JKS OGS126 User Manual

INSTALLATION

INSTRUCTIONS

517-278-1226 • tech@jksmfg.com • www.jksmfg.com

491 W. Gareld Avenue, Coldwater, MI 49036

Product: Adjustable Trackbar

Part Number: JKSOGS125 - JKSOGS126

Welcome

CONGRATULATIONS on purchasing a new Adjustable Trackbar from JKS Manufacturing. We are committed to providing you with the best products avail-

able and your satisfaction is our rst priority.

PLEASE READ these Installation Instructions carefully, and save them for future reference, as they contain

important installation and maintenance information.

Important

NOT COMPATIBLE WITH right hand drive

vehicles.

CHECK TORQUE SPECIFICATIONS regularly.

Tools Required

Metric/Standard Socket Wrench Set

Torque Wrench

Tie Rod End Remover *

Tape Measure

1-1/2” Open-End Wrench

9/16” Drill Bit

Flat Metal File *

Heavy Duty Ratchet Strap *

Anti-Seize Lubricant

Grease Gun with Zerk Fitting Coupler

Wheel Bearing Grease

* Asterisk denotes tools that are not required for some applica-

tions. Thoroughly read instructions rst to determine which tools

will be required for your application.

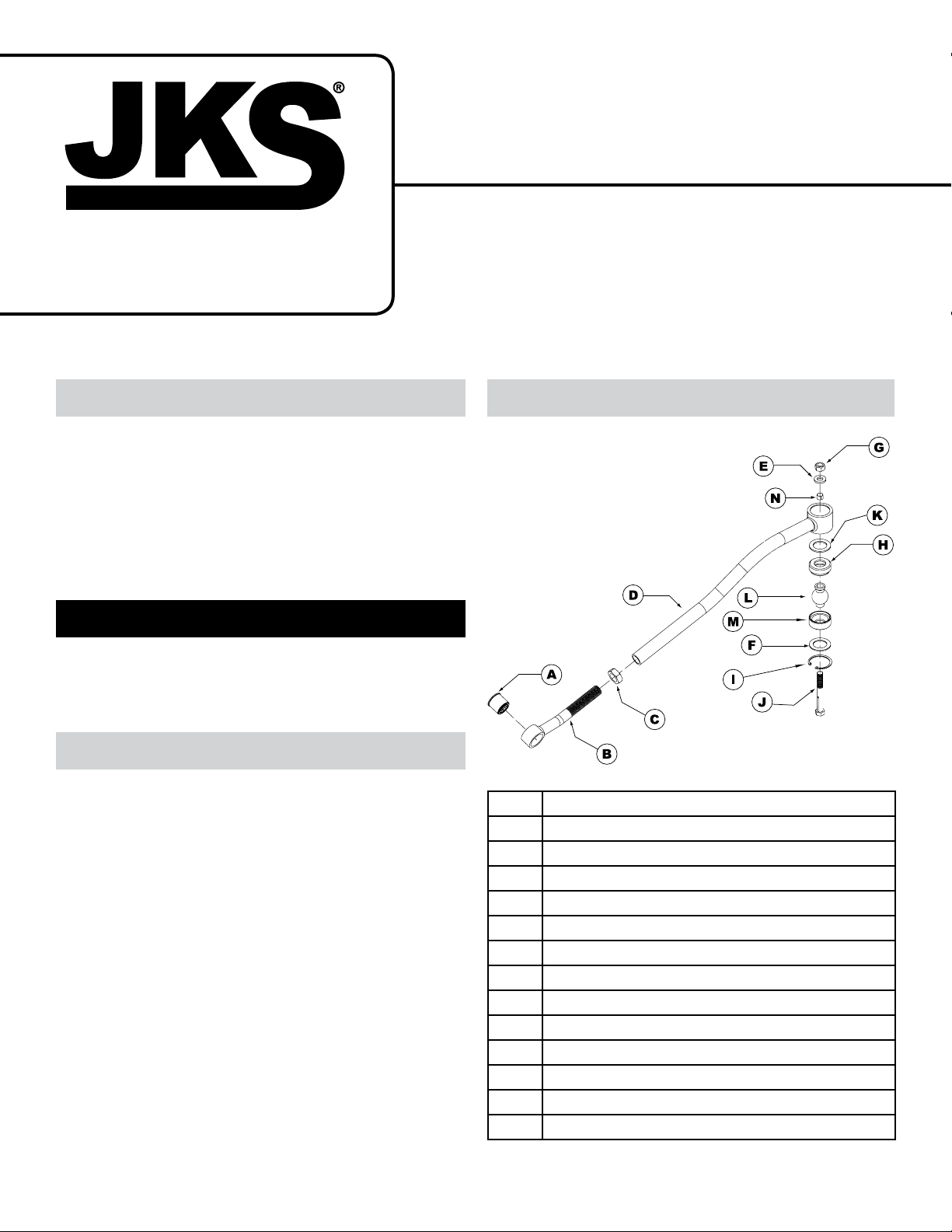

Parts

A

OE Rubber Bushing

B

Male Threaded (Axle) End

C

1” NF Jam Nut

D

Female Threaded (Chassis) End

E

9/16” SAE Flat Washer

F

Preload Washer

G

9/16” NF GR8 Ovalok Nut

H

Polyurethane Bushing

I

Snap Ring

