Page 1

MODEL HF106

IMPORTANT SAFETY

INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including

the followings:

Read all instructions before using this appliance.

DANGER – To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always unplug this sewing

machine from the electric outlet immediately after using and before cleaning.

2. Always unplug before replacing a sewing machine bulb. Replace bulb with same type rated

15 Watts.

WARNING – To reduce the risk of burns, fire, electric shock,or injury to persons:

1. Do not allow to be used as a toy. Close attention is necessary when this sewing machine

is used by or near children.

2. Use this appliance only for its intended use as described in this owner’s manual.

Use only attachments recommended by the manufacturer as contained in this owner’s

manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working

properly, if it has been dropped or damaged, or dropped into water.

Return this sewing machine to the nearest authorized dealers or service center for

examination,

repair, electrical or mechanical adjustment.

4. Never operate the appliance with any air opening blocked. Keep ventilation openings of

this sewing machine and foot controller free from accumulation of lint, dust and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being

adminis-tered.

8. To disconnect, turn all controls to the off (“O”) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing

machine needle.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch this sewing machine off (“O”) when making any adjustment in the needle area,

such as threading the needle, changing the needle, threading the bobbin or changing the

presser foot, and the like.

15. Always unplug this sewing machine from the electrical outlet when removing covers,

lubricating, or when making any other adjustments mentioned in this owner’s manual.

SAVE THESE INSTR UCTIONS

Designs and specifications are subject to change without prior notice.

