JKS 9604 User Manual

INSTALLATION

INSTRUCTIONS

517-278-1226 • tech@jksmfg.com • www.jksmfg.com

491 W. Gareld Avenue, Coldwater, MI 49036

Product: Bar Pin Eliminators™

Part Number: JKS9604

Welcome

CONGRATULATIONS on purchasing new Bar Pin

Eliminators from JKS Manufacturing. We are committed to providing you with the best products available

and your satisfaction is our rst priority.

PLEASE READ these Installation Instructions carefully, and save them for future reference, as they contain

important installation and maintenance information.

Important

NOT COMPATIBLE WITH Old Man Emu™ shock

absorbers.

INSTALLATION OF BAR PIN ELIMINATORS effectively reduces the static length of shock absorber

by 0.40”.

Tools Required

Metric/Standard Socket Wrench Set

6mm or 1/4” Allen Head Socket with Long Extension

Torque Wrench

Wheel Bearing Grease

Bench Vice or C-Clamp

Hammer and Punch *

Sanding or Grinding Wheel *

Factory Service Manual (recommended)

* Asterisk denotes tools that are not required for some applica-

tions. Thoroughly read instructions rst to determine which tools

will be required for your application.

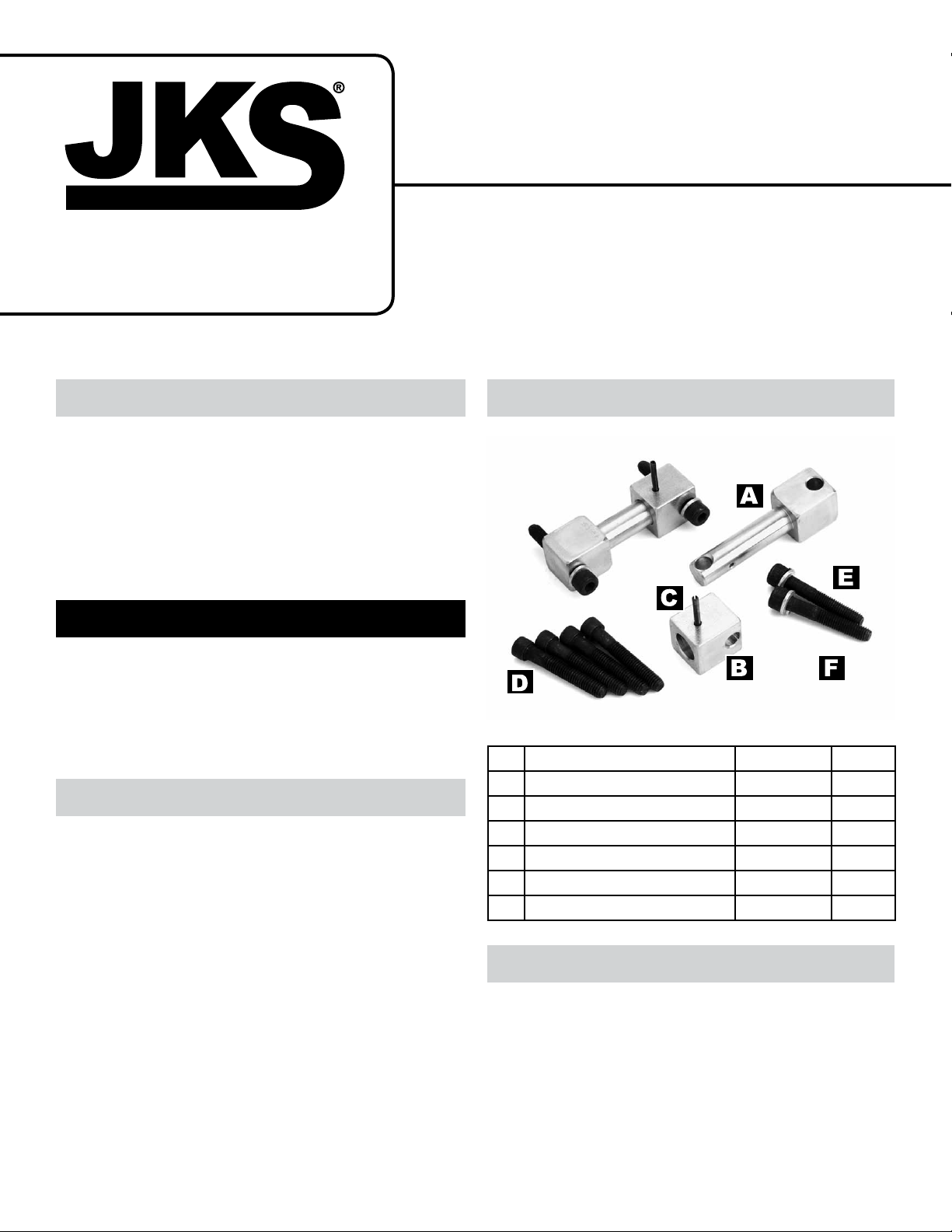

Parts

Description Part # QTY

A

Cross Pin / Block Combo 03075 2

B

Mounting Block 03074 2

C

1/8” Roll Pin 64083 2

D

M8 x 50mm Cap Bolt 39593 4

E

5/16” x 2” Cap Bolt 23261 4

F

Split Washer 33620 4

Installation

1. REMOVE SHOCK ABSORBERS

Remove the rear shock absorbers per factory ser-

vice manual instructions for your vehicle.

Remove the factory bar pin from the upper shock

absorber bushing. H I N T: A hammer and punch

may be useful for removing bar pin.

JKS 9604JKS Bar Pin Eliminator Installation

Page 1

Inspect shock bushings for wear and deterioration.

If new bushings are needed, replace with standard

5/8” ID hourglass type bushings before installing

Bar Pin Eliminators.

