User's Manual

PK80 Series

80-Column Printer

Intermec Technologies Corporation

Corporate Headquarters Technical Communications Department

6001 36th Ave. W. 550 Second Street SE

Everett, WA 98203 Cedar Rapids, IA 52401

U.S.A. U.S.A.

www.intermec.com

The information contained herein is proprietary and is provided solely for the purpose of allowing customers

to operate and service Intermec-manufactured equipment and is not to be released, reproduced, or used for

any other purpose without written permission of Intermec.

Information and specifications contained in this document are subject to change without prior notice and do

not represent a commitment on the part of Intermec Technologies Corporation.

E 2003-2005 by Intermec Technologies Corporation. All rights reserved.

The word Intermec, the Intermec logo, Norand, ArciTech, CrossBar, Data Collection Browser, dcBrowser,

Duratherm, EasyCoder, EasyLAN, Enterprise Wireless LAN, EZBuilder, Fingerprint, i-gistics, INCA (under

license), InterDriver, Intermec Printer Network Manager, IRL, JANUS, LabelShop, Mobile Framework,

MobileLAN, Nor*Ware, Pen*Key, Precision Print, PrintSet, RoutePower, TE 2000, Trakker Antares, UAP,

Universal Access Point, and Virtual Wedge are either trademarks or registered trademarks of Intermec

Technologies Corporation.

Throughout this manual, trademarked names may be used. Rather than put a trademark (™ or ®) symbol in

every occurrence of a trademarked name, we state that we are using the names only in an editorial fashion,

and to the benefit of the trademark owner, with no intention of infringement.

There are U.S. and foreign patents pending.

Bluetooth is a trademark of Bluetooth SIG, Inc., U.S.A.

ii PK80 Series 80-Column Printer User’s Manual

Document Change Record

This page records changes to this document. The document was originally released as Revision A.

Revision Date Description of Change

B 05/2003 Updated information about Bluetooth configuration

C 10/2003 Added Easy Print commands, default and downloable fonts.

D 04/2004 Added printer behavior information to Chapter 2, “Operations.” Added additional down-

loadable fonts to Appendix B, “Fonts.” Updated p rinter paper specifications in Chapter 1,

“Introduction.” Added Appendix C, “Graphics Printing.”

E 12/2004 Added additional setting page length commands to Appendix C, “Graphics Printing.”

F 02/2005 Updated Chapter 4, “Troubleshooting,” to include the latest self-test information.

iiiPK80 Series 80-Column Printer User’s Manual

iv

PK80 Series 80-Column Printer User’s Manual

Contents

Before You Begin ix..............................................................

Safety Summary ix........................................................

Safety Icons x............................................................

Global Services and Support xi...............................................

WhoShouldReadthisManual? xii...........................................

Related Documents xii.....................................................

Contents

Donotrepairoradjustalone ix........................................

First aid ix........................................................

Resuscitation ix....................................................

Energized equipment ix..............................................

Warranty Information xi.............................................

Web Support xi....................................................

Telephone Support xi................................................

1

Introduction

About the Printer 2..............................................................

Cables 3................................................................

Hinges on Printer Cover 3..................................................

Paper 4.................................................................

Material Breakdown 4...............................................

Caliper Breakdown 5................................................

Printer Dimensions 5......................................................

Remote Connections 6.....................................................

User Panel 6.............................................................

Forward and Reverse Buttons 6........................................

Radio Button 7....................................................

Vehicle Battery 7.........................................................

Specifications 8.................................................................

Inside Sales 9...................................................................

What’s New 10.................................................................

1...............................................................

2

Operation

Check List 12..................................................................

Open the Printer 12.............................................................

Install the Ribbon Cartridge 13.....................................................

Adjust the Print Head Gap 14.....................................................

11.................................................................

vPK80 Series 80-Column Printer User’s Manual

Contents

Fill the Paper Tray 15............................................................

Fill the Compact Paper Tray 15..............................................

Fill the Dashboard Mount Paper Tray 17......................................

Load Paper into Printer 19........................................................

Position the Paper 19......................................................

Adjust the Pinfeed Holders 20...............................................

Set the Paper 21..........................................................

Printer Behavior 22..............................................................

Expectations 22..........................................................

Indicators 22............................................................

Printer Runs Out of Paper 23...............................................

Printer Head Jams 23......................................................

Print Job Status Report 24..................................................

Timing Out 24..........................................................

3

4

Maintenance

Operation Guidelines 26..........................................................

General Cleaning 27.............................................................

Outside Cleaning 27.............................................................

Inside Cleaning 28..............................................................

Old Ribbon Cartridge Removal 29...........................................

Mask Spring Cleaning 30...................................................

Troubleshooting

Check the Power Source 34........................................................

Large Print Jobs 34..............................................................

Printer Cold-Boot 34............................................................

25..............................................................

33..........................................................

Self-Test 34....................................................................

Sample Self-Test 36.......................................................

Report Failure 37.........................................................

Possible Printer Problems 38.......................................................

Communications with Host Computer 39............................................

vi PK80 Series 80-Column Printer User’s Manual

Contents

Communications Pin-Out Configurations 40..........................................

A

B

Commands

Commands 44..................................................................

Bluetooth Wireless Configuration Commands 44................................

Easy Print Commands 45...................................................

Query Commands 46......................................................

Interpreting the Reply to a Query 46...................................

ESC{ST?} — Status 47..............................................

ESC{CF?} — Configuration 48.......................................

ESC{VR?} — Version 49............................................

ESC{MY?} — Memory 50...........................................

ESC{PH?} — Print Head 51..........................................

ESC{FN?} — Fonts 52..............................................

PK80F Control Sequences 53......................................................

Radio Queries 55...............................................................

Bluetooth QUERY ESC{BL?} 55.............................................

Fonts

Default Fonts 58................................................................

43................................................................

57......................................................................

C

Downloadable Fonts 58..........................................................

Graphics Printing

Graphics Overview 60............................................................

Pin Labels 60............................................................

Graphics Command Format 60..............................................

Column Reservation Numbers 60............................................

Graphics Mode 61..............................................................

Eight-Pin Graphics Modes 61...............................................

Nine-Pin Graphics Modes 61................................................

ESC K — Select Single-Density Graphics Mode 61...............................

ESC L — Select Low-Speed Double-Density Graphics Mode 62.....................

ESC Y — Select High-Speed Double-Density Graphics Mode 62....................

ESC Z — Select Low-Speed Quadruple-Density Graphics Mode 62..................

ESC ^ — Select 9-Pin Graphics Mode 63......................................

ESC * — Select Graphics Mode 63...........................................

ESC ? — Reassign Graphics Mode 64.........................................

ESC + — Print Character Graphics 64........................................

ESC t — Print Character Graphics 64.........................................

59.........................................................

viiPK80 Series 80-Column Printer User’s Manual

Contents

Line Spacing 65.................................................................

ESC 0 — Select 1/8-inch Line Spacing 65......................................

ESC 1 — Select 7/72-inch Line Spacing 65.....................................

ESC A — Select n/72-inch Line Spacing 65....................................

ESC 2 — Select 1/6-inch Line Spacing 65......................................

ESC 3 — Select n/216-inch Line Spacing 65....................................

Page Length 66..........................................................

Set Page Length (lines) 66............................................

Set Page Length (inches) 66..........................................

User-Defined Characters 67.......................................................

ESC : — Copy ROM to RAM 67............................................

ESC & — Define User-Defined Characters 67..................................

ESC % — Select User-Defined Set 68.........................................

ESC 6 — Enable Printing of Codes 128–159 68.................................

ESC 7 — Cancel Printing of Codes 128–159 69.................................

ESC I — Printable Code Area Expansion 69....................................

viii PK80 Series 80-Column Printer User’s Manual

Before You Begin

Safety Summary

Before You Begin

This section provides you with safety information, technical support

information, and sources for additional product information.

Your safety is extremely important. Read and follow all warnings and

cautions in this document before handling and operating Intermec

equipment. You can be seriously injured, and equipment and data can be

damaged if you do not follow the safety warnings and cautions.

Donotrepairoradjustalone

Do not repair or adjust energized equipment alone under any

circumstances. Someone capable of providing first aid must always be

present for your safety.

First aid

Always obtain first aid or medical attention immediately after an injury.

Never neglect an injury, no matter how slight it seems.

Resuscitation

Begin resuscitation immediately if someone is injured and stops breathing.

Any delay could result in death. To work on or near high voltage, you

should be familiar with approved industrial first aid methods.

Energized equipment

Never work on energized equipment unless authorized by a responsible

authority. Energized electrical equipment is dangerous. Electrical shock

from energized equipment can cause death. If you must perform

authorized emergency work on energized equipment, be sure that you

comply strictly with approved safety regulations.

ixPK80 Series 80-Column Printer User’s Manual

Before You Begin

Safety Icons

This section explains how to identify and understand dangers, warnings,

cautions, and notes that are in this manual. You may also see icons that tell

you when to follow ESD procedures and when to take special precautions

for handling optical parts.

A warning alerts you of an operating procedure, practice, condition,

or statement that must be strictly observed to avoid death or serious

injury to the persons working on the equipment.

Avertissement: Un aver tissement vous avertit d ’un e procédure de

fonctionnement, d’une méthode, d’un état ou d’un rapport qui doit

être strictement respecté pour éviterl’occurrencedemortoude

blessures graves aux personnes manupulant l’équipement.

A caution alerts you to an operating procedure, practice, condition, or

statement that must be strictly obs erved to prevent equipment damage

or destruction, or corruption or loss of data.

Attention: Une précaution vous avertit d’une procédure de

fonctionnement, d’une méthode, d’un état ou d’un rapport qui doit

être strictement respecté pour empêcher l’endommagement ou la

destruction de l’équipement, ou l’altération ou la perte de données.

Note: Notes either provide extra information about a topic or contain

special instructions for handling a particular condition or set of

circumstances.

x PK80 Series 80-Column Printer User’s Manual

Global Services and Support

Warranty Information

To understand the warranty for your Intermec product, visit the Intermec

web site at www.intermec.com and click Service & Support.TheIntermec

Global Sales & Service page appears. From the Service & Support menu,

move your pointer over Support,andthenclickWarranty.

Disclaimerofwarranties:Thesamplecodeincludedinthisdocumentis

presented for reference only. The code does not necessarily represent

complete, tested programs. The code is provided “as is with all faults.” All

warranties are expressly disclaimed, including the implied warranties of

merchantability and fitness for a particular purpose.

Web Support

Visit the Intermec web site at www.intermec.com to download our cu rrent

manuals in PDF format. To order printed versions of the Intermec

manuals, contact your local Intermec representative or distributor.

