Page 1

67 Series

Spectrophotometers

Operating Manual

670 00

Page 2

Page 3

IMPORTANT

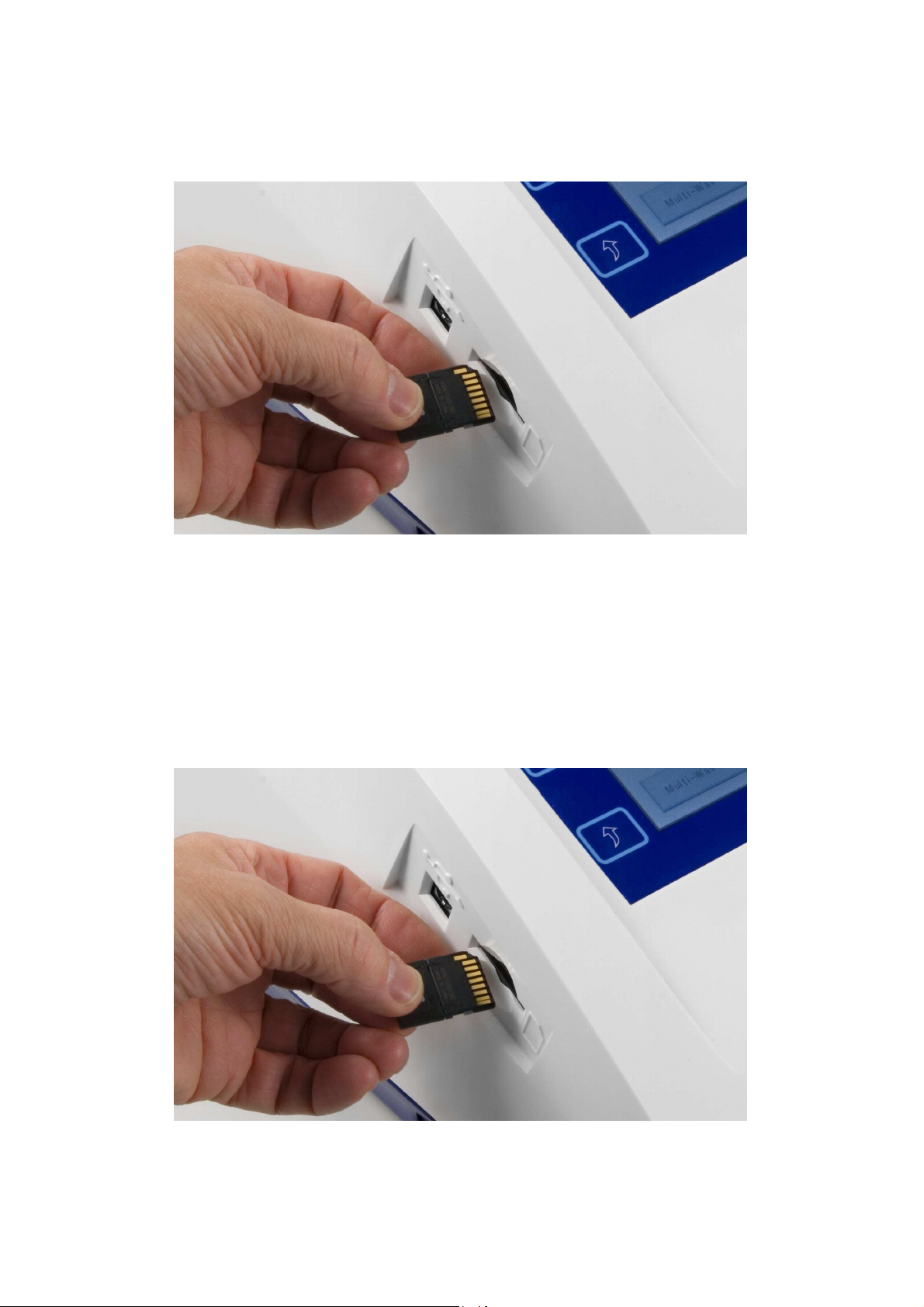

Please ensure the SD Card is fitted into the socket as detailed

in the image below.

-------------------------------------------------------------------------------------------------------------------------

IMPORTANT

Please ensure the SD Card is fitted into the socket as detailed

in the image below.

Page 4

Page 5

67 Series Spectrophotometer

PC Software

Installation

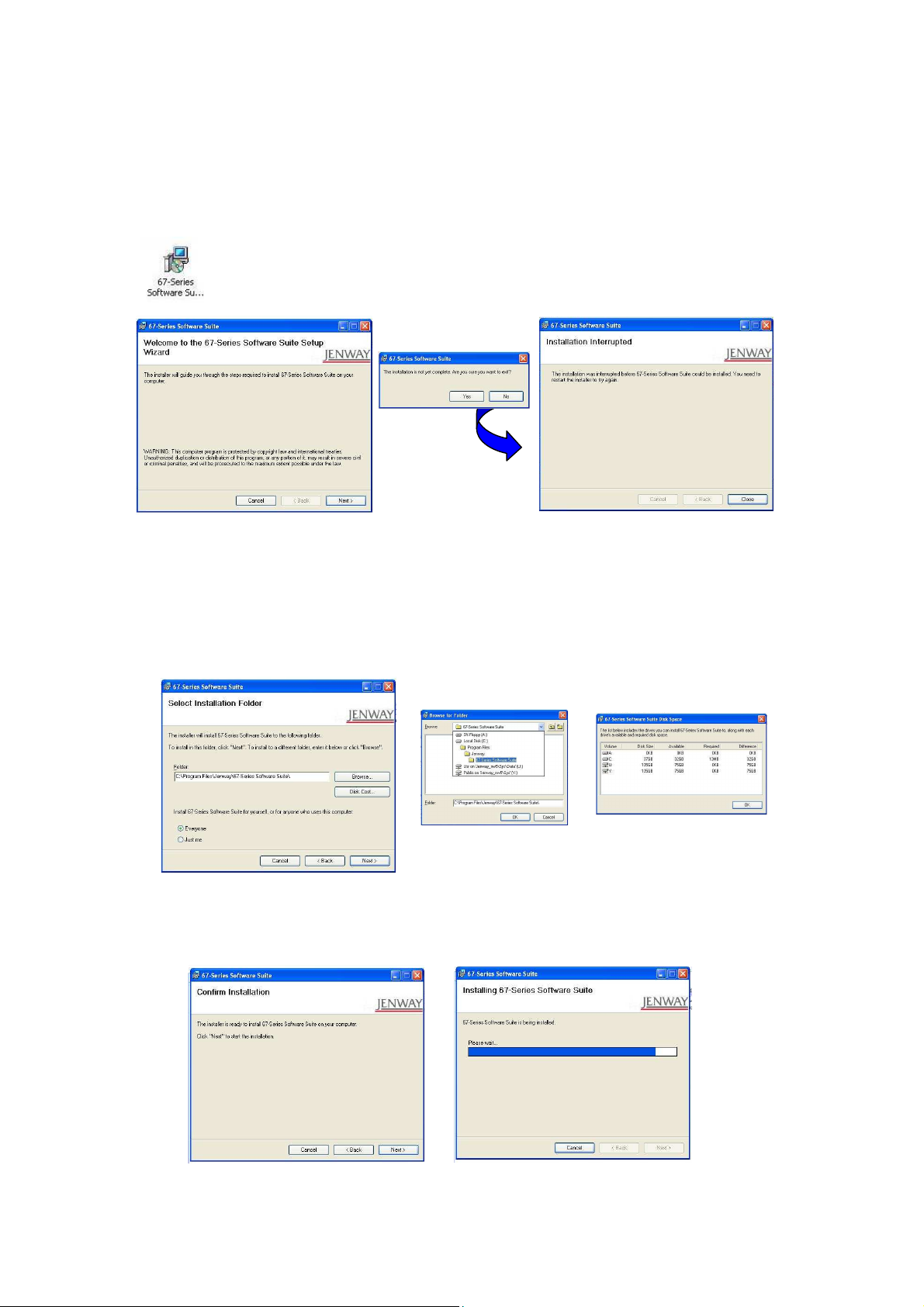

Insert the 67-Series Software Suite installation CD and select the 67-Series

Software Suite icon to open the following screen. Selecting Next commences the

installation. The installation can be aborted by selecting Cancel.

The default installation destination is C:\Program Files\Jenway\67-Series Software Suite\. To

select the default destination select Next, to alter the destination select Browse. To review

the disk space requirements select Disk Cost. The 67-Series Software Suite can be set up

to be used by all users or a single user by checking the appropriate box. To progress the

installation select Next, to return to the previous screen select Back, to exit the installation

select Exit.

Select Next to commence the installation. To review or change any of the installation

parameters select Back. To exit the installation at this stage select Cancel, the software will

not be installed if you choose to exit.

Page 6

When the installation is complete select Close.

The 67-Series Software Suite icon is displayed on desktop

Getting Started

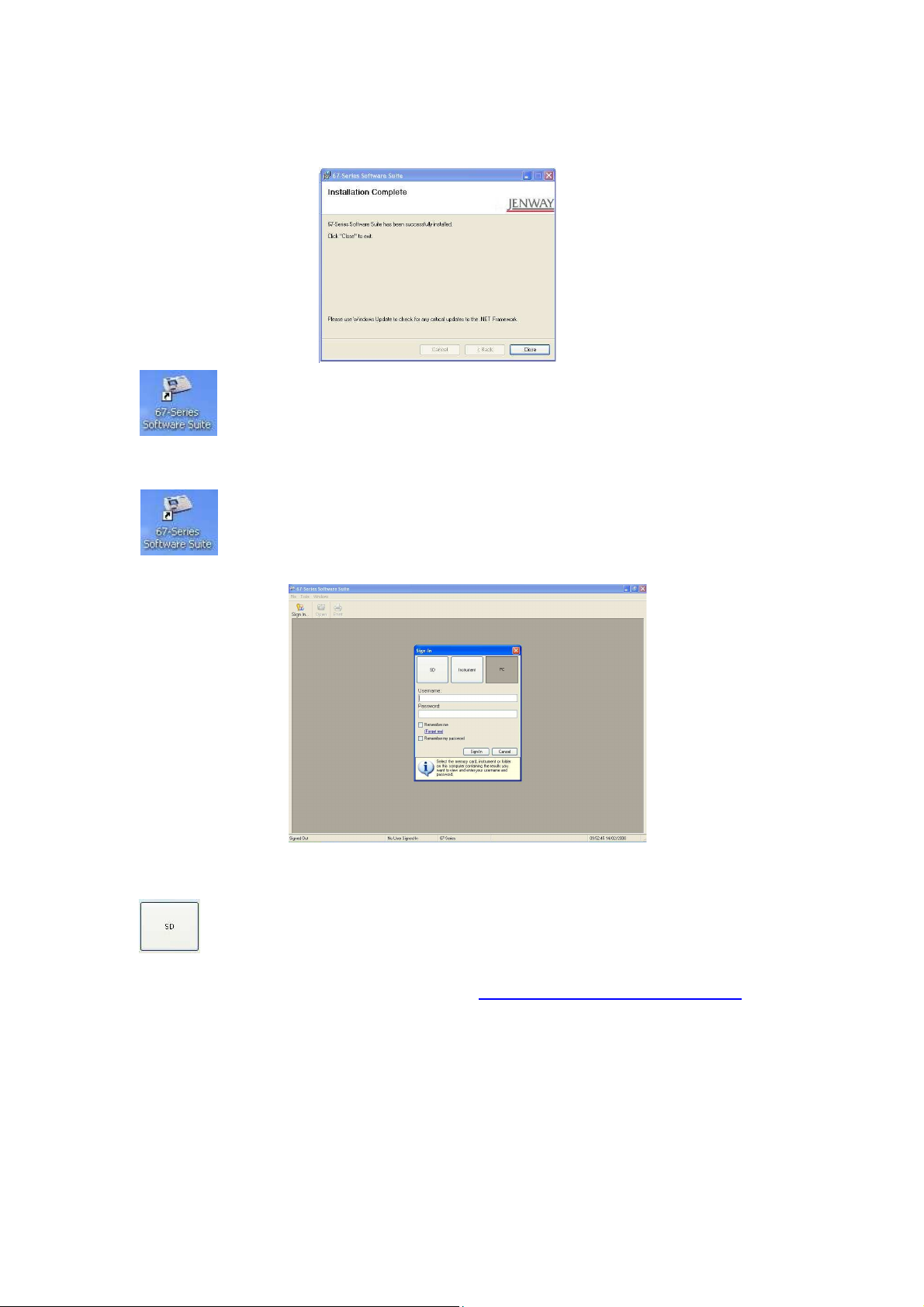

Ensure the PC and spectrophotometer are connected via the USB cable and

select the 67-Series Software Suite desktop icon to open the 67-Series

Software Suite main screen.

