User’s Guide

EasyCoder® PD41

Printer

Intermec Technologies Corporation

Corporate Headquarters

6001 36th Ave.W.

Everett, WA 98203

U.S.A.

www.intermec.com

The information contained herein is proprietary and is provided solely for the

purpose of allowing customers to operate and service Intermec-manufactured

equipment and is not to be released, reproduced, or used for any other purpose

without written permission of Intermec.

Information and specifications contained in this document are subject to

change without prior noticed and do not represent a commitment on the part

of Intermec Technologies Corporation.

© 2005 by Intermec Technologies Corporation. All rights reserved.

The word Intermec, the Intermec logo, Norand, ArciTech, CrossBar, Data

Collection Browser, dcBrowser, Duratherm, EasyADC, EasyCoder, EasyLAN,

Enterprise Wireless LAN, EZBuilder, Fingerprint, i-gistics, INCA (under

license), InterDriver, Intermec Printer Network Manager, IRL, JANUS,

LabelShop, Mobile Framework, MobileLAN, Nor*Ware, Pen*Key, Precision

Print, PrintSet, Ready-to-Work, RoutePower, SmartSystems, TE 2000,

Trakker Antares, and Virtual Wedge are either trademarks or registered

trademarks of Intermec Technologies Corporation.

Throughout this manual, trademarked names may be used. Rather than put a

trademark (™ or ®) symbol in every occurrence of a trademarked name, we state

that we are using the names only in an editorial fashion, and to the benefit of

the trademark owner, with no intention of infringement.

There are U.S. and foreign patents pending.

Microsoft, Windows, and the Windows logo are registered trademarks of

Microsoft Corporation in the United States and/or other countries.

ii EasyCoder PD41 Printer User’s Guide

Contents

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . vii

Global Services and Support. . . . . . . . . . . . . . . . viii

Warranty Information . . . . . . . . . . . . . viii

Web Support . . . . . . . . . . . . . . . . . . . . viii

Telephone Support . . . . . . . . . . . . . . . viii

Who Should Read This Manual . . . . . . . . . . . . . . ix

Related Documents . . . . . . . . . . . . . . . . . . . . . . . ix

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1

Description of EasyCoder PD41. . . . . . . . . . . . . . . . . . . . . .2

Unpacking the Printer . . . . . . . . . . . . . . . . . . . . . .2

Product Identification. . . . . . . . . . . . . . . . . . . . . . .4

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Controls and Indicators . . . . . . . . . . . . . .5

Rear View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Media Compartment . . . . . . . . . . . . . . . . . . . . . . .7

Print Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . .7

Installing the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Connecting the Printer to your System . . . . . . . . . .8

Connecting the Printer through the USB

interface . . . . . . . . . . . . . . . . . . . . . . .9

Connecting the Printer to a Network. . . .9

Connecting the Printer through the Serial

Port. . . . . . . . . . . . . . . . . . . . . . . . . . .9

Connecting the Printer through the Parallel

Port. . . . . . . . . . . . . . . . . . . . . . . . . .10

Printing a Test Label. . . . . . . . . . . . . . . . . . . . . . .10

Operating the Printer . . . . . . . . . . . . . . . . . . . . . .11

2

Loading Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Tear-Off (straight-through) Operation . . . . . . . . .12

Tear-Off. . . . . . . . . . . . . . . . . . . . . . . . .12

Peel-Off (Self-Strip) Operation. . . . . . . . . . . . . . .15

Peel-Off . . . . . . . . . . . . . . . . . . . . . . . . .15

Loading Thermal Transfer Ribbon . . . . . . . . . . . .18

Loading Ribbon . . . . . . . . . . . . . . . . . . .18

EasyCoder PD41 Printer User’s Guide iii

LED indicators and the Print Button . . . . . . . . . . . . . . . . .21

LED indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Print Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Maintaining the Printer . . . . . . . . . . . . . . . . . . . 25

3

General Maintenance Advice . . . . . . . . . . . . . . . . . . . . . . .26

Printhead Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Internal Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

External Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4

Printer Operation Problems . . . . . . . . . . . . . . . . . . . . . . . .30

Print Quality Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Ready-to-Work™ Indicator . . . . . . . . . . . . . . . . . . . . . . . . . 32

Ready-to-Work LED Flashing or Off . . . . . . . . . . 32

Troubleshooting Adjustments. . . . . . . . . . . . . . . . . . . . . . .32

Ribbon Wrinkling Adjustments . . . . . . . . . . . . . . 32

Clearing Media Jams . . . . . . . . . . . . . . . . . . . . . .33

Printhead Adjustments. . . . . . . . . . . . . . . . . . . . . 34

Label Gap Sensor Adjustments. . . . . . . . . . . . . . .37

Setting up the Printer. . . . . . . . . . . . . . . . . . . . . . 39

5

The Printer Startup Sequence . . . . . . . . . . . . . . . . . . . . . . . 40

Changing Configuration Settings . . . . . . . . . . . . . . . . . . . . 41

Using PrintSet 4 . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Using the Printer’s Home Page . . . . . . . . . . . . . . .41

Using the Command Line . . . . . . . . . . . . . . . . . . 41

Running Testmode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Testmode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Extended Testmode . . . . . . . . . . . . . . . . . . . . . . . 43

Upgrading Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

iv EasyCoder PD41 Printer User’s Guide

Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

A

Printer Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Media Specifications. . . . . . . . . . . . . . . . . . . . . . .53

B

Media Roll Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Internal Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Ribbon Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Paper Types and Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Non-Adhesive Strip . . . . . . . . . . . . . . . . . . . . . . .56

Self-Adhesive Strip . . . . . . . . . . . . . . . . . . . . . . . .57

Self-Adhesive Labels . . . . . . . . . . . . . . . . . . . . . . .58

Tickets with Gaps. . . . . . . . . . . . . . . . . . . . . . . . .60

Tickets with Black Mark. . . . . . . . . . . . . . . . . . . .62

Setup Parameters . . . . . . . . . . . . . . . . . . . . . . . . . .65

C

Setup Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Serial Communication Setup . . . . . . . . . . . . . . . . . . . . . . .66

Feed Adjust Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Media Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Media Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Paper Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Direct Thermal Printing . . . . . . . . . . . .72

Thermal Transfer printing . . . . . . . . . . .73

Contrast. . . . . . . . . . . . . . . . . . . . . . . . .74

Print Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

D

RS-232 Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Interface cable. . . . . . . . . . . . . . . . . . . . . . . . . . . .76

USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

EasyCoder PD41 Printer User’s Guide v

EasyLAN Ethernet Interface. . . . . . . . . . . . . . . . . . . . . . . . 78

Parallel IEEE 1284 Interface. . . . . . . . . . . . . . . . . . . . . . . . 78

Interface cable . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

E

EasyLAN Ethernet Interface. . . . . . . . . . . . . . . . . . . . . . . . 82

Parallel IEEE 1284 Interface. . . . . . . . . . . . . . . . . . . . . . . . 82

Cutter Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Internal Rewinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Printhead Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

vi EasyCoder PD41 Printer User’s Guide

Before You Begin

Before You Begin

This section provides you with safety information, technical

support information, and sources for additional product

information.

Safety Information

Your safety is extremely important. Read and follow all warnings

and cautions in this document before handling and operating

Intermec equipment. You can be seriously injured, and

equipment and data can be damaged if you do not follow the

safety warnings and cautions. Be sure to read the EasyCoder PD41

Safety Instructions, where the basic safety precautions regarding

the operation of the PD41 are described and illustrated.

This section explains how to identify and understand warnings,

cautions, and notes that are in this document. You may also see

icons that tell you when to follow ESD procedures.

A warning alerts you of an operating procedure,

practice, condition, or statement that must be

strictly observed to avoid death or serious injury to

the persons working on the equipment.

A caution alerts you to an operating procedure,

practice, condition, or statement that must be

strictly observed to prevent equipment damage or

destruction, or corruption or loss of data.

This icon appears at the beginning of any

procedure in this manual that could cause you to

touch components (such as printed circuit boards)

that are susceptible to damage from electrostatic

discharge (ESD). When you see this icon, you must

follow standard ESD guidelines to avoid damaging

the equipment you are servicing.

Note: Notes either provide extra information about a

topic or contain special instructions for handling a

particular condition or set of circumstances.

EasyCoder PD41 Printer User’s Guide vii

Before You Begin

Global Services and Support

Warranty Information

To understand the warranty for your Intermec product, visit the

Intermec web site at www.intermec.com and click Service &

Support. The Intermec Global Sales & Service page appears.

From the Service & Support menu, move your pointer over

Support, and then click Warranty.

Disclaimer of warranties: The sample code included in this

document is presented for reference only. The code does not

necessarily represent complete, tested programs. The code is

provided “as is with all faults.” All warranties are expressly

disclaimed, including the implied warranties of merchantability

and fitness for a particular purpose.

Web Support

Visit the Intermec web site at www.intermec.com to download

our current manuals in PDF format. To order printed versions of

the Intermec manuals, contact your local Intermec representative

or distributor.

Visit the Intermec technical knowledge base (Knowledge

Central) at intermec.custhelp.com to review technical

information or to request technical support for your Intermec

product.

Telephone Support

These services are available from Intermec Technologies

Corporation.

