Page 1

WORKSHOP MANUAL

727 (N SERIES)

ENGINE CONTROL SYSTEM

(4HK1 ENGINE)

SECTION 1A

International Service & Parts

Tokyo, Japan

Page 2

N O T I C E

Before using this Workshop Manual to assist you in performing

vehicle service and maintenance operations, it is recommended

that you carefully read and thoroughly understand the information

contained in Section - 0A under the headings “GENERAL REPAIR

INSTRUCTIONS” and “HOW TO USE THIS MANUAL”.

All material contained in this Manual is based on the latest product

information available at the time of publication.

All rights are reserved to make changes at any time without prior

notice.

Page 3

Engine Control System 1A-1

ENGINE

Engine Control System

CONTENTS

Engine Control System . . . . . . . . . . . . . . . . . . . . 1A-2

Precautions on Service . . . . . . . . . . . . . . . . . . . 1A-2

Function and Operation. . . . . . . . . . . . . . . . . . . 1A-4

Component Layout . . . . . . . . . . . . . . . . . . . . . 1A-20

Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . 1A-25

Strategy-Based Diagnostics . . . . . . . . . . . . . . 1A-31

Functional Check List . . . . . . . . . . . . . . . . . . . 1A-37

Hearing Diagnostic . . . . . . . . . . . . . . . . . . . . . 1A-37

On-Board Diagnostic (OBD) System Check . . 1A-39

Inactive CHECK ENGINE Lamp (MIL) . . . . . . 1A-41

CHECK ENGINE Lamp (MIL) Remains Active 1A-44

Engine Cranks But Will Not Run. . . . . . . . . . . 1A-46

Diagnosis with Tech 2 Scan Tool. . . . . . . . . . . 1A-48

Diagnostic Chart . . . . . . . . . . . . . . . . . . . . . . . 1A-67

DTC11 - No Signal CKP Sensor . . . . . . . . . . . 1A-73

DTC13 - TCV Fault . . . . . . . . . . . . . . . . . . . . . 1A-75

DTC14 - Pump ROM Fault . . . . . . . . . . . . . . . 1A-78

DTC15 - Pump Cam Sensor (NE Sensor)

Short Break Fault . . . . . . . . . . . . . . . . . . . . . . 1A-80

DTC16 - No Signal from Pump Cam Sensor

(NE Sensor) . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-82

DTC21 - ECT Sensor Fault. . . . . . . . . . . . . . . 1A-84

DCT23 - IAT Sensor Fault. . . . . . . . . . . . . . . . 1A-88

DTC24 - AP Sensor Output Fault . . . . . . . . . . 1A-91

DTC25 - VS Sensor Circuit Fault . . . . . . . . . . 1A-95

DTC31 - Idle Up Volume Fault . . . . . . . . . . . . 1A-98

DTC32 - MAP Sensor Fault . . . . . . . . . . . . . 1A-101

DTC34 - Exhaust Brake Open Wiring Fault . 1A-104

DTC35 - Neutral Switch Signal Fault . . . . . . 1A-106

DTC36 - Clutch Switch Signal Fault

(M/T Vehicle only) . . . . . . . . . . . . . . . . . . . . . 1A-108

DTC41 - FT Sensor Cir cuit High Voltage . . . 1A-110

DTC51 - Atmospheric Pressure Sensor Fault 1A-113

DTC52 - ECM Internal Fault . . . . . . . . . . . . . 1A-114

DTC53 - Engine Driver Unit Fault . . . . . . . . . 1A-116

DTC55 - Pump Unmatched

(Difference from ECM Specifications). . . . . . 1A-118

DTC65 - Idle Position Switch Fault . . . . . . . . 1A-120

Symptom Diagnosis Chart . . . . . . . . . . . . . . 1A-122

Hard Starting. . . . . . . . . . . . . . . . . . . . . . . . . 1A-123

Vehicle Speed Variation . . . . . . . . . . . . . . . . 1A-127

Lack Power or Faulty Response . . . . . . . . . . 1A-130

Unstable Idling . . . . . . . . . . . . . . . . . . . . . . . 1A-134

Engine Not Stall . . . . . . . . . . . . . . . . . . . . . . 1A-137

Starter Motor does Not Run . . . . . . . . . . . . . 1A-139

Quick On Start (QOS) System does Not

Operate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-142

Excessive Black Smoke in Exhaust Gas. . . . 1A-144

Excessive White Smoke in Exhaust Gas . . . 1A-147

Noisy Engine. . . . . . . . . . . . . . . . . . . . . . . . . 1A-149

Nasty Smell. . . . . . . . . . . . . . . . . . . . . . . . . . 1A-152

Poor Fuel Economy. . . . . . . . . . . . . . . . . . . . 1A-155

Excessive Engine Oil Consumption . . . . . . . 1A-159

Large Engine Vibration . . . . . . . . . . . . . . . . . 1A-161

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . 1A-164

Wiring Harness Repair: Shielded Cable. . . . . . 1A-165

Removal Procedure . . . . . . . . . . . . . . . . . . . 1A-165

Installation Procedure . . . . . . . . . . . . . . . . . . 1A-165

Twisted Leads . . . . . . . . . . . . . . . . . . . . . . . . . 1A-166

Removal Procedure . . . . . . . . . . . . . . . . . . . 1A-166

Installation Procedure . . . . . . . . . . . . . . . . . . 1A-166

Weather-Pack Connector. . . . . . . . . . . . . . . . . 1A-168

Removal Procedure . . . . . . . . . . . . . . . . . . . 1A-168

Installation Procedure . . . . . . . . . . . . . . . . . . 1A-168

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . 1A-169

Com-Pack III. . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-170

General Information . . . . . . . . . . . . . . . . . . . 1A-170

Metri-Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-171

Removal Procedure . . . . . . . . . . . . . . . . . . . 1A-171

Installation Procedure . . . . . . . . . . . . . . . . . . 1A-171

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . 1A-171

Page 4

1A-2 Engine Control System

Engine Control System

Precautions on Servic e

Circuit Test Tools

Unless otherwise specified in diagnostic procedures,

do not use Test Light to diagnose the powertrain

electrical system. When diagnostic procedures need

probe connector, use Connector Test Adapter Kit 58840-0385-0.

On-Market Electrical Equipment and Vacuum

Devices

On-market electrical equipment and vacuum devices

refer to those components that will be installed to

vehicles after shipme nt from manufacturing plants. Be

careful that installation of these components is not

considered during the process of vehicle design.

CAUTION:

Do not install on-market vacuum devices to

vehicles.

CAUTION:

Connect on-market electrical equipment, as well as

its power supplies and grounds, to the circuits

isolated from the electronic control system.

The on-market electrical equipment, even when

installed to vehicles in normal manner, may bring

functional troubles to the electronic control system.

Affected devices include those not connected to the

vehicle electrical equipment system, for example,

mobile phones or radios. Therefore, when you intend to

diagnose the powertrain, check such the on-market

electrical equipment has not been installed to the

vehicle and, if installed, remove it. If faults still occur

even after removal of on-market electric al equipment,

diagnose the vehicle according to normal procedures.

List of Abbreviations

Damage by Electrostatic Discharge

Electronic components used in the electronic control

system are designed to wor k at very low volt ages and,

for this reason, they are susceptible to damage by

electrostatic discharge and some types of electronic

components may be damaged even by the static

electricity of less than 100 V that is usua lly not sens ed

by persons. Persons’ sensitivity level is 4,000 V.

Persons are electrostatically charged in various ways

and the most typical el ectrification sources are fric tion

and induction. Shown below are examples.

• Electrification by friction occurs when a person

slides on the seat in the vehicle.

• Electrification by i nduction occurs when a person

with insulating shoes is standing near a highly

electrifiable substance and touches a ground

momentarily. Electric charges with the same

polarity flow out and resultantly the person is

charged at high opposite polarity. Since static

electric charges cause damages, it is important

when you handle or test electronic components.

CAUTION:

To prevent damages by electrostatic discharge,

follow the guidelines shown below.

• Do not touch ECM connector pins as well as

electronic components soldered to the ECM

circuit board.

• Do not unpack each replacement component

until preparations are completed for the

component.

• Before taking out a component from the

package, connect the package to the normal

grounding line of the vehicle.

• When you intend to slide on the seat, change

the posture from standing to sitting, or wa lk by

a certain distance to handle a component,

touch an appropriate grounding material.

Abbreviation Original form Meaning in this manual

A/C Air Conditioner Air conditioning units (cooler, heater, etc.)

AP Accelerate Position Depressing stroke of accelerator pedal

CKP Crankshaft Position Rotating reference signal of crankshaft

CMP Camshaft Position Rotating reference signal of pump camshaft

DLC Data Link Connector DLC connector (Tech 2 communication connector)

DTC Diagnosis Trouble Code DTC code

DVM Digital Volt Meter Special service tool (part No. 5-8840-0366-0)

ECT Engine Coolant Temperature Coolant temperature

ECM Engine Control Modulle Engine control computer

EDU Engine Driver Unit Fuel pump spill valve drive unit

Page 5

Engine Control System 1A-3

Abbreviation Original form Meaning in this manual

EGR Exhaust Gas Recirculation Exhaust gas recirculation

ISM Intake Step Motor Intake throttle valve drive motor

ITP Intake Throttle Position Intake throttle valve opening

MIL Malfunction Indicator Lamp CHECK ENGINE Lamp

SPV Spill Control Valve Valve for high pressure circuit in the fuel pump

SW Switch

TCV Timing Control Valve Injection timing control valve in the fuel pump

Key SW Key switch Starter switch

Wire Color

All wiring harnes ses are i den tifi ed us in g c ol ored jacket.

The wiring harness used for the main circuit in an

electrical system is i den tif ied wi th sin gl e c olor whi le the

wiring harness us ed for th e sub -circui t is id entifi ed with

color stripe. The following rule is used in each wiring

diagram to indicate size and color of a wiring harness.

eg. : 0.5 GRN / RED

Legend

1. Red (stripe color)

2. Green (base color)

3. Harness size (0.5 mm

Symbol Color Symbol Color

B Black BR Brown

W White LG Light green

RRedGRGray

1

2

3

LNW21ASH000101-X

2

)

G Green P P ink

Y Yellow LB Light blue

L Blue V Violet

O Orange

Page 6

1A-4 Engine Control System

Function and Operation

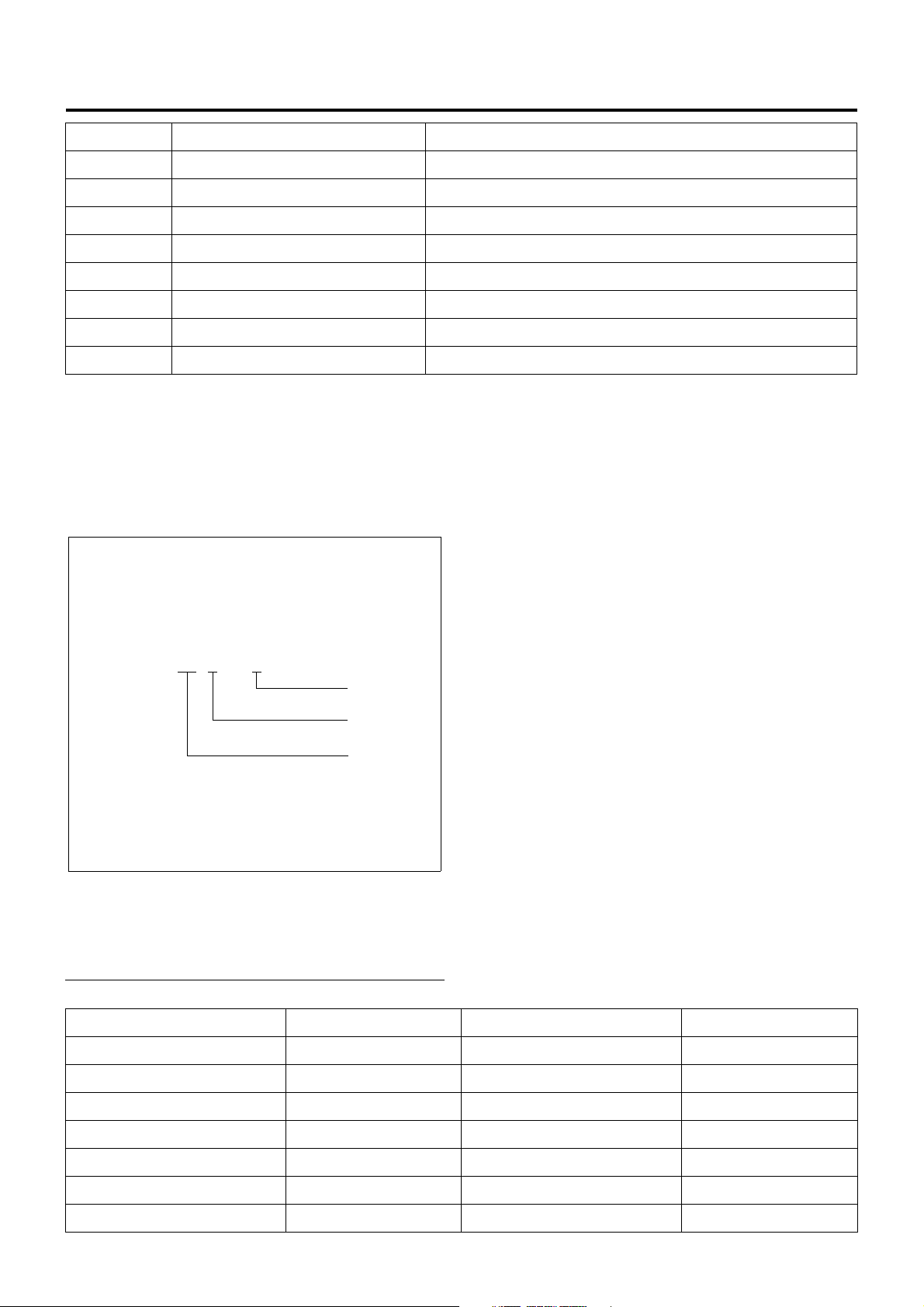

Electronic Control System

The electronic control system processes the data,

which has been collected with various types of sensors,

by means of the control program installed to ECM

(engine control module) to totally control engine

parameters such as fuel injection amount, injection

timing, engine startup, altitude compensation, and

EGR.

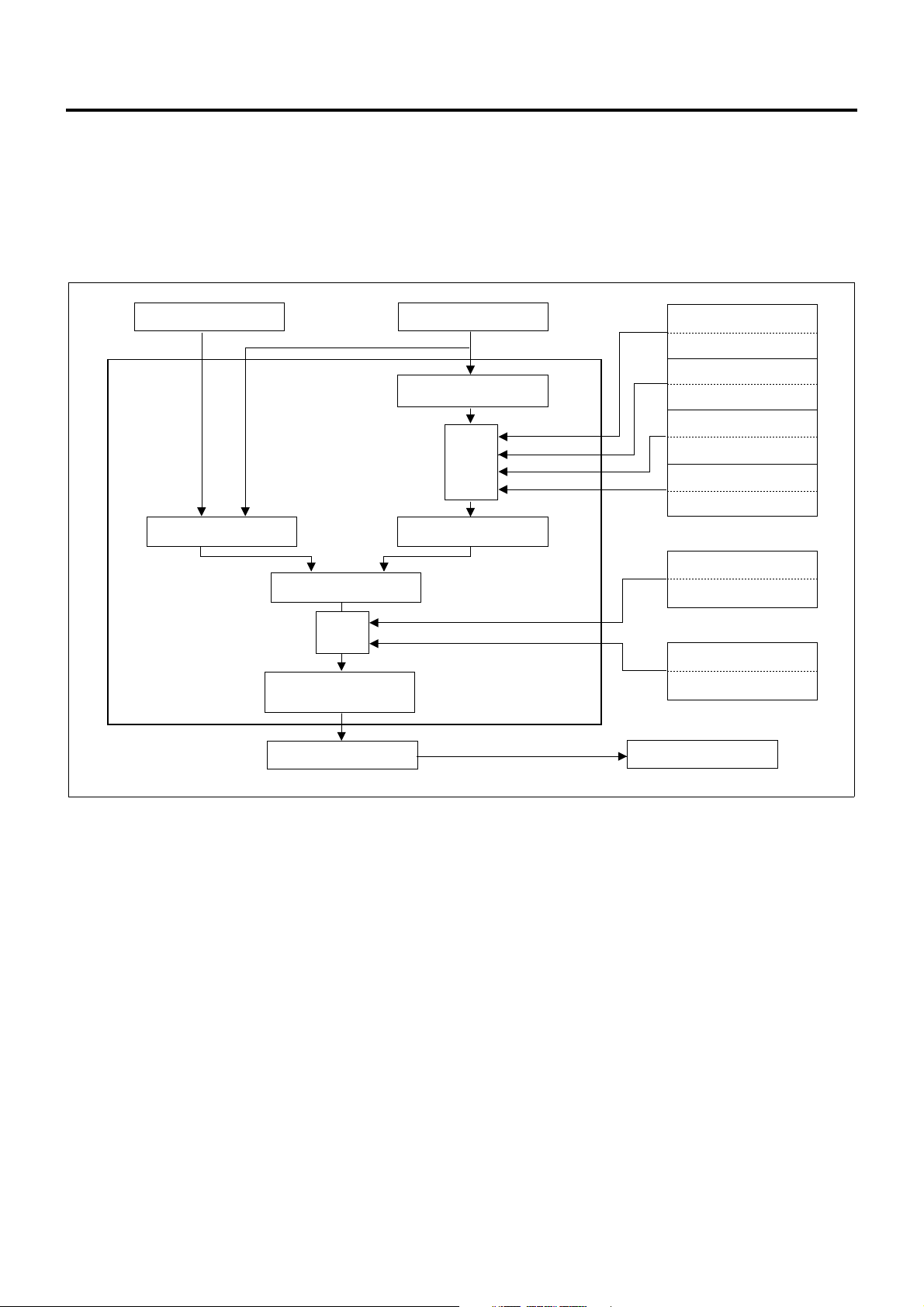

Sensor Actuator Control

Engine Rotating Speed

(Built-in Injection Pump)

Crankshaft Position

Accelerator Position

Coolant Temperature

Fuel Temperature

(Built-in Injection Pump)

Intake Air Pressure

Vehicle Speed

ECM

Engine Driver Unit

Injection Pump

Spill Control Valve

Timing Control Valve

EGR Valve

Engine

Control

Module

Intake Throttle Valve

Exhaust Magnetic Valve

Fuel Injection Volume

Control

Fuel Injection Timing

Control

Idle Rotating Speed

Control

Starting Control

Altitude Control

EGR Control

Intake Air Throttle

Control

Exhaust Brake Control

Idle Up Volume

Intake Air Temperature

Atmospheric Pressure

(Built-in ECU)

ECM

ECM Description

The ECM is mounted in the glove box. The ECM

monitors va ri ou s da ta se n t fr om d iv e rsi fi e d se ns or s a n d

controls systems in the powertrain. The ECM

diagnoses these s ystems to detect faults with resp ect

to system operations and inform the driver of faulty

condition via the CHECK ENGINE Lamp (MIL) and

stores DTCs (diagnosti c trouble codes ). DTC identifi es

the trouble generation area to aid repairs by service

operators.

Glow Plug

Glow Lamp

CHECK ENGINE Lamp

Swirl Change-Over Valve

Warm-Up System

Control

Starting Aid Control

Self Diagnosis

Intake Air Swirl Control

LNW21ALF000301-X

Function of ECM

ECM supplies 5 V and 12 V voltages to various sensors

and switches. Since powers are supplied via high

resistances in ECM , Test Light, eve n when connected

to the circuit, will not be lit. In a spe cial case, a normal

voltmeter does not indicate correct values since the

resistance of the instru ment is to o low. To get accu rate

readings, you need a digital voltmeter whose input

impedance is at least 10 M Ω. The special tool 5-88400366-0 is a pro per ch oice fo r this m easurement. In t he

ECM, the output circuit is con trolled by regulating the

Page 7

Engine Control System 1A-5

grounding system or power circuit via transistor or

either of the devices listed below.