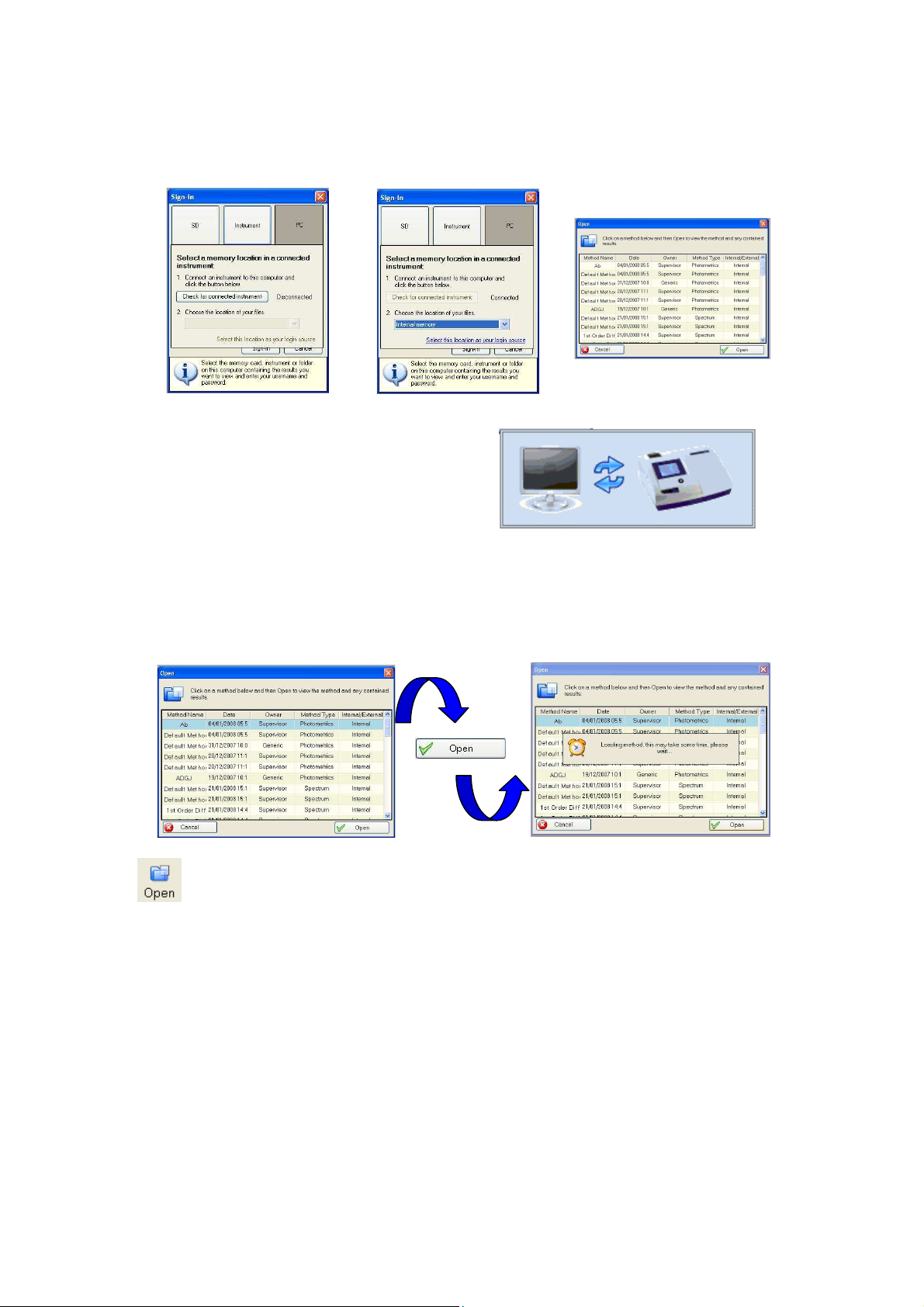

There are three options for accessing saved methods and data: SD, Instrument and PC.

SD allows the user to access methods and data saved on an SD or SD/USB card

inserted in the PC.

Selecting SD allows the user to browse through the PC directory for the inserted SD or

SD/USB card. Select the required folder, OK and Select SD card as your login source.

Entering the Username, Password and selecting Sign-In accesses that specific users

methods and data (the Username and Password that are required are the same as when

logging into the instrument), the user or password can be saved by ticking the appropriate

boxes. Highlighting the required method and selecting Open accesses the saved method.

Data processing for SD is detailed in the Data Processing section.

Page 7

Note: If the selected location does not contain a valid SD card the error message This

location does not contain a valid SD card will be displayed.

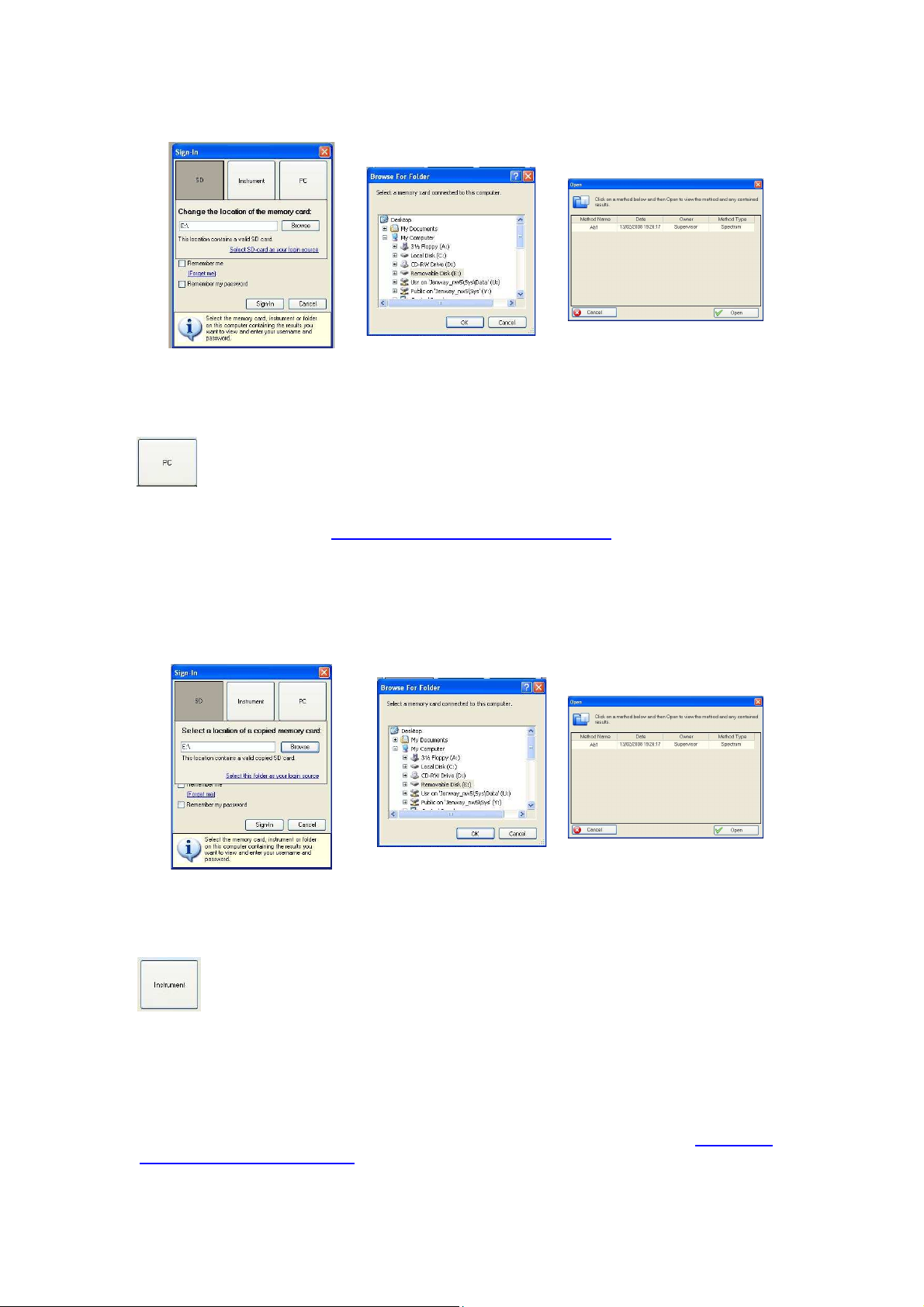

PC allows the user to access methods and data saved to a PC.

Selecting PC allows the user to browse through the PC directory for the desired folder. Select

the required folder, OK and Select this folder as your login source. Entering the

Username, Password and selecting Sign-In accesses that specific users methods and data

(the Username and Password that are required are the same as when logging into the

instrument), the user or password can be saved by ticking the appropriate boxes. Highlighting

the required method and selecting Open accesses the saved method.

Data processing for PC is detailed in the Data Processing section.

Note: If the selected location does not contain a valid SD card the error message This

location does not contain a valid copied SD card will be displayed.

Instrument allows the user to access data saved to either the internal memory of

the spectrophotometer or a memory card inserted in the spectrophotometer.

Selecting Instrument allows the user to browse through data saved to either the internal

memory of the spectrophotometer or a memory card inserted in the spectrophotometer.

Select the Check for connected instrument (the default status is Disconnected), whilst

searching the Check for connected instrument button updates to read Cancel and the

status updates to Searching… when connected the status reads Connected. Choose the

desired location of the files from the dropdown bar (the option for Inserted Memory Card is

only available if an SD or SD/USB card is inserted in the spectrophotometer) and Select this

location as your login source. Entering the Username and Password and Sign-In

accesses that specific users methods and data (the Username and Password that are

Page 8

required are the same as when logging into the instrument), the user or password can be

saved by ticking the appropriate boxes. To access the required method highlight that line and

select Open. Data processing for Instrument is detailed in the Data Processing section.

Note: Whenever the PC and spectrophotometer

are communicating the

spectrophotometer’s screen updates to

show:

Data Processing

Data processing is the same for the SD, PC and Instrument options.

All available methods are displayed in the Open box. Highlighting the required method and

selecting Open opens the method.

Once a method is opened further methods can be opened by selecting the open icon.

Note: Clicking on the column titles alters the order in which the methods are displayed.

Method Name orders the methods alphabetically, Date orders the results in date

order, Owner orders the methods by owner type, Method Type orders the methods

alphabetically and Internal/Ext orders the methods by the order they appear on the

spectrophotometer’s screen.

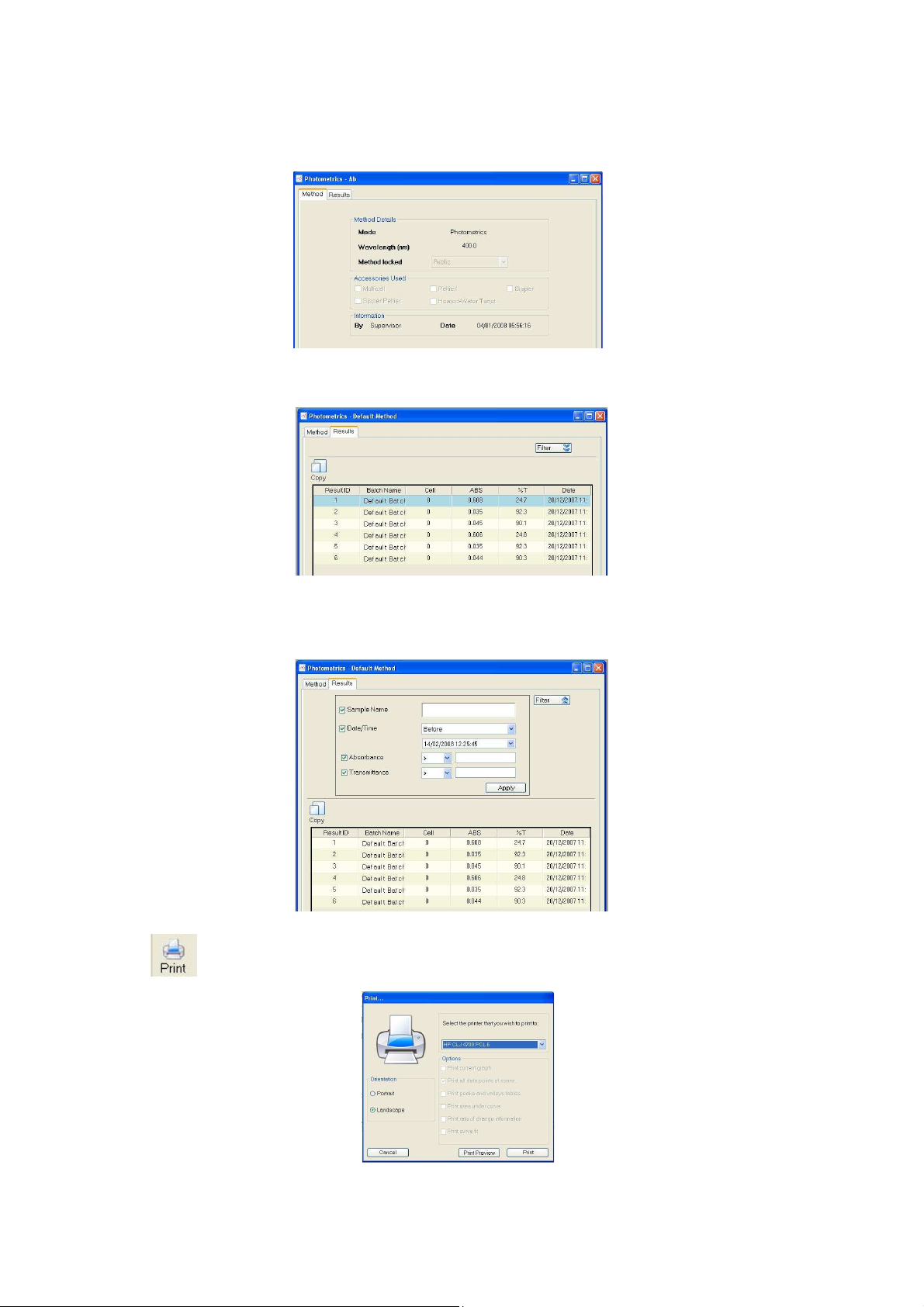

Photometrics

The photometrics screen displays two tabs Method and Results

The Method tab displays the Method Details, Accessories Used (if any) and Information of

the photometric measurement (this information cannot be edited).

