INSTALLATION

INSTRUCTIONS

517-278-1226 • tech@jksmfg.com • www.jksmfg.com

491 W. Gareld Avenue, Coldwater, MI 49036

Product: Quicker Disconnect

Part Number: JKS3100 - JKS3104

Welcome

CONGRATULATIONS on purchasing a set

of new Quicker Disconnects™ from JKS Manufacturing.

We are committed to providing you with the best products

available and your satisfaction is our rst priority.

PLEASE READ these Installation Instructions carefully,

and save them for future reference, as they contain important installation and maintenance information.

Important

NOT COMPATIBLE WITH aftermarket swaybars. Install

product with Original Equipment swaybar only.

SOME VEHICLES MAY REQUIRE extended front brake

hoses or other modications to compensate for additional suspension travel.

NEVER DISCONNECT swaybar when operating vehicle

on public roads.

WHEN DISCONNECTED, the Quicker Disconnects

must be completely removed from the vehicle and the

swaybar must be secured to prevent interference with

other suspension components or axle.

Tools Required

Metric/Standard Socket Wrench Set

Torque Wrench

15/16” Open-End Wrench

#1 Philips Screwdriver or Small Punch

Medium Strength Threadlocker

Angle Measuring Tool

Grease Gun with Zerk Fitting Coupler

Wheel Bearing Grease

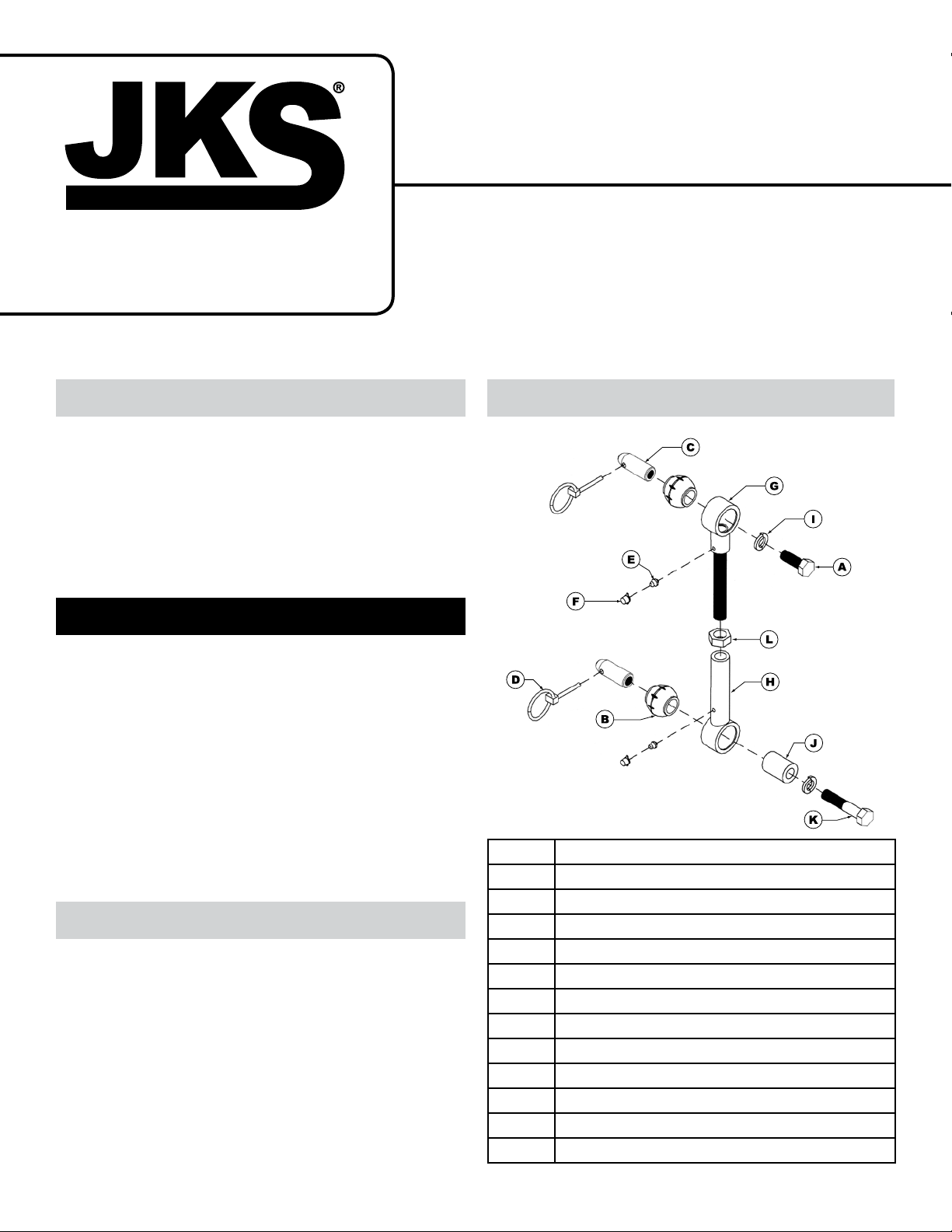

Description

A

1/2" x 1-1/4” NF GR5 Bolt

B

Spherical Bushing

C

Stainless Steel Post

D

Click Pin

E

Press-In Grease Zerk

F

Grease Zerk Cap

G

Upper Male Threaded End

H

Lower Female Threaded End

I

1/2” Lock Washer

J

OE Bracket Spacer

K

1/2” x 2-1/2” NF GR5 Bolt

L

5/8” Jam Nut

Parts

JKS3100 - JKS 3104JKS Quicker Disconnect Installation

Page 1

Installation

1. REMOVE ORIGINAL EQUIPMENT (OE)

SWAYBAR LINKS