• Output driver module (ODM)

• Quad drive module (QDM)

ECM and Components

The ECM is designed to offer excellent drivability and

fuel economy while achieving exhaust gas emission

control requirements. The ECM monitors engine and

vehicle functions via various electronic sensors such as

CKP (crank position) and VS (vehicle speed) sensors.

Voltages from ECM

The ECM supplies reference voltages to various

switches and sensors. Resistances of the ECM are

very high and this allows the ECM to supply voltages to

these devices, and voltag es actually applied to circuits

are low and even connecting Test Light to individual

circuits may fail turn-on. Since the voltmeter normal ly

used in service factories has low input impedance,

correct readings may not be obtained . To get a ccurate

readings, a digi tal voltm eter whose i nput impeda nce is

10 MΩ (for example, 5-8840-0366-0) should be used.

Input/output devices of the ECM include analog-todigital converter, signal buffer, counter, and special

driver. By using electronic switches, th e ECM controls

most system components and turning off a switch

closes the ground circuit. These switches are divided

into four-switch or seven-s wit ch groups, and the former

group is called quad dr i ver m odu le ( QD M) an d c ontro ls

up to four output pins respectively while the latter group

is called output driver module (ODM) and controls up to

seven outputs respectively . Note that all the outputs are

necessarily not used in the control.

Electrically Erasable Programmable ROM

(EEPROM)

EEPROM is a permanent memory chip and soldered to

the board in the ECM. EEPROM stores program and

calibration data, both of which are necessary for the

ECM to control the powertrain. Different from

conventional ROMs, EEPROM cannot be replaced with

new component. If EEP ROM fails, the complete ECM

assembly must be replaced with new one.

engine fault to the user.

In a service factory, 4 pins and 6 pins of DLC (data link

connector) can be short to check the DTC while the

CHECK ENGINE Lamp (MIL) is flashing.

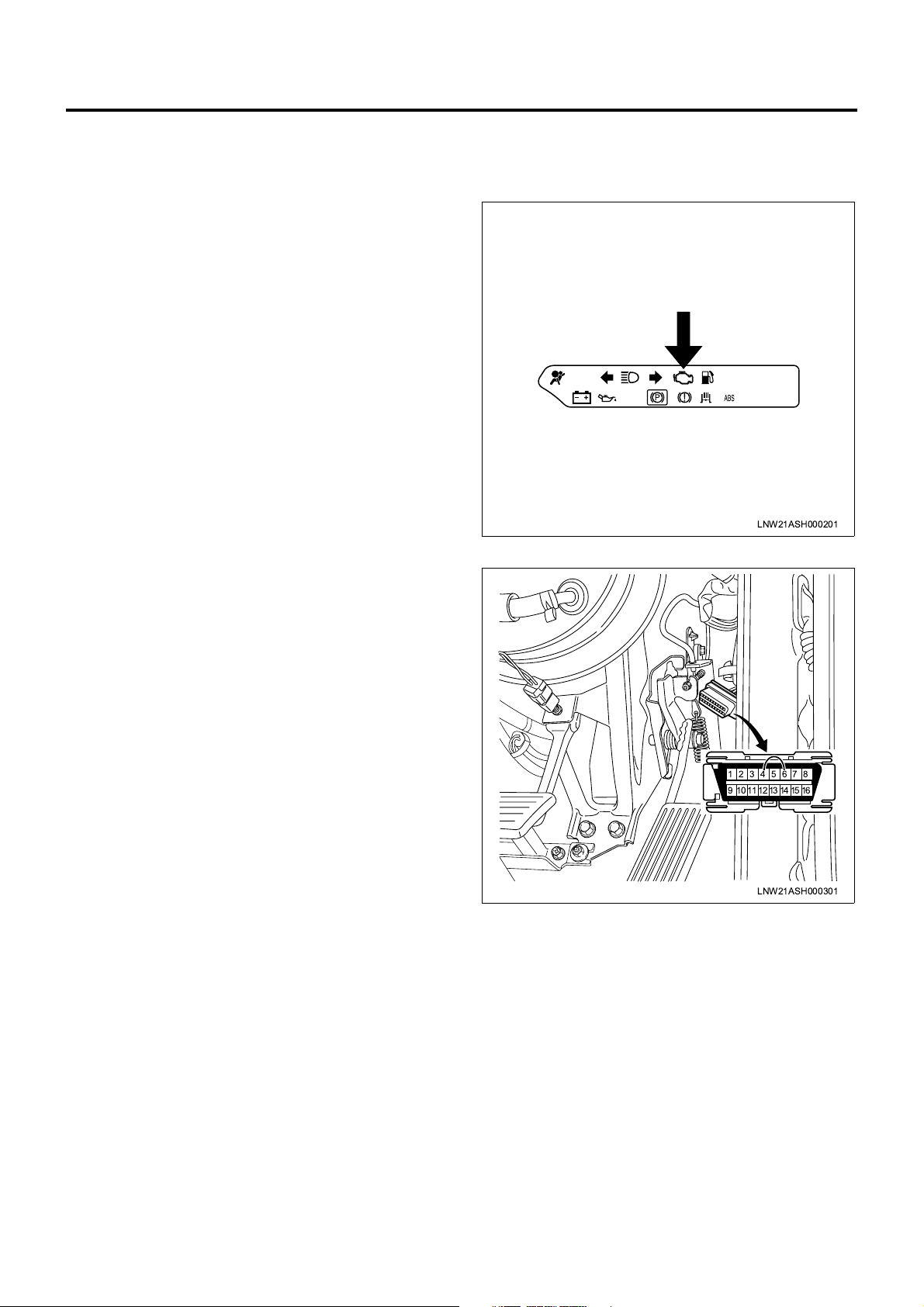

LNW21ASH000201

87654321

161514131211109

LNW21ASH000301

Precautions on ECM Service

The ECM is designed to withstand ordinary currents

used in operations of a vehicle. Be careful that the

circuits must not be overloaded. To test the ECM to

check open wiring or short, ECM circuits must be

connected to the ground or voltages must not be

applied to the ECM. To test ECM circuits, the digital

voltmeter 5-8840-0366-0 should always be used.

CHECK ENGINE Lamp (MIL)

Used as a means of communication between ECM and

user usually in the user mode, by light on and off. If this

lamp illuminates during operation, it warns some

Page 8

1A-6 Engine Control System

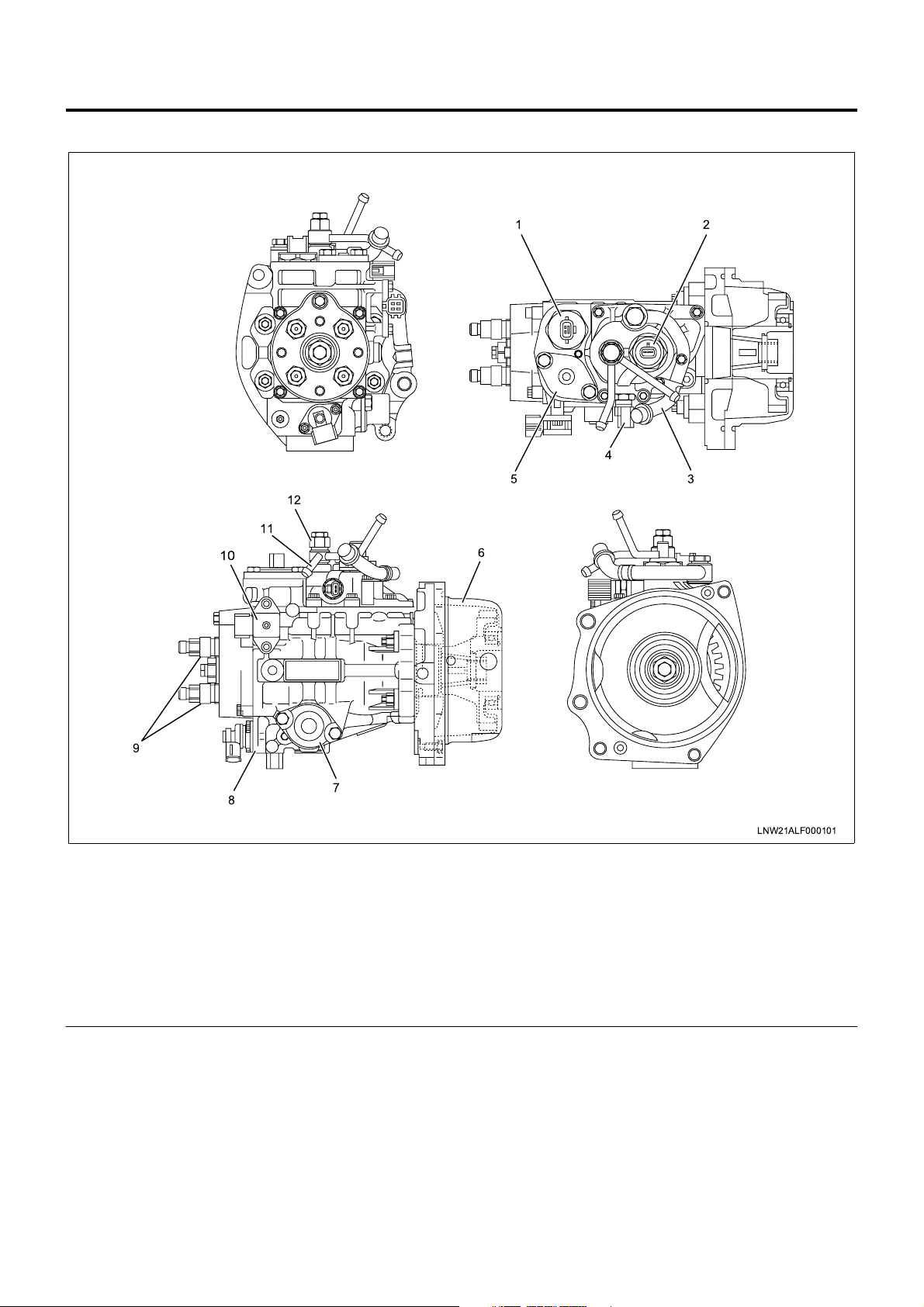

Electronically Controlled Distributor Injection Pump

12

11

10

12

4

5

6

3

9

8

7

Legend

1. Spill control valve

2. Pump cam position sensor (engine speed

sensor)

3. Inlet pipe

4. Fuel temperature sensor

5. Accumulator

6. Bearing cover

An electronically contr olled distribu tor inj ectio n pump is

employed to meet the requirements of the long-term

exhaust gas control without impairing the fuel efficiency

and output. These features allow finer particles of

injected fuel, and optimum injection timing and injection

amount while the vehicle is traveling, which was

impossible with the former injection pump.

LNW21ALF000101

7. Timer

8. Timing control valve

9. Delivery valve holder

10. Compensation ROM

11 . Overflow pipe

12. Overflow valve

Fuel Dehumidifying Agent

Sliding parts in the in jec ti on p ump are lubricated by t he

fuel (light oil) as in the ex isting d istr ibutor ty pe in jecti on

pump. If dehumidifying agent is mixed in the fuel, it

may exert adverse influence on the sliding parts.

Particularly, dehumidifying agent of alcohol type is

characterized by introducing moisture into water,

causing rust generation. It should be explained to

customers not to use fu el dehumid ifying ag ent or other

fuel additives.

Page 9

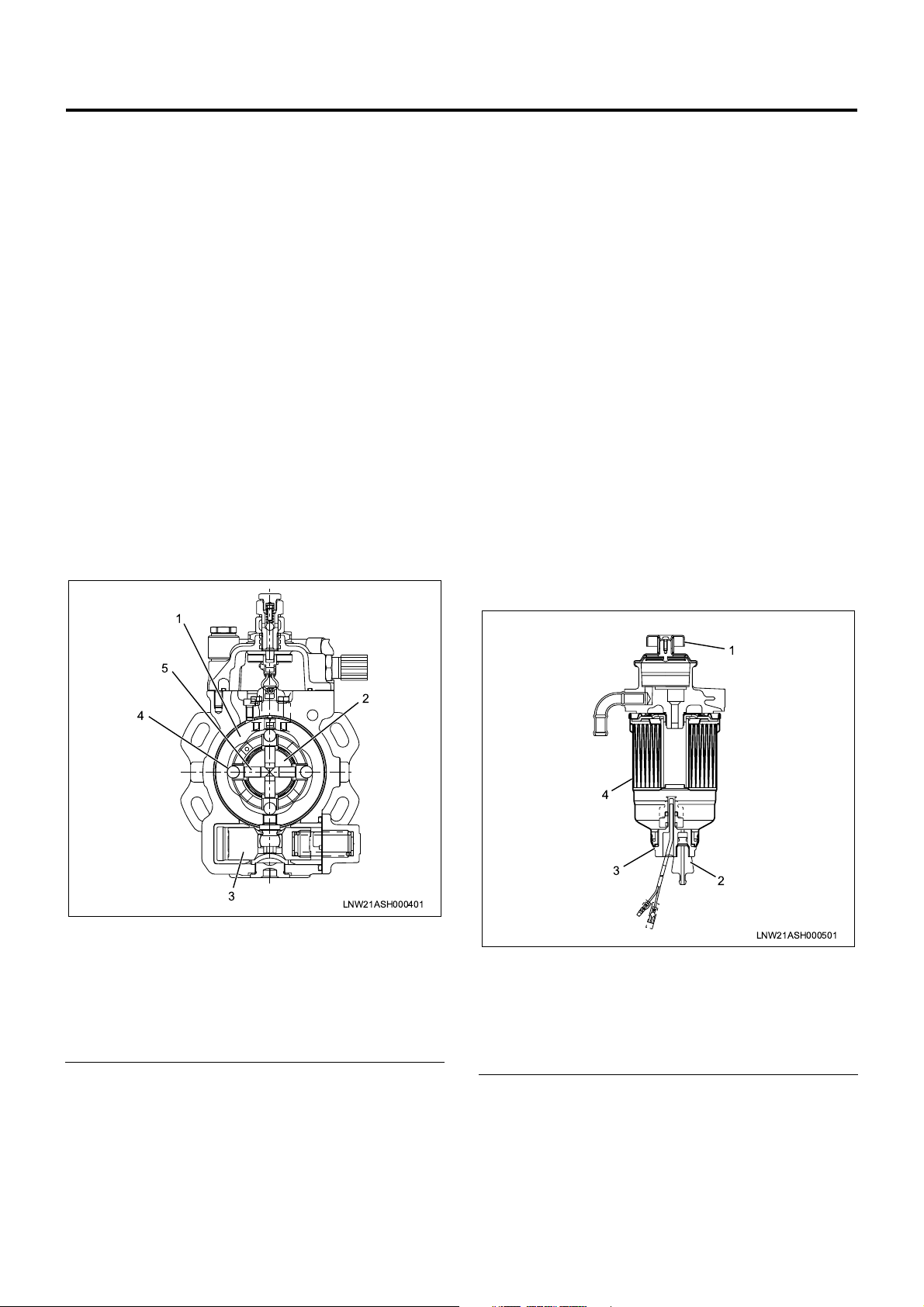

Structure and Operation

1. Higher pressure of injection fuel

An inner cam with a cam ring and radial plunger

are used to in crease the pressure o f the injection

fuel.

The cam ring is supported on th e pump body side

and provided with projections (cams) on the

internal periphery.

Four plungers are provided at an interval of 90°,

incorporated in the rotor i ntegrated with the drive

shaft, and in contact with the internal periphery of

the cam ring in the radial direction through the

roller.

When the drive shaft rotates, the plunger moves

on the cam ri ng int er nal s ur fac e throug h the rolling

of the roller, pushed out in the shaft center

direction with th e inner cam and compresses the

fuel.

Four plungers operate simultaneously. This

enables higher pr essure (75 ~ 130 M Pa) and high

rigidity is o btained since the lo ad bec om es rel ati ve

load in the radial direction.

Plunger diameter is ø7.5mm and the cam lift is

2.5mm.

1

Engine Control System 1A-7

3. Fuel injection amount control

Fuel injection amount is adjusted by opening or

closing the fuel high pressur e circuit with the high

response SPV (spill control valve).

EDU (engine driver unit; a high voltage driver) is

employed to drive the SPV at a high speed . EDU

can drive the SPV o f high fuel pressure at a high

speed by the high voltage and high speed

energizing system.

4. Pump ROM

In order to compensate the variation of correlation

between the fuel pump and engine, variation of the

injection amount in herent to the injection pump is

corrected.

5. Air bleeding of injection pump

a. Pumping until the pump is hard to operate.

b. Start the engine. If not started, repeat

pumping.

c. After the engine is started, keep the engine

speed at 1000 to 1500rpm for about 10

seconds.

d. Stop the engine.

e. Check for fuel leakage.

5

2

4

3

LNW21ASH000401

Legend

1. Cam ring

2. Rotor

3. Timer piston

4. Roller

5. Plunger

2. Injection timing control

Injection timi ng is ad ju sted by shifting the cam ring

phase with the fue l p ress ure app li ed t o th e back of

the timer piston. The fuel pressu re applied to the

timer piston is controlled with the ECM (engine

control module) through the timing control valve.

Legend

1. Priming pump

2. Plug

3. Sensor

4. Cartridge

1

4

3

2

LNW21ASH000501

Page 10

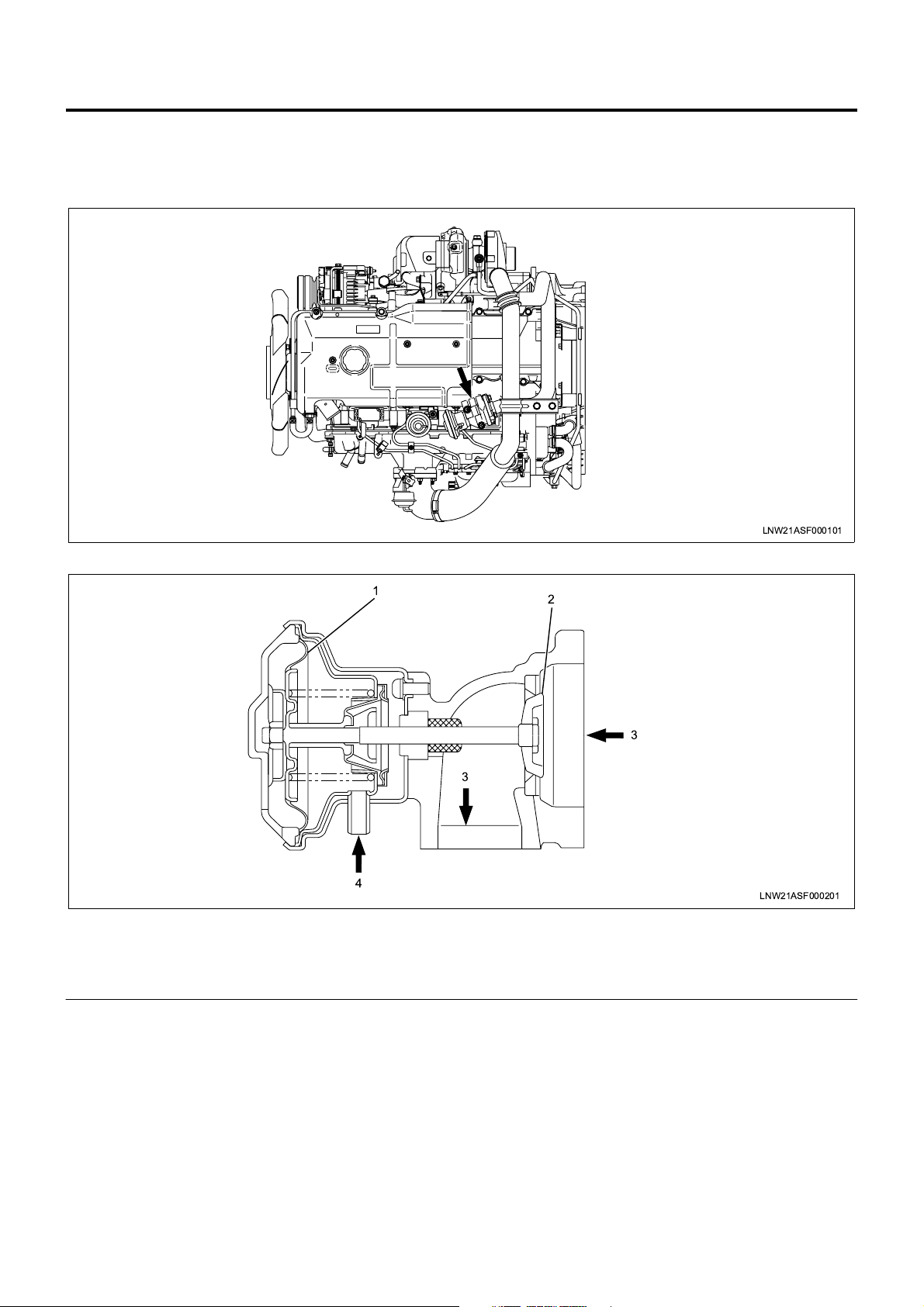

1A-8 Engine Control System

EGR (Exhaust Gas Recirculation) Valve

In order to decrease NOx (nitrogen oxide) in the

exhaust gas, an EGR system is employed.

