Page 1

HR-1250E1

High Pressure Washer

Operator’s Manual 1

Page 2

Introduction

THANK YOU for purchasing a John Deere product.

READ THIS MANUAL carefully to learn how to operate

and service your machine correctly. Failure to do so could

result in personal injury or equipment damage. This manual

and safety signs on your machine may also be available in

other languages. (See your John Deere dealer to order.)

THIS MANUAL SHOULD BE CONSIDERED a permanent

part of your machine and should remain with the machine

when you sell it.

MEASUREMENTS in this manual are given in both

metric and customary U.S. unit equivalents. Use only

correct replacement parts and fasteners. Metric and inch

fasteners may require a specific metric or inch wrench.

RIGHT HAND AND LEFT HAND sides are determined by

facing the motor end of the machine.

The SERIAL NUMBER is located in the Specification or

Identification Numbers section. Accurately record all the

numbers to help in tracing the machine should it be stolen.

Your dealer also needs these numbers when you order

parts. File the identification numbers in a secure place

off the machine.

WARRANTY is provided from your John Deere dealer for

customers who operate and maintain their equipment as

described in this manual. The warranty is explained on

the warranty certificate shown in this manual.

This warranty provides you the assurance that your

dealer will back products where defects appear within

the warranty period. Should the equipment be abused,

or modified to change its performance beyond the original

factory specifications, the warranty will become void.

2 Operator’s Manual

Page 3

Contents

Page

Safety ........................................................................ 5

Safety Signs ...........................................................10

Controls ................................................................. 13

Preparing the Washer ............................................ 14

Operating the Washer ............................................20

Troubleshooting

Service .................................................................... 28

Storage ....................................................................31

Specifications .........................................................33

Accessories ........................................................34-35

Warranty

Notes ........................................................................ 39

.................................................................. 38

..................................................... 26

All information, illustrations and specifications in this manual are based

on the latest information available at the time of publication. The right is

reserved to make changes at any time without notice.

Operator’s Manual 3

Page 4

Contents

4 Operator’s Manual

Page 5

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

Safety

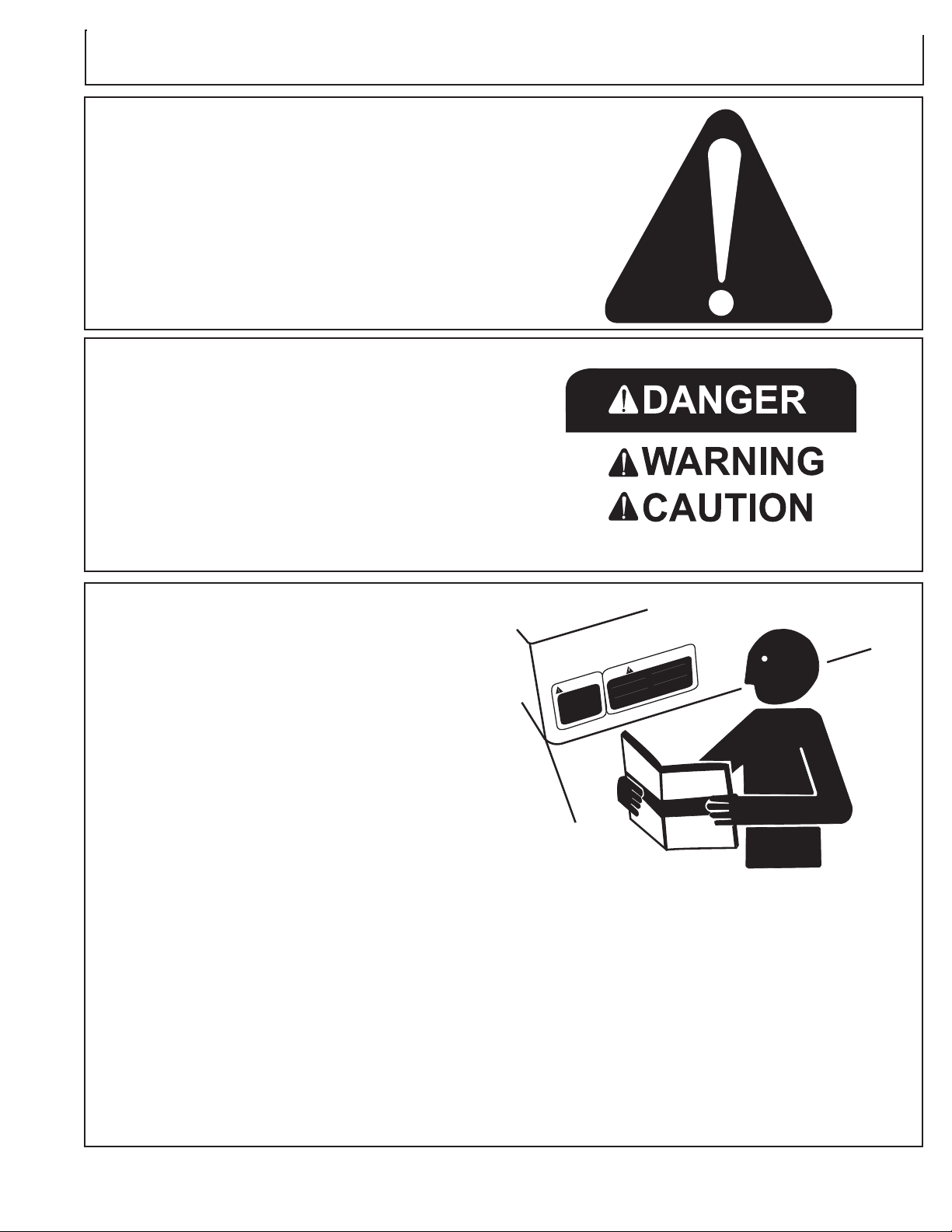

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol

on your machine or in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A signal word--DANGER, WARNING or CAUTION--is used

with the safety-alert symbol. DANGER identifies the most

serious hazards.

DANGER or WARNING safety signs are located near

specific hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual and on

your machine safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from your John Deere dealer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machine in proper working condition.

Unauthorized modifications to the machine may impair the

function and/or safety and affect machine life.

If you do no understand any part of this manual and need

assistance, contact your John Deere dealer.

Operator’s Manual 5

Page 6

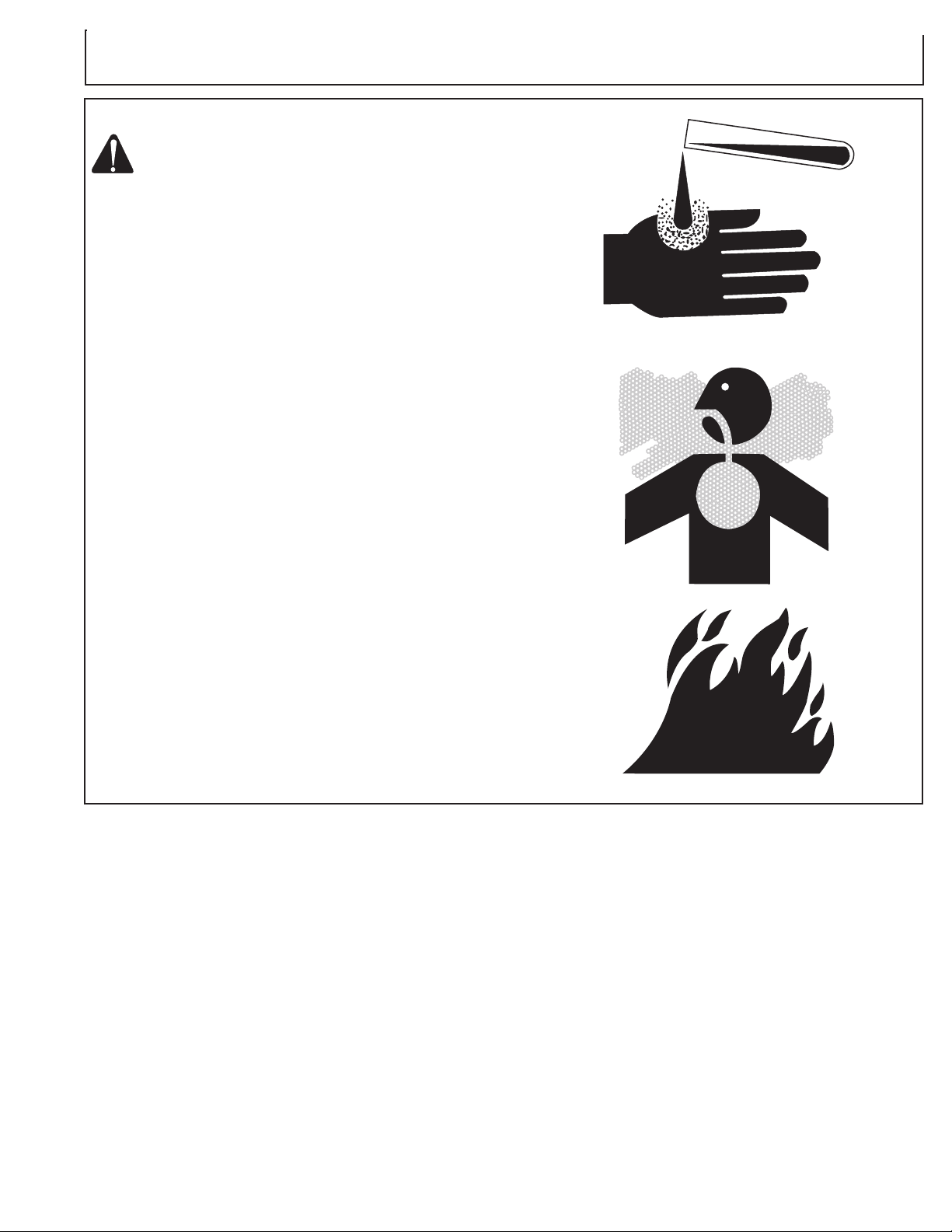

PROTECT AGAINST HIGH PRESSURE

SPRAY

Spray from high pressure nozzles can penetrate the skin

and cause serious injury. Keep spray from contacting

hands or body.

If an accident does occur and the spray appears

to have penetrated the skin, SEEK EMERGENCY

ME D I C A L CA R E . DO NO T TR E AT AS A

SIMPLE CUT. If you are using cleaning agents,

be prepared to tell a physician exactly what kind.

GROUNDING INSTRUCTIONS

This product must be grounded. If it should malfunction

or breakdown, grounding provides a path of least

resistance for electric current to reduce the risk of electric

shock. This product is equipped with a cord having an

equipment-grounding conductor and a grounding plug.

The plug must be plugged into an appropriate outlet that

is properly installed and grounded in accordance with

local codes and ordinances.

DANGER - Improper connection of the equipmentgrounding conductor can result in a risk of electrocution.

Check with a qualified electrician or service person if

you are in doubt as to whether the outlet is properly

grounded. Do not modify the plug provided with the

product--if it will not fit, have a proper outlet installed by

a qualified electrician.

GR O UN D FAU LT CI RC U IT I NT E R RU P TE R

PROTECTION

This pressure washer is provided with a Ground Fault

Circuit Interrupter (GFCI) built into the power cord. This

device provides additional protection from the risk of

electric shock. Should replacement of the plug or power

cord become necessary, use only identical replacement

parts that include GFCI protection.

DO NOT drop the GFCI as damage could result. If the

GFCI is accidentally dropped, be certain to test the GFCI

before using to ensure it is working properly. (Follow

instructions on GFCI for test procedures.)

DO NOT pull on the electrical cord to disconnect from

the outlet, OR carry the unit by the cord.

6 Operator’s Manual

Page 7

EXTENSION CORDS

MSDS

Extension cords are not recommended for use on this

pressure washer. If the use of an extension cord is

unavoidable, it must be plugged into a GFCI found in

circuit boxes or protected receptacles.

Use only 3-wire extension cords that have 3-prong

grounding type plugs and 3-pole cord connectors that

accept the plug from the washer. Use only extension

cords that are intended for outdoor use. These extension

cords are identified by a marking “Acceptable for use

with outdoor appliances; store indoors while not in use”.

Use only extension cords having an electrical rating not

less than the rating of the product. Do not use damaged

extension cords. Examine extension cord before using

and replace if damaged. Do not abuse extension cord

and do not yank any cord to disconnect. Keep cord

away from heat and sharp edges. Always disconnect the

extension cord from the receptacle before disconnecting

the product from the extension cord.

WARNING: To reduce the risk of electrocution,

keep all connections dry and off the ground. Do not

touch plug with wet hands.

On extension cords:

Cable Length Wire Gauge

Up to 50 feet 14 AWG

50 to 100 feet 12 AWG

CLEANING DETERGENT PRECAUTIONS

Know the detergent being used. Be prepared to tell a

physician exactly what you are using in the event of an

emergency. Read all detergent labels and follow all

instructions exactly regarding preparation, use, safety,

transportation, and disposal. Keep all detergents out of

the reach of children, pets and livestock.

NEVER spray combustible liquids of any kind.

Do not use highly corrosive detergents or acid-type

cleaners with this washer.

Direct exposure to hazardous chemicals can cause injury.

Potentially hazardous chemicals used with the pressure

washer includes such items as detergents.

A Material Safety Data Sheet (MSDS) provides specific

details on detergents; physical and health hazards, safety

procedures and emergency response techniques.

Check the MSDS before you start any job using a detergent.

That way you will know exactly what the risks are and how to

do the job safely. Then follow procedures and recommended

equipment. (See your John Deere dealer for MSDS Sheets

on products used with this equipment.)

Use of smaller cords will cause electric motor stalling or

circuit breaker stoppage.

HANDLE CHEMICAL PRODUCTS SAFELY

Operator’s Manual 7

Page 8

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of injury, read this

operator’s manual completely. When using this product,

the following basic precautions should always be

followed:

1. Read all the instructions before using the product.

2. This product is equipped with a Ground Fault Circuit

Interrupter (GFCI) in the power cord to reduce the risk

of electrical shock. If replacement of the plug or cord

is needed, use only identical replacement parts.

3. Follow the grounding instructions included in this

manual.

4. High pressure water spray can cut skin. Do not direct

spray at persons. Keep operating area clear of all

persons or pets. Warn children that the water spray

can cut. Supervise children closely.

5. Do not allow children or untrained person to operate

the washer.

6. Do not spray electrical switches, receptacles or light

bulbs, or glass or fragile objects that may shatter.

