Page 1

ON-BOARD DIAGNOSTICS

V6 and V8 Engine Management

Vehicle Coverage:

X-Type 2.5L V6 and 3.0L V6 2001 model year onwards

X-Type 2.0L V6 2001 model year onwards

S-Type 3.0L V6, 4.2L V8 (normally aspirated and supercharged) from 2002 model year onwards

XK Range 4.2L V8 (normally aspirated and supercharged) from 2003 model year onwards

New XJ 4.2L V8 2003 model year onwards.

Includes Anti-lock Braking System (ABS) monitors from 2004 model year

Jaguar Cars Revision Date: May 2004 Page 1 of 113

Page 2

1 Contents

1

Contents .........................................................................................................................................................................................................................................2

2 OBDII Systems ............................................................................................................................................................................................................................... 6

3 Engine Management System .........................................................................................................................................................................................................7

3.1.1 Fuel Injection....................................................................................................................................................................................................................7

3.1.2 Ignition..............................................................................................................................................................................................................................8

3.1.3 Variable Valve Timing (Normally Aspirated Engines) ......................................................................................................................................................8

3.1.4 Variable Air Intake System (V6 Engines).........................................................................................................................................................................8

3.1.5 Exhaust Gas Recirculation (V8 Engines).........................................................................................................................................................................8

3.1.6 Electronic Throttle Control ...............................................................................................................................................................................................9

3.1.7 Idle Speed Control ...........................................................................................................................................................................................................9

3.1.8 Vehicle Speed Control .....................................................................................................................................................................................................9

4 Sensors and Actuators .................................................................................................................................................................................................................10

5 Mode $06 Data .............................................................................................................................................................................................................................12

6 On Board Monitoring ....................................................................................................................................................................................................................14

6.1 Catalyst Efficiency Monitor....................................................................................................................................................................................................14

6.2 Misfire Monitor.......................................................................................................................................................................................................................18

6.2.1 Misfire Detection ............................................................................................................................................................................................................22

6.3 Heated Oxygen Sensor Monitor............................................................................................................................................................................................27

6.3.1 Downstream Oxygen Sensors High/Low Input Monitor.................................................................................................................................................27

6.3.2 Downstream Oxygen Sensors Heater Circuit High........................................................................................................................................................29

6.3.3 Downstream Oxygen Sensors Heater Circuit Low ........................................................................................................................................................30

6.3.4 Downstream Oxygen Sensors No Activity Detected......................................................................................................................................................30

6.3.5 Upstream Oxygen Sensors Circuit.................................................................................................................................................................................34

6.3.6 Upstream Oxygen Sensors Slow Response..................................................................................................................................................................35

6.3.7 Upstream Oxygen Sensors Heater Circuit.....................................................................................................................................................................36

6.3.8 Control Module...............................................................................................................................................................................................................37

6.4 Fuel System Monitor .............................................................................................................................................................................................................38

6.4.1 Fuel System Secondary Trim.........................................................................................................................................................................................41

6.5 Evaporative Emissions System Monitor................................................................................................................................................................................42

6.5.1 Leak Test Operation ......................................................................................................................................................................................................42

6.6 Fuel Tank Pressure Sensor Circuit .......................................................................................................................................................................................52

6.6.1 High/Low Input Failure ...................................................................................................................................................................................................52

6.6.2 Range/Performance Failure...........................................................................................................................................................................................52

6.7 Exhaust Gas Recirculation System Monitor (V8 Engines)....................................................................................................................................................53

6.7.1 High/Low Input Failure ...................................................................................................................................................................................................53

6.7.2 Exhaust Gas Recirculation Valve Range/Performance Failure .....................................................................................................................................53

Jaguar Cars Revision Date: May 2004 Page 2 of 113

Page 3

Crankshaft/Camshaft Position Sensor ..................................................................................................................................................................................55

6.8

6.8.1 Open and Short Circuit Detection of the Crank Signal ..................................................................................................................................................55

6.8.2 Intermittent Crank Failure Detection ..............................................................................................................................................................................55

6.8.3 Crank Request Signal High Input Monitor .....................................................................................................................................................................55

6.8.4 Open/Short Circuit .........................................................................................................................................................................................................55

6.8.5 Missing Phase Detection ...............................................................................................................................................................................................55

6.9 Mass Airflow Sensor and Manifold Absolute Pressure Sensor............................................................................................................................................. 58

6.9.1 High/Low Input Failure and Ground Monitor..................................................................................................................................................................58

6.9.2 Range/Performance Failure...........................................................................................................................................................................................58

6.10 Barometric Pressure Sensor .............................................................................................................................................................................................64

6.10.1 High/Low Input Failure ...................................................................................................................................................................................................64

6.10.2 Range/Performance Failure...........................................................................................................................................................................................64

6.11 Intake Air Temperature Sensor .........................................................................................................................................................................................65

6.11.1 High/Low Input Failure ...................................................................................................................................................................................................65

6.11.2 Range/Performance Check 1.........................................................................................................................................................................................66

6.11.3 Range/Performance Check 2.........................................................................................................................................................................................66

6.12 Intake Air Temperature Sensor 2 Monitor (V8 Supercharged Only) .................................................................................................................................67

6.12.1 High/Low Input Failure ...................................................................................................................................................................................................67

6.12.2 Range/Performance Check 1.........................................................................................................................................................................................67

6.12.3 Range/Performance Check 2.........................................................................................................................................................................................67

6.12.4 Range/Performance Check 3.........................................................................................................................................................................................67

6.13 Engine Coolant Temperature Sensor ................................................................................................................................................................................68

6.13.1 High/Low Input Failure ...................................................................................................................................................................................................68

6.13.2 Range/Performance Failure...........................................................................................................................................................................................69

6.14 Thermostat Monitor............................................................................................................................................................................................................73

6.15 Throttle Position Sensor ....................................................................................................................................................................................................74

6.16 Engine Oil Temperature Sensor ........................................................................................................................................................................................75

6.16.1 High/Low Input Failure ...................................................................................................................................................................................................75

6.16.2 Range/Performance Failure...........................................................................................................................................................................................75

6.17 Fuel Rail Temperature Sensor ..........................................................................................................................................................................................76

6.17.1 High/Low Input Failure ...................................................................................................................................................................................................76

6.17.2 Range/Performance Failure...........................................................................................................................................................................................76

6.18 Fuel Rail Pressure Sensor.................................................................................................................................................................................................78

6.18.1 High/Low Input Failure ...................................................................................................................................................................................................78

6.18.2 Stuck Detection ..............................................................................................................................................................................................................78

6.18.3 Offset Detection .............................................................................................................................................................................................................78

6.19 Fuel Injectors .....................................................................................................................................................................................................................80

6.20 Fuel Pumps........................................................................................................................................................................................................................81

6.20.1 Primary Fuel Pump - No Commands Received.............................................................................................................................................................81

Jaguar Cars Revision Date: May 2004 Page 3 of 113

Page 4

Primary Fuel Pump - Not Working When Requested ....................................................................................................................................................81

6.20.2

6.20.3 Primary Fuel Pump Circuit High/Low Fault....................................................................................................................................................................81

6.20.4 Secondary Fuel Pump Monitor ......................................................................................................................................................................................83

6.21 Fuel Level Sensor.............................................................................................................................................................................................................. 84

6.21.1 Fuel Level Stuck Monitor ...............................................................................................................................................................................................84

6.21.2 Fuel Level Noisy Monitor ...............................................................................................................................................................................................84

6.22 Knock Sensor ....................................................................................................................................................................................................................85

6.22.1 High/Low Input Failure ...................................................................................................................................................................................................85

6.22.2 Knock Sensor Processor Failure ...................................................................................................................................................................................86

6.23 Variable Valve Timing........................................................................................................................................................................................................86

6.24 Ignition Amplifiers/Coils .....................................................................................................................................................................................................88

6.25 Charge Air Cooler Water Pump.........................................................................................................................................................................................89

6.26 Idle Speed Control.............................................................................................................................................................................................................90

6.27 Starter Relay...................................................................................................................................................................................................................... 92

6.28 Air Conditioning Clutch Relay............................................................................................................................................................................................92

6.29 Park/Neutral Switch ........................................................................................................................................................................................................... 93

6.30 Accelerator Pedal Position Sensor Monitor.......................................................................................................................................................................94

6.31 Throttle Control..................................................................................................................................................................................................................95

6.31.1 Sensor Power Supply Monitor .......................................................................................................................................................................................95

6.31.2 Analogue Ground Monitor..............................................................................................................................................................................................95

6.31.3 Throttle Actuator Control Monitor................................................................................................................................................................................... 96

6.31.4 Throttle Motor Relay Monitor .........................................................................................................................................................................................96

6.31.5 Throttle Motor Relay Driver Monitor............................................................................................................................................................................... 96

6.31.6 Throttle Return Spring Monitor.......................................................................................................................................................................................97

6.31.7 Throttle Limp Home Spring Monitor...............................................................................................................................................................................97

6.31.8 Throttle Watchdog Monitor.............................................................................................................................................................................................97

6.32 Intake Manifold Tuning Valve System .............................................................................................................................................................................101

6.33 Generator Monitor............................................................................................................................................................................................................101

6.33.1 Generator Charge Line Monitor (V6 Only)...................................................................................................................................................................101

6.33.2 Generator Field Line Failure (V6 Only)........................................................................................................................................................................101

6.33.3 Charging System/Generator Load Failure ...................................................................................................................................................................101

6.34 Engine Control Module ....................................................................................................................................................................................................102

6.34.1 ECM Control Relay Monitor .........................................................................................................................................................................................103

6.34.2 Main Processor Monitor ...............................................................................................................................................................................................103

6.34.3 Sub Processor Monitor ................................................................................................................................................................................................103

6.34.4 Battery Back Up Monitor ..............................................................................................................................................................................................103

6.34.5 Processor Communications Monitor ............................................................................................................................................................................104

6.34.6 Engine Control Module Keep Alive Memory Monitor...................................................................................................................................................104

6.35 Communications Network Monitors.................................................................................................................................................................................107

Jaguar Cars Revision Date: May 2004 Page 4 of 113

Page 5

Anti-lock Braking System System ..............................................................................................................................................................................................108

7

7.1 Wheel Speed Sensors ........................................................................................................................................................................................................108

7.1.1 Wheel Speed Sensor Monitoring (XJ Range, XK Range and S-Type)........................................................................................................................108

7.1.2 Wheel Speed Sensor Monitoring (X-Type) ..................................................................................................................................................................111

7.2 Control Module Failure........................................................................................................................................................................................................113

Jaguar Cars Revision Date: May 2004 Page 5 of 113

Page 6

2 OBDII Systems

California On-Board Diagnostics II (OBD) applies to all gasoline engine vehicles up to 14,000 lbs. Gross Vehicle Weight Rating (GVWR) starting in the 1996

model year and all diesel engine vehicles up to 14,000 lbs. GVWR starting in the 1997 model year.

"Green States" are states in the Northeast that chose to adopt California emission regulations, starting in the 1998 model year. At this time, Massachusetts, New

York, Vermont and Maine are Green States. Green States receive California certified vehicles for passenger cars and light trucks up to 6,000 lbs. GVWR.

The National Low Emissions Vehicle program (NLEV) requires compliance with California OBDII, including 0.020" Evaporative Emissions (EVAP) system

monitoring requirements. The NLEV program applies to passenger cars and light trucks up to 6,000 lbs. GVWR nationwide from 2001 model year through 2003

model year.

Federal OBD applies to all gasoline engine vehicles up to 8,500 lbs. GVWR starting in the 1996 model year and all diesel engine vehicles up to 8,500 lbs. GVWR

starting in the 1997 model year.

OBDII system implementation and operation is described in the remainder of this document.

Jaguar Cars Revision Date: May 2004 Page 6 of 113

Page 7

3 Engine Management System

The Engine Control Module (ECM) controls the engine management system. The system consists of an ECM and a number of sensing and actuating devices.

The sensors supply the ECM with input signals, which relate to engine operating conditions and driver requirements. The ECM uses calibrated data-tables and

maps to evaluate the sensor information. The ECM then uses the results to command an appropriate response from the actuating devices. The system provides

the necessary engine control accuracy and adaptability to:

• Minimize exhaust emissions and fuel consumption.

• Provide optimum driver control under all conditions.

• Minimize evaporative fuel emissions.

• Provide system diagnostics when malfunctions occur.

In addition to these functions the ECM also interfaces with other vehicle systems through the Controller Area Network (CAN) communications network.

The 32-bit ECM is at the center of the system and provides the overall control. Its functions are listed below, each of which are dependent on the engine and

vehicle state at any moment of time and driver requirements.

• Starting: Ensures that conditions are safe to crank the engine.

• Engine: Controls the rate of air and fuel flow into the cylinders; adjusts the intake manifold volume; controls the ignition and intake camshaft timing.

• Fuel supply: Controls the operation of the fuel pumps and the EVAP canister purge valve.

• Cooling: Controls the engine cooling fans.

• Battery: Optimizes the battery charging conditions.

• Air Conditioning (A/C) and screen heater: Controls the speed of the engine when these additional loads are added, also disables the A/C when it is

beneficial to reduce the load on the engine.

• Speed control: Provides the option to maintain a fixed vehicle speed without driver intervention.

• Robustness: Maintains engine running condition under intermittent or permanent single point failures on any sensors or actuators fitted to the system,

and records Diagnostic Trouble Codes (DTCs) of these failures for system diagnosis.

