Page 1

User Guide Delivery Instructions

User Guide

Activations

Set date and time prior to entering Activation codes to ensure

the Activations will be acknowledged.

Data Transfer

Apex version 3.2 or newer is required to transfer data to the

GS3 2630 from a different John Deere Display model (i.e. GS2

1800, GS2 2600, GS3 CommandCenter).

Coverage and Swath Control Maps cannot be transferred from

a different John Deere Display model.

User Guide

This User Guide is intended to assist the operator with com-

mon operations. See the Operator Manual for detailed information.

GS2 1800 Display

1

GS2 1800 Display

Page 2

User Guide Delivery Instructions

User Guide

GS2 1800 Display

2

GS2 1800 Display

Page 3

GreenStar™ 2

1800 Display

PFP11809

Page 4

About This Document

This User Guide will help you learn how to perform common tasks with

your new display. It is a supplement to the display Operator’s Manual.

Read the Operator’s Manual for the following information:

• How to operate your display safely

• Theory of operation

• How to install the display and do initial setup

• Diagnostics

Copyright © 2012 Deere & Company. All Rights Reserved. THIS MATERIAL IS THE

PROPERTY OF DEERE & COMPANY. ALL USE AND/OR REPRODUCTION NOT

SPECIFICALLY AUTHORIZED BY DEERE & COMPANY IS PROHIBITED. All information,

illustrations and specifications in this manual are based on the latest information available

at the time of publication. The right is reserved to make changes at any time without notice.

Page 5

User Guide Display General

User Guide

Section Contents

TURNING THE DISPLAY ON/OFF ...................................... 2

Turn ON the display.............................................................................. 2

Turn OFF the display............................................................................ 2

HOME PAGES ..................................................................... 3

Accessing Home Page Setup............................................................... 3

Adding Home Pages............................................................................. 3

Changing the Left Hand Region ........................................................... 4

GS2 1800 Display

1

GS2 1800 Display

Page 6

User Guide Display General

User Guide

Turning the Display On/Off

The display will turn on and off with the vehicle key switch.

Turn ON the display

1. Turn vehicle key switch directly to the Run position.

IMPORTANT: Do NOT allow the display to boot up with the key

in Accessory Mode and then crank the engine.

NOTE: Implement controllers may take several minutes to load (if

connected).

Turn OFF the display

Turn vehicle key switch to shut down vehicle and wait for the display to

save settings.

IMPORTANT: Never pull the power plug without first turning

off the vehicle key switch. Data loss could occur.

NOTE: The display requires a constant power source, so that it can save

data and settings after the key is switched off. The Status LED is amber

while the display saves data and settings.

GS2 1800 Display

2

GS2 1800 Display

Page 7

User Guide Display General

User Guide

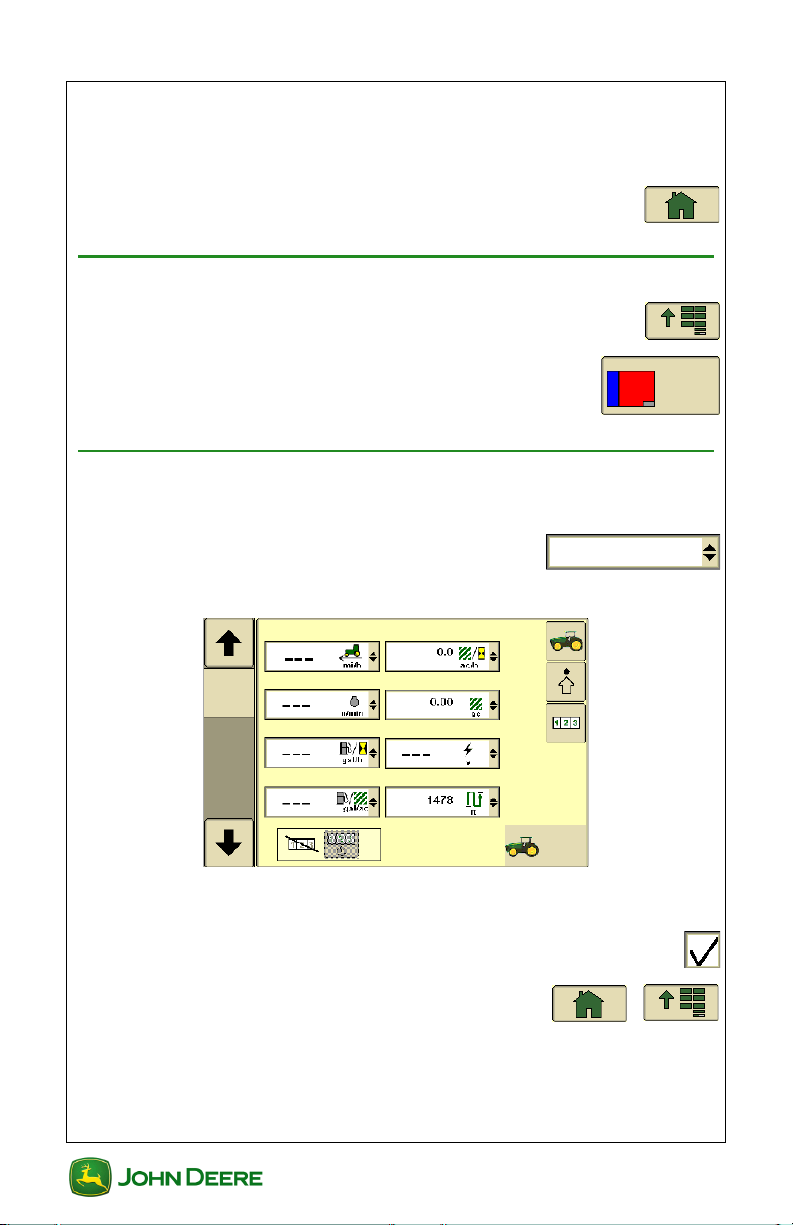

Home Pages

Home Pages are used to quickly cycle through commonly viewed pages.