7. Dirt and debris removed by spray can cause eye injury.

Wear eye protection.

8. Wet surfaces can be slippery. Wear shoes and keep

both feet on the ground. Do not climb on items being

cleaned. Do not overreach or stand on unstable

support. Keep good footing and balance at all

times.

9. When the spray trigger is released, water pressure

is trapped in the discharge hose. Release trapped

pressure by triggering the spray gun after the washer

is turned off.

10. Do not operate the washer when fatigued or under

the influence of drugs or chemicals. Stay alert.

Watch what you are doing.

11. Follow the maintenance instruction specified in this

manual.

SAVE THESE INSTRUCTIONS

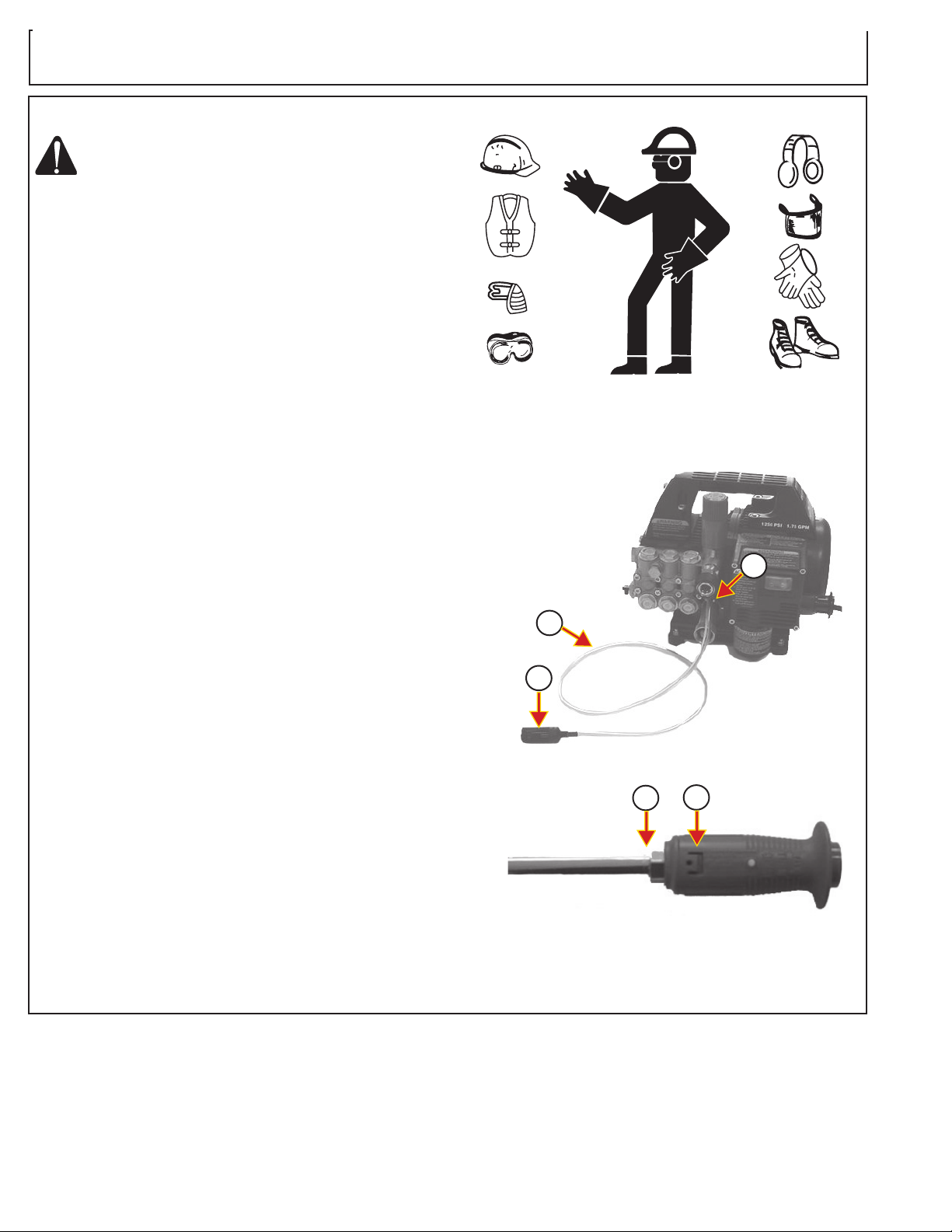

WEAR PROTECTIVE CLOTHING

Wear close fitting clothing and safety equipment

appropriate to the job.

Wear a suitable hearing protective device such as

earmuffs or earplugs to protect against objectionable or

uncomfortable loud noises.

Operating equipment safely requires the full attention of

the operator. Do not wear radio or music headphones while

operating machine.

8 Operator’s Manual

Page 9

PREPARE FOR EMERGENCIES

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital and fire department near your telephone.

Be prepared if a fire starts.

INSPECT HIGH PRESSURE WASHER

Be sure all covers, guards and shields are in place.

Locate all operating controls and safety labels.

Keep all hardware and plumbing fittings tight.

Inspect power cord for damage before using. There is a hazard

of electrical shock from crushing, cutting or heat damage.

Inspect high pressure hose for kinking, cuts or abrasive

wear.

SE R V ICE HI G H PR E S S U R E WAS H E R

SAFELY

Before servicing washer, disconnect unit from power source,

relieve water pressure and allow unit to cool down.

Service washer in a clean dry flat area.

Operator’s Manual 9

Page 10

SAFETY SIGNS

34-1423 and 34-1424

Location: Motor Housing

34-1428 and 34-1429

Location: Handle Sides

34-1427

Location: Motor Housing

10 Operator’s Manual

Page 11

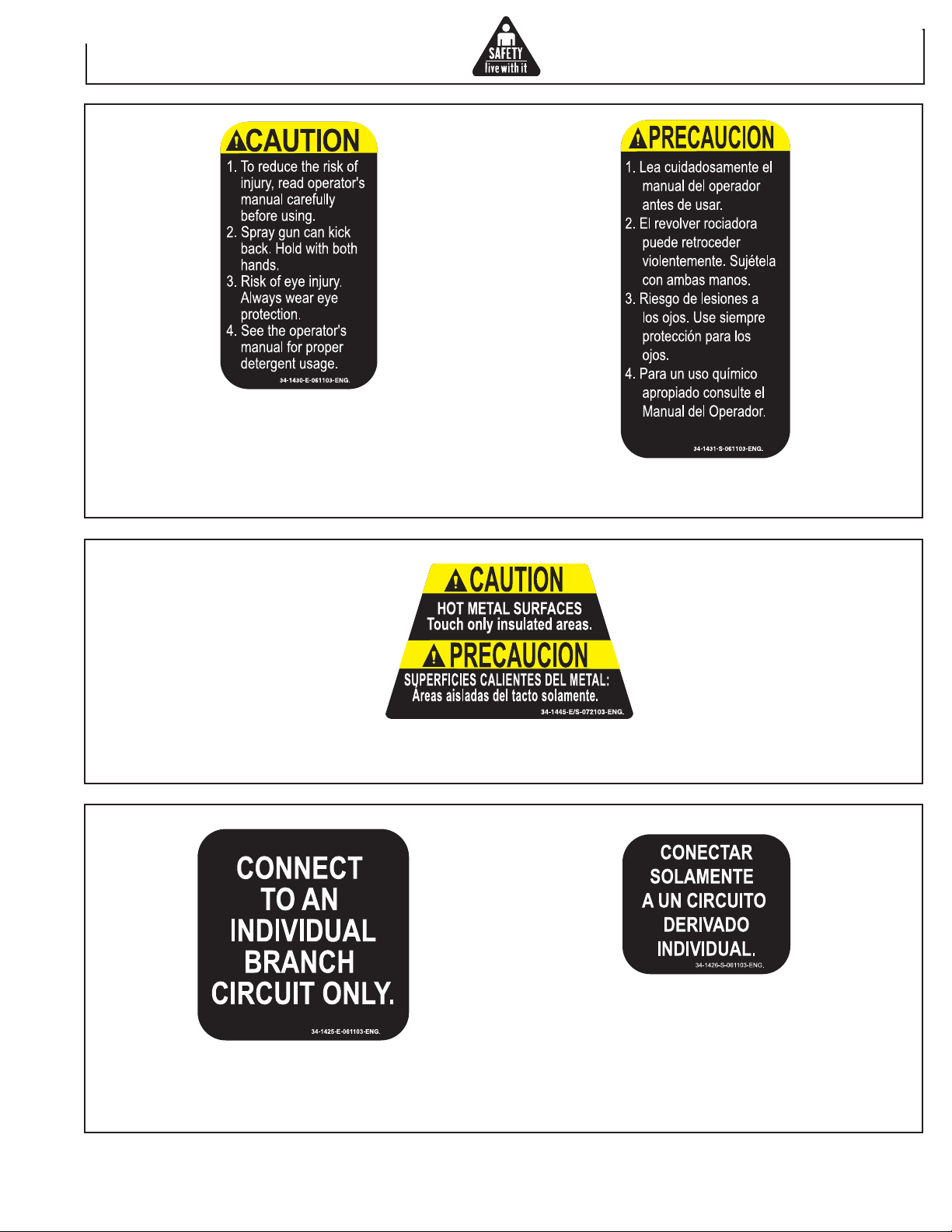

34-1430 and 34-1431

Location: Motor Housing

34-1445

Location: Handle

34-1425 and 34-1426

Location: Motor Housing

Operator’s Manual 11

Page 12

RISK OF ELECTROCUTION.

DO NOT REMOVE THIS TAG.

FAILURE TO FOLLOW THE ABOVE

INSTRUCTIONS COULD RESULT

IN A SEVERE ELECTRICAL SHOCK.

34-1035-E/F/S-111899-ENG

1. Connect only to a properly grounded outlet. Do not

remove ground pin.

2. Inspect cord before using. Do not use if cord is

damaged.

3. Keep all connections dry and off the ground.

4. Do not touch plug with wet hands.

5. This unit may be provided with a Ground Fault Circuit

Interrupter (GFCI) built into the power cord plug. If

replacement of the plug or cord is needed, use only

identical replacement parts. If this unit is not provided

with a GFCI, this unit should only be connected to a

power supply receptacle protected by a ground fault

circuit interrupter.

6. Do not use an extension cord with this machine.

7. Read the operator's manual before using.

WARNING

ADVERTISSEMENT

•Brancher seulement á une prise correctement mise á la

terre. Ne pas enlever la broche de mise á la terre.

•Vérifier le cordon avant l'utilisation. Ne pas utiliser le cordon

s' il est endommage.

•Conserver toutes les connexions au sec et au-dessus du sol.

•Ne pas toucher la prise avec des mains humides.

•Cet appareil peut être équipé d'un disjoncteur de fuite à la

terre incorporé dans la fiche du cordon électrique. S'il s'avère

nécessaire de remplaçer la fiche ou le cordon, n'utiliser que

des pièces de rechange identiques. Si cet appareil ne

comporte pas un disjoncteur de fuite à la terre, ne le relier

qu'à une prise de courant protégée par un disjoncteur de

fuite à la terre.

•L' utilisation d' une rallonge n' est pas recommandée.

•Lire le manuel de l' opérateur av

ant d' utiliser l' appareil.

RISQUE D' ÉLECTROCUTION NE

PAS ENLEVER CETTE ÉTIQUETTE

DES CHOCS ÉLECTRIQUES SÉVÉRES

SERONT POSSIBLES SI LES DIRECTIVES

CI-DESSUS NE SONT PAS SUIVIES.

•Conecte solamente a una toma corr

iente que está bien

fundado. No quite la pata de conexión de la tierra.

•Antes de usar inspeccióne la cuerda. No use si la cuerda està

dañando.

•Mantenga los conexiones secos y apar tados de la tierra.

•No torque el enchufe con manos mojados.

•Este producto debe conectarse a tierra.

Asegúrese de que la

lavadora a presión esté equipada con un Interruptor de

circuito de falla a tierra (Ground Fault Circuit Interrupter,

GFCI) incorporado en el cordón de alimentación. Si no lo

tiene, debe conectarse la lavadora a presión únicamente en

un receptáculo que esté protegido por un Interruptor de

circuito de falla a tierra. Desconéctela cuando no esté en uso.

•No use una cuerda extensión con la unidad.

•Antes de usar lea y entienda todas las instrucciónes y el

manual de operación.

ADVERTENCIA

SI NO SIGA LAS INSTRUCCIÓNES HAY EL

RIESGO DE ELECTROCUCIÓN SEVERA.

RIESGO DE ELECTROCUCION.

NO QUITE EST

A ETIQUETA.

