Janome DC4030PR Instruction Manual

INSTR UCTION BOOK

IMPORTANT SAFETY INSTRUCTIONS

This sewing machine is not a toy. Do not allow children to play with this machine.

The machine is not intended for use by children or mentally infirm persons without proper supervision.

This sewing machine is designed and manufactured for household use only.

Read all instructions before using this sewing machine.

DANGER— To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always unplug this sewing machine from the

electric outlet immediately after using and before cleaning.

2. Always unplug before replacing a se wing machine bulb. Replace bulb with same type rated 12 Volts, 5 Watts.

WARNING— To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Do not allow children to play with the machine. The machine is not intended for use by children or infirmed

persons without proper supervision.

Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or near

children.

2. Use this appliance only for its intended use as described in this owner’s manual.

Use only attachments recommended by the manufacturer as contained in this owner’s manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water.

Return this sewing machine to the nearest authorized dealer or service center for examination, repair, electrical or

mechanical adjustment.

4. Never operate the appliance with any air opening blocked. Keep ventilation openings of this sewing machine and

foot controller free from accumulation of lint, dust and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

8. To disconnect, turn all controls to the off (“O”) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch this sewing machine off (“O”) when making any adjustment in the needle area, such as threading the

needle, changing the needle, threading the bobbin or changing the presser foot, and the like.

15. Always unplug this sewing machine from the electrical outlet when removing covers, lubricating, or when making

any other adjustments mentioned in this owner’s manual.

SA VE THESE INSTRUCTIONS

Please note that on disposal, this product must be safely recycled in accordance with relevant National legislation relating

to electrical/electronic products. If in doubt please contact your retailer for guidance. (European Union only)

TABLE OF CONTENTS

SECTION I. NAME OF PARTS

Names of Parts .............................................................. 2

Standard Accessories.................................................... 3

SECTION II. GETTING READY TO SEW

Connecting Machine to Power Supply........................... 4

Before Using Your Sewing Machine............................... 4

Operating Instructions.................................................... 4

For Your Safety............................................................... 4

Controlling Sewing Speed ............................................. 5

Speed Control Slider...................................................... 5

Machine Operating Buttons ........................................ 5-6

Presser Foot Lifter ......................................................... 7

Thread Cutter................................................................. 7

Extension T ab le.............................................................. 7

To Drop or Raise the Feed Dog ..................................... 8

Presser Foot Pressure Adjusting Lever ......................... 8

Carrying Handle............................................................. 8

Changing Needle ........................................................... 9

Selecting Thread and Needles ...................................... 9

Removing and Attaching the Foot Holder.................... 10

Changing Presser Foot................................................ 10

Bobbin Winding....................................................... 10-12

Threading the Machine ................................................ 13

Needle Threader .......................................................... 13

Drawing Up Bobbin Thread.......................................... 14

Adjust the Needle Thread T ension for a Straight Stitch ... 14

Adjust the Needle Thread T ension for a Zigzag Stitch .... 15

SECTION IV. CARE OF YOUR MACHINE

Clean the Hook Race and Feed Dog........................... 37

Assemble the Hook Race ............................................ 37

Replacing the Light Bulb.............................................. 38

Attaching the Light Bulb............................................... 38

Problems and Warning Signals.................................... 39

Troubleshooting............................................................ 40

SECTION III. BASIC SEWING

Straight Stitch............................................................... 16

Using the Seam Guides on the Needle Plate.............. 17

Turn a Square Corner .................................................. 17

Quilting......................................................................... 17

Sewing on Heavy Fabrics ............................................ 18

Manual Stitch Length ................................................... 18

Variable Needle Position.............................................. 18

Pintucking .................................................................... 19

Automatic Reverse Stitch............................................. 19

Triple Stretch Stitch...................................................... 19

Straight Stretch ............................................................ 20

Auto-lock Stitch............................................................ 20

Saddle Stitch................................................................ 20

Zigzag Stitch ................................................................ 21

Overcasting.................................................................. 21

Tricot Stitch .................................................................. 22

Overedge Stitch ........................................................... 22

Serging Stitch............................................................... 22

Button Sewing.............................................................. 23

Automatic Buttonhole.............................................. 24-25

Adjusting the Stitch Width and Density in Buttonholes..... 26

Double Layer Buttonhole ............................................. 26

Round End Buttonhole................................................. 26

Keyhole Buttonhole...................................................... 26

Knit Buttonhole ............................................................ 27

Faux Chain Buttonhole ................................................ 27

Stretch Buttonhole ....................................................... 27

Corded Buttonhole....................................................... 28

Zipper Sewing ......................................................... 29-30

Blind Hemming............................................................. 31

Bartacking .................................................................... 32

Applique ....................................................................... 33

Patchwork .................................................................... 33

Satin Stitch................................................................... 34

Elongation .................................................................... 34