Visit the Intermec technical knowledge base (Knowledge Central) at

intermec.custhelp.com to review technical information or to request

technical support for your Intermec product.

Before You Begin

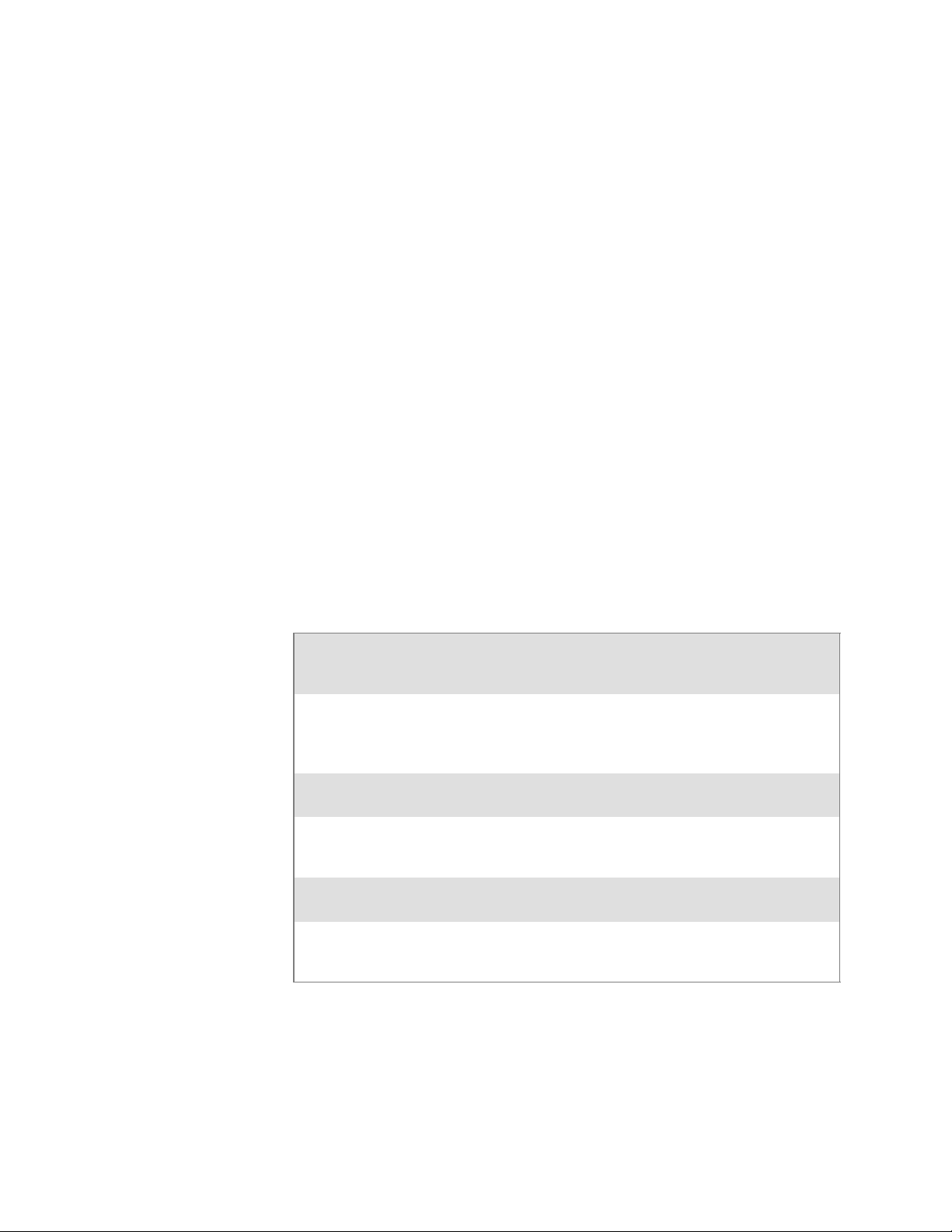

Telephone Support

These services are available from Intermec Technologies Corporation.

In the U.S.A. and Can ada

call 1-800-755-5505

Service Description

Factory Repair and

On-site Repair

Technical S u pport Get technical support on your

Service Contract

Status

Schedule Site Surveys

or Installations

Ordering Products Talk to sales administration,

Request a return authorization

number for authorized service

center repair, or request an

on-site repair technician.

Intermec product.

Inquire about an existing

contract, renew a contract, or ask

invoicing questions.

Schedule a site survey, or request

a product or system installation.

place an order, or check the

status of your order.

Outside the U.S.A. and Canada, contact your local Intermec

representative. To search for your local representative, from the Intermec

web site, click Contact.

and choose this option

1

2

3

4

5

xiPK80 Series 80-Column Printer User’s Manual

Before You Begin

WhoShouldReadthisManual?

This manual provides you with information about the features of the

PK80 Series 80-Column Printer, and how to install, configure, operate,

maintain, and troubleshoot the printer.

Related Documents

This table contains a list of related Intermec documents and their part

numbers.

Document Title Part Number

PK80 Series 80-Column Printer Installation Instructions 962-018-022

PK80F 80-Column Printer Quick Start Guide 962-018-021

The Intermec web site at www.intermec.com contains many of our

documents that you can download in PDF format.

To order printed versions of the Intermec manuals, contact your local

Intermec representative or distributor.

xii PK80 Series 80-Column Printer User’s Manual

Introduction

1

The PK80 Series 80-Column Wireless Printer is used in the route accounting industry to produce high-quality customer invoices, receipts,

load reports, transfers, and other documents. A unique “sleep” feature

saves energy when the printer is not printing, eliminating the ON/OFF

switch. Data input is normally provided by mobile computers.

1PK80 Series80-Column User’s Manual

IntroductionChapter —1

About the Printer

The Fixed Mount Printer (PK80F) can hang on a wall, on a mounting

plate secured to a wall, or secured directly to a wall. Mobile computers

communicate with this printer through a wireless radio or a wired serial

connection. There is no internal paper tray, thus paper is loaded from a

separate dashboard mount, compact paper tray, or a box. The printer

mechanism is permanently attached inside the printer.

2 PK80 Series 80-Column User’s Manual

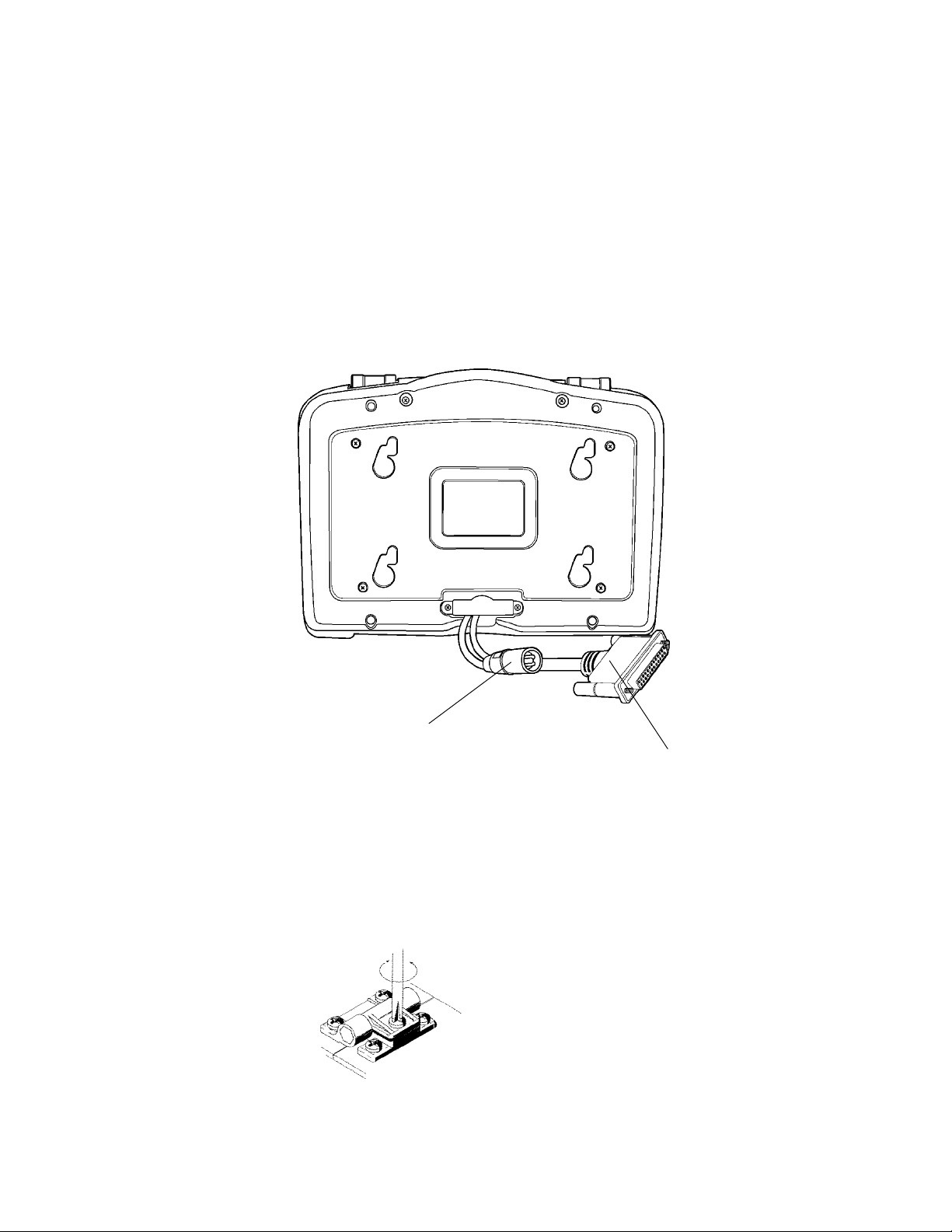

Cables

Introduction—Chapter 1

Communications to the printer is centered around radio technology, such

as a Bluetooth PAN (Personal Area Network) radio module. This will allow for new vehicle configurations.

The Fixed Mount Printer has a 12-volt dc power cable at the bottom of

the printer, which connects the pr inter to a power source, such as the vehicle battery.

The printer also communicates with an Intermec®700 Series Mobile

Computer through an RS-232 DB25-pin data communications cable also

found on the bottom of the printer.

Hinges on Printer Cover

All printer covers are hinged to the printer. These hinges have a tension

screw (turn clockwise to tighten, turn counterclockwise to loosen), should

you need to adjust them.

