John Deere 444J User Manual

J

444J | 544J | 624J

LOADERS

POWERLLEL

™

LINKAGE

125–180 SAE NET HORSEPOWER

PAGES

2–3

Nearly everyone offers tool carriers.

But John Deere’s Powerllel

™

loaders are

something else. Their innovative linkage

design provides an unmatched combination

of powerful digging performance, level lift,

and unsurpassed visibility throughout the

entire boom range. Add to that the J-Series

loaders’ highly popular Quad-Cool

™

system,

low-effort excavator-style pilot-operated

hydraulics, smooth-as-silk powershift

transmission, and multi-function sealed

switch module, and you’ve got a highly

versatile and reliable material mover

that’s in a class by itself.

Take versatility

to a higher level.

Take versatility

to a higher level.

Take versatility

to a higher level.

Powerful digging forces and parallel lift — the Powerllel linkage’s

patented design delivers the best of both. So you can have your

loader and forklift, too.

Refined torque curves in all three loaders deliver impressive

torque reserves of 37, 41, and 54 percent. For extra power

when you need it.

444J and 544J ride on a wide stance, providing additional lateral

stability for handling heavy loads and working on rough terrain.

Worksite Pro

™

quick-coupler lets you quickly and easily switch

attachments without leaving the seat. It’s standard equipment,

letting you go from bucket, to forks, to whatever, and do more

with one machine.

444J 544J 624J

Peak Net Horsepower...........125 .................160.................180

Bucket Capacity....................2.5 cu. yd........3.0 cu. yd........3.5 cu. yd.

Full Turn Tipping Load..........14,330 lb. .......17,470 lb. .......19,889 lb.

Breakout Force .....................16,233 lb........21,372 lb. .......28,102 lb.

Operating Weight..................23,926 lb........28,625 lb. .......33,534 lb.

Powerllel Loader key specifications

FPO: 127375

1. The power in the Powerllel

™

linkage

comes from an innovative design that

allows load forces to work with, not

against, the boom. For big breakout

in tough digging.

2. Unique Y-link,low-mounted boom

cylinders, and high-visibility forks

provide clearly superior visibility

throughout the entire lift arc.

3. Unlike others that lose performance past

the level bucket position, Powerllel loaders

deliver outstanding breakout throughout the

entire bucket and angle range. To conquer

tough tasks such as loading logs and

above-ground-level digging.

1

Operators benefit from a virtually unobstructed

view that takes the work out of precisely placing

loads — whether it’s pipe on trailers or aggregate

into trucks.

Want to test the power of these loaders? Demo

one against a comparable-size tool carrier in

tough digging. The result will win you over.

Standard Worksite Pro

™

quick-coupler lets

you change attachments from the cab quickly

and easily. Accommodates a wide variety of

Worksite Pro buckets and forks.

3

2

Who says you have to sacrifice loader power

to get parallel lift? Powerllel loaders deliver

the best of both. Unlike traditional linkages,

John Deere’s unique design separates the

bell crank from the cross tube, attaching

instead to the loader tower through a unique

Y-shape link. This “free-floating” bell crank

nearly doubles boom cylinder torque — for

unsurpassed boom and bucket breakout,

even in tough digging. Impressive torque

throughout the entire dump and rollback

range also makes these machines ideal for

tough tasks such as sorting or loading logs.

But don’t just look for these Powerllel

advantages in the pages of a spec sheet.

The best way to appreciate them is on your

jobsite. Wherever the job, whatever the load,

you’ll discover parallel lift with no parallel.

