Page 1

查询M80C186XL10供应商

16-BIT HIGH-INTEGRATION EMBEDDED PROCESSOR

M80C186XL20, 16, 12, 10

Y

Low Power, Full Static Version of

M80C186

Y

Operation Modes:

Ð Enhanced Mode

Ð DRAM Refresh Control Unit

Ð Power-Save Mode

Ð Direct Interface to 80C187

Ð Compatible Mode

Ð NMOS 80186 Pin-for-Pin

Replacement for Non-Numerics

Applications

Y

Integrated Feature Set

Ð Static, Modular CPU

Ð Clock Generator

Ð 2 Independent DMA Channels

Ð Programmable Interrupt Controller

Ð 3 Programmable 16-Bit Timers

Ð Dynamic RAM Refresh Control Unit

Ð Programmable Memory and

Peripheral Chip Select Logic

Ð Programmable Wait State Generator

Ð Local Bus Controller

Ð Power-Save Mode

Ð System-Level Testing Support (High

Impedance Test Mode)

The Intel M80C186XL is a Modular Core re-implementation of the M80C186 microprocessor. It offers higher

speed and lower power consumption than the standard M80C186 but maintains 100% clock-for-clock functional compatibility. Packaging and pinout are also identical.

Y

Completely Object Code Compatible

with Existing 8086/8088 Software and

Has 10 Additional Instructions over

8086/8088

Y

Speed Versions Available

Ð 20 MHz (M80C186XL20)

Ð 16 MHz (M80C186XL16)

Ð 12.5 MHz (M80C186XL12)

Ð 10 MHz (M80C186XL)

Y

Direct Addressing Capability to

1 MByte Memory and 64 Kbyte I/O

Y

Complete System Development

Support

Ð All 8086 and 80C186 Software

Development Tools Can Be Used for

M80C186XL System Development

Ð ASM 86 Assembler, PL/M-86,

Pascal-86, Fortran-86, iC-86 and

System Utilities

Ð In-Circuit-Emulator (ICE

Y

Available in 68-Pin:

TM

Ð Ceramic Pin Grid Array (PGA)

Y

Military Temperature Range:

b

Ð

55§Ctoa125§C(TC)

-186)

271276– 1

*Other brands and names are the property of their respective owners.

Information in this document is provided in connection with Intel products. Intel assumes no liability whatsoever, including infringement of any patent or

copyright, for sale and use of Intel products except as provided in Intel’s Terms and Conditions of Sale for such products. Intel retains the right to make

changes to these specifications at any time, without notice. Microcomputer Products may have minor variations to this specification known as errata.

March 1995COPYRIGHT©INTEL CORPORATION, 1996 Order Number: 271276-002

Page 2

M80C186XL20, 16, 12, 10

16-BIT HIGH INTEGRATION EMBEDDED PROCESSOR

CONTENTS PAGE

INTRODUCTION ААААААААААААААААААААААААА 10

M80C186XL BASE ARCHITECTURE ААААА 10

M80C186XL Clock Generator ААААААААААААА 10

Bus Interface Unit ААААААААААААААААААААААААА 11

M80C186XL PERIPHERAL

ARCHITECTURE ААААААААААААААААААААААА 11

Chip-Select/Ready Generation Logic АААААА 11

DMA Unit ААААААААААААААААААААААААААААААААА 12

Timer/Counter Unit ААААААААААААААААААААААА 12

Interrupt Control Unit АААААААААААААААААААААА 12

Enhanced Mode Operation АААААААААААААААА 12

Queue-Status Mode ААААААААААААААААААААААА 12

DRAM Refresh Control Unit ААААААААААААААА 13

Power-Save Control ААААААААААААААААААААААА 13

Interface for 80C187 Math

Coprocessor АААААААААААААААААААААААААААА 13

ONCE Test Mode ААААААААААААААААААААААААА 13

ABSOLUTE MAXIMUM RATINGS АААААААА 14

DC CHARACTERISTICS ААААААААААААААААА 14

CONTENTS PAGE

AC CHARACTERISTICS ААААААААААААААААА 16

Major Cycle Timings (Read Cycle) ААААААААА 16

Major Cycle Timings (Write Cycle) ААААААААА 18

Major Cycle Timings (Interrupt

Acknowledge Cycle) АААААААААААААААААААА 20

Software Halt Cycle Timings ААААААААААААААА 22

Clock Timings ААААААААААААААААААААААААААААА 23

Ready, Peripheral and Queue Status

Timings

Reset and Hold/HLDA Timings АААААААААААА 27

AC TIMING WAVEFORMS ААААААААААААААА 33

EXPLANATION OF THE AC

SYMBOLS АААААААААААААААААААААААААААААА 36

DERATING CURVES ААААААААААААААААААААА 37

M80C186XL EXECUTION TIMINGS АААААА 38

INSTRUCTION SET SUMMARY АААААААААА 39

FOOTNOTES ААААААААААААААААААААААААААААА 44

ААААААААААААААААААААААААААААААААА 25

2

Page 3

M80C186XL

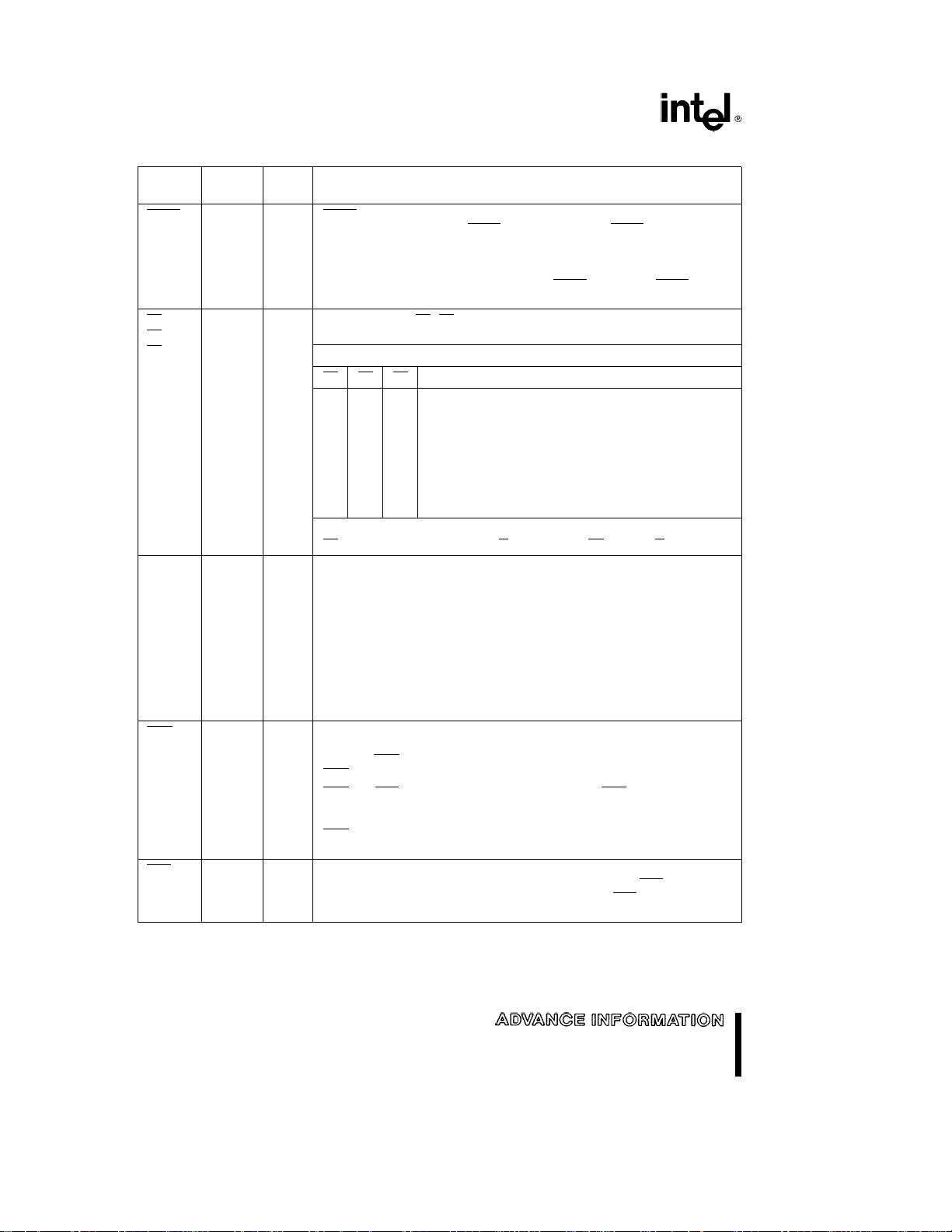

271276– 2

Figure 1. M80C186XL Block Diagram

3

Page 4

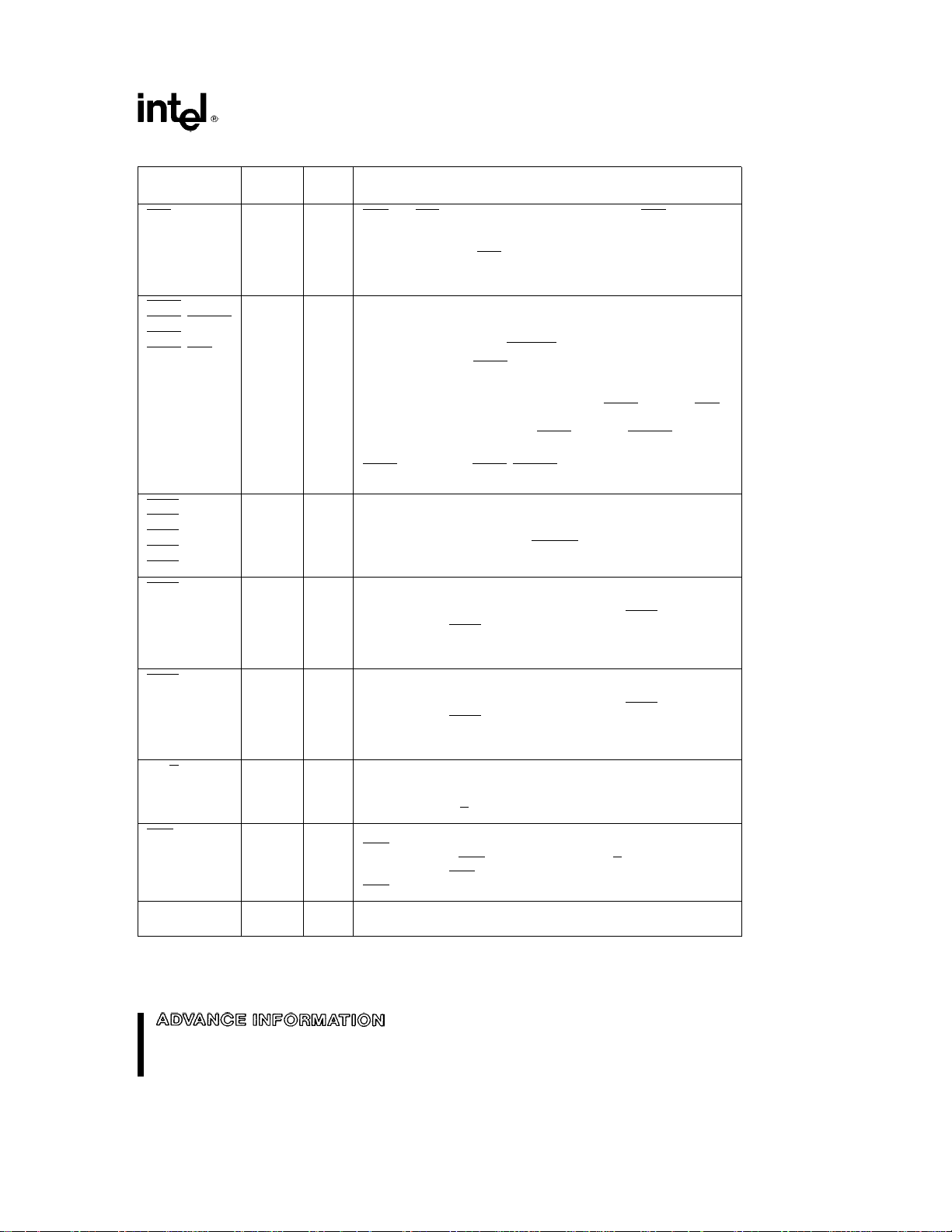

M80C186XL

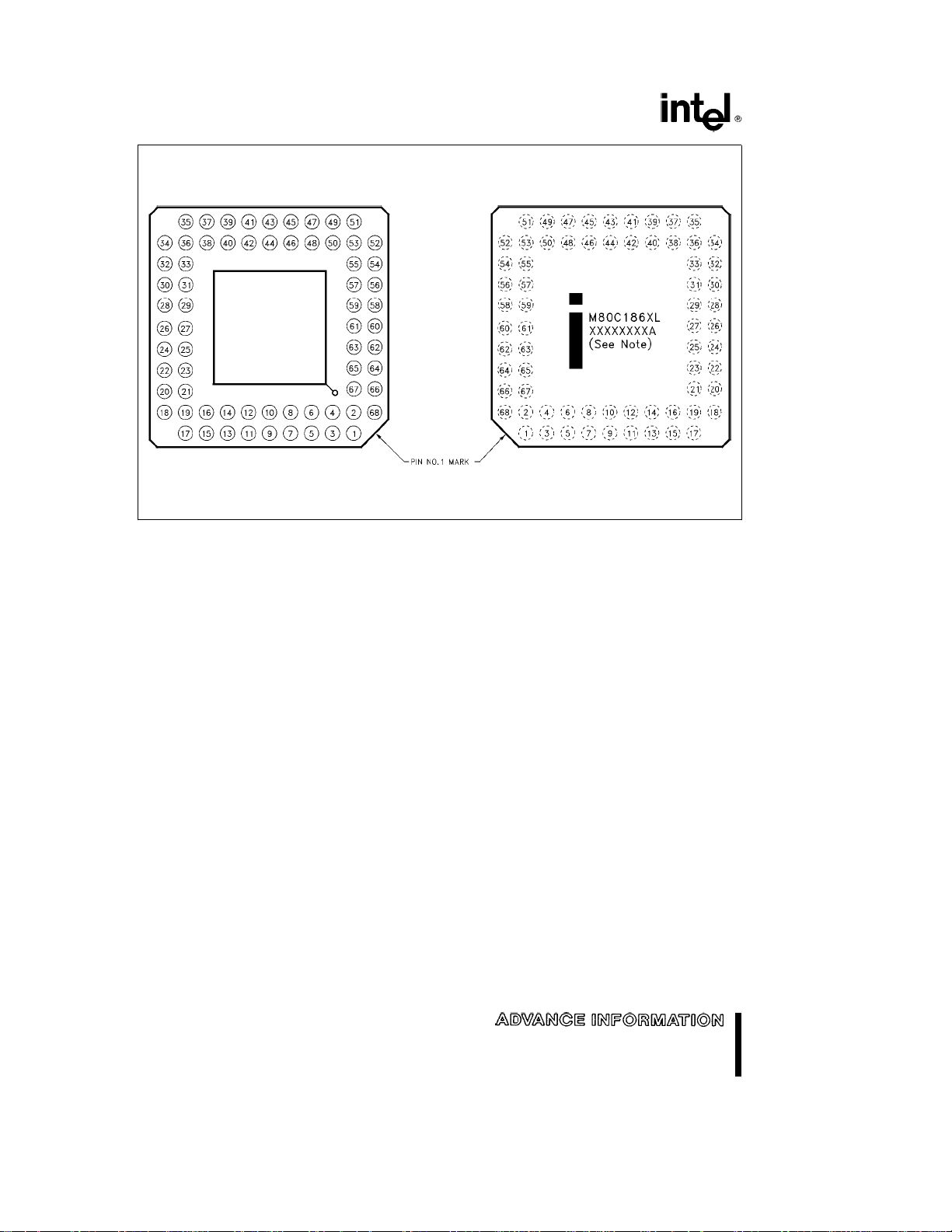

Pins Facing Up Pins Facing Down

NOTE:

XXXXXXXXA indicates the Intel FPO number.