The map page is included in the cycle by default.

• Select Home to view each Home Page .......................

Accessing Home Page Setup

1. Menu ............................................................................

2. Layout Manager ..................................................

Adding Home Pages

Three additional pages can be added to the Home Pages cycle.

1. Select a Home Page from the list box .........

• A preview of the selected Home Page is shown on the screen.

2. Use the thumb wheel to scroll between the different Home

Page options.

3. Check the box to save the page to the Home Page cycle ..

4. Select Home or Menu to exit ........................

GS2 1800 Display

3

GS2 1800 Display

Page 8

User Guide Display General

User Guide

Changing the Left Hand Region

There are several page options to be displayed in the Left Region of the

screen. The left hand region will remain constant when the main region of

the screen changes.

1. In Layout Manager, Select Left Region

from list box.

2. Use the thumb wheel to scroll between the Left Region options.

GS2 1800 Display

4

GS2 1800 Display

Page 9

User Guide Dual Display

User Guide

Section Contents

GETTING STARTED............................................................ 2

Accessing Multiple Display Settings ..................................................... 2

MODEL YEAR 2010 8R COMMANDCENTER .................... 3

Connecting a Second Display .............................................................. 3

Changing Multiple Display Settings ...................................................... 3

GS3 COMMANDCENTER.................................................... 4

Connecting a Second Display .............................................................. 4

Changing Multiple Display Settings ...................................................... 4

TROUBLESHOOTING TIPS ................................................ 6

Restore Settings before Making Adjustments ...................................... 6

Allow Controller to Appear on the CommandCenter ............................ 6

Force All Controllers to Appear in the Second Display......................... 6

Other Tips (Next VT, Change VT) ........................................................ 6

GS2 1800 Display

1

GS2 1800 Display

Page 10

User Guide Dual Display

User Guide

Getting Started

This section includes tips for using two John Deere ISOBUS displays

together in Model Year 2010 and newer John Deere vehicles. In dual

display mode, the 8R and GS3 CommandCenters are compatible with the

following displays:

GS2 1800

GS2 2600

GS3 2630

Using two displays allows the operator to monitor the implement on one

display and run functions like guidance, section control, and

documentation on the other.

Accessing Multiple Display Settings

1. Menu ............................................................................

2. Display ..................................................................

3. Settings softkey ..............................................................

4. Multiple Displays softkey ...............................................

GS2 1800 Display

2

GS2 1800 Display

Page 11

User Guide Dual Display

User Guide

Model Year 2010 8R CommandCenter

The 8R CommandCenter was introduced for the 2010 model year 8R

Tractors. The 8R CommandCenter does not have GreenStar capabilities

(such as AutoTrac) on the display and therefore, no multiple display setup

is required.

Connecting a Second Display

1. With key switched OFF, connect the display to the corner post

harness connector.

2. Switch key ON to start vehicle and power the displays.

Changing Multiple Display Settings

Only the Implement Bus Virtual Terminal setting should be changed by

the operator.

• On/Off checkbox – check the box to enable the setting on

the CommandCenter.

• Function Instance – Refer to ISO Implement or ISO

Display Manual for necessary adjustments.

Multiple Display Settings options are described below:

• Implement Bus Virtual Terminal – Allows communication

between the CommandCenter and a controller (e.g. Receiver,

SeedStar II).

▪ Check box ON to allow a controller to run on the Com-

mandCenter.

▪ Check box OFF to allow a controller to run on another

connected display.

NOTE: Cycle power for changes to save and take effect.

GS2 1800 Display

3

GS2 1800 Display

Page 12

User Guide Dual Display

Change Settings

User Guide

GS3 CommandCenter

The GS3 CommandCenter was introduced with Model Year 2011 Rseries tractors and Model Year 2012 S-series combines. The GS3

CommandCenter has GreenStar capabilities (such as AutoTrac) built into

the display.

Connecting a Second Display

To use a second display as a companion to the GS3 Com-

mandCenter, please do the following:

• With key switched OFF, connect the display to the corner post

harness connector.

• Switch key ON to start vehicle and power the displays.

• Follow the instructions on the GS3 CommandCenter screen.

Changing Multiple Display Settings

Multiple Display Settings options can be adjusted by the oper-

ator:

1. Select Change Settings ...................................

Multiple Display Settings options are described below:

• On/Off checkbox - check the box to enable the setting on

the GS3 CommandCenter.

• Function Instance - Refer to ISO Implement or ISO Display Manual for necessary adjustments.

• GreenStar – No adjustment required. GreenStar will run on the

second connected John Deere display.

• Original GreenStar Monitor – No adjustment required. Original

GreenStar Monitor will run on the second connected John Deere

display.

• Implement Bus – Allows communication between the GS3 CommandCenter and controller (e.g. Receiver, SeedStar II).

▪ Check box ON to allow a controller to appear on the

CommandCenter.

▪ Check box OFF to allow a controller to appear on

another connected display.

GS2 1800 Display

4

GS2 1800 Display

Page 13

User Guide Dual Display

Save Settings and

Restart Display

User Guide

• Vehicle Bus – No adjustment required.

2. Select Save Settings and Restart Display ........

GS2 1800 Display

5

GS2 1800 Display

Page 14

User Guide Dual Display

Restore Factory

Default Settings

Change VT

User Guide

Troubleshooting Tips

The following information may be helpful for managing which display will

run a controller (e.g. StarFire Receiver, SeedStar II).

