Page 1

Intel® 440GX AGPset

Design Guide

March 1999

Order Number: 290651-001

Page 2

Information in this document is provided in connection with Intel products. No license, express or implied, by estoppel or otherwise, to any intellectual

property rights is granted by this document. Except as provided in Intel's Terms and Conditions of Sale for such products, Intel assumes no liability

whatsoever, and Intel disclaims any express or implied warranty, relating to sale and/or use of Intel products including liability or warranties relating to

fitness for a particular purpose, merchantability, or infringement of any patent, copyright or other intellectual property right. Intel products are not

intended for use in medical, life saving, or life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order .

®

The Intel

440GX AGPset may contain design defects or errors which may cause the products to deviate from published specifications. Current

characterized errata are available on request.

2

I

C is a two-wire communications bus/protocol developed by Philips. SMBus is a subset of the I2C bus/protocol and was developed by Intel.

Implementations of the I

North American Philips Corporation.

2

C bus/protocol or the SMBus bus/protocol may require licenses from various entities, including Philips Electronics N.V. and

Copies of documents which have an ordering number and are referenced in this document, or other Intel literature may be obtained by:

calling 1-800-548-4725 or

by visiting Intel's website at http://www.intel.com.

Copyright © Intel Corporation, 1999

*Third-party brands and names are the property of their respective owners.

Intel® 440GX AGPset Design Guide

Page 3

Contents

1 Introduction................................................................................................................1-1

1.1 About This Design Guide..............................................................................1-1

1.2 References....................................................................................................1-2

1.3 Intel

1.4 Design Recommendations............................................................................1-8

2 Motherboard Layout and Routing Guidel ine s ...... ....... ...... .........................................2-1

2.1 BGA Quadrant Assignment...........................................................................2-1

2.2 Board Description .........................................................................................2-3

2.3 Routing Guidelines........................................................................................2-5

2.4 Placement & Layout....................................................................................2-14

2.5 Post-Layout Simulation.............. ....... ...... ....... ...... ...... ....... ...... ....... ...... .......2-14

®

Pentium® II Processor / Intel® 440GX AGPset Overview ...................1-3

1.3.1 Intel

1.3.2 Intel

1.3.3 PCI-to-ISA/IDE Xcelerator (PIIX4E).................................................1-6

1.4.1 Voltage Definitions...........................................................................1-8

1.4.2 General Design Recommendations.................................................1-9

1.4.3 Transitioning from Intel

2.3.1 GTL+ Description.............................................................................2-6

2.3.2 GTL+ Layout Recommendations.....................................................2-6

2.3.3 Single Processor Design..................................................................2-6

2.3.4 Dual Processor Systems..................................................................2-8

2.3.5 Single Processor Systems—Single-End Termination (SET) ...........2-8

2.3.6 Additional Guidelines .....................................................................2-10

2.3.7 Design Methodology ......................................................................2-11

2.3.8 Performance Requirements...........................................................2-12

2.3.9 Topology Definition ........................................................................2-13

2.3.10 Pre-Layout Simulation (Sens i tivity Analysis). ....... ..........................2-13

2.5.1 Crosstalk and the Multi-Bit Adjustment Factor...............................2-15

®

Pentium® II Processor................... ...... ....... ...... ......................1 - 3

®

440GX AGPset ......................................................................1-4

1.3.2.1 System Bus Interface......................................................1-5

1.3.2.2 DRAM Interface..............................................................1-5

1.3.2.3 Accelerated Graphics Port Interface...............................1-5

1.3.2.4 PCI Interface...................................................................1-6

1.3.2.5 System Clocking.............................................................1-6

1.3.3.1 Instrumentation...............................................................1-7

1.3.3.2 Remote Service Boot......................................................1-7

1.3.3.3 Remote Wake-Up ...........................................................1-8

1.3.3.4 Power Management........................................................1-8

“

440BX AGPset to Intel“ 440GX

AGPset Design ................................................................................1-9

2.3.3.1 Single Processor Network Topology and Conditions......2-6

2.3.3.2 Single Processor Recommended Trace Lengths ...........2-7

2.3.4.1 Dual Processor Network Topology and Conditions........2-8

2.3.4.2 Dual Processor Recommended Trace Lengths..............2-8

2.3.5.1 Set Network Topology and Conditions ...........................2-8

2.3.5.2 SET Trace Length Requirements...................................2-9

2.3.6.1 Minimizing Crosstalk.....................................................2-10

2.3.6.2 Practical Considerations.............. ....... ...... ....... ...... .......2-10

Intel® 440GX AGPset Design Guide

iii

Page 4

2.6 Validation....................................................................................................2-15

2.6.1 Flight Time Measurement ..............................................................2-15

2.6.2 Signal Quality Measurement..........................................................2-16

2.7 Timing Analysis...........................................................................................2-17

2.8 AGP Layout and Routing Guidelines..........................................................2-19

2.8.1 AGP Connector (“Up Option) Layout Guidelines ...........................2-19

2.8.2 On-board AGP Compliant Device (“Down” Option)

Layout Guidelines ...... ...... ....... ...... ............................................. ....2 - 20

2.9 82443GX Memory Subsystem Layout and Routing Guidelines..................2-22

2.9.1 100 MHz 82443GX Memory Array Considerations........................2-22

2.9.1.1 Matching the Reference Planes ...................................2-23

2.9.1.2 Adding Additional Decoupling Capacitor ......................2-23

2.9.1.3 Trace Width vs. Trace Spacing ....................................2-24

2.9.2 Memory Layout & Routing Guidelines ...........................................2-24

2.9.3 4 DIMM Routing Guidelines [NO FET]...........................................2-30

2.9.4 PCI Bus Routing Guidelines ..........................................................2-30

2.9.5 Decoupling Guidelines: Intel

2.9.6 Intel

®

440GX AGPset Clock Layout Recommendations................2-32

®

440GX AGPset Platform...............2-31

2.9.6.1 Clock Routing Spacing.................................................2-32

2.9.6.2 System Bus Clock Layout.............................................2-32

2.9.6.3 PCI Clock Layout..........................................................2-33

2.9.6.4 SDRAM Clock Layout...................................................2-33

2.9.6.5 AGP Clock Layout ........................................................2-34

3 Design Checklist........................................................................................................3-1

3.1 Overview.......................................................................................................3-1

3.2 Pull-up and Pull-down Resistor Values.........................................................3-1

3.3 Intel

®

Pentium® II Processor Checklist.........................................................3-2

3.3.1 Intel

3.3.2 Intel

3.3.3 Intel

®

Pentium® II Processor ...........................................................3-2

®

Pentium® II Processor Clocks................................................3-5

®

Pentium® II Processor Signals...............................................3-5

3.3.4 Uni-Processor (UP) Slot 1 Checklist................................................3-7

3.3.5 Dual-Processor (DP) Slot 1 Checklist..............................................3-7

3.3.6 Slot 1 Decoupling Capacitors ..........................................................3-7

3.3.7 Voltage Regulator Module, VRM 8.2 ...............................................3-7

3.4 Intel

®

440GX AGPset Clocks........................................................................3-8

3.4.1 CK100 - 100 MHz Clock Synthesizer...............................................3-8

3.4.2 CKBF - SDRAM 1 to 18 Clock Buffer...............................................3-9

3.4.3 GCKE and DCLKWR Connection....................................................3-9

3.5 82443GX Host Bridge.................................................................................3-10

3.5.1 82443GX Interface.........................................................................3-10

3.5.2 82443GX GTL+ Bus Interface .......................................................3-12

3.5.3 82443GX PCI Interface..................................................................3-12

3.5.4 82443GX AGP Interface ................................................................3-13

3.6 Intel

®

440GX AGPset Memory Interface ....................................................3-14

3.6.1 SDRAM Connections.....................................................................3-14

3.6.2 DIMM Solution With FET Switches................................................3-15

3.6.3 Registered SDRAM .......................................................................3-15

iv

Intel® 440GX AGPset Design Guide

Page 5

3.7 82371EB (PIIX4E).......................................................................................3-16

3.7.1 PIIX4E Connections...... ....... ...... ....... ...... ...... .................................3-16

3.7.2 IDE Routing Guidelines..................................................................3-20

3.7.2.1 Cabling..........................................................................3-20

3.7.2.2 Motherboard .................................................................3-20

3.7.3 PIIX4E Power And Ground Pins ....................................................3-22

3.8 PCI Bus Signals..........................................................................................3-22

3.9 ISA Signals .................................................................................................3-23

3.10 ISA and X-Bus Signals.. ....... ...... ....... ...... ....... .............................................3-23

3.11 USB Interface..............................................................................................3-24

3.12 IDE Interface...............................................................................................3-24

3.13 Flash Design...............................................................................................3-25

3.13.1 Dual-Footprint Flash Design ..........................................................3-25

3.13.2 Flash Design Considerations.........................................................3-25

3.14 System and Test Signals ............................................................................3-28

3.15 Power Management Signals.......................................................................3-28

3.15.1 Power Button Implementation........................................................3-30

3.16 Miscellaneous .............................................................................................3-31

3.17 82093AA (IOAPIC)......................................................................................3-32

3.18 Manageability Devices................................................................................3-33

3.18.1 Max1617 Temperature Sensor......................................................3-33

3.18.2 LM79 Microprocessor System Hardware Monitor..........................3-33

3.18.3 82558B LOM Checklist ..................................................................3-34

3.18.4 Wake On LAN (WOL) Header........................................................3-35

3.19 Software/BIOS ............................................................................................3-35

3.19.1 USB and Multi-processor BIOS .....................................................3-35

3.19.2 Design Considerations...................................................................3-36

3.20 Thermals / Cooling Solutions......................................................................3-36

3.20.1 Design Considerations...................................................................3-36

3.21 Mechanicals................................................................................................3-36

3.21.1 Design Considerations...................................................................3-37

3.22 Electricals....................................................................................................3-37

3.22.1 Design Considerations...................................................................3-37

3.23 Layout Checklist..........................................................................................3-38

3.23.1 Routing and Board Fabrication......................................................3-38

3.23.2 Design Consideration.....................................................................3-38

3.24 Applications and Add-in Hardware..............................................................3-38

3.24.1 Design Consideration.....................................................................3-38

4 Debug Recommendations ......... ............................................. ....... ...... ....... ...............4- 1

4.1 Slot 1 Test Tools...........................................................................................4-1

4.2 Debug/Simulation Tools....... ...... ............................................. ....... ...... ....... ..4-1

4.2.1 Logic Analyzer Interface (LAI)..........................................................4-1

4.2.2 In-Target Probe (ITP).......................................................................4-1

4.2.3 Bus Functional Model (BFM) ...........................................................4-2

4.2.4 I/O Buffer Models.............................................................................4-2

4.2.5 FLOTHERM* Model.........................................................................4-2

Intel® 440GX AGPset Design Guide

v

Page 6

4.3 Debug Features............................................................................................4-2

4.3.1 Intel

®

Pentium® II Processor LAI Issue ...........................................4-2

4.3.2 Debug Logic Recommendations......................................................4-4

4.3.2.1 Debug Considerations....................................................4-5

4.3.3 Debug Layout ..................................................................................4-5

4.3.3.1 Design Considerations ...................................................4-5

4.3.4 Debug Procedures...........................................................................4-5

5 Third-Party Vendor Information .................................................................................5-1

5.1 Processors....................................................................................................5-1

5.1.1 Voltage Regulator Modules .............................................................5-2

5.1.2 Voltage Regulator Control Silicon....................................................5-2

5.2 Intel

®

440GX AGPset ...................................................................................5-3

5.2.1 Clock Drivers ...................................................................................5-3

5.2.2 Power Management Components ....... ...... ...... ....... ...... ....... ...... ......5-3

5.2.3 FET Switches(4 DIMM/FET Design)................................................5-3

5.3 Other Processor Components ......................................................................5-4

5.3.1 Slot 1 Connector..............................................................................5-4

5.3.2 Mechanical Support .........................................................................5-4

5.3.3 Heat sinks........................................................................................5-4

5.3.4 Heat sink attachment: Rivscrews* and associated tools..................5-4

5.3.5 Thermal interface materials .............................................................5-4

A Intel

®

440GX AGPset Platform Reference Design................................................... A-1

vi

Intel® 440GX AGPset Design Guide

Page 7

Figures

1-1 Intel® Pentium® II Processor / Intel® 440GX AGPset

System Block Diagram..................................................................................1-4

2-1 Major Signal Sections (82443GX Top View).................................................2-1

2-2 Example ATX Placement for a UP Pentium

2-3 Example NLX Placement for a UP Intel

®

Intel

440GX AGPset Design .......................................................................2-2

®

Intel

440GX Design.....................................................................................2-3

®

II processor/

®

Pentium® II processor /

2-4 Four Layer Board Stack-up...........................................................................2-4

2-5 Six Layer Board Stack-up With 4 Signal Planes and 2 Power Planes..........2-4

2-6 Six Layer Board Stack-up With 3 Signal Planes and 3 Power Planes..........2-5

2-7 Recommended Topology for Single Processor Design ................................2-6

2-8 Solution Space for Single Processor Design (Based on Results

of Parametric Sweeps)..................................................................................2-7

2-9 Recommended Topology for Dual Processor Design...................................2-8

2-10 Topology for Single Processor Designs With Single-End

Termination (SET).........................................................................................2-9

2-11 Solution Space for Single Processor Designs With Single-End

Termination (SET).........................................................................................2-9

2-12 GTL+ Design Process.................................................................................2-12

2-13 Pre-layout simulation process.....................................................................2-14

2-14 AGP Connector Layout Guidelines.............................................................2-19

2-15 On-board AGP Compliant Device Layout Guidelines.................................2-21

2-16 FET Switch Example............................................ ...... ....... ...... ....... .............2-22

2-17 Registered SDRAM DIMM Example...........................................................2-23

2-18 Matching the Reference Planes and Adding Decoupling Capacitor..........2-24

2-19 4 DIMMs (Single or Double-Sided) .............................................................2-24

2-20 Motherboard Model—Data (MDxx), 4 DIMMs.............................................2-25

2-21 Motherboard Model—DQMA[0,2:4,6:7], 4 DIMMs......................................2-26

2-22 Motherboard Model—DQM_A[1,5], 4 DIMMs.............................................2-26

2-23 Motherboard Model—DQM_A[1,5], 4 DIMMs.............................................2-26

2-24 Motherboard Model—DQM_B[1,5], 4 DIMMs.............................................2-27

2-25 Motherboard Model—CS_A#/CS_B#, 4 DIMMs.........................................2-27

2-26 Motherboard Model—SRAS_A#, 4 DIMMs.................................................2-27

2-27 Motherboard Model—Data (MDxx) Lines, 4 DIMMs (No FET) ...................2-30

2-28 PCI Bus Layout Example............................................................................2-31

2-29 82443GX Decoupling..................................................................................2-31

2-30 Clock Trace Spacing Guidelines.................................................................2-32

2-31 AGP Clock Layout.......................................................................................2-34

3-1 Pull-up Resistor Example..............................................................................3-2

3-2 GCKE & DCLKWR Connections...................................................................3-9

3-3 Current Solution With Existing FET Switches.............................................3-15

3-4 Series Resistor Placement for Primary IDE Connectors.............................3-21

3-5 Dual Footprint Flash Layouts......................................................................3-25

3-6 nterfacing Intel’s Flash with PIIX4E in Desktop ..........................................3-26

3-7 Interfacing Intel’s Flash with PIIX4E in Desktop .........................................3-28

3-8 PWRGOOD & PWROK Logic.....................................................................3-29

4-1 LAI Probe Input Circuit..................................................................................4-3

Intel® 440GX AGPset Design Guide

vii

Page 8

Tables

2-1 Recommended Trace Lengths for Single Processor Design........................2-7

2-2 Recommended Trace Lengths for Dual Processor Designs2.......................2-8

2-3 SET Trace Length Requirements.............................................. ....... ...... ......2-9

2-4 Recommended 100 MHz System Flight Time Specs .................................2-13

2-5 System Timing Requirements for Validating Setup/Hold Windows ............2-16

2-6 Ringback Guidelines at the Intel

2-7 Intel

®

Pentium® II Processor and Inte®l 440GX AGPset

®

Pentium® II Processor Edge Fingers...2-16

System Timing Equations...........................................................................2-17

2-8 Intel

®

Pentium® II Processor and Intel® 440GX AGPset

System Timing Terms.................................................................................2-17

2-9 Intel

®

Pentium® II Processor and Intel® 440GX AGPset 100 MHz

Timing Specifications..................................................................................2-18

2-10 Recommended 100 MHz System Timing Parameters................................2-18

2-11 Recommended 100 MHz System Flight Time Specs .................................2-18

2-12 Data and Associated Strobe.......................................................................2-19

2-13 Source Synchronous Motherboard Recommendations..............................2-20

2-14 Control Signal Line Length Recommendations ..........................................2-20

2-15 Source Synchronous Motherboard Recommendations..............................2-21

2-16 Control Signal Line Length Recommendations ..........................................2-21

2-17 MDx lines Reference Planes Routing.........................................................2-23

2-18 FET Switch DQ Route Example .................................................................2-25

2-19 Motherboard Model: SRAS_B#, 4 DIMMs..................................................2-28

2-20 Motherboard Model: SCAS_A#, 4 DIMMs..................................................2-28

2-21 Motherboard Model: SCAS_B#, 4 DIMMs..................................................2-28

2-22 Motherboard Model: WE_A#, 4 DIMMs......................................................2-29

2-23 Motherboard Model: WE_B#, 4 DIMMs......................................................2-29

2-24 Motherboard Model: MA_A[14:0], 4 DIMMs ...............................................2-29

2-25 Motherboard Model: MA_B[12,11,9:0]#, MA_B[14,13,10], 4 DIMMs..........2-30

3-1 Slot Connectivity...........................................................................................3-2

3-2 GND & Power Pin Definition......... ....... ...... ............................................. ......3-4

3-3 Processor Frequency Select.........................................................................3-8

3-4 82443GX Connectivity................................................................................3-10

3-5 Strapping Options.......................................................................................3-13

3-6 SDRAM Connectivity ..................................................................................3-14

3-7 PIIX4E Connectivity....................................................................................3-16

3-8 IDE Series Termination...............................................................................3-20

3-9 PIIX4E PWR & GND...................................................................................3-22

3-10 Non-PIIX4E PCI Signals.............................................................................3-23

3-11 Non-PIIX4E ISA Signals .............................................................................3-23

3-12 Non-PIIX4E IDE..........................................................................................3-24

3-13 Flash Vpp Recommendations....................................................................3-27

5-1 Slot 1 Connector...........................................................................................5-1

5-2 Retention Mechanism, Retention Mechanism Module

Attach Sink Suppor.......................................................................................5-1

5-3 GTL+ Bus Slot 1 Terminator Cards ..............................................................5-1

5-4 Voltage Regulator Modules ..........................................................................5-2

5-5 Voltage Regulator Control Silicon Vendors ..................................................5-2

5-6 Clock Driver Vendors....................................................................................5-3

5-7 Power Management Component Vendors. ....... ...... ...... ....... ...... ....... ...... ......5-3

5-8 FET Switch Vendors.....................................................................................5-3

viii

Intel® 440GX AGPset Design Guide

Page 9

Revision History

Date Revision Description

3/99 -001 Initial Release.