• Diagnosis: Notifies the driver when a system malfunction occurs and records data for system diagnosis.

3.1.1 Fuel Injection

The ECM controls one injector per cylinder in sequential operation. The size of the injector used is so that stoichiometric control is possible at minimum load with

allowance for EVAP canister purge valve correction, and at maximum load to provide sufficient fuel flow at all engine speeds. The timing of injector firing, relative

to intake valve closing, during normal starting and running conditions is optimized to provide the best compromise between emissions and performance, time to

first-ignition and smooth engine operation at start-up, for all engine conditions at all temperatures. The mass of fuel per-injection is derived from a calculation

based on a ratiometric match to the metered airflow.

Jaguar Cars Revision Date: May 2004 Page 7 of 113

Page 8

The ECM is capable of adapting to fuel system tolerances and engine internal wear under all operating conditions. The ECM continually monitors the differential

pressure between the fuel rail and plenum, and uses this value to calculate the injector pulse width with the required mass of fuel per-injection. The ECM also

continually monitors the temperature of the fuel being injected into the engine and provides compensation for the changing flow characteristics of the fuel system

at different temperatures. By monitoring the battery supply voltage the ECM can ensure that the fuel supply to the engine is unaffected by voltage fluctuation.

3.1.2 Ignition

The system uses one ignition coil per-cylinder. A base ignition map is provided so that the engine can be optimized for emissions, fuel economy, performance

and avoidance of cylinder knock throughout its speed and load range. Ignition timing during starting is used during engine cranking and under speed modes to

provide the best compromise between emissions, time to first ignition and smooth engine operation at start up, at all temperatures. Provision is made to

compensate for the effect of changing air intake temperature on the combustion detonation limit. The system contains the necessary hardware for the detection

of combustion knock within the engine cylinders; the ECM uses this information to gradually adjust the ignition timing until the combustion knock is at a safe and

inaudible level.

3.1.3 Variable Valve Timing (Normally Aspirated Engines)

The ECM controls the fully variable phase change system, which acts on the intake camshafts. The target positions of both camshafts are optimized to provide

the best compromise between performance, refinement, fuel economy and emissions. During transient operation, the rate of change of the Camshaft Position

(CMP) is controlled to optimize drivability. Operation of the Variable Valve Timing (VVT) will be restricted if environmental conditions exist that could affect

normal operation of the VVT, for example very low ambient temperatures. Provision is made to ensure that the intake camshafts are restrained in the retard

position during engine start. The ECM will also detect a variable valve timing mechanical malfunction, and act to compensate for the malfunction.

3.1.4 Variable Air Intake System (V6 Engines)

The ECM controls two intake manifold tuning valves. Each valve is a two positional device; the switching point of the valve is dependant on engine speed and a

definable change in engine performance. The valve switching points are optimized for maximum torque in the wide-open Throttle Position (TP).

3.1.5 Exhaust Gas Recirculation (V8 Engines)

The ECM controls the flow of exhaust gases to reduce oxides of nitrogen in emissions by re-circulating metered amounts of exhaust gas into the intake of the

engine. This lowers the combustion temperature, limiting the formation of nitrogen oxides. The Exhaust Gas Recirculation (EGR) flow is optimized for fuel

economy, emissions and drivability for all engine-operating conditions.

Jaguar Cars Revision Date: May 2004 Page 8 of 113

Page 9

3.1.6 Electronic Throttle Control

The electronic throttle controls the airflow into the engine under closed loop feedback control of the ECM. The correct throttle disc position is calculated as a

function of driver demand and of the engine's momentary operating mode. A fail safe system is incorporated that complies with legislative requirements, including

mechanical limp-home operation.

3.1.7 Idle Speed Control

Idle speed is dependent on Engine Coolant Temperature (ECT) and gear selection (neutral or drive). Idle speed is optimized for combustion stability, idle quality,

Idle Speed Control (ISC) capability and fuel economy at all operating conditions. Compensations to the idle speed will be made for conditions, such as variable

ambient air temperature, to increase idle speed to satisfy charging system requirements.

3.1.8 Vehicle Speed Control

The engine management system incorporates a speed control system. This enables the driver to set a speed, and control and maintain the speed of the vehicle

without having to operate the accelerator pedal. The speed control switches are momentary action switches, mounted on the steering wheel. The function of the

switches is organized so that a function relating to a switch of higher priority always overrides a function relating to a lower priority switch. The switch priority is:

• 1. Cancel

• 2. Set

• 3. Resume

Jaguar Cars Revision Date: May 2004 Page 9 of 113

Page 10

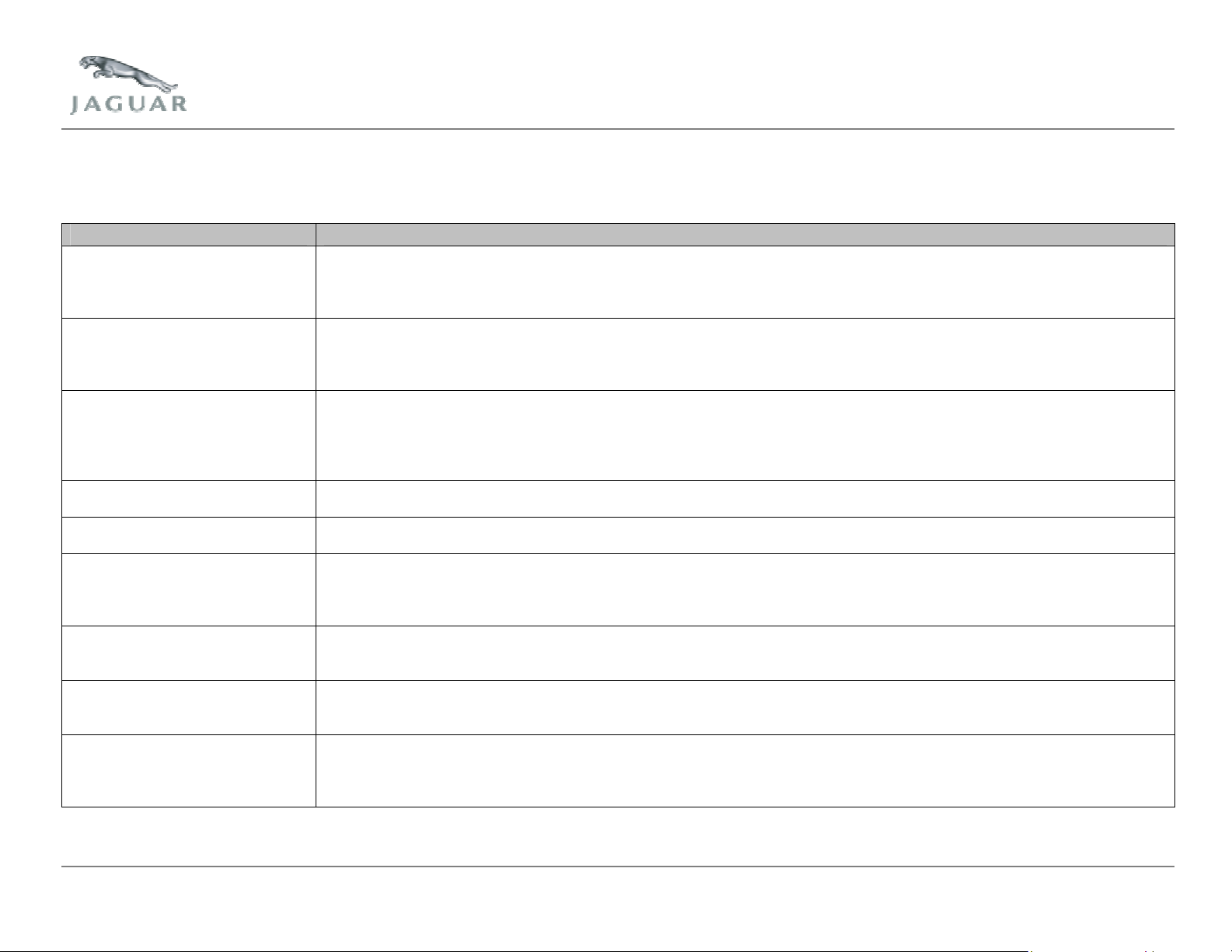

4 Sensors and Actuators

The following table defines the function of the engine mounted sensors and actuators:

Component Function

Fuel injectors Delivers fuel to the engine cylinder intake ports in sequential order. There are 12 fuel injection holes per cylinder,

delivering fuel droplets as small as 60 microns in diameter. This size of fuel droplet reduces fuel wetting of the intake port

and promotes excellent fuel air mixing. Reducing noxious emissions and improving fuel economy while the engine is

warming up.

On-plug ignition coil The ECM controls one coil per spark plug in sequential order. The ignition coil provides the energy to the spark plug to

ignite the air fuel mixture in the engine cylinder. The ignition coil works on the principle of 'mutual induction'. By closing and

then opening the ignition coil primary circuit, the primary current increases, and then suddenly decreases to induce the

high voltage in the secondary circuit needed to fire the spark plug.

CMP sensor Signals from the CMP sensors are used to synchronize the ECM to the engine cycle during engine starting. For example,

whether the Crankshaft Position (CKP) sensor is indicating an induction or firing stroke. The position of both intake

camshafts is monitored to allow the ECM to control the phase of the intake camshafts relative to the position of the

crankshaft. On engines with VVT, the CMP sensor provides feedback control on the intake camshaft's position relative to

the position of the crankshaft and exhaust camshafts.

Oil control solenoid - VVT

(normally aspirated engines)

Manifold Absolute Pressure

(MAP) sensor

Knock sensor The knock sensors produce a voltage signal with respect to the engine's combustion level. The knock sensor detects and

Fuel rail pressure sensor Continuously monitors the fuel pressure between the fuel rail and plenum, this value is used by the ECM as one of its

Fuel rail temperature sensor The fuel rail temperature sensor continuously monitors the temperature of fuel being injected into the engine; this value is

Intake manifold tuning valves (V6

engines)

Jaguar Cars Revision Date: May 2004 Page 10 of 113

The oil control solenoid is a hydraulic actuator, which advances and retards the intake camshaft timing, thereby altering

the camshaft-to-crankshaft phasing.

The manifold absolute pressure sensor is used for EGR diagnostic testing only.

reports combustion knock within the engine cylinders. The ECM uses this information to gradually adjust the ignition timing

until the combustion knock is at a safe and inaudible level. The knock control system cannot advance the ignition past the

mapped values; it retards the ignition timing to reduce combustion knock and then advances to its original value.

factors to calculate the injector pulse-width required to deliver the correct mass of fuel per injection. The ECM also uses

this information to demand a specific fuel flow rate from the fuel pump via the fuel pump module.

used by the ECM to provide compensation for the changing flow characteristics of the fuel system with temperature. The

ECM therefore ensures that engine performance is unaffected by temperature changes in the fuel supply.

The intake manifold tuning valves are a two positional 'open or close' device used to create a variable air intake system.

The intake manifold tuning valve positions are switched, via signals from the ECM, to optimize torque across the engine

speed and load range. The intake manifold tuning valves work in conjunction with the operation of the throttle body

sensors.

Page 11

Component Function

Throttle body assembly The throttle body controls the airflow into the engine by use of the throttle motor and TP sensor. Throttle-disc position is

operated by the throttle motor using signals received from the Accelerator Pedal Position (APP) sensor, via the ECM. The

ECM, via the TP sensor, monitors throttle disc angle. The ECM on application of external loads, for example the A/C

compressor, makes compensation to the throttle disc angle.

Mass Airflow (MAF) sensor with

integrated Intake Air Temperature

(IAT) sensor

CKP sensor The CKP sensor is an inductive pulse generator, which scans protrusions on a pulse ring, to inform the ECM of the

ECT sensor The thermistor type sensor provides an input signal to the ECM, which is proportional to the temperature of the engine

Engine Oil Temperature (EOT)

sensor

Heated Oxygen Sensor (HO2S) 1 The HO2S 1 is a linear characteristic type sensor, fitted forward of the exhaust system's catalytic converter. The sensor is

HO2S 2 The HO2S 2 is a non-linear characteristic type sensor fitted to the exhaust system's catalytic converter, and is used by the

EGR valve A defined portion of the engine's exhaust emissions is extracted and returned to the intake mixture via a solenoid valve, as

Air intake control flap solenoid

(S/C engine)

Engine oil pressure switch This switch is connected to the Instrument Pack (IPK) and is used for a low oil pressure warning. It is not used by the

The MAF sensor informs the ECM of the rate of airflow entering the engine by producing a voltage, which increases as the

rate of airflow increases. The MAF sensor also takes into account the density of air entering the engine so it is possible to

maintain the required air fuel ratio, and compensate for variations in atmospheric pressure and temperatures. The integral

IAT sensor measures the temperature of the air entering the intake system. The ECM uses this information to compensate

for higher than normal IAT upon combustion detonation.

crankshaft's position and engine speed.

coolant being circulated around the coolant system.

The thermistor type sensor provides an input signal to the ECM, which is proportional to the temperature of the oil being

circulated around the engine oil passageways.

used by the ECM as a primary sensor to measure oxygen content within the exhaust system. The sensor is used in

conjunction with the ECM to provide closed loop fuelling control.

ECM as a secondary sensor to measure oxygen content within the exhaust system. Used in conjunction with the ECM and

the HO2S 1, the HO2S 2 aids closed loop fuelling control. It is also used to monitor catalyst efficiency.

controlled by the ECM.

