Page 1

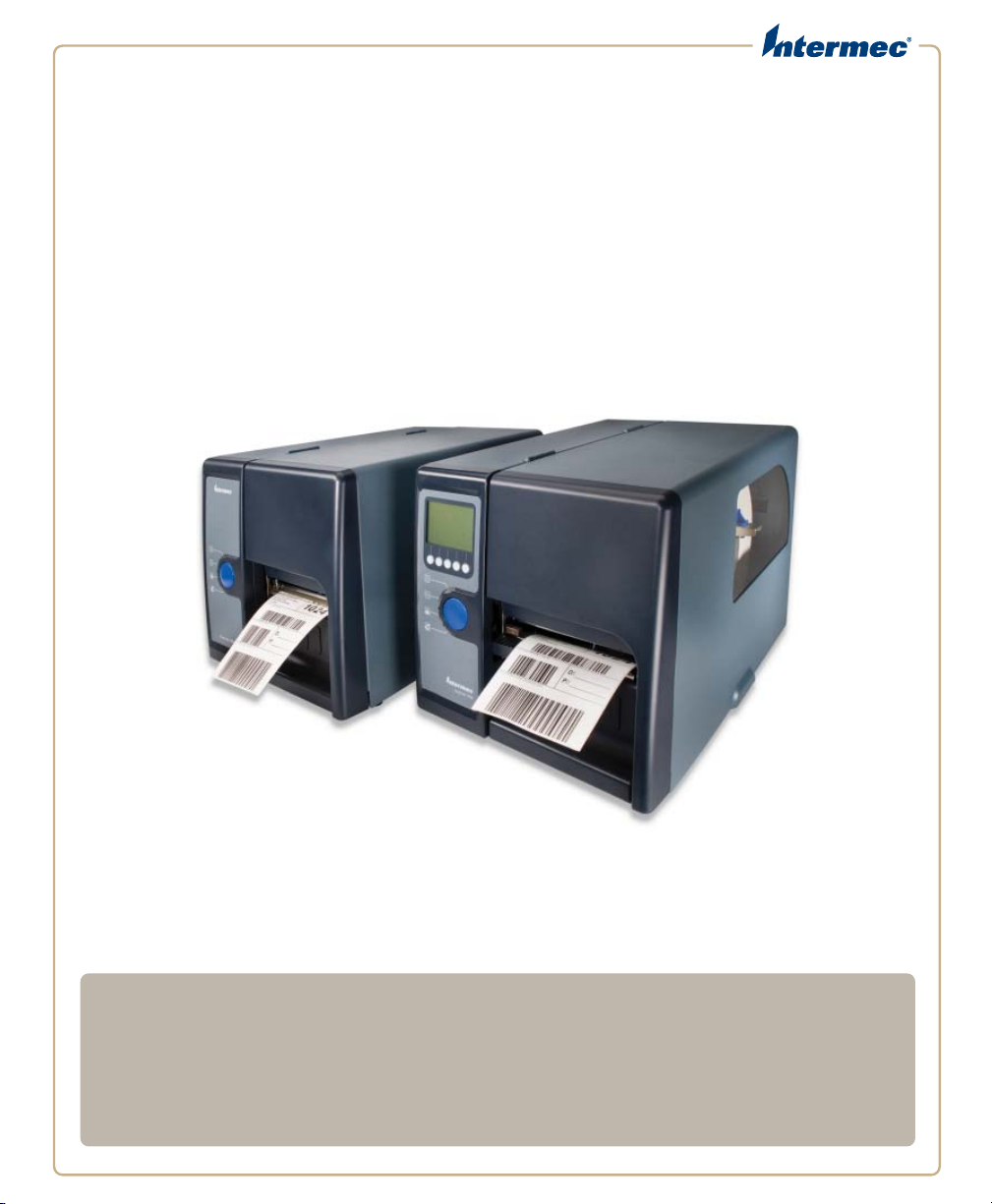

PD41 | PD42

Commercial Printer

User’s Manual

Page 2

Intermec Technologies Corporation

Worldwide Headquarters

6001 36th Ave.W.

Everett, WA 98203

U.S.A.

www.intermec.com

The information contained herein is provided solely for the purpose of allowing customers to

operate and service Intermec-manufactured equipment and is not to be released, reproduced, or

used for any other purpose without written permission of Intermec Technologies Corporation.

Information and specifications contained in this document are subject to change without prior

notice and do not represent a commitment on the part of Intermec Technologies Corporation.

© 2009 by Intermec Technologies Corporation. All rights reserved.

The word Intermec, the Intermec logo, Norand, ArciTech, Beverage Routebook, CrossBar,

dcBrowser, Duratherm, EasyADC, EasyCoder, EasySet, Fingerprint, i-gistics, INCA (under license),

Intellitag, Intellitag Gen2, JANUS, LabelShop, MobileLAN, Picolink, Ready-to-Work, RoutePower,

Sabre, ScanPlus, ShopScan, Smart Mobile Computing, SmartSystems, TE 2000, Trakker Antares,

and Vista Powered are either trademarks or registered trademarks of Intermec Technologies

Corporation.

There are U.S. and foreign patents as well as U.S. and foreign patents pending.

Wi-Fi is a registered certification mark of the Wi-Fi Alliance.

Microsoft, Windows, and the Windows logo are registered trademarks of Microsoft Corporation

in the United States and/or other countries.

This product includes software developed by the OpenSSL Project for use in the OpenSSL Toolkit

(www.openssl.org).

This product includes cryptographic software written by Eric Young (EAY@cryptsoft.com).

ii PD41 and PD42 Commercial Printer User’s Manual

Page 3

Contents

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Global Services and Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Warranty Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Web Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Telephone Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Service Location Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Who Should Read This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Using the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1

Learning About the Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

What’s New?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Identifying the Parts of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Selecting the Printer Command Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Understanding the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Understanding the Print Button and LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . 6

Understanding the PD42 Screen and Soft Keys . . . . . . . . . . . . . . . . . . . . . . 8

Understanding Printer States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Contents

Loading Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Loading Media for Tear-Off Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Loading Media for Peel-Off (Self-Strip) Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Loading Thermal Transfer Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Printing a Test Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Creating and Printing Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Connecting the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2

Connecting the Printer to Your PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Connecting the Printer to a PC Through the USB Device Port . . . . . . . . . . . . . . . 24

Connecting the Printer to a PC Through the Serial Port . . . . . . . . . . . . . . . . . . . . . 24

Connecting the Printer to a PC Through the IEEE 1284 Port . . . . . . . . . . . . . . . . 25

Connecting the Printer to Your Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setting Up Ethernet Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Manually Configuring IP Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

PD41 and PD42 Commercial Printer User’s Manual iii

Page 4

Contents

Setting Up 802.11 Radio Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Configuring 802.11 Wireless Security Using IPL . . . . . . . . . . . . . . . . . . . . 31

Configuring 802.11 Wireless Security Using Fingerprint . . . . . . . . . . . . 34

Connecting Peripherals to the USB Host Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Using a USB Mass Storage Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Connecting a Keyboard to the USB Host Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Connecting a Bar Code Scanner to the USB Host Port. . . . . . . . . . . . . . . . . . . . . . . 39

Connecting a USB Hub to the USB Host Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Configuring the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3

Configuring the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Configuring the PD42 Printer from the Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Configuring the Printer From the Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Configuring Communications Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Configuring Media Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Configuring Print Engine Settings (Fingerprint only) . . . . . . . . . . . . . . . 46

Configuring Web Shell Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Configuring Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Configuring General Network Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Configuring Mail Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Configuring SNMP Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Configuring TCP/IP Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Configuring the Network Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Configuring Avalanche Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Configuring Wireless LAN Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Configuring 802.1x Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Configuring SmartSystems Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Configuring the Printer Using PrintSet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Configuring the Printer Using Commands Sent From Your PC . . . . . . . . . . . . . . 59

Configuring the Printer Using SmartSystems Foundation . . . . . . . . . . . . . . . . . . .59

Choosing an Ethernet or Wireless Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Using the PD42 Screen to Choose the Network Type . . . . . . . . . . . . . . . . . . . . . . . . 60

Using Printer Commands to Choose the Network Type . . . . . . . . . . . . . . . . . . . . .60

Upgrading the Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Downloading Fonts and Graphics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

iv PD41 and PD42 Commercial Printer User’s Manual

Page 5

Troubleshooting and Maintaining the Printer. . . . . . . . . . . . . . . . . . . . . . 65

4

Troubleshooting the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Contacting Product Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Understanding Error Messages on the PD42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Troubleshooting Printer Problems and Finding Solutions . . . . . . . . . . . . . . . . . . . 69

Troubleshooting Communication Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Using the Line Analyzer in Fingerprint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Using Dump Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Using Testmode and Extended Testmode to Troubleshoot. . . . . . . . . . . . . . . . . . . 74

Using Testmode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Using Extended Testmode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Adjusting the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Preventing Ribbon Wrinkling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Clearing Media Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Adjusting the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Adjusting Printhead Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Adjusting Printhead Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Adjusting Printhead Dot Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Adjusting the Label Stop Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Maintaining the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Cleaning the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Cleaning the Media Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Cleaning the Exterior of the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Contents

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

A

Printer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

RS-232 Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

USB Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

USB Host Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Ethernet Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Parallel IEEE 1284 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Media Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Accessories for the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

PD41 and PD42 Commercial Printer User’s Manual v

Page 6

Contents

Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

B

Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

IPL Default Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Fingerprint Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

ESim Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

Fingerprint, IPL, and ESim Setup Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . 119

C

Fingerprint Setup Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Fingerprint Ser-Com, UART1 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Fingerprint Net-Com, NET1 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Fingerprint Com Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Fingerprint Network Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Fingerprint Emulation Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Fingerprint Feedadjust Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Fingerprint Media Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Fingerprint Print Defs Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

IPL Setup Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

IPL Ser-Com Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

IPL COM Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

IPL Network Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

IPL Test/Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

IPL Media Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

IPL Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

ESim Setup Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

ESim Serial-Com Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

ESim Net-Com, NET1 Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

ESim Com Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

ESim Network Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

ESim Feedadjust Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

ESim Media Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

ESim Print Defs Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

ESim Charset Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

ESim Date Time Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Advanced Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

D

Printer File System (Fingerprint) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

Device Tree Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

Devices and Directories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

vi PD41 and PD42 Commercial Printer User’s Manual

Page 7

Contents

Customing the Printer Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Web Style Guide Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Content of a Web Style Guide File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Required Environment Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Optional Environment Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

x-www-url-Encoding Syntax Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Memory and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Creating a Web Style Guide File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

I

PD41 and PD42 Commercial Printer User’s Manual vii

Page 8

Contents

viii PD41 and PD42 Commercial Printer User’s Manual

Page 9

Before You Begin

This section provides you with safety information, technical support

information, and sources for additional product information.

Safety Information

Your safety is extremely important. Read and follow all warnings and

cautions in this document before handling and operating Intermec

equipment. You can be seriously injured, and equipment and data can

be damaged if you do not follow the safety warnings and cautions.

This section explains how to identify and understand dangers,

warnings, cautions, and notes that are in this document. You may also

see icons that tell you when to follow ESD procedures and when to

take special precautions for handling optical parts.

A caution alerts you to an operating procedure, practice,

condition, or statement that must be strictly observed to prevent

equipment damage or destruction, or corruption or loss of data.

Before You Begin

Note: Notes either provide extra information about a topic or contain

special instructions for handling a particular condition or set of

circumstances.

Global Services and Support

Warranty Information

To understand the warranty for your Intermec product, visit the

Intermec web site at www.intermec.com and click Support >

Returns and Repairs > Warranty.

Disclaimer of warranties: The sample code included in this document

is presented for reference only. The code does not necessarily

represent complete, tested programs. The code is provided “as is with

all faults.” All warranties are expressly disclaimed, including the

implied warranties of merchantability and fitness for a particular

purpose.

PD41 and PD42 Commercial Printer User’s Manual ix

Page 10

Before You Begin

Web Support

Visit the Intermec web site at www.intermec.com to download our

current manuals (in PDF). To order printed versions of the Intermec

manuals, contact your local Intermec representative or distributor.

Visit the Intermec technical knowledge base (Knowledge Central) at

www.intermec.com and click Support > Knowledge Central to

review technical information or to request technical support for your

Intermec product.

Telephone Support

In the U.S.A. and Canada, call 1-800-755-5505.

Outside the U.S.A. and Canada, contact your local Intermec

representative. To search for your local representative, from the

Intermec web site, click About Us > Contact Us.

Service Location Support

For the most current listing of service locations, go to

www.intermec.com and click Support >Returns and Repairs >

Repair Locations.