Restore Settings before Making Adjustments

Default settings should be restored before attempting any

other troubleshooting tips.

• Select Restore Factory Default Settings ...........

NOTE: This option will not appear if settings are already set to default.

Allow Controller to Appear on the CommandCenter

A controller does not appear. Try the following steps:

1. Ensure the Implement Bus is turned ON in the

CommandCenter.

2. Cycle power of the display.

NOTE: If the controller does not appear, check all harness connections.

Force All Controllers to Appear in the Second Display

A controller appears on the opposite display. Try the following:

1. Select the Implement Bus checkbox.

2. Ensure the Implement Bus is turned OFF in the

3. Cycle power of the display.

Other Tips (Next VT, Change VT)

If you desire for a specific controller to run on another display,

1. Navigate to the appropriate controller page.

2. Select Next VT or Change VT ..........................

CommandCenter.

some controllers may be capable of moving to the display

without the use of Multiple Display Settings.

GS2 1800 Display

6

GS2 1800 Display

Page 15

User Guide GreenStar General

User Guide

Section Contents

GETTING STARTED............................................................ 2

Access GreenStar Applications ............................................................ 2

GreenStar Activations........................................................................... 2

What Needs to Be Set Up .................................................................... 2

Using the Setup Wizard ........................................................................ 2

Change Field Name.............................................................................. 3

MACHINE SETUP ................................................................ 4

Machine Offsets.................................................................................... 4

Connection Type Examples.................................................................. 5

IMPLEMENT SETUP............................................................ 6

Implement Offsets ................................................................................ 6

Coverage Recording Source ................................................................ 8

DATA MANAGEMENT......................................................... 9

Backup Data from the Display .............................................................. 9

Importing Data to the Display ............................................................. 10

View Memory Remaining.................................................................... 11

Transferring Data between Two Displays........................................... 11

Data Cleanup...................................................................................... 12

RECORD A BOUNDARY................................................... 13

This Chapter pertains to GreenStar™ applications including, but not

limited to AutoTrac™ and Swath Control.

GS2 1800 Display

1

GS2 1800 Display

Page 16

User Guide GreenStar General

User Guide

Getting Started

Access GreenStar Applications

All information and functionality related to GreenStar applications is

accessed with the GreenStar Softkey.

1. Menu ............................................................................

2. GreenStar ..............................................................

GreenStar Activations

Activations are required for GreenStar applications other than Manual

Guidance. Check the Activations page to see if an Application is Activated

and checked ON.

1. Menu .............................................................................

2. GreenStar ..............................................................

3. Settings Softkey .............................................................

4. Activations .....................................................................

What Needs to Be Set Up

The amount of setup information that must be entered depends on the

applications being used. A Setup Wizard is available to guide you through

each setup page.

Using the Setup Wizard

1. Menu ............................................................................

2. GreenStar ..............................................................

GS2 1800 Display

2

GS2 1800 Display

Page 17

User Guide GreenStar General

User Guide

3. Setup Wizard ..................................................................

a. Basic Setup - For quick Straight Track guidance

setup.

b. Standard Setup - For Equipment, Documentation,

fields, and Guidance setup.

4. Fill out the necessary items on each setup page and

press Next to continue.

NOTE: All items must be filled out on each page before the Next

button will appear.

Change Field Name

Several types of setup data are tied to Field Names including Guidance

lines and maps.

NOTE: Field Names can only be edited or deleted indivdually using apex

or another type of desktop software. To delete all data and setup

infromation in the display, Backup data to a USB and select that option.

1. Menu ............................................................................

2. GreenStar ..............................................................

3. Quick Change Field ......................................................

4. Select or create a new Client, Farm, and Field name.

NOTE: The Client is the land owner in many cases.