Decorative Stitch Pattern with Auto Lock Stitch .......... 35

Adjusting Pattern Balance ........................................... 36

1

r

e

w

#0

#9

t

@8

q

#1

#2

@4

@9

y

#3

u

@3

i

@5

@7

o

@6

@2

$0

#4

!0

!1

@1

@0

#8

!2

!9

!8

#5

#6

!3

#7

!4

!7

!5

!6

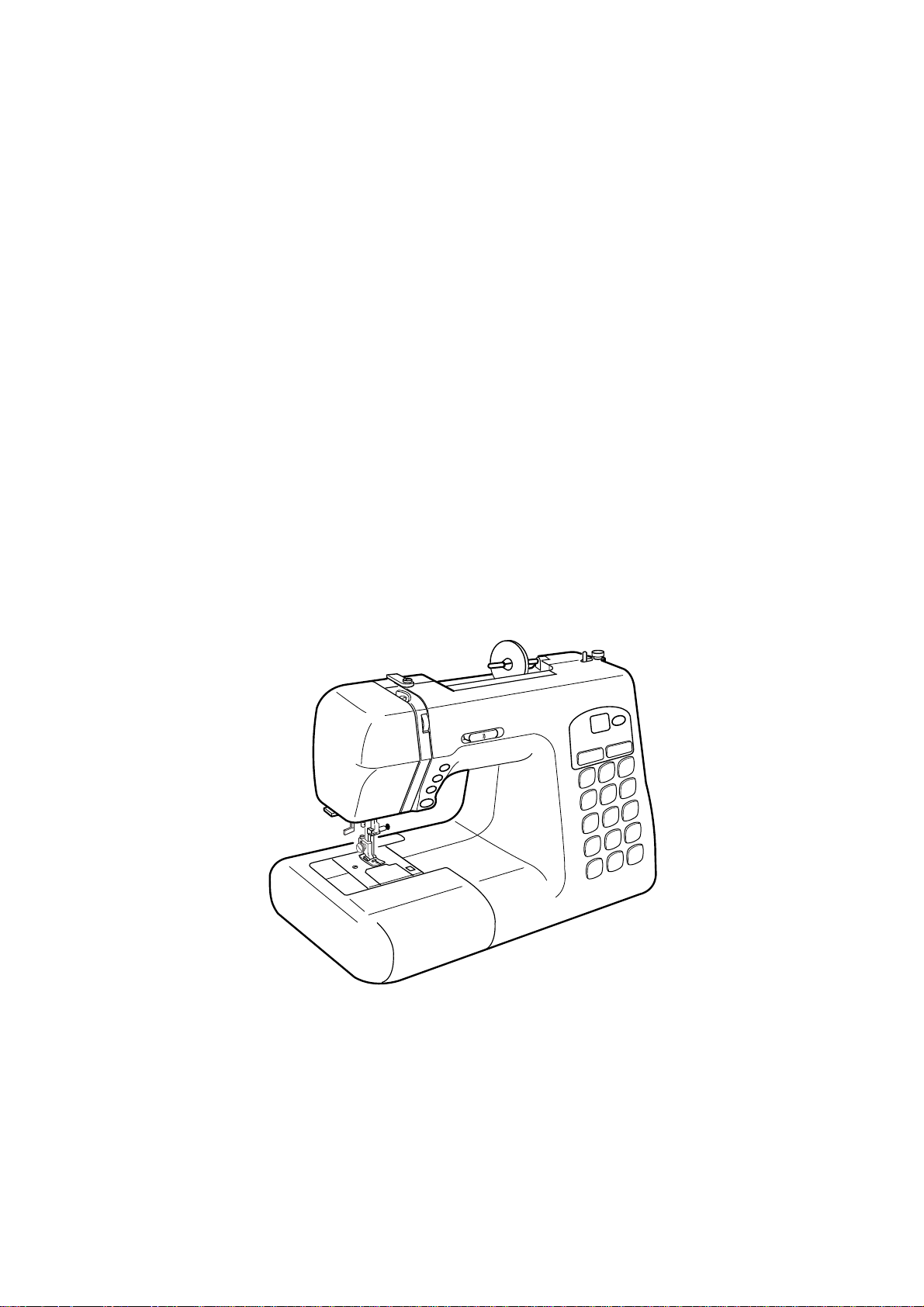

SECTION I. NAME OF PARTS

Names of Parts

Extension table (Accessory box)

q

w Needle plate

e Needle threader

r Thread cutter

t Face cover

y Thread take-up lever

u Upper thread guide

i Thread tension dial

o Spool pin

!0 Large spool holder

!1 Speed control slider

!2 Indicator window

!3 Elongation button

!4 Stitch width adjusting button

!5 Stitch length adjusting button

!6 Stitch pattern selection button

!7 Up/down needle position button

!8 Auto-lock button

!9 Reverse stitch button

@0 Start/stop button

@1 Feed balancing dial

@2 Hook cover release button

@3 Hook cover plate

@4 Foot holder

@5 Presser foot

@6 Needle

@7 Needle clamp screw

@8 Thumb screw

@9 Machine sockets

#0 Power switch

#1 Handwheel

#2 Bobbin winder stopper

#3 Bobbin winder spindle

#4 Carrying handle

#5 Presser foot lifter

#6 Buttonhole lever

#7 Free-arm

#8 Drop feed dog lever

#9 Foot control

$0 Power supply cord

*The design and specifications are subject to change without a prior notice.