PAGES

4–5

Power + parallel lift =

Powerllel

Power + parallel lift =

Powerllel

Power + parallel lift =

Powerllel

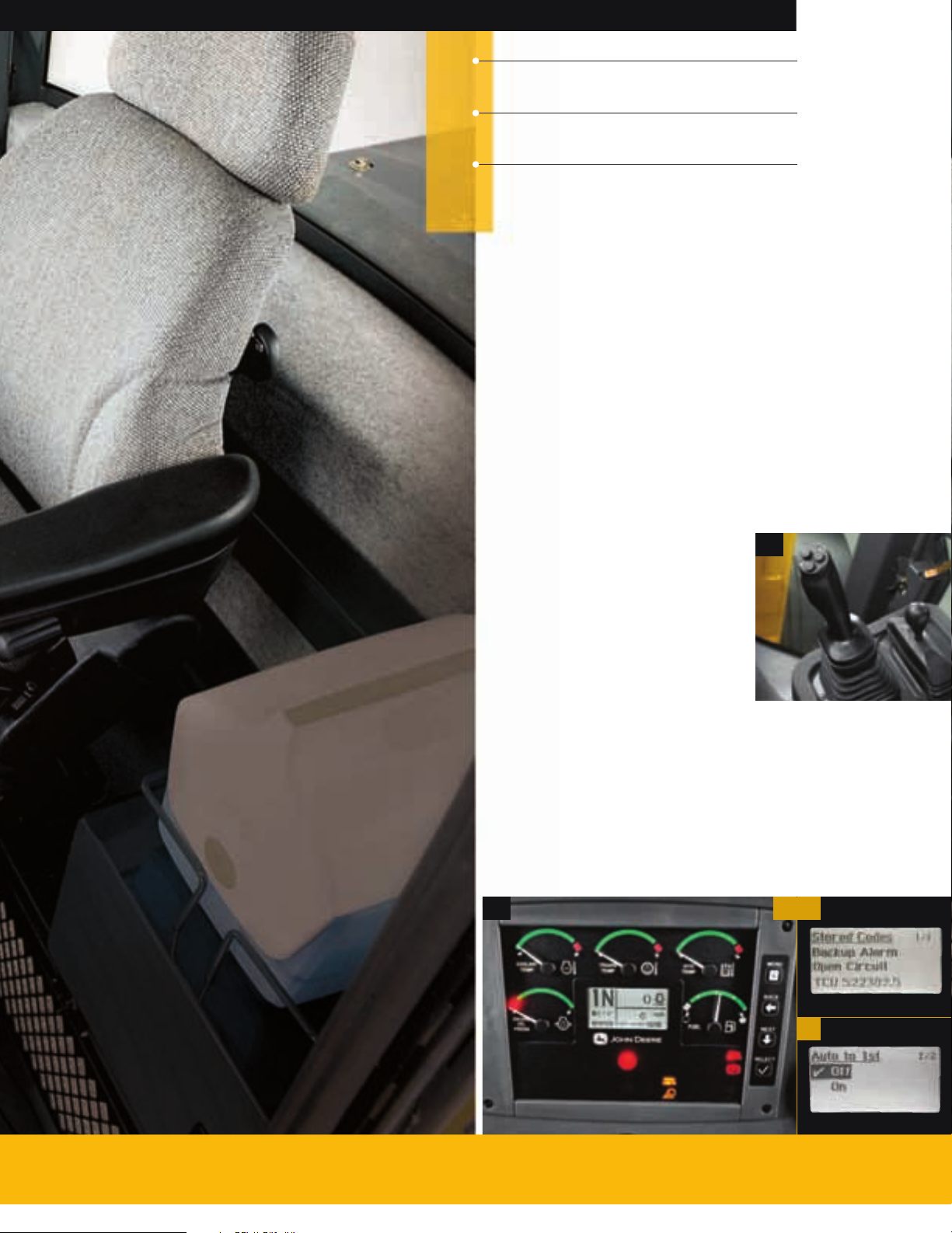

From the convenient controls that customize

machine operation, to the comfortable fully

adjustable armchair seat, the J-Series

loaders have everything your operators need

to be their productive best. All-around

visibility is unobstructed, and an improved

HVAC system helps keep the view clear,

the cab comfortable. Your choice of single-

or two-lever pilot-operated controls and

an all-new sealed switch module allow

convenient, fingertip control of multiple

machine operations. Up-front, a state-of-

the-art multi-function monitor with easy-to-

read messaging, large analog gauges, and

LED warning lights provides vital machine

information at a glance.

PAGES

6–7

Hard work never

felt this easy.

Hard work never

felt this easy.

Hard work never

felt this easy.

Conveniently positioned switch module helps reduce operator

fatigue with clearly visible backlit and sealed controls.

Standard air-ride armchair seat adjusts multiple ways for

extra comfort.

Eleven automotive-style louvers including two directed at

the pedals and independently adjustable defrosters provide

effective airflow to help keep the glass clear and the

pressurized cab comfortable.

2

1

1. Choose from single-lever joystick or two-lever

fingertip pilot-operated controls. Single-lever

control can also be equipped with an optional

fingertip FNR selector for convenient direction

and full-range gear changes. Both controls also

include John Deere’s innovative Quick-Shift

feature that allows pushbutton gear changes,

one gear at a time.

2. Advanced, multi-language monitor with analog

gauges and LED indicators provides:

A. Vital and general operating information

including transmission mode, gear, engine

rpms, and ground speed.

B. Diagnostic readings of most sensors and

switches, enabling technicians to quickly

troubleshoot problems.

C. Customized machine settings that let an

operator match operating characteristics to

specific applications by preselecting trans-

mission functions such as Quick Shift and

Auto-to-1st for maximum productivity.

A B

C

Since the hydraulic system provides only the power

required, there’s no wasted horsepower or fuel.

When rpms drop below 2,200, the horsepower

actually goes up.

The John Deere Power Bulge advantage helps

maintain good boom and bucket speed into the pile.

Smart-shift technology ensures that gear changes

are smooth as silk, regardless of whether the

bucket is empty or fully loaded.

Responsive steering and full 80-degree articulation

increase maneuverability in tight quarters — for

fast cycle times and fewer “three-point” turns.

1. Backlit buttons in the sealed switch

module allow fingertip control of numerous

functions. No tools are required to adjust

boom height kick-out, return-to-carry, or

return-to-dig. Instead, the operator sets

these from the seat.

2. Return-to-dig places the attachment

at a predetermined level position. The

switch has two presets, for increased

convenience and productivity in

applications requiring frequent

changeover between attachments.

3. Boom height kick-out sets maximum

desired dump height, while return-to-

carry sets the lowered boom position.

Use these two John Deere advantages

to speed production in repetitive

loading applications.

3

2

1

PAGES

8–9

If you’ve got maximum productivity in mind, the

J-Series loaders deliver. But it’s not just their

torque reserves and Power Bulge advantage

that make these such impressive performers.

Excavator-style hydraulics sense the load and

deliver the multi-function power needed for fast

work cycles. You won’t find a smoother shifting

loader, either. The powershift torque-converter

transmission employs smart-shift technology to

continuously evaluate speed and load conditions,

and adjusts clutch-pack engagement to suit.

For more productivity without extra effort.

More power and

control means

more productivity.

More power and

control means

more productivity.

More power and

control means

more productivity.

Loading...

Loading...