Intel® 440GX AGPset Design Guide

ix

Page 10

x

Intel® 440GX AGPset Design Guide

Page 11

Introduction

1

Page 12

Page 13

Introduction

Introduction

This document provides design guidelines for developing Intel® Pentium® II processor / Intel®

440GX AGPset based systems. Motherboard and memory subsystem design guidelines are

covered. Special design recommendations and concerns are presented. Likely design issues have

been identified and included here in a checklist format to alleviate problems during the debug

phase. One reference board design is presented:

Dual Processor (DP), 4 DIMM design

•

These designs use the Intel

82443GX Host Bridge and the 82371EB PIIX4E.

Note: The Intel

processor will also be offered as an Intel boxed processor, intended for system integrators who

build systems from motherboards and other components. Some hints for early debug problems are

also included.

®

Pentium® II processor may be installed in a Slot 1 connector. The Intel® Pentium® II

1.1 About This Design Guide

This document is intended for hardware design engineers who are experienced in the design of PC

motherboards or memory subsystem. This document is organized as follows:

®

Pentium® II processor and Intel® 440GX AGPset consisting of the

1

Chapter 1, Introduction. This chapter provides an overview of the features on reference design.

Chapter 1 also provides a general component overview of the Intel

Intel 440GX AGPset. The Wired for Management Initiative is also discussed which is an Intel

initiative to improve the manageability of desktop, mobile, and server systems. This chapter also

provides design recommendations which Intel feels will provide flexibility to cover a broader range

of products within a market segment.

Chapter 2, Motherboard Layout and Routing Guidelines. This Chapter provides detailed

layout, routing, and placement guidelines for the motherboard and memory subsystem. Design

guidelines for each bus (Host GTL+, PCI, DRAM, and AGP) are covered. This chapter provides

details on design methodology, Timing analysis, simulation, and design validation.

Chapter 3, Design Checklist. This chapter provides a design checklist that is intended to be used

when reviewing your Intel

AGPset reference design provided in this Design Guide. Items which have been found to be

incorrect on previous design s are p rovided as a tool to allow the quick debug of In tel

processor based systems.

Chapter 4, Debug Recommendations. This chapter presents debug recommendations that may

assist in the development of the Intel

utilizing them. This chapter also provides tool information, logic suggestions, technical support

options, and a summary of the problems which have been found to be associated with system

debug.

Chapter 5, Third Party Vendor Information. This chapter includes information regarding

various third-party vendors who provide products to support the Intel

Appendix A, Intel

schematics used in the single processor and dual processor reference designs.

®

440GX AGPset design. The checklist is based on the Intel® 440GX

®

Pentium® II processor, Intel® 440GX AGPset, and prod ucts

®

440GX AGPset Reference Design Schematics. This appendix provides the

®

Pentium® II processor and

®

Pentium® II

®

440GX AGPset.

®

Intel® 440GX AGPset Design Guide

1-1

Page 14

1.2 References

Introduction

•

Intel® Pentium® II Processor Datas

•

Intel® 440GX AGPset

•

Intel 82371EB PCI-to-ISA/IDE Xcelerator (PIIX4)

•

Intel Architecture Software Developer’s Manual

(order number 243190)

•

Intel Architecture Software Developer’s Manual

(order number 243191)

•

Intel Architecture Software Developer’s Manual

(order number 243192)

•

Intel Architecture MMX™ Technology Developer’s Guide

•

AP-485 CPUID Application Note

•

AP-585 Layout Application Note

•

AP-586 Thermal Application Note

•

AP-587 Power Application Note

•

AP-589 EMI

•

AP-524 Intel® Pentium® Pro Processor GTL+ Layout Guidelines

•

AP-525 Intel® Pentium® Pro Processor Thermal Design Guidelines

•

Multi-Processor Specification 1.4

•

+ Processor Fan/Heat Sink Target Specification

•

+ Slot 1 Test Kit User’s Guide

•

+ Slot 1 Processor Enabling Technologies Supplier Guide

•

PCI Local Bus Specification

•

Universal Serial Bus Specification

(WWW; order number 243334)

Datasheet (WWW; order number 290638)

heet

Datasheet (WWW; order number 290562)

, Volume 1; Basic Architecture

, Volume 2; Instruction Set Reference

, Volume 3; System Programming Guide

(order number 243006)

(WWW; order number 41618)

(WWW; order number 243330)

(WWW; order number 243331)

(WWW; order number 243332)

(order number 242016)

, Revision 1.0 or later

, Revision 1.0 or later

, Revision 3.0

, Revision 2.1

, Revision 1.0

(order number 242765)

(order number 242766)

Intel® 440GX AGPset Design Guide

1-2

Page 15

Introduction

1.3 Intel® Pentium

Overview

The following is a list of features that a Intel® Pentium® II processor / Intel® 440GX System will

provide:

Full Support for up to two Intel® Pentium® II processors, with system bus frequencies of

•

100 MHz

Intel® 440GX AGPset

•

— 82443GX Host Bridge Controller (GX)

— 82371EB PCI ISA IDE Accelerator (PIIX4E)

100 MHz Memory Interface: A wide range of DRAM support including

•

— 64-bit memory data interface plus 8 ECC bits and hardware scrubbing

— SDRAM (Synchronous) DRAM Support

— 16Mbit, 64Mbit, 128Mbit, and 256Mbit DRAM Technologies

4 PCI Add-in Slots

•

— PCI Specification Rev 2.1 Compliant

1 AGP Slot:

•

— AGP Interface Specification Rev 1.0 Compliant

®

II Processor / Intel

®

440GX AGPset

— AGP 66/133 MHz, 3.3V device support

Integrated IDE Controller with Ultra DMA/33 support

•

— PIO Mode 4 transfers

— PCI IDE Bus Master support

Integrated Universal Serial Bus (USB) Controller with 2 USB ports

•

Integrated System Power Management Support

•

On-board Floppy, Serial, Parallel Ports, ISA Add-in slots

•

I/O APIC device support for MP interrupt support

•

1.3.1 Intel® Pentiu m®

The Intel® Pentium® II processor is a follow-on to the Intel® Pentium® Pro processor. This high

performance Intel Architecture processor offers features that can be designed into products for the

following market segments:

Desktop Home Market Segment

Desktop Corporate Market Segment

Workstation Market Segment

Server Market Segment

New applications and hardware add-ins from third party vendors are being developed that take

advantage of the MMX™ technology incorporated into the Intel

contact your local Intel field sales representative for information on IHVs and ISVs utilizing Intel’s

MMX™ technology.

Processor

II

®

Pentium® processor. Please

Intel® 440GX AGPset Design Guide

1-3

Page 16

Intel introduced the Intel® Pentium® II processor as 350/100 and 400/100 speeds with 512 KB L2

cache versions.

1.3.2 Intel® 440GX AGPset

The Intel® 440GX AGPset is the fourth generation chipset based on the Inte l® Pentium® Pro

•

processor architecture. It has been designed to interface with the Intel

processor’ s system bu s at 100 MHz. Along with its Host-to-PCI bridg e interface, the 8 2443GX

host bridge controller has been optimized with a 100 MHz SDRAM memory controller and

data path. The 82443GX also features the Accelerated Graphics Port (AGP) interface. The

82443GX component includes the following functions and capabilities:

Support for single and dual Intel® Pentium® II processor configurations

•

64-bit GTL+ based system data bus Interface

•

32-bit system address bus support

•

64/72-bit main memory interface with optimized support for SDRAM

•

32-bit PCI bus interface with integrated PCI arbiter

•

AGP interface with up to 133 MHz data transfer rate

•

Extensive data buffering between all interfaces for high throughput and concurrent operations

