Page 1

Vectris

®

INSTRUCTIONS FOR USE

Page 2

2

Page 3

TABLE OF CONTENTS

Product Information Material 6

Product system 7

Applications 8

Questions & answers 9

Composition and storage 10

Working times 11

Description of assortments

Working Procedure Preparation 18

Framework design 20

Cementation 28

Single Crowns Starting situation 30

Working method for different preparations 30

Fabricating the silicone matrix 31

Sealing the dies 32

Preparing the die for the vacuum-forming process 32

Vacuum-forming the Vectris Single – Version A 33

Vacuum-forming the Vectris Single – Version B 34

Removing the framework from the die 35

Finishing 36

The result 36

3-unit anterior bridges Starting situation 38

Fabricating the duplicate model for the vacuum forming process 38

Contouring the pontic 39

Transferring the pontic to the duplicate model 40

Fabricating the Transil matrix 41

Sealing the dies 42

Preparing the dies for the vacuum-forming process 42

Placing Vectris Pontic into the Transil matrix

and vacuum-forming the pontic 42

Vacuum-forming the Vectris Frame 44

Removing the framework from the die 45

Finishing 46

The result 46

3-unit inlay-retained bridge Starting situation 48

Fabricating the duplicate model for the vacuum forming process 49

Contouring the pontic 50

Transferring the pontic to the duplicate model 51

Fabricating the Transil matrix 52

Sealing the dies 53

Preparing the dies for the vacuum-forming process 54

Placing Vectris Pontic into the Transil matrix

and vacuum-forming the pontic 54

Vacuum-forming the Vectris Frame 56

Removing the framework from the die 57

Finishing 58

The result 58

3

Page 4

4

Page 5

5

Vectris

®

PRODUCT INFORMATION

PRODUCT INFORMATION

Page 6

Vectris

®

Metal-free, tooth-coloured, translucent frameworks follow today’s trend in dentistry and offer

advanced aesthetic and functional properties. The

fibre reinforced framework material Vectris is

ideally suited for the fabrication of FRC frameworks (Fibre Reinforced Composite).

FRC technology emulates the principles of natural

fibre bonds, which are capable of withstanding the

extreme stresses that occur in natural surroundings. FRC materials consist of elastic fibres that

are embedded in an organic matrix. This type of

structure enables modern dental technology to

manufacture FRC frameworks.

Since its introduction, Vectris has been accepted as

an alternative to alloys, ceramics and zirconium

oxide. Vectris has also proved suitable for reinforcing long-term temporaries. In addition, this

innovative material enables dental practitioners to

treat clinical cases, such as missing posterior teeth,

with a tooth conserving solution, i.e. a Vectrisbased inlay-retained bridge that is cemented in

place using an adhesive cementation technique.

In response to the experience gathered over the

past few years, the procedure for fabricating

Vectris frameworks has been adjusted to allow

for a functional framework design that closely

resembles the accepted framework design used in

the metal-ceramic technique.

6

Material

Vectris is a light-curing, translucent, tooth-coloured

framework material. It is part of the category of

fibre reinforced composites (FRC = Fibre Reinforced

Composite).

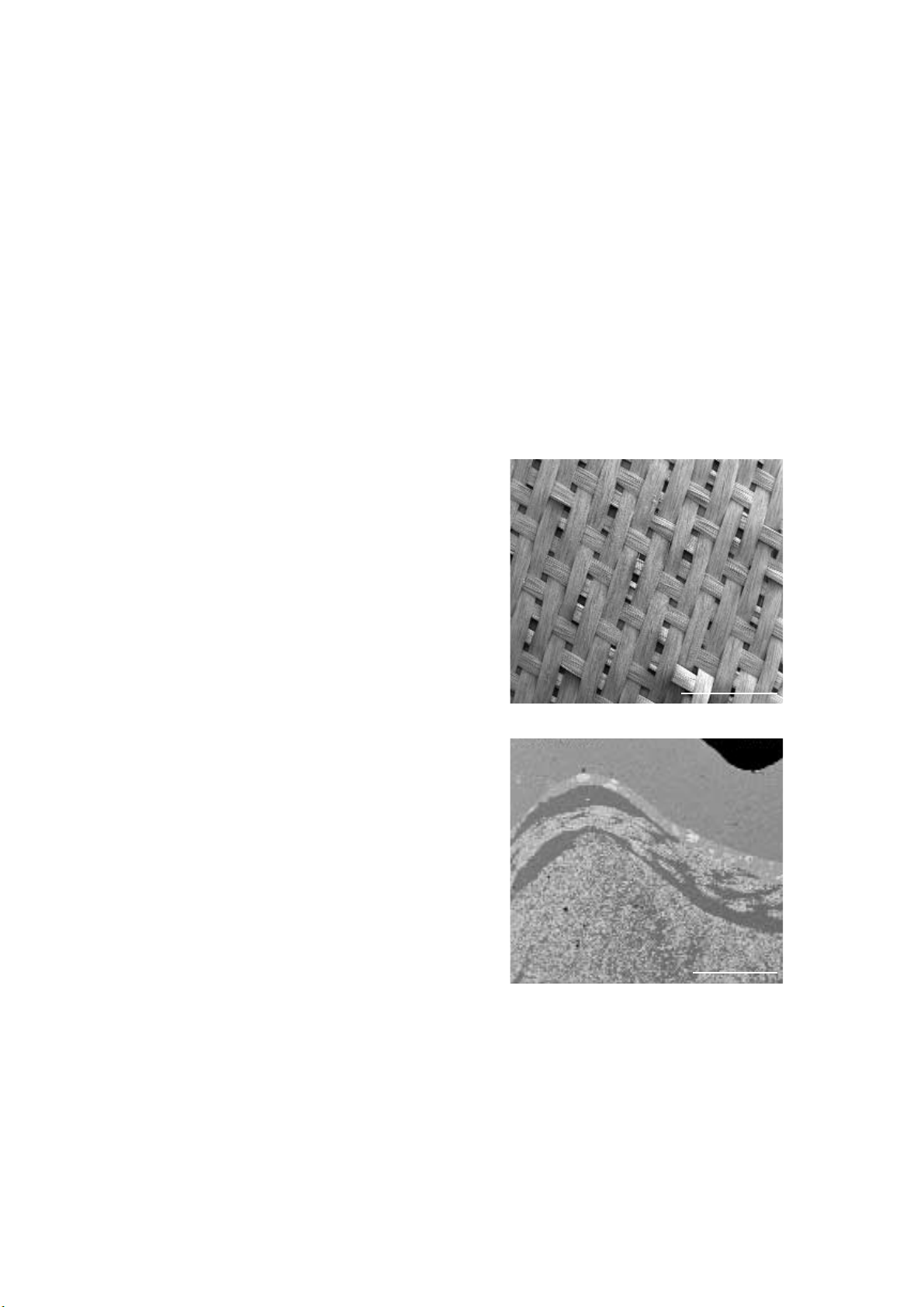

Vectris consists of several layers of fibre wafers and

uniaxially oriented fibre bundles embedded in an

organic polymer matrix. This matrix assures a

strong bond and homogeneously distributes the

masticatory forces exerted on the veneering

material throughout the framework.

1 mm

2 mm

We would like to thank Paolo Miceli from Italy for his

valuable cooperation in developing the technique

presented in these Instructions.