For technical support in South Korea, use the after service locations

listed below:

AWOO Systems

102-1304 SK Ventium

522 Dangjung-dong

Gunpo-si, Gyeonggi-do Korea, South 435-776

Contact: Mr. Sinbum Kang

Telephone: +82-31-436-1191

E-mail: mjyun@awoo.co.kr

IN Information System PTD LTD

6th Floor

Daegu Venture Center Bldg 95

Shinchun 3 Dong

Donggu, Daegu City, Korea

E-mail: jmyou@idif.co.kr or korlim@gw.idif.co.kr

x PD41 and PD42 Commercial Printer User’s Manual

Page 11

Who Should Read This Manual

This user’s guide is written for the person who is responsible for

installing, configuring, and maintaining the PD41 or PD42 printer.

This user’s guide provides you with information about the features of

the printer, and how to install, configure, operate, maintain, and

troubleshoot it.

Before you work with the printer, you should be familiar with your

network and general networking terms, such as IP address.

Related Documents

The Intermec web site at www.intermec.com contains our

documents (as PDF files) that you can download for free.

To do wnload documents

1 Visit the Intermec web site at www.intermec.com.

2 Click Support > Manuals.

3 Use the Product Category field, the Product Family field, and

the Product field to help you locate the product whose

documentation you want to download.

Before You Begin

PD41 and PD42 Commercial Printer User’s Manual xi

Page 12

Before You Begin

xii PD41 and PD42 Commercial Printer User’s Manual

Page 13

1

Using the Printer

In this chapter, you will find these sections:

• Learning About the Printers

• Loading Media

• Loading Thermal Transfer Ribbon

• Printing a Test Label

• Creating and Printing Labels

1

Page 14

Chapter 1 — Using the Printer

Learning About the Printers

The PD41 and PD42 Commercial Printers are dependable and

versatile printers suitable for medium-duty applications in

manufacturing, transportation, and warehousing environments.

With all-metal chassis and covers, proven printing mechanics and

powerful electronics, they provide the sturdiness and performance

your business depends on. The PD42 features an intuitive user

interface with a large graphical screen and programmable buttons.

Throughout this manual, both models of the printer are referred to as

“printer” unless the information is specific to one model.

What’s New?

There have been many updates to the PD41 and PD42 printers. This

version of the printer user’s guide contains these changes:

• Ability to choose between these command languages: IPL, ESim,

ZSim, DSim, Fingerprint, and Direct Protocol.

• Support for IPv6.

• Ethernet is now standard on both printers.

• 802.11 option is available on both printers.

• USB mass storage device support for booting the printer and

downloading fonts.

The PD41 and PD42 Commercial Printers with an RC11

802.11b/g radio installed are Wi-Fi® certified for interoperability

with other 802.11b/g wireless LAN devices.

2 PD41 and PD42 Commercial Printer User’s Manual

Page 15

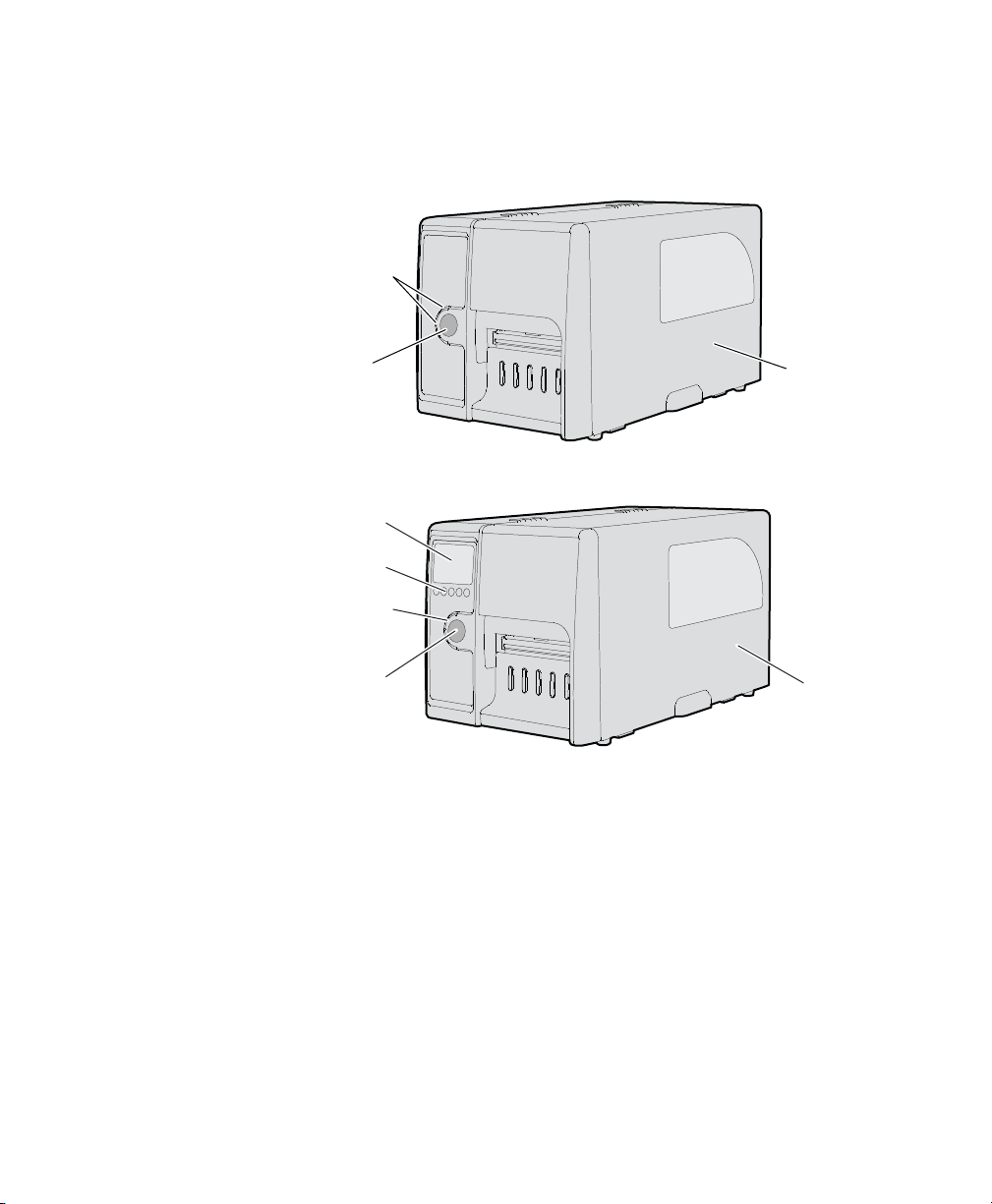

Identifying the Parts of the Printer

Control LEDs (4)

Print button

Soft keys (5)

Display

Media cover

Use this section to familiarize yourself with the parts of the PD41 and

PD42 printers.

Control LEDs (4)

Chapter 1 — Using the Printer

Print button

Front View of the PD41 Printer

Front View of the PD42 Printer

Media cover

PD41 and PD42 Commercial Printer User’s Manual 3

Page 16

Chapter 1 — Using the Printer

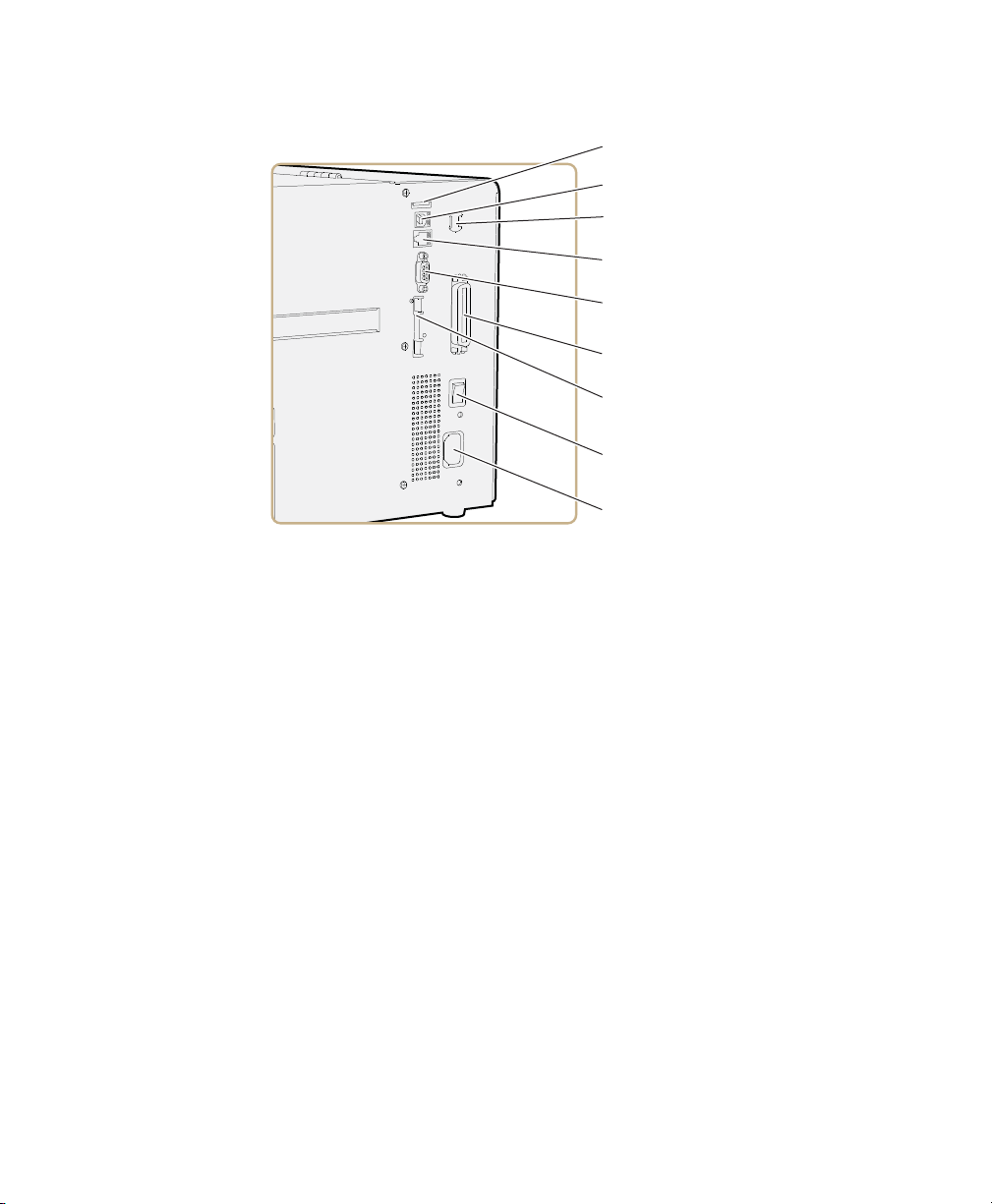

Ethernet RJ-45

USB port

USB host port

RS-232 serial port

IEEE 1284 parallel port

CompactFlash

Power On/Off switch

AC power cord socket

Wireless 802.11 port

Rear View of the PD41 and PD42 Printers

Selecting the Printer Command Language

The PD41 and PD42 printers come loaded with five different printer

command languages. On the PD42 printer, you select the command

language the first time you power up the printer. For more

information see the following procedure.

The PD41 printer always starts up using the Fingerprint printer

language because it does not have a screen to select the command

language. You will need to use the printer home page or PrintSet to

choose a printer command language. For help, see “Configuring the

Printer From the Home Page” on page 44 or “Configuring the

Printer Using PrintSet” on page 58.

The language you select automatically runs each time you turn on

your printer. The printer language you choose affects the

functionality of the printer and how you interact with it.

4 PD41 and PD42 Commercial Printer User’s Manual

Page 17

Chapter 1 — Using the Printer

Printer Command Language Descriptions

Command

Language

Fingerprint Intermec Fingerprint is a BASIC-inspired programming

IPL Intermec Printer Language (IPL) is an easy-to-use

ZSim ZSim is a Zebra™ interpreter program that interprets ZPL

DSim DSim is a Datamax™ simulation program that runs

ESim ESim is a built-in protocol for use with Intermec bar code

Description

language that lets you design label formats and write

custom printer application software.

programming language that lets you design, download,

and modify formats.

II or later programs. To set up, configure, and use ZSim,

see the ZSim User’s Guide.

Datamax programs. To set up, configure, and use DSim,

see the DSim User’s Guide.

label printer. To set up, configure, and use ESim, see the

ESim Programmer’s Reference Manual.

To select the printer command language on the PD42 printer

• Press the soft key that corresponds to the printer language you

want to run on your printer.

Choose command

language

FP IPL ZSIM

DSIM ESIM

PD42 Startup Screen: This screen appears the first time you turn on the

PD42.

PD41 and PD42 Commercial Printer User’s Manual 5

Page 18

Chapter 1 — Using the Printer

Once your printer is running a particular printer language, you can

change the printer language from the Setup menu.