In the USA and

Canada call 1-800755-5505 and

Services Description

Factory Repair

and On-site

Repair

Te c h n i ca l

Support

Service

Contract Status

viii EasyCoder PD41 Printer User’s Guide

Request a return authorization

number for authorized service

center repair, or request an onsite repair technician.

Get technical support on your

Intermec product.

Inquire about an existing

contract, renew a contract, or

ask invoicing questions.

choose this option

1

2

3

Before You Begin

In the USA and

Canada call 1-800755-5505 and

Services Description

Schedule Site

Surveys or

Installations

Ordering

Products

Schedule a site survey, or

request a product or system

installation.

Talk to sales administration,

place an order, or check the

status of your order.

choose this option

4

5

Outside the U.S.A. and Canada, contact your local Intermec

representative. To search for your local representative, from the

Intermec web site, click Contact.

Who Should Read This Manual

This User’s Guide is for the person who is responsible for

installing, configuring, and maintaining the EasyCoder PD41

Printer.

This User’s Guide provides you with information about the

features of the EasyCoder PD41, and how to install, configure,

operate, maintain, and troubleshoot it.

Related Documents

This table contains a list of related Intermec documents and their

part numbers.

Document Title Part Number

EasyCoder PD41 Quick Start Guide 1-960655-00

Intermec Fingerprint v8.70.0/v10.0.0 Programmer’s

Reference Manual

EasyCoder PD41 Safety Instructions 1-960662-00

EasyLAN Ethernet for PD41 Installation Intructions 1-960656-00

EasyCoder PD41 Internal Rewinder Installation

Instructions

EasyCoder PD41 Parallel Interface Installation

Instructions

EasyCoder PD41 Cutter Installation Instructions 1-960657-00

EasyCoder PD41 Printhead Installation Instructions 1-960658-00

EasyCoder PD41 Printer User’s Guide ix

1-960582-07

1-960659-00

1-960661-00

Before You Begin

The Intermec web site at www.intermec.com contains our

documents (as PDF files) that you can download for free.

To d ownloa d docume nts

1 Visit the Intermec web site at www.intermec.com.

2 Click Service & Support > Manuals.

3 In the Select a Product field, choose the product whose

documentation you want to download.

To order printed versions of the Intermec manuals, contact your

local Intermec representative or distributor.

x EasyCoder PD41 Printer User’s Guide

Getting Started

1

This chapter introduces the EasyCoder PD41, and explains how

to get your new printer connected to your system and print a test

label. The chapter covers the following topics:

• Description of the EasyCoder PD41

• Installing the Printer

EasyCoder PD41 Printer User’s Guide 1

Chapter 1 — Getting Started

Description of EasyCoder PD41

The EasyCoder PD41 printer is a dependable and versatile

printer suitable for medium-duty applications in manufacturing,

transportation and warehouse environments. It has all-metal

chassis and covers, proven printing mechanics and powerful

electronics providing sturdiness, performance and reliability.

The EasyCoder PD41 can print demanding crisp variable-data

labels continuously at 150 millimeters per second (mm/s) or 6

inches per second (ips). It takes industry standard 213mm (8.35

in) label rolls and 450 meters (18000 inches) of ribbon. The

printer accepts a wide range of paper types with different

thicknesses, as well as both ink-in and ink-out ribbon.

The EasyCoder PD41 offers versatile connectivity through serial

and USB interfaces. It is also equipped with Parallel IEEE 1284

and / or EasyLan Ethernet interfaces depending on the chosen

configuration.

The EasyCoder PD41 supports the unique and flexible Intermec

Fingerprint language, which allows the user or third-party

developer to create custom-made application programs and label

formats in a BASIC-like environment.

The printer is also designed to work with the Intermec Direct

Protocol programming language (a slave protocol, subset of

Fingerprint), the Intermec InterDriver and Intermec LabelShop.

The InterDriver allows you to print labels from standard MS

Windows applications, such as Microsoft Office. Intermec

LabelShop is a series of label-design programs that work under

MS Windows.

Other features, such as a cutter and an internal rewinder, are

available as option kits.

Unpacking the Printer

Unpack the printer and its accessories on a flat surface such as a

table.

Unpack the Printer

1 Open the box and lift out the printer and included

accessories.

2 EasyCoder PD41 Printer User’s Guide

Chapter 1 — Getting Started

2 Check that no visible damage has occured during

transportation. Keep the packing material in case you need to

move or reship the printer.

3 Check to make sure any options you ordered are included.

4 In addition to the options you may have ordered, the box

should contain the following:

• Intermec EasyCoder PD41 printer

• Power supply adapter with either one power cord for

115V U.S. wall sockets or two different power cords for

230V European and 240V U.K. wall sockets

•USB cable

• Empty ribbon core (for thermal transfer printing)

• High Media Edge Guide

•Quick Start Guide

• A PrinterCompanion CD containing software, this and

other related manuals.

If you find any damage has occured during transportation, notify

the carrier immediately. If the delivery is missing parts or is

otherwise incorrect, report it to the distributor.

EasyCoder

PD41

Power cable

EU

UK

US

USB cable

EasyCoder PD41 Printer User’s Guide 3

High media

edge guide

Printer

Companion CD

Empty

ribbon core

Chapter 1 — Getting Started

The discharge of electrostatic energy accumulated

on the human body, clothing, or other surfaces can

damage or destroy the printhead or electronic

components used in this printer. Avoid touching

the electrical connectors while unpacking and

setting up the printer.

Product Identification

The machine and serial number labels are attached to the

printer’s rear plate, and contain information on type, model and

serial number as well as AC voltage and frequency.

Front View

Side door

Control

LEDs

Print

Button

EasyCoder PD41: Front view

4 EasyCoder PD41 Printer User’s Guide

Chapter 1 — Getting Started

Controls and Indicators

Front panel: LEDs and Print button.

The blue button on the front panel is the Print button, which

also functions as a control button in Testmode. The significance

of each of the four LEDs surrounding the Print button is

described in the table below. A more complete description of the

LEDs can be found in Chapter 2.

Control LEDs

LED name Light Color Symbol Function

Power Green Power indicator.

Ready/Data Green Printer ready.

Error Red Error indicator.

Ready-to-Work

EasyCoder PD41 Printer User’s Guide 5

™ Blue Intermec Ready-to-Work™

indicator.