2

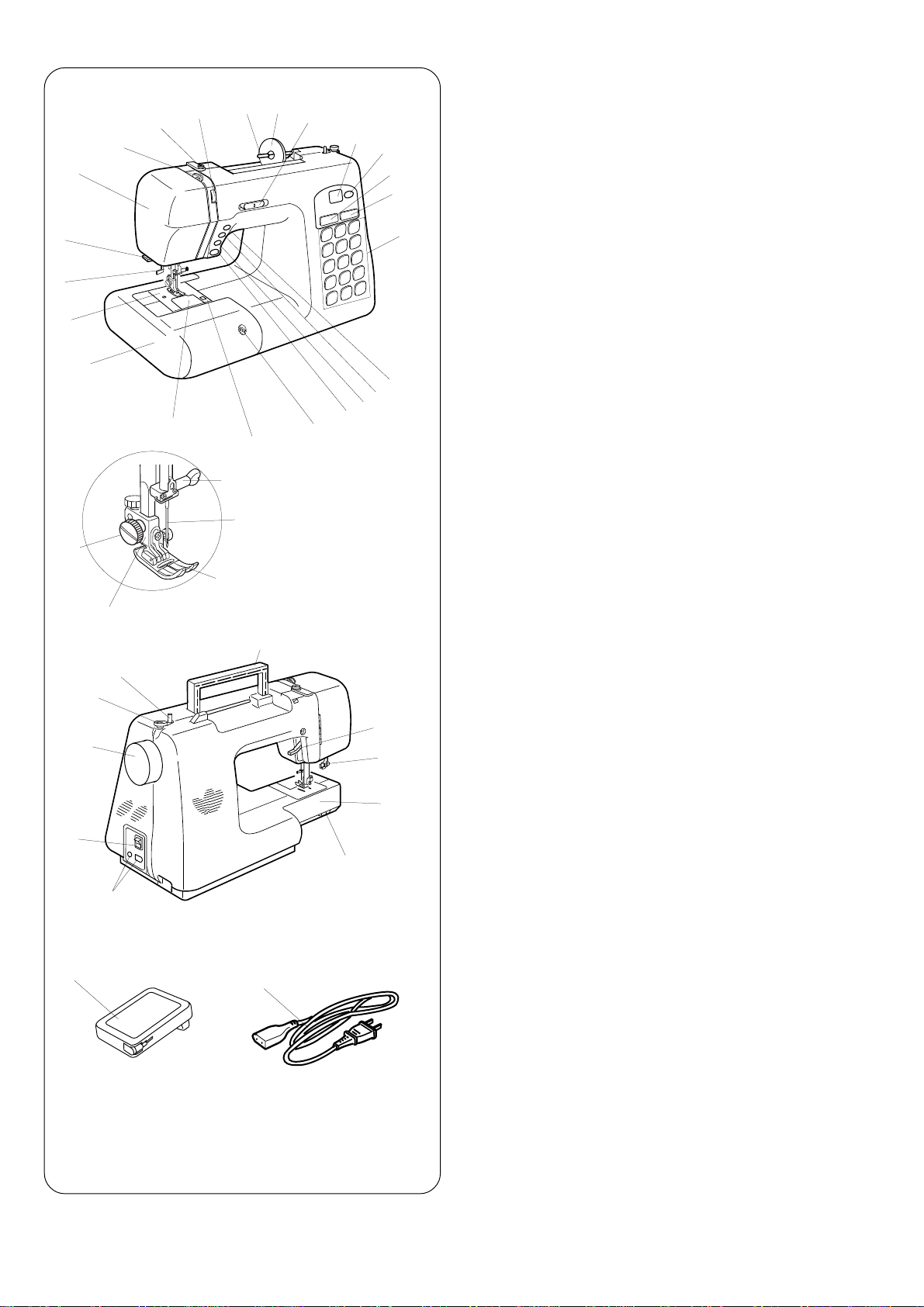

Standard Accessories

qwert

yu io !0

!1

!2 !3

!4

q Bobbin

w Needle set

e Overcast foot: M

r Satin stitch foot: F

t Zipper foot: E

y Automatic buttonhole foot: R

u Overedge foot: C

i Blind hem foot: G

o Screwdriver

!0 Quilter

!1 Seam ripper/Buttonhole opener

!2 Lint brush

!3 Large spool holder

!4 Small spool holder

3

q

w

e

r

r

q

t

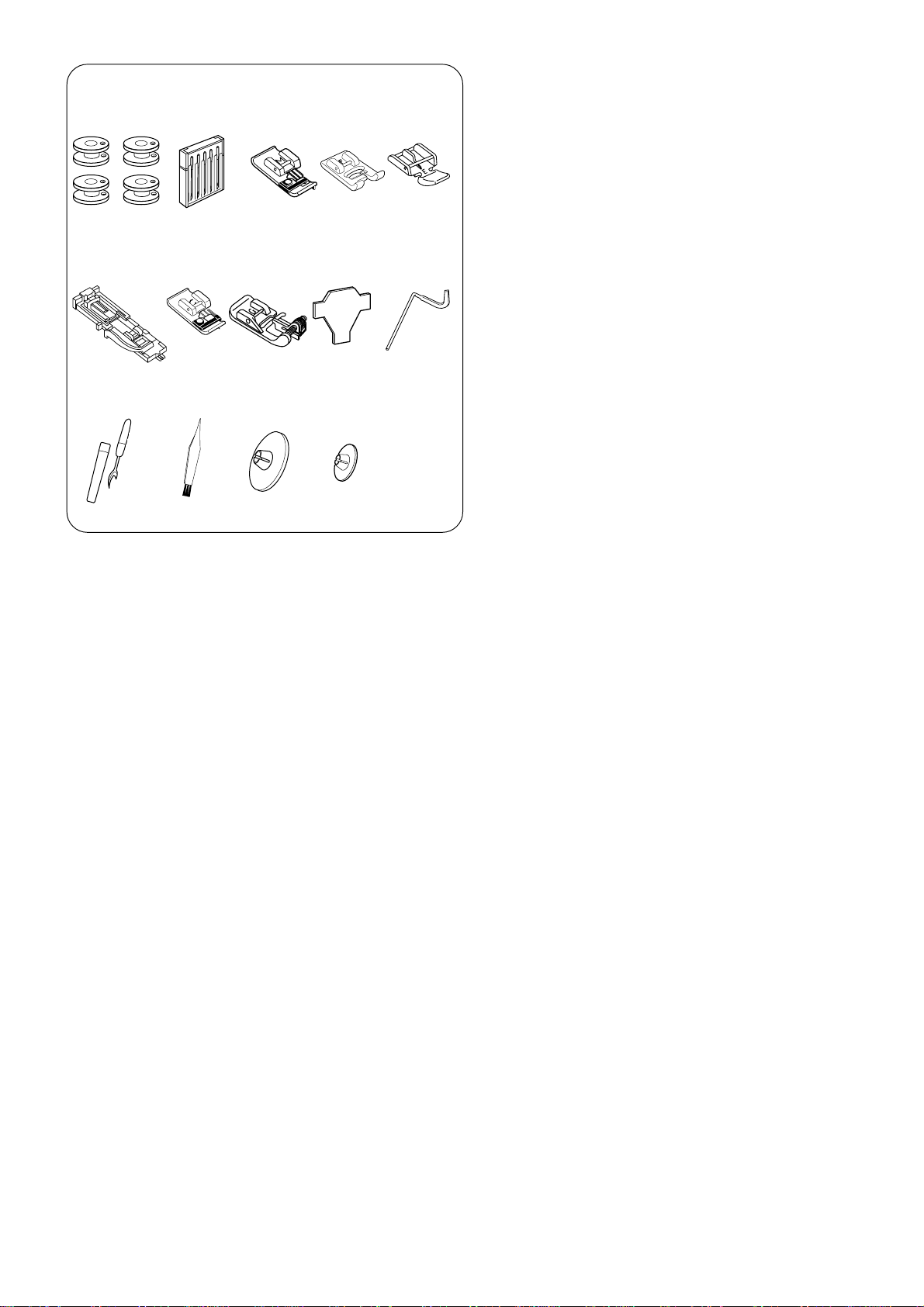

SECTION II. GETTING READY TO SEW

Connecting Machine to Power Supply

Before connecting the power cord, make sure the voltage

and frequency shown on the machine conform to your

electrical power.

Using the start/stop button

q Machine socket

w Power supply plug

e Power switch

r Machine plug

1. Turn off the power switch e.

2. Insert the machine plug r into the machine socket q.

3. Insert the power supply plug w into the outlet.

4. Turn on the power switch e

w

Using the foot control

q Foot control plug

w Machine socket

e Power supply plug

r Power switch

t Machine plug

y Foot control

u Red mark

1. Turn off the power switch r.

2. Insert the foot control plug q, and machine plug t

into the machine socket w.

3. Insert the power supply plug e into the outlet.

4. Turn on the power switch r.

y

e

u

Operating Instructions:

The symbol “O” of a switch indicates the “off” position of

a switch.

For appliances with a polarized plug (one blade wider

than the other). To reduce the risk of electric shock, this

plug is intended to fit in a polarized outlet only one way.

If it does not fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified electrician to install

the proper outlet. Do not modify the plug in any way.

CAUTION:

Do not pull the foot control cord beyond the red mark u.

NOTE:

The start/stop button does not work when the foot control

is connected.

When the machine is turned on, the mark is lit after

one second, and the indicator window will show .

Before Using Your Sewing Machine

Before using your sewing machine for the first time,

place a waste fabric under the presser foot and run the

machine without thread for a few minutes. Wipe away

any oil which may appear.

For Y our Safety

* While in operation, always keep your eyes on the

sewing area. Do not touch any moving parts such as

the thread take-up lever, handwheel or needle.

* Always turn off the power switch and unplug from the

power supply:

- When leaving the machine unattended.

- When attaching or removing any parts.

- When cleaning the machine.

* Do not place anything on the foot control, when not

sewing.

