Page 1

Memory Craft 15000

InstructIon Manual

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the

following:

This sewing machine is designed and manufactured for household use only.

Read all instructions before using this sewing machine.

To reduce the risk of electric shock:

DANGER

1. An appliance should never be left unattended when plugged in. Always unplug this sewing

machine from the electric outlet immediately after using and before cleaning.

WARNING

1. Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used

by or near children.

2. Use this appliance only for its intended use as described in this owner’s manual.

Use only attachments recommended by the manufacturer as contained in this owner’s manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if

it has been dropped or damaged, or dropped into water.

Return this sewing machine to the nearest authorized dealer or service center for examination,

repair, electrical or mechanical adjustment.

4. Never operate the appliance with any air opening blocked. Keep ventilation openings of this

sewing machine and foot controller free from accumulation of lint, dust and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

8. To disconnect, turn all controls to the off (“O”) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing machine

needle and/or cutting blade.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch this sewing machine off (“O”) when making any adjustment in the needle area, such as

threading the needle, changing the needle, threading the bobbin or changing the presser foot, and

the like.

15. Always unplug this sewing machine from the electrical outlet when removing covers, lubricating, or

when making any other adjustments mentioned in this owner’s manual.

—

—

To reduce the risk of burns, fire, electric shock, or injury to persons:

SA VE THESE INSTRUCTIONS

For Europe only:

This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been given

supervision or instruction concerning use of the appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance. Cleaning and user maintenance shall not be made

by children without supervision.

For outside Europe (except U.S.A and Canada):

This appliance is not intended for use by persons (including children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

Please note that on disposal, this product must be safely recycled in accordance with relevant

National legislation relating to electrical/electronic products. If in doubt please contact your

retailer for guidance. (European Union only)

Page 3

FCC Caution

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

–Reorient or relocate the receiving antenna.

–Increase the separation between the equipment and receiver.

–Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

–Consult the dealer or an experienced radio/TV technician for help.

This transmitter must not be co-located or operated in conjunction with any other antenna or transmitter.

IC (Industry Canada) Notice

This device complies with Industry Canada licence-exempt RSS standard(s).

Operation is subject to the following two conditions:

(1) this device may not cause interference, and (2) this device must accept any interference, including interference that

may cause undesired operation of the device.

Directive 1999/5/EC

Hereby, Janome Sewing Machine Co., Ltd., declares that this MC15000 is in compliance with the essential

requirements and other relevant provisions of Directive 1999/5/EC.

Page 4

TABLE OF COTENTS

GETTING READY TO SEW

Names of Parts ....................................................................... 1-2

Standard Accessories ............................................................. 3-4

Thread Cutter Switch .............................................................. 5-6

Placing the thread cutter switch to the left ...............................5

Adjusting the lateral position ....................................................6

Adjusting the longitudinal position ...........................................6

Foot Control Preparation ............................................................6

Extension Table ..........................................................................7

Free arm sewing ......................................................................7

Accessory Storage .....................................................................7

Accessory Case ..........................................................................7

Connecting the Power Supply ....................................................8

Controlling Sewing Speed ..........................................................9

Speed control slider .................................................................9

Foot Control ................................................................................9

Extra Wide Table ........................................................................9

Machine Operating Buttons ......................................................10

Common Keys ..........................................................................11

Setting the Spool of Thread ......................................................12

Additional spool pin................................................................12

Winding the Bobbin ............................................................ 12-14

Removing the bobbin .............................................................12

Winding the bobbin ................................................................13

Inserting the bobbin ...............................................................14

Threading the Machine .............................................................15

Automatic Needle Threader ......................................................16

Drawing up the Bobbin Thread .................................................17

Replacing Needles ...................................................................18

Fabric, Thread and Needle Chart .............................................18

Replacing the Presser Foot ......................................................19

Replacing the Foot Holder .................................................. 20-21

Removing the presser foot holder..........................................20

Attaching the dual feed holder ...............................................20

Detaching and attaching the dual feed foot ...........................21

Attaching the darning foot PD-H ............................................21

Attaching the embroidery foot P ............................................21

Replacing the Needle Plate ......................................................22

Raising and Lowering the Presser Foot ...................................23

Knee Lifter ................................................................................23

Retractable Sewing Light ..........................................................24

Optic Magnifier .........................................................................24

Mode Selection .........................................................................25

On-screen Help ........................................................................25

ORDINARY SEWING MODE

Ordinary Stitch Patterns ..................................................... 26-27

Function Keys in Ordinary Sewing Mode ........................... 28-29

Utility Stitches ..................................................................... 30-42

Straight stitches .....................................................................30

Starting to sew .......................................................................30

Sewing from the edge of thick fabric......................................30

Changing sewing direction.....................................................30

Turning a square corner ........................................................30

Securing seams .....................................................................31

Cutting threads ......................................................................31

Using the seam guide lines....................................................31

Angle scale on the needle plate.............................................31

Variety of Straight Stitches ................................................. 32-34

Sewing with the Dual Feed Device ...........................................33

Dual feed balancing dial ........................................................33

Zigzag Stitches .........................................................................34

Variety of Overcasting Stitches ................................................35

Manual Stitch Settings ........................................................ 36-37

Altering needle drop position (straight stitches) .....................36

Altering stitch width ................................................................36

Altering stitch length ..............................................................36

Adjusting thread tension ........................................................37

Adjusting foot pressure control ..............................................37

Foot up for pivoting ................................................................37

Favorite Stitch Adjustment ...............................................38-39

Cloth Guide ...............................................................................40

Other Utility Stitches ........................................................... 41-42

Buttonholes and Specialty Stitches .................................... 43-55

Variety of Buttonholes ..............................................................43

B1 Sensor (Square) Buttonhole .......................................... 44-47

Manual settings......................................................................46

Using the stabilizer plate........................................................47

B2 Automatic (square) buttonhole ...................................... 48-49

Other Buttonholes .....................................................................50

B13 Welted Buttonhole (Bound buttonhole) ....................... 51-52

Corded Buttonhole ....................................................................53

Specialty Stitches ............................................................... 53-55

B14 Button Sewing ...................................................................53

B15 Darning ..............................................................................54

Fly Stitches (B17 to B20) ..........................................................55

Eyelets (B21 to B25) .................................................................55

Decorative Stitches ............................................................. 56-59

Quilting(Q) ................................................................................60

Using the quilting guide bar ...................................................60

Q1-Q3 Patchwork pieceing ....................................................60

Q80-Q85 Hand-look quilt stitches ..........................................60

S1-S31 Decorative satin stitches ..............................................61

Elongation ratio ......................................................................61

Created Stitches (CS) ...............................................................62

Twin Needle Sewing .................................................................63

Programming a Pattern Combination .......................................64

Mirror image of patterns.........................................................64

Bridge stitches .......................................................................64

Editing a Pattern Combination ..................................................65

Deleting a pattern ..................................................................65

Inserting a pattern ..................................................................65

Startover Key ............................................................................66

Current pattern startover........................................................66

First pattern startover.............................................................66

Checking Pattern Combination Length .....................................67

Monogramming ................................................................... 68-70

Function keys.........................................................................68

Manual thread tension ...........................................................69

Individual thread tension adjustment .....................................69

Unified thread tension adjustment .........................................69

Spacing .................................................................................69

Reduce the size of letters ......................................................69

Programming a monogram ....................................................70

Saving a Pattern Combination ..................................................71

Creating a new folder.............................................................71

Changing the folder name or file name..................................71

Opening a Pattern Combination ...............................................72

Sewing Application ...................................................................73

Seaming.................................................................................74

Overedge ...............................................................................75

Blind Hem ........................................................................76-77

Shell Tuck ..............................................................................77

Rolled Hem ............................................................................78

Zipper Sewing ..................................................................79-83

Lapped zipper sewing ................................................... 79-81

Concealed zipper sewing .............................................. 82-83

Gathering ...............................................................................84

Basting .................................................................................84

Button Sewing........................................................................85

Tacking .................................................................................86

Applique .................................................................................87

Patchwork ..............................................................................88

Quilting ........................................................................... 89-91

Straight stitches (with dual feed) .........................................89

Quilting guide bar for dual feed foot

Clasp stitches .....................................................................89

Free quilting ........................................................................90

One stitch off .......................................................................90

Foot height for free motion quilting .....................................90

Sculpture stitches ...............................................................91

....................................89

Page 5

TABLE OF COTENTS

Hand-look quilt stitches .......................................................91

Variable zigzag ...................................................................91

CUSTOMIZING MACHINE SETTINGS

Machine Setting Mode ............................................................ 92

Registering the custom settings ........................................... 92

Common Setting Mode ....................................................... 93-96

Ordinary Sewing Setting Mode ........................................... 97-99

Wireless LAN Setting Mode ............................................ 100-102

Connecting a Wireless Network...........................................100

Network Settings..........................................................101-102

Language Selection Mode ......................................................103

Correcting Deformed Stitch Patterns ......................................103

EMBROIDERY MODE

Embroidery Unit ...............................................................104-106

Attaching the embroidery unit ..............................................104

Extending the carriage arm..................................................105

Detaching the embroidery unit .............................................106

Attaching the Embroidery Foot ...............................................107

Attaching the Straight Stitch Needle Plate ..............................108

Special Bobbin Holder for Embroidery ...................................109

Bobbin Winding While Working on an Embroidery Project .....109

Embroidery Hoops ..................................................................110

Stabilizers ...............................................................................111

Setting the Fabric in an Embroidery Hoop ..............................112

Attaching the Embroidery Hoop to the Machine .....................113

Thread Holder .........................................................................113

Selecting Built-in Embroidery Designs ...................................114

Monogramming ................................................................115-119

Function Keys ......................................................................116

Programming a monogram ..................................................117

Monogram placement ..........................................................117

2- Letter monogram .............................................................118

Editing a monogram.............................................................119

Ready to Sew Window ....................................................120-123

Function keys.......................................................................120

Pattern information ..............................................................120

Stitch back/forward keys ......................................................121

Cross key .............................................................................121

Color section key .................................................................121

Color list key ........................................................................121

Jog keys...............................................................................121

Trace key .............................................................................122

Hoop back key .....................................................................122

Adjust Key............................................................................123

• Autothreadtensionlevel ...............................................123

• Cuttingthetailsofjumpthreads ....................................123

• Embroideryfootheight ...................................................123

Embroidery mode key ..........................................................123

Starting to Sew Embroidery ....................................................124

Fringe designs ................................................................ 125-126

Applique Designs ............................................................ 127-128

Frame Designs .......................................................................129

Lace Designs ..........................................................................130

Quilting Designs .....................................................................130

Editing Mode ....................................................................131-140

Selecting a hoop size...........................................................131

Opening the embroidery designs .........................................131

Editing tool bar information ..................................................132

Selecting a pattern ...............................................................132

Moving a pattern ..................................................................132

Selecting a pattern with pattern selection keys....................133

Resizing a pattern ................................................................133

Duplicating a pattern ............................................................133

Deleting a pattern ................................................................134

Rotating a pattern ................................................................134

Flipping a pattern .................................................................135

Creating a square frame ......................................................136

Grouping patterns ................................................................137

Sewing order........................................................................138

Color grouping .....................................................................138

Zooming in the editing window ............................................139

Customizing the display colors ............................................139

Monogramming in an arc .....................................................140

Free Arm Embroidery .............................................................141

Border Designs ............................................................... 142-143

