INSTALLATION

INSTRUCTIONS

517-278-1226 • tech@jksmfg.com • www.jksmfg.com

491 W. Gareld Avenue, Coldwater, MI 49036

Product: Telescoping Trackbar™

Part Number: JKS9800

Applications: Jeep® Wrangler YJ, 1987-95

Welcome

CONGRATULATIONS on purchasing a new Telescoping

Trackbar™ from JKS Manufacturing. We are committed

to providing you with the best products available and your

satisfaction is our rst priority.

PLEASE READ these Installation Instructions carefully,

and save them for future reference, as they contain important installation and maintenance information.

Important

COMPATIBLE WITH the front of 1987-95 Wrangler YJ

models only. Do not attempt to modify or install this

product on any other application or location.

NOT COMPATIBLE WITH coil-spring conversion systems.

NEVER UNLOCK TRACKBAR when operating vehicle

on public roads.

CHECK TORQUE SPECIFICATIONS regularly.

Tools Required

Metric/Standard Socket Wrench Set

Torque Wrench

1-1/8” and 9/16” Open-End Wrenches

Drill with 1/2” Drill Bit

Grease Gun with Zerk Fitting Coupler

Wheel Bearing Grease

Welder *

* Asterisk denotes tools that are not required for some applica-

tions. Thoroughly read instructions rst to determine which tools

will be required for your application.