To change the printer command language from the PD42 Setup menu

1 Press the Setup ( ) button.

2 Press until you see PRINT DEFS and then press .

3 Press until you see CMD LANGUAGE and then press .

4 Press until you reach the command language you want to use,

and then press .

5 Press ( ) to exit the Setup menu.

You can also use the printer home page or PrintSet to choose a printer

command language. For help, see “Configuring the Printer From

the Home Page” on page 44 or “Configuring the Printer Using

PrintSet” on page 58.

Understanding the Front Panel

The PD41 control panel consists of one button and four LEDs. The

PD42 control panel consists of one button, four LEDs, a screen, and

five soft keys. Use the next two sections to understand how to use the

front panel on each printer.

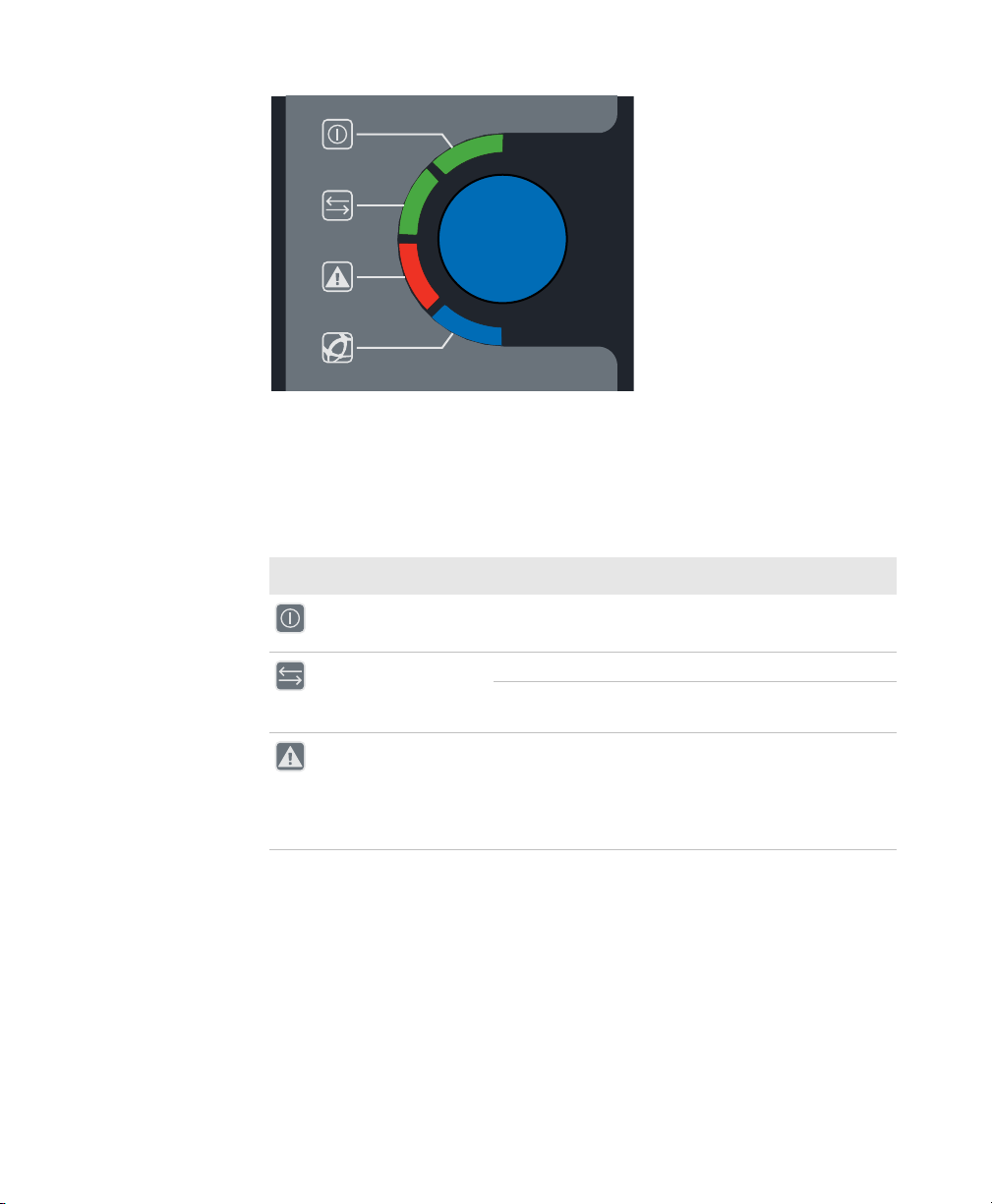

Understanding the Print Button and LEDs

The blue button on the front panel is the Print button. The main

function of the Print button is to feed media and pause print jobs.

When the printer is in a different state such as Testmode, the Print

button performs other functions. For more information, see

“Understanding Printer States” on page 10. There are four LEDs

surrounding the Print button.

6 PD41 and PD42 Commercial Printer User’s Manual

Page 19

Chapter 1 — Using the Printer

The Print Button and Four Surrounding LEDs

The four LEDs can be on, off, or flashing depending on the state of

the printer.

Understanding the Printer LEDs

Symbol LED Color Description

Power Green The printer is powered on.

‘

Ready/Data Green The printer is ready to receive data.

Flashing

The printer is transferring data.

green

Error Solid or

flashing

red

There is an error condition with the

printer. Most causes of an error

condition are hardware related. For

help, see “Printer Problems and

Possible Solutions” on page 69.

PD41 and PD42 Commercial Printer User’s Manual 7

Page 20

Chapter 1 — Using the Printer

Understanding the Printer LEDs (continued)

Symbol LED Color Description

Understanding the PD42 Screen and Soft Keys

The PD42 screen communicates detailed information about the

current state of the printer. The printer can tell you if a specific error

has occurred or if it is waiting for input from you.

Ready-to-Work™ Blue Turns on when the printer is

operational.

Flashing

blue

The printer is not fully operational

because:

• the printer is waiting for an IP

address.

• an error condition has occurred.

• the printer is in Testmode or

Extended Testmode. For more

information, see “Using

Testmode and Extended

Testmode to Troubleshoot”

on page 74.

Off The printer is in Setup or Info

mode.

The printhead temperature is too

high.

Fingerprint

10.6.0

Test

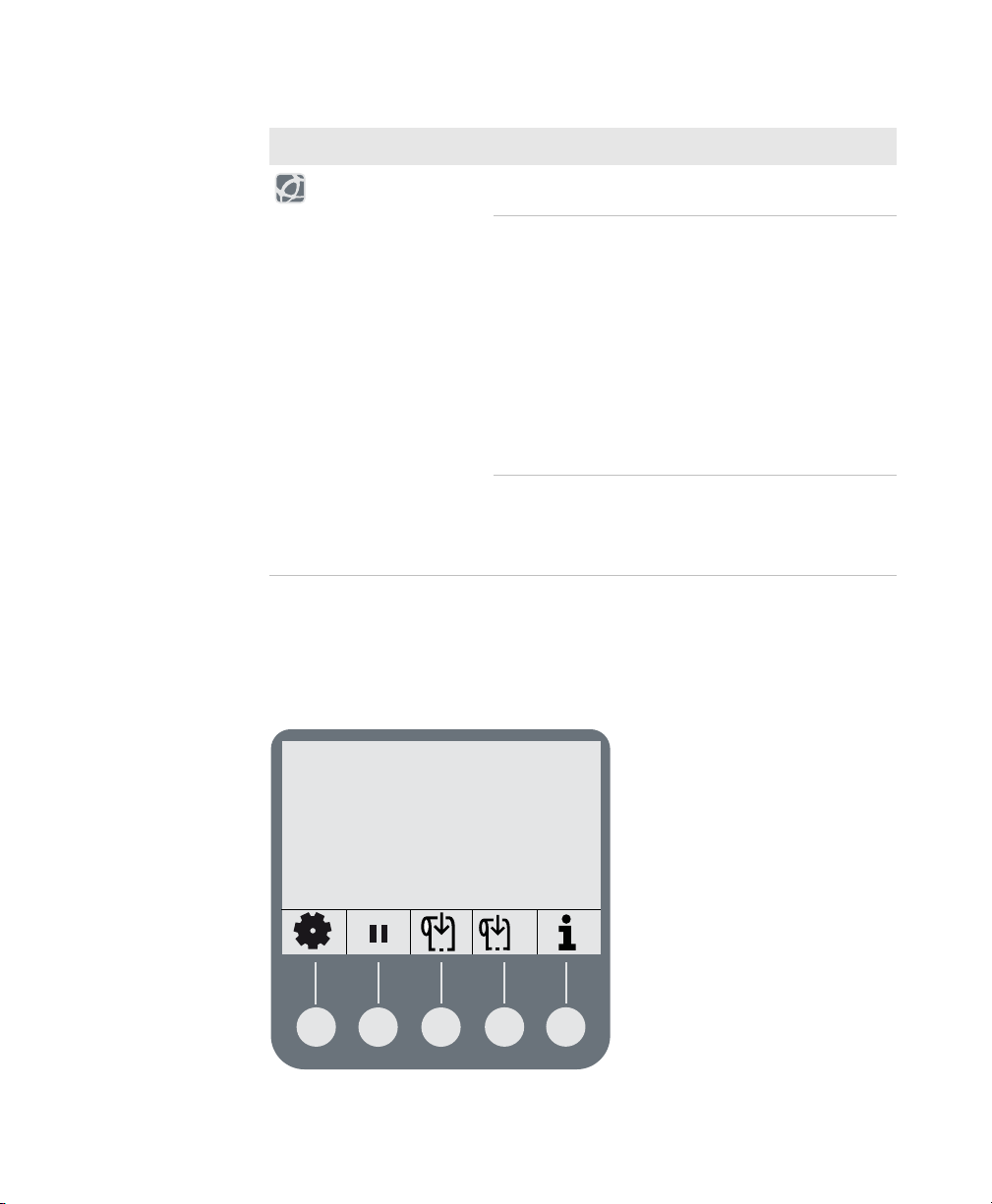

The PD42 Screen and Soft Keys

8 PD41 and PD42 Commercial Printer User’s Manual

Page 21

Chapter 1 — Using the Printer

Test

Below the display screen, there are five buttons that act as “soft keys.”

The function of the buttons depends on the state of the printer. The

function of the button is indicated with a small icon in the screen

right above the associated button.

Understanding the Soft Key Functions

Soft Key Function

F1 to F5 The function of these keys is defined by the Fingerprint

application.

Enters or exits Setup mode.

Pauses the printer.

Feeds out media.

Performs a testfeed.

Enters or exits Information mode.

Moves to the left or the previous option.

Moves to the right or the next option.

Moves up a level in the menu system.

Applies a setting or selects a command.

Allows you to edit a value.

Decreases the selected number.

Increases the selected number.

Exits or cancels editing, test mode, and dump mode.

Continue.

Saves to file.

PD41 and PD42 Commercial Printer User’s Manual 9

Page 22

Chapter 1 — Using the Printer

Note: If the printer is running a Fingerprint application, access to

Setup mode is controlled by the application.

Understanding Printer States

The printers can enter various states which indicate the current mode

of operation.

PD41 and PD42 Printer States

State Explanation

PUP Power-UP (starting up)

Power off The printer is turned off.

Idle The printer is operational and is waiting for print

Running application The printer is running a Fingerprint application.

Setup mode (PD42 only) You can access Setup mode through

Information mode

(i-mode)

Printing The printer is printing labels.

Printing (wait for LTS) The printer is waiting for the label taken sensor to

Paused The printer is paused during a print job.

Testmode The printer is in Testmode. For more information,

Extended Testmode The printer is in Extended Testmode. For more

Dumpmode The printer is in Dumpmode, which means it is

Upgrading Firmware is being upgraded.

Error The printer is in an error state.

jobs.

the soft keys associated with the screen. Use Setup

mode to change some of the printer settings.

(PD42 only) You can access Information mode

from the soft keys when the printer is idle. In

Information mode, the printer cycles through

some of the interface settings in 5 second intervals.

indicate that a label has been taken.

see “Using Testmode” on page 74.

information, see “Using Extended Testmode” on

page 75.

listening on all communication ports and prints

incoming characters.

10 PD41 and PD42 Commercial Printer User’s Manual

Page 23

Chapter 1 — Using the Printer

The state of the printer also determines the functions and icons that

are active in the screen.

Fingerprint

10.2.0

F1 F2 F3 F4 F5

Test

Idle

Running application

Paused

Testmode

TEST

Setup, navigation

Setup, edit value

Extended Testmode

TEST

Dumpmode

i-mode

Printing

Upgrading

Active Soft Keys in Different Printer States

Loading Media

The printers can print on labels, tickets, tags, and continuous stock.