Page 2

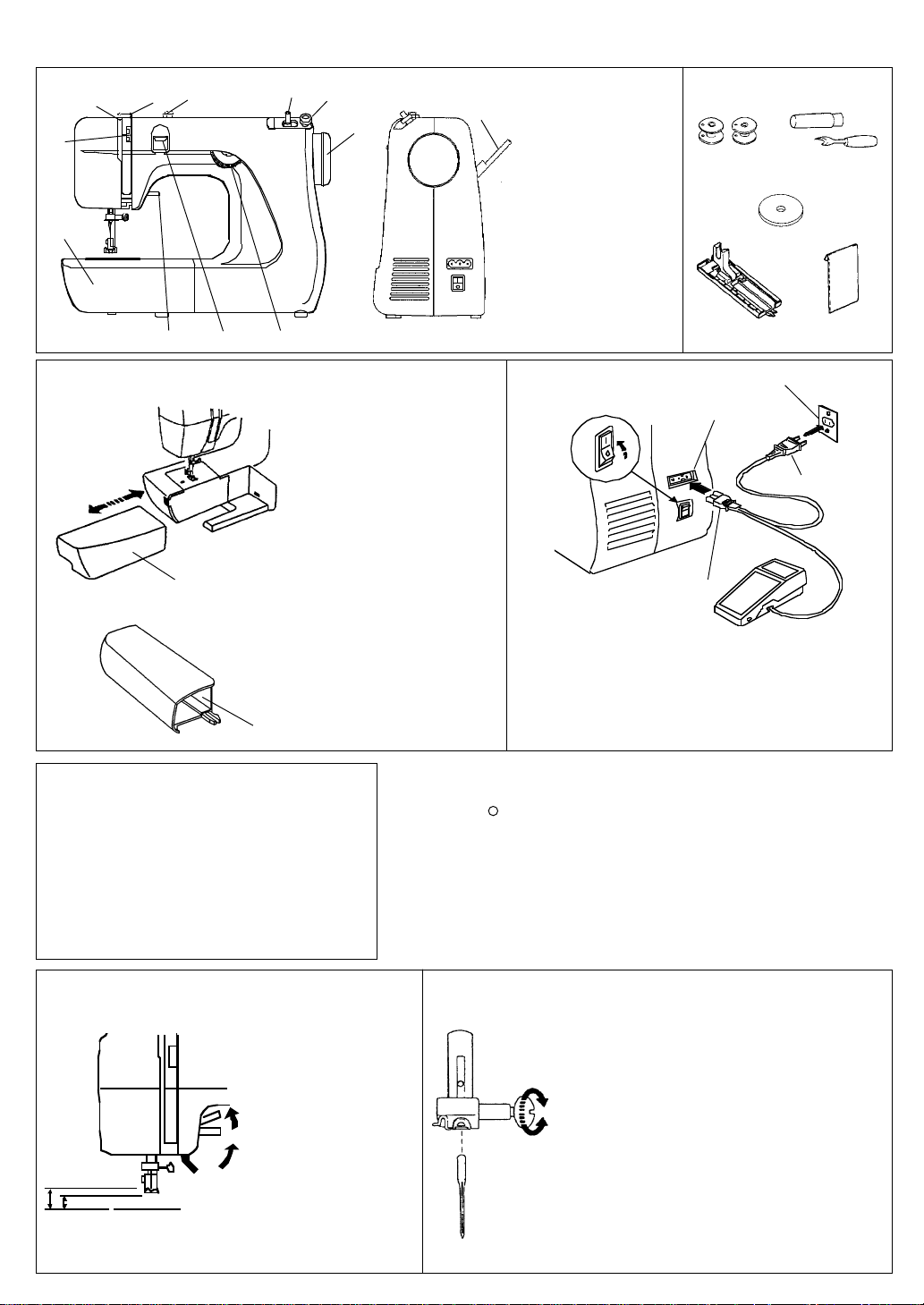

1. Name of Parts

2

3

4

1

5

11

6

10

9

8

7

1. Thread guide

12

2. Thread take-up lever

3. Tension dial unit

4. Extension table

5. Presser foot lifter

6. Reverse button

7. Pattern selector dial

8. Handwheel

9. Bobbin winder stopper

10. Bobbin winder spindle

11. Bobbin winder thread

guide

12. Spool pin

2. Standard Accessories

Bobbins

Buttonhole foot

Seam ripper

Felt

Needles

3. Free Arm Sewing

For free arm sewing, pull out the

extension table to the left and

remove it.

To replace extension table:

Slide the extension table along

the free arm inserting the tab

into the slot.

Extension table

Accessory kit

Standard accessories are

located inside the extension

table.

Accessory storage

5. Controlling Sewing Speed

The foot control regulates sewing speed.

The harder depress the foot control, the faster the

machine runs.

4. Power Connection

Power switch

1. Turn the power switch off. Insert the machine plug into

the machine socket.

2. Insert the power plug into the power outlet. Turn the

power switch on.

Disconnect the power plug when the machine is not in use.

Machine socket

Machine plug

Power outlet

Power plug

Operating Instructions:

The symbol “ “ of a switch indicates the “OFF” position of a switch.

For appliances with a polarized plug (one blade is wider than the other).

To reduce the risk of electric shock, this plug is intended to fit in a polarized

outlet only one way. If it does not fit fully in the outlet, reverse the plug.

If it still does not fit, contact a qualified electrician to install the proper outlet.

Do not modify the plug in any way.

Foot controller Model YC-482-J or TJC-150 is used with sewing machine

Model HF106.

6. Raising and Lowering the Presser Foot

The presser foot lifter

raises and lowers the

presser foot.

You can raise it about 1/4”

higher than normal up

position.

This helps when removing

the foot or when sewing

thick materials.

7. Changing the Needle

To remove the needle:

Loosen the needle clamp screw by turning

it toward you.

Remove the needle by pulling it downward.

To replace the needle:

Insert a new needle into the needle clamp with

flat side away from you.

Push the needle up as far as it will go.

Tighten the needle clamp screw firmly with a

screwdriver.

