JKS BSE251 User Manual

INSTALLATION

INSTRUCTIONS

517-278-1226 • tech@jksmfg.com • www.jksmfg.com

491 W. Gareld Avenue, Coldwater, MI 49036

Product: Hydraulic Bump Shocks

Part Number: JKSBSE251

Applications: Wrangler JK, 2007+ (rear only)

Welcome

CONGRATULATIONS on purchasing a set of new Hydraulic BumpShocks from JKS Manufacturing! We are committed to providing you with the best products available and

your satisfaction is our rst priority.

PLEASE READ these Installation Instructions carefully,

and save them for future reference, as they contain impor-

tant installation and maintenance information.

Important

INSTALLATION of this product is not reversible and

should only be performed by an experienced mechanic or fabricator.

CHASSIS MODIFICATIONS are required to install this

product. Do not attempt installation if you are inexperienced or uncomfortable with cutting and welding on

your vehicle’s frame.

THESE INSTRUCTIONS provide an overview of the installation process only, and are in no way a substitute

for the experience one needs to do the job properly.

DO NOT EXCEED maximum range of bump shock adjustment – see illustration on page 4.

Tools Required

Hydraulic Floor Jack and Jack Stands

Metric/Standard Socket Wrench Set

Spanner or Strap Wrench *

(or similar tool for tightening Bump Shock Nut)

Metal Cutting Tool (for cutting through frame)

Grinding/Sanding Tool

(for light material removal and smoothing)

Emory Cloth

(or similar abrasive for paint/plating removal)

Tape Measure

Felt Tip Marker (or similar marking tool)

Clamping Tool *

(for holding product in place during welding)

Welding Equipment

Drill with 1/8” and 3/8” Bits

Coil Spring Compressor *

Spray Lubricant (WD-40 or equivalent)

Anti-Seize Lubricant

Satin Black Spray Paint

Factory Service Manual (recommended)

* Asterisk denotes tools that are not required for some applica-

tions. Thoroughly read instructions rst to determine which tools

will be required for your application.

JKSB SE 251JKS Hydraulic Bump Shocks Installation

Page 1

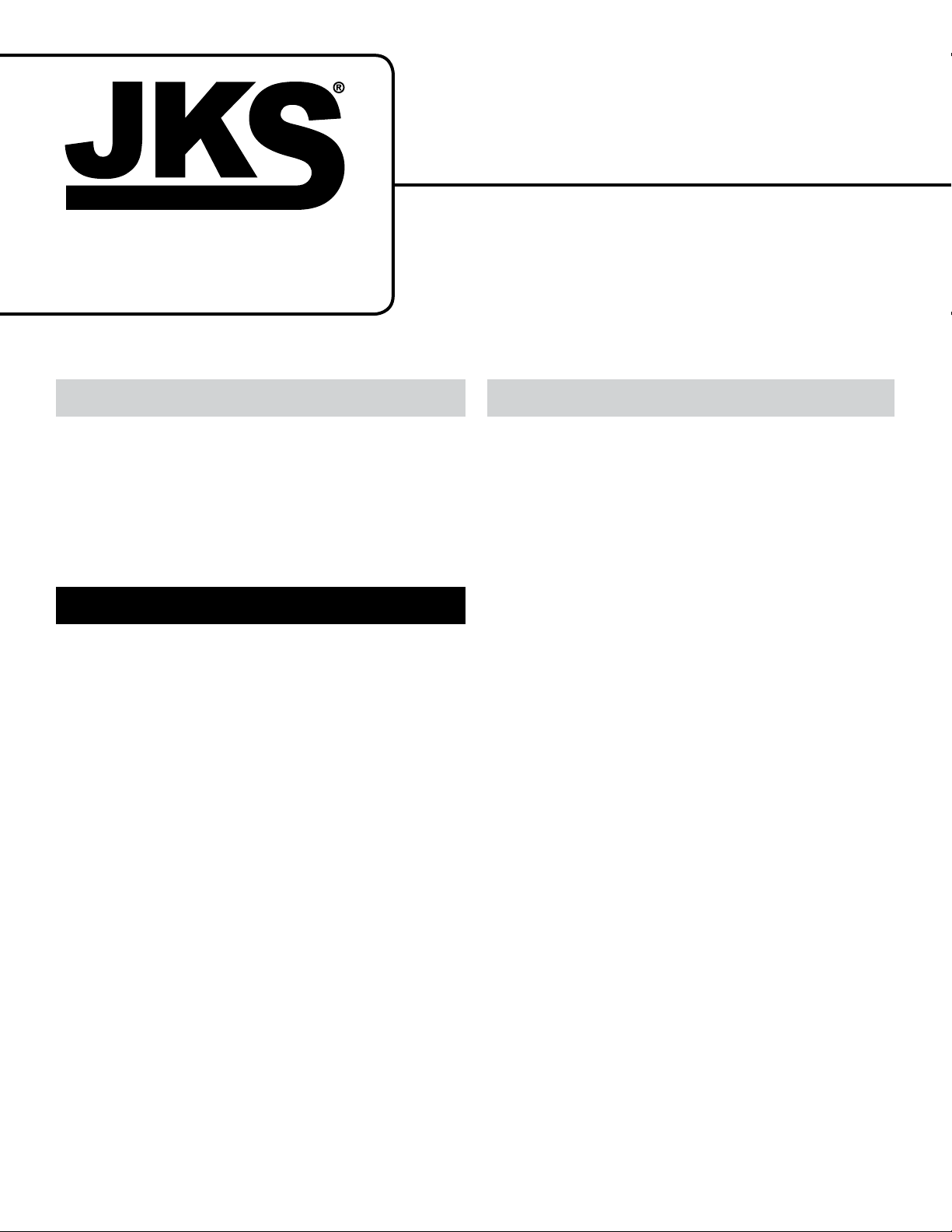

Parts

Remove the factory upper bump stop holders from

the chassis brackets. H I N T: The bump stop holder

is welded to the chassis bracket and must be cut

free.