GS2 1800 Display

3

GS2 1800 Display

Page 18

User Guide GreenStar General

User Guide

Machine Setup

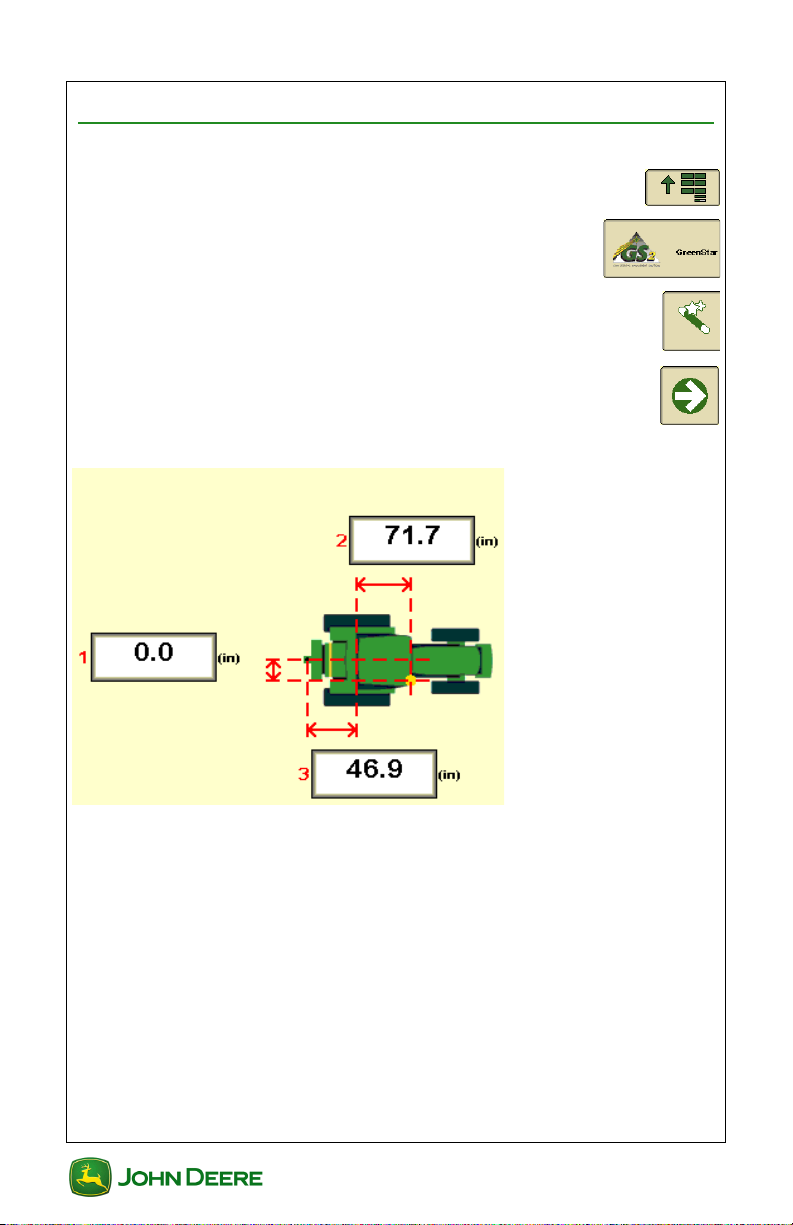

Machine Offsets

1. Menu ............................................................................

2. GreenStar ..............................................................

3. Setup Wizard ..................................................................

4. Next ................................................................................

1- Lateral distance from the center point of the machine to the center of the GPS receiver.

2- In-line distance from the non-steering axle to the center of the GPS Receiver.

3- In-line distance from the non-steering axle to the connection (or pivot) point.

Non-Steering Axle:

•Rear Axle

○ Row Crop Tractor (Wheel)

○ Self-Propelled Sprayer

○ Track Tractor

•Front Axle

○ Four Wheel Drive

GS2 1800 Display

4

GS2 1800 Display

Page 19

User Guide GreenStar General

User Guide

○ Combine

○ Self-Propelled Forage Harvester

Offset toggles reciever to side other side of implement.

Axle toggles non-steering axle to front.

Connection Type Examples

Rear Rigid 3-pt Front Rigid 3-pt

Rear Pivot 2-pt Rear Pivot Drawbar

Rear Pivot Wagon-Hitch

5

GS2 1800 Display

GS2 1800 Display

Page 20

User Guide GreenStar General

User Guide

Implement Setup

Implement Offsets

NOTE: Grayed out settings were automatically detected from the

implement controller. They can be changed in the implement controller

setup (e.g. SeedStar, SprayStar). The display may need to be restarted

for those changes to take effect.

NOTE: Implement settings can be recalled by selecting the Implement

Name that was set when settings were entered.

1. Menu ............................................................................

2. GreenStar ..............................................................

3. Setup Wizard ..................................................................

4. Next ................................................................................

5. Enter Offsets

NOTE: Offset toggles implement offset (3) to other side.

GS2 1800 Display

6

GS2 1800 Display

Page 21

User Guide GreenStar General

User Guide

1- In-line distance from the connection (or pivot) point to the first working point of

the implement.

2- In-line distance from the first working point to the second working point. (e.g.

location of seed drop, spray nozzles, cutter bar).

NOTE: 1+2 = The point where map recording happens and where Swatch

Control Pro turns sections on/off.

3- Lateral distance from the center point of the machine to the center point of the

working width of the implement.

NOTE: This measurment (3) is used for map recording on implement

configurations that are offset to one side.

4- In-line distance from the connection (or pivot) point to control point of the

implement.

NOTE: This measurment (4) is important for modeling the position of the

implement, particularly on curves.

Connection (or Pivot) Point- The point where the implement connects to the

machine or the pivot point between the implement and machine depending on

Connection Type. It should be the same point used in measurement C of machine

setup.

Control Point- Point the that the implement rotates around; usually the center of

all transport wheels. This point is at the connection point for 3-point mounted

implements.

6. Enter Widths

GS2 1800 Display

7

GS2 1800 Display

Page 22

User Guide GreenStar General

User Guide

Implement Width (Working Width)- The actual width of planter, sprayer, or

harvester.

Coverage Recording Source

1. Select Coverage Recording

source

2. Next ................................................................................

GS2 1800 Display

8

GS2 1800 Display

Page 23

User Guide GreenStar General

Transfer

Data

User Guide

Data Management

All settings and recorded data can be transferred to and from a display of

the same model or Apex desktop software. All data and settings are

imported or exported as a Data Profile.

Backup Data from the Display

1. Turn off all types of Recording and stop the vehicle.

2. Insert USB flash drive.

NOTE: The display’s internal memory has 256 MB of capacity for field

data.

3. A “USB Detected” message will appear if the display

recognizes the USB memory device. Read and

Accept.

Troubleshooting Tips!!! Try the other USB port (if equiped) or a

different USB memory device.

NOTE: The USB must be formatted to FAT or FAT32.

4. Menu ............................................................................

5. GreenStar ..............................................................

6. Read and Accept any alert messages .........................

7. Transfer Data .........................................................

8. Backup Data ................................................

9. Select or create a Profile name where the

data will be stored on the USB.

IMPORTANT: Backup of data to an existing Profile will overwrite all data and settings in that Profile.

10. Check the box if you would like to Delete All Data and Setup

Information from the internal Memory. This clears the internal

GS2 1800 Display

9

GS2 1800 Display

Page 24

User Guide GreenStar General

Delete files from internal memory after backup

is complete

Transfer

Data

User Guide

memory and will reset the Setup Information to factory defaults

after backup is complete.