Remove front swaybar drop links and mounting

hardware per the factory service manual instructions for your vehicle.

2. INSTALL UPPER TAPERED POST

Mount the tapered Stainless Steel Post (C) on

outboard side of the swaybar, ensuring small

Click Pin holes are horizontal or parallel with the

ground.

Apply medium strength threadlocker to the tip of

1/2” x 1-1/4” Bolt (A).

3. INSTALL LOWER TAPERED POST

Locate the original lower drop link U-bracket on

the axle housing. Insert the gold colored steel OE

Bracket Spacer (J) into the U-bracket.

IMPORTANT: The supplied OE Bracket Spacers must

be installed to prevent the U-bracket from collapsing

when the mounting bolt is tightened.

Apply medium strength threadlocker to the tip of

1/2” x 2-1/2” Bolt (K).

Insert the 1/2” x 2-1/2” Bolt (K) with 1/2” Lock

Washer (I) completely through the holes in Ubracket and OE Bracket Spacers (J) from the

inboard side of bracket.

Thread the tapered Stainless Steel Post (C) on to

the 1/2” x 2-1/2” Bolt (K) from the outboard side

of U-bracket, ensuring small Click Pin holes are

horizontal or parallel with the ground.

Tighten the 1/2" x 2-1/2” Bolt (K) to 65 ft-lb. us-

ing a torque wrench. H I N T: A small Philips head

screwdriver or punch inserted into the Click Pin

hole will enable you to prevent the tapered Stainless Steel Post from rotating when tightening the

mounting bolt.

Secure tapered post to swaybar by inserting the

1/2" x 1-1/4” Bolt (A) and 1/2” Lock Washer (I) from

the inboard side and tighten to 65 ft-lb. using a

torque wrench.

HINT: A small Philips head screwdriver or punch

inserted into the Click Pin hole will enable you

to prevent the tapered Stainless Steel Post from

rotating when tightening the mounting bolt.