Chapter 1 — Getting Started

Rear View

Side door

Machine

labels

EasyCoder PD41: Rear View

Connectors

Intake for

external

media supply

Ethernet RJ-45 connector

USB port

MAC address label

Serial RS-232 port

Parallel IEEE 1284 port

I

O

Compact Flash slot

Power On/Off switch

AC power cord socket

Rear view: Connection sockets

6 EasyCoder PD41 Printer User’s Guide

Media Compartment

EasyCoder PD41: Media Compartment

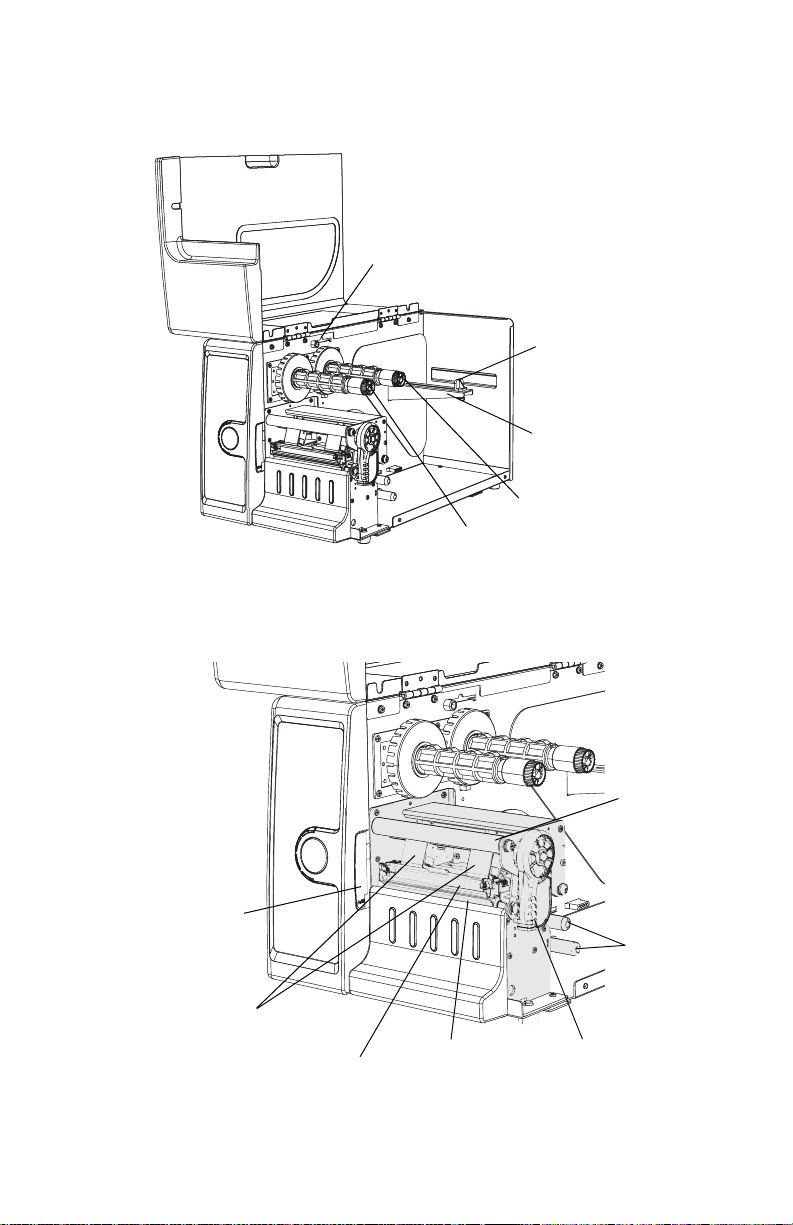

Print Mechanism

Chapter 1 — Getting Started

Ink position lever

Edge guide

Media supply post

Ribbon supply shaft

Ribbon rewind shaft

Ribbon

rod

Label taken

sensor

Media

feed

rods

Printhead

balance boxes

Thermal printhead

EasyCoder PD41: Print Mechanism

EasyCoder PD41 Printer User’s Guide 7

Tea r b ar

Printhead

lever

Chapter 1 — Getting Started

Installing the Printer

Plugging in the Printer

1 Make sure the Power Switch is turned off.

2 Connect the power cable to the printer.

3 Plug the power cable into your electrical outlet.

1

2

3

Connecting the Printer to your System

The EasyCoder PD41 is fitted with a USB Type B connector for

the USB interface port and one 9-pin D-style subminiature

(DB9) socket for the RS-232 serial interface port. In addition to

this the printer is, depending on configuration, fitted with a 36pin Centronics socket for the parallel (IEEE 1284) port and/or

an RJ-45 socket for the Ethernet network connection.

Information on the socket and connector types can be found in

Appendix D, “Interfaces.”

8 EasyCoder PD41 Printer User’s Guide

Chapter 1 — Getting Started

Connecting the Printer through the USB interface

In order to use the USB connection, you need to install the

Intermec InterDriver software on your computer. This can be

found on the PrinterCompanion CD along with instructions on

how to install it. The USB interface is not suitable for terminal

connections and thus not for programming.

Connecting the Printer to a Network

The printer is set to automatically receive an IP number from the

network (DHCP). The blue Ready-to-Work LED is lit steadily if

the printer has been succesfully connected to the network. The IP

number will be printed on the test label (see next section on how

to print test labels), which can be used to check the printer’s

settings on the printer home page. This is accessed by entering

the printer’s IP number in the adress field of your web browser,

for example http://255.255.255.001

If your network does not assign IP numbers automatically, or the

Ready-to-Work indicator is flashing to indicate a network error,

you can use PrintSet 4 (found on the Printer Companion CD) to

correct the network settings. Alternatively, set up a terminal

connection through the serial interface and use the Fingerprint

SETUP command. See Chapter 5, “Configuring Setup”, or refer

to the Intermec Fingerprint v10.X.X Programmer’s Reference

Manual.

The network connection can be used either with LabelShop or

the Intermec InterDriver. It can also be used to directly send

commands to the printer through a terminal connection, such as

one established through the Windows HyperTerminal program.

In this case, it utilizes the Raw TCP protocol through port 9100.

Connecting the Printer through the Serial Port

The serial connection can be used either with LabelShop or the

Intermec InterDriver. It can also be used to directly send

commands to the printer through a terminal connection, such as

one established through the Windows HyperTerminal program.

The printer’s default serial communication settings are: baud rate

9600, 8 data bits, no parity, 1 stop bit and no flow control. See

Appendix C, “Setup parameters,” for more information.

EasyCoder PD41 Printer User’s Guide 9

Chapter 1 — Getting Started

Connecting the Printer through the Parallel Port

Use the parallel interface (also referred to as“centronics”), with

Intermec LabelShop or the Intermec InterDriver. The parallel

port supports Windows plug-n-play and additional status

reporting through IEEE 1284 nibble ID mode.

Printing a Test Label

In order to verify that the printer is fully functional and to obtain

its current configuration, you can print a test label. This

procedure is part of the Testmode function, described in full in

Chapter 5.

Printing test labels

1 Switch off the printer’s power.

2 Load media as described in Chapter 2, “Loading Media”.

3 Press and hold down the blue Print button.

4 Keep the Print button pressed down, and turn on the power

switch. Do not release the print button until after about ten

seconds when the printer enters Testmode and three of the

front LEDs will start blinking one at a time.

5 The paper type is specified by releasing the Print button at the

cue of different LED flash patterns. In order to establish the

correct media setting, release the Print button at the

appropriate time according to the following table.

Setting the Paper Type

Flashing LED determines Media Type

Data/Ready Green Labels with gap

Error Red Tickets with black mark

Ready-to-Work Blue Continuos stock

The printer will print several test labels containing the

printer’s setup parameters. It will then enter Dumpmode.

6 Press the Print button once to exit.

10 EasyCoder PD41 Printer User’s Guide

Operating the Printer

2

This chapter explains the basic operation of the printer. You will

learn how to load media for different types of operation and

familiarize yourself with the printer’s control LEDs and the Print

button. This chapter covers the following topics:

• Loading Media

• LED indicators and the Print button

EasyCoder PD41 Printer User’s Guide 11

Chapter 2 — Operating the Printer

Loading Media

The EasyCoder PD41 can print on labels, tickets, tags and

continuous stock in various formats.

Tear-Off (straight-through) Operation

This section describes the case when media is torn off manually

against the printer’s tear bar. This method is also known as

“straight-through” printing. Different sorts of media can be used

in Tear-Off operation:

• Non-adhesive continuous stock

• Self-adhesive continuous stock with liner

• Self-adhesive labels with liner

• Tickets with gaps, with or without perforations

• Tickets with black marks, with or without perforations

Tea r-Off

1

Open the side door.

12 EasyCoder PD41 Printer User’s Guide

2

1

2

Pull out the printhead lever and turn

it counterclockwise.

Tear-Off, continued

Chapter 2 — Operating the Printer

3

Lift the label feed guide.

5

4

Load a media roll onto the media

supply hub, pushing it all the way in.

6

Lock the position of the media roll

with the media edge guide.

EasyCoder PD41 Printer User’s Guide 13

Guide the media through the rods.

Chapter 2 — Operating the Printer

Tear-Off, continued

7

Route the media through the print

mechanism.

9

8

If using fan-fold media, load it

through the rear intake and route the

media the same way as a media roll.

10

Reset the label feed guide and the

printhead lever.

14 EasyCoder PD41 Printer User’s Guide

Close the side door. Press the Print

button to advance the media.

Chapter 2 — Operating the Printer

Peel-Off (Self-Strip) Operation

This section describes the case when self-adhesive labels are

separated from the liner immediately after printing. The same

procedure is followed when installing media for Batch Takeup,

with the difference that both label and liner is rewound, and the

label-taken sensor is not used. These modes of operation require

an optional internal rewinder unit, see Appendix E, “Options.”

This is also known as self-strip operation. The label-taken sensor

can hold the printing of the next label in a batch until the present

label has been removed. Only self-adhesive labels with liner can

be used in peel-off operation.

Peel-Off

1

Remove the front cover.

2

Open the cover, mount the media roll,

and route the media through the

media feed rods.

EasyCoder PD41 Printer User’s Guide 15

Chapter 2 — Operating the Printer

Peel-Off, continued

3

Route the liner through the print

mechanism and back as shown

above.

5

4

Wrap the liner on the liner takeup roll

and lock it in place.

6

Reset the label feed guide and the

printhead lever.

16 EasyCoder PD41 Printer User’s Guide

Reattach the front cover.

Peel-Off, continued

Chapter 2 — Operating the Printer

7

Push in the location indicated above

to bring out the label-taken sensor.

9

8

Turn the Label-Taken Sensor (LTS) to a

fully horizontal position.

10

Close the side door.

EasyCoder PD41 Printer User’s Guide 17

Press the Print button to feed the

media.

Chapter 2 — Operating the Printer

Loading Thermal Transfer Ribbon

Thermal transfer printing makes it possible to use a wide range of

receiving face materials and gives a durable printout that is less

vulnerable to fat, chemicals, heat, sunlight etc than direct thermal

printing. Make sure to select a ribbon type that matches the type

of receiving material and set up the printer accordingly.

The EasyCoder PD41 can use transfer ribbon rolls wound with

the ink-coated side facing either outward or inward.

The ribbon is normally loaded in conjunction with a new media

roll. For clarity, however, the illustrations below do not show the

media roll. See the previous sections for information on how to

load media for your type of operation.

Loading Ribbon

1

Open the side door.

2

1

2

Pull out the printhead lever, and turn

it counterclockwise.