•

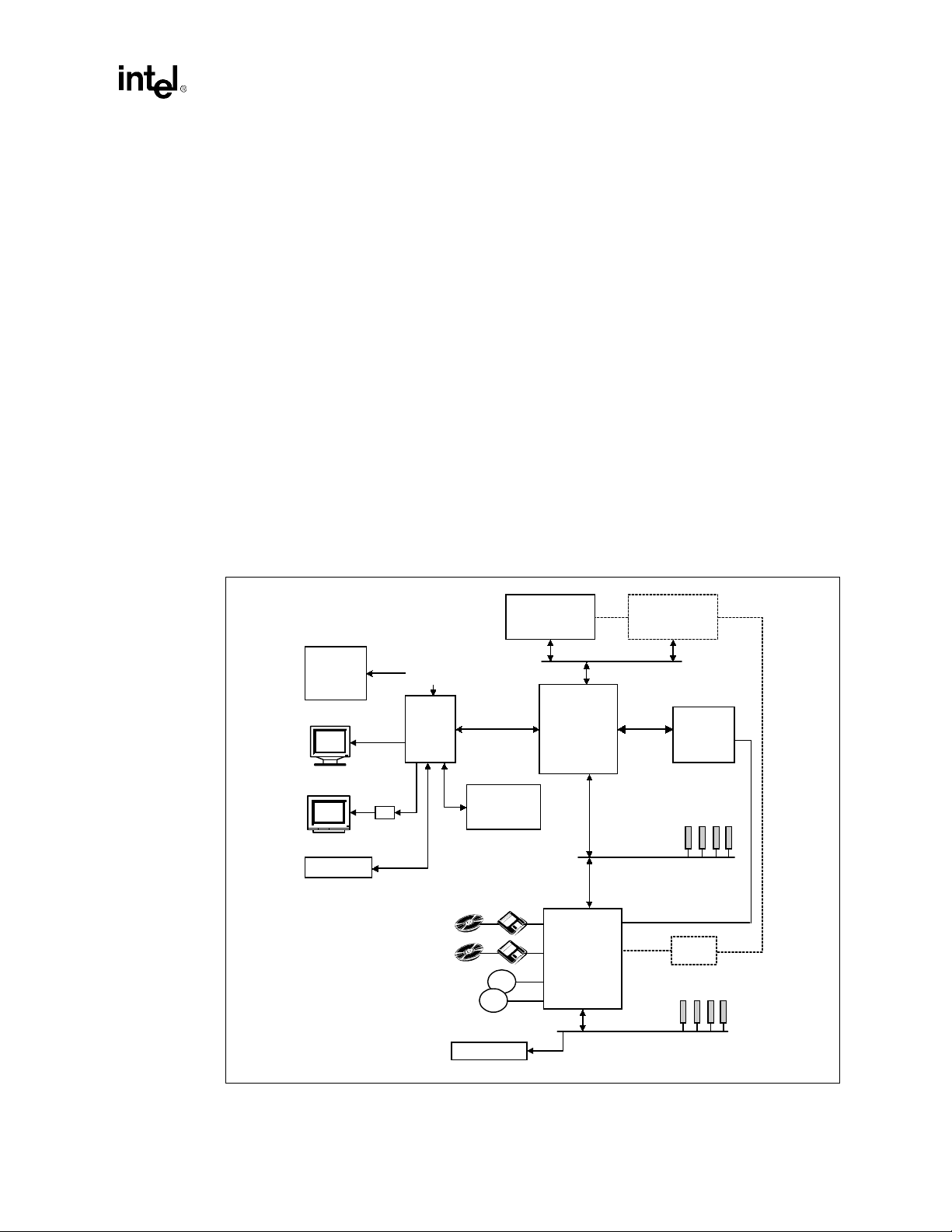

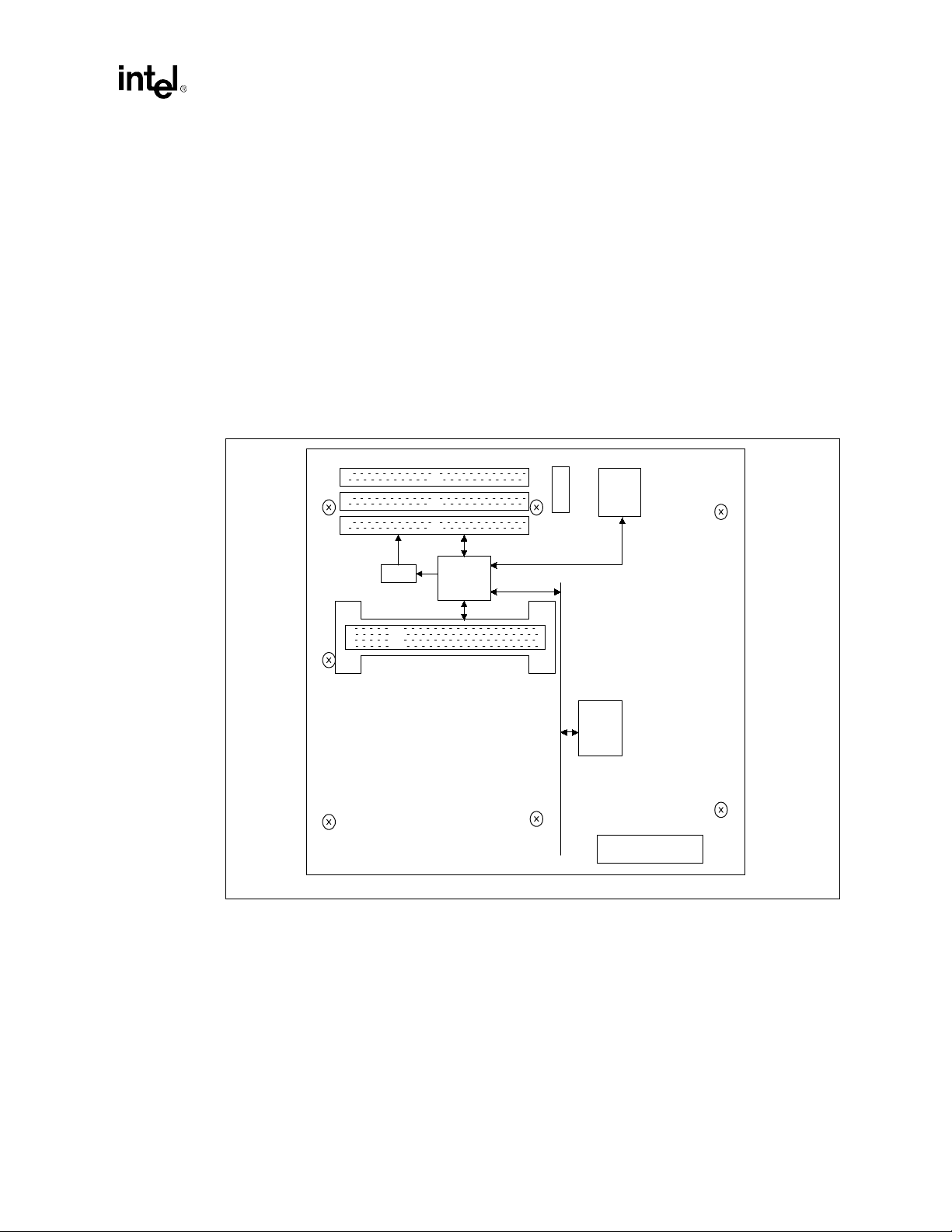

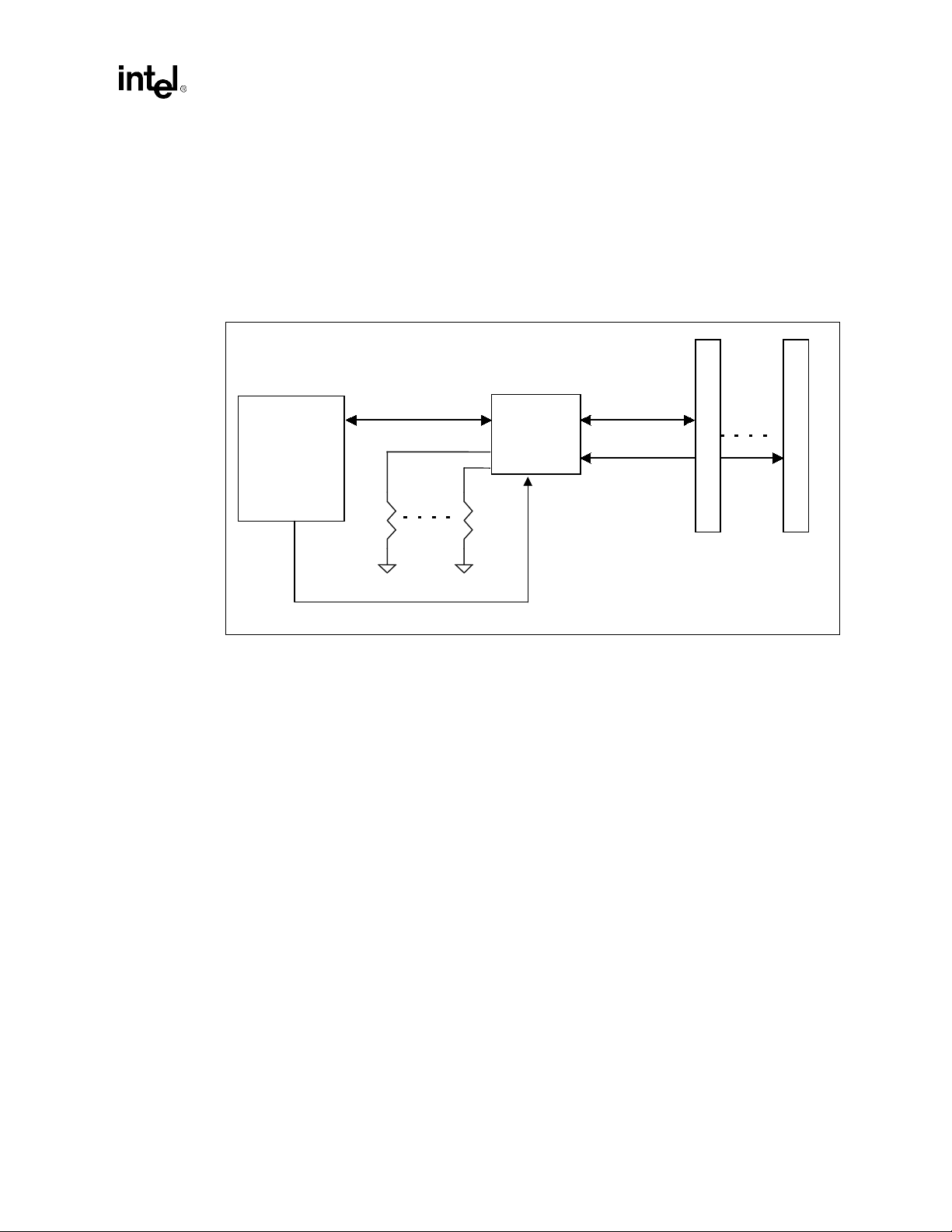

Figure 1-1.

®

Pentium® II Processor / Intel® 440GX AGPset System Block Diagram

Intel

®

Pentium® II

Introduction

Video

- DVD

- Camera

- VCR

Display

TV

Video BIOS

- VMI

- Video Capture

Graphics

Encoder

2 IDE Ports

(Ultra DMA/33)

Device

Local Memory

2 USB

Ports

System BIOS

2X AGP Bus

Graphics

USB

USB

Pentium®

Processor

82443GX

Host Bridge

II

Host Bus

82371EB

(PIIX4E)

(PCI-to-ISA

Bridge)

Pentium®

Processor

72 Bit

w/ECO

100 MHz

SDRAM Support

Primary PCI Bus

(PCI Bus #0)

System Mgnt (SM) Bus

ISA Bus

II

Main

Memory

PCI Slots

IO

APIC

ISA Slots

sys_blk.vsd

Intel® 440GX AGPset Design Guide

1-4

Page 17

Introduction

Figure 1-1 shows a block diagram of a typical platform based on the Intel® 440GX AGPset. The

82443GX system bus interface supports up to two Intel

bus frequency of 100 MHz. The physical interf ace design is based on the GTL+ specif ication and is

compatible with the Intel

DRAM interface (64-bit Data plus ECC). This interface supports 3.3V DRAM technologies.

The 82443GX is designed to support the PIIX4E I/O bridge. The PIIX4E is a highly integrated

multifunctional component that s up ports the following functions and capabilities:

PCI Rev 2.1 compliant PCI-to-ISA Bridge with support for 33 MHz PCI operations

•

ACPI Desktop Power Management Support

•

Enhanced DMA controller and standard interrupt controller and timer functions

•

Integrated IDE controller with Ultra DMA/33 support

•

USB host interface with support for 2 USB ports

•

System Management Bus (SMB) with support for DIMM Serial Presence Detect

•

Support for an external I/O APIC component

•

®

440GX AGPset solution. The 82443GX provides an optimized 72-bit

1.3.2.1 System Bus Interface

The Intel® Pentium® II processor supports a second level cache size of 512 KB with ECC. All

cache control logic is provided on the processor. The 82443GX supports a maximum of 32 bit

address or 4 GB memory address space from the processor p erspecti ve. The 8244 3GX provi des bus

control signals and address paths for transfers between the processors bus, PCI bus, Accelerated

Graphics Port and main memory. The 82443GX supports a 4-deep in-order queue (i.e., it provides

support for pipelining of up to 4 outstanding transaction requests on the system bus).

®

Pentium® II processors at the maximum

For system bus-to-PCI transfers, the addresses are either translated or directly forwarded on the

PCI bus, depending on the PCI address space being accessed. If the access is to a PCI configuration

space, the processor I/O cycle is mapped to a PCI configuration space cycle. If the access is to a

PCI I/O or memory space, the processor address is passed without modification to the PCI bus.

Certain memory address range (later referred in a document as a Graphics Aperture) are dedicated

for a graphics memory address space. If this space or portion of it is mapped to main DRAM, then

the address will be translated via the AGP address remapping mechanism and the request

forwarded to the DRAM subsystem. A portion of the graphi cs aperture can be mapped on A GP and

corresponding system bus cycles that hit that range are forwarded to AGP without any translation.

Other system bus cycles forwarded to AGP are defined by the AGP address map.

1.3.2.2 DRAM Interface

The 82443GX integrates a main memory controller that supports a 64/72-bit DRAM interface

which operates at 100 MHz. The integrated DRAM controller features: supports up to 4 doublesided DIMMs, 8M to 256M using 16Mbit technology, 1 GB using 64Mbit technology, and 2 GB

using 128M or 256M technol ogy, two copies of MAxx are pro vid ed for optimi zed timing, an d ECC

with hardware scrubbing.

1.3.2.3 Accelerated Graphics Port Interface

The 82443GX supports an AGP interface. The AGP interface can reach a maximum theoretical

~532 Mbytes/sec transfer rate.

Intel® 440GX AGPset Design Guide

1-5

Page 18

1.3.2.4 PCI Interf ac e

The 82443GX PCI interface is 33 MHz Revision 2.1 compliant and supports up to five external

PCI bus masters in addition to the I/O bridge (PIIX4E).

1.3.2.5 System Clocking

The 82443GX operates the system bus interface at 100 MHz, PCI at 33 MHz and AGP at

66/133 MHz. The 443GX clocking scheme uses an external clock synthesizer which produces

reference clocks for the system bus and PCI interfaces. The 82443GX produces a single 100 MHz

SDRAM clock output which is fed to a 1 to 18 clock buffer to support 1 to 4 DIMMs.

1.3.3 PCI-to-ISA/IDE Xcelerator (PIIX4E)

The PCI-to-ISA/IDE Xcelerator (PIIX4E) is a multi-function PCI device implementing a PCI-toISA bridge function, a PCI IDE function, a Universal Serial Bus host/hub function, and an

Enhanced Power Management function. As a PCI-to-ISA bridge, the PIIX4E integrates many

common I/O fu nctions found in ISA -based PC systems; a seven channel DMA Controller, two

82C59 Interrupt Controllers, an 8254 Timer/Counter, and a Real Time Clock. In addition to

Compatible transfers, each DMA channel also supports Type F transfers.

Introduction

The PIIX4E contains full support for both PC/PCI and Distributed DMA protocols implementing

PCI based DMA. The Interrupt Controller has Edge or Level sensitive programmable inputs and

fully supports the use of an external I/O Advanced Programmable Interrupt Controller (APIC) and

Serial Interrupts. Chip select decoding is provided for BIOS, Real Time Clock, Keyboard

Controller, second external Microcontroller, as well as 2 Programmable Chip Selects. The PIIX4E

provides full Plug and Play compatibility. The PIIX4E can be configured as a Subtractive Decode

bridge or as a Positive Decode bridge.

The PIIX4E supports two IDE connectors for up to four IDE devices providing an interface for

IDE/EIDE hard disks and CD ROMs. Up to four IDE devices can be supported in Bus Master

mode. The PIIX4E contains support for “Ultra DMA/33” synchronous DMA compatible devices.

The PIIX4E contains a Universal Serial Bus (USB) Host Controller that is Universal Host

Controller Interface (UHCI) compatible. The Host Controller’s root hub has two programmable

USB ports.

The PIIX4E supports Enhanced Power Management, including full Clock Control, Device

Management for up to 14 devices, and Suspend and Resume logic with Power On Suspend,

Suspend to RAM or Suspend to Disk. It fully supports Operating System Directed Power

Management via the Advanced Configuration and Power Interface (ACPI) specification. The

PIIX4E integrates both a System Management Bus (SMBus) Host and Slave interface for serial

communication with other devices.

For more information on the PIIX4E, please refer to thePIIX4 d atasheet.

1.3.4 Wired for Management Initiative

Wired for Management (WfM) is an Intel initiative to improve the manageability of desktop, and

server systems. The goal of WfM is to reduce the Total Cost of Ownership (TCO) through

improved manageability in the following four technology areas:

Instrumentation

•

Remote Service Boot

•

Remote Wake-Up

•

Power Management

•

Intel® 440GX AGPset Design Guide

1-6

Page 19

Manageability features in each of these four technology areas combine to form the Wired for

Management Baseline Specification. A copy of the Wired for Management Baseline Specification

can be obtained from:

ftp://download.intel.com/ial/wfm/baselin e.pdf

An on-line Design Guide is available at:

http://developer.intel.com/ial/WfM/design/index.htm

Future versions of the specification, which preserve today's investments, will be available at this

site.

1.3.3.1 Instrumentation

A component's instrumentation consists of co de that maintains attributes with up-to-the-minute

values and adjusts the component's operational characteristics based on these values. By provi ding

instrumentation, the platform provides accurate data to management applications, so those

applications can make the best decisions for managing a system or product.

The WfM 1.1a Baseline requires that compliant desktop and mobile platforms utilize the DMI

Version 2.00 Management Interface (MI) and Component Interface (CI) application programming

interfaces and host a DMI v2.00 Service Provider , as def ined by the DMTF. Intel's DMI 2.0 Service

Provider Software Development Kit (SDK) provides a DMI Service Provider and binaries that

support DMI Version 2.00. This kit is available at:

Introduction

http://developer.intel.com/ial/WfM/tools/sdk/index.htm.

Intel's LANDesk© Client Manager product includes the Service Provider and component

instrumentation. Information regarding this product can be found at:

http://developer.intel.com/ial/WfM/tools/ldcm/index.htm

The WfM Baseline Instrumentation specification identifies specific DMI standard groups,

including event generation groups, that must be instrumented for a Baseline-compliant platform.

This reference design provides support for the SMBIOS revision 2.0 specification which along

with appropriate component instrumentation will supply some of the required data in the specified

DMI 2.0 groups. This reference design also provides additional optional instrumentation hardware

support with the LM79 and Maxim MAX1617 components.

1.3.3.2 Remote Service Boot

The WfM Baseline specifies the protocols by which a client requests and do wn loads an executable

image from a server and the minimum requirements on the client execution environment when the

downloaded image is executed. The Baseline specification includes a set of APIs for the particular

network controller used. The code supporting the Preboot eXecution Environment (PXE) and the

network controller is provided on the EtherExpress

T wo implementation option s are a v ailable: 1) NIC with Option ROM and Wak e on LAN Header or

2) a LAN on Motherboard implementation. For the second option, the Preboot execution

environment and the network controller code must be incorporated into the system BIOS.

In addition, the BIOS must provide the _SYSID_ and _UUID_ data structures. The details of the

BIOS requirements can be obtained from the Intel web site.

©

PRO/100 WFM adapters Option ROM.

Intel® 440GX AGPset Design Guide

http://developer.intel.com/ial/WfM/design/pxedt/index.htm

1-7

Page 20

1.3.3.3 Remote Wake-Up

If a PC supports a reduced power state, it must be possible to bring the system to a fully powered

state in which all management interfaces are available. Typically, the LAN adapter recognizes a

special packet as a signal to wake up the system. This reference design utilizes a Wake on LAN

(WOL) Header to provide standby power to the NIC and the interface for the wake up signal. The

physical connection to the NIC and motherboard is via a WOL Cable provided with the design kit.

See the WOL Header Recommendations document at:

ftp://download.intel.com/ial/wfm/wol_v14.pdf.

The system BIOS must enable the wake event an d pr o v ide wa k e up status. The d etails of the BI OS

requirements can be obtained from the Intel Corporation w eb site:

http://developer.intel.com/ial/WfM/design/rwudt/index.htm

1.3.3.4 Power Management

WfM Baseline compliant systems have four distinct power states: Working, Sleeping, Soft Off, and

Mechanical Off. Soft off is usually provided by a user accessible switch that will send a soft off

request to the system. The PIIX4 provides the power button input for this purpose and

implementation details are described in th e schematics. A second optional “override” switch

located in a less obvious place (or removal of the power cord) stops current flow forcing the

platform into the mechanical off state without OS consent. Note that a second “override” switch is

required for legal reasons in some jurisdictions (for example, some European countries). The BIOS

may support the power management requirement either through the APM revision 1.2 or ACPI

revision 1.0 specifications. This reference design’s BIOS implementation incorporates both

interfaces. The PIIX4 provides hardware level register support for both the APM and ACPI

specifications. See Intel's web site for additional information:

Introduction

http://developer.intel.com/ial/WfM/design/pmdt/index.htm.

1.4 Design Recommendations

1.4.1 Voltage Definitions

For the purposes of this document the following nominal voltage definitions are used:

Vcc 5.0V

Vcc

Vcc

Vcc

V

TT

V

REF

3.3

CORE

2.5

3.3V

Voltage is dependent on the five bit VID setting

2.5V

1.5V

1.0V

Intel® 440GX AGPset Design Guide

1-8

Page 21

1.4.2 General Design Recommendations

1. Intel recommends using an industry standard programmable Voltage Regulator Module

(VRM) installed in a VRM header o r an onb oard p rogrammab le v olt age re gulator d esign ed for

®

Intel

Pentium® II processors.

Introduction

2. Systems should be capable of varying the system bu s to processor cor e freq uency ratio per the

System Bus to Core Frequency Multiplier Configuration table of the Intel

processor datasheet. The Intel

®

Pentium® II processor uses the following signals to configure

®

Pentium® II

the internal clock multiplier ratio: LINT[0]/INTR, IGNNE#, A20M#, LINT[1]/NMI. Follow

the recommendations in this document to ensure that adequate hold times are met on the

strapping signals. Ensure the output of the strapping logic is a Vcc

logic level for connection

2.5

to the Slot 1 connector. This can be accomplished using an open-drain output driver with pullups to Vcc

2.5

.

3. Please prepare for additional thermal margin for increases of 1-5W for higher performance or

otherwise enhanced processor.

4. Motherboard designs targeted for system integrators should design to the Boxed Intel

Pentium

Pentium

®

II processor electrical, mechanical and thermal specif ications provided in the Intel®

®

II processor datasheet, most notably the required fan power header, fan/heatsink

®

physical clearance on the motherboard.

5. Motherboard designs should incorporate a retention mechanism, retention mechanism attach

mount and heatsink support mounting holes and keep out areas for the Intel

processor and boxed Intel

®

Pentium® II processor.

®

Pentium® II

1.4.3 Transitioning from Intel 440BX AGPset to Intel 440GX

AGPset Design

1. The 82443GX supports 2GB u sing 12 8M or 25 6M memory technol ogy. The design guidelines

for MAA14 and MAB14 are the same as MAA-13 and MAB-13 on the 82443BX.

2. Intel

®

440GX AGPset supports 100 MHz system bus and 100 MHz SDRAM Memory only.