12 Operator’s Manual

34-1035

Location: Power Cord

Page 13

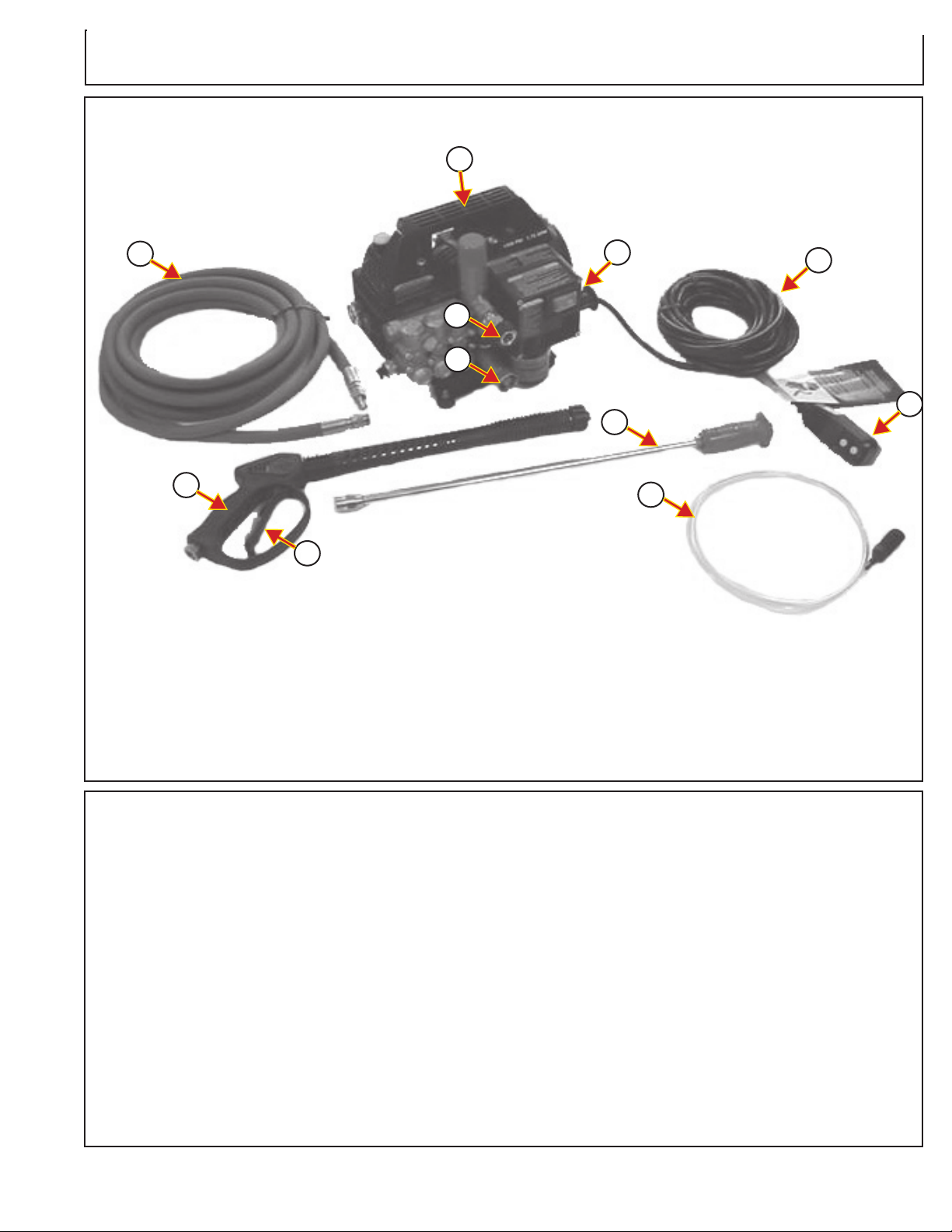

CONTROLS

Controls

B

K

A

E

C

D

F

H

J

G

I

A--On/Off Switch

B--Handle

C--High Pressure Outlet

Operator’s Manual 13

D--Water Inlet Fitting

E--Power Cord

F--Ground Fault Circuit

Interrupter

G--Detergent Hose

H--Nozzle Wand

I--Gun Trigger

J--Gun

K--Discharge Hose

Page 14

Preparing the Washer

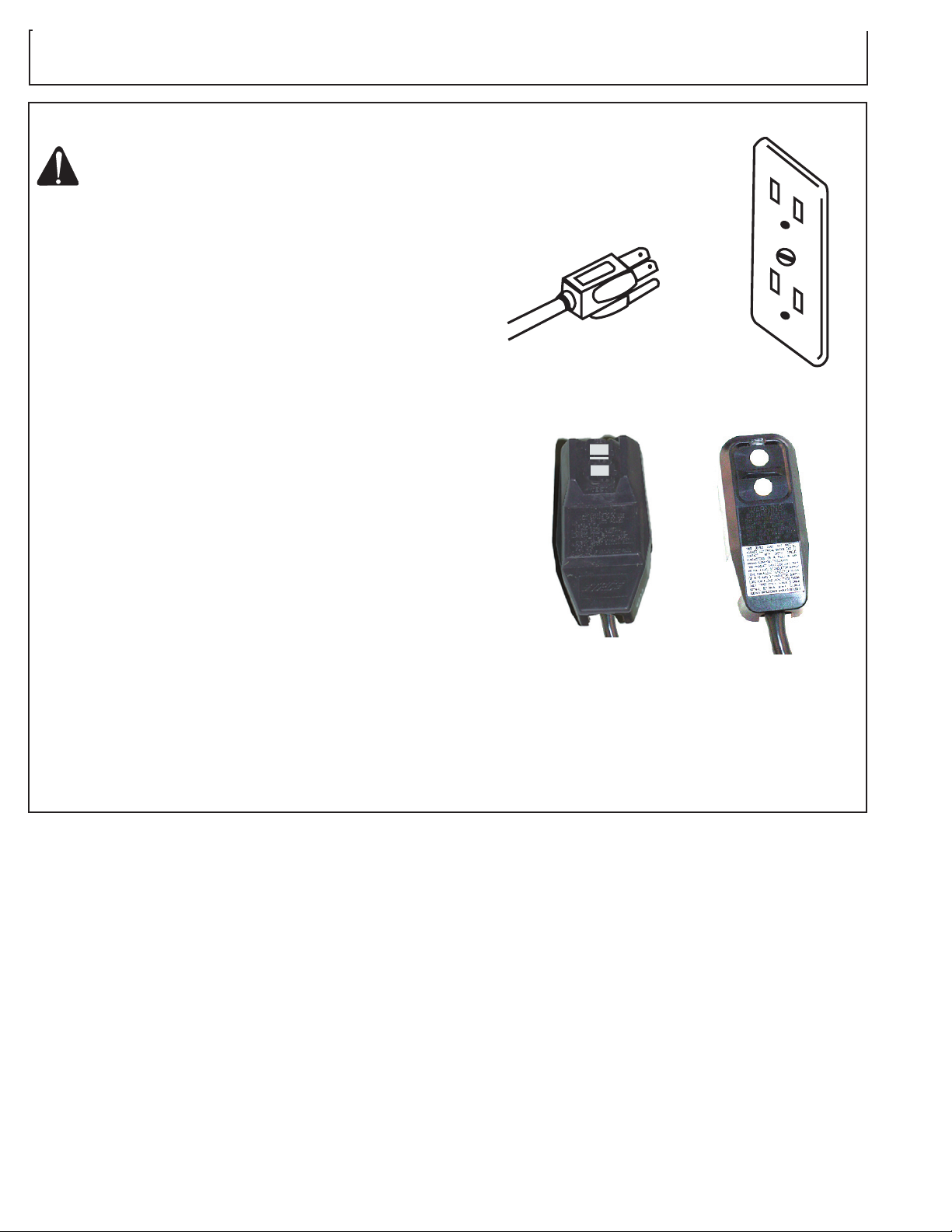

ELECTRICAL REQUIREMENTS

CAUTION: To avoid electrical shock, connect

the washer to a properly grounded electrical

receptacle. Do not use an adapter or remove third

(ground) prong.

Make certain the connection between the washer

power cord and receptacle is kept dry.

The following electrical requirements must be met:

1. The electrical supply must provide a minimum of 110 to

120 volts. With the washer operating, line voltage must

not drop below 108 volts.

IMPORTANT: Operating the pressure washer with

low line voltage may damage electrical

components and cause motor to stall.

2. This pressure washer is equipped with a Ground Fault

Circuit Interrupter in the power cord to reduce the risk

of electrical shock. However the GFCI will not protect

against all faults, short circuits, or overloads.

IMPORTANT: The GFCI MUST be reset each time the

washer is unplugged and plugged in

again.

14 Operator’s Manual

Page 15

Preparing the Washer

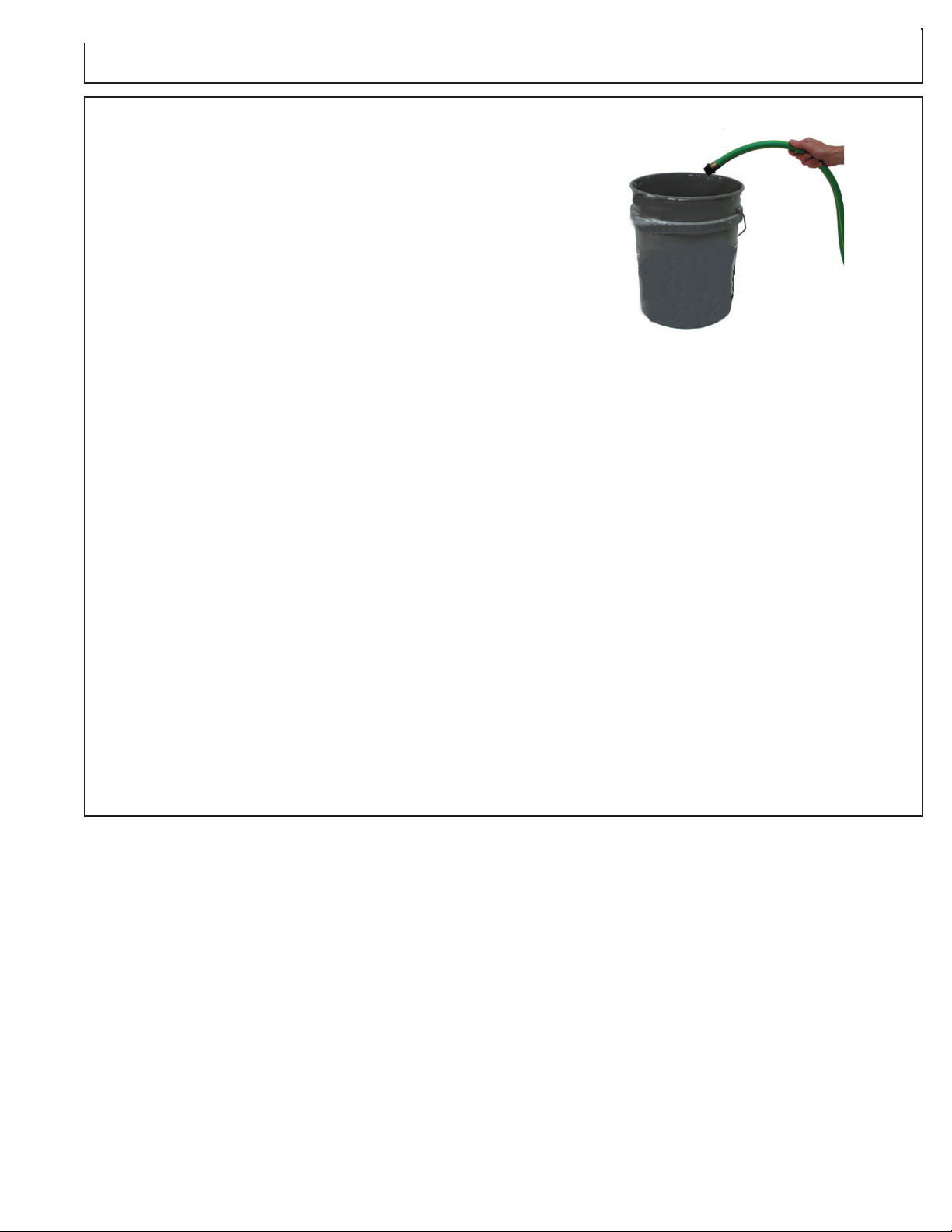

INLET WATER SUPPLY REQUIREMENTS

1. Inlet water supply must be a minimum of 20 PSI (1.4

bar).

Attempting to operate the washer with less than

adequate water supply will cause rapid wear of packings,

valves and bearings that will dramatically shorten pump

life. Symptoms of inadequate water supply are pump

shuddering and flattening of the supply hose.

2. Inlet water flow must be at least 125% of pump rated

flow. Check volume by timing how long it takes to fill a

5 gallon (19 L) container. For example, a flow rate of

3.0 GPM would fill a 5 gallon container in 5/3 minute

(100 seconds).

3. Water supply hose should be a good grade of garden

hose with a minimum I.D. 5/8 in. (16mm) and no longer

than 50 ft. (15.24 m). If longer supply hose must be

used, check to be certain flow is at least equal to the

“GPM Supply Required”.

4. If non-pressurized (static draw) water supply is used,

check to be certain flow is at least 125% of pump rated

flow. In static draw situations, water flow rate (GPM)

can be increased by elevating the water supply tank

or changing to a larger inside diameter water supply

hose.

5. Adding on extension to the supply hose will reduce water

flow rates. Check for adequate water flow rate each

time an extension is added. Water flow rates can be

increased by using the largest possible internal diameter

supply hose.

IMPORTANT: Inlet water temperature must not be more

than 125° F (60° C). Damage to the pump

may result.

Operator’s Manual 15

Page 16

Preparing the Washer

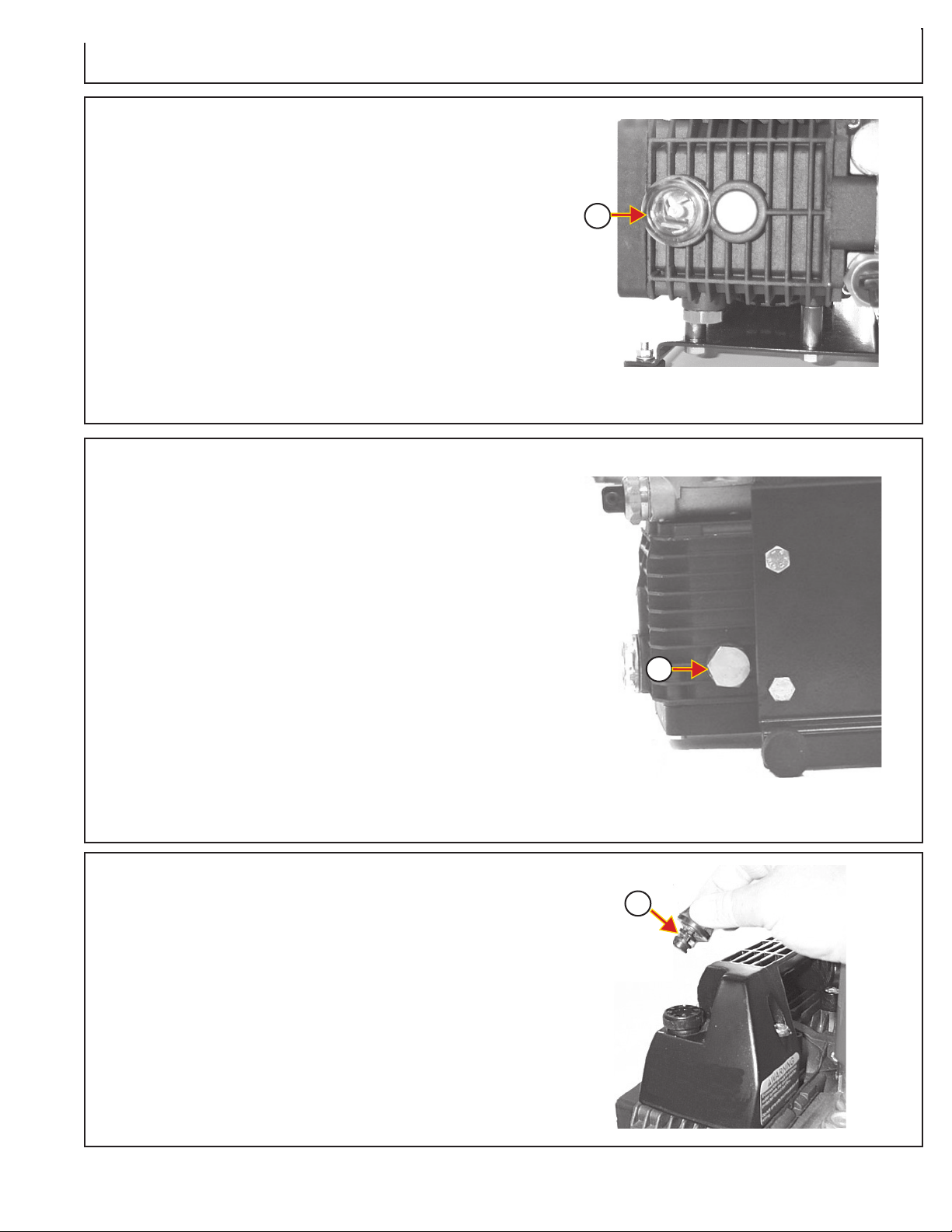

CHECK PUMP OIL

1. Remove shipping plug and install vented plug (A) on

pump.