Page 7

7

PRODUCT INFORMATION

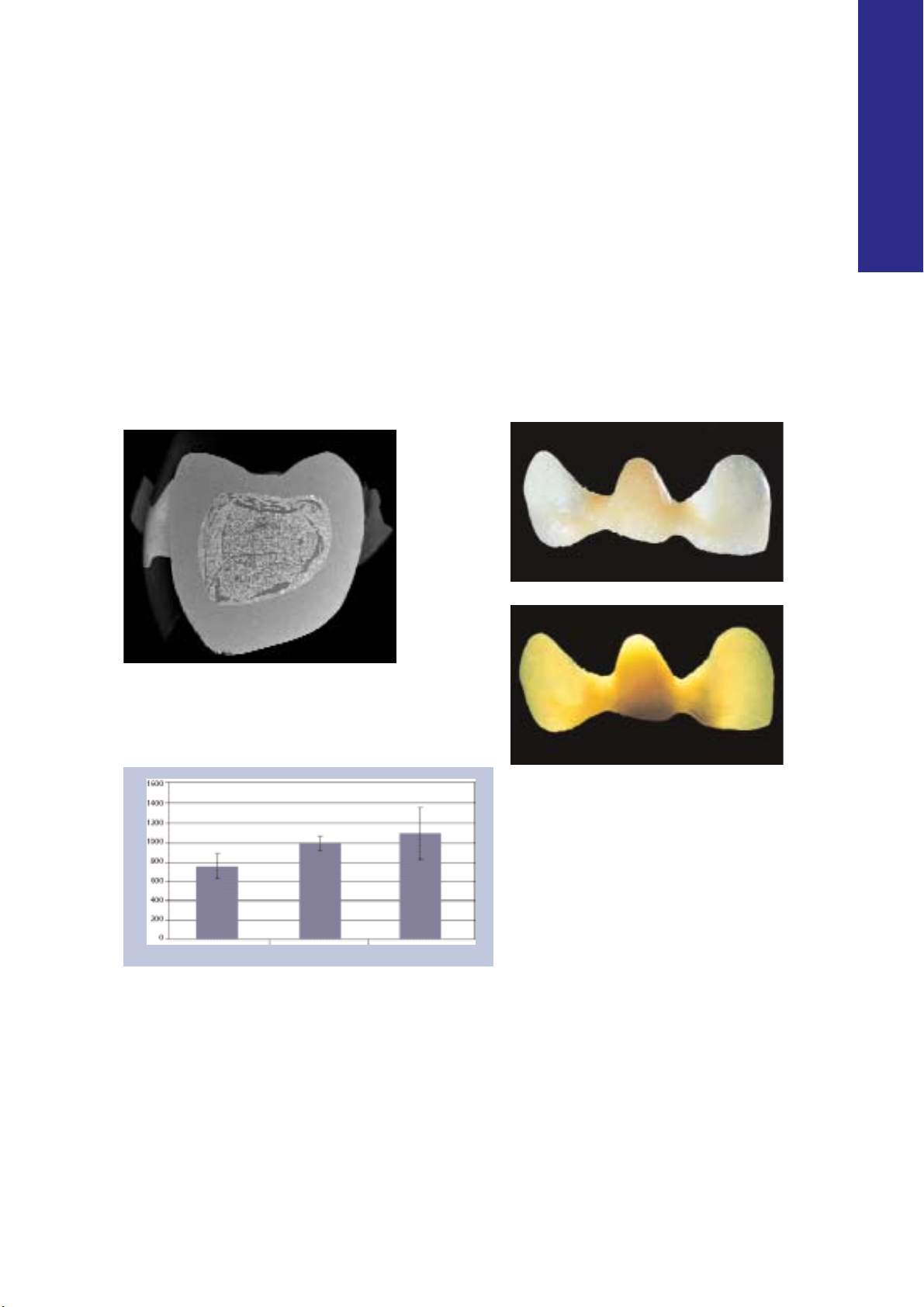

Fracture resistance (N)

Vectris framework fabricated

using the previous technique

Vectris framework fabricated

using the Transil technique

With Academy Gold XH

Physical properties

Vectris frameworks are characterized by an intimate stress-free fit and beneficial physical properties

thanks to a special manufacturing process that

combines the use of vacuum, pressure and light.

The frameworks are automatically formed and

polymerized in the VS1 framework former.

Furthermore, a newly developed working

technique – based on the Transil matrix material –

facilitates the fabrication of cusp-supporting frameworks. The flexural strength of these frameworks is superior to that of previous FRC frameworks.

Aesthetic properties

The translucent, tooth-coloured fibre wafers permit the fabrication of highly aesthetic frameworks.

Light can pass through the restoration without

being blocked by opaque areas of the substructure. The advantage of the FRC framework is also

apparent at the transition from the pink tissue

colour to the white tooth colour. The grey margins typically associated with metal restorations

are not present in Vectris-based reconstructions.

The cervical area exhibits a lifelike aesthetic

appearance.

Source: R&D, Ivoclar Vivadent AG, Schaan, 2003

Flexural strength of 3-unit posterior bridges using different

framework materials and designs. All frameworks are

veneered with SR Adoro.

Page 8

8

PRODUCT SYSTEM

Compatibility with SR Adoro

®

The metal-free Vectris frameworks can be veneered with

SR Adoro. SR Adoro is a microfilled, light/heat-curing

veneering composite for fixed

metal-supported and metalfree dental reconstructions.

SR Adoro offers several

advantages over glass-filled and hybrid composite

materials as regards wear, polishability, handling,

plaque resistance and surface finish. Furthermore,

the formulation of SR Adoro assures a smooth,

non-sticky consistency and endows the material

with excellent modelling properties. SR Adoro

demonstrates a high degree of translucency as the

light refraction index of the matrix and microfiller

are coordinated with each other. In addition,

the foundation material of SR Adoro exhibits

opalescent characteristics, which are equal to

those of the natural tooth in every respect. These

characteristics facilitate the fabrication of restorations that exhibit vibrant aesthetic properties. The

SR Adoro Liner, which is adjusted to the Vectris

framework material, establishes a strong bond

with the conditioned Vectris fibres.

Compatibility with SR Ivocron

®

SR Ivocron, a clinically proven,

high-quality PMMA veneering

material, is suitable for the

veneering of metal-free long-term

temporaries. By choosing the

appropriate monomer, SR Ivocron

can be processed in a cold-curing,

heat-curing or pressure-heat

curing technique. Consequently,

the processing technique can be

matched to the indication in

question as well as to the

technician's preferred working technique.

SR Ivocron is available in Chromascop shades. The

SR Ivocron system also includes specially coloured

cervical materials and is therefore compatible with

the SR Vivodent PE shade guide.

Compatibility with Ivoclar Vivadent

apparatus

Vectris VS1 is a high

performance, fully automated framework former

that has been especially

designed for the fabrication

of metal-free crown and

bridge frameworks. In the

VS1, the frameworks are

formed under pressure and then

polymerized with light using a single program.

Compatibility with Ivoclar Vivadent

cementation systems

Select one of the recommended cementation systems from the Ivoclar Vivadent

range. An array of suitable composite

resins are available for the adhesive

cementation of metal-free

restorations.

Adhesive cementation:

–Variolink II (CEM Kit Professional Set

or

CEM Kit Esthetic Cementation

System)

– Multilink

Zirconium oxide temporary cements are suited for

the cementation of long-term temporaries that

are intended to remain in the oral cavity for a

maximum duration of 12 months.

Page 9

9

PRODUCT INFORMATION

Indication

Adhesive cementation

– frameworks for anterior and posterior crowns

– frameworks for 3-unit anterior and posterior bridges in

conjunction with Transil

– frameworks for 3-unit inlay-retained bridges in conjunction with

Transil

Temporary cementation

Frameworks for long-term temporaries intended for a maximum

duration of wear of 12 months.

Contraindication

– fabrication of bridge frameworks without using Transil

– fabrication of posterior Vectris frameworks without cusp support,

if Transil is not used

–Vectris frameworks for bridges consisting of 4 or more units

–Vectris frameworks for inlay-retained bridges consisting of 4 or

more units

– cantilever extension bridges

– more than 4 fixed, permanent Vectris units per quadrant

–rehabilitation of quadrants with Vectris frameworks without

sufficient support by the remaining tooth structure

– conventional cementation of fixed Vectris restorations

– metal-free temporary restorations intended for a period of wear

longer than 12 months

– patients with occlusal dysfunctions or parafunctions, such as

bruxism, etc

– patients who practise insufficient oral hygiene

– inability to meet the manufacturer’s preparation guidelines and

recommended minimum layer thicknesses

– veneering of permanent Vectris-based restorations using

composites that are not indicated for Vectris

– all uses not explicitly stated as indications by the manufacturer

APPLICATIONS

Page 10

10

QUESTIONS

&

ANSWERS

What material should be used to prepare an

impression that can be poured several times?

A silicone, polyether or similar material should be used for

impression taking as these materials provide an optimum

reproduction of detail. Additionally, the impressions taken

with these materials can be poured several times.

Hydrocolloid and alginate materials are unsuitable and

cannot be poured more than once.

What if the impression needs to be poured only

once or if it has been damaged during the first

pouring?

In this case, a duplicating impression (Double Take) is

prepared with the help of the master model or a multi-

section model. Then, the impression is poured with type IV

stone.

Can the model be cut up into detachable

segments before preparing the duplicating

impression?

Ideally, the model is divided up into detachable segments

after the duplicating impression has been prepared. Block

out the cut lines with wax, if you have divided up the model

first.

MODEL PREPARATION

Can you wear latex gloves to process the matrix

material?

Latex gloves inhibit the curing of Transil. Therefore, Transil

should not come into direct or indirect contact with latex

gloves. For the processing of Transil, use vinyl gloves.

Does Transil need to be used each and every

time?

It is advisable to use Transil each time, as this material clearly

improves the adaptation of the Vectris fibres to the model,

provides a homogenous layer thickness and facilitates the

working procedure. It is imperative to use Transil for the

fabrication of bridges and inlay-retained bridges. The only

cases that do not require the use of Transil are dies of

posterior crowns with a flat occlusal preparation.