Connecting the patterns in the editing window ....................143

AcuFil Quilting with Hoop ASQ22 ................................... 144-151

AcuFil hoop ASQ22 .............................................................144

AcuFil template ....................................................................144

Preparing quilt layers ...........................................................144

Printing the template sheet ..................................................145

Marking the centerlines........................................................145

Setting quilt layers in hoop ASQ22 ......................................146

Sewing AcuFil design pattern ..............................................146

Adjusting the size of the last pattern ....................................147

Creating original AcuFil designs ..........................................148

Editing designs ............................................................149-150

Sewing the border design ....................................................151

Eliminating blank margin......................................................151

CUSTOMIZING EMBROIDERY MODE SETTINGS

Embroidery Mode Settings ............................................. 152-154

Saving and Opening a File ............................................. 155-157

Saving a file .........................................................................155

Creating a new folder...........................................................156

Deleting a file or folder .........................................................156

Opening a file.......................................................................156

Changing a name of the file or folder...................................157

Direct PC-Link ........................................................................157

CARE AND MAINTENANCE

Cleaning the Hook Area .........................................................158

Cleaning the Inside of the Thread Guide ................................159

Troubleshooting .............................................................. 160-162

Troubleshooting (automatic needle threader) ......................162

STITCH CHART

Ordinary Sewing ............................................................. 163-165

Embroidery ..................................................................... 166-175

INDEX

............................................................................. 176-178

Page 6

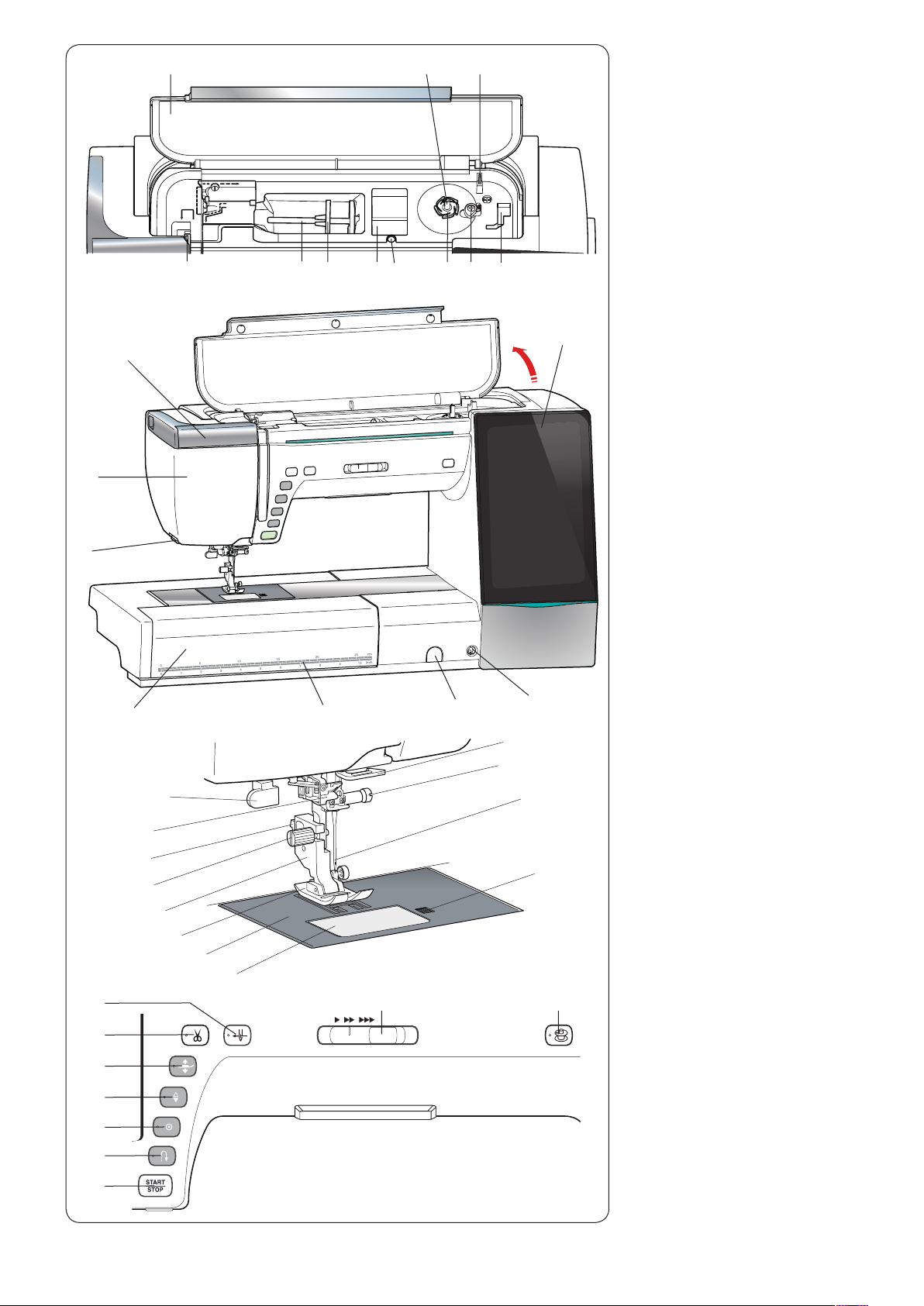

y

!1

u

!0

i

q

w

e

r o

t

!2

!3

!4

!5

!6

!7

!8

@8

@9

@0

#0

@1

@2

@3

@4

@5

@6

@7

#2 #9 $0

#3

#1

!9

GETTING READY TO SEW

Names of Parts

q

Top cover

w

Thread take-up lever

e

Spool pin

r

Spool holder (large)

t

Foot compartment

y

Hole for additional spool pin

u

Bobbin thread cutter A

i

Bobbin winder stopper

o

Foot compartment (for P foot)

!0

Bobbin thread cutter B

!1

Bobbin winder spindle

!2

Retractable light

!3

Face plate

!4

Thread cutter/holder

!5

Extension table

!6

Centimeter/inch measurements

!7

Feed balancing dial cap

!8

Knee lifter socket

!9

Visual touch screen

@0

Buttonhole lever

@1

Automatic needle threader

@2

Lever

@3

Thumbscrew

@4

Presser foot holder

@5

Presser foot

@6

Needle plate

@7

Hook cover plate

@8

Lower thread guide

@9

Needle clamp screw

#0

Needle

#1

Hook cover release button

#2

Needle threader button

#3

Thread cutter button

#4

Presser foot lifter button

#5

Needle up/down button

#6

Auto-lock button

#7

Reverse button

#8

Start/stop button

#9

Speed control slider

$0

Bobbin winding button

#4

#5

#6

#7

#8

* Design and specifications are subject to change without prior notice.

1

Page 7

w

e

q

!1

!0

o

Hand wheel

q

Touch panel stylus holder

w

Dual feed balancing dial

e

USB ports

r

Power switch

t

Power inlet

y

Foot control jack

u

Cover

i

Dual feed drive

o

Presser foot lifter

!0

Carrying handle

!1

Embroidery unit socket

!2

Embroidery unit

!3

Carriage arm

!4

Carriage arm release lever

!5

q

r

!5

t

y

u

!4

!2

i

!3

w

q

Semi-hard fabric cover

w

Embroidery unit case

e

Accessory case

r

Extra wide table

e

r

2

Page 8

q

!7

y

!1

@5

!9

!2

w

@1

u

i

!3

@3

e

!4

!8

@0

@6

o

r

!5

@2

!0

!6

t

@7

@4

Standard Accessories

q

Zigzag foot A (set on the machine)

w

Overedge foot M

e

Satin stitch foot F

r

Blind hemming foot G

t

Zipper foot E

y

Concealed zipper foot Z

u

Automatic buttonhole foot R

i

Stabilizer plate

o

Rolled hem foot D

!0

Open toe satin stitch foot F2

!1

Darning foot PD-H

!2

Free motion quilting closed-toe foot QC

!3

Free motion quilting open-toe foot QO

!4

Free motion quilting zigzag foot QV

!5

Button sewing foot T

!6

1/4˝ seam foot O

!7

Dual feed holder (twin)

!8

Dual feed holder (single)

!9

Dual feed foot AD (twin)

@0

Dual feed foot VD (single)

@1

Dual feed quilt piecing foot OD (twin)

@2

Dual feed zipper foot ED (single)

@3

AcuFeed open toe foot UD (twin)

@4

Embroidery foot P

#0

#7

#4

#1

#5

#8

#2

@8 @9

#3

$1

#6

@5

Straight stitch needle plate

@6

Bobbin x 5 (1 set on the machine)

@7

Needle set

@8

Additional spool pin

@9

Felt

#0

Screwdriver

#1

Lint brush

#2

Seam ripper (buttonhole opener)

#3

Quilting guide bar

#4

Spool holder (large) (set on the machine)

#5

Spool holder (small)

#6

Net

#7

Spool stand

#8

Button shank plate

#9

Scissors

$0

Touch panel stylus

$1

Cloth guide

$2

Bobbin holder cleaner

#9

$2

$0

3

Page 9

q w

e

r

Embroidery hoop SQ14 (with template)

q

Embroidery hoop SQ23 (with template)

w

Embroidery hoop GR (with template)

e

Embroidery hoop ASQ22 (with template)

r

Embroidery hoop FA10 (with template)

t

Magnetic clamps (for SQ23 and GR)

y

Magnetic clamps (for ASQ22)

u

Bobbin holder for embroidery

i

Felt

o

Stabilizers

!0

Bobbin thread for embroidery

!1

Foot control (with thread cutter switch)

!2

Knee lifter

!3

Optic magnifier (20/40/60)

!4

Power cable

!5

USB cable

!6

Instruction book

!7

Key icon reference chart

!8

Instructional video DVD

!9

Horizon Link Suite CD-ROM (with installation

@0

guide)

i

u

!2

t

y

o

!0

!1

!5

!7

!4

!6

!8

!3

!9

4

@0

Page 10

z

q

w

Thread Cutter Switch

After sewing, depress the thread cutter switch q on the

right side of the foot control to trim the both needle and

bobbin threads.

Do not depress the thread cutter switch until the start/stop

button turns green w.

q Thread cutter switch

NOTE:

•Threadsaretrimmedwhenthethreadcutterswitch

is depressed for more than 0.5 seconds.

•Thethreadcutterswitchdoesnotworkwithoutthe

foot control being depressed first.

Placing the thread cutter switch to the left

The thread cutter switch position can be adjusted for

your convenience.

If you wish to attach the thread cutter switch to the left

side of the foot control, follow the procedure below.

NOTE:

Phillips head screwdriver is not included with this

machine.

x

c

e

e

r

t

z Remove the setscrews A e, B r and washers t

with a Phillips head screwdriver.

e Setscrew A

r Setscrew B

t Washer

x Turn the base plate 180 degrees.

c Attach the foot control and thread cutter switch

with the setscrews and the washers t. Tighten the

setscrews A e and B r. Be sure that the cable is not

caught between the foot control and the base plate.

r

t

e

e

5

Page 11

z

Adjusting the lateral position

z Loosen the setscrews w under the switch.

x Slide the switch to left or right, and fix it at the

desired position by tightening the setscrews using a

Phillips head screwdriver.

Adjusting the longitudinal position

z Remove the setscrews w and washers q.

x Attach the switch to the desired position and fix it

with the setscrews and washers.