4

r

e

w

q

y

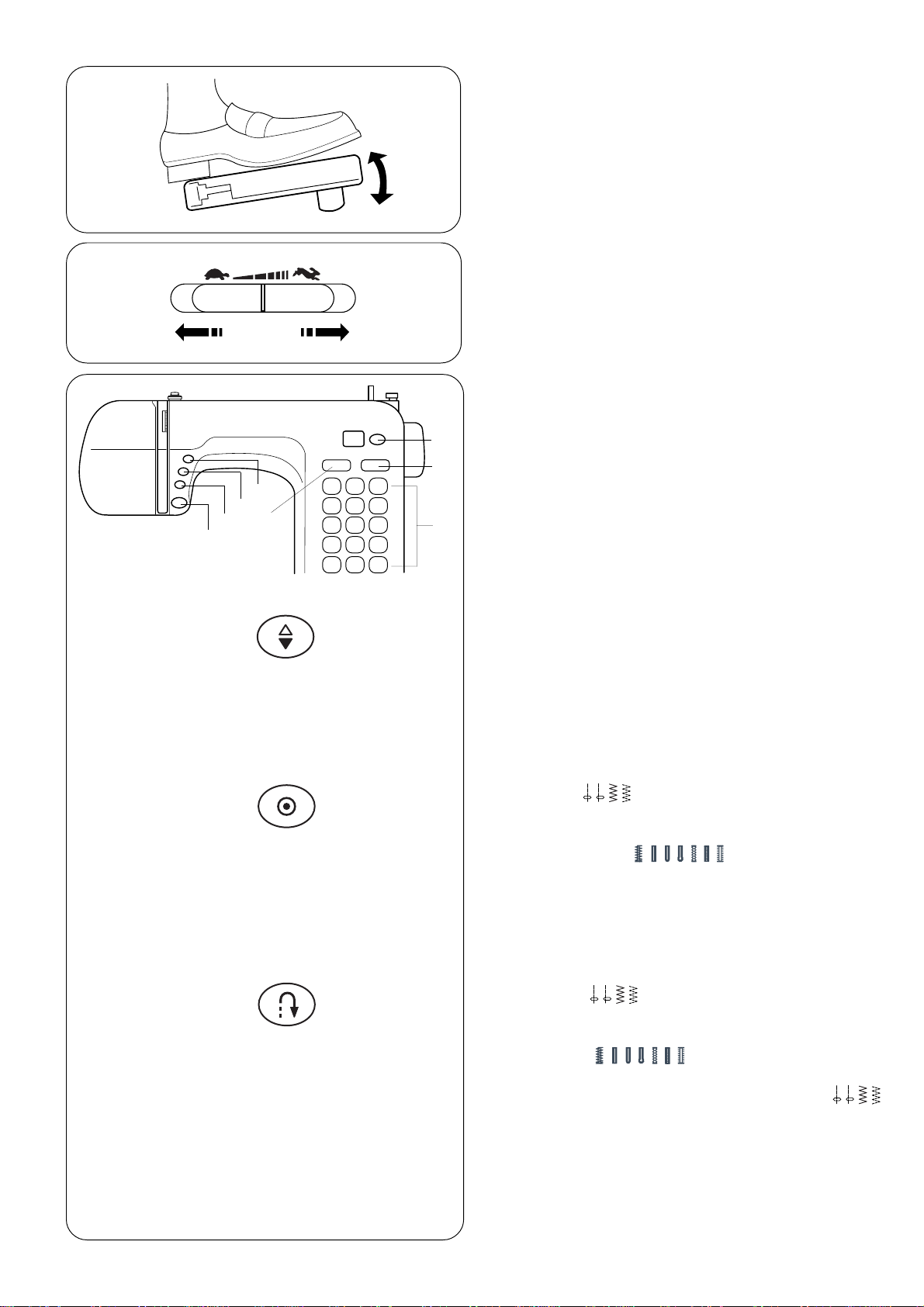

Controlling Sewing Speed

Sewing speed is varied by the foot control.

The machine runs at the maximum speed set by the

speed control slider when the foot control is fully depressed.

Operating Instructions:

Foot controller Model 21317 is for use with this sewing

machine.

Speed Control Slider

Sewing speed can be varied by the speed control Slider

according to your sewing needs.

To increase sewing speed, slide the lever to the right.

To decrease sewing speed, slide the lever to the left.

Machine Operating Buttons

t

u

i

q

w

e

q q

q Up/down needle position button

q q

Press this button to set the needle position up or down

when the machine stops. The machine will stop with the

needle up or down depending on the needle position

determined by this button.

• The button is lit orange when needle position is set

down position.

w w

w Auto-lock button

w w

When stitches are selected, the machine will

immediately sew locking stitches when the Auto-lock

button is pressed, then automatically stop. When sewing

other stitches (except ), the machine will

sew locking stitches at the end of the pattern being sewn

and automatically stop.

• The button is lit green until locking stitch is automatically

stopped.

e e

e Reverse stitch button

e e

When stitches are selected, the machine will

sew in reverse while the reverse stitch button is pressed.

If you press the reverse stitch button when sewing other

stitches (except ), the machine will

immediately sew locking stitches and automatically stop.

If you press the reverse button when stitch pattern

has been selected and the foot control is not connected,

the machine will start sewing in reverse as long as the

button is pressed and the machine will stop when the

button is released.

• The button is lit red until locking stitch is automatically

stopped.

5

r

rr

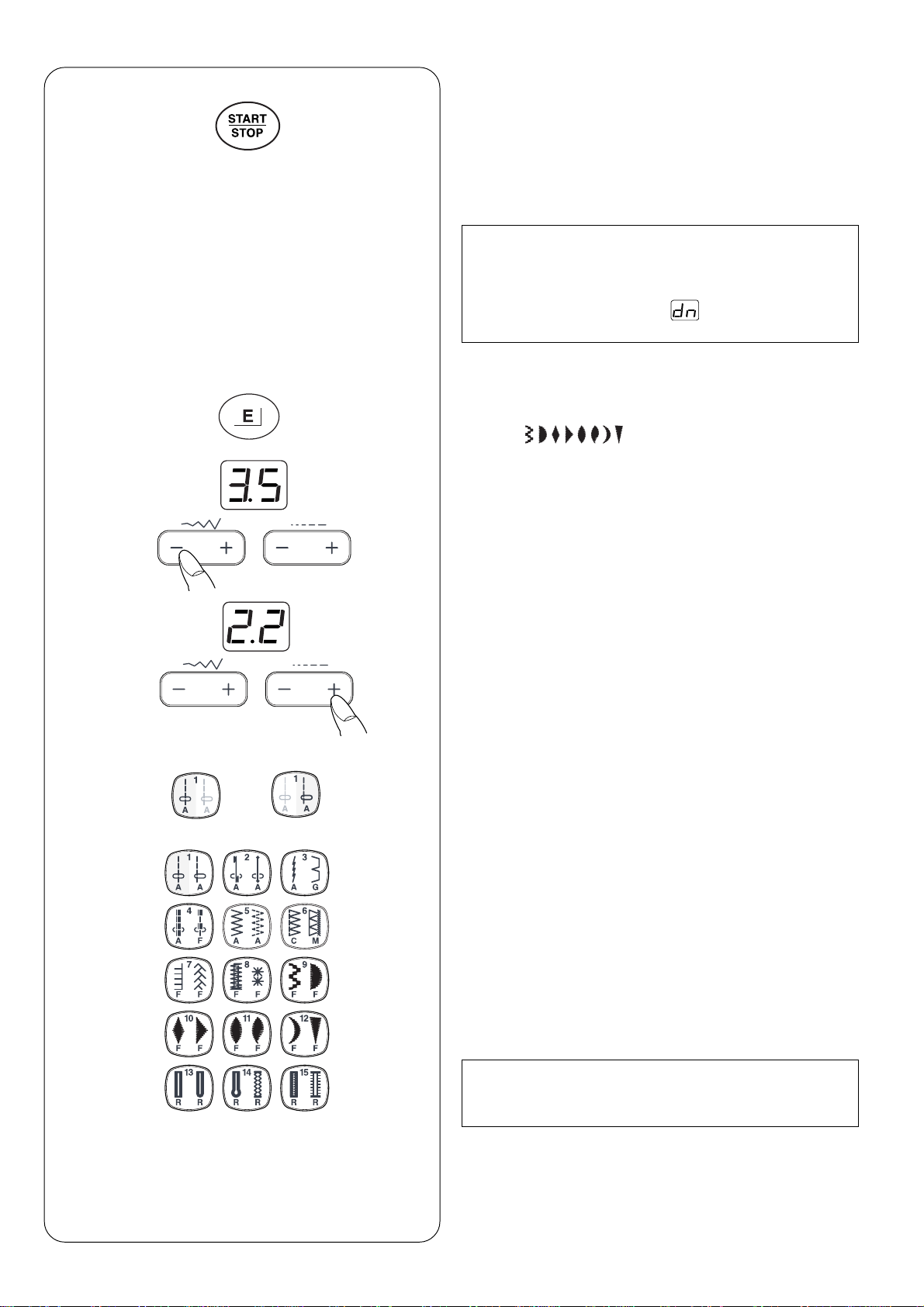

r Start/stop button

rr

Press this button to start or stop the machine.

The machine starts running slowly for the first few

stitches; it then runs at the speed set by the speed

control lever. The machine will run slowly as long as this

button is pressed.

• The button is lit green when the machine is stopped.

• The button is lit red when the machine is running.

Notes:

• The Start/stop button cannot be used when the foot

control is connected to the machine.

• If you start the machine with the presser foot up, the

Indicator window will show .

Lower the foot then restart the machine.

t

y

u

i

(1) (2)

tt

t Elongation button

tt

Stitches can be elongated up to five times

their normal length by pressing this button (see page

34).

yy

y Stitch width adjusting button

yy

Press “+” or “–” to change the stitch width or needle drop

position (see page 18 or 21).

The button is lit green and the indicator will show the

stitch width or needle drop position.

uu

u Stitch length adjusting button

uu

Press “+” or “–” to change the stitch length (see page 36).