Figure 2. M80C186XL Pinout Diagrams

Ceramic Pin Grid Array

271276– 3

4

Page 5

M80C186XL

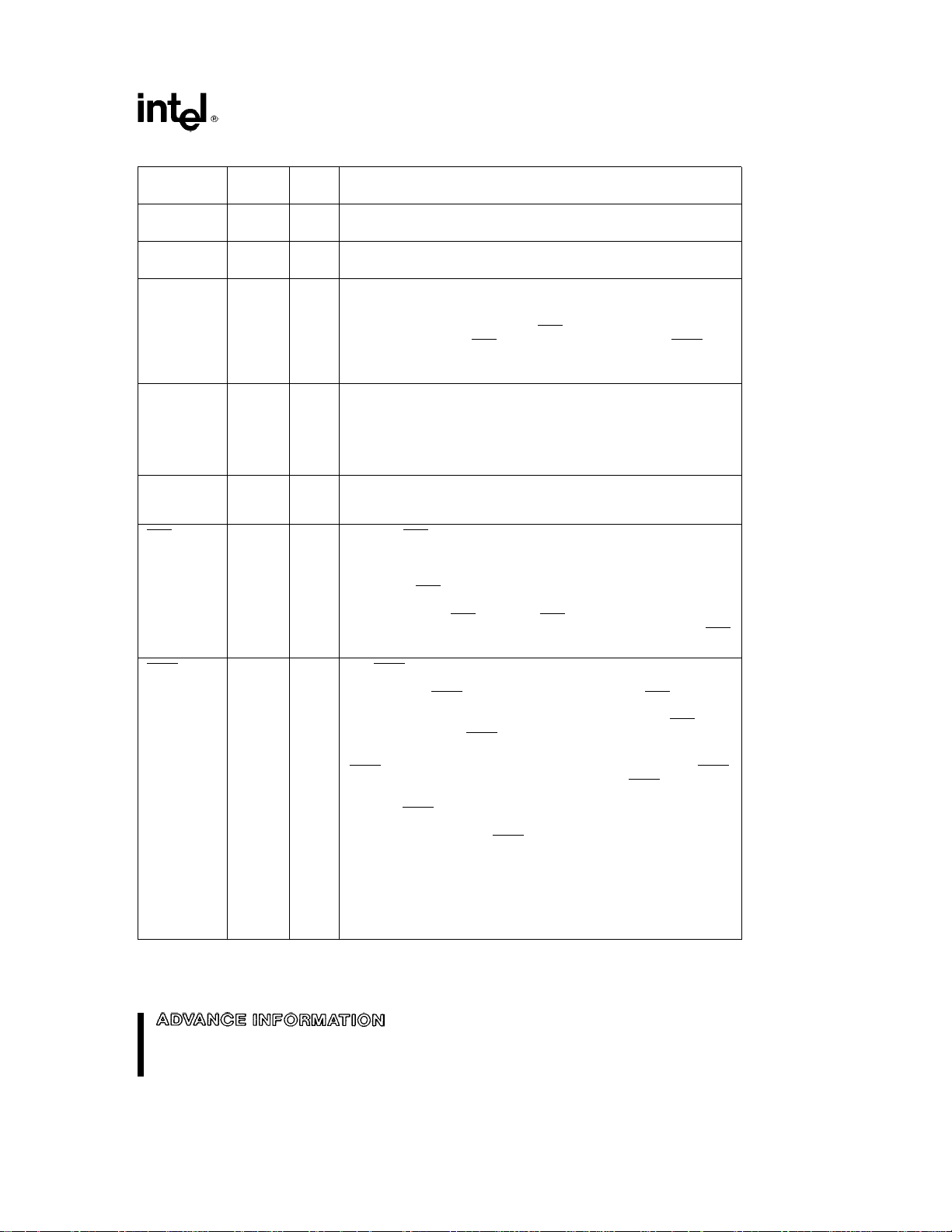

Table 1. M80C186XL Pin Description

Symbol

V

CC

V

SS

RESET 57 O RESET Output indicates that the M80C186XL CPU is being reset, and

X1 59 I Crystal Inputs X1 and X2 provide external connections for a

X2 58 O

CLKOUT 56 O Clock Output provides the system with a 50% duty cycle waveform.

RES 24 I An active RES causes the M80C186XL to immediately terminate its

TEST/BUSY 47 I/O The TEST pin is sampled during and after reset to determine whether

PGA

Pin No.

Type Name and Function

9 I System Power:a5 volt power supply.

43 I

26 I System Ground.

60 I

can be used as a system reset. It is active HIGH, synchronized with

the processor clock, and lasts an integer number of clock periods

corresponding to the length of the RES

clockout periods after RES

goes inactive. When tied to the TEST/

BUSY pin, RESET forces the M80C186XL into enhanced mode.

RESET is not floated during bus hold.

fundamental mode or third overtone parallel resonant crystal for the

internal oscillator. X1 can connect to an external clock instead of a

crystal. In this case, minimize the capacitance on X2. The input or

oscillator frequency is internally divided by two to generate the clock

signal (CLKOUT).

All device pin timings are specified relative to CLKOUT. CLKOUT is

active during reset and bus hold.

present activity, clear the internal logic, and enter a dormant state.

This signal may be asynchronous to the M80C186XL clock. The

M80C186XL begins fetching instructions approximately 6(/2 clock

cycles after RES

is returned HIGH. For proper initialization, VCCmust

be within specifications and the clock signal must be stable for more

than 4 clocks with RES

held LOW. RES is internally synchronized.

This input is provided with a Schmitt-trigger to facilitate power-on RES

generation via an RC network.

the M80C186XL is to enter Compatible or Enhanced Mode. Enhanced

Mode requires TEST

to be HIGH on the rising edge of RES and LOW

four CLKOUT cycles later. Any other combination will place the

M80C186XL in Compatible Mode. During power-up, active RES is

required to configure TEST

/BUSY as an input. A weak internal pullup

ensures a HIGH state when the input is not externally driven.

ÐIn Compatible Mode this pin is configured to operate as TEST.

TEST

This pin is examined by the WAIT instruction. If the TEST

HIGH when WAIT execution begins, instruction execution will

suspend. TEST

will be resampled every five clocks until it goes LOW,

at which time execution will resume. If interrupts are enabled while the

M80C186XL is waiting for TEST

BUSYÐIn Enhanced Mode, this pin is configured to operate as

BUSY. The BUSY input is used to notify the M80C186XL of Math

Coprocessor activity. Floating point instructions executing in the

M80C186XL sample the BUSY pin to determine when the Math

Coprocessor is ready to accept a new command. BUSY is active

HIGH.

signal. Reset goes inactive 2

input is

, interrupts will be serviced.

5

Page 6

M80C186XL

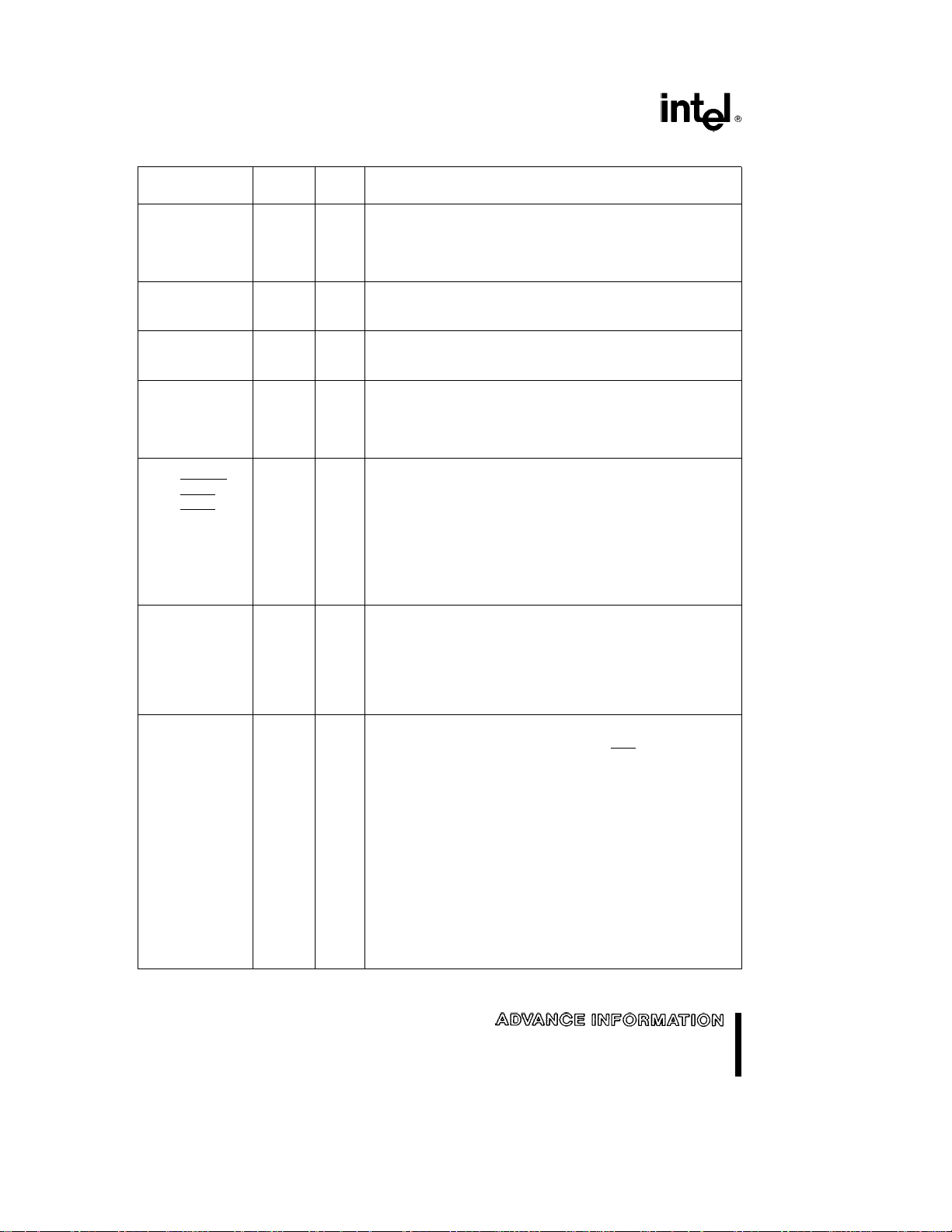

Table 1. M80C186XL Pin Description (Continued)

Symbol

TMR IN 0 20 I Timer Inputs are used either as clock or control signals,

TMR IN 1 21 I

TMR OUT 0 22 O Timer outputs are used to provide single pulse or continous

TMR OUT 1 23 O

DRQ0 18 I DMA Request is asserted HIGH by an external device when it is

DRQ1 19 I

NMI 46 I The Non-Maskable Interrupt input causes a Type 2 interrupt. An

INT0 45 I Maskable Interrupt Requests can be requested by activating one

INT1/SELECT

INT2/INTA0

INT3/INTA1

/IRQ 41 I/O

A19/S6 65 O Address Bus Outputs (16 –19) and Bus Cycle Status (3 –6)

A18/S5 66 O

A17/S4 67 O

A16/S3 68 O During T

AD15 1 I/O Address/Data Bus (0 –15) signals constitute the time multiplexed

AD14 3 I/O

AD13 5 I/O

AD12 7 I/O

AD11 10 I/O

AD10 12 I/O

AD9 14 I/O

AD8 16 I/O

AD7 2 I/O

AD6 4 I/O

AD5 6 I/O

AD4 8 I/O

AD3 11 I/O

AD2 13 I/O

AD1 15 I/O

AD0 17 I/O

PGA

Pin No.

44 I

42 I/O

Type Name and Function

depending upon the programmed timer mode. These inputs are

active HIGH (or LOW-to-HIGH transitions are counted) and

internally synchronized. Timer Inputs must be tied HIGH when

not being used as clock or retrigger inputs.

waveform generation, depending upon the timer mode selected.

These outputs are not floated during a bus hold.

ready for DMA Channel 0 or 1 to perform a transfer. These

signals are level-triggered and internally synchronized.

NMI transition from LOW to HIGH is latched and synchronized

internally, and initiates the interrupt at the next instruction

boundary. NMI must be asserted for at least one CLKOUT period.

The Non-Maskable Interrupt cannot be avoided by programming.

of these pins. When configured as inputs, these pins are active

HIGH. Interrupt Requests are synchronized internally. INT2 and

INT3 may be configured to provide active-LOW interruptacknowledge output signals. All interrupt inputs may be

configured to be either edge- or level-triggered. To ensure

recognition, all interrupt requests must remain active until the

interrupt is acknowledged. When Slave Mode is selected, the

function of these pins changes (see Interrupt Controller section

of this data sheet).

indicate the four most significant address bits during T

signals are active HIGH.

2,T3,TW

initiated bus cycle or HIGH to indicate a DMA-initiated or refresh

and T4, the S6 pin is LOW to indicate a CPU-

bus cycle. During the same T-states, S3, S4 and S5 are always

LOW. These outputs are floated during bus hold or reset.

memory or I/O address (T

The bus is active HIGH. A

byte of the data bus, pins D

when a byte is to be transferred onto the lower portion of the bus

) and data (T2,T3,TWand T4) bus.

1

is analogous to BHE for the lower

0

through D0. It is LOW during T

7

in memory or I/O operations. These pins are floated during a bus

hold or reset.