Tighten the setscrews securely using a Phillips head

screwdriver.

q

w

Foot Control Preparation

z Remove the cable tie q from the cable.

x

c

q

w

x If you wish to use the thread cutter switch, you need

to connect it with the foot control.

Insert the pin connector w into the jack e on the foot

control.

e

c Turn the foot control upside down.

Open the cover of the foot control.

v

v Draw out the cable from the foot control.

6

Page 12

Extension T able

The extension table provides an extended sewing area

and can be removed for free arm sewing.

To remove:

Draw the table to the left.

To attach:

Slide the table on the base and push it to the right.

Free arm sewing

The free arm is used for stitching sleeves, waistbands,

pant legs or any other tubular garments.

It is also useful for darning socks or elbows.

Accessory Storage

The accessories can be conveniently stored in the

accessory case, the compartment in the extension table

and the compartment under the top cover.

t

e

q

w

r

y

To store the accessories in the compartment of the

extension table, push up the lid towards you to open the

accessory storage.

q Foot compartment

w Foot compartment for P foot

e Lid

r Straight stitch needle plate (Place it upside down as

shown.)

t Automatic buttonhole foot and stabilizer plate

Dual feed holder (twin)

y

Accessory Case

To store the other accessories, open the accessory case

and store in the appropriate places. Optional accessories

can also be stored in this case.

7

Page 13

w

q

Connecting the Power Supply

z First make sure the power switch q is off.

x Insert the machine plug w of the power supply cord

into the power inlet e.

c Insert the power supply plug r into the wall outlet t,

and turn the power switch q on.

q Power switch

w Machine plug

e Power inlet

r Power supply plug

t Wall outlet

NOTE:

Makesuretousethepowercablethatcamewiththe

machine.

If you turn off the power switch, wait for 5 seconds

beforeturningitonagain.

e

e

u

w

y

r

r

q

t

t

If you wish to use the foot control, pull out the cord from

the foot control and insert the pin connector into the jack

on the machine (see page 6).

z First make sure the power switch q is off.

x Insert the machine plug w of the power supply cord

c Draw out the cord from the foot control and insert the

v Insert the power supply plug r into the wall outlet t,

q Power switch

w Machine plug

e Power inlet

r Power supply plug

t Wall outlet

y Pin connector

u Jack

Operating Instructions:

Thesymbol“O”onaswitchindicatesthe“off”positionof

the switch.

Foot controller Model 21390 is for use with sewing

machine MC15000.

For the U.S.A. and Canada only

Polarizedplug(onebladewiderthantheother):

Toreducetheriskofelectricshock,thisplugisintended

to fit in a polarized outlet only one way. If it does not fit

fully in the outlet, reverse the plug. If it still does not fit,

contact a qualified electrician to install the proper outlet.

Do not modify the plug in any way.

8

WARNING:

While in operation, always keep your eyes on the

sewing area, and do not touch any moving parts such

as the thread take-up lever, handwheel or needle.

Always turn off the power switch and unplug the

machine from the power supply:

- when leaving the machine unattended.

- when attaching or removing parts.

- when cleaning the machine.

Do not place anything on the foot control.

into the power inlet e.

pin connector y into the jack u on the machine.

and turn the power switch on.

NOTE:

•Thestart/stopbuttondoesnotworkwhenthefoot

control is connected.

•Thefootcontrolcannotbeusedintheembroidery

mode.

•Donotdepressthethreadcutterswitchwhen

inserting the pin connector y into the jack u.

Page 14

Controlling Sewing Speed

Speed control slider

You can limit the maximum sewing speed in both the

ordinary sewing mode and embroidery mode with the

speed control slider according to your sewing needs.

To increase the sewing speed, move the slider to the right.

To decrease the sewing speed, move the slider to the left.

The sewing speed can be changed while stitching.

Foot Control

Pressing on the foot control can vary sewing speed.

The harder you depress the foot control, the faster the

machine runs.

NOTE:

The machine runs at the maximum speed set by the

speed control slider when the foot control is fully

depressed.

NOTE:

This machine is equipped with an automatic shutdown

safety feature to prevent overheating whenever the

machine is running overloaded. Follow the safety

instructions that appear on the visual touch screen.

r

Extra Wide Table

Peel off the backing paper from the rubber soles and

attach them to the bottom of the legs

q Rubber sole

w Leg

Attach the 4 legs to the table top with the setscrew.

Attach the table support to the underside of the table by

inserting the hooks into the slots.

e Setscrew

r Table support

Remove the extension table.

Place the assembled table on the machine.

Adjust the table height by turning the adjusting screws.

t Adjusting screw

e

w

q

t

9

Page 15

r t y u

e

w

q

Machine Operating Buttons

q Start/stop button

Press this button to start or stop the machine. This

button can be used either in the ordinary sewing mode or

embroidery mode.

In the ordinary sewing mode, the machine starts running

slowly for the first few stitches. It then runs at the speed

set by the speed control slider.

The machine runs slowly as long as this button is being

pressed.

The button turns red when the machine is running, and

green when it stops.

NOTE:

The start/stop button cannot be used in the ordinary

sewing mode when the foot control is connected.

w Reverse button

When sewing stitch pattern U1, U4, U9-12, Q1-3 or

BR1-10, the machine will sew in reverse as long as the

reverse button is pressed.

If stitch pattern U1, U4, U9-12, Q1-3 or BR1-10 has

been selected and the foot control is not connected,

the machine will start sewing in reverse as long as the

reverse button is pressed.

If you press the reverse button when sewing any other

patterns, the machine will immediately sew locking

stitches and automatically stop.

i

e Auto-lock button

When sewing stitch pattern U1, U4, U9-12, Q1-3 or

BR1-10, the machine will immediately sew locking

stitches and automatically stop when the auto-lock button

is pressed.

When sewing all other patterns, the machine will sew to

the end of the current pattern, sew locking stitches and

stop automatically.

The machine will trim the threads automatically after

locking the stitch when the thread cut after auto-lock

option is turned on (refer to page 99).

r Needle up/down button

The machine will always stop with the needle down

except when buttonholes, darning, tacking, eyelets or

monograms are selected.

Press this button to bring the needle bar up or down.

t Presser foot lifter button

The presser foot will go up or go down by pressing this

button.

You can also use the presser foot lifter and knee lifter to

raise and lower the presser foot.

NOTE:

The thread cutter button does not function:

- directly after turning on the power.

- when the presser foot is raised with the foot lifter.

- after being pressed 3 times in a row.

u Needle threader button

Press this button to thread the needle thread through the

needle eye (refer to page 16).

i Bobbin winding button

Press this button to wind the bobbin (refer to page 13).

y Thread cutter button

Press this button when you finish sewing to trim the

threads. The needle bar and presser foot automatically

rise after trimming the threads.

Refer to page 31.

10

Page 16

w r t yq e

Common Keys

CAUTION:

Do not press the visual touch screen with hard or

sharp objects like pencils, screwdrivers or the like.

Use the touch panel stylus included in the standard

accessories.

q Home key

Press this key to enter the category selection of the

ordinary sewing mode or embroidery mode.

w Mode switch key

Press this key to enter into embroidery mode or to return

to ordinary sewing mode.

e Open file key

Press this key and the open file window will open.

You can open pattern combinations, monograms and

embroidery designs saved in the machine’s internal

memory or on a USB flash drive.

r Set mode key

Press this key to enter the setting mode. You can

customize the machine settings to your preference.

The machine settings for common settings, ordinary

sewing, embroidery, wireless LAN and language

selection are available in this mode.

u

t Help movie key

Press this key to view the on-screen movie about the

essential operations.

y Lockout key

Press this key to lockout the machine when threading the

machine, replacing the accessories etc.

To reduce the risk of injury, all the buttons and keys

except for the presser foot lifter and needle threader

button are deactivated.

To unlock the machine, press the unlock key u on the

window.

11

Page 17

w

r

Setting the Spool of Thread

Openthetopcover.

Lift up the spool pin. Place the spool of thread on the

spool pin.

Attach the large spool holder, and press it firmly against

the spool of thread.

NOTE:

Use the small spool holder to hold narrow or small

spools of thread.

If you use a slippery thread such as monofilament

transparent thread, put the net on the spool of thread

to prevent the thread from slipping off the spool and

jamming around the spool pin.

Additional spool pin

Use the additional spool pin when you need to wind a

bobbinwithoutunthreadingthemachinewhileworkingon

a sewing project (refer to page 109).

Set the spool stand q under the additional spool pin w.

Insert the additional spool pin w into the hole e.

Place the felt r and a spool on the pin.

q Spool stand

w Additional spool pin

e Hole for additional spool pin

r Felt

z

x

e

w

q

q

NOTE:

Theadditionalspoolpinisalsousedfortwinneedle

sewing.

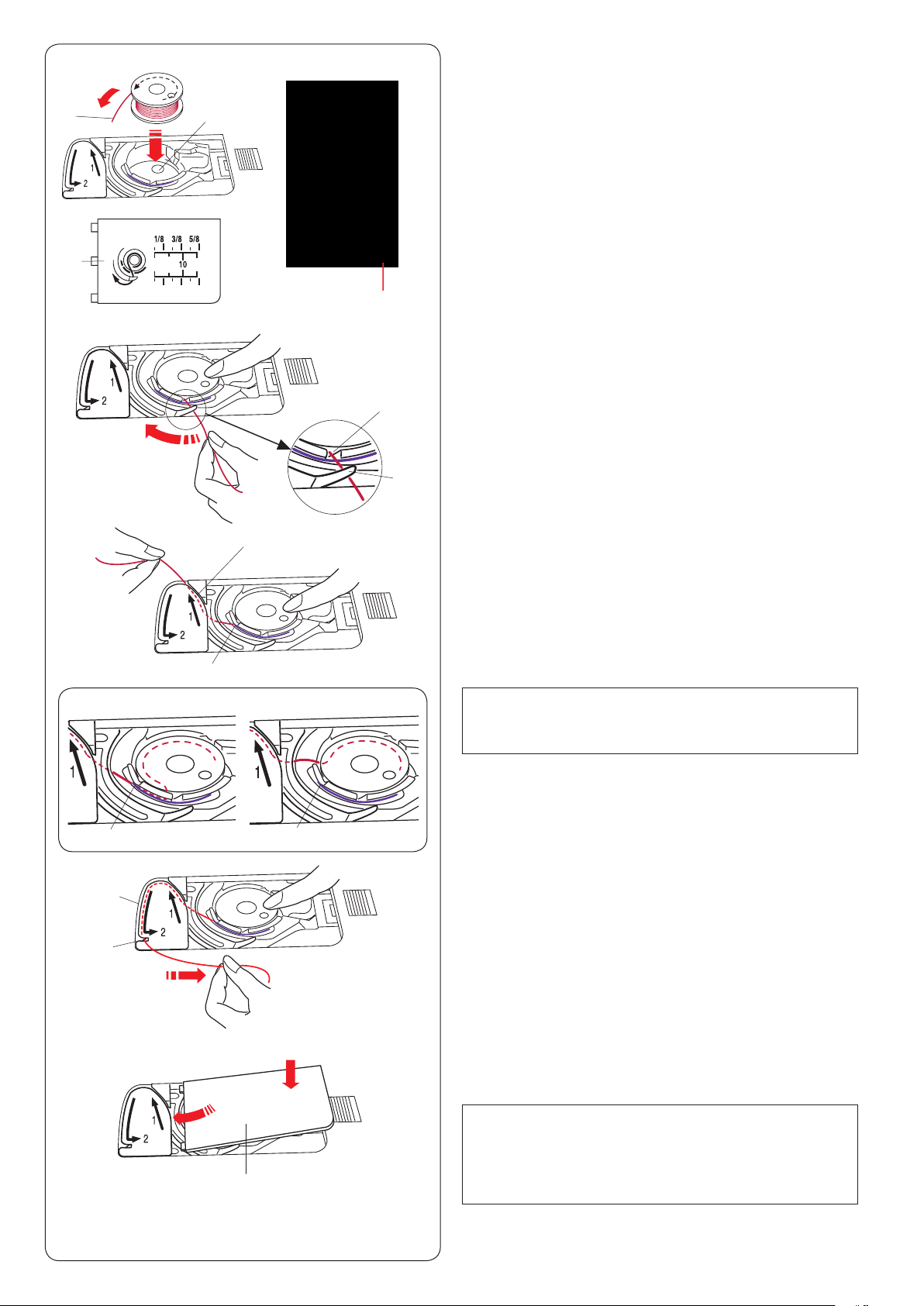

Winding the Bobbin

Removing the bobbin

CAUTION:

Press the lockout key or turn the power switch off.

z Slidethehookcoverreleasebuttonq to the right,

and remove the hook cover plate w.

q Hookcoverreleasebutton

w Hook cover plate

x Removethebobbinfromthebobbinholder.