11. A green status bar will appear while data is transferring. When

finished, a “Data Transfer is Complete” message will appear.

IMPORTANT: To prevent data loss, do NOT remove the USB or

crank the engine during data transfer.

Importing Data to the Display

1. Turn off all types of Recording and stop the vehicle.

2. Insert USB memory device with a Data Profile from a display of

the same model or Apex.

3. A “USB Detected” message will appear if the display

recognizes the USB memory device. Read and

Accept.

Troubleshooting Tips!!! Try the other USB port (if equiped) or a

different USB memory device.

NOTE: The USB must be formatted to FAT or FAT32.

4. Menu ............................................................................

5. GreenStar ..............................................................

6. Read and Accept any alert messages .........................

7. Transfer Data .........................................................

8. Import Data ..................................................

9. Select Data Profile to be imported ................

IMPORTANT: The imported Profile will overwrite all data and

setup information in the display.

GS2 1800 Display

10

GS2 1800 Display

Page 25

User Guide GreenStar General

Yes

No

Recording

User Guide

10. A “Import File” message will appear. Read and

select Yes to import the file or select No to decline the

import file.

11. A green status bar will appear while data is

transferring. When finished, a “Data Transfer is Complete”

message will appear.

IMPORTANT: To prevent data loss, do NOT remove the USB or

crank the engine during data transfer.

View Memory Remaining

1. Menu ............................................................................

2. GreenStar ..............................................................

3. GS2 ..................................................................................

4. Diagnostic .....................................................................

5. Select Recording from the list .....................

6. View “Memory Space Left (MB)”. Status bar will indicate the

amount of used internal memory space.

Transferring Data between Two Displays

Apex or a compatible 3rd party desktop software is required for

transferring data and setup information between different John Deere

Display models (i.e. Original GreenStar Display, GS2 1800, GS2 2600,

GS3 2630, and GS3 CommandCenter). Due to different file versions, data

will not load when transferred directly between different models.

Follow the steps for backup and import to transfer setup information and

data between two displays of the same model. The data will NOT be

merged. All setup information and data on the second display will be

replaced. Think of the transfer as moving a CF card from one GS2 2600

to another.

GS2 1800 Display

11

GS2 1800 Display

Page 26

User Guide GreenStar General

Cleanup

Data Cleanup

Select the type of data you wish to delete

Client:

Field:

Farm:

Delete Selected

Data

User Guide

Data Cleanup

Data cleanup removes Clients, Farms, or Field Names from the display's

internal memory.

1. Menu ............................................................................

2. GreenStar ..............................................................

3. GS2 ..................................................................................

4. Settings ..........................................................................

5. Data Cleanup ..................................................................

6. Select the type of data to delete:

7. Select items to delete:

NOTE: If an item has been selected in the setup wizard it will be grayed

out and will not be able to delete it.

NOTE: To select a checkbox, scroll and select the entire checkbox list

area. Select the desired checkbox. To exit the checkbox list, press the

Cancel "X" button on the display.

8. Delete Selected Data ..........................................

12

GS2 1800 Display

GS2 1800 Display

Page 27

User Guide GreenStar General

Yes

User Guide

Record a Boundary

Field boundaries are useful for calculating field area or when using Swath

Control. The Setup Wizard must be completed before creating a

boundary.

1. Menu ............................................................................

2. GreenStar ..............................................................

3. Field ................................................................................

4. Boundary ........................................................................

5. Choose Exterior or Internal Boundary ........

NOTE: An Exterior Boundary must be created before an Internal

Boundary can be created. An Internal Boundary will require a Name.

6. Enter Boundary Offset ...........................

7. Select which side to apply the Offset ...............................

8. Next ................................................................................

9. Record the boundary ......................................................

10. Pause boundary recording .............................................

11. Stop boundary recording ................................................

12. Select Yes to complete the boundary .........................

NOTE: When Stop Boundary Recording is selected, the beginning and

end of the boundary line will be connected with a straight boundary line.

GS2 1800 Display

13

GS2 1800 Display

Page 28

User Guide GreenStar General

User Guide

NOTES

14

GS2 1800 Display

GS2 1800 Display

Page 29

User Guide Guidance

User Guide

Section Contents

GETTING STARTED............................................................ 2

Accessing Guidance Functions ............................................................ 2

Requirements for Guidance Operation ................................................. 2

AutoTrac Status Pie.............................................................................. 3

CHOOSE TRACKING MODE .............................................. 4

Straight Track Mode ............................................................................. 4

AB Curve Mode .................................................................................... 4

Adaptive Curve Mode ........................................................................... 4

GUIDANCE TRACK SETUP ................................................ 6

Step 1) Enter Track Spacing ................................................................ 6

Step 2) Select Tracking Mode and Guidance Track ............................. 6

Step 3) Create a Guidance Track ......................................................... 6

Create AB Straight Track...................................................................... 6

Create an AB Curve Track ................................................................... 8

Create Adaptive Curve Track ............................................................... 8

Create a Circle Track............................................................................ 9

Delete Track ......................................................................................... 9

RUN PAGE......................................................................... 11

GUIDANCE SETTINGS...................................................... 12

Accessing Guidance Settings ............................................................. 12

General Guidance Settings ................................................................ 12

AutoTrac Settings ............................................................................... 12

Advanced AutoTrac Settings (if equipped) ......................................... 13

Curve Track Settings .......................................................................... 13

Lightbar Settings................................................................................. 14

Shift Track Settings ............................................................................ 14

GS2 1800 Display

1

GS2 1800 Display

Page 30

User Guide Guidance

User Guide

Getting Started

This section includes basic functions for using Guidance.