J

9/16” x 4-1/2” GR8 Greaseable Bolt

K

Preload Washer

L

2.5” Johnny Joint Ball

M

Polyurethane Bushing

N

Tapered Split Cone

JKSOGS125 - J KS OGS126JKS Adjustable Trackbar Installation

Page 1

Installation

1. REMOVE ORIGINAL EQUIPMENT

(OE) FRONT TRACK BAR

Remove front track bar and mounting hardware

per the factory service manual instructions for

your vehicle. HI N T: If difcult to remove, use

universal puller tool to separate OE track bar ball

stud from chassis rail bracket.

2. MOUNT ADJUSTABLE TRACKBAR TO

CHASSIS BRACKET

Using a 9/16” drill bit, enlarge the tapered mount-

ing hole in the chassis rail bracket located on the

driver-side of the vehicle.

Locate Chassis End (D) of Adjustable Trackbar

and insert the 9/16” x 4-1/2” Greaseable Bolt (J)

through the Johnny Joint spherical bushing (L).

Place the Tapered Split Cone (N) over the bolt

threads with the narrow end facing away from the

trackbar.

Apply anti-seize lubricant to bolt threads.

Mount chassis end of Adjustable Trackbar to chas-

sis rail bracket by inserting the

9/16” x 4-1/2” Greaseable Bolt (J) upwards into en-

larged hole. Secure with 9/16” Flat Washer – only

if required – (E) and 9/16” Ovalok Nut (G).

IMPORTANT: Flat Washers are supplied for use with

1984-01 Cherokee XJ and 1993-1998 Grand Cherokee

ZJ models ONLY. Do NOT use Flat Washer on Wrangler TJ models.