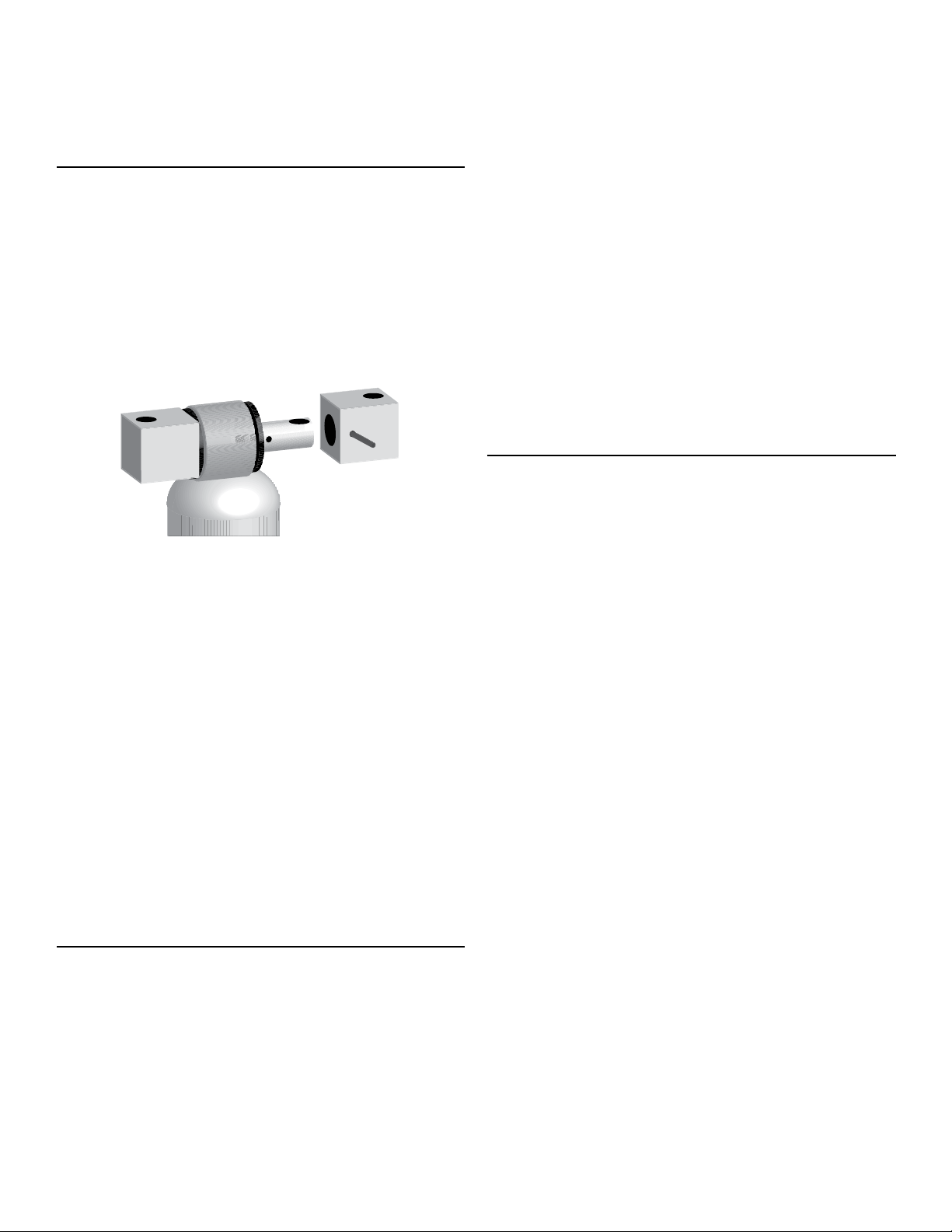

2. MOUNT BAR PIN ELIMINATOR TO

SHOCK ABSORBER

Apply a thin coating of wheel bearing grease to

the Cross Pin (A).

Insert Cross Pin (A) through upper bushing of

shock absorber.

Slide remaining Mounting Block (B) onto opposite

end of Cross Pin (A), making sure bolt and roll pin

holes are correctly positioned.

Determine whether rear upper shock mounting

holes in chassis require metric or standard bolts.

HINT: Depending on the vehicle, the rear shocks

mount to the chassis with either metric or standard

bolts. Both types of bolts are supplied with the Bar

Pin Eliminators.

Place a Split Washer (F) on each of the appropri-

ate Cap Bolts (D or E).

Position Bar Pin Eliminator on mounting surface of

chassis. Insert Cap Bolts through mounting blocks

and thread into original shock mounting holes.

HINT: Mounting Blocks of Bar Pin Eliminator must

lay completely at against mounting surface of

chassis bracket.

Using a torque wrench, tighten mounting bolts to

25-35 ft-lbs.

Install shock absorber to lower mount per factory

service manual instructions.

©2013 JKS Manufacturing, Inc & Aftermarketing, LLC

Revision Date 10/31/2013

IMPORTANT: This product is designed to preload

the shock absorber bushings for maximum performance and longevity. Therefore, you should

nd it necessary to compress the bushing approximately 1/16” to 1/8” before the mounting

bolts and/or roll pins can be inserted.

If you are able to install the mounting block without compressing the shock bushing, insert a SAE

5/8” at washer (not supplied) between the bushing and Mounting Block to ensure proper bushing

preload.

Squeeze Mounting Blocks together to compress

the shock absorber bushing until bolt and roll pin

holes align. HINT: A bench vice or C-clamp is useful for compressing shock absorber bushing.

Tap the 1/8” Roll Pin (C) through Mounting Block

(B) and into corresponding hole in Cross Pin (A).

3. RE-INSTALL SHOCK ABSORBERS

Clean any dirt or debris from the upper shock

mounting surface on chassis. HINT: A sanding or

grinding wheel is useful for removing any stubborn

material.

2 Page

JKS 9604

JKS Bar Pin Eliminator Installation

Loading...

Loading...