Page 3

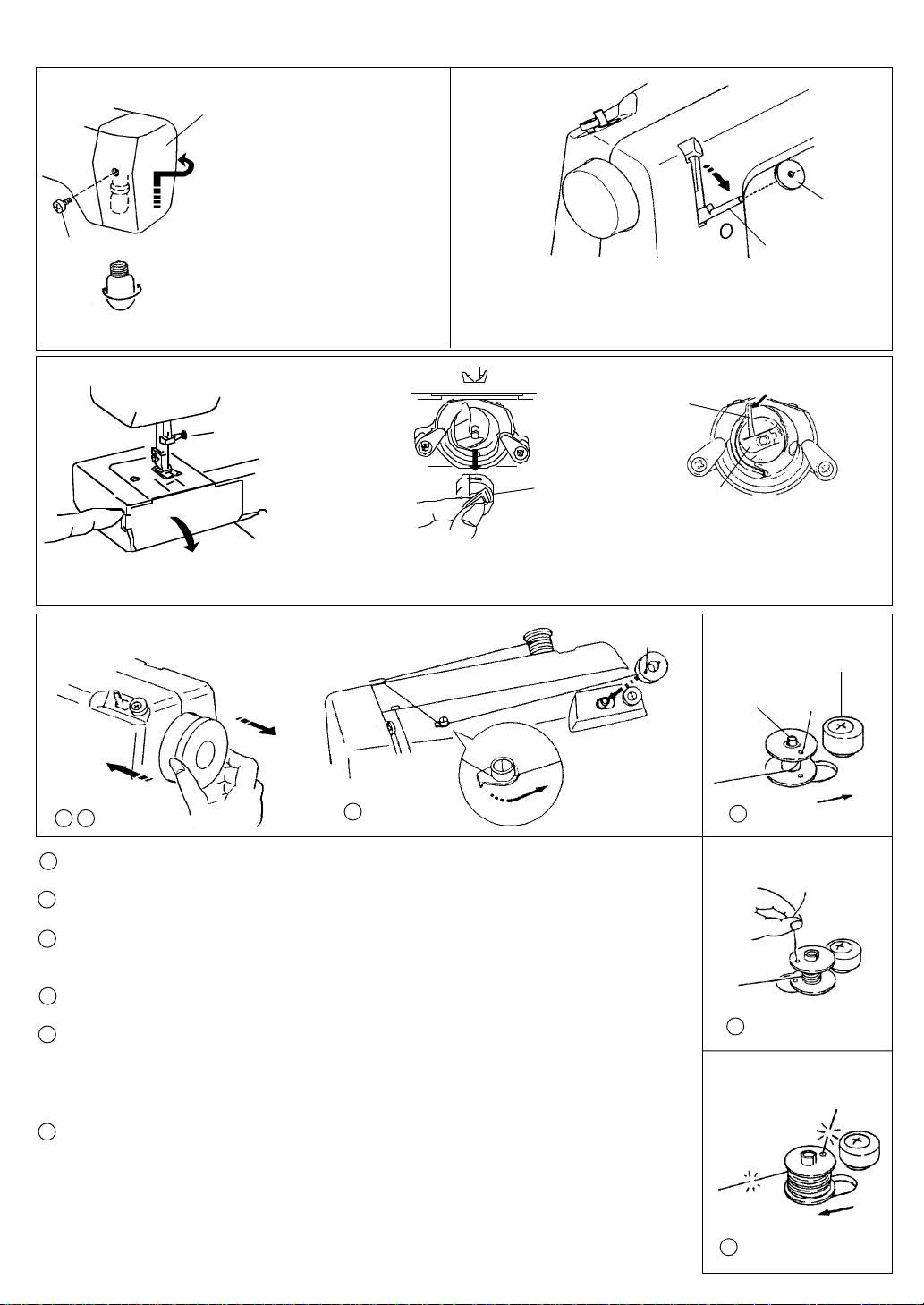

8. Sewing Light 9. Spool Pin

Face Plate

To replace:

Loosen the setscrew and remove

the face plate to the direction of

Setscrew

Bulb

arrow.

Turn the bulb counterclockwise to

remove it.

Turn t the bulb clockwise to

replace it.

The spool pin holds the spool of thread for feeding the

thread to the machine.

Pull out the spool pin and place the felt on it.

Felt

Spool pin

10. Removing and Inserting the Bobbin Case

Open

Raise the needle by turning the handwheel

Open the hook cover.

toward you.

Lift the latch and pull out the bbobin case.

11. Winding the Bobbin

1

6

1 Pull the handwheel out to the right.

2

Latch

Hook race recess

Finger

Latch

When inserting the bobbin case,

place the finger into the recess of

the hook race.

Bobbin winder

stopper

Bobbin winder

spindle

3

2 Pull the thread from the spool and draw it around the thread guides.

3 Draw the thread through the hole on the bobbin from the inside to outside, put

the bobbin on the bobbin winder spindle and push to the right.

4 Hold the free end of the thread with your hand and depress the foot control.

5 Stop the machine when it has made a few turns. Cut the thread close to the

hole on the bobbin. Depress the foot control again.

When the bobbin is fully wound, push the bobbin winder spindle to the left and

cut the thread.

6 Push the handwheel in for sewing.

Note: Do not move the bobbin winder spindle while the machine is running.

4

5

Page 4

12. Threading the Bobbin Case

Tension spring

Bobbin case

Bobbin

Place the bobbin into the bobbin

case.

Make sure the thread unwinds in

the direction of the arrow.

13. Threading the Machine

Thread

Slit

Delivery eye

Pull the thread into the

bobbin case slit.

