John Deere 3029, 4039, 4045, 6059, 6068 Repair Manual

3029 4039, 4045 6059, 6068 Engines (Saran) ( -499999CD)

COMPONENT r

TECHNICAL MANUAL

John Deere Usine de Saran

CTM3274 (01JUL99)

European Version

Printed in Germany

ANGLAIS

3029, 4039, 4045, 6059, 6068

Engines (Saran) ) 01JUL99( CTM3274 -499999CD)(

Introduction

FOREWORD

This manual is written for an experienced technician. Essential tools required in performing certain service work are identified in this manual and are recommended for use.

Live with safety: Read the safety messages in the introduction of this manual and the cautions presented throughout the text of the manual.

N This is the safety-alert symbol. When you see this symbol on the machine or in this manual, be alert to the potential for personal injury.

Use this component technical manual in conjunction with the machine technical manual. An application listing in the introduction identifies product-model/component type-model relationship. See the machine technical manual for information on component removal and installation, and gaining access to the components.

This manual is divided in two parts: repair and operation and tests. Repair sections contain

necessary instructions to repair the component. Operation and tests sections help you identify the majority of routine failures quickly.

Information is organized in groups for the various components requiring service instruction. At the beginning of each group are summary listings of all applicable essential tools, service equipment and tools, other materials needed to do the job, service parts kits, specifications, wear tolerances, and torque values.

Component Technical Manuals are concise service guides for specific components. Component technical manuals are written as stand-alone manuals covering multiple machine applications.

Fundamental service information is available from other sources covering basic theory of operation, fundamentals of troubleshooting, general maintenance, and basic type of failures and their causes.

|

DX,CTMIFC -19-22MAY92 |

CTM3274 (01JUL99) |

Saran Liter Engines |

|

060799 |

PN=3

Introduction

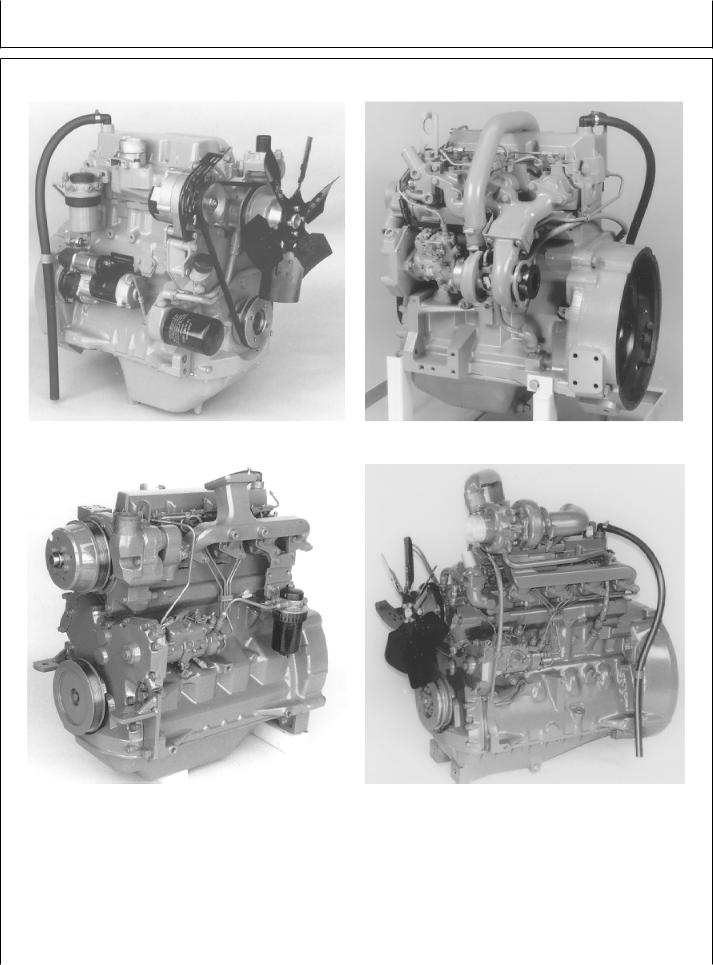

ENGINE IDENTIFICATION VIEWS

-UN-23FEB99 |

-UN-19MAY98 |

CD30699 |

CD30518 |

3029D |

3029T |

-UN-23FEB99 |

-UN-23FEB99 |

CD30701 |

CD30702 |

4039D |

4039T |

|

CD,3274,G00,27 -19-04JAN99 |

CTM3274 (01JUL99) |

Saran Liter Engines |

|

060799 |

PN=4

Introduction

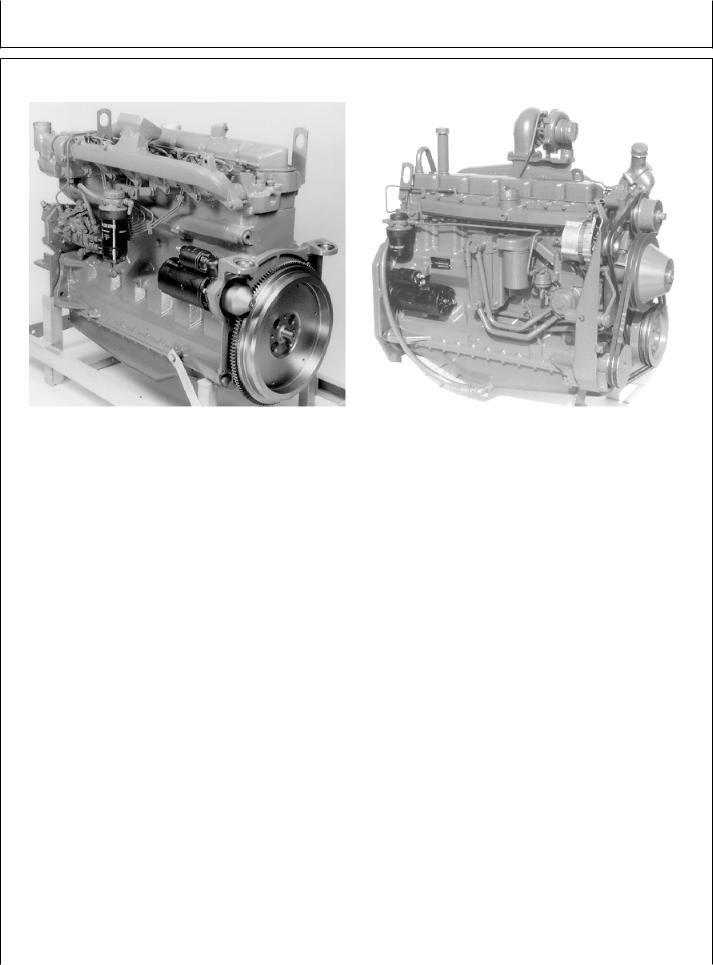

ENGINE IDENTIFICATION VIEWS (CONT'D)

-UN-23FEB99 |

-UN-23FEB99 |

CD30703 |

CD30704 |

6068D |

6068H |

|

CD,3274,G00,28 -19-04JAN99 |

CTM3274 (01JUL99) |

Saran Liter Engines |

|

060799 |

PN=5

Engine application chart

This Component Technical Manual contains service information on the 3029, 4039, 4045, 6059 and 6068 engines produced by JOHN DEERE Saran (FRANCE) for the applications listed in the application chart.

NOTE: Information on how to remove and reinstall the engine in the vehicle is contained in the relevant Technical Manual.