For more information on media types, media dimensions, and media

specifications, see “Media Specifications” on page 98.

PD41 and PD42 Commercial Printer User’s Manual 11

Page 24

Chapter 1 — Using the Printer

Loading Media for Tear-Off Printing

Use this section to load media when you are manually tearing off

labels against the tear bar on the printer. You can use these types of

media for tear-off printing:

• Non-adhesive continuous stock

• Self-adhesive continuous stock with liner

• Self-adhesive labels with liner

• Tickets with gaps, with or without perforations

• Tickets with black marks, with or without perforations

To load media for tear-off printing

1 Open the media cover.

2 Pull out the printhead lever and turn it counterclockwise. Lift up

on the label feed guide.

3 Load a media roll onto the media supply hub. Be sure to push the

roll all the way against the inner wall of the printer and adjust the

edge guide.

12 PD41 and PD42 Commercial Printer User’s Manual

Page 25

Chapter 1 — Using the Printer

Test

4 Route the media through the print mechanism.

5 If you are using fanfold media, load it through the external media

slot at the rear of the printer and route it the same way as you

would a media roll.

6 Reset the label feed guide and the printhead lever.

7 Close the media cover.

8 Press the Print button to advance the media. If you are switching

to a new type of media, you must run a Testfeed ( ) to

calibrate the sensors on the printer.

Loading Media for Peel-Off (Self-Strip) Printing

Use the procedure in this section when you are using self-adhesive

labels that are separated from the liner immediately after printing.

Peel-off printing is also called self-strip printing. With peel-off

printing, you use the label taken sensor to sense when a label has been

removed. After a label is removed, the sensor lets the printer know it is

okay to print another label. Peel-off printing only supports selfadhesive labels with a liner.

You can also use this procedure to load media for batch takeup. For

batch takeup, both the label and liner are rewound and the label taken

sensor is not used.

PD41 and PD42 Commercial Printer User’s Manual 13

Page 26

Chapter 1 — Using the Printer

Peel-off printing and batch takeup printing require you to install the

internal rewinder kit. For more information on the internal rewinder

kit, see “Accessories for the Printer” on page 107.

To load media for peel-off printing

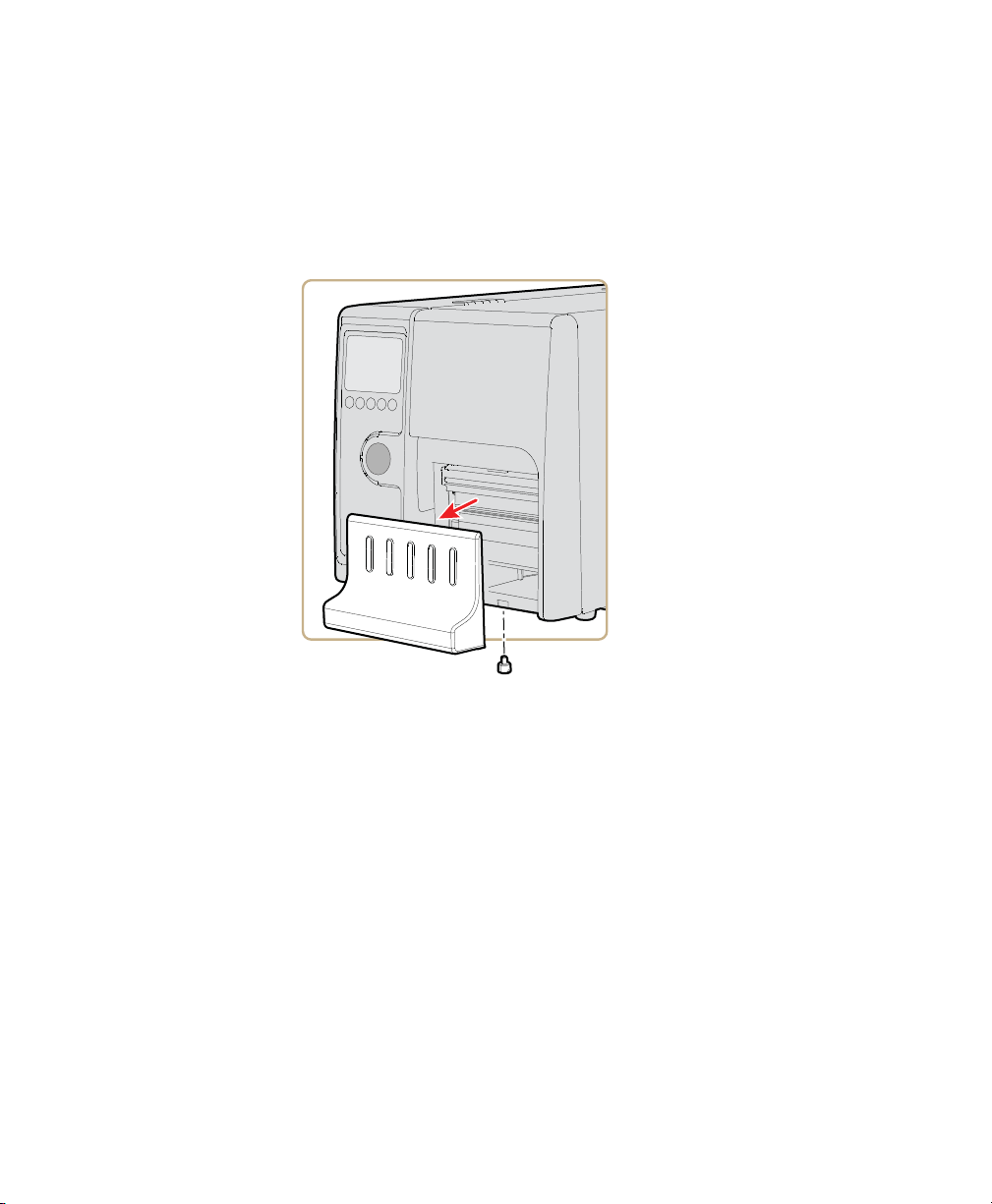

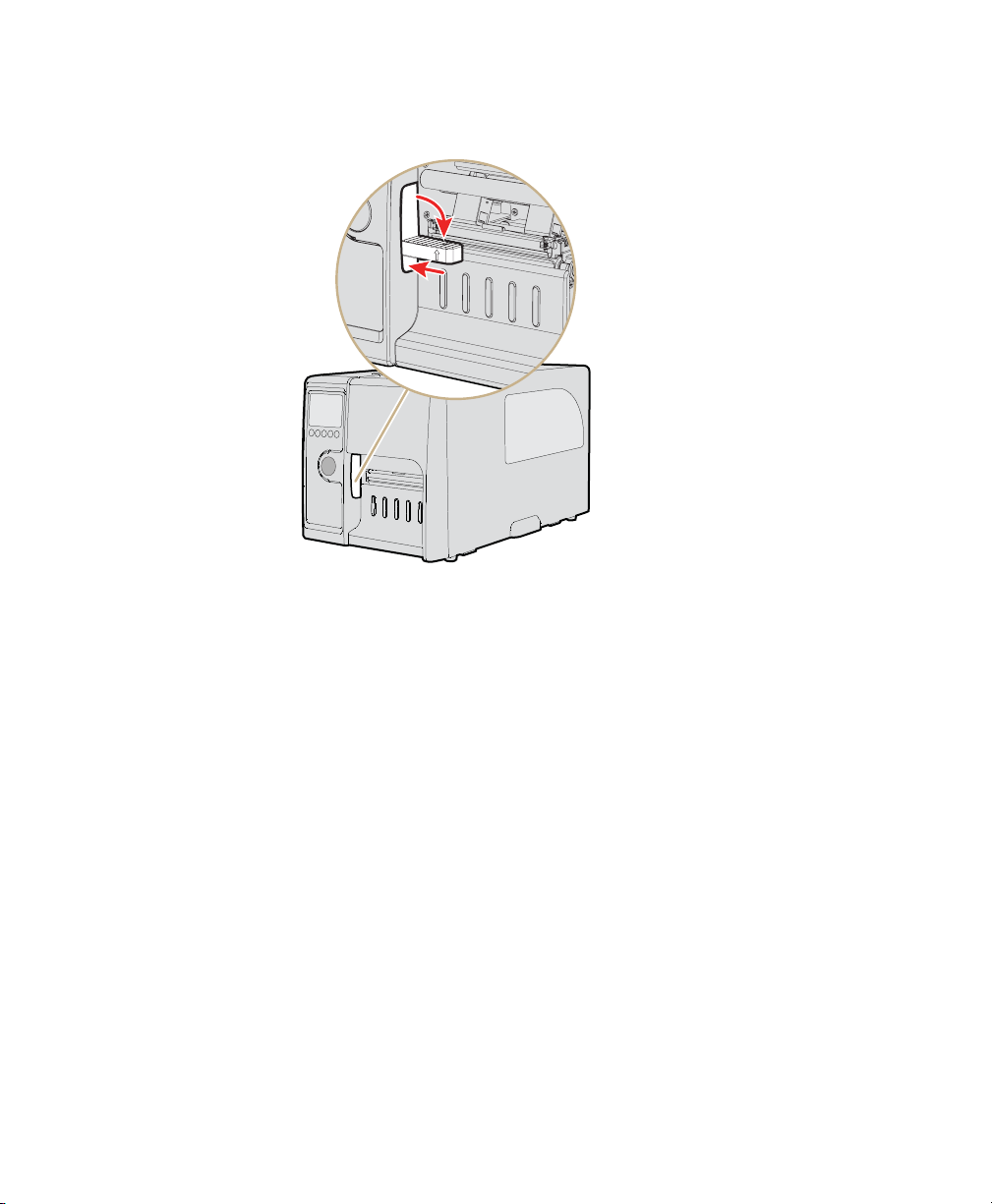

1 Remove the thumbscrew that attaches the front cover and remove

it.

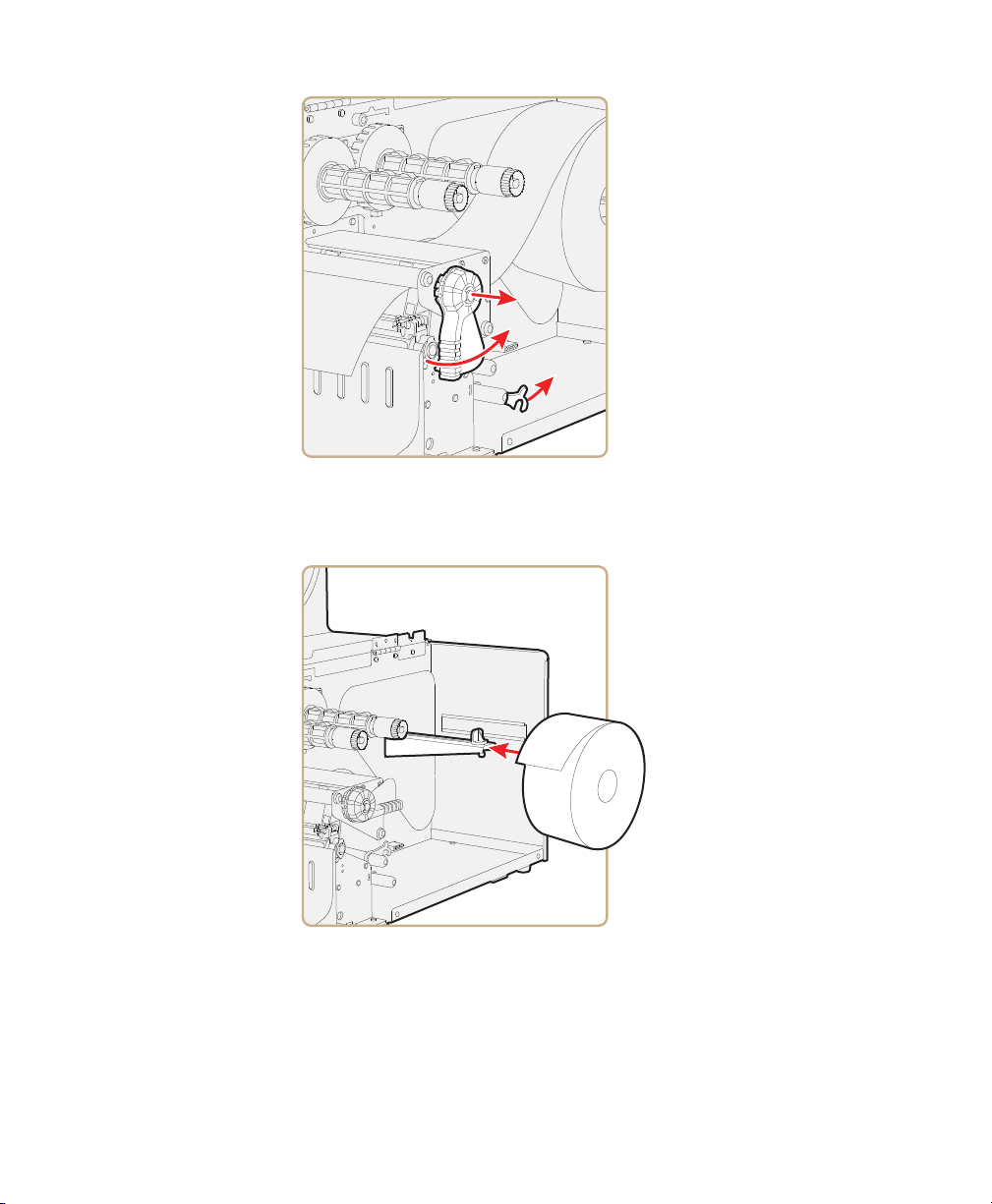

2 Open the media cover, pull out the printhead lever and turn it

counterclockwise. Lift up on the label feed guide.