Can Transil be applied intraorally?

Transil must not be applied intraorally.

What characteristics should the exterior surface

of the Transil matrix exhibit?

The exterior surface should be as smooth as possible so that

it does not hinder the passage of light. Use the

accompanying Vectris foil to smooth the exterior surface

(prior to polymerization) or use a scalpel (after polymeriza-

tion). Light becomes scattered on rough, uneven surfaces

and, consequently, fails to penetrate the matrix effectively.

How thick should the Transil matrix be?

The matrix should be 3 to 6 mm thick. If it is thinner than

that, it may become deformed. If the matrix is thicker, the

Vectris material may not polymerize and cure properly.

Is it necessary to apply a Vectris foil if Transil is

used?

It is imperative to apply a Vectris foil only if you do not use

Transil. If you use Transil, you may employ the foil to smooth

the exterior surface of the silicone matrix while it is still soft.

How long is the working time of Transil?

The working time is approximately 1 minute.

SILICONE MATRIX

What is the minimum thickness for Vectris

frameworks?

Single crowns and bridge abutments must exhibit a mini-

mum framework thickness of at least 0.3. to 0.4 mm. The

surfaces should not be ground after the vacuum-forming

process has been completed.

What are the dimensions of the connector area

in bridges and inlay-retained bridges?

The connector area between the bridge abutment and

pontic should measure at least 3 x 3 mm in bridges and

inlay-retained bridges.

What are the appropriate dimensions for the

pontic/abutment contact area (occlusal and

palatal/lingual) when the pontic is placed?

The pontic/abutment contact area should measure at least

3 x 3 mm and should be at least 0.3 mm thick. It is

advisable to shape the pontic/abutment contact area in such

a way that it supports the cusps. The pontic should reach at

least 4 mm into the tooth for inlay-retained bridges.

What are the minimum dimensions of the inlay

box for inlay-retained bridges?

The proximal aspect of the box should be no less than

3.5 mm and the occlusal depth no less than 2.5 mm.

Observe the preparation guidelines.

FRAMEWORK DESIGN

Page 11

11

PRODUCT INFORMATION

What do I need to watch out for while carrying

out the sandblasting (conditioning) process?

Use Al2O3of a grit size of 80 to 100 microns (type 100) at a

pressure of maximum 1 bar (14.5 psi).

How long is the reaction time of the wetting

liquid?

Allow the liquid to react for 1 minute.

CONDITIONING

Can frameworks made of Vectris be veneered

with composites that are not explicitly recommended by the manufacturer?

Fixed, adhesively cemented restorations made of Vectris

must not be veneered with any other materials than those

recommended by the manufacturer. Temporarily cemented

long-term provisional restorations, which are intended to

remain in the oral cavity for no longer than 12 months, may

be veneered with other composites.

VENEERING

What equipment is needed to process Vectris?

A Vectris VS1 framework former is required to process

Vectris.

Can you cut slits into the Vectris Frame?

As Vectris Frame adapts very closely to the die because of the

Transil matrix, it is not necessary to cut slits. In fact, cutting

slits should be avoided, as the fibres would be severed in the

process. This weakens the strength of the restoration.

What happens if the stipulated curing depths

are not observed?

If the stipulated curing depths are not observed, the material

may not be able to polymerize completely. Clinical failure

may ensue.

Is it necessary to sandblast and condition the

pontic before Vectris Frame is applied?

After the vacuum-forming process, any Vectris matrix

material that has been squeezed downwards is carefully

removed with an appropriate instrument. Then, the Vectris

frame is directly applied on the inhibition layer of the pontic

(avoid contamination). Next, the Transil matrix is placed on

the die and the vacuum-forming process in the VS1 is

started. The inhibition layer provides a bond to the Vectris

Frame.

Do you ever sandblast and condition the pontic?

Only sandblast and condition the pontic if you have modified

the pontic surfaces by grinding and removed the inhibition

layer in the process.

V ACUUM

-

FORMING

Page 12

12

COMPOSITION

–Vectris Single

Dimethacrylate (48-50 wt%); glass fibres

(44–46 wt%); silicon dioxide (5–6 wt%).

Additional ingredients: stabilizers, catalysts and

pigments (<1 wt%)

–Vectris Pontic

Dimethacrylate (30–32 wt%); glass fibres

(64–66 wt%); silicon dioxide (3–4 wt%).

Additional ingredients: stabilizers, catalysts and

pigments (<1 wt%)

–Vectris Frame

Dimethacrylate (44-46 wt%); glass fibres

(49–51 wt%); silicon dioxide (5–6 wt%).

Additional ingredients: stabilizers, catalysts and

pigments (<1 wt%)

–Vectris Glue

Dimethacrylate (38–40 wt%); barium glass filler

and silicon dioxide (59–61 wt%).

Additional ingredients: stabilizers, catalysts and

pigments (< 1 wt%)

–Vectris Wetting Liquid

Silane in a water/alcohol solution

– SR Model Separator

Polyglycol, polyethylene glycol in a water/alcohol

solution

–Transil

Vinyl polysiloxane, polymethylhydrogen siloxane,

organic platinum complex and silicone dioxide

Warning

Vectris has been developed solely for use in dentistry. Prevent

contact of the eyes and skin with uncured material (Vectris fibres).

If the material comes into contact with the skin, rinse with copious

amounts of water. Contact of the skin with uncured material may

cause slight irritation and sensitization to methacrylate. Use suction

equipment and a protective mask when grinding the material.

Finishing the Vectris frameworks creates glass fibre dust, which

may cause the skin to itch. Wearing suitable gloves is

recommended. Thoroughly clean the skin that has come into

contact with glass fibre dust. Many commercially available

protective gloves do not provide effective protection against the

sensitizing effect of methacrylates. Observe the danger signs and

notes on the primary packaging and labels of the individual

materials.

Interaction

Latex gloves have an adverse effect on the polymerization of

polyvinyl siloxanes. For this reason, Transil must not come into

direct or indirect contact with latex gloves. It is advisable to use

vinyl gloves or to thoroughly wash and rinse the hands prior to

using Transil.

General

Ignoring the stipulated contraindications or limitations on the use

of the material (Questions & Answers) may result in the clinical

failure of the restoration fabricated. Make sure to use original

Ivoclar Vivadent materials and equipment when fabricating

prosthetic reconstructions with Vectris.

Side effects

Side effects are not known to date. In rare cases, an allergic reaction may occur. Vectris must not be used if the patient is suspected

or known to be allergic to any of the material’s ingredients.

Storage

– Store unopened and opened packages of Vectris framework

material at 18–25 ºC (64–77 ºF).

– Store opened Vectris packages in a place that is protected from

light and use up the contents as soon as possible.

– Reseal Vectris Glue immediately after use (exposure to light may

result in premature polymerization).

– Store Transil at 12–28 ºC (54–82 ºF).

– Observe the notes on the storage and dates of expiration of the

individual packages.

– Do not use materials after the date of expiration.

– Keep out of the reach of children.

Note on the cleaning of Vectris restorations

Ultrasonic cleaning liquid is very aggressive. If used inappropriately,

the topmost layer of the composite surface may dissolve. Do not

use basic cleaning liquids that have a pH-value higher than 8.

Page 13

13

WORKING TIMES

PRODUCT INFORMATION

Vectris materials are sensitive to light. The working

time of the material depends on the layer thickness

and the prevailing light conditions. The times listed

below represent mean values at a light intensity of

3000 lux, which corresponds to the light encountered

in a well-lit working space. Be aware of the maximum

time limit when removing the Vectris framework

materials from the packaging.

Vectris Single 2 minutes and 30 seconds

Working time

Vectris Pontic 3 minutes

Vectris Frame 2 minutes and 30 seconds

Vectris Glue 2 minutes and 30 seconds

Page 14

14

DESCRIPTION OF ASSORTMENTS

Vectris Kit

Vectris Single

Vectris Single is suitable for fabricating frameworks for anterior and

posterior crowns.

Vectris Pontic

Vectris Pontic is employed to create cusp-supporting pontics or to

reinforce the cusps in single crowns. Vectris Pontic is characterized

by high flexural strength. As the pontic is wrapped in foil, it can be

easily measured out and cut to size. These strips, when cut, are fitted

into the Transil matrix one by one.

Vectris Frame

Vectris Frame is wrapped around the cusp-supporting pontic and

bridge abutments. This technique results in a bridge framework with

having physical properties. The flexible structure of Vectris Frame

evenly distributes the masticatory forces on the bridge and increases

the torsional resistance.