Accessing Guidance Functions

1. Menu ............................................................................

2. GreenStar ..............................................................

3. Guidance .......................................................................

NOTE: The Guidance button is also available on the Run (map) page.

Requirements for Guidance Operation

The following items are required for guidance to function:

• AB Lines

• GPS Signal

• Tracking Mode

• Track Spacing

The following items are optional when operating guidance:

• Client, Farm, and Field

• Coverage Map

• Field Boundaries

Read the AutoTrac Status Pie section for AutoTrac require-

ments.

GS2 1800 Display

2

GS2 1800 Display

Page 31

User Guide Guidance

User Guide

AutoTrac Status Pie

The AutoTrac Status Pie indicates what items are remaining to be setup

for AutoTrac to function.

Stage 1: Installed

• SSU is detected

Stage 2: Configured

• Tracking Mode has been selected

• Guidance AB Line has been defined

• AutoTrac Activation detected

• StarFire signal is present

• SSU has no active faults pertaining to the steering

function

• Hydraulic oil warmer than minimum temperature

• Speed is less than maximum

• TCM message is currently available and valid

• In proper operating gear

Stage 3: Enabled

• Select Auto

Stage 4: Activated

•Press Resume Switch on the Machine

GS2 1800 Display

3

GS2 1800 Display

Page 32

User Guide Guidance

User Guide

Choose Tracking Mode

GreenStar guidance has several different tracking modes to suit almost

any field layout and operator preference.

Straight Track Mode

Straight Track mode assists operator in driving straight

parallel paths by using display and audible tones to

alert operator when machine is off track.

AB Curve Mode

AB Curves allows an operator to drive

a curved line in the field with two end

points (beginning and end). The

passes parallel to the track in either

direction will be generated based on

the original driven track. Each pass is

generated from the original driven

pass to ensure that steering errors

are not propagated through the entire

field. The passes are not identical

copies of the original pass. The

curvature of the pass changes to

maintain pass to pass error.

A—Start Recording of AB Curve

B—Stop Recording of AB Curve

C—Paths Generated

Adaptive Curve Mode

Adaptive Curve allows the operator to

record a manually driven path. The

vehicle can be guided along

subsequent passes, based on the

previous recorded pass. The passes

are not identical copies of the original

pass. The curvature of the pass

changes to maintain pass to pass

error. When necessary, the operator

can change the curve path anywhere

in the field by simply steering the

machine off the propagated path.

4

GS2 1800 Display

GS2 1800 Display

Page 33

User Guide Guidance

User Guide

NOTE: The curvature of the path changes as the subsequent paths get

more convex or concave.

GS2 1800 Display

5

GS2 1800 Display

Page 34

User Guide Guidance

User Guide

Guidance Track Setup

Step 1) Enter Track Spacing

Track Spacing is entered as part of the Setup Wizard.

1. GreenStar ..............................................................

2. Spacing ..........................................................................

• Implement Width – used to generate on screen map and for

area calculations.

• Track Spacing – define the desired overlap or skip between

passes

Step 2) Select Tracking Mode and Guidance Track

1. GreenStar ..............................................................

2. Guidance .......................................................................

3. Select desired Tracking Mode ........

4. Select the name of track or create a New

Track. Check the Edit Track box to make

changes to and existing Track.

5. Next ................................................................................

Step 3) Create a Guidance Track

Use the following steps for the appropriate track type.

Create AB Straight Track

There are several ways to create an AB Straight Track. Straight Track

must be selected in the Tracking Mode list on the Guidance page.

GS2 1800 Display

6

GS2 1800 Display

Page 35

User Guide Guidance

User Guide

A + B Method

1. Drive to desired beginning of AB line, Set A ...................

2. Drive toward desired end of AB line, Set B ....................

A + Heading Method

1. Drive to desired beginning of AB line, Set A ...................

2. Set Heading ...................................................................

3. Enter desired Heading to Set B ...............................

Auto B Method

1. Drive to desired beginning of AB line, Set A ...................

2. Drive toward desired end of AB line. Automatically Set

B The B point will automatically set after 49 feet (15

meters).

Lat / Long Method

1. Set A Point Latitude and Longitude .................................

2. Enter coordinates to Set A ...........................

3. Set B Point Latitude and Longitude .................................

4. Enter coordinates to Set B ...........................

GS2 1800 Display

7

GS2 1800 Display

Page 36

User Guide Guidance

User Guide

Lat / Long + Heading Method

1. Set A Point Latitude and Longitude .................................

2. Enter coordinates to Set A ...........................

3. Set Heading ...................................................................

4. Enter desired Heading of B point .....................

Create an AB Curve Track

AB Curves must be selected in the Tracking Mode list on the Guidance

page.

1. Record initial pass ..........................................................

a. Selecting Pause will allow user to pause recording

vehicles path.

b. When recording is un-paused it will connect the two

points into a straight line.

A – Recording Turned ON then PAUSED

B – Bridge segment is generated to connect points

C – Recording UNPAUSED

2. Stop Recording at the end of the desired AB Curve .....

Create Adaptive Curve Track

Adaptive Curves must be selected in the Tracking Mode list on the

Guidance page.

GS2 1800 Display

8

GS2 1800 Display

Page 37

User Guide Guidance

User Guide

1. Record initial pass ...........................................................

a. Selecting Pause will allow user to pause recording

vehicles path.

b. When recording is un-paused it will connect the two

points into a straight line.

2. Stop Recording at the end of the desired Adaptive

Curve.

