Page 1

GE Security

e

Micro Recessed Door/Window

Sensor

Installation Instructions

www.GESecurity.com

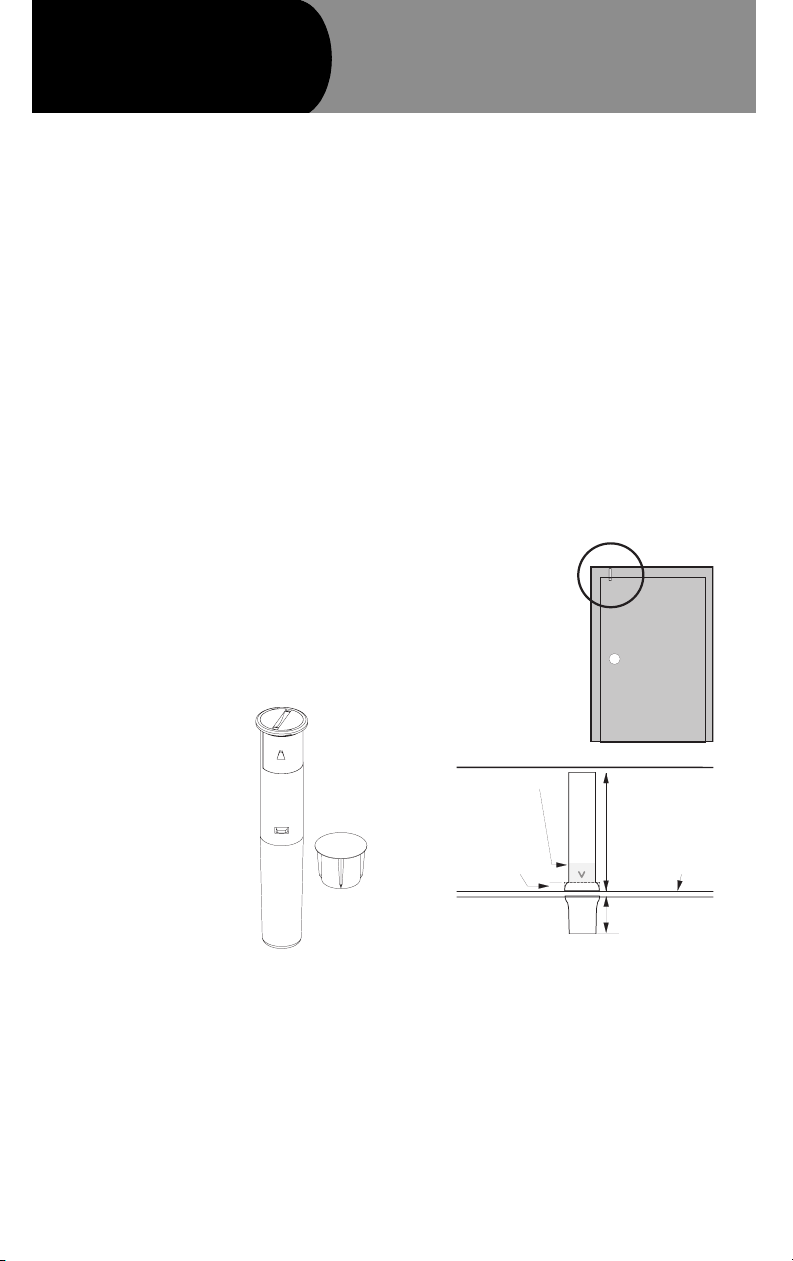

Product Summary

The sensor detects the opening/closing of a door

or window. The sensor is typically installed in the

door or window frame and the magnet is installed

in the door or window. When the door or window

is opened (magnet moved away from the sensor),

the sensor transmits an open (TRIP) signal. When

the door or window is closed (magnet aligned

with the sensor), the sensor transmits a close

(RESTORE) signal.

The sensor transmits supervisory signals every 64

minutes (approximately). The sensor is powered

by a 3.0 volt, long-life, lithium battery.

Tools Needed

• electric drill

• 5/8 in. paddle or twist drill bit

• 3/4 in. twist drill bit

• standard slotted screwdriver

• tape measure or ruler

• pencil, pen, or piece of chalk

• RF Sniffer

Installation Guidelines

• Try to keep sensors

Sensor

within 100 feet of the

panel or repeater.

• Avoid mounting a sen-

sor in an area where it

will be exposed to

moisture.

• Avoid mounting a sen-

Magnet

sor where temperatures exceed 120° F

(49 ° C).

• Avoid mounting a sen-

Figure 1. Sensor and

Magnet

sor where temperatures fall below 10° F (-12° C).

• Whenever possible, mount the sensor in the

casing, not in the moving door or window. In

the case of double doors, mount the sensor in

the least used door, with the magnet in the other

door. This is done to avoid excessive jarring

which can reduce battery life.