The button is lit green and the indicator will show the stitch

length.

ii

i Stitch pattern selection button

ii

Press the desired stitch pattern selection button to

select the desired stitch.

(1) To select the pattern on the left side of pattern

selection button, press it once.

The button is lit green and the pattern on the left

side is selected.

(2) To select the pattern on the right side of pattern

selection button, press it twice.

The button is lit orange and the pattern on the right

side is selected.

* The indicator window will show the pre-set stitch length

of the selected stitch pattern.

* The alphabet under the stitch pattern indicates the

suitable presser foot type for the selected stitch

pattern.

Note:

Raise the needle above the fabric when selecting the

stitch pattern.

6

e

q

w

q

e

w

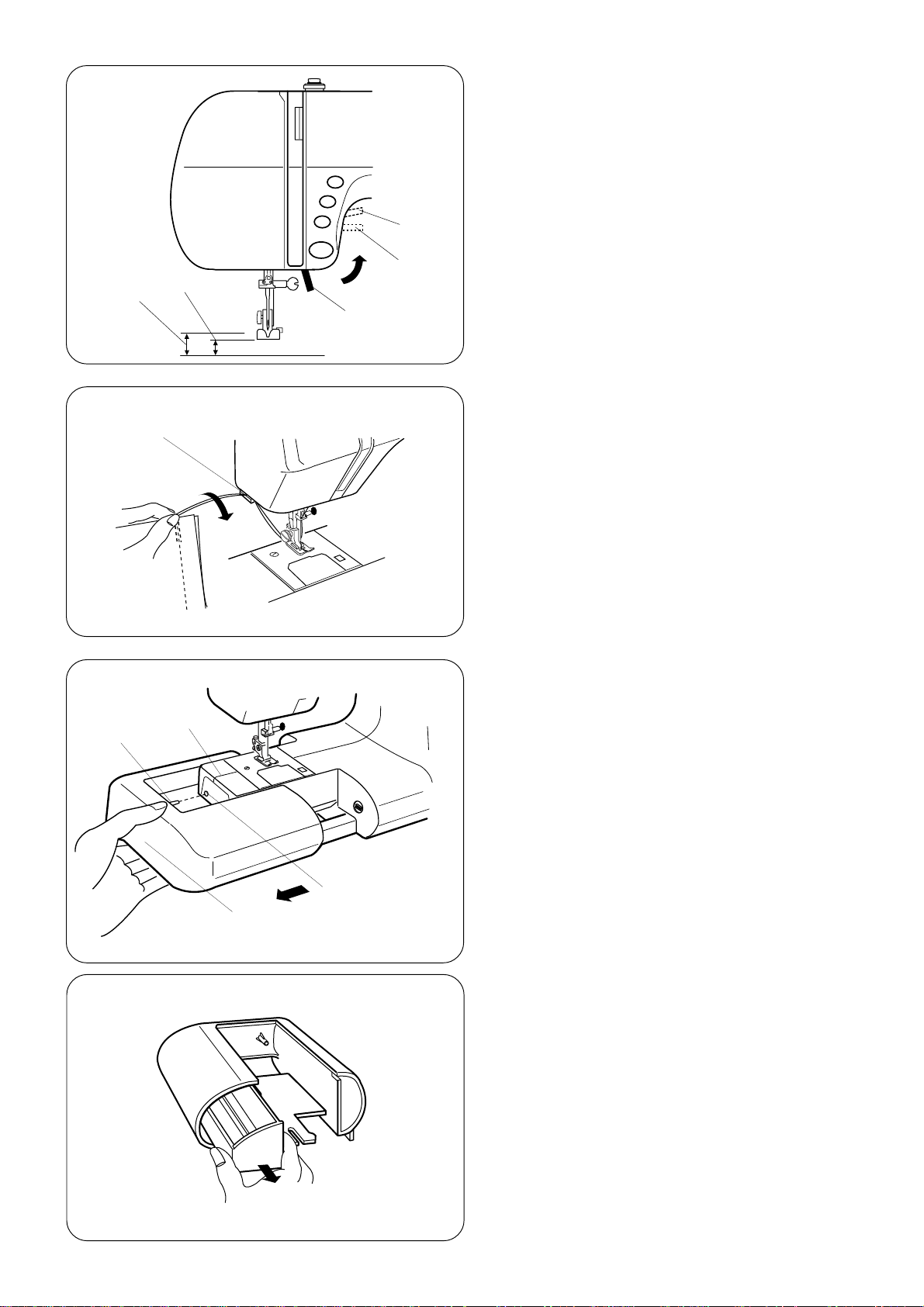

Presser Foot Lifter

q Presser foot lifter

w Normal up position

e Highest position

The presser foot lifter q raises and lowers the presser

foot.

You can raise it about 1/4˝ (0.6 cm) higher than the normal

up position w for easy removal of the presser foot, or to

help you place thick material under the foot.

Thread Cutter

q Thread cutter

You do not need a pair of scissors to cut the thread after

sewing. Simply use the built-in thread cutter.

w

r

q

e

Extension T able

• Detaching the table

Pull the table away from the machine, as illustrated, for

“free-arm” sewing of cuffs and sleeves.

• Attaching the table

Push the extension table q, inserting the pin w into the

hole e, until the extension table q snaps into the

machine.

q Extension table

w Pin

e Hole

r Free-arm

• Accessory case

Many sewing accessories are stored in the accessory

case.