3. There is no 3 DIMM support with the Intel 440GX AGPset.

Intel® 440GX AGPset Design Guide

1-9

Page 22

Introduction

1-10

Intel® 440GX AGPset Design Guide

Page 23

Motherboard Design

2

Page 24

Page 25

Motherboard Layout and Routing Guidelines

Motherboard Layout and Routing

Guidelines

This chapter describes layout and rou tin g recommendati ons to in sure a rob us t design. Foll o w these

guidelines as closely as possibl e. Any d eviations from the guidelines listed here should be

simulated to insure adequate margin is still maintain ed in the design

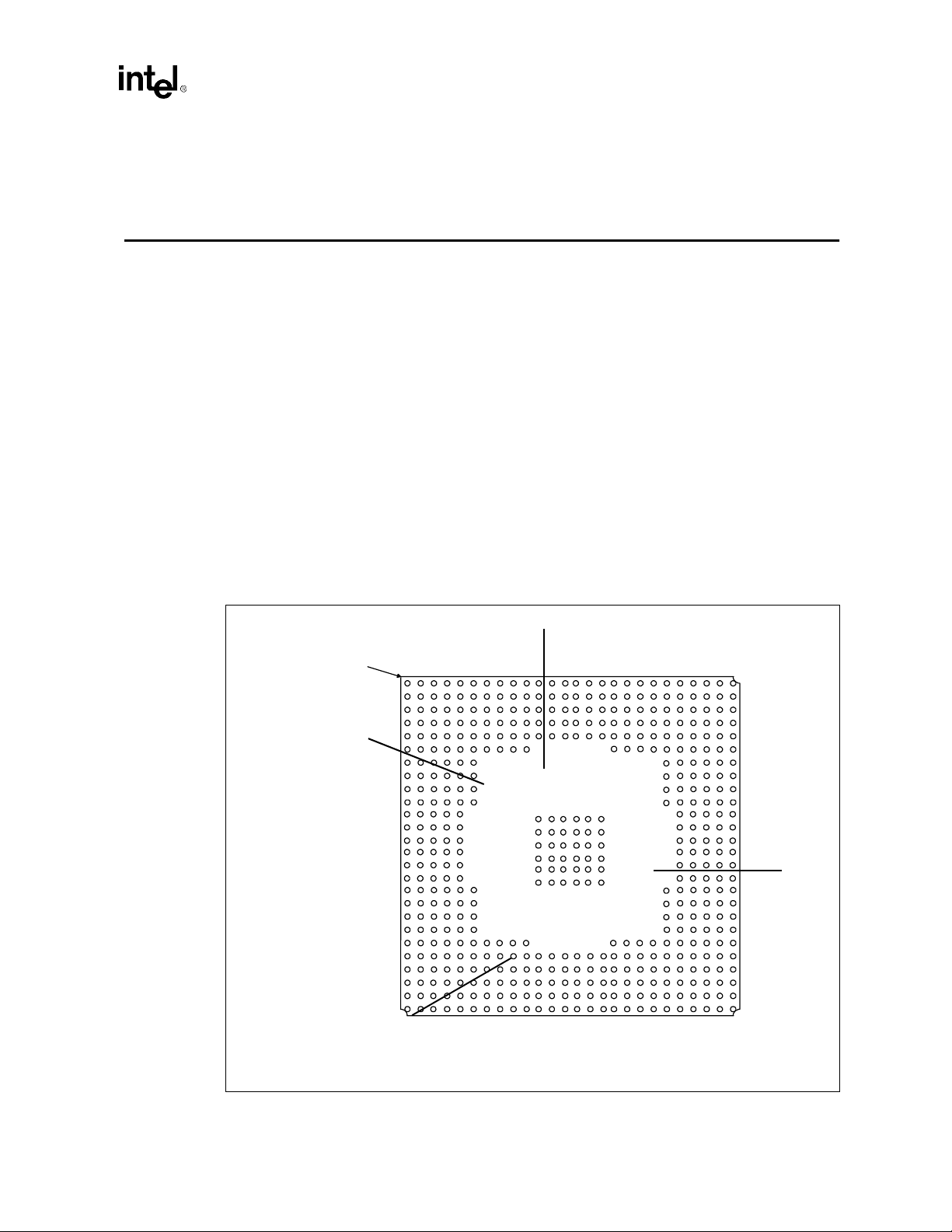

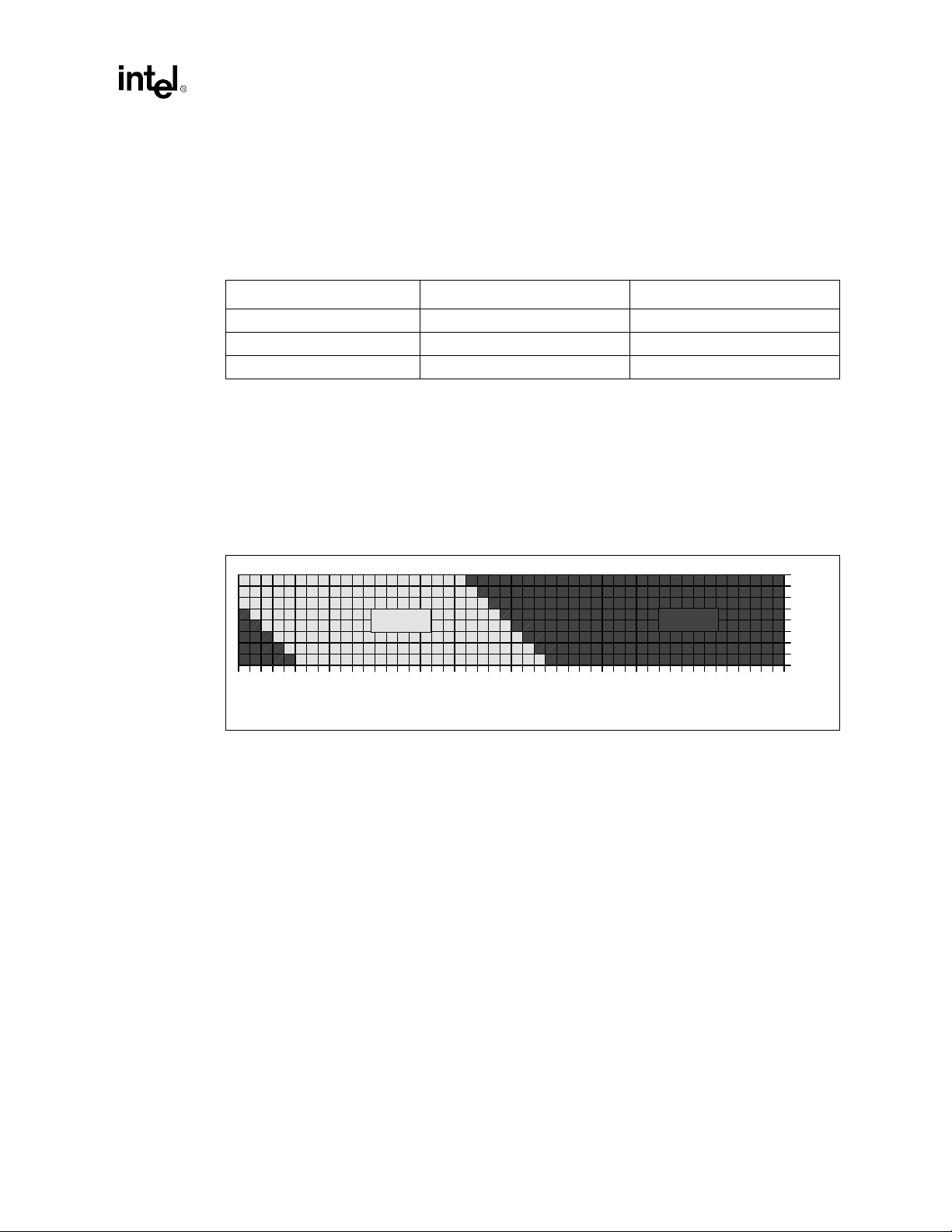

2.1 BGA Quadrant Assignment

Intel assigned pins on the 82443GX to simplify routing and keep board fabrication costs down, by

permitting a motherboard to be routed in 4-layers. Figure 2-1 shows the 4 signal quadrants of the

82443GX. The component placement on the motherb oard should be d one with th is general f low in

mind. This simplifies routing and minimizes the number of signals which must cross. The

individual signals within the respective groups have also been optimized to be routed using only 2

PCB layers.

Note: The Intel

Figure 2-1. Major Signal Sections (82443GX Top View)

®

82443GX AGPset Datasheet contains a complete list of signals and Ball assignments.

PCI

Quadrant

Pin #1 Corner

AGP

Quadrant

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

24 25 26

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

U

V

W

Y

AA

AB

AC

AD

AE

AF

2

GTL+

Quadrant

Intel® 440GX AGPset Design Guide

SDRAM

Quadrant

v001

2-1

Page 26

Motherboard Layout and Routing Guidelines

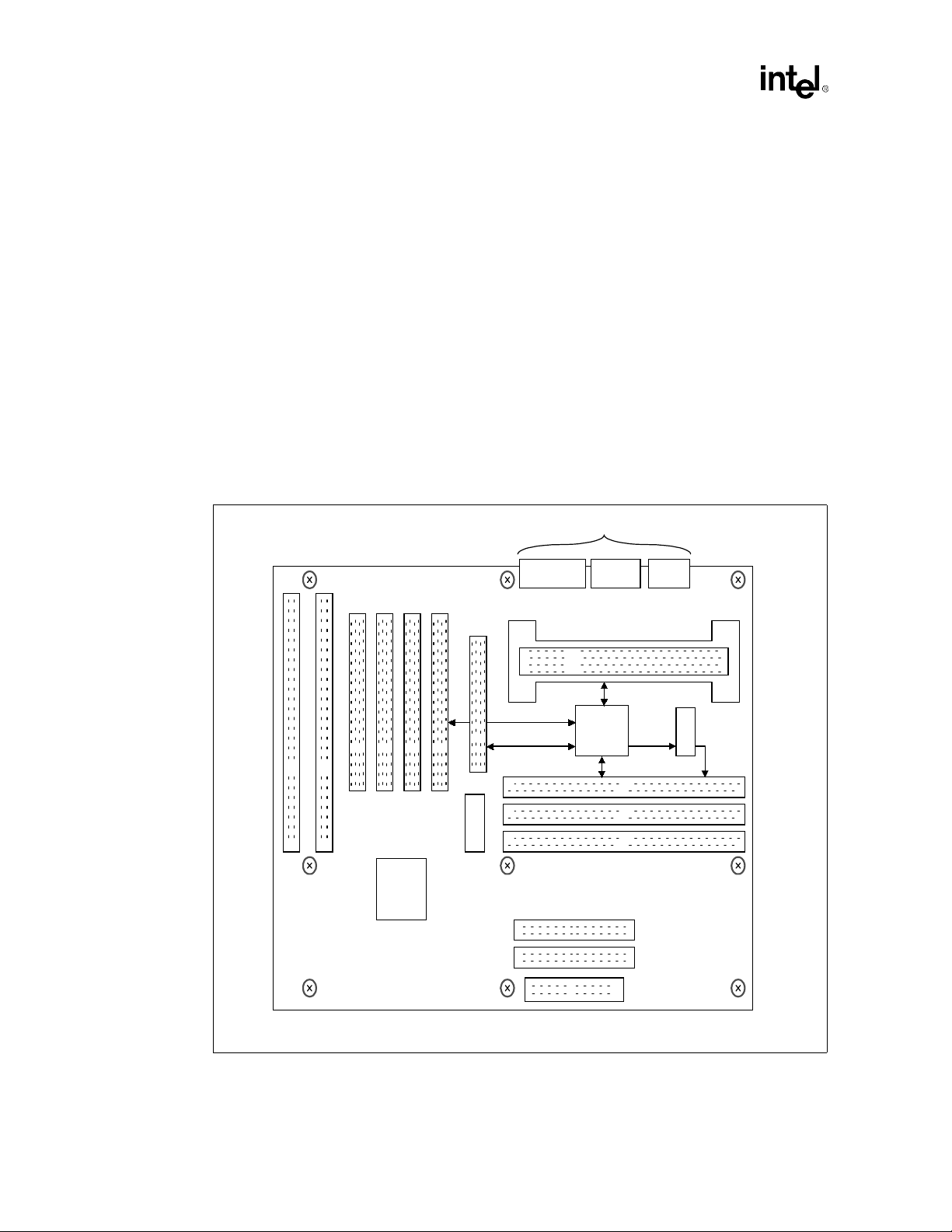

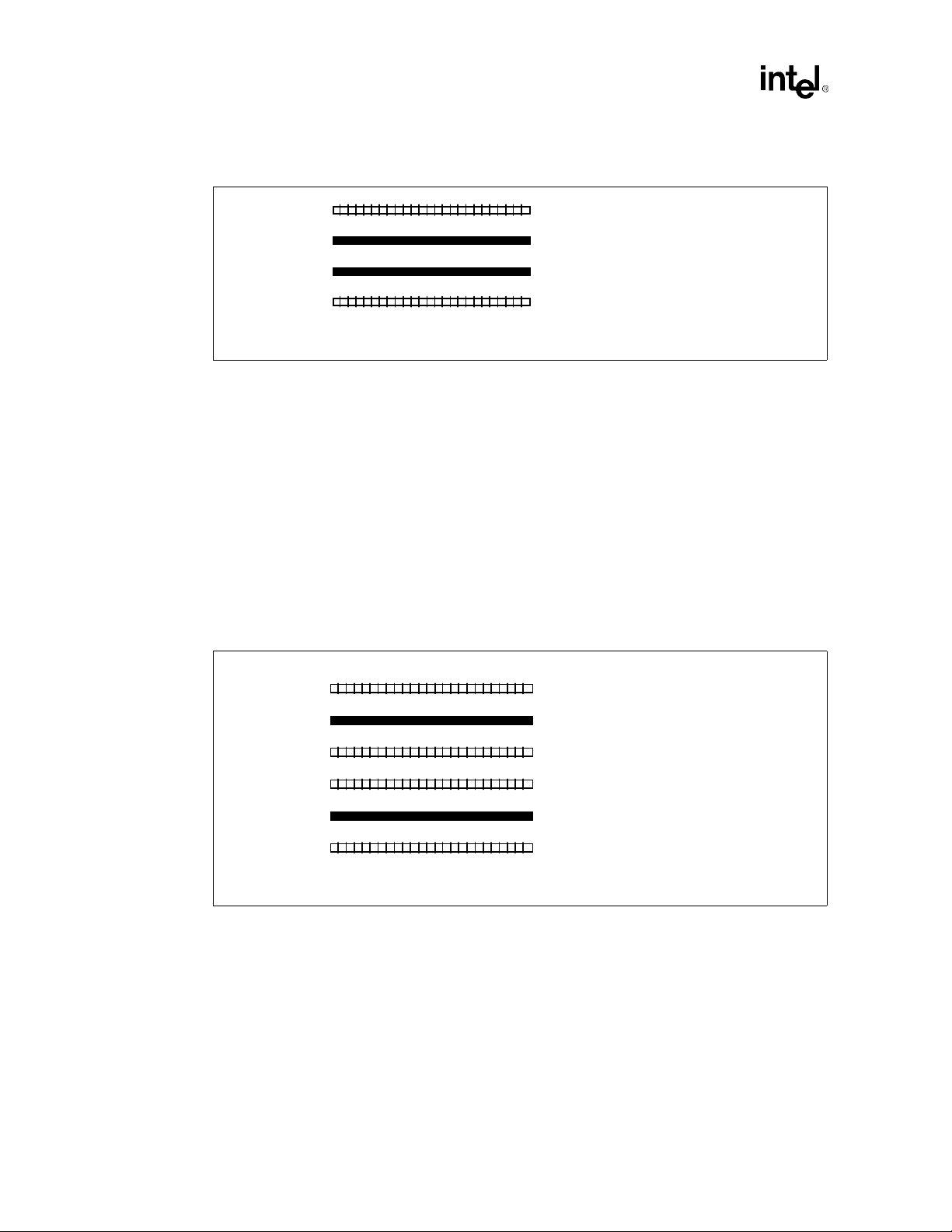

Figure 2-2 and Figure 2-3 show the proposed component placement for a single processor f or both

ATX and NLX form factor designs.

ATX Form Factor:

1. The ATX placement and layout below is recommended for single (UP) Intel

processor / Intel

®

440GX AGPset system design.

2. The example placement below shows 4 PCI slots, 2 ISA slots, 4 DIMM sockets, and one AGP

connector.

3. For an ATX form factor design, the AGP compliant graphics device can be either on the

motherboard (device down option), or on an AGP connector (up option).

4. The trace length limitation between critical connections will be addressed later in this

document.

5. The figure below is for reference only and the trade-off between the number of PCI and ISA

slots, number of DIMM socket, and other motherboard peripherals need to be evaluated for

each design.