3000-SERIES TRACTORS |

ENGINE MODEL |

SERIAL NUMBER |

|

3100 . . . . . . . . . . . . . . . . . . . . . . . . |

CD3029DRT65 |

(189846 - |

) |

3110 . . . . . . . . . . . . . . . . . . . . . . . . |

CD3029DRT65 |

|

|

3200/3200X . . . . . . . . . . . . . . . . . . . . |

CD4039DRT35 |

(181345 - |

) |

3210/3210X . . . . . . . . . . . . . . . . . . . . |

CD4039DRT35 |

|

|

3300/3300X . . . . . . . . . . . . . . . . . . . . |

CD4045DRT35 |

(182145 - |

) |

3310/3310X . . . . . . . . . . . . . . . . . . . . |

CD4045DRT35 |

|

|

3400/3400X . . . . . . . . . . . . . . . . . . . . |

CD4039TRT35 |

(181775 - |

) |

3410/3410X . . . . . . . . . . . . . . . . . . . . |

CD4039TRT35 |

|

|

4000-SERIES TELESCOPIC |

ENGINE MODEL |

SERIAL NUMBER |

|

HANDLERS |

|

|

|

4400 . . . . . . . . . . . . . . . . . . . . . . . . |

CD4039TF005 |

(237697 - |

) |

4500 . . . . . . . . . . . . . . . . . . . . . . . . |

CD4039TF005 |

|

|

5000-SERIES TRACTORS |

ENGINE MODEL |

SERIAL NUMBER |

|

(Agritalia-built) |

|

|

|

5300/5300N . . . . . . . . . . . . . . . . . . . . |

CD3029DAT01 |

(315424 - |

) |

5400/5400N . . . . . . . . . . . . . . . . . . . . |

CD3029TAT02 |

(289398 - |

) |

5500/5500N . . . . . . . . . . . . . . . . . . . . |

CD4039TAT01 |

(346168 - |

) |

5000-SERIES TRACTORS |

ENGINE MODEL |

SERIAL NUMBER |

|

(Augusta-built) |

|

|

|

5400N . . . . . . . . . . . . . . . . . . . . . . . |

CD3029TLV01 |

|

|

5500N . . . . . . . . . . . . . . . . . . . . . . . |

CD4039TLV01 |

(201353 - |

) |

5000-SERIES TRACTORS |

ENGINE MODEL |

SERIAL NUMBER |

|

(For India) |

|

|

|

5300 . . . . . . . . . . . . . . . . . . . . . . . . |

CD3029DPY01 |

(383283 - |

) |

(Continued on next page) |

CD,3274,G00,24 -19-04JAN99 |

CTM3274 (01JUL99) |

Saran Liter Engines |

|

060799 |

PN=6

Engine application chart

ENGINE APPLICATION CHART (CONT')

6000-SERIES TRACTORS |

ENGINE MODEL |

SERIAL NUMBER |

|||

6100 |

(Direct fan drive) . . . . . . . . . . . . |

CD4045DL001 |

(101582 |

- |

) |

6100 |

(Viscous fan drive) . . . . . . . . . . . |

CD4045DL002 |

(101582 |

- |

) |

6200 |

(Direct fan drive) . . . . . . . . . . . . |

CD4039TL001 |

(101625 |

- |

) |

6200 |

(Viscous fan drive) . . . . . . . . . . . |

CD4039TL004 |

(101625 |

- |

) |

6300 |

(Direct fan drive) . . . . . . . . . . . . |

CD4039TL003 |

(101649 |

- |

) |

6300 |

(Viscous fan drive) . . . . . . . . . . . |

CD4039TL006 |

(101649 |

- |

) |

6400 |

(Direct fan drive) . . . . . . . . . . . . |

CD4045TL001 |

(101682 |

- |

) |

6400 |

(Viscous fan drive) . . . . . . . . . . . |

CD4045TL003 |

(101682 |

- |

) |

6506 |

(Viscous fan drive) . . . . . . . . . . . |

CD6068DL001 |

(214852 |

- |

) |

6600 |

(Viscous fan drive) . . . . . . . . . . . |

CD6059TL001 |

(128886 |

- |

) |

6800 |

(Viscous fan drive) . . . . . . . . . . . |

CD6068TL001 |

(124505 |

- |

) |

6900 |

(Viscous fan drive) . . . . . . . . . . . |

CD6068TL002 |

(186326 |

- |

) |

WATERLOO TRACTORS |

ENGINE MODEL |

SERIAL NUMBER |

|||

7600 |

. . . . . . . . . . . . . . . . . . . . . . . . |

T06068TRW01 |

|

|

|

ZWEIBRÜCKEN COMBINES |

ENGINE MODEL |

SERIAL NUMBER |

|||

2054 |

. . . . . . . . . . . . . . . . . . . . . . . . |

6068HZ001 |

(116452 - |

) |

|

2254 |

. . . . . . . . . . . . . . . . . . . . . . . . |

6068HZ001 |

|

|

|

ENGINES FOR CHINESE COMBINES SERIAL NUMBER

CD6059TYC01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

(367019 - |

) |

CD6059TYC02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

(363170 - |

) |

ENGINES FOR GOLDONI TRACTORS |

SERIAL NUMBER |

|

CD3029DFG21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

(287123 - |

) |

CD3029DFG22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

(287325 - |

) |

CD3029TFG21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

(287526 - |

) |

(Continued on next page) |

CD,3274,G00,25 -19-04JAN99 |

|

CTM3274 (01JUL99) |

Saran Liter Engines |

|

060799 |

PN=7

Engine application chart

ENGINE APPLICATION CHART (CONT')

SARAN OEM ENGINES |

SERIAL NUMBER |

SARAN OEM ENGINES |

SERIAL NUMBER |

||

CD3029DF |

|

|

CD3029TF |

|

|

CD3029DF001 |

|

|

CD3029TF001 |

|

|

CD3029DF005 |

(162670 - |

) |

CD3029TF002 |

(170797 - |

) |

CD3029DF031 |

|

|

CD3029TF031 |

|

|

CD3029DF032 |

|

|

CD3029TF032 |

(176015 - |

) |

CD3029DF033 |

(177875 - |

) |

CD3029TF033 |

(177880 - |

) |

CD3029DF034 |

|

|

CD3029TF120 |

|

|

CD3029DF120 |

|

|

CD3029TF121 |

|

|

CD3029DF121 |

|

|

CD3029TF123 |

(354029 - |

) |

CD3029DF122 |

(263024 - |

) |

CD3029TF160 |

|

|

CD3029DF123 |

(312932 - |

) |

CD3029TF161 |

(288419 - |

) |

CD3029DF124 |

(340207 - |

) |

CD3029TF162 |

|

|

CD3029DF128 |

|

|

CD3029TF163 |

(342829 - |

) |

CD3029DF160 |

|

|

|

|

|

CD3029DF161 |

(288417 - |

) |

|

|

|

CD3029DF162 |

|

|

|

|

|

CD3029DF163 |

|

|

|

|

|

CD3029DF164 |

|

|

|

|

|

CD3029DF165 |

|

|

|

|

|

CD4039DF |

|

|

CD4039TF |

|

|

CD4039DF001 |

|

|

CD4039TF001 |

|

|

CD4039DF002 |

|

|

CD4039TF002 |

|

|

CD4039DF004 |

(152613 - |

) |

CD4039TF003 |

(169516 - |

) |

CD4039DF005 |

(165009 - |

) |

CD4039TF004 |

(152616 - |

) |

CD4039DF006 |

(340212 - |

) |

CD4039TF005 |

|

|

CD4039DF007 |

(378895 - |

) |

CD4039TF006 |

(339780 - |

) |

CD4039DF008 |

|

|

CD4039TF007 |

(379066 - |

) |

CD4039DF031 |

|

|

CD4039TF008 |

|

|

CD4039DF032 |

|

|

CD4039TF031 |

|

|

|

|

|

CD4039TF032 |

(166826 - |

) |

CD4045DF001 |

|

|

CD4045TF001 |

|

|

CD4045DF031 |

|

|

CD4045TF002 |

(170081 - |

) |

|

|

|

CD4045TF003 |

(342250 - |

) |

|

|

|

CD4045TF008 |

|

|

|

|

|

CD4045TF031 |

|

|

(Continued on next page) |

CD,3274,G00,29 -19-04JAN99 |

|

CTM3274 (01JUL99) |

Saran Liter Engines |

|

060799 |

PN=8

Engine application chart

ENGINE APPLICATION CHART (CONT')

SARAN OEM ENGINES |

SERIAL NUMBER |

SARAN OEM ENGINES |

SERIAL NUMBER |

|

CD6059DF |

|

CD6059TF |

|

|

CD6059DF001 |

|

CD6059TF001 |

|

|

CD6059DF002 |

|

CD6059TF002 |

(158390 - |

) |

CD6059DF003 |

|

CD6059TF003 |

(158394 - |

) |

|

|

CD6059TF004 |

|

|

|

|

CD6059TF005 |

(166159 - |

) |

|

|

CD6059TF006 |

(166960 - |

) |

|

|

CD6059TF008 |

(341217 - |

) |

CD6068DF001 |

|

CD6068TF001 |

|

|

|

|

CD6068TF002 |

(187378 - |

) |

|

|

CD6068TF003 |

|

|

|

|

CD6068TF004 |

(344260 - |

) |

|

|

CD6068TF008 |

|

|

|

|

CD6068TF009 |

|

|

|

CD,3274,G00,30 -19-04JAN99 |

CTM3274 (01JUL99) |

Saran Liter Engines |

|

060799 |

PN=9

HANDLE FLUIDS SAFELYÐAVOID FIRES

When you work around fuel, do not smoke or work near heaters or other fire hazards.

Store flammable fluids away from fire hazards. Do not incinerate or puncture pressurized containers.

Make sure machine is clean of trash, grease, and debris.