7

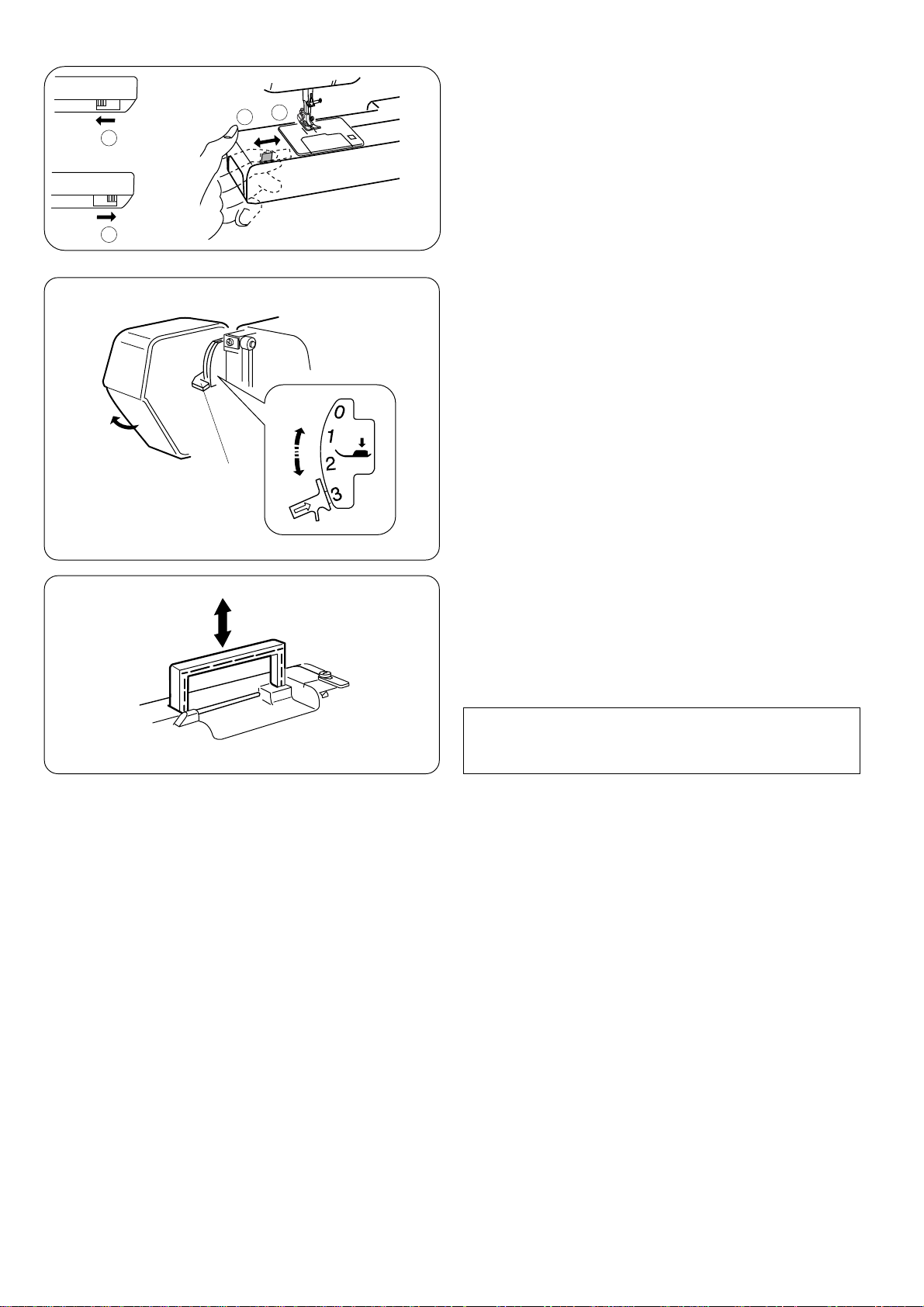

To Drop or Raise the Feed Dog

The drop feed dog lever is located underneath the free

1

2

1

2

arm bed on the back side of the machine.

q To drop the feed dog, push the lever in the direction

of the arrow, as illustrated.

w To raise the feed dog, push the lever in the direction

of the arrow, as illustrated, and turn the handwheel

toward you. Feed dog must be up for normal sewing.

Presser Foot Pressure Adjusting Lever

The presser foot pressure adjusting lever should be set

at “3” for regular sewing.

Reduce the pressure to “2” for the applique, cutwork,

draw work and basting.

Set the pressure at “1” when sewing the chiffon, lace,

organdy and other fine fabrics. Velour and knits with a lot

of stretch may also require the pressure at “1”.

q Presser foot pressure adjusting

q

Carrying Handle

Use the carrying handle when carrying your sewing

machine.

To use the carrying handle, pull it up as far as it will go.

Press down the carrying handle to store it.

Note:

Press down and store the carrying handle when it is

not in use.

8

z

c

q

w

x

e

Changing Needle

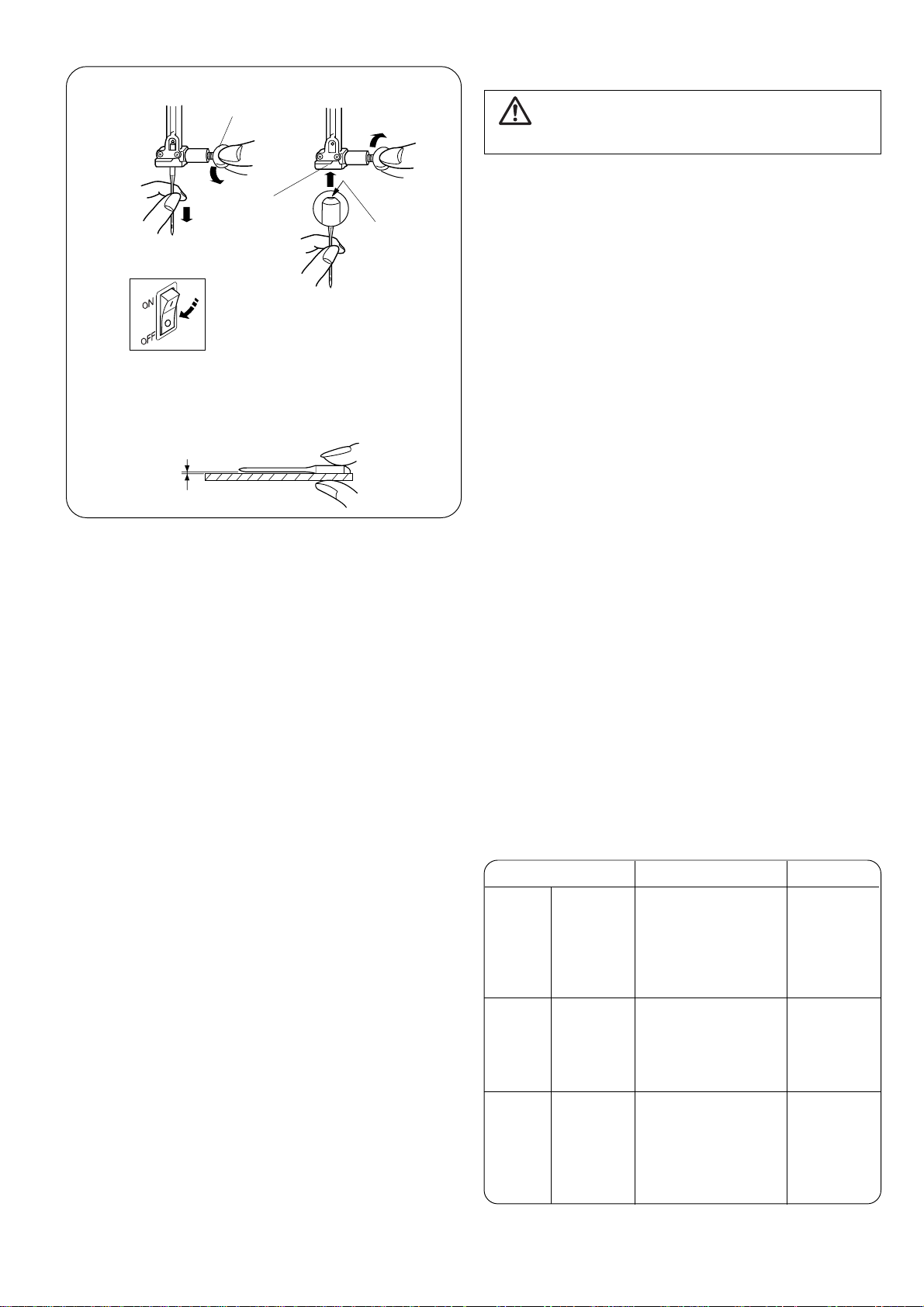

CAUTION:

Turn off the power switch when changing a needle.

q Needle clamp screw

w Needle clamp

e Flat side

z Raise the needle to its highest position by turning the

handwheel counterclockwise, and lower the presser

foot. Loosen the needle clamp screw q by turning it

counterclockwise. Remove the needle from the needle

clamp w.

x Insert a new needle into the needle clamp w with the

flat side e to the rear. When inserting the needle into

the needle clamp w, push it up as far as it goes. Tighten

the needle clamp screw q firmly by turning it clockwise.

c To see if the needle is good, place the flat side of the

needle onto something flat (needle plate, glass, etc.).

The gap between the needle and the flat surface should

be consistent. Never use a bent or blunt needle.

A damaged needle can cause permanent snags or runs

in knits, fine silks and silk-like fabrics.

Selecting Thread and Needles

For general sewing, use needle size 11/75 or 14/90. A

fine thread and needle should be used for sewing

lightweight fabrics, so the fabric will no be marred. Heavy

fabrics requires a needle large enough to the fabric

without fraying the needle thread.

Always test the needle size on a small pierce of fabric,

which will be used for actual sewing.

In general, use same thread for needle and bobbin.