18 EasyCoder PD41 Printer User’s Guide

Loading Ribbon, continued

Chapter 2 — Operating the Printer

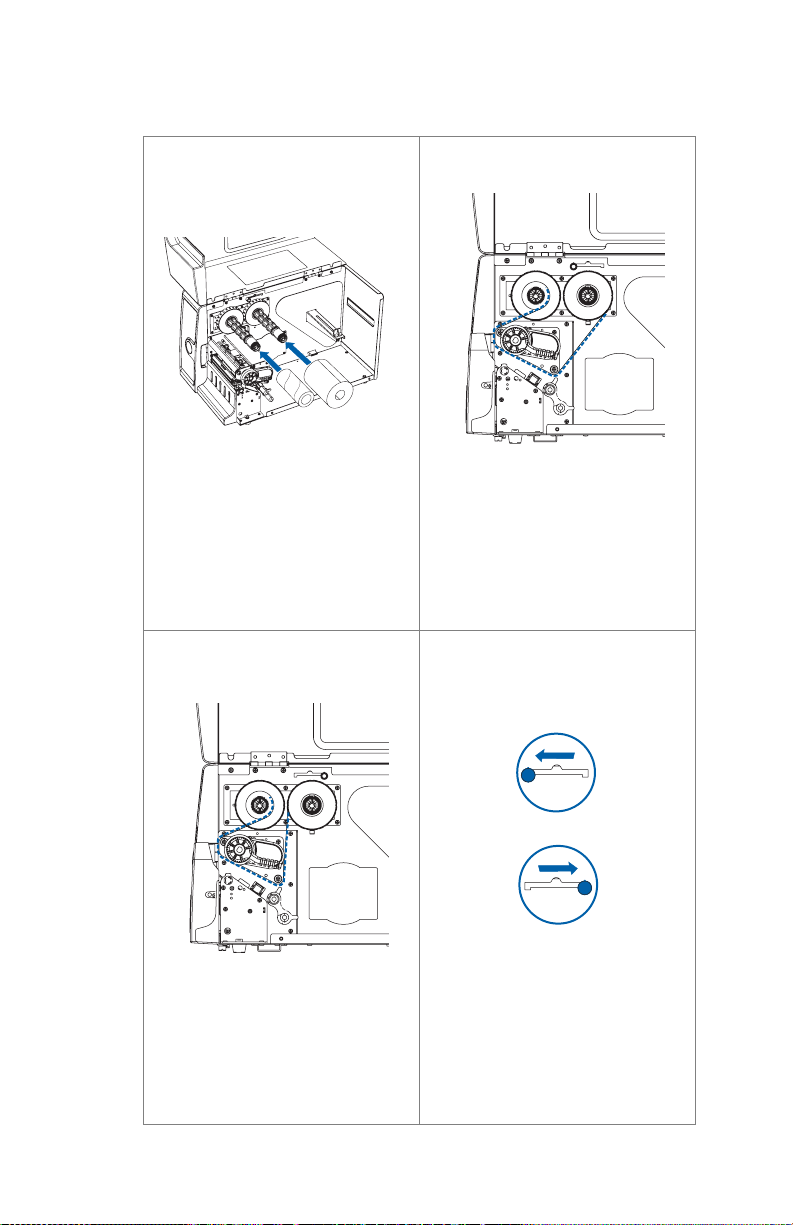

3

Push the ribbon roll onto the right

ribbon hub, and the empty ribbon

core on the left hub.

4b

4a

In case you are using ink-out ribbon,

route the ribbon as shown here.

5

In case you are using ink-in ribbon,

route the ribbon as shown in this

figure.

EasyCoder PD41 Printer User’s Guide 19

Move the ink-position lever to the left

for ink-out ribbon, and to the right for

ink-in ribbon.

Chapter 2 — Operating the Printer

Loading Ribbon, continued

6

Reset the printhead lever to its

original position. Close the side door.

20 EasyCoder PD41 Printer User’s Guide

Chapter 2 — Operating the Printer

LED indicators and the Print Button

The PD41 printer can be in the following “states”, which indicate

its current mode of operation.

PD41 Printer States

State Explanation

Power Off

Upgrading Firmware is being upgraded.

TestMode See Chapter 5 for description.

Extended TestMode See Chapter 5 for description.

PUP Power-UP (starting up)

Idle

Application running

Printing

Printing (wait for LTS) Waiting for label-taken sensor to indicate

that label has been taken.

Paused Paused during print job

Error Error state

LED indicators

The four LED indicators will be turned on, off or flash

depending on which state the printer is in. The Power LED will

always be lit for all states except Power Off.

The blue Ready-to-Work LED shows the operational status of the

printer. In simple terms, it is lit when the printer is operational.

When the Ready-to-Work indicator is turned off, or flashes, it

indicates that the printer is not fully operational. There are a

number of conditions that can cause this behaviour; refer to

Chapter 4, “Troubleshooting” for a detailed explanation. It can

also flash when in Testmode or Extended Testmode, see

“Running Testmode” in Chapter 5.

The red Error LED will be lit or flash when an error condition

has occured. This will also cause the Ready-to-Work LED to flash

or turn off.

EasyCoder PD41 Printer User’s Guide 21

Chapter 2 — Operating the Printer

The green Ready/Data indicator will be turned on, off or flash

depending on the printer’s current state. The behavior of the

green Data/Ready and red Error LEDs is shown in the table

below.

Ready/Data and Error LED behavior

State Ready/Data Error

Power Off Off Off

Upgrading LEDs turned on one after the other.

Testmode See Chapter 5 for description.

Extended Testmode See Chapter 5 for description.

PUP On Off

Idle On/Flash

Application running On Off

Printing On/Flash

Printing (wait for LTS) Quick flashes

Paused Flash

Error Off On / Flash

1

1

2

3

Off

Off

Off

Off

4

Footnotes on flashing LED behavior:

1 Flashing with 50% duty ctycle, 0.8 second period when receiving

data, synchronized with Ready-to-Work LED.

2 Two fast flashes, 1.6 second period.

3 Flashing with 50% duty cycle, 0.8 second period, not sycnhronized

with Ready-to-Work LED.

4 Error LED will be lit for Out of Paper, Out of Ribbon, Head

Lifted, Cutter Error and Testfeed not Done conditions. Will flash

as (2), when thermal printhead is too hot. Will flash as (3) for

other error conditions caught by the Direct Protocol error handler.

Print Button

The Print button has different functionality depending on the

printer’s state. Different actions can be specified by pressing the

button less than and more than one second respectively.

22 EasyCoder PD41 Printer User’s Guide

Chapter 2 — Operating the Printer

Print Button function

State Button pressed < 1 s Button pressed > 1 s

Power Off No action

Upgrading No action

Testmode See “Running Testmode” in Chapter 5

Extended

Te s t m o de

Idle Formfeed/Printfeed Testfeed

Application

running

Printing Pause print job

Paused Continue print job Cancel print job

Error See Chapter 4, “Troubleshooting”

See “Running Testmode” in Chapter 5

Defined by application

EasyCoder PD41 Printer User’s Guide 23

Chapter 2 — Operating the Printer

24 EasyCoder PD41 Printer User’s Guide

Maintaining the

3

Printer

This chapter explains basic maintenance of the printer. By

following the instructions in this chapter you avoid common

problems, and increase the lifetime of your printer. This chapter

covers the following topics:

• General Maintenance Advice

• Printhead Cleaning

• Internal Cleaning

• External Cleaning

EasyCoder PD41 Printer User’s Guide 25

Chapter 3 — Maintaining the Printer

General Maintenance Advice

In order to attain optimal productivity and a long life for your

EasyCoder PD41, it is recommended that you regularly inspect

the printer and its operation environment to ensure the printer is

operated correctly.

Read the EasyCoder PD41 Safety Instructions for basic operational

safety requirements. Keep the printer in a dry area, away from

larger electrical motors, welders and similar which might affect

printer operation.

Clean you printer regularly, as described in the procedures below,

in order to maintain the quality of your labels and extend the life

of your printer.

Always unplug the power cord before cleaning the

printer.

Printhead Cleaning

Cleaning the printhead on a regular basis is important for the life

of the printhead and to maintain high printout quality. You

should clean the printhead using cleaning cards or a cotton swab

moistened with isopropyl alcohol, preferably each time you load

a new supply of transfer ribbon.

Isopropyl alcohol [(CH3)2CHOH] is a highly

flammable, moderately toxic, and mildly irritating

substance.

Cleaning the printhead

1 Open the side door.

2 Remove the media and ribbon.

3 Pull out the printhead lever and flip it counterclockwise a

quarter of turn.

26 EasyCoder PD41 Printer User’s Guide

Chapter 3 — Maintaining the Printer

4 Use a cleaning card or a soft cotton swab moistened with

isopropyl alcohol to dissolve any contamination on the line of

heat-emitting dots at the front/bottom of the printhead.

5 Wait 30 seconds and carefully rub off any contamination.

Repeat if necessary.

Never use any hard or sharp tools to peel away

stuck labels or similar,. The printhead is delicate

and can easily be damaged.

6 Allow the printhead to dry for a minute or more before

loading a new supply of media and ribbon.

Internal Cleaning

Regular cleaning of the printer’s media compartment ensures

smoother printing operation and avoids problems with media

jams.

Use a soft cloth moistened with isopropyl alcohol to clean the

inside of the printer. Be sure to keep the following parts clean:

• Drive roller and tear bar.

• Media edge guides and media path.

• Label sensors.

Isopropyl alcohol [(CH3)2CHOH;CAS67-63-0] is

a highly flammable, moderately toxic, and mildly

irritating substance.

If there are stuck labels, or adhesive residue from labels, peel as

much as possible with your fingers, and then use isopropyl

alcohol to dissolve the remaining adhesive.

External Cleaning

Making sure to keep the printer clean externally will reduce the

risk of dust or foreign particles reaching the inside of the printer

and affect printer functionality.