2. Check oil in pump. With washer on level surface, the

oil should fill the oil level sight glass (B). If necessary,

top with HYGARD® or SAE30W non-detergent oil.

A

B

CONNECT DISCHARGE HOSE TO GUN

1. Apply pipe tape or sealant to threads on gun.

2. Attach discharge hose to gun using two open-end

wrenches. Tighten hose fitting enough to prevent

leaks.

IMPORTANT: Do not attach nozzle wand to gun handle

until water system is primed.

16 Operator’s Manual

Page 17

CONNECT HOSES AND PRIME PUMP

Preparing the Washer

1. Hose washer with screen (A) is already attached into

end of brass hose coupler.

NOTE: Conical screen in washer (A) should protrude out of

coupler and into flow from inlet hose.

IMPORTANT: If washer is to be connected to a well water

system, use 851-0207 water inlet filter (A).

This will increase sand filtering capability

and avoid damage to the pump.

A

A

2. Install inlet water hose (A) and hand tighten. Install high

pressure discharge hose (B) with quick connect.

B

A

Operator’s Manual 17

Page 18

Preparing the Washer

3. Open water supply. Squeeze trigger on gun. Allow

water to run (with motor off) until water runs out of

pressure hose. Start motor and cycle trigger on gun

until “crackling” sound (air in lines) stops. Turn off water

supply.

INSTALLING NOZZLE WAND

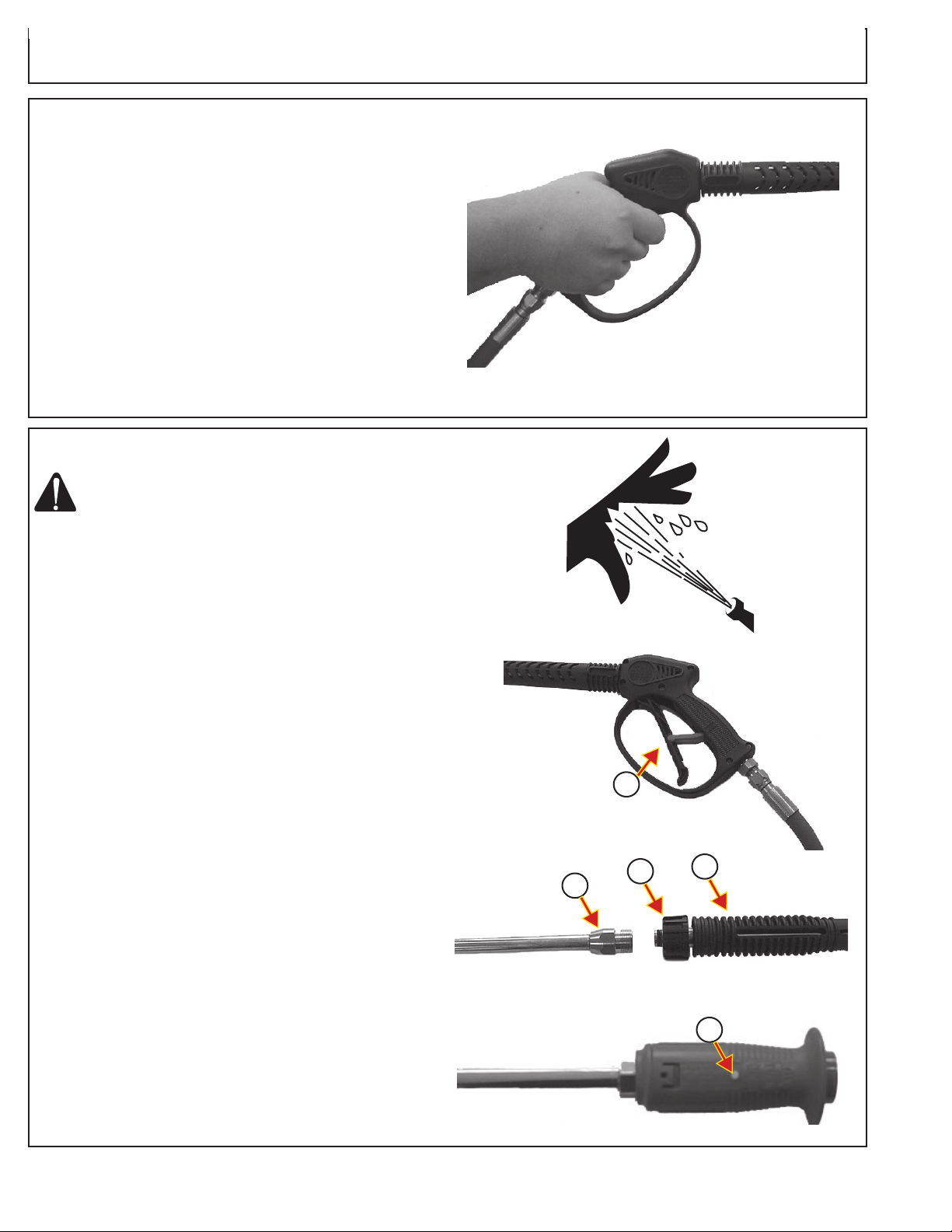

CAUTION: To avoid injury from escaping fluids

under pressure, relieve the pressure in the

system by stopping the washer and depressing

gun trigger. Lock trigger before adjusting

nozzle.

IMPORTANT: Do not attach nozzle wand until water

system is primed.

1. Place trigger lock (A) in locked position.

2. Insert connection fitting of nozzle wand (B) into gun

(C). Tighten threaded collar (D) on gun down on wand

threads to attach wand.

NO TE: W hen c hanging accessori es, t he wan d is

disconnected here and the accessory is connected

at this point. Washer wand has yellow dot (E) on

nozzle.

B

A

D

C

E

18 Operator’s Manual

Page 19

Preparing the Washer

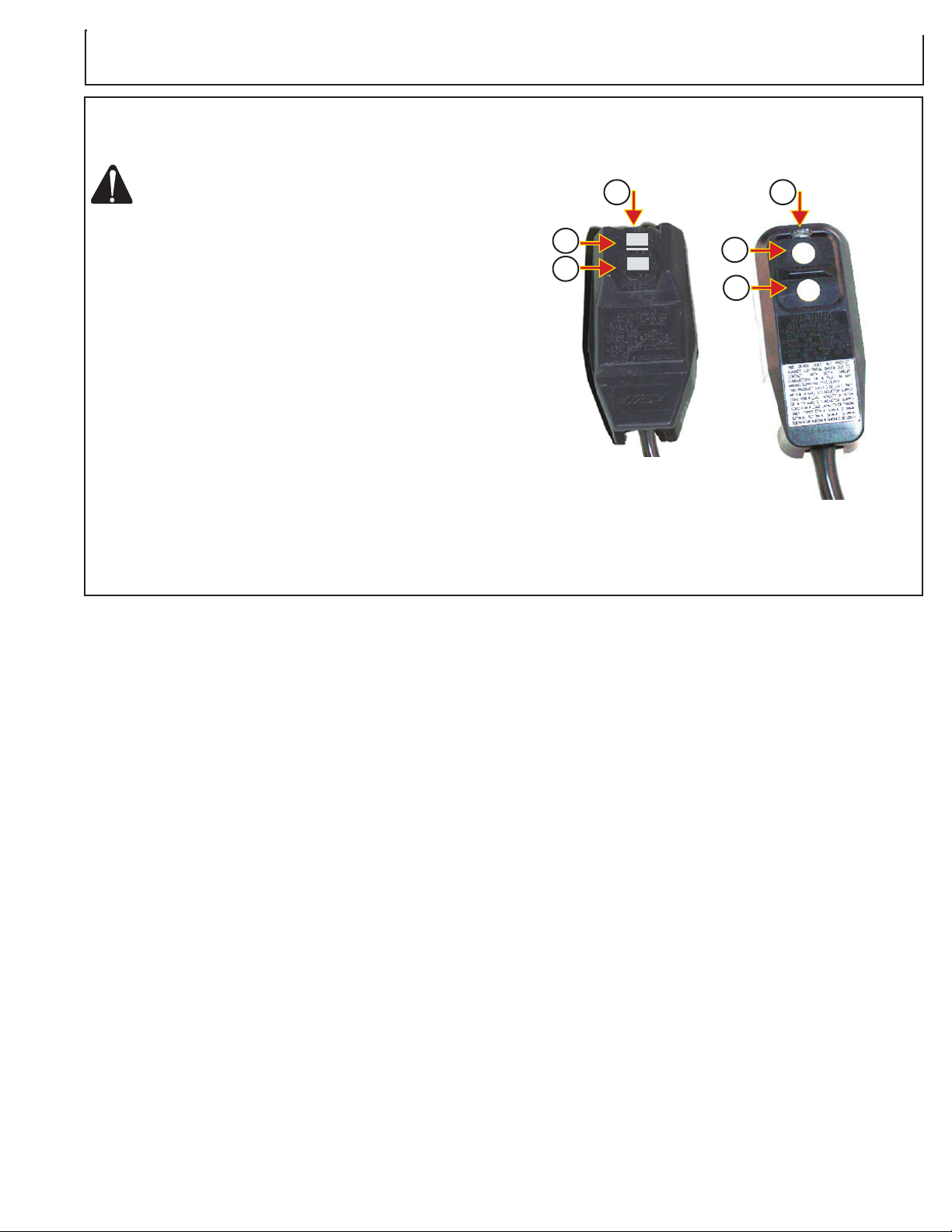

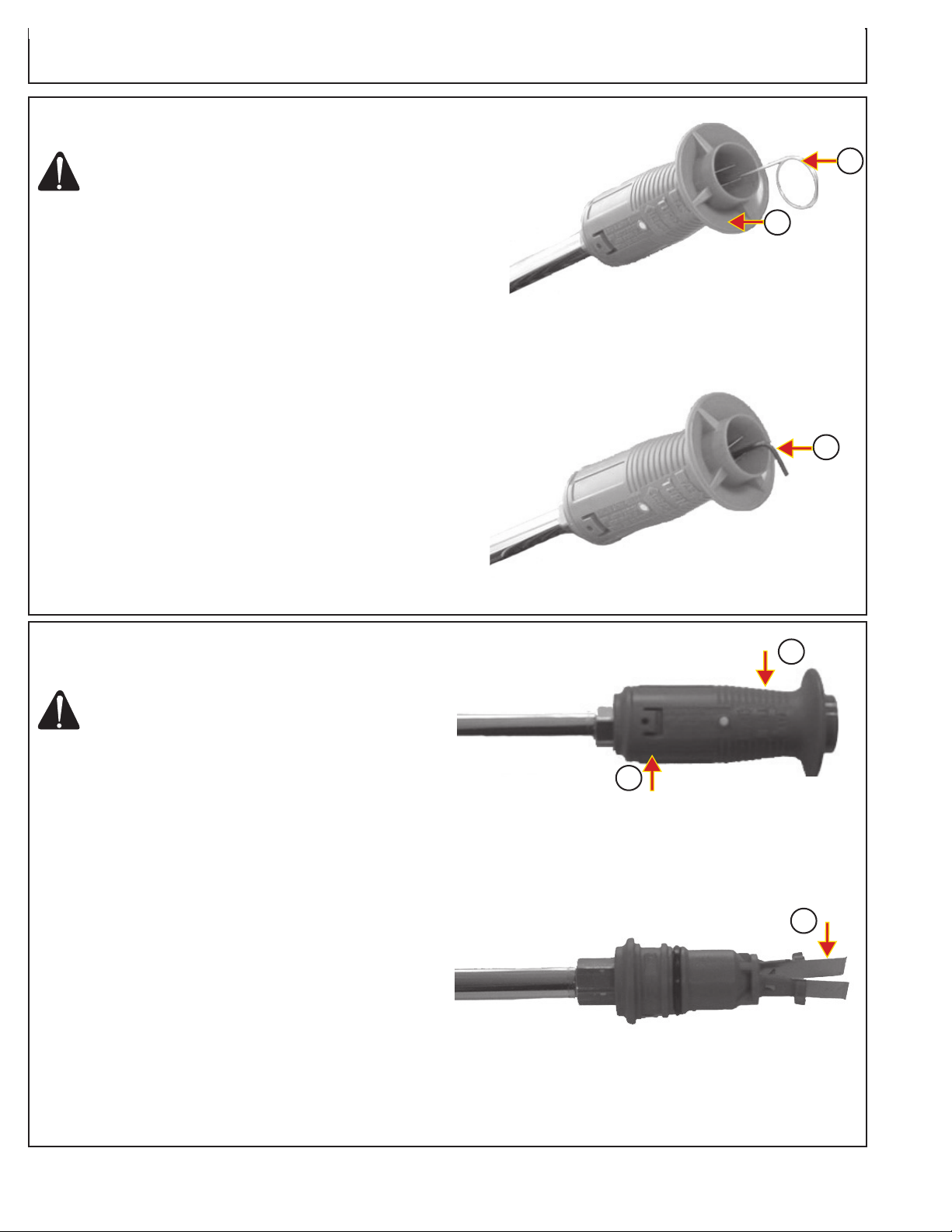

TE S T I N G GR O U N D FA U LT CI R C U I T

INTERRUPTER (GFCI)

CAUTION: Ground Fault Circuit Interrupter (GFCI)

MUST be tested before each use of the washer.