When sewing stretch, very fine fabrics and synthetics,

use a BLUE TIPPED needle. The blue tipped needle

effectively prevents skipped stitches.

Thread

Needle

#9/65–11/75

#11/75–14/90

#14/90

Light

Medium

Fabric

Lawn

Georgette

Tricot

Wool,

Polyester

Cotton,

Polyester

Fine jersey

Wool

Silk #80-100

Cotton #80-100

Synthetic #80-100

Silk #50

Cotton #60-80

Synthetic #50-80

Cotton #50

9

Heavy

Denim

Jersey

Coating

Quilting

Silk #50

Cotton #40-50

Synthetic #40-50

Silk #30

Cotton #50

#14/90–16/

100

#16/100

q

q

q

w

w

e

e

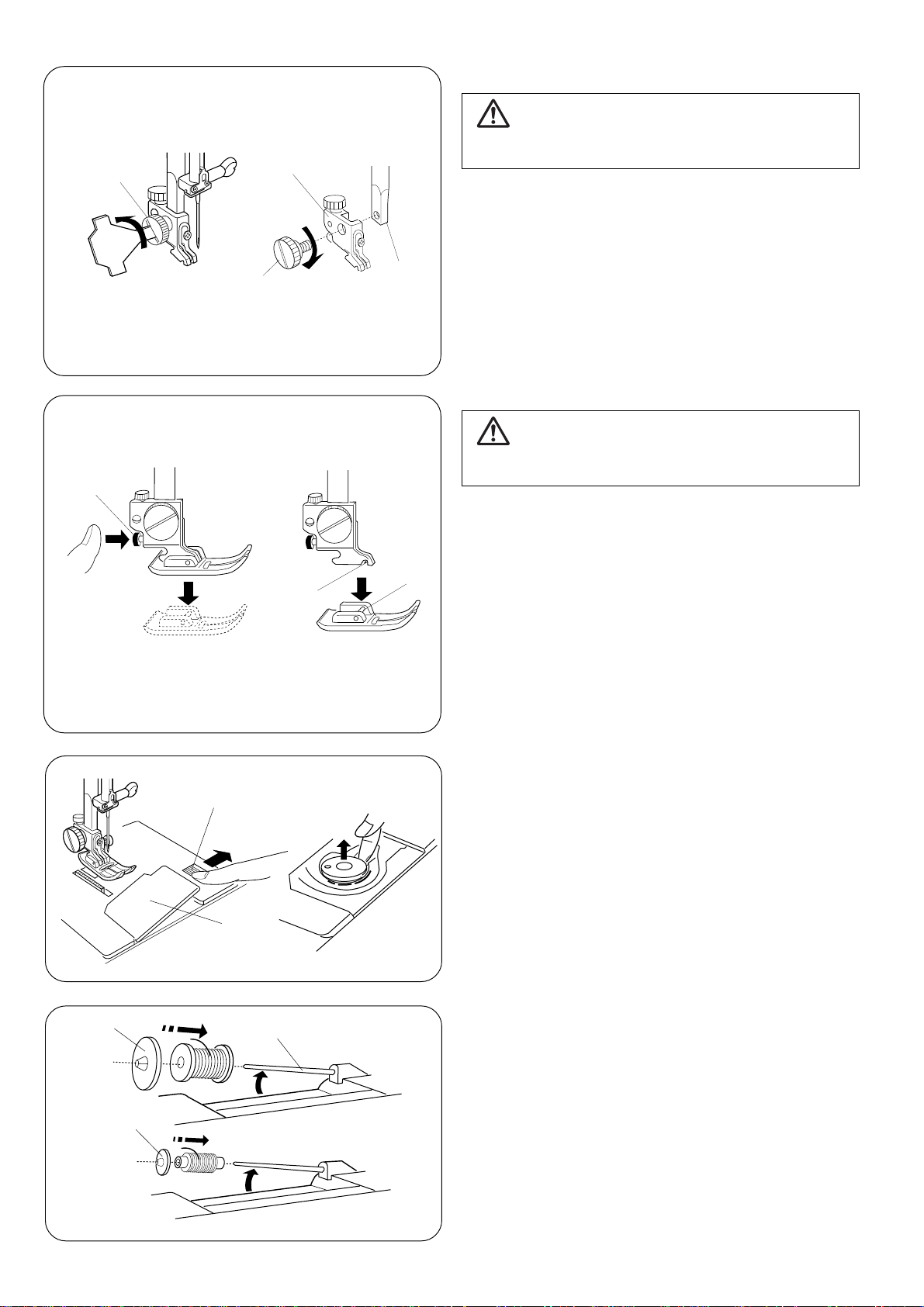

Removing and Attaching the Foot Holder

CAUTION:

Turn off the power switch when removing or attaching

the foot holder.

q Thumb screw

w Foot holder

e Presser bar

•To remove

Remove the thumb screw q by turning it

counterclockwise with a screwdriver.

•To attach

Match the hole in the foot holder w with the threaded

hole in the presser bar e. Fit the thumb screw q into

the hole. Tighten the screw q by turning it clockwise

with a screwdriver.

Changing Presser Foot

CAUTION:

Turn off the power switch when changing the presser

foot.

q Snap-on button (red button)

w Groove

e Pin

•To remove

Raise the needle to its highest position by turning the

handwheel counterclockwise. Raise the presser foot,

and press the red button q on the back of the foot

holder.

•To attach

Place the selected presser foot so that the pin e on

the foot lies just under the groove w on the foot

holder. Lower the presser bar to lock the foot into

place.