Delivery form

Vectris Kit

– 4x4 Vectris Single

dimensions: diameter: 24 mm

– 2x2 Vectris Pontic

dimensions: length: 150 mm

– 4x4 Vectris Frame

dimensions: length: 40 mm; width: 25 mm

– 3x 2 ml Vectris Glue

– 1x 5 ml Vectris Wetting Liquid

– 1x 25 Vectris Foil

– 1x 10 ml Vectris Model Separator

–Vectris Pliers

– 2x 50 ml Transil Cartridge

– 12 Mixing Tips

Page 15

15

PRODUCT INFORMATION

Vectris Glue

Vectris Glue holds the Vectris material in place in the Transil matrix

until the vacuum-forming process is carried out and serves as an

additional aid to adaptation.

Vectris Wetting Liquid

The wetting liquid is applied to condition the fully completed

surfaces of Vectris frameworks in order to achieve an effective bond

to the following Vectris material and the SR Adoro Liner.

Vectris Model Separator

The Vectris Model Separator is suitable for separating working dies

during the fabrication of metal-free restorations and adjoining stone

surfaces during composite veneering.

Vectris Foil

The foil reduces the formation of an inhibited layer during the lightcuring process and, consequently, enables the framework material to

cure completely. The foil is only used for applications without Transil.

Vectris Pliers

These pliers are used to cut Vectris Pontic to size.

Transil

Transil is utilized to manufacture reproducible, cusp-supporting

Vectris frameworks. This silicone enables users to design frameworks

according to the classic metal-ceramic technique. Transil offers easy

and fast handling properties. The disposable mixing tips are used to

mix the two components to a homogeneous mixture. Cuspsupporting, anatomically designed Vectris frameworks provide

increased strength and reduce the risk of delamination.

Dispenser

The dispenser is suitable for Ivoclar Vivadent materials that are mixed

in a 1:1 ratio (e.g. Gingitech, Virtual, etc).

Page 16

16

Page 17

17

WORKING PROCEDURE

Vectris

®

WORKING PROCEDURE

Page 18

18

PREPARATION GUIDELINES AND MINIMUM

REQUIREMENTS FOR VECTRIS FRAMEWORKS

As Vectris restorations are luted in place using an adhesive cementation method, a tooth-conserving

preparation technique can be used.

Anterior crowns and bridge abutments

Evenly reduce the anatomical shape and observe the stipulated minimum thickness. Prepare a 360°

shoulder with rounded inner edges or a deep chamfer of at least 0.8 mm. For anterior crowns, the labial

and/or palatal/lingual surfaces should be reduced by at least 1.0 mm. Reduce the incisal crown third by at

least 1.5 mm. Prepare smooth, rounded transitions so that no internal line angles or edges are present.

0.8

0.8

≥1

≥1

1.5

Posterior crowns and bridge abutments

Evenly reduce the anatomical shape and observe the stipulated minimum thickness. Prepare a 360° shoulder

with rounded inner edges or a deep chamfer. For posterior crowns, reduce the labial and/or palatal/lingual

surfaces by at least 1.0 mm. Reduce the occlusal crown third of posterior teeth by at least 1.5 mm. Prepare

smooth, rounded transitions so that no internal line angles or edges are present.

1.5

1.5

1.5

≥1

≥1

0.8

0.8

Page 19

19

WORKING PROCEDURE

Inlay-retained bridges

Provide a preparation depth of at least 2.5 mm and an isthmus width of at least 2 mm in the fissure area.

The walls of the proximal box should be slightly flared. The bucco-lingual cavity width should be at least

3.5 mm in the proximal box. The proximocentral length should measure at least 4.0 mm, while the axial

depth should be at least 1.2 mm. A defect- and tooth-oriented preparation method may be used to prepare

the proximal shoulder. Ideally, a shoulder of at least 1.5 mm should be prepared. Round all internal angles to

allow for an optimum fit. Do not locate preparation margins on surfaces involved in masticatory functions.

Eliminate proximal contacts. Do not prepare slice-cut or feather edge margins.

Please refer to the SR Adoro Instructions for Use and the SR Adoro Clinical Guide for further information.

2.5

≥4

≥1.2

≥3.5

2.5

≥ 3.5

2.5

2

Page 20

20

Duplicate die/model ✔* ✔* ✔✔* ✔

Transil matrix ✔✔* ✔✔✔

Framework thickness at least at least at least at least at least

Vectris abutment 0.3–0.4 mm 0.3–0.4 mm 0.3–0.4 mm 0.3–0.4 mm 0.3–0.4 mm

Joint face of the connector ––at least at least at least

3 x 3 mm 3 x 3 mm 3 x 3 mm

Thickness of pontic/abutment ––at least at least at least

contact layer 0.3 mm 0.3 mm 0.3 mm

Length of the pontic/abutment ––at least at least at least

contact layer 3 mm 3 mm 3 mm

Long Pontic ribbon ––1 x1 x1 x

Medium-sized Pontic ribbon ––1 x1 x1 x

Short Pontic ribbon – ✔* 2–3 x 3–5 x 3–5 x

Grit size of Al2O3jet medium 80–100 µm 80–100 µm 80–100 µm 80–100 µm 80–100 µm

Pressure 1 bar (14.5 psi) 1 bar (14.5 psi) 1 bar (14.5 psi) 1 bar (14.5 psi) 1 bar (14.5 psi)

Cleaning with air or steam

Minimum reaction time 1 min. 1 min. 1 min. 1 min. 1 min.

of the wetting liquid

Anterior

crowns

Posterior

crowns

Anterior

bridges

Posterior

bridges

Inlay-retained

bridges

It is essential to observe the following points when designing Vectris frameworks:

1. Designing the silicone matrix

2. Designing the framework for single crowns

2.1 Anterior crowns

2.2 Posterior crowns with a flat occlusal preparation

2.3 Posterior crowns with a deep occlusal preparation

2.4 Posterior crowns without supporting cusps

3. Designing the pontic

3.1 Pontic

3.2 Joint face of the connector

3.3 Pontic/abutment contact layer

4. Trimming the margins of Vectris frameworks

5. Placing Vectris Pontic into the Transil matrix

The indicated numbers of Pontic strips are reference values and may differ depending

on the situation in question.

FRAMEWORK DESIGN

✔ indicated

✔* advisable

contraindicated

Page 21

21

WORKING PROCEDURE

1. Designing the silicone matrix

If the silicone matrix (laboratory silicone and Transil) has been shaped correctly, the work required to finish the Vectris

framework is reduced to a minimum.

Single crowns without Transil

For single crowns, always adapt the laboratory silicone (Sil-Tech) to the die in a conical shape and adapt precisely to the

preparation margin. This method ensures that the Vectris Single effectively adapts to the cervical area during the vacuumforming process. If the silicone forms a shoulder, Vectris Single cannot adapt properly to the margin. The result is thick

cervical margins. Such margins would need to be removed mechanically after the vacuum-forming process.

correct

incorrect

Single crowns with Transil

It is advisable to first apply a layer of laboratory silicone (Sil-Tech), form it into a conical shape and then cut a shoulder

about 1 cm down from the preparation margin in order to support the following Transil matrix. If necessary, retention

grooves may be cut into the silicone (Sil-Tech). Next, separate the laboratory silicone with a thin layer of Vaseline and apply

Transil. The Transil matrix should be 3 to 6 mm thick to exhibit adequate stability.

correct

incorrect

Page 22

22

2. Designing the framework for single crowns

Whether Transil should be utilized to fabricate the framework for a single crown depends on the preparation. In principle,

it is advisable to create a Transil matrix for every framework to facilitate the adaptation of the Vectris fibres to the die.

2.1 Anterior crowns

When the framework for an anterior crown is fabricated, it is advisable to use the Transil technique to facilitate the adaptation of Vectris Single to the die. The Transil technique helps to attain a consistent layer thickness on both the tooth

surface and incisal edge of steep, sharply pointed anterior preparations in particular. Upon completion of the vacuumforming process, merely trim the margins of the Transil matrix. Do not grind the surfaces.

correct

incorrect

2.2 Posterior crowns with a flat occlusal preparation

If a flat occlusal preparation is present, it is not necessary to use Transil. With flat preparations, Vectris Single adequately

adapts to the preparation margins during the vacuum-forming process and a consistent layer forms on the occlusal

surface even without the use of Transil. Adapt the laboratory silicone as described above. After separating it with Vectris

Model Separator, apply Vectris Glue and Vectris Single and then cover it with a Vectris foil. Start the vacuum-forming

process in the Vectris VS1. Upon completion of the program, trim and taper the margins. Do not grind the surfaces.

correct

incorrect

Page 23

23

2.3 Posterior crowns with a deep occlusal preparation

It is imperative to use Transil if a deep occlusal preparation is present. The Transil technique ensures that the material

consistently adapts to all surfaces of the die, including the occlusion. If Transil is not employed, the occlusal surface would

become completely filled with Vectris matrix material and, consequently, would need to be reduced another time by

grinding this material off. Upon completion of the vacuum-forming process, merely trim the margins of the Transil matrix.