Page 9

The Results tab displays a table of the all the results in the chosen method.

Selecting Filter displays a drop down allowing the results to be filtered by Sample Name,

Date/Time, Absorbance or Transmittance values. After inputting the required filter

parameters select Apply and the results table will be updated to include the filtered results.

Selecting the print icon opens the Print box. This allows the user to choose the

printer, the orientation of the printout and gives the option of printing directly or

viewing a Print Preview.

Page 10

Selecting the copy icon allows the results to be pasted directly into other

programmes (e.g. a spreadsheet) for further data manipulation or editing.

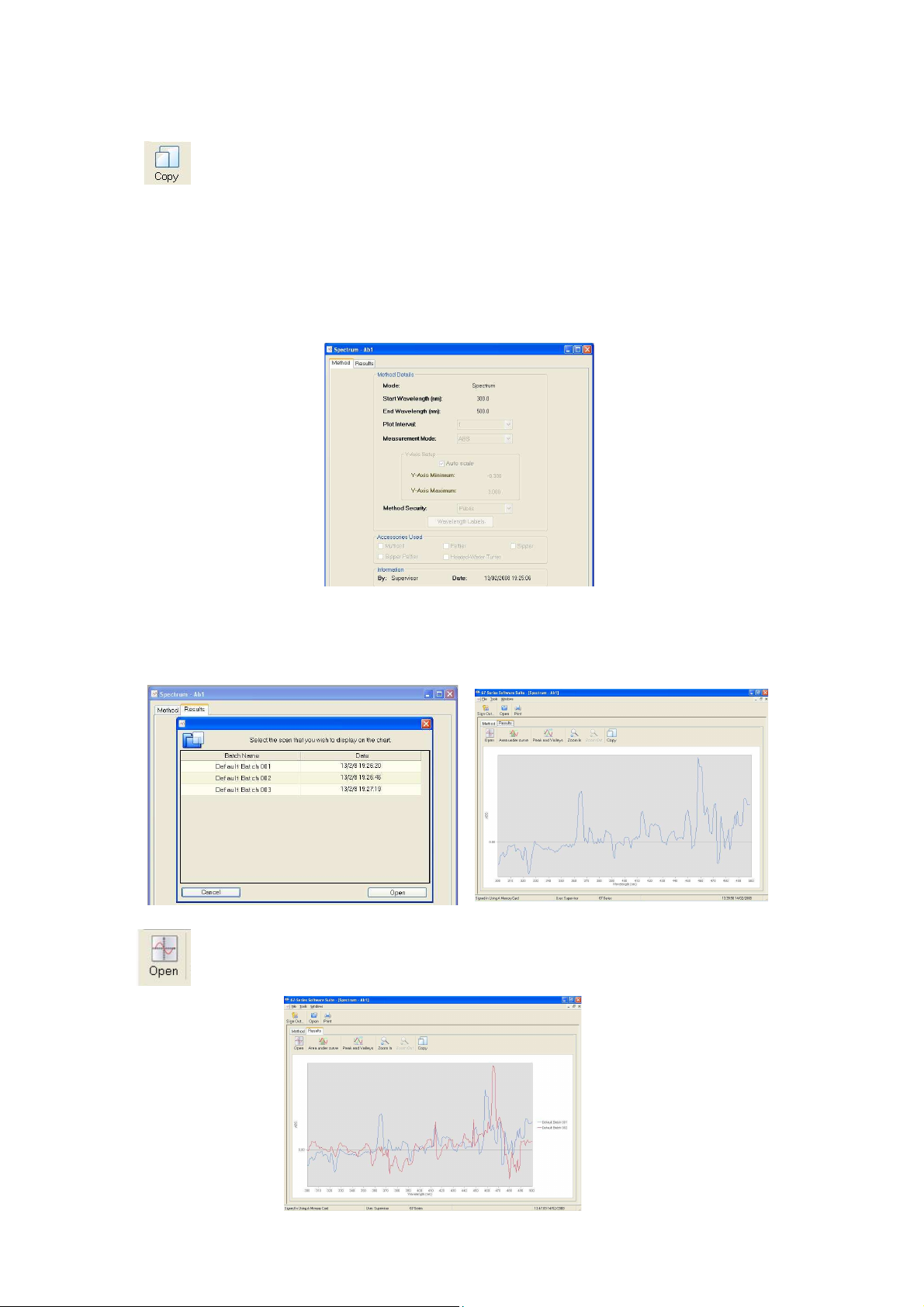

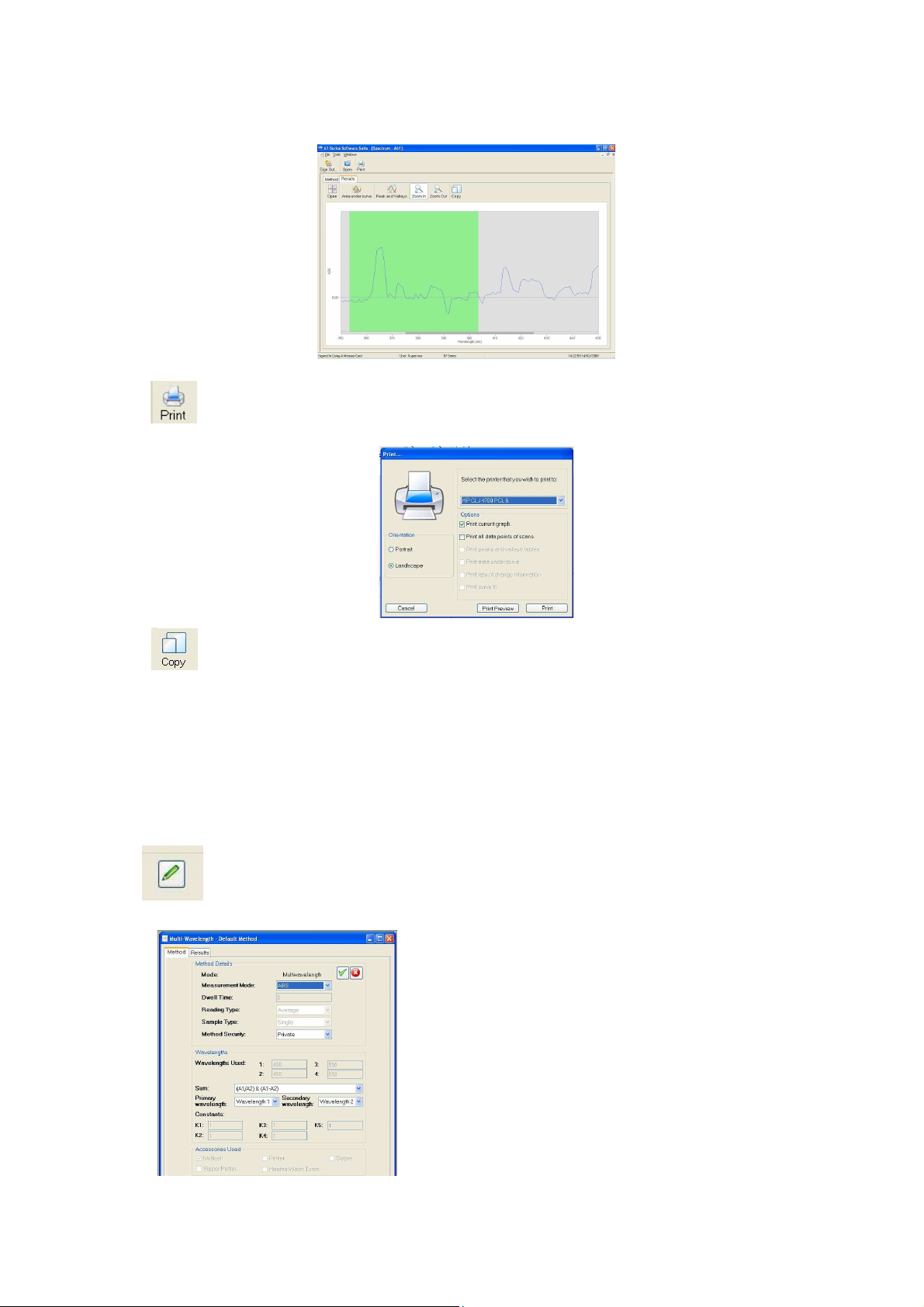

Spectrum Scanning

The spectrum screen displays two tabs Methods and Results.

The Method tab displays the Method Details, Accessories Used (if any) and Information of

the spectrum scan (this information cannot be edited).

The Results tab displays a table of the all the results in the chosen method. The desired

results can be opened by highlighting the required data line and selecting Open, the chosen

spectrum is displayed.

Selecting the open icon displays a table of all of the results. Highlighting the desired

result and selecting Open will overlay the chosen spectrum.

Page 11

Holding the cursor over the spectrum trace or the data name will highlight the chosen

spectrum and fade any other spectra.

To return to the original spectrum select the open icon and reselect the original data

set.

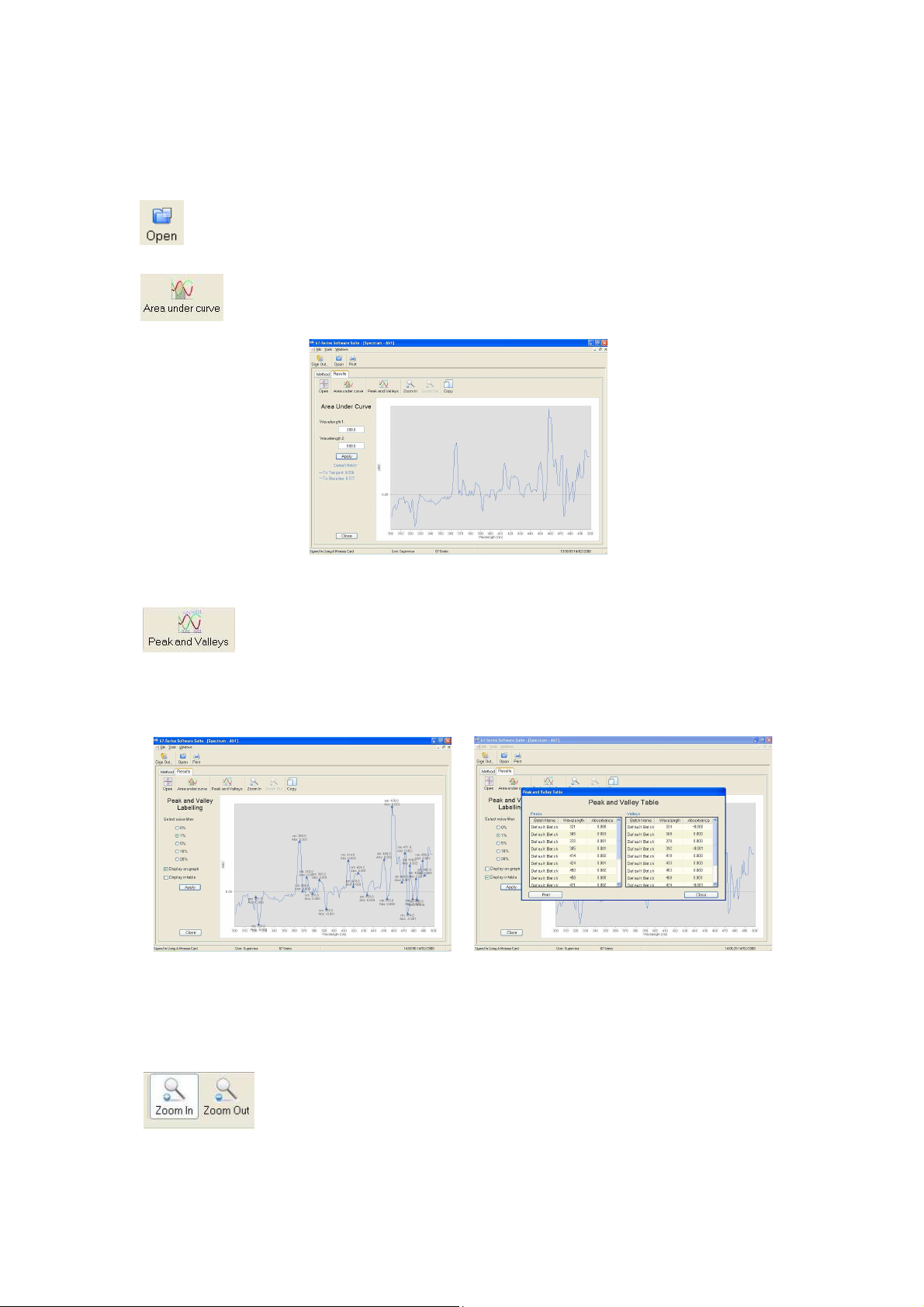

Selecting the area under curve icon displays the following screen. Inputting the

required wavelength limits and selecting Apply will calculate the area under the

curve to both the tangent and the baseline.

