION

ADVERTENCIA PRECAUCION

• Riesgo de Inyeccion o Lision Severa:

Mantenga la boquilla despejada. No dirija

el chorro hacia persona alguna o hacia

usted.

• Riesgo de Asfixia: Unicamente para uso

en el exterior.

• Resgo de Fuego: No fume mientras este

reabastecimiento de combustible. Permita

que el motor se enfrie dos o tres minutos

antes del reabastecimiento. No opere el

producto dupante el reabastecimiento.

• Riesgo de Electrocucion: No dirija el

chorro hacia conexiones electricas. Tomas

de corriente o lineas de alimentacion de

corriente.

• Riesgo de Explosion: No rocie liquidos

inflamables.

• Riesgo de Lesion: Use unicamente

equipo con clasificacion adecuada.

• Para Reducir el Reisgo de que Ocurran

Lesiones: Lea y entienda el manual de

operacion y todas las instrucciones antes

de usar el producto.

• Permanezca Alerta: Sostenga la

pistola/varilla

firmemente con ambas manos para evitar

golpes de retorceso peligrosos.

• Use siempre proteccion ocular.

• No se extienda demasiado o se pare en un

apoyo inestable. mantenga una buena

posicion y balance todo el tiempo.

• Antes de comenzar, abra siempre el

suministro de agua a la bomba.

• Proteja la bomba de la congelacion.

• Coloque el seguro del gatillo en la posicion

apagado cuando no este usando el

producto.

OPERACION

• Despues de asegurarse que todas las

conexiones estan seguras, abra la

entrada del suministro de agua

completamente no se opere sin agua no

se use con agua con temperaturas de

mas de 70°F/21°C.

• Dirija la pistola hacia una direccion

segura y ajuste la boquilla a una presion

baja. Sujete la varilla con seguridad

para evitar el movimiento de retroceso.

Apriete el gatillo hasta que abra y afiance

la unidad al comenzar la operacion.

Encienda la unidad halando firmemente

la cuerda de arranque.

• Despues de que el motor este trabajando.

Ajuste la boquilla a la posicion deseada.

Apreite el gatillo para rociar y sueltelo

para detener el rociado.

• Despues de detener el motor. cierre

siempre el suministro del agua y apriete

el gatillo para liberar la presion atrapada.

34-1884-102506-S.

RISK OF BURNS

MUFFLER AND

ADJACENT AREAS

MAY EXCEED 150°F.

RIESGO DE QUEMAR

EL AMORTIGUADOR Y LAS

AREAS ADYACENTES PUEDEN

TENER TEMPERATURAS POR

ARRIBA DE 150°F.

34-0598-010699-E/S-ENG.

WARNING

ADVERTENCIA

34-0599-E/S-030600-ENG

No ponga combustible cuando

el producto este en operacion.

Permita que el motor se enfrie

por 2 minutos antes de

reablastecer de combustible.

RISK OF FIRE

Do not add fuel when

product is operating. Allow

engine to cool for two (2)

minutes before refueling.

RIESGO DE FUEGE

CAUTION/PRECAUCION

RISK OF INJECTION OR SEVERE INJURY.

Never put your hand, fingers or body directly

over the spray nozzle.

34-1253-030801-ENG.

WARNING

ADVERTENCIA

RIESGO DE INYECCION O LISION SEVERA

Nunca coloque la mano, los dedos o el cuerpo

directamente sobre la boquilla de rocío.

NO RETIRE LAS CALCOMANIAS DE SEGURIDAD DE LA UNIDAD A MENOS QUE LAS

REEMPLACE POR LAS CALCOMANIAS DE SEGURIDAD MAS RECIENTES!