NOTE:

Usetheplasticbobbinsforhorizontalhookmarked

witha“J”.Usingotherbobbins,suchaspre-wound

paperbobbins,maycausestitchingproblemsand/

ordamagetothebobbinholder.

12

Page 18

Winding the bobbin

w

c

z

r

e

t

q

q

v

w

x

e

z Pull the thread from the spool.

Hold the thread with both hands and pass the thread

into the guide slot q.

q Guide slot

x Draw the thread to the left and forward around the

thread guide w.

Draw the thread to the rear and to the right around

and under the guide plate e.

Firmly pull the thread to the right while holding it with

both hands.

w Thread guide

e Guide plate

NOTE:

You can adjust the bobbin winding speed in the

setting mode (refer to page 96).

c Put the bobbin on the bobbin winder spindle.

r Bobbin

t Bobbin winder spindle

v Pass the thread to the bobbin.

Hold the thread with both hands and wind it around

the bobbin clockwise several times.

b

m ,

u

y

o

n

!0

i

b Insert the thread into one of the slits u of the flange

plate y and pull the thread to cut.

y Flange plate

u Slit

n Push the bobbin stopper i to the left.

i Bobbin stopper

m Press the bobbin winding button o. The visual touch

screen will show the bobbin winding sign.

o Bobbin winding button

When the bobbin is fully wound, it will stop spinning

and the bobbin stopper returns to its original position

automatically.

, Remove the bobbin. Cut the thread with bobbin thread

cutter B !0.

! 0 Bobbin thread cutter B

NOTE:

For safety purposes, the machine will automatically

stop 1.5 minutes after starting bobbin winding.

13

Page 19

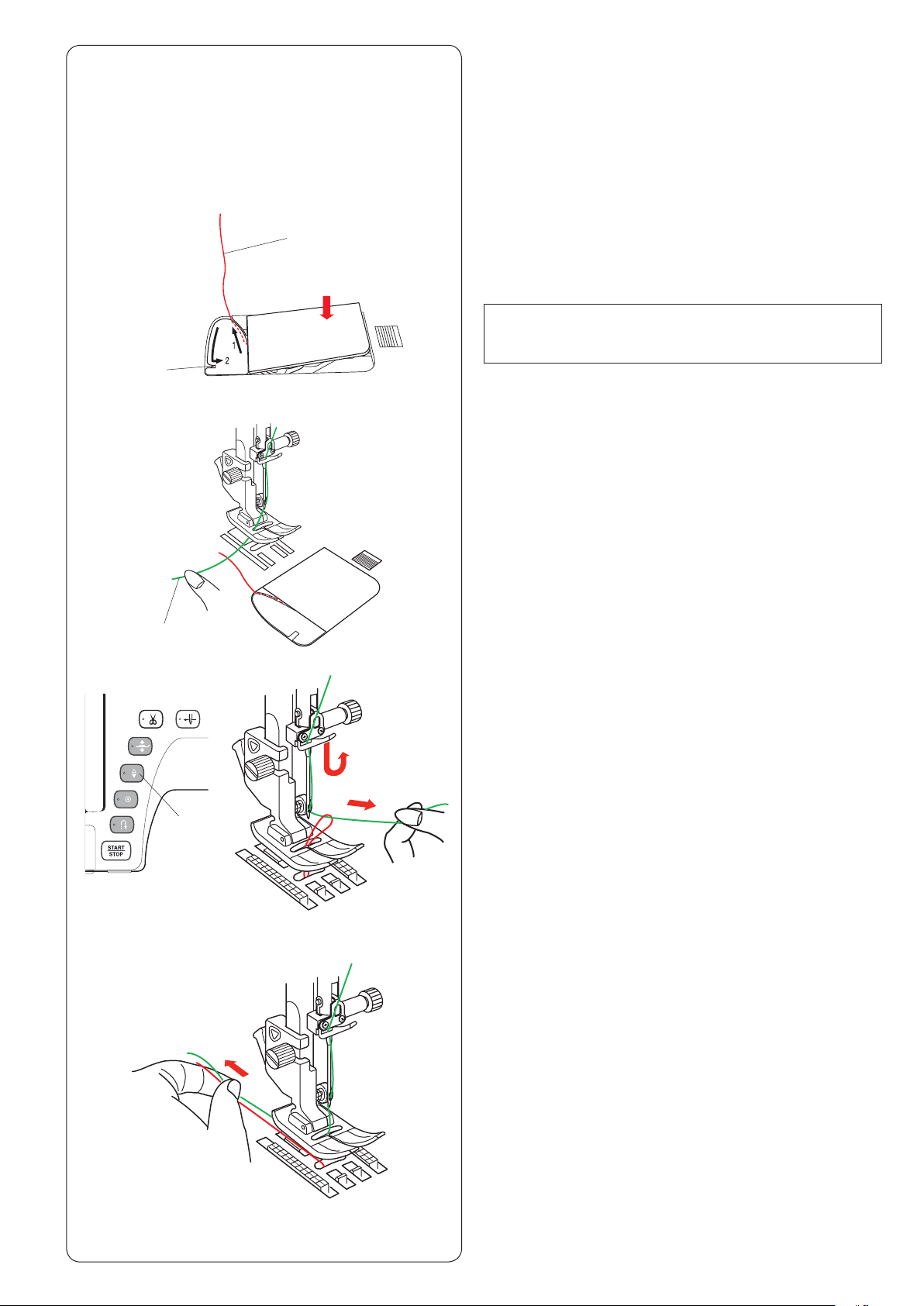

Inserting the bobbin

z

x

r

z Press the lockout key.

Place a bobbin in the bobbin holder with the thread

ew

q

t

running off counterclockwise as shown on the hook

cover plate.

q Lockout key

w End of thread

e Bobbin holder

r Hook cover plate

x Hold the bobbin with your fingertip so it does not

rotate.

Guide the thread into the front notch of the bobbin

holder.

Pull the thread to the left to pass it under the guide.

t Front notch

y Guide

y

c

v

i

o

!0

Correct

i

u

i

Wrong

c Draw the thread to the left to pass it into the guide

path marked “1”.

Make sure that the thread comes out from the side

notch of the bobbin holder.

u Guide path 1

i Side notch

NOTE:

If the thread does not come out from the side notch,

rethread from step z.

v Continue to draw the thread along the guide path

marked “2” and pull the thread to the right through the

slit. The thread will be cut to a proper length and held

in place.

o Guide path 2

! 0 Slit (Thread cutter)

b

r

b Set the left edge of the hook cover plate into opening.

Push down the hook cover plate to fit in place.

NOTE:

Unless otherwise noted, you can start sewing without

drawing up the bobbin thread.

Refer to page 17 for how to draw up the bobbin

thread.

14

Page 20

v

x

z

Threading the Machine

Press the needle up/down button to raise the take-up lever

to the highest position.

Press the lockout key to lockout the machine. The presser

foot will go down and the upper thread tension disks will

open.

q Lockout key

Pass the thread in order from z to m.

z

x

b

n

e

r

c

m

y

c

w

r

q

z Hold the thread with both hands and pass the thread

into the guide slot.

w Guide slot

x Hold the thread with both hands and draw the thread

around the corner of the guide.

Firmly pull the thread toward you along the right

channel until the thread snaps.

e Corner of the guide

r Right channel

c Draw the thread down along the right channel and

around the bottom of the thread guide plate.

Pull the thread up along the left channel.

r Right channel

t Thread guide plate

y Left channel

v

u

b

n

m

i

o

t

v While holding the thread at the spool, firmly draw the

thread up and to the back of the take-up lever. Draw

the thread forward to draw it into the eye of the take-

up lever.

u Eye of the take-up lever

b Then pull the thread down along the left channel and

through the lower thread guide.

i Lower thread guide

n Slide the thread from the right of the needle bar thread

guide to the left.

o Needle bar thread guide

m Thread the needle with the needle threader (refer to

the next page).

15

Page 21

z

q

w

Automatic Needle Threader

NOTE:

The needle threader can be used with a #11 to #16

needle.

Thread size 50 to 90 is recommended.

Do not use thread size 30 or thicker.

Make sure the machine is locked out.

z Draw the thread through the slit q of the needle

threader. The thread should pass under the hook w.

q Slit

w Hook

x

c

x Pull the thread up and slip it between the thread cutter

and face plate from behind.

Pull the thread toward you to cut.

c Press the needle threader button e.

The needle thread will be automatically threaded to

the needle eye.

e Needle threader button

e

r

v

v Pull the thread loop r to take the thread end out

through the needle eye to the rear.

r Thread loop

NOTE:

•Theautomaticneedlethreadercannotbeused

with the twin needle.

•Ifthethreadiscaughtinthehookandthethread

loop is not formed, remove the thread from the

hook and pull it to take the thread end out through

the needle eye.

16

Page 22

z

w

q

Drawing up the Bobbin Thread

After using auto thread cutting or threading the bobbin

holder, you can start sewing without drawing up the

bobbin thread.

However, you need to draw up the bobbin thread when

sewing gathering stitches etc.

z

Remove the bobbin. Insert the bobbin into the bobbin

holder again and rethread the bobbin holder according

to the instructions on page 14, but leave a 10 cm (4˝)

tail of bobbin thread as shown.

q Bobbin thread

NOTE:

Do not cut the bobbin thread with the thread cutter.

w Thread cutter

x

c

e

r

x

Raise the presser foot. Hold the needle thread lightly

with your left hand.

e Needle thread

c

Press the needle up/down button twice to lower and

raise the needle and pick up the bobbin thread.

r Needle up/down button

v

v

Pull both threads 10 cm (4˝) under and behind the

presser foot.

17

Page 23

w

q

Replacing Needles

CAUTION:

Always make sure to press the lockout key to lockout

the machine or turn the power switch off before

replacing the needle.

Raise the needle by pressing the needle up/down button.

Press the lockout key.

q Lockout key

Loosen the needle clamp screw by turning it

counterclockwise.