Document No. 466-2157 Rev. C

• To avoid electrical wiring, mount the sensor in

March 2009

the header (top) of the door or window frame.

WARNING!

Some installations may have electrical wiring running through door or window frames. Use caution

to avoid electrical shocks. To minimize the risk of

electrical shock from concealed wires, mount the

sensor in the top of the door or window frame (see

Figure 2)

Magnet Installation

1. Determine a suitable location for the sensor.

2. Measure and mark where the magnet will be installed in the door or window.

3. Measure the distance between the door or window and the frame header.

4. Drill a 5/8 in. diameter hole 3/4 in. deep into the door or window (see Figure 2).

NOTE:

Countersinking

requires 2 drill bit

sizes: 3/4 in. and 5/8 in.

Metal Clip

Drill into Door

or Window 1/8 in.

with 3/4 in. bit.

Figure 2. Preferred Installation Method:

Countersink Mounting Dimensions

Drill 3-3/4 in. deep

with 5/8 in. bit.

Door Clearance

Drill 3/4 in. deep

with 5/8 in. bit.

5. Push the magnet into the hole, magnet side first.

6. Measure and mark where the sensor will be installed in the frame.

Sensor Countersink Mounting

To install the sensor in countersunk applications (preferred), drill a 1/8 in. deep starter hole in the frame

with a 3/4 in. twist type drill bit. Finish the hole by

drilling with a 5/8 in. drill bit, until the complete hole

depth measures 3-3/4 in. (see Figure 2).

1

Page 2

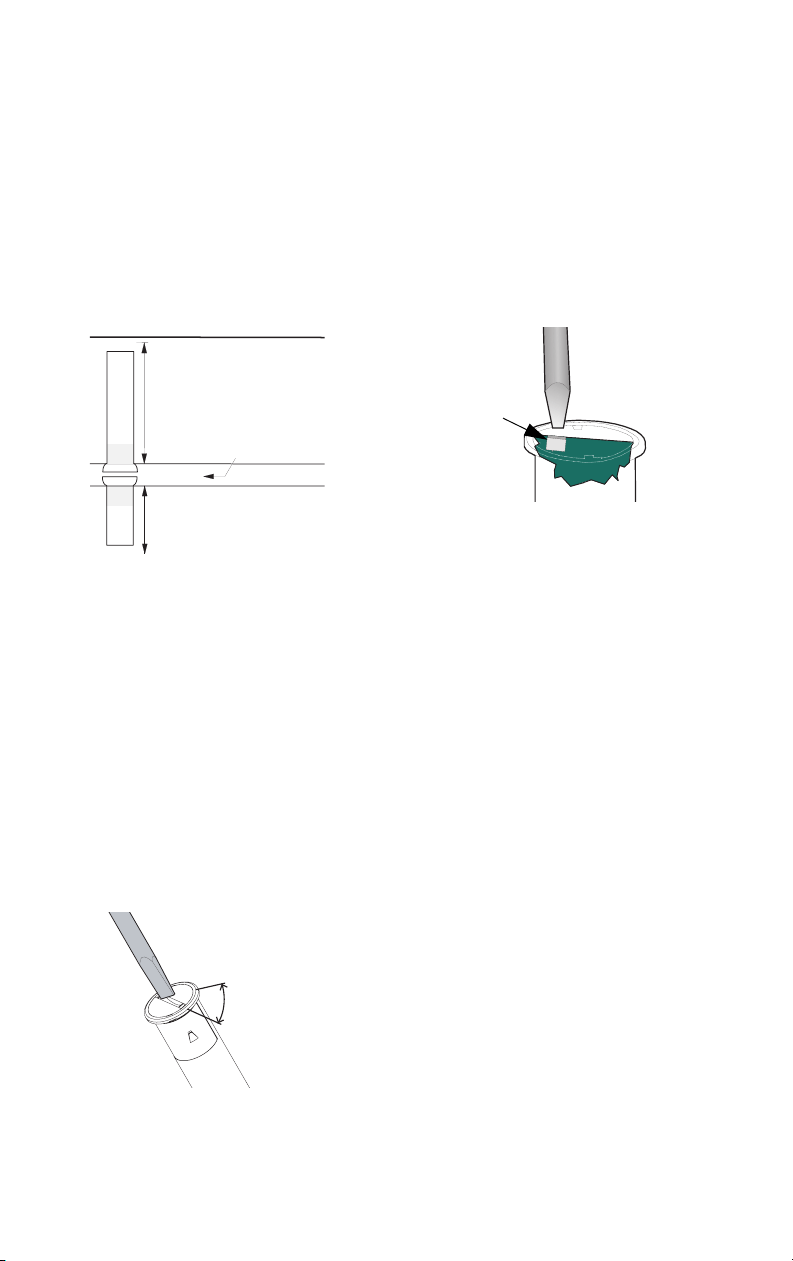

Sensor Non-Countersink Mounting

1. To install the sensor in non-countersunk applications, there must be at least 1/4 in. of clearance between the door or window and the

frame. Drill a hole with a 5/8 in. drill bit until

the hole depth measures 3-3/4 in. (see Figure

3).