Create a Circle Track

Drive Circle Method

1. Record initial circle pass ................................................

2. Stop Recording at the end of the circle pass .................

Lat/Lon Method

1. Set Center Point Latitude and Longitude ........................

2. Enter coordinates for Center Point ...............

Delete Track

1. GreenStar ..............................................................

2. Guidance .......................................................................

3. Select Type of Track to delete ...................

GS2 1800 Display

9

GS2 1800 Display

Page 38

User Guide Guidance

Yes

User Guide

4. Select Track name to delete ......................

5. Delete Track ..................................................................

6. Select Yes to delete track ............................................

10

GS2 1800 Display

GS2 1800 Display

Page 39

User Guide Guidance

User Guide

Run Page

• Pass Accuracy

• Variance from “0” shows Off-track Error

• Status Pie .........................................................................

• Steering On/Off Button ..................................................

• GPS Accuracy Indicator ................................................

11

GS2 1800 Display

GS2 1800 Display

Page 40

User Guide Guidance

General

Settings

Turning View

Turn Predictor

AutoTrac Deactivation

Message

Tracking Tones

AutoTrac

Settings

User Guide

Guidance Settings

Accessing Guidance Settings

1. Menu ............................................................................

2. GreenStar ..............................................................

3. GS2 ..................................................................................

4. Settings ..........................................................................

General Guidance Settings

1. General Settings .......................................................

2. Choose selected settings.

3. Next Page ......................................................................

4. Set Tracking Tones ........................................

5. Set Lead Compensation ...................................

6. Accept ..........................................................................

AutoTrac Settings

1. AutoTrac Settings .....................................................

12

GS2 1800 Display

GS2 1800 Display

Page 41

User Guide Guidance

Line Sensitivity

Heading

Line Sensitivity

Tracking

Heading

Lead

Steering

Response Rate

Curve

Sensitivity

Acquire

Sensitivity

Curve

Settings

Smooth Tight Turns ON

User Guide

2. Enter Steering Sensitivity .........................................

3. Accept ..........................................................................

Advanced AutoTrac Settings (if equipped)

Use Advanced AutoTrac Settings to optimize AutoTrac performance.

AutoTrac Advanced settings are only available on some vehicle types.

• Describes each function .....................................................

Curve Track Settings

1. Curve Track Settings ................................................

2. Smooth Tight Turns .........................

13

GS2 1800 Display

GS2 1800 Display

Page 42

User Guide Guidance

Smooth Tight Turns OFF

Smooth Tight Turns ON

Clear

Data

Repeat Mode

Lightbar Settings

Steer Towards Direction

Off-Track Direction

User Guide

3. Select Implement In-Ground Turn Radius ...........

4. Next Page ....................................................................

5. Choose Recording Source ................

a. Clear Adaptive Curve Data

b. When recording a new path, Repeat Mode

should be unchecked or OFF. To follow

existing paths, Repeat Mode should be ON

or checked.

6. Accept ..........................................................................

Lightbar Settings

1. Lightbar Settings ......................................................

2. Select Step Size for distance that each light on

the Lightbar represents.

3. Select how the Lightbar indicates where

to steer when off the track.

4. Accept ..........................................................................

Shift Track Settings

14

GS2 1800 Display

GS2 1800 Display

Page 43

User Guide Guidance

Shift Track

Shifts Off

Small Shifts

Large Shifts

Shift Size

Yes

User Guide

Select Type of Shifts

1. Shift Track Settings ................................................

2. Select type of shifts

3. Accept ..........................................................................

Clear Shifts

1. GreenStar ..............................................................

2. Guidance ........................................................................

3. Clear shifts .....................................................................

4. Select Yes to clear shifts .............................................

GS2 1800 Display

15

GS2 1800 Display

Page 44

User Guide Guidance

User Guide

NOTES

16

GS2 1800 Display

GS2 1800 Display

Page 45

User Guide Performance Monitor

User Guide

Section Contents

MONITOR MACHINE PERFORMANCE.............................. 2

View in Performance Monitor ............................................................... 2

View on Homepages ............................................................................ 2

PERFORMANCE MONITOR SETUP................................... 3

Setup Area Counter.............................................................................. 3

PERFORMANCE MONITOR TOTALS ................................ 4

Acre Counter Manual Start and Stop.................................................... 4

Resetting Performance Monitor Totals ................................................. 4

GS2 1800 Display

1

GS2 1800 Display

Page 46

User Guide Performance Monitor

User Guide

Monitor Machine Performance

Performance Monitor provides productivity information such as vehicle

speeds, acre counters, and fuel efficiency data. The information available

to be displayed depends on the vehicle on which the display is installed.

View in Performance Monitor

1. Menu ............................................................................

2. Performance Monitor ...........................................

3. Performance Information ..............................................

4. Performance Totals .......................................................

NOTE: The Performance Totals page will populate several options such

as travel counters and vehicle information.

View on Homepages

Use Layout Manager to add a Performance Monitor screen for any Home

Page.

GS2 1800 Display

2

GS2 1800 Display

Page 47

User Guide Performance Monitor

AUTO

User Guide

Performance Monitor Setup

Setup Area Counter

1. Menu ............................................................................

2. Performance Monitor ...........................................

3. Settings ..........................................................................

4. Enter Implement Width ...................................

5. Select a control source to start and stop the Area Counter. The

available options depend on the vehicle configuration.

• Implement Whisker Switch .........................................

• Use source from John Deere implement ................

• Manual ....................................................................

• Front Hitch

• Rear Hitch

GS2 1800 Display

3

GS2 1800 Display

Page 48

User Guide Performance Monitor

User Guide

Performance Monitor Totals

Performance Monitor calculates a running total of several values including

acres and distance.

Acre Counter Manual Start and Stop

NOTE: Manually starting and stopping the Area Counter is not necessary

when the Area Counter control source is set to an option other than

Manual.