14 PD41 and PD42 Commercial Printer User’s Manual

Page 27

Chapter 1 — Using the Printer

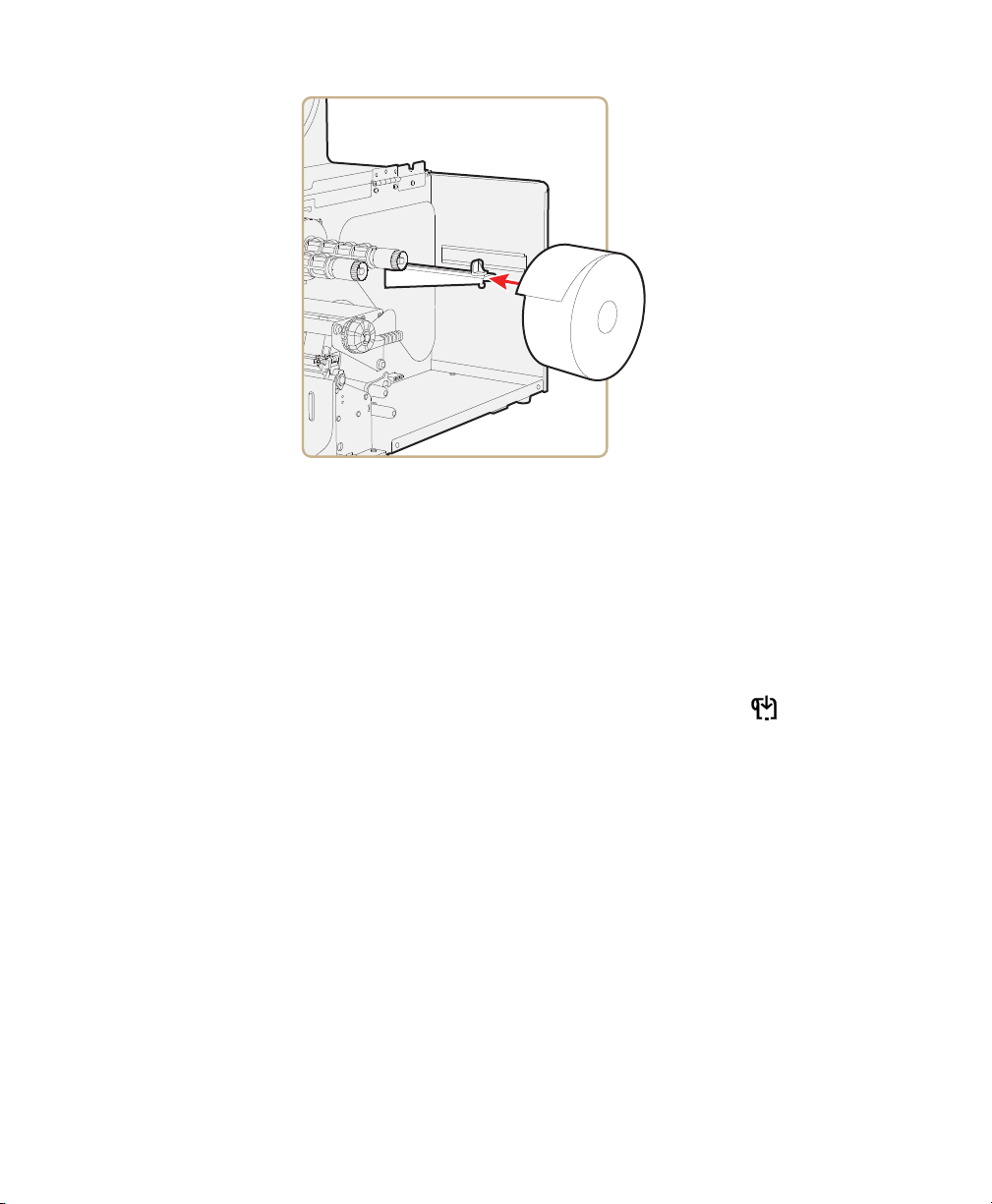

3 Load a media roll onto the media supply hub. Be sure to push the

roll all the way against the inner wall of the printer and adjust the

edge guide.

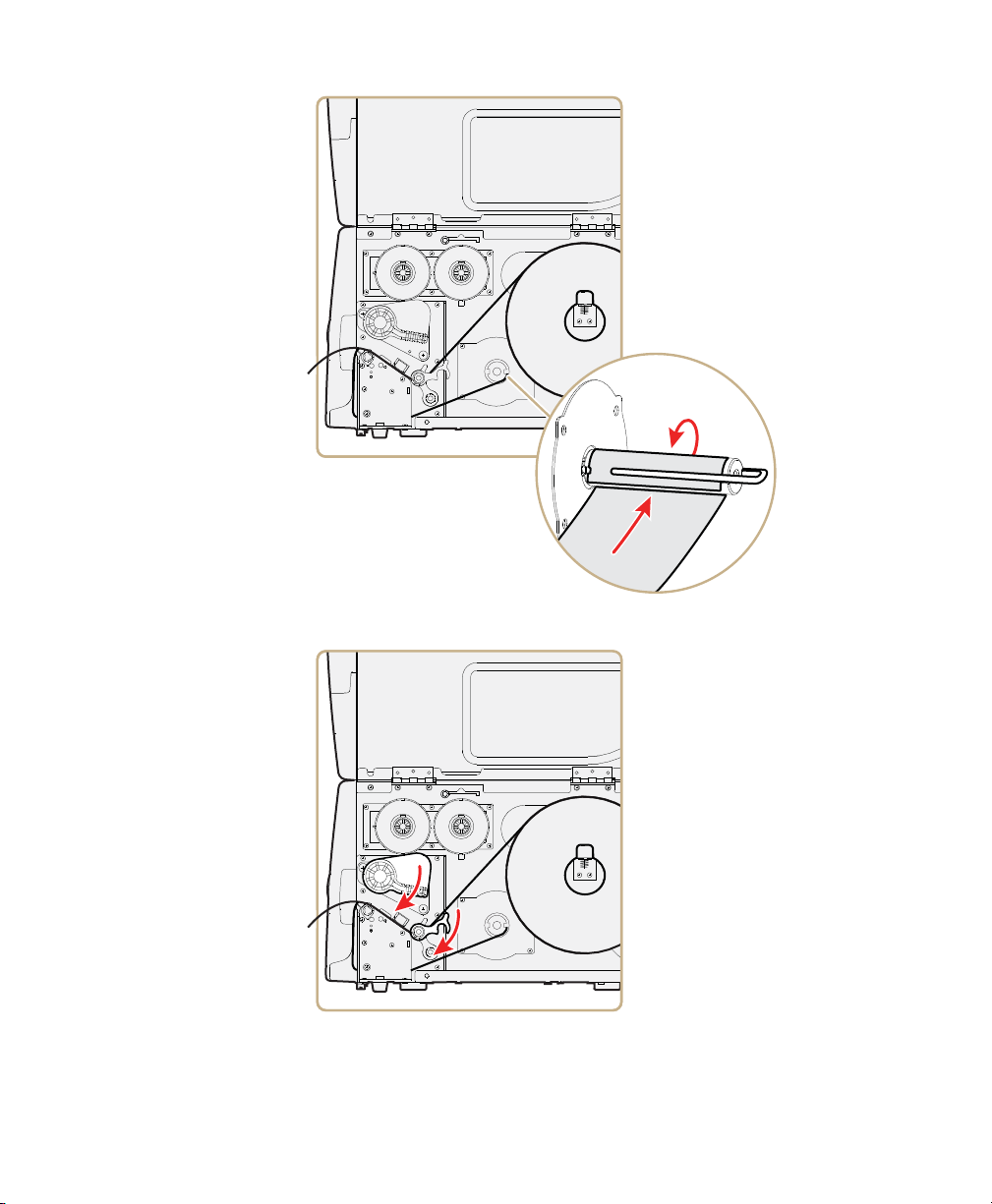

4 Route the media through the print mechanism and back into the

media compartment.

5 Wrap the liner around the internal rewinder takeup roll and lock it

in place.

PD41 and PD42 Commercial Printer User’s Manual 15

Page 28

Chapter 1 — Using the Printer

6 Reset the label feed guide and the printhead lever.

7 Reattach the front cover and secure with the thumbscrew.

16 PD41 and PD42 Commercial Printer User’s Manual

Page 29

Chapter 1 — Using the Printer

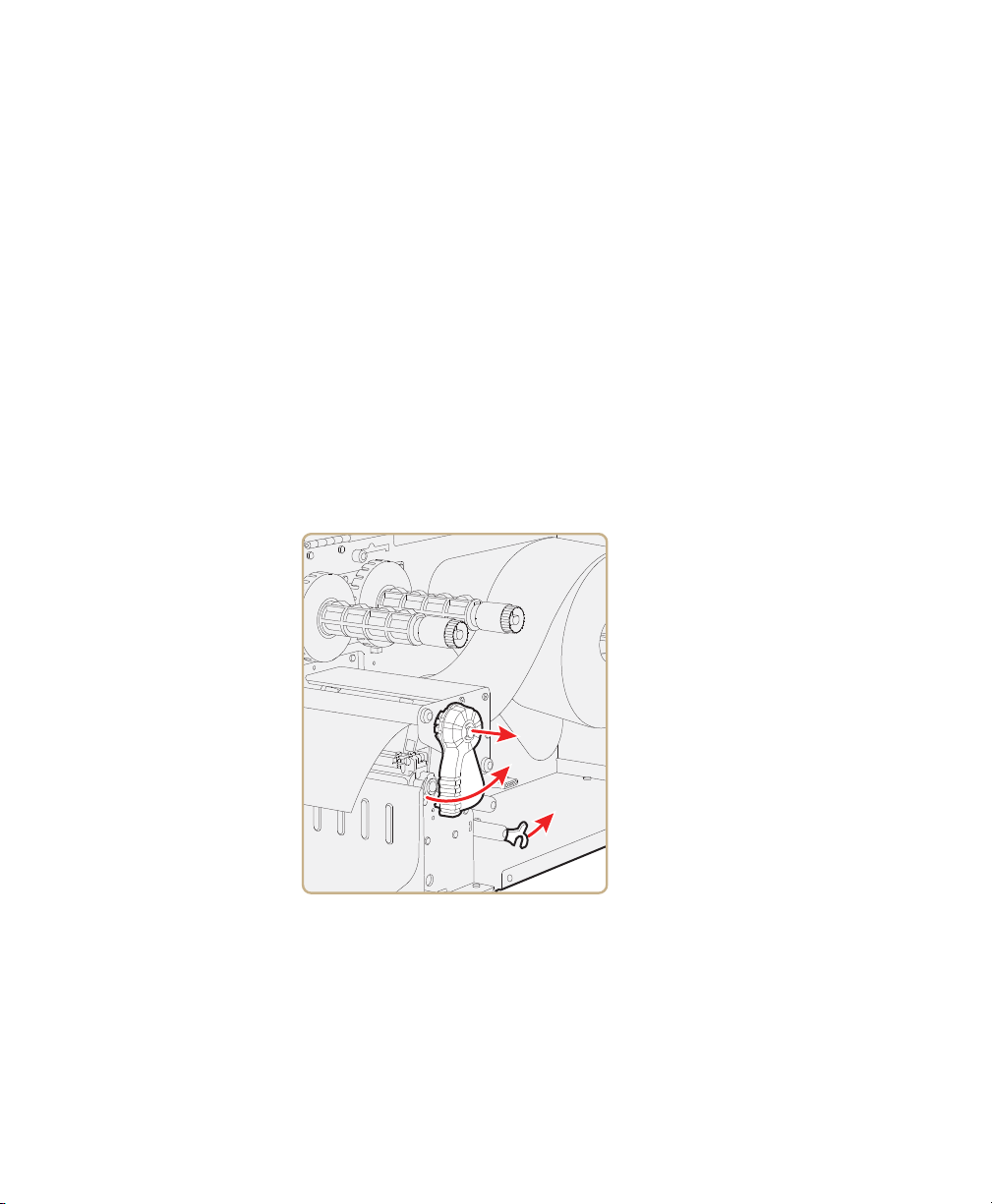

8 Push in on the lower part of the label taken sensor and bring it out

to a fully horizontal position.