Selecting the peaks and valleys icon displays the following screen. Selecting

the required noise filter and Apply will display the both the wavelength values

and the absorbances. These values can be displayed on the spectrum, in a

table or both by selecting the appropriate boxes. Alternatively selecting a

peak or valley with the cursor will manually label the wavelength and

absorbance value.

To exit from the Peaks and Valleys screen select Close.

Selecting the zoom in icon displays the green ‘zoom area’ on the spectrum.

Placing this over the desired area and clicking the left mouse button will

zoom in to the green highlighted area. This process can be repeated up to

four times. Once zoomed in it is possible to return to the previous zoom

level by selecting the zoom out icon.

Page 12

Selecting the print icon opens the Print box. This allows the user to choose the

printer, the orientation of the printout, what data is displayed on the printout and

gives the option of printing directly or viewing a Print Preview.

Selecting the copy icon allows the results to be pasted directly into other

programmes (e.g. a spreadsheet) for further data manipulation or editing.

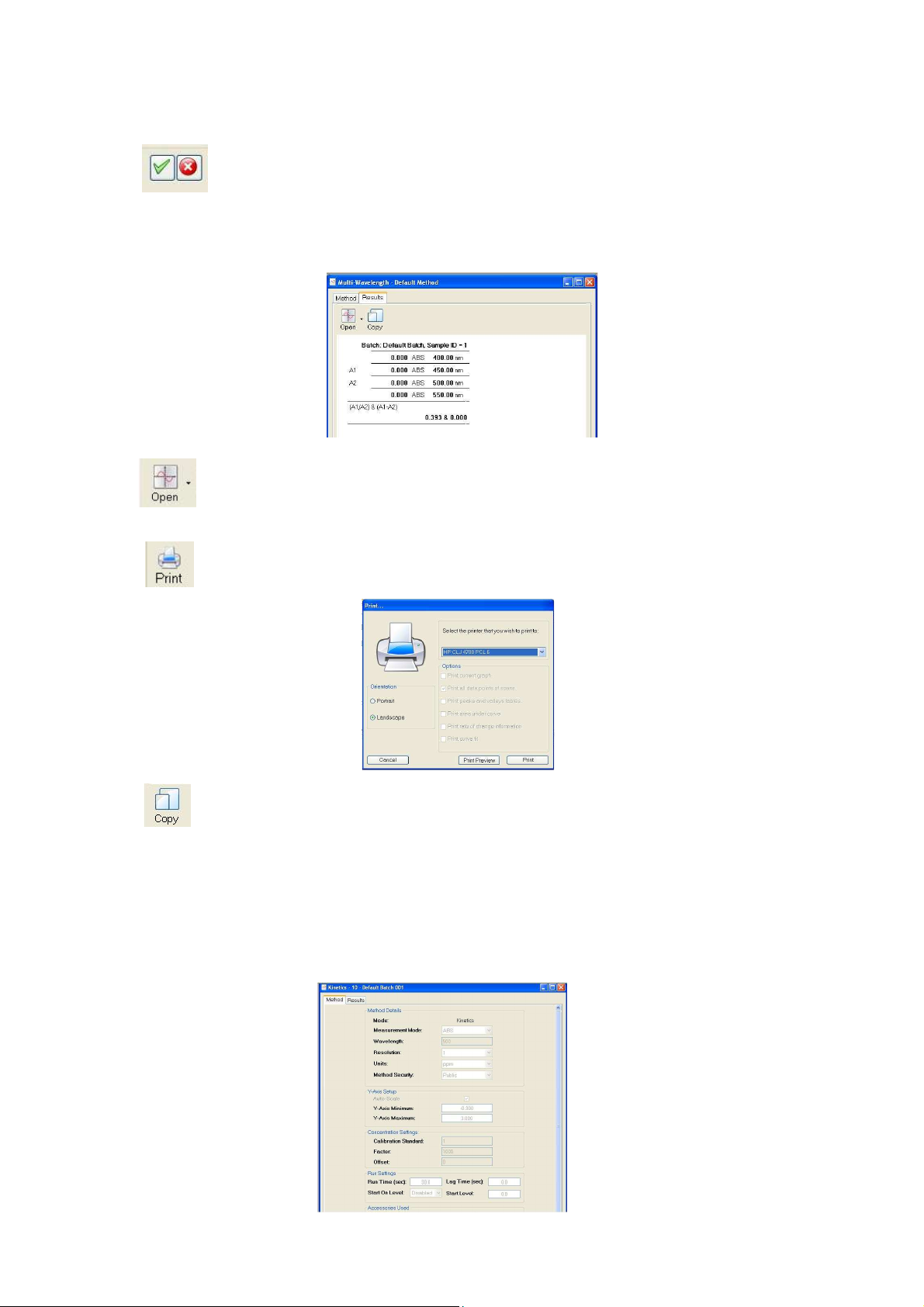

Multi-Wavelength

The multi-wavelength screen displays two tabs Methods and Results.

The Method tab displays the Method Details, Wavelengths, Accessories Used (if any) and

Information of the multi-wavelength measurement.

Selecting the edit sum icon allow the Measurement Mode, Method Security,

Sum, Primary and Secondary wavelengths to be edited.

Measurement Mode can be set as either %T or

Absorbance. The Method Security can be set to

Private, Public or Read-Only. Sum can be altered to

select one of the three available multi-wavelength

equations and the Primary and Secondary

Wavelengths can be altered to any recorded

wavelength.

Page 13

After inputting the required parameters select the tick icon to save the changes or

the cross icon to cancel

The Results tab displays the data of the multi-wavelength measurement alongside the results

of the Sum calculation.

Selecting the open icon allows access to the other results saved in the method.

Selecting the print icon opens the Print box. This allows the user to choose the

printer, the orientation of the printout and gives the option of printing directly or

viewing a Print Preview.

Selecting the copy icon allows the results to be pasted directly into other

programmes (e.g. a spreadsheet) for further data manipulation or editing.

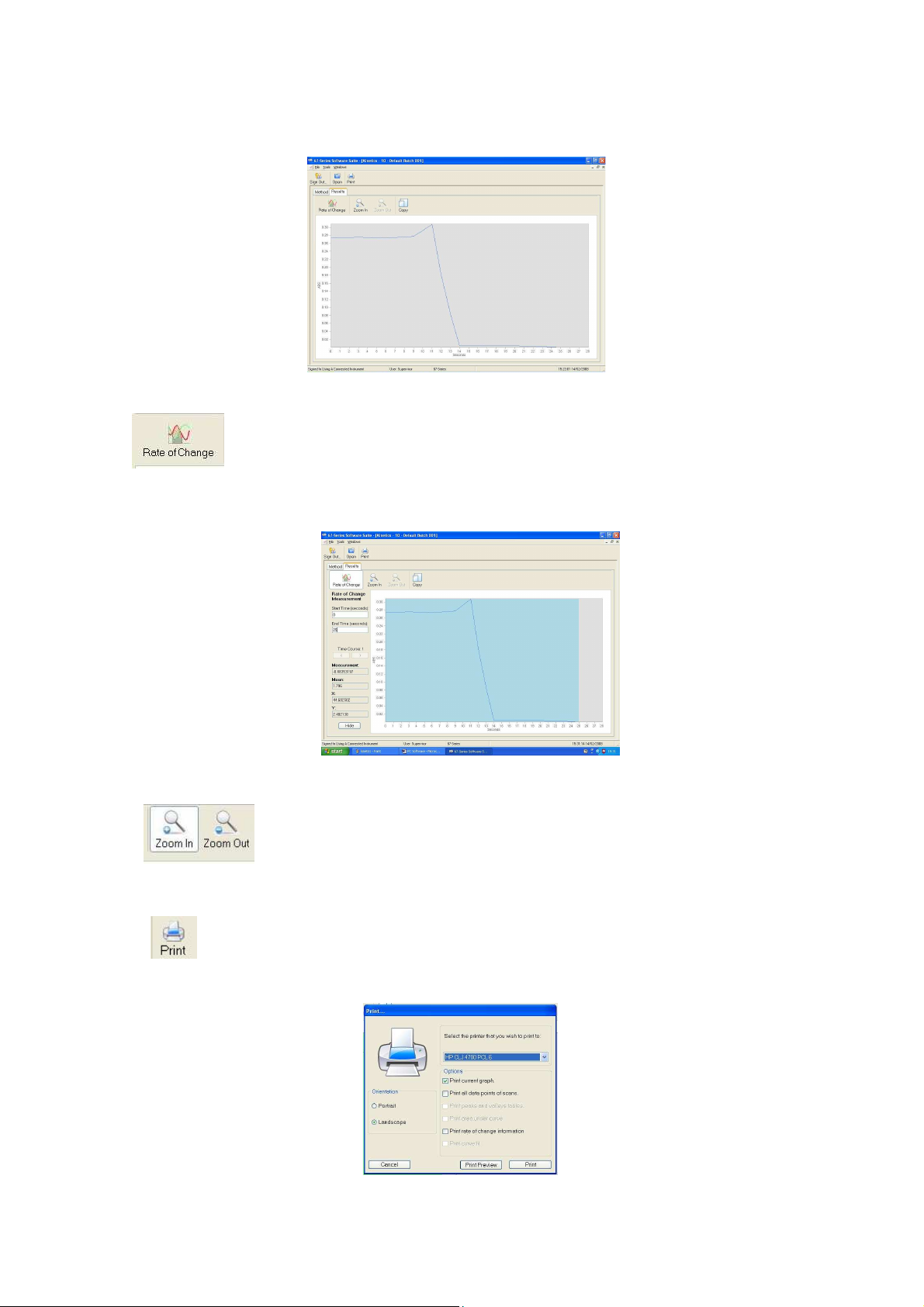

Kinetics

The kinetics screen displays two tabs Methods and Results.

The Method tab displays the Method Details, Y-Axis Set-up, Concentration Settings, Run

Settings, Accessories Used (if any) and Information of the kinetics measurement.

Page 14

The Results tab displays the chosen result.

Selecting the rate of change icon displays the following screen. Entering the

required Start Time and End Time automatically updates the Measurement,

Mean, X and Y calculations.

Alternatively holding down the left mouse button and dragging over the desired

area edits the Start Time and End Time. To return to the original Result tab

screen select Hide.

Selecting the zoom in icon displays the green ‘zoom area’ on the spectrum.

Placing this over the desired area and clicking the left mouse button will

zoom in to the green highlighted area. This process can be repeated up to

four times. Once zoomed in it is possible to return to the previous zoom

level by selecting the zoom out icon.

Selecting the print icon opens the Print box. This allows the user to choose the

printer, the orientation of the printout, what data is displayed on the printout and

gives the option of printing directly or viewing a Print Preview.

Page 15

Selecting the copy icon allows the results to be pasted directly into other

programmes (e.g. a spreadsheet) for further data manipulation or editing.

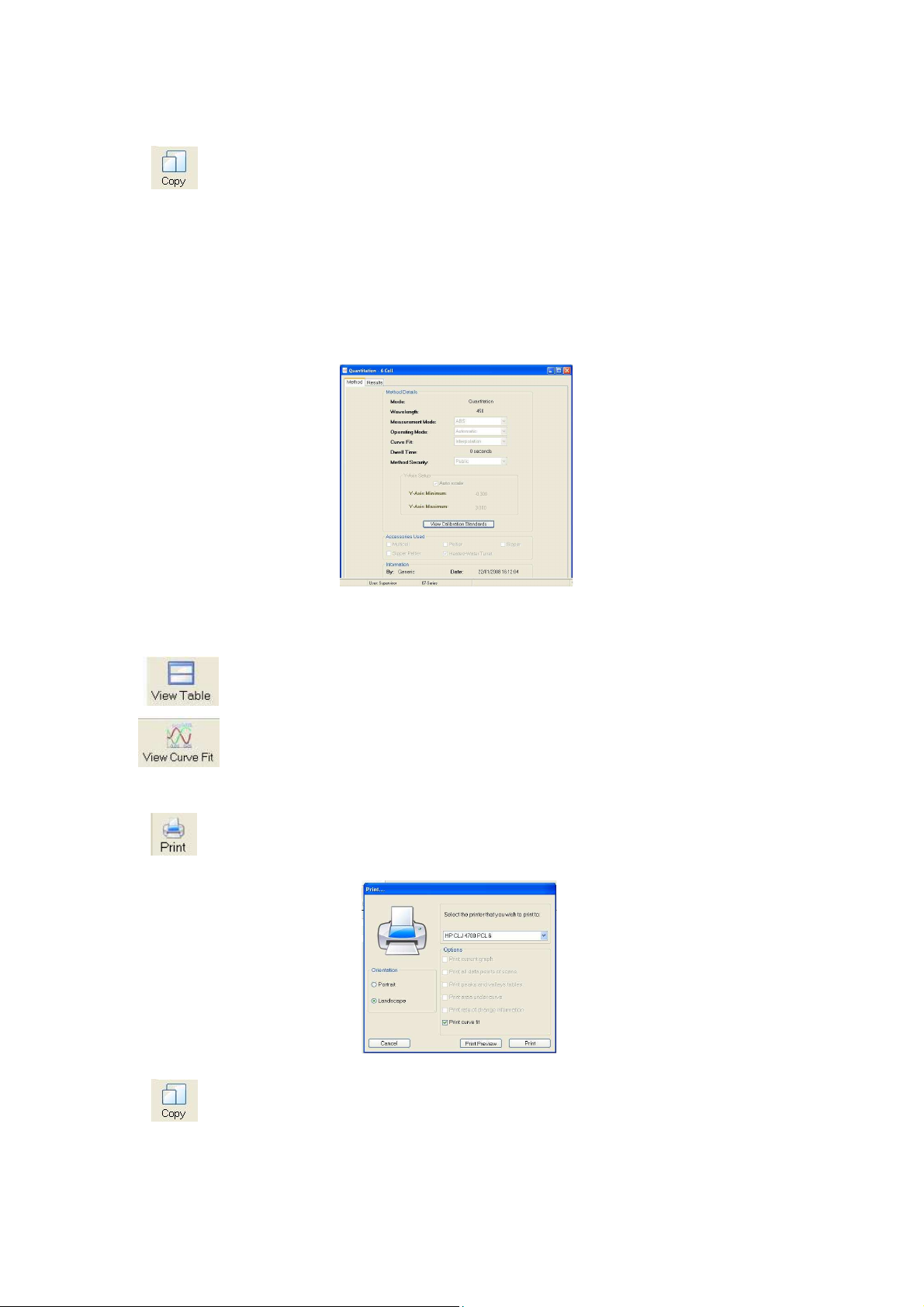

Quantitation

The quantitation screen displays two tabs Methods and Results.