Calcomania: Precautión- Permilta Que Se Enfríe (#34-0599)

Calcomania: Advertencia-Silenciador Caliente (#34-0598)

Calcomania: Reiesgo de inyección (#34-1253)

Calcomania: Declaraciones De Advertencia/Precaución/Operación (#34-1884)

Manual del Operador 29

Page 30

INSTALACION Y PREPARACION

VESTIMENTA:

Una vestimenta apropiada es esencial para su seguridad. Se recomienda que

utilice cualquier medio necesario para proteger los ojos, los oídos y la piel. Al

usar agentes limpiadores detergentes con esta lavadora, puede requerirse una

vestimenta adicional de seguridad (tal como una máscara respiratoria).

PELIGRO

RIESGO DE EXPLOSION O

INCENDIO!

NO COLOQUE LA UNIDAD EN

UN AREA DONDE PUEDAN

ESTAR PRESENTES VAPORES

INFLAMABLES. ¡UNA CHISPA

PODRIA CAUSAR UNA EXPLOSION

O UN INCENDIO!

¡RIESGO QUE LA UNIDAD

REVIENTE!

NO ALMACENE NI OPERE LA

UNIDAD EN UN AMBIENTE

HELADO.

ADVERTENCIA

¡RIESGO DE ASFIXIA!

NO OPERE EN UN AREA

CERRADA. USE ESTE PRODUCTO

EN AREAS BIEN VENTILADAS

SOLAMENTE!

EL ESCAPE DEL MOTOR

CONTIENE MONOXIDO DE

CARBONO, UN GAS VENENOSO,

INODORO E INVISIBLE. EL

RESPIRAR ESTE GAS PUEDE

CAUSAR LESIONES GRAVES,

ENFERMEDAD Y POSIBLEMENTE

LA MUERTE.

PREPARACION:

1. Al operar esta unidad, debería colocarse solamente sobre una supercie

nivelada para asegurar una lubricación apropiada del motor y de la bomba

de agua.

2. NO coloque la unidad en un área:

a. con ventilación insuciente.

b. donde haya evidencia de pérdidas de aceite o combustible.

c. donde puedan estar presentes vapores de gas inamable.

3. Asegúrese de inmovilizar las ruedas para evitar que la unidad se mueve

durante el funcionamiento. Si aplicable, je el mango a la unidad y alinee

losorices de la base y del mango. Ubique las dos perillas y los oricios

del mango y atornille rmemente dentro de las perillas roscadas.

4. Saque el ensamble de la manguera y el ensamble de la pistola de la caga.

Si aplicable, atornille el extremo macho de la manguera dentro del extremo

hembra de la pistola. Ajuste rmemente.

5. Si cualquier parte de la unidad se congela, esto puede causar una acumulación

excesiva de presión en la misma lo que podría causar que reviente, resultando

en posibles lesiones al operador o a los observadores.

TANQUE DE COMBUSTIBLE DEL MOTOR:

PELIGRO

¡RIESGO DE INCENDIO!

¡NO FUME AL CARGAR

COMBUSTIBLE!

MIENTRAS LA UNIDAD ESTA

FUNCIONANDO O ESTA CALIENTE

NO LLENE EL TANQUE DE

COMBUSTIBLE. PERMITA QUE LA

UNIDAD Y EL MOTOR SE ENFRIEN

DURANTE DOS MINUTOS ANTES

DE CARGAR COMBUSTIBLE.

NO LLENE EL TANQUE DE

COMBUSTIBLE HASTA QUE

SE DERRAME. PERMITA 1/4"

DE ESPACIO DE TANQUE

APROXIMADAMENTE PARA LA

EXPANSION DEL COMBUSTIBLE.

ADVERTENCIA

RIESGO DE EXPLOSION O

INCENDIO!

MIENTRAS LA UNIDAD ESTA

FUNCIONANDO O ESTA CALIENTE,

ALMACENE SIEMPRE EL

COMBUSTIBLE ALEJADO DE LA

LAVADORA.

30 Manual del Operador

1. Repase las “Precauciones contra incendio y de ventilación”, antes de cargar

combustible.

2. Ubique las Calcomanías de Seguridad en su unidad y preste atención a

sus advertencias.