9 Close the media cover.

10 Press the Print button to advance the media.

Loading Thermal Transfer Ribbon

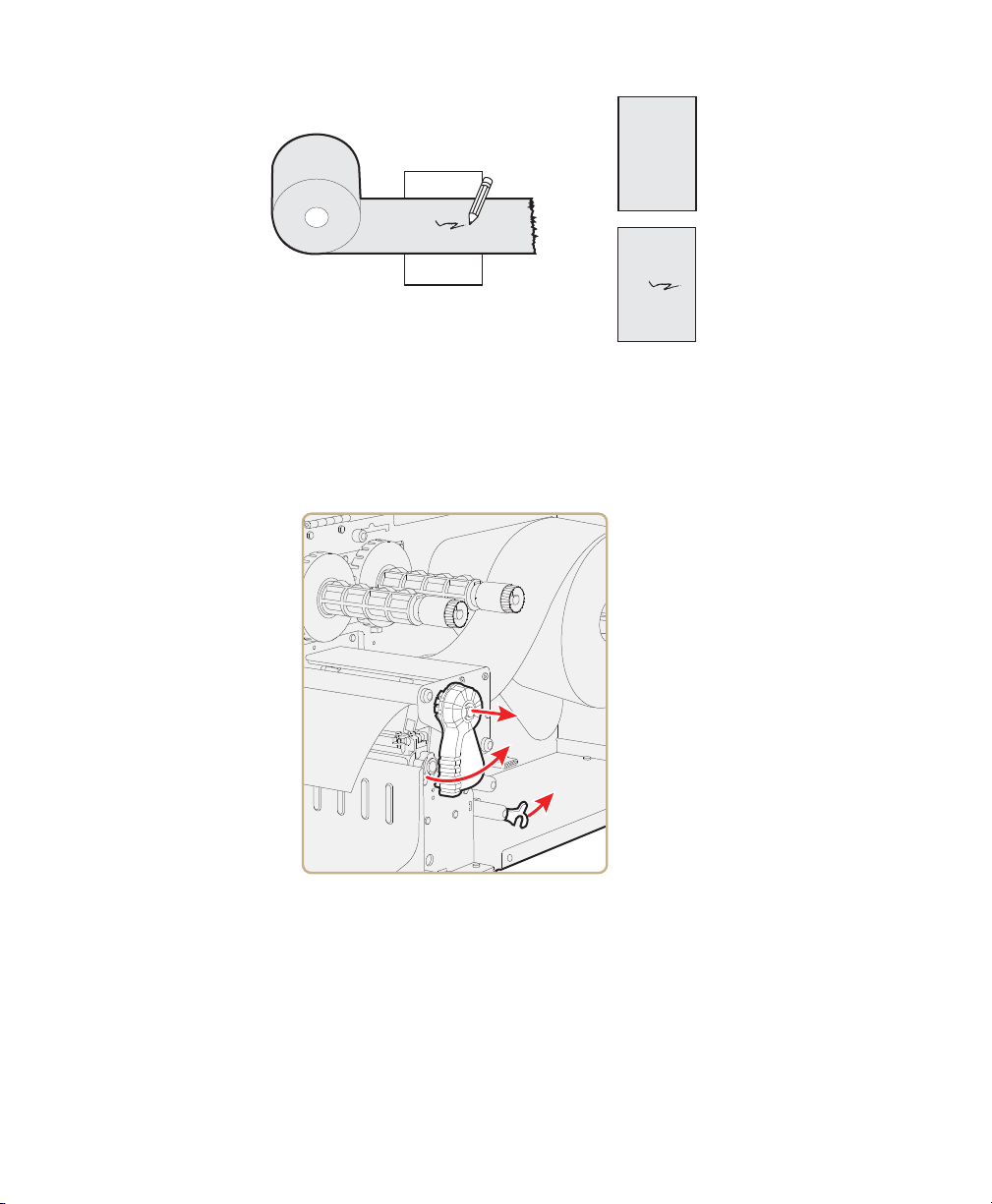

Thermal transfer printing gives you a durable printout that is less

vulnerable to chemicals, heat, sunlight and so on than direct thermal

printing. Make sure you select a ribbon type that matches the media

you are using and configure the printer for thermal transfer paper.

The printer supports thermal transfer ribbon rolls with the ink-coated

side facing either inward or outward. To determine which type of

ribbon you have, use a pen or other sharp object to scratch through

the ribbon against a piece of paper. If you see a mark on the paper,

your ribbon is wound ink out.

PD41 and PD42 Commercial Printer User’s Manual 17

Page 30

Chapter 1 — Using the Printer

= Ink out

= Ink in

Determining Whether Your Ribbon is Wound Ink In or Ink Out

To load thermal transfer ribbon

1 Open the media cover.

2 Pull out the printhead lever and turn it counterclockwise.

3 Slide the ribbon roll onto the ribbon hub closest to the media roll

holder and slide the empty ribbon core onto the hub closest to the

front of the printer.

18 PD41 and PD42 Commercial Printer User’s Manual

Page 31

Chapter 1 — Using the Printer

4 For ink out ribbon (—): route the ribbon around the printhead and

set the ink position lever to the left.

5 For ink in ribbon(---): route the ribbon around the printhead and

set the ink position lever to the right.

6 Load media in the printer For help, see “Loading Media for Tear-

Off Printing” on page 12 or “Loading Media for Peel-Off

(Self-Strip) Printing” on page 13.

7 Press the Print button to advance the media.

PD41 and PD42 Commercial Printer User’s Manual 19

Page 32

Chapter 1 — Using the Printer

SELECT MEDIA

GAP

SELECT MEDIA

MARK

SELECT MEDIA

CONTINUOUS

Printing a Test Label

To verify that the printer is fully functional and to obtain the current

configuration, you can print the test labels. The test labels contain

hardware and software configuration information.

To print a set of test labels

1 Turn off the printer.

2 Load media and ribbon (if necessary). For help see, “Loading

Media” on page 11 and “Loading Thermal Transfer Ribbon”

on page 17. Make sure the printhead is down.

3 Press and hold the Print button.

4 Continue to keep the Print button pressed down and turn on the

Power switch. After approximately ten seconds, the printer screen

lights up, runs a media setup routine, enters Testmode, and three

of the LEDs start to flash one at a time (green, red, and then blue).

5 Continue to press the Print button until the printer starts cycling

through the selectable media types: gap, mark and continuous.

6 Select your media type by releasing the Print button when your

type of media appears on the screen.

The printer prints several test labels containing hardware, setup,

and network information and then enters Dump mode.

7 Press the Print button once or press the cancel soft key ( ) to

exit Dump mode.

20 PD41 and PD42 Commercial Printer User’s Manual

Page 33

Creating and Printing Labels

The easiest way to create and print labels, is to use the label design

software LabelShop®. You can download LabelShop from the

PrinterCompanion CD that shipped with your printer or you can

download it from the Downloads page for your printer on

www.intermec.com.

You can also use Fingerprint and IPL to create and print labels. For

more information, see either the Intermec Fingerprint Command

Reference Manual or the IPL Command Reference Manual.

Chapter 1 — Using the Printer

PD41 and PD42 Commercial Printer User’s Manual 21

Page 34

Chapter 1 — Using the Printer

22 PD41 and PD42 Commercial Printer User’s Manual

Page 35

22

Connecting the Printer

Use this chapter to understand how to connect the printer to

your PC or your network. This chapter contains these sections:

• Connecting the Printer to Your PC

• Connecting the Printer to Your Network

23

Page 36

Chapter 2 — Connecting the Printer

Connecting the Printer to Your PC

You can easily connect the PD41 or PD42 commercial printer to your

PC using one of these ports:

• USB device port

• RS-232 serial interface port

• IEEE 1284 communications port (optional)

Note: You cannot use the USB device port and IEEE 1284 port at the

same time. To select the active interface, go to Setup mode > COM: >

Interface.

Connecting the Printer to a PC Through the USB Device Port

Intermec recommends that you only connect one printer to each PC,

either directly, or through a hub. To connect the printer to a PC

through the USB device port, you need:

• USB Type B to USB Type A cable

• Intermec InterDriver® software

The USB cable you need is included in the shipping box with the

printer. The InterDriver printer driver is available on the

PrinterCompanion CD that ships with the printer. To make sure you

have the latest version of InterDriver, you may want to go to the

downloads page for the printer on www.intermec.com.

To connect the printer to a PC through the USB port

1 Download and install the InterDriver software on your PC.

2 Connect the USB cable to the Type B connector on the back of the

printer and connect the other end to your PC.

You do not need to set up any parameters for USB communications.

Connecting the Printer to a PC Through the Serial Port

The serial communication parameters control the communication

between the printer and the connected PC on the serial port, referred

to as “uart1:” on the printer.

24 PD41 and PD42 Commercial Printer User’s Manual

Page 37

Chapter 2 — Connecting the Printer

Make sure the serial port settings on the printer match the settings on

the connected device. The default serial communication settings on

the printer are: 9600 baud rate, 8 data bits, no parity, 1 stop bit and no

flow control.

You can use a serial connection to communicate with your PC and

run PrintSet, LabelShop, or InterDriver. You can also use the serial

port to send commands directly to the printer through a terminal

connection, for instance with Telnet.

To connect the printer to a PC through the serial port, you need:

• DB9 to DB9 RS-232 cable (P/N 1-974024-018)

To connect the printer to a PC through the serial port

1 Connect one end of the RS-232 cable to the back of the printer and

connect the other end of the cable to a serial COM port on the PC.

2 If necessary, change the PC serial port configuration to match

your printer.

Connecting the Printer to a PC Through the IEEE 1284 Port

You can use the parallel connection with LabelShop or the Intermec

InterDriver. The parallel port supports Universal Plug and Play

(UPnP) and additional status reporting through IEEE 1284 nibble ID

mode.

If you are using a parallel port to communicate with the printer, you

need:

• an IEEE 1284 interface adapter installed in the printer.

• a parallel cable to run between the printer and the PC.

If you did not have the parallel interface installed at the factory, you

can install the field installable option (P/N 1-971164-800) in the

optional I/O board port of your printer. You can purchase a parallel

cable from Intermec (P/N 1-974022-018) or from your local computer

store.

To connect your printer to a PC parallel port

• Connect the IEEE 1284 cable connector to the interface adapter

port on the back of the printer and connect the other end of the

cable into a parallel port on the PC.

PD41 and PD42 Commercial Printer User’s Manual 25

Page 38

Chapter 2 — Connecting the Printer

Connecting the Printer to Your Network

Using either the integrated Ethernet or the optional 802.11 wireless

network interface provides features such as security, FTP server, web

server, and Alert handling.

Setting Up Ethernet Communications

Use the Ethernet port to set up the PD41 or PD42 as a network

printer. The printer is set to automatically retrieve an IP number from

the network (DHCP) once it is turned on. You can use the network

connection either with LabelShop or the Intermec InterDriver. You

can also use it to directly send commands to the printer through a

terminal connection (Telnet), or you can send instructions via FTP.

For terminal connections, it utilizes the Raw TCP protocol through

port 9100.

To connect the printer to your Ethernet network

1 Connect the Ethernet cable to the Ethernet port in the rear of the

printer and connect the other end to your network.

2 Turn the printer on. Wait for the blue Ready-to-Work LED to stop

blinking, and for the message “IP configuration error” to

disappear from the screen.

3 Enter Information mode by pressing ( ) to obtain the IP address

of your printer.

Information mode cycles through the interfaces installed on the

printer in five-second intervals and displays them on the screen.

The IP address is displayed under net1: in Fingerprint and net in

IPL.

4 On your PC, enter the IP address of the printer in the address field

of your web browser (for example http://10.200.27.94) and press

Enter.

26 PD41 and PD42 Commercial Printer User’s Manual

Page 39

Chapter 2 — Connecting the Printer

Entering the IP address brings up the home page of the printer,

where you can check and modify printer settings.

5 You will be prompted to enter a login name and a password. By

default, the login name is admin and the password is pass.

