INSTALLATION

INSTRUCTIONS

517-278-1226 • tech@jksmfg.com • www.jksmfg.com

491 W. Gareld Avenue, Coldwater, MI 49036

Product: Switchblade™ Swaybar System

Part Number: JKS9100

Applications: Wrangler TJ, 1997-06 (front)

Welcome

CONGRATULATIONS on purchasing a SwitchBlade™

Swaybar System from JKS Manufacturing. We are committed to providing you with the best products available and

your satisfaction is our rst priority.

PLEASE READ these Installation Instructions carefully,

and save them for future reference, as they contain important installation and maintenance information.

WE WELCOME your feedback regarding these Installation

Instructions and appreciate any suggestions you may have

to improve this document for other users.

Important

TUBULAR FRONT CROSSMEMBER must be intact and

free of damage in order to install this product.

CHECK BUMPER COMPATIBILITY before installing. It

may be necessary to modify or replace front bumper

to ensure proper clearance for this product.

STEERING STOP ADJUSTMENTS may be necessary to

prevent interference between tires and blade arms at

full steering lock.

Tools Required

Metric/Standard Socket Wrench Set

Torque Wrench

3/8” Allen Head Socket

3/4” & 14mm Open End Wrenches

Tie Rod End Remover *

Long Philips Screwdriver

Tape Measure

Angle Measuring Tool

Soft Mallet & Block of Wood *

(for seating bushings into crossmember)

Silicone Lubricant

Blue RTV Silicone Gasket Maker

Medium Strength Threadlocker

Hammer & 3/16” Pin Punch

(for driving 1/4” Dowel Pin into Indexing Head)

Die Grinder with Sanding or Grinding Wheel *

(or equivalent tool for removing debris from

crossmember)

Metal Cutting Tool *

(such as die grinder with cutting wheel or metal cutting

saw for cutting connecting rod and to clearance front

bumper)

Bolt Cutting Tool * (such as metal band saw or

equivalent tool for cutting bumper mounting bolts)

Factory Service Manual (recommended)

* Asterisk denotes tools that are not required for some applica-

tions. Thoroughly read instructions rst to determine which tools

will be required for your application.