. These

1

1

6

Page 7

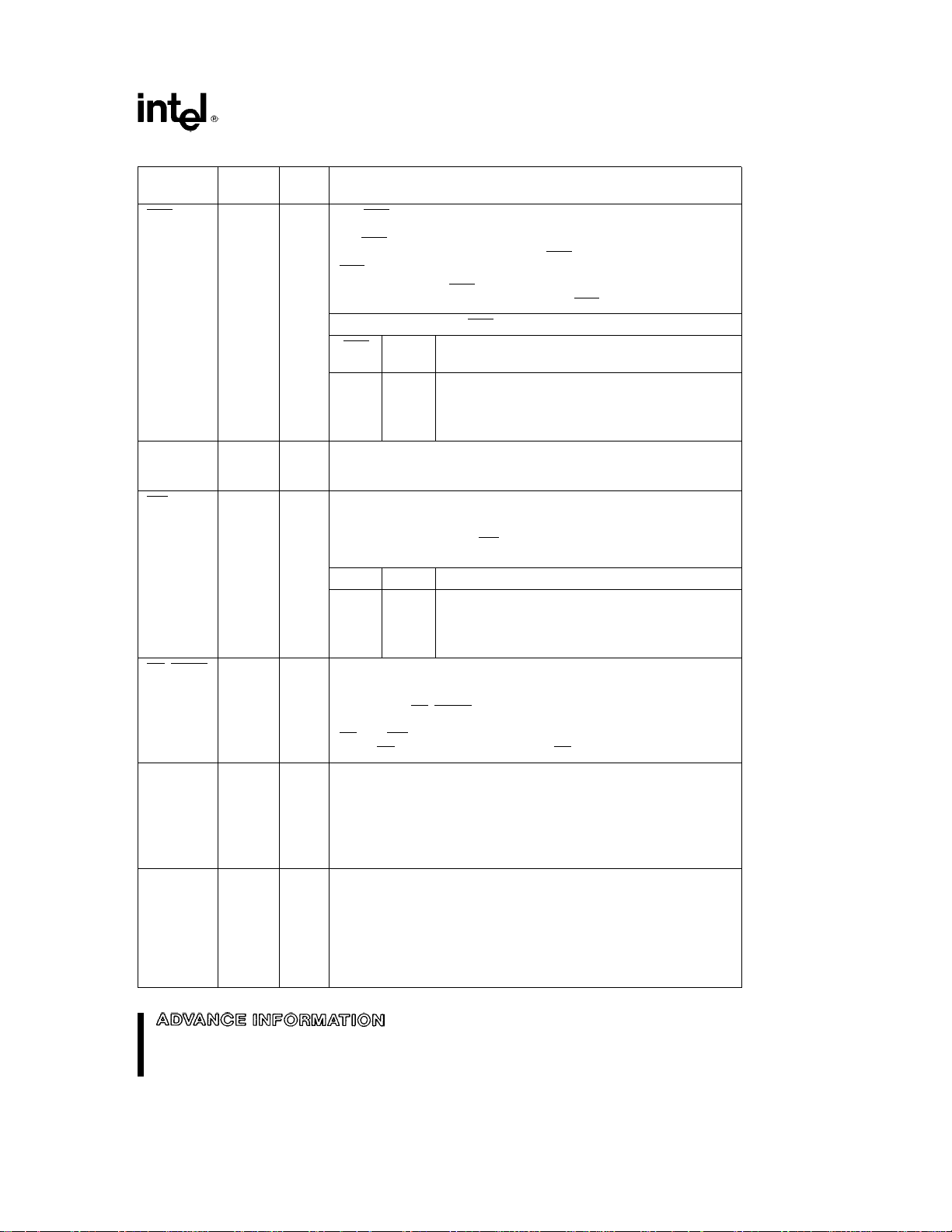

M80C186XL

Table 1. M80C186XL Pin Description (Continued)

Symbol

BHE 64 O The BHE (Bus High Enable) signal is analogous to A0 in that it is used

ALE/QS0 61 O Address Latch Enable/Queue Status 0 is provided by the M80C186XL

WR/QS1 63 O Write Strobe/Queue Status 1 indicates that the data on the bus is to be

RD/QSMD 62 O/I Read Strobe is an active LOW signal which indicates that the

ARDY 55 I Asynchronous Ready informs the M80C186XL that the addressed

SRDY 49 I Synchronous Ready informs the M80C186XL that the addressed

PGA

Pin No.

Type Name and Function

to enable data on to the most significant half of the data bus, pins D15–

D8. BHE

will remain LOW through T

BHE

will be LOW during T1when the upper byte is transferred and

AND TW. BHE does not need to be latched.

will float during HOLD or RESET.

3

In Enhanced Mode, BHE will also be used to signify DRAM refresh

cycles. A refresh cycle is indicated by both BHE

BHE and A0 Encodings

BHE A0

Value Value

Function

0 0 Word Transfer

0 1 Byte Transfer on upper half of data bus (D15–D8)

1 0 Byte Transfer on lower half of data bus (D

1 1 Refresh

to latch the address. ALE is active HIGH, with addresses guaranteed

valid on the trailing edge.

written into a memory or an I/O device. It is active LOW, and floats

during bus hold or reset. When the M80C186XL is in Queue Status

Mode, the ALE/QS0 and WR

/QS1 pins provide information about

processor/instruction queue interaction.

QS1 QS0 Queue Operation

0 0 No queue operation

0 1 First opcode byte fetched from the queue

1 1 Subsequent byte fetched from the queue

1 0 Empty the queue

M80C186XL is performing a memory or I/O read cycle. It is guaranteed

not to go LOW before the A/D bus is floated. An internal pull-up

ensures that RD

/QSMD is HIGH during RESET. Following RESET the

pin is sampled to determine whether the M80C186XL is to provide ALE,

RD

, and WR, or queue status information. To enable Queue Status

Mode, RD

must be connected to GND. RD will float during bus HOLD.

memory space or I/O device will complete a data transfer. The ARDY

pin accepts a rising edge that is asynchronous to CLKOUT and is active

HIGH. The falling edge of ARDY must be synchronized to the

M80C186XL clock. Connecting ARDY HIGH will always assert the

ready condition to the CPU. If this line is unused, it should be tied LOW

to yield control to the SRDY pin.

memory space or I/O device will complete a data transfer. The SRDY

pin accepts an active-HIGH input synchronized to CLKOUT. The use of

SRDY allows a relaxed system timing over ARDY. This is accomplished

by elimination of the one-half clock cycle required to internally

synchonize the ARDY input signal. Connecting SRDY high will always

assert the ready condition to the CPU. If this line is unused, it should be

tied LOW to yield control to the ARDY pin.

and A0 being HIGH.

7–D0

)

7

Page 8

M80C186XL

Table 1. M80C186XL Pin Description (Continued)

Symbol

LOCK 48 O LOCK output indicates that other system bus masters are not to gain

S0 52 O Bus cycle status S0 –S2

S1

S2 54 O

HOLD 50 I HOLD indicates that another bus master is requesting the local bus. The

HLDA 51 O

UCS 34 O/I Upper Memory Chip Select is an active LOW output whenever a memory

LCS 33 O/I Lower Memory Chip Select is active LOW whenever a memory reference is

PGA

Pin No.

53 O

Type Name and Function

control of the system bus. LOCK

requested by the LOCK prefix instruction and is activated at the beginning

of the first data cycle associated with the instruction immediately following

the LOCK prefix. It remains active until the completion of that instruction.

No instruction prefetching will occur while LOCK is asserted. LOCK floats

during bus hold or reset.

information:

M80C186XL Bus Cycle Status Information

S2 S1 S0 Bus Cycle Initiated

0 0 0 Interrupt Acknowledge

0 0 1 Read I/O

0 1 0 Write I/O

0 1 1 Halt

1 0 0 Instruction Fetch

1 0 1 Read Data from Memory

1 1 0 Write Data to Memory

1 1 1 Passive (no bus cycle)

The status pins float during HOLD.

S2

may be used as a logical M/IO indicator, and S1 as a DT/R indicator.

HOLD input is active HIGH. The M80C186XL generates HLDA (HIGH) in

response to a HOLD request. Simultaneous with the issuance of HLDA,

the M80C186XL will float the local bus and control lines. After HOLD is

detected as being LOW, the M80C186XL will lower HLDA. When the

M80C186XL needs to run another bus cycle, it will again drive the local bus

and control lines.

In Enhanced Mode, HLDA will go low when a DRAM refresh cycle is

pending in the M80C186XL and an external bus master has control of the

bus. It will be up to the external master to relinquish the bus by lowering

HOLD so that the M80C186XL may execute the refresh cycle.

reference is made to the defined upper portion (1K – 256K block) of

memory. UCS

is software programmable.

UCS

UCS and LCS are sampled upon the rising edge of RES. If both pins are

held low, the M80C186XL will enter ONCE Mode. In ONCE Mode all pins

assume a high impedance state and remain so until a subsequent RESET.

UCS has a weak internal pullup that is active during RESET to ensure that

the M80C186XL does not enter ONCE Mode inadvertently.

made to the defined lower portion (1K –256K) of memory. LCS

float during bus HOLD. The address range activating LCS

programmable.

does not float during bus hold. The address range activating

is active LOW. The LOCK signal is

are encoded to provide bus-transaction

does not

is software

8

Page 9

M80C186XL

Table 1. M80C186XL Pin Description (Continued)

Symbol

LCS UCS and LCS are sampled upon the rising edge of RES. If both

(Continued)

MCS0/PEREQ 38 O/I Mid-Range Memory Chip Select signals are active LOW when a

MCS1

/ERROR 37 O/I

MCS2

MCS3

/NPS 35 O

PCS0 25 O Peripheral Chip Select signals 0–4 are active LOW when a

PCS1

PCS2

PCS3

PCS4

PCS5/A1 31 O Peripheral Chip Select 5 or Latched A1 may be programmed to

PCS6/A2 32 O Peripheral Chip Select 6 or Latched A2 may be programmed to

DT/R 40 O Data Transmit/Receive controls the direction of data flow through

DEN 39 O Data Enable is provided as a data bus transceiver output enable.

N.C. Ð Ð Not connected. To maintain compatibility with future products, do

PGA

Pin No.

36 O

27 O

28 O

29 O

30 O

Type Name and Function

pins are held low, the M80C186XL will enter ONCE Mode. In ONCE

Mode all pins assume a high impedance state and remain so until a

subsequent RESET. LCS

only during RESET to ensure that the M80C186XL does not enter

ONCE mode inadvertently.

memory reference is made to the defined mid-range portion of

memory (8K –512K). These lines do not float during bus HOLD. The

address ranges activating MCS0 – 3

In Enhanced Mode, MCS0

Extension Request). When connected to the Math Coprocessor,

this input is used to signal the M80C186XL when to make numeric

data transfers to and from the coprocessor. MCS3

(Numeric Processor Select) which may only be activated by

communication to the 80C187. MCS1

Enhanced Mode and is used to signal numerics coprocessor errors.

MCS0

/PEREQ and MCS1/ERROR have weak internal pullups

which are active during reset.

reference is made to the defined peripheral area (64K byte I/O or 1

MByte memory space). These lines do not float during bus HOLD.

The address ranges activating PCS0–4

programmable.

provide a sixth peripheral chip select, or to provide an internally

latched A1 signal. The address range activating PCS5 is softwareprogrammable. PCS5

programmed to provide latched A1, this pin will retain the previously

latched value during HOLD.

provide a seventh peripheral chip select, or to provide an internally

latched A2 signal. The address range activating PCS6

programmable. PCS6/A2 does not float during bus HOLD. When

programmed to provide latched A2, this pin will retain the previously

latched value during HOLD.

an external data bus transceiver. When LOW, data is transferred to

the M80C186XL. When HIGH the M80C186XL places write data on

the data bus. DT/R

DEN

is active LOW during each memory and I/O access (including

80C187 access). DEN

During RESET, DEN

DEN

also floats during HOLD.

not connect to these pins.

has a weak internal pullup that is active

are software programmable.

becomes a PEREQ input (Processor

becomes ERROR in

are software

/A1 does not float during bus HOLD. When

floats during a bus hold or reset.

is HIGH whenever DT/R changes state.

is driven HIGH for one clock, then floated.

becomes NPS

is software-

9

Page 10

M80C186XL

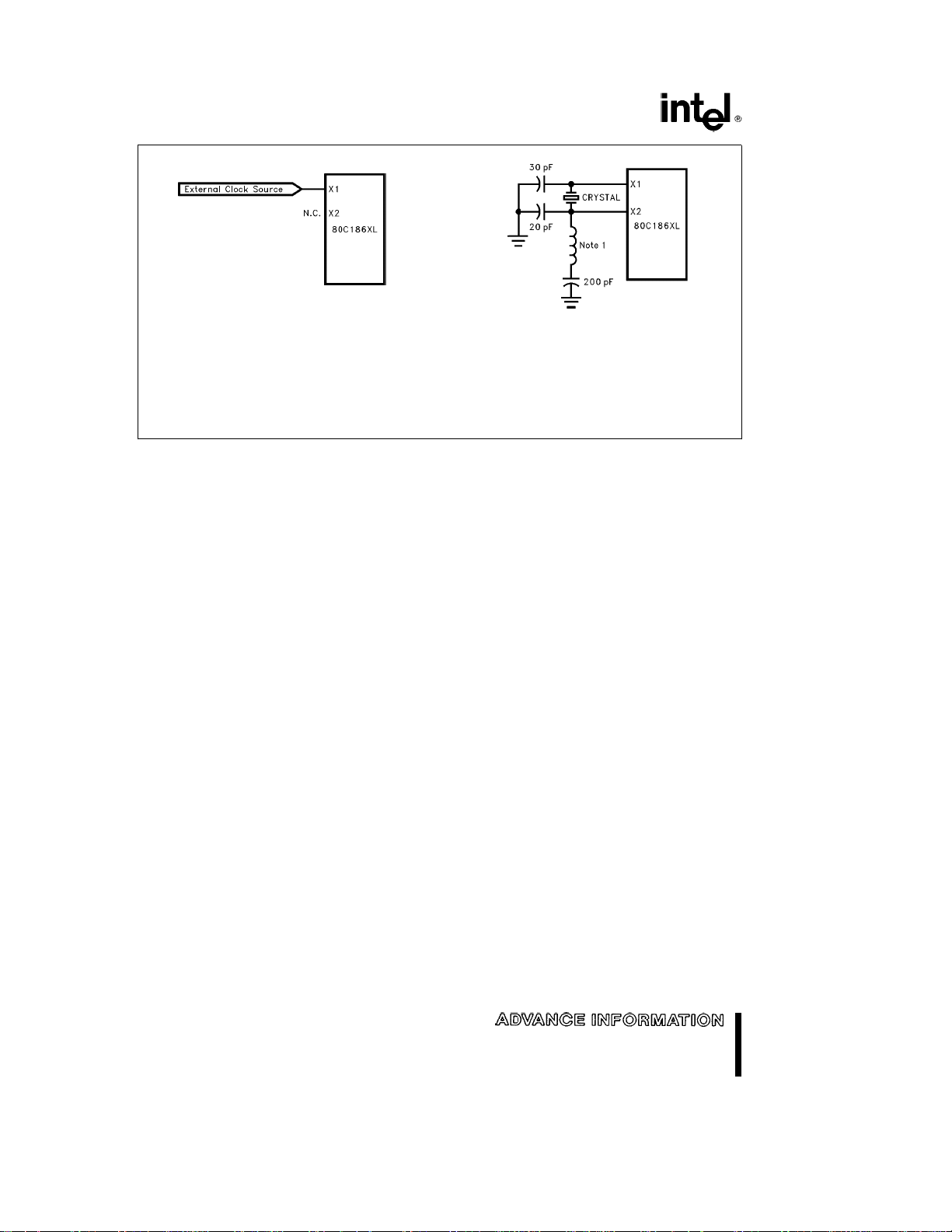

(3a)

271276– 4

Figure 3. M80C186XL Oscillator Configurations (see text)

INTRODUCTION

The following Functional Description describes the

base architecture of the M80C186XL. The

M80C186XL is a very high integration 16-bit microprocessor. It combines 15 –20 of the most common

microprocessor system components onto one chip.