The EGR valve is vacuum control type.

LNW21ASF000101

Legend

1. Diaphragm

2. Valve

1

3

4

2

3

LNW21ASF000201

3. Exhaust gas

4. Vacuum

Page 11

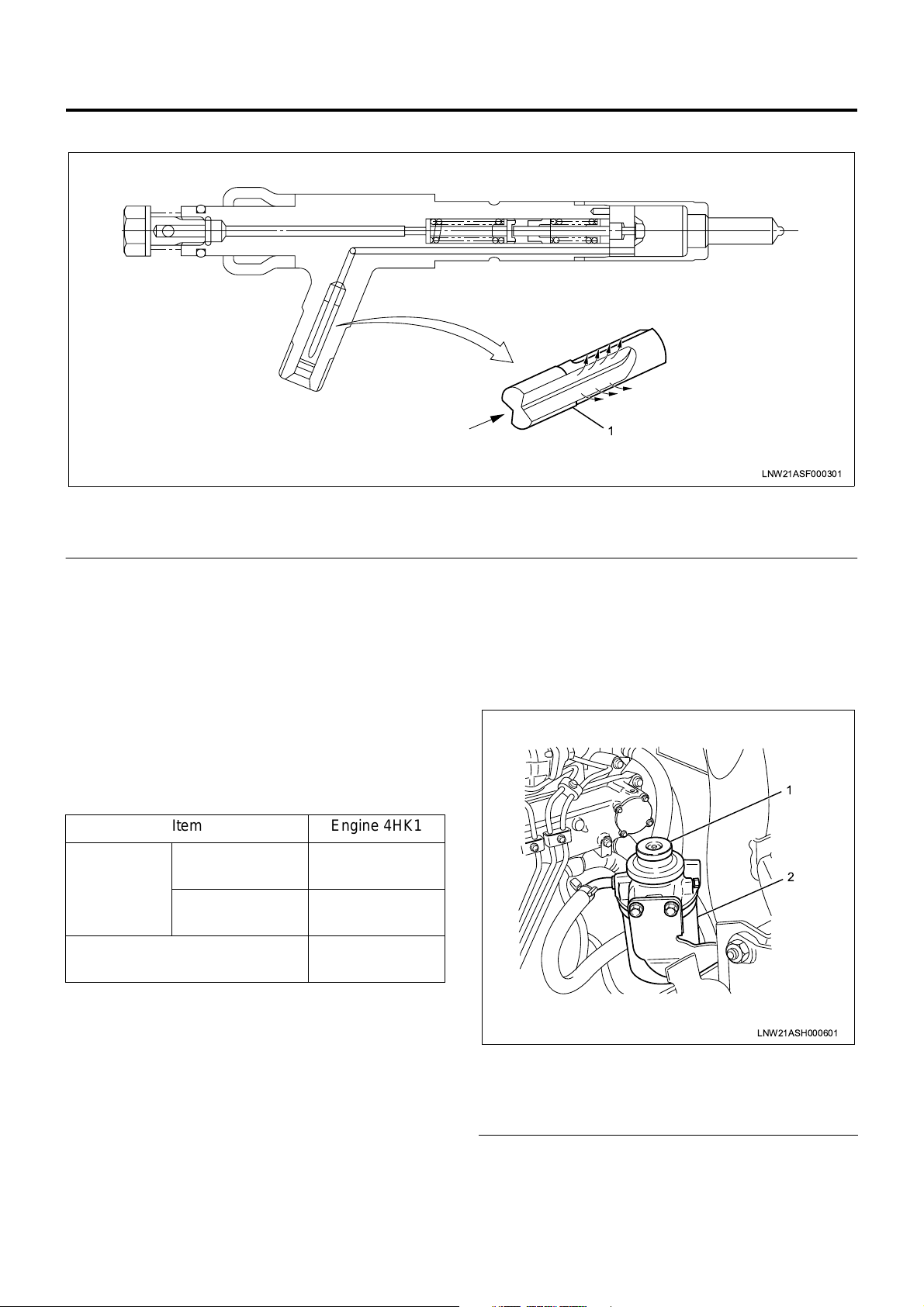

Injection Nozzle

Legend

1. Edge filter

Engine Control System 1A-9

1

LNW21ASF000301

A two-step valve opening pressure nozzle is used as

the injection no zzle. Spray pa rticle size i s reduced by

reducing the injection hole diameter.

To prevent clogging of the nozzle injection hole, an

edge filter is provided at the nozzle holder inlet.

Reference:

If the injection nozzle hole is clogged, ECM corrects the

cylinder inside condition.

The cylinder correction amount in the Tech 2 data list is

helpful to know the injection nozzle condition.

Item Engine 4HK1

Valve

opening

pressure

MPa(kg/cm

1st valve op ening

pressure

2nd valve

2

)

opening pressure

No. of injection holes - Injection

18.0 {185}

(Nominal value)

22.0 {225}

(Nominal value)

5 -ø0.25

hole diameter (mm)

Fuel Filter with Sedimentor

In order to secure the lubrication efficiency in the

injection pump, a fuel filter with sedimentor to remove

moisture in the fuel is provided.

This filter is pro vided with a priming pump to bleed th e

air from the injection pump.

1

2

LNW21ASH000601

Legend

1. Priming pump

2. Fuel filter & sedimentor

Page 12

1A-10 Engine Control System

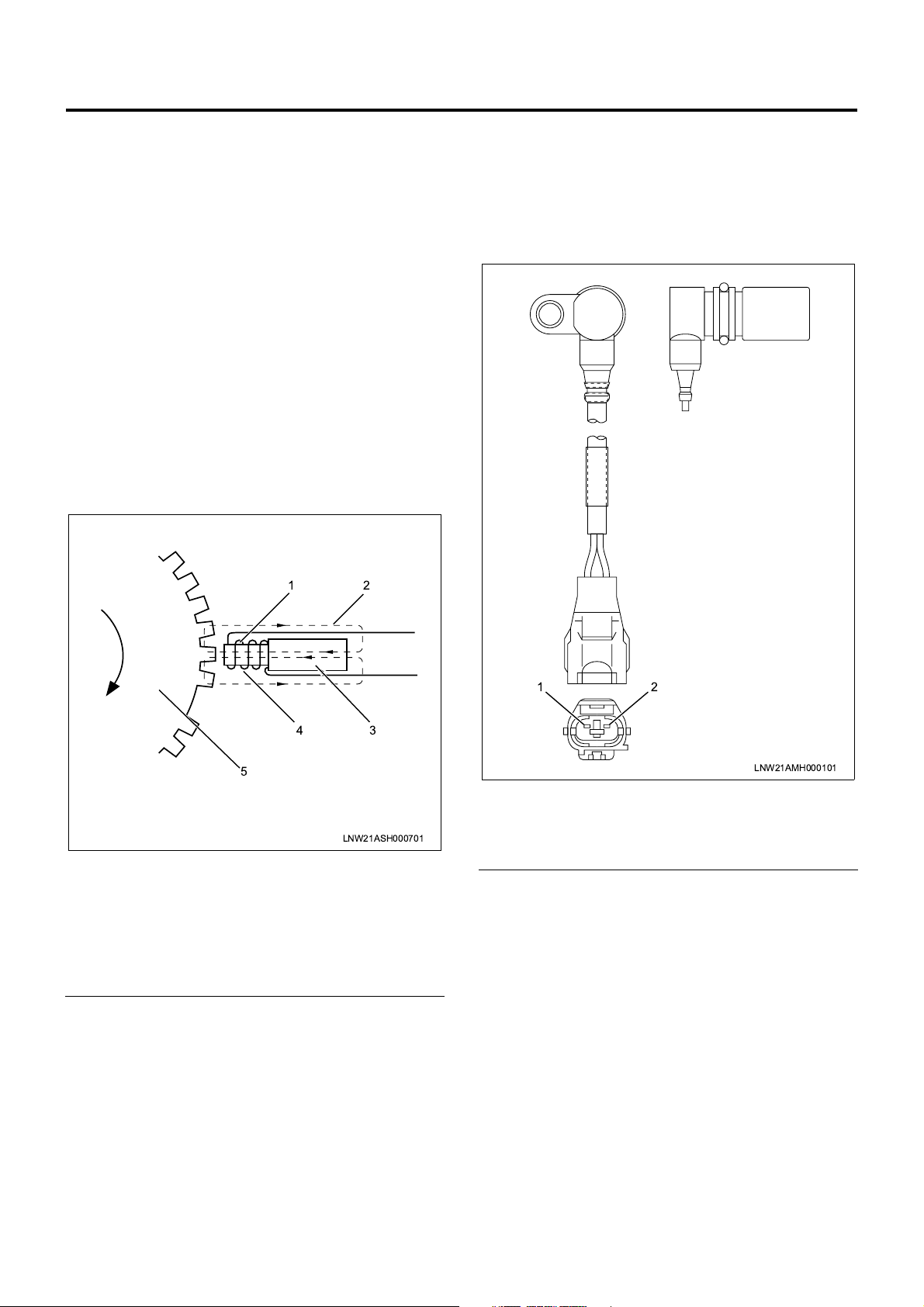

Pump CMP (Cam Position) Sensor (Engine Rotation

Sensor ) = NE Sensor

The pump CMP sensor is positioned on the outer

surface of the cam ring of the pump chamber. The

pulser installed to the injection pump drive shaft

interrupts the magnetic flux generated by the

permanent magnet and iron core of the sensor

according to the shaft rotation to generate AC wave

signal to the coil. This is transmitted to ECM (engine

control module) and converted to square wave signal .

engine speed and cam position are calculated by this

signal.

• Calculation of engine speed: No. of pulses per

hour is counted.

• Calculation of cam position: When the cam ring

slides, timing of sign al read from the pulse of the

sensor installed to the cam ring varies. ECM

calculates the time difference be tween this signal

and signal of the crank position sensor and

calculates the cam position.

CKP (Crank Position) Sensor

CKP sensor to detec t the crank position is installed to

the flywheel housin g. The sensor detec ts the rotating

angle of the crankshaft in non-contact condition with

the pointer installed to the flywheel and sends pulse

signal to ECM. ECM calc ulates the injection timin g at

the pump cam position based on this pulse signal.

Legend

1. Iron core

2. Magnetic flux

3. Permanent magnet

4. Coil

5. Pulser

12

21

34

5

LNW21AMH000101

Legend

LNW21ASH000701

1. (–) Pin

2. (+) Pin

Page 13

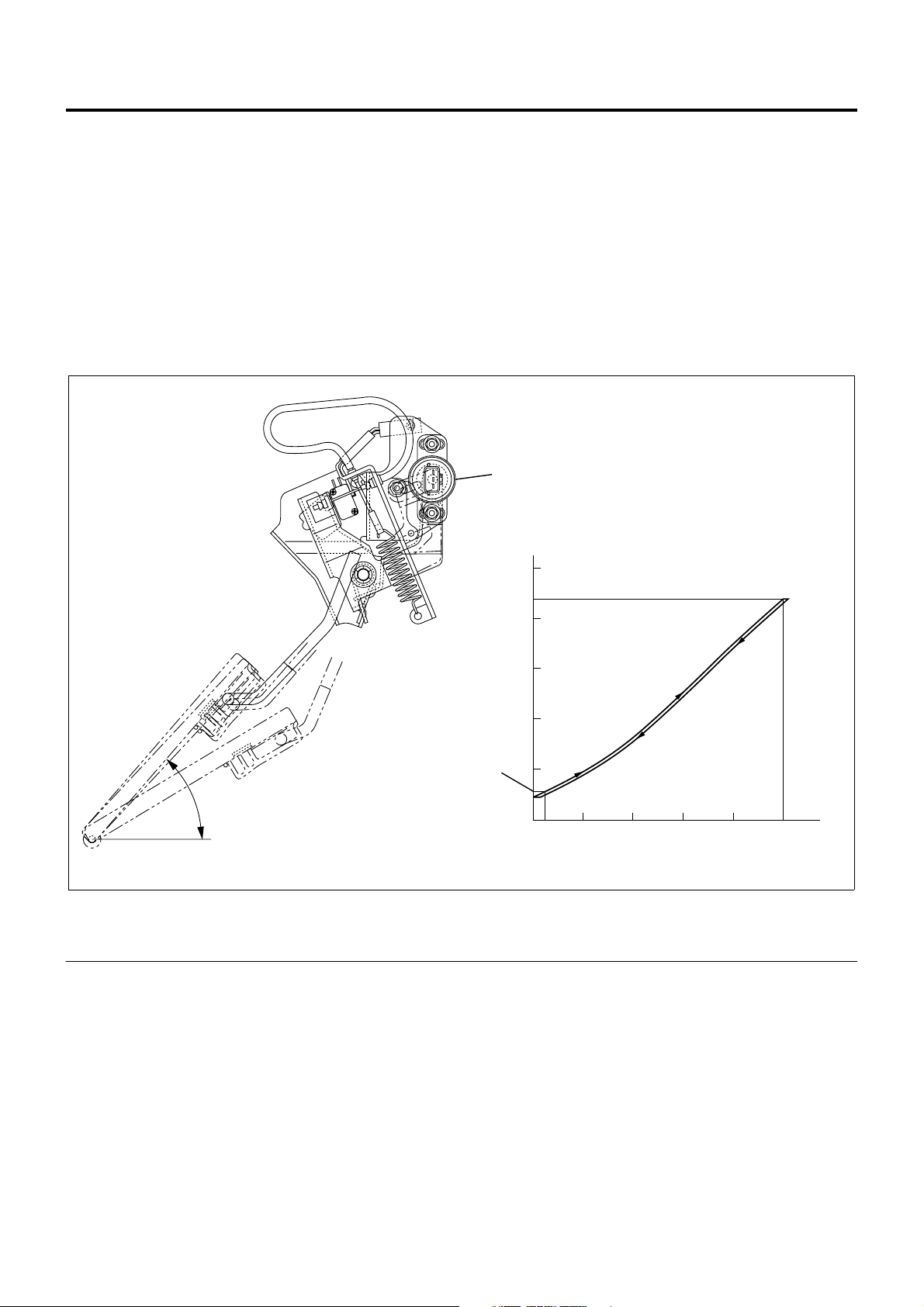

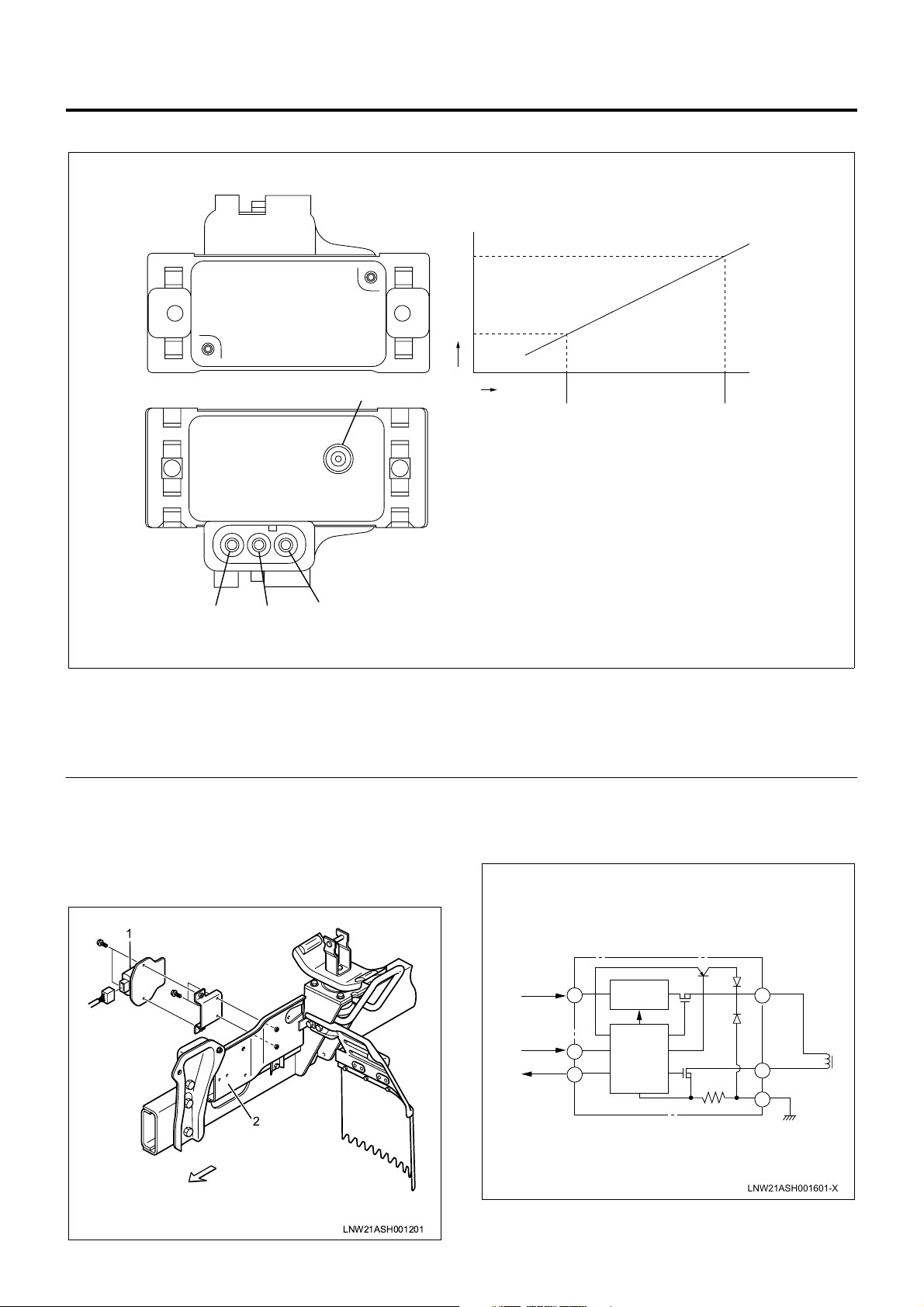

Accelerator Position Sensor

The accelerator control is accelerator position sensor

type. This sensor is a potentiometer (variable

resistance) installed to the accelerator pedal.

Reference voltage i s constantly applied to the sens or

from ECM (engine control modul e) and the accelerat or

pedal stepping ang le is detected from varying voltage .

An accelerator switch (idle position switch) is also

installed to the accelerator pedal. The accelerator

switch is turned ON when the accelerator pedal is

released and OFF when the accelerator pedal is

stepped on.