For more information on using the web page to configure the

printer, see “Configuring the Printer From the Home Page” on

page 44.

If your network does not assign IP numbers automatically, or the

Ready-to-Work indicator is flashing to indicate a network error, you

can use PrintSet (available on the PrinterCompanion CD or as a

download from www.intermec.com) to correct the network settings.

Manually Configuring IP Settings

You can configure the IP settings of your printer by sending

Fingerprint or IPL commands through a serial connection. After you

configure the IP settings, you can disconnect the printer from your PC

and communicate with the printer using 802.11 communications.

PD41 and PD42 Commercial Printer User’s Manual 27

Page 40

Chapter 2 — Connecting the Printer

To configure the IP settings serially using Fingerprint

1 Connect the printer to your PC using a serial cable. For help, see

“Connecting the Printer to a PC Through the Serial Port” on

page 24.

2 Send the following commands to permanently assign the IP

address, subnet mask, default router, and name server:

setup "network,IP selection,manual"

setup "network,IP address,xxx.xxx.xxx.xxx"

setup "network,netmask,xxx.xxx.xxx.xxx"

setup "network,default router,xxx.xxx.xxx.xxx"

setup "network,nameserver,xxx.xxx.xxx.xxx"

where xxx is a number from 0 to 255.

3 Disconnect the printer from the PC.

4 On your PC, enter the IP address of the printer in the address field

of your web browser (for example http://10.200.27.94) and press

Enter.

The home page of the printer appears.

To configure the IP settings serially using IPL

1 Connect the printer to your PC using a serial cable. For help, see

“Connecting the Printer to a PC Through the Serial Port” on

page 24.

2 Send the following commands to permanently assign the IP

address, subnet mask, default router, and name server:

<SI>nn[,m1[,m2]]

where:

n is the IP address of the printer in the format n.n.n.n, where n is a

number from 0 to 255.

,m1 is the subnet mask address in the format n.n.n.n, where n is a

number from 0 to 255.

,m2 is the router address in the format n.n.n.n, where n is a number

from 0 to 255.

Note: You must specify at least two of the three parameters for the

command to take effect.

28 PD41 and PD42 Commercial Printer User’s Manual

Page 41

Chapter 2 — Connecting the Printer

3 Disconnect the printer from the PC.

4 On your PC, enter the IP address of the printer in the address field

of your web browser (for example http://10.200.27.94) and press

Enter.

The home page of the printer appears.

Setting Up 802.11 Radio Communications

The printer can have an internal 802.11 b/g radio to transfer and

receive data using wireless communications. This user’s guide

assumes that you have already set up your wireless communications

network including your access points. The following procedures

include information on setting up wireless security for both IPL and

Fingerprint.

The printer supports these authentication modes: none, WEP, WPA

Personal and Enterprise mode (802.1x authentication), WPA2

Personal and Enterprise mode (802.1x authentication).

Note: WPA and WPA2 Enterprise mode and dynamic WEP currently

support PEAP, TTLS, LEAP, and EAP-Fast.

To set up the printer to work in your wireless network, you need these

items:

• Serial cable (P/N 1-974024-018)

• Host PC running Windows or Linux

• PrintSet. You can download PrintSet from the Downloads page

for your printer on www.intermec.com or you can download it

from the PrinterCompanion CD that shipped with your printer.

• (optional) Serial port software such as HyperTerminal®

To set up the printer for wireless communications using PrintSet

1 Download and install PrintSet on your PC.

2 Connect one end of the serial cable to the back of the printer and

connect the other end of the cable to a serial COM port on the PC.

PD41 and PD42 Commercial Printer User’s Manual 29

Page 42

Chapter 2 — Connecting the Printer

3 If necessary, change the PC serial port configuration to match

your printer:

Parameter Default Setting

Baud rate 9600

Data bits 8

Parity None

Stop bits 1

4 Start PrintSet on your PC.

5 In the General Tasks box, click Add Printer and step through the

screens of the Add Printer Wizard until you have successfully

added your printer.

6 In the Printer Tasks box, click Wireless Setup Wizard and step

through the screens to set up wireless network and security

parameters.

To set up the printer for wireless communications using

HyperTerminal

1 Connect one end of the serial cable to the back of the printer and

connect the other end of the cable to a serial COM port on the PC.

2 On your PC, open HyperTerminal and set these serial port

parameters:

Parameter Default Setting

Baud rate 9600

Data bits 8

Parity None

Stop bits 1

.

3 From the host PC, check the wireless settings. For help, see

“Manually Configuring IP Settings” on page 27.

If you are using IPL, send these commands to the printer:

<STX><SI>wt,SSID<ETX>

<STX><SI>wt,WEP<ETX>

30 PD41 and PD42 Commercial Printer User’s Manual

Page 43

Chapter 2 — Connecting the Printer

<STX><SI>wt,WEP1<ETX>

<STX><SI>wt,PAC<ETX>

<STX><SI>wt,ACQUIRE_PAC<ETX>

<STX><SI>wt,WEP2<ETX>

<STX><SI>wt,WEP3<ETX>

<STX><SI>wt,WEP4<ETX>

<STX><SI>wt,AUTH<ETX>

<STX><SI>wt,WPA<ETX>

<STX><SI>wt,WPA2<ETX>

<STX><SI>wt,WPA_PSK<ETX>

<STX><SI>wt,ROAM<ETX>

<STX><SI>wt,CHANNEL<ETX>

<STX><SI>wt,AP_MAC<ETX>

<STX><SI>wt,SIGNAL<ETX>

<STX><SI>wt,SPEED<ETX>

<STX><SI>wt,ACTIVE<ETX>

If you are using Fingerprint, send this command to the printer:

setup write "wlan","uart1:"

setup write "8021x","uart1:"

4 Set up the printer to use the correct SSID and authentication

modes. For help, see the next section, Configuring 802.11

Wireless Security Using IPL or “Configuring 802.11 Wireless

Security Using Fingerprint” on page 34.

5 If you are going to use certificates for validation, transfer the

certificate to the printer. The printer can accept .pfx, .pem, and

.der certificates.

6 Verify that the printer is connected to the access point and make

sure it has an IP address allocated to it.

Use the following sections to set most of your wireless

communication settings. For help with additional commands and

information, see either the Intermec Fingerprint Command Reference

Manual or the IPL Command Reference Manual. You can download

both documents from the Intermec web site at www.intermec.com.

Configuring 802.11 Wireless Security Using IPL

Use the following procedures to configure 802.11 wireless security

parameters on your printer using IPL.

PD41 and PD42 Commercial Printer User’s Manual 31

Page 44

Chapter 2 — Connecting the Printer

To configure the printer to use WEP authentication

1 Send the following commands to login as an admin and set the

SSID:

<STX><ESC>.x,su -p pass admin<ETX>

<STX><SI>ws,SSID,xxxxx<ETX>

where xxxxx can be from 0 to 32 ASCII characters, not including

the double quote.

Note: The default password for logging in as an admin is “pass.” If

you have changed the password, you will need to use your password

instead of “pass.”

2 Send the following commands to configure the WEP keys. The

following example sets WEP key 1 to 1234 and enables WEP key 1.

<STX><SI>ws,WEP1, 0x0001020304<ETX>

<STX><SI>ws,.WEP_KEY,1<ETX>

3 Send the following command to activate the settings.

<STX><SI>ws,ACTIVE,1<ETX>

To configure the printer to use WPA-PSK or WPA2-PSK mode

1 Send the following commands to login as an admin and set the

SSID:

<STX><ESC>.x,su -p pass admin<ETX>

<STX><SI>ws,SSID,xxxxx<ETX>

where xxxxx can be from 0 to 32 alphanumeric characters

2 Send one of the following commands to turn on WPA or WPA2

authentication. Send the WPA-PSK or WPA2-PSK command to set

a pre-shared key:

<STX><SI>ws,WPA,ON<ETX>

<STX><SI>ws,WPA2,ON<ETX>

<STX><SI>ws,WPA_PSK, xxxxxxxxxx<ETX>

where xxxxxxxxxx is a value between 8 and 64 characters.

3 Send the following command to activate the settings:

<STX><SI>ws,ACTIVE,1<ETX>

32 PD41 and PD42 Commercial Printer User’s Manual

Page 45

Chapter 2 — Connecting the Printer

To configure the printer to use WPA or WPA2 Enterprise mode

1 Send the following commands to login as an admin and set the

SSID:

<STX><ESC>.x,su -p pass admin<ETX>

<STX><SI>ws,SSID,xxxxx<ETX>

where xxxxx can be from 0 to 32 alphanumeric characters.

Note: The default password for logging in as an admin is “pass.” If

you have changed the password, you will need to use your

password instead of “pass.”

2 Send one of the following commands to enable WPA-802.1x or

WPA2-802.1x authentication. You should also send the WPA_PSK

command that does not contain a value:

<STX><SI>ws,WPA,ON<ETX>

<STX><SI>ws,WPA2,ON<ETX>

<STX><SI>ws,WPA_PSK, <ETX>

3 Send these commands to configure the EAP_TYPE:

<STX><SI>ws,EAP_TYPE,xxxx<ETX>

where xxxx can be OFF, LEAP, PEAP, TTLS, or EAP-FAST.

<STX><SI>ws,.EAP_USER,xxxx<ETX>

<STX><SI>ws,.EAP_PASS,xxxx<ETX>

where xxxx is the unique username and the unique password for

this protocol.

4 If you are using EAP-FAST, you can use PAC and ACQUIRE_PAC

commands. The PAC setting specifies the PAC file to use for EAPFAST authentication. The ACQUIRE_PAC setting checks to see if

automatic PAC file provisioning is enabled. You can set

ACQUIRE_PAC to on or off.

• Send the following command to set PAC to use /tmp/my.pac

with a pass phrase of “verysecret”:

<STX><SI>ws,PAC,/tmp/my.pac @verysecret<ETX>

• Send the following command to set ACQUIRE_PAC to on:

<STX><SI>ws,ACQUIRE_PAC,ON<ETX>

PD41 and PD42 Commercial Printer User’s Manual 33

Page 46

Chapter 2 — Connecting the Printer

5 If you are using TTLS, you may need to send this command to set

the TTLS outer name:

<STX><SI>ws,TTLS_USER, xxxx <ETX>

where xxxx is the outer name.

6 If you are using certificates for validation, here are some

commands you may need to use.

• Send the following commands to set a certificate and enable

validation:

<STX><SI>ws,CA_CERT,c:/testCA.pfx@export<ETX>

<STX><SI>ws,VALIDATE,ON<ETX>

where c:/testCA.pfx is the location and name of the certificate

and export is the passphrase.

• Send the following commands to set a common name for

server 1 and server 2:

<STX><SI>ws,.SERVER_CN1,xxxxxxxxxx <ETX>

<STX><SI>ws,.SERVER_CN2,xxxxxxxxxx <ETX>

where xxxxxxxxxx can be a value from 0 to 64 characters.

• Send the following command to make sure your values match

those used by the access point:

<STX><SI>wt,[variable name]<ETX>

All variables are returned with the exception of EAP_PASS

which always returns “****” if configured and CA_CERT

which transmits the name of the last certificate authority

successfully installed. An additional read-only variable for the

supplicant state, called STATE, is also returned.

• You may need to send the following command several times for

the wireless station to connect:

<STX><SI>ws,ACTIVE,1<ETX>

Configuring 802.11 Wireless Security Using Fingerprint

Use the following procedures to configure 802.11 wireless security

parameters on your printer using IPL.

34 PD41 and PD42 Commercial Printer User’s Manual

Page 47

Chapter 2 — Connecting the Printer

To configure the printer to use WEP authentication

1 Send the following commands to login as an admin and set the

SSID:

run"su -p pass admin"

setup write "wlan","uart1:"

setup "wlan","SSID","xxxxx"

where xxxxx can be from 0 to 32 ASCII characters, not including

the double quote.

Note: The default password for logging in as an admin is “pass.” If

you have changed the password, you will need to use your

password instead of “pass.”

2 Send the following commands to configure the WEP keys. The

following example sets WEP key 1 to 1234 and enables WEP key 1.

setup "wlan","WEP1","0x0001020304"

setup "wlan",".WEP_KEY","1"

setup "wlan","ACTIVE","1"

setup write "wlan","uart1:"

To configure the printer to use WPA-PSK or WPA2-PSK mode

1 Send the following commands to login as an admin and set the

SSID:

run"su-p pass admin"

setup write "wlan","uart1:"

setup "wlan","SSID","xxxxx"

where xxxxx can be from 0 to 32 alphanumeric characters.