DC power cable

RS-232 DB25-pin data communications cable

3PK80 Series80-Column User’s Manual

Paper

IntroductionChapter —1

Use of paper that matches the following specifications ensures

optimum PK80 performance. Variation from these specifications, use

of aged paper, or use of paper exposed to elements such as dirt or

humidity may cause printing problems.

The printer works with 1–3 ply carbonless paper that is single-edge glued

and designed for sprocket feed. Standard paper size is 8.5 x 11” or 8.5 x

12” (241 x 305 mm international). Use 3-ply forms up to a maximum of

0.009 inch (0.23 mm) thick.

A soft, flexible, rubber type cement applied to one perforation strip only is

preferred. The resultant lamination should wrap around a 1-1/4 inch diameter roll without curl or wrinkle.

Material Breakdown

The following tables show the material broken down per ply:

14# CBF (Carbonless Back and Front)

Target Under Over

Basis Weight 14# 13.3 14.7

Caliper 2.9 2.6 3.2

Moisture 5.0 4.0 6.0

Smoothness (RS) 165 110 230

Smoothness (CB) 270 220 320

Brightness (Wht) 88 86 90

Colors available: White, Canary, Pink, Goldenrod, Blue, Green

15# CF (Carbonless Front)

Target Under Over

Basis Weight 15# 14.43 15.8

Caliper 3.0 2.5 3.2

Moisture 5.0 4.0 6.0

Smoothness (RS) 140 100 180

Smoothness (CF) 140 100 180

Brightness (Wht) 85 84 86

Colors available: White, Canary, Pink, Goldenrod, Blue, Green

4 PK80 Series 80-Column User’s Manual

Introduction—Chapter 1

16# CB (Carbonless Back)

Target Under Over

Basis Weight 16# 15.2 16.8

Caliper 3.3 2.8 3.8

Moisture 5.7 4.2 6.7

Smoothness (RS) 180 120 270

Smoothness (CB) 270 220 320

Brightness (Wht) 86 84 88

Opacity (Wht) 81 78.5 82

20# OCR La ser Bond

Target Under Over

Basis Weight 20# 15.2 16.8

Caliper 4.0 3.8 4.2

Moisture 3.8 4.7 5.0

Smoothness 140 100 170

Brightness (Wht) 94 82 N/A*

Opacity (Wht) 85 84 N/A

* Not Applicable

Printer Dimensions

Caliper Breakdown

The following information show the caliper of forms broken down per ply:

1-Ply (20#)

Targeted: 4.0

Maximum: 4.2

2-Ply (15# and 16#)

Targeted: 6.3

Maximum: 7.0

3-Ply (14#, 15#, and 16#)

Targeted: 9.2

Maximum: 10.2

See the PK80 Series 80-Column Printer Installation Instructions for Fixed

Mount Printer assembly dimensions. Below are the width, length, and

depth dimensions for the Fixed Mount Printer.

Width Length Depth

10.25” W 14.25” L 5.00” H

(26.04 cm) (36.20 cm) (12.70 cm)

5PK80 Series80-Column User’s Manual

IntroductionChapter —1

Remote Connections

User Panel

A printer and a mobile computer, using the Personal Area Network (PAN)

radio, can operate while up to 30 feet (10 meters) apart.

The printer user panel is located in the center top of the printer and has

three buttons and two Light-Emitting Diodes (LEDs).

Forward

Button

Power LED

Reverse

Button

Radio Button

Radio LED

Forward and Reverse Buttons

Use the Forward and Reverse buttons as follows:

Forward (Left) Button

S Press this button to power on the printer.

S Press this button to feed one line.

S Press and hold this button longer to feed up to five lines, one line at a

time.

S Press and hold this button longer than five feed lines to do a Form Feed,

which moves the paper to the top of the next page, or form. Press this

button again during a Form Feed to stop the paper feed.

S Press and hold this button longer than a Form Feed to perform a self-

test. See Chapter 4, “Troubleshooting,” for more information about this test.

S Press this button any time during a printing job to cancel the current

print job. The print buffer is flushed, all automatic reporting is cancelled, and the printer is ready to print again.

S When there is a paper out, press this button to clear the paper out

mode. Insert the paper, then continue to press this button to feed the

paper into the printer.

Reverse (Right) Button

S Press this button to power on the printer.

S Press and hold this button to do a Back Feed, which pulls the paper

back into the printer line-by-line.

Both Forward and Reverse Buttons

Press both buttons to power off the printer. The current print buffer is

flushed and all automatic reporting is cancelled.

6 PK80 Series 80-Column User’s Manual

Introduction—Chapter 1

Power LED

The power (left) LED shows a steady green when the power is plugged in

and when the printer is awake after coming out of a sleep mode.

Radio Button

Press the third button, the Radio Button,totoggletheradioonoroff.

S If the button is pressed when the RF power is off, then the printer emits

one short beep before turning on the RF power.

S If this button is pressed when the RF power is on, the printer emits two

short beeps before turning off the RF power.

Single Color (Blue)Radio LED

The single-color (blue) radio LED indicator shows the curre nt status of

the RF power for this printer as follows:

Printer State Radio State Radio Power State

Asleep Off Off

Awake Off Off

Asleep Momentary flash at 1 every 5 seconds On

Awake On On

Vehicle Battery

Single Color (Green) Power LED

Thesinglecolor(green)LEDindicatorshowsthecurrentstatusofthe

printer power as follows:

Printer State Color LED and Meaning

Asleep Off

Awake Green

Power is provided to the printer through a cable permanently installed in

the vehicle. See “Inside Sales” for ordering information and part numbers.

7PK80 Series80-Column User’s Manual

IntroductionChapter —1

Specifications

Note: Various print fonts do affect the print speed.

Print Speed: 230 cps

Weight:

Fixed Mount Printer: 11.15 lbs (5.06 kg)

Mounting plate: 7.4 lbs (3.36 kg)

Compact paper tray: 5.85 lbs (2.66 kg)

Dashboard mount: 25.95 lbs (11.76 kg)

Temperature:

Operating: –4_ to 140_ F (–20_to 60_ C)

Storage: –22_ to 149_ F (–30_ to 65_ C)

Humidity:

Noncondensing: 77_ to 140_ F(25_ to 60_ C) at 90% R.H.

Low condensation: 14_ F(–10_ C)@0%R.H.to

High condensation: 140_ F(60_ C) @ 90% R.H.

Altitude:

Operating: –100 to 5000 meters

Storage: 15,000 meters

Electrical:

Voltage: 12 volts dc (nominal)

Current: 100 mA (sleep mode with no charge)

Vibration: 12.5 GRMS for 6 hours @ –31_ to 158_ F (–35_ to 70_ C)

ESD: Level 4 (15 kV noncontact and 8 kV contact)

8 PK80 Series 80-Column User’s Manual

Inside Sales

Introduction—Chapter 1

Contact Inside Sales at 1-800-255-6292 for these supplies:

Cables:

4’ power cable P/N: 226-215-001

8’ Battery cable P/N: 206-875-002

16’ Battery cable P/N: 206-875-006

22’ Battery cable P/N: 206-875-009

”Y” power cable P/N: 226-325-001

Y-data DB9 Pwr 3P to DB25 P/N: 321-582-001

Cleaning solutions:

MICRO-CLEAN II P/N: 901-438-001

Guide Shaft Cleaner P/N: 901-439-001

Paper:

1-ply: P/N: 816-027-111

2-ply: P/N: 816-027-012

3-ply: P/N: 816-027-013

Ribbon cartridges with:

Black ribbon: P/N: 805-060-001

Purple ribbon: P/N: 805-060-002

9PK80 Series80-Column User’s Manual

IntroductionChapter —1

What’s New

The following information was added since the last release of this publication:

S Updated self-test information in Chapter 4, “Troubleshootting.”

10 PK80 Series80-Column User’s Manual

Operation

2

This chapter provides instructions how to set up the PK80 Series 80-Column Printer for the first time and lists some common printer behavior.

11PK80 Series 80-Column User’s Manual

OperationChapter —2

Check List

Make sure the following tasks are done:

S Printer is unpacked.

S Packaging material is removed from around the printer. Save the box

and materials for future use, such as servicing, relocations, etc.

S Twist tie is removed from the print head.

S Power cable is hooked up to the vehicle battery or power source.

S Printer is mounted in the vehicle.

The following tasks must be done. Specific instructions for these tasks are

described on the pages given:

1 Install the ribbon cartridge (page 13).

2 Load the paper into the paper tray (page 15).

3 Feed the paper into the printer (starting on page 19).

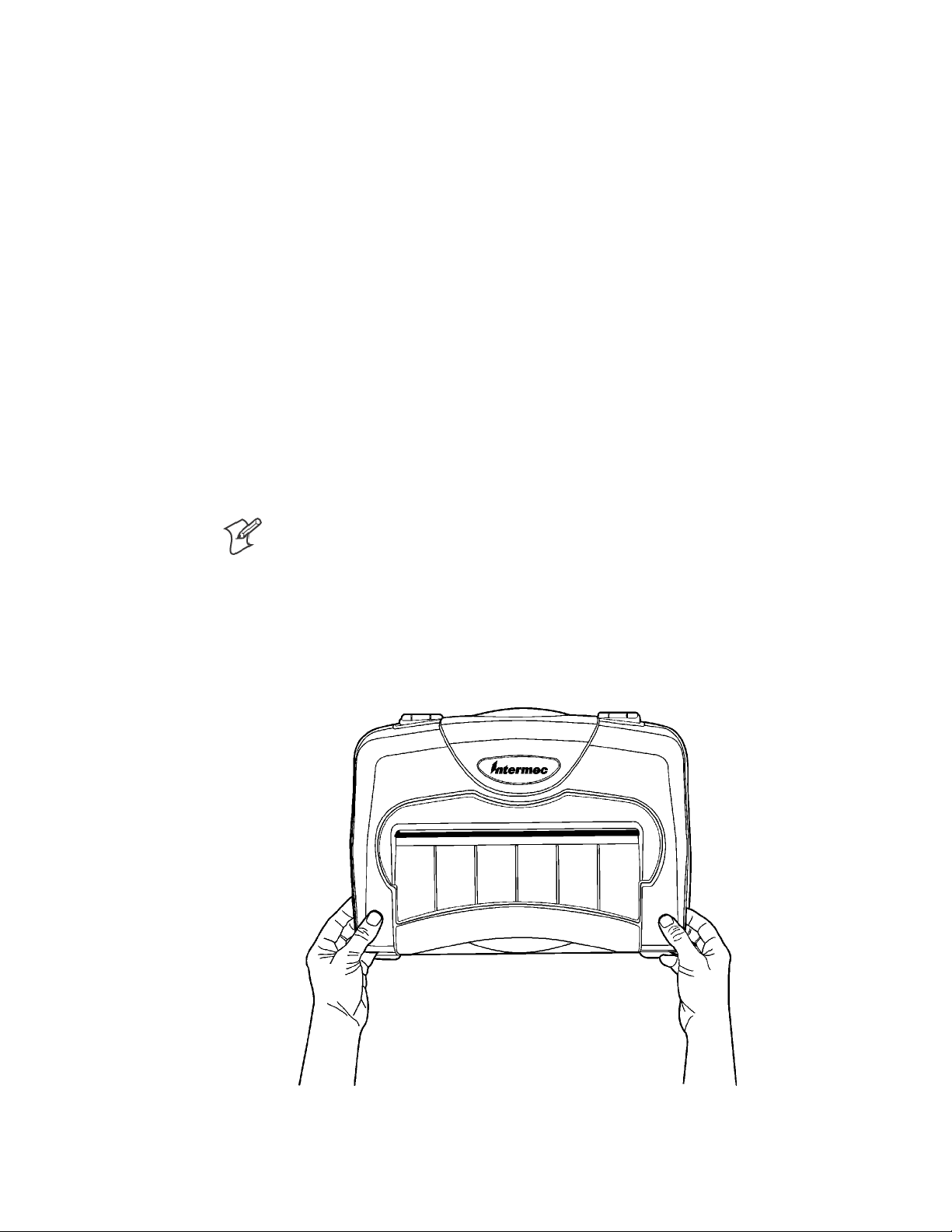

Open the Printer

Note: Complete these tasks before starting any printer operations.