Do not grind the surfaces.

correct

incorrect

2.4 Posterior crowns without supporting cusps

It is imperative to use Transil if only limited remaining tooth structure is available (e.g. no cusp support). The missing tooth

structure must be compensated by the framework and not by the veneering material. Contour the missing portions (e.g.

cusp support) in wax in order to be able to apply the veneering material in a consistent layer thickness of approx. 1.5 mm

at a later stage. Next, create a Transil matrix, fill up the missing portions with Vectris Pontic and vacuum-form in the Vectris

unit. Then, apply Vectris Single and again vacuum-form in the Vectris unit to complete the framework. This method allows

for the fabrication of shape- and cusp-supporting frameworks. Furthermore, the consistent thickness of the veneering

material facilitates the creation of a harmonious shade effect and provides a maximum level of beauty and function.

correct

incorrect

WORKING PROCEDURE

Vectris Pontic

Page 24

3. Designing the pontic

The pontic, connector and pontic/abutment contact surface are first contoured in wax and/or resin (Light Tray) and then a

silicone matrix is fabricated.

3.1 Pontic

Pontics are designed taking aesthetic and functional aspects as well as oral hygiene into consideration. The pontic must

not be larger than 10 mm in width and height to ensure that the material cures to an adequate depth. As a rule, the

pontic should be designed in such a way that it supports the cusps to ensure that the masticatory forces are evenly

distributed throughout the framework and to provide adequate support of the veneering material. Furthermore, cuspsupporting pontics reduce the risk of delamination.

correct

3.2 Joint face of the connector

The design of the interdental connector between the pontic and the bridge abutment has a considerable effect on the stability and long-term clinical success of the restoration after it has been adhesively cemented in place. The dimension of the

interdental connector should measure at least 3 x 3 mm, i.e. the surface of the connector should be at least 9 mm2.

incorrect

24

≥ 3 mm

≥ 3 mm

Page 25

25

WORKING PROCEDURE

3.3 Pontic/abutment contact layer

The pontic/abutment contact layer has a significant effect on the stability and torsional resistance of the bridgework. The

contact layer is designed according to the space available. For full coverage bridges, the contact layer should measure at

least 3 x 3 mm and be 0.3 mm thick. If enough space is available, it is advisable to contour a cusp-supporting pontic/

abutment contact layer in wax in order to attain a consistent layer thickness of approx. 1.5 mm in the veneering material.

For inlay-retained bridges, the pontic/abutment contact layer should be at least 0.3 mm thick and 4 mm long.

Limited space available Ideal space available

Pontic/abutment contact

area on anterior teeth

Pontic/abutment contact

area on molars

Pontic/abutment contact

area on premolars

≥ 0.3 mm

≥ 0.3 mm

≥ 0.3 mm

Page 26

26

4. Trimming the margins of Vectris frameworks

After completing the vacuum-forming process, trim the margins of the Vectris restoration by 0.5 mm to the inner edge of

the chamfer or shoulder preparation. Make sure that the framework continues to be supported by the die after trimming

the margins.

correct

incorrect

Bridge design if limited

space is available

Bridge design if ideal

space is available

≥ 3 mm

≥ 3 mm

Page 27

27

5. Placing Vectris Pontic into the Transil matrix

The Transil matrix is filled with Vectris Pontic material according to the schematic below. Basically the schematic applies to

all pontics. It may be necessary to trim the length of the individual Vectris Pontic strips to match the dimensions of the

pontic in question. Vectris Pontic strips in three different lengths are placed to fill the pontic:

short Vectris Pontic strips are used for creating cusp tips, occlusal surfaces and the base surface of the pontics

medium-size Vectris Pontic strips are used for the portion between bridge abutments

long Vectris Pontic ropes are used for connecting the bridge abutments and establishing the pontic/abutment contact

surfaces

The long Vectris Pontic strip is the most important part as it endows the pontic and the resultant bridgework with its

actual strength. Always employ a long Vectris Pontic strip to connect the two bridge abutments. Use a medium-size Vectris

Pontic strip to establish a connector area of 3 x 3 mm between the bridge abutments. It is advisable to place the Vectris

Pontic strips in the following order:

1. Slightly moisten the cavity of the Transil matrix with Vectris Glue

2. Insert short Vectris Pontic strips to create a cusp-supporting structure (if necessary, place short strips on the

bridge abutments as well)

3. Place a long Vectris Pontic strip to connect the bridge abutments

4. Insert a medium-size Vectris Pontic strip to establish a connector area of 3 x 3 mm between the bridge abutments

5. Place short Pontic strips and contour the base surface of the pontic

WORKING PROCEDURE

short

short

short

short

medium-size

long

short

medium-size

long

Page 28

28

CEMENTATION

Adhesive cementation of metal-free restorations results in a tight bond between the restoration and prepared tooth. Such

a bond enhances the fracture resistance of the restoration. The translucent shade of the adhesive and the virtually invisible

margins promote the aesthetic appearance of the restoration. The following materials are suitable for the adhesive

cementation method:

–Variolink II (CEM Kit Professional Set or CEM Kit Esthetic Cementation System)

– Multilink

Temporary cementation

Zinc oxide containing temporary cements are suitable for metal-free long-term temporaries that are intended to remain

in the oral cavity for a maximum duration of 12 months.

Preparing the restoration for cementation

The contact surfaces of the restoration are roughened with type 100 Al203at 1 bar (14.5 psi) pressure in the laboratory

to promote chemical bonding with the luting composite. Following the try-in and subsequent cleaning, the contact

surfaces are again roughened using a 25 µm finishing diamond. This step is carried out immediately before adhesive

cementation. Finally the surfaces are silanized (e.g. with Monobond S) to enable a chemical bond.

Please refer to the SR Adoro Clinical Guide for further information on appropriate

cementation techniques.

Page 29

29

Vectris

®

SINGLE CROWNS

SINGLE CROWNS

Page 30

30

VECTRIS SINGLE CROWNS

Tip:

It is advisable to pour a duplicate die to carry out the vacuum-forming process, as the sharply pointed incisal edges may

cause delamination of the stone die.

Starting situation

Fabricate a master model or a model with detachable segments on the basis of the impression in the usual manner. Expose

and mark the preparation margin. It is advisable to apply a sealer to harden the surface and to protect the stone die. The

application of the sealer must not cause any changes in the dimension of the stone die. Subsequently, a spacer can be

applied, depending on the customary working method.

Working method for different preparations

The following instructions describe the procedure for a flat occlusal preparation (Version A) and a deep occlusal preparation

(Version B).

Fabricate a model with detachable segments. Mark the preparation margins...

…and apply a sealer to harden the surface. Completed working die.

Version A

Flat occlusal preparation

Version B

Deep occlusal preparation

Page 31

31

Fabricating the silicone matrix

Silicone matrix made of laboratory silicone (Sil-Tech)

Remove the individual dies from the model. Carefully cover the die with laboratory silicone and adapt the material

exactly to the preparation margin. Prepare a shoulder approx. 1 cm down from the preparation margin to facilitate the

repositioning of the Transil matrix.

Tip:

Smooth out the exterior surface with a Vectris foil while the material is still soft. Mark the laboratory silicone and Transil

with a waterproof pen to obtain an exact repositioning of the matrices.

SINGLE CROWNS

Fit the laboratory silicone to the die in a conical shape. Fit the laboratory silicone to the die in a conical shape and prepare a shoulder approx. 1 cm

down from the preparation margin.

Version A

Flat occlusal preparation

Version B

Deep occlusal preparation

Silicone matrix made of Transil

If a deep occlusal preparation (Version B) is present, prepare a second matrix using Transil (transparent silicone). Separate

the laboratory silicone with a thin coat of Vaseline to prevent the two silicone materials from sticking to each other. Insert

the Transil cartridge into the dispenser, mount a new mixing tip and apply Transil to the die in a single step. Transil should

be applied in a layer thickness of approx. 3 to 6 mm to obtain sufficient stability. The setting reaction may be accelerated

by using a hot air dryer. After the material has set, smooth out the exterior surface to enhance the passage of light.

Subsequently, remove the Transil matrix from the die.

Apply a thin coat of Vaseline to the laboratory silicone and then apply Transil. Smooth out the exterior surface of the Transil matrix with a scalpel.

Page 32

32

Sealing the dies

Vectris Model Separator is applied in two coats. Apply the first layer slightly more generously than the second one and

make sure to fully cover all areas of the die. Watch out for sharp edges in particular. Allow the first layer to react for

3 minutes. Subsequently, apply the second layer of Vectris Model Separator in a thin coating, invert the die and allow to

dry for 3 minutes.