Do not store oily rags; they can ignite and burn spontaneously.

PREVENT BATTERY EXPLOSIONS

Keep sparks, lighted matches, and open flame away from the top of battery. Battery gas can explode.

Never check battery charge by placing a metal object across the posts. Use a volt-meter or hydrometer.

Do not charge a frozen battery; it may explode. Warm battery to 16ÊC (60ÊF).

PREPARE FOR EMERGENCIES

Be prepared if a fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service, hospital, and fire department near your telephone.

CTM3274 (01JUL99) |

00-1 |

Group 00

Safety

00

1

TS227 -UN-23AUG88

DX,FLAME -19-29SEP98

TS204 -UN-23AUG88

DX,SPARKS -19-03MAR93

TS291 -UN-23AUG88

DX,FIRE2 -19-03MAR93

Saran Liter Engines

060799

PN=10

Safety

PREVENT ACID BURNS

00

2 Sulfuric acid in battery electrolyte is poisonous. It is strong enough to burn skin, eat holes in clothing, and cause blindness if splashed into eyes.

Avoid the hazard by:

1. Filling batteries in a well-ventilated area.

2. Wearing eye protection and rubber gloves.

3. Avoiding breathing fumes when electrolyte is added.

4. Avoiding spilling or dripping electrolyte.

5. Use proper jump start procedure.

If you spill acid on yourself:

1.Flush your skin with water.

2.Apply baking soda or lime to help neutralize the acid.

3.Flush your eyes with water for 15Ð30 minutes. Get medical attention immediately.

If acid is swallowed:

1.Do not induce vomiting.

2.Drink large amounts of water or milk, but do not exceed 2 L (2 quarts).

3.Get medical attention immediately.

TS203 -UN-23AUG88

TS203 -UN-23AUG88

DX,POISON -19-21APR93

CTM3274 (01JUL99) |

00-2 |

Saran Liter Engines |

|

|

060799 |

PN=11

Safety

AVOID HIGH-PRESSURE FLUIDS

Escaping fluid under pressure can penetrate the skin causing serious injury.

Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying pressure.

Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids.

If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information is available from Deere & Company Medical Department in Moline, Illinois, U.S.A.

WEAR PROTECTIVE CLOTHING

Wear close fitting clothing and safety equipment appropriate to the job.

Prolonged exposure to loud noise can cause impairment or loss of hearing.

Wear a suitable hearing protective device such as earmuffs or earplugs to protect against objectionable or uncomfortable loud noises.

Operating equipment safely requires the full attention of the operator. Do not wear radio or music headphones while operating machine.

CTM3274 (01JUL99) |

00-3 |

00

3

X9811 -UN-23AUG88

DX,FLUID -19-03MAR93

TS206 -UN-23AUG88

DX,WEAR -19-10SEP90

Saran Liter Engines

060799

PN=12

Safety

SERVICE MACHINES SAFELY

00

4 Tie long hair behind your head. Do not wear a necktie, scarf, loose clothing, or necklace when you work near machine tools or moving parts. If these items were to get caught, severe injury could result.

Remove rings and other jewelry to prevent electrical shorts and entanglement in moving parts.

WORK IN VENTILATED AREA

Engine exhaust fumes can cause sickness or death. If it is necessary to run an engine in an enclosed area, remove the exhaust fumes from the area with an exhaust pipe extension.

If you do not have an exhaust pipe extension, open the doors and get outside air into the area.

WORK IN CLEAN AREA

Before starting a job:

·Clean work area and machine.

·Make sure you have all necessary tools to do your job.

·Have the right parts on hand.

·Read all instructions thoroughly; do not attempt shortcuts.

CTM3274 (01JUL99) |

00-4 |

TS228 -UN-23AUG88

DX,LOOSE -19-04JUN90

TS220 -UN-23AUG88

DX,AIR -19-04JUN90

T6642EJ -UN-18OCT88

DX,CLEAN -19-04JUN90

Saran Liter Engines

060799

PN=13

Safety

REMOVE PAINT BEFORE WELDING OR HEATING

Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when paint is heated by welding, soldering, or using a torch.

Do all work outside or in a well ventilated area. Dispose of paint and solvent properly.

Remove paint before welding or heating:

·If you sand or grind paint, avoid breathing the dust. Wear an approved respirator.

·If you use solvent or paint stripper, remove stripper with soap and water before welding. Remove solvent or paint stripper containers and other flammable material from area. Allow fumes to disperse at least 15 minutes before welding or heating.

AVOID HEATING NEAR PRESSURIZED FLUID LINES

Flammable spray can be generated by heating near pressurized fluid lines, resulting in severe burns to yourself and bystanders. Do not heat by welding, soldering, or using a torch near pressurized fluid lines or other flammable materials. Pressurized lines can be accidentally cut when heat goes beyond the immediate flame area.

ILLUMINATE WORK AREA SAFELY

Illuminate your work area adequately but safely. Use a portable safety light for working inside or under the machine. Make sure the bulb is enclosed by a wire cage. The hot filament of an accidentally broken bulb can ignite spilled fuel or oil.

CTM3274 (01JUL99) |

00-5 |

00

5

TS220 -UN-23AUG88

DX,PAINT -19-03MAR93

TS953 -UN-15MAY90

DX,TORCH -19-03MAR93

TS223 -UN-23AUG88

DX,LIGHT -19-04JUN90

Saran Liter Engines

060799

PN=14

Safety

USE PROPER LIFTING EQUIPMENT

00

6 Lifting heavy components incorrectly can cause severe injury or machine damage.

Follow recommended procedure for removal and installation of components in the manual.

PRACTICE SAFE MAINTENANCE

Understand service procedure before doing work. Keep area clean and dry.

Never lubricate, service, or adjust machine while it is moving. Keep hands, feet , and clothing from power-driven parts. Disengage all power and operate controls to relieve pressure. Lower equipment to the ground. Stop the engine. Remove the key. Allow machine to cool.

Securely support any machine elements that must be raised for service work.

Keep all parts in good condition and properly installed. Fix damage immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or debris.

On self-propelled equipment, disconnect battery ground cable (-) before making adjustments on electrical systems or welding on machine.

On towed implements, disconnect wiring harnesses from tractor before servicing electrical system components or welding on machine.

CTM3274 (01JUL99) |

00-6 |

TS226 -UN-23AUG88

DX,LIFT -19-04JUN90

TS218 -UN-23AUG88

DX,SERV -19-04FEB99

Saran Liter Engines

060799

PN=15

Safety

USE PROPER TOOLS

Use tools appropriate to the work. Makeshift tools and procedures can create safety hazards.

Use power tools only to loosen threaded parts and fasteners.

For loosening and tightening hardware, use the correct size tools. DO NOT use U.S. measurement tools on metric fasteners. Avoid bodily injury caused by slipping wrenches.

Use only service parts meeting John Deere specifications.

DISPOSE OF WASTE PROPERLY

Improperly disposing of waste can threaten the environment and ecology. Potentially harmful waste used with John Deere equipment include such items as oil, fuel, coolant, brake fluid, filters, and batteries.

Use leakproof containers when draining fluids. Do not use food or beverage containers that may mislead someone into drinking from them.

Do not pour waste onto the ground, down a drain, or into any water source.

Air conditioning refrigerants escaping into the air can damage the Earth's atmosphere. Government regulations may require a certified air conditioning service center to recover and recycle used air conditioning refrigerants.

Inquire on the proper way to recycle or dispose of waste from your local environmental or recycling center, or from your John Deere dealer.

CTM3274 (01JUL99) |

00-7 |

00

7

TS779 -UN-08NOV89

DX,REPAIR -19-04JUN90

TS1133 -UN-26NOV90

DX,DRAIN -19-03MAR93

Saran Liter Engines

060799

PN=16

Safety

LIVE WITH SAFETY

00

8 Before returning machine to customer, make sure machine is functioning properly, especially the safety systems. Install all guards and shields.