JKS9100JKS Switchblade Swaybar Installation

Page 1

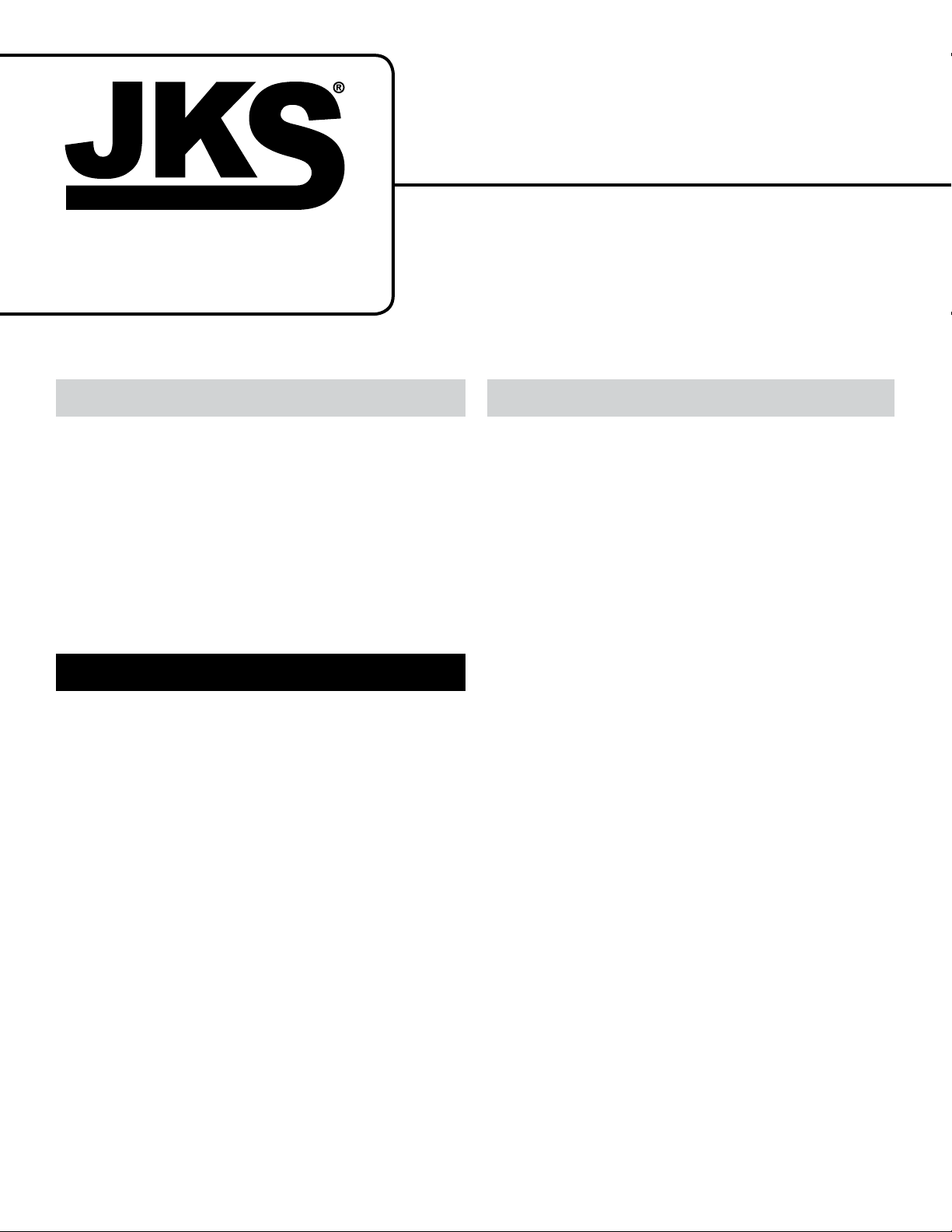

Parts

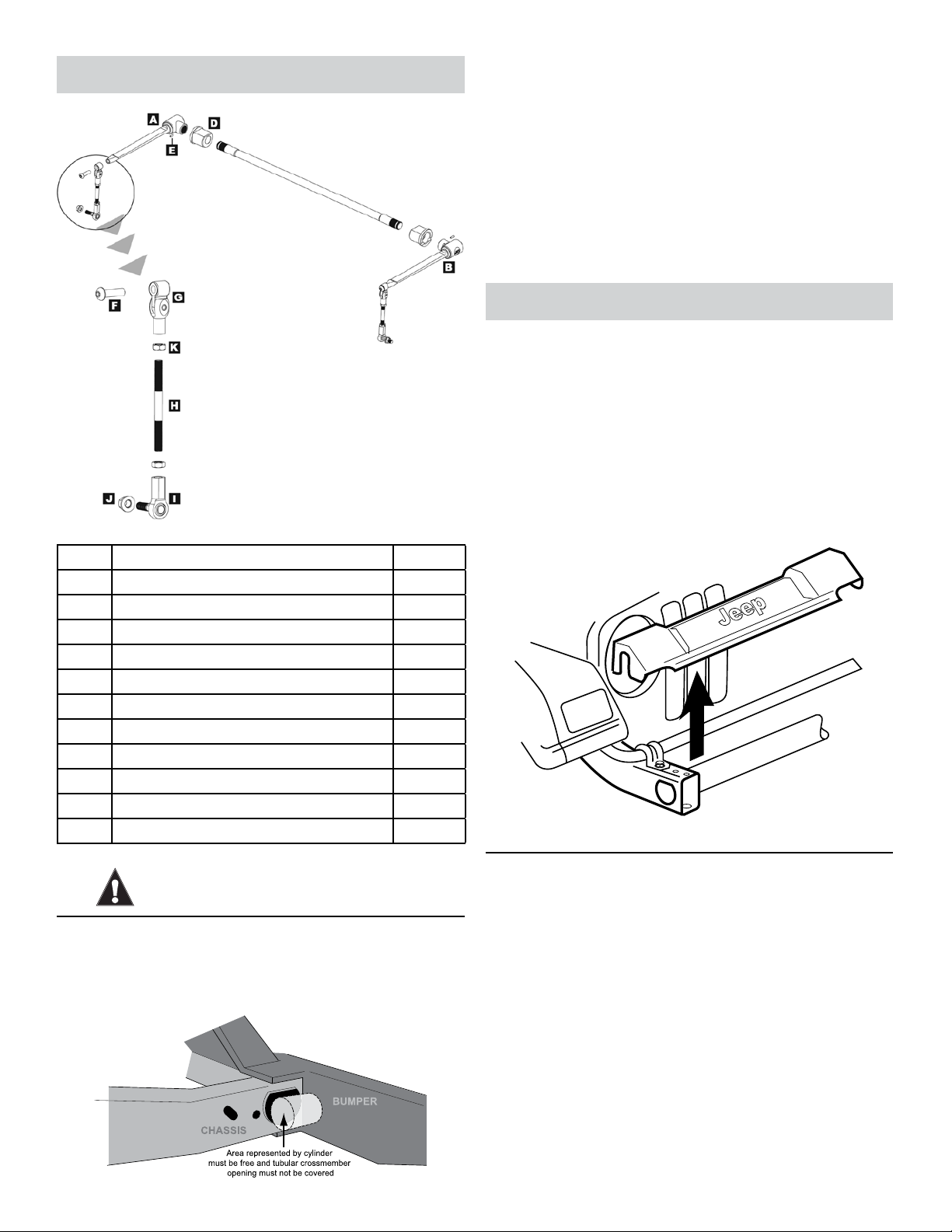

If the bumper interferes with this product, it will be

necessary to clearance the bumper or mounting sys-

tem to allow tment. Due to the number of possible

bumper congurations and other variables beyond

our control, we cannot provide instructions for this

procedure nor can we encourage it to be attempted.

If any bumper modications are necessary to install

this product, it is the sole responsibility of the installer or vehicle owner to ensure the work is performed

properly and neither structural integrity nor safety

have been compromised.

Installation

1. REMOVE FRONT BUMPER

Disconnect any auxiliary driving/fog lamps mount-

ed to front bumper, if equipped.

Remove the mounting hardware that secures the

front bumper to the chassis.

Remove the front bumper assembly from the

vehicle.

Remove the front bumper valence from the chas-

sis.

Description QTY

A

Blade Arm Assembly (Left-Hand) 1

B

Blade Arm Assembly (Right-Hand) 1

C

Torsion Bar 1

D

Torsion Bar Bushing 2

E

1/4” Dowel Pin 2

F

1/2” x 1-3/4” Socket Head Cap Screw 2

G

Gimbal Joint Assembly 2

H

Connecting Rod 2

I

Rod End 2

J

1/2” Flanged Locking Nut 2

K

1/2” Jam Nut 4

ATTENTION INSTALLER

BEFORE YOU INSTALL THIS PRODUCT, verify the

front bumper and its mounting system do not interfere

with the D-shaped tubular crossmember openings or

surrounding area, as illustrated below.

2. REMOVE FRONT SWAYBAR

Remove the mounting hardware that secures the

front swaybar links to the swaybar and axle housing. H I NT: If difcult to remove, use special factory

removal tool PN MB991113 (Miller Special Tools,