The M80C186XL is object code compatible with the

8086/8088 microprocessors and adds 10 new instruction types to the 8086/8088 instruction set.

The M80C186XL has two major modes of operation,

Compatible and Enhanced. In Compatible Mode the

M80C186XL is completely compatible with NMOS

80186, with the exception of 8087 support. The Enhanced mode adds three new features to the system

design. These are Power-Save control, Dynamic

RAM refresh, and an asynchronous Numerics Coprocessor interface.

271276– 5

(3b)

Note 1:

XTAL Frequency L1 Value

20 MHz 12.0 mH

25 MHz 8.2 mH

32 MHz 4.7 mH

40 MHz 3.0 mH

LC network is only required when using a third

overtone crystal.

g

20%

g

20%

g

20%

g

20%

third-overtone mode crystal, depending upon the

frequency range of the application. This is used as

the time base for the M80C186XL.

The output of the oscillator is not directly available

outside the M80C186XL. The recommended crystal

configuration is shown in Figure 3b. When used in

third-overtone mode, the tank circuit is recommended for stable operation. Alternately, the oscillator

may be driven from an external source as shown in

Figure 3a.

The crystal or clock frequency chosen must be twice

the required processor operating frequency due to

the internal divide by two counter. This counter is

used to drive all internal phase clocks and the external CLKOUT signal. CLKOUT is a 50% duty cycle

processor clock and can be used to drive other system components. All AC Timings are referenced to

CLKOUT.

M80C186XL BASE ARCHITECTURE

M80C186XL Clock Generator

The M80C186XL provides an on-chip clock generator for both internal and external clock generation.

The clock generator features a crystal oscillator, a

divide-by-two counter, synchronous and asynchronous ready inputs, and reset circuitry.

The M80C186XL oscillator circuit is designed to be

used either with a parallel resonant fundamental or

10

Intel recommends the following values for crystal selection parameters.

Temperature Range: Application Specific

ESR (Equivalent Series Resistance): 60X max

C

(Shunt Capacitance of Crystal): 7.0 pF max

0

C1(Load Capacitance): 20 pFg5pF

Drive Level: 2 mW max

Page 11

M80C186XL

Bus Interface Unit

The M80C186XL provides a local bus controller to

generate the local bus control signals. In addition, it

employs a HOLD/HLDA protocol for relinquishing

the local bus to other bus masters. It also provides

outputs that can be used to enable external buffers

and to direct the flow of data on and off the local

bus.

The bus controller is responsible for generating 20

bits of address, read and write strobes, bus cycle

status information and data (for write operations) information. It is also responsible for reading data

from the local bus during a read operation. Synchronous and asynchronous ready input pins are provided to extend a bus cycle beyond the minimum four

states (clocks).

The M80C186XL bus controller also generates two

control signals (DEN

external transceiver chips. This capability allows the

addition of transceivers for simple buffering of the

multiplexed address/data bus.

During RESET the local bus controller will perform

the following action:

Drive DEN

#

cle, then float them.

Drive S0–S2 to the inactive state (all HIGH) and

#

then float.

Drive LOCK HIGH and then float.

#

Float AD0–15, A16 – 19, BHE, DT/R.

#

Drive ALE LOW

#

Drive HLDA LOW.

#

RD

/QSMD, UCS, LCS, MCS0/PEREQ, MCS1/

ERROR

and TEST/BUSY pins have internal pullup

devices which are active while RES

cessive loading or grounding certain of these pins

causes the M80C186XL to enter an alternative

mode of operation:

RD/QSMD low results in Queue Status Mode.

#

UCS and LCS low results in ONCE Mode.

#

TEST/BUSY low (and high later) results in En-

#

hanced Mode.

and DT/R) when interfacing to

,RDand WR HIGH for one clock cy-

is applied. Ex-

Chip-Select/Ready Generation Logic

The M80C186XL contains logic which provides programmable chip-select generation for both memories and peripherals. In addition, it can be programmed to provide READY (or WAIT state) generation. It can also provide latched address bits A1 and

A2. The chip-select lines are active for all memory

and I/O cycles in their programmed areas, whether

they be generated by the CPU or by the integrated

DMA unit.

The M80C186XL provides 6 memory chip select outputs for 3 address areas; upper memory, lower

memory, and midrange memory. One each is provided for upper memory and lower memory, while four

are provided for midrange memory.

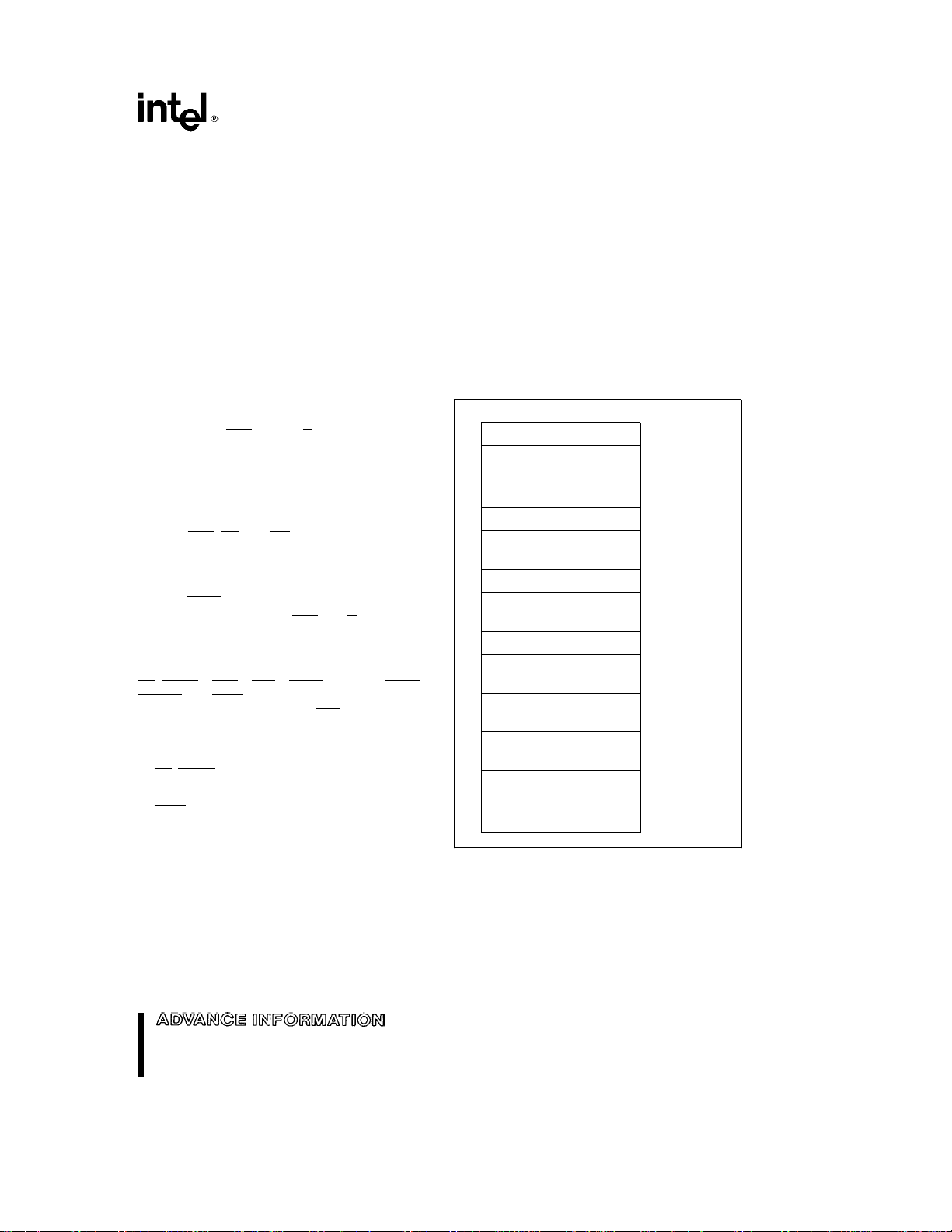

OFFSET

Relocation Register FEH

DMA Descriptors Channel 1

DMA Descriptors Channel 0

Chip-Select Control Registers

Time 2 Control Registers

Time 1 Control Registers

Time 0 Control Registers

Interrupt Controller Registers

DAH

D0H

CAH

C0H

A8H

A0H

66H

60H

5EH

58H

56H

50H

3EH

20H

M80C186XL PERIPHERAL

ARCHITECTURE

All the M80C186XL integrated peripherals are controlled by 16-bit registers contained within an internal 256-byte control block. The control block may be

mapped into either memory or I/O space. Internal

logic will recognize control block addresses and respond to bus cycles. An offset map of the 256-byte

control register block is shown in Figure 4.

Figure 4. Internal Register Map

The M80C186XL provides a chip select, called UCS

for the top of memory. The top of memory is usually

used as the system memory because after reset the

M80C186XL begins executing at memory location

FFFF0H.

11

,

Page 12

M80C186XL

The M80C186XL provides a chip select for low

memory called LCS

tains the interrupt vector table, starting at location

00000H.

The M80C186XL provides four MCS lines which are

active within a user-locatable memory block. This

block can be located within the M80C186XL 1 Mbyte

memory address space exclusive of the areas defined by UCS

size of this memory block are programmable.

The M80C186XL can generate chip selects for up to

seven peripheral devices. These chip selects are active for seven contiguous blocks of 128 bytes above

a programmable base address. The base address

may be located in either memory or I/O space.

The M80C186XL can generate a READY signal internally for each of the memory or peripheral CS

lines. The number of WAIT states to be inserted for

each peripheral or memory is programmable to provide 0–3 wait states for all accesses to the area for

which the chip select is active. In addition, the

M80C186XL may be programmed to either ignore

external READY for each chip-select range individually or to factor external READY with the integrated

ready generator.

Upon RESET, the Chip-Select/Ready Logic will perform the following actions:

All chip-select outputs will be driven HIGH.

#

Upon leaving RESET, the UCS line will be pro-

#

grammed to provide chip selects to a 1K block

with the accompanying READY control bits set at

011 to insert 3 wait states in conjunction with external READY (i.e., UMCS resets to FFFBH).

No other chip select or READY control registers

#

have any predefined values after RESET. They

will not become active until the CPU accesses

their control registers.

. The bottom of memory con-

and LCS. Both the base address and

DMA Unit

The M80C186XL DMA controller provides two independent high-speed DMA channels. Data transfers

can occur between memory and I/O spaces (e.g.,

Memory to I/O) or within the same space (e.g.,

Memory to Memory or I/O to I/O). Data can be

transferred either in bytes (8 bits) or in words (16

bits) to or from even or odd addresses. Each DMA

channel maintains both a 20-bit source and destination pointer which can be optionally incremented or

decremented after each data transfer (by one or two

depending on byte or word transfers). Each data

transfer consumes 2 bus cycles (a minimum of 8

clocks), one cycle to fetch data and the other to

store data.

Timer/Counter Unit

The M80C186XL provides three internal 16-bit programmable timers. Two of these are highly flexible

and are connected to four external pins (2 per timer).

They can be used to count external events, time external events, generate nonrepetitive waveforms,

etc. The third timer is not connected to any external

pins, and is useful for real-time coding and time delay applications. In addition, the third timer can be

used as a prescaler to the other two, or as a DMA

request source.

Interrupt Control Unit

The M80C186XL can receive interrupts from a number of sources, both internal and external. The

M80C186XL has 5 external and 2 internal interrupt

sources (Timer/Couners and DMA). The internal interrupt controller serves to merge these requests on

a priority basis, for individual service by the CPU.

Enhanced Mode Operation

In Compatible Mode the M80C186XL operates with

all the features of the NMOS 80186, with the exception of 8087 support (i.e. no math coprocessing is

possible in Compatible Mode). Queue-Status information is still available for design purposes other

than 8087 support.

All the Enhanced Mode features are completely

masked when in Compatible Mode. A write to any of

the Enhanced Mode registers will have no effect,

while a read will not return any valid data.

In Enhanced Mode, the M80C186XL will operate

with Power-Save, DRAM refresh, and numerics coprocessor support in addition to all the Compatible

Mode features.

If connected to a math coprocessor, this mode will

be invoked automatically. Without an NPX, this

mode can be entered by tying the RESET output

signal from the M80C186XL to the TEST

put.

/BUSY in-

Queue-Status Mode

The queue-status mode is entered by strapping the

RD

pin low. RD is sampled at RESET and if LOW,

the M80C186XL will reconfigure the ALE and WR

pins to be QS0 and QS1 respectively. This mode is

available on the M80C186XL in both Compatible

and Enhanced Modes.

12

Page 13

M80C186XL

DRAM Refresh Control Unit

The Refresh Control Unit (RCU) automatically generates DRAM refresh bus cycles. The RCU operates

only in Enhanced Mode. After a programmable period of time, the RCU generates a memory read request to the BIU. If the address generated during a

refresh bus cycle is within the range of a properly

programmed chip select, that chip select will be activated when the BIU executes the refresh bus cycle.

Power-Save Control

The M80C186XL, when in Enhanced Mode, can enter a power saving state by internally dividing the

processor clock frequency by a programmable factor. This divided frequency is also available at the

CLKOUT pin.

All internal logic, including the Refresh Control Unit

and the timers, have their clocks slowed down by

the division factor. To maintain a real time count or a

fixed DRAM refresh rate, these peripherals must be

re-programmed when entering and leaving the power-save mode.

Interface for 80C187 Math

Coprocessor

In Enhanced Mode, three of the mid-range memory

chip selects are redefined according to Table 2 for

use with the 80C187. The fourth chip select, MCS2

functions as in compatible mode, and may be pro-

grammed for activity with ready logic and wait states

accordingly. As in Compatible Mode, MCS2

tion for one-fourth a programmed block size.