TS231 -19-07OCT88

TS231 -19-07OCT88

DX,LIVE -19-15APR98

CTM3274 (01JUL99) |

00-8 |

Saran Liter Engines |

|

|

060799 |

PN=17

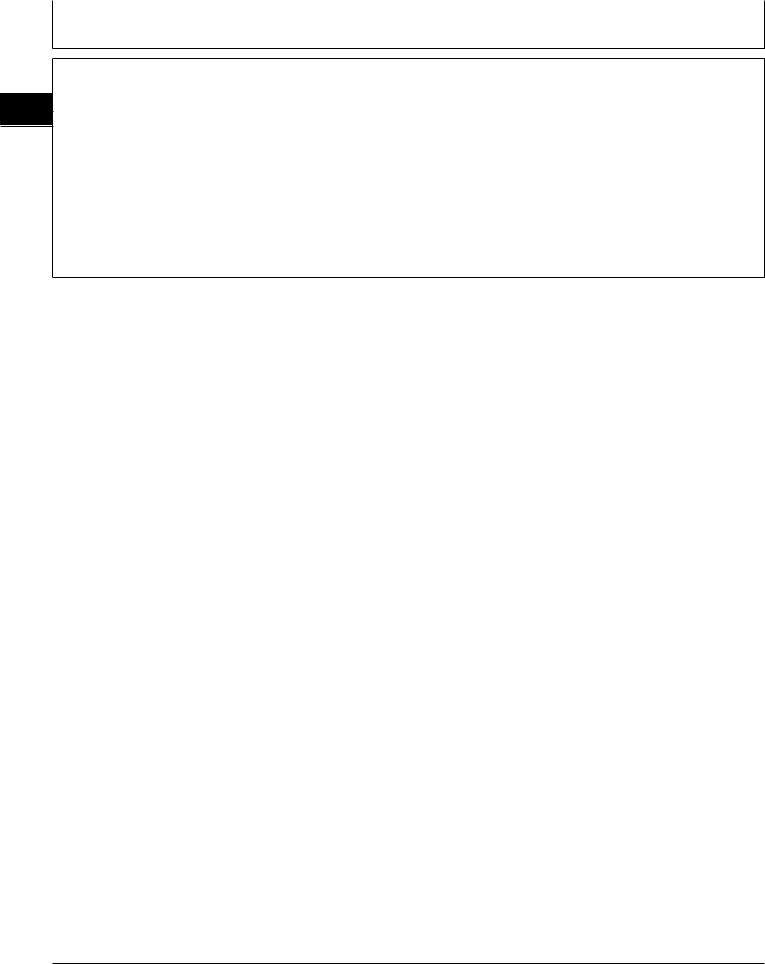

ENGINE IDENTIFICATION

The engine can be identified from the serial plate (A) located on the right-hand side of the engine.

Some applications also have an additional serial plate located on top of the flywheel housing. Refer to the engine type to identify repair information in the Component Technical Manual.

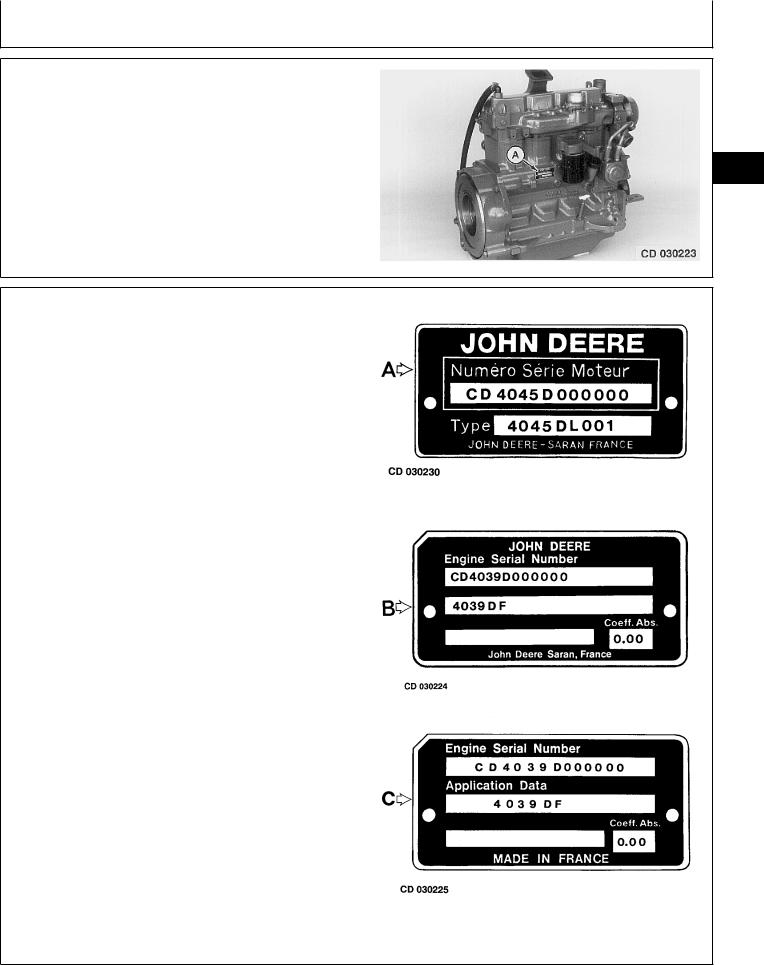

ENGINE PLATE INFORMATION (EARLIER DESIGN)

Three types of plates are used on engines and give the following information:

First line (all plates)

CD . . . . . . . . . . . . . Manufacturing factory

(CD = Saran, T0 = Dubuque) 4045 . . . . . . . . . . Engine model designation

4 = Number of cylinders

045 = Total displacement

(045 = 4.5 liters) D . . . . . . . . . Aspiration code

D = Naturally Aspirated H = air-to-air aftercooled T = Turbocharged

000000 . . . . Sequential serial number

Second line (all plates)

4045D . . . . . . . . . . . See above L . . . . . . . . . . User code

F = OEM application L = Mannheim

RW = Waterloo Tractor Z = Zweibrücken

001 . . . . . . . . Application number

Third line (OEM plates only)

First field . . |

. . . . . . . Not used |

Second field . |

. . . . . . Absorption coefficient of smoke |

|

emissions (shown on certain OEM |

|

engines) |

|

AÐPlate used on John Deere equipment |

|

BÐPlate used on OEM engines |

|

CÐGeneric plate used on certain OEM engines |

CTM3274 (01JUL99) |

01-1 |

Group 01

General information

07MAR95- |

1 |

|

01 |

-UN |

|

|

|

CD30223 |

|

CD,3274,G01,1 -19-24FEB92

CD30230 -UN-07MAR95

CD30224 -UN-07MAR95

CD30225 -UN-07MAR95

CD,3274,G01,2 -19-04JAN99

Saran Liter Engines

060799

PN=18

General information/Repower engine plate

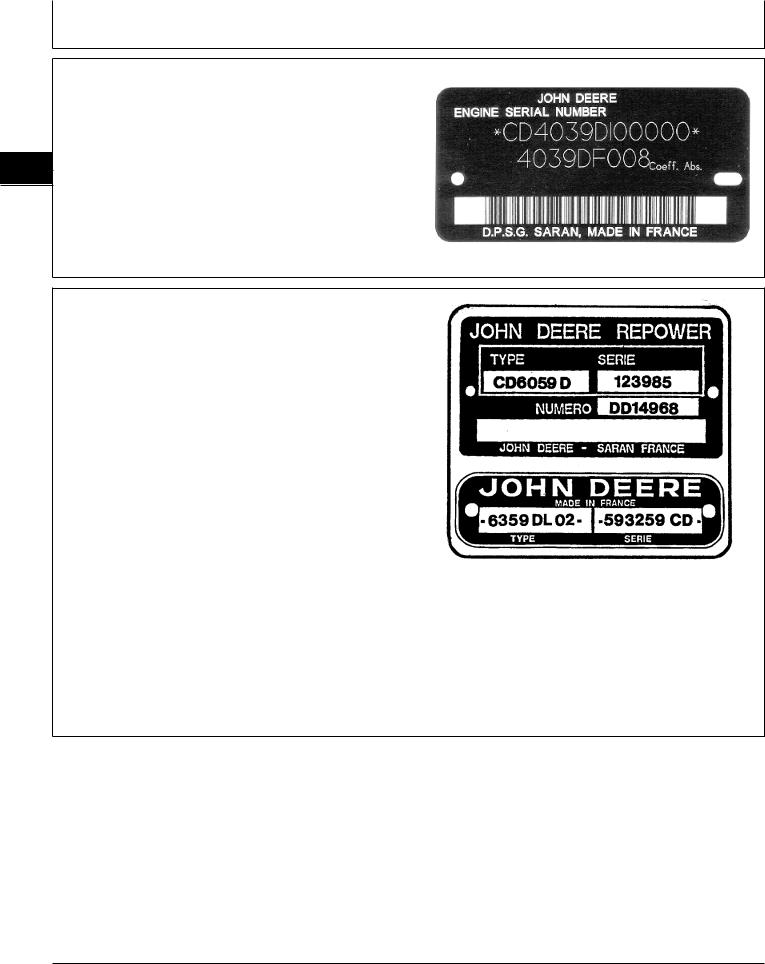

ENGINE PLATE INFORMATION (LATER

DESIGN)

A new engine plate design as shown, is now affixed to the engine.