If the results in each one of the following steps are

not as described, shut washer off immediately. DO

NOT operate until the washer has been inspected

by a qualified electrician or your dealer.

1. Plug GFCI into grounded receptacle. Connect high

pressure outlet hose and turn on water supply.

2. Press and release “RESET” button (A) to verify power

to the washer.

3. Press “TEST” button (B). Red indicator bar (C) on reset

button should appear. (Power to the washer should be

interrupted).

4. Press and release the “RESET” button. Power should

be restored to the washer.

NOTE: GFCI test instruction are also found on the front of

the GFCI.

C

B

A

C

A

B

Operator’s Manual 19

Page 20

Operating the Washer

STARTING MOTOR

IMPORTANT: To prevent possible pump damage, do

not allow washer pump to run in bypass

(with gun trigger released) for longer than

3 minutes.

The washer ON/OFF switch (A) is a rocker switch that

includes a circuit breaker for protection against motor

electrical overload.

Move the ON/OFF switch to the “ON” position.

LOCKING GUN TRIGGER

CAUTION: Gun trigger should be locked when not

in use or whenever adjustments are being made

to gun or nozzle. This will help prevent accidental

discharge of high pressure fluid.

1. Pivot lock (A) down to prevent trigger engagement.

2. Pivot lock up to release trigger.

A

A

ADJUSTING SPRAY NOZZLE PRESSURE AND

PATTERN

CAUTION: High pressure spray can cause serious

injury. Keep away from spray. Never point the gun

at yourself or anyone else. Never put your hand,

fingers, eyes or body directly over spray. Do not

point spray toward fragile materials.

Spray nozzle can be adjusted in four ways to obtain best

results.

Pressure Adjustments:

1. For high pressure spray pull nozzle cover toward the gun

handle (A).

2. For detergent spray push nozzle cover away from gun

handle (B). In this position, nozzle sprays at low pressure

and draws detergents into the system if the detergent the

hose is attached and in solution.

Pattern Adjustment:

1. For 0° Pinpoint Pattern-Turn nozzle fully clockwise (C).

2. For 60° Fan-Type Pattern-Turn nozzle cover fully

counterclockwise (D).

3. For Infinate Adjustment-Turn nozzle for desired spray

pattern anywhere between 0° and 60°.

D

BA

C

In the high pressure spray position, water pressure can be

varied by turning the pressure adjusting knob (E) clockwise

to increase pressure and counterclockwise to decrease

pressure.

20 Operator’s Manual

E

Page 21

Operating the Washer

8" - 10"

(20-25 cm)

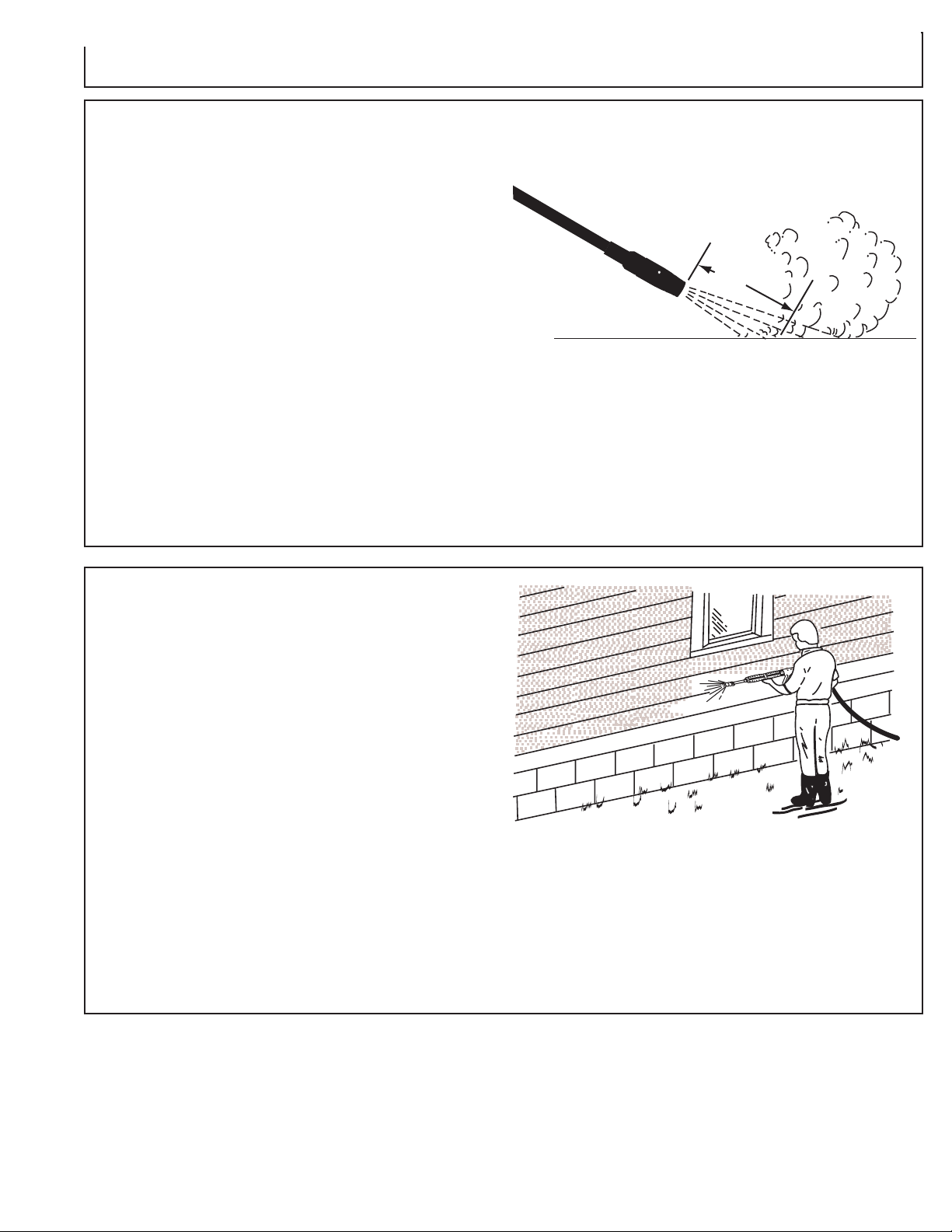

CLEANING HORIZONTAL SURFACES

Move nozzle wand from side to side. Direct spray at an

angle to force debris ahead and away from the cleared

area.

Depending on the material to be removed and nozzle

pressure, hold nozzle end 8 to 10 inches (20 to 25 cm) from

the surface and use slow, overlapping strokes. If debris

is easy to remove, move nozzle back to cover more area

for faster cleaning.

CLEANING VERTICAL SURFACES

IMPORTANT: Remember that the washer can deliver

a high pressure spray that can break

glass and gouge soft wood and other

materials.

When cleaning building interiors or exteriors without

detergents, work from top to bottom. This will help

eliminate streaks. In interiors, start with the ceiling first,

then the walls and the floor last.

Clean around windows carefully. If glass panes are not

well-caulked and puttied, the high pressure spray could

break the glass.

Never spray directly overhead. Always spray ahead to

avoid dripping or falling debris.

Operator’s Manual 21

Page 22

Operating the Washer

REMOVING PAINT

IMPORTANT: Remember that high pressure spray can

gouge soft woods and other materials, as

well as loosen grout.

1. Place nozzle end in high pressure position and very

narrow spray pattern.

2. Direct spray at a 45° angle about 4 to 12 inches (10 to

30 cm) from surface.

3. Spray in a back and forth motion, try to get beneath the

loose and bubbled paint.

4. Do not be concerned with the paint that remains. It

should be sufficiently bonded so as not to cause

repainting problems.

5. Some remaining paint may curl up at the edges. These

edges should be scraped with a steel brush or scraper

just before painting.

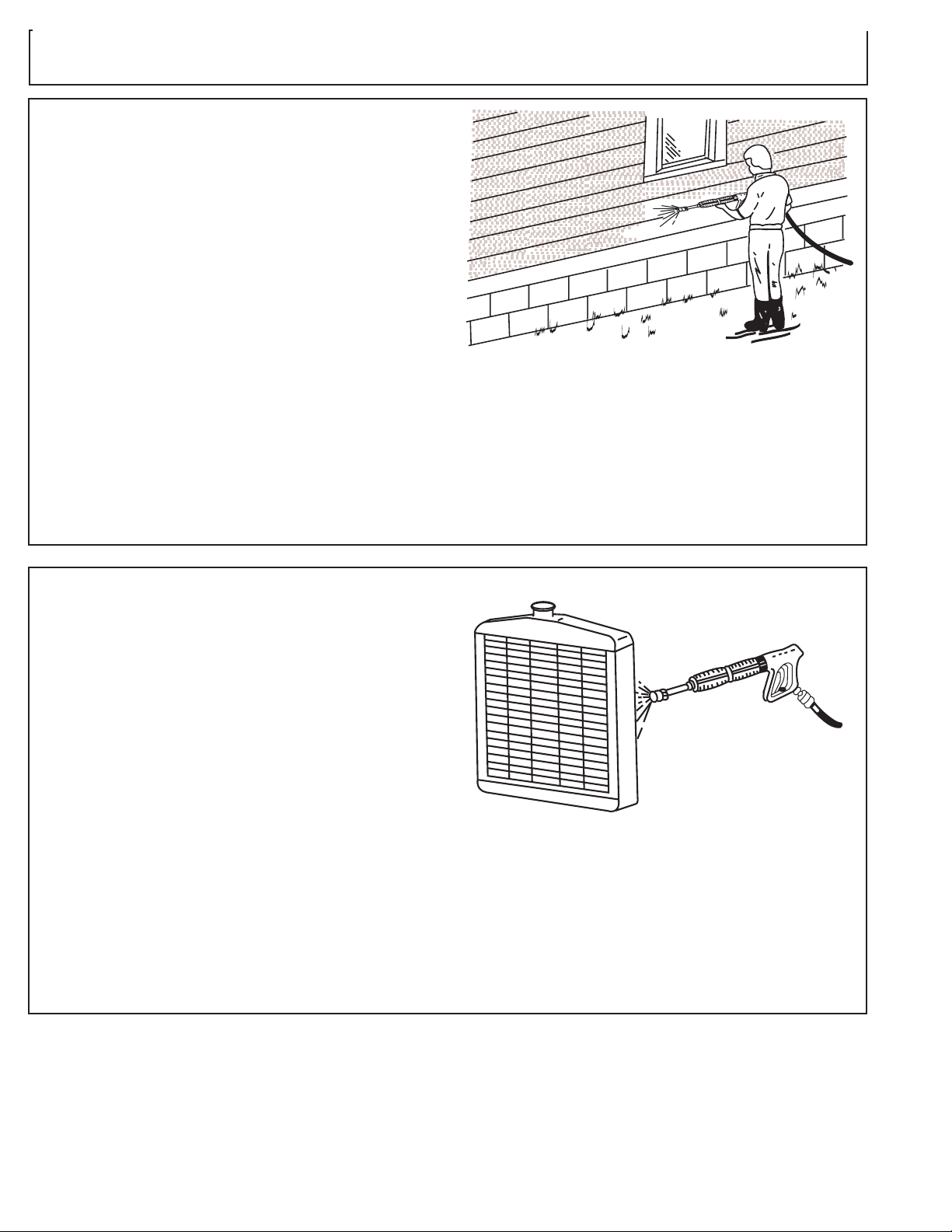

CLEANING RADIATOR FINS

IMPORTANT: Some engine and radiator manufacturers

may not permit cleaning radiators with a

high pressure washer. See equipment

Operator’s Manual.

1. Use clean water without detergent.

IMPORTANT: Spray straight into the radiator to prevent

bending fins.

2. If possible, direct spray in the direction opposite to

normal air flow through the radiator.

22 Operator’s Manual

Page 23

Operating the Washer

DETERGENT USAGE GUIDE

CAUTION: Use detergents carefully. Read

labels thoroughly and follow all instructions

for preparation, use, safety, transportation and

disposal. Be prepared to tell a physician exactly

what detergents you are using in the event of an

emergency. Keep all detergents out of reach of

children.

Be aware that two detergents can be mixed

on the sprayed surface. In this regard, some

detergents may give off harmful fumes or start

an unpredictable chemical reaction when mixed

with another detergent.

NEVER SPRAY FLAMMABLE LIQUIDS such as

gasoline, fuel oil, alcohol, naptha, etc.

Be sure to read and follow all detergent labels exactly

regarding preparation, use, safety, transportation, and

disposal. Keep in mind that the washer’s detergent

system further dilutes the detergent with water, and that

some detergents may not be concentrated enough to

properly work with the system.

Some detergents may not give premix instructions and

may require experimenting to determine proper dilution

for your application.

If you are not familiar with the detergent, always test

a small area of the surface to be cleaned for adverse

reaction. Do this a day in advance. Thoroughly rinse

area with water.

Operator’s Manual 23

Page 24

Operating the Washer

CLEANING WITH DETERGENTS

CAUTION: Wear goggles, respirator, and

protective clothing to help prevent injury from

detergents and spray.

IMPORTANT: DO NOT direct pressure washer spray at

the washer.

1. Mix detergent as instructed by the manufacturer.

2. Be sure that water supply is adequate and turned on

fully.

3. Slide detergent hose (B) onto barbed detergent valve

(A).

4. Insert threaded end of detergent strainer (C) into

detergent hose (B).

5. Insert detergent hose into solution. Be sure that hose

is clear and fully submerged in solution.

IMPORTANT: The detergent system will work only if the

nozzle is in the low pressure position.

6. Slide nozzle collar forward (D) into the low pressure

position.

7. Start washer and squeeze gun trigger. If detergent does

not spray within one minute, check to make sure the

detergent hose is in the solution and is not plugged.

8. To help avoid streaking, apply detergent to the lowest

surface first, and move up, using long overlapping

strokes. Allow solution to soak for several minutes.

IMPORTANT: Remember that high pressure spray

can gouge soft woods, damage other

materials and loosen grout.

9. Slide nozzle collar to the rear (E) to place in high

pressure position. With the nozzle approximately 6 to

10 inches (15 to 25 cm) and at an angle to the surface,

power rinse the area from the top down.