Engine Control System 1A-11

1

(V)

5

(WOT)

4

3

2

Output Voltage

2

1

49

(Idle)

0

10 20 30

Stroke (on Pedal)

Legend

1. Accelerator position sensor 2. Accelerator switch operating point

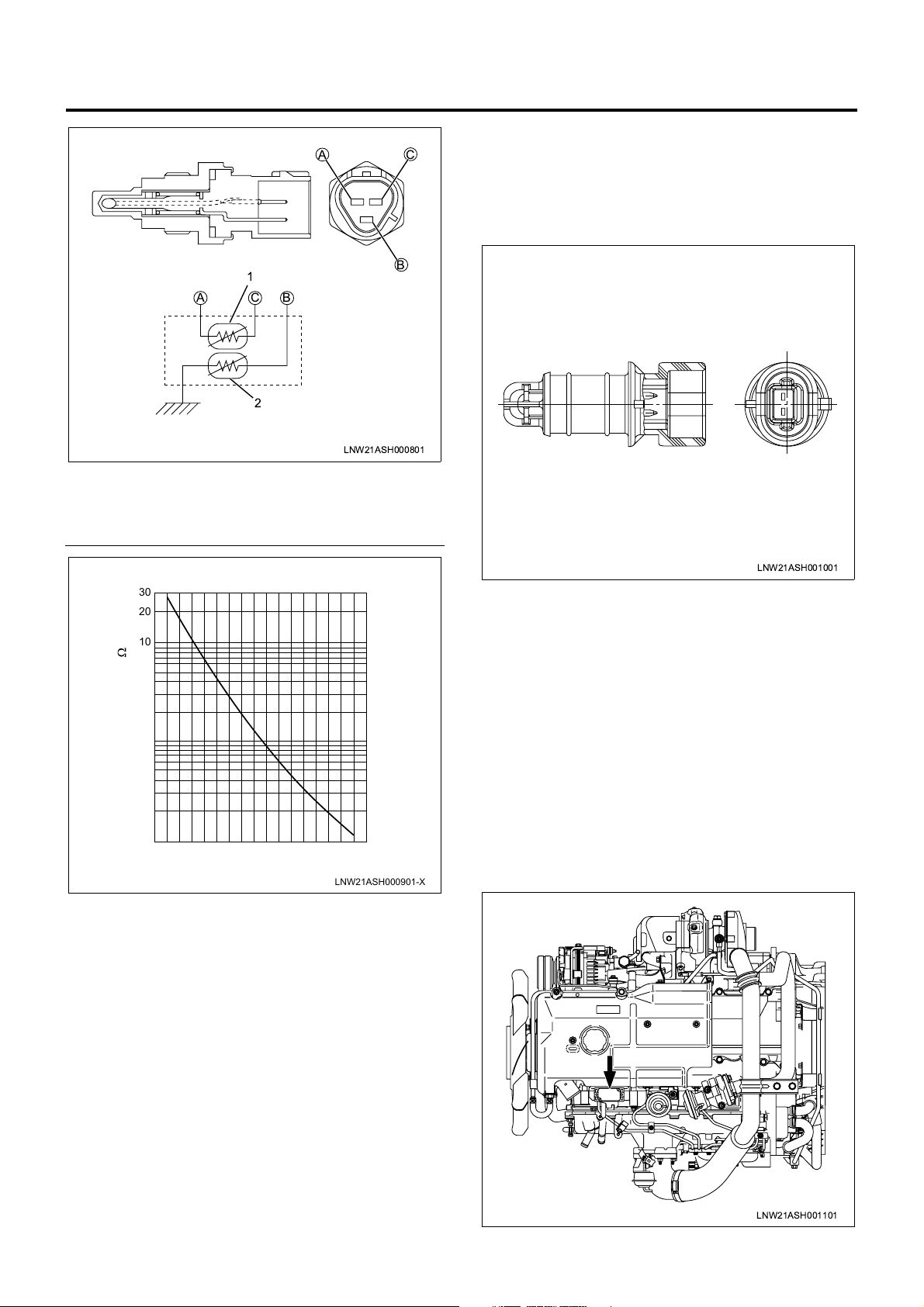

Engine Coolant Temperature Sensor (Coolant

Temperature Sensor / ECT)

The engine coolant tempe ratur e s ensor se rves for both

the ECM and thermo m eter unit. The engine coolant

temperature sensor is of the thermistor type that the

electric resistance reduces with the increase of the

temperature. It is installed on the left front of the

cylinder head.

40 50 (mm)

LNW21AMF000701-X

Page 14

1A-12 Engine Control System

Intake Air Temperature Sensor

AC

Intake air temperatur e sensor is installed to the i ntake

duct. Thermistor is used for the temperature detec tor

as in the thermo sensor to convert the changes of

temperature to changes of resistance values and

transmits to ECM.

ACB

Legend

1. Thermistor for ECM

2. Thermistor for thermo meter

[Thermistor Characteristics]

30

20

10

7.0

5.0

3.0

2.0

1.0

0.7

Resistance Value (k )

0.5

0.3

0.2

0.1

-20 1200 10020 8040 60

Engine Coolant Temperature ( C)

1

2

LNW21ASH000801

B

LNW21ASH001001

Atmospheric Pressure Sensor

The atmospheric pressure sensor is incorporated in

ECM.

MAP (Intake Air Pressure) Sensor

The MAP sensor is installed to the cylinder head cover.

The MAP sensor is composed of piezo type

semiconductor pressure element. Reference voltage is

constantly applied to the MAP sensor from ECM and

manifold pressure is detected by the changes of

voltage. When the manifol d pressure is low ( at idling),

low voltage signal is sent to ECM and when the

pressure is high (at ful l throttle), high voltage signa l is

LNW21ASH000901-X

transmitted to ECM.

Fuel Temperature Sensor

Fuel temperature sensor is installed in the pump

chamber full of fuel. Thermistor is used for the

temperature detector as in the thermo sensor and

convert the changes of temperature to changes of

resistance and values transmits to ECM.

Vehicle Speed Sensor

The vehicle speed sensor is used commonly with the

speedometer. ECM receives signal from the

speedometer.

By one turn of the sp eedome ter driven gear, 25 pulses

are generated indicating 60 km/h at 637rpm.

LNW21ASH001101

Page 15

MAP (Intake Air Pressure) Sensor

Engine Control System 1A-13

[MAP Sensor Characteristics]

Output Voltage (V)

6

5

4

3

Legend

1. Pressure at idling (low pressure)

2. Pressure at ratin g p oint (a bsolut e pre ssure (high

pressure))

3. Power pin

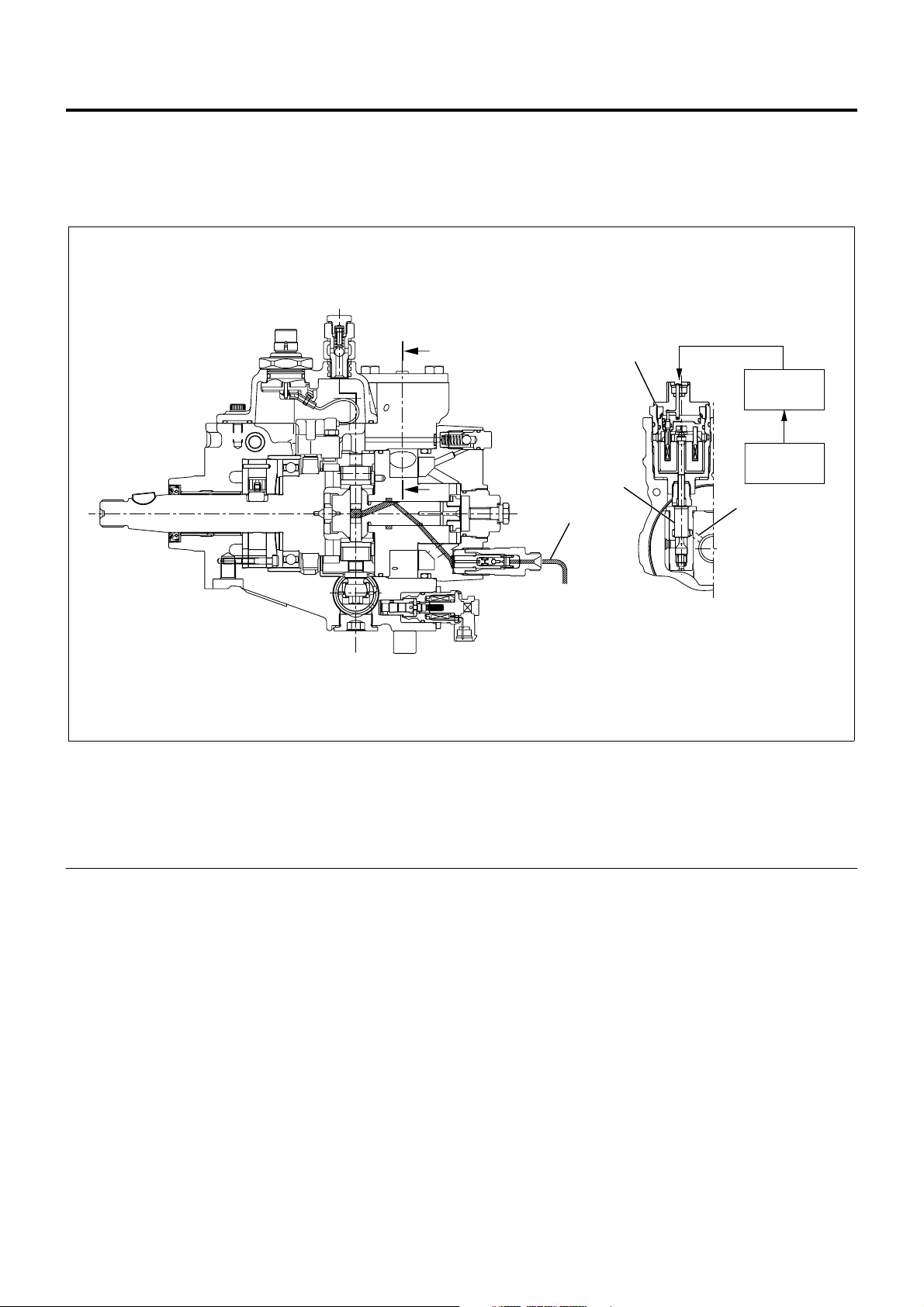

EDU (Engine Driver Unit)

EDU enables SPV high speed drive at high fuel

pressure by the high voltage and high speed energizing

system.

Maximum charging voltage is about 150V.

Absolute

Pressure

4. Output pin

5. Ground pin

6. Vacuum hose connected pipe

Legend

1. EDU

2. Left side cover

21

LNW21AMF000801-X

1

2

LNW21ASH001201

Connecting Diagram

Battery

ECM

ECM

A

B

C

High Voltage

Generating

Circuit

Control

Circuit

SPV+

D

E

SPV

F

Ground

LNW21ASH001601-X

Page 16

1A-14 Engine Control System

SPV (Spill Control Valve)

Fuel injection amount is controlled with the highresponse SPV by opening and closing the fuel high

pressure circuit.

SPV is incorporated in the injection pump.

Legend

1. SPV drive signal

2. EDU

3. ECM

4. High pressure fuel

B

B

6

7

5

1

2

3

4

8

LNW21AMF000901

5. Valve

6. High pressure fuel passage

7. SPV

8. B-B section

Page 17

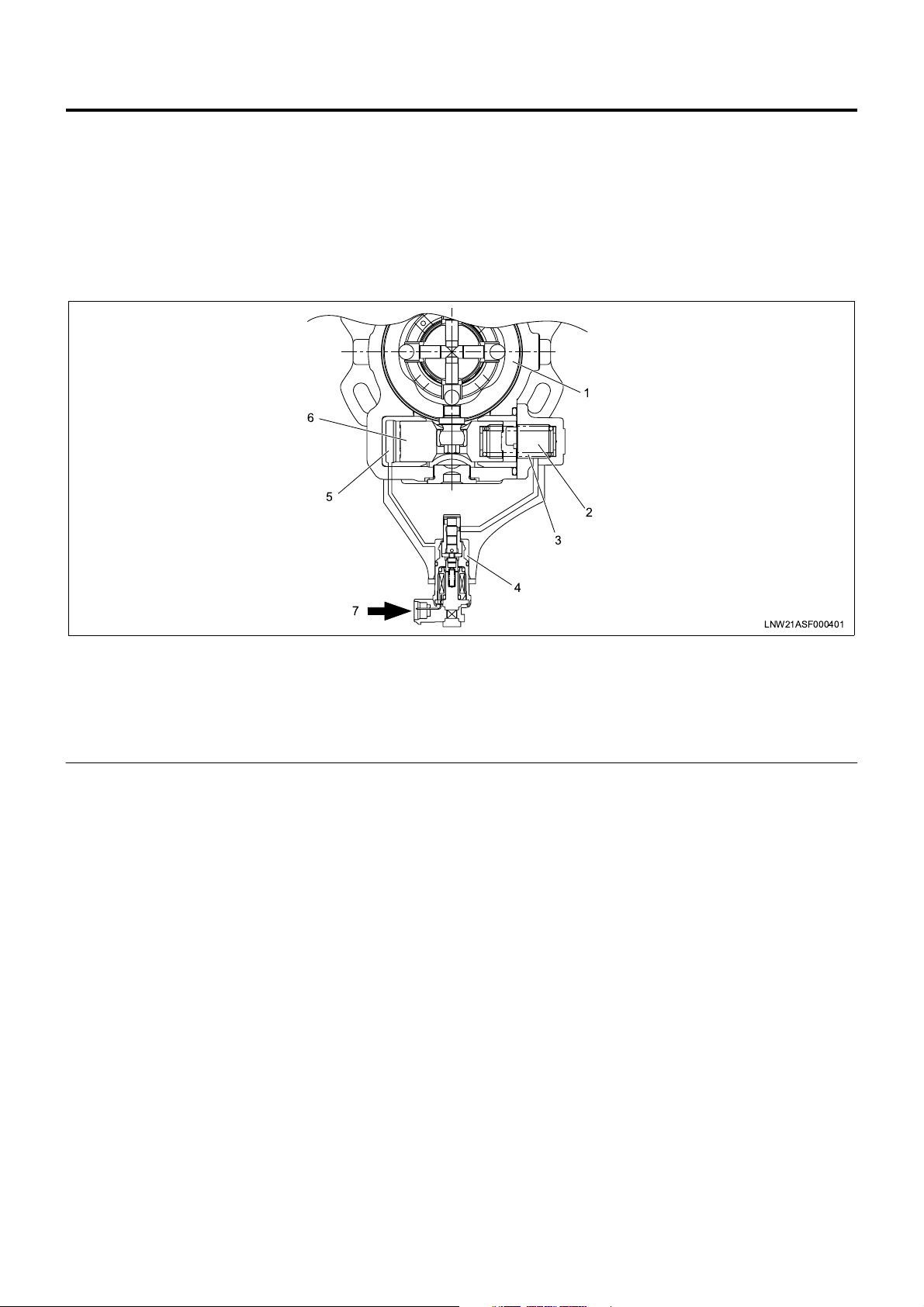

TCV (Timing Control Valve)

TCV using a solenoid valve is installed to the oil

pressure timer. Duty (energizing rate) controlled

current with ECM increases or decreases the valve

opening time to control the oil pressure in the high

pressure chamber si de. The timer piston is mo ved by

the balance with the timer s pring. By sliding the cam

ring connected movably with the timer piston in the

rotating direction, the injection timing is controlled.

6

5

Engine Control System 1A-15

1

2

3

7

Legend

1. Cam ring

2. Low pressure chamber

3. Timer spring

4. TCV

Electronic Control Distributor Pump System

System Overview

The accelerator control uses an accelerator position

sensor. The accelerator sensor of the potentio meter

(variable resistanc e) type is installed to the ac celerator

pedal. Reference volta ge is constantly applied to the

sensor from the ECM (engin e con tr ol module) to det ec t

the accelerator ped al stepping angle from changes of

voltage. An idle posi tion switc h (acceler ator switch ) is

also installed to the accelerator pedal. The idle position

switch (accelerator switch ) is turned ON when the

accelerator pedal is released and OFF when the

accelerator is stepped on.

ECM detects the accelerator pedal stepping angle as

AP (accelerator position) signal and after calculating,

transmits SPV (spill controller valve) drive signal to

EDU (engine driver unit).

EDU enables high spee d drive of SPV which controls

fuel injection amount.

The fuel injectio n amount is contr olled by opening and

closing the fuel high pressure circuit with the high

response SPV.

SPV is incorporated in the injection pump.

The spill control valve and timing control valve are

4

LNW21ASF000401

5. High pressure chamber

6. Timer piston

7. From ECM

electronically controlled with ECM (engine control

module).

Page 18

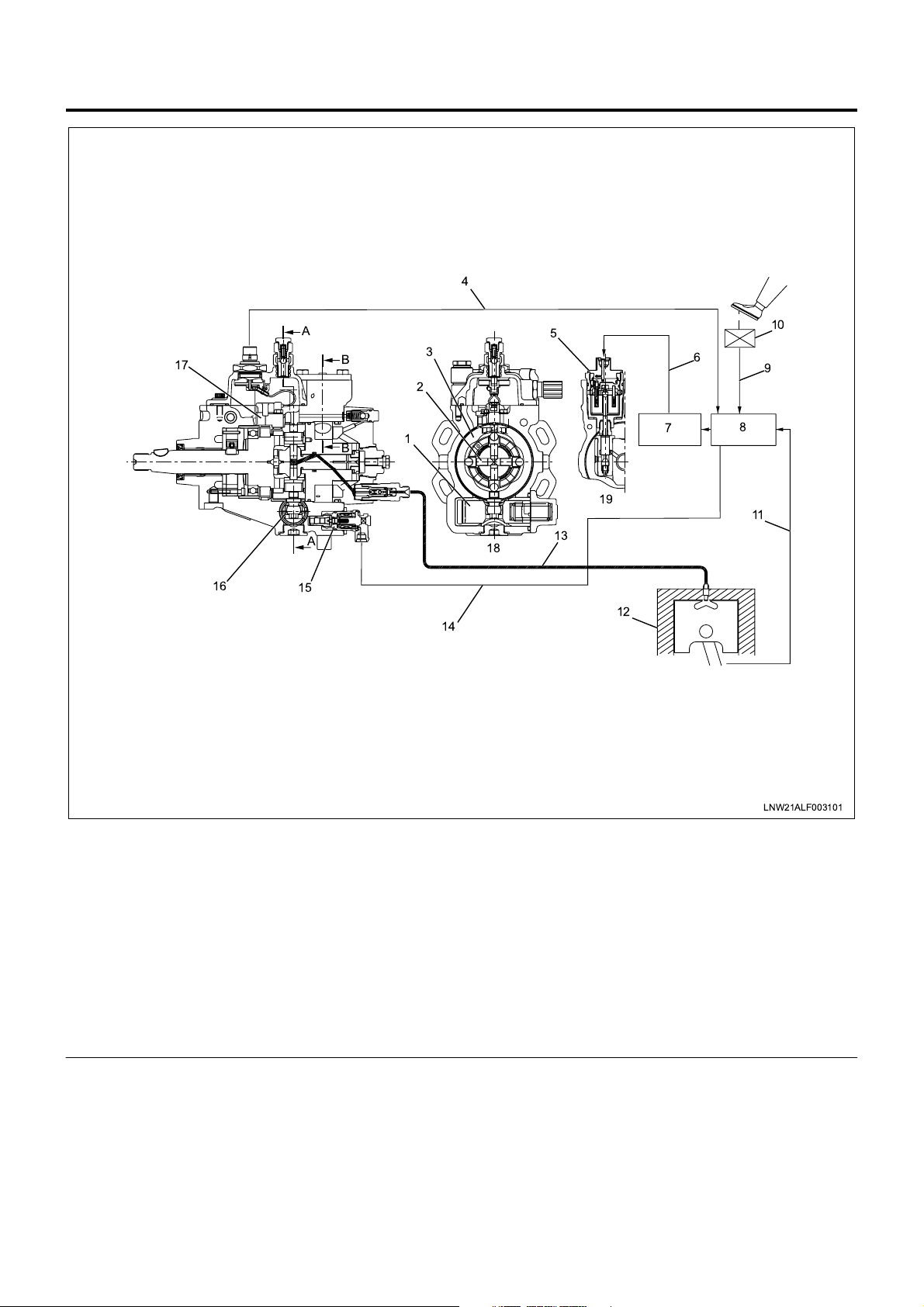

1A-16 Engine Control System

4

17

16

15

A

B

B

A

3

2

1

18

14

5

6

7

19

13

12

10

9

8

11

Legend

1. Timer piston

2. Plunger

3. Cam ring

4. Pump cam position signal (engine speed signal)

5. Spill control valve

6. Spill control valve drive signal

7. Engine driver unit

8. Engine control module

9. Accelerator pedal opening signal

10. Accelerator position signal

Fuel Injection Amount Control

The electromagnetic spi ll valve is o pened by the signal

from ECM (engine contr ol m odul e) , pres su r e in the fuel

forced feed unit (rotor unit) is decreased and injection is

completed. Injection amount is controlled at this timing.