01

2 Information on this new plate is the same as previously.

REPOWER ENGINE PLATE

A specific plate is fixed on repower engines for proper identification. This plate gives the following information:

First line |

|

First field . . . . . . . . . . . |

Engine type |

Second field . . . . . . . . . |

Sequential serial number |

Second line |

|

DDРРРРР . . . . . . . |

Repower engine part number |

The third line contains a bar code information for factory use.

NOTE: The serial number plate from original engine must be fixed on the repower plate as shown.

CTM3274 (01JUL99) |

01-2 |

CD30705 -UN-22FEB99

CD,3274,G01,10 -19-04JAN99

CD30706 -UN-22FEB99

CD,3274,G01,6 -19-04JAN99

Saran Liter Engines

060799

PN=19

General information/Engine references

OEM ENGINE OPTION CODE LABEL

An option code label is secured to the top of the valve cover and identifies the factory installed options on each OEM engine to ensure correct parts acquisition.

Always provide option code information and engine base code when ordering repair parts. A listing of option codes is given in Parts Catalogs and Operator's Manual.

NOTE: Before ªhot tankº cleaning, ensure that option codes are recorded elsewhere.

ENGINE REFERENCES

Direction of engine rotation:

Clockwise rotation when viewed from water pump end.

Engine front reference:

The water pump end is the ªfrontº of the engine. Cylinder number 1 is at the front of engine.

Engine side references:

ªRight-handº and ªleft-handº sides are determined by facing the flywheel end (rear) of the engine. Right-hand side is the camshaft side while left-hand side is the fuel injection pump side.

CTM3274 (01JUL99) |

01-3 |

10MAY95- |

3 |

|

01 |

-UN |

|

|

|

CD30433 |

|

CD,3274,G01,3 -19-01FEB94

CD30525 -UN-04MAY98

CD,CTM125,005 -19-01DEC97

Saran Liter Engines

060799

PN=20

General information/Basic engine specifications (3029 - 4039 & 6059)

BASIC ENGINE SPECIFICATIONS (3029 - 4039 & 6059)

|

|

UNIT of |

|

|

|

|

|

|

01 |

|

Measure |

3029D |

3029T |

4039D |

4039T |

6059D |

6059T |

GENERAL |

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Number of Cylinders |

--- |

3 |

3 |

4 |

4 |

6 |

6 |

|

Bore |

mm |

106.5 |

106.5 |

106.5 |

106.5 |

106.5 |

106.5 |

|

|

(in.) |

(4.19) |

(4.19) |

(4.19) |

(4.19) |

(4.19) |

(4.19) |

|

Stroke |

mm |

110 |

110 |

110 |

110 |

110 |

110 |

|

|

(in.) |

(4.33) |

(4.33) |

(4.33) |

(4.33) |

(4.33) |

(4.33) |

|

Displacement |

L |

2.9 |

2.9 |

3.9 |

3.9 |

5.9 |

5.9 |

|

|

(in.3) |

(179) |

(179) |

(239) |

(239) |

(359) |

(359) |

|

Compression Ratio |

--- |

17.8:1 |

17.8:1 |

17.8:1 |

17.8:1 |

17.8:1 |

17.8:1 |

|

Firing Order |

--- |

1-2-3 |

1-2-3 |

1-3-4-2 |

1-3-4-2 |

1-5-3-6-2-4 |

1-5-3-6-2-4 |

|

Injection System |

--- |

Direct |

Direct |

Direct |

Direct |

Direct |

Direct |

|

Aspiration |

--- |

Natural |

Turbocharged |

Natural |

Turbocharged |

Natural |

Turbocharged |

|

Rated Speed* |

rpm |

2500 |

2500 |

2500 |

2500 |

2500 |

2500 |

|

Power** |

kW |

43 |

59 |

60 |

82 |

89 |

123 |

|

@ Rated Speed |

(hp) |

(58) |

(79) |

(80) |

(110) |

(120) |

(165) |

|

Power** |

kW |

35 |

|

49 |

76 |

|

123 |

|

@ 1800 rpm |

(hp) |

(47) |

|

(66) |

(102) |

|

(165) |

|

Power** |

kW |

31 |

|

40 |

63 |

|

104 |

|

@ 1500 rpm |

(hp) |

(42) |

|

(54) |

(85) |

|

(140) |

|

Weight (dry) |

kg |

323 |

330 |

422 |

458 |

518 |

525 |

|

|

(lbs) |

(712) |

(728) |

(931) |

(1010) |

(1143) |

(1158) |

|

*Vary by application; refer to the machine technical or operator's |

|

|

|

|

|||

|

manual for specific engine speeds and powers. |

|

|

|

|

|

||

|

**Without fan. |

|

|

|

|

|

CD,3274,G01,8 -19-01FEB94 |

|

|

|

|

|

|

|

|

||

CTM3274 (01JUL99) |

01-4 |

Saran Liter Engines |

|

|

060799 |

PN=21

General information/Basic engine specifications (4045 & 6068)

BASIC ENGINE SPECIFICATIONS (4045 & 6068)

|

UNIT of |

|

|

|

|

|

|

Measure |

4045D |

4045T |

6068D |

6068T |

6068H |

GENERAL |

|

|

|

|

|

|

Number of Cylinders |

--- |

4 |

4 |

6 |

6 |

6 |

Bore |

mm |

106.5 |

106.5 |

106.5 |

106.5 |

106.5 |

|

(in.) |

(4.19) |

(4.19) |

(4.19) |

(4.19) |

(4.19) |

Stroke |

mm |

127 |

127 |

127 |

127 |

127 |

|

(in.) |

(5.00) |

(5.00) |

(5.00) |

(5.00) |

(5.00) |

Displacement |

L |

4.5 |

4.5 |

6.8 |

6.8 |

6.8 |

|

(cu.in.) |

(276) |

(276) |

(414) |

(414) |

(414) |

Compression Ratio |

--- |

17.8:1 |

17.2:1 |

17.8:1 |

17.2:1 |

17.2:1 |

Firing Order |

--- |

1-3-4-2 |

1-3-4-2 |

1-5-3-6-2-4 |

1-5-3-6-2-4 |

1-5-3-6-2-4 |

Injection System |

--- |

Direct |

Direct |

Direct |

Direct |

Direct |

Aspiration |

--- |

Natural |

Turbo- |

Natural |

Turbo- |

Air-to-air |

|

|

|

charged |

|

charged |

aftercooler |

Rated Speed* |

rpm |

2400 |

2400 |

2400 |

2400 |

2200 |

Power** |

kW |

63 |

86 |

97 |

130 |

140 |

at Rated Speed |

(hp) |

(85) |

(115) |

(130) |

(175) |

(190) |

Power** |

kW |

|

84 |

|

|

|

at 1800 rpm |

(hp) |

|

(113) |

|

|

|

Power** |

kW |

|

70 |

|

116 |

|

at 1500 rpm |

(hp) |

|

(95) |

|

(155) |

|

Weight (dry) |

kg |

474 |

487 |

588 |

602 |

|

|

(lbs) |

(1046) |

(1074) |

(1297) |

(1328) |

|

01

5

*Vary by application; refer to the machine technical or operator's manual for specific engine speeds and powers.

**Without fan. |

CD,3274,G01,9 -19-04JAN99 |

|

CTM3274 (01JUL99) |

01-5 |

Saran Liter Engines |

|

|

060799 |

PN=22

General information/Fuel specifications

DIESEL FUEL

Consult your local fuel distributor for properties of the diesel fuel available in your area.

01 In general, diesel fuels are blended to satisfy the low

6temperature requirements of the geographical area in which they are marketed.

Diesel fuels specified to EN 590 or ASTM D975 are recommended.

In all cases, the fuel shall meet the following properties:

· Cetane number of 40 minimum.

Cetane number greater than 50 is preferred, especially for temperatures below -20ÊC (-4ÊF) or elevations above 1500 m (5,000 ft).

· Cold Filter Plugging Point (CFPP) below the expected low temperature OR Cloud Point at least 5ÊC (9ÊF) below the expected low temperature.

·Fuel lubricity should pass a minimum of 3100 gram load level as measured by the BOCLE scuffing test.

·Sulfur content:

ÐSulfur content should not exceed 0.5% Sulfur content less than 0.05% is preferred.

ÐIf diesel fuel with sulfur content greater than 0.5% sulfur content is used, reduce the service interval for engine oil and filter by 50%

ÐDO NOT use diesel fuel with sulfur content greater than 1.0%

Bio-diesel fuels may be used ONLY if the fuel properties meet DIN 51606 or equivalent specification.

DO NOT mix used engine oil or any other type of lubricant with diesel fuel.