3. Se recomienda un combustible de octano 77 mínimo para usar con esta

unidad. NO MEZCLE ACEITE CON GASOLINA

4. Compre combustible en cantidades que puedan usarse dentro de los 30

días. Se recomienda el uso de gasolina limpia, fresca y sin plomo. Si la

gasolina sin plomo no está disponible puede usarse gasolina con plomo.

NO use gasolina que contenga metanol o alcohol.

5. Agregue aceite al motor durante el arranque inicial, (20 oz.). Para el nivel

apropiado de aceite vea el Manual del motor. El nivel de aceite debe

revisarse cada vez a pertir de ese momoento antes de arrancar el motor.

6. Llene el tanque de combustible de acuerdo con las instrucciones adjuntas

del manual del motor.

7. Repase el manual del motor adjunto de esta lavadora a presión para

los procedimientos correctos de arranque y mantenimiento del motor.

Page 31

INSTALACION Y PREPARACION

ADVERTENCIA

BOQUILLAS DE CONEXION RAPIDA: Pueden conectarse rápidamente

varias boquillas al extremo de la vara para cambiar el patrón de rociado.

Asegúrese que la conexión está seguramente calzada, al usar los conectores

rápidos (C.R.). En caso contrario el agua a alta presión puede despedir la

boquilla de la vara, causando lesiones graves o daños importantes. Reérase

al número estampado en la boquilla, para determinar el patrón de abanico

del rociado. Los primeros dos dígitos indican el patrón de abanico del rociado

en grados, por ej.: 15=15º, 25=25º, 65=65º.

1. Boquilla de 15º (AMARILLA): Esta es una boquilla biselada. El rociado

debería dirigirse a un ángulo de 45º sobre la supercie y usarse como

un raspador para sacar pintura, grasa y suciedad. Usos: preparación de

supercies (eliminación de manchas de moho y escamas de pintura).

2. Boquilla de 25º (VERDE): Esta es una boquilla de limpieza por descarga

de agua. Este patrón es más apropiado para limpiar suciedad, lodo, y

hollín. Usos: Barrido en mojado de senderos, cordones de las aceras y

entradas de garages, limpieza de suelos de los establos, lavado de los

fondos de las piscinas de natación, desengrasado de motores.

3. La boquilla de 65 ° (NEGRA): Ésta es una boquilla de aplicación de

detergente de baja presión. Este patrón amplio de rociado distribuye

la solución sobre vastas áreas a baja presión. Usos: aplicación de

detergente, neblina o enjuague.

¡RIESGO DE INYECCION

CAUSANTE DE LESIONES

GRAVES!

¡NUNCA MIRE DIRECTAMENTE

AL ORIFICIO DE LA

BOQUILLA A MENOS QUE

ESTE DESCONECTADO DEL

CONJUNTO DE LA PISTOLA/

VARA!

CONEXION DE LAS BOQUILLAS DE

BOQUILLAS DE CONEXION RAPIDA

CONEXION RAPIDA

(C.R.)

CONEXION DE LA BOQUILLA:

1. Asegúrese que la pistola a gatillo esté asegurada en la posición "OFF"

(DESCONECTADO). Vea la ADVERTENCIA, a la derecha.

2. Retraiga el anillo de cierre sobre el adaptador de conexión rápida para

sacar la boquilla.

Manual del Operador 31

¡RIESGO DE LESIONES GRAVES!

¡CUANDO NO SE USA, LA PISTOLA

A GATILLO DEBERIA ESTAR

SIEMPRE ASEGURADO EN LA

POSICION DESCONECTADO!

ADVERTENCIA

Page 32

INSPECCIONE EL TAMIZ DE

ENTRADA DE AGUA

INSTALACION Y PREPARACION

SUMINISTRO DE AGUA:

1. Seleccione una manguera de suministro de agua que sea de calidad de

manguera de jardín que mida 3/4" de DI por lo menos y que no sea más

larga que 50 pies.