2 Send one of the following WPA/WPA2 ON commands to turn on

WPA or WPA2 authentication. Send the WPA-PSK or WPA2-PSK

command to set a pre-shared key:

setup "wlan","WPA","ON"

setup "wlan","WPA2","ON"

setup "wlan","WPA_PSK","xxxxxxxxxx"

setup "wlan","ACTIVE","1"

setup write "wlan","uart1:"

where xxxxxxxxxx is a value between 8 and 64 characters.

PD41 and PD42 Commercial Printer User’s Manual 35

Page 48

Chapter 2 — Connecting the Printer

To configure the Printer to use WPA or WPA2 Enterprise mode

1 Send the following commands to login as an admin and set the

SSID:

run"su-p pass admin"

setup write "wlan","uart1:"

setup "wlan","SSID","xxxxx"

where xxxxx can be from 0 to 32 alphanumeric characters.

2 Send one of the following WPA/WPA2 ON commands to set up

WPA-802.1x or WPA2-802.1x authentication. You should also

send the WPA_PSK command that does not contain a value:

setup "wlan","WPA","ON"

setup "wlan","WPA2","ON"

setup "wlan","WPA_PSK",""

setup write "wlan","uart1:"

• To view the 802.1x values, send this command:

setup write "8021x","uart1:"

3 Send these commands to configure the EAP_TYPE:

setup "8021x","EAP_TYPE","xxxx"

where xxxx can be OFF, LEAP, PEAP, TTLS, or EAP-FAST.

setup "8021x",".EAP_USER","xxxx"

setup "8021x","EAP_PASS","xxxx"

where xxxx is the unique username and the unique password for

this protocol.

4 If you are using TTLS, you may need to send this command to set

the TTLS outer name:

setup "8021x","TTLS_USER","xxxx"

where xxxx is the outer name.

5 If you are using EAP-FAST, you can use PAC and ACQUIRE_PAC

commands. The PAC setting specifies the PAC file to use for EAPFAST authentication. The ACQUIRE_PAC setting checks to see if

automatic PAC file provisioning is enabled. You can set

ACQUIRE_PAC to on or off.

• Send the following command to set PAC to use /tmp/my.pac

with a pass phrase of “verysecret”:

setup "8021x","PAC","/tmp/my.pac @verysecret"

36 PD41 and PD42 Commercial Printer User’s Manual

Page 49

Chapter 2 — Connecting the Printer

• Send the following command to set ACQUIRE_PAC to on:

setup "8021x","ACQUIRE_PAC","ON"

6 If you are using certificates for validation, here are some

commands you may need to use.

• Send the following commands to set a certificate and enable

validation:

setup "8021x","CA_CERT","c:/test.pfx@export"

setup "8021x","VALIDATE","ON"

where c:/test.pfx is the location and name of the certificate and

export is the passphrase.

• Send the following commands to set a common name for

server 1 and server 2:

setup "8021x",".SERVER_CN1","xxxxxxxxxx"

setup "8021x",".SERVER_CN2","xxxxxxxxxx"

where xxxxxxxxxx can be a value from 0 to 64 characters.

• Send the following command to make sure your values match

those used by the access point:

setup write "8021x","uart1:"

• You may need to send the following command several times for

the wireless station to connect:

setup "wlan","ACTIVE","1"<ETX>

Connecting Peripherals to the USB Host Port

You can connect these peripheral devices to the USB host interface

port on the printer:

• USB mass storage device

• Keyboard

• Bar code scanner

• USB hub

PD41 and PD42 Commercial Printer User’s Manual 37

Page 50

Chapter 2 — Connecting the Printer

Using a USB Mass Storage Device

You can use a USB mass storage device to store additional fonts and

images for the printer. You can also use the device to upgrade your

firmware. For more information on using the USB mass storage

device to upgrade the printer, see“Upgrading the Firmware” on

page 61.

Connecting a Keyboard to the USB Host Port

You can use an external USB keyboard to:

• input data in Fingerprint applications. Some applications may

require more complex input from users than the simple push of a

button.

• manage setup in Fingerprint, Direct Protocol, and IPL. In the

installed keyboard layouts, the arrow keys on the keyboard are

mapped to the up, down, right, and left functions in the Setup

menu. The five function keys F1 to F5 correspond to the five soft

keys on the front panel, starting from the left. The Enter key will

have the same apply and select function.

The printer comes with four keyboard layouts installed (US, Swedish,

French, and German).

To change keyboard layout

1 Plug your USB-keyboard into the USB host connector in the back

of the printer.

2 Turn the printer on.

3 Press Setup ( ).

4 Navigate to COM > USB KEYBOARD.

5 Choose a keyboard layout.

6 Exit Setup by pressing ( ).

Fingerprint users can create their own custom keyboard layouts. For

help, see the Fingerprint Command Reference Manual.

38 PD41 and PD42 Commercial Printer User’s Manual

Page 51

Chapter 2 — Connecting the Printer

Connecting a Bar Code Scanner to the USB Host Port

You can connect a bar code scanner of HID (Human Interface Device)

type to the printer. The scanner will send data to the “usbhost:” device

in the same way as a USB keyboard. You can then use this data in a

Fingerprint application.

The keyboard layout you choose in setup (see previous procedure)

applies for connected scanners too.

Note: You can only use a bar code scanner with printers that are

running Fingerprint firmware.

Connecting a USB Hub to the USB Host Port

You can connect a USB hub to the printer so that you can connect

several USB devices to the printer at the same time.

Note: You can only connect one USB mass storage device and one

HID (keyboard or scanner) peripheral to the USB hub at a time.

PD41 and PD42 Commercial Printer User’s Manual 39

Page 52

Chapter 2 — Connecting the Printer

40 PD41 and PD42 Commercial Printer User’s Manual

Page 53

33

Configuring the Printer

Use this chapter to understand how to configure the printer,

upgrade firmware, and download fonts and graphics. This

chapter contains these sections:

• Configuring the Printer

• Upgrading the Firmware

• Downloading Fonts and Graphics

41

Page 54

Chapter 3 — Configuring the Printer

Configuring the Printer

You can change the configuration settings of your printer:

• directly from the screen.

• from the printer home page.

• using PrintSet.

• using commands sent from your PC.

• using SmartSystems Foundation.

Configuring the PD42 Printer from the Screen

To configure the PD42 printer from the screen, you need to enter

Setup mode.

To enter Setup mode

• Press the button.

While in Setup mode, use the soft keys to navigate. For help using the

soft keys, see “Understanding the PD42 Screen and Soft Keys” on

page 8.

Use the following illustrations to understand the Setup menu. The

main nodes of the setup tree are organized in a loop. You can view

detailed illustrations of each menu in Appendix C “Fingerprint, IPL,

and ESim Setup Menus” on page 119. Each main node branches

out to a number of sub-nodes. At startup, the firmware determines if

optional equipment such as a cutter or an interface board is installed

in the printer, and these are added to the Setup tree.

42 PD41 and PD42 Commercial Printer User’s Manual

Page 55

Chapter 3 — Configuring the Printer

SETUP:

SER-COM, UART1

SETUP:

PRINT DEFS

SETUP:

MEDIA

SETUP:

FEEDADJ

Starting point

SETUP:

COM

SETUP:

EMULATION

SETUP:

NET-COM, NET1

SETUP:

NETWORK

The Main Nodes of the Setup Menu in Fingerprint

Starting point

SETUP:

COM

SETUP:

NETWORK

SETUP:

CONFIGURATION

SETUP:

MEDIA

SETUP:

SER-COM

SETUP:

TEST/SERVICE

The Main Nodes of the Setup Menu in IPL

PD41 and PD42 Commercial Printer User’s Manual 43

Page 56

Chapter 3 — Configuring the Printer

SETUP:

DATE TIME

SETUP:

SERIAL-COM

Starting point

SETUP:

NET-COM, NET1

SETUP:

COM

SETUP:

CHARSET

SETUP:

PRINT DEFS

SETUP:

MEDIA

SETUP:

FEEDADJ

The Main Nodes of the Setup Menu in ESim

Configuring the Printer From the Home Page

If you are using an Ethernet or 802.11 wireless connection, you can

change configuration settings from the home page of the printer.

Note: You should have already connected your printer to your

network and obtained an IP address. If not, see “Connecting the

Printer to Your Network” on page 26.

To access the home page of the printer

1 Start your web browser.

2 In the address field, type the IP address of your printer and press

Enter. The home page of your printer appears.

The home page displays the assigned name, firmware version,

Active Command Set, MAC address, and IP address of your

printer. The home page also displays the contents of the image

buffer, as well as the status of the Ready-to-Work indicator.

SETUP:

NETWORK

3 Click Configuration.

44 PD41 and PD42 Commercial Printer User’s Manual

Page 57

Chapter 3 — Configuring the Printer

4 Click the link for the settings you want to configure.

5 You will be prompted to enter a login name and a password. By

default, the login name is admin and the password is pass.

Use the next sections to understand and configure the settings in each

configuration page.

Configuring Communications Settings

Use the communications page to configure serial communications,

the communications interface, and the keyboard layout.

To configure communications settings

1 Click Printer > Communication.

2 Choose the settings you want to change.

3 Click Submit Setup.

Configuring Media Settings

Use the media page to view and change media settings such as

XSTART position, media type, and contrast.

To configure media settings

1 Click Printer > Media.

PD41 and PD42 Commercial Printer User’s Manual 45

Page 58

Chapter 3 — Configuring the Printer

2 Enter the correct information for the media you are using.

3 Click Submit Setup.

Configuring Print Engine Settings (Fingerprint only)

Use the print engine page to adjust the media feed direction (start and

stop adjust positions) and print speed. The value of the head

resistance is read-only and is measured by the firmware when the

printer starts up.

To configure print engine settings

1 Click Printer > Print Engine.

2 Enter the correct information for the print engine.

3 Click Submit Setup.

Configuring Web Shell Settings

Use the Web Shell page to view and change test and default settings.

You can also use the Web Shell page to print test labels and change the

command language.

To configure Web Shell settings

1 Click Printer > Web Shell.

2 Select the action you want to take or the setting you want to

change.

• For the actions in the top of the screen, the printer performs

the action and may prompt you to reboot the printer.

• For the settings in the bottom of the screen, select your desired

settings and click Submit Setup. You will receive a message

that reads “Application change will take effect at reboot.” You

can choose to select Reboot or wait until you are done making

other configuration changes.

46 PD41 and PD42 Commercial Printer User’s Manual

Page 59

Chapter 3 — Configuring the Printer

Use the following table to understand the Web Shell settings.

Understanding the Web Shell Settings

Setting Description

Testfeed [value] Calibrates the label stop sensor performs a

testfeed. Selecting this setting is equivalent to

issuing the TESTFEED command on the

printer.

Ribbon Sensor Detects is the printer has run out of ribbon

during printing.

Default Setup Returns the printer to factory default settings.

Passwords, alerts, and the selected application

are not changed.

Reboot Reboots the printer.

Print Test Label Prints the predefined test label you choose.

Command Language Sets the command language to Fingerprint,

Direct Protocol, IPL, ESim, ZSim, or DSim. You

need to reboot the printer for the change to take

effect.

Fingerprint Application Defines the application to run as the default on

startup. You need to reboot the printer for the

change to take effect.

Standard I/O Defines the port the printer listens to. You need

to reboot the printer for the change to take

effect.

Configuring Alerts

Use the Alerts page to view and change the printer alert settings.

To configure alerts

1 Click Printer > Alerts.

2 Change the alert settings:

• Choose Enabled or Disabled from the Setting list.

• Specify a Delay repeat in the text field.

• Select seconds or occurrences in the Delay Unit list.

• Enter a message in the Message text field.

3 Select the Notification method.

PD41 and PD42 Commercial Printer User’s Manual 47

Page 60

Chapter 3 — Configuring the Printer

4 Click Submit Settings.

Use the following table to understand the Alert Settings.

Understanding the Alert Settings

Setting Description

Label Not Taken

(Fingerprint only)

Cutter Error There was an error related to the label cutter.

Head Lifted A printer job was sent to the printer while the

Out of Ribbon You have thermal transfer ribbon selected and the

Pause Mode The printer is in Pause mode.

Setup Mode The printer is in Setup mode.

Error Condition

(Fingerprint only)

Application Break

(Fingerprint only)

Print Job Complete

(Fingerprint only)

Odometer Count 1 The amount of media printed has reached a preset

Notification Method The method used to send an alert message. You can

Sent when the printed label is not taken from the

printer. This setting applies to label and ticket media

and requires an optional label taken sensor.

printhead was lifted.

printer is out of ribbon.

An error has occurred in the Fingerprint application.

The error does not have to be critical to the print job

for the printer to send this alert.

A running Fingerprint application has been

interrupted manually or because of an error.

The print job has been successfully completed.