INSTALLATION

INSTRUCTIONS

517-278-1226 • tech@jksmfg.com • www.jksmfg.com

491 W. Gareld Avenue, Coldwater, MI 49036

Product: Front Trackbar Brace

Part Number: JKSOGS161

Applications: Jeep Wrangler JK, 2007+ (front)

Welcome

CONGRATULATIONS on purchasing a new Front Trackbar

Brace from JKS Manufacturing. We are committed to

providing you with the best products available and your

satisfaction is our rst priority.

PLEASE READ these Installation Instructions carefully,

and save them for future reference, as they contain important installation and maintenance information.

Important

INSTALLATION REQUIRES WELDING by a qualied

welder or metal fabricator.

JKS ADJUSTABLE TRACKBAR IS REQUIRED if existing track bar interferes with steering damper.

Tools Required

Hydraulic Floor Jack & Jack Stands

Metric/Standard Socket Wrench Set

Black Felt Tip Marker (or equivalent)

Torque Wrench

Die Grinder with Sanding Wheel

(or equivalent tool for removing paint)

Welding Equipment

Weldable Corrosion Resistant Coating,

3M® PN 05917 (or equivalent)

Satin Black Spray Paint

Anti-Seize Lubricant *

Factory Service Manual (recommended)

* Asterisk denotes tools that are not required for some applica-

tions. Thoroughly read instructions rst to determine which tools

will be required for your application.

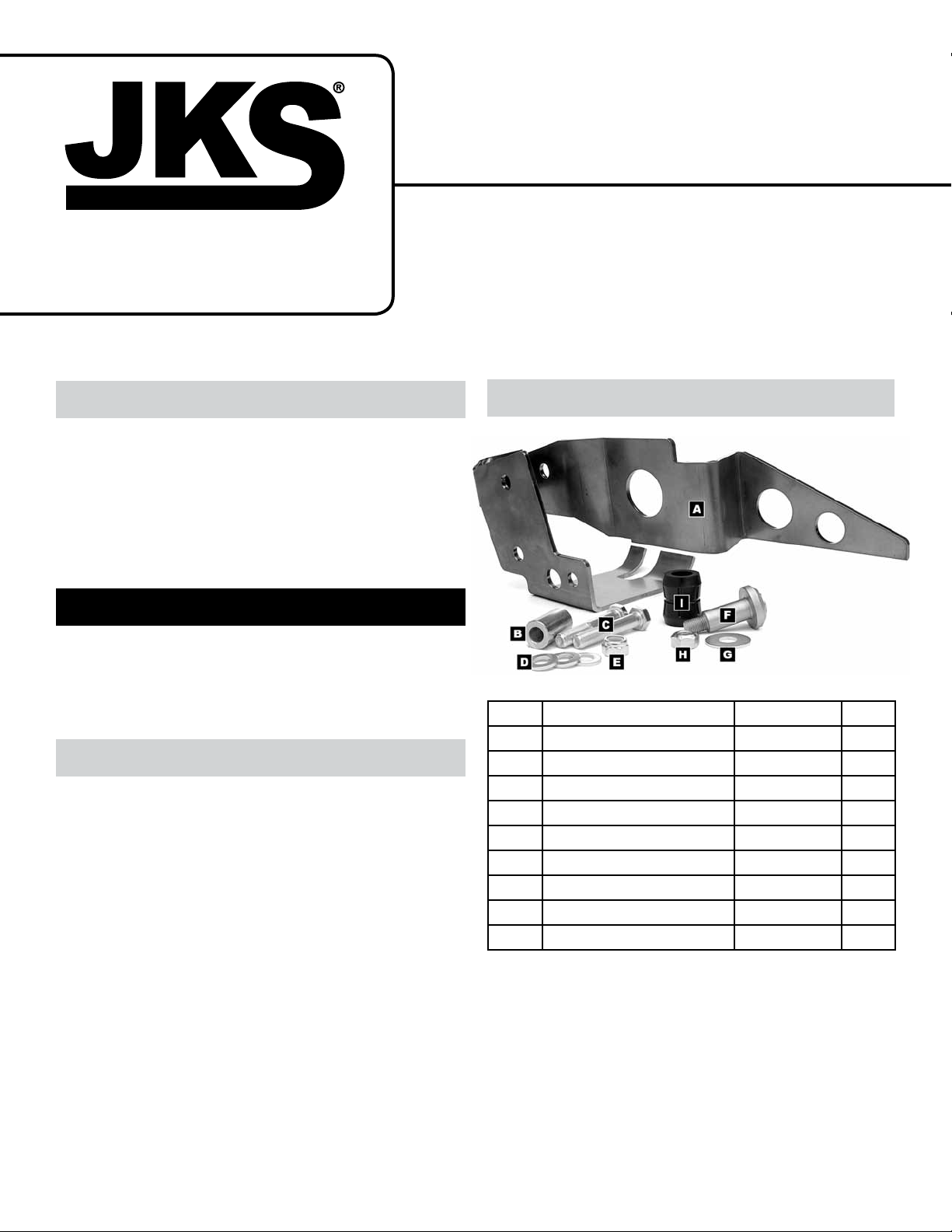

Parts

Description Part# QTY

A

Front Trackbar Brace 03030 1

B

Steel Sleeve 123 1

C

M14 x 80mm Bolt 1111329 0 2

D

9/16 SAE Washer W96S 3

E

M14 Nylock Nut 11129 042 1

F

Stabilizer Stud 103031 1

G

7/16” Fender Washer 33010 1

H

7/16” Locking Nut 37306 1

I

5/8” Poly Bushing 2611 1

JKSOGS161JKS Front Trackbar Brace Installation

Page 1

Installation

1. REMOVE FRONT TRACK BAR

Raise and support vehicle chassis with jack

stands positioned behind the front lower suspension arm brackets.