10. If surface is not clean, repeat above procedures.

IMPORTANT: To avoid damage and contamination with

other detergents, siphon a gallon (3.78 L)

of clear water through the system after

each use.

C

B

E

A

D

24 Operator’s Manual

Page 25

Operating the Washer

SHUTDOWN

IMPORTANT: Shutdown procedures should be followed

at the end of each cleaning operation.

1. If a detergent was used, place detergent inlet strainer

in CLEAN water and operate trigger to spray water for

a period of three minutes. This will flush the system of

detergents and help prevent the detergent valve from

sticking or corrosion.

2. Turn unit off and unplug washer.

3. Turn inlet water supply off. Squeeze trigger momentarily

to relieve pressure. Disconnect hoses.

4. Allow motor to cool, then wipe washer down with a damp

cloth.

Operator’s Manual 25

Page 26

Troubleshooting

Symptom Problem Solution

Low Nozzle Pressure. Unit not properly primed. Prime unit.

Insufficient inlet water supply. Check water supply requirements.

(See Service Section.)

Partially plugged water inlet screen. Clean inlet screen. (See Service

Section.)

Kink in water inlet hose. Remove kink.

Nozzle set for low pressure. Slide wand collar rearward.

Worn nozzle. Replace nozzle.

Worn pump components. See your John Deere dealer.

Unloader valve recirculating. See your John Deere dealer.

No Pressure or Fluid at Nozzle. Unit not properly primed. Prime unit.

Plugged water inlet screen. Clean or replace inlet screen.

Kink in water inlet hose. Remove kink.

Closed water supply. Turn on water supply. Check supply

hose for leaks or blockage.

Plugged nozzle. Inspect and clean or replace nozzle.

Unloader valve recirculating. See your John Deere dealer.

Pump Surges or Fluctuates, Pump unit not properly primed. Prime pump.

Giving Low Nozzle Pressure.

Insufficient inlet water supply. Check water supply requirements.

Plugged nozzle. Inspect and clean or replace nozzle.

Internal pump problem. See your John Deere dealer.

Unloader valve recirculating. See your John Deere dealer.

Air in system (after priming). See your John Deere dealer.

Motor Will Not Come On When No power at receptacle. Check electrical power fuse or circuit

Switch is Pressed. breaker.

Motor overload protector (on/off) Allow motor to cool and try again.

switch) tripped. Check voltage requirements. Contact

your John Deere dealer if condition

persists.

Switch malfunction. See your John Deere dealer.

Faulty motor. See your John Deere dealer.

26 Operator’s Manual

Page 27

Troubleshooting

Symptom Problem Solution

Motor Shuts Off - GFCI Trips. Power interruption. Reset GFCI. If problem continues,

contact your customer service or have

electrical system checked by a

qualified electrician.

Electrical short in power cord or in Reset GFCI. Try again. If problem

washer. persists, do not operate.

Contact your

customer service.

Motor Shuts Off - Trips On-Off Excessive discharge pressure Inspect and clean or replace nozzle.

Switch. caused by partially clogged nozzle.

Low voltage. Check electrical system requirements.

Check extension cords for proper

gauge.

Internal pump malfunction. See your John Deere dealer.

Water Continues to Flow from Spray gun valve malfunction.

Replace gun.

Nozzle after Gun Trigger is

Released.

Motor Hums - Does Not Turn. Pump plungers - sticking to Use a 4 mm hex wrench to manually

packing due to drying. turn and free pump. (See Service

Section.)

Motor malfunction. See your John Deere dealer.

Fan Spray is uneven or Clogged nozzle. Clean nozzle. (See Service Section.)

distorted.

Clogged fan spray shutters. Clean fan shutters.

Pump Oil is Milky or White. Water in oil. Change oil. Do not direct spray at

washer.

Does not draw soap. Nozzle not in “soap” position. Push adjustable colar forward. (See

“Adjusting Spray Nozzle Pressure

Pattern”.)

Too many hose extensions in use. Use only one hose extension.

Operator’s Manual 27

Page 28

Service

TE S T I N G GR O U N D FA U LT CI R C U I T

INTERRUPTER (GFCI)

CAUTION: Ground Fault Circuit Interrupter (GFCI)

MUST be tested before each use of the washer.

If the results in each one of the following steps is

not as described, shut washer off immediately. DO

NOT operate until the washer has been inspected

by a qualified electrician or your dealer.

1. Plug GFCI into grounded receptacle. Connect high

pressure outlet hose and turn on water supply.

2. Press and release “RESET” button (A) to verify power

to the washer.

3. Press “TEST” button (B). Red indicator bar (C) on reset

button should appear. (Power to the washer should be

interrupted.)

4. Press and release the “RESET” button. Power should

be restored to the washer.

C

B

A

C

A

B

NOTE: GFCI test instructions are also found on the front

of the GFCI.

CLEANING INLET WATER

CAUTION: Disconnect power cord from electrical

receptacle before cleaning inlet screen.

IMPORTANT: Do not operate washer with water inlet

screen removed. Foreign material may

enter and damage pump or valves.

Inspect the water inlet screen (A) (inside brass fitting)

periodically for buildup of scale, grit and dirt. Clean as

necessary. If it is corroded or broken, replace.

CLEANING DETERGENT HOSE STRAINER

Check detergent hose strainer for detergent or contaminant

buildup.

A

Remove strainer from hose and back flush with clean water

and a stiff bristle brush.

NOTE: If strainer frequently becomes plugged, check

detergent to be sure it is thoroughly mixed.

28 Operator’s Manual

Page 29

Service

CHECKING WATER PUMP OIL LEVEL

IMPORTANT: If oil is white or foaming, water is in the

oil reservoir. Change oil.

NOTE: Wa t e r in oil occurs as a result of sp r a y or

condensation. Milky oil is not indicative of a pump

malfunction.

1. Put unit on level surface.

2. Oil level should be at the center of sight glass (A).

3. Add oil if necessary with HYGARD® or SAE30W nondetergent oil. Do not overfill.

CHANGING WATER PUMP OIL

IMPORTANT: Change pump break-in oil after first 25

hours of operation and at 250 hour intervals

thereafter.

1. Place unit on level surface.

2. Run unit for a few minutes to warm oil.

3. Stop washer. Use an 22 mm deep well socket to remove

drain plug (A) to drain oil into container. Install plug.

Do not pollute; dispose of waste oil properly.

A

A

4. Remove vented plug (A). Fill pump with 11 oz.

HYGARD

should be at the center of sight glass. Replace plug.

Operator’s Manual 29

®

or SAE30W non-detergent oil. Oil level

A

Page 30

Service

CLEANING OR R E P L A C I N G N O Z Z L E

ORIFICE

CAUTION: To avoid injury from high pressure

spray, nozzle wand MUST be disconnected from

gun before servicing.

1. Rotate nozzle collar (A) to open shutter.

2. Insert cleaning tool (B) (provided) into orifice and turn.

3. Flush nozzle wand with water.

4. If nozzle can not be cleaned thoroughly, insert a

2.0 mm hex wrench (C) (provided) into orifice, turn

counterclockwise and remove orifice.

5. Check orifice for wear or damage; clean or replace if

necessary.

B

A

C

CLEANING OR REPLACING ADJUSTABLE

FAN SHUTTERS

CAUTION: To avoid injury from high pressure

spray, nozzle wand MUST be disconnected from

gun before servicing.

CAUTION: Fan shutter metal edges are extremely

sharp. Wear gloves.

1. Slide nozzle collar rearward.

2. Gently pry tabs (B) open and remove nozzle end (A).

3. Clean regulator and fan shutter assembly (C).

4. Squeeze nozzle end tabs inward, and slide nozzle end

back over nozzle assembly.

A

B

C

30 Operator’s Manual

Page 31

Storage

Service

STORING WASHER

IMPORTANT: Protect washer from freezing tempera-

tures. If unit will experience freezing

conditions, pump must be filled with

antifreeze to prevent cracking of pump

manifold and unloader valve due to

water expansion. Draining alone will not

remove all the water.

CAUTION: If the washer will be used where

food is prepared, stored or consumed, or

where sanitation is required, use a nontoxic

antifreeze.

NOTE: This operation requires two people: one to operate

washer and one to add antifreeze.

1. Install short piece (2 to 4 feet long) garden hose on

water inlet.

2. Raise open end of hose above washer and insert

funnel.

IMPORTANT: Be careful not to kink hose.

3. Fill hose with 50 - 50 mix of antifreeze.

4. While adding antifreeze, start washer, depress spray

gun trigger, and let run for 15 seconds.

5. Release trigger for 15 seconds.

NOTE: Trigger must be released to pull antifreeze into

unloader valve.

6. Repeat cycle of 15 seconds trigger on, 15 seconds

trigger off.

IMPORTANT: Dispose of sprayed solution safely

according to instructions on the antifreeze

container.

↑

{ }

Operator’s Manual 31

Page 32

Storage

REMOVING WASHER FROM STORAGE

IMPORTANT: Before starting unit, thaw out any possible

ice from wand, gun or hose.

1. Connect and open water supply. Squeeze trigger on

gun. Allow water to run (without motor running) until

water runs out of pressure hose.

2. If unit was stored with antifreeze solution, purge solution

from washer, before using. Dispose of sprayed solution

safely according to instructions on the antifreeze

container.

32 Operator’s Manual

Page 33

Specifications

SPECIFICATIONS

ITEM SPECIFICATION

Water Pump ................................................................... 1.75 GPM (6.62 L/min)

1250 PSI (86 Bar) (8613 kPa) at pump

1100 PSI (76 Bar) (7579 kPa) at discharge fitting

Electric Motor ................................................................. 120 volts, 13.5 amps, single phase, 60 Hertz, 1.5 HP,

1725 RPM, thermal-protected manual reset.

Electrical Power Requirements ...................................... Voltage at power supply with washer running must be

greater than 108 VAC.

Water Supply Requirements ..........................................

Inlet water supply volume - 3 GPM (11.4 L/m) minimum

Inlet water supply hose - 5/8 in. (15.9 mm) minimum I.D.

50 ft. (15.2 m) maximum length

Discharge Hose .............................................................25 ft. x 3/8 in. (7 m x 6.4 mm) minimum 3000 PSI (207 Bar)

working pressure, acid and oil resistant

Power Cord .................................................................... 35 ft. (10.7 m), 14 gauge, 3 conductor, water resistant,

with ground fault circuit interrupter (GFCI).

Nozzle Wand ..................................................................

Color of dot - Yellow

Inlet water supply pressure - 20 PSI (1.4 Bar) minimum

Nozzle size -- .047 in. (1.2 mm)

RECORD SERIAL NUMBER

Write you model number, machine serial number (see

serial number tag (A) in illustration) and date of purchase

in the spaces provided below. Your dealer needs this

information when ordering parts.

Model No. ______________________________________________

Machine Serial No. _______________________________________

A

Date of Purchase ________________________________________

(To be filled in by purchaser)

Operator’s Manual 33

Page 34

Accessories

HIGH PRESSURE HOSE: 851-0007

IMPORTANT: DO NOT use more than 1 extension hose.

The higher restriction will cause unloader

valve to function all the time.

One additional pressure hose may be connected to the

existing hose. This allows the operator to move around a

greater distance without moving unit.

WATER FILTER: 851-0207

Use when water supply is a rural well or a static draw to

help filter incoming water.

WAND EXTENSION: 50-0180

The wand extension adds 24 inches between the gun and

nozzle wand to help reach hard to reach places.

34 Operator’s Manual

Page 35

Accessories

ROTATING BRUSH: 50-0179

Water pressure and low act against gears to turn the

brushes. When used with the detergent system, the brush

scrubs the dirt away.

ROTATING NOZZLE W/LANCE:

18-0369 - 1.20 mm

18-0370 - 1.25 mm

18-0371 - 1.40 mm

The rotating high pressure nozzle provides a rotating 0°

spray that helps dislodge dirt and debris.

Operator’s Manual 35

Page 36

Accessories

ALL-PURPOSE CLEANER: AW-4018-JD01

Use John Deere All Purpose Cleaner concentrate for

most cleaning jobs. Contains water-soluble solvents for

soil penetration on vehicles and is safe to use on rubber

and wax finishes.

SURFACE PREPARATION: AW-4034-JD01

Use John Deere Surface Preparation to clean, remove

mildew, and condition surfaces of all types of siding, farm

buildings and mobile homes. It is safe to use on ferrous

and nonferrous metal surfaces and removes mildew stains

and chalk buildup.

DEGREASING: AW-4059-JD01

Apply John Deere Degreaser as directed by container

label, allow to soak for a few minutes, then wash with all

purpose cleaner. Rinse with clear water.

Cover sensitive parts such as air cleaner, electrical

components, etc. when cleaning engines.

36 Operator’s Manual

Page 37

Accessories

HY-GARD

®

Use TY6354 John Deere HY-GARD® when adding or

changing oil in pressure washer pump.

SPRAY WAX

Mix TY8277 John Deere Spray Wax at a ratio of ONE

ounce of wax to 1-1/2 gallon of water to give a long lasting

finish to painted metal surfaces.

Operator’s Manual 37

Page 38

STATEMENT OF WARRANTY

The John Deere warrants all parts, (except those referred to below), of your new pressure

washer to be free from defects in materials and workmanship during the following

periods:

For One (1) Year from the date of original purchase:

High Pressure Pump

Regulating Valve

GFCI

For Ninety (90) days from the date of original purchase:

Trigger Gun High Pressure Hose

Variable Wand Strainer/Filters

On/Off Switch

Defective parts not subject to normal wear and tear will be repaired or replaced at our

option during the warranty period. In any event, reimbursement is limited to the purchase

price paid.

EXCLUSIONS

1. Normal wear parts:

Pump Packings Spray Nozzles

Pump Valves Screw Connects

Detergent Valves O-rings

2. This warranty does not cover parts damaged due to normal wear, misapplication,

misuse, operation at other than recommended speeds, pressures or temperature. Parts

damaged or worn because of the use of caustic liquids or by operation in abrasive or

corrosive environments or under conditions causing pump cavitation are not warranted.

Failure to follow recommended operating and maintenance procedures also voids

warranty.

3. The use of other than genuine manufacturer repair parts will void warranty.

4. Warranty will be void if used in any application other than consumer/homeowner.

Parts returned, prepaid to our factory or to an Authorized John Deere Service Center

will be inspected and replaced free of charge if found to be defective and subject

to warranty. There are no warranties which extend beyond the description of the

face hereof. Under no circumstances shall the manufacturer bear any responsibility

for loss of use of the unit, loss of time or rental, inconvenience, commercial loss or

consequential damages.