Apply a generous coating of Vectris Model Separator and allow it to dry for 3 minutes.

Apply the second layer of Vectris Model Separator in a thin coating,invert the die and allow it

to dry for 3 minutes.

Version A

Flat occlusal preparation

Version B

Deep occlusal preparation

Preparing the die for the vacuum-forming process

Before removing the Vectris Single from the packaging, adjust the height of the model carrier in the vacuum former so that

the distance between the model and the upper rim of the container is 2 to max. 3 cm. If necessary, further adjust the

height by means of the spacer rings. Finally, check the position of the membrane.

Check the height of the model on the model carrier and, if necessary, adjust by means of the spacer rings.

Version A

Flat occlusal preparation

Version B

Deep occlusal preparation

2– max. 3 cm

2– max. 3 cm

Page 33

33

SINGLE CROWNS

Vacuum-forming the Vectris Single – Version A

Application of Vectris in the Vectris VS1 framework former: Position the die in the framework former, apply a small

amount of Vectris Glue to the die to keep Vectris Single in place while it is on the die. Remove the Vectris Single from the

light-protected package, place Vectris Single on the die using tweezers and lightly press it into place. Next, cover the Vectris

Single with a Vectris foil to reduce the inhibited layer. Then, close the Vectris VS1 unit and start Program 1 to commence

the vacuum-forming and polymerization process. The program takes 10 minutes to complete.

Position the die in the Vectris VS1 unit; apply a small amount of Vectris Glue to the die.

Remove the Vectris Single from the light-protected package; place it on the die with tweezers and lightly press it into place.

Cover with Vectris foil; start Program 1 for the vacuum-forming and polymerization process.

Page 34

34

Vacuum-forming the Vectris Single – Version B

Application of Vectris outside the Vectris VS1 framework former: Remove the Vectris Single from the light-protected

package and place it on the die with tweezers. Place the Transil matrix on the Vectris Single in the correct position, push it

downwards and mount the die on the model carrier of the Vectris VS1.

Remove the Vectris Single from the light-protected package and place it on the sealed die.

Place the Transil matrix over the Vectris Single and press it downwards.

Position the die with the Transil matrix in the VS1. Start the vacuum-forming and

polymerization process. The program takes 10 minutes to complete.

Page 35

35

SINGLE CROWNS

Removing the framework from the die

After completion of the vacuum-forming process, first remove the Vectris foil or Transil matrix from the framework and

then carefully remove the framework from the die while it is still warm. If the restoration is removed at a later stage, it is

advisable to warm up the stone die by means of water vapor. The framework exhibits an even layer thickness after it has

been removed from the die.

Upon completion of the vacuum-forming process, remove the Vectris foil or

Transil matrix from the framework.

Excellent adaptation of the occlusal surface

Version A

Flat occlusal preparation

Version B

Deep occlusal preparation

Page 36

36

Finishing

Remove large areas of excess material with a separating disk and then trim the remaining excess material with cross-cut

tungsten carbide burs. It is advisable to use a slow rotational speed and light pressure. The thickness of the walls, which

is 0.3 to 0.4 mm after the vacuum-forming process, must not be reduced by grinding. Trim the margins by

approx. 0.5 mm to the inner edge of the chamfer or shoulder preparation. Make sure that the framework continues to

be supported by the die after having trimmed the margins.

Remove large pieces of excess material with a separating disk.

The result

Trim the margins by approx. 0.5 mm using a tungsten carbide bur.

The SR Adoro Instructions for Use provide detailed information on the conditioning and veneering

of Vectris frameworks.

Page 37

37

Vectris

®

3-

UNIT ANTERIOR BRIDGES

3-

UNIT ANTERIOR BRIDGES

Page 38

38

3-

UNIT ANTERIOR BRIDGES

Starting situation

Fabricate a master model or a model with detachable segments on the basis of the impression in the usual manner. Expose

and mark the preparation margin. It is advisable to apply a sealer to harden the surface and to protect the stone die from

abrasion. The application of the sealer must not cause any changes in the dimension of the stone die. Subsequently, a

spacer can be applied, if this is the customary method of working.

Fabricate a model with detachable segments and apply a sealer.

Fabricating the duplicate model for the vacuum-forming process

Bridge constructions for the anterior region in particular often involve sharply pointed incisal edges. As these edges are

prone to delamination during the vacuum-forming process, a duplicate model has to be prepared. The master model is

utilized to contour the pontic (including the pontic/abutment contact layer), to check the fit of the restoration and to

veneer the framework. Pour the original impression a second time and create a small duplicate model for the vacuumforming process. Make sure to eliminate undercut areas to facilitate the subsequent application of the Transil matrix.

Fabricate a duplicate model from the original impression and eliminate undercut areas.

–A silicone, polyether or similar material should be used for impression taking as these materials provide an

optimum reproduction of detail. Additionally, the impressions taken with these materials can be poured

several times.

– Hydrocolloid and alginate materials are unsuitable and, besides, cannot be poured more than once.

The following pages provide instructions on how to fabricate the framework of a 3-unit Vectris bridge (full crown bridge)

for the anterior region. For posterior bridges, the Vectris material is placed in the Transil matrix in a similar technique as for

3-unit inlay-retained bridges. Further information that is relevant to the fabrication of posterior bridges can be found on

page 20 onwards.

Page 39

39

3-

UNIT ANTERIOR BRIDGES

Contouring the pontic

First, seal the dies with a wax/stone or resin/stone separator. Form the pontic on the master model in a shape- and cuspsupporting manner similar to the metal-ceramic technique, using wax or composite (Light Tray). This step helps to obtain a

homogeneous layer thickness in the following veneering material. The palatal or lingual abutment/pontic contact layers

should exhibit the following dimensions:

– surface: at least 3 x 3 mm

– thickness: at least 0.3 mm

– joint face of the connector: at least 3 x 3 mm

It is advisable to contour the pontic insert in a shape-and cusp-supporting design, depending on the space available. Check

the pattern in the articulator and adjust as necessary. If a full wax-up has been prepared, the wax rim may be used for

checking purposes.

Contour the pontic on the master model.

Check as to whether the minimum requirements are met by means of the wax rim.

Conduct a final check in the articulator.

Tip:

The pontic can be contoured using a tray material (Light Tray) and adjusted by grinding after completion of the

polymerization process.

≥ 3 mm

≥ 3 mm

Page 40

40

Transferring the pontic to the duplicate model

Transfer the fully contoured pontic to the duplicate model and use a small amount of wax to hold it in place. Block out the

basal surface of the pontic using laboratory silicone (Sil-Tech) in order to ensure that the following Transil matrix can be

removed easily. It is important to block out this area since it will determine the way in which the Vectris Frame wraps

around the Vectris Pontic. The portion of the basal surface that is in contact with the laboratory silicone should not be too

wide. The following instructions should be observed when transferring the pontic to the duplicate model:

1. Reduce the basal surface of the duplicate model and prepare retention.

2. Transfer the pontic to the duplicate model and hold it in place with a small amount of wax.

3. Block out the reduced basal surface using laboratory silicone (Sil-Tech).

4. Reduce the blocked out area by means of a scalpel or bur.

Reduce the basal surface of the duplicate model and transfer the pontic to the model.

Block out the basal reduction with laboratory silicone and then reduce the blocked out area.

Pontic on the duplicate model after completion of the transfer process.

Page 41

41

3-

UNIT ANTERIOR BRIDGES

Fabricating the Transil matrix

Separate the laboratory silicone with a thin coat of Vaseline to prevent the two silicone materials from sticking to each

other. Insert the Transil cartridge into the dispenser, mount a fresh mixing tip and apply Transil to the die and pontic in a

single step. Transil should be applied in a layer thickness of approx. 3 to 6 mm to obtain sufficient stability. The setting

reaction may be accelerated by using a hot air dryer. After the material has set, smooth out the exterior surface and form it

into a conical shape to enhance the passage of light. Subsequently, remove the Transil matrix from the die.

Apply a thin coating of Vaseline to the laboratory silicone and then apply Transil.

Smooth out the exterior surface of the Transil matrix and form it into a conical shape.

Tip:

A Vectris foil may be used to smooth out the exterior surface while it is still soft.

Tip:

In order to facilitate the flowing off of Vectris matrix material, small spillways may be cut into the palatal and labial

portions of the laboratory silicone after the Transil matrix has been removed.

Page 42

42

Sealing the dies

After having removed the matrix and cleaned the duplicate model, apply two layers of Vectris Model Separator. Apply the

first layer slightly more generously than the second one and make sure to fully cover all areas of the die. Watch out for

sharp edges in particular. Allow the first layer to react for 3 minutes. Subsequently, apply the second layer of Vectris Model

Separator in a thin coating, invert the model and allow it to dry for another 3 minutes.