LNW21ALF003101

11. Crankshaft position signal

12. Engine

13. High pressure fuel passage

14. Injection timing control si gna l

15. Timing control valve

16. Timer piston

17. Pump cam position sensor (engine speed

sensor)

18. A-A section

19. B-B section

Page 19

Operation

ECM calculates the bas ic injection amount op timum to

the engine operating conditions and the maximum

injection amount at that engine condition, compares

and selects lower injection amount. By adding the

phase compensated with the compensation ROM to

that injection amount, the final injection amount is

determined.

Engine Control System 1A-17

At the time of start, the optimum fuel injection amount is

determined by the starter signal and coolant

temperature. (Injec tion amount increases more wh en

the coolant temperature is lower.)

Accelerator Position

Sensor

Basic Injection Amount

Select Lower Injection

Amount Side

Compen-

sation

Injection Amount

Determine

EDU

Engine Speed Sensor

Basic Max. Injection

Amount

Compen-

sation

Max. Injection Amount

Intake Air Pressure

Sensor

Increase When Higher

Intake Air Temperature

Sensor

Varying Depending on

Conditions

Fuel Temperature Sensor

Increases When Lower

Coolant Temperature

Sensor

Increases When Lower

Fuel Temperature Sensor

Compensates to Increasing

Side When Higher

Compensation ROM

Compensation Value

of Each Pump

Electromagnetic Spill Valve

LNW21AMF001001-X

1. Basic injection amount

Determined by accelerator opening and engine

speed.

2. Max. injection amount

Maximum injection amount is determined by

adding compensati on by signals of sen sors to the

basic maximum injection amount (amount which

can be theoretic ally in jec ted ) dete rm in ed ba se d on

the engine speed.

a. Intake air pressure compensation

When the intake air pressure is high, the air

amount is increased and the injection amount is

increased.

b. Intake air temperature compensation

Injection amount is increased or decreased

depending on the difference of density based

on the intake air temperature.

c. Fuel temperature compensation

When the fuel temperature decreases, the

injection amount is increased.

d. Coolant temperature compensation

When the coolant temperature is lower, the

injection amount is increased to secure the

operability immediately after the cold start.

3. Injection amount compensation

Since the actual injection amount decreases in

comparison with the des ignated value of injection

amount when the fuel temperature is higher,

designated injection amount value is increased.

Fuel Injection Timing Control

• Timing control valve is duty-controlled according to

a signal from ECM (engine control module) to

control the fuel injection start timing.

• Using the crankshaft angle feed back system,

highly precise control is effected.

Page 20

1A-18 Engine Control System

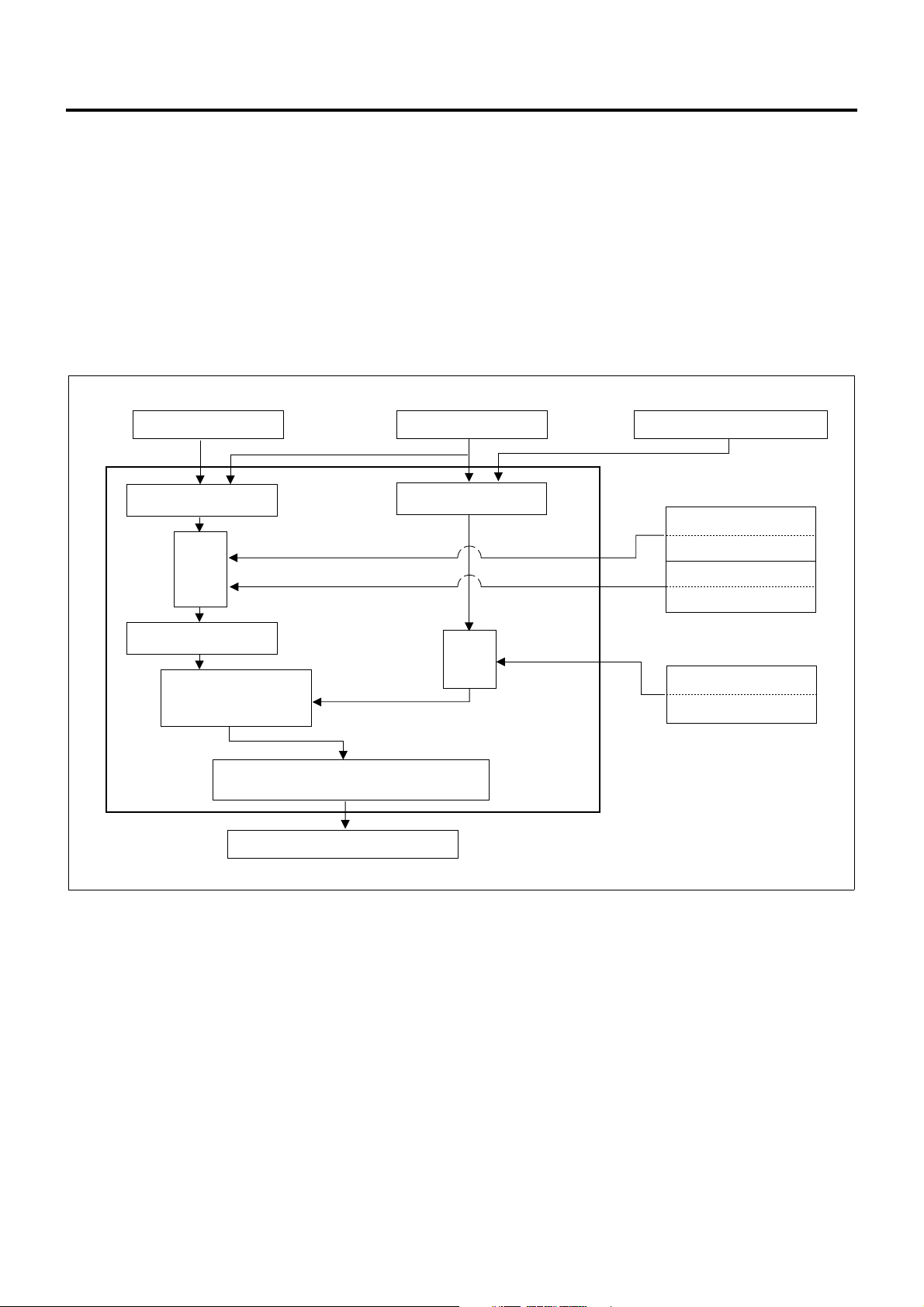

Operation

ECM calculates the o ptimum target injection ti ming for

the engine condition, adding the compensation by

signals from sensors based on the basic target

injection timing.

At the time of start, the injection timing is determined by

the starter signal, coolant temperature and engine

speed (at the higher engine spee d, the injecti on timing

angle advances.)

Crank angle feed back system is emp loyed to c alculate

the actual inject ion timing and feed back the res ult at

the target injection timing.

Accelerator Position

Sensor

Basic Target Injection

Timing

Compen-

sation

Target Injection Timing

Comparison with Target

Injection Timing and

Actual Injection Timing

Calculation of Duty Ratio

Actual Injection Timing

Timing Control Valve

Speed Sensor

Compen-

sation

Crank Position Sensor

Intake Air Pressure

Sensor

Angle Advances

When Lower

Coolant Temperature

Sensor

Angle Advances

When Lower

Compensation ROM

Compensation Value

of Each Pump

1. Basic target injection timing

Determined based on the accel erator opening and

engine speed.

2. Injection timing compensation

a. Intake air pressure compensation

Basic target inje ction timing is compens ated by

the intake air pres sure. Whe n the at mospheric

pressure is low on a altitude, for instance, the

injection timing angle is advanced.

b. Coolant temperature compensation

Basic target injection timing is compensated

based on the coolant tem perature. When the

coolant temperatu re is low, the injection timing

angle is advanced.

LNW21AMF001101-X

3. Feedback control

a. Calculation of actual injection timing

When relation between the compression TDC

position and crank angle reference position

signal is correct on the engine side and the

relation between the injection waveform and

cam angle signal is cor rect on the pump side,

actual injection timing θn can be calculated by

calculating the phase di fference θi between the

crank angle refere nce position signal and c am

angle signal.

Page 21

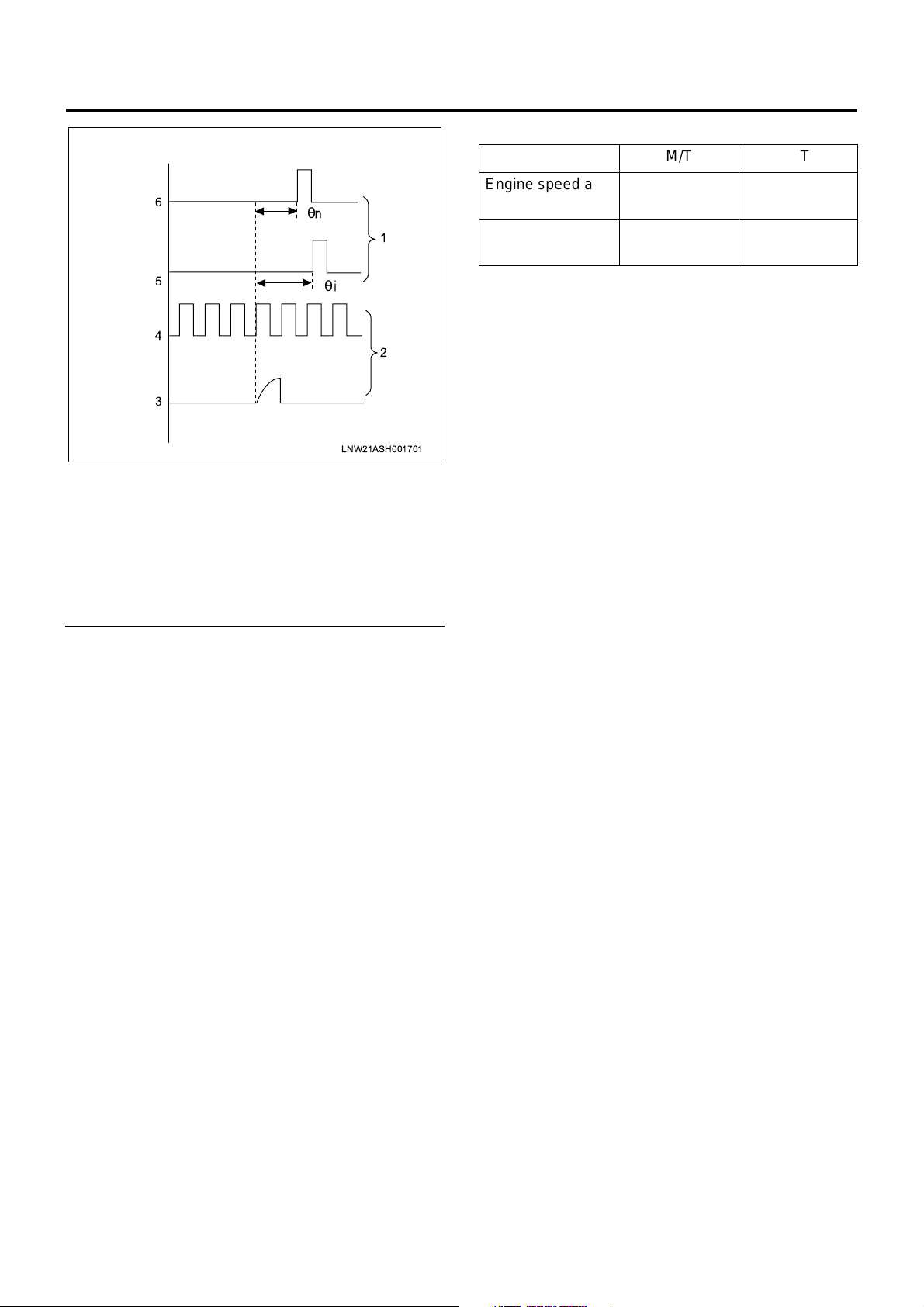

Engine Control System 1A-19

Idle Speed (P.N Range in A/T Vehicle) [r/min]

M/T A/T

6

5

4

3

θ

Legend

1. Engine

2. Pump

3. Injection waveform

4. Cam angle signal

5. Crank angle reference positi on signal

6. Actual compression TDC

θ

LNW21ASH001701

Engine speed at

no load

1

2

Air conditioner

system ON

Approx. 580 Approx. 650

Approx. 800 Approx. 870

b. Feedback control

Timing control valve duty ratio is cal culated so

that the actual injection timing coincides the

target injection timing.

Idle Speed Control

• Idle speed is controlled by increasing or

decreasing the specified fuel injection amount

value based on the signal from ECM (engine

control module).

Operation

1. Feedback control

When there is a difference between the target

speed calculated by the E CM an d eng ine speed at

the idle speed, the fuel injection amount is

controlled by changing the signal to the

electromagnetic spi ll va lv e and co ntrol s s o th at the

engine speed coincides the idle speed.

2. Warm-up control

Optimum fast idle engine speed is controlled at

idling by the coolant temperature.

3. Estimated control

Immediately after changing over the air

conditioning switch, before the engine speed

changes, the injection amount is changed by a

constant amount to preven t change of idle speed

by the change of load given to the engine.