The ECM directly controls the solenoid, to open and close the air intake control flap in the air cleaner assembly. The

control flap is opened at high engine speed and loads to satisfy engine air charge requirements.

engine management system.

Jaguar Cars Revision Date: May 2004 Page 11 of 113

Page 12

5 Mode $06 Data

SAE J1979 Mode $06 Data

Test ID Comp ID Description Units

$02 $00 Catalyst system efficiency below threshold 1 - bank (delay time) msec

$04 $00 Catalyst system efficiency below threshold 2 - bank (delay time) msec

Conversion for TID $02 and $04: Multiply by 4 to get result in milliseconds.

$06 $00 EVAP system leak detected (20 thou) kPa

$07 $00 EVAP system leak detected (gross leak) kPa

$08 $00 EVAP system leak detected (40 thou) kPa

Conversion for TID $06 and $08: Multiply by 6.25/1024, then subtract 4.125 to get result in kPa.

Conversion for TID $07: Multiply by 6.25/1024 to get result in kPa.

$09 $00 EGR system flow malfunction (GA changing rate low) g/sec

$0A $00 EGR system flow malfunction (GA changing rate high) g/sec

Conversion for TID $09 and $0A: Multiply by 400/65536, then subtract 200 to get result in g/sec. Result can be positive or negative.

$0B $00 EVAP system flow check None

$0C $00 EVAP system flow check None

Conversion for TID $0B and $0C: Multiply by 0.5/65536.

$0D $00 EVAP system flow check None

$0E $00 EVAP system flow check None

Conversion for TID $0D and $0E: Multiply by 2/65536.

$0F $00 EVAP system flow check rpm

$10 $00 EVAP system flow check rpm

$11 $00 EVAP system flow check rpm

Conversion for TID $0F, $10 and $11: Multiply by 100/256 to get result in RPM.

$12 $00 EVAP system flow check g/sec

Conversion for TID $12: Multiply by 1/1024 to get result in g/sec.

$13 $00 Catalyst system efficiency below threshold 1 - bank (high airflow) None

$14 $00 Catalyst system efficiency below threshold 2 - bank (high airflow) None

Conversion for TID $13 and $14: Multiply by 1.25/256

$1A $00 Upstream HO2S 11 lean to rich response time counter msec

$1B $00 Upstream HO2S 21 lean to rich response time counter msec

Conversion for TID $1A and $1B: Multiply by 64 to get result in msec.

Jaguar Cars Revision Date: May 2004 Page 12 of 113

Page 13

SAE J1979 Mode $06 Data – Continued

$1C $00 Upstream HO2S 11 minimum sensor current for test cycle mA

$1D $00 Upstream HO2S 21 minimum sensor current for test cycle mA

$1E $00 Upstream HO2S 11 maximum sensor current for test cycle mA

$1F $00 Upstream HO2S 21 maximum sensor current for test cycle mA

Conversion for TID $1C, $1D, $1E and $1F: Multiply by 1/256, then subtract 128 to get result in mA. Result can be positive or negative.

$21 $00 EGR system flow malfunction (MAP changing rate low) kPa

$22 $00 EGR system flow malfunction (MAP changing rate high) kPa

Conversion for TID $21 and $22: Multiply by 500/65536, then subtract 133.35 to get result in kPa. Result can be positive or negative.

Jaguar Cars Revision Date: May 2004 Page 13 of 113

Page 14

6 On Board Monitoring

The vehicle drive train is continually monitored throughout its life to maintain its proper function and ensure that emission levels do not exceed accepted limits.

6.1 Catalyst Efficiency Monitor

Catalytic converters oxidize unburned Hydrocarbons (HC) and Carbon Monoxide (CO) by combining them with oxygen to produce water vapor, and reduce

nitrogen oxides to nitrogen and oxygen. When the engine air fuel ratio is lean, the oxygen content of the catalytic converter reaches its maximum value. When

the air fuel ratio is rich, the oxygen content is depleted. If the air fuel ratio remains rich for an extended period, the converter may fail to convert the harmful

gases.

The Catalyst monitor operates once per trip, and is not a continuous monitor.

The monitor waits until all entry conditions are met, including the modeled catalyst temperature reaching its threshold. Once all entry conditions are met, the

monitor starts to run. The fuelling is cycled rich and lean (called dither) by approximately 3% to get a reaction at the downstream Oxygen Sensor (O2S). At the

start of the monitor, delay counters operate so that the fuelling is stable when the diagnosis takes place. If the entry conditions then drop out, the monitor result

and execution timer are held at the values that they were when the entry conditions dropped out. The next time entry conditions are met the monitor carries on

from where it stopped previously. This will happen for a maximum of four attempts, after this, the monitor will reset and the diagnosis restarts.

The monitor runs for a calibratable period of time, after which the monitor results are made. The monitor results are decided by accumulating the locus of the

downstream O2S signal versus the accumulation of the upstream O2S. The more active the downstream sensor, the less oxygen storage capacity the catalyst

has, so the higher the locus value.

With a 100,000-mile catalyst, the downstream O2S is not so active, so lower locus values are obtained.

A judgment is made when the monitor has finished. The judgment made can either be "normal" or "fail". The normal judgment is made if the accumulated count

is lower than a calibratable threshold at the judgment point. The failure judgment is made if the accumulated count equals or exceeds the calibratable threshold

at the judgment point. If a failure judgment is made, then the relevant DTCs are stored within the engine management system.

Jaguar Cars Revision Date: May 2004 Page 14 of 113

Page 15

A

A

A

A

A

A

Note: Unless specifically included in the tables below, IAT, ECT, vehicle speed and time after start up are not critical to enable these monitors.

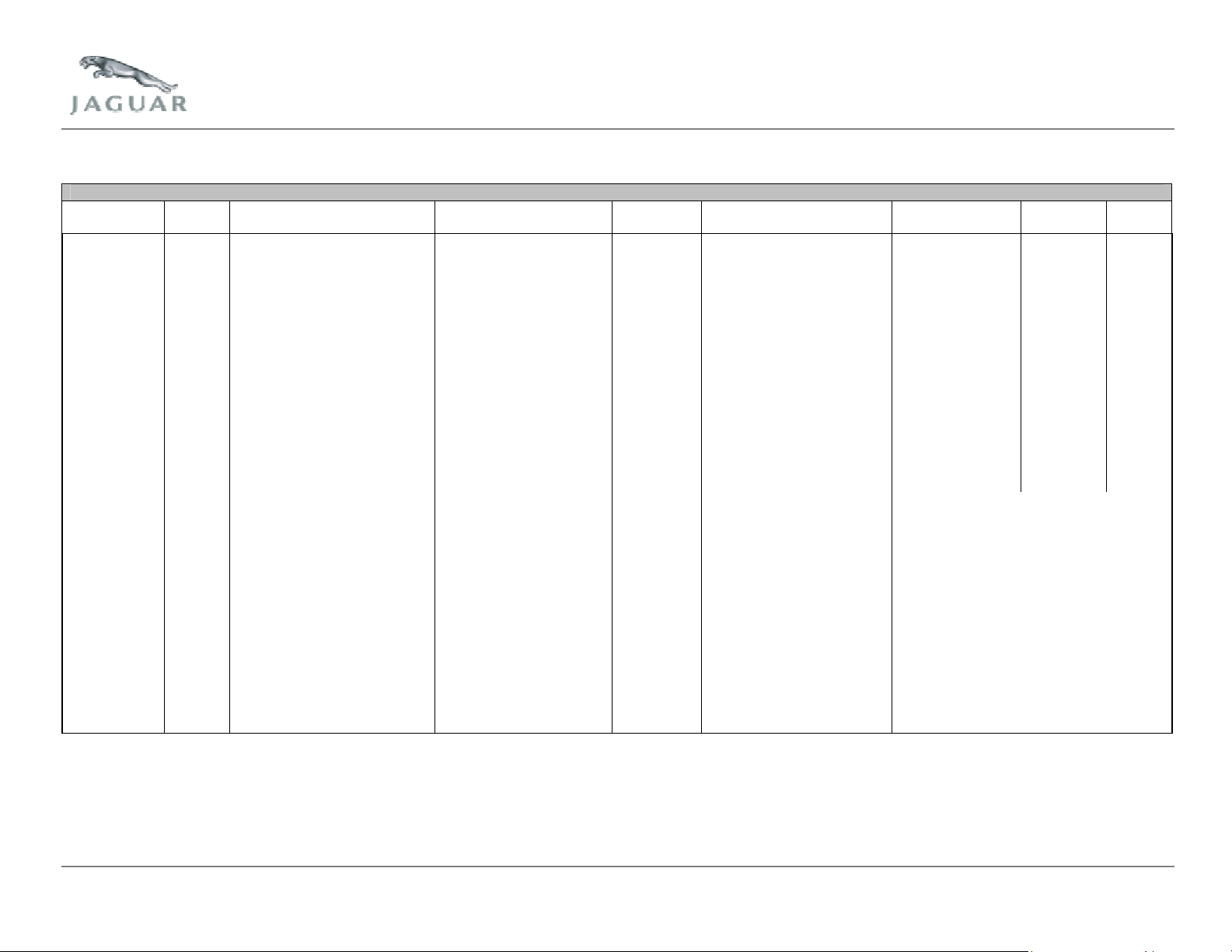

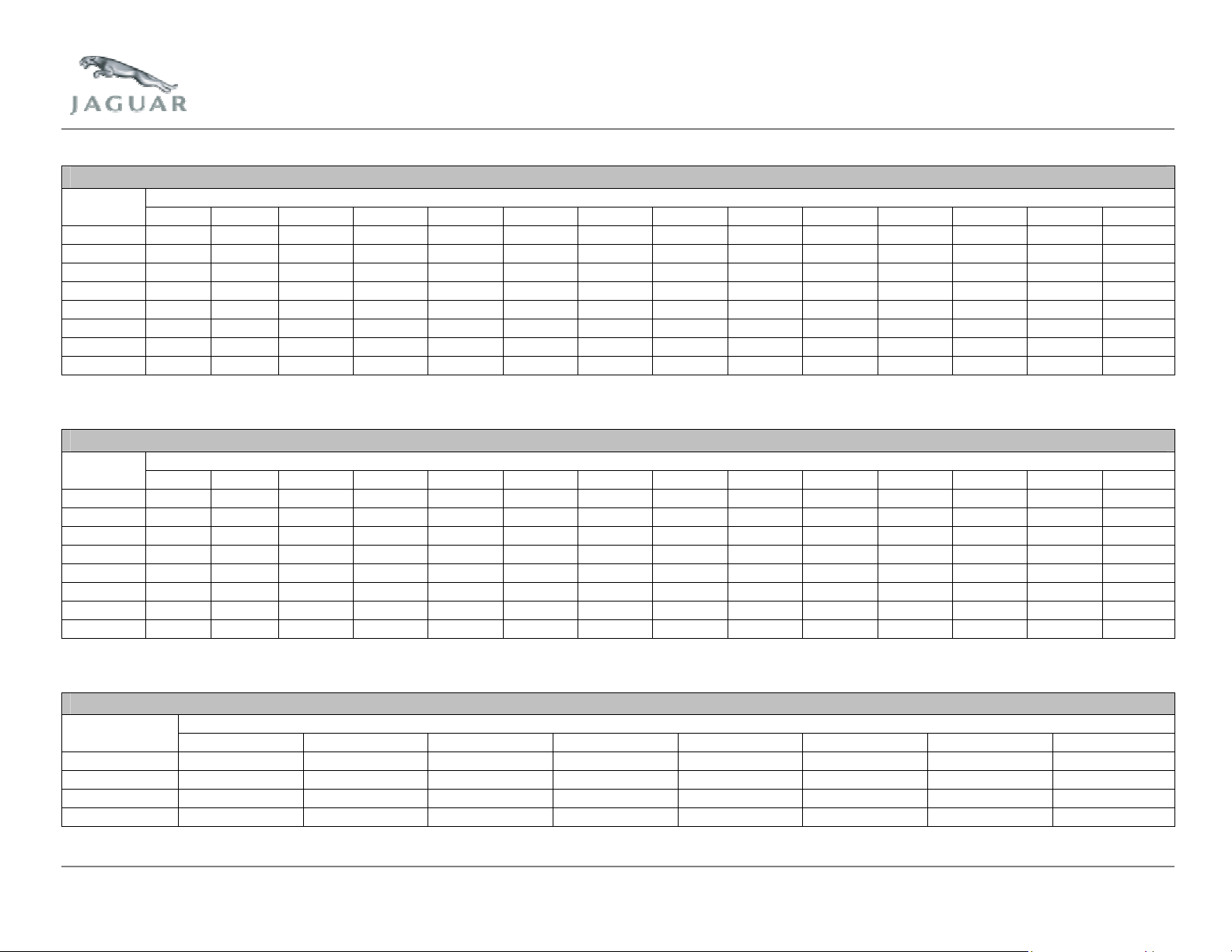

Catalyst Monitor Operation – Up to 2004 Model Year

Strategy DTCs Description Malfunction Criteria Value Secondary Parameter Enable

Conditions

Catalyst

efficiency bank

1

Catalyst

efficiency bank

2

Disable: P0101, P0102, P0103, P0104, P0106,

Bank 1 P0031, P0032, P0037, P0038, P0137,

P0420 Ratio of locus of upstream/

downstream HO2S during

mixture dither.