For Service or Warranty Consideration, contact

®

Mi-T-M

Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

38 Operator’s Manual

Page 39

Notes

Guide d’utilisation 39

Page 40

Introduction

MERCI de la confiance témoignée par l’achat d’un produit

John Deere.

LIRE ATTENTIVEMENT LE PRÉSENT LIVRET afin de

pouvoir utilser et entretenir correctement la machine,

sinon des dommages corporels ou matériels pourraient en

résulter. Ce manuael et les symboles de securité peuvent

ègalement être disponibles en d’autres langues. (Voir votre

concessionnare John Deere pour les commander.)

CE LIVRET DOIT ÊTRE CONSIDÉRÉ comme faisant partie

intégrante de la machine et doit toujours l’accompagner

même en cas de revente.

LES MESURES données dans cette publication sont

exprimées en unités métriques et leurs équivalents

US habituels. N’utiliser que les pièces de rechange et

les éléments de fixation appropriés. Les éléments de

boulonnerie métrique et US néessitent l’emploi de clés

,étriques et US correspondantes.

LES INDICATIONS DE CÔTÉ, telles que droite et

guache, sont déterminées en faisant face au moteur de

la machine.

Les NUMÉROS D’SERIAL de la machine à l’une des

sections «Caractéristiques» ou «Numéros de série».

Noter correctement toutes les positions pour faciliter les

recherches en cas de vol. Les communiquer également

au concessionnaire lors de toute commande de pièces.

Prendre soin de recopier les numéros d’identification sur

une feuille séparée qui sera conservée dans un endriot

sûr.

LA GARANTIE fait partie du programme de soutien John

Deere destiné aux clients qui utilisent et entretiennent

leur matériel tel que décret dans ce livret. Les conditions

de garantie dont bénéficie cette machine figurent sur le

certificat de garantie dans le livret.

Cette garantie donne l’assurance que John Deere

reprendra ses matériels, s’il s’avère qu’ils sont défectueux,

pendant la période de garantie. Toute utilisation abusive

ou modification visant à dépasser les performances

spécifiées par le constructeur annuleront la garantie.

40 Guide d’utilisation

Page 41

Table de matières

Page

Sécurité ................................................................... 42

Commandes ..........................................................51

Préparation de l’appareil de lavage ..................... 52

Utilisation de l’appareil de lavage ...................... 58

Dépannage ...............................................................64

Entretien .................................................................66

Remisage ................................................................ 69

Caractéristiques ..................................................... 71

Accessoies .............................................................. 72

Garantie ...................................................................76

Note .......................................................................... 77

Toutes les informations, illustrations et caractéristiques contenues

dans la présente publication sont à jour au moment de la publication,

le constructeur se réservant le droit d’apporter sans notification toute

modification jugée appropriée.

Guide d’utilisation 41

Page 42

Table de matières

42 Guide d’utilisation

Page 43

Sécurité

W

AR

NI

N

G

W

A

R

N

I

NG

S I

N

T

HE

M

A

NU

A

LS

.

W

A

R

N

I

NG

S I

N

T

HE

M

A

NU

A

LS

.

CA

U

T

I

ON

O C

AU

T

I

ON

S

IN

O

T

H

E

M

A

N

UA

L

S

O C

AU

T

I

ON

S

IN

O

T

H

E

M

A

N

UA

L

S

O C

AU

T

I

ON

S

IN

O

T

H

E

M

A

N

UA

L

S

O C

AU

T

I

ON

S

IN

O

T

H

E

M

A

N

UA

L

S

DANGER

AVERTISSEMENT

ATTENTION

RECONNAÎTRE LES SYMBOLES DE MISE EN

GARDE

Voici le symbole de mise en garde. Lorsqu’il apparaît sur

la machine ou dans la présente publication, c’est pour

prévenir d’un risque potentiel de blessure.

Respecter tous les conseil de sécurité ainsi que les

consignes générales de prévention des accidents.

COMPRENDRE LES TERMES DE MISE EN

GARDE

Le symbole de mise en garde est accompagné d’un terme,

tel que DANGER, AVERTISSEMENT ou ATTENTION. Le

terme DANGER repère les dangers les plus graves.

Les autocollants avec DANGER ou AVERTISSEMENT

signalent des dangers spécifiques. Les autocollants avec

ATTENTION se réfèrent à des précautions d’ordre général.

Dans la présente publication, le terme ATTENTION

accompagne les messages de sécurité.

RESPECTER LES CONSEILS DE SÉCURITÉ

Lire attentivement tous les conseils de sécurité contenus

dans cette publication et ceux apposés sur la machine.

Veiller à ce que les autocollantes soient lisibles. Remplacer

ceux qui manqueraient ou seraient endommagés.

S’assurer que les autocollants adéquats sont apposés

sur les noveaux équipements et les pièces de rechange.

Des autocollants de rechange sont disponibles chez le

concessionnaire John Deere.

Apprendre à utiliser la machine et à en manipuler les

commandes. Ne pas confier la machine à une personne

non formée à cet effet.

Maintenir la machine en permanence en bon état. Toute

modification illicite risque d’en affecter la fonctionnement

et/ou la sécurité et d’en réduire la durée de vie.

Prendre contact avec le concesionnaire John Deere cas

de difficultés à comprendre certaines parties de cette

publication et pour obtenir une assistance.

Guide d’utilisation 43

Page 44

PROTECTION CONTRE LES JETS SOUS

HAUTE PRESSION

Les jets haute pression peuvent pénétrer sous la peau

en causant de graves blessures. Éviter que ces jets

n’entrent en contact avec les mains ou toute autre partie

du corps.

En cas d’accident, consulter immédiatement un médecin.

En cas d’accident, si le jet semble avoir pénétré sous la peau,

OBTENIR DES SOINS MÉDICAUX D’URGENCE. NE

PAS TRAITER LA BLESSURE COMME UNE COUPURE

ORDINAIRE. Si on utilise des agents nettoyants, être

en mesure d’en indiquer le type exact au médecin.

INSTRUCTIONS DE MISE À LA TERRE

Ce produit doit être mis à la terre. S’il fonctionne mal ou

tombe en panne, la mise à la terre fournit un chemin de

moindre résisitance au courant électrique, réduisant ainsi

les risques de choc électricque. Ce produit est équipé

d’un cordon d’alimentation avec conducteur de mise à la

terre de l’équipment et une prise mâle de mise à la terre.

La prise mâle doit être branchée dans une prise femelle

appropriée correctement installée et mise à la terre

conformément aux normes et réglementations locales.

DANGER - Un branchement incorrect du conducteur

de mise à la terre de l’équipement peut entraîner des

risques d’électrocution. Vérifier avec un dépanneur ou

un électricien qualifié en cas de doutes concernant la

mise à la terre. Ne pas modifier la prise mâle fournie

avec le produit: si elle ne convient pas, une prise murale

appropriée doit être installée par un électricein qualifié.

PROTECTION PAR DISJONCTEUR DE FUITE À LA

TERRE

Cet appareil de lavage à haute pression est muni d’un

disjoncteur de fuite à la terre (GFCI) incorporé au cordon

d’alimentation. Ce dispositif fourmit une protection

supplémentaire contre les risques de choc électrique. Si

le remplacement du cordon d’alimentation ou de la prise

est nécessaire, n’utiliser que des pièces de rechange

identiques comportant la protection GFCI.

NE PAS faire tomber le disjoncteur de fuite à la terre,

sous peine de l’endommager.

NE PAS tirer sur le cordon électrique pour le débrancher

de la prise, et NE PAS transporter l’appareil en le tenant

par son cordon.

44 Operator’s Manual

Page 45

RALLONGES

L’usage de rallonges n’est pas recommandé sur l’appareil

de lavage à haute pression. Cependant, s’il est inévitable,

la rallonge doit être branchée sur un disjoncteur de fuite

à la terre (GFCI) comme il s’en trouve dans les boîtiers

à disjoncteurs ou les prises protégées.

N’utiliser que des rallonges à 3 fils munies de prises

tripolaires avec raccordement à la terre et adaptées à la

prise de l’appareil de lavage. N’utiliser que des rallonges

pour usage extérieur, identifiées par la mention «Rallonge

acceptable pour usage extérieur: la ranger à l’intérieur si

elle n’est pas en service». Utiliser des rallonges d’une

capacité au moins égale à celle du produit. Ne pas utiliser

de rallonge endommagée. L’examiner avant de l’utiliser

et la remplacer si elle est abîmée. Ne pas la maltraiter

et ne pas la déconnecter en tirant violemment. Garder

les rallonges à l’écart de la chaleur et d’angles coupants.

Toujours déconnecter la rallonge de la prise avant de

déconnecter l’équipement de la rallonge.

ATTENTION: Pour réduire le risque d’electrocution,

maintenir toutes les connections sèches

et au-dessus du sol. Ne toucher aucune

prise avec des mains mouillées.

Pour des rallonges:

Longueur du cordon Diamètre du fil

Jusqu’à 15 m (50 pi) 14 AWG

De 15 à 30 m (50 à 100 pi) 12 AWG

L’utilisation de rallonges ayant un calibre plus petit

provoquera l’arrêt du moteur ou du disjoncteur.

PRÉ CAUTION S À PREN DRE AVEC LES

DÉTERGENTS DE NETTOYAGE

Savoir quel détergent on utilise. En cas d’urgence, être

capable d’indiquer exactement au médecin le produit

utilisé. Lire toutes les indications relatives au produit et

suivre exactement toutes les instructions relatives à sa

préparation, à son utilisation, à la sécurité, à son transport

et à la manière d’en disposer. Maintenir tous les produits

chimiques hors de portée des enfants, des animaux

familiers et du bétail.

NE JAMAIS pulvériser de liquides combustibles.

Ne pas utiliser de produits chimiques hautement corrosifs

ni de produits de nettoyage de type acide avec cet appareil

de lavage à haute pression.

Operator’s Manual 45

Page 46

MANIPULER LES PRODUITS CHIMIQUES

MSDS

AVEC SOIN

Une exposition directe à des produits chimiques dangereux

peut provoquer des blessures graves. Les produits chimiques

potentiellement dangereux utilisés avec l’équipement John

Deere comprennent des produits tels que des lubrifiants,

des liquides de refroidissement, des peintures et des

adhésifs.

Une fiche signalétique de sécurité des produits (MSDS)

fournit des détails spécifiques sur les produits chimiques:

risques physiques et pour la santé, consignes de sécurité

et techniques d’intervention d’urgence.

Vérifier la fiche signalétique de sécurité des produits avant

de débuter tout travail si vous utilisez un produit chimique

dangereux. Vous saurez ainsi exactement quels sont les

risques et comment effectuer le travail en toute sécurité.

Suivez ensuite les instructions et utilisez l’équipement

recommandé. (Contactez votre concessionnaire John Deere

pour les fiches signalétiques de sécurité des produits portant

sur les produits chimiques utilisés avec votre équipement

John Deere)

46 Operator’s Manual

Page 47

CONSEILS DE SÉCURITÉ IMPORTANTS

AVERTISSEMENT: Veuillez lire ce livret d’entretien au

complet, afin de réduire le risque de blesures. Lorsque

vous utilisez ce produit, les précautions de base

suivantes devraient toujours être suivies:

1. Lire toutes les instructions avant d’utiliser ce

produit.

2. Ce produit est muni d’un disjoncteur de fuite à la

terre (GFCI) dans le cordon d’alimentation électrique

afin de réduire les risques de choc électrique. Si le

remplacement du cordon d’alimentation ou de la prise

est nécessaire, n’utilisez que des pièces de rechange

identiques.

3. Suivre les instructions de mise à la terre fournies

dans ce manuel.

4. Les jets haute pression peuvent couper la peau. Ne

pas diriger le jet vers des personnes. Eloigner les

persones de la zone de travail. Avertir les enfants

que le jet peut couper. Surveiller les enfants avec

attention.

5. Ne pas permettre à des enfants ou à du personnel

inexpérimenté de faire fonctionner l’appareil de

lavage.

6. Ne pas diriger le jet vers des prises électriques, des

prises de courant, des ampoules, de la vitre ou des

objets fragiles qui pourraient se briser.

7. La poussière et les débris retirés par le jet peuvent

causer des blessures aux yeux. Porter des lunettes

de protection.

8. Les surfaces mouillées peuvent être glissantes.

Porter des chaussures et garder les deux pieds

posés sur le sol. Ne pas grimper sur les articles que

vous nettoyez. Ne pas essayer d’atteindre des objets

hors de votre portée, ni se tenir debout sur un support

instable. Garder un bon équilibre en tout temps.

9. Lousque la gâchette est relâchée, de la pression

d’eau demeure emprisonnée dans le flexible de

décharge. Relâcher cette presion en actionnant la

gâchette du pistolet après l’arrêt de l’appareil de

lavage.

10. Ne pas faire fonctionner l’appareil de lavage lorsque

vous êtes fatigué ou sous l’influence de drogues

ou de produits détergents. Soyez alerte. Porter

attention à ce que vous faites.

11. Suivre les instructions d’entretien contenues dans

ce manuel.

CONSERVER CES INSTRUCTIONS

Operator’s Manual 47

Page 48

PORTER DES VÊTEMENTS DE PROTECTION

Porter des vêtements ajustés et l’équipement de sécurité

appropriés au travail.

Porter des protecteurs d’oreilles tels que des cache-oreilles

ou des bouchons d’oreilles pour se protéger contre les bruits

intenses inconfortables.

L’opérateur doit être trés attentif de façon à opérer l’équipement

en toute sécurité. Ne pas porter de casque d’écoute ou de

radio lorsque vous faites fonctionner la machine.

PRÉPAREZ-VOUS POUR LES URGENCES

Gardez une trousse de premiers soins et un extincteur à

portée de la main.

Gardez le numéro du médecin, de l’ambulance, de l’hôpital et

des pompiers près de votre téléphone en cas d’urgence.

Soyez prêt si un incendie débute.

INSPECTER L’APPAREIL DE LAVAGE À HAUTE

PRESSION

Assurez-vous que tous les couvercles, garants et dispositif

de protection sont en place.

Repérez toutes les commandes et les étiquettes de

sécurité.

Assurez-vous que les raccords de plomberie et boulonnerie

sont bien resserrés.