Remove the needle from the clamp.

w Needle clamp screw

Insert a new needle into the needle clamp with the flat

side of the needle to the rear.

e Flat side

r

Fabric

Fine

Medium

Heavy weight

Lawn

Georgette

Tricot

Sheeting

Jersey

Wool

Knit

Denim

Tweed

Coating

Quilting

e

Thread Needle

Silk #80-100

Cotton #80-100

Synthetic #80-100

Silk #50

Cotton #50-80

Synthetic #50-80

Silk #30-50

Cotton #40-50

Synthetic #40-50

Universal needle

Universal needle

Universal needle

When inserting the needle into the needle clamp, push it

up against the stopper pin and tighten the needle clamp

screw firmly with a screwdriver.

To check needle straightness, place the flat side of the

needle onto something flat (a needle plate, glass etc.).

The gap between the needle and the flat surface should

be consistent.

r Gap

Never use a blunt needle.

Fabric, Thread and Needle Chart

• Forgeneralsewing,useredneedle.

Blue needle

#9/65-11/75

Red needle

Purple needle

#11/75-14/90

Red needle

Purple needle

#14/90-16/100

• Finethreadsandneedlesshouldbeused

for sewing fine fabrics.

• Ingeneral,usethesamethreadforboth

needle and bobbin.

• Useablueneedleforsewingnefabrics,

stretch fabrics, tricot and buttonholes to

prevent skipped stitches.

• Useapurpleneedleforsewingknits,free

quilting and across the hem to prevent

skipped stitches.

• Useastabilizerorinterfacetostretchor

fine fabrics to prevent seam puckering.

• Alwaystestthethreadandneedlesizeon

a small piece of the same fabric you will

use for actual sewing.

NOTE:

•1xtwinneedle,2xblueneedle(#11/75),1xred

needle (#14/90) and 1 x purple needle (#14/90)

are included in the needle case.

•Theautomaticneedlethreadercannotbeused

for threading a thread size #30 and thicker.

For embroidery:

•Ingeneral,useablueneedle.

•Usearedneedleorpurpleneedleforthickerfabrics.

•Useapurpleneedlefordensestitchembroideryand

Quilting designs.

•Janomebobbinthreadforembroideryisrecommended

for bobbin.

18

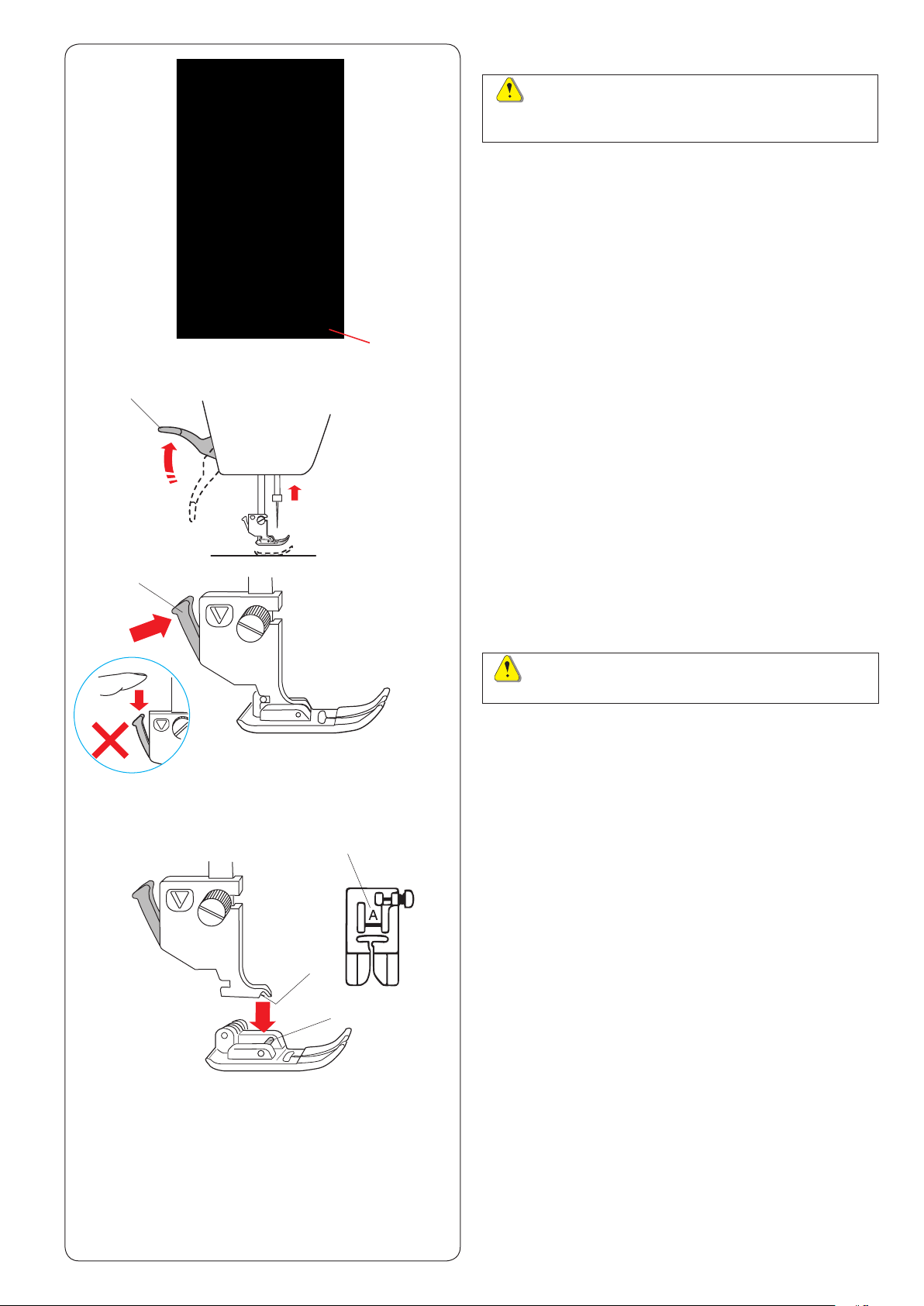

Page 24

q

Replacing the Presser Foot

CAUTION:

Always make sure to press the lockout key to lock out

the machine.

Raise the needle by pressing the needle up/down button.

Press the lockout key.

q Lockout key

w

Raise the presser foot lifter.

w Presser foot lifter

e

Press the black lever on the backside of the foot holder.

The presser foot will snap off.

e Lever

CAUTION

To avoid damaging the lever, do not push it down.

t

r

y

Place the desired foot under the foot holder so that the

pin of the foot lies just under the groove of the foot holder.

Lower the presser foot lifter to lock the foot in place.

r Pin

t Groove

Each foot is marked with an identification letter.

y Identification letter

19

Page 25

e

w

q

Replacing the Foot Holder

Replace the foot holder, if you use the dual feed feet,

darning foot or embroidery foot.

CAUTION:

Press the lockout key to lockout the machine before

replacing the foot holder.

Removing the presser foot holder

Raise the needle by pressing the needle up/down button.

Press the lockout key and raise the presser foot with the

presser foot lifter.

q Lockout key

w Presser foot lifter

Loosen the thumbscrew and remove the presser foot

holder.

e Thumbscrew

NOTE:

Use the foot holders included in the standard

accessories only.

q

w

e

w

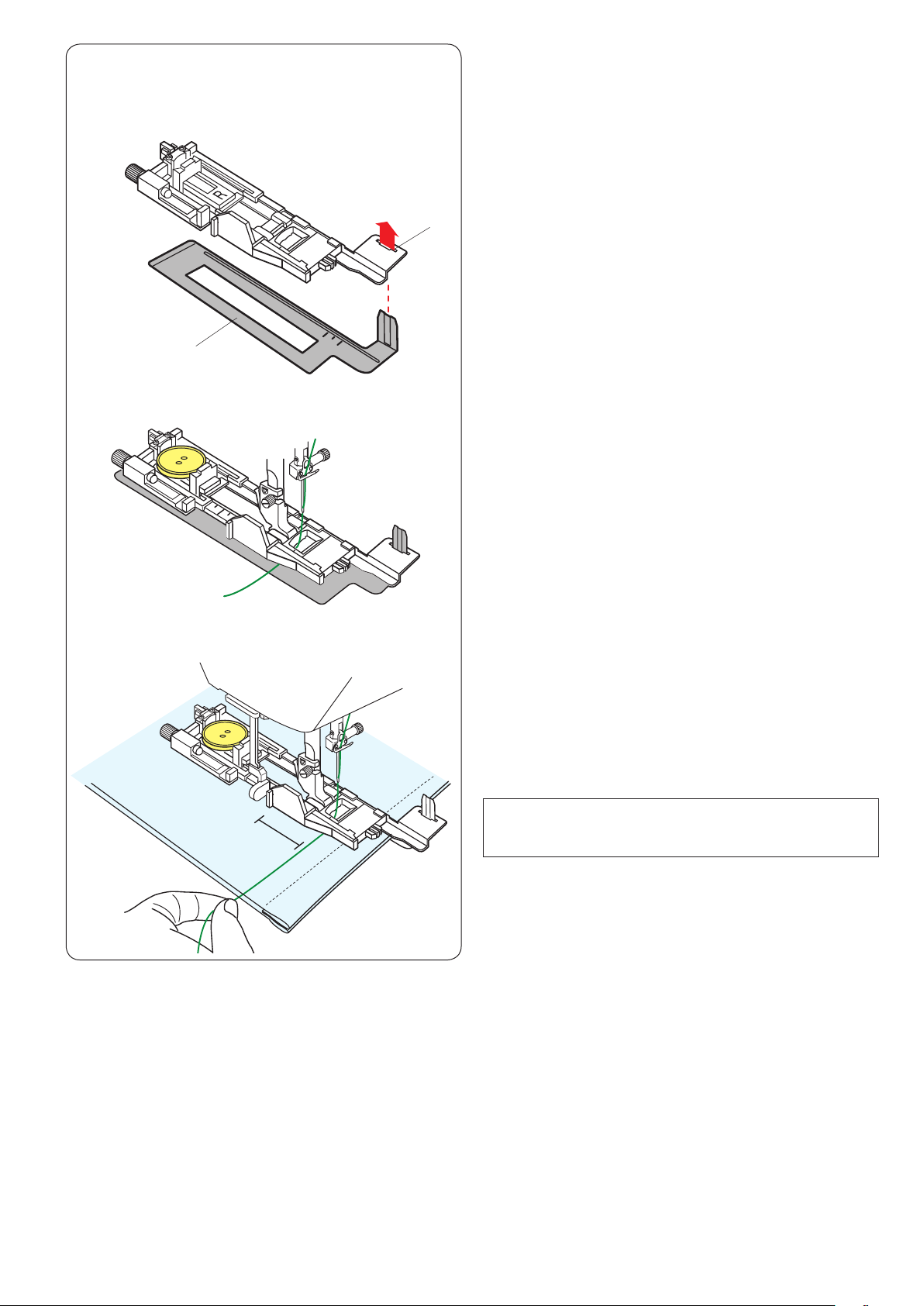

Attaching the dual feed holder

Attach the dual feed holder to the presser bar.

q Dual feed holder

Tighten the thumbscrew with your fingers.

Push the dual feed link to engage it with upper feed drive.

w Dual feed link

e Upper feed drive

Lower the presser foot lifter. Lower the needle to the

lowest position by turning the hand wheel.

Tighten the thumbscrew securely with the screwdriver.