2. Inspeccione el tamiz de entrada de agua para asegurar que esté limpio y

libre de obstrucciones. La limpieza periódica del tamiz de agua ayudará a

prevenir problemas con la bomba. El tamiz restringe el ujo apropiado de agua

a la bomba, a medida que se obstruye. Esto puede resultar en cavitaciones

que causarán la falla prematura de los empaques de las bombas. Retire el

tamiz de la unidad, usando un destornillador. Si fuera necesario, limpie o

reemplace.

3. Conecte la mangueras:

a. Connecte un extremo de la manguera de suministro de agua a la entrada

de agua de la unidad.

b. Conecte el otro extremo de la manguera a su suministro presurizado

de agua. No use un suministro de agua no presurizado (por ej. agua

de pozo o estanque) con esta unidad.

c. Efectúe la conexión rápida de la manguera de descarga de alta presión

a la salida de agua de la unidad.

d. Connecte la manguera de descarga de alta presión a la pistola.

4. Siga los requerimientos de agua entrante listados abajo:

a. La presión de agua debe estar a un mínimo de 20 libras por pulgada

cuadrada (PSI) y un máximo de 125 PSI. (Un grifo típico al aire

libre suministrará generalmente estas PSI si está completamente

ABIERTO).

b. Los GPM (galones por minuto) entrantes deben ser ser 1 galón más

aproximadamente que los GPM salientes deben indicados en la placa

de nombre de la lavadora a presión. (Usted puede inspeccionar los

GPM observando el tiempo requerido para llenar un recipiente de 5

galones.)

c. La temperatura del agua de entrada no debe exceder 125°F. Puede

resultar un daño excesivo a la bomba si la temperatura del agua excede

este nivel aceptable.

5. Nunca permita que la unidad opere sin que esté conectada la tubería de

agua de entrada y el suministro de agua completamente abierto.

VALVULA DE DESCARGA TERMICO:

Para asegurar que la temperatura del agua no exceda niveles acetables, nunca

permita que la lavadora a presión siga funcionando en el modo de sobrepaso

(con la unidad prendida y el disparador cerrado) por más de tres minutos.

Su unidad incluyen una válvula para liberación de calor. La encontrará en el

lado opuesto a la entrada de agua de su bomba. La válvula de liberación de

calor puede comenzar a abrirse y liberar agua si la tmeperatura del agua en la

bomoba llega a más de 60°C (140°F). Esto permitirá que entre agua más fria

al sistema.

32 Manual del Operador

Page 33

INSTALACION Y PREPACION

PROCEDIMIENTOS DE INSPECCION ANTES DEL ARRANQUE:

Efectúe los procedimientos siguientes antes de arrancar la unidad:

1. Inspeccione el nivel de aceite en la bomba y en el motor.

2. Inspeccione el tamiz de entrada de agua. Limpie o reemplace si fuera

necesario. Vea “Suministro de agua”.

3. Inspeccione todas las conexiones de las mangueras para asegurar

que estén bien ajustadas. Vea “Suministro de agua”.

4. Inspeccione por pérdidas de combustible del sistema. ¡NO ARRANQUE

LA UNIDAD, si encuentra una pérdida de combustible! Vea las

“Precauciones contra incendio y de ventilación”. Asegúrese que se

reemplacen todas las piezas dañadas y que se corrijan todos los

problemas mecánicos antes de operar la unidad. Consulte con el

Servicio al Cliente, si usted requiere servicio.

5. Inspeccione las mangueras de alta presión por dobleces, cortes y

pérdidas. ¡NO USE LA MANGUERA, si halla un corte o una pérdida! Antes

de arrancar la unidad reemplace la manguera. Vea las “Precauciones

misceláneas de seguridad”. Asegúrese que se reemplacen todas las

piezas dañadas y que se corrijan los problemas mecánicos antes de

operar la unidad. Consulte con el Servicio al Cliente, si usted requiere

servicio.

FINAL DE LAS INSTRUCCIONES DE PREPARACION

ADVERTENCIA

LAS PAGINAS SIGUIENTES CONTIENEN INSTRUCCIONES DE

OPERACION Y MANTENIMIENTO.