The Method tab displays the Method Details, Y-Axis Set-up, Accessories Used (if any)

and Information of the kinetics measurement. By clicking on View Calibration Standards

the calibration standards used in the result are displayed.

The Results tab displays the calculated concentrations in a table or displays the curve fit.

Selecting the view table icon displays the calculated concentrations in a table

Selecting the view curve fit icon displays the curve fit.

Selecting the print icon opens the Print box. This allows the user to choose the

printer, the orientation of the printout, what data is displayed on the printout and

gives the option of printing directly or viewing a Print Preview.

Selecting the copy icon allows the results to be pasted directly into other

programmes (e.g. a spreadsheet) for further data manipulation or editing.

Page 16

Signing Out & Logging In As A Different User

Once all of the required data processing has been completed select the sign out

icon to return to the main 67-Series Software Suite screen.

Selecting the sign in icon opens the sign in dialogue box and allows other users to

process their data (refer to the Getting Started section for sign in dialogue box

details).

Exiting 67-Series Software Suite

Once all of the data has been processed select Exit from the File menu

to exit the 67-Series Software Suite.

Page 17

67 Series Spectrophotometers

Models 6700, 6705 & 6715

Operating Manual

670 005/REV D/11-11

Page 18

Page 19

1

Contents

Page

Safety 7

Guarantee 8

SECTION 1 - Introduction

1.1 Instrument Description 9

1.2 Instrument Specifications 10-11

1.3 Good Practice Guidelines 11-12

SECTION 2 - Getting Started

2.1 Unpacking 13-14

2.2 Installation 14-15

2.2.1 Location 14

2.2.2 Supply voltage 14

2.2.3 Mains connections 14

2.2.4 Touch screen functions 15

2.2.5 Toolbar icons 16-20

2.2.6 Rear panel layout 21

2.2.7 Power on and self tests 22

SECTION 3 - Systems of Operation

3.1 Multi-User and Free Operation 23

3.2 Memory Structure 23

3.2.1 Memory selection 23

3.2.2 Memory Hierarchy 24

3.3 Creating Methods 24-25

3.4 File and Data Management 25-26

SECTION 4 - Instrument Settings

4.1 Menu Options 27

4.2 Set Time & Date 27

4.3 User Preferences 27

4.3.1 Adjust User PIN 28

4.3.2 Language 28

4.3.3 Method View Settings 28

4.3.4 Touch Screen Click 29

4.3.5 Brightness 29

4.3.6 Adjust Date & Time 29

4.4 About 30

4.5 Form Feed 30

4.6 Administration Functions 30

4.6.1 Instrument ID 31

4.6.2 Screen Dump 31

4.6.3 Modify Users 31

4.6.3.1 Create New User 32

4.6.3.2 Delete User 32

4.6.3.3 Delete All Users 32

4.6.3.4 Reset User PIN 33

4.7 Memory Manager 33

Page 20

2

SECTION 5 - Photometrics Mode

5.1 Principles of Measurement 34

5.2 Free Operation 34-37

Setting Method ID 35

Setting Wavelength 36

Setting Method Security 36

Setting Batch ID 36

Auto Log Settings… 37

5.3 Logged In Measurement 38-41

Creating a New Method 39

Setting Method ID 39

Setting Wavelength 39

Setting Method Security 40

Setting Batch ID 40

Auto Log Settings… 41

File & Data Management 42-43

5.4 Performing Measurements – all users 44

Zeroing the Instrument 44

Measuring the Sample 44

SECTION 6 - Spectrum Mode

6.1 Principles of Measurement 45

6.2 Free Operation 45-52

Setting Method ID 46

Selecting Measurement Mode 46

Setting Wavelengths (Start & End) 47

Selecting Plot Interval 48

Setting Method Security 49

Setting Additional Set-up Parameters using the Toolbar Icons 49-52

Setting Analysis Points 49

Setting Auto-Scale 50

Selecting Plot Colour 50

Selecting Axis Colour 51

Setting Batch ID 51

Setting Graph Data Points 51

Selecting Printer Media 52

Auto Log Settings… 52

6.3 Logged In Measurement 53-56

Creating a New Method 54

Setting Method ID 54

Selecting Measurement Mode 54

Setting Wavelengths (Start & End) 55

Selecting Plot Interval 56

Setting Method Security 56

Setting Additional Set-up Parameters using the Toolbar Icons 57-60

Setting Analysis Points 57

Setting Auto-Scale 58

Selecting Plot Colour 58

Selecting Axis Colour 59

Setting Batch ID 59

Page 21

3

Setting Graph Data Points 59

Selecting Printer Media 60

Auto Log Settings… 60

File & Data Management 61-62

6.4 Performing Measurements – all users 63-69

Performing a Scan 63

Peforming a Baseline 63

Scanning the Sample 63-64

Analysing the Scan 64-65

Area Under Curve 65

Co-ordinate Tagging 66

Auto Peak & Valley Tagging 66-67

Obtaining Derivative Spectra 67

Overlaying Scans 68

Adding or Subtracting Spectra 69

SECTION 7 - Multi-Wavelength Mode

7.1 Principles of Measurement 70

7.2 Free Operation 70-75

Setting Method ID 71

Selecting Measurement Mode 72

Selecting Sample Style 72

Setting Method Security 72

Setting Wavelengths 73

Calculations 73

Sum 73-74

Setting Batch ID 74

Selecting Printer Media 74

Auto Log Settings... 75

7.3 Logged In Measurement 76-83

Creating a New Method 77

Setting Method ID 77

Selecting Measurement Mode 77

Selecting Sample Style 78

Setting Method Security 78

Setting Wavelengths 79

Calculations 79

Sum 79-80

Setting Batch ID 80

Selecting Printer Media 80

Auto Log Settings… 81

File & Data Management 82-83

7.4 Performing Measurements – all users 84

SECTION 8 - Kinetics Mode

8.1 Principles of Measurement 85

8.2 Free Operation 85-93

Setting Method ID 86

Setting Wavelength 87

Selecting Measurement Mode 87

Run Settings… 87-89

Page 22

4

Setting Run Time 88

Setting Lag Time 88

Setting Start On Level 88

Setting Start Level 89

Setting Method Security 89

Standard 89

Factor 90

Selecting Resolution 90

Selecting Units 90

Setting Auto-Scale 91

Selecting Axis Colour 91

Setting Batch ID 92

Setting Graph Data Points 92

Selecting Printer Media 92

Auto Log Settings… 93

8.3 Logged In Measurement 94-104

Creating a New Method 95

Setting Method ID 95

Setting Wavelength 95

Selecting Measurement Mode 96

Run Settings… 96-97

Setting Run Time 96

Setting Lag Time 97

Setting Start On Level 97

Setting Start Level 97

Setting Method Security 98

Setting Concentration Parameters 98-99

Standard 98

Factor 99

Selecting Resolution 99

Selecting Units 99

Setting Auto-Scale 100

Selecting Axis Colour 100

Setting Batch ID 101

Setting Graph Data Points 101

Selecting Printer Media 101

Auto Log Settings… 102

File & Data Management 103-104

8.4 Performing Measurements – all users 105

SECTION 9 - Quantitation Mode

9.1 Principles of Measurement 106

9.2 Free Operation 106-113

Setting method ID 107

Selecting Measurement Mode 108

Setting Wavelength 108

Selecting Resolution 108

Selecting Units 109

Replicates Setup… 109

Setting Method Security 109

Selecting Calibration Standards 110

Page 23

5

Setting Curve Fit 110

Setting Auto Scale 111

Selecting Plot Colour 111

Selecting Axis Colour 112

Setting Batch ID 112

Setting Graph Data Points 112

Selecting Printer Media 113

Auto Log Settings… 113

9.3 Logged In Measurement 114-123

Creating a New Method 115

Setting Method ID 115

Selecting Measurement Mode 115

Setting Wavelength 116

Selecting Resolution 116

Selecting Units 116

Replicates Setup… 117

Setting Method Security 117

Selecting Calibration Standards 118

Setting Curve Fit 118

Setting Auto Scale 119

Selecting Plot Colour 119

Selecting Axis Colour 120

Setting Batch ID 120

Setting Graph Data Points 120

Selecting Printer Media 121

Auto Log Settings… 121

File & Data Management 122-123

9.4 Performing Measurements – all users 124

Post Quantitation Tools 125

SECTION 10 - Fitting & Using Alternative Modules/Accessories

10.1 Integral Printer Unit 126

10.2 Cell Holder Modules 127

10.3 Automatic 8 & 6 Cell Changer Modules 128-132

10.4 Sipper Pump Module 133-139

10.5 Peltier Module 140-142

10.6 Sipper/Peltier Module 143-151

SECTION 11 - Maintenance & Troubleshooting

11.1 General 152

11.2 Light Source Replacement 152-155

Tungsten lamp – Model 6700 153

Flash lamp module – Models 6705/6715 154-155

SECTION 12 - Declaration of Conformity 156-158

Glossary of

Icons 159-161

Page 24

6

Page 25

7

Safety

This is important information; please read carefully before installing or using this instrument.

1. The 67 Series Spectrophotometers are designed for operation by trained personnel who are

aware of the principles and applications involved. For further help and advice please contact your local

distributor, e-mail sales@jenway.com or visit www.jenway.com

2. The spectrophotometer is a sensitive electronic and optical instrument designed for use in a

laboratory environment. Careful adherence to the installation instructions must be observed. If in doubt

contact a relevant and competent authority for advice before proceeding.

3. In addition to observing the instructions detailed in the Operating Manual and Service Manual for

this instrument all installation, operating and service personnel must be aware of, and employ, a safe

system of work.

4. Voltage levels hazardous to life are present in this instrument, for personal safety only trained

engineers aware of the risk and avoidance of electric shock should remove protective covers from the

instrument.

5. This instrument is designed for minimal maintenance, which must be carried out carefully following

the procedures detailed in this manual. All safety instructions in these procedures, as well as those

defined locally for the area or environment where the work is being carried out must be observed.

6. Other than for those items defined in the maintenance procedures herein there are no user

serviceable items in this instrument. Removal of covers and attempted adjustment or service by

unqualified personnel will invalidate any warranty and incur additional charges for repair.

7. Reference should always be made to the Health and Safety Data for any chemicals or reagents

used. All available information, advice and warnings on the handling, storage, use and disposal of

such must be carefully observed. When not available this data must be requested from the supplier

before proceeding in any way.

8. It is important that good laboratory practice is observed when handling samples, chemicals,

reagents and ancillary equipment in order to carry out measurement and analysis with this instrument.

Suitable safety and personal protective equipment must be used at all times.

9. If it is suspected that safety protection has been impaired in any way, the spectrophotometer must

be made inoperative and secured against any intended operation. The fault condition must be

reported to the appropriate servicing authority. In all such reports the model number and serial

number of the spectrophotometer must be quoted.

Page 26

8

Guarantee

Please read this important guarantee information:

Notwithstanding the description and specification(s) of the instruments contained in the Operating

Manual, Jenway hereby reserves the right to make changes as it sees fit to the instruments or to any

components of the instruments.

This Manual has been prepared solely for the convenience of Jenway customers and nothing in

this Manual shall be taken as a warranty, condition or representation concerning the description,

merchantability, fitness for purpose, or otherwise of the instruments or components.

The 67 Series spectrophotometers are guaranteed for a period of 3 years from the date of purchase.

Within this period we undertake to supply replacements free of charge for parts that may on

examination prove to be defective, provided that the defect is not the result of misuse, accident or

negligence.