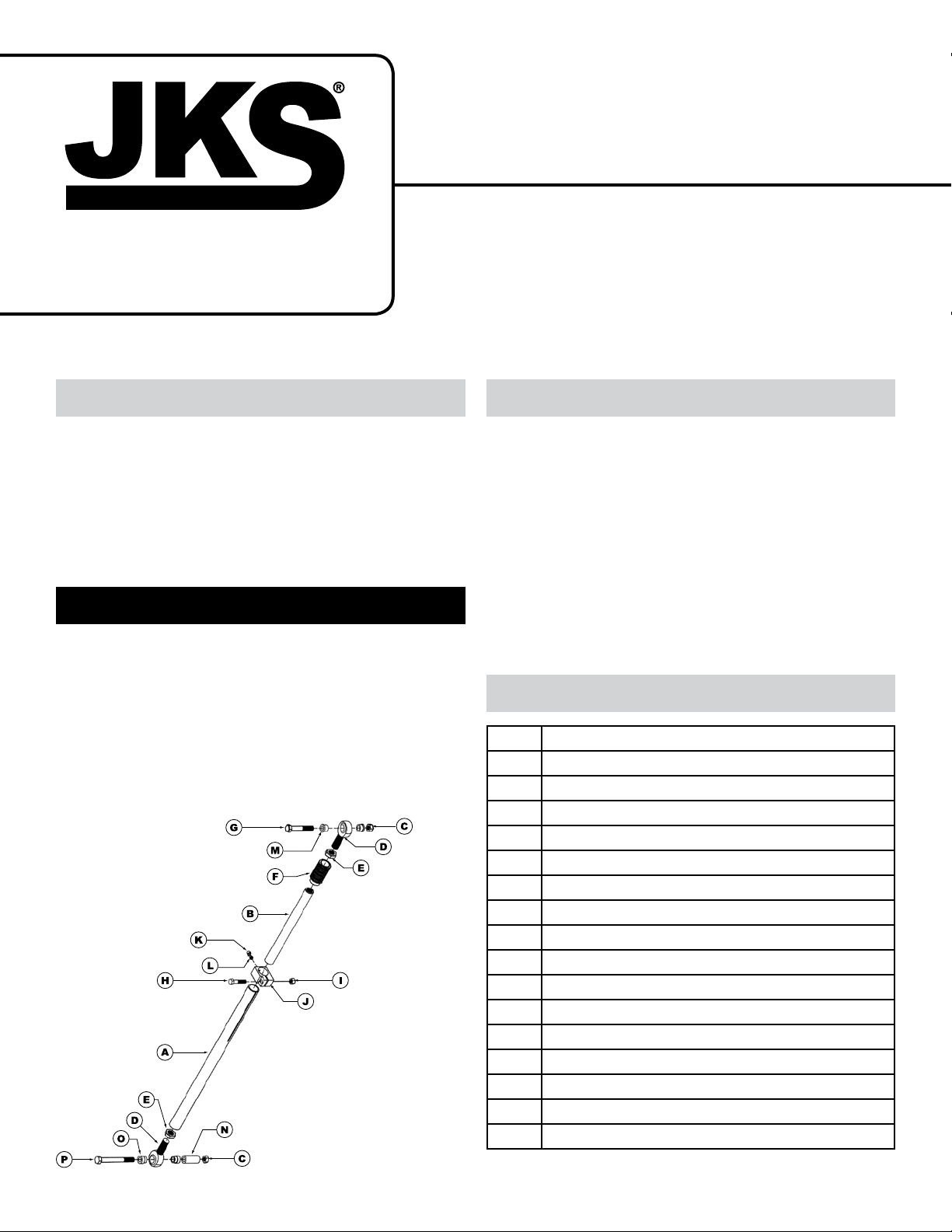

Parts

Description

A

Outer Tube (Chassis End)

B

Slip Shaft (Axle End)

C

1/2” Ovalok Nut

D

3/4” Teon Lined Rod End

E

3/4” Jam Nut

F

Polyurethane Dust Boot

G

1/2” x 3” GR8 Bolt

H

3/8” x 1-3/4” GR8 Bolt

I

3/8” Nylock Nut

J

Clamp

K

Grease Zerk Cap

L

Grease Zerk

M

1/8” Shoulder Spacer (narrow)

N

1.85” OE Bracket Spacer

O

5/16” Shoulder Spacer (wide)

P

1/2” x 4-1/2” GR8 Bolt

JKS9800JKSTelescoping Trackbar Installation

Page 1

Installation

1. REMOVE ORIGINAL EQUIPMENT (OE)

FRONT TRACK BAR

Remove front track bar and mounting hardware –

including U-bracket from chassis – according to the

factory service manual instructions for your vehicle.

Also remove any aftermarket track bar relocation

or riser bracket from axle, if installed. Such parts

are commonly supplied with suspension lift kits.

IMPORTANT: It will be necessary for the OE pitman

arm to be installed on the steering box if aftermarket

relocation/riser bracket is removed from the axle.

However, if special circumstances require the relocation/riser bracket to be retained, it will also be necessary to retain the drop pitman arm.

2. MOUNT TELESCOPING TRACKBAR TO

CHASSIS BRACKET

Insert 1.85” Spacer (N) into chassis rail bracket

where the OE track bar originally mounted. HINT:

The 1.85” Spacer (marked with an “X”) prevents

the OE bracket from collapsing.

Insert a 5/16” (wide) Shoulder Spacer (O) into

each side of the Rod End (D) at the Chassis End

(A) of Telescoping Trackbar. HI NT: The Shoulder

Spacers must “sandwich” the Rod End to allow full

exibility of the joint when installed.

Insert a 1/8” (narrow) Shoulder Spacer (M) into

each side of Rod End (D) at the Axle End (B) of

Telescoping Trackbar. HI N T: Shoulder Spacers

must “sandwich” the Rod End to allow full exibility

of the joint when installed.