Preparing the dies for the vacuum-forming process

Before removing the Vectris Single from the packaging, adjust the height of the model carrier in the vacuum former so that

the distance between the die and the upper rim of the container is 2 to max. 3 cm. If necessary, the height may be further

adjusted with the help of the spacer rings. Finally, check the position of the membrane.

Placing Vectris Pontic into the Transil matrix and vacuum-forming the pontic

Slightly moisten the Transil matrix with Vectris Glue to facilitate the adaptation of the Vectris Pontic strips. Remove the

Vectris Pontic from the light-protected package, cut it to the desired length, remove it from the foil and place it into the

Transil matrix using tweezers. Observe the schematic below when filling in the individual Vectris strips. Place the Transil

matrix on the duplicate model in the correct position, push it into place and mount the model on the model carrier of the

Vectris VS1. Start Program 1 to commence the vacuum-forming and polymerization process. The program takes 10 minutes

to complete.

Apply a generous coat of Vectris Model Separator and allow to dry for approx. 3 minutes. Apply the second layer of Vectris Model Separator in a thin coating and allow to dry for

3 minutes upside down.

Schematic of the order in which the individual Vectris strips have to be placed. Moisten the Transil matrix with Vectris Glue.

Page 43

43

3-

UNIT ANTERIOR BRIDGES

First, place a short Vectris strip… …then insert a long Vectris strip for the pontic/abutment inserts…

…and complete with medium-sized and short strips; place the pontic on the duplicate model.

The vacuum forming and polymerization process takes 10 minutes with Program 1.

Page 44

44

Important:

If it is impossible to avoid modifications involving grinding, then sandblast the entire pontic surface with type

100 Al2O3at 1 bar (14.5 psi) pressure.After sandblasting, remove residue by tapping it off and not by cleaning the

surfaces with steam or an air gun. If necessary, a clean disposable brush may be used for this purpose. Apply

Vectris wetting liquid immediately after having removed the residue. Use a disposable brush to apply the liquid

and allow it to react for 60 seconds. Disperse excess material with oil-free compressed air and replace the pontic

on the duplicate model.

Vacuum-forming the Vectris Frame

Remove only the Transil matrix; leave the pontic on the duplicate model. Remove any Vectris matrix material that has been

squeezed downwards, using an appropriate instrument. If the pontic inadvertently comes off along with the Transil matrix,

carefully remove it from the matrix and reposition it on the duplicate model. Do not grind or contaminate the pontic.

Subsequently, remove the Vectris Frame from the light-protected package and place it on the Vectris Pontic. Do not cut

slits into the Vectris Frame. Place the Transil matrix over the duplicate model, push it into place and position the model

at the centre of the container in the framework former. Start Program 1 to commence the vacuum-forming and

polymerization process. The program takes 10 minutes to complete.

Place the Vectris Frame on the pontic, place the Transil matrix over the model and press it into place.

The vacuum-forming process results in optimum shape and adaptation of the Vectris Frame.

Page 45

45

3-

UNIT ANTERIOR BRIDGES

Removing the framework from the die

Upon completion of the vacuum forming process, remove

the Transil matrix and lift the framework from the die. If the

framework cannot be readily removed, warm up the framework and the duplicate model by means of a steam jet and

then try again. Remove excess material using a separating

disk while the framework is still on the model.

Subsequently, carefully remove the framework from the die.

…and carefully remove the framework from the die, using an appropriate instrument.

Remove excess material while the framework is still on the model…

Page 46

46

Finishing

Remove excess material in the marginal areas with cross-cut tungsten carbide burs. It is advisable to use a slow rotational

speed and light pressure. The thickness of the walls, which is 0.3 to 0.4 mm after the vacuum forming process,

must not be reduced by grinding. Trim the marginal areas by approx. 0.5 mm to the inner edge of the chamfer or

shoulder preparation. Make sure that the framework continues to be supported by the die after trimming the margins.

Remove excess with tungsten carbide burs; thin out the margins…

The result

….and trim by approx. 0.5 mm to the inner edge of the chamfer or shoulder preparation.

The SR Adoro Instructions for Use provide detailed information on the conditioning and veneering of 3-unit

anterior bridges made of Vectris.

Page 47

47

Vectris

®

3-

UNIT INLAY-RETAINED BRIDGES

3-

UNIT INLAY

-

RETAINED BRIDGES

Page 48

48

3-

UNIT INLAY-RETAINED BRIDGES

Starting situation

Fabricate a master model or a model with detachable

segments on the basis of the impression in the usual

manner. Expose and mark the preparation margin. It is

advisable to apply a sealer to harden the surface and to

protect the stone die from abrasion. The application of the

sealer must not cause any changes in the dimension of the

stone die. Subsequently, a spacer can be applied, if this is

the customary method of working.

Fabricate a working model.

Page 49

49

3-

UNIT INLAY

-

RETAINED BRIDGES

Fabricating the duplicate model for the vacuum forming process

For inlay-retained bridges, the abutment teeth are cut to obtain an appropriate cavity for the abutment/pontic contact

surface. Consequently, a duplicate model has to be prepared. The master model is utilized to contour the pontic (including

the pontic/abutment contact layer), to check the fit of the restoration and to veneer the framework. Pour the original

impression a second time and create a small duplicate model for the vacuum-forming process. Make sure to eliminate

undercut areas to facilitate the subsequent application of the Transil matrix.

In addition, reduce the cusps of the abutment teeth in such a way that the height of the cavity measures at least 0.5 mm

to enable the Vectris fibres to adapt to the cavity effectively. The height may be marked with a pencil to facilitate the

following reduction.

Fabricate a duplicate model from the original impression and eliminate undercut areas.

Mark the height of the cavity and reduce the cusps.

Completed duplicate model for the vacuum-forming process

–A silicone, polyether or similar material should be used for impression taking as these materials provide an

optimum reproduction of detail. Additionally, the impressions taken with these materials can be poured

several times.

– Hydrocolloid and alginate materials are unsuitable and cannot be poured more than once.

Page 50

50

Contouring the pontic

First, seal the dies with a wax/stone or resin/stone separator. Contour the pontic on the master model in a cusp-supporting

manner similar to the metal-ceramic technique, using wax or composite (Light Tray). This step helps to obtain a

homogeneous layer thickness in the following veneering material. The occlusal abutment/pontic contact area in the cavity

should exhibit the following dimensions:

– cover the entire surface of the cavity

– length of the abutment/pontic area in the cavity: at least 4 mm

– thickness of the contact layer: at least 0.3 mm

– joint face of the connector: at least 3 x 3 mm

Check the pattern in the articulator and adjust as necessary. If a full wax-up has been prepared, the wax rims may be used

for checking purposes.

Contour the pontic on the master model.

Check the pattern in the articulator.

Conduct a final check of the duplicate model and check the dimensions of the pontic.

Tip:

The pontic can be contoured using a tray material (Light Tray) and adjusted by grinding after completion of the

polymerization process.

≥ 0.3 mm

≥ 3 mm

≥ 3 mm

≥ 4 mm

≥ 4 mm

Page 51

51

3-

UNIT INLAY

-

RETAINED BRIDGES

Transferring the pontic to the duplicate model

Transfer the fully contoured pontic to the duplicate model and use a small amount of wax to hold it in place. Block out the

basal surface of the pontic using laboratory silicone (Sil-Tech) in order to ensure that the following Transil matrix can be

removed effortlessly. It is important to block out this area because this determines the way in which the Vectris Frame is

wrapped around the Vectris Pontic. The portion of the basal surface that is in contact with the laboratory silicone should

not be too wide. It is advisable to follow the following instructions to transfer the pontic to the duplicate model:

1. Reduce the basal surface of the duplicate model and prepare retention

2. Transfer the pontic to the duplicate model and use a small amount of wax to hold it in place

3. Block out the reduced basal surface using laboratory silicone (Sil-Tech)

4. Reduce the blocked out area by means of a scalpel or bur

Reduce the basal surface of the duplicate model and transfer the pontic to the model.

Block out the reduced basal surface with laboratory silicone and then reduce the blocked out area.

The basal surface should not be too wide.

Pontic on the duplicate model after completion of the transfer process.

Page 52

52

Fabricating the Transil matrix

Separate the laboratory silicone with a thin coat of Vaseline to prevent the two silicone materials from sticking to each

other. Insert the Transil cartridge into the dispenser, mount a new mixing tip and apply Transil to the die and pontic in a

single step. Transil should be applied in a layer thickness of approx. 3 to 6 mm to obtain sufficient stability. The setting

reaction may be accelerated by using a hot air dryer. After the material has set, smooth out the exterior surface and form it

into a conical shape to enhance the passage of light. Subsequently, remove the Transil matrix from the die.

Apply a thin coating of Vaseline to the laboratory silicone and then apply Transil.