Page 22

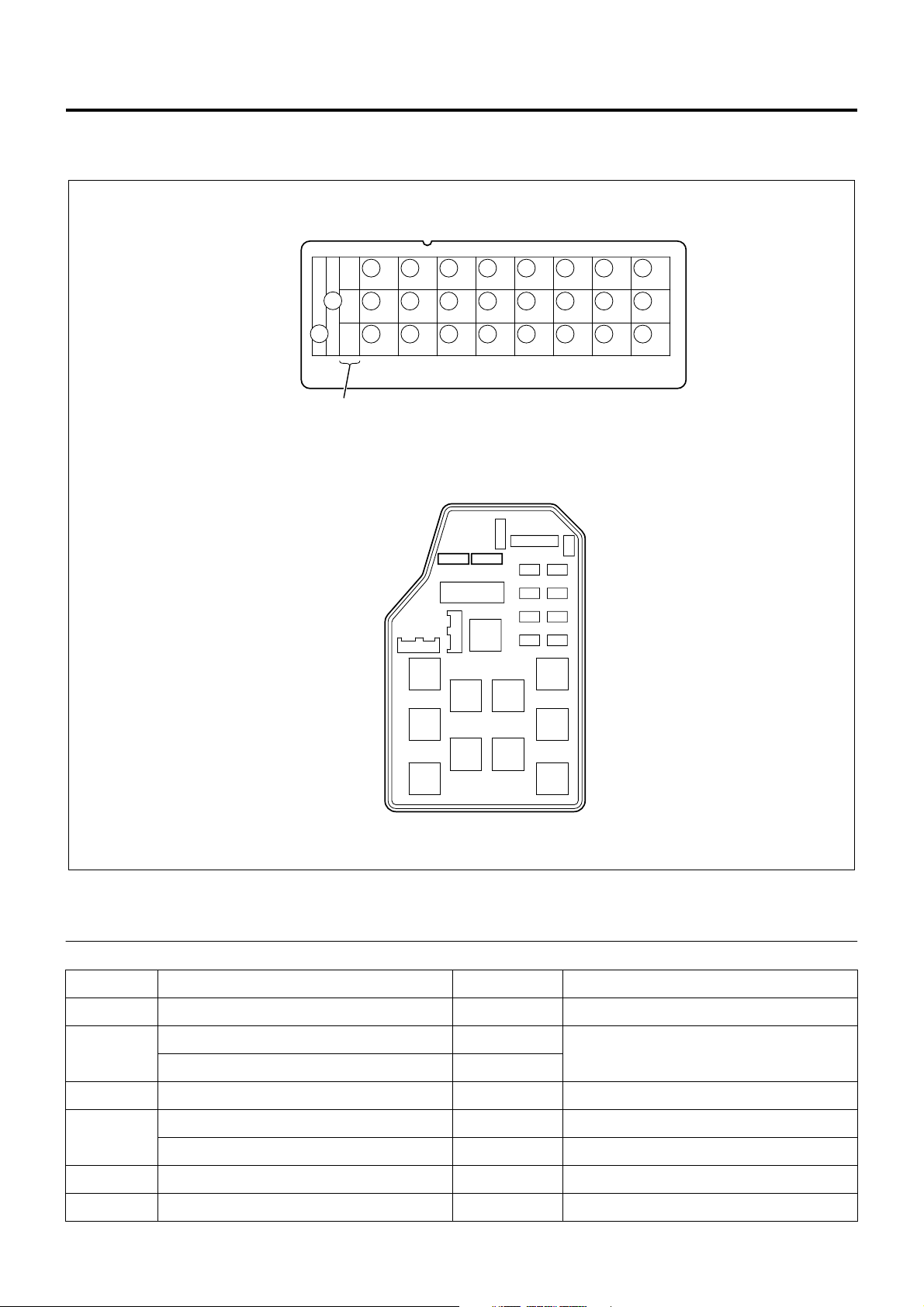

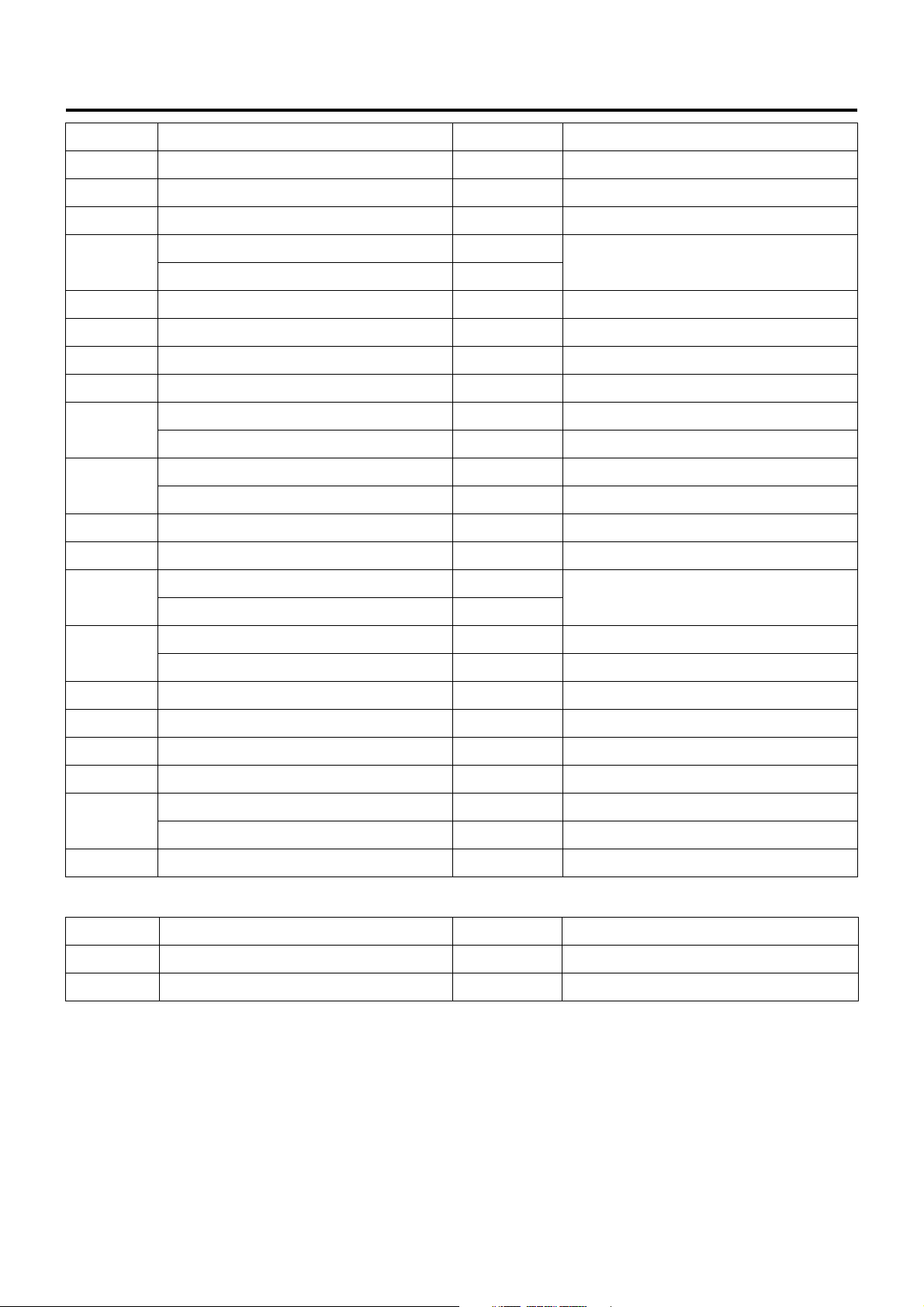

1A-20 Engine Control System

Component Layout

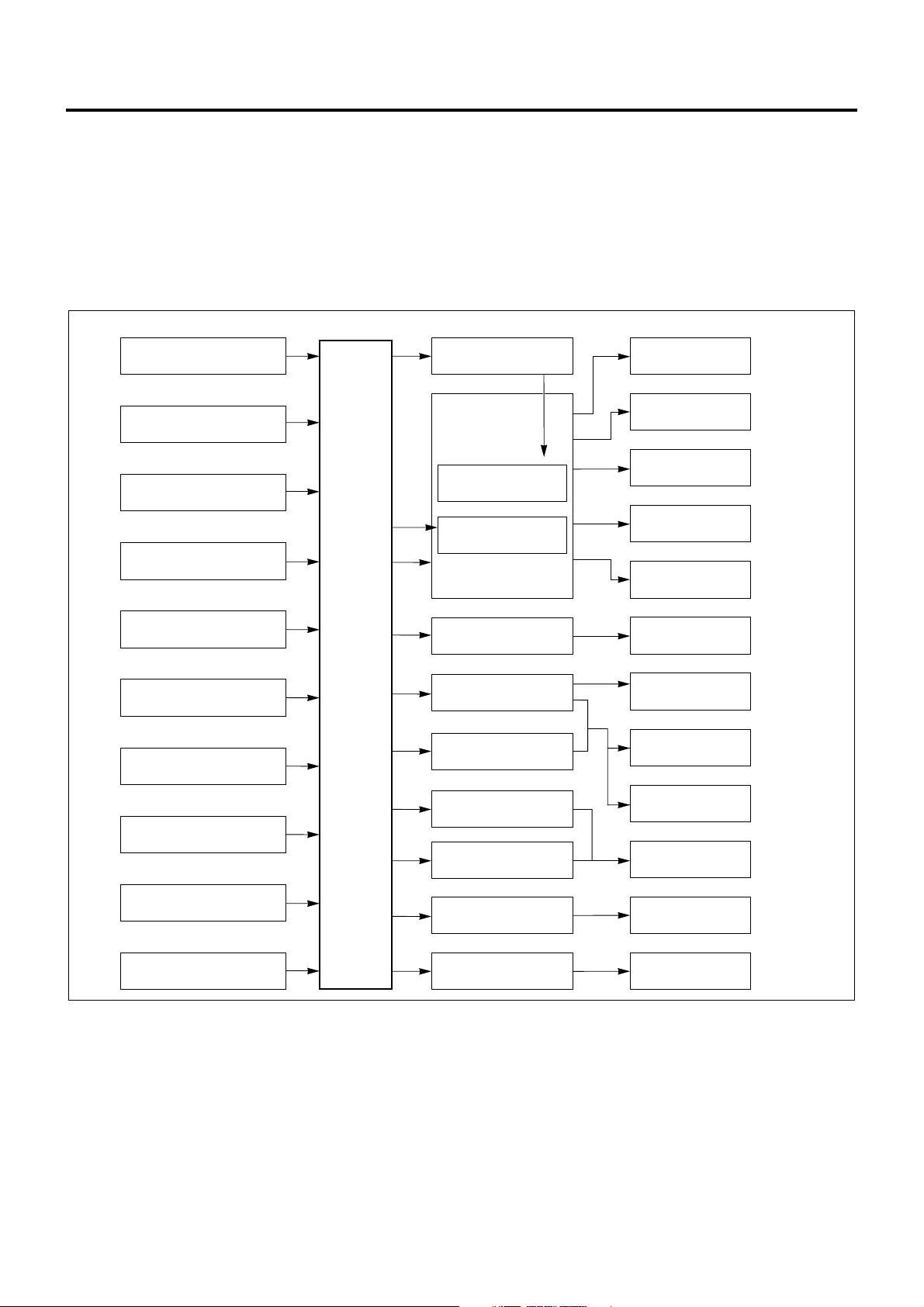

Fuse Layout

[Fuse Box Label, In Glove Box]

22

19

16

13

10

1

4

7

25

23

26

[Fuse Box, Front Left of Radiator]

24

1

20

21

17

18

27 28

14

15

11

12

2

5

8

6

9

3

LNW21ALF000401-X

Legend

1. Spare fuse

No. Indication on label Capacity Devices connected

1 CONTROLLER 10A Control unit

HAZARD,HORN (12V) 15A

2

Hazard warning flashing lamp, horn

HAZARD,HORN (24V) 10A

3—10A—

AIR CON (12V) 10A Air conditioner

4

HEATER,AIR CON (24V) 15A Heater, air conditioner

5 FUEL, SEAT HEATER (24V) 10A Fuel, seat heater

6 ABS, HAB, RETARDER (24V) 15A ABS, HAB, retarder

Page 23

Engine Control System 1A-21

No. Indication on label Capacity Devices connected

7 ROOM LAMP 15A Room lamp

8 STOP LAMP 10A Stop lamp

9 POWER WINDOW (24V) 20A Power window

10

11 FOG.CORNER 10A Fog lamp, cornering lamp

12 ELEC.PTO (24V) 10A PTO switch (electric PTO)

13 WIPER,WASHER 15A Wiper, window washer

14 TURN 10A Turn signal lamp

15

16

17 MIRROR 10A Electrically operated mirror

18 CIGAR,AUDIO 10A Cigarette lighter, audio

19

20

21 AIR BAG 10A SRS airbag

TAIL.ILLUMI (12V) 15A

Tail lamp

TAIL.ILUMI (24V) 10A

GENERATOR (12V) 15A Generator

ELEC.PTO (24V) 20A PTO solenoid valve (electric PTO)

MIRROR HEAT (12V) 10A Heated side mirror

ENG.CONT (24V) 15A ECM

METER (12V) 10A

Meter

METER (24V) 15A

ENGINE STOP (12V) 10A Engine stop

HSA (24V) 10A HSA

22 STARTER 10A Starter

23 H/LAMP RH 10A Headlamp, RH

24 H/LAMP LH 10A Headlamp, LH

25

26 POWER WINDOW (12V) 30A Power window

External Fuse Box

No. Indication on label Capacity Devices connecte d

27 MARKER LAMP 10A Marker lamp

28 COND FAN 10A Condenser fan

HEATER (12V) 30A Heater

ENG CONTROLLER (24V) 30A ECM (except for turbocharged vehicles)

Page 24

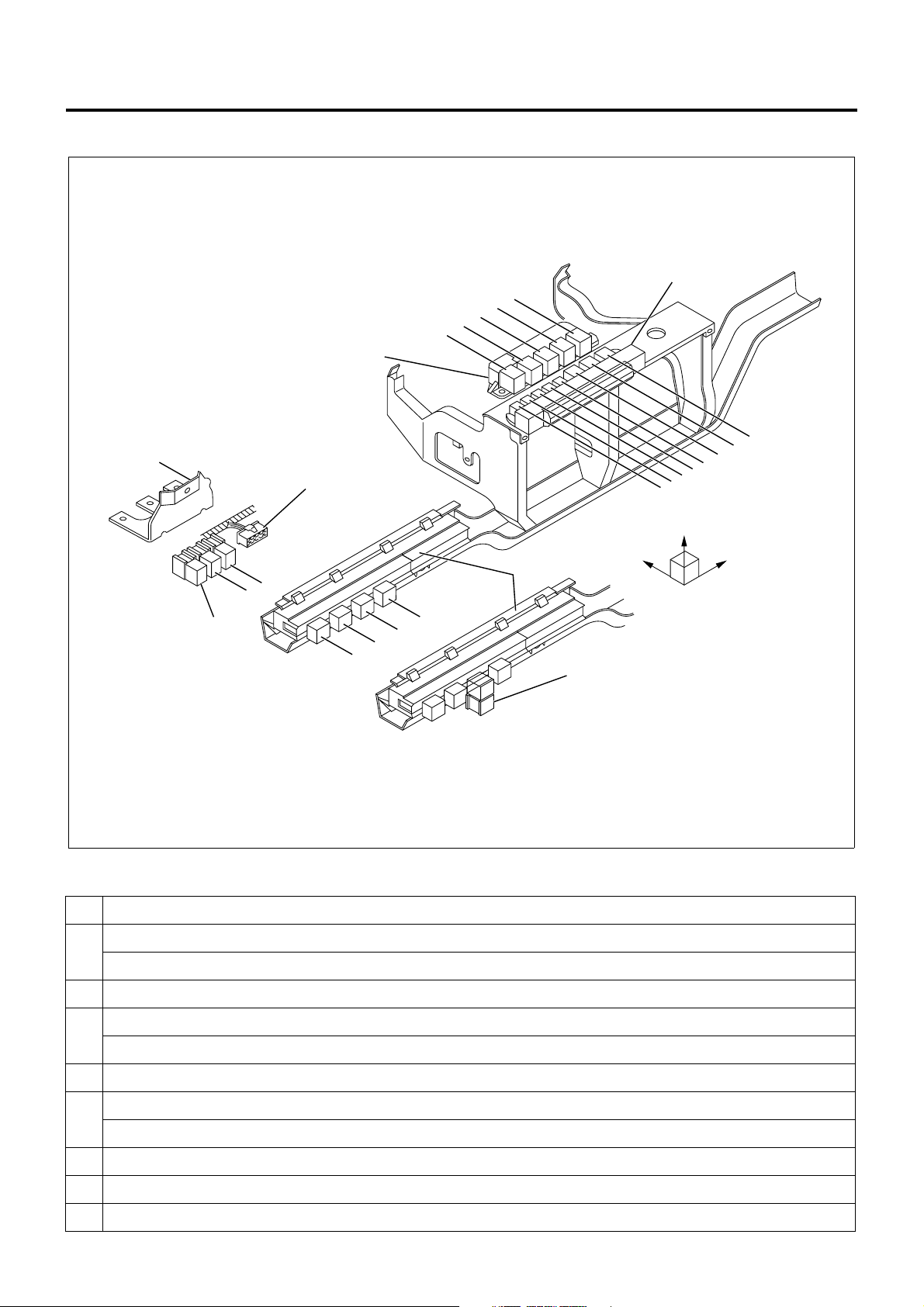

1A-22 Engine Control System

Relay Layout

Relay Box No.2

Bracket

Spare Power Circuit

18

16

15

14

13

Relay Box No.1

8

7

6

5

Upper

12

11

10

9

20

19

Cooler Relay

1

4

3

2

No. Legend

12 V: On relay

1

24 V: C harge relay

2 Horn relay

Fuse &

Relay Box

RightFront

17

LNW21ALF006101-X

12 V: ABS, VSV, FICD, EXH brake

3

24 V: Headlamp relay

4Tail relay

12 V: Headlamp relay

5

24 V: 4WD relay

6 Dimmer relay

7 Power window relay

8 Fog lamp relay

Page 25

No. Legend

9 Cornering lamp relay

10 Air conditioner thermo relay

12 V: C harge relay

11

24 V: Key on relay

12 Heater & air conditioner relay

24 V: PTO cut relay for electric PTO in fire engine (MT)

24 V: PTO solenoid relay for electric PTO (AT)

12 V: Exhaust brake cut relay (MT)

13

24 V: Idle on relay for fire engine (AT)

24 V: Idle stop, wiper relay (with CFS (clutch free system))

24 V: PTO solenoid relay for electric PTO (MT)

24 V: PTO buzzer relay for electric PTO (AT)

12 V: OD off relay (AT)

14

24 V: Idle keep relay for fire engine (AT)

Engine Control System 1A-23

24 V: Idle stop, radio relay (with CFS)

24 V: PTO main relay for electric PTO (MT)

24 V: Garbage relay for garbage collector (AT)

15

24 V: Indicator lamp relay for fire engine (AT)

24 V: Idle stop, engine control module relay (with CFS)

4WD relay

16

24 V: Idle stop, mirror relay (with CFS)

24 V: Full automatic air conditioner, high relay

17

24 V: Automatic air conditioner, high relay

24 V: Shift lock relay for fire engine (AT)

24 V: Shift relay for fire engine (AT)

18

24 V: PTO main relay for electric PTO (MT)

19 24 V: PTO solenoid relay for electric PTO (MT)

20 24 V: PTO cut relay for electric PTO (MT)