To open the PK80 Series Printer, place your hands on both corners, fingers under the lips, and lift upwards. To close, simply press down on the

same areas.

12 PK80 Series80-Column User’s Manual

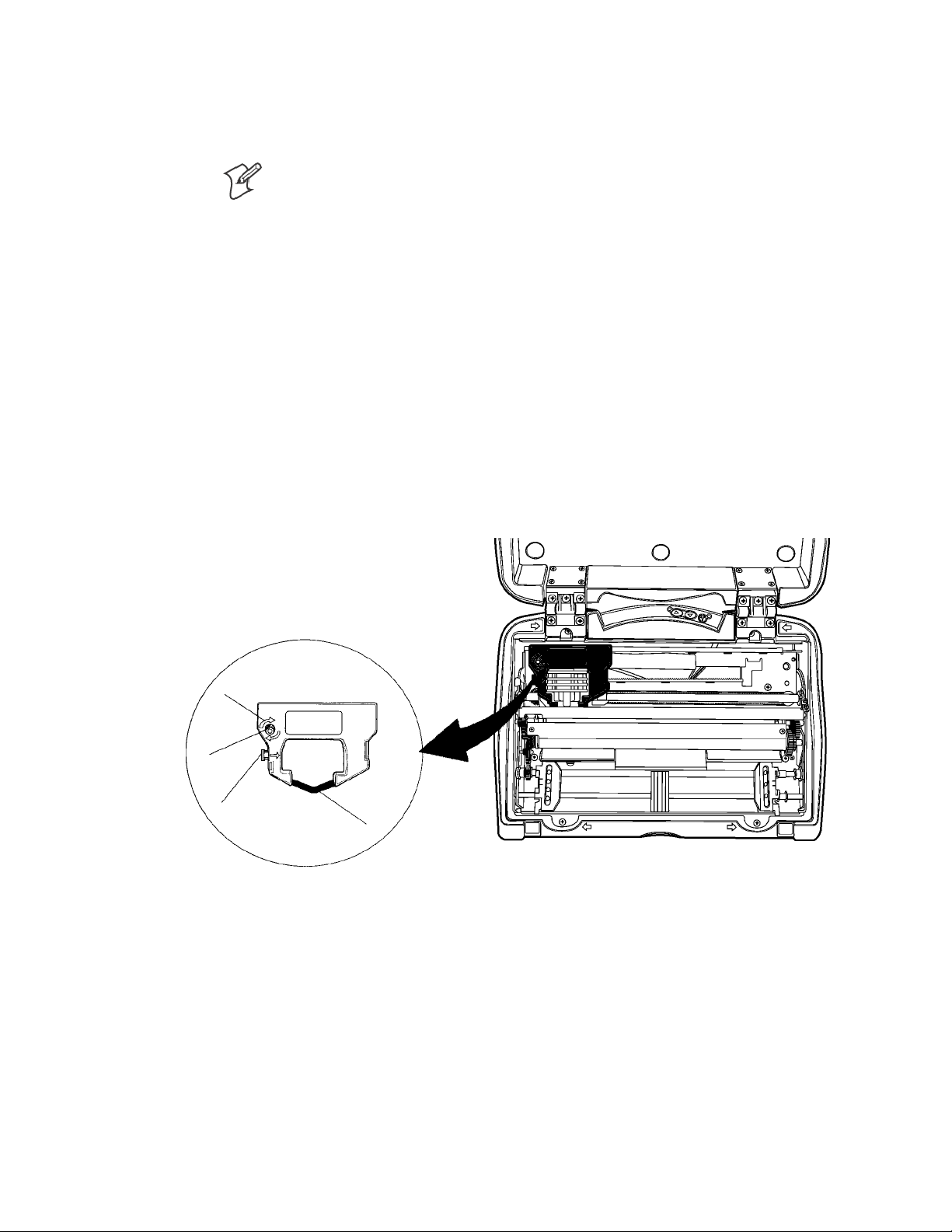

Install the Ribbon Cartridge

Note: Additional ribbon cartridges are sold separately. See “Inside Sales”in

Chapter 1 for ordering information and part numbers.

Ensure that the ribbon cartridge is in the printer and is fully seated (cartridge makes a distinct “snap” or “click”) with the visible portion of the

ribbon straight and even before you do any printing.

1 Turn the ribbon advance knob (in the direction of the raised arrows) to

remove any slack in the ribbon.

2 Squeeze the ribbon cartridge locking tab into the cartridge, then lower

the cartridge over the print head.

3 Lower the tab side of the cartridge until it clicks.

4 Release the tab and press down on the arrow to fully seat the ribbon car-

tridge (tab clicks outward).

5 Turn the ribbon advance knob (follow raised arrows) to align the ribbon

in the front of the print head.

Operation—Chapter 2

4

3

2

1

1 Ribbon

2Lockingtab

3Advanceknob

4 Tightens ribbon

13PK80 Series 80-Column User’s Manual

OperationChapter —2

AdjustthePrintHeadGap

When the printer is powered on or awakened, the print head will find

“home” by advancing away from home, then returning to home, or by returning to home if starting from another location, such as where it stopped

when the last printing job was complete.

When printing is complete, the print head remains where it stopped with a

low hold energy applied to the print head. Further printing activity begins

from this stopped point. If there is no activity after ten seconds, the print

head returns to its home position and is no longer held in place. If the

print head is moved fr om this position, the printer will relocate to its

home position before printing again.

The head gap adjuster is near the printer mechanism on the side opposite

the green thumb wheel. The print head adjuster has five notches between

the print head and the platen for different paper thicknesses.

Verify the thickness of the paper loaded into the printer.

S If you are using single-sheet forms, set the head gap adjuster to the third

notch away from the paper.

S If you are using multiple-sheet forms (2-ply or 3-ply), set the head gap

adjuster to the fourth notch away from the paper.

S If you experience frequent head jams, set the head gap adjuster to the

fifth notch away from the paper. This may stop the head jams.

S If the 2-ply and 3-ply paper have light printing, setting the gap adjuster

to a closer setting will darken the print.

1

5

This illustrating shows the print head adjuster set on its third notch.

14 PK80 Series80-Column User’s Manual

Fill the Paper Tray

Note: Do not exceed the recommended amounts of paper quantity or

thickness. When loading multiple-sheet paper, be sure to have the original

faced up, with the leading edge towards the rear of the printer.

The Fixed Mount Printer can load paper from a compact paper tray (next

paragraph), a dashboard mount paper tray (page 17),oraseparatebox.

Fill the Compact Paper Tray

The compact paper tray is designed to hold 6.25” x 8.5” forms. Larger

formswillhavetobecurvedtofitinthepapertraybox.Thefollowing

instructions are written for 8.5” x 11” forms.

If you are using a compact paper tray to feed paper into the Fixed Mount

Printer, then do the following to load paper into that tray:

1 Hold a stack of paper, upto2.5inches(6cm)thick,with the original on

top. Bend the paper to fit the paper tray.

Operation—Chapter 2

15PK80 Series 80-Column User’s Manual

OperationChapter —2

2 Using the open area of the paper tray, lower the paper into the paper

tray, then pull out your hand. The top of the form should be facing up

and be nearest you.

Open area of paper tray

3 Pull the top of the form out and up to the printer. Lift the lid and lay

the paper onto the pinfeed holders. If you are looking at the front of the

form at this point, then the paper is positioned wrong in the paper tray.