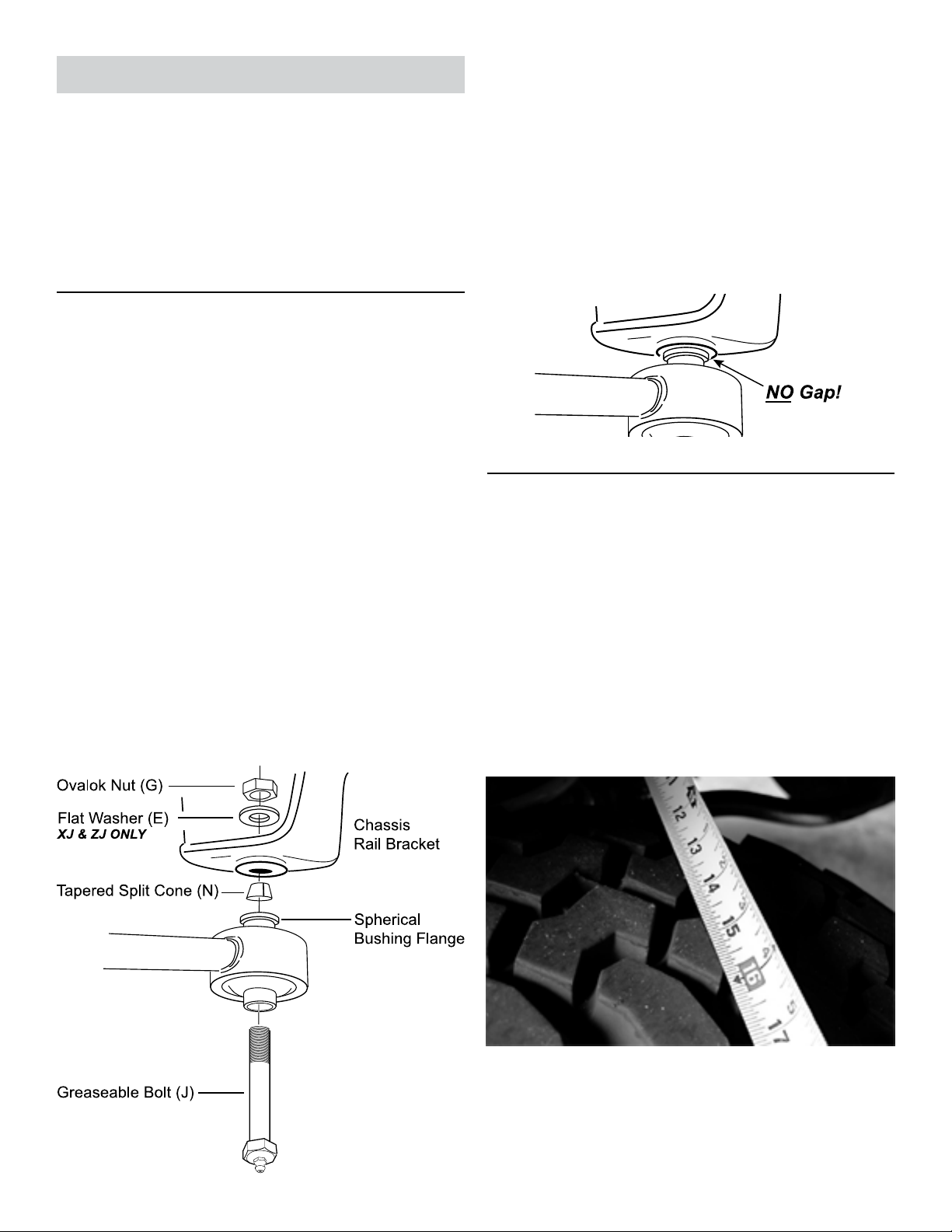

HI N T: Tapered Split Cone (N) should be located between

ange of spherical bushing (L) and mounting surface of

chassis rail bracket, with the narrow end of tapered cone

facing up towards chassis.

Tighten 9/16” x 4-1/2” Greaseable Bolt (J) to 110

ft-lb. using a torque wrench.

IMPORTANT: The upper ange of spherical bushing

must t ush against the chassis rail bracket. If any

gap exists, it will be necessary to le the bottom edge

of the Tapered Split Cone until completely ush with

bottom of chassis rail bracket.

3. CENTER FRONT AXLE HOUSING

The front axle housing must be in perfect lateral alignment with vehicle chassis before Adjustable Trackbar

installation can be completed.

Before you center the axle housing, make sure the

vehicle is at normal ride height, on level ground,

with the suspension supporting the full vehicle

weight.

Determine if the axle housing is centered by mea-

suring the distance between the tire and chassis,

using the exact same points on each side of the

vehicle to ensure accuracy.

2 Page

HI N T: For example, measure from the edge of a tire tread

lug to the outboard side of the chassis, then repeat the

measurement on the other side of vehicle using the exact

same points.

JKSOGS125 - J KS OGS126

JKS Adjustable Trackbar Installation

Loading...

Loading...