DX,FUEL1 -19-12FEB99

CTM3274 (01JUL99) |

01-6 |

Saran Liter Engines |

|

|

060799 |

PN=23

General information/Oil specifications

DIESEL ENGINE OIL

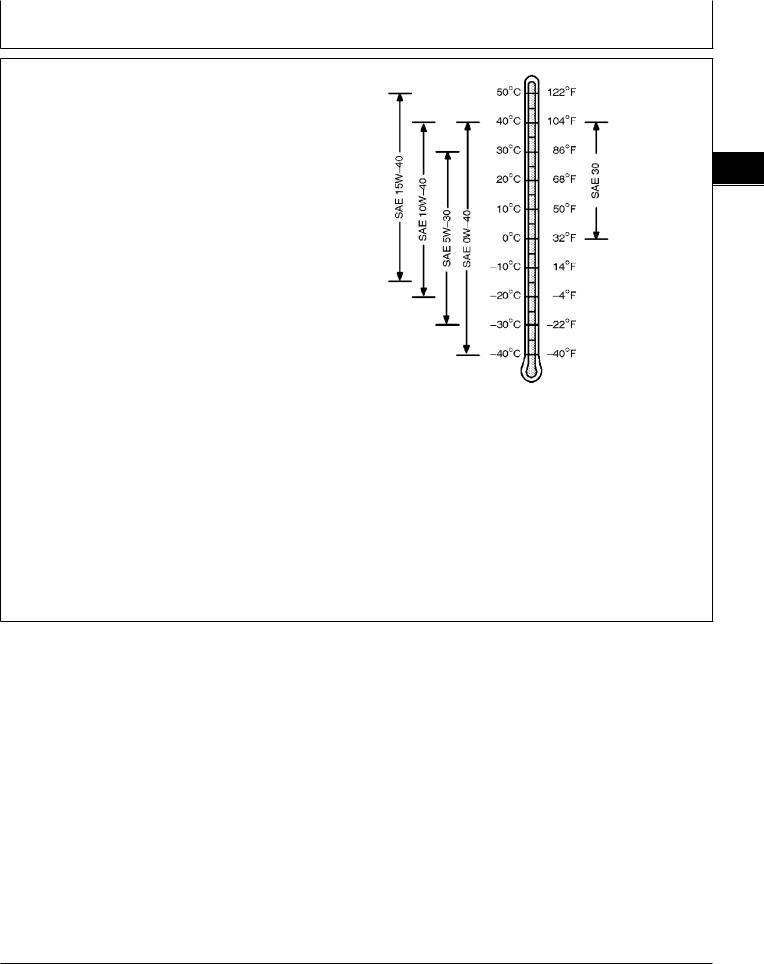

Use oil viscosity based on the expected air temperature range during the period between oil changes.

The following oil is preferred.

· John Deere PLUS-50®

The following oil is also recommended:

· John Deere TORQ-GARD SUPREME®

Other oils may be used if they meet one or more of the following:

·API Service Classification CG-4

·API Service Classification CF-4

·ACEA Specification E3

·ACEA Specification E2

Multi-viscosity diesel engine oils are preferred.

If diesel fuel with sulfur content greater than 0.5% is used, reduce the service interval by 50%.

Extended service intervals may apply when John Deere preferred engine oils are used. Consult your John Deere dealer for more information.

01

7

TS1661 -UN-10OCT97

DX,ENOIL -19-10OCT97

CTM3274 (01JUL99) |

01-7 |

Saran Liter Engines |

|

|

060799 |

PN=24

General information/Coolant specifications

DIESEL ENGINE COOLANT

The engine cooling system is filled to provide year-round protection against corrosion and cylinder liner pitting, and winter freeze protection to -37ÊC

01 (-34ÊF).

8

John Deere COOL-GARD is preferred for service.

If John Deere COOL-GARD is not available, use a low silicate ethylene glycol base coolant concentrate in a 50% mixture of concentrate with quality water.

The coolant concentrate shall be of a quality that provides cavitation protection to cast iron and aluminum parts in the cooling system. John Deere COOL-GARD meets this requirement.

A 50% mixture of ethylene glycol engine coolant in water provides freeze protection to -37ÊC (-34ÊF). If protection at lower temperatures is required, consult your John Deere dealer for recommendations.

Water quality is important to the performance of the cooling system. Distilled, deionized, or demineralized

water is recommended for mixing with ethylene glycol base engine coolant concentrate.

IMPORTANT: Do not use cooling system sealing additives or antifreeze that contains sealing additives.

Coolant drain intervals

Drain the factory fill engine coolant, flush the cooling system, and refill with new coolant after the first 3 years or 3000 hours of operation. Subsequent drain intervals are determined by the coolant used for service. At each interval, drain the coolant, flush the cooling system, and refill with new coolant.

When John Deere COOL-GARD is used, the coolant drain interval is 3 years or 3000 hours operation.

If COOL-GARD is not used, the drain interval is reduced to 2 years or 2000 hours of operation.