16 PK80 Series80-Column User’s Manual

Fill the Dashboard Mount Paper Tray

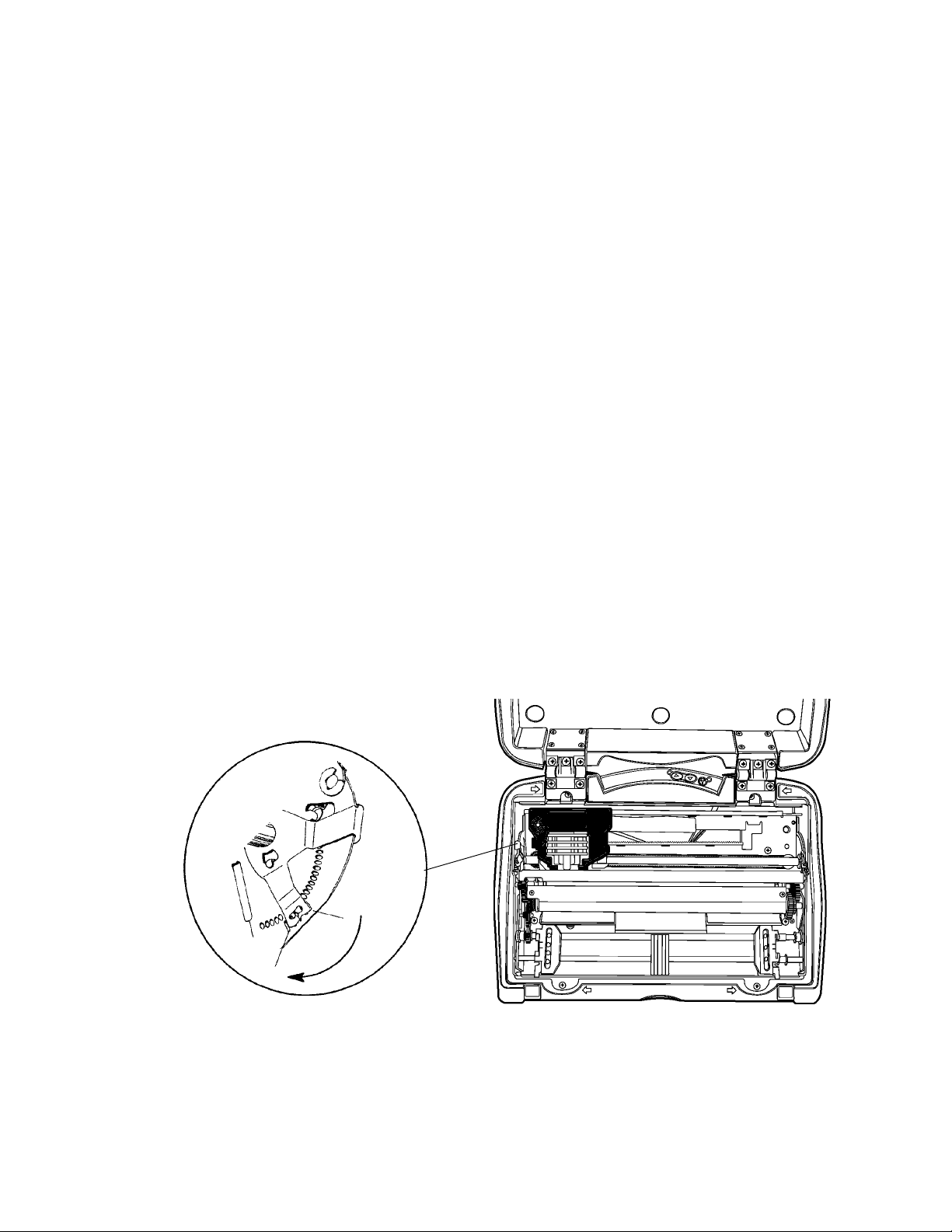

If you are using a dashboard mount, do the following to load paper:

1 On the front door of the box area of the dashboard mount, pull the two

latches with springs (circled in the following illustration) inwards (part A),

then pull to open the door (part B).

Operation—Chapter 2

Part A

Squeeze latches

inwards to open

the door.

Part B

17PK80 Series 80-Column User’s Manual

OperationChapter —2

2 With the original facing you, insert a stack of paper inside the box.

3 Squeeze the latches inwards, close the door, r elease the latches to secure

the door. Pull the top form out through the back, then over the printer

into the mechanism. Paper loading instructions start on the next page.

18 PK80 Series80-Column User’s Manual

Load Paper into Printer

Follow these steps to load the paper into the printer, or paper jams

may occur.

Paper for the PK80 Series Printer has perforated strips that fit onto the

pinfeed holder pins, guiding the paper into the printer. This paper is sold

separately in 1-, 2-, or 3-ply f orms. See “Inside Sales” in Chapter 1 for order-

ing information and part numbers.

Positionthe Paper

1 Open the pinfeed holders outward.

2 Take the top edge of the sheet of paper and position it, original side fac-

ing down, over the pinfeed holder pins.

3 Align the first few holes of the paper, on each side of the paper, onto the

pinfeed holder pins.

4 Close the pinfeed holders.

Operation—Chapter 2

5 Raise the paper bail.

Note: Go to the next page to adjust the pinfeed holders.

19PK80 Series 80-Column User’s Manual

OperationChapter —2

Adjust t he Pinfeed Holders

Note: There are two pinfeed holders, one next to the green thumb wheel

and one opposite the same wheel. Always loosen the pinfeed holder opposite the green thumb wheel.

Adjusting the pinfeed holder next to the green thumb wheel may cause

information to print in the wrong place. If this pinfeed holder is moved,

correct its location by releasing the pinfeed holder tab, moving the pinfeed

holder as close to the green thumb wheel as possible, then locking the

pinfeed holder tab, before adjusting the opposite pinfeed holder.

If the paper does not properly fit on the two pinfeed holders Follow these

steps to adjust the area between the two pinfeed holders to fit the width of

the paper. See the illustration on the next page.

1 With the pinfeed holders open, release the locking tab on the pinfeed

holder opposite the green thumb wheel.

2 Adjust the pinfeed holders to align the pins with the paper.

3 Close the pinfeed holder.

4 Ensure that the paper is smooth (no folds, bulges, bows, etc.) between

the pinfeed holders. If so, push the locking tab down on the pinfeed

holder that you adjusted.

1

2

3

4

1 Pinfeed holder

2 Locked pinfeed holder locking tab

3 Released pinfeed holder locking tab

4 Thumb wheel (green)

20 PK80 Series80-Column User’s Manual

Set the Paper

Operation—Chapter 2

Do the following to feed the paper into the printer:

1 Press, and hold, the Forward button on the user panel to feed the paper

into the printer (6).

2 Lower the paper bail (7). An empty printer autofeeds new paper approx-

imately 0.1” (0.25 cm) beyond the top of the paper bail.

Note: The ideal distance to feed paper beyond the paper bail may vary

due to environmental conditions (such as humidity) and specific aspects

of certain paper. Use the green thumb wheel to position the paper to a

desired distance per your conditions.

Note: If your paper has a preprinted logo on every page, make sure the

print head is below the preprinted logo. If not, you can adjust the position of the paper, either by pressing, then releasing, the Forward button

to move the paper forward or the Reverse button to move the paper

back, or by using the green thumb wheel.

3 Closetheprinterlid.Makesurethepaperwillpassthroughthepaper

slot when the printer starts printing.

21PK80 Series 80-Column User’s Manual

OperationChapter —2

Printer Behavior

Expectations

This lists behaviors you can expect when working with your printer.

Below are some tips to remember when working with Bluetooth:

S The Bluetooth connection is automatically closed when the printer falls

asleep.

S The Bluetooth connection is automatically closed when there has been

no Bluetooth activity for a period of time. You can configure this period

of time via the {BL:xxx} command, where “xxx” ranges from 60 to

65535 seconds (1 minute to more than 18 hours).

S For the Bluetooth Query, add the “I” parameter, which responds with

the inactivity timer specified in the previous bullet.

See Appendix A, “Commands” for more information about the “I” parameter and the inactivity timer.

Indicators

If the power LED is green, but the printer is not printing, press and hold

both the Forward and Reverse buttons. If the power LED lights up, refer

to the following table:

Printer Failure Indicators

Sets of Beeps Meaning

1 set of 13 beeps Configuration error.

2 sets of 3 beeps Paper Out.

3 sets of 4 beeps Home switch failure.

4 sets of 2 beeps Head Jam.

4 sets of 4 beeps Flash write error.

12 sets of 12 beeps Operating system software failure.

22 PK80 Series80-Column User’s Manual

Printer Runs Out of Paper

When a paper outage occurs, the printer emits three short beeps, pauses,

then emits three more short beeps to indicate the printer is out of paper.

Below is what you should expect when you do any of the following:

Do nothing

The printer times out, reports a “Time Out” status, cancels the print

job, and cancels automatic reporting.

Insert paper before the printer times out

The printer reports a “Paper In” status and resumes printing.

Stop the print job— press the Forward button

The printer reports a “Kill Job” status, flushes the print buffer, cancels

automatic reporting, and readies for another print job.

Turn off the printer — press both the Forward and Reverse buttons

The printer reports a “Printer Off” status, flushes the print buffer, cancels automatic reporting, and shuts down.

See Chapter 1, “Introduction,” for information about the Forward and Re-

verse buttons on the control panel.

Operation—Chapter 2

Printer Head Jams

The printer reports all activity to the print job status report described on

the next page.

When the printer head jams, the printer emits two short beeps, pauses,

emits two more beeps, pauses again, and continues until it emits eight

beeps in all. What to expect when you do one of the following:

Do nothing

The printer times out, reports a “Time Out” status, cancels the print

job, and cancels automatic reporting.

Stop the print job— press the Forward button

The printer reports a “Kill Job” status, flushes the print buffer, cancels

automatic reporting, and readies for another print job after the print

head jam is cleared.

Turn off the printer — press both the Forward and Reverse buttons

The printer reports a “Printer Off” status, flushes the print buffer, cancels automatic reporting, and shuts down.

See Chapter 1, “Introduction,” for information about the Forward and Re-

verse buttons on the control panel.

Go to page 14 for information about the print head.

The printer sends all activity to the print job status report described on the

next page.

23PK80 Series 80-Column User’s Manual

OperationChapter —2

Print Job Status Report

This simple protocol assures that data delivered to the printer is printed

without mechanical error. Each print job to be monitored begins with an

“ESC s n” command, where the “ESCs” marks the start of the print job,

and bit fields within “n” specify the level of error reporting. The end of

the print job is marked by an “ESC e” command.

Note: Spaces are not part of the actual sequences. They are only included

here for readability.

Once the print job status is enabled, any detection of a requested condition (see the definition of “n” below) is reported immediately, without the

need to query the printer. The printer will send the same string that results

from receipt of a status command (ESC{ST?}). In addition, if reque sted,

the printer will automatically send the status when the last print line or

FormFeed within the start/end markers is complete.

S ESC s n Start of print job (0x1B 0x73 n)

Timing Out

Settoreportstatusatendofjob

Settoreportpaperout

Settoreportprintheadjam

Set to report when paper is present after paper out

Settoreporttimeoutduringprint

Settoreportfwd/revkeypressesduringprint

Must be zero (reserved)

Note:Ann of all zeroes (0x00) will cancel any active auto status messages

set by a previous ESC s n without an ESC e.

S ESC e End of print job (0x1B 0x65)

Response is identical to the status command with Paper Jam and Print Status fields added. Status can still be requested by sending the usual sequence

(ESC{ST?}). See Appendix A, ”Commands,” for information.

When a time out occurs (ESC{BLI}), a status request is sent indicating the

printer has timed out. The current print buffer is flushed, and subsequent

automatic reporting is cancelled.

The printer will not time out if the sixth bit is set (cancel timeout) when

the ESC s n command is sent to mark the beginning of the print job. If

the job has completed printing and the printer is idle, then pressing the

Forward button on the control panel will not send the “print job kill”

message, since there is nothing in the print buffer.

However, pressing both the Forward and Reverse buttons to turn the

printer off will generate the printer off message.

24 PK80 Series80-Column User’s Manual

Maintenance

3

The printer lasts longer and performs better when it is operated correctly

and kept clean.