20

Page 26

w

q

q

w

Detaching and attaching the dual feed foot

Pull the foot toward you to remove it.

Insert the pins of the foot into the slits of the foot holder

and gently push the foot until it snaps into place.

q Pin

w Slit

Attaching the darning foot PD-H

Attach the darning foot PD-H to the presser bar by

putting the pin on the needle clamp screw.

q Pin

w Needle clamp screw

Tighten the thumbscrew firmly with the screwdriver.

Attaching the embroidery foot P

Attach the embroidery foot P to the presser bar from

behind (refer to page 107).

21

Page 27

w

q

Replacing the Needle Plate

Use the straight stitch needle plate when sewing with the

dual feed foot and also when embroidering.

CAUTION:

Always make sure to press the lockout key to lockout

the machine before replacing the needle plate.

e

Raise the needle and press the lockout key.

Press the presser foot lifter button to raise the presser

foot.

q Lockout key

w Unlock key

e Presser foot lifter button

Slide the extension table to the left to remove it.

Push down the needle plate release lever and the needle

plate will snap off.

r Needle plate release lever

A message will appear warning that the needle plate is

not secured.

Remove the needle plate to the right.

r

Place the straight stitch needle plate on the machine.

Set the left edge of the needle plate into the opening.

Push down on the mark of the needle plate until it locks

in place.

Make sure the warning message disappears and the

straight stitch is automatically selected.

Turn the hand wheel slowly and make sure that the

needle does not hit the needle plate.

Press the unlock key to unlock.

CAUTION:

Never press the needle plate release lever while

running the machine.

22

Page 28

q

Raising and Lowering the Presser Foot

You can raise and lower the presser foot with the presser

foot lifter button, the presser foot lifter or the knee lifter.

q Presser foot lifter button

w Presser foot lifter

You can raise the presser foot about 6 mm (1/4˝) higher

than the normal up position by exerting more pressure

when lifting the presser foot lifter or knee lifter.

This helps you to place layers of thick fabrics or

embroidery hoops under the foot.

w

w

NOTE:

The presser foot cannot be lowered with the presser

foot lifter if the foot was raised with the presser foot

lifter button.

The knee lifter cannot be used in the embroidery

mode.

Knee Lifter

The knee lifter is extremely helpful when sewing

patchwork, quilting etc., since it allows you to handle the

fabric while your knee controls the presser foot.

Attaching the knee lifter

Match the ribs on the knee lifter with the notches in the

knee lifter socket and insert the knee lifter.

q Knee lifter

w Knee lifter socket

q

r

e

Adjusting the knee lifter

The angle of knee lifter can be adjusted to fit your knee.

Loosen the setscrew and slide the angle bar in or out to

adjust the angle of the knee lifter.

Tighten the setscrew to secure the angle bar.

e Setscrew

r Angle bar

Using the knee lifter

Push the knee lifter with your knee to move the presser

foot up and down.

The knee lifter controls zigzag width of the variable

zigzag (refer to page 91).

NOTE:

Do not touch the knee lifter while stitching, otherwise

the fabric will not be fed smoothly.

23

Page 29

w

q

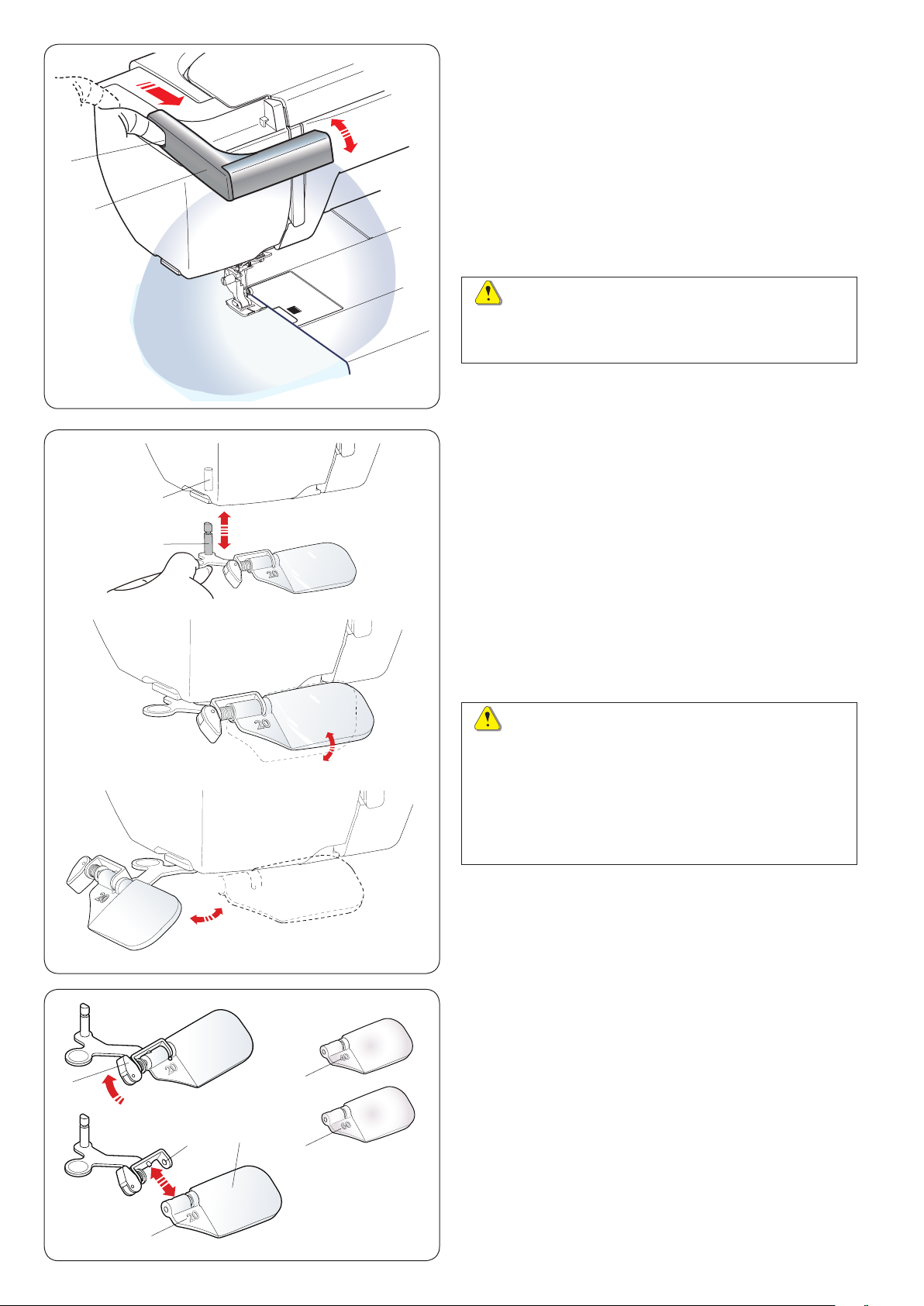

Retractable Sewing Light

In addition to the twin LED lights, the machine is

equipped with a retractable light.

Place your finger in the groove and slide the arm towards

you. The light will turn on automatically.

Adjust the angle of the light to illuminate the working

area.

q Arm

w Groove

Push back the arm to turn the light off and store it.

CAUTION:

Do not hit or exert excessive force on the arm of the

retractable sewing light as this may cause damage

when it is extended.

Optic Magnifier

Use the magnifier to get a larger view of the needle area.

w

q

Attaching the magnifier

Hold the knob with your fingers and insert the pin into the

hole in the bottom of the face plate.

Push the magnifier up until it snaps to fit.

Adjust the angle to get the best view.

q Pin

w Hole

Removing the magnifier

If the magnifier is not in use, turn it to the left out of sight

or pull it down to remove.

CAUTION:

Do not use or leave the magnifier in the direct sunlight,

otherwise it may cause a fire or burn.

Do not look at the sun through the magnifier as it can

damage your eyes.

Do not hit or exert excessive force on the optic

magnifier as this may cause damage when it is

attached.

q

r

e

w

r

r

Replacing the magnifier

To remove the lens, push or pull the lever q to the

opposite side to draw the pin out of the lens.

Remove the lens from the metal.

To attach the lens, insert it into the metal part e as

illustrated.

Push or pull the lever q to the opposite side to fix the

lens.

Higher numbers r indicates stronger magnification.

q Lever

w Lens

e Metal part

r Number

24

Page 30

w

q

e

w

e

r

t

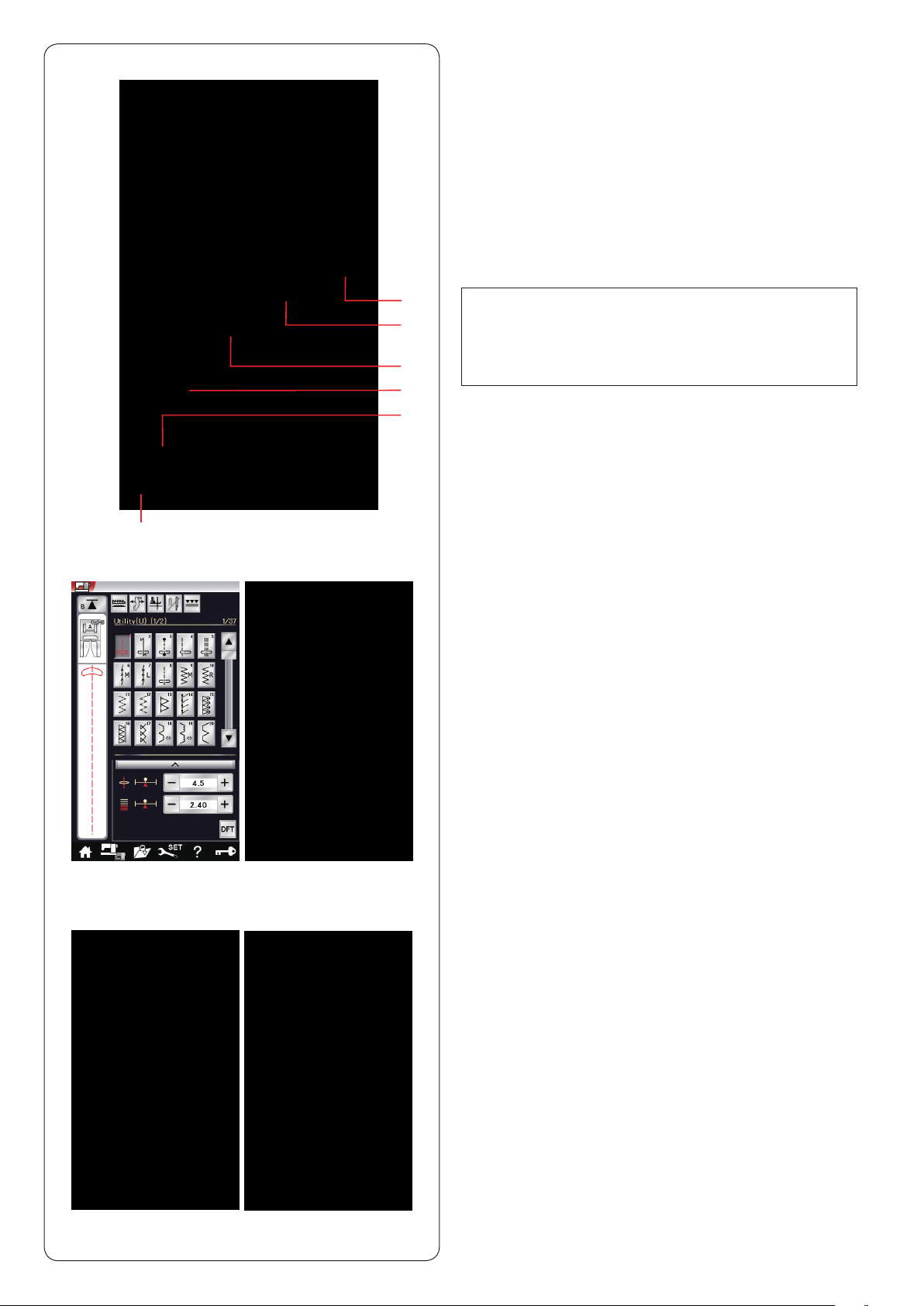

Mode Selection

When you turn the power switch on, the visual touch

screen will show the ordinary sewing mode after a few

seconds.