DX,COOL8 -19-12FEB99

CTM3274 (01JUL99) |

01-8 |

Saran Liter Engines |

|

|

060799 |

PN=25

General information/Metric cap screw torque values

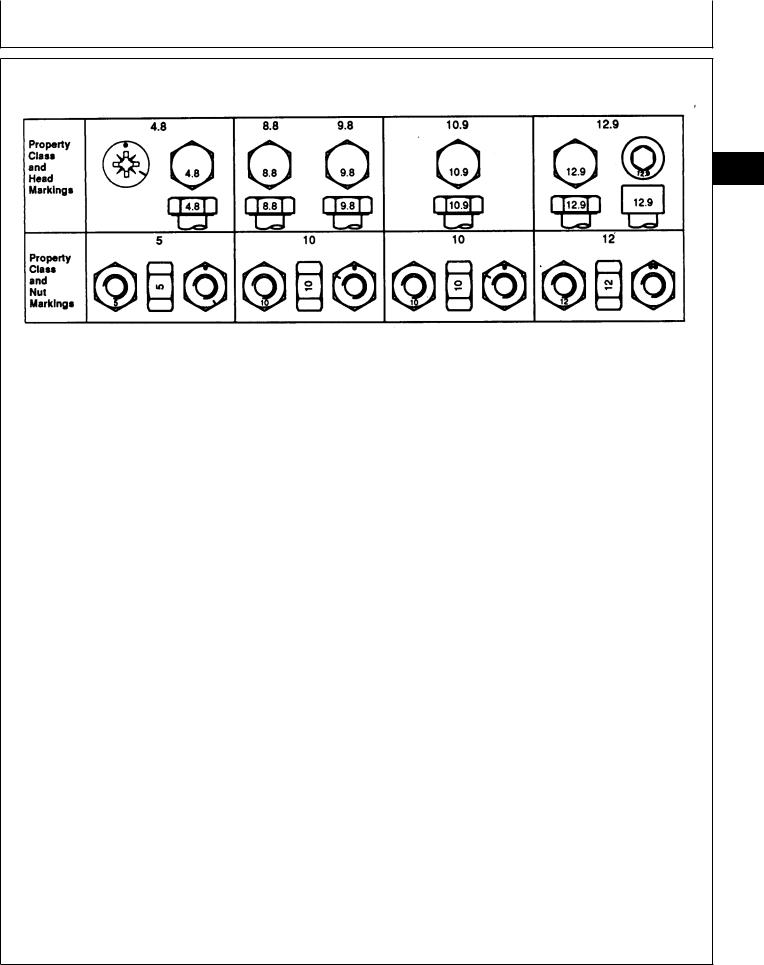

METRIC BOLT AND CAP SCREW TORQUE VALUES

01

9

TS1163 -19-04MAR91

|

|

Class 4.8 |

|

|

Class 8.8 or 9.8 |

|

|

Class 10.9 |

|

|

Class 12.9 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Size |

Lubricateda |

Drya |

Lubricateda |

Drya |

Lubricateda |

Drya |

Lubricateda |

Drya |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N´m |

lb-ft |

N´m |

lb-ft |

N´m |

lb-ft |

N´m |

|

lb-ft |

N´m |

lb-ft |

N´m |

lb-ft |

N´m |

lb-ft |

N´m |

lb-ft |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M6 |

4.8 |

3.5 |

6 |

4.5 |

9 |

6.5 |

11 |

|

8.5 |

13 |

9.5 |

17 |

12 |

15 |

11.5 |

19 |

14.5 |

M8 |

12 |

8.5 |

15 |

11 |

22 |

16 |

28 |

|

20 |

32 |

24 |

40 |

30 |

37 |

28 |

47 |

35 |

M10 |

23 |

17 |

29 |

21 |

43 |

32 |

55 |

|

40 |

63 |

47 |

80 |

60 |

75 |

55 |

95 |

70 |

M12 |

40 |

29 |

50 |

37 |

75 |

55 |

95 |

|

70 |

110 |

80 |

140 |

105 |

130 |

95 |

165 |

120 |

M14 |

63 |

47 |

80 |

60 |

120 |

88 |

150 |

|

110 |

175 |

130 |

225 |

165 |

205 |

150 |

260 |

190 |

M16 |

100 |

73 |

125 |

92 |

190 |

140 |

240 |

|

175 |

275 |

200 |

350 |

255 |

320 |

240 |

400 |

300 |

M18 |

135 |

100 |

175 |

125 |

260 |

195 |

330 |

|

250 |

375 |

275 |

475 |

350 |

440 |

325 |

560 |

410 |

M20 |

190 |

140 |

240 |

180 |

375 |

275 |

475 |

|

350 |

530 |

400 |

675 |

500 |

625 |

460 |

800 |

580 |

M22 |

260 |

190 |

330 |

250 |

510 |

375 |

650 |

|

475 |

725 |

540 |

925 |

675 |

850 |

625 |

1075 |

800 |

M24 |

330 |

250 |

425 |

310 |

650 |

475 |

825 |

|

600 |

925 |

675 |

1150 |

850 |

1075 |

800 |

1350 |

1000 |

M27 |

490 |

360 |

625 |

450 |

950 |

700 |

1200 |

|

875 |

1350 |

1000 |

1700 |

1250 |

1600 |

1150 |

2000 |

1500 |

M30 |

675 |

490 |

850 |

625 |

1300 |

950 |

1650 |

|

1200 |

1850 |

1350 |

2300 |

1700 |

2150 |

1600 |

2700 |

2000 |

M33 |

900 |

675 |

1150 |

850 |

1750 |

1300 |

2200 |

|

1650 |

2500 |

1850 |

3150 |

2350 |

2900 |

2150 |

3700 |

2750 |

M36 |

1150 |

850 |

1450 |

1075 |

2250 |

1650 |

2850 |

|

2100 |

3200 |

2350 |

4050 |

3000 |

3750 |

2750 |

4750 |

3500 |

DO NOT use these values if a different torque value or tightening procedure is given for a specific application. Torque values listed are for general use only. Check tightness of fasteners periodically.

Shear bolts are designed to fail under predetermined loads. Always replace shear bolts with identical property class.

Fasteners should be replaced with the same or higher property class. If higher property class fasteners are used, these should only be tightened to the strength of the original.

a ªLubricatedº means coated with a lubricant such as engine oil, or fasteners with phosphate and oil coatings. ªDryº means plain or zinc plated without any lubrication.

Make sure fasteners threads are clean and that you properly start thread engagement. This will prevent them from failing when tightening.

Tighten plastic insert or crimped steel-type lock nuts to approximately 50 percent of the dry torque shown in the chart, applied to the nut, not to the bolt head. Tighten toothed or serrated-type lock nuts to the full torque value.

DX,TORQ2 -19-20JUL94

CTM3274 (01JUL99) |

01-9 |

Saran Liter Engines |

|

|

060799 |

PN=26

General information/Inch cap screw torque values

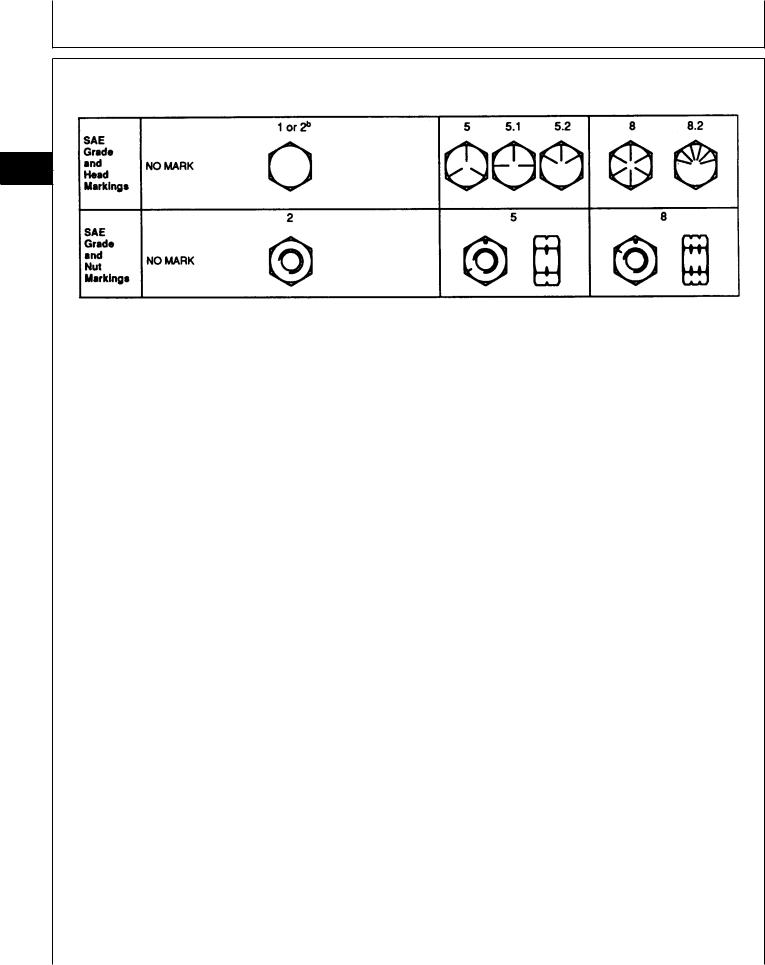

UNIFIED INCH BOLT AND CAP SCREW TORQUE VALUES

01

10

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-19-04MAR91 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TS1162 |

|

|

|

Grade 1 |

|

|

Grade 2b |

|

Grade 5, 5.1, or 5.2 |

|

Grade 8 or 8.2 |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Size |

Lubricateda |

|

Drya |

Lubricateda |

|

Drya |

Lubricateda |

Drya |

Lubricateda |

|

Drya |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N´m |

lb-ft |

|

N´m |

lb-ft |

N´m |

lb-ft |

|

N´m |

lb-ft |

N´m |

lb-ft |

N´m |

lb-ft |

N´m |

lb-ft |

|

N´m |

|

lb-ft |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1/4 |

3.7 |

2.8 |

|

4.7 |

3.5 |

6 |

4.5 |

|

7.5 |

5.5 |

9.5 |

7 |

12 |

9 |

13.5 |

10 |

|

17 |

|

12.5 |

|

|

5/16 |

7.7 |

5.5 |

|

10 |

7 |

12 |

9 |

|

15 |

11 |

20 |

15 |

25 |

18 |

28 |

21 |

|

35 |

|

26 |

|

|

3/8 |

14 |

10 |

|

17 |

13 |

22 |

16 |

|

27 |

20 |

35 |

26 |

44 |

33 |

50 |

36 |

|

63 |

|

46 |

|

|

7/16 |

22 |

16 |

|

28 |

20 |

35 |

26 |

|

44 |

32 |

55 |

41 |

70 |

52 |

80 |

58 |

|

100 |

|

75 |

|

|

1/2 |

33 |

25 |

|

42 |

31 |

53 |

39 |

|

67 |

50 |

85 |

63 |

110 |

80 |

120 |

90 |

|

150 |

|

115 |

|

|

9/16 |

48 |

36 |

|

60 |

45 |

75 |

56 |

|

95 |

70 |

125 |

90 |

155 |

115 |

175 |

130 |

|

225 |

|

160 |

|

|

5/8 |

67 |

50 |

|

85 |

62 |

105 |

78 |

|

135 |

100 |

170 |

125 |

215 |

160 |

240 |

175 |

|

300 |

|

225 |

|

|

3/4 |

120 |

87 |

|

150 |

110 |

190 |

140 |

|

240 |

175 |

300 |

225 |

375 |

280 |

425 |

310 |

|

550 |

|

400 |

|

|

7/8 |

190 |

140 |

|

240 |

175 |

190 |

140 |

|

240 |

175 |

490 |

360 |

625 |

450 |

700 |

500 |

|

875 |

|

650 |

|

|

1 |

290 |

210 |

|

360 |

270 |

290 |

210 |

|

360 |

270 |

725 |

540 |

925 |

675 |

1050 |

750 |

|

1300 |

|

975 |

|

|

1-1/8 |

400 |

300 |

|

510 |

375 |

400 |

300 |

|

510 |

375 |

900 |

675 |

1150 |

850 |

1450 |

1075 |

|

1850 |

|

1350 |

|

|

1-1/4 |

570 |

425 |

|

725 |

530 |

570 |

425 |

|

725 |

530 |

1300 |

950 |

1650 |

1200 |

2050 |

1500 |

|

2600 |

|

1950 |

|

|

1-3/8 |

750 |

550 |

|

950 |

700 |

750 |

550 |

|

950 |

700 |

1700 |

1250 |

2150 |

1550 |

2700 |

2000 |

|

3400 |

|

2550 |

|

|

1-1/2 |

1000 |

725 |

|

1250 |

925 |

990 |

725 |

|

1250 |

930 |

2250 |

1650 |

2850 |

2100 |

3600 |

2650 |

|

4550 |

|

3350 |

|

|

|

DO NOT use these values if a different torque value |

Fasteners should be replaced with the same or |

|

|

||||||||||||||||||

|

or tightening procedure is given for a specific |

|

higher grade. If higher grade fasteners are used, |

|

|

|||||||||||||||||

|

application. Torque values listed are for general use |

these should only be tightened to the strength of the |

||||||||||||||||||||

|

only. Check tightness of fasteners periodically. |

|

original. |

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Shear bolts are designed to fail under predetermined |