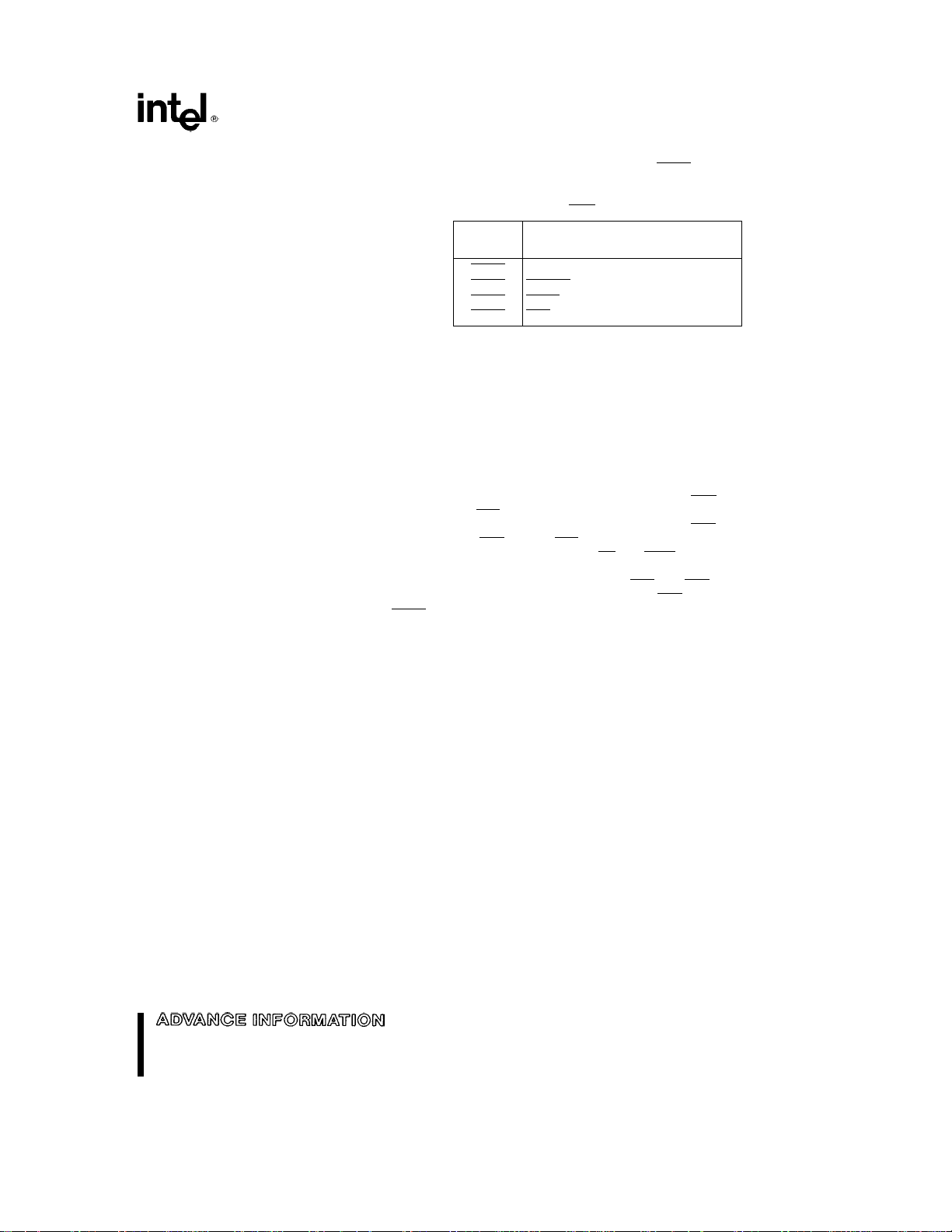

Table 2. MCS

Compatible

Mode

MCS0 PEREQ Processor Extension Request

MCS1

MCS2

MCS3

ERROR NPX Error

MCS2 Mid-Range Chip Select

NPS Numeric Processor Select

Assignments

Enhanced Mode

will func-

ONCE Test Mode

To facilitate testing and inspection of devices when

fixed into a target system, the M80C186XL has a

test mode available which allows all pins to be

placed in a high-impedance state. ONCE stands for

‘‘ON Circuit Emulation’’. When placed in this mode,

the M80C186XL will put all pins in the high-impedance state until RESET.

The ONCE mode is selected by tying the UCS

the LCS

pled on the low-to-high transition of the RES

The UCS

up resistors similar to the RD

to guarantee ONCE Mode is not entered inadvertently during normal operation. LCS

be held low at least one clock after RES

to guarantee entrance into ONCE Mode.

LOW during RESET. These pins are sam-

and the LCS pins have weak internal pull-

and TEST/BUSY pins

and UCS must

and

pin.

goes high

13

Page 14

M80C186XL

ABSOLUTE MAXIMUM RATINGS*

Case Temperature under Bias ÀÀÀb55§Ctoa125§C

Storage Temperature ААААААААААb65§Ctoa150§C

Voltage on Any Pin with

Respect to Ground АААААААААААА

/Package Power Dissipation АААААААААААААААААА1W

Not to exceed the maximum allowable die temperature based on thermal resistance of the package.

b

1.0V toa7.0V

NOTICE: This data sheet contains information on

products in the sampling and initial production phases

of development. It is valid for the devices indicated in

the revision history. The specifications are subject to

change without notice.

*

WARNING: Stressing the device beyond the ‘‘Absolute

Maximum Ratings’’ may cause permanent damage.

These are stress ratings only. Operation beyond the

‘‘Operating Conditions’’ is not recommended and extended exposure beyond the ‘‘Operating Conditions’’

may affect device reliability.

NOTICE: The specifications are subject to change

without notice.

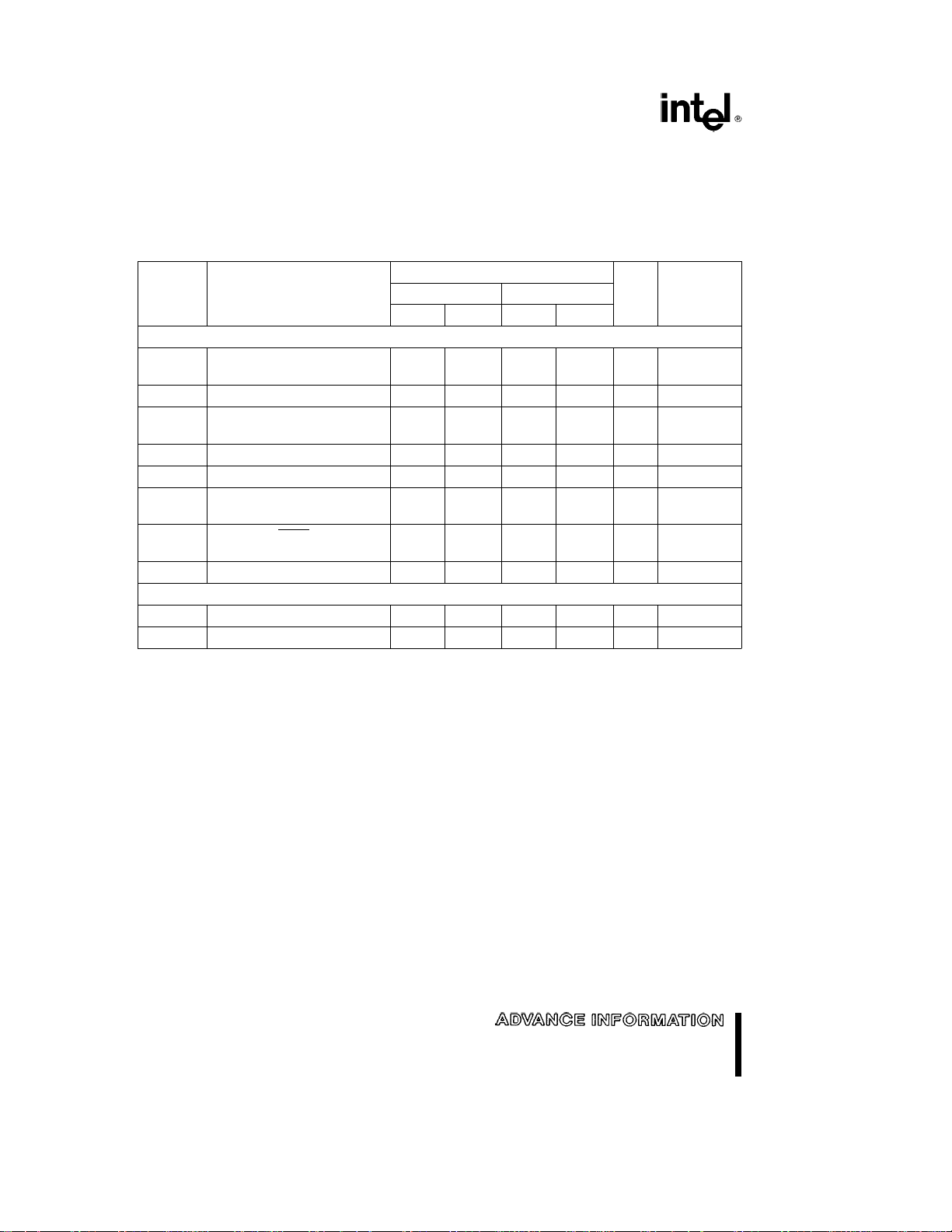

DC CHARACTERISTICS T

eb

55§Ctoa125§C, V

C

CC

e

5Vg10%

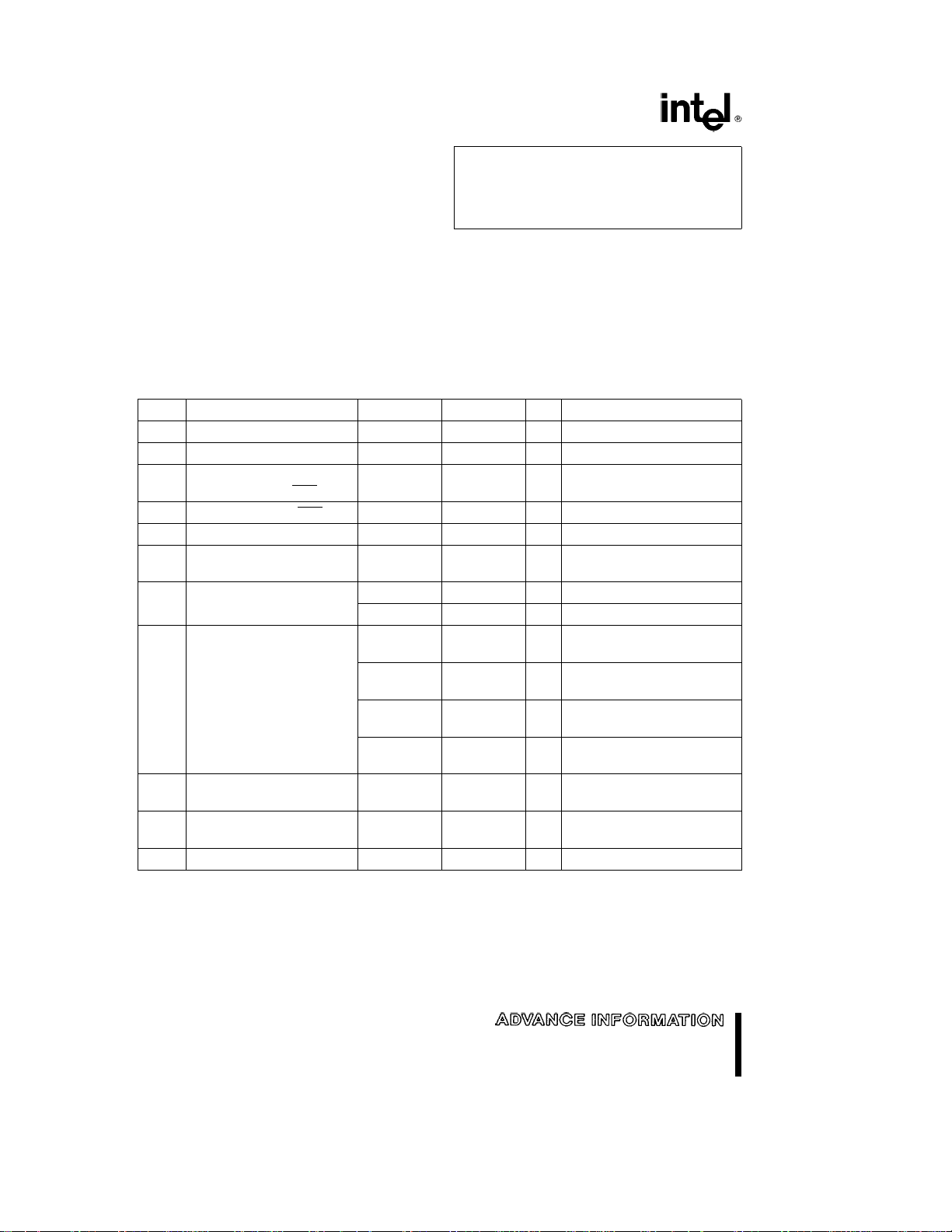

Symbol Parameter Min Max Units Test Conditions

V

V

V

V

V

V

V

I

Input Low Voltage (Except X1)

IL

Clock Input Low Voltage (X1)

IL1

Input High Voltage 0.2 V

IH

(All except X1 and RES

Input High Voltage (RES) 3.0 V

IH1

Clock Input High Voltage (X1) 3.9 V

IH2

Output Low Voltage 0.45 V I

OL

Output High Voltage 2.4 V

OH

Power Supply Current 100 mA@20 MHz,b55§C

CC

)

b

0.5 0.2 V

b

0.5 0.6 V

a

0.9 V

CC

b

V

0.5 V

CC

CC

CC

CC

CC

a

a

a

CC

CC

b

0.3 V

0.5 V

0.5 V

0.5 V

OL

I

OL

VI

OH

VI

OH

V

CC

e

2.5 mA (S0, 1, 2)

e

2.0 mA (others)

eb

2.4 mA@2.4V

eb

200 mA@V

(3)

e

5.5V

CC

90 mA@16 MHz,b55§C

(3)

e

V

5.5V

CC

80 mA@12.5 MHz,b55§C

(3)

e

5.5V

V

CC

70 mA@10 MHz,b55§C

(3)

e

V

5.5V

CC

I

I

V

Input Leakage Current

LI

Output Leakage Current

LO

Clock Output Low 0.45 V I

CLO

g

10 mA@0.5 MHz,

0.45V

g

10 mA@0.5 MHz,

0.45VsV

CLO

s

e

V

IN

OUT

4.0 mA

s

V

CC

s

V

CC

(1)

(4)

b

0.5

(4)

14

Page 15

M80C186XL

DC CHARACTERISTICS (Continued) T

eb

55§Ctoa125§C, V

C

CC

e

5Vg10%

Symbol Parameter Min Max Units Test Conditions

V

CHO

C

IN

C

IO

NOTES:

1. Pins being floated during HOLD or by invoking the ONCE Mode.

2. Characterization conditions are a) Frequency

parameter is not tested.