P0430 IAT

ccumulative locus of

downstream sensor

> 17 Engine speed

Closed lop fuelling

ECT

irflow

tmospheric pressure

irflow change

Engine speed change

Throttle angle change

Idle

Sub feedback compensation

ir fuel ratio compensation

Linear air fuel ratio

compensation

Fuel level

1300 to 3000 RPM

ctive

75 to 120 °C

-20 to 110 °C

14 to 65 g/s

> 70.0 kPa

< 30 g/s/s

< 360 RPM/s

< 10 deg/s

Inactive

0.9 to 1.1

0.75 to 1.25

0.5 to 1.5

> 11%

P0107, P0108, P0111, P0112, P0113,

P0116, P0117, P0118, P0121, P0122,

P0123, P0125, P0128, P0222, P0223,

P0301, P0302, P0303, P0304, P0305,

P0306, P0307, P0308, P0443, P0444,

P0445, P0460, P0603, P1224, P1229,

P1251, P1313, P1314, P1316, P1367,

P1368, P1609, P1611, P1631, P1633,

P1637, P1642, P1215, P1216, P1344,

P1234, P1236, P1338, P3029

P0138, P0140, P0171, P0172, P0201,

P0203, P0205, P0207, P0351, P0353,

P0355, P0357

Time

Required

30s

2 DTC

2 DTC

MIL

Jaguar Cars Revision Date: May 2004 Page 15 of 113

Page 16

A

A

A

A

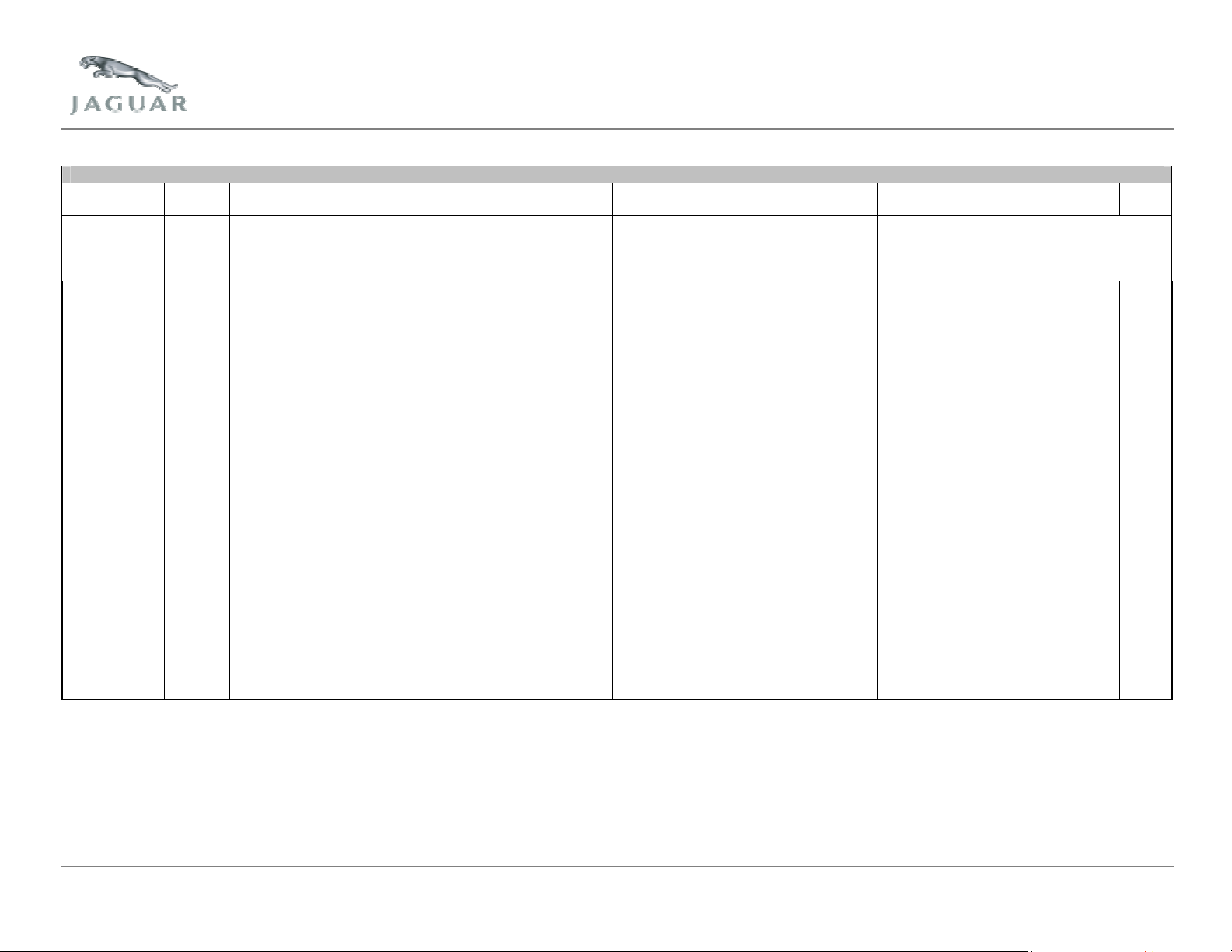

Catalyst Monitor Operation – From 2004 Model Year

Strategy DTCs Description Malfunction Criteria Value Secondary Parameter Enable Conditions Time

Bank 2 P0051, P0052, P0057, P0058, P0157,

P0158, P0160, P0174, P0175, P0202,

P0204, P0206, P0208, P0352, P0354,

P0356, P0358

Catalyst

efficiency bank

1

Catalyst

efficiency bank

2

P0420 Ratio of locus of upstream/

downstream HO2S during

mixture dither.

P0430 IAT

ccumulative locus of

downstream sensor

>=14 (X-Type)

>= 16 (XK8)

>= 17 (XJ)

>= 18 (V6 SType)

Engine speed (RPM)

Closed loop fuelling

ECT

MAF

tmospheric pressure

irflow change

Engine speed change

Throttle angle change

Idle

Sub feedback control

Short term fuel trim

Total fuel trim

Fuel level

1300 to 2900 (X-Type)

1300 to 3000 (V8)

1300 to 3250 (V6 SType)

ctive

75 to 119 °C

-20 to 101 °C

-8.13 to 110 °C (XType)

10 to 65 g/s

10 to 40 g/s (X-Type)

>= 70.0 kPa

>= 75.5 kPa (X-Type

<= 30 g/s/0.512s

<=20 g/s/0.512s (XType)

<= 360 RPM/0.512s

<= 10 deg/1.024s

Inactive

0.9 to 1.1

0.75 to 1.25

0.5 to 1.5

>= 11%

30s

20s (X-Type)

2 DTC

MIL

Required

2 DTC

Jaguar Cars Revision Date: May 2004 Page 16 of 113

Page 17

Catalyst Monitor Operation – From 2004 Model Year - Continued

Strategy DTCs Description Malfunction Criteria Value Secondary parameter Enable Conditions Time

Required

Disable: C1137, C1145, C1155, C1165,

C1175, P0101, P0102, P0103,

P0106, P0107, P0108, P0111,

P0112, P0113, P0116, P0117,

P0118, P0121, P0122, P0123,

P0125, P0128, P0181, P0182,

P0183, P0191, P0192, P0193,

P0222, P0223, P0441, P0443,

P0444, P0445, P0460, P0603,

P1104, P1224, P1229, P1233,

P1234, P1236, P1251, P1313,

P1314, P1316, P1338, P1339,

P1367, P1368, P1609, P1611,

P1631, P1633, P1637, P1642

Bank 1 P0031, P0032, P0037, P0038,

P0133, P0137, P0138, P0140,

P0171, P0172, P0201, P0203,

P0205, P0207, P0351, P0353,

P0355, P0357

Bank 2 P0051, P0052, P0057, P0058,

P0153, P0157, P0158, P0160,

P0174, P0175, P0202, P0204,

P0206, P0208, P0352, P0354,

P0356, P0358

Disable Additions: P0069, P0607, P0627, P0628,

P0629, P2118, P2119, P2135,

P2228, P2229, P2632, P2633,

P2634, P2635, P2636

MIL

2

DTC

2

DTC

2

DTC

2

DTC

Jaguar Cars Revision Date: May 2004 Page 17 of 113

Page 18

6.2 Misfire Monitor

A misfire is caused by a failure of combustion. When this occurs, unburned HC and excess oxygen are exhausted from the cylinder. Consequently, the catalytic

converter may suffer damage through overheating as it tries to convert the excessive HC. Secondly, the O2S will report a lean condition to the ECM, which in

turn will increase the injector pulse width and add more raw fuel to the exhaust stream.

The misfire detection monitor is continuous and is designed to detect levels of misfire that can cause thermal damage to the catalyst and/or result in excessive

tailpipe emissions. Determination of a misfire is made by analysis of changes in crankshaft speed, a misfire causing a drop in acceleration after an anticipated

firing event. This data is analyzed in four ways to ensure all possible combinations of misfire can be detected.

The results of the misfire judgment process on each firing event are used to determine whether two failure levels have been met, 'catalyst damage' misfire and

'excess emissions' misfire. Each fault judgment process has its own failure threshold and calculation period.

Monitor DTCs

P0300 Random/multiple cylinder misfire

P0301 Cylinder 1 (1 bank 1) misfire

P0302 Cylinder 2 (1 bank 2) misfire

P0303 Cylinder 3 (2 bank 1) misfire

P0304 Cylinder 4 (2 bank 2) misfire

P0305 Cylinder 5 (3 bank 1) misfire

P0306 Cylinder 6 (3 bank 2) misfire

P0307 Cylinder 7 (4 bank 1) misfire (V8 engines only)

P0308 Cylinder 8 (4 bank 2) misfire (V8 engines only)

P1313 Catalyst damage misfire, bank 1

P1314 Catalyst damage misfire, bank 2

P1316 Excess emissions misfire

Jaguar Cars Revision Date: May 2004 Page 18 of 113

Page 19

)