On all correspondence, please quote the model and serial number in full and/or the sales order

number.

Any instrument requiring service under this guarantee should be taken to the supplier through whom

it was purchased, or, in the case of difficulty, it should be carefully packed in its original packaging and

consigned, carriage paid, to us. Jenway takes no responsibility for returned goods damaged in transit.

Returned goods will not be processed without a Returns Authorisation Number.

Call the Service Administrator +44 (0) 1785 810475 for the relevant documentation.

Please write the Returns Number on the outside of any packaging and ensure that a copy of a

Decontamination Certificate is visible.

Please register online www.jenway.com or complete and return the Registration Document by fax or

mail.

The Guarantee will be rendered invalid if any specified non-serviceable parts within the instrument are

tampered with (i.e. the monochromator).

Page 27

9

SECTION 1 - Introduction

1.1 INSTRUMENT DESCRIPTION

The 67 Series offer a range of unique features and functions to help in the management of methods

and data at both individual and multi-user levels.

These units have a specially designed user interface based on a high quality, colour TFT LCD with touch

screen technology and QWheel™ support to provide ease-of-use for all operations from set-up to

measurement and data handling.

Five main measuring modes are available: Photometrics, Spectrum, Kinetics, Quantitation and

Multi-Wavelength.

The 67 Series have dual memory options that enable you to store settings and data to either internal

memory or on a removable SD/Multi-Media memory card. By saving to the removable SD card all

settings, methods and results specific to the user can be retained by the individual, offering additional

security and allowing easy transfer of data to a PC for storage, manipulation or off-line review. The SD

card can also be used in any similar model, giving complete flexibility to use any available instrument.

A simple back-up procedure enables easy transfer of all information from the internal memory to the

removable media while quickly enabling a group of instruments to be cloned with identical settings.

It is possible for any user to perform simple measurements (Free Operation) at any time, however,

logging-in with your own PIN code will allow you to create methods, change settings or store results.

Each method can be designated as Public (for open user access), Read-Only (available for all users as

read-only information) or Personal (only accessed through your PIN code).

A number of sampling accessories are available as complete, easily interchangeable modules. These

include a Sipper Pump, Sipper/Peltier, Automatic Cell Changer, plus a comprehensive range of passive

cuvette and test tube holders, which can be fitted in the single cell holder accessory.

The PC Software supplied enables the transfer of data from the instrument or SD card to the PC with

rapid copy and paste into spreadsheets or other computer programmes.

QWheel is a registered trademark of Quantum Research

Page 28

10

1.2 INSTRUMENT SPECIFICATIONS

Technical Specification

6700 6705 6715

Light Source Tungsten Halogen Xenon Xenon

Spectral Bandwidth 4nm 4nm 1.5nm

Stray Light <0.1% at 340nm <0.05% at 220nm <0.05% at 220nm

Wavelength Range 320-1100nm 190-1100nm 190-1100nm

Common Specifications

Optics Sealed, MgF Coated, Split Beam

Wavelength Resolution 0.1nm

Wavelength Accuracy ±1.0nm

Wavelength Repeatability ±0.2nm

Photometric Ranges -0.300 to 3.000A & 0 to 199.9%T

Photometric Resolution 0.001A & 0.1%T

Photometric Accuracy ±0.005 at 1A

Photometric Stability <0.001A per hour

Quantitation Range -99999 to +99999

Number of Standards 20 with up to 5 replicates of each

Curve Fit Algorithms Linear, Quadratic and Cubic Functions

Multi-wavelength Data Points Up to 4 wavelengths

Calculations Difference and ratio

Kinetics Time Limits 30 to 9999 seconds

Kinetics Calibration Standard or factor

Scan Speed 1500nm/minute at 0.1nm data steps

Post Scan Analysis Peak/Valley pick, Peak Ratios, Area, Zoom, Wavelength Table,

Removable Media MM/SD Memory Card or SD/USB memory card

Interface USB, Centronics, Analogue

PC Software Supplied on CD-ROM with USB interface cable

Mains Supply 100 to 230V ac 50 or 60Hz

Sample Compartment 150mm (max. height) x 130mm (w) x 210mm (d)

Size 490x390x220mm

Weight 7.5Kg

Derivatives, Smoothing

Configuration Secure Multi-User and Free Access

Number of Users 10 + Supervisor

Number of Methods >500 (on internal flash memory or removable media)

Results Storage >500 (on internal flash memory or removable media)

Page 29

11

Environmental Operating Conditions:

The 67 Series is designed to work safely under the following conditions:

Temperature 15 to 40ºC

Humidity 0 to 90%RH

Accessory Specifications

Peltier

Temperature Range: 20 to 50° C or 68 to 122° F

Temperature Resolution: 0.1° C or 1° F

Accuracy: ±0.5° C

Stability: ±0.3° C

Red/Green Window: ±0.5° C

Sipper Pump

Modes:

Continuous Aspiration Flow rate dependent on tube ID.

(12ml/min with supplied tube)

Timed aspiration sample/air-gap/wash

sample volumes 75µl min / 9.5ml max.

segment run time 48 secs max.

Memory Non-volatile

1.3 GOOD PRACTICE GUIDELINES

1. For optimum performance all spectrophotometers should be sited in a clean, dry, dust free

atmosphere. When in use ambient temperature and light levels should remain as constant as possible.

2. Adherence to Standard Operating Procedures (SOP) and Good Laboratory Practice (GLP) should be

monitored with regular calibration checks and a suitable Quality Control (QC) programme.

3. The sample chamber lid must be fully closed during measurement and before any readings are

recorded or printed.

4. The correct selection of sample containers is imperative for accurate and reproducible results:

a) Check that the material of the sample container is compatible with the wavelengths to be used

for measurement. In general glass can only be used down to 360nm or 320nm depending on quality.

Standard plastic cuvettes can be used down to 320nm. Special UV versions can be used down to

260nm. Below this level quartz cuvettes must be used.

b) Plastic disposable cuvettes should be used ONCE only.

c) Glass cuvettes should be thoroughly cleaned after use. Discard when scratches become evident in

optical surfaces.

d) Care should be taken when selecting semi-micro or micro cuvettes. The cuvette window on the

inner chamber (the area filled with sample) must be wider than the aperture in the sample holder or

light will reach the detector without passing through the sample. In this case, semi-micro or micro

cuvettes with self-screening black surrounds must be used or alternative holders for these cuvettes

fitted.

e) Glass test tubes and other sample tubes should be used with care. Where possible, matched tubes

should be used and any index mark set to the correct position before measurements are made.

f) Ensure any sample containers used are compatible with the constituents of both the samples and

standards they are to hold. Plastic cuvettes are not compatible with organic solvents.

Page 30

12

g) All sample containers must be handled with care; by the top and non-optical surfaces only. Any

finger marks evident must be removed using a suitable cleaning process.

h) Flow-through cuvettes must be selected with care and consideration for the sample type, sample

volume, pumping system, rinse, sample and waste handling to be used.

5. Samples and standards should not be stored in open cuvettes or sample containers as evaporation

will change the value and lead to staining of the walls which may be irreversible. If stored in stoppered

and sealed cuvettes, they should be filled with little or no air space and the values regularly checked

against a reference standard or quality control material.

6. Cold samples should be allowed to equilibrate to ambient temperature before measurement (unless

a suitable temperature controlled sample holder is in use). Temperature change during measurement

may cause air bubbles to form on the walls of the sample holder. This is a common cause of drift

during measurement.

7. In the preparation of samples and standards high grade borosilicate glass and AR grade chemicals

and reagents must be used. Good quality deionised water or other suitable solvent must be used for

dissolving or diluting samples, chemicals and reagents.

8. All measurements require calibration to a blank, for maximum accuracy this should be prepared

with care using the same deionised water or solvent used for dissolving or diluting the sample. Where

reagents are added to the sample to produce a colour proportional to its concentration a ‘sample

based’ blank should be used. In this case the blank should consist of the sample plus any reagents or

chemicals to be used, except those that produce the colour to be measured.

9. Deviations from the Beer-Lambert Law may occur at high and low concentrations giving non-linear

response during sample concentration measurements. For all new methods a linear range should be

defined by the preparation of a calibration curve. The quantitation mode may be used to construct

such a curve against which sample results are automatically measured.

10. Cuvettes and sample holders must be filled to a minimum level which covers the light path.

Page 31

13

SECTION 2 - Getting Started

2.1 UNPACKING INSTRUCTIONS

•

Refer to label 1 on carton exterior and

ensure instrument type and options/

accessories supplied are correct. Refer to

Distributor in the event of any discrepancy.

•

Check each item as it is removed from

the packaging to ensure it is correct and

undamaged. Refer to Distributor if any item is

missing or damaged.

•

Remove Documentation carton 2. Note

that this contains the Instruction Manual and

other important documents, which MUST

be retained for future reference. Other small

items (CD ROM, SD Card etc) will also be

found inside this carton.

•

Please take some time to familiarise yourself

with the contents of the Instruction Manual

before using the instrument for the first time.

•

Remove the cardboard packing piece 3 and

place to one side.

•

Remove the two foam packing pieces 4 and

place these to one side.

•

Grasp the instrument 5 (which will be sealed

in a polythene bag) firmly at each end, and lift

out of the carton to place on an adjacent flat,

firm and clean surface.

The instrument weighs approximately 10 Kgs.

PLEASE TAKE CARE WHEN LIFTING.

•

Remove the Accessory carton 6. Note that

this contains the Power and USB cables

together with any sample cells or other items

that may have been ordered. Refer to the

Instruction Manual to ensure accessories are

installed correctly before using the instrument

for the first time.

Disposal of Packaging

It is recommended that the Instrument packaging be retained for possible future long-term

storage or transportation. Please note that the Manufacturer or Distributor cannot be held

responsible for any damage incurred as a result of transportation of an inadequately packed

instrument.

2

3

4

5

6

1

Page 32

14

If you wish to dispose of the instrument packaging, please do so in an environmentally

responsible manner. Please refer to the following guidelines: -

Cardboard packing items are made from paper sourced from recycled fibres

or managed forests and can be 100% recycled where appropriate facilities

exist. Ensure cartons are crushed or flattened before disposal.

Foam packing pieces are manufactured with a reprocessed polyethylene content and can be

easily recycled with other low-density polyethylene (LDPE) materials. Polyethylene foam is

manufactured by a CFC and HCFC free process and contains less than 100ppm heavy metal

content. The European Union Packaging Directive confirms that recovery by means of wasteto-energy is a sensible waste management alternative. The Polyethylene foam burns cleanly

and contributes a high calorific value.

2.2 INSTALLATION

2.2.1 LOCATION

In ideal circumstances the installation environment will be clean, dry and dust free with the instrument

protected from extreme variations in ambient lighting and temperature change. Ensure the unit is

positioned so that the mains on/off switch is accessible. If a safety problem should be encountered,

switch off at the mains socket and remove the plug from the supply.

Where conditions are less than ideal, maintenance and cleaning must be carried out regularly and

additional protection offered where possible.

The optional dust cover should be used to protect the instrument when not in use.

2.2.2 SUPPLY VOLTAGE

The 67 series spectrophotometers are powered by a universal switch-mode power supply that operates

from a 90-264Vac mains supply. The correct lead for your supply should be selected.

2.2.3 MAINS CONNECTIONS

The leads supplied have a moulded on plug. However, if this is removed for any reason the wires in the

mains lead are colour coded to conform to the internationally recognised standard such that:

UK CONNECTIONS US CONNECTIONS

Brown Live Black Live

Blue Neutral White Neutral

Green/Yellow Earth Green Earth

Safety

When disposing of any removed plug the connectors must be removed or made incapable of

insertion into a mains socket.

Page 33

15

2.2.4 TOUCH SCREEN FUNCTIONS

1. Standby – this key can be used to enter the standby mode during operation.

2. Instrument Settings – this key can be used to access instrument set up parameters

including user creation, PIN codes, language options, date and time settings, administrative

functions and instrument identification details.

3. Back key – this is used to return to a previous menu level.

4. Save key – pressing this key saves methods and/or data. If an external card is not fitted

then methods/data will automatically be saved to internal memory. If an SD card is inserted

or removed during operation relevant messages and options are given to select the desired

media.

5. Toolbar key – this key is only functional on the completion of measurements and

gives access to the available data manipulation options. The function of this key is context

sensitive, enabling different sets of tools depending on the mode of operation in use.

6. Printer key – this key will initiate a print out to either the internal or external printer unit

via the selected settings options in each mode of operation.

1

2

3

6

5

4

Page 34

16

2.2.5 TOOLBAR ICONS

The spectrophotometer can be used for making measurements at any time without the need for

logging in; but many benefits will be lost and results cannot be saved, only printed.

The Method Screen options will only be displayed if the user logs in. If the user is not logged in the

instrument will automatically display the main measurement screen, with settings at their last used levels.

Method Screens

Methods are stored sequentially by measurement mode. Once the first page is full (8 methods for the

selected mode) cursor arrows are displayed enabling the user to browse to subsequent or previous

pages of 8 methods.

Alternatively, pressing one of the alphanumeric keys along the bottom of the screen will display all

available methods with the initial character that is highlighted.

Note: Repeated pressing of a key sequentially highlights the characters between those displayed.