3. Current is measured with the device in RESET with X1 and X2 driven and all other non-power pins open.

/QSMD, UCS, LCS, MCS0/PEREQ, MCS1/ERROR and TEST/BUSY pins have internal pullup devices. Loading some

4. RD

of these pins above I

on Local Bus Controller and Reset for details.

Clock Output High V

Input Capacitance 10 pF

Output or I/O Capacitance 20 pF

e

eb

200 mA can cause the M80C186XL to go into alternative modes of operation. See the section

OH

b

0.5 V I

CC

1 MHz; b) Unmeasured pins at GND; c) VINata5.0V or 0.45V. This

CHO

@

@

eb

1 MHz

1 MHz

(2)

(2)

500 mA

15

Page 16

M80C186XL

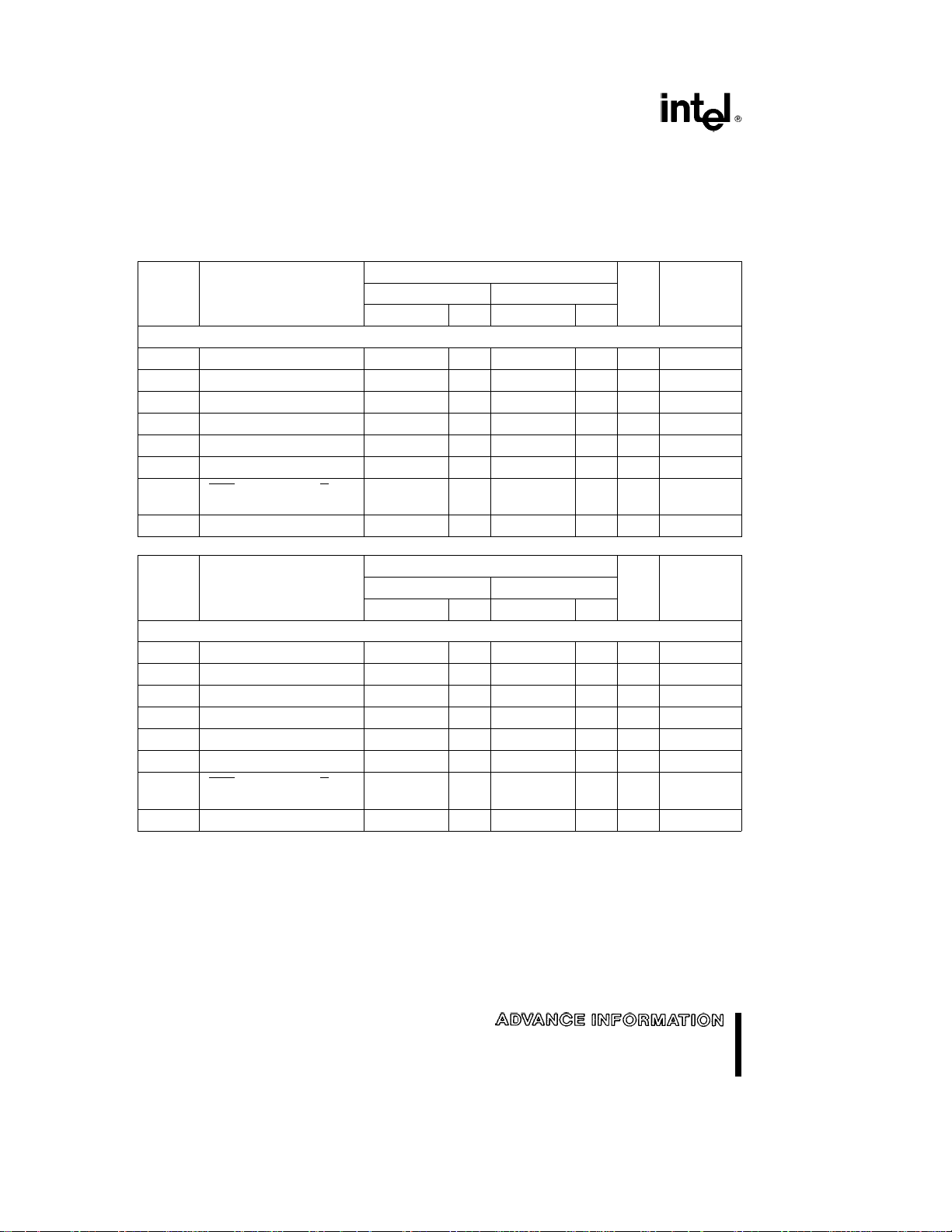

AC CHARACTERISTICS

MAJOR CYCLE TIMINGS (READ CYCLE)

eb

T

All timings are measured at 1.5V and 100 pF loading on CLKOUT unless otherwise noted.

55§Ctoa125§C, V

C

All output test conditions are with C

For AC tests, input V

IL

Symbol Parameter M80C186XL M80C186XL12 Unit

M80C186XL GENERAL TIMING REQUIREMENTS (Listed More Than Once)

T

DVCL

T

CLDX

Data in Setup (A/D) 15 15 ns

Data in Hold (A/D) 3 3 ns

M80C186XL GENERAL TIMING RESPONSES (Listed More Than Once)

T

CHSV

T

CLSH

T

CLAV

T

CLAX

T

CLDV

T

CHDX

T

CHLH

T

LHLL

T

CHLL

T

AVLL

T

LLAX

T

AVCH

T

CLAZ

T

CLCSV

T

CXCSX

T

CHCSX

T

DXDL

T

CVCTV

T

CVDEX

T

CHCTV

T

CLLV

Status Active Delay 3 45 3 35 ns

Status Inactive Delay 3 46 3 35 ns

Address Valid Delay 3 44 3 36 ns

Address Hold 0 0 ns

Data Valid Delay 3 40 3 36 ns

Status Hold Time 10 10 ns

ALE Active Delay 30 25 ns

ALE Width T

ALE Inactive Delay 30 25 ns

Address Valid to ALE Low T

Address Hold from ALE T

Inactive Loading

Address Valid to Clock High 0 0 ns

Address Float Delay T

Chip-Select Active Delay 3 42 3 33 ns

Chip-Select Hold from T

Command Inactive Loading

Chip-Select Inactive Delay 3 35 3 30 ns

DEN Inactive to DT/R Low 0 0 ns Equal

Control Active Delay 1 3 44 3 37 ns

DEN Inactive Delay 3 44 3 37 ns

Control Active Delay 2 3 44 3 37 ns

LOCK Valid/Invalid Delay 3 40 3 37 ns

M80C186XL TIMING RESPONSES (Read Cycle)

T

AZRL

T

CLRL

T

RLRH

T

CLRH

T

RHLH

T

RHAV

Address Float to RD Active 0 0 ns

RD Active Delay 3 44 3 37 ns

RD Pulse Width 2T

RD Inactive Delay 3 44 3 37 ns

RD Inactive to ALE High T

RD Inactive to Address T

Active Loading

CC

e

0.45V and V

e

5Vg10%

L

e

50 pF.

e

2.4V except at X1 where V

IH

Min Max Min Max

b

15 T

CLCL

b

CLAX

CLCL

b

b

b

b

b

18 T

15 T

10 T

30 2T

14 T

15 T

CLCH

CHCL

CLCH

CLCH

CLCL

Values

CLCL

CLCH

CHCL

30 T

CLCH

CLCL

CLCH

CLCL

e

b

V

CC

0.5V.

25 ns

IH

b

15 ns

b

15 ns Equal

b

15 ns Equal

CLAX

b

10 ns Equal

b

25 ns

b

14 ns Equal

b

15 ns Equal

Test

Conditions

Loading

Loading

Loading

16

Page 17

AC CHARACTERISTICS

MAJOR CYCLE TIMINGS (READ CYCLE)

eb

T

All timings are measured at 1.5V and 100 pF loading on CLKOUT unless otherwise noted.

55§Ctoa125§C, V

C

All output test conditions are with C

For AC tests, input V

IL

Symbol Parameter M80C186XL16 M80C186XL20 Unit

M80C186XL GENERAL TIMING REQUIREMENTS (Listed More Than Once)

T

DVCL

T

CLDX

Data in Setup (A/D) 15 10 ns

Data in Hold (A/D) 3 3 ns

M80C186XL GENERAL TIMING RESPONSES (Listed More Than Once)

T

CHSV

T

CLSH

T

CLAV

T

CLAX

T

CLDV

T

CHDX

T

CHLH

T

LHLL

T

CHLL

T

AVLL

T

LLAX

T

AVCH

T

CLAZ

T

CLCSV

T

CXCSX

T

CHCSX

T

DXDL

T

CVCTV

T

CVDEX

T

CHCTV

T

CLLV

Status Active Delay 1 31 1 25 ns

Status Inactive Delay 1 30 1 25 ns

Address Valid Delay 1 33 1 27 ns

Address Hold 0 0 ns

Data Valid Delay 1 33 1 27 ns

Status Hold Time 10 10 ns

ALE Active Delay 20 20 ns

ALE Width T

ALE Inactive Delay 20 20 ns

Address Valid to ALE Low T

Address Hold from ALE T

Inactive Loading

Address Valid to Clock High 0 0 ns

Address Float Delay T

Chip-Select Active Delay 1 30 1 25 ns

Chip-Select Hold from t

Command Inactive Loading

Chip-Select Inactive Delay 1 25 1 20 ns

DEN Inactive to DT/R Low 0 0 ns Equal

Control Active Delay 1 1 31 1 22 ns

DEN Inactive Delay 1 31 1 22 ns

Control Active Delay 2 1 31 1 22 ns

LOCK Valid/Invalid Delay 1 35 1 22 ns

M80C186XL TIMING RESPONSES (Read Cycle)

T

AZRL

T

CLRL

T

RLRH

T

CLRH

T

RHLH

T

RHAV

Address Float to RD Active 0 0 ns

RD Active Delay 1 31 1 27 ns

RD Pulse Width 2T

RD Inactive Delay 1 31 1 27 ns

RD Inactive to ALE High T

RD Inactive to Address T

Active Loading

CC

e

0.45V and V

e

5Vg10%

L

e

50 pF.

e

2.4V except at X1 where V

IH

Min Max Min Max

b

15 T

CLCL

b

CLAX

CLCL

b

b

b

b

b

15 T

15 T

10 T

25 2T

14 T

15 T

CLCH

CHCL

CLCH

CLCH

CLCL

Values

CLCL

CLCH

CHCL

20 T

CLCH

CLCL

CLCH

CLCL

e

b

V

CC

0.5V.

20 ns

IH

b

15 ns

b

10 ns Equal

b

10 ns Equal

CLAX

b

10 ns Equal

b

20 ns

b

14 ns Equal

b

15 ns Equal

M80C186XL

Test

Conditions

Loading

Loading

Loading

17

Page 18

M80C186XL

AC CHARACTERISTICS

MAJOR CYCLE TIMINGS (WRITE CYCLE)

eb

T

All timings are measured at 1.5V and 100 pF loading on CLKOUT unless otherwise noted.

55§Ctoa125§C, V

C

All output test conditions are with C

For AC tests, input V

IL

Symbol Parameter M80C186XL M80C186XL12 Unit

M80C186XL GENERAL TIMING RESPONSES (Listed More Than Once)

T

CHSV

T

CLSH

T

CLAV

T

CLAX

T

CLDV

T

CHDX

T

CHLH

T

LHLL

T

CHLL

T

AVLL

T

LLAX

Status Active Delay 3 45 3 35 ns

Status Inactive Delay 3 46 3 35 ns

Address Valid Delay 3 44 3 36 ns

Address Hold 0 0 ns

Data Valid Delay 3 40 3 36 ns

Status Hold Time 10 10 ns

ALE Active Delay 30 25 ns

ALE Width T

ALE Inactive Delay 30 25 ns

Address Valid to ALE Low T

Address Hold from ALE T

Inactive Loading

T

AVCH

T

CLDOX

T

CVCTV

T

CVCTX

T

CLCSV

T

CXCSX

Address Valid to Clock High 0 0 ns

Data Hold Time 3 3 ns

Control Active Delay 1 3 44 3 37 ns

Control Inactive Delay 3 44 3 37 ns

Chip-Select Active Delay 3 42 3 33 ns

Chip-Select Hold from T

Command Inactive Loading

T

CHCSX

T

DXDL

T

CLLV

Chip-Select Inactive Delay 3 35 3 30 ns

DEN Inactive to DT/R Low 0 0 ns Equal

LOCK Valid/Invalid Delay 3 40 3 37 ns

M80C186XL TIMING RESPONSES (Write Cycle)

T

WLWH

T

WHLH

T

WHDX

T

WHDEX

WR Pulse Width 2T

WR Inactive to ALE High T

Data Hold after WR T

WR Inactive to DEN Inactive T

CC

e

0.45V and V

e

5Vg10%

L

e

50 pF.

e

2.4V except at X1 where V

IH

Min Max Min Max

b

15 T

CLCL

b

CLCL

CLCL

18 T

b

15 T

b

10 T

b

30 2T

b

14 T

b

34 T

b

10 T

CLCH

CHCL

CLCH

CLCH

CLCH

Values

e

b

V

CC

0.5V.

IH

b

15 ns

CLCL

b

15 ns Equal

CLCH

b

15 ns Equal

CHCL

b

10 ns Equal

CLCH

b

25 ns

CLCL

b

14 ns Equal

CLCH

b

20 ns Equal

CLCL

b

10 ns Equal

CLCH

Test

Conditions

Loading

Loading

Loading

Loading

Loading

18

Page 19

AC CHARACTERISTICS

MAJOR CYCLE TIMINGS (WRITE CYCLE)

eb

T

All timings are measured at 1.5V and 100 pF loading on CLKOUT unless otherwise noted.