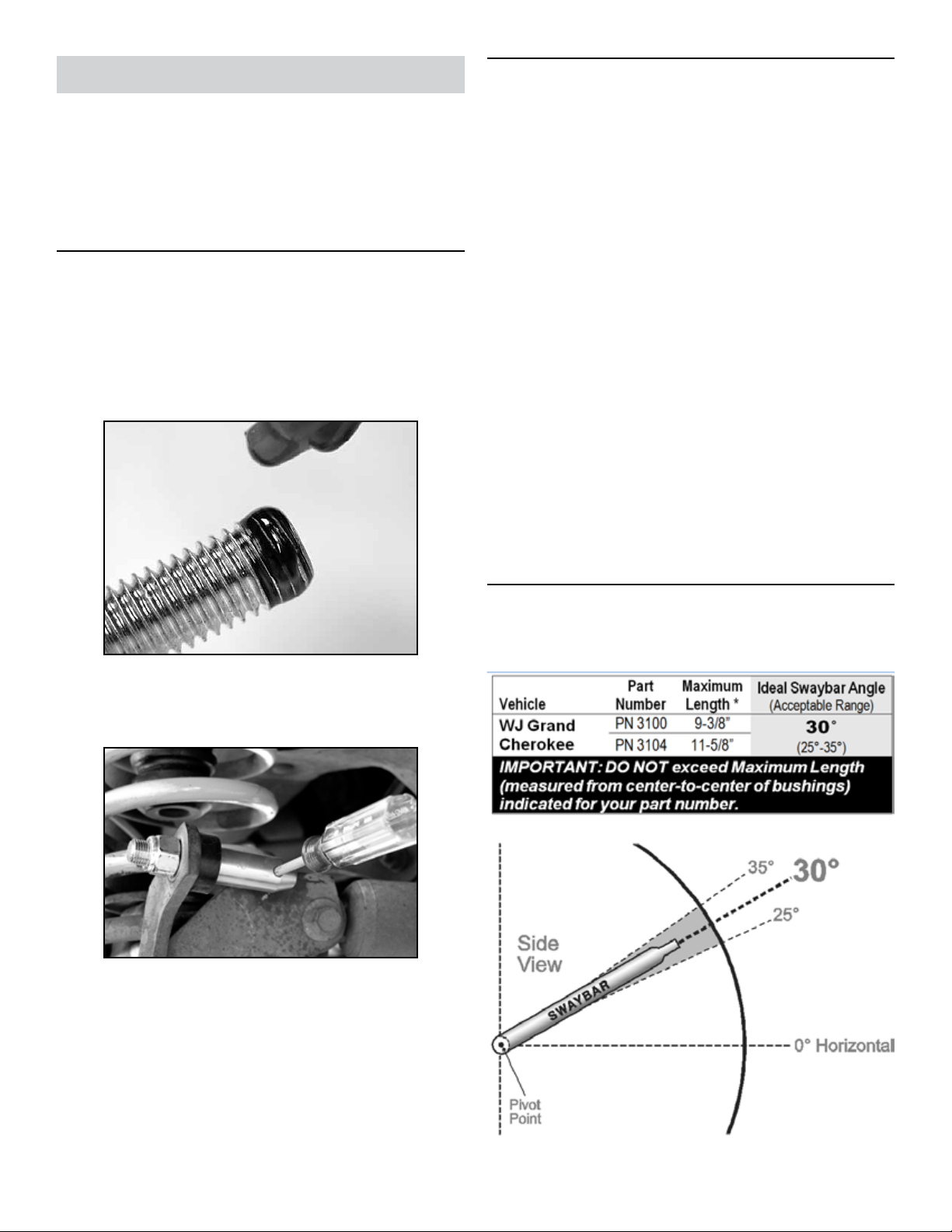

4. SET QUICKER DISCONNECT LENGTH

Determine the Ideal Swaybar Angle for your ve-

hicle according to the following chart.

2 Page

JKS3100 - JKS 3104

JKS Quicker Disconnect Installation

Loading...

Loading...