800-801-5420) or similar tie rod end removal tool.

Remove swaybar links from vehicle.

Remove swaybar mounting bolts and bushing

retainers from chassis.

2 Page

JKS9100

JKS Switchblade Swaybar Installation

Remove front swaybar from vehicle.

CROSS MEMBER

CHASSIS

RAIL

BUSHING

TORSION BAR

CROSS MEMBER

CHASSIS

RAIL

BUSHING

TORSION BAR

BUSHING

TORSION BAR

CROSS MEMBER

CHASSIS

RAIL

HI N T: To guide torsion bar through bushing at far end of

crossmember, insert a Philips head screwdriver through

bushing and into center hole of torsion bar as illustrated

below. Pry torsion bar up using screwdriver while pushing

it through the bushing from the opposite end.

3. PREPARE FRONT CROSS MEMBER

The SwitchBlade Swaybar mounts through the tubular

crossmember that connects the chassis rails together immediately forward of the steering box. Crossmember must

be intact and free of damage in order to install this product.

Inspect the inside surface at each end of the

crossmember for any debris or deformation that

could interfere with installation of Torsion Bar

Bushings (D).

Clean any mud, dirt, rust, burs, slag, or other de-

bris from inside ends of crossmember.

HI N T: A die grinder with sanding wheel or similar tool is

useful for removing stubborn debris.

4. INSTALL TORSION BAR

Insert a Torsion Bar Bushing (D) into each end of

the tubular crossmember. HINT: A block of wood

and soft mallet may be useful to fully seat bushing

into crossmember. Do not use brute force – only

light tapping with mallet. A light application of

silicone lubricant to outer surface of bushing may

also be used. If bushings are still difcult to insert,

contact JKS at 877-533-7557 for technical assis-

tance.

Use caution to avoid damaging bushings when installing torsion bar.