25PK80 Series 80-Column User’s Manual

MaintenanceChapter —3

Operation Guidelines

Do

Ensure that the computer remains connected to th e printer throughout printing or operation.

Make sure the printer cover i s closed (except during maintenance or when loading paper).

Ensure there is paper properly installed in the paper tray or dashboard mount.

Disconnect the printer power cable when jump-starting the vehicle.

Clean the external surface of the printer usi ng a soft cloth moistened with mild soap and water, a good quality

cleaner, such as MICRO-CLEAN II, and if necessary, rubbing alcohol.

Make sure your printer is loaded with paper before communicating with your mobile computer.

Do Not

Spill liquids or food crumbs into the printer.

Sit or stand on the printer.

Usesolventsorabrasivecleanersontheprinter.

Rest objects on, under, or against the printer.

Allow the printer to be knocked over or physically damaged.

Start or stop the vehicle engine while printing.

Overload paper tray (paper jams will occur).

Use objects to remove paper from between the print head and platen (damage to m ask spring/ print head will occur).

26 PK80 Series80-Column User’s Manual

General Cleaning

Maintenance—Chapter 3

Do not use glass cleaners with ammonia. Permanent damage to the

printer cover will occur if such glass cleaners are used.

Do not use abrasives or solvents (or any product containing these

substances) to clean any part of the unit. Permanent damage to the

printer will occur if such substances are used.

Never use ketonic solvents (acetone or ketone) or aromatic solvents

(toluene or xylene) to clean any part of the printer. Doing this can

damage the printer.

Note: MICRO-CLEAN II is the only cleaner recommended for this purpose. Other cleaners can damage the case.

Note: GUIDE SHAFT CLEANER is recommended for cleaning your

80-column printer guide shafts. Cleaning the printer guide shaft can reduce the number of head jams caused by dirt and buildup.

Outside Cleaning

Both cleaners are sold separately. See “Inside Sales” in Chapter 1 for ordering information and part numbers.

Periodic cleaning helps maintain the appearance and reliability of the printer. When cleaning the printer, inspect both the outside and the inside for

obvious signs of damage, wear, or impending failure.

Do not pour liquid cleaners directly on the printer case. Instead, dampen a

soft, lint-free cloth with a quality cleaner and clean the exterior surfaces

with this cloth. Do not use solvent solutions. Inspect all cables and the remote terminal holder or vehicle dock for damage.

27PK80 Series 80-Column User’s Manual

MaintenanceChapter —3

Inside Cleaning

Let the printer cool before you clean the inside of the printer, or you

may burn your fingers.

Open the printer cover and inspect the ribbon cartridge and all visible

moving parts on the printer mechanism for signs of wear or damage.

2

3

4

1

1 Head gap adjuster

2 Ribbon cartridge

3Paperbail

4 Thumb wheel (green)

5 Pinfeed holder

This illustration shows the visible moving parts of the printer mechanism.

5

Use a low-pressure, dry air source, such as “canned air” available at electronic supply houses and typewriter repair facilities, or a vacuum, to remove accumulated paper dust from the printer mechanism.

The printer ribbon contains a special lubricant to ensure that the fine dot

wires inside the print head receive adequate lubrication. Replace the ribbon frequently to prolong the life of the print head. The printer requires

no additional user-applied lubrication. Ribbon cartridges, available in

black or purple, are sold separately. See “Inside Sales” in Chapter 1 for ordering information and part numbers.

28 PK80 Series80-Column User’s Manual

Old Ribbon Cartridge Removal

Physically move the print head mechanism to an open area, then do the

following to remove the old ribbon cartridge:

1 Squeeze the ribbon cartridge locking tab (on the side of the cartridge)

against the ribbon cartridge.

2 Lift the ribbon cartridge to remove the ribbon from the print head. En-

sure the ribbon does not catch.

3 Lift the ribbon cartridge out of the printer.

Maintenance—Chapter 3

Locking Tab

29PK80 Series 80-Column User’s Manual

MaintenanceChapter —3

Mask Spring Cleaning

1

Look at the mask spring behind the print head. If the mask spring needs to

be cleaned, go on to the next page. If the mask spring appears to be in

good condition, install a new ribbon cartridge as described on page 13.

2

1 Print head

2Maskspring

Do the following to clean the mask spring:

1 Unlatch the print head locking tabs to release the print head, lift the

printheadandsetaside,thenliftupthepaperbail.Do not detach the

print head unit.

Never use a sharp object, such as pinchers, to clean between the

print head and the platen (rubber roller). This can damage the mask

spring and print head.

2 Remove the clear plastic paper guide that seats the mask spring, if neces-

sary. Use your fingernails to loosen the base of the paper guide, then

pull the paper guide straight up from the printer mechanism.

3 Removethemetalmaskspringfromthepaperguideandcleanwitha

quality cleaner. Replace if damaged.

4 Put the good, clean mask spring into the paper guide and install the pa-

per guide into the printer.

30 PK80 Series80-Column User’s Manual

Maintenance—Chapter 3

5 Close the paper bail, reinsert the print head, latch the two print head

locking tabs, and install the ribbon.

1

23

4

1 Print head locking tabs

2 Print head (lifted aside)

3Maskspring

4Paperbail(raised)

31PK80 Series 80-Column User’s Manual

MaintenanceChapter —3

32 PK80 Series80-Column User’s Manual

Troubleshooting

4

This chapter helps you correct printing problems that may occur. If you

experience a printing problem, you can perform several tests to find and

possibly cure the problem.

33PK80 Series 80-Column User’s Manual

TroubleshootingChapter —4

Check the Power Source

The printer will automatically power down after a configurable period of

inactivity. Activity is either sending data or pressing a button. The timer

resets during printing. You can awake the printer either by sending data or

pressing either the Forward or the Reverse buttonontheuserpanel.

If there is power, the power LED turns on and the print head moves to its

“home” or starting position. If the printer emits beeps and power LED

lights up or flashes, observe the number of beeps and flashes and refer to

thetableonpage38foranerrormessage.

If there is no reaction from the printer after pressing a button on the user

panel, or only the power LED blinks, verify that the power cables are

properly connected between the printer and its power source (internal battery, vehicle cable, or ac). If neither of these steps “wake” up the problem

printer, then return the printer for service.

Vehicle cable: Attach the printer to another vehicle power cable.

AC power: Plug the printer into another outlet.

Large Print Jobs

Printer Cold-Boot

Self-Test

Printing large files with 15 pages or more can cause lost data issues because

of limited printer buffer size and time out length on the mobile computer.

To prevent problems, you can adjust the time out lengths on the mobile

computer. If you encounter a problem concerning large print jobs, contact

Customer Support at 800-755-5505 for further help

Should you need to reset the Fixed M ount Printer, simply remove power

from the printer, wait a few moments, then return power to the printer.

Note: Each time the printer is powered up, it reads flash values into RAM.

As long as the printer is on and awake, it updates those values in RAM.

When the printer is powered off, or falls asleep, the values are written into

flash. If power is disconnected instead of the printer being powered off or

falling asleep, then updates in RAM are lost.

Press and hold the Forward button through a form feed (more than five

lines). If it is still held down at the end of the form feed, it prints the selftest. Internal tests are performed and a 1-page report is printed. This report provides helpful tips in diagnosing/troubleshooting printer problems.

Note: You can abort the self-test by pressing a button while it is printing.

34 PK80 Series80-Column User’s Manual

Troubleshooting—Chapter 4

When the self-test is performed, the following actions occur:

S Voltage and ambient temperature are obtained

S Validity of diagnostic block program is checked

S Validity of BootBlock program is checked

S Validity of control program is checked

S Validity of loaded fonts is checked

S Self-test report is printed

The self-test report is divided into sections. See page 36 for a sample.

The printer model number is given on line 1 (first line). This identifies the printer type being u s ed, such as PK80F.

The serial number of the printer is listed on line 3 under the “Serial#” heading on line 2. The serial number is also

ontheinsideoftheprinter.

The “Auto Feed” setting, on line 13, is a configurable item. “CR” Carriage Return means no auto linefeed. This is

the most common setting for applications. “CR+LF” me ans a linefeed will be added to each CR. This setting can

produce double-spacing of reports.

The “Interface Mode” setting, line 14, lists the interface protocol for the printer. A typical setting can be DTR with

no, odd, or even parity.

“Baud Rate” on line 16, lists the baud rate for the printer. Most application software autobauds so you do not have

to select it. Bit rate is commonly set to 19200 (19.2K) or 9600 bps.

“A2D History,” lines 63 through 66, is the his tory for voltage measurements and temperature measurements, as recorded by the printer.

“Head Jam History” on lines 68 through 71, gives information on head jams. If the printer is having frequent head

jams, these lines can assist in determining the problem.

“Direction” tells which way the head was moving, “left” toward home and “right” away from home. Home position is at the extreme left, toward the green thumb wheel.

“Step” is the acceleration step at the j am. “0” means no steps were taken, “15” means all steps were taken.

“1–14” means printer jammed during acceleration or deceleration.

“Speed” is the acceleration speed of the print head when the jam occurred.

“Temp” is the ambient temperature at the last head jam. The temperature is listed in Celsius.

“Position” of carriage at the jam in 1/720 inches = 12 * step position. Divide the number by 12 to get the step

position. There are 512 steps across the page. If it is jamming in the middle, it is more likely a dirty ribbon or

obstructionintheprinthead’spath.

“Head Dot Pattern,” appearing after “Total Head Jams,” is printed to verify the individual dot wire s. There should

be nine dots. If some are missing, it could be a print head failure or a circuit board failure.

“Error Log” information appears in the second-to-last group of lines, This information is cleared after every self-test.

This information is very helpful in determining problems.

“HJ” # of head jams while print head is moving

“12Vu” #12-voltundervoltage

“12Vo” # 12-volt over voltage

“Home” # Home detect errors (typically caused by paper scraps or circuit failures)

“EEErr” # EEPROM write failures to diagnostic block

All other values are informational only. Remember that these values are

cleared after the self-test.

35PK80 Series 80-Column User’s Manual

TroubleshootingChapter —4

Sample Self-Test

Note: Lines 10–19 are factory-default printer settings. Take note of these

lines when reading the self-test report.