Figure 2-2. Example ATX Placement for a UP Pentium

Design

®

Pentium® II

®

II processor/Intel® 440GX AGPset

PCI0

PIIX4E

AGP/PCI1

PCI Interface

AGP Interface

CK100

I/O Ports

Pentium® II Slot 1

Host Interface

82443GX

CKBF

SDRAM Interface

SDRAM DIMMs

IDE 0/1

2-2

v002

Intel® 440GX AGPset Design Guide

Page 27

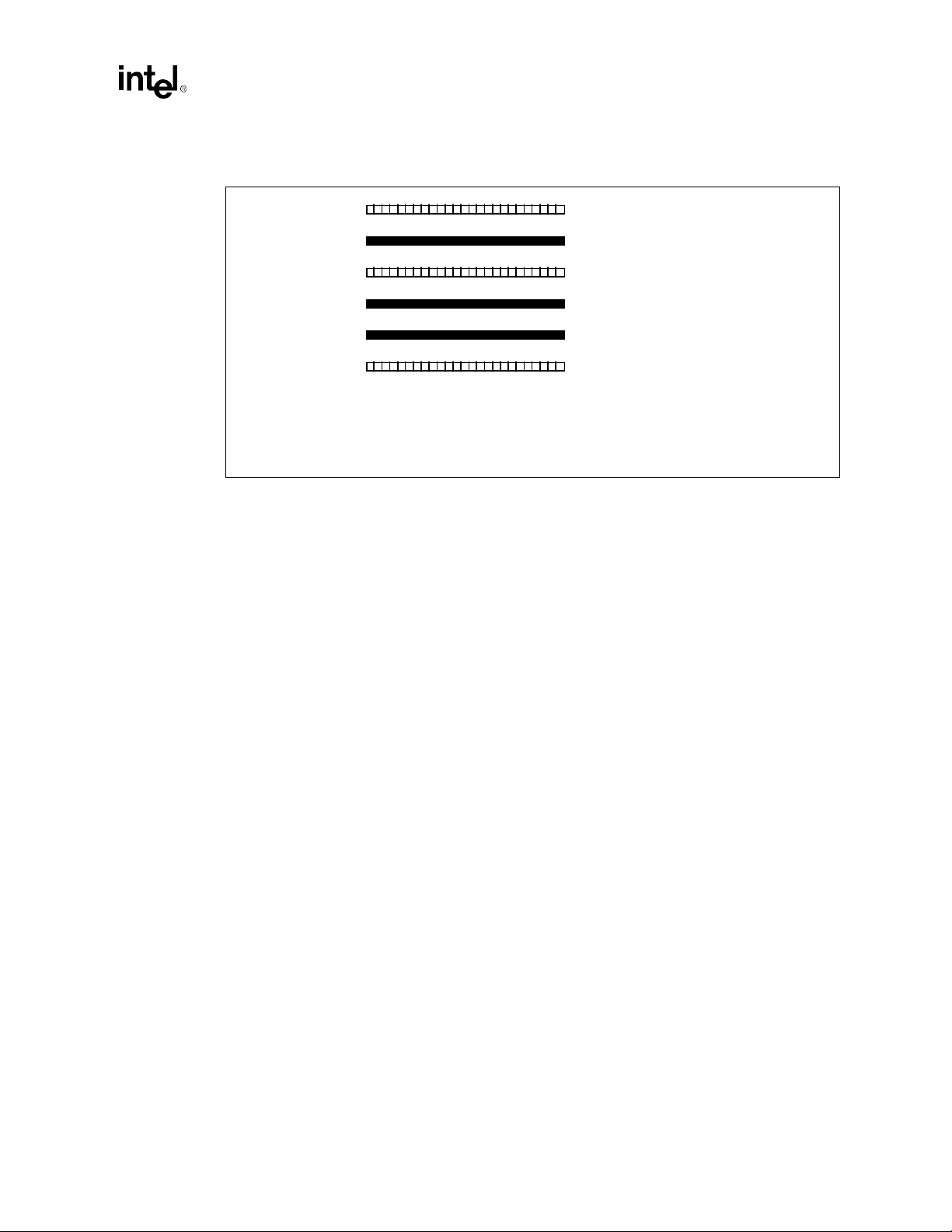

NLX Form Factor:

1. The NLX placement and layout below is recommended for a single (UP) Intel

processor / Intel

®

440GX AGPset system design.

2. The example placement below shows one Slot 1 connector, 4 DIMM sockets, and an AGP

compliant device down.

3. For an NLX form factor design, the AGP compliant graphics device may readily be integrated

on the motherboard (device down option).

4. The trace length limitation between critical connections will be addressed later in this

document.

5. Figure 2-3 is for reference only and the trade-off between the number of DIMM sockets, and

other motherboard peripherals need to be evaluated for each design.

Figure 2-3. Example NLX Placement for a UP Intel

Design

SDRAM DIMMs

Motherboard Layout and Routing Guidelines

®

Pentium® II

®

Pentium® II processor / Intel® 440GX

AGP

CK100

SDRAM

Interface

CKBF

Host Interface

Pentium® II Slot 1

2.2 Board Description

For a single processor / Intel® 440GX AGPset motherboa rd design, a 4 layer stack-up arrangement

is recommended. The stack up of the board is sho wn in Figure 2-4. The impedance of all the signal

layers are to be between 50 and 80 ohms. Lower trace impedance will reduce signal edge rates,

over & undershoot, and have less cross-talk than higher trace impedance. Higher trace impedance

will increase edge rates and may slightly decrease signal flight times.

82443GX

AGP Interface

PCI Interface

I/O Ports

PIIX4E

PCI0/ISA Riser

v003

Intel® 440GX AGPset Design Guide

2-3

Page 28

Motherboard Layout and Routing Guidelines

Figure 2-4. Four Layer Board Stack-up

Z = 60 ohms

Z = 60 ohms

5 mils

47 mils

5 mils

PREPREG

CORE

PREPREG

Primary Signal Layer (1/2 oz. cu .)

Ground Plane (1 oz. cu.)

Power Plane (1 oz. cu)

Secondary Signal Layer (1/2 oz. cu)

Total board thickness = 62.6

Note: The top and bottom routing layers specify 1/2 oz. cu. However, by the time the board is plated, the

traces will end about 1 oz. cu. Check with your fabrication vendor on the exact value and insure

that any signal simulation accounts for this value.

Note: A thicker core may help reduce board warpage issues.

For a dual processor / Intel

®

440GX AGPset design, a 6 layer stack-up is recommended. Two

examples are shown below. Figure 2-5 has 4 signal plane layers and 2 power plane layers.

Figure 2-6 shows 3 signal plane layers and 3 po wer plane layers. The secon d option makes it easier

to accommodate all of the power planes required in a Intel

®

440GX AGPset design.

If a 6 layer stack-up is used, then it is recommended to route most of the GTL+ bus signals on the

inner layers. The primary and secondary signal layer can be used for GTL+ signals where needed.

Routes on the two inner layers should be orthogonal to reduce crosstalk between the layers.

Figure 2-5. Six Layer Board Stack-up With 4 Signal Planes and 2 Power Planes

Z = 66 ohms

Z = 73 ohms

Z = 66 ohms

6 mils

18 mils

6 mils

18 mils

6 mils

PREPREG

CORE

PREPREG

CORE

PREPREG

Primary Signal Layer (1/2 oz. cu.)

Ground Plane (1 oz. cu.)

Inner Layer #1 (1 oz. cu.)

Inner Layer #2 (1 oz. cu)

Power Plane (1 oz. cu)

Secondary Signal Layer (1/2 oz. cu)

Total board thickness = 62.4

2-4

Intel® 440GX AGPset Design Guide

Page 29

Motherboard Layout and Routing Guidelines

Figure 2-6. Six Layer Board Stack-up With 3 Signal Planes and 3 Power Planes

Z = 60 ohms

Z = 59 ohms

Z = 60 ohms

5 mils

18 mils

8 mils

18 mils

5 mils

PREPREG

CORE

PREPREG

CORE

PREPREG

Primary Signal Layer (1/2 oz. cu .)

Ground Plane (1 oz. cu.)

Inner Layer #1 (1 oz. cu.)

Power Plane #1 (1 oz. cu)

Power Plane #2 (1 oz. cu)

Secondary Signal Layer (1/2 oz. cu)

Total board thickness = 62.4

Additional guidelines on board buildup, placement and layout include:

For a 4-layer single processor design, double ended termination is recommended for GTL+

•

signals. One termination resistor is present on the processor substrate, and the other

termination resistor is needed on the motherboard. It may be possible to use single-ended

termination, if the trace lengths can tightly be controlled to 1.5” minimum and 4. 0” maximu m.

For a 6-layer dual processor design, no termination is required on the motherboard for GTL+

•

signals, as each end of the GTL+ bus is terminated on each processor. If a single Slot 1 is

populated in a DP design, the second Slot 1 must be populated with a termination card.

The termination resistors on the GTL+ bus should be 56 ohms.

•

The board impedance (Z) should be between 50 and 80 ohms (65 ohms ±20%)

•

FR-4 material should be used for the board fabrication.

•

The ground plane should not be split on the ground plane layer. If a signal must be routed for a

•

short distance on a power plane, then it should be routed on a VCC plane, not the ground

plane.

Keep vias for decoupling capacitors as close to the capacitor pads as possible.

•

2.3 Routing Guidelines

This section lists guidelines to be followed when routing the signal traces for the board design. The

order of which signals are rou t ed first and last will vary from d esi g ner t o d esi gn er. Some designers

prefer routing all of the clock signals first, while others prefer routing all of the high speed bus

signals first. Either order can be used, as long as the guidelines listed here are followed. If the

guidelines listed here are not followed, it is very important that your design is simulated, especially

on the GTL+ signals. Even when the guidelines are followed, it is still a good idea to simulate as

many signals as possible for proper signal in tegrity, flight time and cross talk.

Intel® 440GX AGPset Design Guide

2-5

Page 30

Motherboard Layout and Routing Guidelines

V

2.3.1 GTL+ Description

GTL+ is the electrical bus technology used for the Intel® Pentium® Pro processor and Intel®

Pentium

drain bus with external pull-up resistors that provide both the high logic level and termination at the

end of the bus. The complete GTL+ specification is contained in the Pentium II processor

databook. The specification defines:

Refer to the 100 MHz GTL+ layout Guidelines for the Pentium

AGPset for more details.

®

II processor system bus. GTL+ is a low output swing, incident wave switching, open-

Termination voltage, V

•

Termination resistance, R

•

Maximum output low voltage, VOL, and output low current, I

•

Output driver edge rate when driving the GTL+ reference load

•

Receiver high and low voltage level, VIL and V

•

Receiver reference voltage, V

•

Receiver ringback tolerance

•

TT

TT

, as a function of the termination voltage

REF

2.3.2 GTL+ Layout Recommendations

This section contains the layout recommendations for the GTL+ signals. The layout

recommendations are deri v e d from pre-l ayout simul ations that Intel h as run us ing t he method olog y

described in Section 2.3.7, “Design Methodology” on page 2-11. Results from the pre-layout

simulations are included in this section.

IH

OL

®

II Processor and Intel® 440GX

See the Intel

be present on the particular stepping of the processor used.

®

P entium® II Proce ssor Specif ication Upd ate for workar ounds for an y errata that may

2.3.3 Single Processor Design

2.3.3.1 Single Processor Network Topology and Conditions

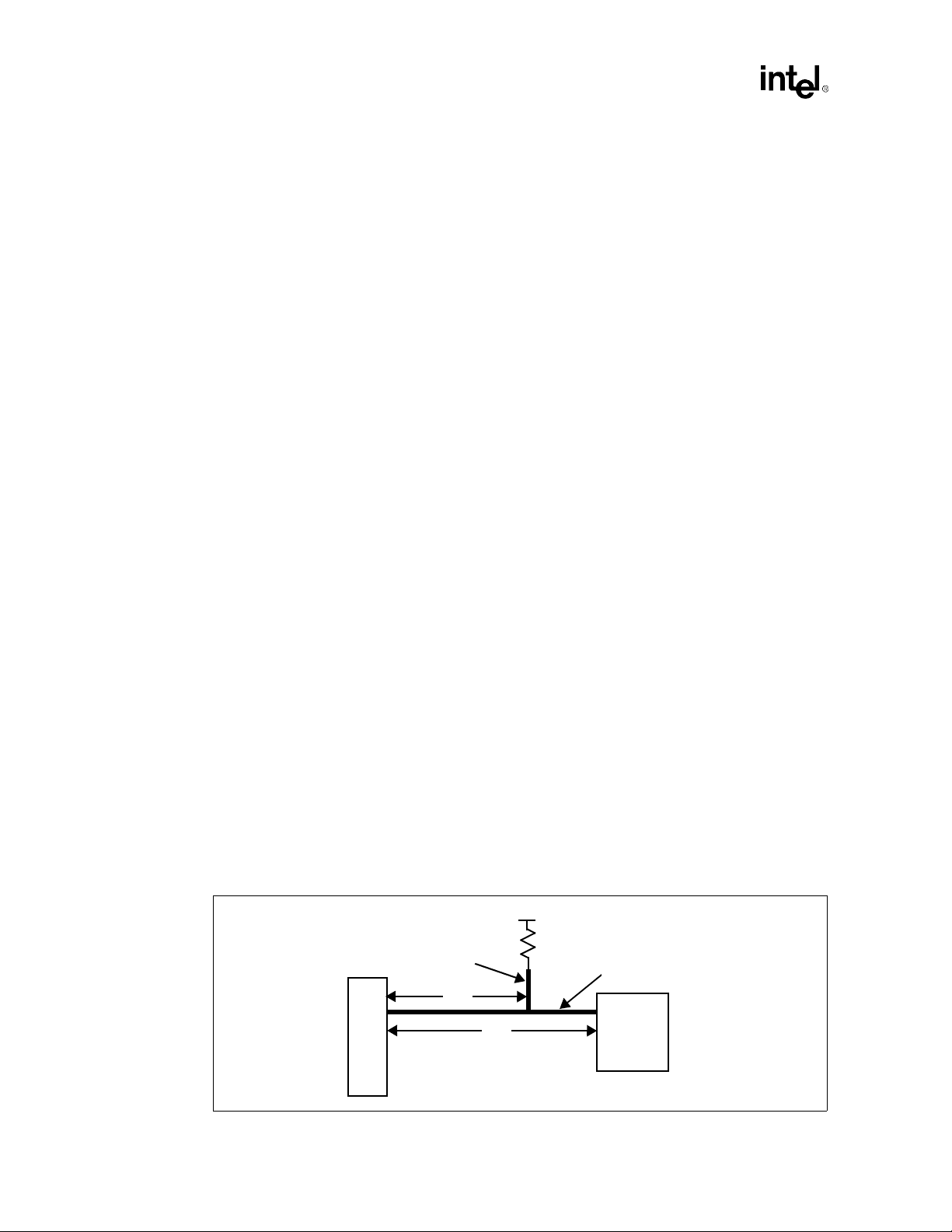

The recommended topology for single processor systems is shown in Figur e 2-7. In addition to the

termination resistor on the Pentium II processor substrate, a termination resistor is placed on the

system board. The recommended value for the termination resistor is 56Ω ± 5%.

Figure 2-7. Recommended Topology for Single Processor Design

TT

R

L4

L2

Slot 1

L1

TT

L3

®

Intel

440GX

AGPset

2-6

Intel® 440GX AGPset Design Guide

Page 31

Motherboard Layout and Routing Guidelines

2.3.3.2 Single Processor Recommended Trace Lengths

Single processor trace length recommendations are summarized in Table 2-1. The recommended

lengths are derived from the parametric sweeps and Monte Carlo analysis described in the

following section.

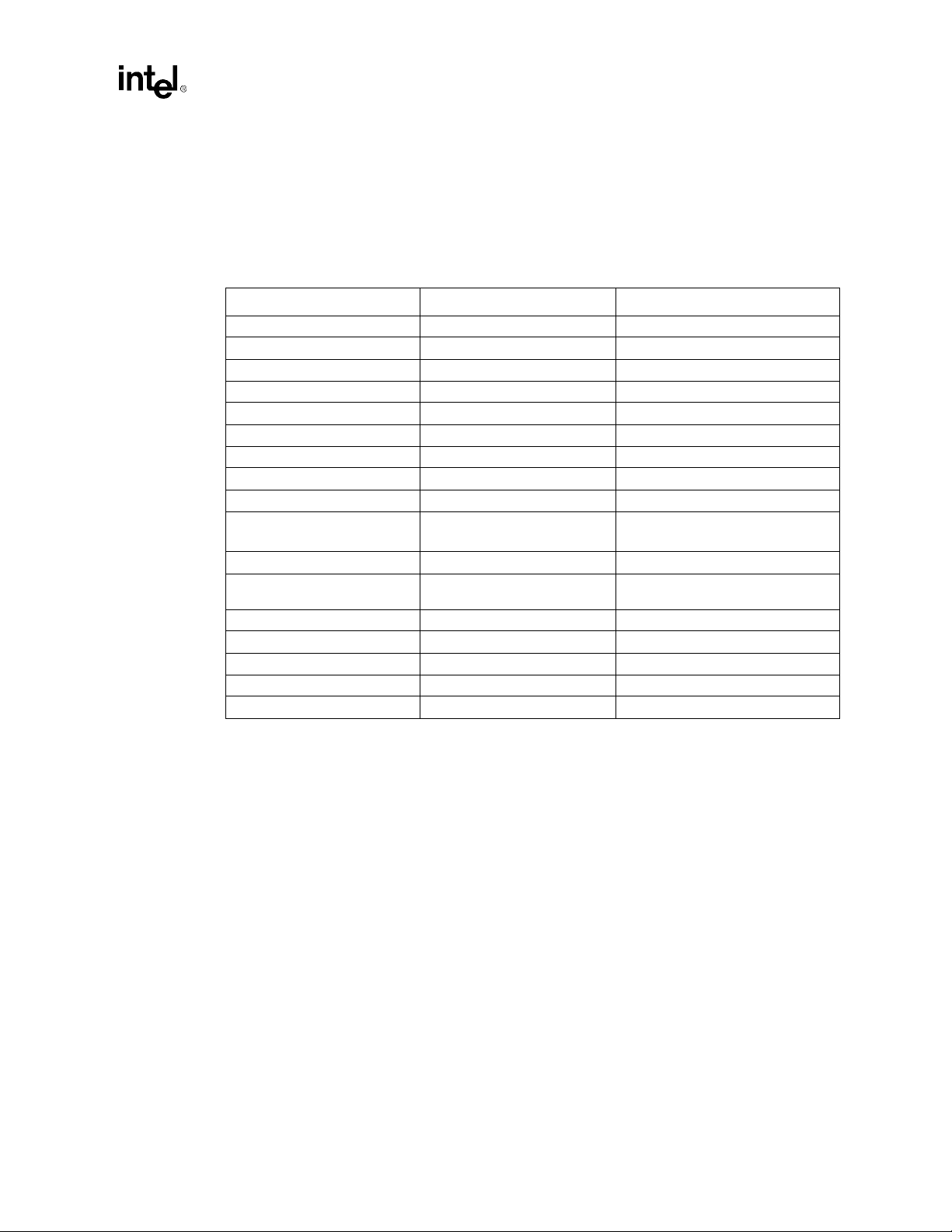

Table 2-1. Recommended Trace Lengths for Single Processor Design

T race Minimum Length Maximum Length

L1 1.50” 6.75”

L3 0.00” 1.50”

L4 0.00” 2.50”

1

2

NOTE:

1.