Inspectez le cordon de secteur pour déceler les dommages

avant utilisation. Il y a un risque de choc électrique de

l’écrasement, de la coupure ou du dommage par la chaleur.

Inspectez le tuyau à haute pression pour déceler le tordu, les

coupes ou l’usage abrasif.

FAIRE L’ENTRETIEN DE L’APPAREIL DE

LAVAGE À HAUTE PRESSION EN TOUTE

SÉCURITÉ

Avant de faire l’entretien de l’appareil de lavage, fermer le

moteur, relâcher la pression et laisser refroidir l’appareil.

Faire l’entretien dans un endroit propre, sec et plat.

48 Operator’s Manual

Page 49

ÉTIQUETTES DE SÉCURITÉ

Emplacement: Cordon d’alimentation

Operator’s Manual 49

34-1432

Page 50

RISK OF ELECTROCUTION.

DO NOT REMOVE THIS TAG.

FAILURE TO FOLLOW THE ABOVE

INSTRUCTIONS COULD RESULT

IN A SEVERE ELECTRICAL SHOCK.

34-1035-E/F/S-111899-ENG

1. Connect only to a properly grounded outlet. Do not

remove ground pin.

2. Inspect cord before using. Do not use if cord is

damaged.

3. Keep all connections dry and off the ground.

4. Do not touch plug with wet hands.

5. This unit may be provided with a Ground Fault Circuit

Interrupter (GFCI) built into the power cord plug. If

replacement of the plug or cord is needed, use only

identical replacement parts. If this unit is not provided

with a GFCI, this unit should only be connected to a

power supply receptacle protected by a ground fault

circuit interrupter.

6. Do not use an extension cord with this machine.

7. Read the operator's manual before using.

WARNING

ADVERTISSEMENT

•Brancher seulement á une prise correctement mise á la

terre. Ne pas enlever la broche de mise á la terre.

•Vérifier le cordon avant l'utilisation. Ne pas utiliser le cordon

s' il est endommage.

•Conserver toutes les connexions au sec et au-dessus du sol.

•Ne pas toucher la prise avec des mains humides.

•Cet appareil peut être équipé d'un disjoncteur de fuite à la

terre incorporé dans la fiche du cordon électrique. S'il s'avère

nécessaire de remplaçer la fiche ou le cordon, n'utiliser que

des pièces de rechange identiques. Si cet appareil ne

comporte pas un disjoncteur de fuite à la terre, ne le relier

qu'à une prise de courant protégée par un disjoncteur de

fuite à la terre.

•L' utilisation d' une rallonge n' est pas recommandée.

•Lire le manuel de l' opérateur av

ant d' utiliser l' appareil.

RISQUE D' ÉLECTROCUTION NE

PAS ENLEVER CETTE ÉTIQUETTE

DES CHOCS ÉLECTRIQUES SÉVÉRES

SERONT POSSIBLES SI LES DIRECTIVES

CI-DESSUS NE SONT PAS SUIVIES.

•Conecte solamente a una toma corr

iente que está bien

fundado. No quite la pata de conexión de la tierra.

•Antes de usar inspeccióne la cuerda. No use si la cuerda està

dañando.

•Mantenga los conexiones secos y apar tados de la tierra.

•No torque el enchufe con manos mojados.

•Este producto debe conectarse a tierra.

Asegúrese de que la

lavadora a presión esté equipada con un Interruptor de

circuito de falla a tierra (Ground Fault Circuit Interrupter,

GFCI) incorporado en el cordón de alimentación. Si no lo

tiene, debe conectarse la lavadora a presión únicamente en

un receptáculo que esté protegido por un Interruptor de

circuito de falla a tierra. Desconéctela cuando no esté en uso.

•No use una cuerda extensión con la unidad.

•Antes de usar lea y entienda todas las instrucciónes y el

manual de operación.

ADVERTENCIA

SI NO SIGA LAS INSTRUCCIÓNES HAY EL

RIESGO DE ELECTROCUCIÓN SEVERA.

RIESGO DE ELECTROCUCION.

NO QUITE EST

A ETIQUETA.

50 Operator’s Manual

Emplacement: Cordon d’alimentation

34-1035

Page 51

COMMANDES

Commandes

B

K

A

E

C

D

F

H

J

G

I

A-- Interrupteur

B-- Poignée

C-- Sortie haute pression

Guide d’utilisation 51

D-- Raccord d’entrée d’eau

E-- Cordon d’alimentation

F-- Disjoncteur de fuite à la

terre

G-- Flexible d’injection

de produits détergents

H-- Tige de gicleur

I--- Gâchette

J-- Pistolet

K-- Flexible de décharge

Page 52

Préparation de l’appareil de lavage

EXIGENCES POUR L’ALIMENTAT I O N

ÉLECTRIQUE

ATTENTION: Pour éviter tout choc électrique,

raccorder l’appareil de lavage à une prise

correctement mise à la terre. Ne pas utiliser

d’adaptateur ni enlever la troisième borne (mise

à la terre).

S’assurer que la branchement entre le cordon

d’alimentatoin de l’appareil de lavage et la prise

est conservé sec.

Les exigences suivantes doivent être satisfaites:

1. L’alimentation électrique doit fournir un courant d’une

tension minimale de 110 à 120 volts. Lorsque l’appareil

de lavage fonctionne, la tension de la ligne ne doit pas

descendre à moins de 108 volts.

IMPORTANT: L’utilisation de l’appareil de lavage sous

une tension trop basse peut endommager

les composants du système électrique.

2. L’appareil de lavage à haute pression est muni

d’un disjoncteur de fuite à la terre dans le cordon

d’alimentation de façon à réduire les risques de choc

électrique. Toutefois, le disjoncteur ne protège pas de

tous les défauts, courts circuits ni surcharges.

IMPORTANT: Le disjoncteur de fuite à la terre DOIT être

réarmé chaque fois que l’apareil de lavage

est débranché et rebranché.

52 Guide d’utilisation

Page 53

Préparation de l’appareil de lavage

EXIGENCES POUR L’ALIMENTATION EN EAU

1. Une alimentation en eau avec une pression de 20 lb/po

(1,4 bar) ou plus est nécessaire.

Faire fonctionner l’appareil de lavage avec un débit

d’alimentation inadéquat provoquera l’usure rapide

des garnitures d’étanchéité, des soupapes et des

roulements réduisant ainsi la durée de vie de la pompe. Si

l’alimentation en eau est inadéquate la pompe vibrera et le

flexible d’alimentation à l’appareil de lavage s’écrasera.

2. L’alimentation en eau doit être au moins 125% de la

capacité de débit de la pompe. Le débit d’alimentation

peut être mesuré en calculant le temps nécessaire

pour remplir un contenant de cinq gallons (19 litres).

Par exemple, celuici se remplira en 5/3minutes (100

secondes) lorsque le débit est de 3.0 gal/min.

3. Le flexible d’alimentation devrait être un bon tuyau

d’arrosage avec un diamétre intérieur minimum de 5/8

po (16mm) et ne pas mesurer plus de 50 pi (15,24m).

Vérifier que le débit d’alimentation est au moins égal fois

qu’un flexible plus long est utilisé.

2

4. Si l’alimentation en eau n’est pas sous pression (par

exemple de l’eau tirée d’une source stationnaire),

assurezvous que l’alimentation en eau est d’au moins

125% di la capacité de débit de la pompe.

5. L’ajout de rallonge au flexible d’alimentation réduira le

débit d’alimentation. Vérifier si le débit d’alimentation est

adéquat chaque fois qu’une rallonge est ajoutée.

IMPORTANT: La température de l’eau d’arrivée ne doit pas

être supérieure à 125°F (60°C). La pompe

pourrait être endommagée.

Operator’s Manual 53

Page 54

VÉRIFIEZ L’HUILE DE POMPE

Préparation de l’appareil de lavage

1. Retirer le bouchon d’expédition et installer le bouchon

d’aspiration (A) sur la pompe.

2. Vérifier le niveau d’huile de la pompe. Avec l’appareil

de lavage sur une surface horizontale, l’huile doit

remplir le viseur (B). Si nécessaire, compléter de HYGARD® ou l’huile non detergente SAE30W.

A

B

FIXER LE FLEXIBLE DE DÉCHARE AU

PISTOLET

1. Appliquer du ruban ou un produit de scellement au

filetage du pistolet.

REMARQUE: Assurez-vous que les joints toriques sont

en place avant de fixer le flexible.

2. Fixer le flexible de décharge au pistolet en utilisant

deux clés à fourche. Resserrez le raccord de flexible

assez pour comprimer le prévenir les fuites.

IMPORTANT: NE PAS fixer la tige de gicleur au pistolet

avant que le système d’eau ne soit

amorcé.

54 Operator’s Manual

Page 55

Préparation de l’appareil de lavage

PRÉPARATION DE L’APPAREIL DE LAVAGE

1. Placer la rondelle de tuyau avec l’écran (A) est déjà

attachée dans l’extrémité du coupleur en laiton de

tuyau.

REMARQUE: La crépine conique dans la rondelle (A)

devrait faire saillie du raccord dans le

flexible d’alimentation.

IMPORTANT: Si l’appareil de lavage est raccordé à un

système d’eau de puit, utiliser le filtre

d’admission d’eau 851-0207 (A). Ceci

permettra de mieux filtrer le sable et

évitera l’endommagement de la pompe.

A

A

2. Installer le flexible d’alimentation (A) et le flexible de

décharge haute pression (B) et serrer à la main.

B

A

Operator’s Manual 55

Page 56

Préparation de l’appareil de lavage

AMORÇAGE DE LA POMPE

3. Ouvrez l’approvisionnement en eau. Serrez le

déclenchement sur le pistolet. Permettez à l’eau de

courir (avec le moteur OFF) jusqu’à ce que l’eau

coure le notre du tuyau de pression. Commencez le

déclenchement de moteur et de cycle sur le pistolet

jusqu’à ce qu’arrêt bruit de “crépitement” (air dans les

lignes). Arrêtez l’approvisionnement en eau.

INSTALLATION DE LA TIGE DE GICLEUR

ATTENTION: Avant d’installer la tige de gicleur,

verrouillez la gàchette pour éviter une décharge

accidentelle et des blessures provenant du jet à

haute pression.

IMPORTANT: NE PAS brancher la tige de gicleur avant

que le système d’eau ne soit amorcé.

1. Placer le verrou de gâchette (A) en position de

verrouillage (indiquée).

2. Insérer le ajustage de raccordement de la tige de

gicleur (B) dans le pistolet (C). Serrez la pistolet (D)

de la tige sur le pistolet du bague filetée pour fixer la

tige.

REMARQUE: Lorsque vous changez d’accessoire, la tige

est débranchée à ce point et les accessoires sont

connectés à sa place. La tige de l’appareil de lavage

à un point jaunt (E) sur le gicleur.

B

A

D

C

E

56 Operator’s Manual

Page 57

Préparation de l’appareil de lavage

TEST DU DISJONCTEUR DE FUITE À LA

TERRE

ATTENTION: Le disjoncteur de fuite à la terre

(GFCI) DOIT être testé avant chaque usage de

l’appareil de lavage.

Si le résultat de chacune des opérations suivantes

n’est pas tel que décrit ci-après, il faut débrancher

l’appareil de lavage immédiatement. Ne pas

utiliser l’appareil de lavage avant qu’il n’ait été

inspecté par un èlectricien qualifié ou par un

concessionnaire.

1. Brancher le disjoncteur (GFCI) dans la prise mise à la

terre. Connecter le flexible de sortie haute pression et

ouvrir l’alimentation en eau.

2. Pousser puis relâcher le bouton de réarmement (A)

pour vérifier le courant vers l’appareil de lavage.

3. Appuyer sur le bouton «TEST» (B). Le témoin rouge

(C) sur le bouton de réarmement devrait apparaître.

(L’appareil de lavage devrait être mis hors tension).

4. Pousser puis relâcher le bouton de réarmement.

L’appareil de lavage devrait de nouveau être mis sous

tension.

REMARQUE: Les instructions pour tester le GFCI se

trouvent aussi sur l’arrière du GFCI.

C

B

A

C

A

B

Guide d’utilisation 57

Page 58

Utilisation de l’appareil de lavage

UTILISATION DE L’APPAREIL DE LAVAGE

IMPORTANT: NE PAS laisser l’appareil de lavage

fonctionner en dérivation (gâchette

relâchée) pendant plus de trois minutes,

sino n, on ri sque de pro voqu er la

défaillance de la pompe.

Le contacteur «ON/OFF» de l’appareil de lavage est un

contacteur à bascule qui comprend un disjoncteur pour

portéger le moteur des surcharges électriques.

VERROUILLAGE DE LA GÂCHETTE

ATTENTION: Lorsque le pistolet n’est pas utillsé

ou avant d’effectuer des modifications, verrouillez

la gàchette. Ceci aidera à éviter une décharge

accidentelle et des blessure provenant du jet à

haute pression.

1. Déplacer le verrou de gâchette (A) vers le bas pour éviter

le déclenchement de la gâchette.

2. Déplacer le verrou vers le haut pour relcher la

gâchette.

A

A

RÉGLAGE DE LA PRESION AU GICLEUR

ATTENTION: Le jet haute pression peut causer

de graves blessures. Rester éloigné du jet et

du gicleur. Ne jamais pointer le pistolet vers les

personnes. Porter des lunettes de protection.

Le gicleur de la tige est un gicleur à pression variable.

1. Pour un jet haute pression, déplacer le colleir vers

l’arrière (A).

1. Pour un jet détergent ou basse pression, déplacer le

collier vers l’avant (B). Le gicleur produira un jet basse

pression.

Réglage de la forme de dispersion du jet:

1. Pour un jet étroit 0°- Tourner le couvercle de gicleur

complètement dans le sens des aiguilles d’une montre

(C).

2. Pour un jet dispersé 60°- Tourner le couvercle de gicleur

dans le sens contraire des aiguilles d’une montre (D).

3. Réglage illimité- Tourner le gicleur pour la forme de

dispersion de jet désirée à n’importe quelle position entre

0° et 60°.

Dans la position du jet haute pression, la pression

d’eau puet se régler en tournant le bouton de réglage

de pression (E) dans le sens des aiguilles d’une montre

pour accroître la pression et dans le sens inverse pour

la réduire.

D

BA

C

E

58 Guide d’utilisation

Page 59

Utilisation de l’appareil de lavage

8" - 10"

(20-25 cm)

N E T T O Y A G E D E S U R F A C E S