Description Part # QTY

A

Bump Shock Assembly RFC/BS02 2

B

Bump Shock Nut RFC/SN50 2

C

Jounce Adapter 03154 2

D

Bump Shock Chassis Tube 03155 2

Installation

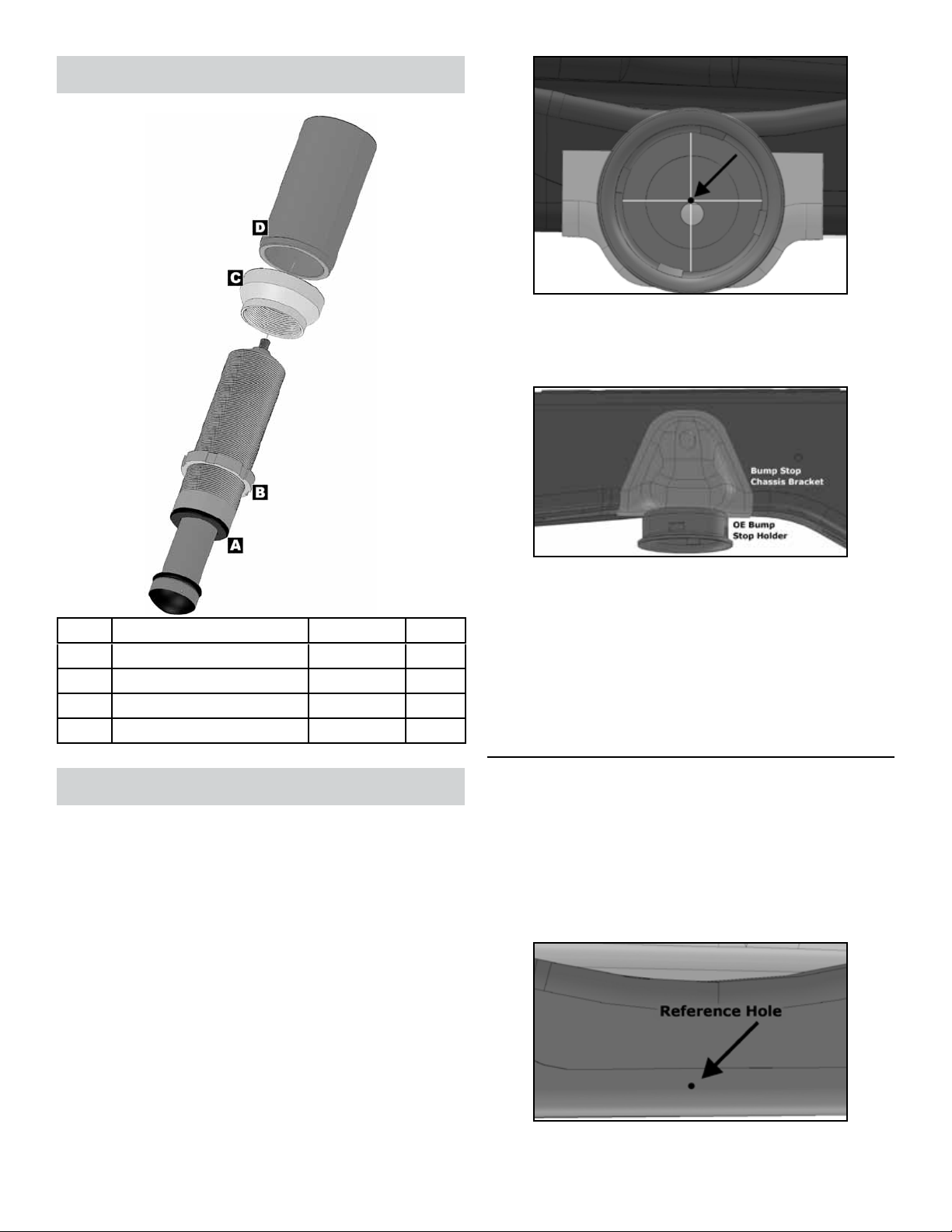

1. PREPARE VEHICLE FOR CHASSIS

MODIFICATIONS

Remove rear track bar, shocks, coil springs, and

any other components that prevent you from ac-

cessing the factory rear bump stop holders. H I N T:

You will need to access this part of the chassis

from multiple directions so make sure you have

plenty of freedom to work.

Drill a small hole exactly through the center of

the factory upper bump stop holders and into the

chassis. Make sure drill is square with chassis.

HINT: This provides a reference point to work from

during installation, as center of BumpShock must

remain at the same centerline as the factory bump

stop.

Next remove the factory bump stop brackets from

the chassis. H I N T: The bracket is welded to the

chassis along its perimeter. It must be carefully

removed without gouging or otherwise damaging

the chassis.

With the bump stop holders and brackets re-

moved, clean the chassis of any remaining weld

material until smooth.

2. FRENCH CUT CHASSIS

The chassis rails must be frenched to accept the supplied

Chassis Tubes (D). When executed correctly, the Hydraulic BumpShock will be positioned on the same centerline

as the OE bump stop holder (identied by the previously

drilled reference hole). Also, the BumpShock must contact

the center of the landing pad on the axle when the suspen-

sion is compressed.

2 Page

JKSB SE 251

JKS Hydraulic Bump Shocks Installation

Loading...

Loading...