EasyCoder PD41 Printer User’s Guide 27

Chapter 3 — Maintaining the Printer

Use a soft cloth, possibly moistened with water or a mild

detergent when cleaning the printer externally. Make sure to keep

the surface surrounding the printer clean as well.

If the printer is used in an environment where the

premises are cleaned by a water hose or steam,

move the printer to another room or cover it very

carefully with a plastic sheet and make sure that the

power cord is unplugged.

28 EasyCoder PD41 Printer User’s Guide

Troubleshooting

4

This chapter helps to diagnose problems that may occur during

printer operation and how to resolve them. This chapter covers

the following topics:

• Printer Operation Problems

•Print Quality Problems

• Troubleshooting Adjustments

EasyCoder PD41 Printer User’s Guide 29

Chapter 4 — Troubleshooting

Printer Operation Problems

The following table lists possible problems that affect the

printer’s operation.

Printing Operation Problems

Problem Solution / Reason

The Power control LED is

not lit when power is

switched on.

Error LED turns solid red

after printing.

Label is jammed after

printing.

When printing, labels are

skipped.

When using cutter, label

was not cut straight.

When using cutter, label

could not feed or

abnormal cutting occurs.

Blue Ready-to-Work LED

blinks.

When using internal

rewinder, abnormal

function occurs.

Printer keeps printing or

feeding when it should

stop.

Printing is slow. • Check application.

• Check that the power cable is correctly

connected to printer and electrical

outlet.

• Check if printer is out of media or

ribbon.

• Check if media is jammed or tangled.

• Check that the print mechanism is

locked and closed correctly.

• Check the cutter.

• Check application.

• Clear the media jam. If the label is

stuck on the thermal printhead, clean

as instructed in Chapter 3.

• Run a new testfeed by holding print

button more than one second.

• Check if label gap sensor is disturbed

by dust or foreign particles.

• Check whether the media thickness

exceeds 0.25mm (9.8 mils).

• Check if the media is loaded correctly.

• Check that the cutter is installed

properly.

• Check if paper feed rods are sticky.

Clean as described in Chapter 3.

• See section later in this chapter

regarding the Ready-to-Work LED.

• Check that media is loaded correctly.

• Check media settings.

• Check label gap sensor position.

•Sensors may be dirty.

30 EasyCoder PD41 Printer User’s Guide

Chapter 4 — Troubleshooting

Print Quality Problems

Print Quality Problems

Problem Solution / Reason

Printout is faded or weak • Check the media settings: Constant,

Factor and Contrast.

• Check if printhead needs cleaning.

• Check printhead pressure.

• Check printhead dotline position.

Printer is working but

nothing is printed

Only partial labels are

printed

Part of the images is not

printed along the feed

direction

Printout darkness is

uneven across media path

Printout is not in desired

position

• Check if media is placed upside down.

• Ensure that the ink-side of the ribbon

faces the media.

• Select the correct media type, direct

thermal or thermal transfer printing.

• Check that the printhead is correctly

connected to the print mechanism.

• Check printhead balance. See later in

this chapter.

• Check if printhead needs cleaning.

• Check that the ribbon does not

wrinkle, and follow instructions on

ribbon adjustments in this chapter.

• Check printhead balance.

• Check printhead pressure.

•Check for errors in printing software

application.

• Check if label gap sensor is disturbed

by media, dust or ribbon.

• Check the lateral position of label gap

sensor.

• Check the edge guide and media guide.

• Check the media (insufficient

transparency, interfering preprint lines

in black mark operation, etc.)

• Check if platen roller needs cleaning or

replacement.

EasyCoder PD41 Printer User’s Guide 31

Chapter 4 — Troubleshooting

Ready-to-Work™ Indicator

The blue Ready-to-Work LED is lit when the printer is

operational. It can be turned off or flash in case something is not

working as expected.

Ready-to-Work LED Flashing or Off

The Ready-to-Work indicator is set to flash when the printer is

receiving data, as well as under several different error conditions.

Normally, this is due to an IP link error, where the printer has a

network card but has not yet received an IP number. Other

causes may be that the printhead is lifted, or the media is loaded

incorrectly. The Ready-to-Work LED will be turned off if the

printhead temperature is too high. An error diagnosis can be

obtained with the command

SYSHEALTH$ through a terminal connection to receive the

printer’s Ready-to-Work status.

SYSHEALTH$. Enter the line PRINT

Troubleshooting Adjustments

This section describes in detail some of the solutions mentioned

in the Troubleshooting tables above.

Ribbon Wrinkling Adjustments

The follwing two procedures can solve ribbon wrinkling

problems.

Ribbon Tension Adjustment

1 Push the knob on the ribbon supply hub.

2 Rotate it clockwise to increase breaking force or

counterclockwise to decrease breaking force.

Ribbon tension adjustment

32 EasyCoder PD41 Printer User’s Guide

Chapter 4 — Troubleshooting

Ribbon Shield Adjustment

The ribbon shield mechanism is located on the thermal

printhead. It has two adjustable screws, A and B, as shown below.

A

B

Ribbon shield adjustment screws

If the label printout matches Test label A, turn screw A

clockwise. If the printout matches Test label B, turn screw B

clockwise. Turn the screw half a circle and perform a new test

printing. Continue until you achieve a smooth printout quality.

Screw adjustment must not exceed two full turns or paper may

not feed smoothly. In such a case, turn the screws

counterclockwise completely and start over the adjustment.

Test Label A

1234567890

Possible printouts due to ribbon wrinkling

Test Label B

1234567890

Clearing Media Jams

Clearing Media Jam in Print mechanism

1 Switch off the power to the printer.

2 Pull the printhead lever out and turn it counterclockwise to

lift the printhead.

3 Pull out the media from the print mechanism.

If the media has been wound up or is stuck on the platen

roller, carefully remove it by hand without using any sharp

EasyCoder PD41 Printer User’s Guide 33

Chapter 4 — Troubleshooting

tools that can damage the platen roller or printhead. Avoid

rotating the platen roller.

Take care to avoid causing the platen roller to

rotate. The electronic components may be

damaged permanently.

4 Cut off any damaged or wrinkled part of the media.

5 Check to see if there is any adhesive somewhere in the print

mechanism. If so, follow the cleaning instructions in the

section “Internal Cleaning” in Chapter 3.

6 Reload the media as described in Chapter 2.

7 Switch on the power.

8 Readjust the media feed by pressing the Print button.

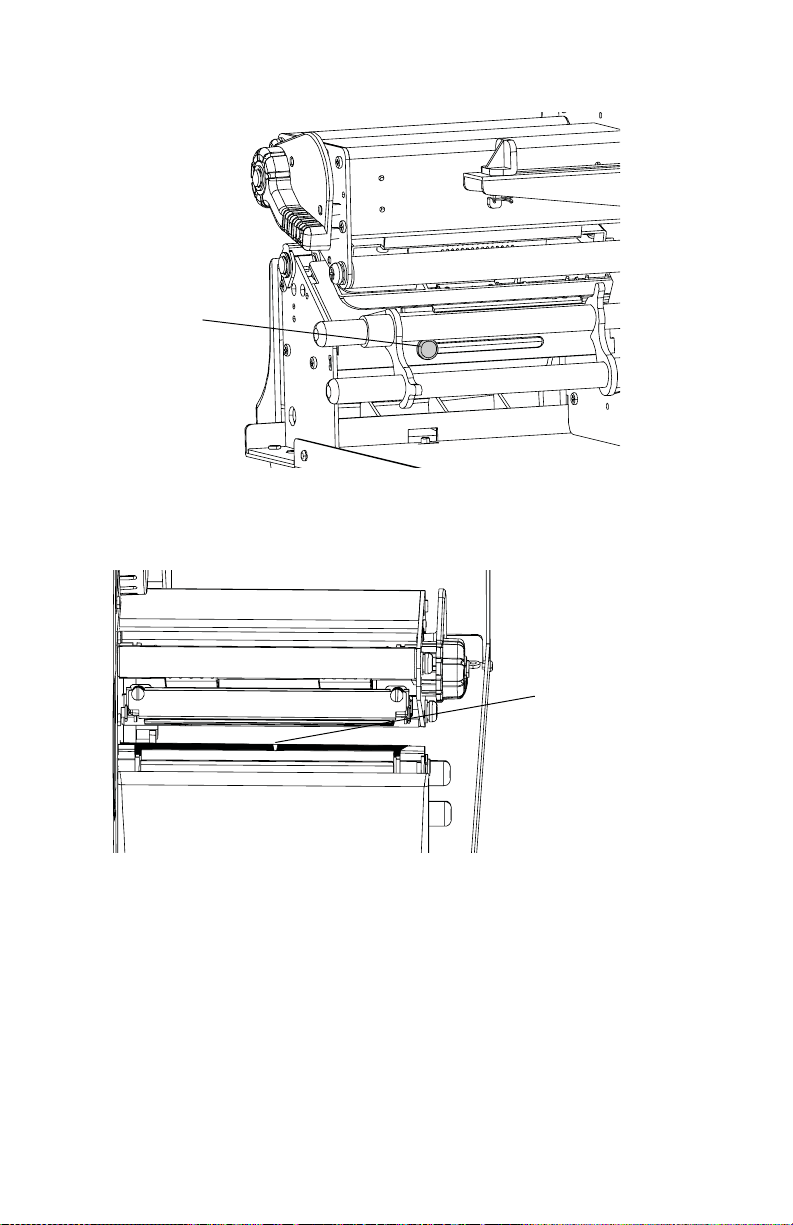

Printhead Adjustments

A correctly adjusted printhead is crucial for obtaining optimal

printout quality.