Raise and support front axle housing with a hy-

draulic jack just enough to relieve any tension from

the track bar mounting bolts.

Remove front track bar mounting hardware from

axle and chassis brackets per the factory service manual instructions for your vehicle. Retain

original hardware and remove front track bar from

vehicle.

Remove steering damper mounting hardware from

the axle housing and tie rod. Remove steering

damper from vehicle and retain original hardware.

Prime entire surface of Trackbar Brace with 3M®

Weldable Corrosion Resistant Coating (or equivalent – must be weldable).

and temporarily tighten to hold the brace securely

to the factory bracket.

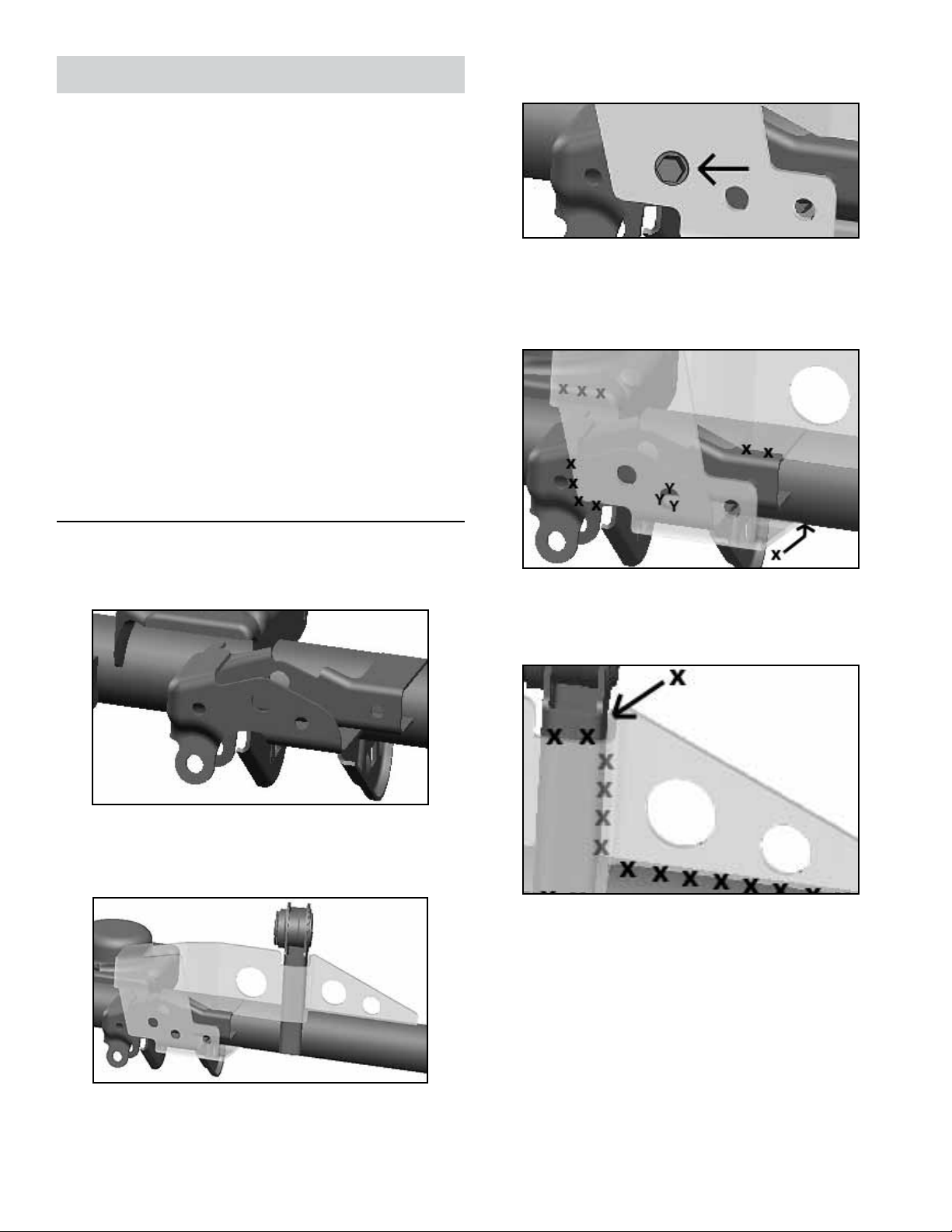

To prepare for welding, clearly mark the weld

locations directly on the axle housing as indicated in the following two illustrations. H I N T: A

felt tip marker is useful for marking locations to be

welded.

2. PREPARE AXLE FOR WELDING

To ensure a proper t, clean any dirt, debris or

grease from surface of factory track bar bracket.

Slide Trackbar Brace over factory track bar

bracket as illustrated. H I N T: Trackbar Brace is de-

signed to provide a snug t and may require some

persuasion to maneuver into position.

H I N T: Be sure to include area on lower spring mount

where it makes contact with Trackbar Brace. Also include

back side of axle tube where Trackbar Brace wraps under-

neath.

HINT: Include area on vertical upper control arm mount.

Remove Trackbar Brace and thoroughly clean lo-

cations on axle housing marked by an “X” or a “Y”.

H I N T: A die grinder with sanding wheel or similar

tool is useful for removing paint from axle housing.

IMPORTANT: The Trackbar Brace must be welded to

bare metal. Remove any paint, rust or other contaminants before welding.

With Trackbar Brace in position, insert one M14

x 80mm Bolt (C) into original mounting hole as

illustrated below. Secure bolt with original ag nut

2 Page

JKSOGS161

JKS Front Trackbar Brace Installation

Loading...

Loading...