Make sure fasteners threads are clean and that you |

||||||||||||||||||||

|

loads. Always replace shear bolts with identical grade. |

properly start thread engagement. This will prevent |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

them from failing when tightening. |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

Tighten plastic insert or crimped steel-type lock nuts |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

to approximately 50 percent of the dry torque shown |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

in the chart, applied to the nut, not to the bolt head. |

|||||||||||

|

a ªLubricatedº means coated with a lubricant such as engine oil, or |

Tighten toothed or serrated-type lock nuts to the full |

||||||||||||||||||||

|

fasteners with phosphate and oil coatings. ªDryº means plain or zinc |

torque value. |

|

|

|

|

|

|

|

|

|

|||||||||||

|

plated without any lubrication. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

b Grade 2 applies for hex cap screws (not hex bolts) up to 152 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

(6-in.) long. Grade 1 applies for hex cap screws over 152 mm (6-in.) |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

long, and for all other types of bolts and screws of any length. |

|

|

|

|

|

|

|

DX,TORQ1 |

-19-20JUL94 |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

CTM3274 (01JUL99) |

|

|

|

|

|

01-10 |

|

|

|

|

|

Saran Liter Engines |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

060799 |

|

PN=27

Group 02

Engine mounting

ENGINE REPAIR STAND

To facilitate engine repair, the D01003AA repair stand can be used in conjunction with D05225ST adapter for 300 series engines.

R26420N -UN-22MAY95

D01003AA repair stand

D05225ST adapter

CD,3274,G02,1 -19-24FEB92

02

1

D05225ST -UN-22MAY95

CTM3274 (01JUL99) |

02-1 |

Saran Liter Engines |

|

|

060799 |

PN=28

Engine mounting/Engine lifting procedure

SAFETY PRECAUTIONS

This repair stand should be used only by qualified service technicians familiar with this equipment.

To maintain shear strength specifications, alloy steel SAE Grade 8 or higher cap screws must be used to mount adapters or engine.

02 For full thread engagement, be certain that tapped

2holes in adapters and engine blocks are clean and not damaged. A thread length engagement equal to 1-1/2 screw diameters minimum is required to maintain strength requirements.

To avoid structural damage or personal injury, do not exceed the maximum weight capacity. When engine weight is more than 450 kg (992 lb), it is recommended to use additional support. Approximate engine weights are listed below:

Ð3 cyl. engines = 330 kg (728 lb)

Ð4 cyl. engines = 450 kg (992 lb)

Ð6 cyl. engines = 580 kg (1279 lb)

To prevent possible personal injury due to engine slippage, recheck to make sure engine is solidly mounted before releasing support from engine lifting device.

Never permit any part of the body to be positioned under a load being lifted or suspended. Accidental slippage may result in personal injury.

CD,3274,G02,2 -19-24FEB92

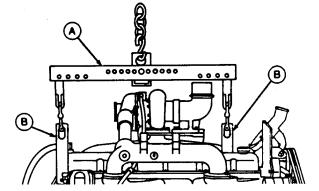

ENGINE LIFTING PROCEDURE

Attach JDG23 engine lifting sling (A), or other suitable sling, to JD-244 engine lifting eyes (B) and hoist the engine using a lifting device.

NOTE: Use of an engine lifting sling (as shown) is the preferred method for lifting engines. However, if a sling is not on hand, engine can be lifted by chain(s) attached to lifting eyes and lifting device.

IMPORTANT: If a turbocharged engine with low-profile design is to be lifted, remove the turbocharger before attaching engine to repair stand.

RG4738 -UN-18MAY90

RG4738 -UN-18MAY90

CD,3274,G02,3 -19-01FEB94

CTM3274 (01JUL99) |

02-2 |

Saran Liter Engines |

|

|

060799 |

PN=29

Engine mounting/Disconnect turbocharger oil line

CLEAN ENGINE

1.Cap or plug all openings on engine. If electrical components (starting motor, alternator, etc...) are not removed prior to cleaning, cover with plastic and tape securely to prevent moisture from entering.

2.Steam-clean engine thoroughly.

IMPORTANT: Never steam-clean or pour cold water on an injection pump while it is still warm. To do so may cause seizure of pump parts.

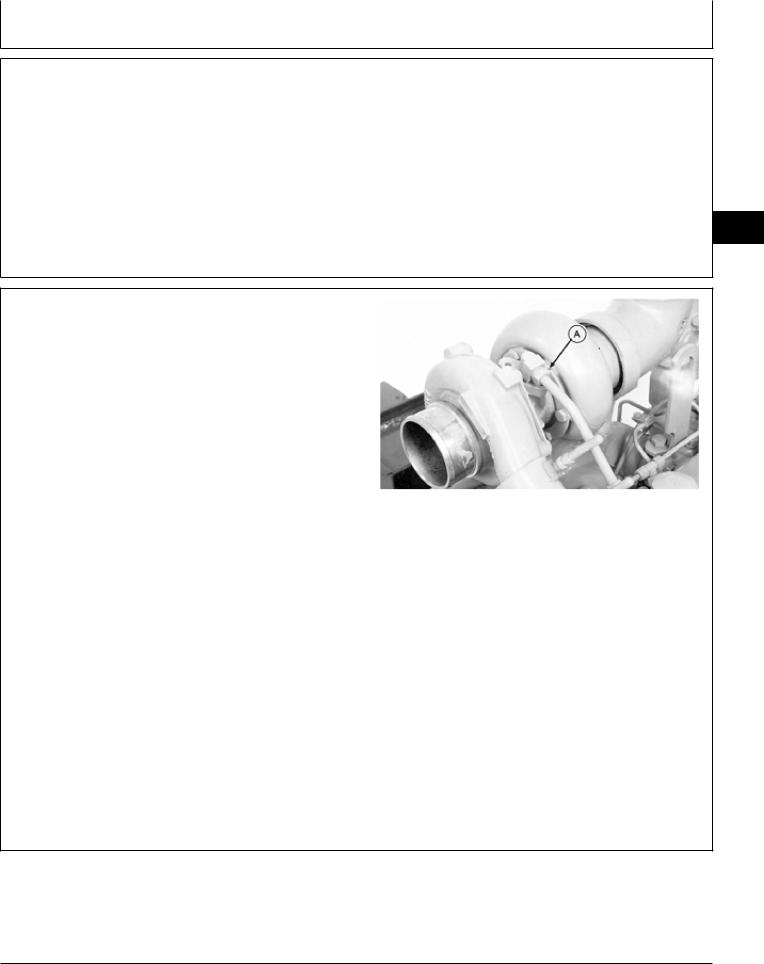

DISCONNECT TURBOCHARGER OIL INLET

LINE

Drain all engine oil and coolant, if not previously done.

IMPORTANT: When servicing turbocharged engines on a rollover stand, disconnect turbo oil inlet line from turbocharger (A) or oil filter housing before rolling engine over. Failure to do so may cause a hydraulic lock upon starting engine. Hydraulic lock may cause severe engine damage.

Hydraulic lock occurs when trapped oil in the oil filter housing drains through the turbocharger, the exhaust and intake manifolds, and then into the cylinder head. After starting the engine, the trapped oil in the manifold and head is released into the cylinders filling them with oil causing hydraulic lock and severe engine damage.

02

3

CD,3274,G02,4 -19-24FEB92

RG5642 -UN-02APR90

CD,3274,G02,5 -19-24FEB92

CTM3274 (01JUL99) |

02-3 |

Saran Liter Engines |

|

|

060799 |

PN=30

Loading...

Loading...