1 Intermec PK80F

2 Copyright 2003 All Rights Reserved

3 Serial# MFG Date –––––––––Hardware–––––––––

4 1234567 01/24/05 PK80F 8in Impact Printer

5 Printer Firmware: – Version 5.54

6 BootBlock: – Version 5.06

7 Comm Controller: – Version 5.30

8 Flash/RAM Memory: – 8/4 Mbit

9

10 Printer Configuration:

11 Printer Timeout: 60S

12 RF Power Down Timeout: Never

13 Auto Feed: CR=CR LF=CRLF

14 Interface Mode: LP

15 Beeper: On

16 Baud Rate (Serial RS-232): 19.2K

17 Data Bits (Serial RS-232): 8

18 Parity (Serial RS-232): None

19 Handshaking (Serial RS-232): Hardware

20

21 Wireless RF Printer Configuration:

22 Wireless Device Address: 00:80:37:19:3A:23

23 Wireless Device Name: “PK80–1234567”

24 Wireless Service Name: “Wireless Printer”

25 Wireless Profile: Serial Port (SPP)

26 Class of Device/Service: 040680 Rendering Imaging Printer

27 Discoverable: Yes

28 Connectable: Yes

29 Bondable: Yes

30 Encryption: No

31 Authentication: No

32 Passkey: Key present

33 Inactivity Disconnect Timeout: 60S

34

35 Fonts: LOC CPI *–––DESCRIPTION–––* V *–DATE–* *–––NAMES–––*

36 R 10.5 255CH PICA CP437 REG 3 02/06/03 PR437 A(41H)

37 R 12.7 255CH ELIT CP437 REG 3 02/06/03 ER437 B(42H)

38 R 10.5 255CH PICA CP437 ITA 3 02/06/03 PI437 C(43H)

39 R 12.7 255CH ELIT CP437 ITA 3 02/06/03 EI437 D(44H)

40 D Vary 224 CH TRADTN ARABIC 4 06/20/01 ARABT d(64H)

41 D Vary 224 CH SMPLFD ARABIC 4 07/11/01 ARABS e(65H)

42 D Vary 224 CH E-MAPD ARABIC 4 07/11/01 ARABE f(66H)

43 D 10.5 224 CH GREEK-DOS MAP 3 02/01/01 GRDOS g(67H)

44 D 10.5 224 CH GREEK-WIN MAP 4 02/01/01 GRWIN h(68H)

45 D 10.5 255CH PICA ISO01 REG 2 10/30/01 ISO10 i(69H)

46 D 12.7 255CH ELIT ISO01 REG 2 10/30/01 ISO12 j(6AH)

47 D 10.5 ISO 8859-09 PICA 2 04/18/03 PRI09 l(6CH)

48 D 12.7 ISO 8859-09 ELITE 2 04/18/03 ERI09 k(6BH)

49 D 10.5 Hebrew ISO8859-8 Map 2 09/29/03 HBISO m(6DH)

50 D 10.5 Hebrew DOS CP862 Map 2 09/29/03 HBDOS n(6EH)

51 D 10.5 254 CH CYRILC CP-866 3 03/27/01 CY110 +(2BH)

52 D 10.5 255 CH CYRILC 8859-5 3 03/27/01 CY210 -(2DH)

53 D 10.5 Code Page 852 PICA 2 05/13/02 DL210 ^(5EH)

54 D 12.7 Code Page 852 ELITE 2 10/28/02 DL212 _(5FH)

36 PK80 Series80-Column User’s Manual

Troubleshooting—Chapter 4

55 D 9.0 DOS10 W/ EURO @ 0x7F 4 05/17/02 DOS10 p(70H)

56

57 Current Statistics:

58 Battery Voltage: 13.2V

59 Total Pages: 205

60 Cold Starts: 56

61 Warm Starts: 1345

62

63 A2D History

64 Curr Low High Min Max Error Page Count

65 12V: 13.20 00.00 00.00 07.00 16.80 00.00 00000 00000

66 000 000 000 000 000 000

67

68 Head Jam History

69 Total Head Jams: 1

70 Motion Direction Ramp Step Speed Temp Position Page

71 Print Right Const 000 High +00.0C 00708 00183

72

73 Head Dot Pattern

74

75

76 Error Log

77 HJ 12Vu 12Vo Home EEErr

78 00000 00000 00000 00000 00000

79

60!#$%&()*+:;<=>?ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz01234567890

61#$%&()*+:;<=>?ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz01234567890!

62$%&()*+:;<=>?ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz01234567890!#

63%&()*+:;<=>?ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz01234567890!#$

Report Failure

If a partialreport generates and a printer error occurs during printing,

refer to the table on the next page for troubleshooting help.

If the printer does not generate a report:

S There may be a printer failure, refer to the troubleshooting table on

thenextpageforpossiblesolutions.

S There may be a power failure, check the power source (internal bat-

tery, charge cable, or ac adaptor).

37PK80 Series 80-Column User’s Manual

TroubleshootingChapter —4

Possible Printer Problems

The following table lists actual printing problems, possible causes, and actions you sh ould take to correct a problem. Call 800-755-5505 or

425-356-1799 if you are advised to contact Customer Support.

Symptom Test or Cause Solution

Printer does not communicate with

themobilecomputer.

Double-spacing on application reports but single-spacing on self-test.

Incorrect protocol selection. Contact Customer Support.

Check line 11 on the self-test report,

if “CF+LF” then this is an incorrect

configuration.

Contact Customer Support.

Printeremits1or2beepsorblinking

green light is the only indicator.

Printer emits 2 sets of 3 beeps Printer out of paper. Press the Forward button to stop the

Printerworksbuteitherorboth

LEDs do not work.

Printer does not work. (1) No voltage. (1) Adjust supply voltage to 11–15

Printer is emitting 4 sets of 2 beeps

and has stopped printing.

No paper feed (paper jam). When I

pull the paper toward the roller the

paper is resistant.

Printer mechanism does not have ad equate power for printing. The 12 V

may be under or over voltage fault.

(Note: Error lights do not flash if high

voltage.)

Discrete cable connecting user panel

board to pivot frame assembly is

loose.

(2) Voltage too high or too low. (2) Adjust supply voltage to 11–15

(3) No data input. (3) Tighten computer connections.

The printer had detected a paper jam

during homing.

(1) Paper tray or dashboard mount

may be too full.

(2) The paper perforation may be

torn.

(3) The paper may be wrinkled,

creased, moist, or perforations may

be missing.

Check power supply if one is used. If

power supply, adjust supply voltage

to 11–15 volts. Check the vehicle

charge cable (see the PK8X Series

80-Column Printer Installation Instructions for information).

beeps. Reload paper — see page 15

for instructions. If the “paper out”

condition still exists, the printer will

beep again.

Call Customer Support or send the

printer in for hardware repair.

volts.

volts.

Power off the printer, clear the jam

as advised below, then power on or

awaken the printer.

(1)Ensuretherearefewerthan200

3-ply sheets in the paper tray or dashboard mount.

(2) Remove the torn paper, load and

center a clean stack of paper, and adjustthepinfeedholders.Seepage20

for instructions.

(3) Replace the paper.

38 PK80 Series80-Column User’s Manual

No paper feed (head jam). When I

move the print head manually from

side to side, the print head is resistant.

(1) Ribbon may be jammed. (1) Remove ribbon cartridge and

(2) Mask spring may be bent or damaged.

(3) Print head gap adjuster may be

too low.

(4) Paper scraps are found in the

printer mechanism or around platen.

Communications with Host C omputer

Troubleshooting—Chapter 4

SolutionTest or CauseSymptom

turn knob. If ribbon resists, replace

ribbon cartridge. See page 13 for instructions.

(2)Replacethemaskspring.Seepage

30 for instructions.

(3) Set the head gap adjuster to the

fifth notch away from the paper. See

page 14 for instructions.

(4) If the ribbon cartridge bumps

against the inside of the printer,

check the white ribbon cable, home

position sensor, and four screws. Remove any paper scraps and do a

cleaning.

The self-test report can verify that the communications protocol options

selected for the printer match those expected by the host computer. If

these options do not match, then reconfigure the printer using Easy Print

commands or the PK80 Configuration program. See Appendix A, “Com-

mands,” for more information about the Easy Print commands.

If the protocol options do match, then the data communications cable may

be defective. Verify that the cable is working by substituting a new cable

or host computer. Also check the computer vehicle dock.

39PK80 Series 80-Column User’s Manual

TroubleshootingChapter —4

x

Communications Pin-Out Configurations

Below are common cable configurations between a mobile computer or a

dock and the printer:

Mobile Computer

Signal Name Pin # Pin # Signal Name

Chassis Ground shell 1 NC (No Connection)

Charge Input 8 9 HHC_CHARGE

SG (Signal Ground) 9 7 GND

DSR (Data Set Ready) 7 6 NC

DTR (Data Terminal Ready) 2 20 NC

CTS (Clear To Send) 6 5 RTS

RTS (Ready To Send) 3 4 CTS

RXD (Receive Data) 5 3 TXD

TXD (Transmit Data) 4 2 RXD

shield

Fi

ed Mount Printer or

Remote Mount Terminal Holder

15-Pin to 25-Pin Cable

P/N: 216-605-XXX

8

1

15-Pin DSUB Male

PC

Signal Name Pin # Pin # Signal Name

DTR (Data Terminal Ready)* 20 20 NC (No Connection)

RC (Receive Carrier)* 17 17 NC

TC (Transmit Carrier)* 15 15 NC

DCD (Data Carrier Detect)* 8 8 NC

SG (Signal Ground) 7 7 GND

DSR (Data Set Ready)* 6 6 NC

CTS (Clear To Send) 5 5 RTS

RTS (Ready To Send) 4 4 CTS

RXD (Receive Data) 3 3 TXD

TXD (Transmit Data) 2 2 RXD

Chassis Ground 1 1 NC

* Signals are not available on the 6100 Dock

15

9

13

1

25-Pin DSUB Male

25

14

Fixed Mount Printer

1

13 1

14

25

13

25

14

25-Pin to 25-Pin Cable

P/N: 216-771-XXX

25-Pin DSUB Male25-Pin DSUB Female

40 PK80 Series80-Column User’s Manual

Troubleshooting—Chapter 4

9-Pin to 25-PinCable

P/N: 321-355-XXX

Vehicle Dock

Signal Name Pin # Pin # Signal Name

CD (Carrier Detect) 1 No Charge

RXD (Receive Data) 2 3 TXD

TXD (Transmit Data) 3 2 RXD

DTR (Data Terminal Ready) 4 20 DSR

Chassis Ground 5 7 Chassis Ground

DSR (Data Send Ready) 6 6 DTR

RTS (Ready To Send) 7 4 CTS

CTS (Clear To Send) 8 5 RTS

RI (Ring Indicator) 9 No Charge

1

5

9-Pin DSUB Female

6

9

shell shell

13

shield

1

25-Pin DSUB Male

Printer

14

25

9-Pin to 25-PinCable

P/N: 321-582-XXX

Vehicle Dock

Signal Name Pin # Pin # Signal Name

CD (Carrier Detect) 1 No Charge

RXD (Receive Data) 2 3 TXD

TXD (Transmit Data) 3 2 RXD

DTR (Data Terminal Ready) 4 20 DSR

Chassis Ground 5 7 Chassis Ground

DSR (Data Send Ready) 6 6 DTR

RTS (Ready To Send) 7 4 CTS

CTS (Clear To Send) 8 5 RTS

RI (Ring Indicator) 9 No Charge

1

5

9-Pin DSUB Female

6

9

shell shell

13

shield

1

25-Pin DSUB Male

Printer

14

25

41PK80 Series 80-Column User’s Manual

TroubleshootingChapter —4

The printer has a 25-pin connector with the following pinout designations

and signal mnemonics:

Printer Communications Connector Pin-Outs

DB25 Signal Name Type I/O Description

20 NC ——— ——— NoConnection

4 CTS (Clear To Send) RS-232 IN Wake up

2 RXD (Receive Data) RS-232 IN Printer’s RxD

3 TXD (Transmit Data) RS-232 OUT Printer’s TxD

5 RTS (Ready To Send) RS-232 OUT Printer’s RTS

9 HHC_Charge Power OUT 11–15 V, up to 1 A per contact

7 GND Power OUT SG (Signal Ground)

42 PK80 Series80-Column User’s Manual

Commands

A

This appendix lists Easy Print and Bluetooth configuration and query

commands and control sequences that are supported by the PK80 Series

80-Column Printer.