Adjusting Printhead Balance

The printer is factory-adjusted for full-size media width. When

using media less than full-width, it is recommended that you

adjust the position of the printhead balance boxes in order for the

printhead to be equally pressured against full media width.

Printhead balance might be poorly adjusted if the printout is

weaker on one side of the media path.

To adjust the printhead pressure, follow these steps:

1 Open the side door.

2 If transfer ribbon has been installed, remove it.

3 Lift the printhead by pulling the printhead lever out and

flipping it a quarter of a turn counterclockwise.

4 Move the balance box on the right side (outer) top the right

(outward) for wider media, and inwards (to the left) for

narrower media.

34 EasyCoder PD41 Printer User’s Guide

Chapter 4 — Troubleshooting

Balance

box

5 Engage the printhead and load the ribbon.

6 Test and readjust if necessary. (Tip: Use direct thermal media

to avoid loading and unloading of ribbon multiple times.)

Adjusting Printhead Pressure

The pressure of the thermal printhead against the platen roller is

factory-adjusted. However, if the printing is weaker on one side

of the media, or if the thermal transfer ribbon starts to crease

(indicated by unprinted white streaks along the media feed

direction), it may be necessary to readjust the printhead pressure.

Note: Before readjusting the printhead pressure, try

the to move the outer balance box as described in

Adjusting Printhead Balance procedure.

1 Open the side door.

2 Remove the ribbon.

3 Lift the printhead by pulling the printhead lever out and

flipping it a quarter of a turn counterclockwise.

4 Use a straight-slot screwdriver to turn the screw at the top of

the balance boxes clockwise to increase the pressure, or

counterclockwise to decrease the pressure.

EasyCoder PD41 Printer User’s Guide 35

Chapter 4 — Troubleshooting

5 Engage the printhead and load the ribbon.

6 Test and readjust if necessary. (Tip: Use direct thermal media

to avoid loading and unloading of ribbon multiple times.)

Adjusting Printhead Dot Line

When using thick or stiff media, the printhead needs to be

moved forward so the dot line is aligned precisely with the top of

the platen roller. They must of course be perfectly parallel as well.

1 Open the side door.

2 Remove the ribbon and engage the printhead.

3 Use a straight-slot screwdriver to turn the two screws at the

top of the printhead bracket counterclockwise a single turn.

4 Lift the printhead by pulling the printhead lever and flipping

it counterclockwise a quarter of a turn.

5 Carefully turn both screws at the front of the printhead

clockwise a quarter of a turn at a time (a full turn

corresponds to 0.55 mm, which is a lot). Make sure to make

identical adjustments on both screws. If you are unsure,

36 EasyCoder PD41 Printer User’s Guide

Chapter 4 — Troubleshooting

tighten both screws completely by turning them

counterclockwise as far as they go and start over.

6 Engage the printhead and lock the printhead by tightening

the two screws at the top of the printhead bracket, that is, the

reverse action of step 3.

7 Load the ribbon (if any).

8 Test and readjust if necessary. (Tip: Use direct thermal media

to avoid loading and unloading of ribbon multiple times.)

Label Gap Sensor Adjustments

The label gap/black mark sensor (also called Label Stop Sensor LSS) is a photoelectric sensor that controls the printer’s media

feed by detecting gaps between labels, or slots or black marks in

continuous stock. This requires the label gap sensor to be aligned

with the gaps, slots or marks on the media. If you are using

irregularly shaped labels, align the sensor with the front tip of the

labels.

Adjusting Label Gap Sensor Position

1 Use the lever at the rear side of the print mechanism to move

the sensor inward or outward.

EasyCoder PD41 Printer User’s Guide 37

Chapter 4 — Troubleshooting

Sensor lever

2 Check the point of detection from the front (with the

printhead lifted.)

Point of

detection

38 EasyCoder PD41 Printer User’s Guide

Setting up the Printer

5

The EasyCoder PD41 has many settings that control printer

operation, communication settings, media types and more. This

chapter describes the printer’s startup sequence and explains how

to set or change setup parameters. It also includes a description of

the two Testmodes available, and a guide on firmware upgrading.

This chapter covers the following topics:

• The Printer Startup Sequence

• Changing Configuration Settings

• Running Testmode

• Upgrading Firmware

EasyCoder PD41 Printer User’s Guide 39

Chapter 5 — Setting up the Printer

The Printer Startup Sequence

When switched on, the printer will go through a sequence of

steps in order to decide what settings should be set and what

application (if any) should be started.

Printer Startup Sequence

1 Check for firmware binary on CompactFlash card. If so,

upgrade.

Note: If the CompactFlash contains an earlier

firmware version than one installed in the printer,

the printer’s firmware will be downgraded.

2 Check if printhead is lifted and button is pressed. If so, go to

Extended Testmode, otherwise continue startup with step 3.

3 Check for the presence of a startup file (autoexec.bat), first on

CompactFlash, then on “c/”. If so, run the startup file.

4 Check to see if button is pressed. If so, go to Testmode.

5 Continue Power-Up. Check APPLICATION file in “c/:” for

program file name. If found, run. If empty, go to idle state.

You can thus control the printer’s behavior after startup by

creating an autoexec.bat file and saving it on a memory card or in

the printer’s permanent memory (device “c/”), writing an

application name in the “APPLICATION” name, or choosing to

go into Testmode.

It is recommended to start custom applications by writing the

name of the desired program (“ProgramName.PRG”) in the

APPLICATION file in “c/”. See the Intermec Fingerprint v10.0.0

Programmer’s Reference Manual to learn how to edit and save a

file to the printer.

Starting a custom application can also be done by creating a

startup file (autoexec.bat) which will execute on startup. This file

must contain Fingerprint commands that are interpreted

immediately. Normal commands are LOAD and RUN. See the

Intermec Fingerprint v10.0.0 Programmer’s Reference Manual to

learn how to create and save such a file to the printer.

The process of entering and using Testmode and Extended

Testmode is described later in this chapter.

40 EasyCoder PD41 Printer User’s Guide

Chapter 5 — Setting up the Printer

Changing Configuration Settings

The complete list of setup options can be found in Appendix C.

Depending on the communication method you use with your

printer, you can set configuration settings with different

methods.

Using PrintSet 4

The recommended way to set your printer’s configuration is to

use the included PrintSet 4 program. PrintSet 4 can

communicate with your printer either via a serial cable or a

network connection. You will find PrintSet 4 on the Printer

Companion CD, and on the Intermec website. This printer

configuration program works on Windows (2000 and XP)

computers, and allows you to easily change all of the setup

parameters. It also includes setup wizards, which guide you

through common configuration tasks.

Using the Printer’s Home Page

If you have a network option and the printer is available on the

network, you can browse to the printer’s home page: Just enter

the printer’s IP number in your browser’s adress field. There you

can enter the configuration page and change the settings. You

will need the printer’s administrator username and password.

Using the Command Line

You can change setup parameters by sending Fingerprint

commands directly through your terminal program (either

through serial or network connection). The Fingerprint

command to use is

and its values you want to set. For example:

SETUP “MEDIA,MEDIA TYPE,LABEL (w GAPS)”

The SETUP is used to both write and read setup parameters. It

can also be used with setup files in which all configuration

parameters are set. For more information on how to use the

SETUP command, see the Fingerprint v10.X.X Programmer’s

Reference Manual.

EasyCoder PD41 Printer User’s Guide 41

SETUP, and should be followed by the node

Chapter 5 — Setting up the Printer

Running Testmode

You can check certain settings, print a test label, or enter the

dump mode for troubleshooting purposes by using the printer

testmodes. Two testmodes are available, Testmode and Extended

Te s t m o de .

Tes tmod e

Normal testmode is used to select the media type, to print test

labels, and to enter dump mode. Testmode is entered by pressing

the Print button while switching the printer’s power on. This

starts the Testmode which will go through a sequence of actions;

these can be controlled by pressing the Print button at the cue of

different LED flash patterns. The sequence of steps in testmode is

shown in the tables below:

Testmod e: Acti va ting

Data/

Ready

Step

1 1 Make sure the printhead

2 1 1 1 LEDs flash fast one at a time.

Error RtW Button Comment

lever is lowered. Press and

hold the Print button and

switch the printer On.

Testmode is activated after

10 seconds.

Keep button pressed.

Testmode: Selecting Media Type

Data/

Ready

Step

3 Release the button when LED corresponding to your media

type flashes

3a 1 0 Labels with gaps.

3b 1 0 Ticket with mark.

3c 1 0 Variable length strip.

4 The printer will automatically perform a sensor calibration

(Testfeed) according to your selection, and will select thermal

transfer printing if ribbons is installed, otherwise direct thermal.

42 EasyCoder PD41 Printer User’s Guide

Error RtW Button Comment

Chapter 5 — Setting up the Printer

Testmod e: Prin t ing Tes t Label s

Data/

Step

Ready Error RtW Button Comment

5 The printer will then print four test labels after the testfeed in

step 4. To skip any test labels tap the button.