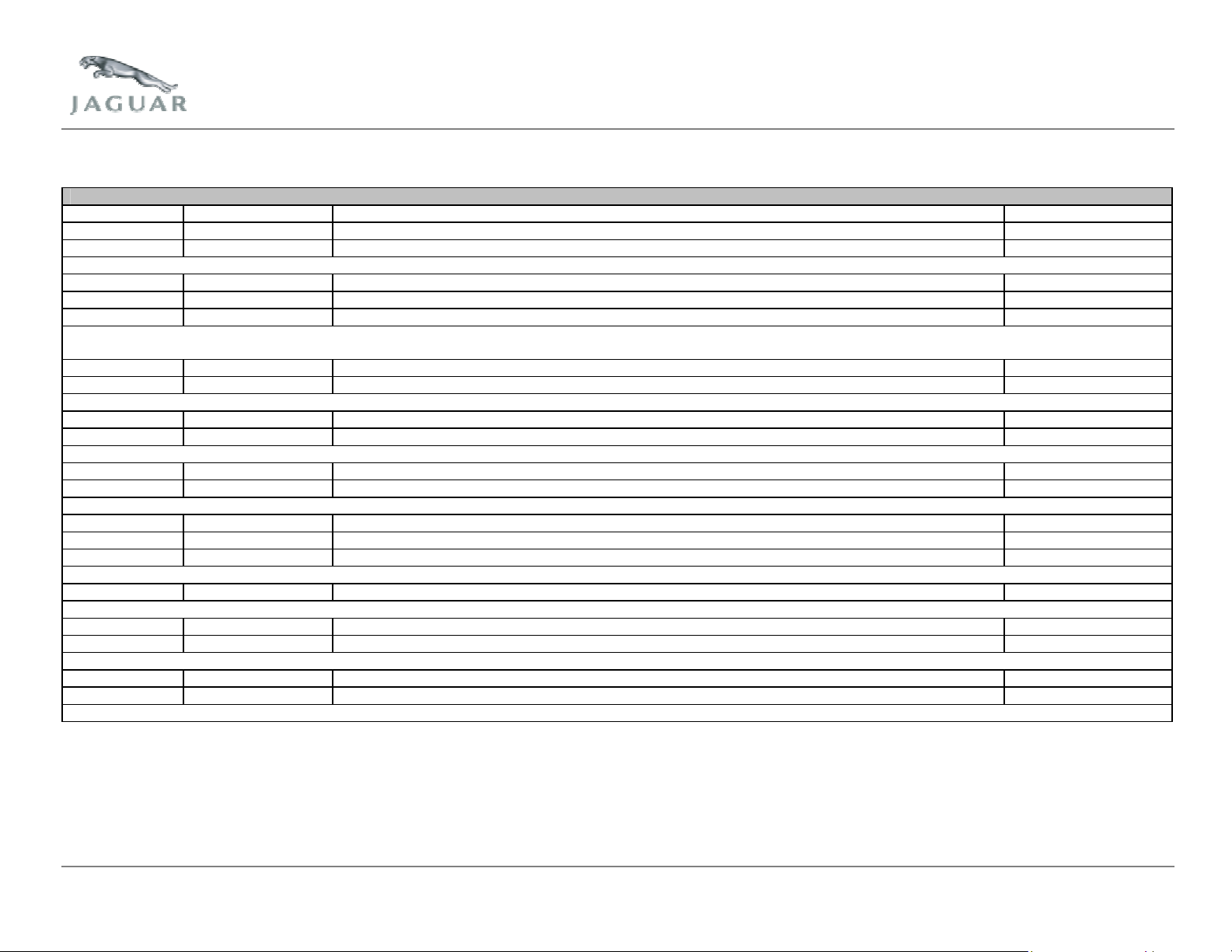

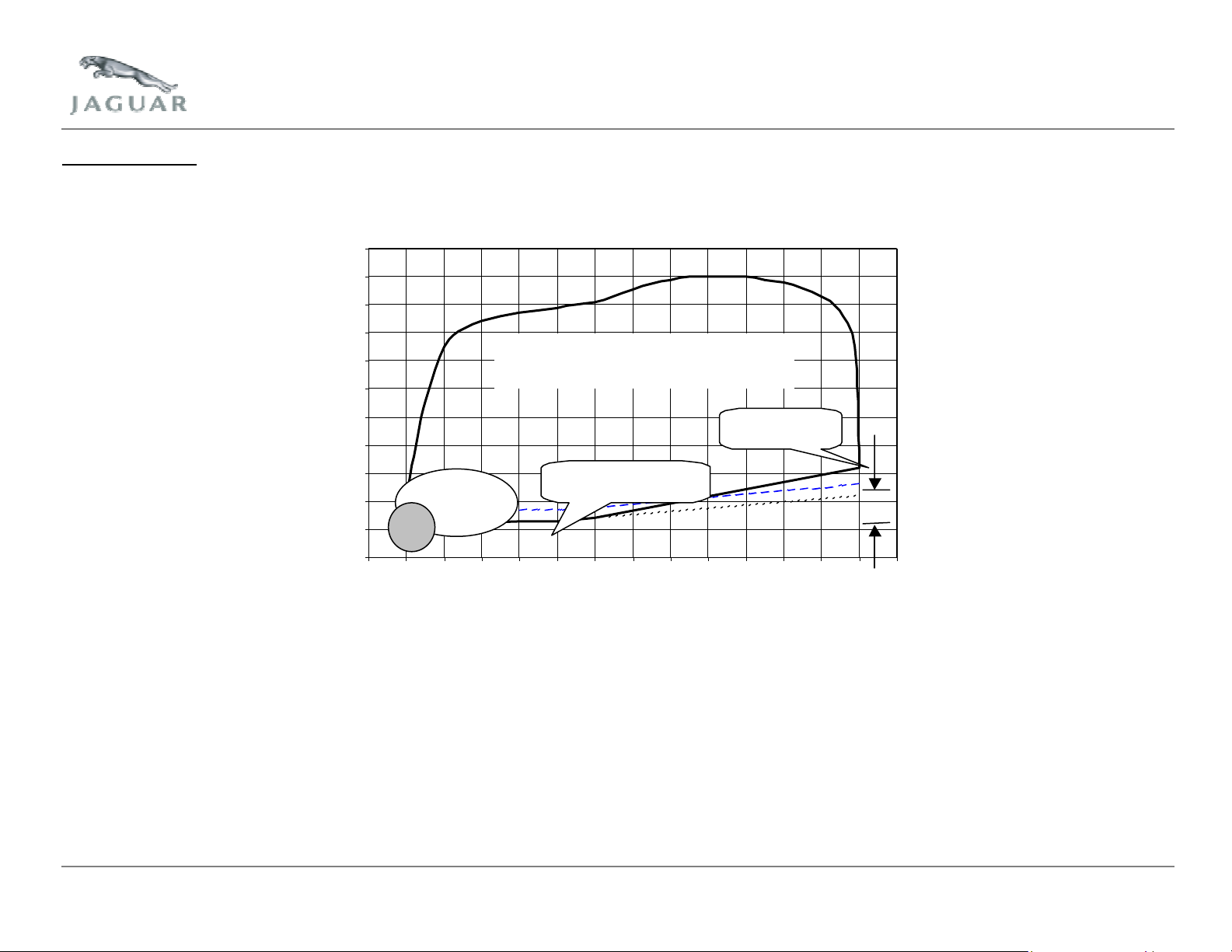

Monitoring Strategy

The misfire monitor operates continuously within the boundaries of the regulated monitor operation window, as shown below:

110

100

90

80

70

60

50

40

Relative Engine Load (%

30

20

10

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 7000

FTP75

Operating

Idle

Misfire Monitor Operating Region

(w ithin solid boundary)

Effect of 4"Hg

'P ressure R elief'

Stabilised engine, sea-level

minimum load line

Engine Speed (rpm)

Region of misfire monitor operation

After engine start, the monitor will enable as soon as the engine speed rises above the minimum operation speed (150 RPM below fully warm stabilized idle

speed). Two revolutions of crank angle data, i.e. One sample of data from each cylinder firing, are 'buffered' before any decisions can be made by the monitor.

Before engine speed has reached the top of the start flare the monitor will be ready to make misfire judgments, which are then made on every cylinder firing,

irrespective of whether the monitor is enabled or not.

Note: Unless specifically included in the tables below, IAT, ECT, vehicle speed and time after start up are not critical to enable these monitors.

Jaguar Cars Revision Date: May 2004 Page 19 of 113

Page 20

A

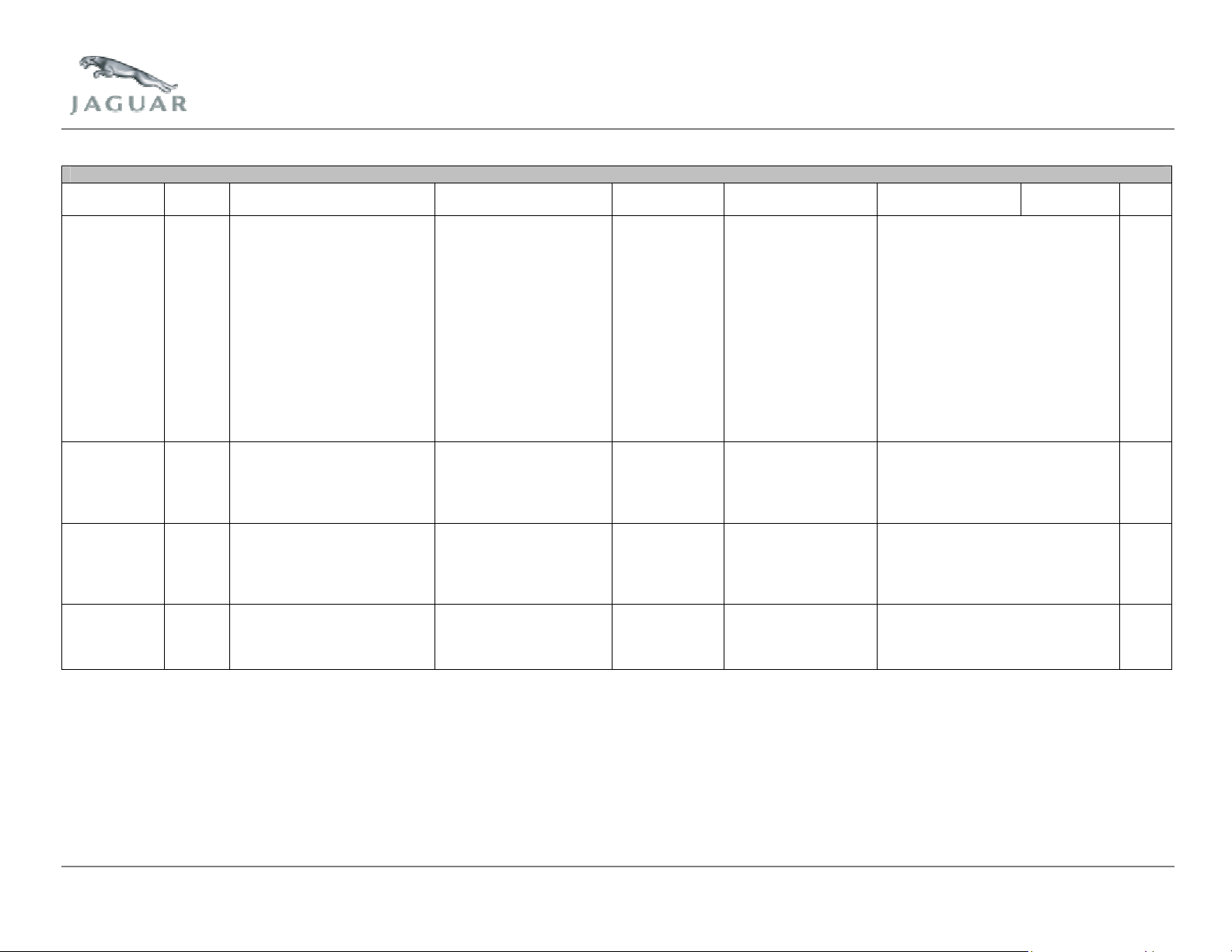

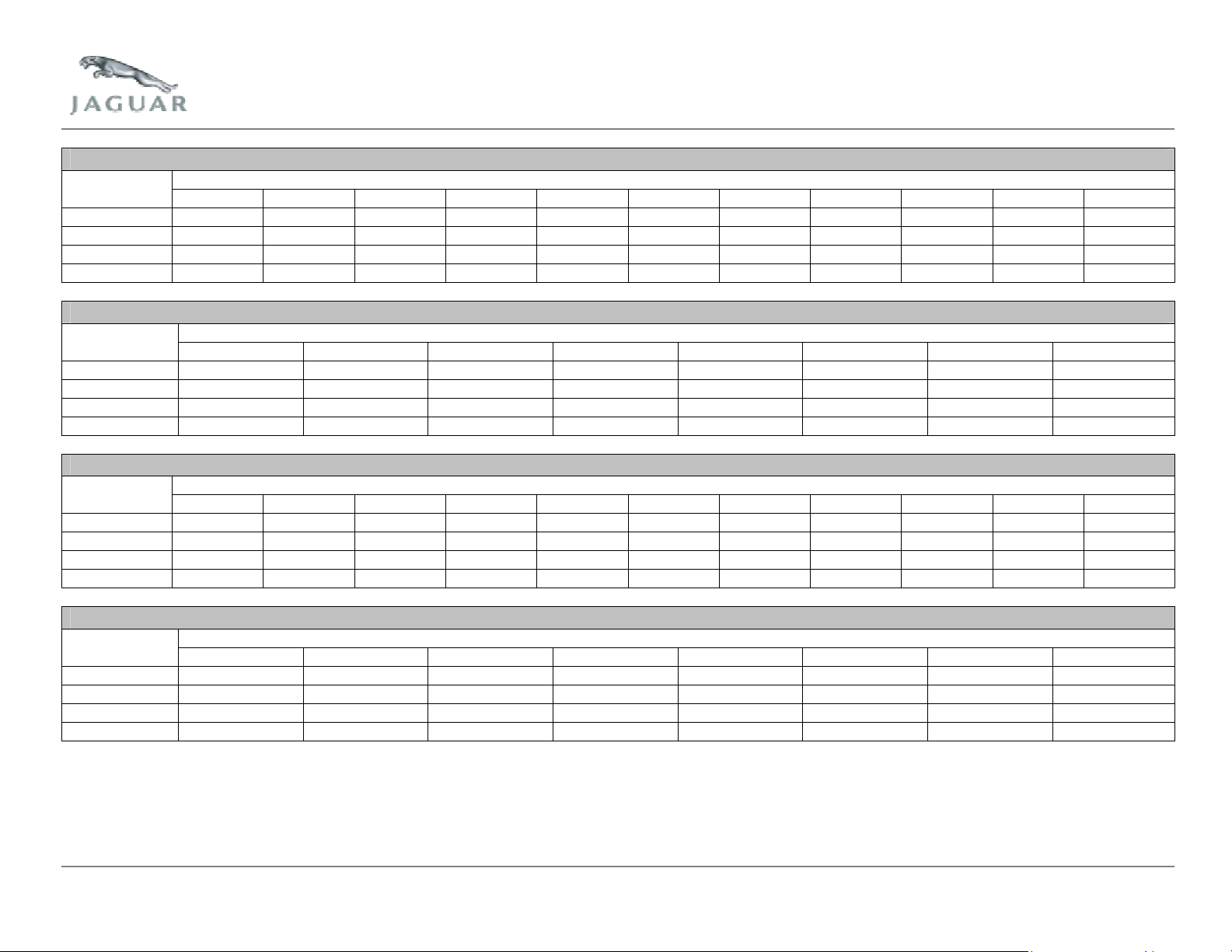

Misfire Monitor Operation – Up to 2004 Model Year

Strategy DTCs Description Malfunction Criteria Value Secondary Parameter Enable

Conditions

Random misfire P0300 Crank speed fluctuation Catalyst damage

Excessive emissions

Misfire cylinder

1

Misfire cylinder

2

Misfire cylinder 3 P0303 IAT

Misfire cylinder 4 P0304 Fuel level

Misfire cylinder 5 P0305 MIS2 1+2 DTC

Misfire cylinder 6 P0306 1+2 DTC

Misfire cylinder

7 (V8)

Misfire cylinder

8 (V8)

Misfire catalyst

damage 1

Misfire catalyst

damage 2

Misfire excess

emissions

Disable: P0101-P0103, P1104, P0111- P0113, P0116- P0118, P0125, P0107,

P0301

P0302

P0307 1+2 DTC

P0308 1+2 DTC

P1313 Catalyst damage % See table MIS1 No

P1314 Catalyst damage % No

P1316 Emissions failure

4.2L S/C Auto

Normally aspirated

Supercharged

Steady state

Engine speed (RPM)