Page 26

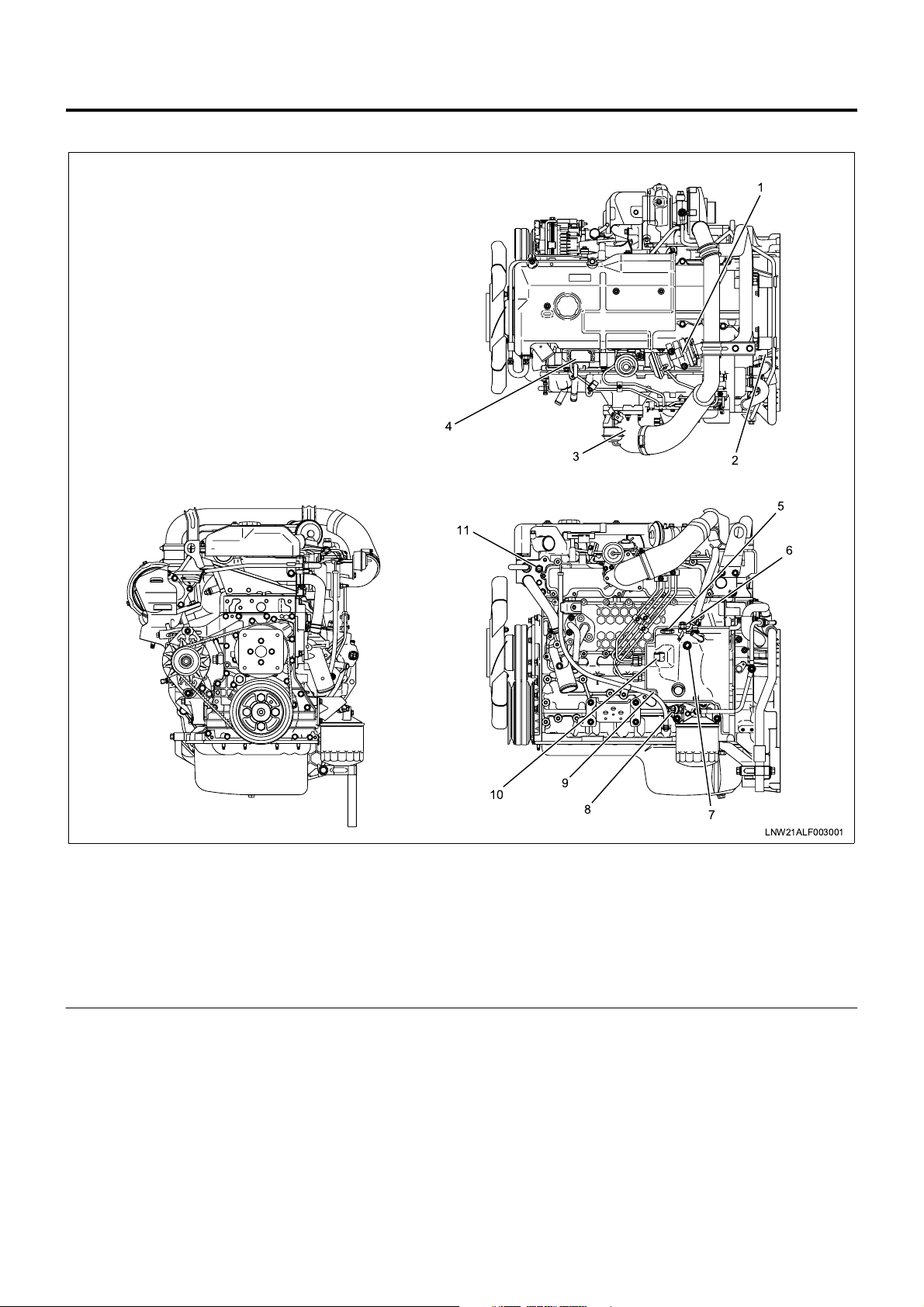

1A-24 Engine Control System

Engine Component Layout

1

4

Legend

1. EGR valve

2. Crank position sensor (CKP sensor)

3. Intake throttle body

4. MAP sensor

5. NE sensor

6. SPV

3

11

10

9

8

7. Fuel temperature sensor (FT sensor)

8. Oil pressure SW

9. TCV

10. ROM

11. Coolant temperature sensor

2

5

6

7

LNW21ALF003001

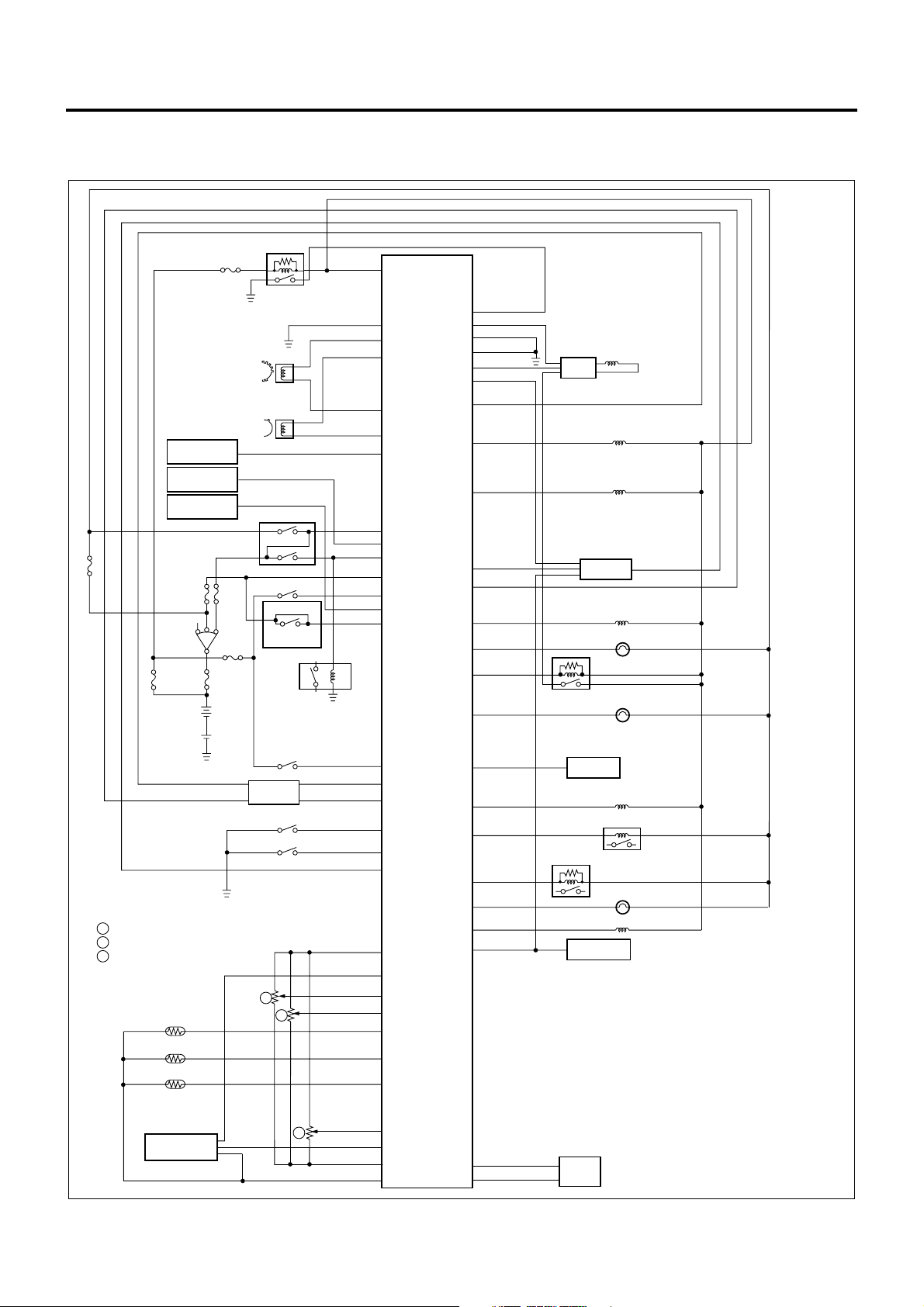

Page 27

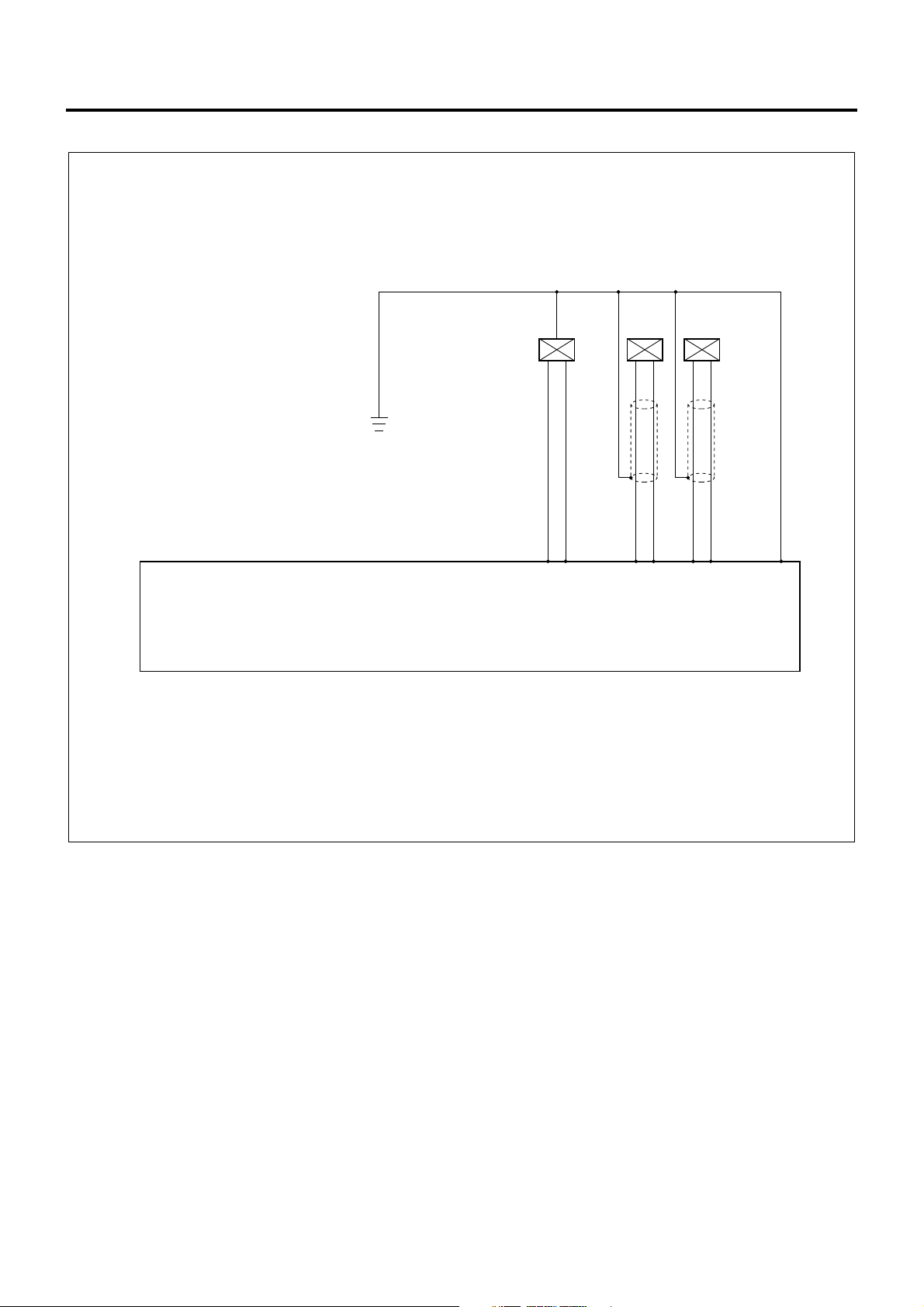

Circuit diagram

ECM wiring diagram (1)

Engine Control System 1A-25

D24

Pump Cam Position Sensor

Crankshaft Position Sensor

Vehicle Speed

Sensor

Cooler

Compressor

Freezer

Compressor

Key SW

1 Accelerator Position Sensor

2 Idle Up Volume

5 PTO Position Sensor

Coolant Temperature

Sensor

Fuel Temperature

Sensor

Intake Air Temperature

Sensor

Main Relay

Neutral SW

Inhibitor SW

Exhaust Brake SW

(A/T)

Clutch SW

(M/T)

Starter Relay

Warm-Up SW

ABS/ASR

ECU

Diagnostic SW

Idle SW

1

2

D13

B6

B5

B12

B11

D7

A17

A20

A2

A3

A21

A19

A6

B2

A16

B8

A9

A10

A5

C3

C4

C11

C10

C1

C12

C15

ECM

D9

D16

D26

A11

D20

A15

D6

D12

A1

B3

B9

A22

D21

D10

D22

A13

D4

D23

B7

D19

A12

B10

Spill Valve

EDU

Timing Control Valve

EGR EVRV

TCM

Swirl Control

Check Engine Lamp

Spill Valve Relay

Glow Lamp

TECH 2

Exhaust Brake VSV1

Glow Relay

Stop Lamp Relay

Exhaust Brake Lamp

Intake VSV

Tachometer

VSV

ECM

: Engine Control Module

EDU

: Engine Driver Unit

EVRV

: Electric Vacuum Regulating Valve

TCM

: Transmission Control Module

VSV

: Vacuum Switching Valve

Intake Air

Pressure Sensor

5

C14

C9

C6

C5 D17

D3

Pump

ROM

LNW21AXF000301-X

Page 28

1A-26 Engine Control System

ECM Wiring Diagram (2)

1.25 B/L

CKP

ROM

0.5

0.5

G/B

G/R

Engine Control Module (ECM)

Compensation ROM and NE Sensor are built in the Injection Pump

Sensor

0.5

W

B5

(+)

0.5

R

B11

()

Sensor

0.5

G

B6

(+)

NE

B12

()

0.5

L

D13D3D17

LNW21ALF000701-X

Page 29

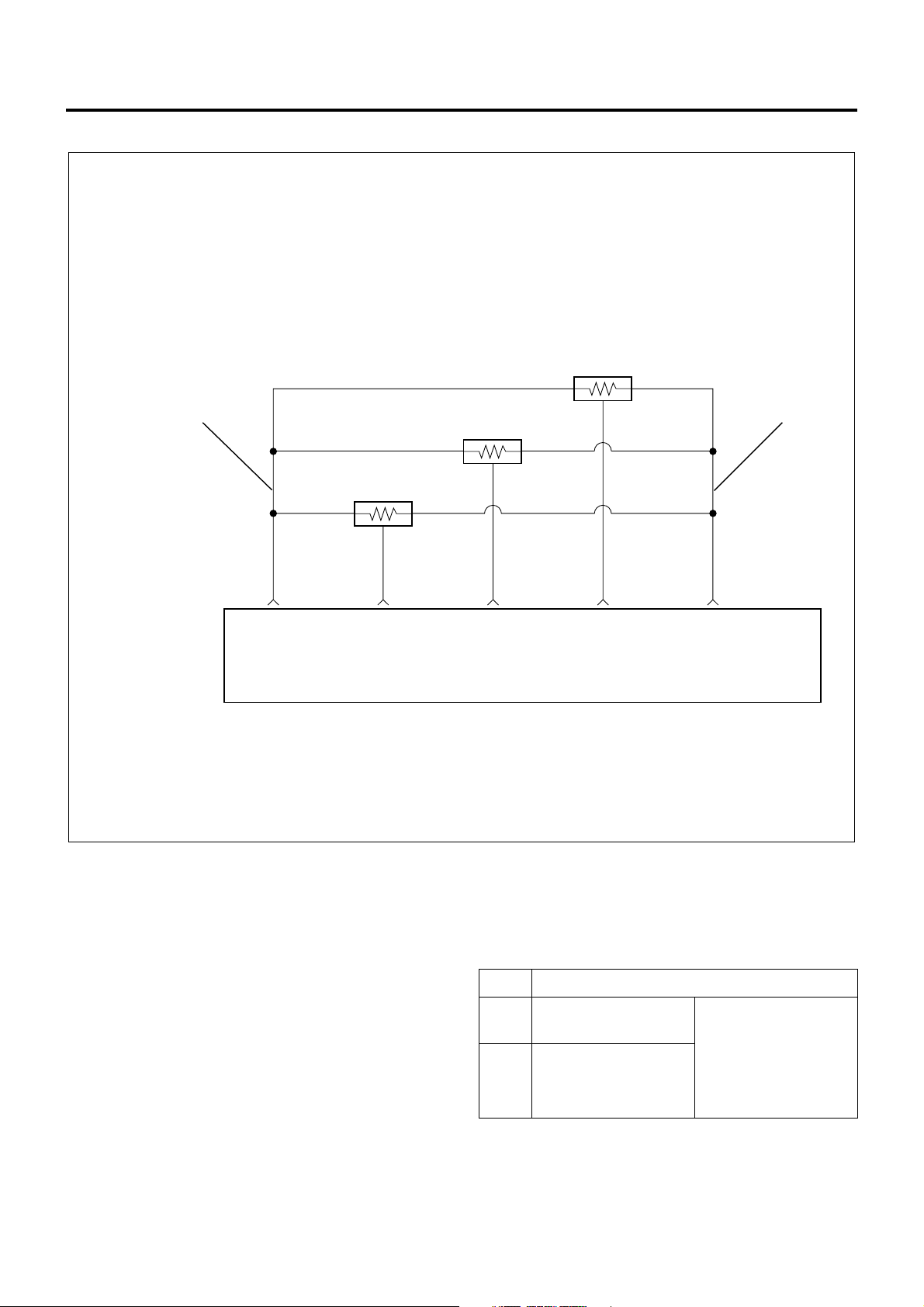

ECM Wiring Diagram (3)

Engine Control System 1A-27

AP (Accelerator Position) Sensor

2 1

Engine Control Module

(ECM)

0.5

Y/B

C6

(Sensor

Ground)

PTO Accelerator Sensor

0.5

R/B

C14

Signal

Idle Up Volume

0.5

Y/G

C10

Signal

0.5

G/O

C11

Signal

0.5

Y/R

C3

(Sensor

Power)

LNW21ALF000501-X

Characteristics of Circuit

• Multiple DTC is generated when several troubles

(failures) occur. When multiple sensors or switches

share a ground, or an open wiring o r short occurs

on the share power sup ply or ground, DTCs with

respect to related sensors or switches are

displayed.

If several DTCs are displayed, it is necessary to

inspect the shared power supply or ground for

open wiring or short.

The harness 1 shown above figure is the power

common to the AP sensor and idle up volume, and

the harness 2 is a common ground. In the event of

open wiring in wire 1 or 2, DTC 24 and 31 are

displayed at the same time. Like this, the case

where two or more DTC’s are displayed is the

multiple DTC.

• If multiple DTC24 and 31 a re di splayed , the power

supply wire 1 or ground wire 2 must be checked.

DTC Sensor actuator (detection item)

24 Accelerator position

sensor

31 idle up volume

Connector not

connected,

harness open wiring,

or

short, failure of

main unit

Page 30

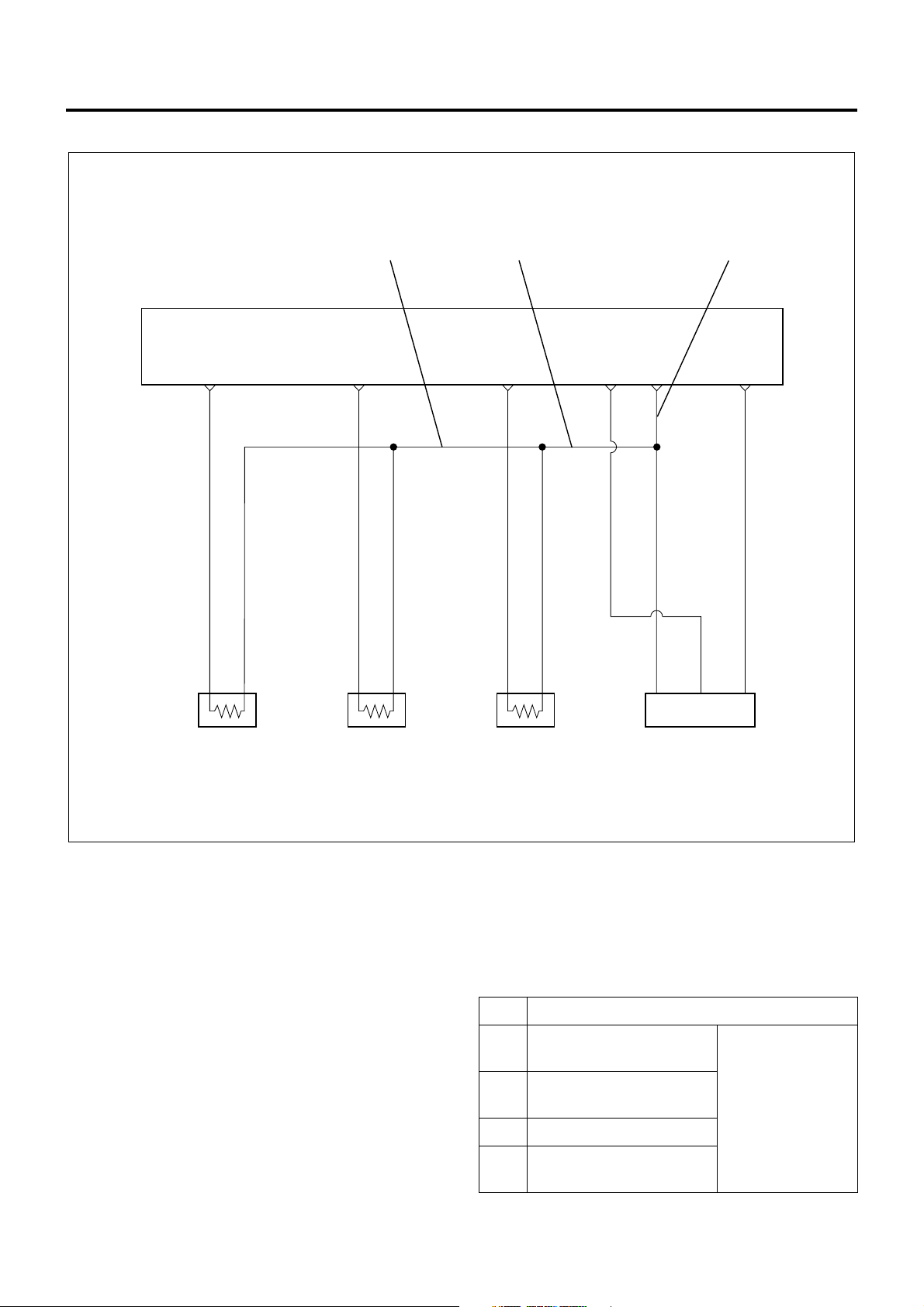

1A-28 Engine Control System

ECM wiring diagram (4)

32 1

ECM

C-1 C-12 C-15 C-9 C-5

0.5

Y/G

0.3

0.5

BLU/

RED

W/

GRN

SIG

Engine Coolant

Temperature

Sensor

GND

0.3

0.5

R/G

W/

GRN

SIG

GND

Fuel Temperature

Sensor

0.3

0.5

R/Y

W/

GRN

SIG

Intake Air

Temperature

Sensor

GND

Sensor

Ground

0.5

W/

GRN

Intake Air

Pressure Sensor

C-4

0.5

L/W

Characteristics of Circuit

• Multiple DTC is generated when several troubles

(failures) occur. When multiple sensors or switches

share a ground, or an open wiring o r short occurs

on the share power sup ply or ground, DTCs with

respect to related sensors or switches are

displayed.

If several DTCs are displayed, it is necessary to

inspect the shared power supply or ground for

open wiring or short.

The harness 1 in above figure is a common ground

for the engine coolant temperature sensor, fuel

temperature senso r, intake air temperature sensor

and intake air pressure sen sor. In the event of the

open wiring in the wi re 1, DTC 21, 23, 41 and 32

are displayed at the same time. In the event of the

open wiring in the wire 2, DTC 21 , 23, and 41 are

displayed at the time. Like this, the case where two

or more DTC’s are displayed is the multiple DTC.

LNW21ALF000601-X

• If multiple DTC21, 23, 41, and 32 are displayed,

the ground wire 1 must be checked.

• If multiple DTC21, 23, and 41 are displayed, the

ground wire 2 must be checked.

• If multiple DTC21 and 23 are displayed, the ground

wire 3 must be checked.

DTC Sensor actuator (detection item)

21 Engine coolant

temperature sensor

23 Intake air temperature

sensor

Connector not

connected,

open wiring or

short of harness,

41 Fuel temperature sensor

32 Intake air pressure

failure of

main unit

sensor

Page 31

ECM Pinouts

ECM is installed in the c en ter c onsol e an d it s i npu t and

output are made through 4 c onnectors of 26 pins, 16

pins, 12 pins and 22 pins respectively, 76 pins in total.

000000 - 0000

0000 24V

000000 0000

MADE IN JAP AN

Engine Control System 1A-29

1

2

3

Legend

1. Engine model, rated voltage

2. Denso parts No.

D13

12

13

25

26

D26

D1

D14

C8

C16

4

LNW21AMF000501

2. Isuzu parts No.

4. Fuel injection unit model

C1

C9

B6

B12

A11

B1

41151269110211312413514615716814115216317418519620721822923102411

1516171819202122

B7

71829310

A22

A1

34567891011

21

14 13 12

A12

No. Connected to No. Connected to

A1 EGR,EVRV A12 Intake throttle VSV

LNW21ASF000501

Page 32

1A-30 Engine Control System

No. Connected to No. Connected to

A2 Startar switch A13 Tech 2 communications (DLC)

A3 Key switch A14 Not used

A4 Not used A15 Accelator position signal output (A/T)

A5 Exhaust brake cut signal (A/T) A16 Exhaust brake cut signal (A/T)

A6 Cluch switch A17 P/N switch, neutral switch

A7 Not used A18 Not used

A8 Not used A19 Freezer switch

A9 Diagnostic switch (DLC) A20 Air conditioner switch

A10 Idle position switch A21 Exhaust brake switch

A11 Power system ground A22 Swirl control VSV

No. Connected to No. Connected to

B1 Not used B7 Stop lamp relay

B2 Warm-up switch B8 Q down (ASR)

B3 Exhaust brake operating signal B9 Exhaust brake answer signal (ASR)

B4 Not used B10 Tachometer output

B5 Crank position sensor (+) B11 Crank position sensor (–)

B6 Pump cam position sensor (+) B12 Pump cam position sensor (–)

No. Connected to No. Connected to

C1 Coolant temperature sensor (+) C9 Intake air pressure

C2 Not used C10 Idle up volume

C3 Sensor power (AP, PTO accelerator, Idle up

volume)

C4 Sensor power (MAP) C12 Fuel temperature sensor (+)

C5 Sensor ground (MAP, coolant temp., intake

temp., fuel temp.)