Testmode: Running the Dump mode

Data/

Ready

Step

6 The printer is now in Dumpmode and the printer scans the

communication ports. The printer will print any characters it

received on the communication ports to a label when exiting

dump mode.

7 Tap the button once to exit Dumpmode. If you tap the button

within two seconds of entering dump mode, no labels are

printed.

8 1 1 The printer will start as on

Error RtW Button Comment

rebooted status. When

operational, Data/Ready

and RtW will be lit.

Extended Testmode

The extended testmode can be used to run additional tests. This

includes the option to print test labels, running a testfeed in slow

mode, entering dump mode and resetting to factory defaults. The

extended Testmode is entered by raising the printhead, and

switching power on while keeping the Print button pressed.

Extended Testmode will run a sequence which can be controlled

via the Print button, and raising or lowering the printhead. The

sequence of steps in the Extended Testmode follows in the table:

EasyCoder PD41 Printer User’s Guide 43

Chapter 5 — Setting up the Printer

Extended Testmode: Activating

Data/

Step

Ready Error RtW Button Comment

1 1 Make sure the printhead is

lifted. Press and hold the

Print button and switch the

printer On. Extended

Testmode is activated after

10 seconds.

2 flash flash flash All 3 LEDs flash rapidly four

times. Extended Testmode is

activated. Release button to

continue.

Extended Testmode: Selecting Function

Data/

Ready

Step

3 flash flash flash 0 LEDs flash fast four times,

4 flash Lower the printhead.

5 1 Press the Print button and

6 Release the button when LED combination corresponding to

your choice of function flashes. Then see corresponding

function table below.

7a 0 0 1 Test Label function.

7b 0 1 0 Testfeed Mode Slow

7c 0 1 1 Dump mode function.

7d 1 0 0 Factory default function.

7e111 Exit Extended Testmode.

Error RtW Button Comment

in four-second intervals.

hold.

function.

The functions 7a-7e are described on the next page.

44 EasyCoder PD41 Printer User’s Guide

Chapter 5 — Setting up the Printer

Extended Testmode: 7a - Test Label Function

Data/

Step

Ready Error RtW Button Comment

7a 1 LED flashes once per

second.

1 Tap the Print button, once

for each of 7test labels.

Press Print button and hold it to exit Test Label function and return to

Step 6.

Extended Testmode: 7b - Testfeed Mode Slow Function

Data/

Ready

Step

7b 1 LEDs flash once per

Press Print button and hold it to exit Testfeed Mode Slow function,

and return to step 6.

Error RtW Button Comment

second.

1 Tap the Print button to

start Testfeed (Mode slow).

Test label is printed.

1LED flashes once per

second.

Extended Testmode: 7c - Dumpmode Function

Data/

Step

Ready Error RtW Button Comment

7c 1 1 LEDs flash once per

second.

1 Tap the Print button to

start Dumpmode.

The printer will autohunt the communucation ports.

Tap the button to exit.

Press >1 second to save dumpmode info.

1 1 Leds flash once per second.

Press button and hold it to exit this function and return to Step 6.

EasyCoder PD41 Printer User’s Guide 45

Chapter 5 — Setting up the Printer

Extended Testmode: 7d - Factory Default Function

Data/

Ready

Step

7d 1 LEDs flash once per

Lift the printhead, tap the Print button, and lower the printhead.

LEDs will flash.

Tap the button. Printer will start resetting to factory defaults. This is

indicated by scrolling LEDs.

Press the button > 1 second to perform testfeed. When done, printer

will be ready for use (out of Testfeed mode.)

Error RtW Button Comment

second.

1 LED flashes once per

second, indicating factory

default reset is done.

Extended Testmode: 7e - Exit

Data/

Ready

Step

7e1111LEDs flash once per

The LEDs flash rapidly, and printer is ready for use.

Error RtW Button Comment

second.

1 Tap the Print button to exit

Extended Testmode.

46 EasyCoder PD41 Printer User’s Guide

Chapter 5 — Setting up the Printer

Upgrading Firmware

The www.intermec.com web site contains the latest software that

you can download for free.

To download firmware updates

1 Visit the Intermec web site at www.intermec.com.

2 Click Service & Support > Downloads.

3 In the Select a Product field, choose the EasyCoder PD41

and you will be presented with the latest software available.

4 Download the latest firmware version to your computer.

5 Extract the zip file to a folder on your computer. Normally,

three versions of the firmware are included with the following

differences and naming convention:

• No suffix: Normal firmware upgrade.

• FD suffix: Firmware upgrade resetting Factory Default.

Only applicable when upgrading through a Compact

Flash card.

• NU suffix: Boots with new firmware, yet printer returns to

previous firmware version on reboot (No Upgrade). Only

applicable when upgrading through a Compact Flash

card.

To upgrade the downloaded firmware to your printer, use any one of the

following methods:

• Use PrintSet 4 and follow the firmware upgrade procedure.

• If you have a network connection, browse to the printer’s

home page (see Chapter 2, “Network connection”), and select

Maintenance. Upload the firmware file.

• Copy the firmware binary file to a CompactFlash card. Turn

the printer off, insert the card into the printer’s

CompactFlash socket and switch on the printer. The printer

will be upgraded automatically.

EasyCoder PD41 Printer User’s Guide 47

Chapter 5 — Setting up the Printer

48 EasyCoder PD41 Printer User’s Guide

Technical Data

A

This Appendix lists technical specifications for the EasyCoder

PD41. The appendix contains:

• Table of Printer Specifications.

EasyCoder PD41 Printer User’s Guide 49

Appendix A — Technical Data

Printer Specifications

Printer Specifications Table

Physical Dimensions

Dimensions (WxLxH) 276 x 454.4 x 283.0 mm

(10.85 x 17.9 x 11.2 inches)

Weight (excl. media) 13 kg (28.7 pounds)

Power Supply

Input Rating 100-240 VAC, 3-1 A, 50-60 Hz

Power Consumption • Stand-by : 12W

• Normal operation/printing: 80W

• Peak: 250W

Printing

Print Technique Direct Thermal/Thermal Transfer

Printhead Resolutions 8 dots/mm (203.2 dpi) or

11.81 dots/mm (300dpi)

Print Speed

8 dots/mm (203 dpi)

11.8 dots/mm (300dpi)

Print Width Max.

8 dots/mm (203 dpi)

11.8 dots/mm (300dpi)

Print Length Max.

8 dots/mm (203 dpi)

11.8 dots/mm (300dpi)

Modes of Operation

Tear-Off (Straightthrough)

Cut-off Option with cutter

Peel-Off (self-strip) Option with internal

Firmware

Operating System Fingerprint v10.0.X Includes Direct

Smooth Fonts TrueType and TrueDoc fonts

50.8 to 152.4 mm/sec . (2 to 6 in./sec.)

50.8 to 101.6 mm/sec. (2 to 4 in./sec.)

104 mm (4.09 in.)

105.7 mm (4.16 in.)

1270 mm (50 in.)

558.2 mm (22 in.)

Yes

rewinder

Protocol

50 EasyCoder PD41 Printer User’s Guide

Appendix A — Technical Data

Printer Specifications Table

Resident scaleable fonts 15

Character Sets • 23 single-byte character sets standard.

• UTF-8 support as standard.

Resident Bar Codes 61

Environment

Operating temperature +5°C to +40°C (+41°F to 104°F)

Storage temperature -20

Operating Humidity 20 to 80% non-condensing

Storage Humidity 10 to 90% non-condensing

Media

Media width 25 to 118 mm (1 to 4.65 inches)

Media Roll diameter 213 mm (8.35 in.) max.

Internal Rewinder

diameter

Media Roll Core

Diameter

Media Thickness 60 μm to 250 μm (2.3 to 9.8 mils)

Transfer Ribbon

Material Wax, hybrid, or resin

Winding Ink on either inside or outside of roll

Ribbon width 30 to 110 mm (1.18 to 4.33 in.)

Ribbon Roll Diameter

(outer)

Inner core Diameter 25.2 to 25.6 mm (1 in.)

Sensors

Label Gap/Black Mark/

Out of Media

Printhead Lifted Yes

Label Taken Yes

Ribbon End Ye s

Controls

LED indicators 4: Power, Data/Ready, Error, Ready-to-Work

Keys One

°C to 70°C (-4°F to 122°F)

Max 114mm (4.49 in.) with cutter.

190 mm (7.5 in.) with internal rewinder.

Max 140 mm (5.51 in.)

38.1 to 76.2 mm (1.5 to 3 in.)

76 mm (2.99 in.) equivalent to 450 meters

(1471 ft) of ribbon.

Yes

EasyCoder PD41 Printer User’s Guide 51

Appendix A — Technical Data

Printer Specifications Table

Electronics

Micropocessor ARM 9

Standard Memory 4 MB Flash, 8 MB SDRAM.