The machine is set for straight stitch sewing.

NOTE:

After turning on the power, it takes several seconds to

display the opening window.

(This is the required boot up procedure.)

To switch to the embroidery mode, first turn the power

switch off then attach the embroidery unit (refer to pages

104-105).

Turn the power switch on and press the mode switch key.

q Mode switch key

A confirmation message w will appear. Do not press the

OK key or X key. Open the carriage arm and a warning

message e will appear. Press the OK key to switch to

the embroidery mode and the carriage will move to the

starting position.

To switch back to the ordinary sewing mode, press

the mode switch key and follow the instructions in the

confirmation message.

On-screen Help

Press the help key to open the help menu.

You can view movies on 7 topics of essential operations

of the machine, total power-on time of the machine or

total operating time of the machine.

Select the help topic by pressing the movie key and the

movie window will open.

q Help key

w Movie key

e Software version

r Total power-on time

t Total operating time

q

o

y i

!0 u

Press the play key to start the movie and press the pause

key to stop playing.

You can search through the movie in forward or reverse

direction by pressing the fast forward key or rewind key.

y Play key

u Pause key

i Fast forward key

o Rewind key

Press the return key to return to the beginning of the

movie.

!0 Return key

Press the X key to close the current window.

25

Page 31

ORDINARY SEWING MODE

Ordinary Stitch Patterns

In the ordinary sewing mode, there are 5 categories

available. Press the home key q to enter the category

selection.

q Home key

w Utility stitches (U)

e Buttonhole and specialty stitches (B)

r Decorative and quilting stitches

t Monogramming

y Sewing applications

Press one of the icon keys to select the category.

w

q

w

e

r

t

y

NOTE:

In this manual, the pattern number refers to the initial

for each group or category.

For example pattern #15 in the buttonholes and

specialty stitches is referred to as pattern B15.

w Utility stitches (U)

You can select utility stitches for seaming, overcasting,

blind hemming, basting and shell tucking.

e

e Buttonholes and specialty stitches (B)

There are various styles of buttonholes, button sewing

stitches, darning, tacking, fly stitches and eyelets

available in this category.

26

Page 32

(A)

(S)

(BR)

r

(Q)

(H)

(D)

r Decorative and quilting stitches

Thiscategoryconsistsofthefollowing10groups.

Applique stitches (A)

Heirloom stitches (H)

Quilting stitches (Q)

Satin stitches (S)

Bridge stitches (BR)

Decorative stitches (D)

Long stitches (L)

Pictograph stitches (P)

Play stitches (PL)

Created stitches (CS)

(L)

(CS)

t

(PL)

(P)

t Monogramming

Youcanprogramletteringaswellasacombinationof

charactersandsymbolpatterns.

y

y Sewing applications

You can select the appropriate stitch for a specific sewing

projectandfabrictypefromthedesignatedapplications

in this category.

27

Page 33

i

q w e r t

y

u

y

Function Keys in Ordinary Sewing Mode

q Drop feed key

This key is available only with the utility stitch group.

Press this key to drop or raise the feed dog.

w Cloth guide key

Press this key for cloth guide sewing (refer to page 40).

e Foot-up key

If this option is turned on, the needle stops at the down

position and the presser foot will automatically go up

when the machine stops.

Press this key to turn this option on or off (refer to page

37).

r Twin needle key

Press this key to set the stitch width for twin needle

sewing (refer to page 63).

t Dual feed key

Press this key for dual feed sewing (refer to page 33).

y Page keys

Press the page key to display the next page or previous

page. Press and hold the page key to turn the pages

continuously.

u Touch bar

Press on the touch bar to display the next page or

previous page.

i Startover key

If you stop sewing in the middle of a stitch pattern and

wish to sew the pattern again from the beginning, press

this key before you start sewing.

Press this key once to startover from the beginning of the

current pattern, or press this key twice to startover from

the beginning of the first pattern of the combination (refer

to page 66).

o !0 !1 !2

o Program key

Press this key to program a pattern combination.

When this key is pressed, the delete key, memory check

key, save file key and cursor keys will appear.

!0 Delete key

Press this key to delete the pattern from the pattern

combination.

!1 Memory check key

Press this key to view the stitch image of the entire

pattern combination.

!2 Save file key

Press this key to save the pattern combination as a file.

!3 Cursor keys

Press one of the cursor keys to move the cursor up or

down.

!3

28

Page 34

!4 !5

!4 Font selection key

You can select one of 5 fonts.

Select the desired font by pressing the corresponding key.

!5 Letter case key

Press this key to select upper case or lower case for

monograms.

!6 Letter size key

Press this key to select the full size (L) or small size (S).

!6

29

Page 35

q

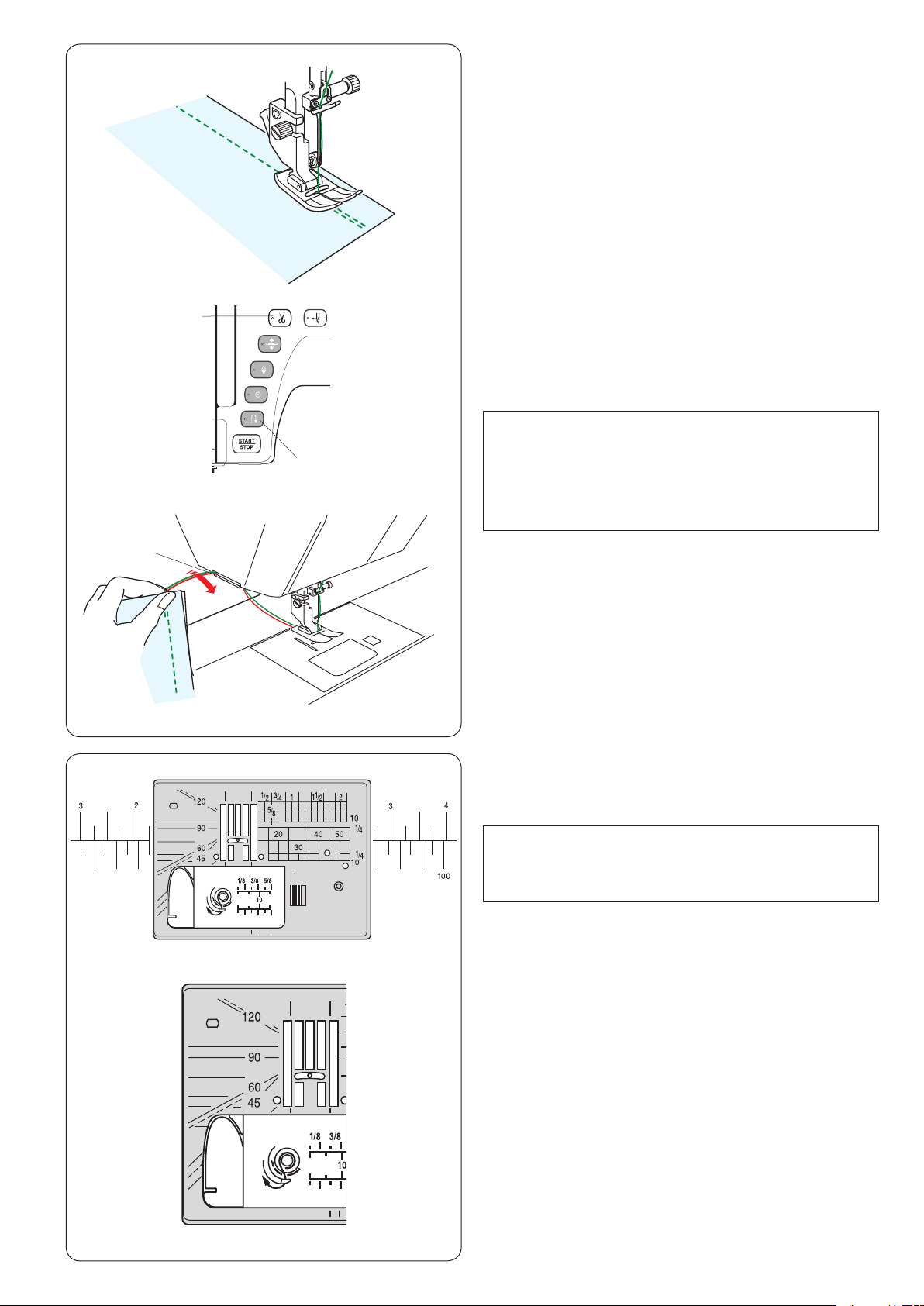

Utility Stitches

Straight stitches

Patterns U1 to U5 are straight stitches for seaming. Press

the pattern selection key for the desired stitch.

Starting to sew

Place the fabric next to the seam guide line on the needle

plate. Lower the needle to the point where you want to

start.

Pull the needle thread towards the rear and lower the

foot.

Press the start/stop button or foot control to start sewing.

Gently guide the fabric along the seam guide line letting

the fabric go naturally.

q Start/stop button

w

Sewing from the edge of thick fabric

The black button on the zigzag foot locks the foot in the

horizontal position.

This is helpful when you start sewing at the extreme edge

of thick fabrics or for sewing across a hem.

Lower the needle into the fabric at the point where you

wish to start sewing.

Lower the foot while pushing in the black button. The foot

is locked in the horizontal position to avoid slipping.

After a few stitches, the black button is released

automatically.

w Black button

Changing sewing direction

Stop the machine and press the presser foot lifter button

to raise the presser foot.

Pivot the fabric around the needle to change the sewing

direction as desired.

Start sewing in a new direction.

NOTE:

If you turn on the foot up option, the presser foot will

automatically go up when the machine stops (refer to

page 37).

e

5/8˝

Turning a square corner

To maintain a 5/8˝ seam allowance after turning a square

corner, use the cornering guide on the needle plate.

Stop sewing when the front edge of fabric reaches the

cornering guide lines.

Press the foot lifter button and turn the fabric 90 degrees.

Start sewing in the new direction.

e Cornering guide

30

Page 36

Securing seams

For fastening the ends of seams, press the reverse

button and sew several reverse stitches.

The machine sews in reverse as long as you press and

hold the reverse button.

q Reverse button

Press the reverse button once when sewing the locka-matic stitch (pattern U2) or locking stitch (pattern

U3) and the machine will lock the stitches off and stop

automatically.

e

w

q

Cutting threads

To cut the threads after finishing sewing, press the

thread cutter button. The needle bar and presser foot will

automatically go up after trimming the threads.

w Thread cutter button

NOTE:

The thread cutter button does not function when the

presser foot is up.