Note: Printer configuration applications may not determine printer communication speed if the printer is out of paper. Make sure the printer has

paper when doing reconfiguration and firmware upgrading.

43PK80 Series 80-Column Printer User’s Manual

CommandsAppendix —A

Commands

Below are the commands and the pages where their information begins:

S Bluetooth Wireless Configuration (next paragraph)

S Easy Print (page 45)

S Query (page 46)

Some of these commands are identified as Easy Print commands, which

must be preceded by ESC EZ. Printers must also receive the “{” as part of

the ESC EZ sequence to be placed into Easy Print mode.

Bluetooth Wireless Configuration Commands

All commands are enclosed in ‘{’ and ‘}’. They begin with three letters; if

there is data that follows the letters are terminated with a colon “:”. Each

parameter can be configured is identified by a unique letter, followed by a

colon, followed by the data for that parameter. If the configuration type

permits, multiple parameters can be changed in one command by separating them with a semicolon “;”. All commands must be sent in uppercase..

Spaces in the data are not allowed unless they are part of the data.

After receiving the command, the data is written to flash and the printer

restarts using the new values. This all takes less than one second.

1 Configure default values. ALL configuration parameters can reset to

their original default (non-printer specific) values by sending “{CDV}” Configure Default Values

2 Configure Bluetooth. As of this date, only the Bluetooth Friendly Name

can be reconfigured by sending a command of the form

“{CBT:<parms>}”

S F: <data> for Friendly Name (Device Name)

Send up to 16 characters.

S D: <data> for Discoverable (<data> = Y/N)

S C: <data> for Connectable (<data> = Y/N)

S B: <data> for Bondable (<data> = Y/N)

S E: <data> for Encryption (<data> = Y/N)

S A: <data> for Authentication (<data> = Y/N)

S P: <data> for Passkey

Send up to 16 characters (default passkey is “passkey”)

S I: for Inactivity Timeout (see pages 22 and 55 for more information)

44 PK80 Series80-Column Printer User’sManual

Example

ESC EZ{CBT:F:MyPrinter}

Name (AKA Bluetooth Device Name) to MyPrinter.

would configure the Bluetooth Friendly

CommandsAppendix —A

Easy Print Commands

ESC EZ{CBT:F:BTPrinter;D:N;C:Y;E:Y;A:Y;P:Passkey1}

would

configuretheBluetoothDeviceNametoBTPrinter,theprinterwouldnot

be discoverable but would be connectable, encryption can be used, authentication is required, and the passkey is ”Passkey1”.

{CT:nnn} Configures the timeout where nnn can be 15–9998 seconds. 9999 sec-

onds will cause the printer to NEVER timeout.

{CB:n} Configures the baud rate where n corresponds to the desire d baud rate:

0=1200, 1=2400, 2=4800, 3=9600, 4=19.2K (19200), 5=38.4K

(38400), 6=57.6K (57600), and 7=115.2K (115200).

{CN:n} Configures the number of data bits where n can be 7 or 8

{CP:n} Configures parity, where n can be N (no parity), E (even parity), or

O(oddparity).

{CC:n} Configures the carriage return to automatically add LF to CR, wh ere n

canbeNforCR=CR,orYforCR=CRLF.

{COMMIT} None of the two letter configuration commands will take affect until the

COMMIT command is sent. When {COMMIT} is sent, the values are

written to flash and the printer is restarted. When it restarts, it will use

the default configuration, which in most printers is NOT Easy Print. To

do additional configuration, you will need to put the printer back into

Easy Print mode.

{CH:n} Configures handshaking. Valid values are None (N), Hardware(H),

Software(S), or Both(B)

{CR:nn} Configures the radio timeout. Values of 0 or 65535 disable the radio

timeout. Other valid value s are 1–65534.

Thefollowingareconfigurableandthestatewillbeindicatedontheself

test printout, but they have no operational effect yet.

{CS:n} Configures the beeper either ON or OFF where n=Y for beeper

ON or N for beeper off.

{LP} This returns the printer to a line printer mode.

{S} This returns a status command. The response is of the

{U:1234;P;D;O;RDY} form where the P position indicates paper is

present and an N in the same position indicates no paper. All other

characters are fixed.

{IPL: 0xAA 0x55} This jumps the printer to the boot code for erasure and subse-

quent downloads.

45PK80 Series 80-Column Printer User’s Manual

CommandsAppendix —A

Query Commands

Note: Any time ESC is used in a command, the command needs to contain the actual ASCII character for ESC (0x1B), not the letters E-S-C.

Thereshouldbenospacesbeforethenextcharacter.Sometimesaspaceis

included in the documentation for readability.

Queries can be sent to the PK80 Printer via the Bluetooth or the RS-232

data link. The printer’s reply to a query returns information about the

printer or the print request. There are three steps involved:

1 Frame your query using the correct command format.

2 Send the Query (for example, via an applications program or a terminal

emulator such as “Terminal” in the Windows Accessories group).

3 Use the appropriate table to interpret the printer’s reply.

Interpreting the Reply to a Query

Consult the table for each Query command to interpret the reply. Each

reply contains several pairs of letters. The first letter or “query character” is

separated from the reply character by a colon (:) and the pair is followed

by a semicolon (;). Example: E:N; (part of the r e ply to a STATUS query).

According to the STATUS table, the E refers to “errors“ in Easy Print

Commands. An N means “no errors.”

Quick Reference

Command Format Description

Status ESC{ST?} Returns information about the printer’s ability to print

the next report, and reports any errors from the last

print reque s t, su c h as paper condition, command errors,

buffer size, or battery voltage.

Configuration ESC{CF?} Returns information about configuration options, such

as baud rate, default mode, time-out, etc.

Version ESC{VR?} Returns the version number of the loaded firmware,

boot code, and download files.

Memory ESC{MY?} Returns the size of all memory available — the amount

used and the amount remaining for the application.

Print Head ESC{PH?} Returnstheprintheadtypeinuseandthenumberof

dots across.

Fonts ESC{FN?} Returns a list of available fonts.

Note: The order of the printer’s reply to a query may change, and new

queries will be added. Therefore, search for the “Query character” to find

data whenever interpreting the reply to a query.

46 PK80 Series80-Column Printer User’sManual

CommandsAppendix —A

ESC{ST?} — Status

This shows whether the next print request is doable, or returns information about errors from the last request.

Query Format

ESC{ST?}

Reply Format

{ST!E:x;S:x;L:x;P:x;J:x;R:x;B:x}

Reply Example

{ST!E:N;S:K;L:D;P:N;J:N;R:21;B:O,H:O}

S ST! ThisisareplytoaSTATUSquery.

S E:N; There are no errors.

S S:K; A key was pressed to cancel a print job.

S L:D; The paper release lever is down, ready to print.

S P:N; Paper is missing.

S J:N; There is no paper jam.

S R:21; 21 K bytesremainintheinputbuffer.

S B:O; Acceptable battery voltage and temperature

Query Reply Definition of Reply

E N No error*

E c Command error (invalid c ommand)

E d Dataerror(suchasaletterinanumeric-onlybarcode.

E f Font not available

E g Global parameter error

E o Overrun of buffer*

E p Field parameter error

E q Qmark not found*

E r Row or Column error

E s Syntax error

S I, P, T, K,

O, C, J

L U, D Lever=Up(U)orDown(D)

P P, N Paper = Present (P) or Not present (N)

J N, J Paper jam = None (N) or Jam (J)

R nn RAM buffer size remaining in K bytes.

B O, T, V Battery condition = Okay (O); Out of temperature range (T); Out of voltage rang e (V)

*Rows marked with asterisk apply to Easy Print and Line Printer Mode. Rows without an asterisk apply only to Easy Print.

Status = Idle (I), Still printing (P), Timeout (T), Key pressed to cancel job or turn unit off

during printing (K), Unit turned off while idle, such as after paper out (O), Complete reportedafterendofjobandforupto200msafterjobisfinished(C),Paperjamdetected(J)

47PK80 Series 80-Column Printer User’s Manual

CommandsAppendix —A

ESC{CF?} — Configuration

This returns information about configurable options.

Query Format

ESC{CF?}

Reply Format

{CF!L:x;B:x;P:x;N:x;H:x;S:x;T:x;R:x}

Reply Example

{CF!L:LP;B:096;P:N;N:8;H:B;S:Y;T:0060;R:0600}

S CF! ThisisareplytoaConfigurationquery.

S L:LP; The default mode is Line Printer.

S B:096; The baud rate is 9600.

S P:N; Noparityisset.

S N:8; There are 8 data bits.

S H:B; Hardware and software handshaking are enabled.

S S:Y; The sound is on.

S T:0060 The timeout is set for 60 seconds.

S R:0600 The radio timeout is set for 600 seconds.

Query Reply Definition of Reply

L LP, EZ Default mode:

Line Printer (LP) or Easy Print (EZ)

B 012, 024, 048,

096, 192, 384

P N, E, O Parity:

N 7, 8 Number of Data Bits: 7 or 8

H N, H, S, B Handshaking:

S Y, N Beeper (Sound):