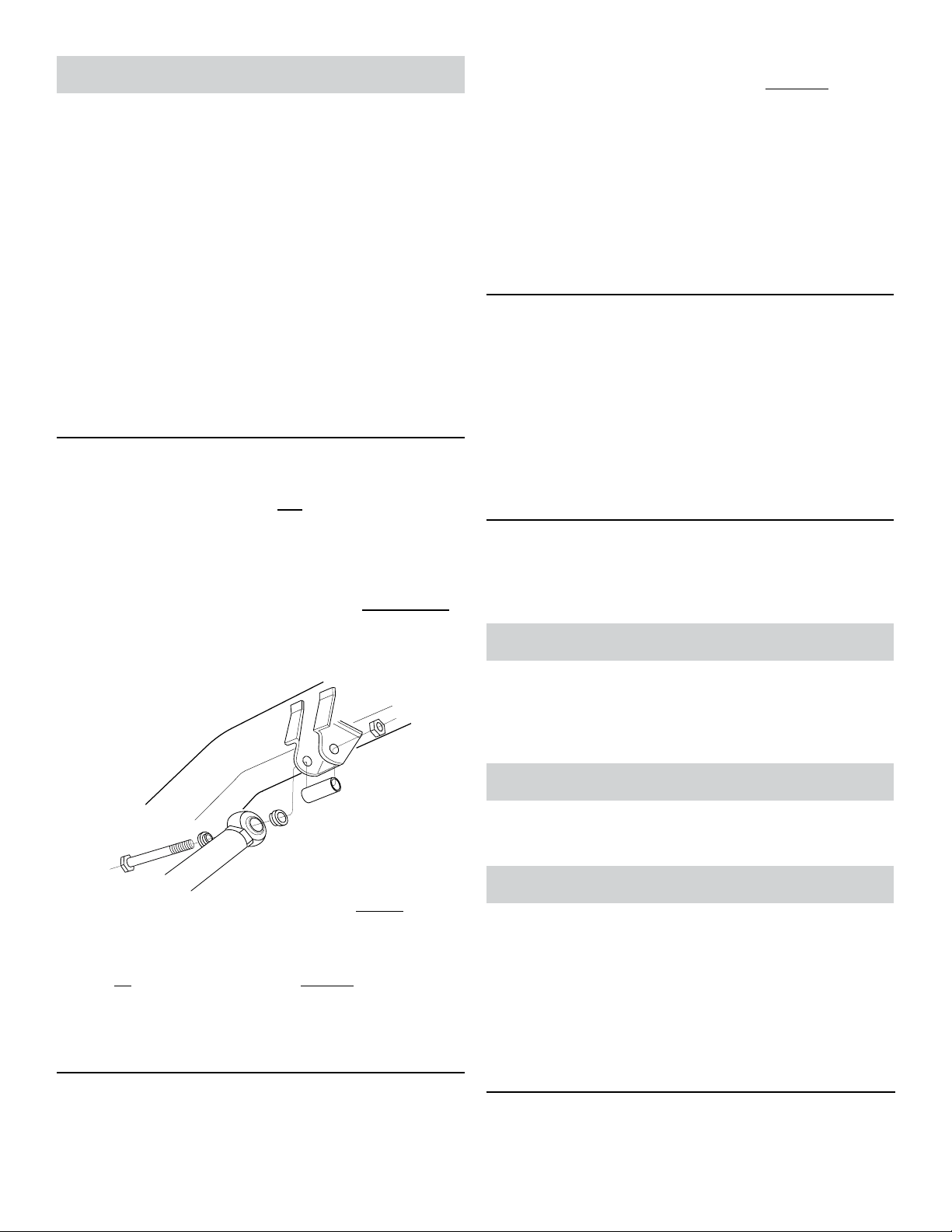

Mount Axle End (A) of trackbar to axle bracket and

secure with a 1/2” x 3” Bolt (G) and 1/2” Ovalok

Nut (C).

Tighten 1/2” x 3” Bolt (G) to 75 ft-lb. using a torque

wrench.

4. TIGHTEN TELESCOPING TRACKBAR

With the vehicle on a level surface, tighten the

Clamp (J) using a 9/16” wrench.

Tighten the 3/4” Jam Nuts (E) located at each end of

the trackbar, but DO NOT thread out Rod Ends (D).

IMPORTANT: Rod Ends have been properly installed

from the factory. Avoid unthreading Rod Ends prior to

installation, as this may sacrice strength

5. LUBRICATE TELESCOPING TRACKBAR

Lubricate the Grease Zerk (L) located on the

Clamp (J) of Telescoping Trackbar using common

wheel bearing grease or equivalent.

Operation

Telescoping Trackbar should remain in the “locked”

position when vehicle is operated on public roads. Once

off-road, the trackbar can be “unlocked” by loosening the

Clamp (J) using a pair of 9/16” wrenches.

Mount Chassis End (A) of trackbar behind the

chassis rail bracket and secure with the 1/2” x

4-1/2” Bolt (P) and 1/2” Ovalok Nut (C). HINT:

When installed correctly, Grease Zerk (L) will point

up and JKS decal will face forward.

Tighten 1/2” x 4-1/2” Bolt (P) to 75 ft-lb. using a

torque wrench.

3. MOUNT TELESCOPING TRACKBAR TO

AXLE BRACKET

Using a 1/2” drill bit, enlarge the hole on the axle

where the OE track bar originally mounted.

2 Page

Troubleshooting

If slippage occurs on Chassis End of Telescoping Trackbar,

weld the 1.85” OE Bracket Spacer (N) in place.

Maintenance

Telescoping Trackbar is factory lubricated, but should be

greased regularly as part of vehicle maintenance schedule.

Regular cleaning with pressurized water is recommended

to maximize ease of operation and reliability. Always lubricate afterwards to evacuate any moisture.

Check torque specications regularly.

©2013 JKS Manufacturing, Inc & Aftermarketing, LLC

Revision Date 10/31/2013

JKS9800

JKSTelescoping Trackbar Installation

Loading...

Loading...