Draw the thread under the tension

spring and into the delivery eye.

Pull out about 4” (10 cm) of the

thread.

Thread guide

Thread guide

2

Thread take-up lever

3

plate

1

Needle bar

thread guide

4

Raise the thread take-up lever to its highest position by turning the handwheel toward you.

Raise the presser foot.

1

Place the spool on the spool pin as shown, with the thread coming from the front of the spool.

2

Draw the thread around the thread guide as shown.

3

Draw the thread around the thread guide plate as shown.

4

Pull the thread up, then draw it through the thread take-up lever as shown.

Draw the thread and slip it into the needle bar thread guide.

5

Thread the needle eye from the front to back. Pull about 4” (10 cm) of the thread.

14. Drawing up the Bobbin Thread

Needle thread

Needle thread

Raise the presser foot. Hold the

needle thread with your left hand.

Bobbin thread

Turn the handwheel toward you

until the needle thread picks up the

bobbin thread.

Bobbin thread

Pull the both threads to the

back and under the presser

foot.

5

Needle

Page 5

15. Selecting Stitch

Raise the needle above the fabric.

Turn the dial to select the desired

pattern.

Note: Do not turn the dial when the

needle is down in the fabric,

otherwise the needle and fabric

could be damaged.

16. Reverse Button

Press the reverse button to sew in reverse.

Machine Setting

17. Straight Stitch Sewing

Stitch

4

2.5

1.5

Thread Tension Dial

2 - 6

To change sewing direction

Stop the machine and turn the

handwheel toward you to bring the

needle down into the fabric.

Raise the presser foot.

Pivot the fabric aroumd the needle to

change sewing direction as shown.

Starting to sew:

Raise the presser foot and position the fabric next to a

stitching guide line on the needle plate.

Lower the needle into the fabric.

Lower the presser foot and smooth the threads toward the

back.

Dpress the foot control.

To fasten the beginning of the seam, press the reverse

button and sew several reverse stitches.

Finishing sewing

To fasten seam ends, press the

reverse button and sew several

stitches in reverse.

Raise the presser foot and

remove the fabric, draw the

threads to the back.

Cut the threads with the groove on

the back of the presser bar as

shown.

Machine setting

Stitch

2

3.5 5

Thread tension dial

2 - 5

18. Zigzag Stitch Sewing

It can also be used for appliques, cut works

and as a decorative stitch.

Thread tension for zigzag sewing

The zigzag stitch is

used to prevent

fabrics from fraying at

the raw edges.

To obtain better zigzag stitches, the

needle thread tension should be

slightly weaker than straight stitch.

The needle thread appears slightly

on the wrong side of the fabric.

Page 6

Machine setting

Stitch

Thread tension dial

2 - 5

19. Tricot Stitch

Place the fabric under the presser foot so that the edge is

just inside the right side of the presser foot.

Guide the fabric so the right hand stitches fall at the edge

of the fabric.

Machine setting

Stitch

Thread tension dial

1 - 5

Buttonhole foot

Changing the

presser foot

Loosen the screw and

replace the presser

foot.

Tighten the screw.

20. Buttonhole

Starting point A

Needle

thread

1

Bobbin thread

A

B

23 4

5

Make a test buttonhole using the same fabric and interfacing as the actual garment.

Procedure

1 Raise the needle and turn the pattern

selector dial to select .

Draw the both threads to the left.

Lower the needle down into the fabric

at the starting point A, and lower the

buttonhole foot.

2 Sew down the left side stopping at the

bottommark B.

3 Raise the needle and select .

5 Raise the needle and select .

Sew 5 stitches of bartack and raise the

needle out from the fabric.

6 Raise the presser foot, remove the fabric

from the machine and cut the threads

leaving 4” (10 cm) tails.

7 Insert a pin at the end of the buttonhole

as shown, then cut the opening with a

seam ripper.

Sew 5 stitches of bartack and stop the

machine.

Note: Make sure not to cut the stitches.

4 Raise the needle and select .

Sew up the right side of the

buttonhole, stop the machine when

you are directly opposite the first stitch

on the left hand side.

Pin

6

Seam ripper

7

Corded Buttonhole

Fillar code

Spur

Forks

With the buttonhole foot raised, hook a fillar cord on

the spur on the back of the foot.

Bring the ends toward you under the foot until they

clear the front end.

Hook both ends into the forks on the front of the foot

to hold them tight.