Refer to the

#42: workaround L1=4.5”.

Intel® Pentium

®

II

Processor Specification Update

(order number 243337); Specifically, erratum

Intel strongly recommends running analog simulations using the available I/O buffer models

together with layout information extracted from your specific design. Simulation will confirm that

the design adheres to the guideli nes.

Figure 2-8. Solution Space for Single Processor Design (Based on Results of Parametric

Sweeps)

2

PASS

0123456789101112

L2 [in]

FAIL

1

0

L3 [in]

Intel® 440GX AGPset Design Guide

2-7

Page 32

Motherboard Layout and Routing Guidelines

2.3.4 Dual Processor Systems

2.3.4.1 Dual Processor Network Topology and Conditions

Figure 2-9. Recommended Topology for Dual Processor Design

®

Intel

440GX

AGPset

L3

L4

L5

Slot 1

2.3.4.2 Dual Processor Recommended Trace Lengths

The recommended trace lengths for dual processor designs are summarized in Table 2-2. Intel’s

simulations have shown that it is desirable to control the amount of imbalance in the network to

meet ringback specifications at the Intel

drives. This control is reflected in the recommendations of Table 2-2.

Table 2-2. Recommended Trace Lengths for Dual Processor Designs

Trace Minimum Length Maximum Length

L3 0.50” 1.50”

1

L4

2

L5

NOTES:

1. L4 & L5 are interchangeable

2. It is possible to find working solutions outside the recommendations of Table 2-2, as the solution space plot

show. Intel strongly recommends that any traces that fall outside the recommended lengths be simulated to

ensure they meeting timing and signal quality specs.

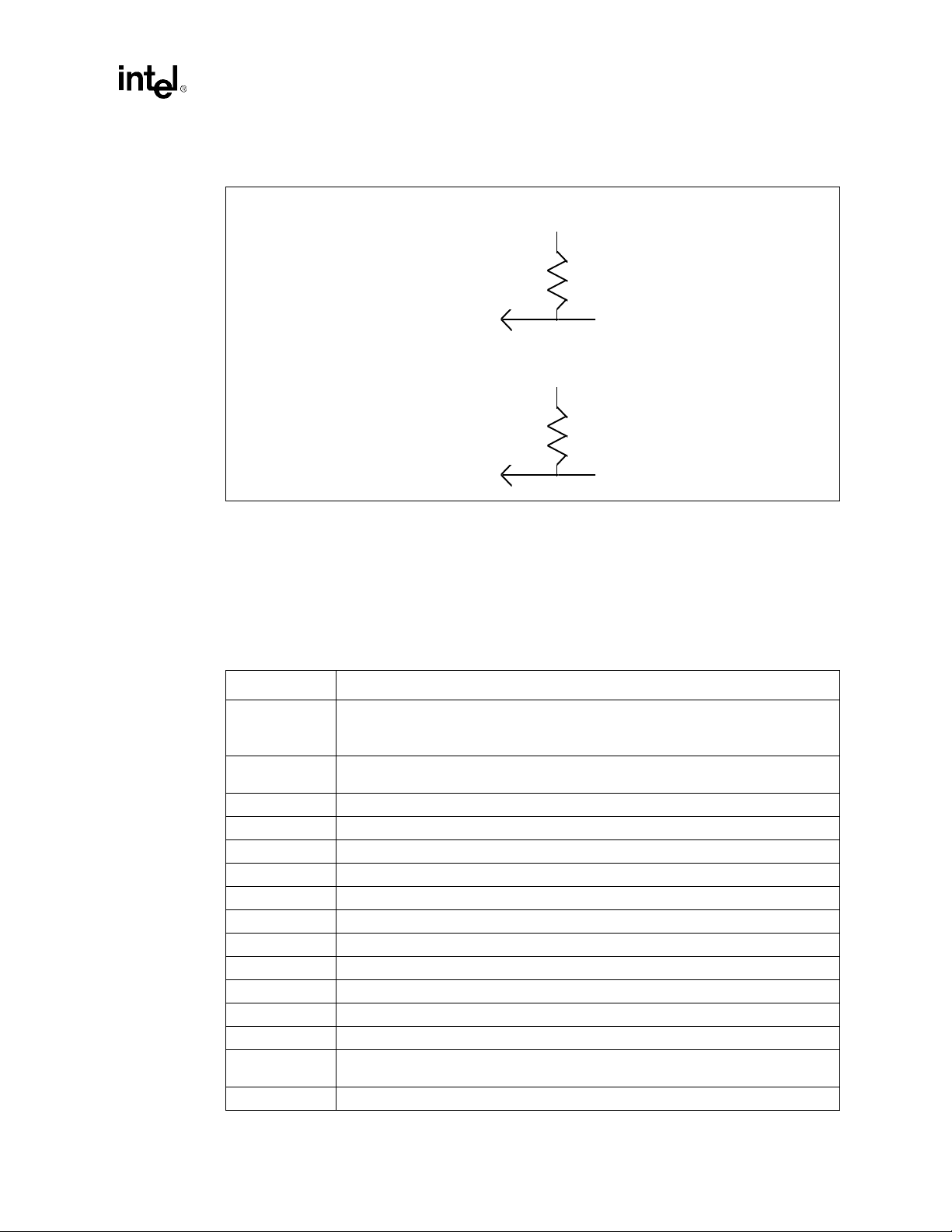

L4 - 1.00”, but L4+L5 must be at least 4.00” L4 + 1.00”, but not greater than 5.00”

1.50” 4.00”

®

Pentium® II processor when the Intel® 440GX AGPset

Slot 1

2

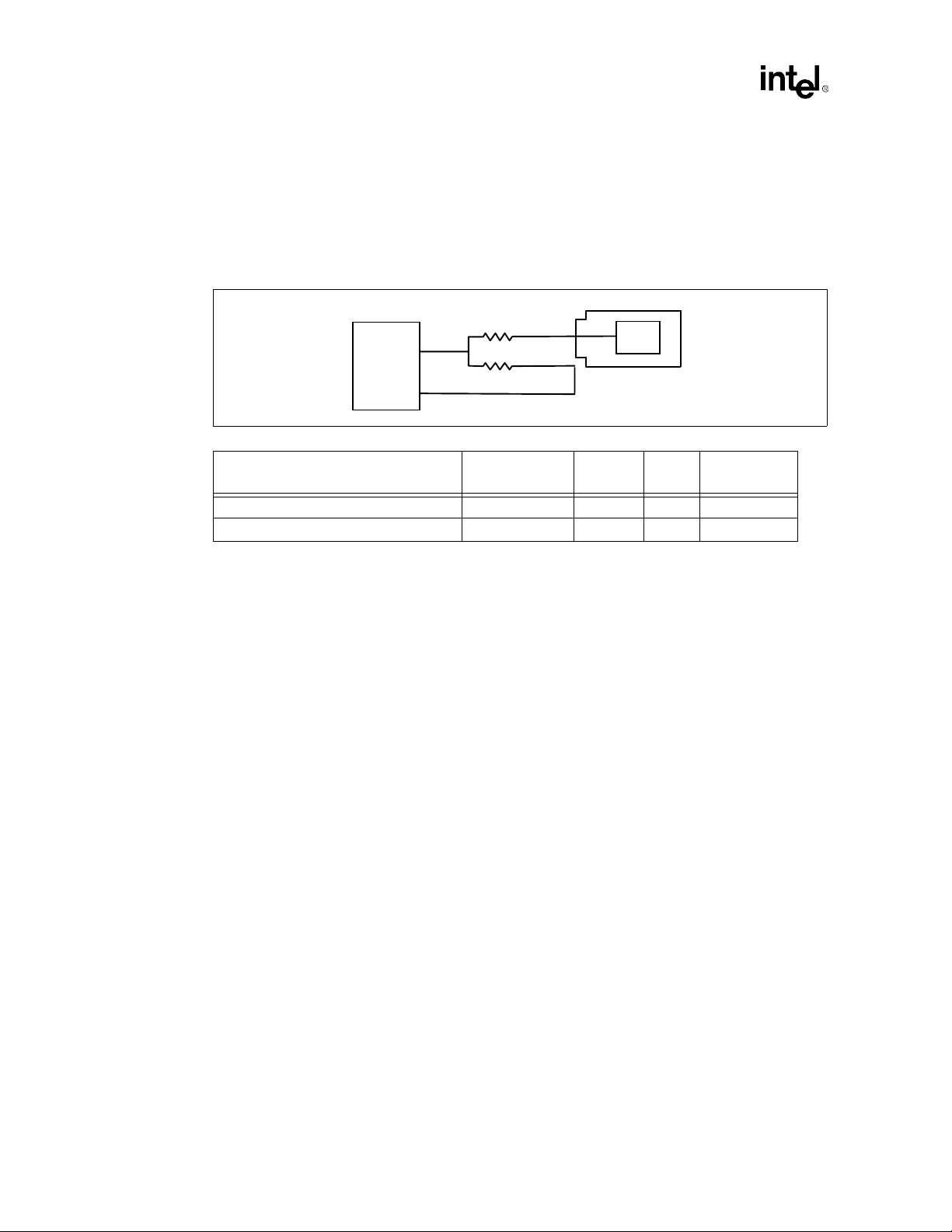

2.3.5 Single Processor Systems—Single-End Termination (SET)

2.3.5.1 Set Network Topology and Conditions

Removal of the termination resistors from the system board can reduce system cost, at the expense

of increased ringing and reduced solution space. Intel has simulated this topolog y, known as single

end termination (SET), and found that it can work. However, the topo logy has some limitations

which are discussed below.

2-8

Intel® 440GX AGPset Design Guide

Page 33

Motherboard Layout and Routing Guidelines

In the SET topology, the only termination is on the Intel® Pentium® II processor substrate. There is

no termination present at the other end of the network. Due to the lack of termination, SET exhibits

much more ringback than the dual terminated topology. Extra care is required in SET simulations

to make sure that the ringback specs are met under the worst case signal quality conditions.

In addition, since there is only one pull-up resisto r per net the rising edge response is substantially

degraded when using slow corner buffers. This effect manifests itself as a degraded flight time,

which results in a reduced maximum trace length that meets the 100 MHz timing requirements.

This loss of design flexibility must be careful ly weighed against the cost savings from removing

the resistors.

Figure 2-10. Topology for Single Processor Designs With Single-End Termination (SET)

®

Intel

440GX

L1

AGPset

Slot 1

2.3.5.2 SET Trace Length Requirements

Intel has performed sensitivity analysis on the SET topology. The required trace lengths for

operation at 100 MHz with the SET topology are based on the sensitivity analysis results, and are

listed in Table 2-3. Intel’s SET simulations were performed assuming a four layer system board, so

that all traces used the microstrip propagation velocity range. The slower propagation of stripline

transmission line structures is not included in the recommendations of Table 2-3.

Table 2-3. SET Trace Length Requirements

Trace Minimum Length Maximum Length

L1 1.50” 4.00”

Figure 2-11. Solution Space for Single Processor Designs With Single-End Termination (SET)

2.5

SUBSTRATE

TRACE LENGTH

2.0

1.5

0.0 1.0 2.0 3.0 4.0 5.0

L1 [in]

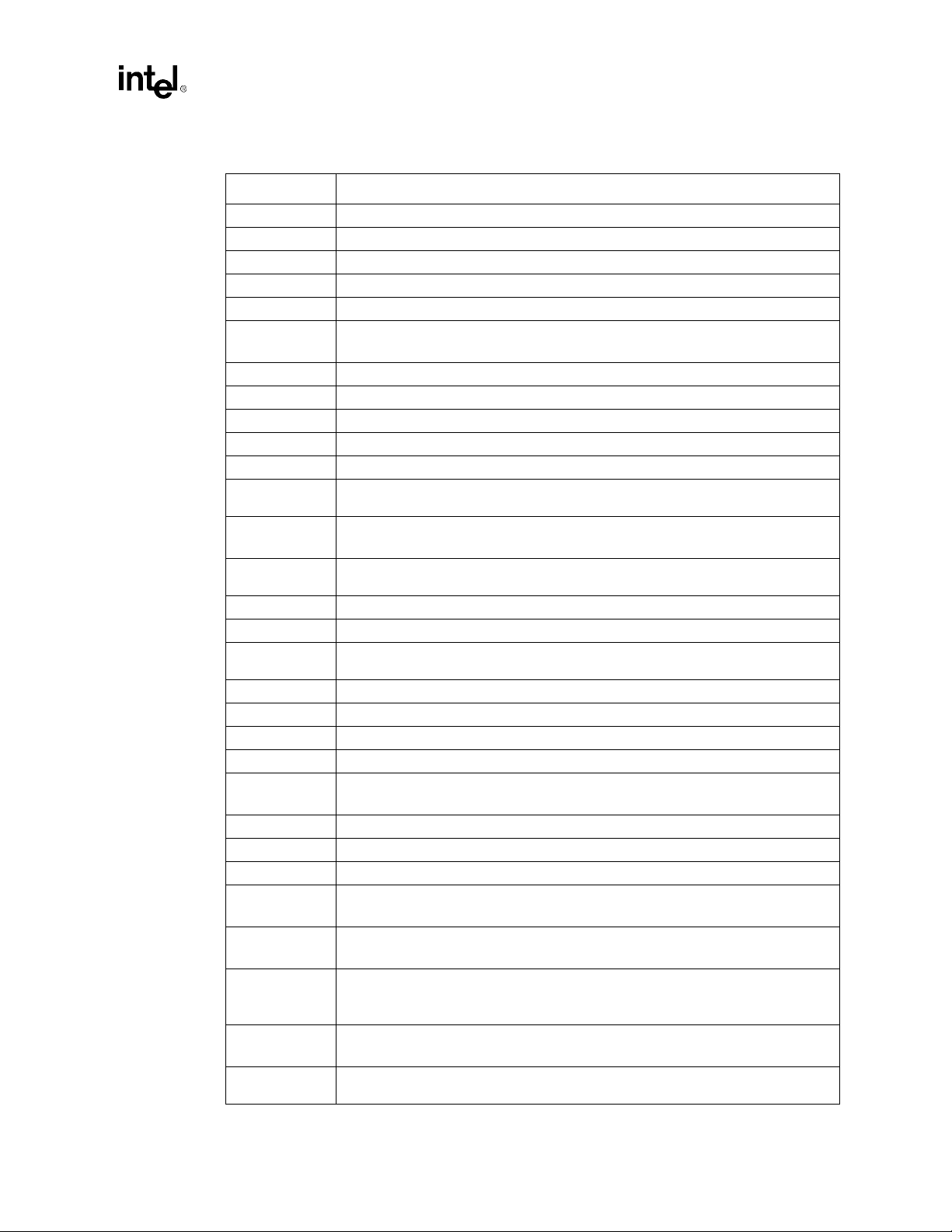

[IN]

Intel® 440GX AGPset Design Guide

2-9

Page 34

Motherboard Layout and Routing Guidelines

2.3.6 Additional Guide l ines

2.3.6.1 Minimizing Crosstalk

The following general rules will minimize the impact of crosstalk in the high speed GTL+ bus

design:

Maximize the space between traces. Maintain a minimum of 0.010” between traces wherever

•

possible. It may be necessary to use tighter spacings when routing between component pins.

Avoid parallelism between signals on adjacent layers.

•

Since GTL+ is a slow signal swing technology, it is important to isolate GTL+ signals from

•

other signals by at least 0.025”. This will avoid coupling from signals that have larger voltage

swings, such as 5V PCI.

Select a board stack-up that minimizes the coupling between adjacent signals.

•

Route GTL+ address, data and control signals in separate groups to minimize crosstalk

•

between groups. The Pentium II processor uses a split transaction bus. In a given clock cycle,

the address lines and corresponding control lines could be driven by a different agent than the

data lines and their corresponding control lines.