Interfaces

RS-232 Serial Ye s

USB Yes

Ethernet Yes/Option

IEEE 1284 Parallel Yes/Option

CompactFlash Ye s

Accesories and Options

Internal Rewinder and Batch Takeup

Cutter

Printhead 203/300 dpi

EasyLAN Ethernet Interface

Parallel IEEE 1284 Interface

52 EasyCoder PD41 Printer User’s Guide

Media Specifications

B

This appendix illustrates the different media types the EasyCoder

PD41 can operate with, and states the allowed dimensions of the

paper, ribbon and rolls. This appendix covers the following

topics:

• Media Roll Sizes

• Paper Types and Sizes

EasyCoder PD41 Printer User’s Guide 53

Appendix B — Media Specifications

Media Roll Sizes

The media roll must comply with the following dimensions:

Media roll dimensions

Core

Diameters: 38 to 76.2 mm (1.5 to 3 inches)

Width: Must not protrude outside the media.

Internal Roll

Max. diamater 212 mm 8.35 inches

Max diameter with

internal rewinder

Max. width 118 mm 4.65 inches

Max. width with cutter 114 mm 4.49 inches

Min. width 25 mm 1.00 inches

Thickness 60 to 250 μm 2.3 to 9.8 mils

Thicker media may be used, but print quality will be reduced.

the stiffness is also important, and must be balanced against

thickness to maintain print quality.

54 EasyCoder PD41 Printer User’s Guide

190 mm 7.5 inches

Appendix B — Media Specifications

The media supply must not be exposed to sand, dust, grit etc.

Any hard particles, no matter how small, can damage the

printhead.

Ribbon Size

The core of the ribbon must be 25.2-25.6 mm (1 inch), as the

empty ribbon core included in the box. The outer dimensions of

the ribbon roll may be:

Max. diameter 76 mm 2.99 inches

Max. width 110 mm 4.33 inches

Min. width 30 mm 1.18 inches

EasyCoder PD41 Printer User’s Guide 55

Appendix B — Media Specifications

Paper Types and Sizes

Non-Adhesive Strip

a: Media Width

Maximum: 118.0 mm 4.65 inches

Minimum: 25.0 mm 1.00 inches

Paper Type Setup

•Variable length strip

•Fixed length strip

NON-ADHESIVE

STRIP

Non-adhesive strip

56 EasyCoder PD41 Printer User’s Guide

Appendix B — Media Specifications

Self-Adhesive Strip

a: Media Width

Maximum: 118.0 mm 4.65 inches

Minimum: 25.0 mm 1.00 inches

b: Liner

The liner must extend evenly on both sides and not more than a total

of 1.6 mm (0.06) inches outside the face material.

c: Media Width (excluding liner)

Maximum: 116.4 mm 4.58 inches

Minimum: 23.8 mm 0.94 inches

Paper Type Setup

•Variable length strip

•Fixed length strip

SELF-ADHESIVE

STRIP

Self-adhesive strip

EasyCoder PD41 Printer User’s Guide 57

Appendix B — Media Specifications

Self-Adhesive Labels

a: Media Width

Maximum: 118.0 mm 4.65 inches

Minimum: 25.0 mm 1.00 inches

b: Liner

The liner must extend evenly on both sides and not more than a total

of 1.6 mm (0.06) inches outside the face material.

c: Label Width (excluding liner)

Maximum: 116.4 mm 4.58 inches

Minimum: 23.8 mm 0.94 inches

d: Label Length

8 dots/mm (203 dpi)

Maximum: 1270 mm* 50 inches

Minimum: 6 mm 0.2 inches

11.81 dots/mm (300 dpi)

Maximum: 558.8 mm* 22 inches

Minimum: 6 mm 0.2 inches

* This is the print length limit set by memory constraints.

e: Label Gap

Maximum: 26.0 mm 1.02 inches

Minimum: 1.2 mm 0.05 inches

Recommended: 3.0 mm 0.12 inches

The Label Gap sensor must be able to detect the front edges of

the labels. It can be moved 0 to 57 mm (0 to 2.24 inches) from

the inner edge of the media.

Paper Type Setup

• Labels with Gaps

58 EasyCoder PD41 Printer User’s Guide

a

c

d

SELF-ADHESIVE

LABELS

Appendix B — Media Specifications

e

b

FEED

DIRECTION

Self-adhesive Labels

EasyCoder PD41 Printer User’s Guide 59

b

Appendix B — Media Specifications

Tickets with Gaps

a: Media Width

Maximum: 118.0 mm 4.65 inches

Minimum: 25.0 mm 1.00 inches

b: Copy Length

8 dots/mm (203 dpi)

Maximum: 1270 mm* 50 inches

Minimum: 6 mm 0.2 inches

11.81 dots/mm (300 dpi)

Maximum: 558.8 mm* 22 inches

Minimum: 6 mm 0.2 inches

* This is the print length limit set by memory constraints.

c: Detection Position

Variable: 0 to 57 mm 0 to 2.24 inches

d: Detection Slit Length

The length of the detection slit (excluding corner radius) must be

minimum 2.5 mm (0.10 inches) on either side of the detection

position.

e: Detection Slit Height

Maximum: 26.0 mm 1.02 inches

Minimum: 1.2 mm 0.05 inches

Recommended: 3.0 mm 0.12 inches

Paper Type Setup

• Tickets with Gaps

Note: Do not allow any perforation to break the edge

of the media as this may cause the media to split and

jam the printer.

60 EasyCoder PD41 Printer User’s Guide

c

Appendix B — Media Specifications

a

b

e

d

TICKETS & TAGS

FEED

DIRECTION

Tickets with Gaps

EasyCoder PD41 Printer User’s Guide 61

Appendix B — Media Specifications

Tickets with Black Mark

a: Media Width

Maximum: 118.0 mm 4.65 inches

Minimum: 25.0 mm 1.00 inches

b: Copy Length

8 dots/mm (203 dpi)

Maximum: 1270 mm* 50 inches

Minimum: 6 mm 0.2 inches

11.81 dots/mm (300 dpi)

Maximum: 558.8 mm* 22 inches

Minimum: 6 mm 0.2 inches

* This is the print length limit set by memory constraints.

c: Detection Position

Variable: 0 to 57 mm 0 to 2.24 inches

d: Black Mark Width

The detectable width of the black mark should be at least 5.0 mm (0.2

inches) on either side of the Label Gap Sensor detection point.

e: Black Mark Length

Maximum: 25.0 mm 0.98 inches

Minimum: 3 mm 0.12 inches

Common: 5 mm 0.2 inches

f: Black Mark Y-Position

It is recommended that you place the black mark as close to the front

edge of ticket as possible and use a negative Stop Adjust value to

control the media feed, so the tickets can be properly torn off.

Paper Type Setup

• Tickets with Mark

62 EasyCoder PD41 Printer User’s Guide

Appendix B — Media Specifications

Note: Preprint that may interfere with the detection

of the black mark should be avoided.

Note: the black mark should be non-reflective carbon

black on a white or near-white background. Do not

allow any perforations to break the edge of the media

as this may cause the media to split and jam the

printer.

a

c

e

f

d

TICKETS

WITH MARKS

FEED

DIRECTION

Tickets with Black Mark

b

EasyCoder PD41 Printer User’s Guide 63

Appendix B — Media Specifications

64 EasyCoder PD41 Printer User’s Guide

Setup Parameters

C

This appendix lists all of the setup parameters that you can

configure to fit your operating environment. This appendix

covers the following topics:

•Setup Description

• Serial Communication Setup

•Feed Adjust Setup

•Media Setup

• Print Definitions Setup

EasyCoder PD41 Printer User’s Guide 65

Appendix C — Setup Parameters

Setup Description

The printer’s Setup parameters are used to set the printer’s

operational behavior. Chapter 5, “Configuring Settings”,

explains how to set or change the parameters, and this is also

explained in the Fingerprint v10.X.X Programmer’s Reference

Manual, under the

SETUP command.

Serial Communication Setup

The serial communication parameters control the

communication between the printer and the connected computer

or other devices on the standard serial port, referred to as

"uart1:".

For the serial communication channel ("uart1:"), the following

parameters can be set. Make sure they match the setup of the

connected device or vice versa. If the setup of the printer and the

setup of the host do not match, the response from the printer to

host will be garbled.

Baud Rate

The baud rate is the transmission speed in bits per second. There

are 10 options:

•300

•600

•1200

•2400

•4800

• 9600 (default)

• 19200

• 38400

• 57600

• 115200

66 EasyCoder PD41 Printer User’s Guide

Appendix C — Setup Parameters

Character Length

The character length specifies the number of bits that will define

a character. Eight bits are recommended, since that option allows

more special characters and characters that are used exclusively in

foreign languages. Refer to the Intermec Fingerprint v10.X.X,

Programmer’s Reference Manual for more information.

• 7 (Characters ASCII 000 to 127 decimal)

• 8 (Characters ASCII 000 to 255 decimal). Default.

Parity

The parity decides how the firmware will check for transmission

errors. There are five options:

• None (default)

•Even

•Odd

•Mark

•Space

Stop Bits

The number of stop bits specifies how many bits will define the

end of a character. There are two options:

•1 (default)

•2

Flow Control

RTS/CTS is a protocol in which communication is controlled

via currents through separate lines in a cable that are set either to

HIGH or LOW. By default, this option is disabled.

CTS on the Printer is connected to RTS on the PC and vice

versa. CTS HIGH from the printer indicates that the unit is

ready to receive data.

CTS LOW from the printer indicated that the receive buffer is

full (see XON/XOFF). In some computer programs, e.g.

Microsoft Windows HyperTerminal, RTS/CTS is designated