4.2L N/A Auto

3.0L Manual

3.0L Auto

ECT

tmospheric pressure

Load

1.3%

1.3%

No

P0108, P0336, P0460, P0603, P0121- P0123, P0137, P0138, P0140,

P0157, P0158, P0160, P0171, P0172, P0174, P0175, P0181- P0183,

P1233, P1339, P0106, P0831, P0832, P1234, P1236, P1338, P0222,

P0223, P1224, P1229, P1230, P1251, P1516, P1609, P1611, P1631,

P1633, P1637, P1642. P0128, P0106, C1137, C1165, C1175

450 - 6500

450 – 6200

580 - 7000

530 - 7000

-8 to 120°C

-8 to 100°C

> 68 kPa

> 11%

> Value in map

Time

Required

200 or 1000

revolutions

1+2 DTC

1+2 DTC

1+2 DTC

MIL

1+2 DTC

1+2 DTC

Jaguar Cars Revision Date: May 2004 Page 20 of 113

Page 21

A

Misfire Monitor Operation – From 2004 Model Year

Strategy DTCs Description Malfunction Criteria Value Secondary Parameter Enable

Conditions

Random misfire

Misfire

cylinder 1

Misfire

cylinder 2

Misfire

cylinder 3

Misfire

cylinder 4

Misfire

cylinder 5

Misfire

cylinder 6

Misfire

cylinder 7 (V8)

Misfire

cylinder 8 (V8)

Misfire catalyst

damage 1

Misfire catalyst

damage 2

Misfire excess

emissions

Disable: C1137, C1145, C1155, C1165, C1175, P0101-P0103, P0106-P0108, P0111-P0113,

X-Type 2005 model year Disable additional: P0069, P0607, P0627-P0629, P0851, P2118, P2119, P2135, P2228, P2229, P2632-

P0300

P0301

P0302

P0303

P0304

P0305

P0306

P0307

P0308

P1313 Catalyst damage % See table MIS1 200 revolutions No

P1314 Catalyst damage % No

P1316 Emissions failure

Crank speed fluctuation Catalyst damage

Excessive emissions

4.2L S/C Auto (XK8)

IAT

Fuel level

MIS2

4.2L normally aspirated

4.2L supercharged

3.0L S-Type

X-Type manual

X-Type automatic

Steady state

Engine speed (RPM)

4.2L NA Auto (XK8)

4.2L NA Auto (XJ)

4.2L S/C Auto (XK8)

3.0L

ECT

tmospheric pressure

Load

1.3%

1.3%

1.3%

4.0%

2.0%

P0116-P0118, P0121-P0123, P0125, P0128, P0137, P0138, P0140, P0157, P0158,

P0160, P0171, P0172, P0174, P0175, P0181-P0183, P0191-P0193, P0222, P0223,

P0335, P0336, P0460, P0603, P0831, P0832. P1104, P1224, P1229, P1233, P1234,

P1236, P1251, P1338, P1339, P1516, P1609, P1611, P1631, P1633, P1637, P1642.

P2636

1000

450 to 6500

450 to 6200

450 to 6600

450 to 6400

530 - 7000

-8 to 119°C

-40 to 119 °C

> 68 kPa

> 75.5 kPa (XType)

> 11%

> Value in map

Time

Required

200 or 1000

revolutions

1+2 DTC

revolutions

1+2 DTC

1+2 DTC

1+2 DTC

1+2 DTC

1+2 DTC

1+2 DTC

1+2 DTC

1+2 DTC

No

MIL

Jaguar Cars Revision Date: May 2004 Page 21 of 113

Page 22

6.2.1 Misfire Detection

For the purposes of misfire detection, “steady - state“ is defined as:

• At least 1 second since fuel cut-off was last invoked.

• At least 1 second since gear change was last made.

• At least 0.5 seconds since rough road detected (1second for 3.0L).

• At least 1 second since acceleration ignition retard was last invoked.

• At least 1 second since >15% shunt control ignition retard was last invoked (3.0L only).

• At least 1 second since fuel cut-off ignition retard was last invoked.

• At least 1 second since ISC feedback status (off to on only) changed.

• At least 1 second since A/C status (on or off) changed.

• At least 1 second since electrical load status (on or off) changed.

• At least 1 second since traction control ignition retard was last invoked.

• Rate of change of engine speed less than 250 RPM/0.064s.

• Rate of change of engine load has been less than 0.1g/revolution for at least 20 firing cycles.

• Rate of change of throttle angle is less than 1.5 degrees/0.008s.

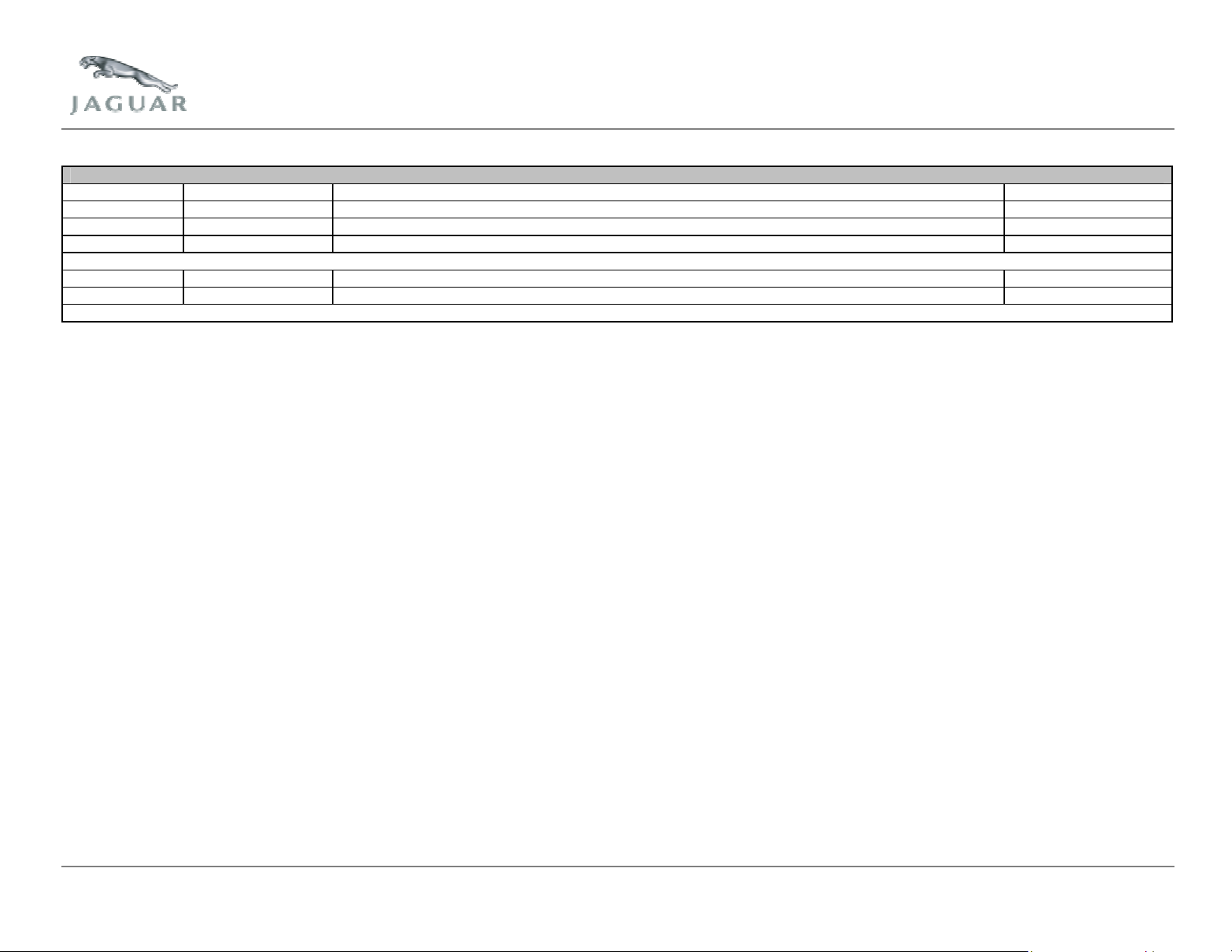

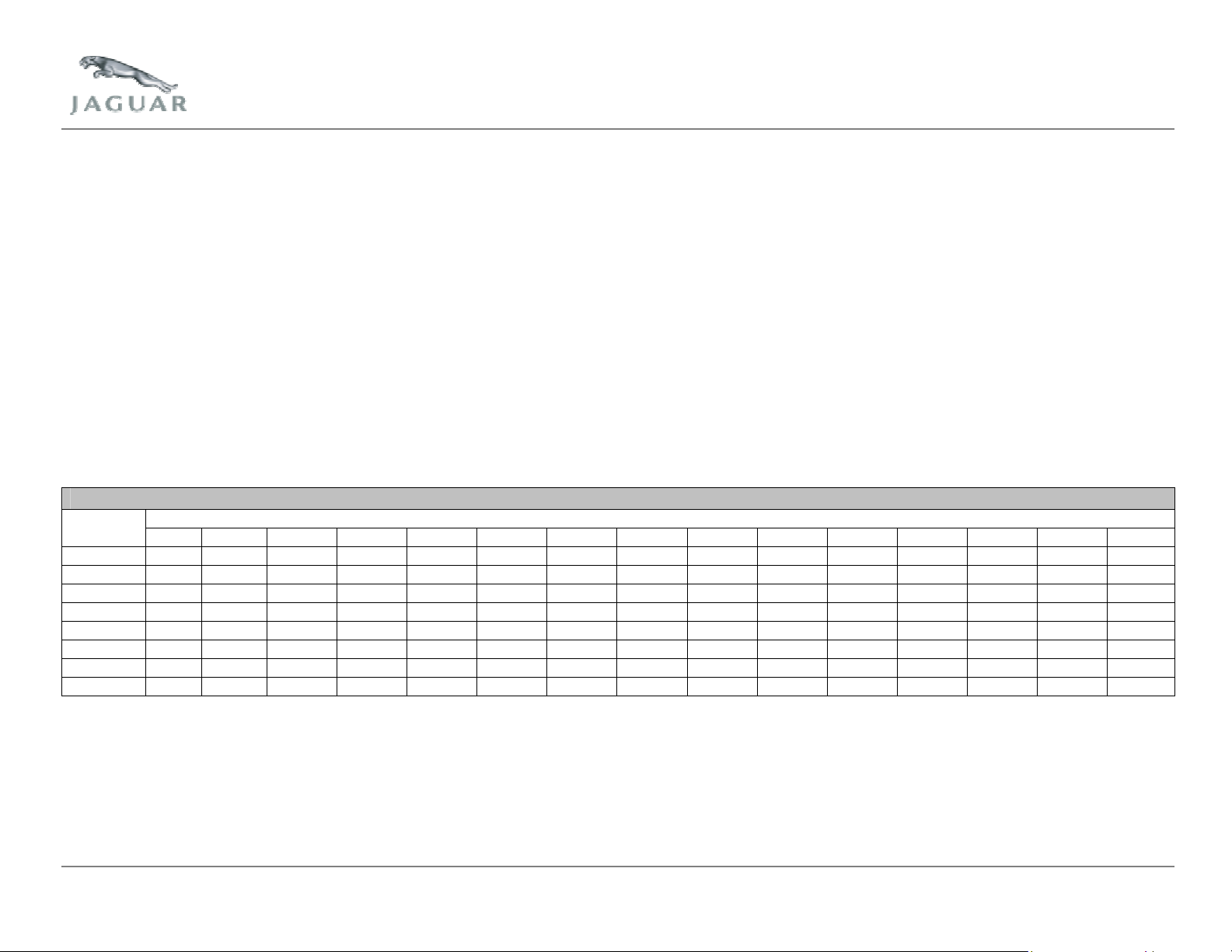

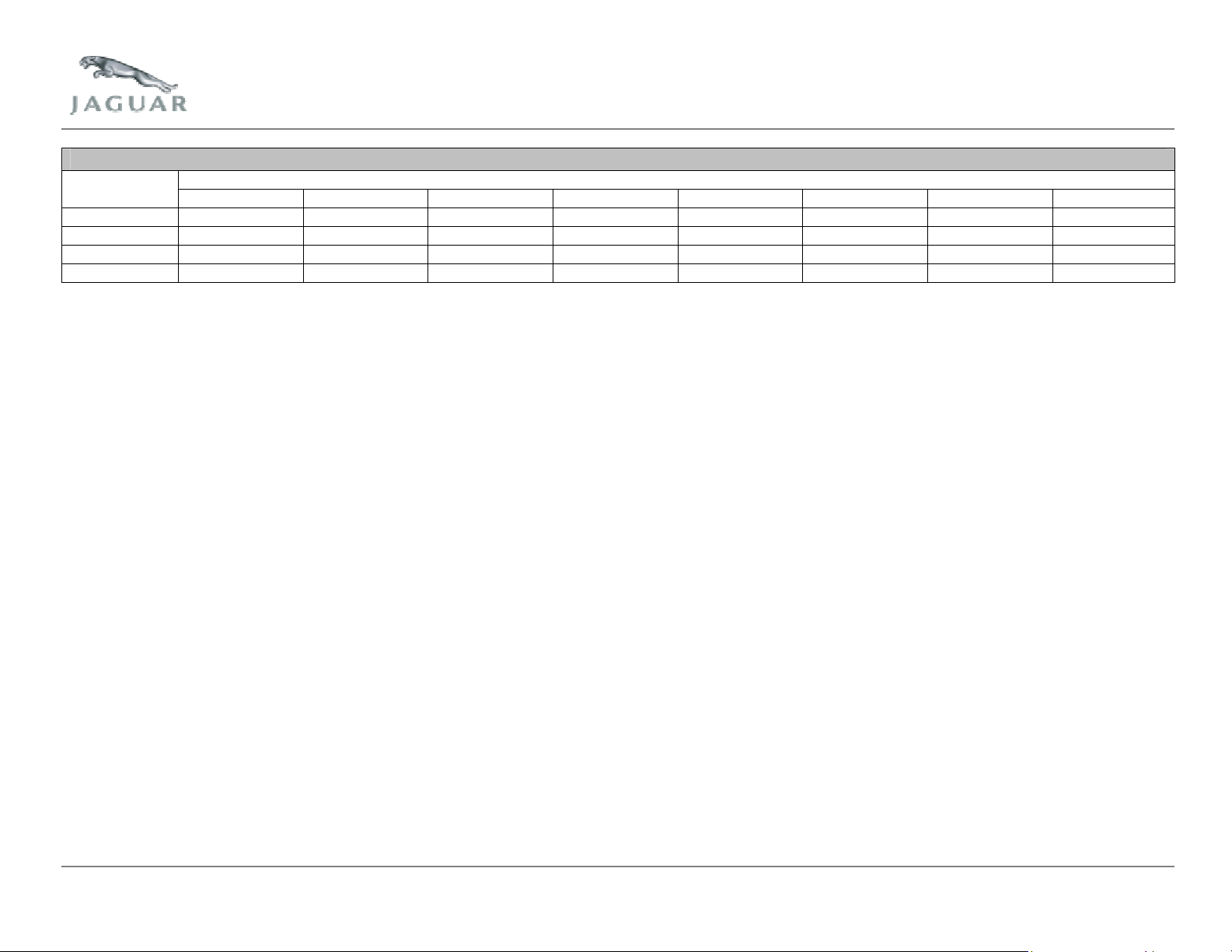

MIS1 – 2.5L

Engine speed (RPM) Engine

load (g/s)