2.3.6.2 Practical Considerations

Distribute VTT with a wide trace. A 0.050” minimum trace is recommended to minimize DC

•

losses. Route the VTT trace to all components on the system bus. Be sure to include

decoupling capacitors. Guidelines for VTT distribu tion and deco upling are contained in Intel

Pentium

Place resistor divider pairs for V

•

V

sure to include decoupling capacitors. Guidelines for V

contained in P Intel

There are six GTL+ signals that can be driven by more than one agent simultaneously. These

•

signals may require extra attention during the layout and validation portions of the design .

When a signal is asserted (driven low) by two agents on the same clock edge, the two falling

wave fronts will meet at some point on the bus. This can create a large undershoot, followed by

ringback which may violate the ringback specifications. This “wired-OR” situation should be

simulated for the following signals: AERR#, BERR#, BINIT#, BNR#, HIT#, and HITM#.

Lossless simulations can overstate the amount of ringing on GTL+ signals. Lossy simulations

•

may help to make your results less pessimistic if ringing is a problem. Intel has found the

resistivity of copper in printed circuit board signal layers higher than the value of

0.662 Ω-mil

of 1.0 Ω-mil

Higher RTT values tend to increase the amount of ringback on the rising edge, while smaller

•

values tend to increase the amount of ringback on the f alling edge. It is not necessary to b udget

for R

I/O Buffer models for the fast corner co rrespond to the m inimum Tco. Slow corner buffers will

•

be at least 500 ps slower. Therefore, it is only necess ary to ensure that t he minimum fligh t time

is met when the network is driven by fast buffer models.

®

II Processor Power Distribution Guidelines.

generation is needed at the processor(s). V

REF

®

Pentium® II Processor Power Distribution Guidelines.

2

/in that has been published for annealed copper. Intel recommends using a value

2

/in for lossy simulations.

variation if your simulations comprehend the expected manufacturing variation.

TT

generation at the Intel® 440GX AGPset component. No

REF

is generated locally on the processor. Be

REF

distribution and decoupling are

REF

®

2-10

I/O Buffer models for the slow corner correspond to the maximum Tco. Fast corner buffer s will

•

be at least 500 ps faster. It is only necessary to ensure that the maximum flight time is met

when the network is driven by slow buffer models, as long as no ringback problems exist.

Intel® 440GX AGPset Design Guide

Page 35

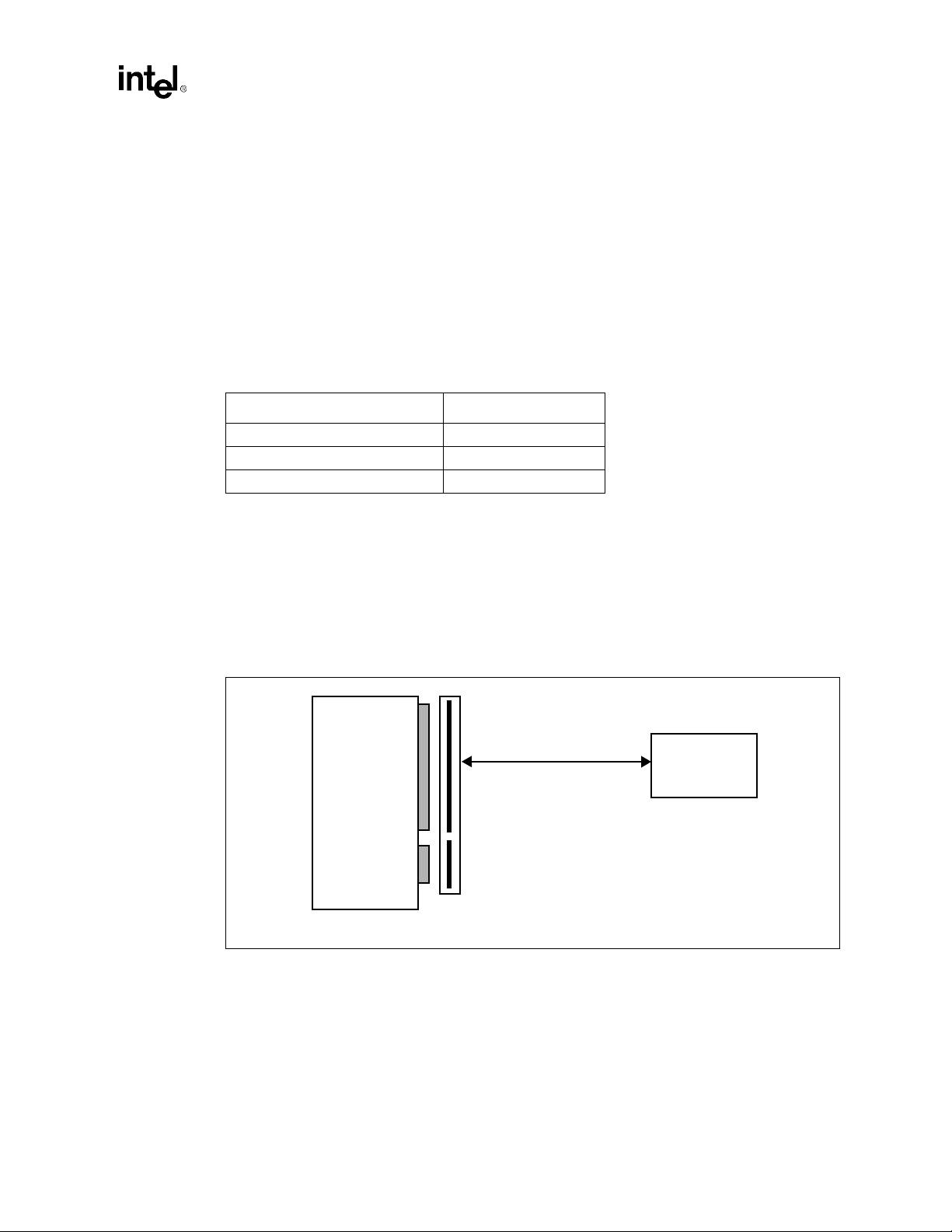

2.3.7 Design Methodology

Motherboard Layout and Routing Guidelines

Intel recommends using the following design methodology when designing systems based on one

or two Intel

from Intel’s experience developing and validating high speed GTL+ bus designs for the Intel

Pentium

®

Pentium® II processors and one Intel® 440GX AGPset. The methodology evolved

®

Pro and Intel® Pentium® II processors.

®

The methodology provides a step-by-step process which is summarized in Figure 2-12. The

process begins with an initial timing analysis and topology definition . Timing and topology

recommendations are included in this section. The heart of the methodology is structured around

extensive simulations and analysis prior to board layout. This represents a significant departure

from traditional design methods. The pre-layout sim ulations provide a detailed picture of the

working “solution space” for the design. By basing the board layout guidelines on the solution

space, the need to iterate between layout and post-layout simulation is minimized. The

methodology includes specific recommendations for analytical techniques and simulation

conditions. Following layout, simulation with the extracted design database is used to verify that

the design meets flight time and signal quality requirements p ri or to building hardware. Finally,

validation verifies that the system meets 100 MHz timing and signal quality requirements with

actual hardware.

Intel® 440GX AGPset Design Guide

2-11

Page 36

Motherboard Layout and Routing Guidelines

Figure 2-12. GTL+ Design Process

Establish System

Perf ormance

Requirements

(Timing Anal ysis)

Define Topologies

Perform Pre-Layout

Simulations

(Sensitivity Analysis)

Define Routing Rules

Place & Route Board

Perform Post-Layout

Simulations

(Ver ification )

Requirements?

Validate Design

2.3.8 Performance Requirements

Prior to performing interconnect simulations, establish the minimum and maximum flight time

requirements. Setup and hold requirements determine the flight time bounds for the host bus. The

system contains multiple paths which must be considered:

Intel® Pentium® II processor driving an AGPset component

•

AGPset component driving a Intel® Pentium® II processor

•

Intel® Pentium® II processor driving a Intel® Pentium® II processor

•

(dual processor systems only)

Meet

No

Yes

2-12

Intel® 440GX AGPset Design Guide

Page 37

Motherboard Layout and Routing Guidelines

gy

Section 2.7, “Timing Analysis” on page 2-17 describes the timing analysis for the 100 MHz host

bus in more detail. Table 2-4 provides recommended flight time specifications for single and dual

®

Intel

Pentium® II processor systems. Flight times are measured at the Intel® Pentium® II

processor edge fingers. See the Pentium

®

II Processor Developer’s Manual

(order number 243502), Chapter 8, “GTL+ Interface Specifications“, for information on GTL+

timing measurements and signal quality specifications.