C6 Sensor ground (AP, PTO accelerator, Idle up

volume)

C7 Not used C15 Intake temperature sensor (+)

C8 Not used C16 Not used

C11 Accelerator position sensor signal

C13 Not used

C14 PTO position sensor signal

No. Connected to No. Connected to

D1 Not used D14 Not used

D2 Not used D15 Not used

D3 Pump ROM communications D16 EDU fail signal input

D4 Exhaust brake VSV1 D17 Pump ROM communications

D5 Not used D18 Not used

Page 33

Engine Control System 1A-31

No. Connected to No. Connected to

D6 Accelerator position signal output (ASR) D19 Exhaust brake indicator lamp

D7 Vehicle speed sensor signal D20 Injection output signal (EDU)

D8 Not used D21 CHEK ENGINE lamp

D9 Main relay D22 Glow indicator lamp

D10 Spill control valve relay D23 Glow relay

D11 Not used D24 Battery power

D12 Timing control valve D25 Not used

D13 Signal ground D26 Power system ground

Strategy-Based Diagnostics

Strategy-Based System Diagnostics

The system diag nostic is a unifo rm approach to repai r

all electrical/electronic (E/E) systems. In the E/E

system, different from genera l vehicle problems, faults

frequently occur along the steps shown as follows:

1. Initial stage:

• A single fault occurs for a short while and,

therefore, the customer may miss it. In this

stage, the customer complaint is unclear and

the fault cannot be reprod uced. But, the ECM

may have stored the fault.

= Past fault

2. Middle stage:

• A single fault occurs for a short while but is

observed intermittent ly. It always occurs und er

certain conditions. The customer complaint

(description of fault) is clear but fault

occurrence conditions are unidentified. If you

comprehend these conditions, you can

reproduce the trouble.

= Intermittent fault (intermittent)

3. Realistic fault:

• The fault occurs certainly and the customer

complaint is realistic and clear. You can

reproduce the fault. However, there may exist

two or more causes.

= Current fault

The diagnostic flow c an always be used to resol ve an

E/E system problem and is a starting point when

repairs are necessar y. Th e following steps will inst ruct

the technician how to proceed with a diagnosis:

1. Verify the customer complaint:

• To verify the customer complaint, the technician

should know the normal operation of the

system.

2. Perform preliminary checks:

• Conduct a thorough visual inspection.

• Review the service history.

• Detecting unusual sounds or odors.

• Gather DTC (diagnostic trouble code)

information using Tech 2

3. Check bulletins and other servic e information.

4. Refer to “Symptom Diagnosis Chart” in this

manual.

• “Symptom Diagnosis Chart” contain information

on a system that may n ot be support ed by one

or more DTCs. “Symptom Diagnosis Chart”

verify proper operation of the system. This will

lead the technician in an organized approach to

diagnostics.

5. Refer to related descriptions such as those for

engine mechanicals.

DTC Stored

Follow the designated DTC chart exactly to make an

effective repair.

No DTC

Select the symptom from the “Symptom Diagnosis

Chart”. Follow to the diagnostic paths or suggestions to

complete the repair. You may refer to the applicable

components/system check in the functional check.

No Matching Symptom

1. Analyze the complaint.

2. Develop a plan for diagnostics.

3. Utilize the wiring diagrams and the theory of

operation.

Call technical as si st anc e for s im il ar c as es wh er e repair

history may be available. Combine technician

knowledge with efficient use of the available service

information.

Intermittents

Conditions that are not always present are call

intermittents. To resolve intermittents, perform the

following steps.

1. Observe history DTCs, DTC modes, and engine

data.

2. Evaluate the symptoms and the condition

described by the customer.

Page 34

1A-32 Engine Control System

3. Use a check sheet or othe r method to identify the

circuit or electrical system component.

No Trouble Found

This condition exists when the vehicles is found to

operate normally. The condition described by the

customer may be normal. Verify the customer

complaint against another vehicle that is operating

normally. The condition may be interm ittent. Verify the

complaint under the conditions described by the

customer before releasing the vehicle.

1. Reexamine the complaint.

When the compl aint cannot be suc cessfully found

or isolated, a re-evaluation is necessary. The

complaint should be re-verified and could be

intermittent as defin ed in Inter mittents, or c ould be

normal.

No. Item Objective Method

2. Repair and verify.

After isolating the cause, the repairs should be

made. Validate for proper operation and verify that

the symptom has been corrected. This may involve

road testing or other methods to verify that the

complaint has been resolved under the following

conditions:

• Conditions noted by the customer.

• If a DTC was diagnosed, verify a repair by

duplicating conditions present when the DTC

was set as noted by Tech 2 data.

Verifying Vehi cle Repair

When the electronic con trol syste m has been re paired,

it is necessary to verify the repa ir is appropriate. If the

repair is incomplete , the CHECK ENGINE Lam p (MIL)

may be lit again while the vehicle is released, or the

drivability may be impaired. Particularly for the

intermittents, it is necessary to reproduce the trouble

under the same conditi ons described by the custo mer

and check the trouble is no longer found.

1 Verifying the

DTC

2 Verifying the idle

speed after

warm-up

3 Verifying Tech 2

data list

4 Verifying the

restartability

5 Verifying the

electromagnetic

compatibility of

strong electric

wave emission

equipment

To check the DTC is not set

after the repair.

To check the idle control is

normally performed.

To provide basic checking for

engine control and

communication con di tio ns .

To check the start control

correctly works.

To check electric wave

emission equipment such as

transceiver, if added, does not

emit interfering waves.

Clear the previous DTC. Sufficiently warm up the

engine under idling, and increase the engine

speed to 2200 rpm and provide racing to verify

the test conditions.

Upon completion of engine warm-up, verify the

idle speed is 580 rpm for a manual transmission

vehicle or 650 rpm for an automatic transmission

vehicle with the air conditioner turned off. If a fault

is detected, refer to "Instable idling" in "

“Symptom Diagnosis Chart" to identify the cause.

Monitor Tech 2 data list and examine the data

using typical value sheet. Check typical values in

Tech 2 data list.

Upon completion of engine warm-up, verify the

cranking time is not more than 5 seconds and the

engine speed is stable after startup.

Turn on and off the electric wave emission

equipment, such as transceiver, to check whether

idle speed will change. If a problem is found,

inform the customer that the electric wave

emission equipment must be dislocated or

changing the power is needed.

Supplementary d escription about strong electric wa ve

emission equipment: If a problem is found in this

checking, provide the following advices to the

customer.

• To install the antenna away from the vehicle

electronic system components such as control unit

and sensor s as far as possible.

• To install the antenna cord at least 20 cm away

from the vehicle electronic system components

such as control unit and sensors.

• Do not arrange the antenna cord together with

other cables. In additi on, isolate the antenna cord

from other cables as far as possible.

• Install additional devices certainly according to

respective instruction manuals.

• Do not install high-power mobile communication

equipment.

Page 35

Engine Control System 1A-33

CAUTION:

Follow the steps below when you verify repairs on

OBD systems. Failure to follow these steps could

result in unnecessary repairs.

1. Review and record Tech 2 data relative to the

issued DTC.

2. Clear the DTC(s).

3. Operate the vehicl e while che cking t he associ ated

Tech 2 data.

Non-OEM Parts

All of the OBD diagnostic s have been calib rated to run

with OEM parts. There fore, installation of general onmarket sensors or switches are will result in incorrect

OBD diagnostics and CHECK ENGINE Lamp (MIL)

activation.

If on-market electroni c de vices such as mobile phon es ,

stereos, and theft deterrent system are improperly

installed, EMI (electromagnetic interference) radiation

occurs and affects the control system. As a result,

incorrect data are sent from sensors to turn on the

CHECK ENGINE Lamp (MIL). To diagnose the vehicle

with the OBD system, turn off or remove all the onmarket parts.

Poor Vehicle Maintenance

The sensitivity of OBD diagnostics will cause the

CHECK ENGINE Lamp (MIL) to turn on if the ve hi cl e is

not maintained properly. Restricted oil filters, fuel filters,

and crankcase deposi ts due to lack of oil changes or

improper oil viscosity can trigger actual vehicle faults

that were not previously monitored prior to OBD

diagnostics. Vehicle maintenance cannot be classified

as "non-vehicle fault", but with the sensitivity of OBD

diagnostics, vehic le maintenance schedules mu st be

more closely followed.

Related System Faults

Many of OBD system diagnostics will not run if the

ECM detects a fault on a related system or component.

Visual/Physical Engine Compartment Inspection

Perform a carefu l visual/physical engine co mpartment

inspection when perfo rming dia gnostic pro cedure. Th is

can often lead repairing a problem without further

steps. Use the followi ng guidelines when per forming a

visual/physical inspection.

• Inspect all vacuum hoses for punches, cuts,

disconnects, and co rrec t rout in g.

• Inspect hoses that ar e difficult to see be hind other

components.

• Inspect all harnesses in the engine compartment

for proper connections, burned or chafed spots,

pinched harnesses, contact with sharp edges or

contact with hot exhaust manifolds or pipes.

Basic Knowledge of Tools Required

IMPORTANT:

Lack of basic knowledge of this powertrain when

performing diagnostic procedures could result in

an incorrect diagnosis or damage to powertrain

components. Do not attempt to diagnose a

powertrain problem without this basic knowledge.

A basic understanding of hand tools, including

scan tool, is necessary to effectively use this

section of the Service Manual.

On-Board Diagnostic Tests

The diagnostic test is a series of steps, the result of

which is a pass or fail reported to the Diagnostic

Executive. When a diagnostic test reports a pass

result, the Diagnostic Executive records the following

data:

• The diagnostic test has been co mpleted sinc e the

last ignition cycle.

• The diagnostic tes t has passed durin g the current

ignition cycle.

• The fault identified by the diagnostic test is not

currently active.

When a diagnostic test reports a fail result, the

Diagnostic Executive records the following data:

• The diagnostic test has been co mpleted sinc e the

last ignition cycle.

• The fault identified by the diagnostic test is

currently active.

• The fault has been active during this ignition cycle.

• The operating conditions at the time of the failure.

Comprehensive Component Monitor Diagnostic

Operation

Comprehensive com ponent moni toring dia gnostics ar e

required to operate the engine properly.

Input Components

Input components are monitored for circuit continuity

and out-of-range values. This includes rationality

checking. Rationality checking refers to indicating a

fault when the signal from a sensor does not seem

reasonable, i.e., accele rator positi on sensor (AP S) that

indicates high throttle position at low engine loads or

low voltage MAP (manifold absolute pressure). Input

components may include, but are not limited to the

following sensors:

• Intake air temperature (IA T) sensor

• Crank position (CKP) sensor

• Engine coolant temperature (ECT) sensor

• Intake air pressure (MAP) sensor

• Accelerator position (AP) sensor

• Fuel temperature (FT) sensor

• Vehicle speed (VS) sensor

Page 36

1A-34 Engine Control System

Output Components

Output components are dia gno se d for pr ope r res pon se

to control module commands. Components where

functional monitoring is not feasible will be monitored

for circuit continuity and out-of-range values if

applicable. Output components to be monitored

include, but are not limited to, the following circuits:

•EGR EVRV

• Tra nsmission control

• Intake throttle

Terms Commonly Used in Diagnosis

Diagnostic

When used as a noun, the word diagnostic refers to

any on-board test run by the vehicle’s Diagnostic

Management System. A diagnostic i s simply a test r un

on a system or c omponent to determine if the system

or component is operating according to specification.

There are many diagnostics, shown in the following list.

• EGR (exhaust gas recirculation)

• Engine speed

• Vehicle speed

• ECT (engine coolant temperature)

• MAP (intake air pressure)

• VSV (Vaccum switching valve)

• IAT (intake air temperature)

• AP (accelerator position)

• FT (fuel temperature)

• Idle position switch

• Brake switch

by the diagnostic p rocedures c ontained in this manual.

The language of communicating the source of the

malfunction is a system of diagnostic trouble codes.

When a malfunction is detect ed by the control modul e,

a diagnostic trouble code is set and the CHECK

ENGINE Lamp (MIL) is illuminated.

Malfunction Indicator Lamp (MIL)

The malfunction indicator lamp (MIL) looks the same as

the MIL you are already familiar with ("Check Engine"

lamp).

Basically, the MIL is turned on when the electronic

control system s uch as ECM (engine control modu le)

fails and a DTC is detected.

Data Link Connector (DLC)

The provision of communication with the control

module is the data link connector (DLC). The DLC is

used to connect to Tech 2, or a scan tool. Some

common uses of Tech 2 are listed below.

• Identifying stored diagnostic trouble codes (DTCs)

• Clearing DTCs

• Performing output control tests

• Reading serial data

Diagnostic Executive

The Diagnostic Executive is a unique segment of

software that is designed to coordinate and prioritize

the diagnostic procedures as well as define the

protocol for recordin g and displaying their results. T he

main responsibilities of the Diagnostic Executive are

listed as following

• Commanding CHECK ENGINE Lamp (MIL) on and

off

• DTC logging and clearing

• Tech 2 data recording

• Acquiring current status information on each

diagnostic

Diagnostic Information

The diagnostic charts and functional checks are

designed to locate a faulty circuit or component through

a process of logi ca l d ec isio ns . T he ch ar ts ar e p re par ed

with the requirement that the vehicle functioned

correctly at the time of assembly and there are not

multiple faults present.

There is a continu ous self-diagnos is on certain co ntrol

functions. This diagnostic capability is complemented

87654321

161514131211109

LNW21ASH001801

Verifying Vehi cle Repair

Verification of vehicle repair will be more

comprehensive for vehicles with on-board diagnostic

(OBD) system diagnostic. Following a repair, the

technician should perform the following steps:

1. Review and record DTC diag nosed o r Tech 2 data

or both.

2. Clear DTC(s).

3. Operate the vehicle within the conditioned

described by Tech 2 data.

Page 37

4. Monitor the DTC st atus info rmation for the spec ific

DTC that has been diagnosed until the ECM

performs the diagnostic test associated with that

DTC.

Following these steps is very important in verifying

repairs OBD systems. Failure to follow these steps

could result in unnecessary repairs.

Diagnostic Trouble Code (DTC)

Whenever the starter switch is turned on, the ECM

executes self-testing for almost wirings and

components and, when detec ts a s ystem faul t, sto res i t

and enables backup co ntrol according to the DTC set.

When a fault occurs that will affect the running, the

ECM turns on the CHECK ENGINE Lamp (MIL) in the

meter panel or blinks the exhaust indicator lamp to

inform the driver of the fact.

Reading Diagnostic Trouble Codes

Current and past DTCs stored to the ECM can be

visualized in the form of blinking CHECK ENGINE

Lamp (MIL) when the DLC (data link connector) is

shorted. To this end, provide the following steps.

1. Turn on the key switch and check the CHECK

ENGINE Lamp (MIL) is turned on. (Bulb check)

Engine Control System 1A-35

87654321

161514131211109

LNW21ASH000301

4. On the CHECK ENGINE Lamp (MIL), read the

number of blinks.

5. Identify the DTC from the DTC Chart.

Diagnostic Trouble Codes Not Stored

Code 12 that shows initiati on of i ndication is repeatedly

displayed.

LNW21ASH000201

2. Keep the key switch turned on and the engine

turned off.

3. Short pins 6 and 4 on the DLC. The DLC is a black

16-way connector and located at the lower right

corner of the instrument panel.

Page 38

1A-36 Engine Control System

Diagnostic Trouble Codes Stored

Code 12 that is displayed three times and then stored

code is displayed three ti mes. When multiple DTCs are

stored, each code is displayed three times, starting

from the lowest n umber. After all DTCs are displayed ,

above sequence is repeated from code 12 as l ong as

DLC is being shorted.

eg.,) Display Start Cord "12"

Display Start

Turn On

Turn Off

eg.,) Trouble Cord "21"

Display Start

Turn On

urn Off

0.4 0.4

0.4 0.4

3.2

1.2

3.23.2 1.2

3.2

Unit (sec)

Unit (sec)

eg.,1 : Diagnostic Trouble Codes not Stored

12 12 12 12 12 12 12 12 12 12 12 12 12 12 12

eg.,2 : Diagnostic Trouble Codes "21", "24" Stored

12 12 12 21 21 21 24 24 24 12 12 12 21 21 21

Clearing Diagnostic Trouble Codes

When the system fails and the DTC is stored to the

ECM, even repairing the faulty po rtion will not clea r the

DTC from the memory. To clear the DTC, conduct the

steps listed below.

• Keep the starter switch turned on and the engine

turned off.

• Short the data link connector.

Perform the following steps.

1. Turn off the idle position switch for not less than 1

second but n ot more than 3 seconds. (Pr ess the

accelerator pedal.)

2. Turn on the idle position sw itch for not le ss than 1

second but not more than 3 seconds. (Release the

4. Turn on the idle position switch for not less than 1

second but not more than 3 seconds. (Release the

accelerator pedal.)

5. Turn off the idle position swi tch for not le ss than 1

second but not more than 3 seconds. (Press the

accelerator pedal.)

6. After the above operations are properly completed,

the CHECK ENGINE L amp (MIL) illumi nates for 3

seconds to report the memory is cleared.

7. Turn off the starter switch. Wait for 5 seconds a nd

turn on the starter switch again.

When Tech 2 ha s been connected to the vehicle, the

DTC can be cleared through the memory clear

operation with Tech 2.

accelerator pedal.)

3. Turn off the idle position switch for not less than 1

second but n ot more than 3 seconds. (Pr ess the

accelerator pedal.)

Endless Display

Endless Display

LNW21AMF000601-X

Page 39

Engine Control System 1A-37

Functional Check List

Hearing The objective is to comprehend the symptom completely based on the

customer complaint and provide accurate diagnostic.

On-Board Diagnosti c Syst em

Check

Inactive CHECK ENGINE Lamp

(MIL) Check

Active CHECK ENGINE Lamp

(MIL) Check

The objective is to identify the faulty por tion on the electronic en gine control

system. (Checking proc edu re )

The objective is to check the CHECK ENGINE Lamp (MIL) when it is not

turned on even after ignition switch turn-on.

The objective is to check the C HECK ENGINE Lam p (MIL) is turn o n through

the DTC is not set while the engine running

Engine is crank but will not run The objective is to check the engine is not started though it is cranked by

turning the starter switch

Hearing Diagnostic

1. Using the Engine Control System Diagnostic

Chart, completely hear and comprehend the

customer complaint.

Reference:

Engine Control System Diagnostic Chart

When receiving the vehicle from the customer in the

service factory, you must verify both the symptom and

failure data using the Engine Control System

Diagnostic Chart.

Proceed the process by focusing on the po ssible

faulty system estimated from the fault (fact)

instead of random hearing.

2. Judge the failure information accurately.

1

Comprehend the situation concretely based on

5W1H principle.

Example: Low temperature, startup stage,

permanent generation, vicinity of engine, metallic

2

sound, etc.

Key points on hearing

• What • Faulty event

• When • Date and time, generation

frequency

• Where • Situation of road

• State • Running condition, driving

condition, weather conditions

• Result • Feeling of fault

LNW21ASH001301

Legend

1. Symptom

2. Failure generation frequency and conditions

t

The reason why this sheet is needed is as follows.

1. The symptom may not be reproduced in the

service factory.

2. The customer complaint is always not represent

failure.

3. If failure conditions are not i npu t to the respo n sibl e

technician correctly, unwanted repair man-hours

will be generated.

• The Engine Control System Diagnostic Chart helps

diagnostic, repair, and repair verification.

Page 40

1A-38 Engine Control System

Engine Control System Diagnostic Chart

Customer

Driver

Vehicle acceptance

date

Registration No.

No engine start

Poor startability

Instable idling

Poor driveability

SymptomFault conditions

Engine stall

Vibration at idling

Data observed at fault occurrence

Fault generation frequency

No cranking No initial combustion Incomplete initial combustion

Long cranking (6 seconds or more)

Others

Incorrect idle speed (idle speed enters into

typical range after warm-up)

Rough idling (idle speed deviates from

the typical range after warm-up)

Surging

Unusual sound

Immediately after engine startup

At operation of A/C

At gear shifting

Engine has transverse vibration and body has vertical vibration (engine’s vertical vibration is weaker than body’s

vibration)

Always

Others

Inspector:

Vehicle model and model

year

Vehicle ID

Engine model

Engine ID

Engine type

Odometer reading km

Unusual idle speed High ( rpm) Low ( rpm)

Others