1. Menu ............................................................................

2. Performance Monitor ...........................................

3. Performance Monitor Main ...........................................

4. Acre Counter Start / Stop ..........................................

ON OFF

Resetting Performance Monitor Totals

1. Menu ............................................................................

2. Performance Monitor ...........................................

3. Totals ..............................................................................

4. Reset Distance ......................................................

5. Reset Average Totals ..................................................

There are two reset buttons on the page. Each is displayed within the

group of values that it resets.

GS2 1800 Display

4

GS2 1800 Display

Page 49

User Guide Swath Control

User Guide

Section Contents

GETTING STARTED............................................................ 2

Turning Swath Control Pro On/Off........................................................ 2

RUN PAGE - SWATH CONTROL........................................ 3

SWATH CONTROL SETTINGS........................................... 4

Turn On/Off Settings............................................................................. 4

Overlap Settings ................................................................................... 4

GS2 1800 Display

1

GS2 1800 Display

Page 50

User Guide Swath Control

User Guide

Getting Started

This section includes basic functions for using Swath Control with product

applications. Use the Setup Wizard to setup the machine and implement

before using Swath Control.

NOTE: Boundaries are not required but may be helpful when using Swath

Control.

Turning Swath Control Pro On/Off

1. Menu ............................................................................

2. GreenStar ..............................................................

3. Select Swath Control On/Off to enable or disable Swath

Control.

GS2 1800 Display

2

GS2 1800 Display

Page 51

User Guide Swath Control

Swath Control Pro Off

User Guide

Run Page - Swath Control

The following information is shown on the Run Page.

Swath Control On/Off enables or disables Swath

Control.

Section Status Bar displays the system status

• Swath Control Off

• Swath Control On - Air Cart example

NOTE: Green bar at bottom - Swath Control Enabled and section On.

NOTE: Tank bar is black - Tank is On.

NOTE: Tank bar is clear - Tank is Off.

• Swath Control On - Product Application example

NOTE: Green or blue triangle - Section status is On.

NOTE: A clear triangle - Section status is Off.

GS2 1800 Display

3

GS2 1800 Display

Page 52

User Guide Swath Control

User Guide

Swath Control Settings

Settings are used to fine tune Swath Control for optimal performance.

1. GreenStar ..............................................................

2. GS2 ..................................................................................

3. Settings ..........................................................................

4. Swath Control Settings ................................................

Turn On/Off Settings

The operator can adjust the Turn on and Turn off settings to fit a specific

machine. The Turn on and Turn off settings are to compensate for

average physical machine reaction time (Electrical & Mechanical) for

applying product. Refer to the Operators Manual for additional

information.

1. Set the Turn on Time ........................................

NOTE: Turn on Time compensates for the time delay between the system

turning on and the product being applied in the field.

2. Set the Turn off Time .........................................

NOTE: Turn off Time compensates for the time delay between the system

turning off and when the product stops being applied in the field.

NOTE: Implement Offset 1 + Implement Offset 2 is the point that Swath

Control uses to turn sections on or off.

Overlap Settings

The system can be set to minimize overlap (0%), minimize skips (100%),

or apply a certain percentage of overlap from 0% to 100%.

GS2 1800 Display

4

GS2 1800 Display

Page 53

User Guide Swath Control

Exterior Boundaries

Amount to Overlap

Interior Boundaries

Amount to Overlap

Previous Coverage

Amount to Overlap

User Guide

1. Set the percentage of overlap

GS2 1800 Display

5

GS2 1800 Display

Page 54

User Guide Swath Control

User Guide

NOTES

GS2 1800 Display

6

GS2 1800 Display

Page 55

User Guide Documentation Basics

User Guide

Section Contents

SECTION CONTENTS ......................................................... 1

GETTING STARTED............................................................ 2

Accessing Documentation Basics ........................................................ 2

DOCUMENTATION BASICS SETUP .................................. 3

Standard Setup Mode........................................................................... 3

DOCUMENTATION BASICS TOTALS................................ 3

Viewing Totals ...................................................................................... 3

GS2 1800 Display

1

GS2 1800 Display

Page 56

User Guide Documentation Basics

User Guide

Getting Started

This section includes basic functions for using Documentation Basics.

Use the Standard Setup Mode in the Setup Wizard to setup

Documentation Basics.

Accessing Documentation Basics

1. Menu ............................................................................

2. GreenStar ..............................................................

3. Setup Wizard ..................................................................

4. Standard Setup Mode ....................................................

GS2 1800 Display

2

GS2 1800 Display

Page 57

User Guide Documentation Basics

User Guide

Documentation Basics Setup

Standard Setup Mode

1. GreenStar ..............................................................

2. Setup Wizard ..................................................................

3. Standard Setup .............................................................

4. Select Machine ................................

5. Select Implement .............................

6. Select Task ...................................................

7. Select Crop Type or Product Type

8. Select Client .................................................

9. Select Farm ..................................................

10. Select Field ..................................................

11. Tracking Mode (optional) .............................

Documentation Basics Totals

Viewing Totals

1. Menu ............................................................................

2. GreenStar ..............................................................

GS2 1800 Display

3

GS2 1800 Display

Page 58

User Guide Documentation Basics

User Guide

3. GS2 ..................................................................................

4. Documentation ..............................................................

5.

Totals ..............................................................................

Reports

A PDF report of the recorded data is created when data is transferred

from the display to the USB flash drive.

Reports will be found on the USB drive on the following path:

<USB-Stick>: \ GS2_1800 \ profile name of backup \ Reporting \

<report>.pdf \ <report>.csv

NOTE: Documentation Basics requires an activation on the display for it

to be an option.

NOTE: John Deere Documentation Basics will only support implements

that are performing one operation only. See operators manual for more

details.

GS2 1800 Display

4

GS2 1800 Display

Loading...

Loading...