55§Ctoa125§C, V

C

All output test conditions are with C

For AC tests, input V

IL

Symbol Parameter M80C186XL16 M80C186XL20 Unit

M80C186XL GENERAL TIMING RESPONSES (Listed More Than Once)

T

CHSV

T

CLSH

T

CLAV

T

CLAX

T

CLDV

T

CHDX

T

CHLH

T

LHLL

T

CHLL

T

AVLL

T

LLAX

T

AVCH

T

CLDOX

T

CVCTV

T

CVCTX

T

CLCSV

T

CXCSX

T

CHCSX

T

DXDL

T

CLLV

Status Active Delay 1 31 1 25 ns

Status Inactive Delay 1 30 1 25 ns

Address Valid Delay 1 33 1 27 ns

Address Hold 0 0 ns

Data Valid Delay 1 33 1 27 ns

Status Hold Time 10 10 ns

ALE Active Delay 20 20 ns

ALE Width T

ALE Inactive Delay 20 20 ns

Address Valid to ALE Low T

Address Hold from ALE T

Inactive Loading

Address Valid to Clock High 0 0 ns

Data Hold Time 1 1 ns

Control Active Delay 1 1 31 1 25 ns

Control Inactive Delay 1 31 1 25 ns

Chip-Select Active Delay 1 30 1 25 ns

Chip-Select Hold from T

Command Inactive Loading

Chip-Select Inactive Delay 1 25 1 20 ns

DEN Inactive to DT/R Low 0 0 ns Equal

LOCK Valid/Invalid Delay 1 35 1 22 ns

M80C186XL TIMING RESPONSES (Write Cycle)

T

WLWH

T

WHLH

T

WHDX

T

WHDEX

WR Pulse Width 2T

WR Inactive to ALE High T

Data Hold after WR T

WR Inactive to DEN Inactive T

CC

e

0.45V and V

e

5Vg10%

L

e

50 pF.

e

2.4V except at X1 where V

IH

Min Max Min Max

b

15 T

CLCL

b

CLCL

CLCL

15 T

b

15 T

b

10 T

b

25 2T

b

14 T

b

20 T

b

10 T

CLCH

CHCL

CLCH

CLCH

CLCH

Values

e

b

V

CC

0.5V.

IH

b

15 ns

CLCL

b

10 ns Equal

CLCH

b

10 ns Equal

CHCL

b

10 ns Equal

CLCH

b

20 ns

CLCL

b

14 ns Equal

CLCH

b

15 ns Equal

CLCL

b

10 ns Equal

CLCH

M80C186XL

Test

Conditions

Loading

Loading

Loading

Loading

Loading

19

Page 20

M80C186XL

AC CHARACTERISTICS

MAJOR CYCLE TIMINGS (INTERRUPT ACKNOWLEDGE CYCLE)

eb

T

All timings are measured at 1.5V and 100 pF loading on CLKOUT unless otherwise noted.

55§Ctoa125§C, V

C

All output test conditions are with C

For AC tests, input V

IL

Symbol Parameter M80C186XL M80C186XL12 Unit

M80C186XL GENERAL TIMING REQUIREMENTS (Listed More Than Once)

T

T

DVCL

CLDX

Data in Setup (A/D) 15 15 ns

Data in Hold (A/D) 3 3 ns

M80C186XL GENERAL TIMING RESPONSES (Listed More Than Once)

T

T

T

T

T

T

T

T

T

T

T

T

CHSV

CLSH

CLAV

AVCH

CLAX

CLDV

CHDX

CHLH

LHLL

CHLL

AVLL

LLAX

Status Active Delay 3 45 3 35 ns

Status Inactive Delay 3 46 3 35 ns

Address Valid Delay 3 44 3 36 ns

Address Valid to Clock High 0 0 ns

Address Hold 0 0 ns

Data Valid Delay 3 40 3 36 ns

Status Hold Time 10 10 ns

ALE Active Delay 30 25 ns

ALE Width T

ALE Inactive Delay 30 25 ns

Address Valid to ALE Low T

Address Hold to ALE T

Inactive Loading

T

CLAZ

T

CVCTV

T

CVCTX

T

DXDL

T

CHCTV

T

CVDEX

Address Float Delay T

Control Active Delay 1 3 44 3 37 ns

Control Inactive Delay 3 44 3 37 ns

DEN Inactive to DT/R Low 0 0 ns Equal

Control Active Delay 2 3 44 3 37 ns

DEN Inactive Delay 3 44 3 37 ns

(Non-Write Cycles)

T

CLLV

LOCK Valid/Invalid Delay 3 40 3 37 ns

CC

e

0.45V and V

e

5Vg10%

L

e

50 pF.

e

2.4V except at X1 where V

IH

Min Max Min Max

b

15 T

CLCL

b

CLCH

CHCL

18 T

b

15 T

CLAX

Values

CLCL

CLCH

CHCL

30 T

e

b

V

CC

25 ns

0.5V.

IH

b

15 ns

b

15 ns Equal

b

15 ns Equal

CLAX

Test

Conditions

Loading

Loading

20

Page 21

AC CHARACTERISTICS

MAJOR CYCLE TIMINGS (INTERRUPT ACKNOWLEDGE CYCLE)

eb

T

All timings are measured at 1.5V and 100 pF loading on CLKOUT unless otherwise noted.

55§Ctoa125§C, V

C

All output test conditions are with C

For AC tests, input V

IL

Symbol Parameter M80C186XL16 M80C186XL20 Unit

M80C186XL GENERAL TIMING REQUIREMENTS (Listed More Than Once)

T

T

DVCL

CLDX

Data in Setup (A/D) 15 10 ns

Data in Hold (A/D) 1 1 ns

M80C186XL GENERAL TIMING RESPONSES (Listed More Than Once)

T

T

T

T

T

T

T

T

T

T

T

T

CHSV

CLSH

CLAV

AVCH

CLAX

CLDV

CHDX

CHLH

LHLL

CHLL

AVLL

LLAX

Status Active Delay 1 31 1 25 ns

Status Inactive Delay 1 30 1 25 ns

Address Valid Delay 1 33 1 27 ns

Address Valid to Clock High 0 0 ns

Address Hold 0 0 ns

Data Valid Delay 1 33 1 27 ns

Status Hold Time 10 10 ns

ALE Active Delay 20 20 ns

ALE Width T

ALE Inactive Delay 20 20 ns

Address Valid to ALE Low T

Address Hold to ALE T

Inactive Loading

T

CLAZ

T

CVCTV

T

CVCTX

T

DXDL

T

CHCTV

T

CVDEX

Address Float Delay T

Control Active Delay 1 1 31 1 25 ns

Control Inactive Delay 1 31 1 25 ns

DEN Inactive to DT/R Low 0 0 ns Equal

Control Active Delay 2 1 31 1 22 ns

DEN Inactive Delay 1 31 1 22 ns

(Non-Write Cycles)

T

CLLV

LOCK Valid/Invalid Delay 1 35 1 22 ns

CC

e

0.45V and V

e

5Vg10%

L

e

50 pF.

e

2.4V except at X1 where V

IH

Min Max Min Max

b

15 T

CLCL

b

CLCH

CHCL

15 T

b

15 T

CLAX

Values

CLCL

CLCH

CHCL

20 T

e

b

V

CC

20 ns

0.5V.

IH

b

15 ns

b

10 ns Equal

b

10 ns Equal

CLAX

M80C186XL

Test

Conditions

Loading

Loading

21

Page 22

M80C186XL

AC CHARACTERISTICS

SOFTWARE HALT CYCLE TIMINGS

eb

T

All timings are measured at 1.5V and 100 pF loading on CLKOUT unless otherwise noted.

55§Ctoa125§C, V

C

All output test conditions are with C

For AC tests, input V

IL

Symbol Parameter M80C186XL M80C186XL12 Unit

M80C186XL GENERAL TIMING REQUIREMENTS (Listed More Than Once)

T

CHSV

T

CLSH

T

CLAV

T

CHLH

T

LHLL

T

CHLL

T

DXDL

T

CHCTV

Status Active Delay 3 45 3 35 ns

Status Inactive Delay 3 46 3 35 ns

Address Valid Delay 3 44 3 36 ns

ALE Active Delay 30 25 ns

ALE Width T

ALE Inactive Delay 30 25 ns

DEN Inactive to DT/R Low 0 0 ns Equal

Control Active Delay 2 3 44 3 37 ns

CC

e

0.45V and V

e

5Vg10%

L

e

50 pF.

e

2.4V except at X1 where V

IH

Min Max Min Max

b

15 T

CLCL

Values

CLCL

IH

b

e

b

V

0.5V.

CC

15 ns

Test

Conditions

Loading

Values

Symbol ParameterTarget M80C186XL16 M80C186XL20 Unit

Min Max Min Max

M80C186XL GENERAL TIMING RESPONSES (Listed More Than Once)

T

CHSV

T

CLSH

T

CLAV

T

CHLH

T

LHLL

T

CHLL

T

DXDL

T

CHCTV

Status Active Delay 3 31 3 25 ns

Status Inactive Delay 3 30 3 25 ns

Address Valid Delay 3 33 3 27 ns

ALE Active Delay 20 20 ns

ALE Width T

CLCL

b

15 T

CLCL

b

15 ns

ALE Inactive Delay 20 20 ns

DEN Inactive to DT/R Low 0 0 ns Equal

Control Active Delay 2 3 31 3 22 ns

Test

Conditions

Loading

22

Page 23

AC CHARACTERISTICS

CLOCK TIMINGS

eb

T

All timings are measured at 1.5V and 100 pF loading on CLKOUT unless otherwise noted.

55§Ctoa125§C, V

C

All output test conditions are with C

For AC tests, input V

IL

Symbol Parameter M80C186XL M80C186XL12 Unit

M80C186XL CLKIN REQUIREMENTS

T

T

T

T

T

CKIN

CLCK

CHCK

CKHL

CKLH

CLKIN Period 50

CLKIN Low Time 20

CLKIN High Time 20

CLKIN Fall Time 5 5 ns 3.5 to 1.0V

CLKIN Rise Time 5 5 ns 1.0 to 3.5V

M80C186XL CLKOUT TIMING

T

CICO

T

CLCL

T

CLCH

T

CHCL

T

CH1CH2

T

CL2CL1

NOTES:

1. External clock applied to X1 and X2 not connected.

2. T

CLCK

3. Tested under worst case conditions: V

4. Tested under worst case conditions: V

CLKIN to CLKOUT Skew 25 21 ns

CLKOUT Period 100

CLKOUT Low Time 0.5 T

CLKOUT High Time 0.5 T

CLKOUT Rise Time 10 10 ns 1.0 to 3.5V

CLKOUT Fall Time 10 10 ns 3.5 to 1.0V

and T

(CLKIN Low and High times) should not have a duration less than 40% of T

CHCK

CC

e

0.45V and V

e

5Vg10%

L

CC

CC

e

50 pF.

e

2.4V except at X1 where V

IH

Values

Min Max Min Max

(1)

%

%

%

%

b

6 0.5 T

e

e

CLCL

CLCL

5.5V T

4.5V T

b

6 0.5 T

ea

125§C.

C

eb

55§C.

C

CLCL

CLCL

e

b

V

CC

%

%

%

%

0.5V.

ns

ns 1.5V

ns 1.5V

ns

CKIN

IH

40

16

16

80

b

5nsC

b

5nsC

M80C186XL

Conditions

e

L

e

L

.

Test

(2)

(2)

100 pF

100 pF

(3)

(4)

23

Page 24

M80C186XL

AC CHARACTERISTICS

CLOCK TIMINGS

eb

T

All timings are measured at 1.5V and 100 pF loading on CLKOUT unless otherwise noted.

55§Ctoa125§C, V

C

All output test conditions are with C

For AC tests, input V

IL

Symbol Parameter M80C186XL16 M80C186XL20 Unit

M80C186XL CLKIN REQUIREMENTS

T

T

T

T

T

CKIN

CLCK

CHCK

CKHL

CKLH

CLKIN Period 31.25

CLKIN Low Time 13

CLKIN High Time 13

CLKIN Fall Time 5 5 ns 3.5 to 1.0V

CLKIN Rise Time 5 5 ns 1.0 to 3.5V

M80C186XL CLKOUT TIMING

T

CICO

T

CLCL

T

CLCH

T

CHCL

T

CH1CH2

T

CL2CL1

NOTES:

1. External clock applied to X1 and X2 not connected.

2. T

CLCK

3. Tested under worst case conditions: V

4. Tested under worst case conditions: V

CLKIN to CLKOUT Skew 17 17 ns

CLKOUT Period 62.5 50 ns

CLKOUT Low Time 0.5 T

CLKOUT High Time 0.5 T

CLKOUT Rise Time 10 8 ns 1.0 to 3.5V

CLKOUT Fall Time 10 8 ns 3.5 to 1.0V

and T

(CLKIN Low and High times) should not have a duration less than 40% of T

CHCK

CC

e

0.45V and V

e

5Vg10%

L

CC

CC

e

50 pF.

e

2.4V except at X1 where V

IH

Values

Min Max Min Max

(1)

%

%

%

b

5 0.5 T

e

e

CLCL

CLCL

5.5V. T

4.5V. T

b

5 0.5 T

ea

125§C.

C

eb

55§C.

C

CLCL

CLCL

e

b

V

CC

%

%

%

0.5V.

ns

ns 1.5V

ns 1.5V

CKIN

IH

25

10

10

b

5nsC

b

5nsC

Conditions

L

L

.

Test

(2)

(2)

e

100 pF

e

100 pF

(3)

(4)

24

Page 25

AC CHARACTERISTICS

READY, PERIPHERAL AND QUEUE STATUS TIMINGS

eb

T

All timings are measured at 1.5V and 100 pF loading on CLKOUT unless otherwise noted.

55§Ctoa125§C, V

C

All output test conditions are with C

For AC tests, input V

IL

Symbol Parameter M80C186XL M80C186XL12 Unit

M80C186XL READY AND PERIPHERAL TIMING REQUIREMENTS (Listed More Than Once)

T

SRYCL

Synchronous Ready (SRDY) 15 15 ns

Transition Setup Time

T

CLSRY

T

ARYCH

SRDY Transition Hold Time

ARDY Resolution Transition 15 15 ns

Setup Time

T

CLARX

T

ARYCHL

T

ARYLCL

ARDY Active Hold Time

ARDY Inactive Holding Time 15 15 ns

Asynchronous Ready 25 25 ns

(ARDY) Setup Time

T

INVCH

INTx, NMI, TEST/BUSY, 15 15 ns

TMR IN Setup Time

T

INVCL

DRQ0, DRQ1 Setup Time

M80C186XL PERIPHERAL AND QUEUE STATUS TIMING RESPONSES

T

CLTMV

T

CHQSV

NOTES:

1. To guarantee proper operation.

2. To guarantee recognition at clock edge.

Timer Output Delay 40 33 ns

Queue Status Delay 37 32 ns

CC

e

0.45V and V

(2)

e

5Vg10%

L

(1)

(1)

(2)

e

50 pF.

e

2.4V except at X1 where V

IH

Min Max Min Max

(1)

15 15 ns

(1)

(2)

15 15 ns

15 15 ns

Values

e

b

V

CC

0.5V.

IH

M80C186XL

Test

Conditions

25

Page 26

M80C186XL

AC CHARACTERISTICS

READY, PERIPHERAL, AND QUEUE STATUS TIMINGS

eb

T

All timings are measured at 1.5V and 100 pF loading on CLKOUT unless otherwise noted.