Use the thread cutter on the face plate to cut

specialized or thick threads if the auto thread cutter

does not work well.

To use the thread cutter on the face plate, remove the

fabric and draw it to the back.

Pull the threads up and slip them between the thread

cutter and face plate from behind.

Pull the threads toward you to cut.

e Thread cutter

Using the seam guide lines

The seam guides on the needle plate and hook cover

help you measure seam allowance.

NOTE:

The numbers on the needle plate indicate the distance

from the center needle position in millimeters and

inches.

Angle scale on the needle plate

The angle scales are marked at 45, 60, 90 and 120

degrees.

Use the broken lines when piecing the patchwork pieces

with the 1/4˝ seam foot O.

31

Page 37

Variety of Straight Stitches

U1 Straight stitch in center needle position

Use this stitch for seaming, rolled hemming etc.

U2 Lock-a-matic stitch

Use this stitch to secure the beginning and the end of a

seam with backstitching.

When you reach the end of the seam, press the reverse

button once.

The machine will sew four reverse stitches, four forward

stitches, and then stop sewing automatically.

U3 Locking stitch

This unique stitch is used where an invisible locking

stitch is needed.

The machine will sew several locking stitches at the

beginning and continue sewing forward.

When you press the reverse button at the end of the

seam, the machine will sew several locking stitches in

place, then stop sewing automatically.

U4 Straight stitch in left needle position

Use this stitch to seam fabrics close to the edge.

U5 Triple stretch stitch

This strong, durable stitch is recommended for areas

where both elasticity and strength are needed to ensure

comfort and durability.

Use it to reinforce areas such as crotch and armhole

seams.

Also use it when constructing items such as backpacks

for extra strength.

U6, U7 Stretch stitches

These are narrow stretch stitches designed to eliminate

puckering on knit fabrics and bias seams, while

permitting the seam to be pressed completely open flat.

Use U7 for seaming fine fabrics or stretch fabrics.

32

Page 38

e

q

r

w

t

y

Sewing with the Dual Feed Device

Patterns U1 to U4 and Q1 to Q7 can be sewn with the

dual feed device.

The dual feed device is extremely effective when sewing

hard to feed materials such as PVC coated fabric or

leather.

It also eliminates layer slippage.

The following 5 types of dual feed feet are available in

the standard accessories.

q Dual feed foot AD (twin):

For regular sewing with dual feed

w Dual feed foot VD (single):

For sewing narrow areas with dual feed

e Dual feed quilt piecing foot OD (twin):

For 1/4˝ seam piecing with dual feed

r Dual feed zipper foot ED (single):

For zipper application with dual feed

t Dual feed AcuFeed open toe foot UD (twin):

For open toe better view sewing with dual feed

Attach the desired dual feed foot to the respective dual

feed holder and attach to the machine (refer to page 20).

Press the dual feed key y and select the desired pattern.

NOTE:

The patterns not suitable for dual feed sewing are

grayed out.

The dual feed key will gray out or not be indicated

if you selected a pattern not suitable for dual feed

sewing.

e

w

Place the fabric under the foot and lower the needle at

the point where you wish to start.

Start sewing at medium speed.

When seaming plaid fabrics, match the plaids of the

upper and lower layers and pin them together.

Remove the pins as you sew.

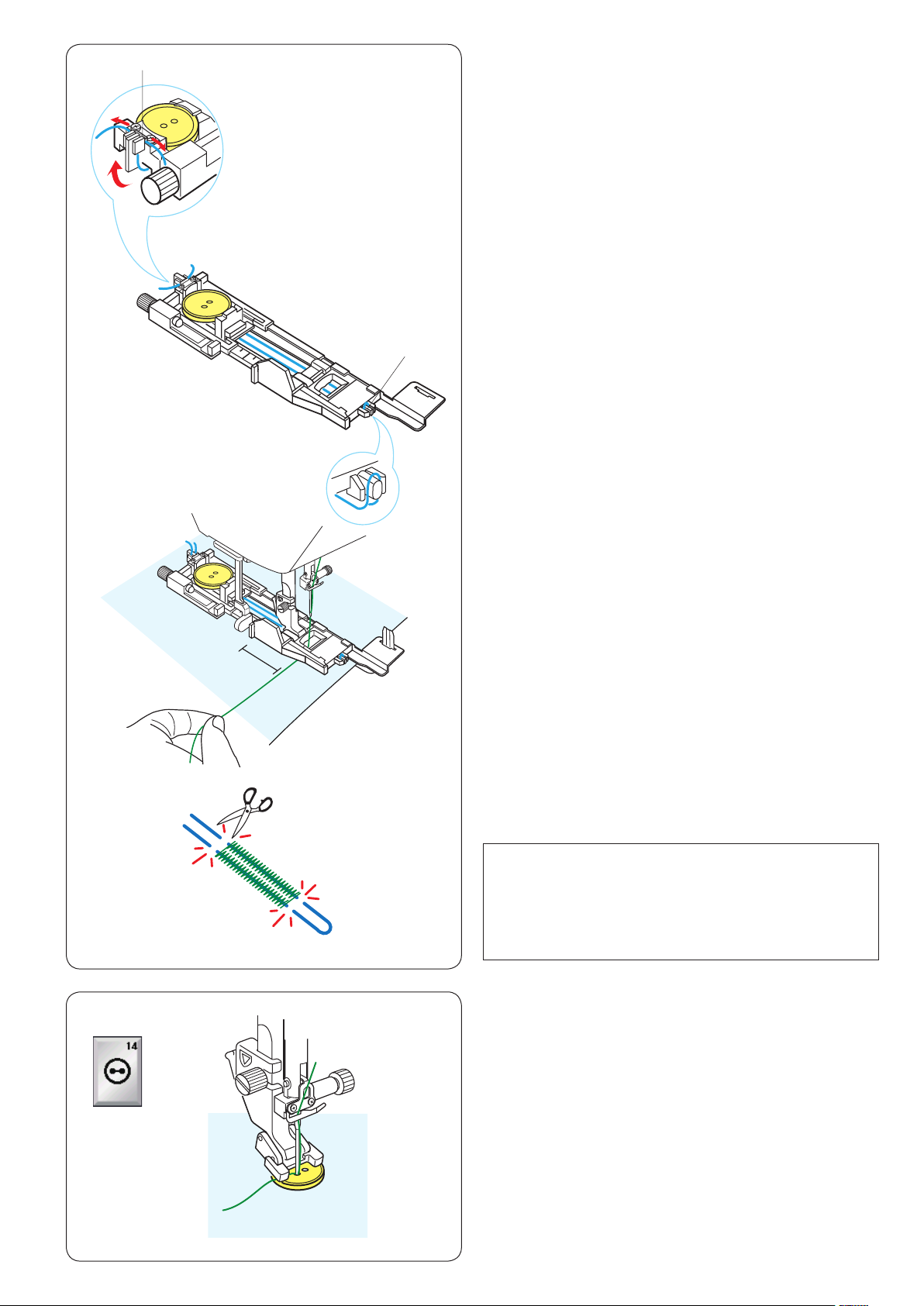

Dual feed balancing dial

The dual feed balancing dial should be set at “0”,

however you may need to adjust the dual feed balance

depending on the type of fabric.

Check the feed balance by test sewing on a scrap piece

of the fabric you intend to use.

(A): If the lower layer puckers, turn the dual feed balancing

dial toward “+”.

(B): If the upper layer puckers, turn the dual feed

balancing dial toward “–”.

q

q Upper layer

w Lower layer

e Dual feed balancing dial

33

Page 39

U8 Basting

See page 84 for sewing instructions.

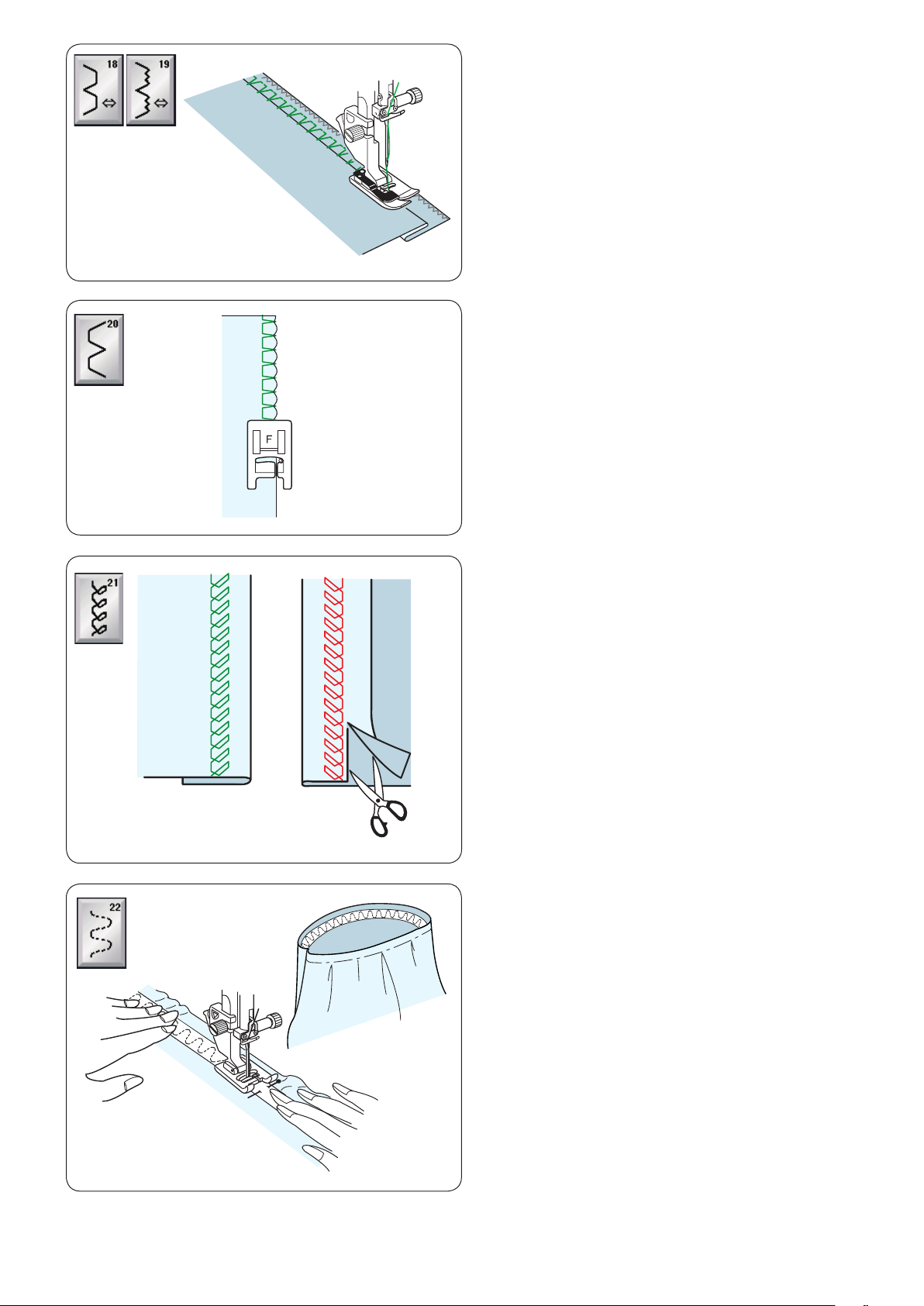

Zigzag Stitches

U9, U10 Zigzag stitches