w

e

q

w

q

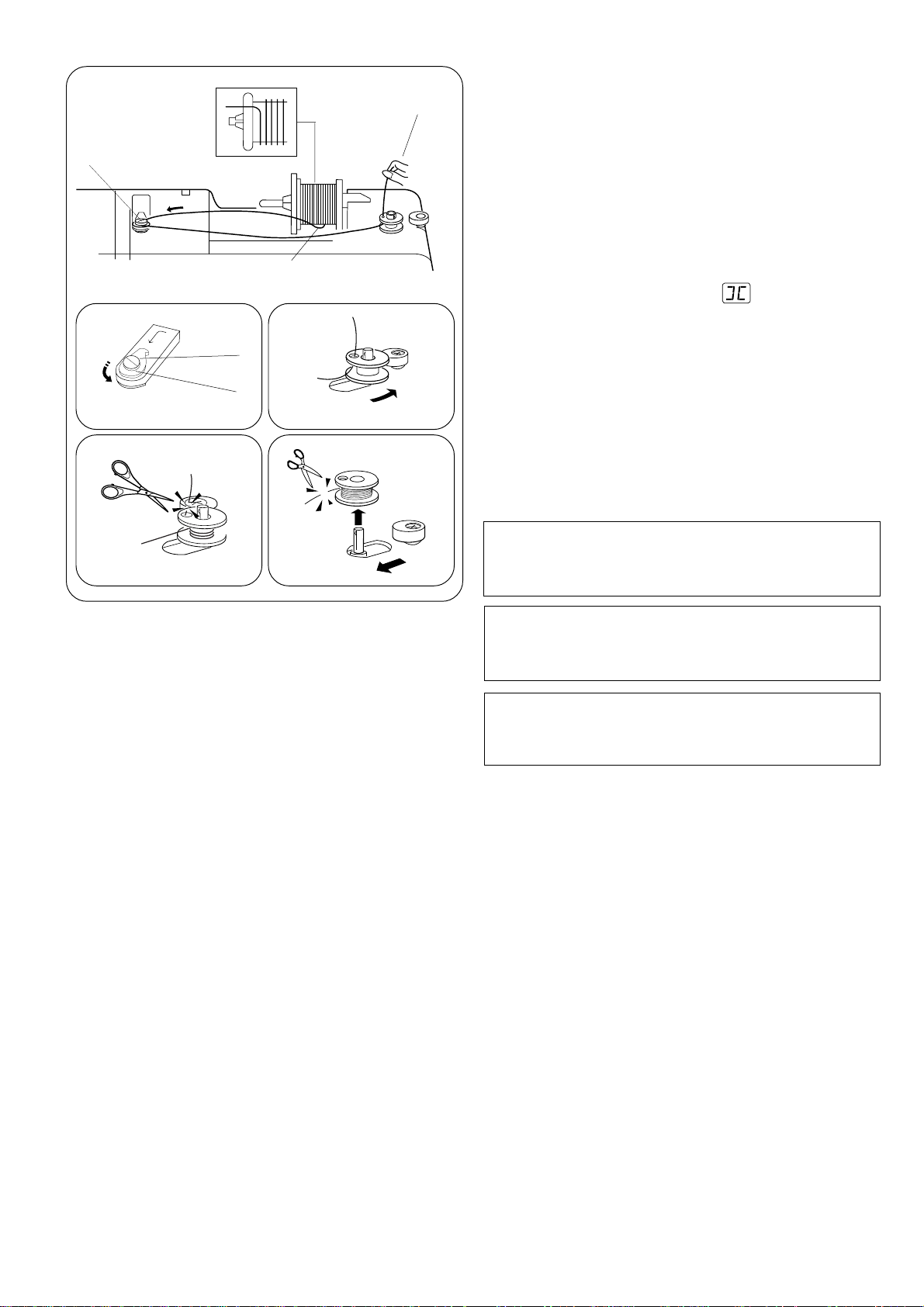

Bobbin Winding

• Removing the bobbin

q Hook cover plate release button

w Hook cover plate

Gently slide the hook cover plate release button q to the

right and remove the cover plate w.

Lift out the bobbin.

• Horizontal spool pin

q Spool pin

w Large spool holder

e Small spool holder

Lift up the spool pin q. Place a spool of thread on the

spool pin with the thread coming off the spool as shown.

Attach the large spool holder w, and press it firmly

against the spool of thread.

The small spool holder e is used with narrow or small

spools of thread.

10

c

• Winding the bobbin

z Draw the thread from the spool.

x Guide the thread around the thread guide.

x

z

x

nm

v b

c Thread through the hole in the bobbin from the inside

to the outside.

v Put the bobbin on the bobbin winder spindle.

b Push the bobbin to the right.

The indicator window will show sign.

n With the free end of the thread held in your hand,

depress the foot control. Stop the machine when it

has wound a few layers, and then cut the thread

close to the hole in the bobbin.

m Depress the foot control again. When the bobbin is

fully wound, it stops automatically. Return the bobbin

winder to its original position by moving the spindle to

the left, and cut the thread as shown.

NOTE:

The machine will not sew until the spindle has been

returned to the left.

NOTE:

Make sure that the carrying handle is not being raised

when winding the bobbin.

NOTE:

The machine motor automatically stops after 2 minutes

if you do not stop the machine.

11

z

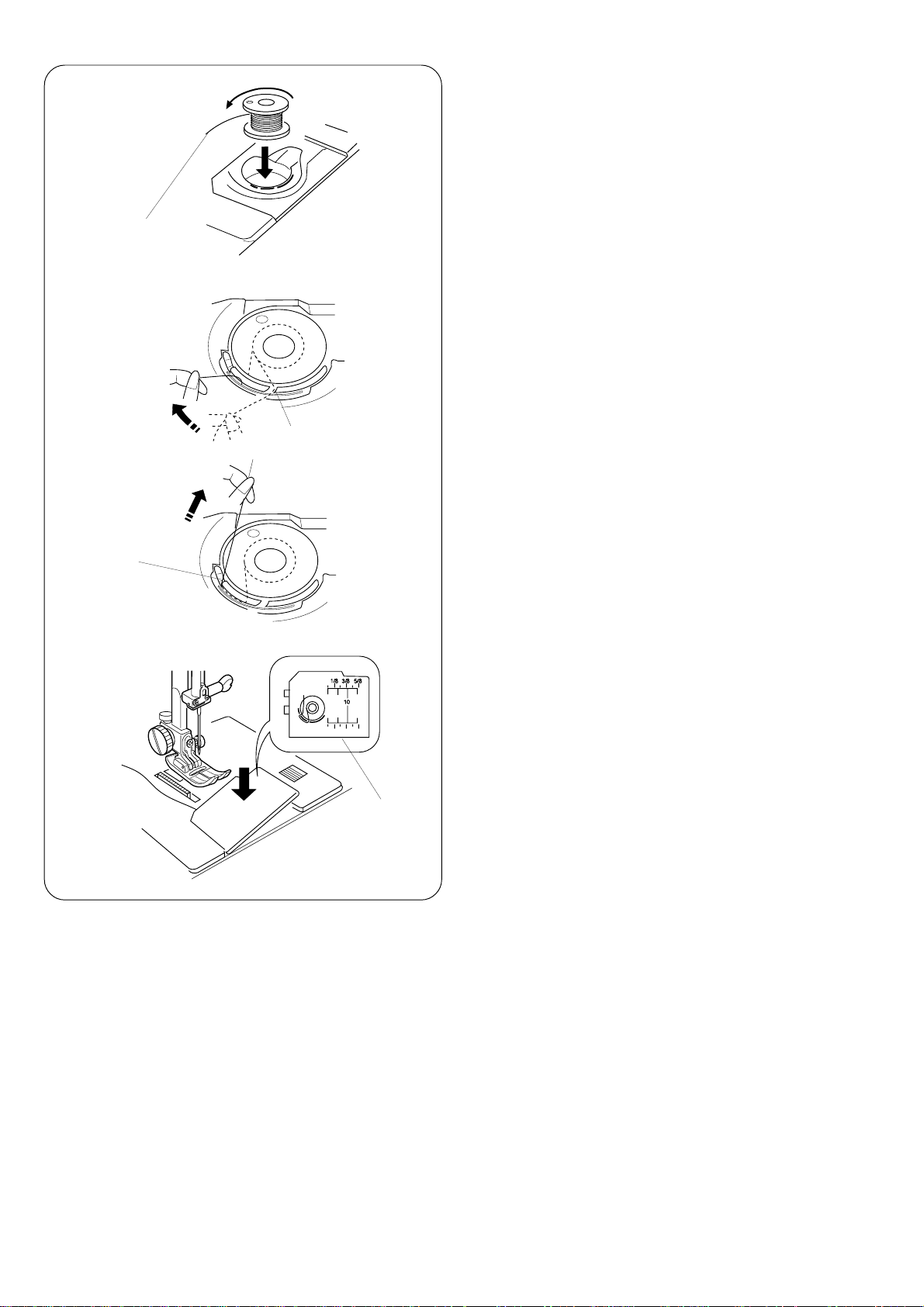

• Inserting the bobbin

q End of thread

w Notch

e Notch

r Threading diagram

z Place a bobbin in the bobbin holder with the thread

running off counterclockwise.

q

x

c

v

x Guide the thread into the first notch w on the front

side of the bobbin holder. Draw the thread to the left,

sliding it between the tension spring blades.

w

c Continue to draw the thread lightly until the thread

slips into the second notch e. Pull out about 6˝

(15 cm) of thread.

e

v Attach the hook cover plate. Check the threading by

referring to the diagram r shown on the hook cover

plate.

r

12

Loading...

Loading...