Create a New Method

For the following functions first touch a method or result to select it.

Open the Selected Method

Erase the Selected Method/Result

Browse Results – linked to the selected method

Open specific results in the selected batch

Page 35

17

Photometrics Mode

Mode settings – method name, wavelength, method security (if logged in)

Accessory options – varies with type of accessory module fitted

Allows selection of internal or external printer

Allows set-up of batch ID and the Auto Log options

Press to accept settings entered

Spectrum Mode

Mode settings – method name, measurement mode, wavelength range, plot interval,

method security (if logged in)

Analysis Points – up to 30 wavelengths at which absorbance will be reported

Measurement display – auto scaling, axis setting and colour selection

Accessory options – varies with type of accessory module fitted

Allows selection of internal or external printer, graph details, batch ID and enables or disables

the Auto Log feature

Press to accept settings entered

Page 36

18

Multi-Wavelength Mode

Mode settings – method name, measurement type, reading type, sample style, method

security (if logged in)

Setting wavelengths – allows from 2 to 4 wavelengths to be set

Calculations - allows the selection of calculations and constants

Accessory options – varies with type of accessory module fitted

Allows selection of internal or external printer, graph details, batch ID and the Auto Log

options

Press to accept settings entered

Page 37

19

Kinetics Mode

Mode settings - method name, wavelength, measurement mode, run settings, method

security (if logged in)

Calibration – allows setting of Concentration cal standard, factor, resolution and units of

measurement

Measurement display – allows auto scaling, axis setting and colour selection

Accessory options – varies with type of accessory module fitted

Allows selection of internal or external printer, graph details, batch ID and the Auto Log

options

Press to accept settings entered

Page 38

20

Quantitation Mode

Mode settings – method name, measurement mode, wavelength, resolution, units of

measurement, replicates set up, method security (if logged in)

Calibration – allows the number and levels of standards to be set

Measurement display – allows selection of type of curve fit, auto scaling, axis setting and

colour selection

Accessory options – varies with type of accessory module fitted

Allows selection of internal or external printer, graph details, batch ID and the Auto Log

options

Press to accept settings entered

Status Bar

To view the set parameters in any of the measurement modes press the status bar once and a drop

down menu will appear. Pressing this bar again will return it to its original status.

Page 39

21

2.2.6 REAR PANEL LAYOUT

Power Switch On/Off switch for the unit.

Power In Socket IEC type connection socket for the mains supply cable.

Printer Socket 25 way Centronics parallel output socket compatible with Postscript printers.

Analogue Output 2 x 4mm pin sockets for analogue devices.

USB Socket type B connector for communication to PC.

SD Card Socket will accept 128MB to 2GB SD or Multi-media memory cards.

Printer socket

USB SocketAnalogue O/P SD Card Socket

Power

switch

Power in socket

Page 40

22

2.2.7 POWER ON AND SELF-TESTS

response

Dark test… Checks detector and light seal on sample chamber

Wavelength calibration… Performs a wavelength calibration

followed by the Main Menu Screen:

This screen gives you access to the five operating modes that can be used directly for making

measurements without logging in. It should be noted that if the user is not logged in results can

only be viewed and printed but not stored. In addition, methods cannot be created or retrieved.

Note: For the Model 6700 allow 30 minutes warm up prior to use.

For all models the LCD display may take up to 10 minutes to reach full brightness.

Connect the mains supply cable to the rear panel mains input socket and plug the other end into a

suitable mains supply socket.

Lift the sample chamber lid on the instrument and ensure that there is no sample or other item present

in the sample holder, close the lid.

Switch on the supply socket, then the instrument, using the Power switch located on the rear panel.

The instrument will then perform the power on self-test protocol. The power on and self-test screens

will be shown:

System test… Checks internal connections / Checks internal and external memory status

Accessory test… Checks for fitted ‘active’ accessories / Verifies communication and

Page 41

23

SECTION 3 - Systems of Operation

3.1 MULTI-USER AND FREE OPERATION

The 67 Series spectrophotometers focus on secure, multi-user operation. But to ensure that anyone

can acquire quality results in an emergency or when otherwise required (stat or free operation), they

may also be used without the operator having to log in. Such free operation is restricted to making

measurements with no access to methods while results will only be displayed or printed.

Secure, multi-user operation requires each designated user to enter a PIN code to access methods

and results. When creating methods a user can opt to share them with other users, as Public (can

be modified) or Read-Only (can be used but not modified), or to keep them Personal. Up to 10

users and a Supervisor with administrative rights can be set up on each instrument but by using the

removable media (see below) an almost infinite number of users can be securely accommodated.

3.2 MEMORY STRUCTURE

The 67 Series spectrophotometers have a dual memory structure based on removable media and

fixed internal memory. The removable media is based on SD memory cards with a wide range of

capacities available.

The following table gives details of the removable media available (subject to change by manufacturers

range consolidation):

Card Capacity

2 GB

3.2.1

MEMORY SELECTION

When the power is turned on the internal memory is selected as the default memory location, even

if a removable memory card is fitted in the instrument. If the user inserts a removable media memory

card during use a message will be displayed giving the user the option to switch the default memory

location to the removable media memory card so that any methods and results that are saved are sent

to this card. Should the card be removed during use a warning message will be displayed and the

internal memory will then be set as the default location.

SD Card Part Number

019 133

Page 42

24

3.2.2 MEMORY HIERARCHY

The top level of the memory hierarchy is the user, defined by a user name and recognised by their

unique PIN code. In general it is considered that this will be an individual but in practice this can

be made more flexible by considering the user as a group sharing the same PIN code. For instance

different departments or shifts could be identified by their own PIN codes.

Different types of tests could also be separated by PIN codes with only users trained in carrying out

specific tests given the relevant PIN codes to access the tests for which they have been trained. In

education a PIN code for each semester or part of the curriculum would restrict students or year

groups access to only the current work, protecting that to be used in the future. The implementation

and benefits of this function are only limited by the imagination.

Below the user level are the Methods created by that user or for that group, and those with Public or

Read-Only status that all users can access, below each method are the results stored by the user for

THAT METHOD.

3.3 CREATING METHODS

The ability to create and re-call methods is only available to logged in users.

To log in touch the Log In… key on the bottom right-hand side of the Main Menu screen that is

displayed after completion of the start-up tests.

A table of users is then displayed, touching your name (department, user group or other identifier)

then brings up a numeric entry screen for inputting the four digits of the relevant PIN code.

For first time use the only user in the table will be the Supervisor with a default PIN Code of 1234

(once logged in this can subsequently be changed to a number combination of the Supervisor’s

choice).

By pressing the Settings key on the display surround and selecting the Administrative Functions

option the Supervisor can create new users. On creation a new user has a default PIN Code of 0000

that, like the Supervisor’s, can be changed by selecting User Preferences, then Adjust PIN Code.

NOTE: Once the Supervisor’s PIN CODE is changed it must be kept safe as there is no other way of

accessing this function – however the Supervisor does have the right to re-set other users’ PIN Codes

back to the default.

For further information on these functions see the Section on Instrument Settings and

Administrative Functions.

Read-Only

Methods

User defined

by PIN Code

Public

Methods

Methods

Created by User

Results appended

to user accessible

methods

Page 43

25

When successfully logged in the user is returned to the main menu screen from which the required

mode of measurement can be selected.

The Browse screen is then displayed from which an existing method can be re-called using the

alphanumeric search keys along the bottom menu bar. If insufficient methods have been created to fill

the first page all available methods will be shown.

3.4 FILE & DATA MANAGEMENT

Save Tools Print Settings Erase Search Open Save

Results Results

Saving Methods

Having entered all your required settings on the tabbed pages the method can be saved by simply

pressing the Save key on the display surround. If you do not save at this point but continue to make

measurements using the method, it will automatically be saved when you save the first result.

If you continue without saving a result you will be prompted to save the method as you exit the

operating mode or return to the settings options. Alternatively, when the Auto Log option is set to

On or Timed and the destination option is Memory all results will be saved automatically.

Sharing Methods

Methods can be shared with other users by setting the security level at either Read-Only where other

users can use but not modify the method or, Public where they can use and modify the method.

Other users must then ensure that under Method View Settings (Settings/User Preferences/Method

View Settings) they have enabled Public and/or Read-Only methods or turned All Methods on.

Recalling Methods

Following selection of the operating mode from the main menu the method browse screen is

displayed. This will show all methods that the current user has access to, based on their selections in

the Method View Settings (refer to Sharing Methods). If the first page is full, cursor arrows will be

displayed to enable navigation to and from additional pages.

Alternatively, selection may be made using the alphanumeric menu bar at the bottom of the screen.

Repeated pressing of each character set will display the full alphanumeric range and the screen will

show all methods starting with the highlighted character.

Touch the required method when it is displayed on the screen to highlight it, touch the Open File icon

to display the main measurement screen for that method.

Editing Methods

Use the Recalling Methods procedure to recall the required method. With the measurement screen

displayed touch the Settings option. Adjust the settings as required and touch the Enter icon

on completion. The modified method can then be saved by pressing the Save key on the display

surround. If you do not save at this point but continue to make measurements using the method, it

will automatically be saved when you save the first result. If you continue without saving a result you

will be prompted to save the method as you exit the operating mode or return to the settings options.

Note: If the Method name was not changed during editing it will be saved with the same name but

with a new date and time to ensure traceability. If the old method is no longer required it should be

deleted as detailed in Deleting Methods.

Page 44

26

Deleting Methods

To delete methods highlight the required method in the Browse screen as described in Recalling Methods and

then touch the Erase icon.

A warning message will be displayed to ensure this action is required. On confirmation the selected file will be

deleted.

If the current user does not have the required privileges to delete the selected method then an information

message will be displayed advising that the method cannot be deleted.

Privileges required for deleting designated methods:

Public Methods – only the Supervisor and Originator can delete these.

Read-Only Methods – only the Supervisor and Originator can delete these.

Personal Methods – Only the Originator can delete these methods. (The Supervisor can delete these by re-

setting the Originator’s PIN code and then logging in as the Originator).

Saving Results

After completion of a measurement the result can be saved by simply pressing the Save key on the display

surround. The result is saved under the method that created it, with the entered Batch ID and an incremental

number along with the time and date of the measurement. Results can also be saved as part of the Auto Log

function by selecting Memory under the Auto Log option, which will vary depending on the type of sampling

accessory fitted.

Printing Results

After completion of a measurement the result can be printed, by simply pressing the Print key on the display

surround. The result will be printed to either the internal or external printer, as selected by the user in the Printer

Settings option.

The first result of any new batch is preceded by a print header, which gives details of the method settings and

Batch ID. Results can also be printed as part of the Auto Log function, which will vary depending on the type of

sampling accessory fitted.

Recalling Results

Stored results are always directly linked to the method that created them. To access results first recall the method

as described in Recalling Methods. With the method highlighted touch the Search Results icon. This will open

a screen detailing all results available to the current user. Touch the required result or batch (depending on the

mode) and then the Open Specific Result icon. This will display the results on the screen. The Tools option

can then be used to work on these results (depending on mode). It is also possible to print the result by simply

pressing the Print key on the display surround. Options to print to the Internal or External printer or to the CSV

file will be displayed. Printing to the CSV (Comma Separated Values) file will save the data in CSV format on the

external data card. (If a card is not fitted the instrument will display a prompt). This is in text format and can be

viewed and printed in Excel

®

.

In Kinetics mode an additional option is available (Analogue Mode). This allows results to be output via the rear

panel analogue sockets to a chart recorder or similar device.

Sharing Results

Results attached to Personal Methods cannot be accessed by any other user.

Results attached to Read-Only and Public Methods can be accessed by all users, based on their current

Method View Settings.

Page 45

27

SECTION 4 - Instrument Settings

4.1 MENU OPTIONS

A number of settings can be stored for each signed in user including language, method view settings,

display brightness and time/date display choices so that these do not have to be reset each time a new

user logs in. These can be found under User Preferences.

Note: Administration Functions and Memory Manager options will be greyed out and unavailable

unless the Supervisor has logged in.

– When switching on the product for the first time, or if the previously entered settings

need to be checked, this key should be selected to give access to the following display:

4.2 SET TIME & DATE

To set the correct date and time select the Set Time & Date key. The time and date can be reset using

the up and down arrows. To accept the new settings select the Enter key. Touching the Cancel key

will return you to the main menu without accepting any alterations to the current settings.

4.3 USER PREFERENCES

Selecting User Preferences gives access to the following options:

These settings are saved for each user and the individual’s selections are retained when that user logs

in. Adjust User PIN and Method View Settings options are only available to the Supervisor.

Note: Adjust User PIN and Method View Settings will only be available to the Supervisor.

Page 46

28

4.3.1 ADJUST USER PIN – available to logged in users only

To alter your User PIN select the Adjust User PIN key. A warning message will be shown prior to the

numeric keypad. Enter your new 4 digit code using the numeric keypad as shown below. The Del key

allows individual digits to be changed. The Cancel key will return you to the previous menu without

altering the original PIN code. The Clear key will clear all digits entered from the screen. The Enter key

accepts the new code and returns you to the previous menu.

4.3.2 LANGUAGE

The preferred language can be selected using the Language key. Select the preferred language from

the options available and press the OK key and the will update to show all screens in English, French,

German, Italian or Spanish.