0.30 148 148 138 116 100 100 100 90 82 74 42 32 32 20 18

0.60 124 124 108 108 90 82 70 64 58 50 42 32 32 20 18

0.80 106 106 106 100 82 74 60 56 50 42 36 30 24 20 18

1.00 100 100 100 82 74 66 50 50 42 32 30 28 32 20 20

1.20 88 88 88 74 62 44 42 40 32 32 28 28 32 30 30

1.40 88 88 88 74 62 60 56 56 48 36 36 32 32 36 36

1.60 88 88 88 74 62 60 56 56 48 36 36 32 32 36 36

2.00 88 88 88 74 62 60 56 56 48 36 36 32 32 36 36

Note: The figures in the map denote the number of misfires in 200 engine revolutions corresponding to catalyst damage misfire failure.

700 730 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 7000

Jaguar Cars Revision Date: May 2004 Page 22 of 113

Page 23

MIS1 – 3.0L (S-Type)

Engine speed (RPM) Engine

load (g/s)

680 730 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 7000

0.25 150 150 135 130 125 116 106 99 99 80 76 72 72 68 64

0.3 138 138 125 120 119 110 100 93 93 74 70 66 66 62 58

0.4 126 126 120 110 109 100 90 83 83 64 60 56 56 52 48

0.6 121 121 118 118 102 93 80 69 67 56 55 46 46 43 42

0.9 117 117 111 100 84 72 60 53 52 48 39 31 31 27 26

1.2 93 93 93 76 67 58 56 50 51 38 32 23 23 23 23

1.3 84 84 84 77 64 61 50 41 44 27 27 26 26 25 25

1.6 100 100 100 77 73 68 50 46 57 50 41 36 38 39 38

Note: The figures in the map denote the number of misfires in 200 engine revolutions corresponding to catalyst damage misfire failure.

MIS1 – 3.0L (X-Type)

Engine speed (RPM) Engine

load (g/s)

0.30 148 148 134 116 106 90 70 68 64 56 40 20 26 26 24

0.60 126 126 120 106 90 76 64 58 50 38 32 20 20 20 24

0.80 100 100 100 90 76 64 56 50 40 26 20 18 18 18 24

1.00 84 84 84 80 62 56 42 38 40 26 20 14 14 18 20

1.20 68 68 68 64 50 46 40 34 26 26 30 26 26 26 26

1.40 78 78 78 64 56 46 26 20 26 30 30 30 28 26 34

1.60 78 78 78 64 56 46 50 50 34 30 34 32 34 32 34

2.00 78 78 78 64 56 46 50 50 34 30 34 32 34 32 34

Note: The figures in the map denote the number of misfires in 200 engine revolutions corresponding to catalyst damage misfire failure.

700 730 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 7000

Jaguar Cars Revision Date: May 2004 Page 23 of 113

Page 24

MIS1 – 4.2L Normally Aspirated

Engine speed (RPM) Engine

load (g/s)

600 650 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500

0.3 187 187 179 167 140 122 118 104 94 89 74 60 51 62

0.4 183 183 175 163 137 119 114 100 94 86 70 56 47 58

0.6 173 173 165 153 134 109 109 109 92 83 68 53 44 56

0.8 164 164 156 146 133 120 106 94 83 66 53 41 30 40

1.2 151 151 143 114 96 75 75 63 50 33 20 20 20 20

1.6 122 122 114 94 75 58 50 29 26 20 20 20 20 20

2.2 120 120 112 92 74 58 45 33 26 27 26 31 31 34

2.8 120 120 112 92 74 60 48 36 31 30 26 31 31 34

Note: The figures in the map denote the number of misfires in 200 engine revolutions corresponding to catalyst damage misfire failure.

MIS1 – 4.2L Supercharged

Engine speed (RPM) Engine

load (g/s)

600 650 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6200

0.4 186 186 180 164 150 134 117 101 89 77 64 68 72 74

0.6 186 186 178 160 150 130 110 97 85 73 60 64 68 70

1 183 183 175 159 142 125 108 93 77 63 49 51 52 53

1.6 158 158 150 134 117 104 90 72 54 50 46 52 57 60

2.2 125 125 117 109 100 93 85 66 47 49 52 58 64 68

2.8 122 122 114 88 62 52 42 50 57 56 56 68 80 84

3.4 116 116 108 84 60 55 50 54 58 57 57 69 74 77

3.8 116 116 108 84 60 55 50 53 61 65 70 71 73 77

Note: The figures in the map denote the number of misfires in 200 engine revolutions corresponding to catalyst damage misfire failure.

MIS2 – 2.5L Automatic

Engine speed (RPM) EOT (°C)

700 730 1000 1500 2000 2500 3000 7000

-10 0.64 0.64 0.64 0.43 0.43 0.43 0.43 0.72

20 0.39 0.39 0.39 0.33 0.33 0.33 0.34 0.63

50 0.27 0.27 0.27 0.25 0.26 0.26 0.27 0.56

80 0.22 0.22 0.22 0.20 0.22 0.22 0.23 0.52

Jaguar Cars Revision Date: May 2004 Page 24 of 113

Page 25

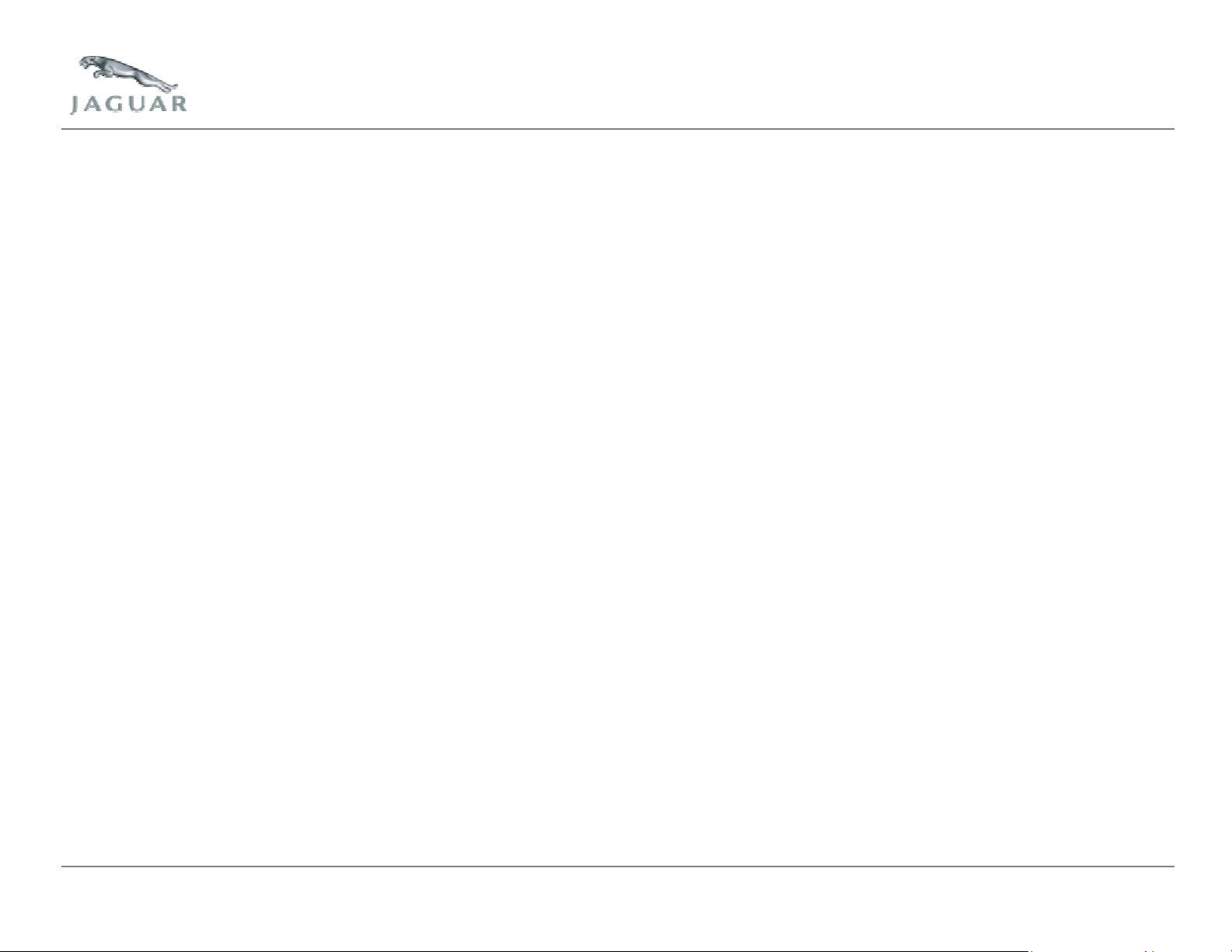

MIS2 – 2.5L Automatic (2005 Model Year X-Type)

Engine speed (RPM) EOT (°C)

500 650 1000 1150 1380 1800 2300 2550 2760 3000 7000

-8 0.45 0.45 0.45 0.45 0.45 0.46 0.47 0.47 0.47 0.47 0.72

15 0.32 0.32 0.32 0.32 0.33 0.37 0.38 0.38 0.38 0.38 0.63

45 0.26 0.26 0.26 0.26 0.28 0.32 0.32 0.32 0.32 0.32 0.57

80 0.21 0.21 0.23 0.24 0.25 0.26 0.27 0.28 0.28 0.28 0.53

MIS2 – 2.5L Manual

Engine speed (RPM) EOT (°C)

700 730 1000 1500 2000 2500 3000 7000

-10 0.47 0.47 0.47 0.33 0.33 0.34 0.35 0.64

20 0.32 0.32 0.32 0.26 0.26 0.27 0.28 0.57

50 0.23 0.23 0.23 0.21 0.22 0.23 0.24 0.53

80 0.19 0.19 0.19 0.18 0.19 0.20 0.20 0.49

MIS2 – 2.5L Manual (2005 Model Year X-Type)

Engine speed (RPM) EOT (°C)

500 650 785 960 1165 1410 1725 2180 2700 3000 7000

-8 0.50 0.50 0.50 0.43 0.37 0.33 0.33 0.33 0.37 0.37 0.66

15 0.36 0.36 0.36 0.31 0.27 0.25 0.27 0.28 0.30 0.30 0.59

45 0.26 0.26 0.26 0.24 0.21 0.22 0.24 0.25 0.25 0.26 0.55

80 0.20 0.20 0.20 0.20 0.18 0.18 0.20 0.20 0.20 0.21 0.50

MIS2 – 3.0L S-Type Automatic

Engine speed (RPM) EOT (°C)