55§Ctoa125§C, V

C

All output test conditions are with C

For AC tests, input V

IL

Symbol Parameter M80C186XL16 M80C186XL20 Unit

M80C186XL READY AND PERIPHERAL TIMING REQUIREMENTS

T

SRYCL

Synchronous Ready (SRDY) 15 10 ns

Transition Setup Time

T

CLSRY

T

ARYCH

SRDY Transition Hold Time

ARDY Resolution Transition 15 10 ns

Setup Time

T

CLARX

T

ARYCHL

T

ARYLCL

ARDY Active Hold Time

ARDY Inactive Holding Time 15 10 ns

Asynchronous Ready 25 15 ns

(ARDY) Setup Time

T

INVCH

INTx, NMI, TEST/BUSY, 15 10 ns

TMR IN Setup Time

T

INVCL

DRQ0, DRQ1 Setup Time

M80C186XL PERIPHERAL AND QUEUE STATUS TIMING RESPONSES

T

CLTMV

T

CHQSV

NOTES:

1. To guarantee proper operation.

2. To guarantee recognition at clock edge.

Timer Output Delay 27 22 ns

Queue Status Delay 30 27 ns

CC

e

0.45V and V

(2)

e

5Vg10%

L

(1)

(1)

(2)

e

50 pF.

e

2.4V except at X1 where V

IH

Min Max Min Max

(1)

15 10 ns

(1)

(2)

15 10 ns

15 10 ns

Values

e

b

V

CC

0.5V.

IH

Test

Conditions

26

Page 27

AC CHARACTERISTICS

RESET AND HOLD/HLDA TIMINGS

eb

T

All timings are measured at 1.5V and 100 pF loading on CLKOUT unless otherwise noted.

55§Ctoa125§C, V

C

All output test conditions are with C

For AC tests, input V

IL

Symbol Parameter M80C186XL M80C186XL12 Unit

M80C186XL RESET AND HOLD/HLDA TIMING REQUIREMENTS

T

RESIN

T

HVCL

RES Setup 15 15 ns

HOLD Setup

M80C186XL GENERAL TIMING RESPONSES (Listed More Than Once)

T

T

CLAZ

CLAV

Address Float Delay T

Address Valid Delay 3 44 3 36 ns

M80C186XL RESET AND HOLD/HLDA TIMING RESPONSES

T

CLRO

T

CLHAV

T

CHCZ

T

CHCV

Reset Delay 40 33 ns

HLDA Valid Delay 3 40 3 33 ns

Command Lines Float Delay 40 33 ns

Command Lines Valid Delay

(after Float)

CC

e

0.45V and V

(1)

e

5Vg10%

L

e

50 pF.

e

2.4V except at X1 where V

IH

Values

Min Max Min Max

15 15 ns

CLAX

30 T

44 36 ns

CLAX

IH

e

V

b

0.5V.

CC

25 ns

M80C186XL

Test

Conditions

NOTE:

1. To guarantee recognition at next clock.

27

Page 28

M80C186XL

AC CHARACTERISTICS

RESET AND HOLD/HLDA TIMINGS

eb

T

All timings are measured at 1.5V and 100 pF loading on CLKOUT unless otherwise noted.

55§Ctoa125§C, V

C

All output test conditions are with C

For AC tests, input V

IL

Symbol Parameter M80C186XL16 M80C186XL20 Unit

M80C186XL RESET AND HOLD/HLDA TIMING REQUIREMENTS

T

RESIN

T

HVCL

RES Setup 15 15 ns

HOLD Setup

M80C186XL GENERAL TIMING RESPONSES (Listed More Than Once)

T

T

CLAZ

CLAV

Address Float Delay T

Address Valid Delay 1 33 1 22 ns

M80C186XL RESET AND HOLD/HLDA TIMING RESPONSES

T

CLRO

T

CLHAV

T

CHCZ

T

CHCV

Reset Delay 27 22 ns

HLDA Valid Delay 1 25 1 22 ns

Command Lines Float Delay 28 25 ns

Command Lines Valid Delay 32 26 ns

(after Float)

CC

e

0.45V and V

(1)

e

5Vg10%

L

e

50 pF.

e

2.4V except at X1 where V

IH

Values

Min Max Min Max

15 10 ns

CLAX

20 T

CLAX

IH

e

V

b

0.5V.

CC

20 ns

Test

Conditions

NOTE:

1. To guarantee recognition at next clock.

28

Page 29

AC CHARACTERISTICS

M80C186XL

NOTES:

1. Status inactive in state preceding T

2. If latched A

3. For write cycle followed by read cycle.

of next bus cycle.

4. T

1

5. Changes in T-state preceding next bus cycle if followed by write.

and A2are selected instead of PCS5 and PCS6, only T

1

.

4

Figure 5. Read Cycle Waveforms

CLCSV

271276– 7

is applicable.

29

Page 30

M80C186XL

AC CHARACTERISTICS

NOTES:

1. Status inactive in state preceding T

2. If latched A

3. For write cycle followed by read cycle.

4. T1of next bus cycle.

5. Changes in T-state preceding next bus cycle if followed by read, INTA, or halt.

and A2are selected instead of PCS5 and PCS6, only T

1

.

4

CLCSV

Figure 6. Write Cycle Waveforms

30

271276– 8

is applicable.

Page 31

AC CHARACTERISTICS

M80C186XL

NOTES:

1. Status inactive in state preceding T

2. The data hold time lasts only until INTA

occurs one clock later in Slave Mode.

3. INTA

4. For write cycle followed by interrupt acknowledge cycle.

is active upon T1of the first interrupt acknowledge cycle and inactive upon T2of the second interrupt acknowl-

5. LOCK

edge cycle.

6. Changes in T-state preceding next bus cycle if followed by write.

.

4

goes inactive, even if the INTA transition occurs prior to T

Figure 7. Interrupt Acknowledge Cycle Waveforms

CLDX

271276– 9

(min).

31

Page 32

M80C186XL

AC CHARACTERISTICS

NOTE:

1. For write cycle followed by halt cycle.

271276– 10

Figure 8. Software Halt Cycle Waveforms

32

Page 33

WAVEFORMS

M80C186XL

271276– 11

Figure 9. Clock Waveforms

Figure 10. Reset Waveforms

Figure 11. Synchronous Ready (SRDY) Waveforms

271276– 12

271276– 13

33

Page 34

M80C186XL

AC CHARACTERISTICS

Figure 12. Asynchronous Ready (ARDY) Waveforms

271276– 19

34

271276– 14

Figure 13. Peripheral and Queue Status Waveforms

Page 35

AC CHARACTERISTICS

Figure 14. HOLD/HLDA Waveforms (Entering Hold)

M80C186XL

271276– 20

Figure 15. HOLD/HLDA Waveforms (Leaving Hold)

271276– 15

35

Page 36

M80C186XL

EXPLANATION OF THE AC SYMBOLS

Each timing symbol has from 5 to 7 characters. The first character is always a ‘T’ (stands for time). The other

characters, depending on their positions, stand for the name of a signal or the logical status of that signal. The

following is a list of all the characters and what they stand for.

A: Address

ARY: Asynchronous Ready Input

C: Clock Output

CK: Clock Input

CS: Chip Select

CT: Control (DT/R

D: Data Input

DE: DEN

H: Logic Level High

OUT: Input (DRQ0, TIM0, . . . )

L: Logic Level Low or ALE

O: Output

QS: Queue Status (QS1, QS2)

R: RD Signal, RESET Signal

S: Status (S0

SRY: Synchronous Ready Input

V: Valid

W: WR Signal

X: No Longer a Valid Logic Level

Z: Float

Examples:

T

T

T

Ð Time from Clock low to Address valid

CLAV

Ð Time from Clock high to ALE high

CHLH

Ð Time from Clock low to Chip Select valid

CLCSV

, DEN,...)

,S1,S2)

36

Page 37

DERATING CURVES

M80C186XL

Typical Output Delay Capacitive Derating

271276– 16

Figure 16. Capacitive Derating Curve

Typical Rise and Fall Times for TTL Voltage Levels

271276– 17

Figure 17. TTL Level Rise and Fall Times for Output Buffers

Typical Rise and Fall Times for CMOS Voltage Levels

271276– 18

Figure 18. CMOS Level Rise and Fall Times for Output Buffers

37

Page 38

M80C186XL

M80C186XL EXECUTION TIMINGS

A determination of M80C186XL program execution

timing must consider the bus cycles necessary to

prefetch instructions as well as the number of execution unit cycles necessary to execute instructions.

The following instruction timings represent the minimum execution time in clock cycles for each instruction. The timings given are based on the following

assumptions:

The opcode, along with any data or displacement

#

required for execution of a particular instruction,

has been prefetched and resides in the queue at

the time it is needed.

No wait states or bus HOLDs occur.

#

All word-data is located on even-address bound-

#

aries.

All jumps and calls include the time required to fetch

the opcode of the next instruction at the destination

address.

All instructions which involve memory accesses can

require one or two additional clocks above the minimum timings shown due to the asynchronous handshake between the bus interface unit (BIU) and execution unit.

With a 16-bit BIU, the M80C186XL has sufficient bus

performance to ensure that an adequate number of

prefetched bytes will reside in the queue most of the

time. Therefore, actual program execution time will

not be substantially greater than that derived from

adding the instruction timings shown.

38

Page 39

M80C186XL

INSTRUCTION SET SUMMARY

Function Format

DATA TRANSFER

e

MOV

Move:

Register to Register/Memory 1000100w modreg r/m 2/12

Register/memory to register 1000101w modreg r/m 2/9

Immediate to register/memory 1100011w mod000 r/m data data if we1 12 –13 8/16-bit

Immediate to register 1011w reg data data if we1 3 –4 8/16-bit

Memory to accumulator 1010000w addr-low addr-high 8

Accumulator to memory 1010001w addr-low addr-high 9

Register/memory to segment register 10001110 mod0reg r/m 2/9

Segment register to register/memory 10001100 mod0reg r/m 2/11

PUSHePush:

Memory 11111111 mod110 r/m 16

Register 01010 reg 10

Segment register 000reg110 9

Immediate 011010s0 data data if se010

PUSHAePush All 01100000 36

POPePop:

Memory 10001111 mod000 r/m 20

Register 01011 reg 10

Segment register 000reg111 (regi01) 8

POPAePopAll 01100001 51

XCHGeExchange:

Register/memory with register 1000011w modreg r/m 4/17

Register with accumulator 10010 reg 3

INeInput from:

Fixed port 1110010w port 10

Variable port 1110110w 8

OUTeOutput to:

Fixed port 1110011w port 9

Variable port 1110111w 7

XLATeTranslate byte to AL 11010111 11

LEAeLoad EA to register 10001101 modreg r/m 6

LDSeLoad pointer to DS 11000101 modreg r/m (modi11) 18

LESeLoad pointer to ES 11000100 modreg r/m (modi11) 18

LAHFeLoad AH with flags 10011111 2

SAHFeStore AH into flags 10011110 3

PUSHFePush flags 10011100 9

POPFePop flags 10011101 8

Shaded areas indicate instructions not available in 8086/8088 microsystems.

Clock

Cycles

Comments

39

Page 40

M80C186XL

INSTRUCTION SET SUMMARY (Continued)

Function Format

DATA TRANSFER (Continued)

SEGMENT

CS 00101110 2

SS 00110110 2

DS 00111110 2

ES 00100110 2

ARITHMETIC

ADD

Reg/memory with register to either 000000dw modreg r/m 3/10

Immediate to register/memory 100000sw mod000 r/m data data if s we01 4/16

Immediate to accumulator 0000010w data data if we1 3/4 8/16-bit

ADCeAdd with carry:

Reg/memory with register to either 000100dw modreg r/m 3/10

Immediate to register/memory 100000sw mod010 r/m data data if s we01 4/16

Immediate to accumulator 0001010w data data if we1 3/4 8/16-bit

INCeIncrement:

Register/memory 1111111w mod000 r/m 3/15

Register 01000 reg 3

SUBeSubtract:

Reg/memory and register to either 001010dw modreg r/m 3/10

Immediate from register/memory 100000sw mod101 r/m data data if s we01 4/16

Immediate from accumulator 0010110w data data if we1 3/4 8/16-bit

SBBeSubtract with borrow:

Reg/memory and register to either 000110dw modreg r/m 3/10

Immediate from register/memory 100000sw mod011 r/m data data if s we01 4/16

Immediate from accumulator 0001110w data data if we1 3/4 8/16-bit

DECeDecrement

Register/memory 1111111w mod001 r/m 3/15

Register 01001 reg 3

CMPeCompare:

Register/memory with register 0011101w modreg r/m 3/10

Register with register/memory 0011100w modreg r/m 3/10

Immediate with register/memory 100000sw mod111 r/m data data if s we01 3/10

Immediate with accumulator 0011110w data data if we1 3/4 8/16-bit

NEGeChange sign register/memory 1111011w mod011 r/m 3/10

AAAeASCII adjust for add 00110111 8

DAAeDecimal adjust for add 00100111 4

AASeASCII adjust for subtract 00111111 7

DASeDecimal adjust for subtract 00101111 4

MULeMultiply (unsigned): 1111011w mod100 r/m

Register-Byte 26–28

Register-Word 35–37

Memory-Byte 32–34

Memory-Word 41–43

e

e

Add:

Segment Override:

Shaded areas indicate instructions not available in 8086/8088 microsystems.

Clock

Cycles

Comments

40

Page 41

M80C186XL

INSTRUCTION SET SUMMARY (Continued)

Function Format

ARITHMETIC (Continued)

IMULeInteger multiply (signed): 1111011w mod101 r/m

Register-Byte 25–28

Register-Word 34–37

Memory-Byte 31–34

Memory-Word 40–43

IMULeInteger Immediate multiply 011010s1 modreg r/m data data if se0 22 – 25/

(signed)

DIVeDivide (unsigned): 1111011w mod110 r/m

Register-Byte 29

Register-Word 38

Memory-Byte 35

Memory-Word 44

IDIVeInteger divide (signed): 1111011w mod111 r/m

Register-Byte 44–52

Register-Word 53–61

Memory-Byte 50–58

Memory-Word 59–67

AAMeASCII adjust for multiply 11010100 00001010 19

AADeASCII adjust for divide 11010101 00001010 15

CBWeConvert byte to word 10011000 2

CWDeConvert word to double word 10011001 4

LOGIC

Shift/Rotate Instructions:

Register/Memory by 1 1101000w modTTTr/m 2/15

Register/Memory by CL 1101001w modTTTr/m 5an/17an

Register/Memory by Count 1100000w modTTTr/m count 5an/17an

TTT Instruction

000 ROL

001 ROR

010 RCL

011 RCR

1 0 0 SHL/SAL

101 SHR

e

And:

AND

Reg/memory and register to either 001000dw modreg r/m 3/10

Immediate to register/memory 1000000w mod100 r/m data data if we1 4/16

Immediate to accumulator 0010010w data data if we1 3/4 8/16-bit