2. Insert sensor into the hole in the frame. Force the metal teeth into the frame by applying firm pressure on the sensor.

3. Close the door or window.

Drill 3-3/4 in. deep

with 5/8 in. bit.

Gap between door/window and

frame must be 1/4 in. or more for

non-countersunk applications.

6. Exit Program mode.

Alternative Add Sensor Method

The following method can be used as an alternative to step 4 in the “Add Sensor to Panel Memory” section.

1. Remove the sensor cover by inserting a screwdriver in the top and rotating counterclockwise.

2. Using a screwdriver press the Add Sensor button located at the top of the circuit board (see

Figure 5).

Add Sensor

Button

Drill 3/4 in. deep

with 5/8 in. bit.

Figure 3. Optional Method: Non-Countersunk

Mounting Dimensions

Adding the Sensor to Panel Memory

Below are general guidelines for adding (learning)

the sensor into panel memory. Refer to your panel

Installation Instructions for complete details.

1. Set the panel to Program mode.

2. Proceed to the LEARN SENSORS menu.

3. Select the appropriate sensor group and sensor number.

4. Insert the blade of a standard screwdriver into

the slot at the top of the sensor. Press in firmly

while slowly rotating the top 1/8 turn counterclockwise, then rotate it back (see Figure 4)

Figure 4. Rotating the Sensor Top to Add

Sensor to Panel Memory

5. Repeat the above steps until all sensors are added (learned) into the panel.

Figure 5. Alternative Add Sensor to Panel

Memory Method

Testing

The following steps describe general guidelines

for testing the sensor. Refer to your panel Installa-

tion Instructions for complete details.

Note

The sensor has a built-in power-saver feature that turns

on automatically when the sensor is tripped more than

once, within a 4-1/4 minute time period.

When the power-saver feature is on, the sensor transmits only half the usual number of data rounds when

tripped. For example, during a dealer sensor test you

normally expect to hear up to 8 data rounds. When the

power-saver feature is on, you may hear only up to 4

data rounds.

To be sure the sensor has acceptable transmitting

range to the panel, leave the sensor undisturbed in the

closed (non-alarm) condition for 5 minutes before tripping it for testing. This gives the sensor enough time to

turn off the power-saver feature so you can get accurate sensor test results.

1. Set the panel to the Dealer Sensor Test mode.

2. Trip the sensor by opening the door or window to verify that it has an acceptable transmitting range with the panel.

3. Listen for interior siren beeps to indicate how many rounds the panel receives from the sensor. You should hear 6 to 8 beeps.

• Use an RF Sniffer to help diagnose faulty sen-

sors.

2

Page 3

Applying the Weather-Resistant Label

Sensors mounted on the bottom or side of a window/door frame may be exposed to driving rains.

For these applications, place one of the the

included weather-resistant labels (brown or gray)

to the top of the sensor (Figure 6), after installation, programming, and testing are completed.

The label helps seal the edge of the sensor so

water cannot enter the sensor.

Apply label

here

Figure 6. Weather-Resistant Label Location

Use the appropriate color label to help the sensor

blend in with the frame. If using the brown label

on a gray sensor, it is recommended that the sensor be flush-mounted so that no gray is visible.

Specifications

Model No.: 60-741-95 (white), 60-741-11-95 (brown)

RF Frequency: 319.5 MHz

Compatibility: GE Security 319.5 MHz Learn Mode Control

Panels and Receivers

Battery Type: 3.0V lithium battery

Recommended Battery: Not field replaceable

Typical Standby Current: 1 µA

Estimated Battery Life: 10 years

Supervisory Interval: 64 min

Typical RF Output (mW): 1

Operating Temperature Range: 14° to 122 ° F (-10° to 50° C)

Storage Temperature Range: 14 ° to 140° F (-10 ° to 60° C)

Relative Humidity: 5-90% non-condensing

Dimensions (in.): 3-3/4 x 3/4 (L x W)

Weight (lbs.): 1.5

Notices

This device complies with FCC Rules Part 15. Operation is

subject to the following two conditions.

This device may not cause harmful interference.

This device must accept any interference that may be

received, including interference that may cause undesired

operation.

Changes or modifications not expressly approved by GE

Security, Inc. can void the user’s authority to operate the

equipment.

FCC ID: B4Z-710-DRILL

US Patent Numbers 4,855,713 and 4,864,636

3

Page 4

g

GE Security

1275 Red Fox Road, Arden Hills, MN 55112

USA & Canada: 800-777-5484 Technical Support: 800-777-2624

©2009 GE Security, Inc. All names are trademarks of their owners. All rights

4

Loading...

Loading...