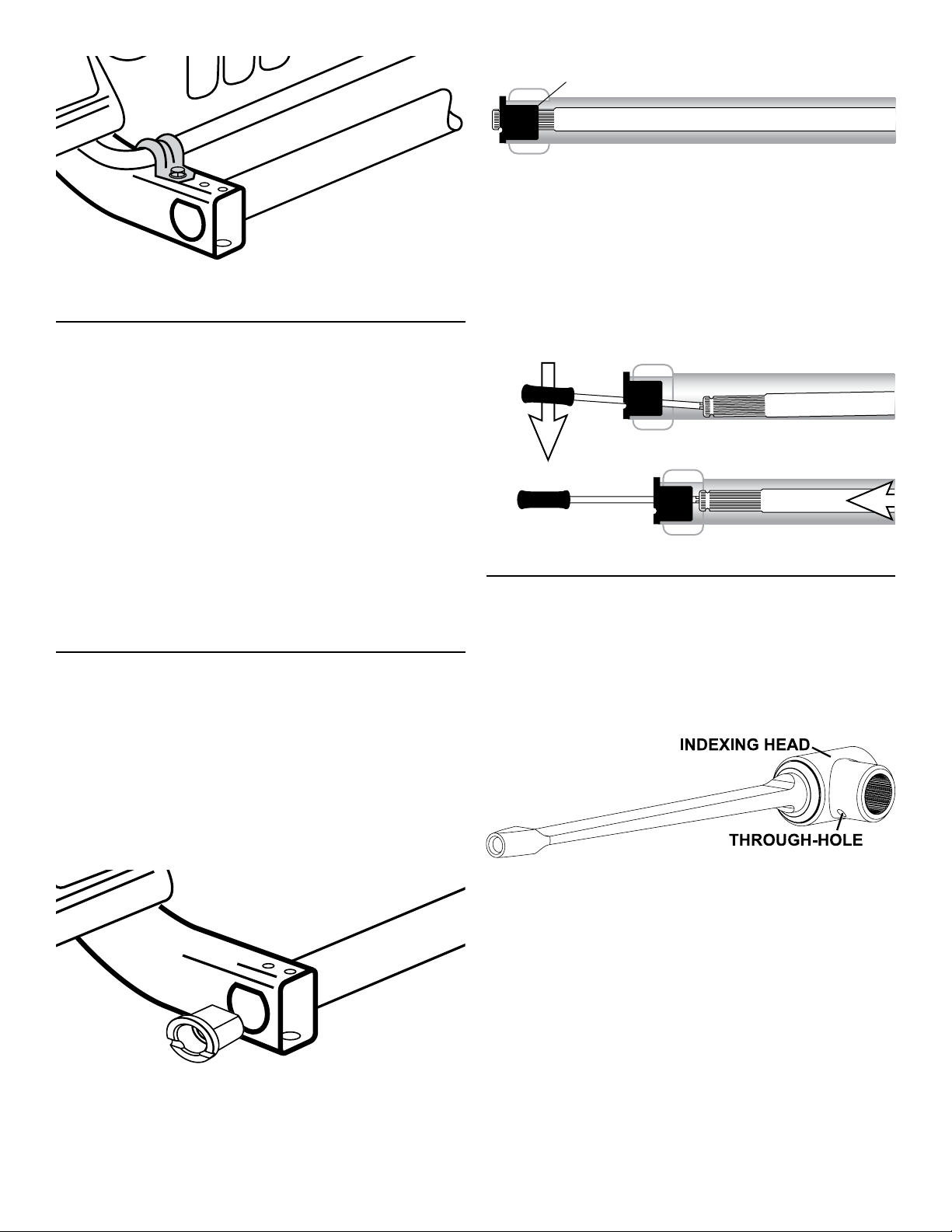

5. INSTALL BLADE ARMS

Locate the Blade Arm Assemblies (A & B) and

identify their correct mounting location by reading the label applied to the Indexing Heads. “RH”

indicates Right-Hand side, and “LH” indicates LeftHand side. Hint: When installed correctly, the 1/4”

through-hole will be on bottom of Indexing Head.

BLADE ARM ASSEMBLY

Wipe down the Torsion Bar (C) with a light applica-

tion of Silicone lubricant.

Install Torsion Bar (C) by guiding it through the

Torsion Bar Bushings (D) until it is centered.

JKS9100JKS Switchblade Swaybar Installation

Slide the splined opening of the Indexing Head on

to end of Torsion Bar (C). HI NT: It may be neces-

sary to gently tap side of Indexing Head with a

rubber mallet to fully engage splines. Use a clean,

soft towel to protect the polished nish.

Slowly pivot the Blade Arm Assembly (A) up or

down until the 1/4” through-hole in Indexing Head

aligns with the access groove in the Torsion Bar

Bushing (D) as illustrated below.

Insert a 1/4" Dowel Pin (E) into the through-hole as

shown below.

Drive the 1/4” Dowel Pin (E) into through-hole until

it is centered as shown below. HI N T: A hammer

Page 3

Loading...

Loading...