Lower the needle down into the fabric at the starting

point, and lower the presser foot.

Sew a buttonhole over the fillar cord.

Pull the left end of the cord to tighten it and cut.

Page 7

Machine setting

Stitch

21. Blind Hemming

0.4 - 0.7 cm

Wrong side

of the fabric

Wrong side

of the fabric

Thread tension dial

1 - 4

Fabric preparation:

Fold up the fabric as

shown.

Machine setting

22. Shell Tuck

Stitch

Thread tension dial

3 - 9

23. Balancing Thread Tension

Correct thread tension for the

straight stitches

Lower the foot, stitch slowly for

better control so that the

needle catches the folded edge

at the leftmost position.

Fold the fabric in bias with the wrong side together.

Place the folded edge under the right side of the slot

on the foot. The needle should fall off the folded

edge at the right swing to form tucks.

Needle thread is too tight.

Right side

of the fabric

Spread the fabric flat with the

right side up.

Decrease

tension

24. Selecting Needles and Threads

Fine

Medium

Heavy

Fabric

Crepe de Chine,

Voile, Lawn,

Organdy, Georgette

Cotton, Pique,

Serge,

Parcale

Denim, Tweed,

Gabardine,

Caoting

Thread

Fine Silk

Fine Cotton

Fine Synthetic

50 Silk

50-80 Cotton

50-60 Synthetic

50 Silk

40-50 Cotton

40-50 Synthetic

Needle thread is too loose.

Needle

#9

#11

#11

#14

In general, fine threads and needle are used for

sewing thin fabrics, and thicker threads and

needle are used with heavy fabrics.

Always test threads and needle size on a small

piece of fabric which will be used for actual

sewing.

Use the same thread for needle and bobbin.

When sewing stretch, very fine fabrics and

#14

#16

synthetic, use a Blue Tipped needle to prevent

skipped stitch.

Increase

tension

Page 8

25. Cleaning the Feed Dog

Care of Your Machine

Screws

Remove the needle and presser foot.

Remove the 2 setscrews and remove the needle plate.

26. Dismantling and Assembling the Hook Race

Hook race ring holder

Raise the needle to its highest position

and open the hook cover. Open the

bobbin case latch and pull out the

bobbin case out from the machine.

Open the hook race ring holders.

Rremove the hook race ring.

Take out the hook race ring and

shuttle hook.

Troubleshooting

Problem

1. The needle thread is not threaded properly.

The needle thread breaks.

2. Needle thread tension is too tight.

3. The needle is bent or blunt.

4. The needle is incorrectly inserted.

5. The thread is either too heavy or too fine for the needle.

Clean out dust and lint clogging on the feed dog with a

lint brush.

Replace the needle plate and secure it with the

setscrew.

Clean the hook race with a lint brush

and soft dry cloth.

Clean the shuttle hook.

Replace all the parts by following the

procedure in reverse.

Cause

Reference

See No. 6

See No.11

See No. 3

See No. 3

See No. 12

The biobbin thread breaks.

The needle breaks.

Skipped stitches

Seam puckering

Stitches form loops on the

wrong side of the fabric.

The cloth is not feeding.

Noisy operation

1. The bobbin thread is not threaded properly.

2. The bobbin thread is too tight.

3. Lint has collected in the bobbin case.

1. The needle is incorrectly inserted.

2. The stitch selector has been turned when the needle is in the fabric.

3. The needle is too fine for the fabric being sewn.

1. The needle is incorrectly inserted or bent.

2. The needle and/or thread is not suitable for the fabric being sewn.

3. The Blue Tipped needle is not used when sewing stretch, very fine or

synthetic fabrics.

4. The needle thread is not threaded properly.

1. The needle thread tension or bobbin thread tension is too tight.

2. The needle and/or bobbin thread are not threaded properly.

1. The needle thread tension is too loose.

2. The needle is either too heavy or too fine for the thread.

3. The needle and/or bobbin thread are not threaded properly.

1. The feed dog is packed with lint.

1. The feed dog or shuttle hook is packed with lint.

2. The shuttle hook needs oiling.

639-800-464 (E) Printed in Thailand

See No. 6

See No. 13

See No. 25

See No. 3

See No. 8

See No. 12

See No. 3

See No. 12

See No. 12

See No. 6

See No. 11

See No. 6

See No. 11

See No. 12

See No. 6

See No. 12

See No. 12

See No. 13

Loading...

Loading...