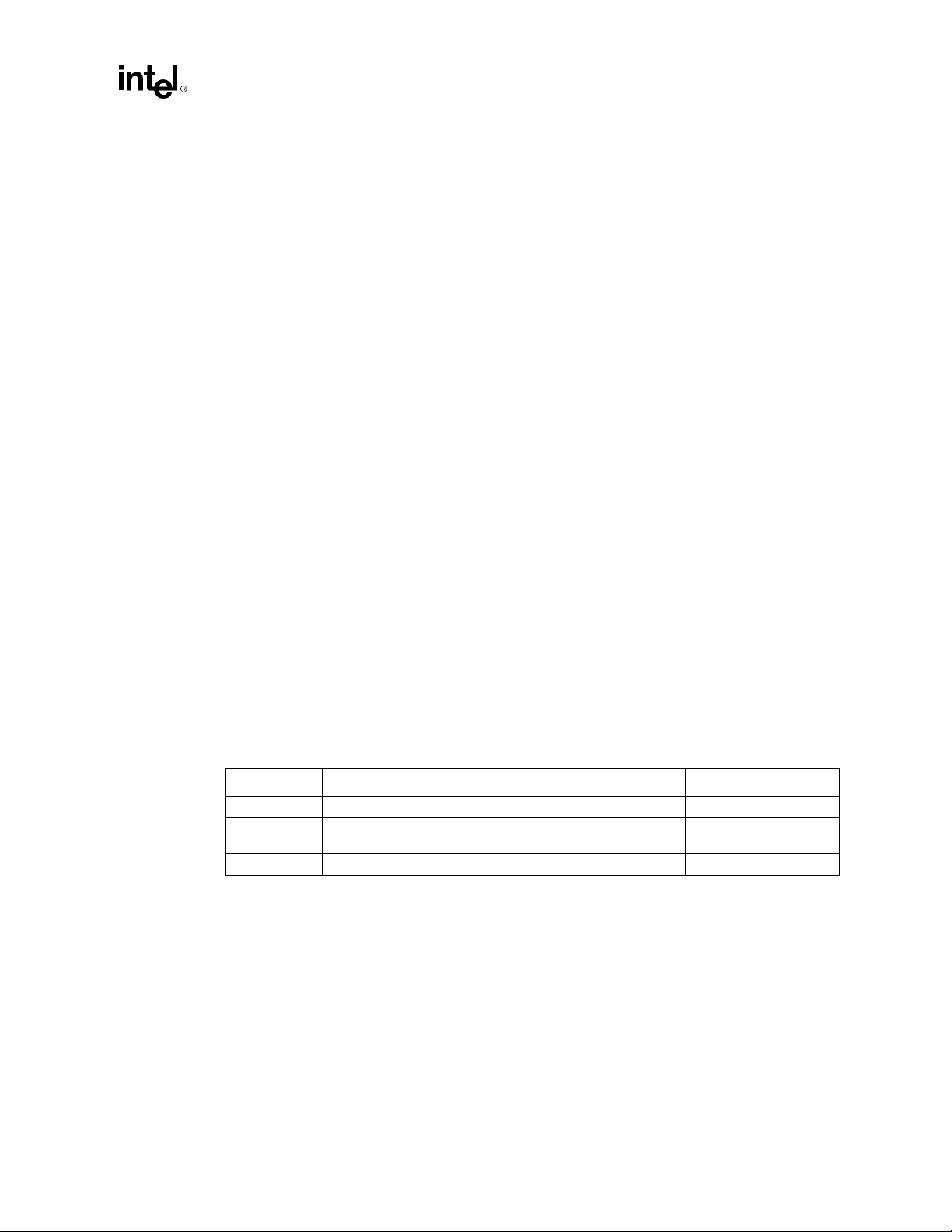

Table 2-4. Recommended 100 MHz System Flight Time Specs

Driver Receiver T

®

Pentium® II processor

Intel

®

Intel

440GX AGPset

®

Intel

Pentium® II processor Intel® Pentium® II processor

AGPset 0.36 2.13

®

Pentium® II processor

Intel

flight,min

0.37 1.76

1.23 2.39

2.3.9 Topology Definition

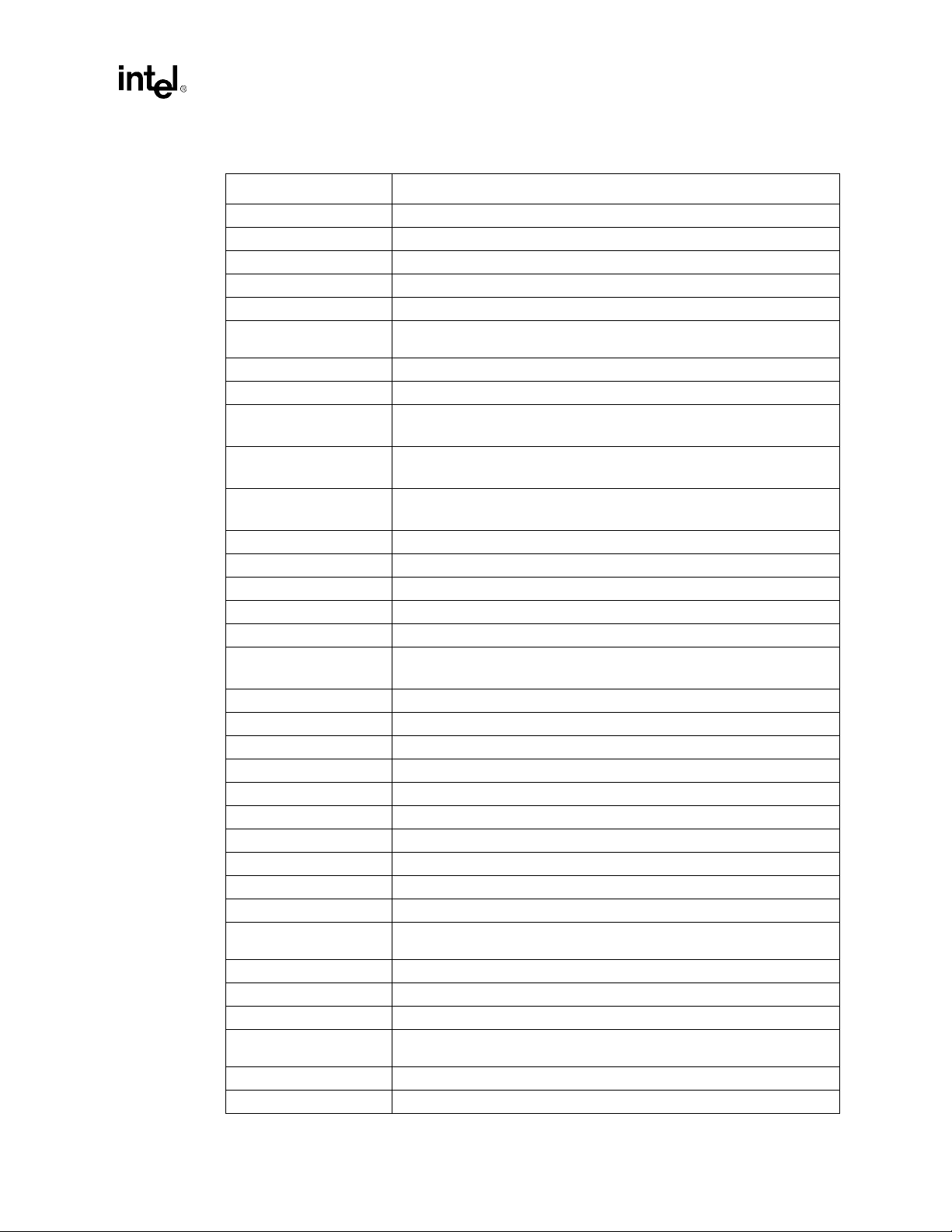

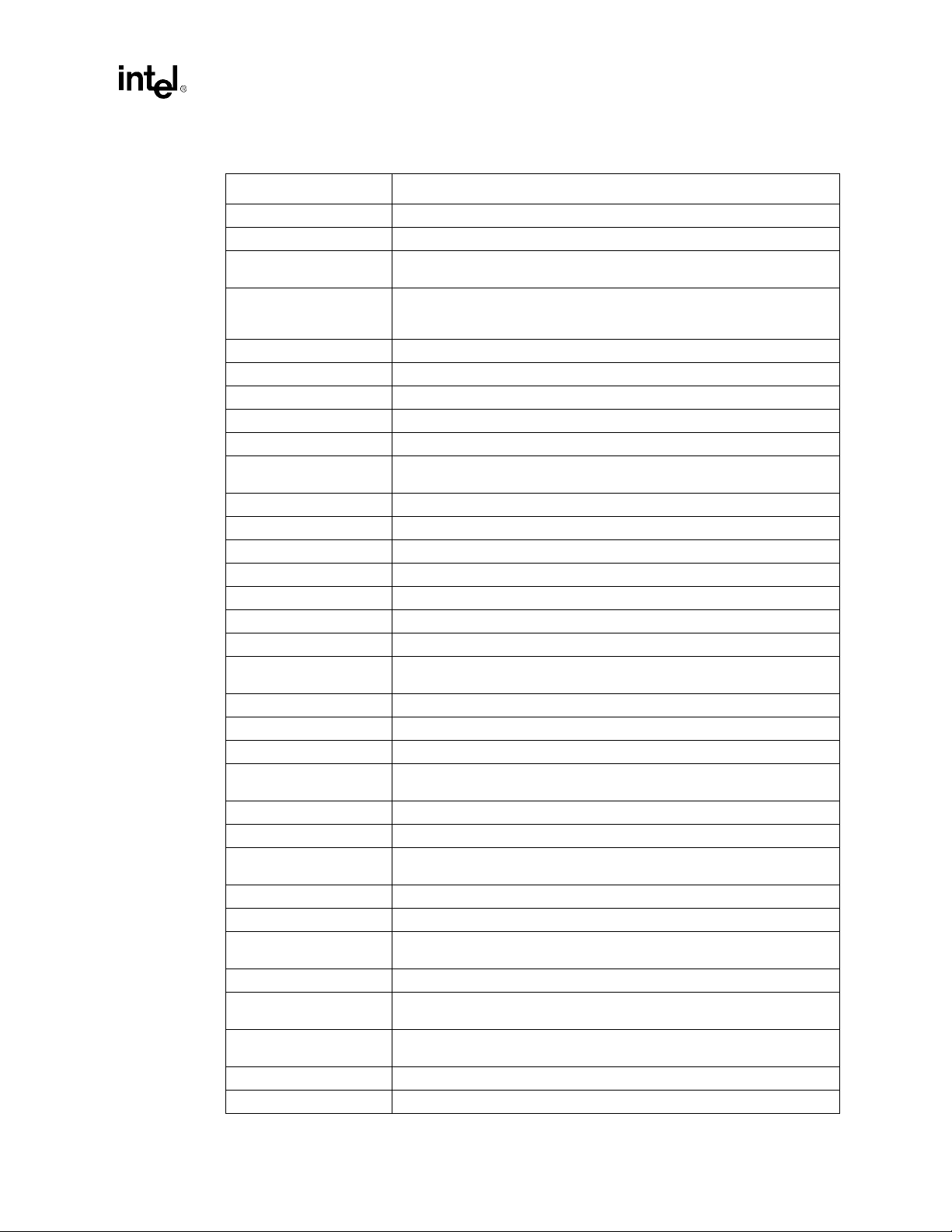

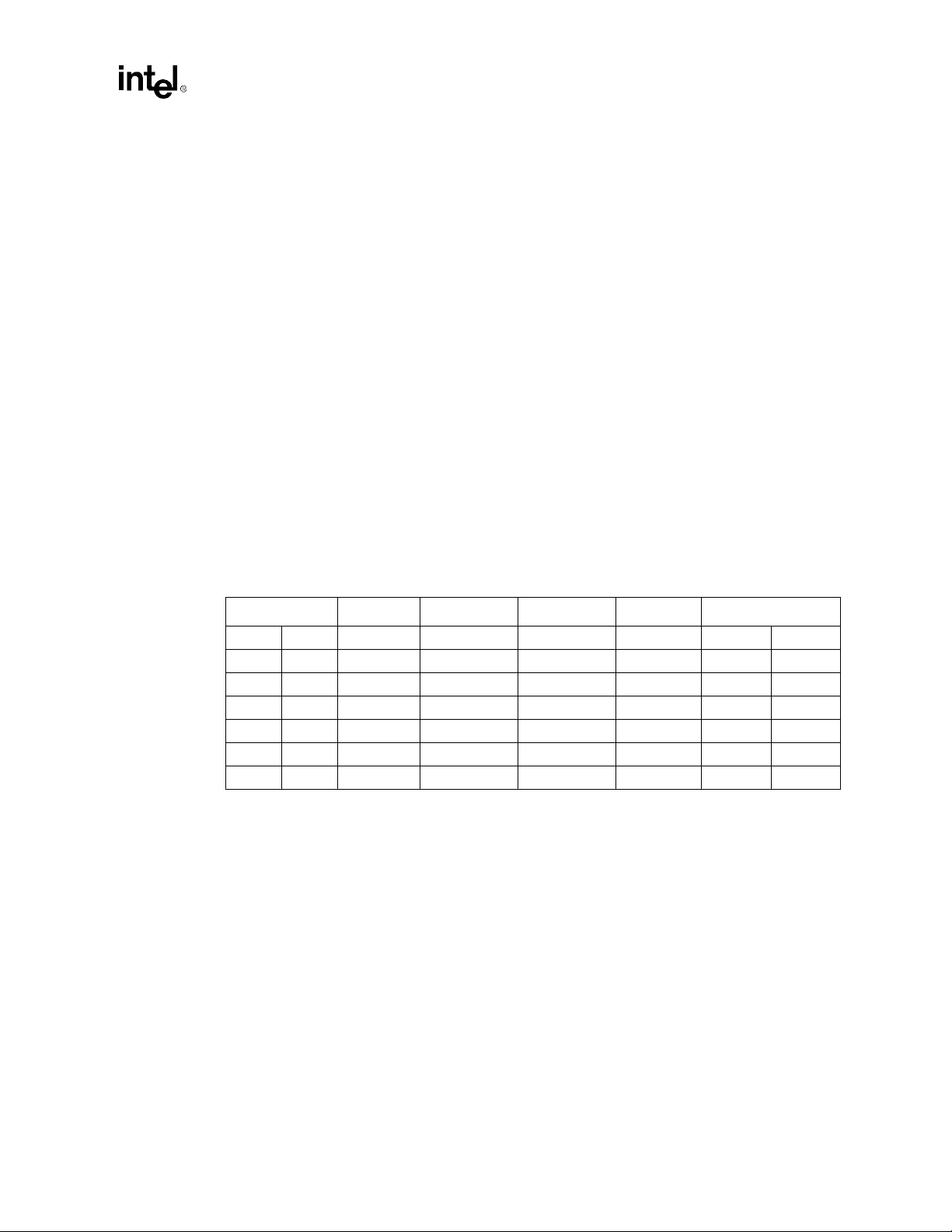

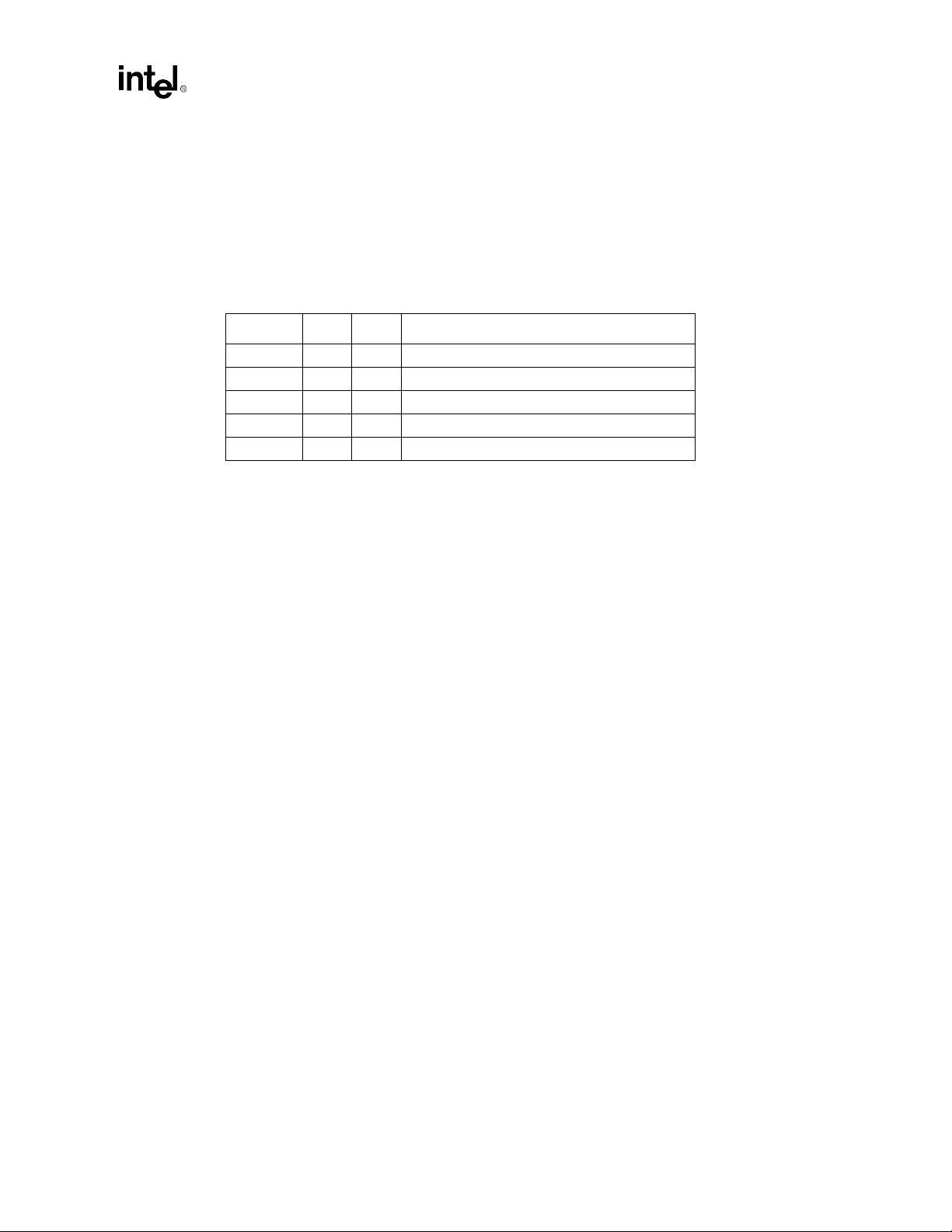

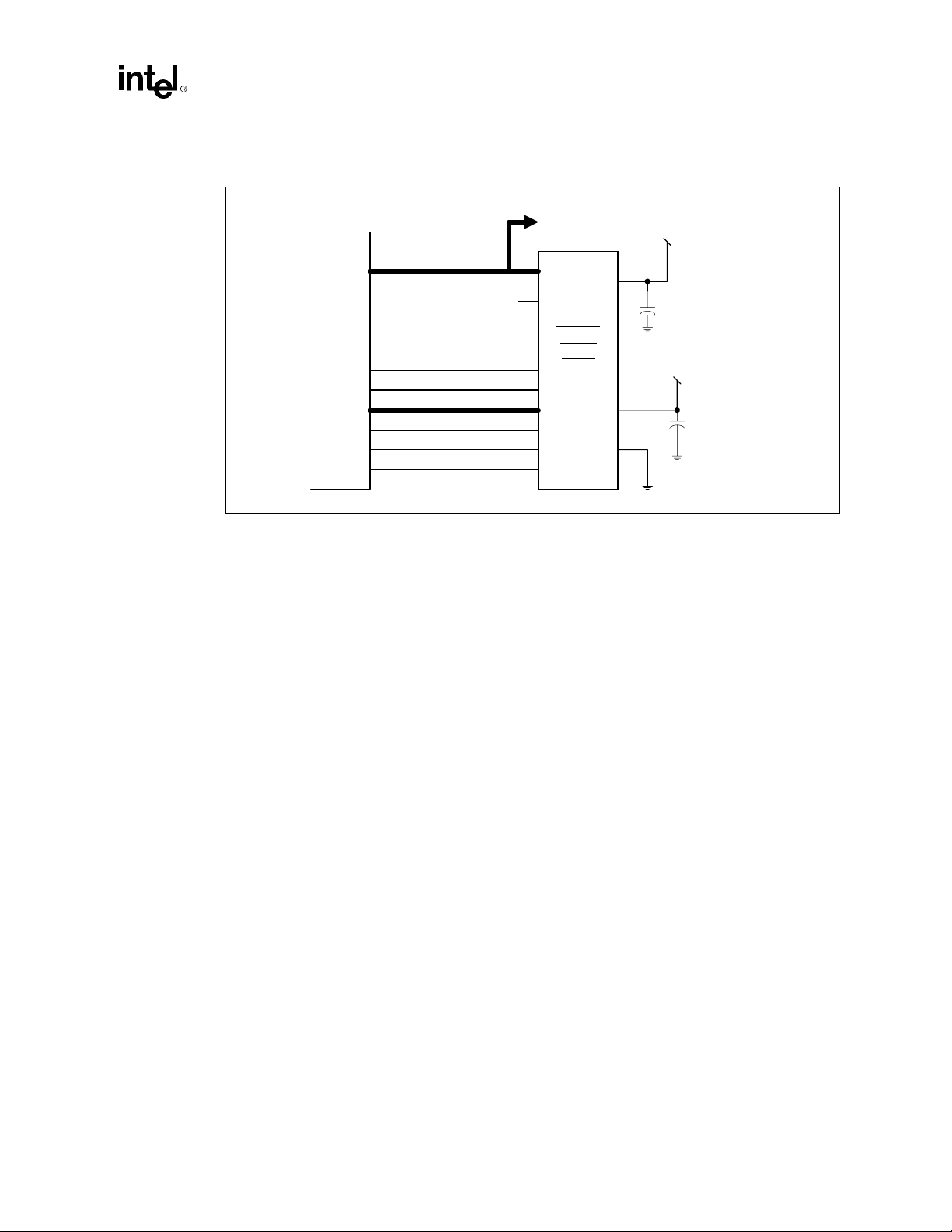

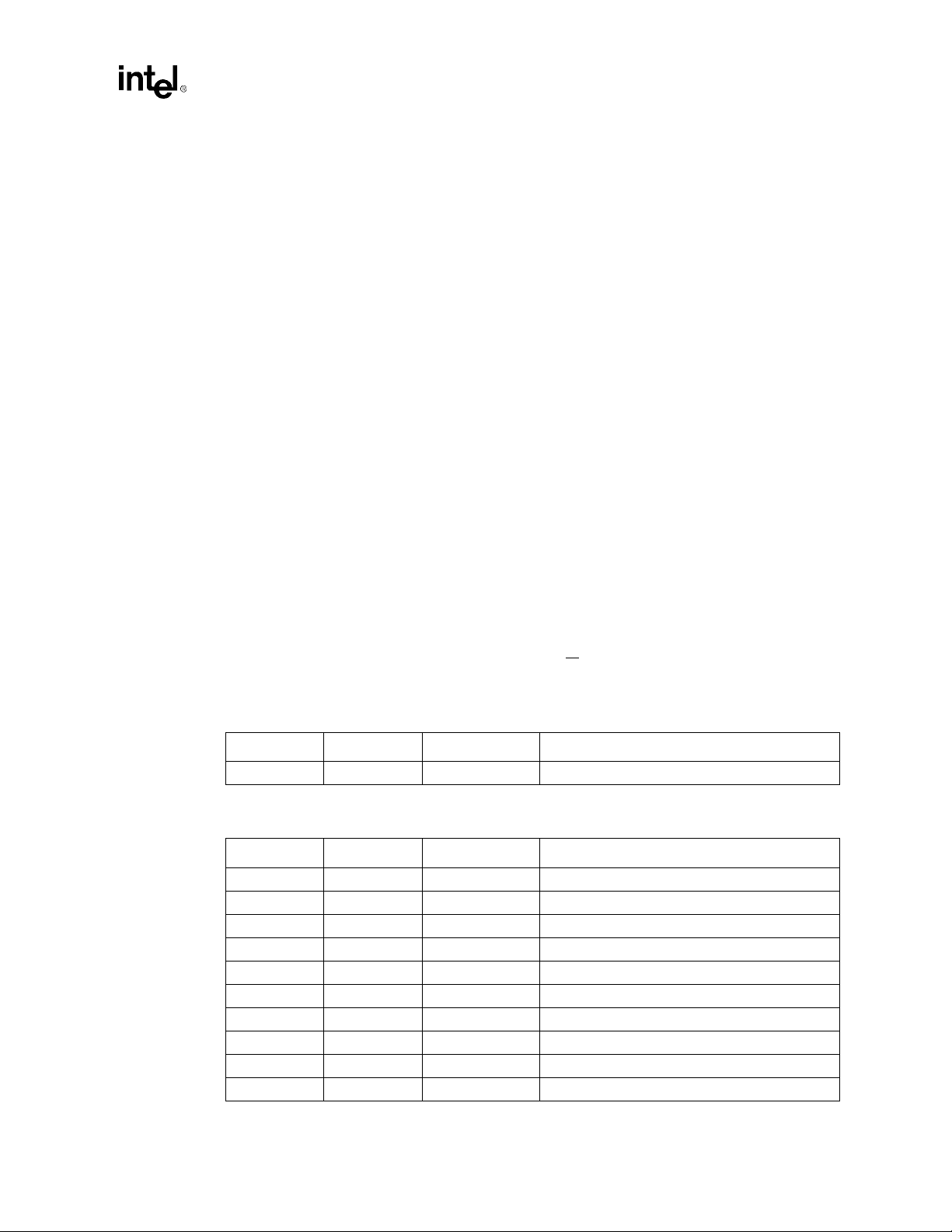

GTL+ is sensitive to transmission line stubs, which can result in ringing on the risin g edge caused