Smooth out the exterior surface of the Transil matrix and form it into a conical shape.

Tip:

A Vectris foil may be used to smooth out the outer surfaces while the matrix material is still soft.

Tip:

In order to facilitate the flowing off of the Vectris matrix matrial, small spillways may be cut into the palatal and labial

portions of the laboratory silicone after the Transil matrix has been removed.

Page 53

53

3-

UNIT INLAY

-

RETAINED BRIDGES

Sealing the dies

After having removed the matrix and cleaned the duplicate

model, apply Vectris Model Separator in two coats. Apply

the first layer slightly more generously than the second one

and make sure to fully cover all areas of the die. Watch out

for sharp edges in particular. Allow the first layer to react

for 3 minutes. Subsequently, apply the second layer of

Vectris Model Separator in a thin coating, invert the model

and allow it to dry for another 3 minutes.

Apply a generous coat of Vectris Model Separator and allow it to dry for approx. 3 minutes.

Apply the second layer of Vectris Model Separator in a thin coating and allow it to dry for

another 3 minutes upside down.

Page 54

54

Schematic of the order in which the individual Vectris strips have to be placed. Moisten the Transil matrix with Vectris Glue.

First, place a short Vectris strip on each cusp … …then place a long Vectris strip to establish the pontic/abutment contact surface…

Placing Vectris Pontic into the Transil matrix and vacuum-forming the pontic

Slightly moisten the Transil matrix with Vectris Glue to facilitate the adaptation of the Vectris Pontic strips. Remove the

Vectris Pontic from the light-protected package, cut it to the desired length, remove it from the foil and place it into the

Transil matrix using tweezers. Insert the individual strips as indicated in the schematic below. Then, place the Transil matrix

on the duplicate model in the correct position, press it into place and mount the model on the model carrier of the

Vectris VS1 framework former. Start Program 1 to commence the vacuum-forming and polymerization process. The

program takes 10 minutes to complete.

Preparing the model for the vacuum-forming process

Before removing the Vectris Pontic from the packaging, adjust the height of the model carrier of the vacuum former so

that the distance to the upper rim of the container is 2 to max. 3 cm. If necessary, the height may be further adjusted with

the help of the spacer rings. Finally, check the position of the membrane.

Page 55

55

Complete the buccal and palatal areas…

… and contour the base surface using short Vectris strips. Then place the pontic on the

duplicate model.

…and a medium-sized Vectris for the area between the bridge abutments.

The vacuum forming and polymerization process takes 10 minutes with Program 1.

3-

UNIT INLAY

-

RETAINED BRIDGES

Page 56

56

Important:

If it is impossible to avoid modifications involving grinding, then sandblast the entire pontic surface with type

100 Al2O3at 1 bar (14.5 psi) pressure.After sandblasting, remove residue by tapping it off and not by cleaning the

surfaces with steam or an air gun. If necessary, a clean disposable brush may be used for this purpose. Apply

Vectris wetting liquid immediately after having removed the residue. Use a disposable brush to apply the liquid

and allow it to react for 60 seconds. Disperse excess material with oil-free compressed air and replace the pontic

on the duplicate model.

Vacuum-forming the Vectris Frame

Remove the Transil matrix but leave the pontic on the duplicate model. Remove any Vectris matrix material that has been

squeezed downwards, using an appropriate instrument. If the pontic inadvertently comes off along with the Transil

matrix, carefully remove it from the matrix and reposition it on the duplicate model. Do not grind the pontic and avoid

contaminating it.

Subsequently, remove the Vectris Frame from the light-protected package and place it on the Vectris Pontic. Do not cut

slits into the Vectris Frame. Place the Transil matrix over the duplicate model, push it into place and position the model

at the centre of the container in the framework former. Start Program 1 to commence the vacuum forming and

polymerization process. The program takes 10 minutes to complete.

Place the Vectris Frame on the pontic; place the Transil matrix over the model and press it into place.

The vacuum-forming process results in an optimum shape and adaptation of the Vectris Frame.

Page 57

57

3-

UNIT INLAY

-

RETAINED BRIDGES

Removing the framework from the die

Upon completion of the vacuum forming process, remove

the Transil matrix and lift the framework from the die. If the

framework cannot be readily removed, warm up the framework and the duplicate model by means of a steam jet and

then try again. Remove excess material using a separating

disk while the framework is still on the model.

Subsequently, carefully remove the framework off the die.

…and carefully remove the framework off the die, using an appropriate instrument.

Remove excess material while the framework is still on the model…

Page 58

58

Finishing

Remove excess material in the marginal areas with cross-cut tungsten carbide burs. It is advisable to use a slow rotational

speed and light pressure. The thickness of the walls, which is 0.3 to 0.4 mm after the vacuum forming process,

must not be reduced by grinding. The pontic/abutment contact layer should cover the entire surface of the cavity.

Remove excess with tungsten carbide burs and fit the restoration into the preparation.

The result

The SR Adoro Instructions for Use provide detailed information on the conditioning and veneering of 3-unit

inlay-retained bridges made of Vectris.

Page 59

59

Page 60

Ivoclar Vivadent AG

Bendererstrasse 2

FL-9494 Schaan

Liechtenstein

Tel. +423 235 35 35

Fax +423 235 33 60

www.ivoclarvivadent.com

Ivoclar Vivadent Pty. Ltd.

1 – 5 Overseas Drive

P. O. Box 367

Noble Park,Vic. 3174

Australia

Tel. +61 3 979 595 99

Fax +61 3 979 596 45

Ivoclar Vivadent Ltda.

Rua Maestro João Gomes de

Araújo 50; Salas 92/94

Sao Paulo, CEP 02332-020

Brasil

Tel. +55 11 69 59 89 77

Fax +55 11 69 71 17 50

Ivoclar Vivadent Inc.

2785 Skymark Avenue, Unit 1

Mississauga

Ontario L4W 4Y3

Canada

Tel. +1-905 238 57 00

Fax +1-905 238 57 11

Ivoclar Vivadent Marketing

Ltd.

Calle 134 No. 13-83, Of. 520

Bogotá

Colombia

Tel. +57 1 627 33 99

Fax +57 1 633 16 63

Ivoclar Vivadent SAS

B.P. 118

F-74410 Saint-Jorioz

France

Tel. +33 450 88 64 00

Fax +33 450 68 91 52

Ivoclar Vivadent GmbH

Dr. Adolf-Schneider-Str. 2

D-73479 Ellwangen, Jagst

Germany

Tel. +49 (0) 79 61 / 8 89-0

Fax +49 (0) 79 61 / 63 26

Ivoclar Vivadent UK Limited

Meridian South

Leicester

LE19 1WY

Great Britain

Tel. +44 116 265 40 55

Fax +44 116 265 40 57

Ivoclar Vivadent s.r.l.

Via dell’Industria 16

I-39025 Naturno (BZ)

Italy

Tel. +39 0473 67 01 11

Fax +39 0473 66 77 80

Ivoclar Vivadent S.A. de C.V.

Av. Mazatlán No. 61, Piso 2

Col. Condesa

06170 México, D.F.

Mexico

Tel. +52 (55) 55 53 00 38

Fax +52 (55) 55 53 14 26

Ivoclar Vivadent Ltd

12 Omega St, Albany

PO Box 5243 Wellesley St

Auckland, New Zealand

Tel. +64 9 914 9999

Fax +64 9 914 9990

Ivoclar Vivadent Polska

Sp. z.o.o.

ul. Jana Pawla II 78

PL-01-501 Warszawa

Poland

Tel. +48 22 635 54 96

Fax +48 22 635 54 69

Ivoclar Vivadent S.A.

c/Emilio Muñoz, 15

Esquina c/Albarracín

E-28037 Madrid

Spain

Tel. + 34 91 375 78 20

Fax + 34 91 375 78 38

Ivoclar Vivadent AB

Dalvägen 16

S-169 56 Solna

Sweden

Tel. +46 8 514 93 930

Fax +46 8 514 93 940

Ivoclar Vivadent, Inc.

175 Pineview Drive

Amherst, N.Y. 14228

USA

Tel. +1 800 533 6825

Fax +1 716 691 2285

Ivoclar Vivadent – worldwide

Date information prepared: 01/2004

These materials have been developed solely for use

in dentistry. Processing should be carried out

according to the Instructions for Use. Liability cannot

be accepted for damages resulting from failure to

observe the Instructions or the stipulated area of

application. The user is responsible for testing the

material for its suitability for any purpose not

explicitly stated in the Instructions. Descriptions and

data constitute no warranty of attributes and are

not binding.

Printed in Liechtenstein

© Ivoclar Vivadent AG, Schaan / Liechtenstein

579628/0104/0.5/e/BVD

Loading...

Loading...