4.3.3 METHOD VIEW SETTINGS – available to logged in users only

To simplify operation it is possible to restrict the methods displayed by their allocated category.

Selecting Method View Settings enables My Methods (Personal) to be hidden (Off) or displayed

(On). Similarly, Read Only Methods and Public Methods can be hidden or displayed. To simply

display all method categories toggle All Methods to the On status.

Please ensure you remember

your PIN code or store it in a

secure location, or access to

your personal data will

be lost.

OK

Page 47

29

4.3.4 TOUCH SCREEN CLICK

The touch screen can be operated with or without an audible click each time a key is touched. The

click can be toggled on or off via the Touch Screen Audible Click: Off key.

4.3.5 BRIGHTNESS

Selecting the Brightness key and then using the left and right arrows on the display shown below can

adjust the brightness of the display. Selecting the Enter key will update the display setting and return

the instrument to the previous display.

4.3.6 ADJUST DATE & TIME

Selecting the Date & Time Preferences key allows the user to display either the time or date. In

addition the date format can be set to either DD/MM/YY or MM/DD/YY. Once the preferred option

is selected, pressing the Back key on the display surround once will return you to the previous menu.

Pressing the Back key twice returns the instrument to the Main Menu.

Page 48

30

4.4 ABOUT

Selecting the About key provides information relating to instrument ID and signed in user details.

Selecting the OK key returns the instrument to the previous menu.

4.5 FORM FEED

Selecting the Form Feed key will feed additional paper through the mechanism of the connected

printer to separate results or enable a clean area for tearing off.

4.6 ADMINISTRATION FUNCTIONS

This function is only available to the Supervisor. It gives access to all user related information. It gives

access to Instrument ID, screen dump control and Modify Users sub-menu.

Page 49

31

4.6.1 INSTRUMENT ID

Selecting the Instrument Id: 67XXCVS key allows the supervisor to alter the instrument identification

code. This is entered by use of the alphanumeric keypad. The Cancel key will return you to the

previous menu without altering the original ID. The Del key allows individual letters or digits to

be removed. The Clear key will clear all digits entered from the screen. The Enter key accepts

the new ID and returns you to the previous menu. For laboratories with more than one 67 series

spectrophotometer it is useful to change this ID to the serial number, department or other unique

identifier for easy recognition of different instruments.

4.6.2 SCREEN DUMP

The screen dump function can be enabled or disabled.

4.6.3 MODIFY USERS

This gives access to the sub-menu which allows the supervisor to modify user parameters.

Page 50

32

4.6.3.1 CREATE NEW USER

Selecting the Create New User key allows the supervisor to enter an additional user on to the

instrument using the alphanumeric keypad as shown. The Clear key will clear all information entered

from the screen. The Del key allows individual letters or digits to be removed. The Cancel key will

return you to the previous menu without adding a new user. The Enter key accepts the new ID and

returns you to the previous menu.

4.6.3.2 DELETE USER

Selecting the Delete User option allows the supervisor to delete a specific user from the instrument.

When the user name is selected from the list the following warning message is displayed:

If Yes is selected the instrument will update and the user will be removed from the instrument.

If Cancel is selected the user will not be deleted from the instrument.

4.6.3.3 DELETE ALL USERS

Selecting this option allows the supervisor to delete all current users (except the supervisor) from the

instrument. The following warning message is displayed:

If Yes is selected the instrument will update and all users will be removed from the instrument.

If Cancel is selected all users will remain on the instrument.

6715 CVS

All users will be permanently

deleted from the instrument.

Are you sure you wish to

continue?

Yes Cancel

6715 CVS

This user will be permanently

deleted from the instrument.

Are you sure you wish to

continue?

Yes Cancel

Page 51

33

4.6.3.4 RESET USER PIN

This option allows the supervisor to reset an individual users PIN code.

Select the Reset User PIN option from the screen. The list of current users will then be displayed on

screen. Select the user. The warning message: ‘Are you sure you wish to continue’ will be displayed

with the options to accept or cancel.

If Yes is selected the user PIN will be reset to the default value and the supervisor has access to all

information relating to that user.

If Cancel is selected no changes will be made to the user codes and the instrument will return to the

Select User Menu.

4.7 MEMORY MANAGER

This option is available only to the Supervisor and allows transfer of data, methods and user

preferences to and from the instrument memory. This enables backup of information stored in the

instrument memory and on any removable media used. Both memory locations can also be formatted.

WARNING – this will permanently delete all information stored in the location being

formatted.

Page 52

34

SECTION 5 - Photometrics Mode

5.1 PRINCIPLES OF MEASUREMENT

The simplest mode of the spectrophotometer is Photometrics. A measurement is made of either the

absorbance or transmittance of a sample. The measurement is at a single wavelength, at one point in

time, with no additional calculations.

Select Photometrics from the Main Menu:

If the user is not logged in (Free Operation) the main measurement screen will be displayed (refer

Section 5.2).

5.2 FREE OPERATION

Settings

If the user is not logged in then the screen will show the following message when the Photometrics

Mode key is selected from the Main Menu:

If Yes is selected the instrument will go to the main measurement screen.

If No is selected the instrument will return to the main menu where the user has the option to Log In.

As you are not logged in

you will not be able to save

results. Are you sure you

want to continue?

Yes No

Page 53

35

To enter the appropriate parameters for the sample(s) to be tested select the Settings key and the

instrument will display the following screen:

Mode settings - method ID, wavelength, method security (if logged in)

Accessory options - varies with type of accessory module fitted

Allows selection of internal or external printers

Allows set-up of batch ID and enables or disables or disables the Auto Save feature

Press to accept settings entered

Setting Method ID

To allocate a Method name select the Method key and enter the preferred name using the

alphanumeric keypad. The Clear key will clear all information entered from the screen. The Del key

allows individual letters or digits to be removed. The Cancel key will return you to the previous menu

and the method name will remain as Default Method. The Enter key accepts the new method ID and

returns you to the previous menu.

Note: The new Method ID can only be used to identify the method on a printout to the internal or

external printer module. The generic user has no additional facility to store or recall results or methods.

Page 54

36

Setting Wavelength

Select the Wavelength key and enter the wavelength using the numeric keypad. The Clear key will

clear all information entered from the screen. The Del key allows individual digits to be removed. The

Cancel key will return you to the previous menu and the wavelength will not alter. The Enter key

accepts the new wavelength and returns you to the previous menu. (At certain wavelengths order

selecting filters may be heard switching in or out). Select the Enter key to confirm and the display will

update to show the new wavelength.

Using the Back key to escape settings will

display:

If Yes is selected all set information will be

lost and the instrument will return to the main

measurement screen.

If No is selected the instrument returns the

Settings screen as shown.

To accept all entered information touch the Enter key to confirm. The instrument will show the main

measurement screen with the updated information.

Setting Method Security

This option is only applicable to logged in users.

Batch ID and Auto Logging can be entered via the Save icon.

Setting Batch ID

Select the Batch ID key and enter the Batch code using the alphanumeric keypad. Select the Enter

key to accept or Cancel to remain as a default.

6715 CVS

Continue? , if so you will

lose any changes you have

made.

Yes Cancel

Page 55

37

Auto Log Settings…

Selecting Auto Log Settings… opens a dedicated sub-menu.

This option can be toggled between On, Off or Timed.

Auto Log Settings

This option can be toggled between Off/On/Timed. When Auto Log option is selected to On the

user can set:

the destination, (toggles between internal or external printer and memory).

When the Auto Log option is set to Timed the user can set:

the timed interval between 3 and 9999 seconds using the numeric keypad;

the destination (toggles between internal or external printer and memory);

the number of repetitions from 2 to 999 using the numeric keypad.

To view the set parameters touch the status bar once and a drop down menu will appear giving this

detail. Touching the bar again will return it to its original position.

Note: If the Auto Log Timed option is selected the Read key will be replaced with Start/Stop keys.

Page 56

38

5.3 LOGGED IN MEASUREMENT

PIN Codes – each user is allocated a 4 digit PIN code that is required when logging in.

Select Log In… from the Main Menu and a list of users will be shown. Select the appropriate user

name and a numeric keypad will be displayed.

Enter your 4 digit PIN code and touch the Enter key to confirm.

Once logged in method screen options will be displayed:

Methods are stored sequentially by measurement mode. Once the first page is full (8 methods for

the selected mode) cursor arrows are displayed in the top corners enabling the user to browse to

subsequent or previous pages of 8 methods.

Alternatively, pressing one of the alphanumeric keys along the bottom of the screen will display all

available methods with the initial character that is highlighted.

Note: Repeated pressing of a key sequentially highlights the characters between those displayed.

Create a New Method

For the following functions first touch a method or result to select it.

Open the Selected Method

Erase the Selected Method

Browse Results – linked to the selected method

Open specific results in the selected batch

Page 57

39

Creating a New Method

Settings

To enter the Method ID, appropriate wavelength for the sample(s) to be tested and the level of Method

Security required for the method being created select the New File icon

Setting Method ID

To allocate a Method name select the Method key and enter the preferred name using the

alphanumeric keypad. The Clear key will clear all information entered from the screen. The Del key

allows individual letters or digits to be removed. The Cancel key will return you to the previous menu

and the method name will remain as Default Method. The Enter key accepts the new method ID and

returns you to the previous menu.

Setting Wavelength

Select the Wavelength key and enter the wavelength using the numeric keypad. The Clear key will

clear all information entered from the screen. The Del key allows individual digits to be removed. The

Cancel key will return you to the previous menu and the wavelength will not alter. The Enter key

accepts the new wavelength and returns you to the previous menu. (At certain wavelengths order

selecting filters may be heard switching in or out). Select the Enter key to confirm and the display will

update to show the new wavelength.

Using the Back key to escape settings will display:

If Yes is selected all set information will be

lost and the instrument will return to the main

measurement screen. If No is selected the

instrument returns the Settings screen as shown.

6715 CVS

Continue? , if so you will

lose any changes you have

made.

Yes Cancel

Page 58

40

Setting Method Security

The 67 Series spectrophotometers can support up to 10 individual users plus one Supervisor who has

full administrative rights.

Logged in users can create methods with three levels of security options:

Personal – these methods are only accessible by the originator.

Public – these methods are available for use and modification by any logged in user.

Read-Only – these methods can be accessed by all logged in users, but can only be modified by the

originator.

The preferred level of protection can be achieved by selecting the Method Security key that toggles

between Personal, Public and Read-Only options.

To accept the selected options touch the Enter key to confirm. The instrument will show the main

measurement screen with the updated information.

Setting Batch ID

Select the Batch ID key and enter the batch code using the alphanumeric keypad. Select Enter to

accept or Cancel to remain as a default.

Page 59

41

Auto Log Settings…

Selecting Auto Log Settings… opens a dedicated sub-menu.

This option can be toggled between On, Off or Timed.

Auto Log Settings

This option can be toggled between Off/On/Timed. When Auto Log option is selected to On the

user can set:

the destination, (toggles between internal or external printer and memory).

When the Auto Log option is set to Timed the user can set:

the timed interval between 3 and 9999 seconds using the numeric keypad;

the destination (toggles between internal or external printer and memory);

the number of repetitions from 2 to 999 using the numeric keypad.

To view the set parameters touch the status bar once and a drop down menu will appear giving this

detail. Touching the bar again will return it to its original position.

Note: If the Auto Log Timed option is selected the Read key will be replaced with Start/Stop keys.

Page 60

42

File & Data Management

Save Tools Print Settings Erase Search Open Save

Results Results

Saving Methods

Having entered all your required settings on the tabbed pages the method can be saved by simply

pressing the Save key on the display surround. If you do not save at this point but continue to make

measurements using the method, it will automatically be saved when you save the first result.

If you continue without saving a result you will be prompted to save the method as you exit the

operating mode or return to the settings options. Alternatively, when the Auto Log option is set to

On or Timed and the destination option is Memory, all results will be saved automatically.

Sharing Methods

Methods can be shared with other users by setting the security level at either Read-Only where other

users can use but not modify the method or, Public where they can use and modify the method.

Other users must then ensure that under Method View Settings (Settings/User Preferences/Method

View Settings) they have enabled Public and/or Read-Only methods or turned All Methods on.

Recalling Methods

Following selection of the operating mode from the main menu the method browse screen is

displayed. This will show all methods that the current user has access to, based on their selections in

the Method View Settings (refer to Sharing Methods). If the first page is full, cursor arrows will be

displayed to enable navigation to and from additional pages. Alternatively, selection may be made

using the alphanumeric menu bar at the bottom of the screen.

Repeated pressing of each character set will display the full alphanumeric range and the screen will

show all methods starting with the highlighted character.

Touch the required method when it is displayed on the screen to highlight it, touch the Open File icon

to display the main measurement screen for that method.

Editing Methods

Use the Recalling Methods procedure to recall the required method. With the measurement screen

displayed touch the Settings option. Adjust the settings as required and touch the Enter icon

on completion. The modified method can then be saved by pressing the Save key on the display

surround. If you do not save at this point but continue to make measurements using the method, it

will automatically be saved when you save the first result. If you continue without saving a result you

will be prompted to save the method as you exit the operating mode or return to the settings options.

Note: If the Method name was not changed during editing it will be saved with the same name but