680 730 1000 1500 2000 2500 3000 7000

-8.1 0.599 0.599 0.599 0.523 0.504 0.504 0.504 0.832

20 0.404 0.404 0.404 0.409 0.399 0.4 0.38 0.709

50 0.34 0.33 0.32 0.32 0.32 0.32 0.35 0.678

80 0.295 0.29 0.27 0.27 0.255 0.26 0.26 0.589

Jaguar Cars Revision Date: May 2004 Page 25 of 113

Page 26

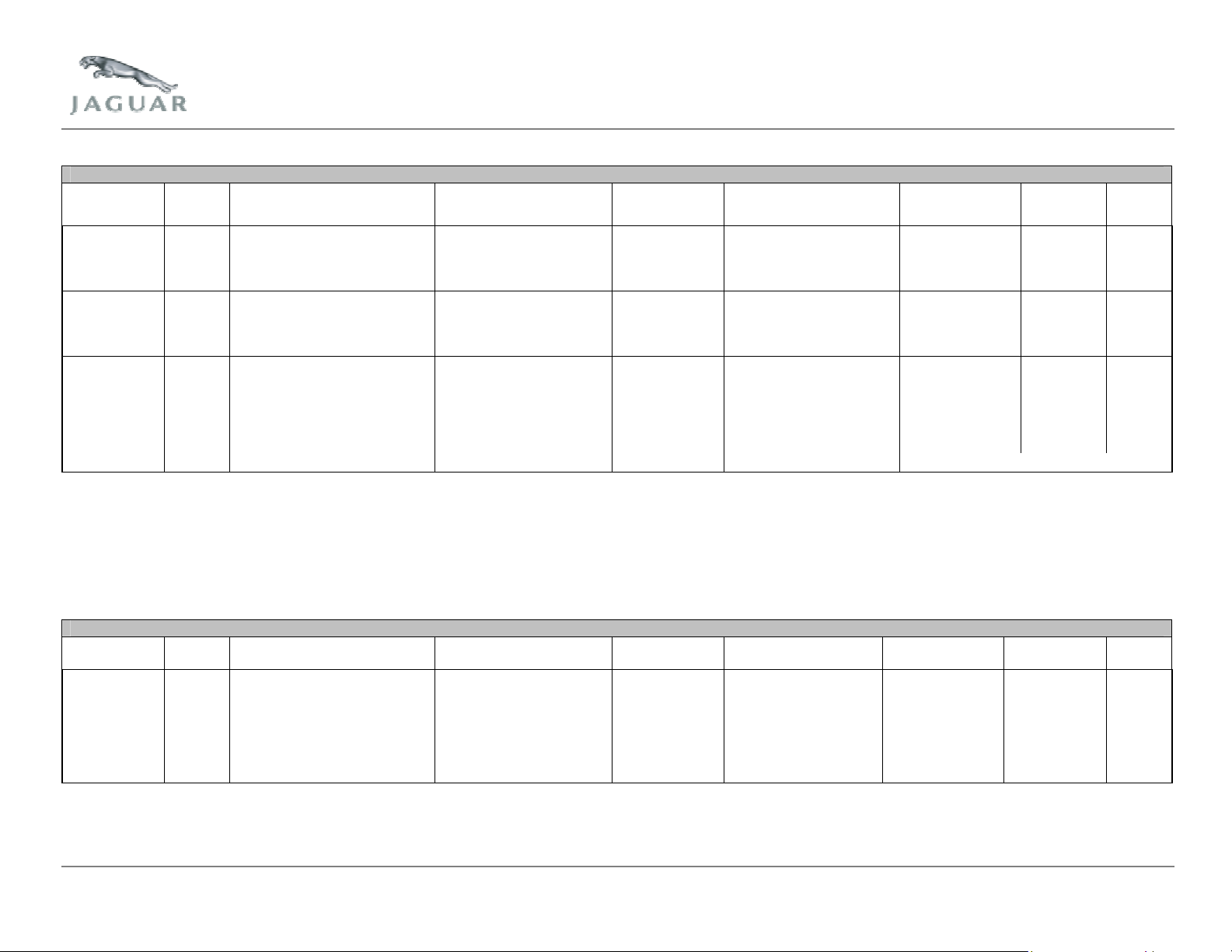

MIS2 – 3.0L S-Type Manual

Engine speed (RPM) EOT (°C)

680 730 1000 1500 2000 2500 3000 7000

-8.1 0.399 0.399 0.399 0.399 0.409 0.432 0.432 0.841

20 0.32 0.32 0.33 0.335 0.335 0.34 0.361 0.77

50 0.3 0.3 0.314 0.29 0.29 0.3 0.3 0.709

80 0.275 0.275 0.27 0.25 0.245 0.25 0.25 0.659

MIS2 – 3.0L X-Type Automatic

Engine speed (RPM) EOT (°C)

700 730 1000 1500 2000 2500 3000 7000

-10 0.55 0.55 0.55 0.44 0.44 0.44 0.44 0.79

20 0.41 0.41 0.41 0.35 0.36 0.36 0.36 0.71

50 0.32 0.32 0.32 0.28 0.29 0.29 0.30 0.65

80 0.24 0.24 0.24 0.22 0.22 0.23 0.24 0.59

MIS2 – 3.0L X-Type Manual

Engine speed (RPM) EOT (°C)

700 730 1000 1500 2000 2500 3000 7000

-10 0.54 0.54 0.54 0.37 0.37 0.38 0.38 0.72

20 0.36 0.36 0.36 0.30 0.30 0.30 0.30 0.64

50 0.25 0.25 0.25 0.24 0.24 0.25 0.25 0.59

80 0.23 0.23 0.23 0.20 0.20 0.20 0.21 0.55

MIS2 – 4.2L Normally Aspirated

Engine speed (RPM) EOT (°C)

600 650 1000 1500 2000 2500 3000 6500

-8 0.45 0.45 0.45 0.45 0.46 0.46 0.46 0.88

20 0.38 0.38 0.38 0.39 0.4 0.4 0.42 0.83

50 0.31 0.31 0.31 0.32 0.33 0.33 0.34 0.75

80 0.24 0.24 0.24 0.25 0.26 0.25 0.26 0.67

Jaguar Cars Revision Date: May 2004 Page 26 of 113

Page 27

MIS2 – 4.2L Supercharged

Engine speed (RPM) EOT (°C)

600 650 1000 1500 2000 2500 3000 6500

-8 0.6 0.6 0.6 0.6 0.62 0.64 0.66 1.21

20 0.5 0.5 0.5 0.51 0.51 0.52 0.54 1.09

50 0.37 0.37 0.37 0.38 0.4 0.41 0.44 0.99

80 0.28 0.28 0.28 0.28 0.29 0.31 0.35 0.9

6.3 Heated Oxygen Sensor Monitor

An O2S comprises of a gas-tight zirconium dioxide ceramic tube covered with thin layer of platinum. One end of the tube is open to atmosphere; the other end is

sealed and protrudes into the exhaust. When the tube is filled with oxygen rich atmospheric air, and the outer walls are exposed to the oxygen depleted exhaust

gases, a chemical reaction takes place and produces a voltage. The voltage output reflects the differences in oxygen concentrations on either side of the ceramic

sensor element. As the oxygen content decreases, the voltage increases. As the oxygen content increases, the voltage decreases.

The oxygen content of the exhaust gas stream is directly related to the air fuel mixture supplied to the engine. The voltage output by the O2S is typically 800 to

1000mV for rich mixtures, and around 100mV for lean mixtures.

The ceramic material in the sensor becomes sensitive to the presence of oxygen in the exhaust gas stream at around 315°C. An internal heater is used to bring

the sensor quickly up to the operating temperature.

The engine management system runs two tests on the upstream and downstream HO2S, one on the sensor operation and one on the sensor’s internal heater.

Note: Only the rear HO2S are used for fuel control.

6.3.1 Downstream Oxygen Sensors High/Low Input Monitor

The downstream O2S are checked for their maximum and minimum output values. The monitor increments an execution timer if the monitor entry conditions are

satisfied. A low voltage failure is judged if the output of the sensor does not exceed a calibrated value prior to the monitor execution timer exceeding its calibrated

failure threshold. A high voltage failure is judged if the sensor output remains above a calibrated value after the monitor execution timer has exceeded its

calibrated failure threshold or after a defined period of over run fuel cut off has been conducted. Additionally, a high voltage failure is invoked if the sensor

voltage exceeds battery short threshold for the required time.

Note: Unless specifically included in the tables below, IAT, ECT, vehicle speed and time after start up are not critical to enable these monitors.

Jaguar Cars Revision Date: May 2004 Page 27 of 113

Page 28

A

A

Heated Oxygen Sensor Monitor Operation – Up to 2004 Model Year

Strategy DTCs Description Malfunction Criteria Value Secondary Parameter Enable

Downstream

HO2S bank 1

high voltage

Downstream

HO2S bank 2

high voltage

P0138 Sensor voltage stuck high Sensor voltage

P0158 Disable: See HO2S

.9 volts

During fuel cut

off, duration >

3.8s

2 volts anytime

ir fuel rate feedback

compensation:

Closed loop compensation:

Closed loop compensation

verage:

ECT:

IAT:

Time after start up

0.75 – 1.25

0.5 – 1.5

0.85 – 1.15

70 – 110 °C

-8 – 100 °C

2 seconds

downstream no

activity check.

Heated Oxygen Sensor Monitor Operation – From 2004 Model Year (XK8, S-Type and New XJ)

Strategy DTCs Description Malfunction Criteria Value Secondary Parameter Enable

Conditions

Downstream

HO2S bank 1

high voltage

Downstream

HO2S bank 2

high voltage

P0138 Sensor voltage stuck high Sensor voltage

P0158 Immediate

Disable: See HO2S downstream no activity check.

= 0.95 volts

>=2 volts anytime

During fuel cut off, duration >= 3.8s (XK8)

>= 5s (S-Type)

>= 3.5s (XJ)

Conditions

Time

Required

60s 2 DTC

2 DTC

Time

Required

3.8s (XK8)

5s (S-Type)

3.5s (XJ)

0.5s (XJ)

MIL

MIL

2 DTC

2 DTC

Jaguar Cars Revision Date: May 2004 Page 28 of 113

Page 29

A

A

A

A

Heated Oxygen Sensor Monitor Operation – From 2004 Model Year (X -Type)

Strategy DTCs Description Malfunction Criteria Value Secondary Parameter Enable

Downstream

HO2S bank 1

low input

Downstream

HO2S bank 2

low input

Downstream

HO2S bank 1

high input

Downstream

HO2S bank 2

high voltage

P0137 Sensor voltage stuck low Sensor voltage

P0157

P0138 Sensor voltage stuck high Sensor voltage

or

P0158 Sensor voltage > 1.24 volts

Disable: See HO2S downstream no activity check.

0.30 volts Heater control

HO2S heater power

Engine speed

MAF

tmospheric pressure

Target Lambda

ECT

IAT

> 0.80 volts Time after start

Closed loop fuelling

Over run fuel cut off time

nytime 0.5s 2 DTC

ctive

>=180 Watt sec

>= 1500 RPM

>= 15 g/s

>= 74.5 kPa

0.75 to 1

70 to 119 °C

-10 to 119°C

>= 30s

ctive

>= 30s (high I/P)

Conditions

Time

Required

151s 2 DTC

2 DTC

151s 2 DTC

6.3.2 Downstream Oxygen Sensors Heater Circuit High

Heater resistance checks are performed when the heater is commanded on. If resistance values are outside of the limits when the heater is enabled, then a

failure judgment is made.

Note: Unless specifically included in the tables below, IAT, ECT, vehicle speed and time after start up are not critical to enable these monitors.

Heated Oxygen Sensor Monitor Operation

Strategy DTCs Description Malfunction Criteria Value Secondary Parameter Enable

Heater control

circuit bank 1

high input

Heater control

circuit bank 2

downstream

high input

P0038 Heater resistance check when

on

P0058 Heater resistance when on Outside limits

Outside limits 0.432s

Disable:

P1609, P0603

Conditions

Time

Required

0.4s (2004

model year)

0.432s

0.4s (2004

model year)

2 DTC

2 DTC

MIL

MIL

Jaguar Cars Revision Date: May 2004 Page 29 of 113

Page 30

6.3.3 Downstream Oxygen Sensors Heater Circuit Low

Heater resistance checks are performed when the heater is commanded off. If resistance values are outside of the limits, then a failure is flagged.

Note: Unless specifically included in the tables below, IAT, ECT, vehicle speed and time after start up are not critical to enable these monitors.

Heated Oxygen Sensor Monitor Operation

Strategy DTCs Description Malfunction Criteria Value Secondary Parameter Enable

Conditions

Heater control

circuit bank 1

low input

Heater control

circuit bank 2

low input

Disable: P1609, P0603

P0037 Heater resistance check when

off

P0057 Heater resistance check when

off

Outside limits 0.384s

Outside limits 0.384s

Time

Required

0.4s (2004

model year)

0.4s (2004

model year)

MIL

2 DTC

2 DTC

6.3.4 Downstream Oxygen Sensors No Activity Detected

The monitor is single shot monitor (runs once per trip), which is designed to operate only when the sensor has been lit off (up to operating temperature). The

monitor can be sub divided into two sections:

Stuck low

(Output voltage less than calibrated threshold (0.4 volts).

The monitor initially examines the fuelling control to ensure the system is stable, that linear airflow rate closed loop control, and sub feedback execution has been

invoked. Once these conditions are satisfied and a calibrated load/airflow has been achieved, a lean stuck timer is incremented. The monitor then checks the

output voltage from the sensor and sets a normal end judgment if a calibrated change in sensor output voltage is observed. If the change in sensor voltage is not

detected and the lean stuck timer exceeds the failure threshold, and the associated failure conditions are satisfied, then a failure end judgment is made.

Stuck high

(Output voltage greater than calibrated threshold (0.4 volts).

Again, the monitor strategy checks for stable air fuel ratio control prior to commencing the examination of the sensors output voltage. The monitor then utilizes

the lean switching characteristics of the sensor during an over run fuel cut off (where the sensors output voltage tends towards 0 volts), to determine its correct

Jaguar Cars Revision Date: May 2004 Page 30 of 113

Page 31

A

A

operation. Finally, if the duration of the fuel cut off exceeds a calibrated period and the output voltage of the sensor is greater than calibrated threshold, then a

failure judgment is set.

Note: Unless specifically included in the tables below, IAT, ECT, vehicle speed and time after start up are not critical to enable these monitors.

Heated Oxygen Sensor Monitor Operation – Up to 2004 Model Year

Strategy DTCs Description Malfunction Criteria Value Secondary Parameter Enable

Conditions

HO2S bank 1

no activity

HO2S bank 2

no activity